Silicone-modified OCA optical adhesive, optical adhesive tape, and preparation methods thereof

A technology of silicone and optical glue, applied in the field of OCA optical glue, can solve the problems of limited performance improvement of temperature resistance and humidity resistance, and achieve the effect of good initial adhesion, good high temperature and high humidity resistance, and low modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

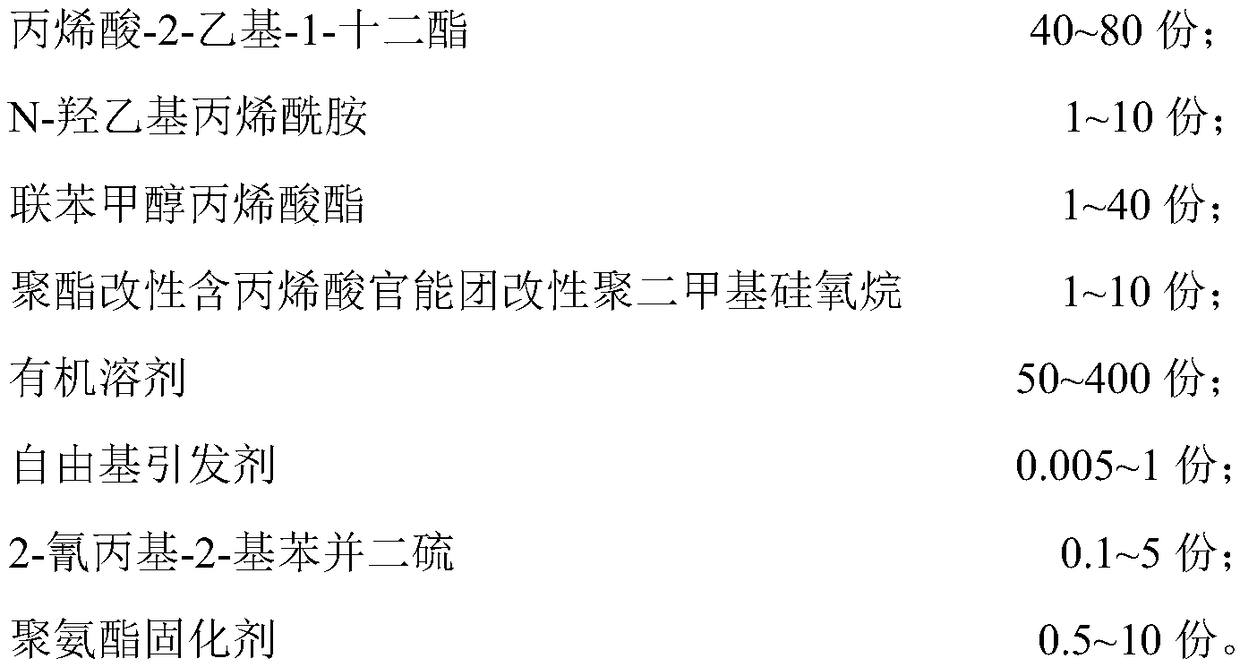

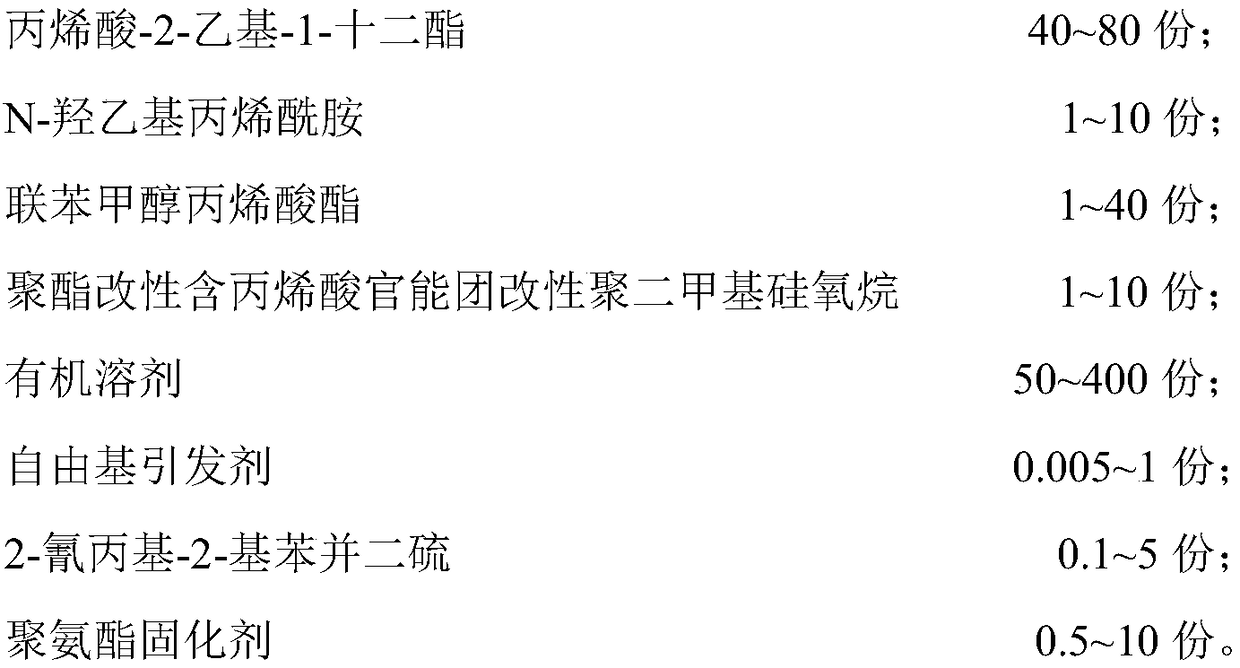

Method used

Image

Examples

Embodiment 1

[0025] A kind of organosilicon modified OCA optical adhesive and the optical adhesive tape that has applied this organosilicon modified OCA optical adhesive, and its preparation process is as follows:

[0026] 1) Synthesis of acrylic acid-2-ethyl-1-dodecyl monomer

[0027] 140 parts of 2-ethyl-1-dodecanol and 45 parts of acrylic acid are dissolved in 200 parts of chloroform, and 15 parts of 4-dimethylaminopyridine and 15 parts of 1-( 3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, the temperature was controlled at 50° C., and the reaction was carried out for 95 hours to prepare the 2-ethyl-1-dodecyl acrylic acid monomer of Example 1.

[0028] 2) Synthesis of Silicone Modified OCA Optical Adhesive

[0029] According to the mass parts of raw materials, 80 parts of 2-ethyl-1-dodecyl acrylate, 9 parts of N-hydroxyethyl acrylamide, 35 parts of biphenylmethanol acrylate, and 9 parts of polyester-modified acrylic acid Mix functional group-modified polydimethylsiloxane, 0.01...

Embodiment 2

[0033] A kind of organosilicon modified OCA optical adhesive and the optical adhesive tape that has applied this organosilicon modified OCA optical adhesive, and its preparation process is as follows:

[0034] 1) Synthesis of acrylic acid-2-ethyl-1-dodecyl monomer

[0035] 120 parts of 2-ethyl-1-dodecanol and 40 parts of acrylic acid are dissolved in 160 parts of chloroform in parts by mass of raw materials, 12 parts of 4-dimethylaminopyridine and 12 parts of 1-( 3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, the temperature was controlled at 45°C, and the reaction was carried out for 70 hours to prepare the 2-ethyl-1-dodecyl acrylic acid monomer of Example 2.

[0036] 2) Synthesis of Silicone Modified OCA Optical Adhesive

[0037] According to the mass parts of raw materials, 70 parts of 2-ethyl-1-dodecyl acrylate, 6 parts of N-hydroxyethyl acrylamide, 10 parts of biphenylmethanol acrylate, and 7 parts of polyester-modified acrylic acid Functional group-modified ...

Embodiment 3

[0041] A kind of organosilicon modified OCA optical adhesive and the optical adhesive tape that has applied this organosilicon modified OCA optical adhesive, and its preparation process is as follows:

[0042] 1) Synthesis of acrylic acid-2-ethyl-1-dodecyl monomer

[0043] Dissolve 80 parts of 2-ethyl-1-dodecanol and 40 parts of acrylic acid in 100 parts of chloroform, add 7 parts of 4-dimethylaminopyridine and 7 parts of 1-( 3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, the temperature was controlled at 40° C., and the reaction was carried out for 50 hours to prepare the 2-ethyl-1-dodecyl acrylic acid monomer of Example 3.

[0044] 2) Synthesis of Silicone Modified OCA Optical Adhesive

[0045] According to the mass parts of raw materials, 50 parts of 2-ethyl-1-dodecyl acrylate, 4 parts of N-hydroxyethyl acrylamide, 10 parts of biphenylmethanol acrylate, and 5 parts of polyester-modified acrylic acid Functional group-modified polydimethylsiloxane, 0.03 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com