Optical polyester film and method of manufacture thereof

An optical polyester film, polyurethane resin technology, applied in polyurea/polyurethane coatings, flat products, other household appliances, etc., can solve the problems of poor optical performance, film adhesion can not meet the needs of optical functional films, etc. Smoothness and blocking resistance, excellent adhesion and high transparency, the effect of improving high temperature and high humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

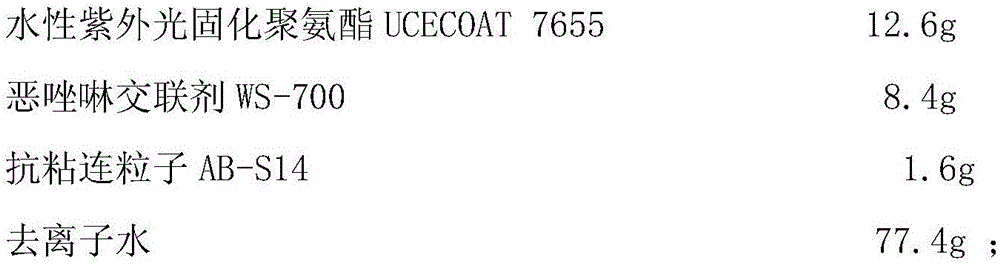

[0042] Preparation of primer coating solution (Ⅰ)

[0043]

[0044] Get 12.6g water-based UV-curable polyurethane UCECOAT7655 (does not contain carboxylic acid group, solid content is 35%, allnex Resin Co., Ltd.), 8.4g oxazoline crosslinking agent WS-700 (solid content is 25%, Nippon Shokubai Co., Ltd. company), 1.6g anti-blocking particles AB-S14 (solid content is 29.9%, Japan Xiai Chemical Co., Ltd.), 10g isopropanol, 77.4g deionized water, uniformly dispersed through a high-shear emulsifier to obtain a solid content of 7% base coat coating solution.

[0045] Preparation of Optical Polyester Film

[0046] The polyethylene terephthalate polyester chip is melt-extruded; the melt is cast to the casting roll and cooled to become a non-oriented cast slab, and then longitudinally stretched at a longitudinal stretching ratio of 3.5 times; then Coat the primer coating solution prepared above on one side of the longitudinal stretch sheet; stretch the longitudinal stretch sheet c...

Embodiment 2

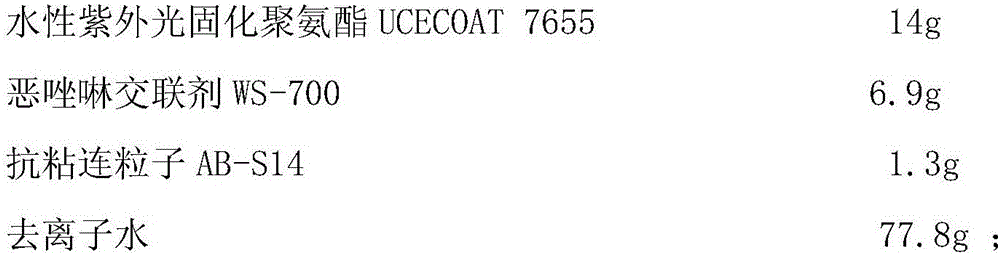

[0048] Change the undercoat coating solution (I) in Example 1 to other than the undercoat coating solution (II), obtain the optical polyester film in the same way as in Example 1, and measure its performance (see Table 1) .

[0049] Preparation of primer coating solution (Ⅱ)

[0050]

Embodiment 3

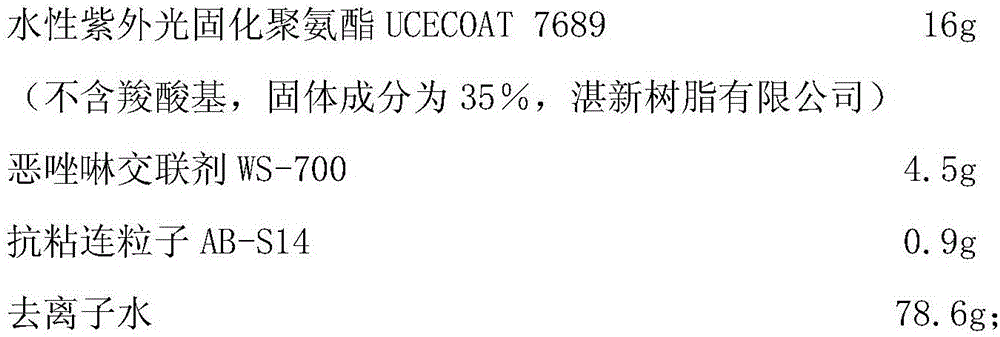

[0052] Change the undercoat coating solution (I) in Example 1 to other than the undercoat coating solution (Ⅲ), obtain the optical polyester film in the same way as in Example 1, and measure its performance (see Table 1) .

[0053] Preparation of primer coating solution (Ⅲ)

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com