Patents

Literature

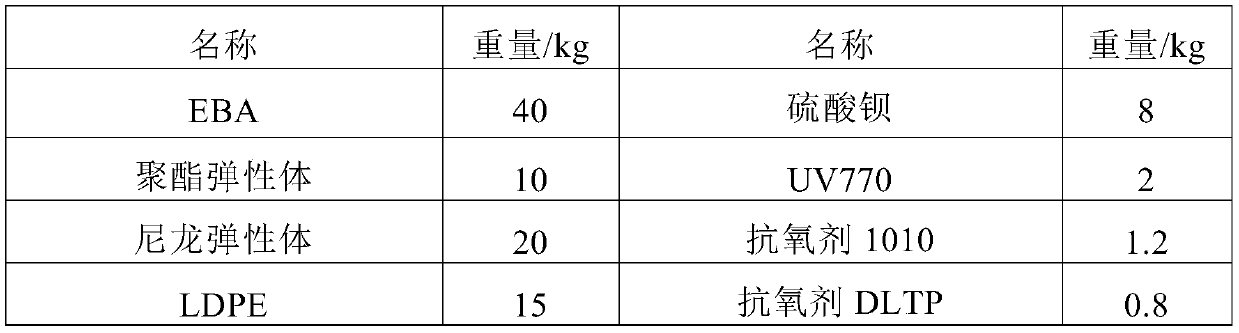

72results about How to "Improve high temperature and high humidity performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

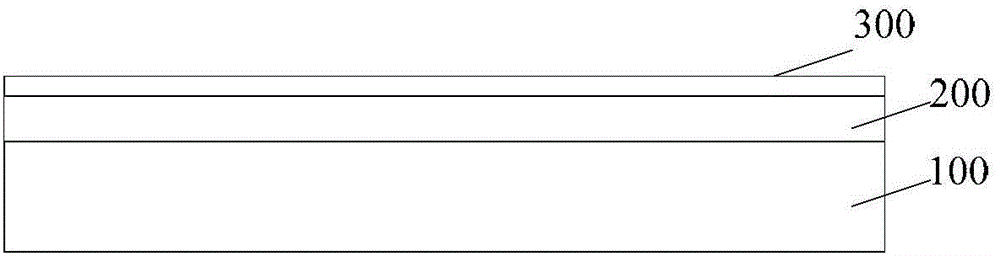

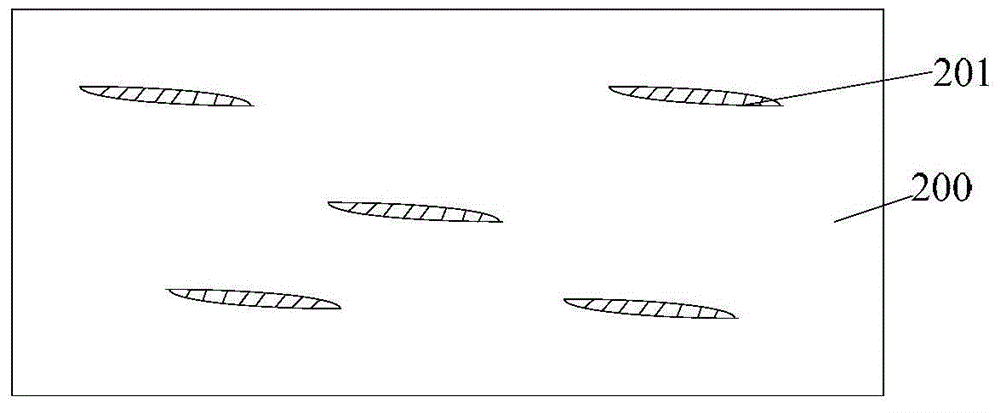

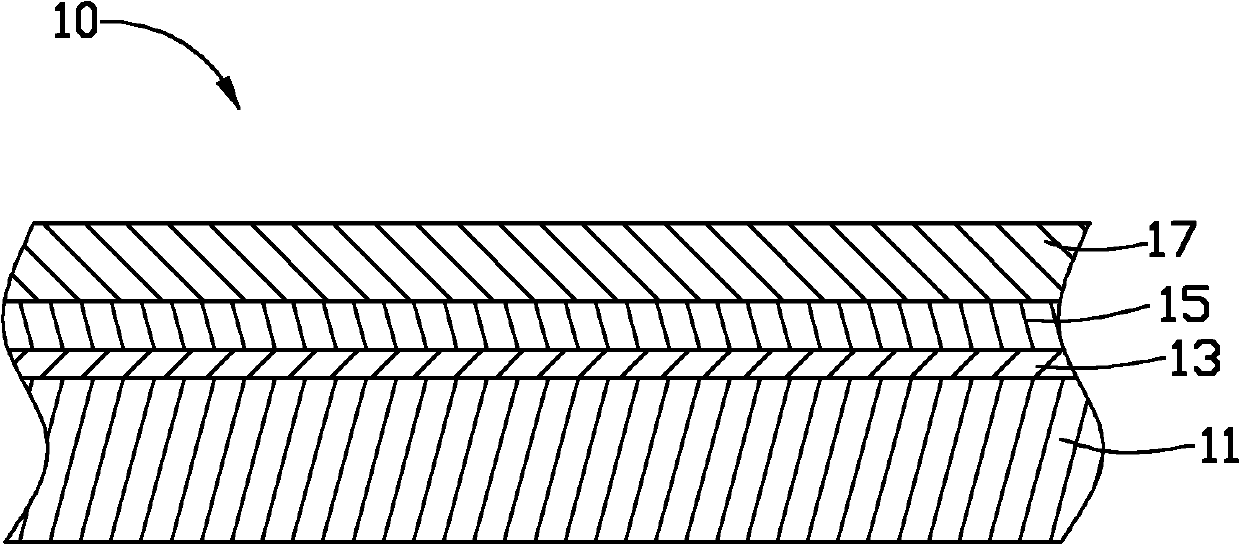

High polymer transparent conductive film and preparation method thereof

ActiveCN104575701AImprove conductivityImprove performanceConductive layers on insulating-supportsCable/conductor manufactureConductive polymerOptoelectronics

The invention provides a high polymer transparent conductive film and a preparation method thereof. The high polymer transparent conductive film comprises a resin substrate layer, a conductive layer and a resin fixing layer, wherein the conductive layer is positioned above the resin substrate layer, and has a plurality of seams for allowing the resin substrate layer to expose; the resin fixing layer is positioned above the conductive layer and in the seams; the conductive layer comprises a conductive polymer and a conductive filler; the thickness of the resin fixing layer is smaller than 300 nm. According to the high polymer transparent conductive film, the resin fixing layer which is very thin is arranged above the conductive layer. The resin fixing layer is relatively high in softness, and can be used for effectively improving the softness of the whole high polymer transparent conductive film. More importantly, the seams for allowing the resin substrate layer to expose are formed in the conductive layer, so that the resin fixing layer above can penetrate into the seams and can be bonded with the resin substrate layer, and the adherence strength between the conductive film and the resin substrate layer can be effectively improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

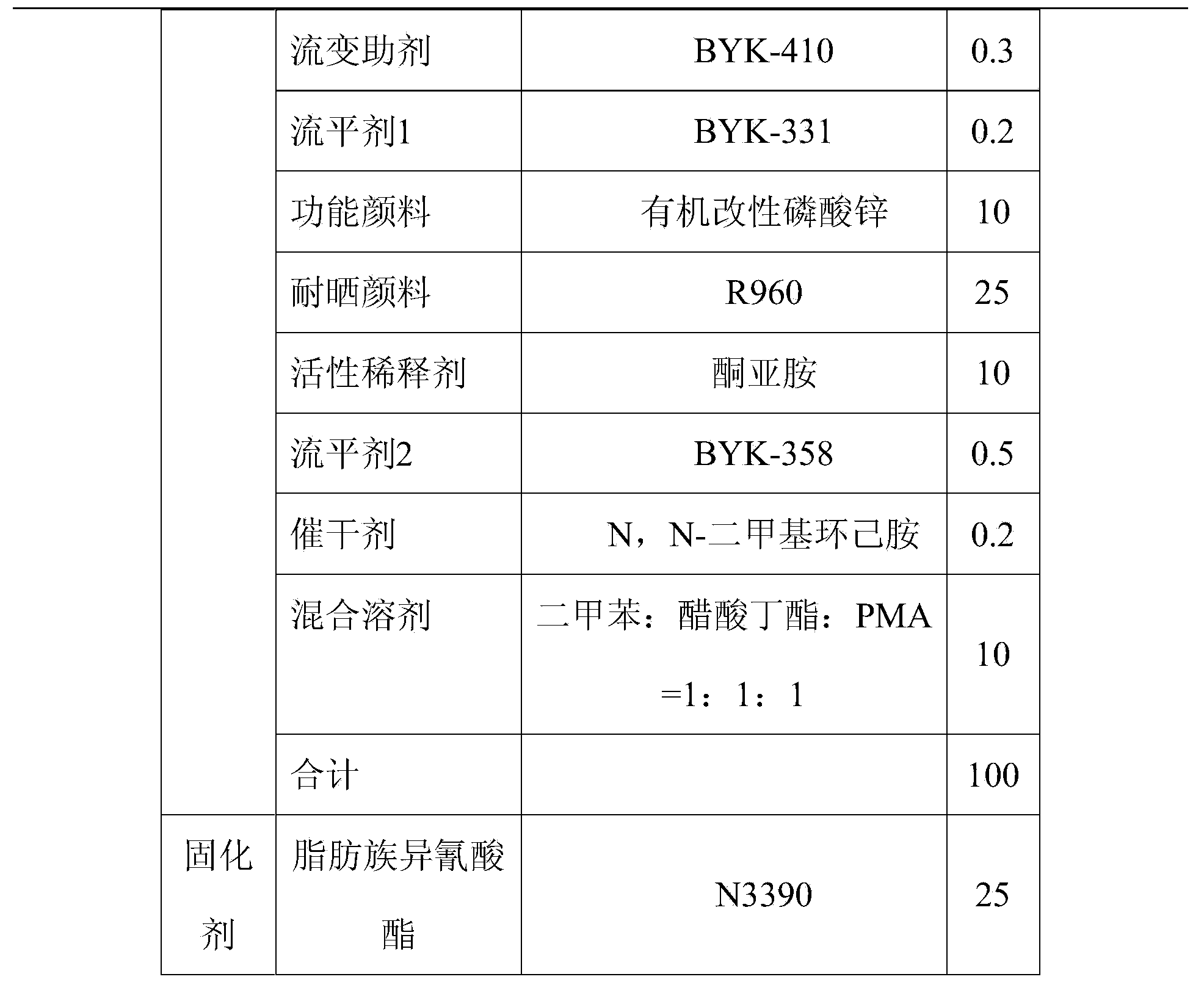

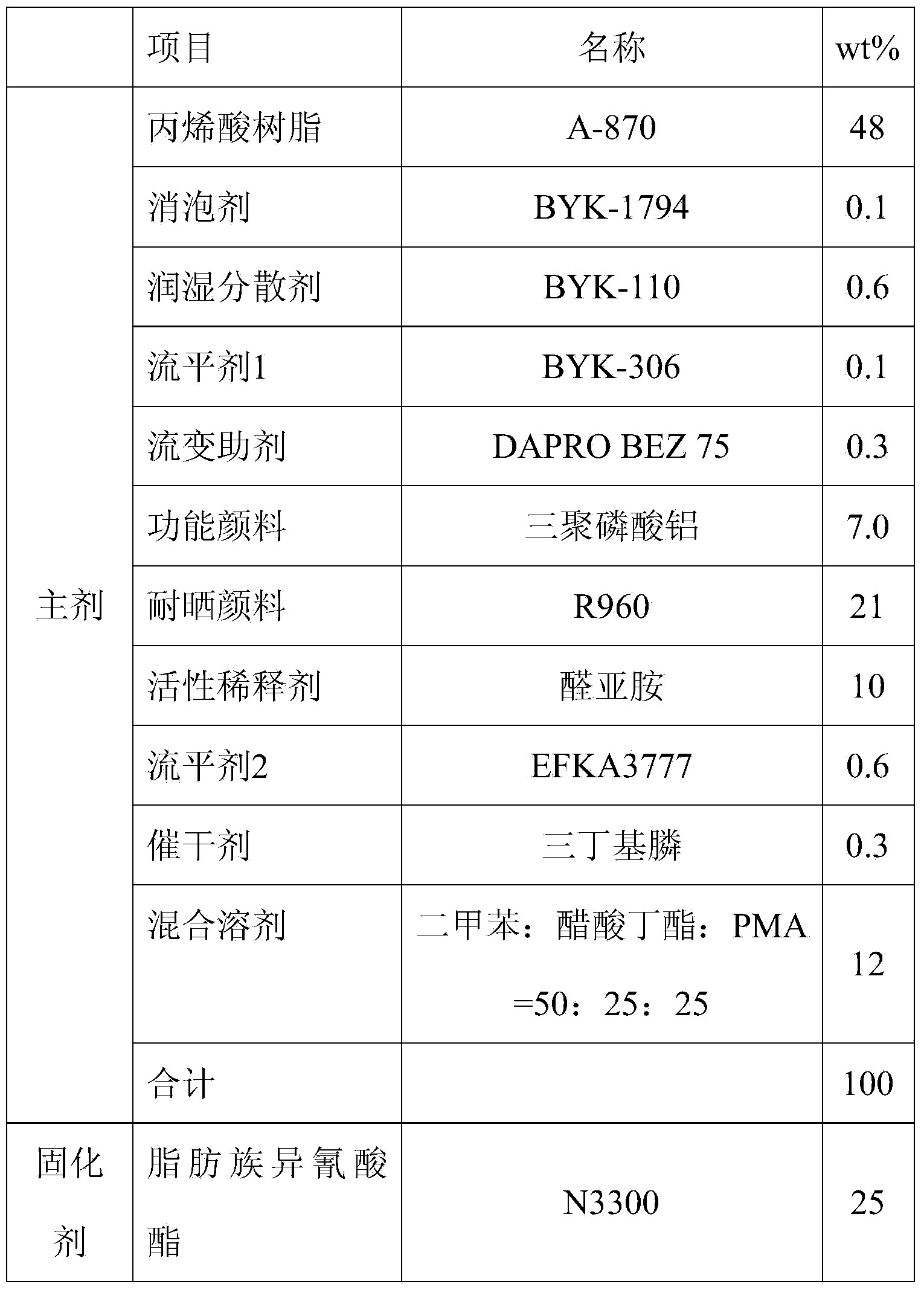

High solid coating for container and preparation method of high solid coating

ActiveCN103666229APromote environmental protectionImprove efficiencyAnti-corrosive paintsPolyurea/polyurethane coatingsChemical industryAcrylic resin

The invention discloses a high solid coating for a container and a preparation method of the high solid coating, and relates to the field of the coating chemical industry. The high solid coating comprises a host and a curing agent; the mass ratio of the host to the curing agent is 4:1; the host comprises the following components by mass: 40-60 percent of high solid low viscosity hydroxy acrylic resin, 1-5 percent of a rheological agent, 1-10 percent of a functional pigment, 20-25 percent of a sunproof pigment, 0-1 percent of an antifoaming agent, 1-3 percent of a wetting dispersant, 0.1-0.5 percent of a flatting agent I, 0.1-0.5 percent of a flatting agent II, 1-10 percent of a reactive diluent, 0.1-5 percent of a drier, and 1-5 percent of a mixed solvent. The coating has the advantages that the content of volatile organic compounds is low, the one-step film formation thickness is 150 microns, the surface dry purpose is achieved within 15 min, the film abrasion resistance is low to 40 mg, the coating is saved, the emission and coating time of volatile organic compounds are reduced, and the corrosion resistance, the abrasion resistance and the weathering resistance meet the requirement for anticorrosion outside the container, and adapt to the rapid production requirement of the container production line.

Owner:洛阳双瑞防腐工程技术有限公司

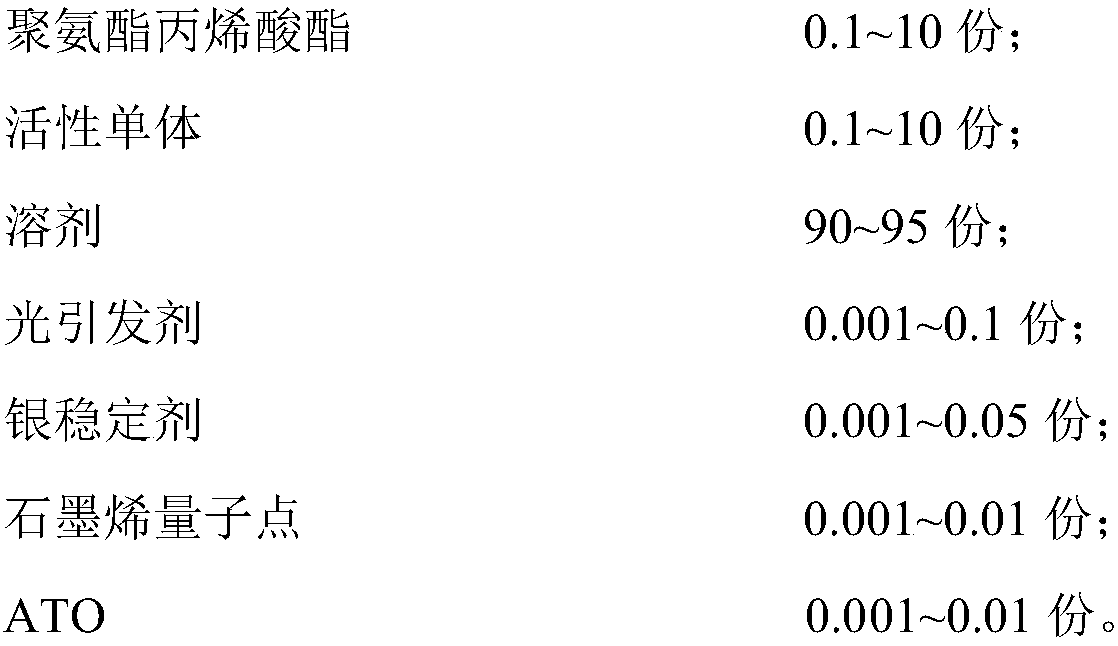

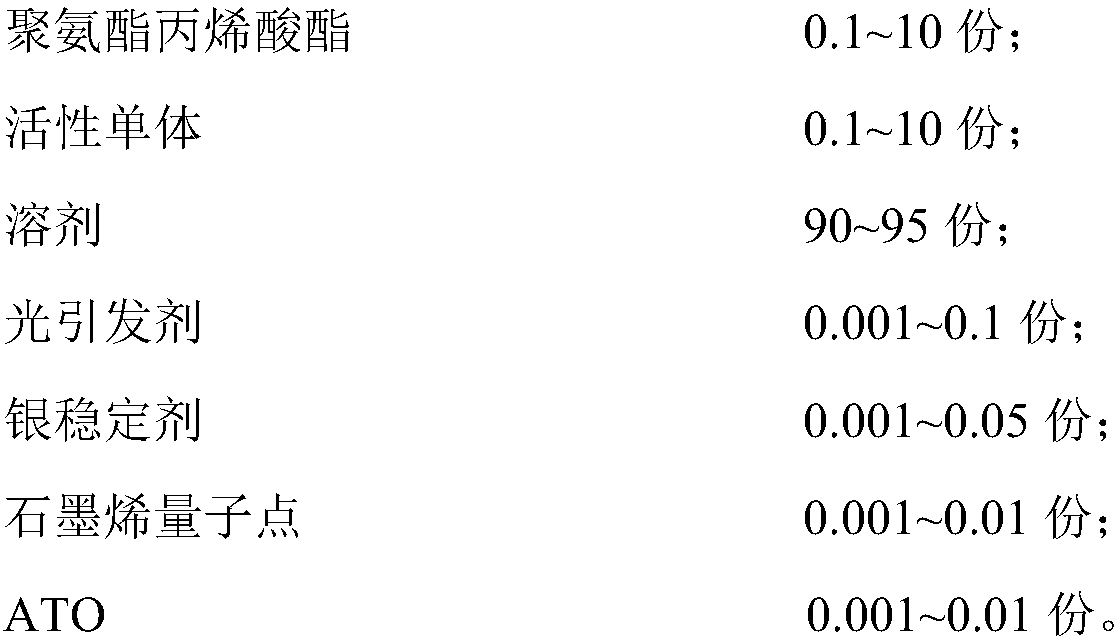

UV light-cured resin applied to silver nanowire conductive film and preparation method of UV light-cured resin

ActiveCN108384439AHigh hardnessGuaranteed hardnessPolyurea/polyurethane coatingsUrethane acrylateSolvent

The invention discloses UV light-cured resin applied to a silver nanowire conductive film and a preparation method of the UV light-cured resin. The UV light-cured resin is prepared from the raw materials: polyurethane acrylate, active monomers, a solvent, a light initiator, a silver stabilizer, graphene quantum dots and ATO. Compared with the existing polyurethane acrylate UV light-cured resin, the UV light-cured resin provided by the invention is greatly improved in the aspects of water resistance, bending resistance, surface hardness and solvent resistance, and is more suitable for the silver nanowire conductive film.

Owner:合肥微晶材料科技有限公司

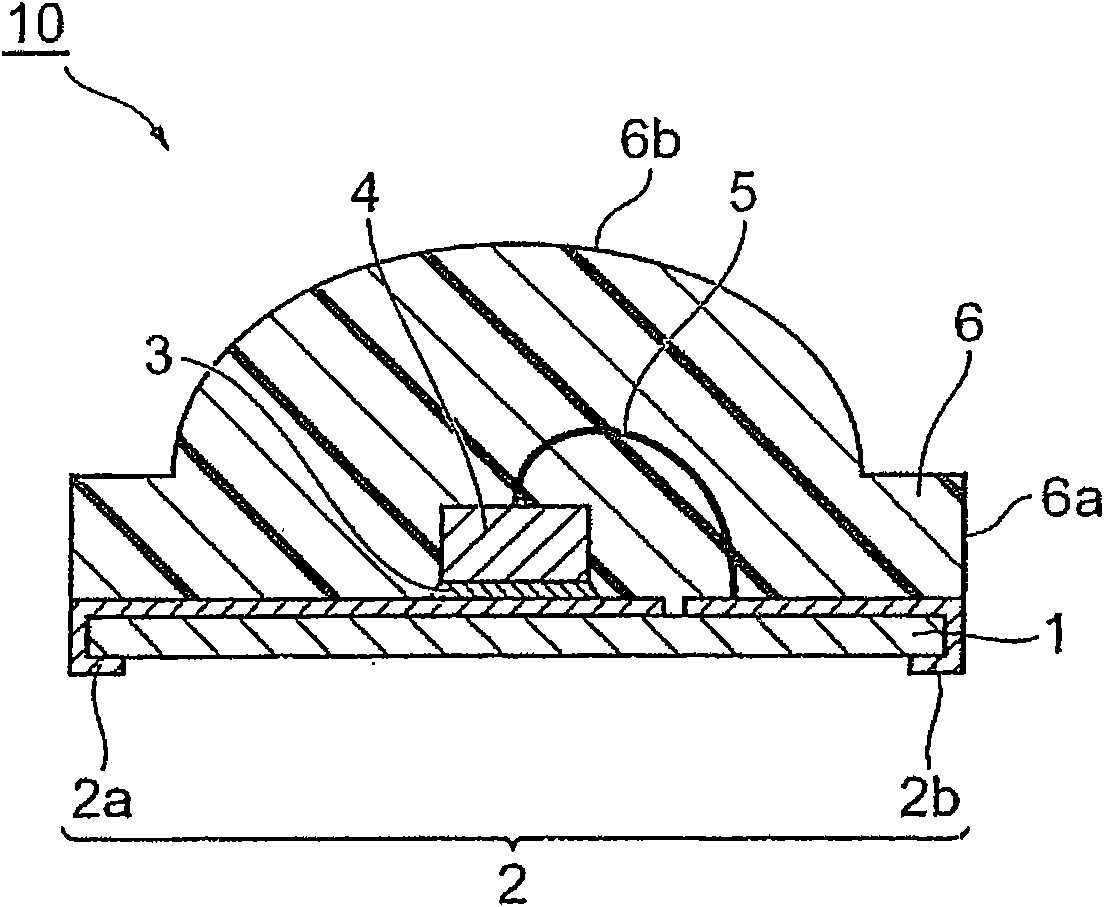

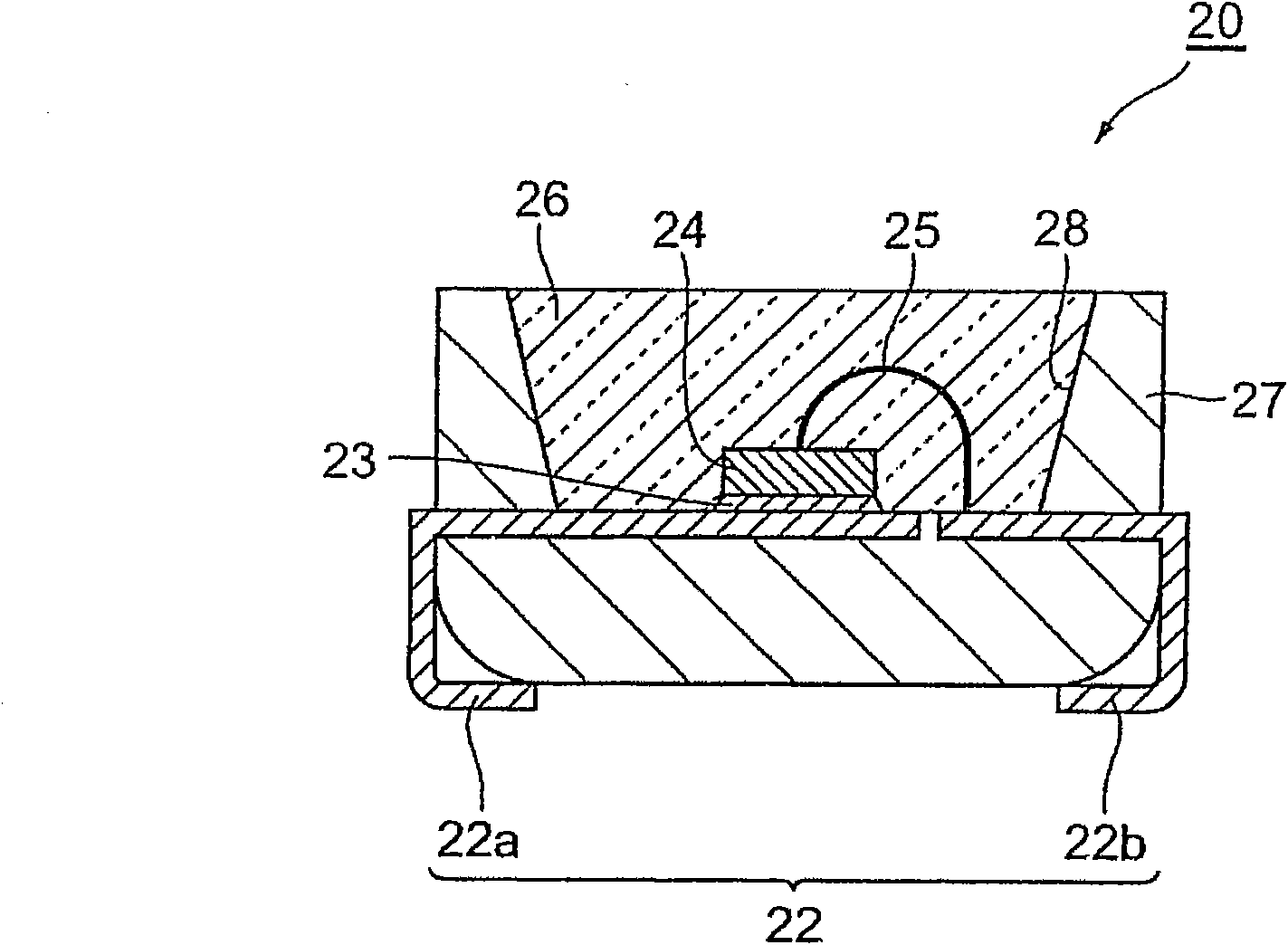

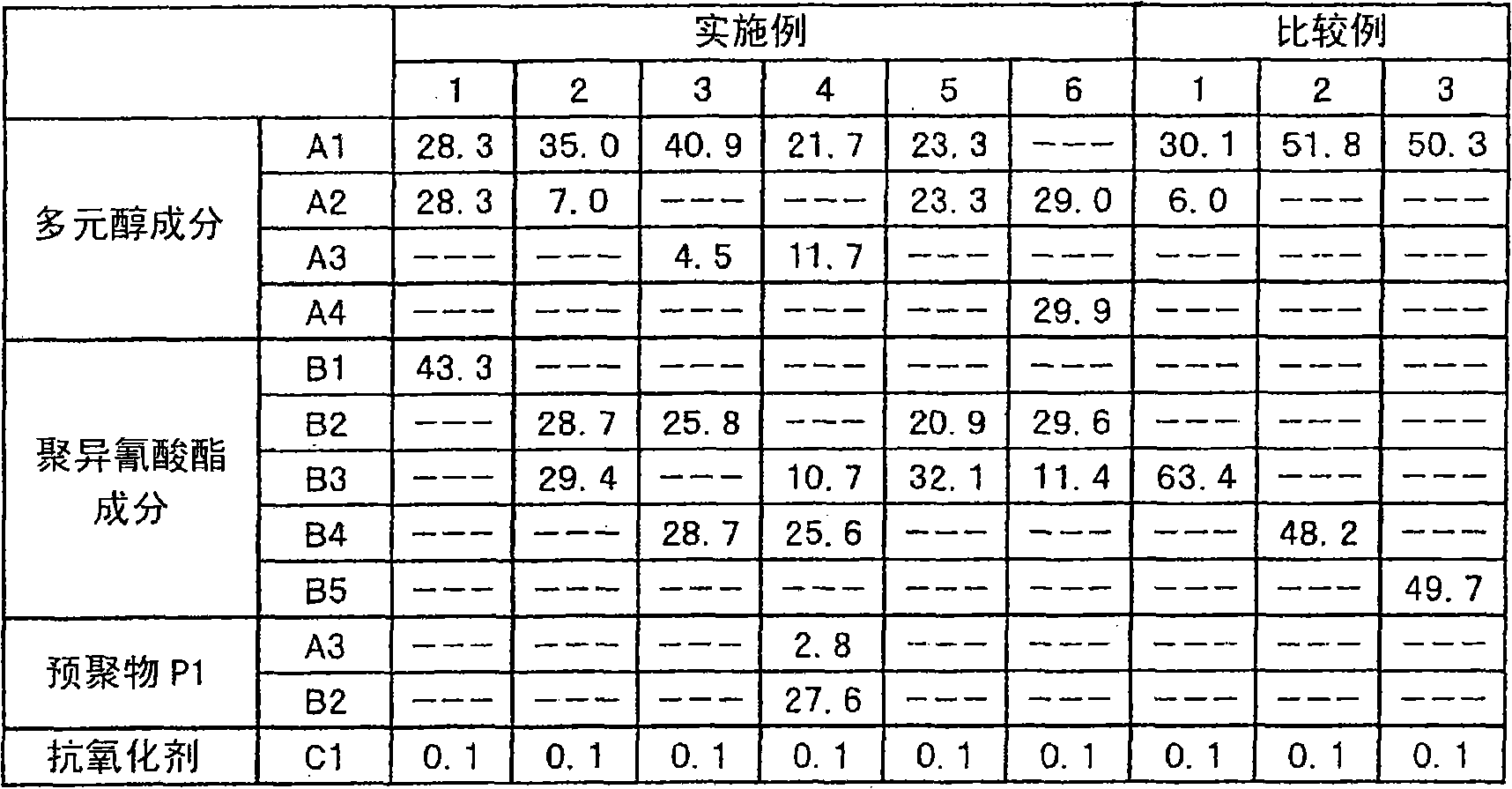

Curable resin composition, led package, and method for production of the led package, and optical semiconductor

InactiveCN101668786AHigh transparencyHigh glass transition temperatureSolid-state devicesSemiconductor devicesChemical structurePolyol

The curable resin composition of the present invention comprises a polyol component containing tri- or higher functional polycaprolactone polyol; and a polyisocyanate component containing bifunctional or trifunctional alicyclic isocyanate having one or more chemical structures in which an isocyanate group is bonded to a secondary carbon atom.

Owner:RESONAC CORPORATION

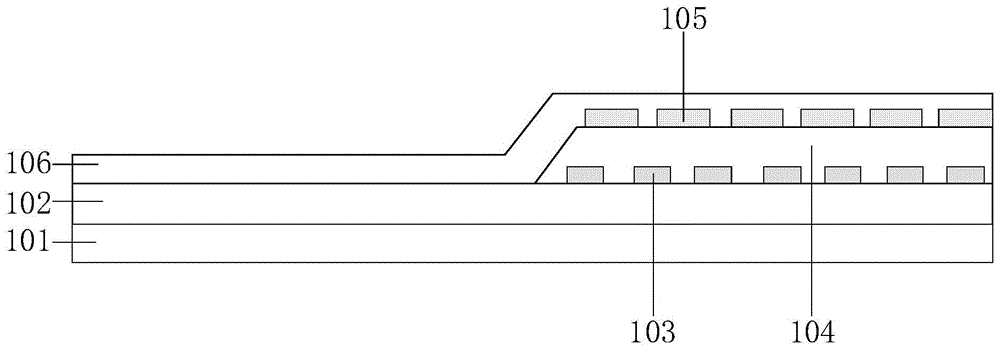

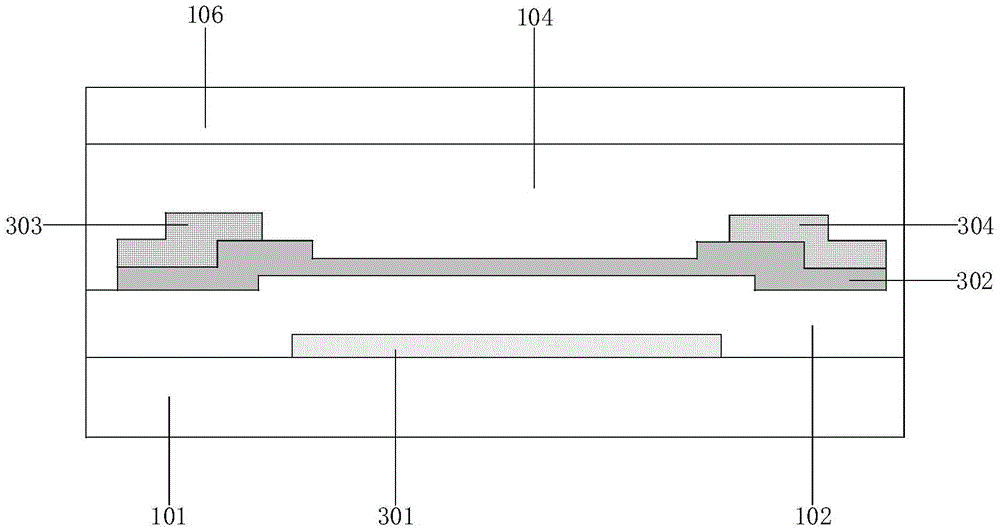

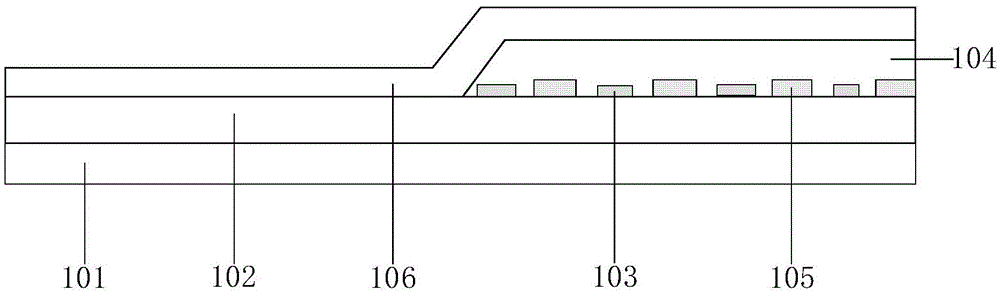

Array substrate and preparation method thereof, display panel and display device

InactiveCN105575979AImprove reliabilityExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporDisplay device

The invention discloses an array substrate and a preparation method thereof, a display panel and a display device. The array substrate is characterized in that a heat conductive layer is arranged on the surface of an organic material layer; and the heat conductive layer plays a heat conduction role, thereby reducing heating expansion degree of the organic material, preventing expansion of the organic material from influencing bonding force between the organic material layer and a gate insulator layer and a passivation layer, and finally, preventing generation of gap between the organic material layer and the gate insulator layer as well as the passivation layer. The technical scheme can prevent gaps from being formed between the layers, and water vapor cannot enter a display region of the display panel through the gaps in the high temperature high moisture high pressure test, thereby preventing bubbles from appearing in the display region, improving high-temperature-resistant and high-moisture-resistant performance of the organic material layer, and finally, improving the reliability and the service life of the display device in severe environment.

Owner:BOE TECH GRP CO LTD +1

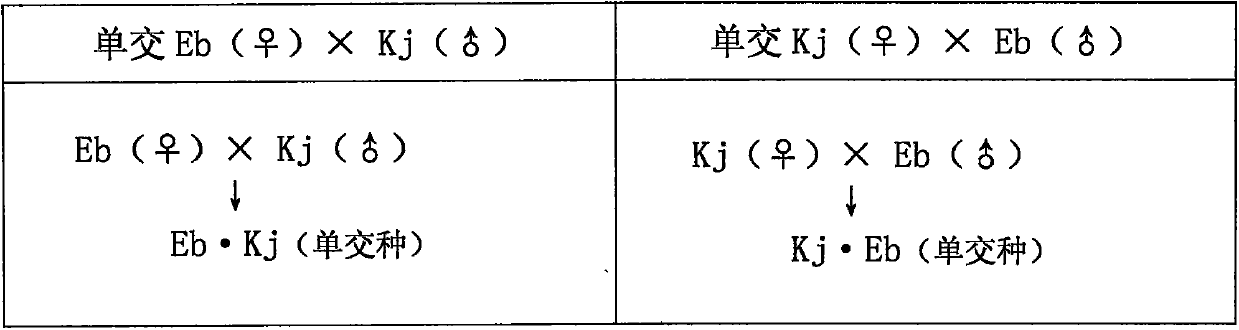

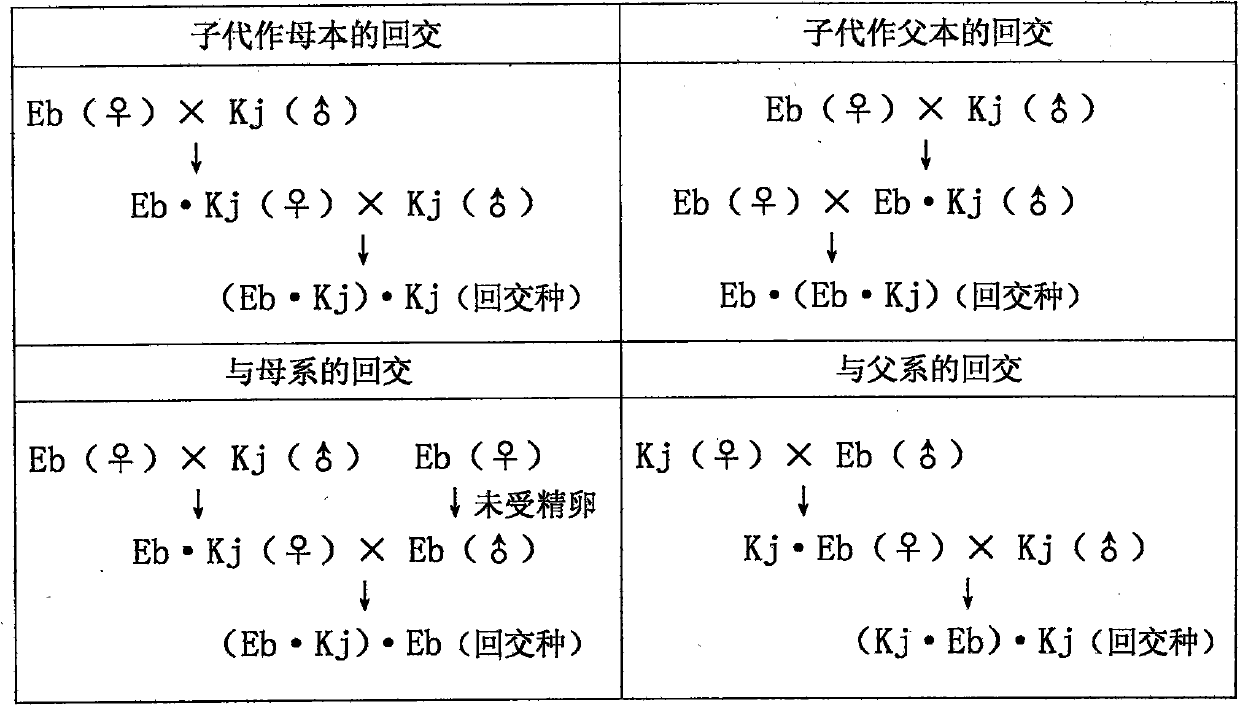

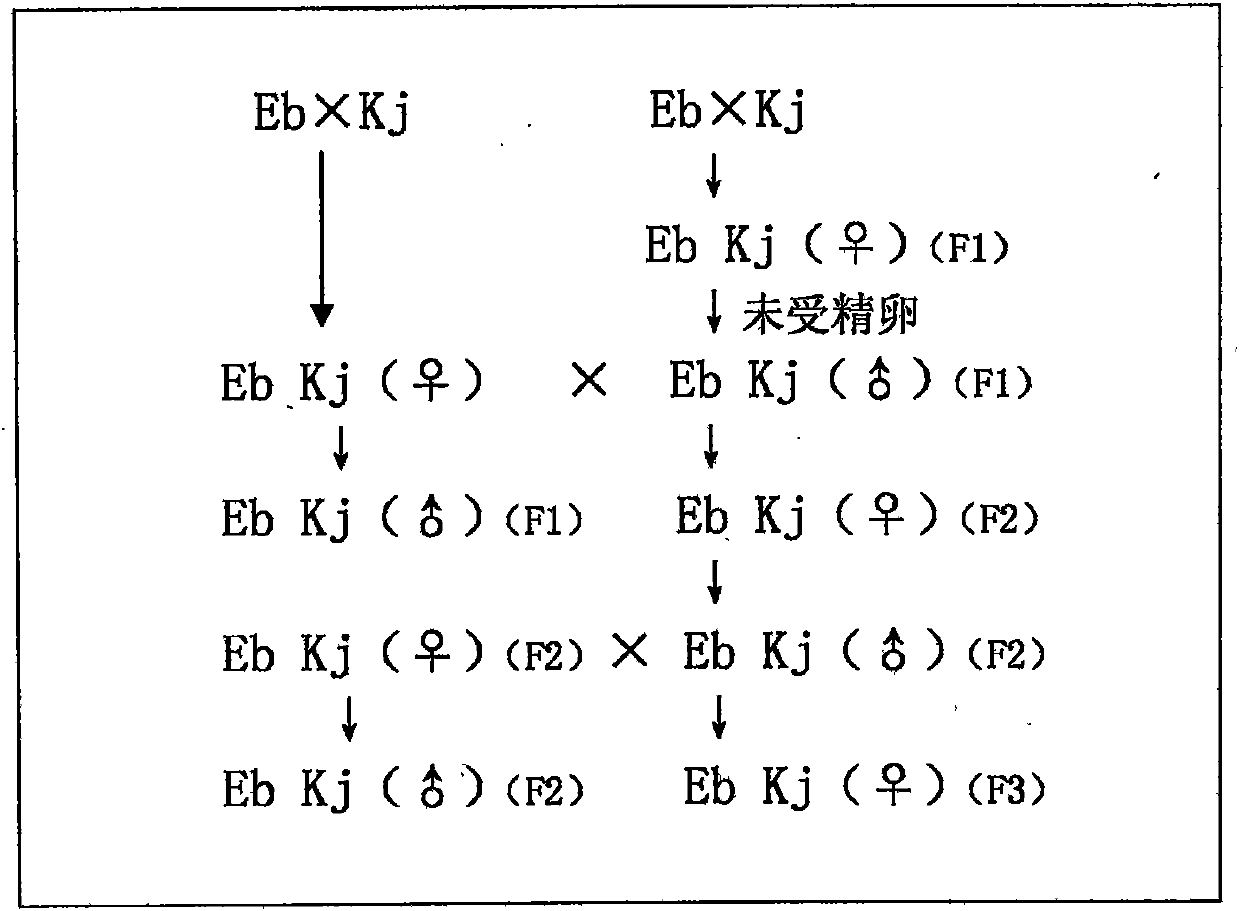

Breeding method for good bee species for facility crop pollination

The invention relates to the bee keeping technology, provides a breeding method for a good bee species for facility crop pollination, and aims at solving the problems that an existing good bee species for facility crop pollination is fewer, poor in quality and poor in pollination effect. The method comprises the steps that local Apis mellifera is bred, a Jolnalof bee species is introduced and bred, a single cross or backcross mode is adopted, and a good variety (strain) which meets the biological property of bees and can be used for effective pollination of facility crops is bred through many times of artificial insemination hybridization. The good properties of being high in collection, high in spawning rate, high in stress resistance, high in disease resistance, docile in temper, low in fodder consumption and the like are achieved, the movement enthusiasm of the pollination bees in a facility crop environment is remarkably improved, crop pollination is effectively achieved, and the pollination effect of the crops is improved.

Owner:GANSU APICULTURE TECH PROMOTION STATION

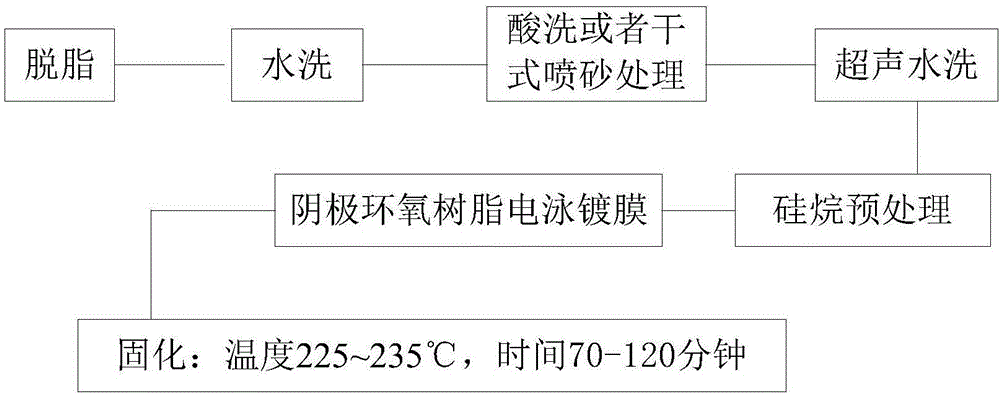

Method for improving performance of epoxy resin plating of neodymium iron boron permanent magnet

ActiveCN106544715AReduce the influence of magnetismImprove high temperature and high humidity performanceElectrophoretic coatingsEpoxyHigh humidity

The invention discloses a method for improving the performance of an epoxy resin plating of a neodymium iron boron permanent magnet. The method comprises the steps that firstly, the neodymium iron boron permanent magnet is coated with the epoxy resin plating in a cathodic electrophoresis mode, so that the neodymium iron boron permanent magnet coated with the epoxy resin plating is obtained; and secondly, the epoxy resin plating coated on the surface of the neodymium iron boron permanent magnet is solidified with the solidification temperature being 225-235 DEG C and the solidification time being 70-120 minutes. By adoption of the method for improving the performance of the epoxy resin plating of the neodymium iron boron permanent magnet, the high-temperature, high-humidity, high-pressure resistance and corrosion resistance of the epoxy resin plating of the neodymium iron boron permanent magnet can be improved, and the binding force of the epoxy resin plating of the neodymium iron boron permanent magnet can be increased; and a solidification process for the epoxy resin plating enables the product to reach the good level of longer than 264 hours in a pressure cooker test (PCT).

Owner:京磁材料科技股份有限公司

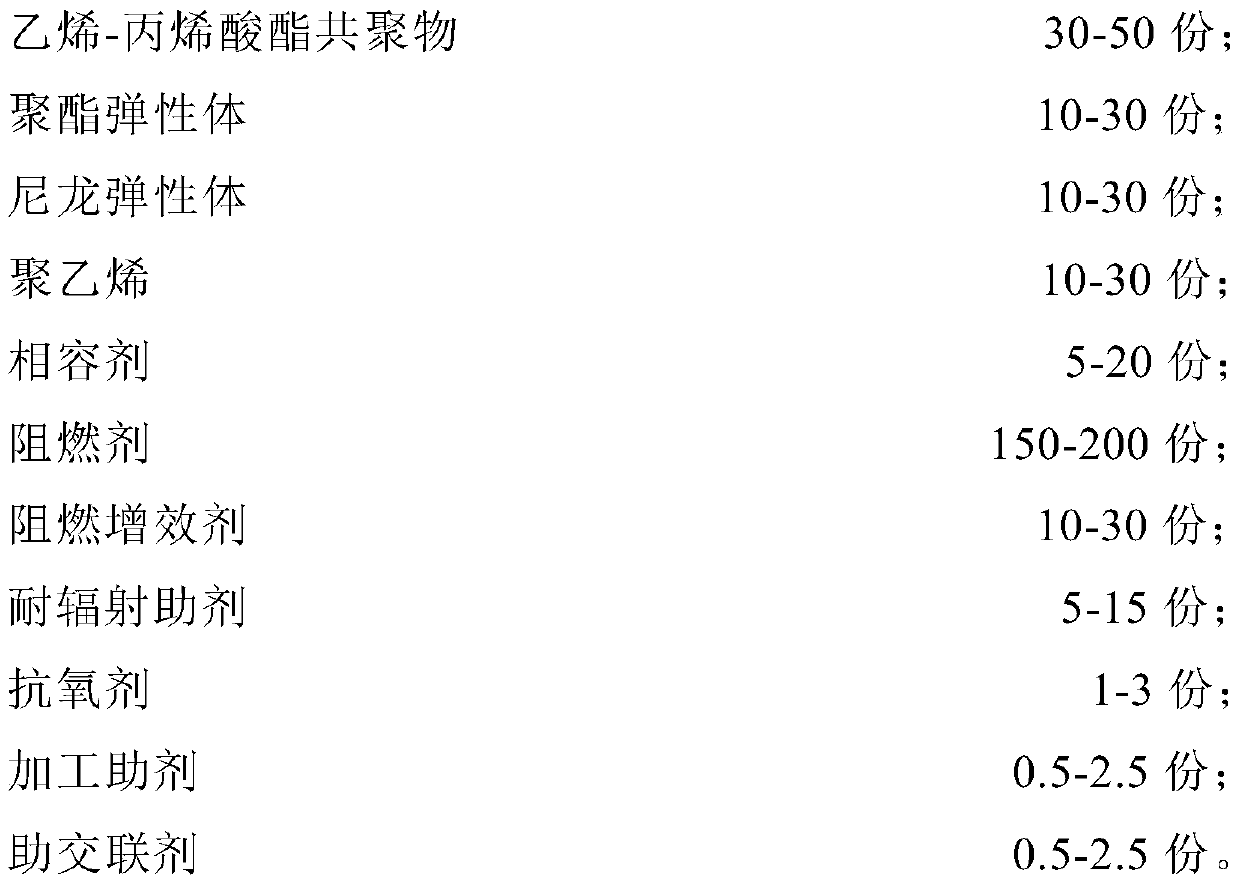

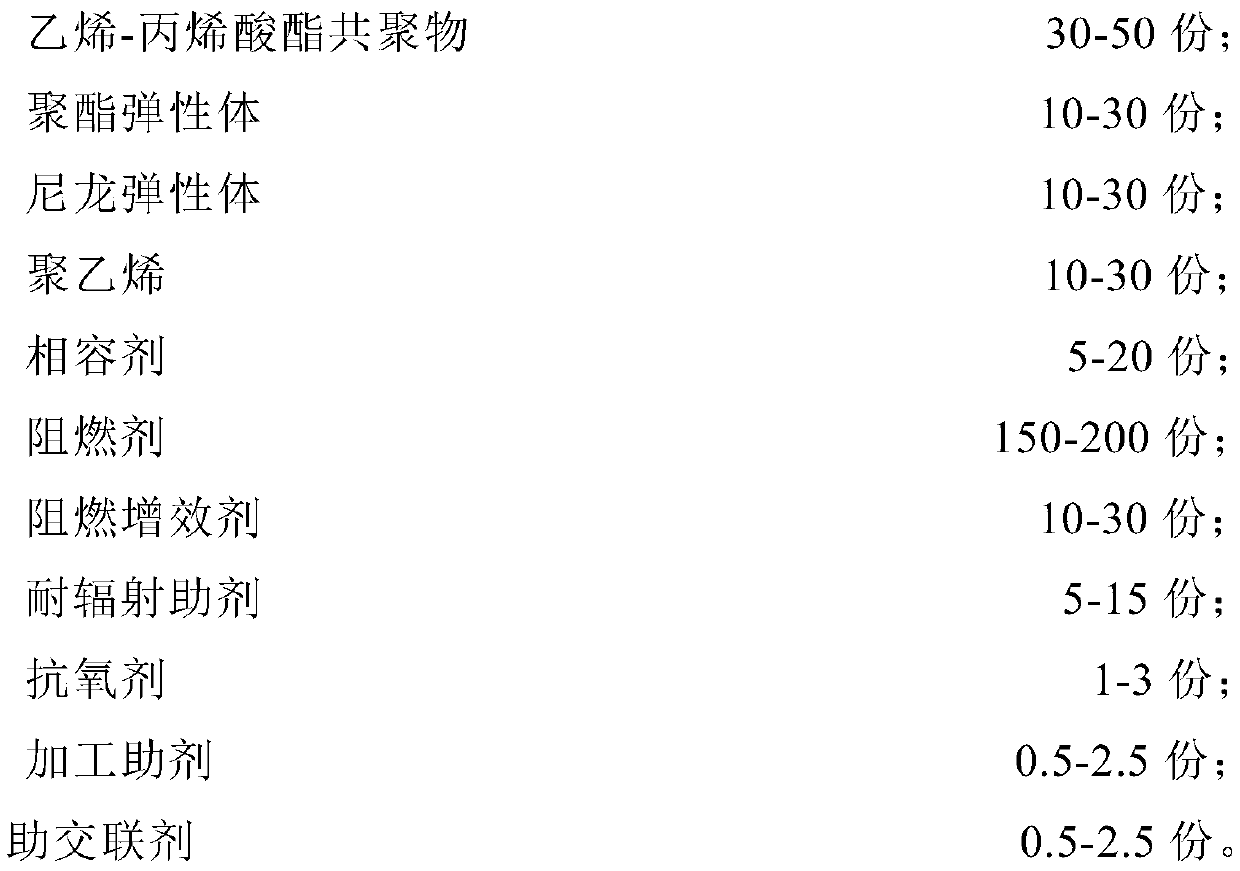

Nuclear-powered ship cable high-flame-resistance low-smoke halogen-free sheath material, and preparation method thereof

InactiveCN109705449AImprove high temperature and high humidity performanceGood low toxicityElastomerPolyester

The invention discloses a nuclear-powered ship cable high-flame-resistance low-smoke halogen-free sheath material, and a preparation method thereof. The nuclear-powered ship cable high-flame-resistance low-smoke halogen-free sheath material comprises, by weight, 30 to 50 parts of ethylene-acrylate copolymer, 10 to 30 parts of polyester elastomer, 10 to 30 parts of nylon elastomer, 10 to 30 parts of polyethylene, 5 to 20 parts of a compatilizer, 150 to 200 parts of a fire retardant, 10 to 30 parts of a flame retardant synergist, 5 to 15 parts of a radiation resistant auxiliary agent, 1 to 3 parts of an anti-oxidant, 0.5 to 2.5 parts of a processing auxiliary agent, and 0.5 to 2.5 parts of an auxiliary crosslinking agent.

Owner:上海至正新材料有限公司

Optical polyester film and method of manufacture thereof

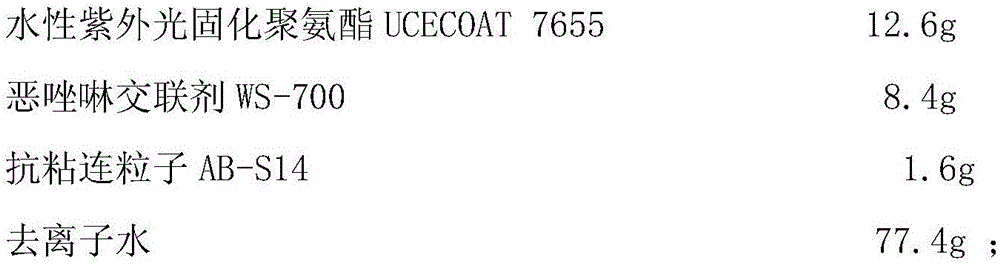

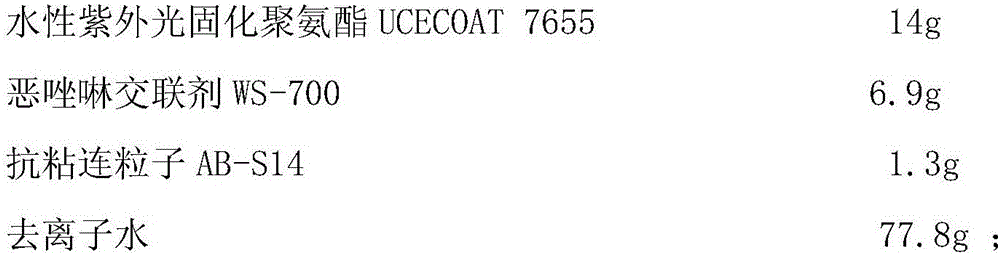

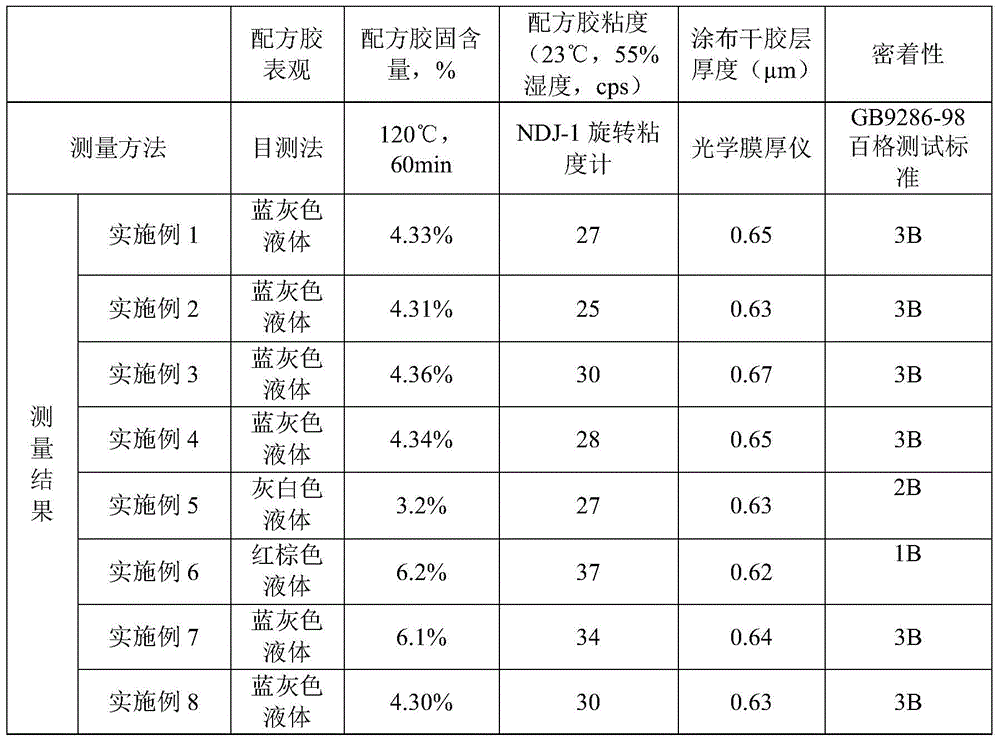

ActiveCN105754128AStrong adhesionExcellent reworkabilityPolyurea/polyurethane coatingsFlat articlesWater basedPolyester

The invention discloses an optical polyester film and a method of manufacture thereof.In the optical polyester film, at least one side of a biaxially stretched basic film is coated with a bottom coating, the bottom coating is made from the components according to percent by weight: 63-96% of water-based ultraviolet-cured polyurethane resin free of carboxylic acid, 3-30% of oxazoline cross-linking agent, and 1-7% of nano-scale anti-blocking particles that are 80 to 200 nm in particle size.The optical polyester film has excellent adhesion and high transparency, has good bonding resistance and is applicable to high-end film material fields such as LCD (liquid crystal display) display device field and high-end IMD (in-mod decoration) processing.

Owner:HEFEI LUCKY SCI & TECH IND

Processing method for electromagnetic shielding of magnesium alloy surface and magnesium alloy product

InactiveCN102560365AImprove electromagnetic shielding performanceImprove corrosion resistanceLiquid surface applicatorsSynthetic resin layered productsEpoxyTitanium metal

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

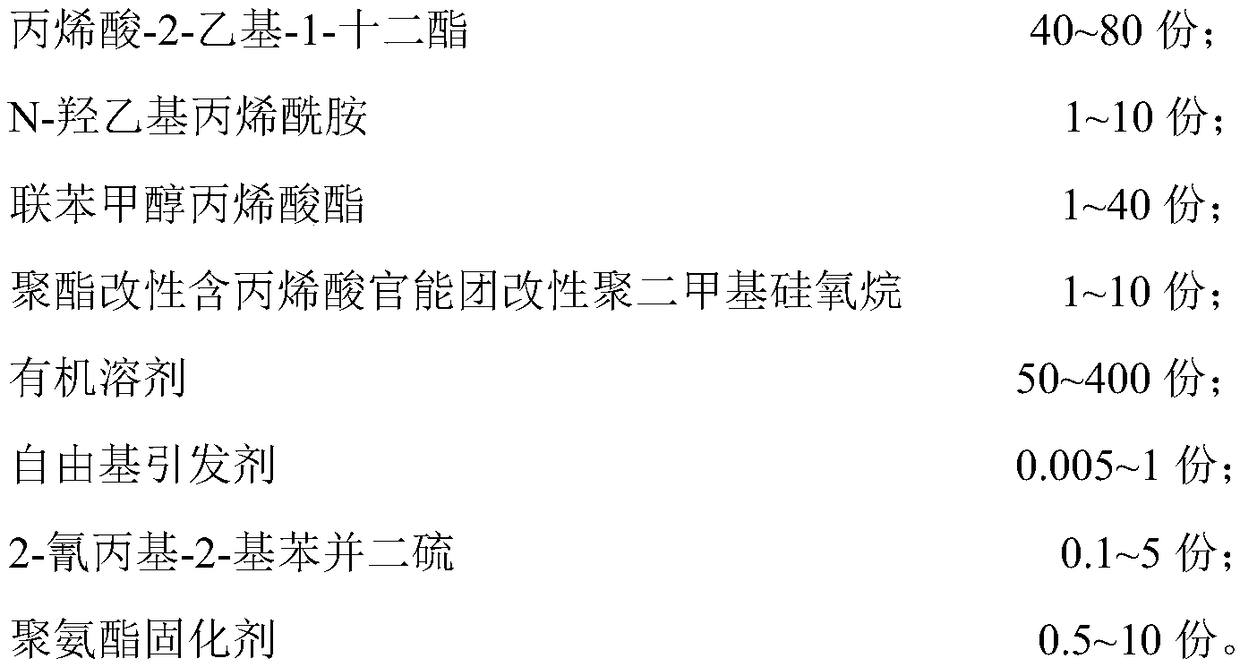

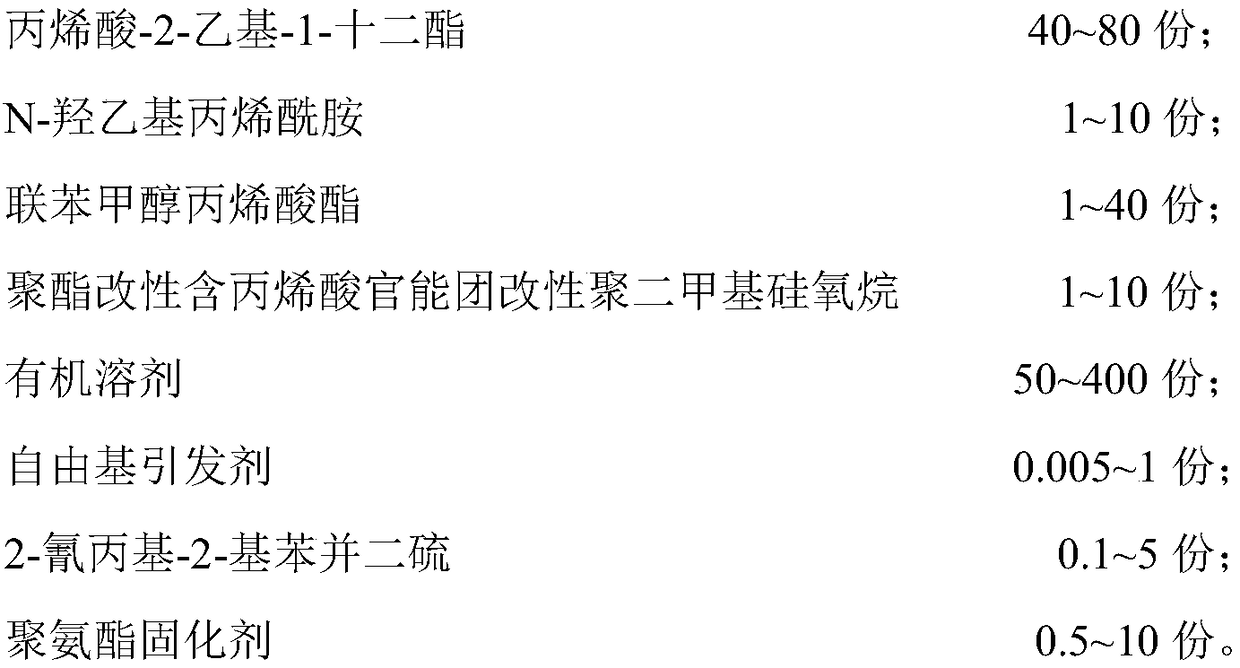

Silicone-modified OCA optical adhesive, optical adhesive tape, and preparation methods thereof

InactiveCN108753181AGood hydrophobicity and heat resistanceImprove humidity and temperature resistanceFilm/foil adhesives without carriersGraft polymer adhesivesAdhesiveLiving polymerization

The invention discloses a silicone-modified OCA optical adhesive which utilizes compounding of 2-ethyl-1-dodecyl acrylate, polyester-modified acrylic functional group-containing modified polydimethylsiloxane and biphenyl methanol acrylate, to make characteristics of the high-temperature and high-humidity resistant monomer, the high-temperature resistant silicone monomer and the high-refractivity monomer be effectively synergized and perform excellent compatibility and adaptability; further, other raw material components are adjusted to achieve higher adaptability. Therefore, the OCA optical adhesive can participate in a polymerization reaction according to a controlled living polymerization (RAFT polymerization) method, and has the advantages of low modulus, good hydrophobic property, andgood initial adhesion performance; performances such as resistance to humidity, heat, impact and aging of the OCA optical adhesive are enhanced. The invention further discloses a preparation method ofthe silicone-modified OCA optical adhesive, an optical adhesive tape using the silicone-modified OCA optical adhesive, and a preparation method of the optical adhesive tape.

Owner:GUANGDONG DONGLI NEW MATERIALS SCI & TECH CO LTD

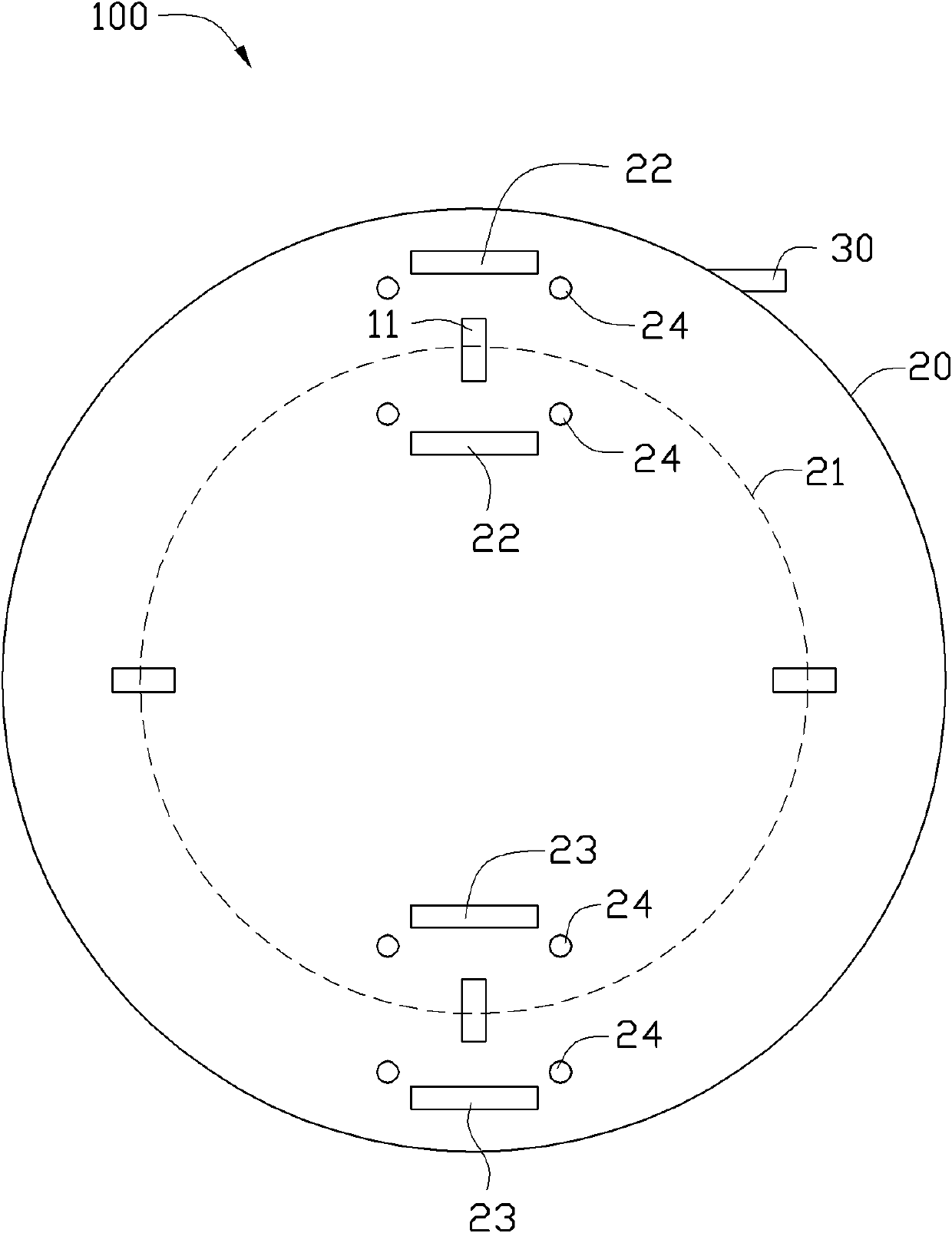

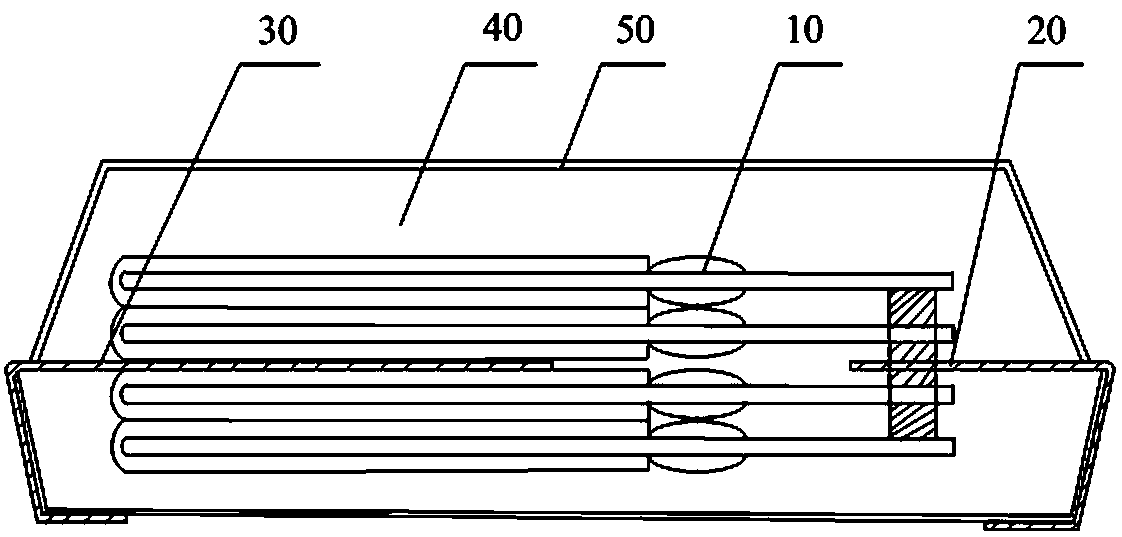

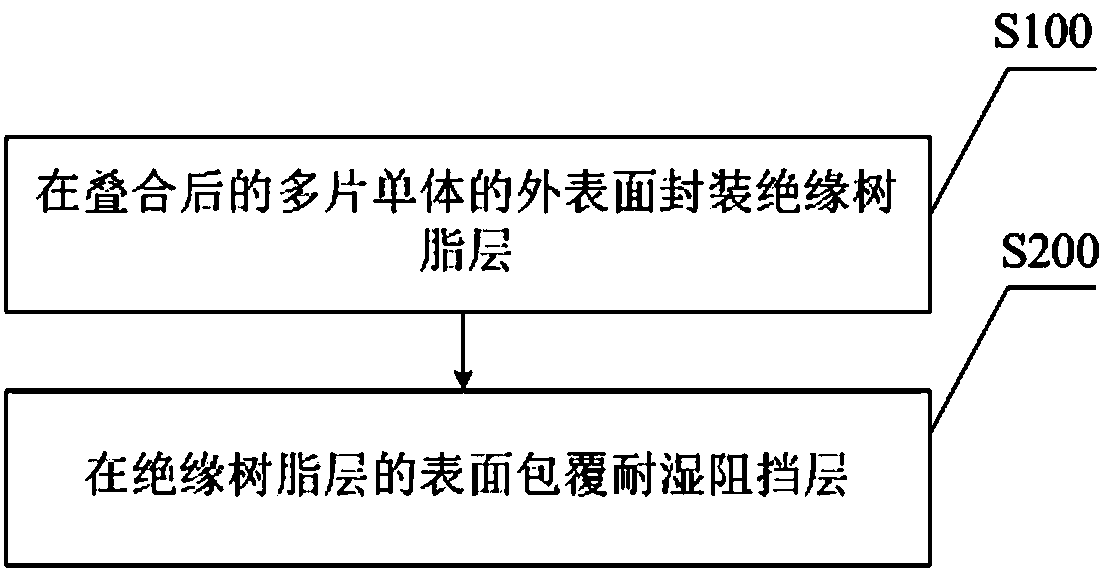

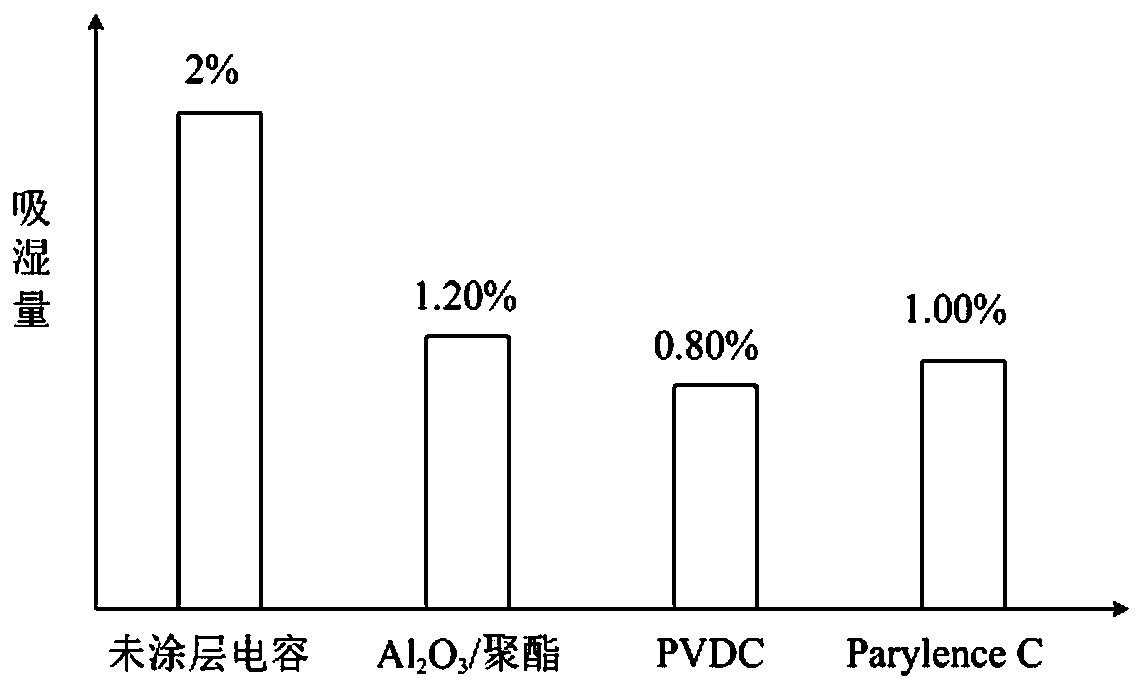

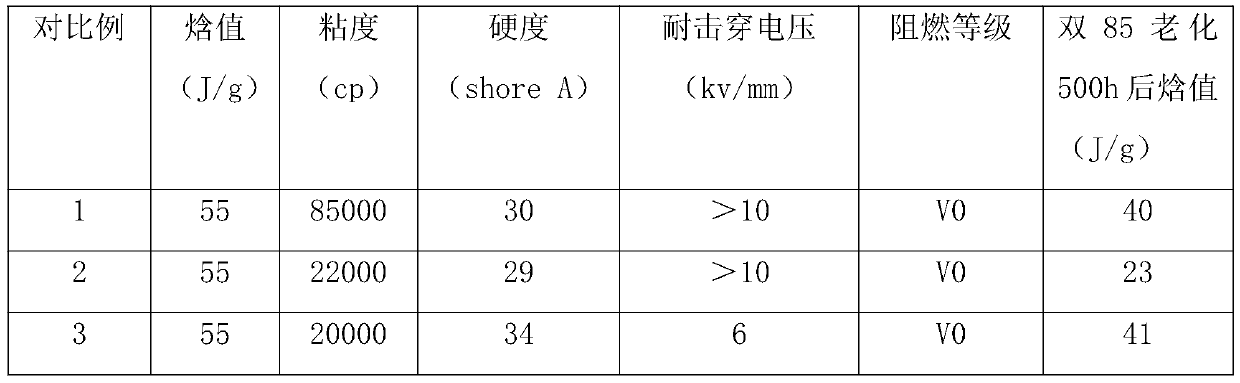

Humidity-resistant laminated solid-state aluminium electrolytic capacitor and manufacturing method thereof

PendingCN108766771AImprove high temperature and high humidity performanceImprove qualitySolid electrolytic capacitorsCapacitor housing/encapsulationElectrolysisMoisture permeability

The invention discloses a humidity-resistant laminated solid-state aluminium electrolytic capacitor and a manufacturing method thereof. The humidity-resistant laminated solid-state aluminium electrolytic capacitor comprises a plurality of stacked single slices, and a positive lead-out terminal and a negative lead-out terminal electrically connected to the stacked single slices; wherein each singleslice comprises a positive end, a negative end and a shielding glue between the positive end and the negative end; the negative ends of each single slice are connected together and connected with thenegative lead-out terminal; the positive ends of each single slice are connected together and connected with the positive lead-out terminal; the outer surface of stacked plurality of single slices isencapsulated with an insulating resin layer; and the outer surface of the insulating resin layer is coated with a moisture-resistant barrier layer for water resisting, wherein the moisture permeability coefficient of the moisture-resistant barrier layer is lower than that of the insulating resin layer. The humidity-resistant laminated solid-state aluminium electrolytic capacitor and the manufacturing method provided by the invention can effectively reduce the equivalent series resistance and leakage current of the laminated solid-state aluminium electrolytic capacitor and improve the productquality.

Owner:YIYANG AIHUA FUXIAN ELECTRONICS

Pouring sealant based on phase-change microcapsules and preparation method of pouring sealant

PendingCN111269689ALow viscosityImproved heat storage and temperature control capabilitiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesTemperature controlCompound a

The invention relates to the technical field of thermal management of electronic components, and particularly discloses a flame-retardant, insulating and reliable pouring sealant based on phase-changemicrocapsules, which is prepared from the following components in percentage by mass: 25 to 40 percent of double-component pouring sealant, 25 to 35 percent of phase-change microcapsules, 30 to 45 percent of flame retardant and 1 to 15 percent of other auxiliary agents. The invention also discloses a preparation method of the pouring sealant. The preparation method comprises the following steps:carrying out surface treatment on the phase-change microcapsules; compounding a flame retardant; and preparing the pouring silica gel. The surface of the phase change microcapsule is treated, so thatthe dispersity of the phase change microcapsule in colloid is improved, and meanwhile, the stability of the system is improved. By adding the phase change microcapsules, the heat storage and temperature control capability of the pouring sealant can be enhanced. The pouring sealant provided by the invention has good heat storage and temperature control performance and good high-temperature and high-humidity resistance.

Owner:STONEPLUS THERMAL MANAGEMENT TECH

Two-component transparent epoxy resin optical fiber adhesive

InactiveCN102757756ANo penetrationGood light transmissionEpoxy resin adhesivesAdhesiveOptical communication

The invention relates to a two-component transparent epoxy resin optical fiber adhesive which is formed by a base resin A and a curing agent B. components A and B are mixed at a proportion of 1: (0.01-0.02) and then used for construction, wherein component A is composed of 94.5%-96% of cycloaliphatic epoxy resin, 3%-5% of a flexibilizer and 0.3%-1.0% of a defoaming agent, and component B is a cation type curing agent. The optical fiber adhesive is transparent, low in viscosity, high in adhesion, not easy to crack, temperature and corrosion resistant; can be widely applied to optical fiber cable connectors, optical components and optical communications; and is simple in preparing process, low in producing cost, and suitable for mass industrial production.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

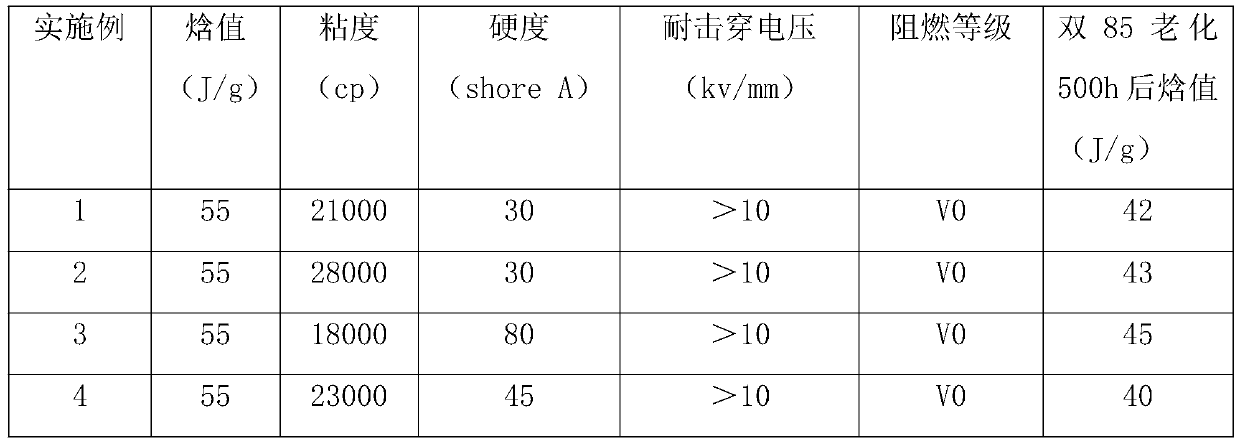

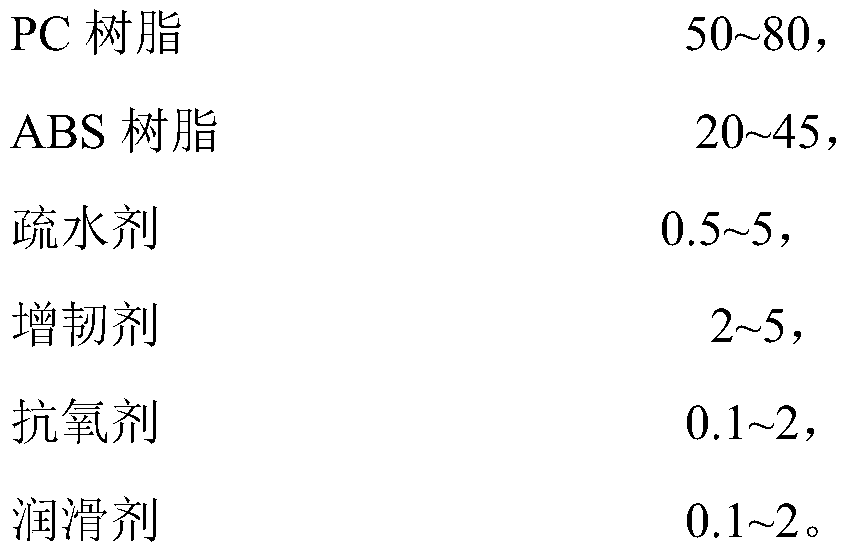

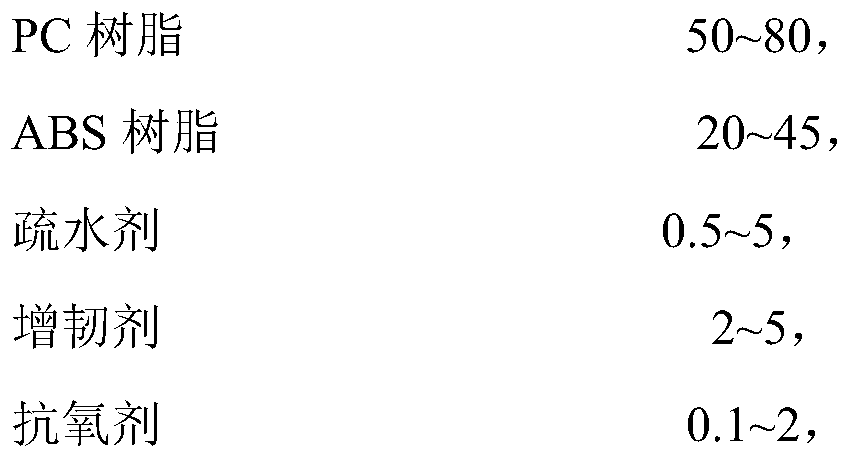

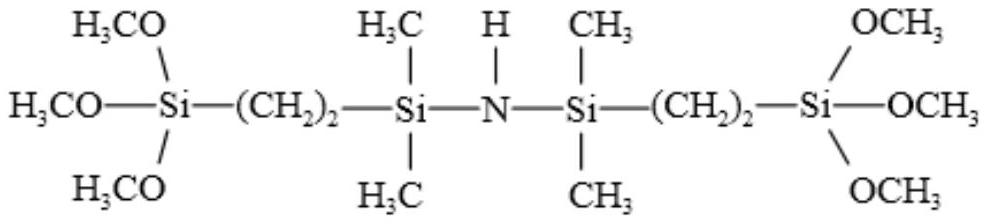

PC/ABS alloy with excellent damp-heat aging resistance and preparation method thereof

InactiveCN111234498AImprove high temperature and high humidity performanceAvoid hydrolysisPolymer scienceAnoxomer

The invention relates to a PC / ABS alloy with excellent damp-heat aging resistance and a preparation method thereof. The PC / ABS alloy comprises the following components in parts by weight: 50-80 partsof PC resin, 20-45 parts of ABS resin, 2-5 parts of a flexibilizer, 0.5-5 parts of a hydrophobic agent, 0.1-2 parts of an antioxidant and 0.1-2 parts of a lubricant. The preparation method of the alloy comprises the following steps: (a) adding the PC resin, the ABS resin, the hydrophobic agent, the flexibilizer, the antioxidant and the lubricant into a mixing stirrer and mixing the materials, and(b) blending and granulating the mixture obtained in the step (a) through a double-screw extruder, and carrying out melt extrusion and granulation to obtain the PC / ABS alloy. Compared with the prior art, the low-molecular-weight hydrophobic additive is adopted to enhance the damp-heat aging resistance of the PC / ABS, and the PC / ABS material with excellent long-term damp-heat aging resistance can beprepared.

Owner:SHANGHAI KUMHOSUNNY JINSHAN PLASTICS CO LTD

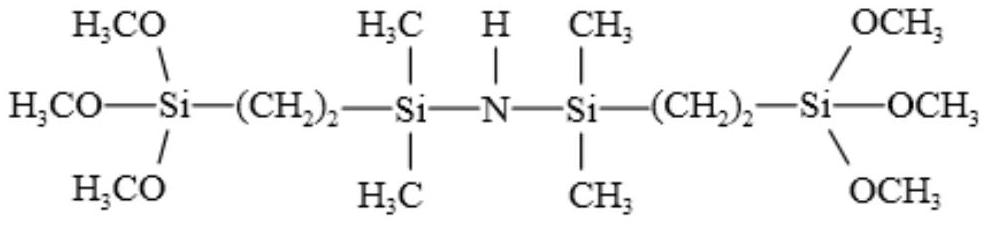

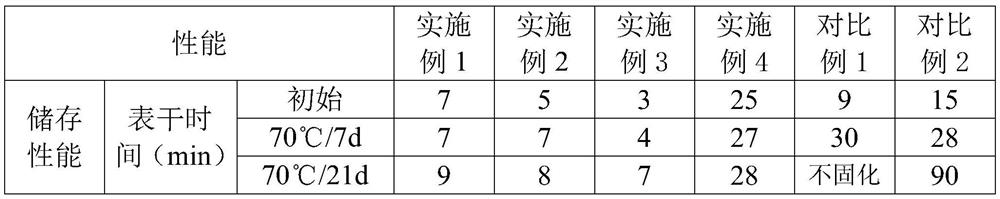

Dealcoholized room temperature vulcanized silicone rubber sealant and preparation method thereof

ActiveCN113956840AEasy to storeImprove storage effectAdhesivesPhotovoltaic energy generationPolymer scienceVulcanization

The invention provides a dealcoholized room temperature vulcanized silicone rubber sealant and a preparation method thereof. The sealant comprises, by weight, A, 100 parts of hydroxyl-terminated polydimethylsiloxane; 0.5-4 parts of an end-capping reagent; 0.01-0.1 part of an end-capping catalyst; 10-30 parts of dimethyl silicone oil; 80-150 parts of a reinforcing filler; 3-8 parts of a cross-linking agent; 0.5-3 parts of a silane coupling agent; and 0.5-5 parts of a moisture curing catalyst. According to the invention, the end-capping reagent is adopted to carry out end capping on the hydroxyl-terminated polydimethylsiloxane, the preparation process is rapid, simple and convenient, the reaction degree is high, the residual silicon hydroxyl is few, and the sealant has excellent high-temperature and high-humidity resistance and storage performance, and can be applied to sealing and bonding in the industries of electronics, photovoltaics, household appliances, automobiles and the like.

Owner:HAINAN NORMAL UNIV

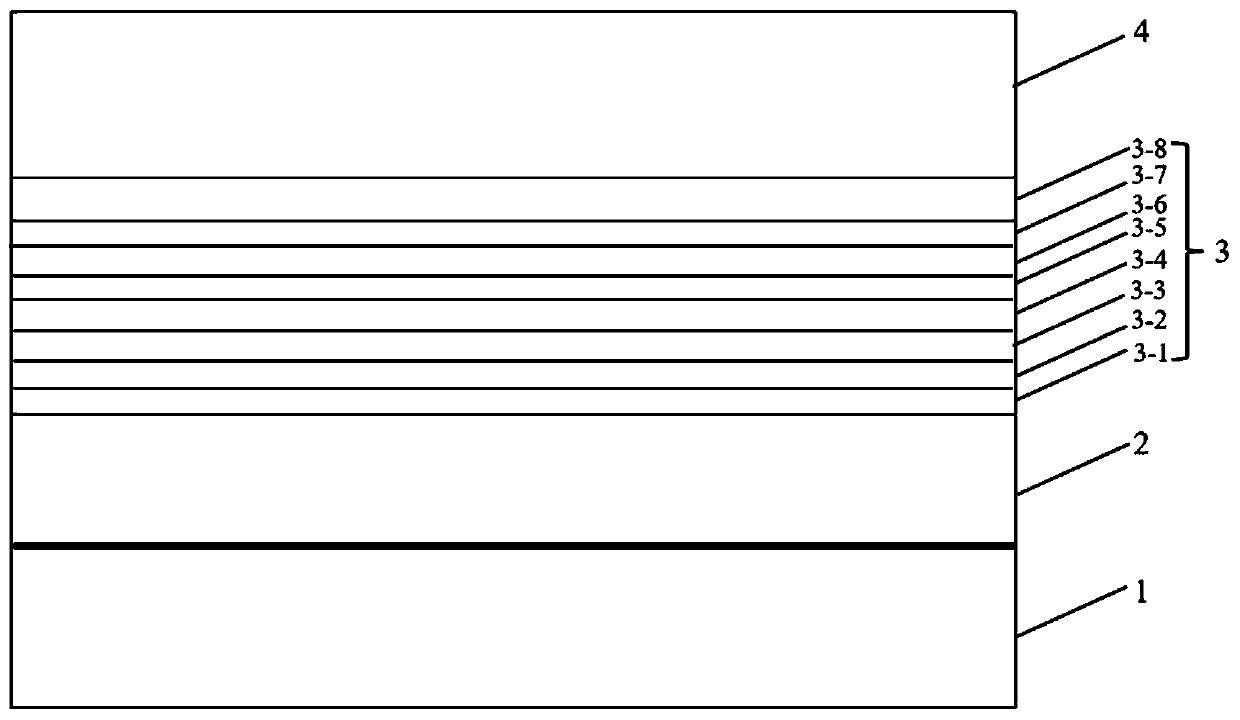

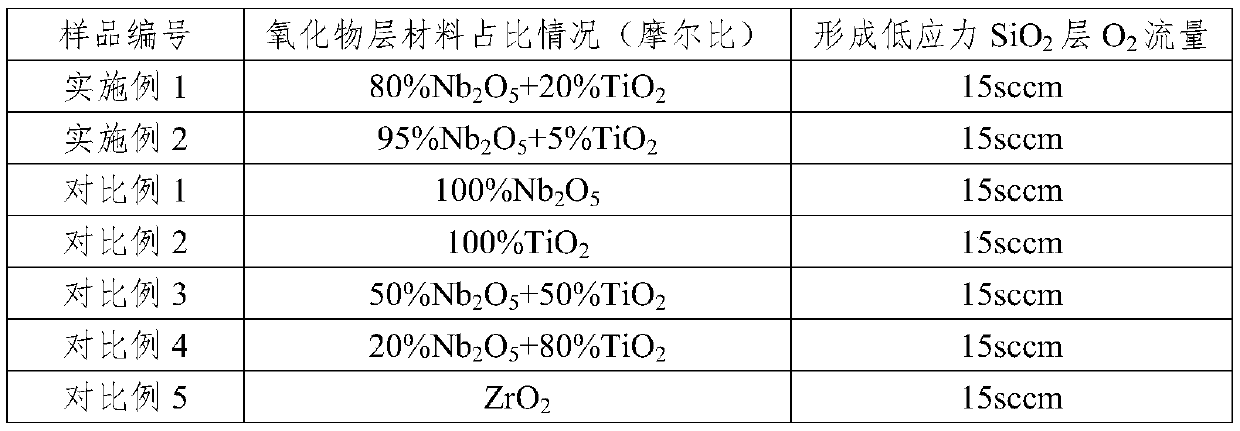

Low-reflection-color neutral low-stress resin lens and preparation method thereof

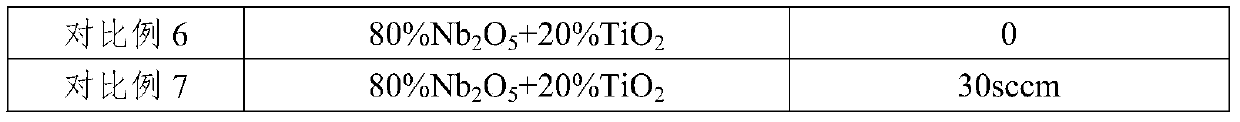

PendingCN111381299AIncreased durabilityGood repeatabilityVacuum evaporation coatingSputtering coatingRefractive indexEyewear

The invention provides a low-reflection-color neutral low-stress resin lens and a preparation method thereof. The low-reflection-color neutral low-stress resin lens comprises a resin lens substrate, ahardening layer and an antireflection layer, wherein the substrate, the hardening layer and the antireflection layer are sequentially arranged, the hardening layer is located on the surface of the resin lens substrate, and the antireflection layer is located on the surface of the hardening layer; the antireflection layer is mainly formed by alternately arranging niobium-titanium composite oxide (composed of Nb2O5 and TiO2, wherein the Nb2O5 accounts for 75%-95% of the molar fraction of the material) layers and low-refractive-index material layers, namely, special low-stress SiO2 film layers.By adjusting the structure of the antireflection layer, the resin lens meeting the antireflection rate is obtained, and meanwhile, a color neutral lens product with a good visual effect is obtained. By strictly controlling the material composition and the preparation process, the temperature resistance and the environmental resistance of the resin lens for preparing glasses are greatly improved, and the resin lens has good application and market prospects.

Owner:JIANGSU WANXIN OPTICAL

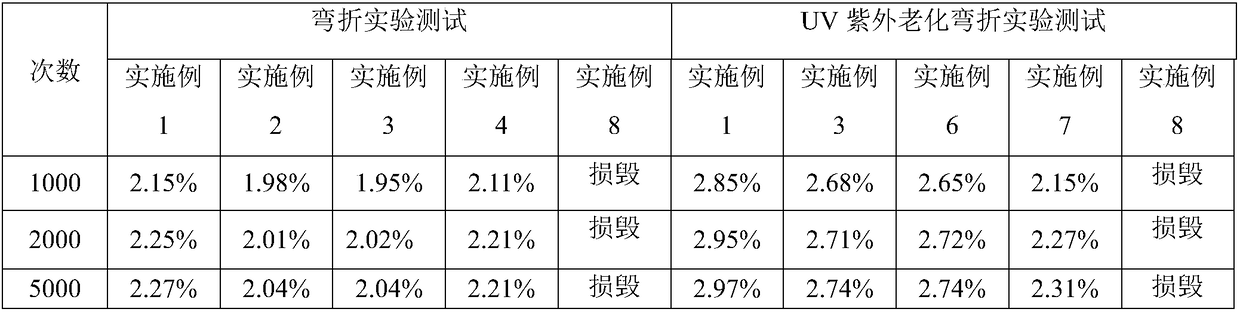

Vacuum coating layer and coating method thereof

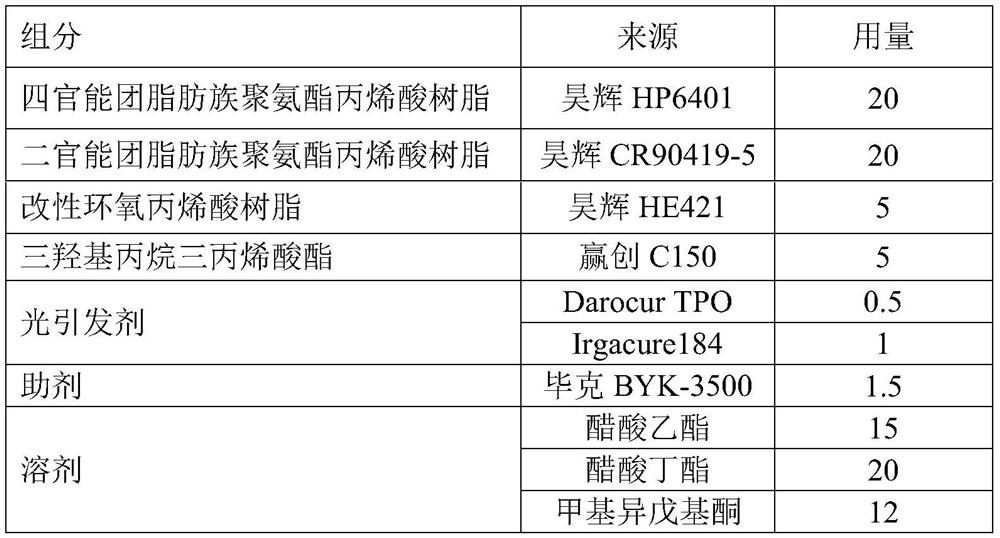

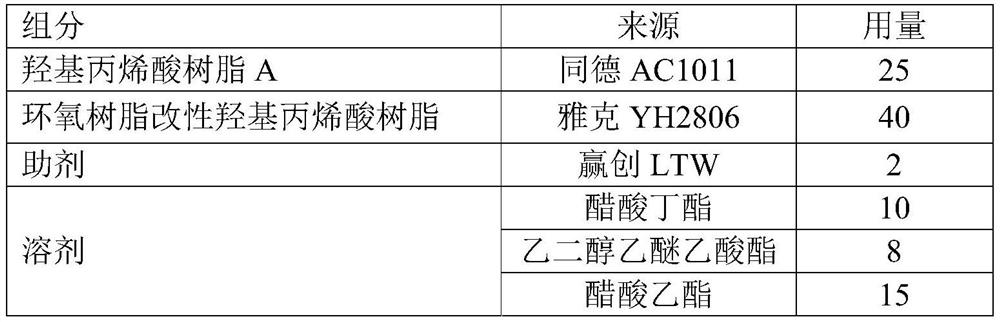

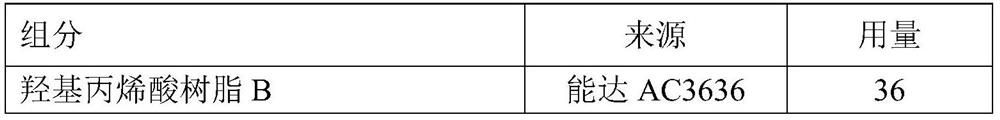

InactiveCN113845834AWith metallic textureImprove the level ofFireproof paintsVacuum evaporation coatingMetal coatingPolymer science

The invention relates to the technical field of paint, in particular to a vacuum coating layer and a coating method thereof. The vacuum coating layer comprises a primer layer, a metal coating layer, a middle paint layer and a finish paint layer which are sequentially stacked, the middle paint layer is made of hydroxyl acrylic resin with a low hydroxyl value; the finish paint layer is made of acrylic resin with a high hydroxyl value; the hydroxyl value of the acrylic resin with the low hydroxyl value is not higher than 3wt%, and the hydroxyl value of the acrylic resin with the high hydroxyl value is not lower than 3.5 wt%. Through interaction of the primer layer, the metal coating layer, the middle paint layer and the finish paint layer, the coating layer which is good in hardness, wear-resistant, weather-resistant and excellent in high-temperature and high-humidity resistance and has metal texture is prepared. Wherein the middle paint layer serves as an adhesion promoting layer, the adhesion between the middle paint layer and the metal coating layer is excellent, it can be guaranteed that the finish paint layer can be stably attached to the metal coating layer , and nano color paste can be added to make the coating layer achieve the metal texture and have the colorful effect at the same time.

Owner:HUIZHOU FEIKAI NEW MATERIAL CO LTD

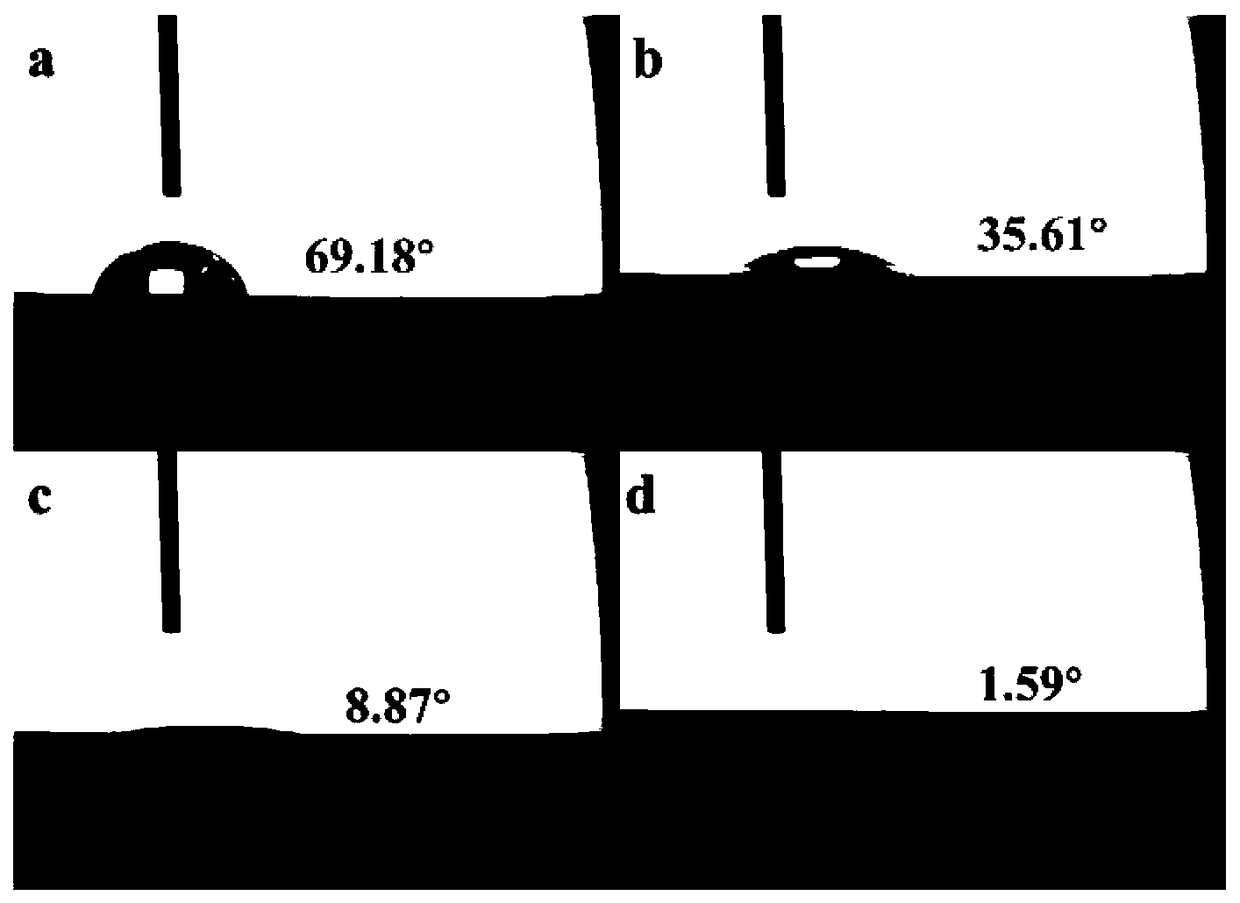

Highly durable super-hydrophilic coating

ActiveCN109401367AImprove high temperature and high humidity performanceReduce surface tensionAlkali metal silicate coatingsHydrophilic coatingSurface layer

Theinvention relates to a highly durable super-hydrophilic coating, comprising a base material, a surface layer and a bottom layer between the base material and the surface layer, wherein the bottom layer is an alcoholic super-hydrophilic silicone coating, and the surface layer is an inorganic water glass layer. The highly durable super-hydrophilic coating can greatly enhance the material bindingforce while retaining the super-hydrophilic surface, and can be used for a long time at normal temperature or high temperature and high humidity.

Owner:江苏先进无机材料研究院

High-thermal-expansion-coefficient thick-film dielectric paste for stainless steel base material and preparation method thereof

InactiveCN110880376ASoftening temperature adjustmentCrystallization temperature adjustmentNon-conductive material with dispersed conductive materialCable/conductor manufactureDielectricActive agent

The invention relates to high-thermal-expansion-coefficient thick-film dielectric paste for a stainless steel base material and a preparation method thereof. The thick-film dielectric paste is characterized by comprising the following components in percentage by weight: 70-80% of lead-free microcrystalline glass powder and 20-30% of an organic bonding phase. The lead-free microcrystalline glass powder is BaO-CaO-Al2O3-SiO2-B2O3-SrO-Sm2O3-ZrO2 series microcrystalline glass powder, and the lead-free microcrystalline glass powder comprises the following components in percentage by weight: 10%-20%of BaO, 10%-15% of CaO, 5%-10% of Al2O3, 20%-30% of SiO2, 5%-20% of B2O3, 5%-10% of SrO, 5%-10% of Sm2O3 and 1%-6% of ZrO2. And the organic bonding phase comprises the following components in percentage by weight: 70%-85% of an organic solvent, 2%-10% of a polymer thickener, 0.5%-5% of a dispersing agent, 0.5%-5% of a leveling agent, 0.5%-5% of a thixotropic agent and 0.5%-5% of a surfactant. Thehigh-thermal-expansion-coefficient thick-film dielectric paste for the stainless steel base material has the characteristics of high uniformity, high stability, high solid content and the like.

Owner:广东顺德弘暻电子有限公司

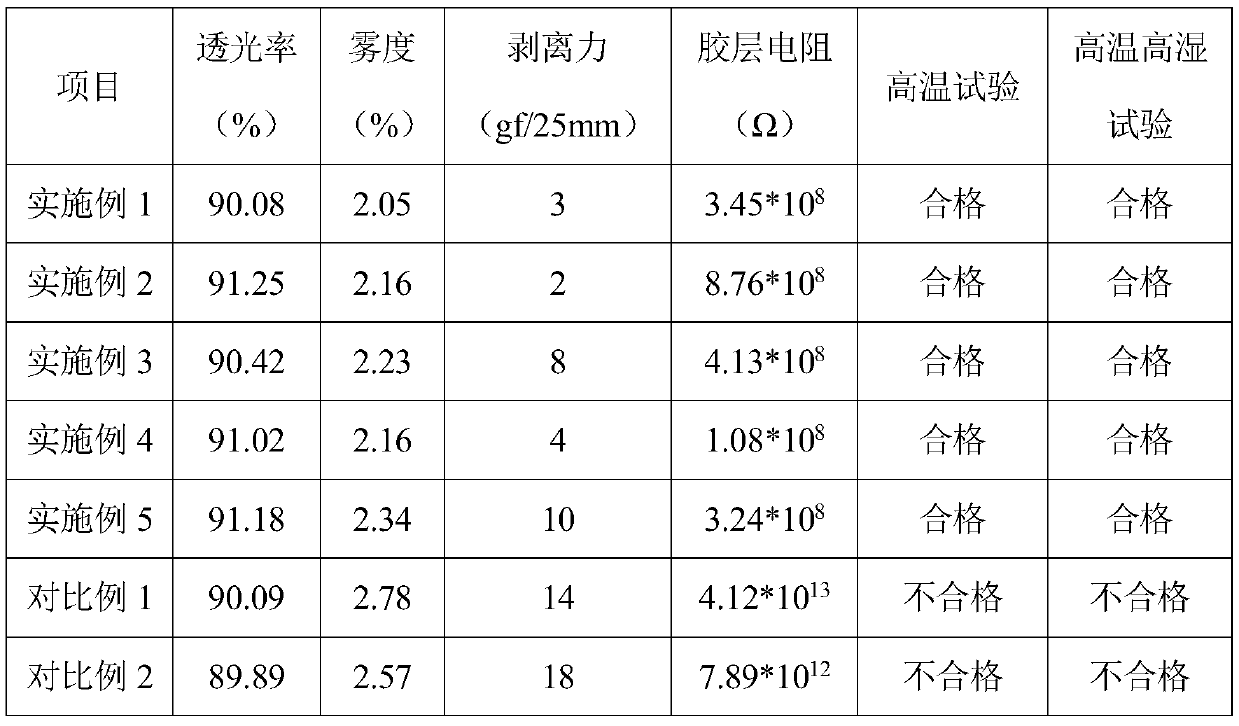

Emulsion pressure-sensitive adhesive for polarizer protective film, and polarizer protective film thereof

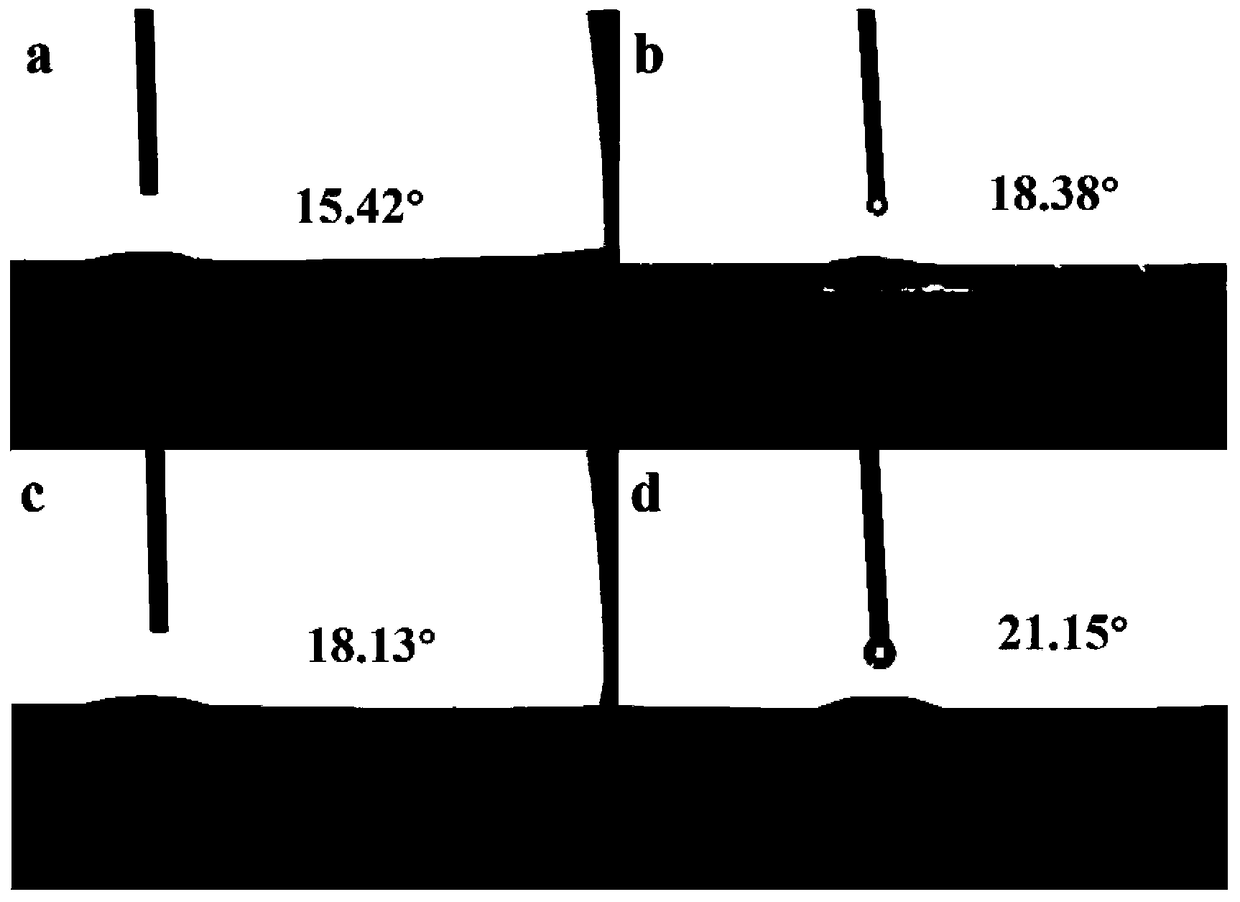

InactiveCN111187584AWith antistatic functionPrevent precipitationEster polymer adhesivesPressure sensitive film/foil adhesivesPolyesterSulfonate

The invention discloses an emulsion pressure-sensitive adhesive for a polarizer protective film, and the polarizer protective film thereof. The pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 100 to 200 parts of deionized water, 0.5 to 1.5 parts of a sulfonate reactive emulsifier, 1 to 4 parts of a double bond-containing quaternary ammonium salt monomer, 15 to 40 parts of a soft monomer, 5 to 10 parts of a hard monomer, 2 to 5 parts of a functional monomer and 1 to 4 parts of closed water-based isocyanate. According to the invention, the pressure-sensitive adhesive disclosed by the invention can be directly coated on the surface of a polyester film, an antistatic agent does not need to be added, the resistance of an adhesive layer is below 109 ohms, and the pressure-sensitive adhesive has an antistatic property; and when the polarizer protective film adhesive layer is attached to the surface of a polarizer, after high-temperature and high-temperature and high-humidity tests are carried out for 500 hours, the protective film and the polarizer are tightly attached, bubbles and bulges do not exist, and the defects of residual adhesive, shadows and the like do not exist when the protective film is torn off.

Owner:HEFEI LUCKY SCI & TECH IND

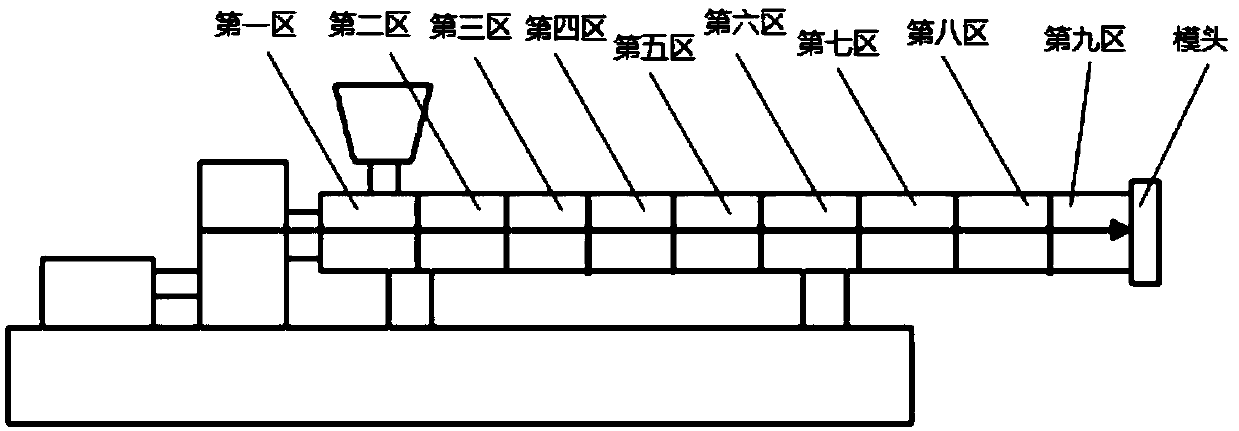

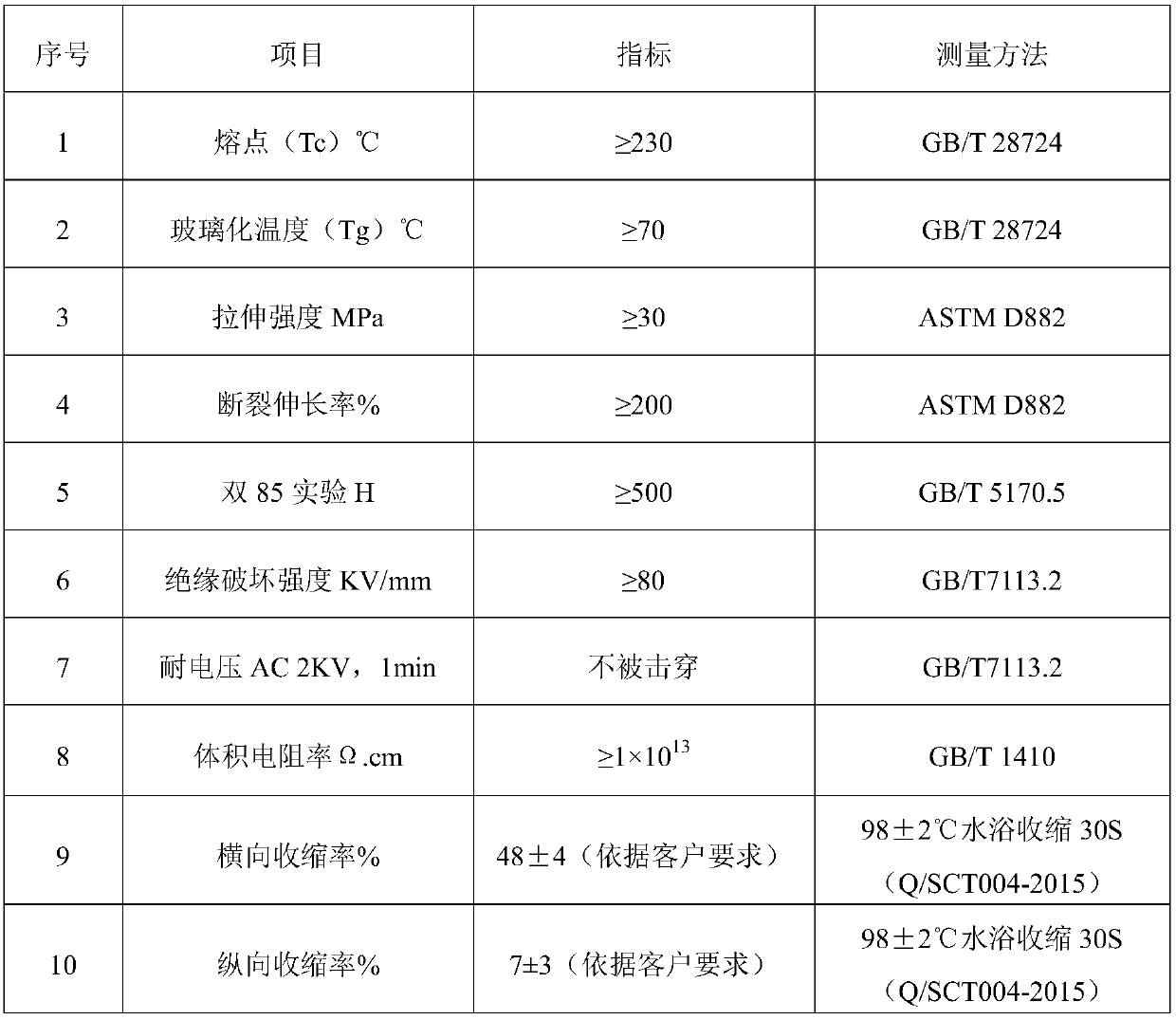

PET heat shrinkable sleeve material with high temperature and high humidity resistance and preparation method of PET heat shrinkable sleeve material

The invention provides a PET heat shrinkable sleeve material with high temperature and high humidity resistance and a preparation method of the PET heat shrinkable sleeve material. The PET heat shrinkable sleeve material with high temperature and high humidity resistance is prepared from the following components in percentage by mass: 45%-65% of PET, 10%-20% of PEN, 10%-25% of PCTG, 1%-2% of TPE,2%-10% of TPEE, 0.1%-3% of a hydrolysis resistant stabilizer and 0.1%-2% of an antioxidant, and the sum of the mass percentages of the components is 100%. The PET heat shrinkable sleeve material adopting the technical scheme not only has good shrinkage performance, but also has excellent mechanical strength and rigidity, and the most outstanding characteristic is that the PET heat shrinkable sleeve material has excellent high temperature and high humidity resistance after shrinkage, and is not brittle for 500 hours or longer especially when a double 85 high temperature and high humidity resistance test is carried out, and the high temperature and high humidity resistance is much higher than that of PET heat shrinkable sleeves on the common market.

Owner:CYG CHANGTONG NEW MATERIAL

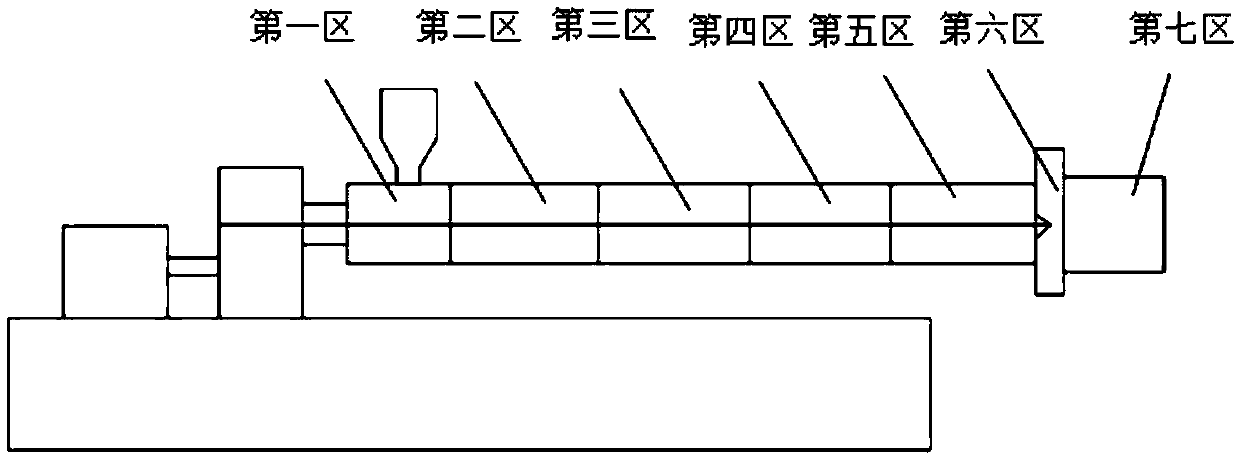

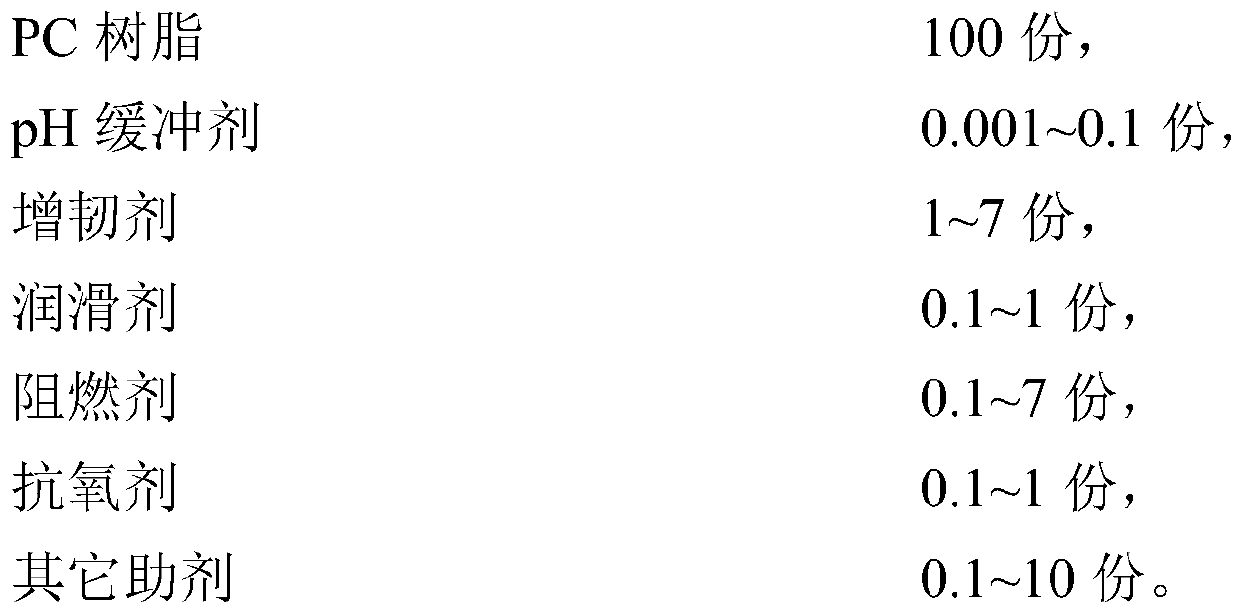

High-temperature-resistant and high-humidity-resistant flame-retardant PC plastic as well as preparation method and application thereof

The invention discloses a high-temperature-resistant and high-humidity-resistant flame-retardant PC plastic as well as a preparation method and application thereof. The flame-retardant PC plastic is prepared from the following raw materials in parts by weight: 100 parts of PC resin, 0.001 to 0.1 part of a pH buffering agent, 1 to 7 parts of a toughening agent, 0.1 to 1 part of a lubricating agent,0.1 to 7 parts of a flame retardant, 0.1 to 1 part of an antioxidant and 0.1 to 10 parts of other auxiliary agents. The preparation method comprises the following steps: uniformly mixing all the rawmaterials in proportion, feeding the mixture into a double-screw extruder through main feeding, plasticizing, exhausting, plasticizing again, vacuumizing, decompressing, extruding and granulating to obtain the product. The high-temperature-resistant and high-humidity-resistant flame-retardant PC plastic is suitable for lighting electric appliances, photovoltaics, IT, mobile phones and the like.

Owner:中广核俊尔(浙江)新材料有限公司 +1

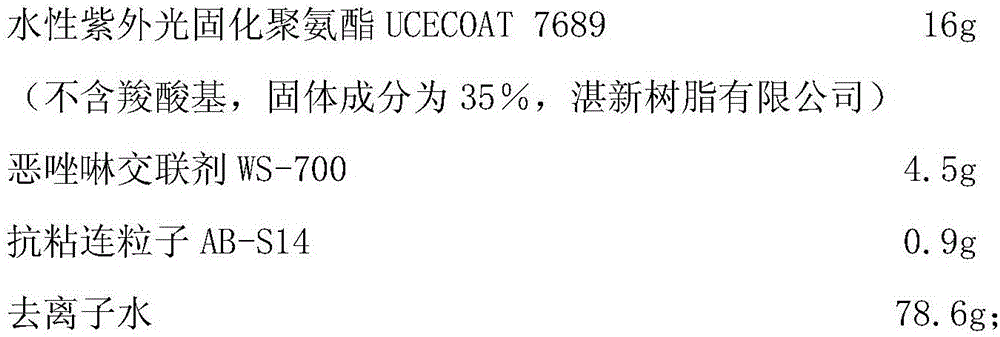

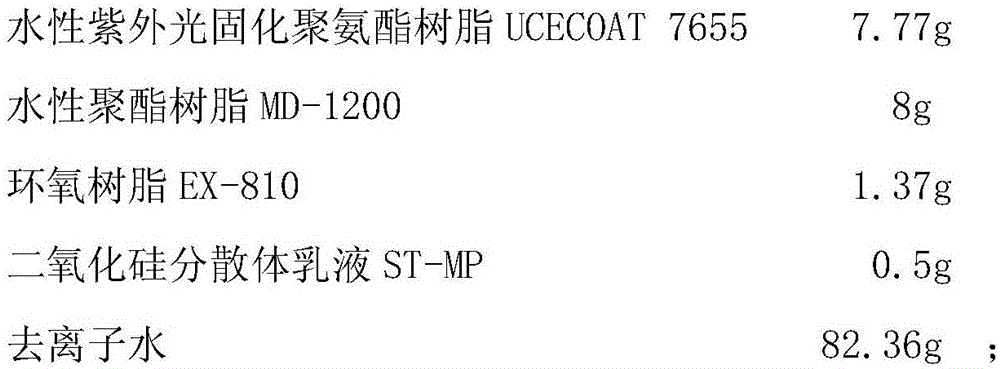

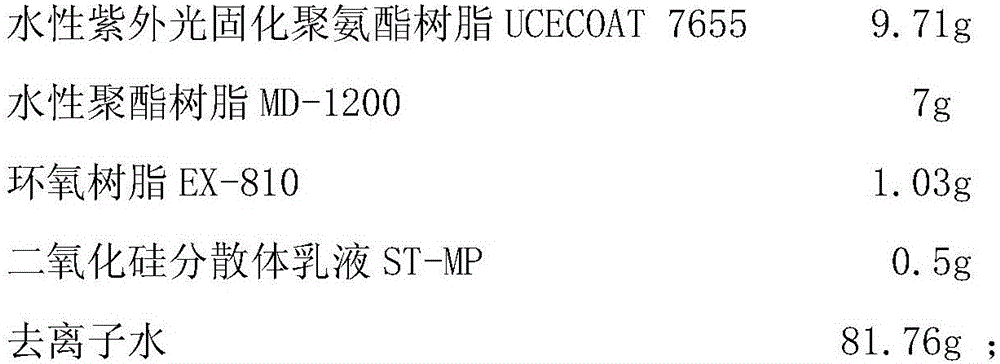

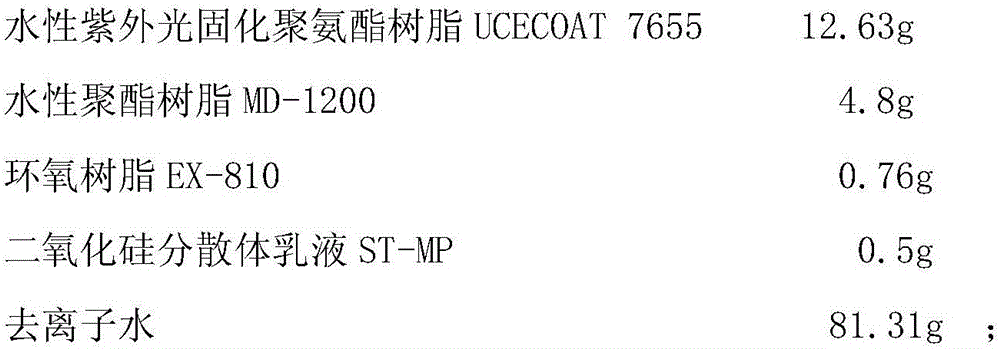

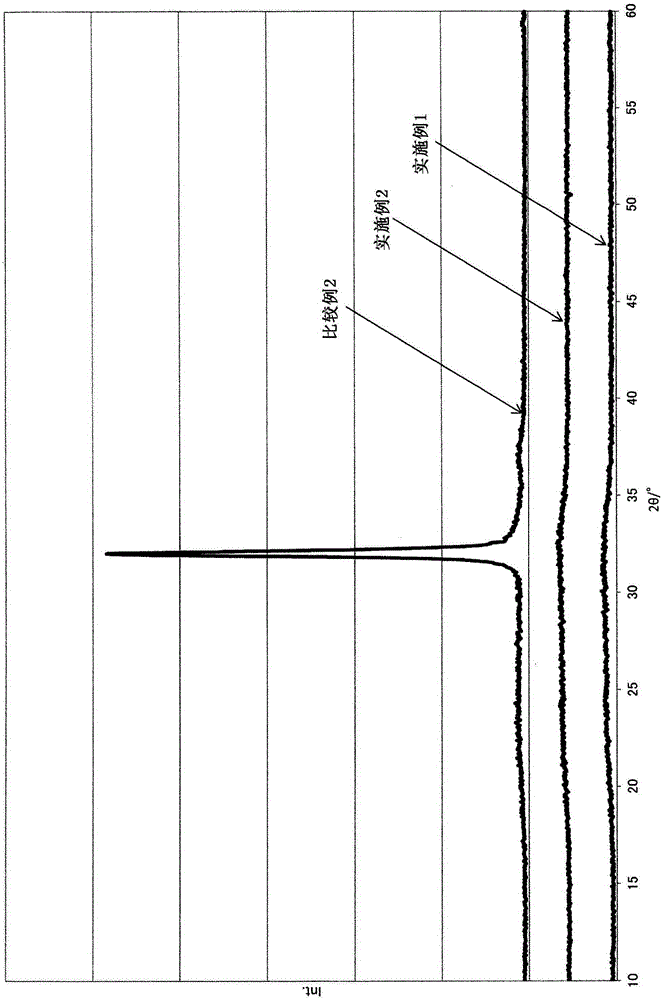

Optical polyester film and optical laminated polyester film

InactiveCN105774155AStrong adhesionExcellent initial adhesionSynthetic resin layered productsPolyurea/polyurethane coatingsEpoxyHigh humidity

The invention discloses an optical polyester film and an optical laminated polyester film.At least one face of a biaxially oriented base film of the optical polyester film is coated with a bottom coating containing an adhesive and anti-adhesion particles, and the adhesive is prepared from, by weight, waterborne ultraviolet light cured polyurethane resin 40-90%, waterborne polyester resin 9-40% and epoxy resin 1-20%.The polyester film layer has excellent initial adhesion to an optical functional layer, also has good adhesion under the conditions of high temperature and high humidity, meanwhile has high transparency and excellent adhesion resistance and is suitable for the fields of LCD, PDP and other display devices.

Owner:HEFEI LUCKY SCI & TECH IND

Single-component epoxy adhesive with low viscosity, high temperature resistance and high air tightness and preparation method of epoxy adhesive

PendingCN109825229ALow viscositySmall finenessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyolAir tightness

The invention provides a single-component epoxy adhesive with low viscosity, high temperature resistance and high air tightness. The single-component epoxy adhesive with low viscosity, high temperature resistance and high air tightness consists of the following raw materials in percentages: 30-100 parts of epoxy resin, 10-50 parts of polyol, 5-50 parts of an anhydride curing agent, 1-10 parts of an amine curing agent and 0.1-1 part of pigment or color paste. The adhesive is low in viscosity and small in fineness, is suitable for automatic dispensing or glue spraying production, and has excellent sealing performance.

Owner:DOCBOND TECH DEV CO LTD

Photovoltaic storage battery sealant based on ethoxyethyl carbonate and furfuryl carboxylate and manufacturing method thereof

InactiveCN106010305AReduce air bubble contentGood adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesCarboxylateFire retardant

The invention discloses a photovoltaic storage battery sealant based on ethoxyethyl carbonate and furfuryl carboxylate and a manufacturing method thereof. The sealant is manufactured from a component A and a component B, wherein the component A is prepared from 2-propenoic acid-2-methyl-2-(dimethylamino) ethyl ester, ethyl acetate, dicyclohexyl phthalate, a fire retardant, mica powder, Irganox5057, and a thermal conducting filler; the component B is prepared from bi-monomer, SBS resin, stannous octoate, a silant crosslinking agent, a platinum or platinum complex, a defoaming agent and a silane tackifier. The materials in the component A and the component B are subjected to processing production respectively, and the sealant is obtained through processing of a vacuum kneading machine and a reaction kettle. Due to the good fire retardant and the thermal conducting filler, by means of mixing of other substances, the content of bubbles inside the sealant is small, and the sealant has the advantages of being excellent in cohesiveness, excellent in high temperature resistance and high humidity resistance, good in flame retardant, heat conduction and electric insulation performance, high in curing speed, convenient to operate and the like.

Owner:哈尔滨永淇化工有限公司

Methoxy ethyl ester and glycerol trilaurate based sealant for photovoltaic storage batteries and manufacturing method of methoxy ethyl ester and glycerol trilaurate based sealant

InactiveCN105969207AReduce air bubble contentGood adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesDibutyl tin dilaurateGlycerol

Owner:哈尔滨永淇化工有限公司

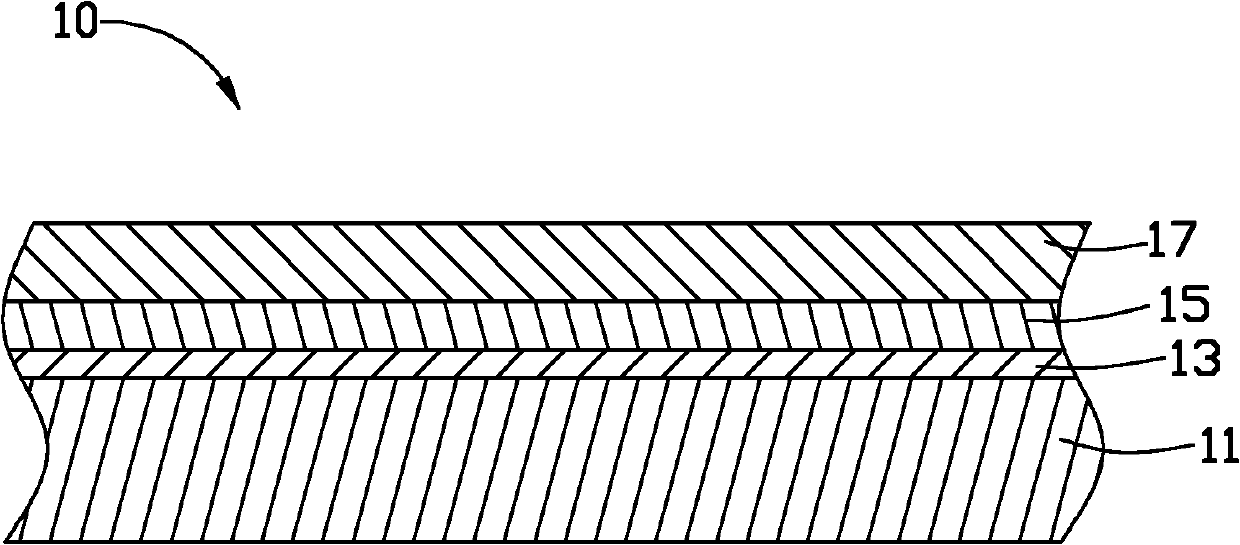

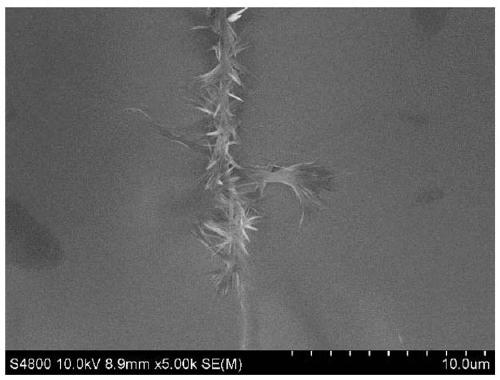

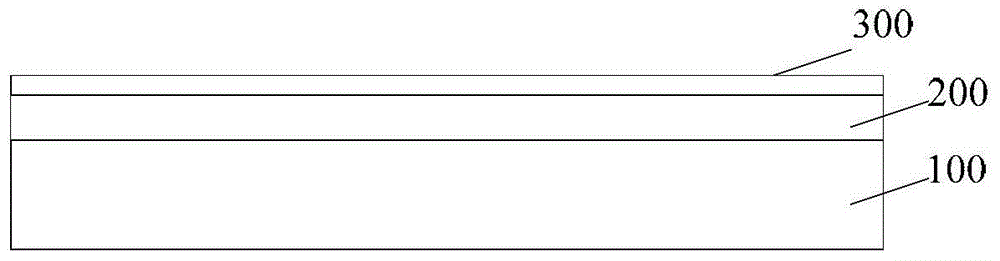

Polymer transparent conductive film and preparation method thereof

ActiveCN104575701BImprove conductivityImprove performanceConductive layers on insulating-supportsCable/conductor manufactureConductive polymerHigh polymer

The invention provides a high polymer transparent conductive film and a preparation method thereof. The high polymer transparent conductive film comprises a resin substrate layer, a conductive layer and a resin fixing layer, wherein the conductive layer is positioned above the resin substrate layer, and has a plurality of seams for allowing the resin substrate layer to expose; the resin fixing layer is positioned above the conductive layer and in the seams; the conductive layer comprises a conductive polymer and a conductive filler; the thickness of the resin fixing layer is smaller than 300 nm. According to the high polymer transparent conductive film, the resin fixing layer which is very thin is arranged above the conductive layer. The resin fixing layer is relatively high in softness, and can be used for effectively improving the softness of the whole high polymer transparent conductive film. More importantly, the seams for allowing the resin substrate layer to expose are formed in the conductive layer, so that the resin fixing layer above can penetrate into the seams and can be bonded with the resin substrate layer, and the adherence strength between the conductive film and the resin substrate layer can be effectively improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

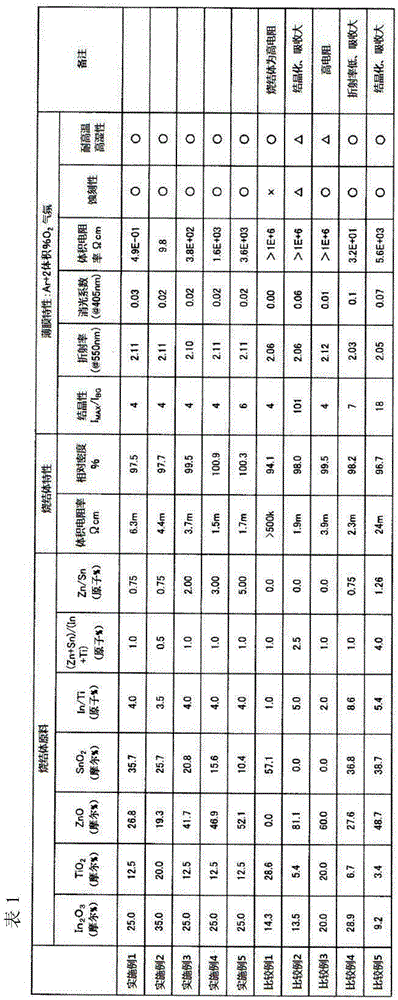

Oxide sintering body, oxide sputtering target, conductive oxide thin film and method for manufacturing oxide sintering body

InactiveCN105481352AImprove transmittanceHigh refractive indexVacuum evaporation coatingSputtering coatingSputteringIndium

The invention relates to an oxide sintering body, an oxide sputtering target, a conductive oxide thin film and a method for manufacturing the oxide sintering body. The oxide sintering body is characterized in that the oxide sintering body contains In, Ti, Zn, Sn and O, the content of In relative to that of Ti satisfies a relational expression 3.0<=In / Ti<=5.0 when represented by an atomic number ratio, the content of Zn and Sn relative to that of In and Ti satisfies a relational expression 0.2<=(Zn+Sn) / (In+Ti)<=1.5 when represented by an atomic number ratio, and the content of Zn relative to that of Sn satisfies a relational expression 0.5<=Zn / Sn<=7.0 when represented by an atomic number ratio. The volume resistivity of the oxide sintering body is low, DC sputtering can be performed, and a transparent conducting film with a high index of refraction can be formed.

Owner:JX NIPPON MINING & METALS CO LTD

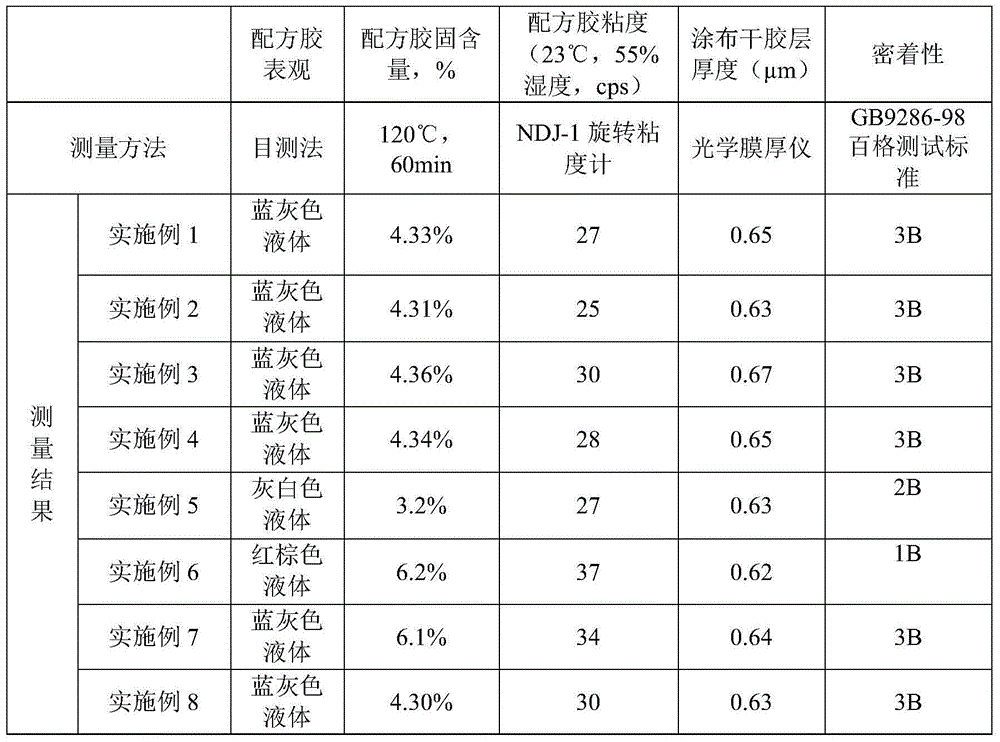

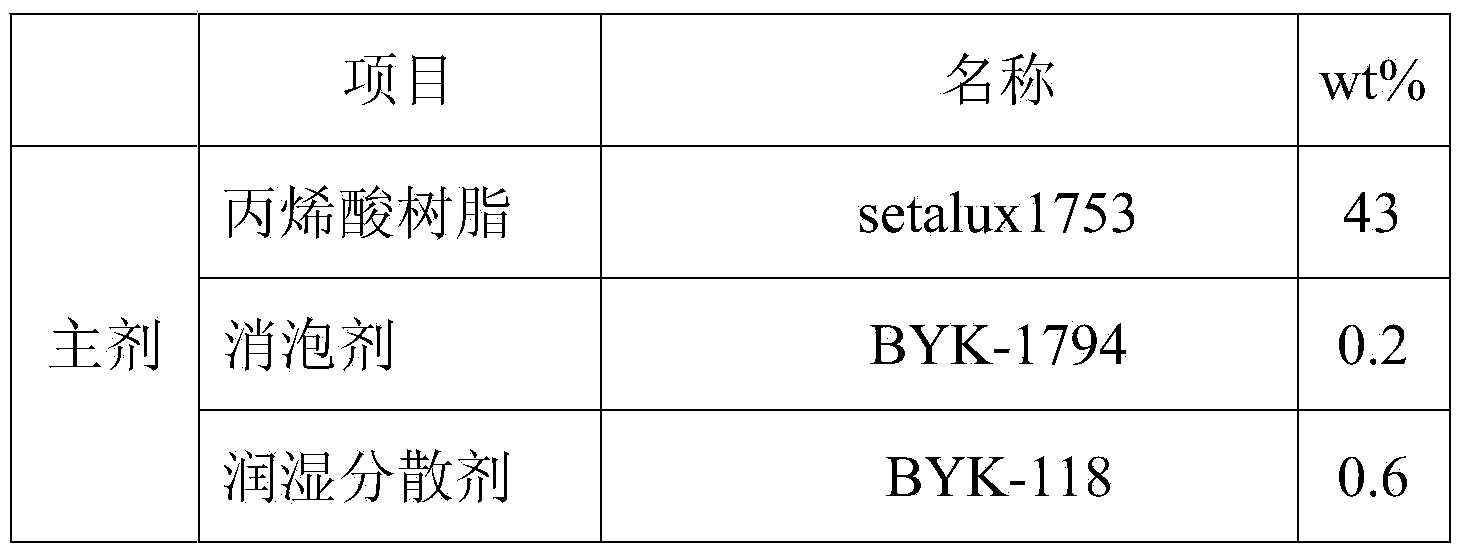

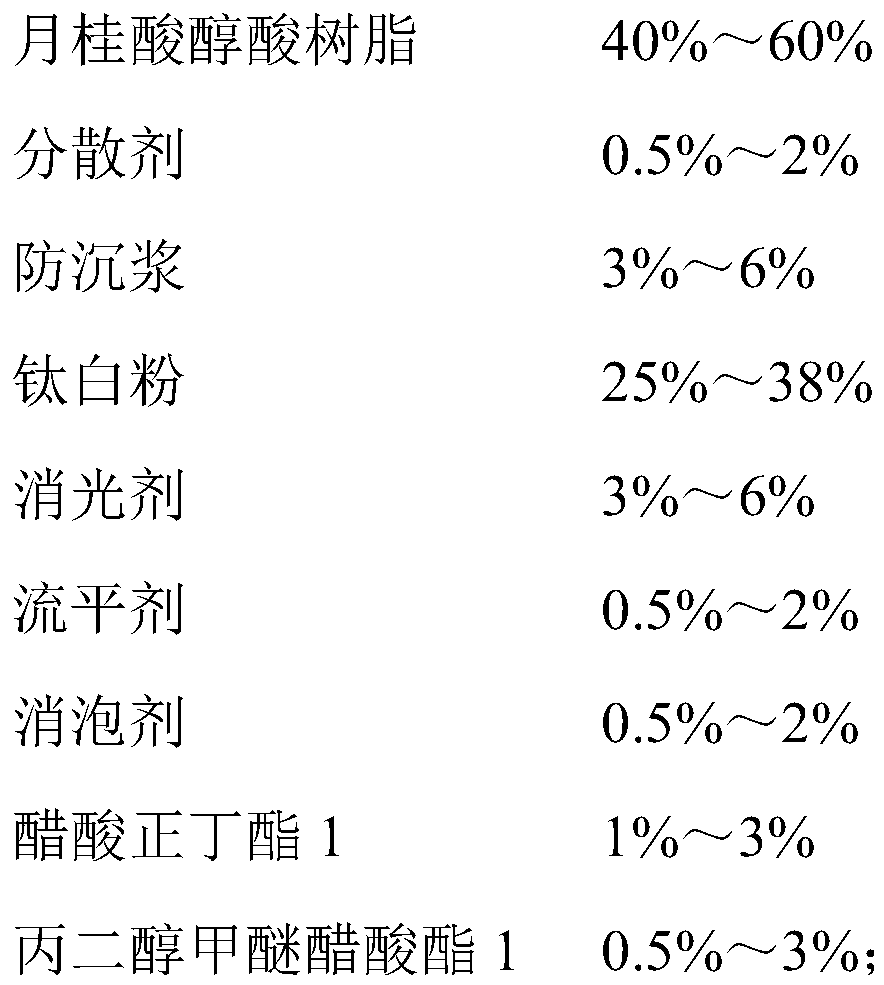

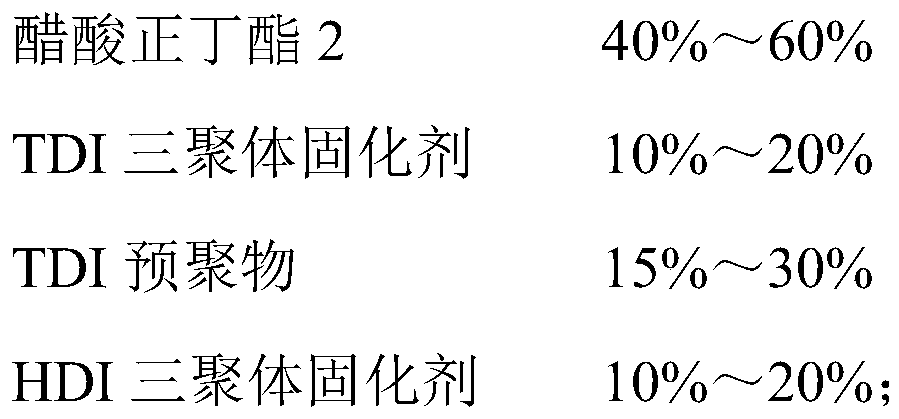

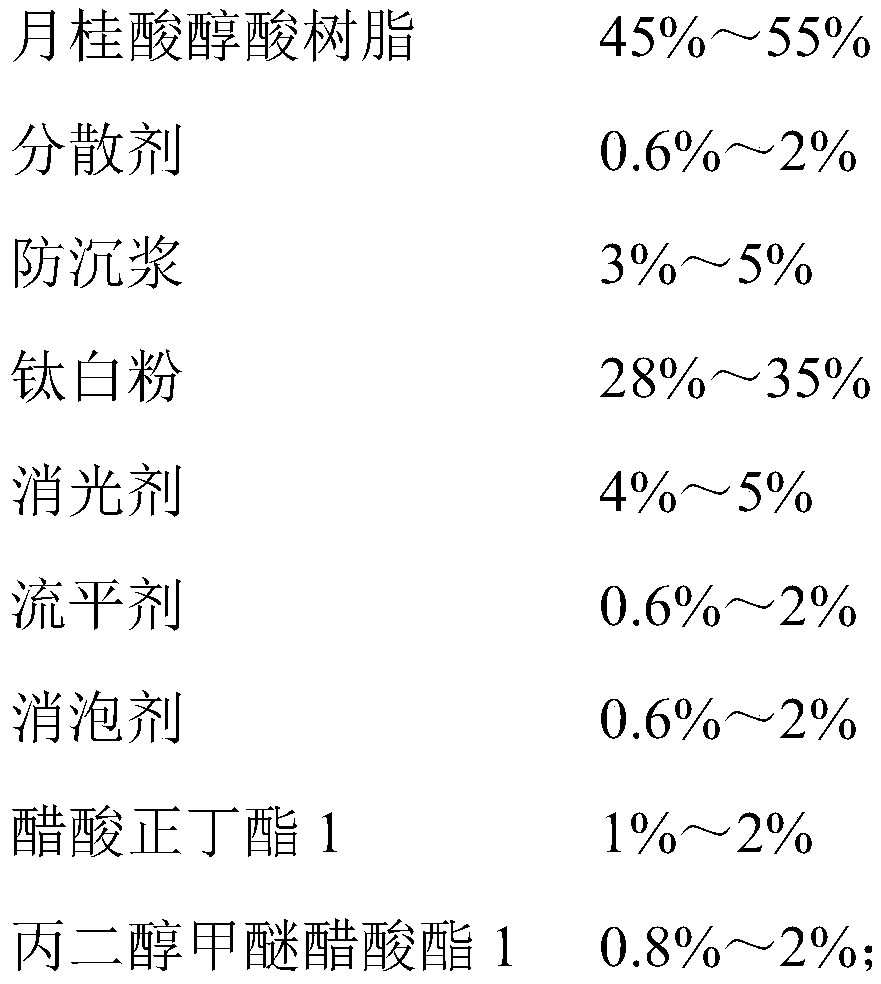

PU matte white finish paint and preparation method thereof

ActiveCN110862758AHigh hardnessIncrease tightnessFireproof paintsPolyurea/polyurethane coatingsPrepolymerN-Butyl acetate

The invention relates to PU matte white finish paint and a preparation method thereof. The white finish paint consists of A, B and C components according to a mass ratio being 1 : 0.5 - 0.6 : 0.5 - 0.7; the A component consists of 40-60% of lauric alkyd resin, 0.5-2% of a dispersing agent, 3-6% of anti-settling slurry , 25-38% of titanium dioxide, 3-6% of a flatting agent, 0.5-2% of a leveling agent, 0.5-2% of a antifoaming agent, 1-3% of n-butyl acetate 1 and 0.5-3% of propylene glycol monomethyl ether acetate 1; the B component consists of 40-60% of n-butyl acetate 2, 10-20% of a TDI trimercuring agent, 15-30% of TDI prepolymer 1 and 10-20% of a HDI trimer curing agent; and the C component consists of 45-60% of n-butyl acetate 3, 35-45% of propylene glycol monomethyl ether acetate 2 and5-10% of xylene. The obtained white finish paint is strong in adhesive force, high in hardness, good in adherence, resistant to high temperature and humidity, excellent in comprehensive performance and wide in application field.

Owner:SHANGHAI CARPOLY PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com