Oxide sintering body, oxide sputtering target, conductive oxide thin film and method for manufacturing oxide sintering body

A manufacturing method and technology of sintered body, applied in the directions of sputtering plating, ion implantation plating, coating, etc., can solve the problem of difficult to use plastic substrates, organic EL devices, not particularly aware of film crystallinity, and inability to have high refractive index Material usage and other issues to achieve the effect of improving productivity, improving characteristics, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

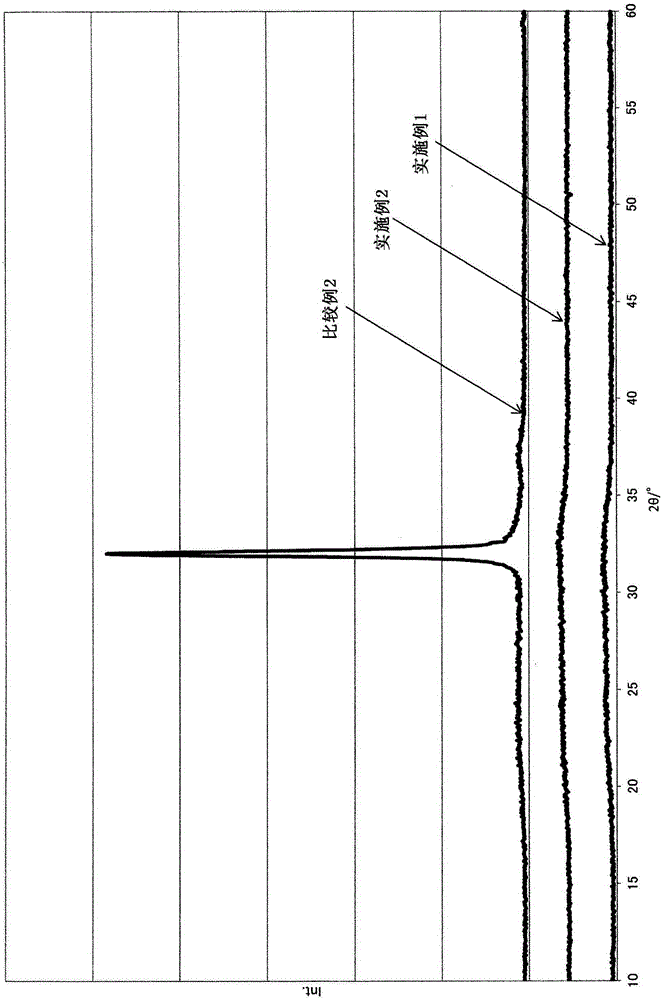

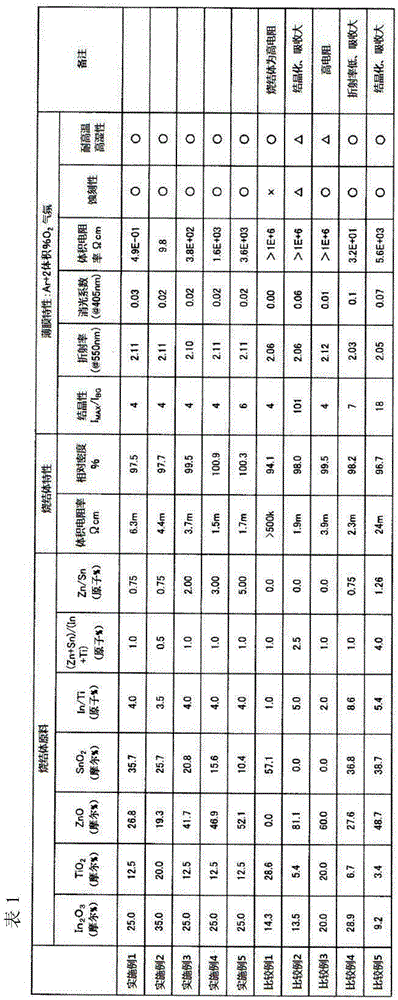

Embodiment 1

[0078] Ready In 2 o 3 Powder, TiO 2 powder, ZnO powder, SnO 2 powder, these powders were prepared in the compounding ratios listed in Table 1, and mixed. Next, the mixed powder was calcined in the atmosphere at a temperature of 1050° C., and then wet pulverized (using ZrO 2 Microbeads) were crushed to an average particle size of 2 μm or less, dried and sieved with a sieve with a pore size of 150 μm. Then, the finely pulverized powder was heated under an argon atmosphere at a temperature of 1100°C and a pressure of 250kgf / cm 2 hot-pressed sintering conditions. Then, the sintered body is machined and finished into a target shape. In addition, as a result of analyzing the component composition of a sputtering target, it confirmed that it was the same as the compounding ratio of a raw material powder.

[0079] Next, sputtering was performed using the 6-inch-diameter target obtained by the above finishing process. The sputtering conditions were set as: DC sputtering, sputteri...

Embodiment 2

[0083] Ready In 2 o 3 Powder, TiO 2 powder, ZnO powder, SnO 2 powder, these powders were prepared in the compounding ratios listed in Table 1, and mixed. Next, the mixed powder was calcined in the atmosphere at a temperature of 1050° C., and then wet pulverized (using ZrO 2 Microbeads) were crushed to an average particle size of 2 μm or less, dried and sieved with a sieve with a pore size of 150 μm. Then, the finely pulverized powder was heated under an argon atmosphere at a temperature of 1150°C and a pressure of 250kgf / cm 2 hot-pressed sintering conditions. Then, the sintered body is machined and finished into a target shape. Next, sputtering was performed under the same conditions as in Example 1 using the 6-inch-diameter target obtained by the above finishing process.

[0084] Table 1 shows the above results. As shown in Table 1, the relative density of the sputtering target reached 97.7%, and the volume resistivity was 4.4 mΩcm, enabling stable DC sputtering. Fur...

Embodiment 3

[0086] Ready In 2 o 3 Powder, TiO 2 powder, ZnO powder, SnO 2 powder, these powders were prepared in the compounding ratios listed in Table 1, and mixed. Next, the mixed powder was calcined in the atmosphere at a temperature of 1050° C., and then wet pulverized (using ZrO 2 Microbeads) were crushed to an average particle size of 2 μm or less, dried and sieved with a sieve with a pore size of 150 μm. Then, the finely pulverized powder was heated under an argon atmosphere at a temperature of 1150°C and a pressure of 250kgf / cm 2 hot-pressed sintering conditions. Then, the sintered body is machined and finished into a target shape. Next, sputtering was performed under the same conditions as in Example 1 using the 6-inch-diameter target obtained by the above finishing process.

[0087] Table 1 shows the above results. As shown in Table 1, the relative density of the sputtering target reaches 99.5%, the volume resistivity is 3.7 mΩcm, and stable DC sputtering can be performe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com