Patents

Literature

294results about How to "Improve initial tack performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly starch adhesive for cementing corrugated boards at low temperature and preparation method of environment-friendly starch adhesive

InactiveCN106085289ALess glueFacilitates quick dryingNon-macromolecular adhesive additivesStarch derivtive adhesivesChemistryAdhesive

The invention relates to an environment-friendly starch adhesive for cementing corrugated boards at a low temperature and a preparation method of the environment-friendly starch adhesive. The starch adhesive is prepared from the following raw materials in parts by weight: 15 to 30 parts of starch, 60 to 80 parts of water, 0.2 to 1 part of sodium hydroxide, 0.05 to 0.2 part of oxidizing agent, 0.1 to 0.5 part of cross-linking agent, 0.1 to 0.5 part of stabilizing agent, 2 to 10 parts of drier, 1 to 5 parts of reinforcing agent and 0.1 to 1 part of penetrating agent. Under the oxidation of the oxidizing agent, besides hydroxyl, groups such as carboxyl and carbonyl are added on molecular chains of the starch, so that the initial adhesion of the adhesive is improved, the cementing quantity is reduced, and the rapidness in drying is facilitated; by adding the penetrating agent, the adhesive can rapidly penetrate through paper and destroy fibers; by adding the cross-linking agent and the reinforcing agent, the adhesive can be instantaneously cross-linked to form a mass structure, the rapid dryness of the adhesive is facilitated, and the adhesive can also be cross-linked with groups on the paper fibers so as to increase the cementing strength and the water resistance of paper boards; and by adding the drier, the drying speed of the starch adhesive can be increased, so that the steam pressure of a paper machine is reduced.

Owner:明辉大秦(上海)环保科技股份有限公司

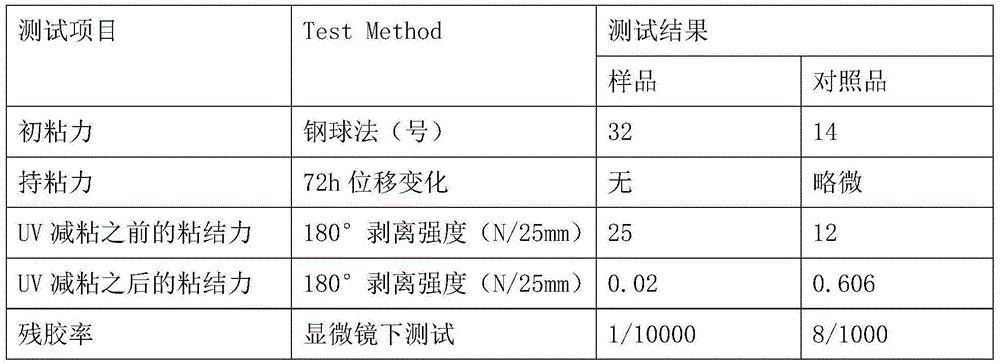

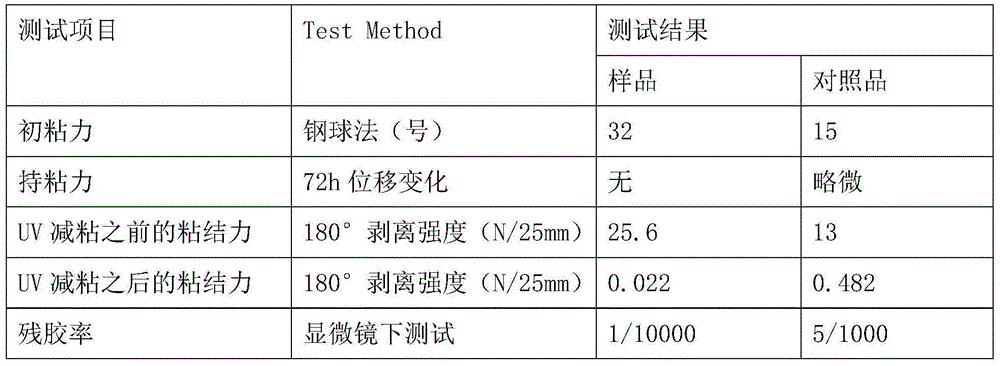

Bi-component cured UV viscosity-decreasing adhesive

ActiveCN105086730AImprove initial tack performanceImprove yield ratePolyurea/polyurethane coatingsAdhesiveDiluent

The invention relates to a bi-component cured UV viscosity-decreasing adhesive. The bi-component cured UV viscosity-decreasing adhesive comprises two components of the component A and the component B. The component A is composed of, by weight, 35-60 parts of cured resin, 22-45 parts of photosensitive monomers, 2-10 parts of photopolymerization initiators, 2-15 parts of diluents and 2-10 parts of auxiliaries, wherein the cured resin is resin containing hydroxyl or resin containing carboxyl; the component B is one of a curing agent containing NCO and a curing agent containing sulfydryl or a mixture of the curing agent containing NCO and the curing agent containing the sulfydryl, the curing agent containing NCO is isocyanate, the content of NCO of the isocyanate ranges from 12.5% to 23.5%, and the molecular weight ranges from 200 to 600; the curing agent containing the sulfydryl is polymercaptans, wherein the content of the sulfydryl ranges from 5% to 15%; the weight of the component B is 5%-20% of that of the component A. The bi-component cured UV viscosity-decreasing adhesive has the advantages that the initial viscous force is strong after curing forming is conducted at room temperature, after UV-irradiation is conducted for decreasing viscosity, the stripping effect is good, and adhesive residues do not exist.

Owner:GUANGZHOU SHENWEI NEW MATERIAL TECH

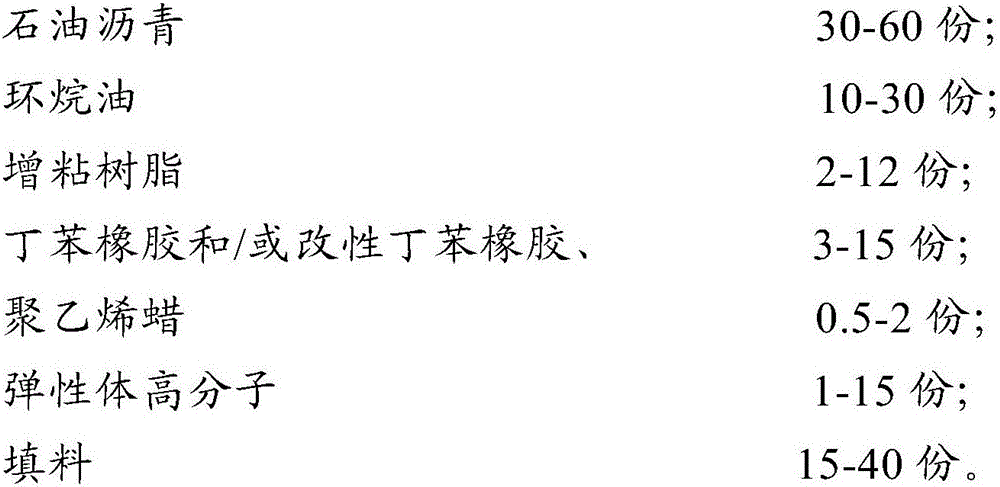

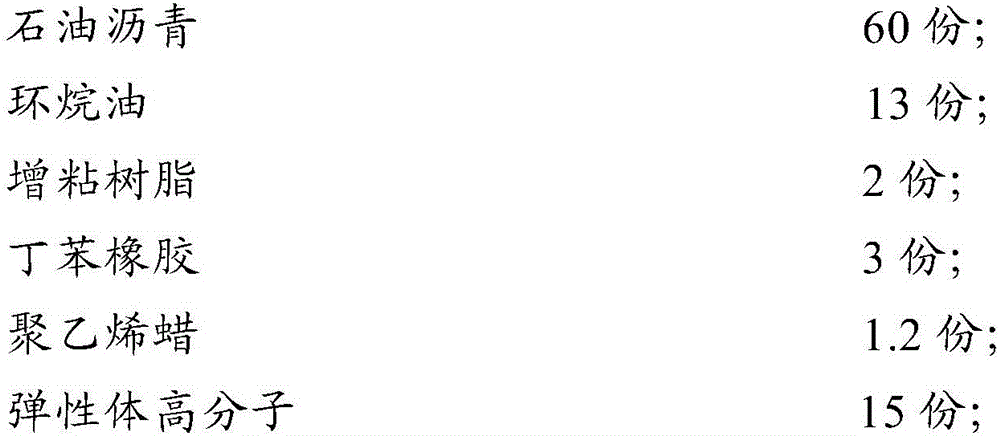

Self-glued asphalt adhesive material, preparation method of self-glued asphalt adhesive material, and self-glued asphalt waterproof coiled material

ActiveCN106398244AImprove heat resistanceGood adhesionLayered productsBuilding insulationsElastomerAdditive ingredient

The invention discloses a self-glued asphalt adhesive material, a preparation method of the self-glued asphalt adhesive material, and a self-glued asphalt waterproof coiled material. A raw material formula of the self-glued asphalt adhesive material comprises the following ingredients of petroleum asphalt, naphthenic oil, tackifying resin, butadiene styrene rubber and / or modified butadiene styrene rubber, polyethylene wax, elastomer polymers and filing materials. By using the high-initial-viscosity and high-heat-resistance self-glued asphalt adhesive material as a bonding layer for bonding the self-glued waterproof coiled material and a base layer (such as a roof); the polyethylene wax in the bonding layer and the petroleum asphalt take a crosslinking reaction, so that the heat resistance performance of the self-glued asphalt adhesive material is improved. The self-glued asphalt adhesive material has good bonding performance, and is fully bonded with the base layer, so that the bonding is firm; in addition, the heat resistance being higher than 90 DEG C can be born; the low-temperature flexibility reaches -30 DEG C; the self-glued asphalt adhesive material has high heat-resistance performance, so that the requirements of facade construction using the waterproof coiled material as the waterproof layer can be met; in addition, the softening overflowing of the self-glued asphalt adhesive material can be prevented. The waterproof requirements of the base layer in various climates can be almost met; the hot melting construction is not needed.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

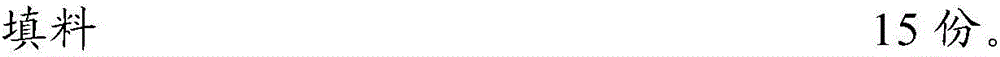

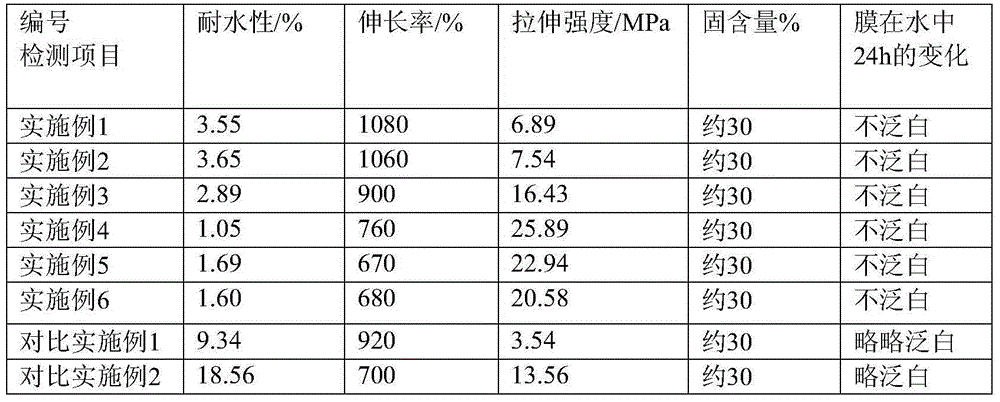

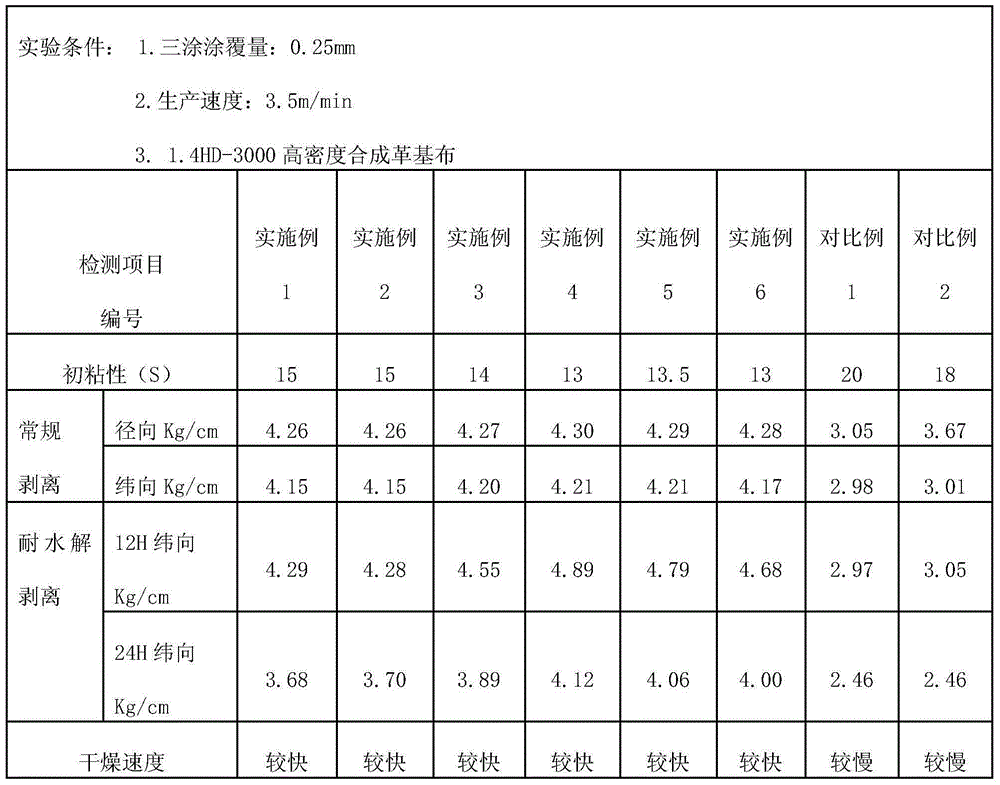

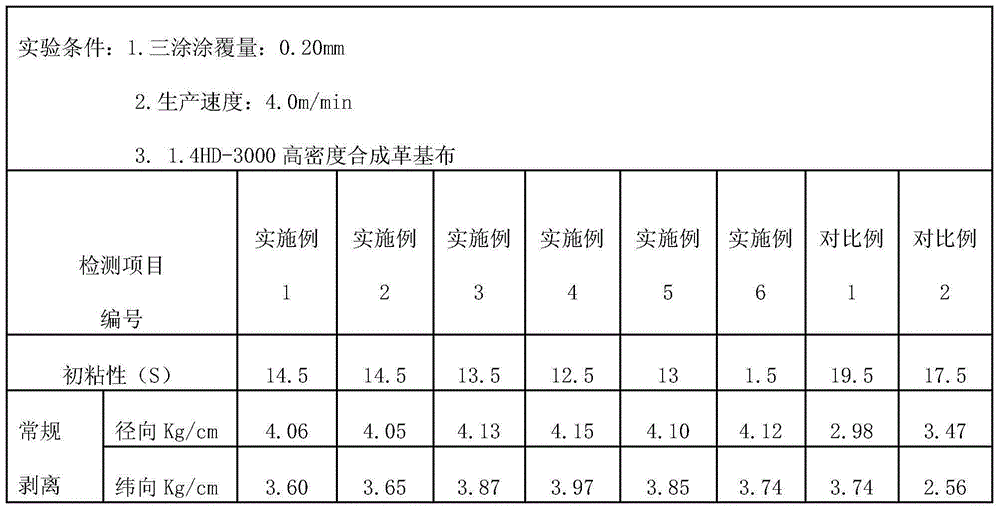

Low-molding-temperature waterborne polyurethane adhesive and preparation method thereof

ActiveCN104031596AImproved sag performanceReduce lossNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a low-molding-temperature waterborne polyurethane adhesive and a preparation method thereof. The low-molding-temperature waterborne polyurethane adhesive is prepared by matching a waterborne polyurethane dispersion, ethylene-vinyl acetate (EVA) emulsion, acrylic emulsion and the like based on low-activation-temperature waterborne polyurethane emulsion, wherein the low-activation-temperature waterborne polyurethane emulsion mainly consists of polyhydric alcohols, diisocyanate, a small molecule alcohol chain extender, a catalyst and a hydrophilic chain extender and has the activation temperature of less than 25 DEG C; the low-molding-temperature waterborne polyurethane adhesive prepared based on the low-activation-temperature waterborne polyurethane emulsion has the activation temperature of 30-60 DEG C, is high in bonding strength, is water-based emulsion, does not contain organic solvents or volatile organic compounds, is green and environment-friendly and can well meet the service requirements of adhesives for automobile roofs. The low-molding-temperature waterborne polyurethane adhesive also can be matched with a certain amount of enhancers, the bonding strength of colloid at the later stage is effectively improved, and the heat resistance of the roof at the later molding stage is guaranteed.

Owner:重庆中科力泰高分子材料有限公司

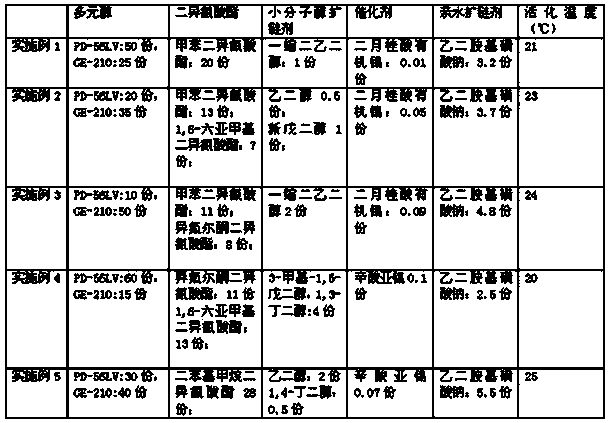

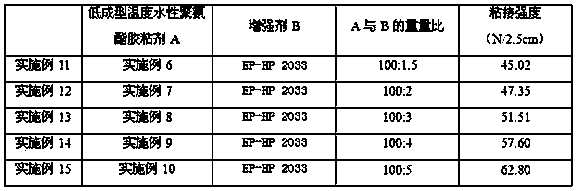

Synthetic leather binding agent and preparation method thereof

ActiveCN105062403AGood light fastnessImprove initial tack performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAlcohol

The invention provides a synthetic leather binding agent and a preparation method thereof. The synthetic leather binding agent is mainly prepared from polyhydric alcohol, diisocyanate, catalysts, epoxy resin and the like. According to the synthetic leather binding agent and the preparation method thereof, chemical modification is conducted on waterborne polyurethane through the epoxy resin, the high degree of branching of the epoxy resin is introduced into a main chain of polyurethane, and the initial adhesion, the peel strength, the drying rate and the water resistance of a dispersion liquid film are improved. The synthetic leather binding agent prepared through the method has good environment protectability. Dispersion liquid has the advantages of being high in initial adhesion, good in peel strength, high in drying rate and excellent in water resistance. Meanwhile, the good levelling property and spreadability are achieved. The using condition of the synthetic leather binding agent is met.

Owner:SHANDONG TIANQING TECH DEV

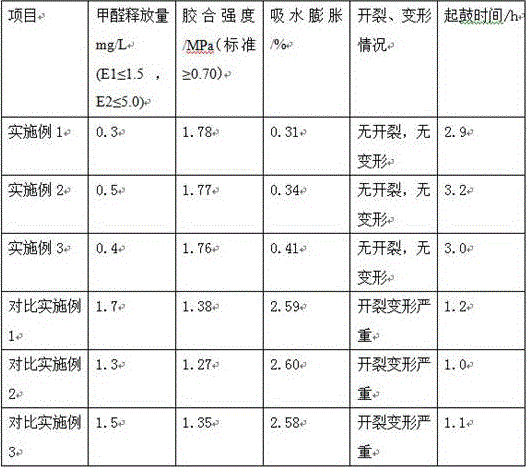

Production method for low-formaldehyde solid wood composite floor

ActiveCN105235024AAvoid gel effectLow residual formaldehydeLaminationLamination apparatusParquetinaSolid wood

The invention relates to a solid wood composite floor, in particular to a production method for a low-formaldehyde solid wood composite floor. The production method comprises the technological steps of wood plate slicing, drying, repairing, selecting, gluing, pre-pressing, hot pressing, edge cutting and sanding, and finished product obtaining. The key of the production method is that the residual amount of formaldehyde in adhesives is reduced by modifying the used urea-formaldehyde resin adhesives, so that the residual amount of the formaldehyde in the solid wood composite floor is reduced; by adopting high-quality plates and controlling process parameters in the production process, the quality of the produced solid wood composite floor is guaranteed. The content of the formaldehyde in the solid wood composite floor manufactured through the method is low, the quality of the floor is stable, and the floor is not prone to damage; the floor has the characteristics of being comfortable in foot feeling, resistant to abrasion, easy to install and clean, and high in stability.

Owner:DALIAN SHENGYU TECH DEV CO LTD

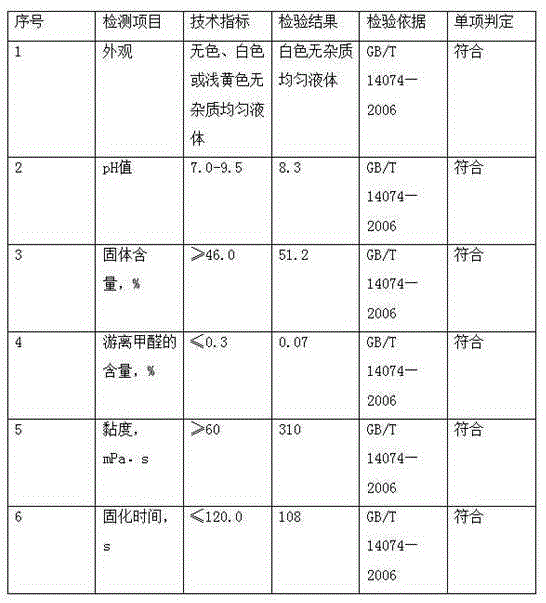

Water-based polyacrylic emulsion laminating adhesive and preparation method thereof

InactiveCN102140320AReduce the amount addedImprove initial tack performanceEster polymer adhesivesWater basedFunctional monomer

The invention discloses a water-based polyacrylic emulsion laminating adhesive and a preparation method thereof, which belong to the field of adhesives. The laminating adhesive with solid content of between 40 percent and 50 percent is prepared from raw materials of monomers, an emulsifier, an initiator, a buffering agent, a pH regulator, a waterborne aid and deionized water by adopting steps of pre-emulsification, seed reaction, polymerization and compounding, wherein the monomers include a hard monomer, a soft monomer and a functional monomer containing -COOH and -OH groups; the emulsifier consists of alkyl ether ammonium sulfate, sulpho sodium succinate and allyloxyl alkyl sodium sulfonate in the ratio of 2:1:(0.4-0.8); and the waterborne aid comprises a waterborne wetting agent, a waterborne defoaming agent and a waterborne preservative. The allyloxyl alkyl sodium sulfonate serving as a reactive emulsifier is introduced into the laminating adhesive, so that the influence of the migration of emulsifier micromolecules onto a paper / plastic interface is reduced, and initial adhesion and bonding strength are enhanced; and the functional monomer containing the -COOH and -OH groups is introduced, so that the bonding strength is enhanced, and the low-temperature adhesive property and ink affinity are improved.

Owner:NANTONG GAOMENG NEW MATERIAL

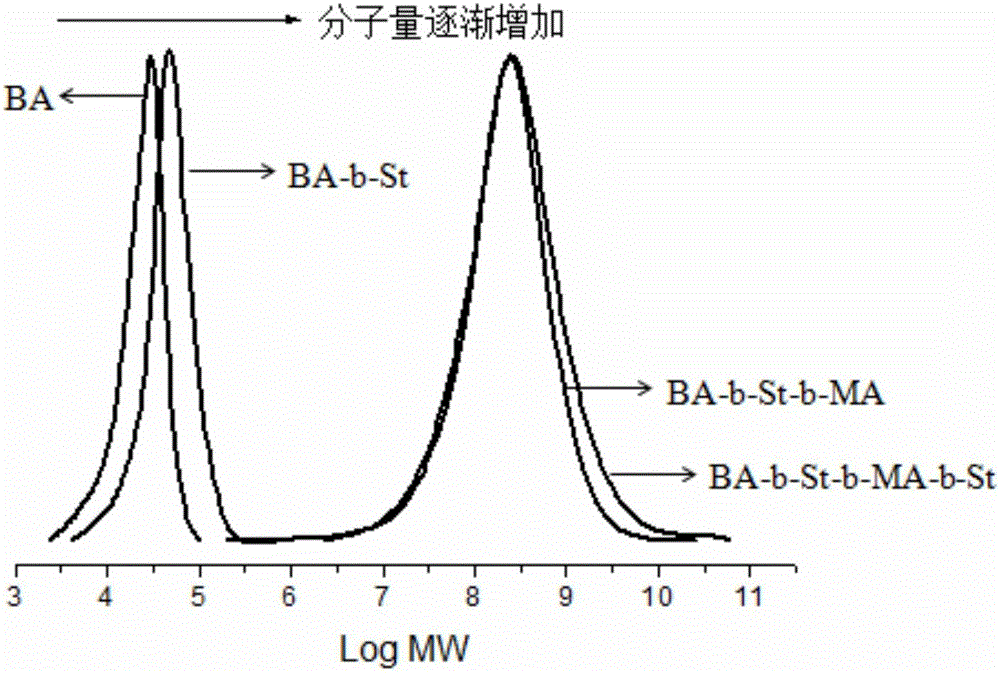

Water-based electrode binding agent and preparation method thereof

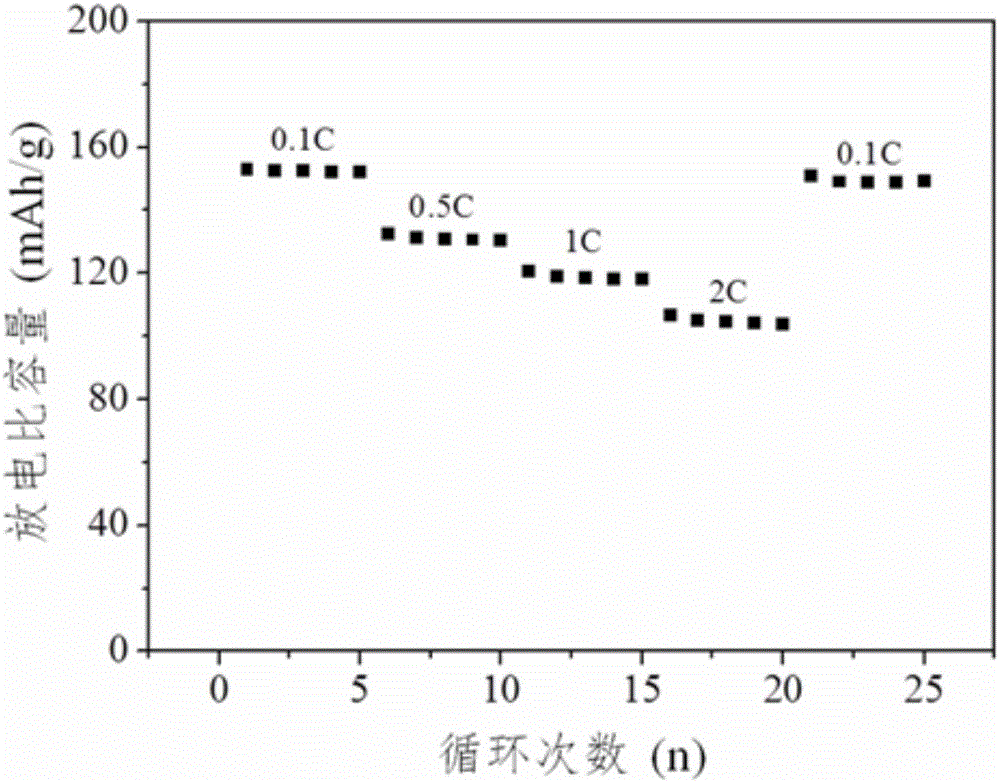

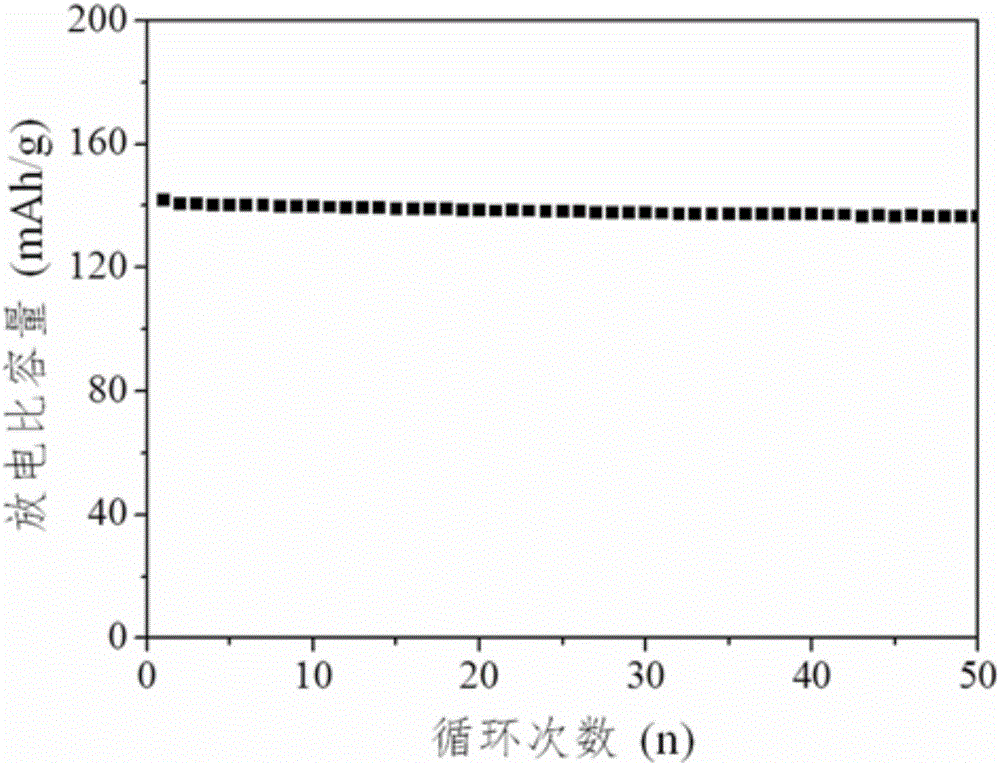

ActiveCN106281147AImprove mechanical propertiesGood compatibilityCell electrodesGraft polymer adhesivesWater basedPollution

The invention discloses a water-based electrode binding agent and a preparation method thereof. According to the water-based electrode binding agent, an emulsion polymerization system is adopted, and a reversible addition-fragmentation chain transfer free-radical polymerization technology is used for preparing butyl acrylate / styrene / methyl acrylate block copolymer latex which is used as the electrode binding agent. A preparation process has the advantages of energy saving and environment protection; compared with a traditional binding agent polyvinylidene fluoride, the water-based electrode binding agent has the advantages of low price, simple process, no pollution and the like; the discharge specific capacity of a used electrode in a lithium iron phosphate electrode can reach 153.4mAh / g, and the discharge specific capacity in a graphite electrode can reach 358.6mAh / g; and therefore, the water-based electrode binding agent has great application prospects.

Owner:浙江杰特维新材料有限公司

Preparation method of aqueous polyurethane for middle-high-density fiberboard

ActiveCN103320083AImprove stabilityLow costPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesPolyesterFiberboard

The invention relates to a preparation method of aqueous polyurethane for a middle-high-density fiberboard. The preparation method comprises the steps of synthesis of a hydrophilic polyurethane prepolymer and blending and modifying of low-molecular-weight amino resin, wherein the hydrophilic polyurethane prepolymer comprises the following components in percentage by weight: 8-15% of polyester polyol, 40-60% of isocyanate a, 1.5-6% of hydrophilic chain extender, 0.5-3% of catalyst, 10-25% of isocyanate b, 0.5-3% of amino silane coupling agent and 4-10% of neutralizer. According to the aqueous polyurethane prepared by utilizing the preparation method, a -NCO group in the resin is reasonably closed; and due to the introduction of MUF (melamine-modified urea formaldehyde) resin, a microstructure of the resin is improved, the molecular weight of the aqueous polyurethane is reduced and the stability of the resin is improved. The aqueous polyurethane is synthesized by utilizing manners of inner-crosslikining and blending dual-modifying, the cost is much lower than that of the commercially available PMDI (polydiphenylmethane diisocyanate) resin, and the pressed fiberboard can meet emission loads of formaldehyde and VOC (volatile organic compounds) in export requirements of automotive trims.

Owner:DONGYING ZHENGHE WOOD IND

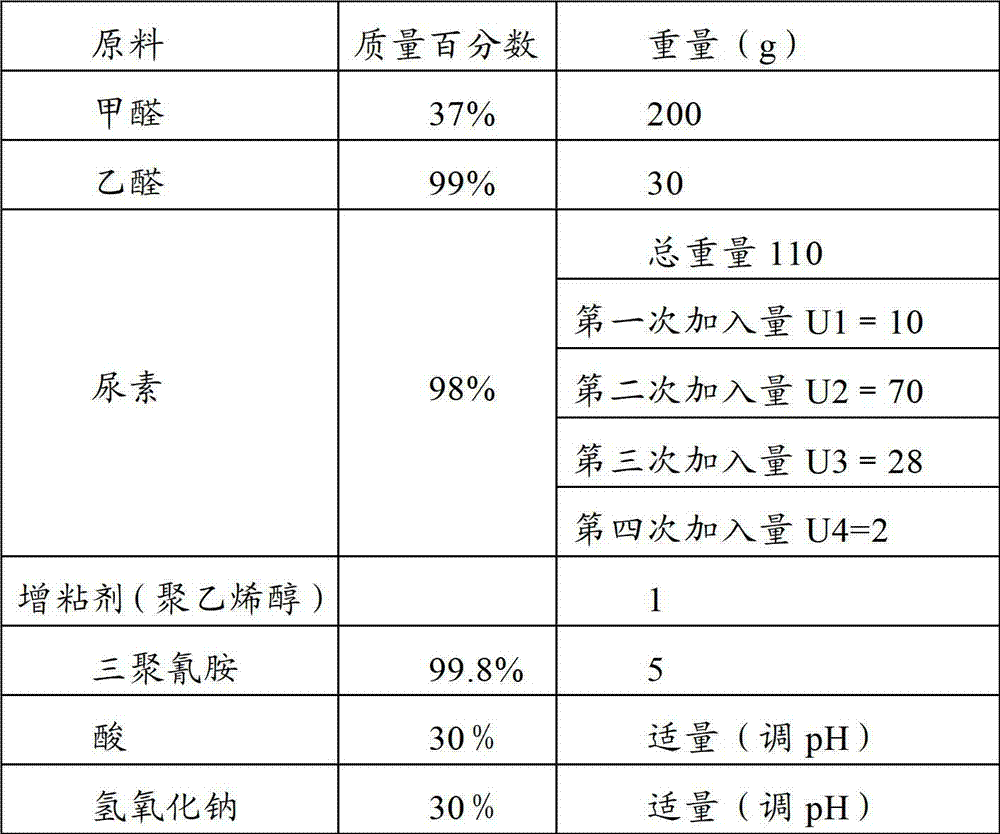

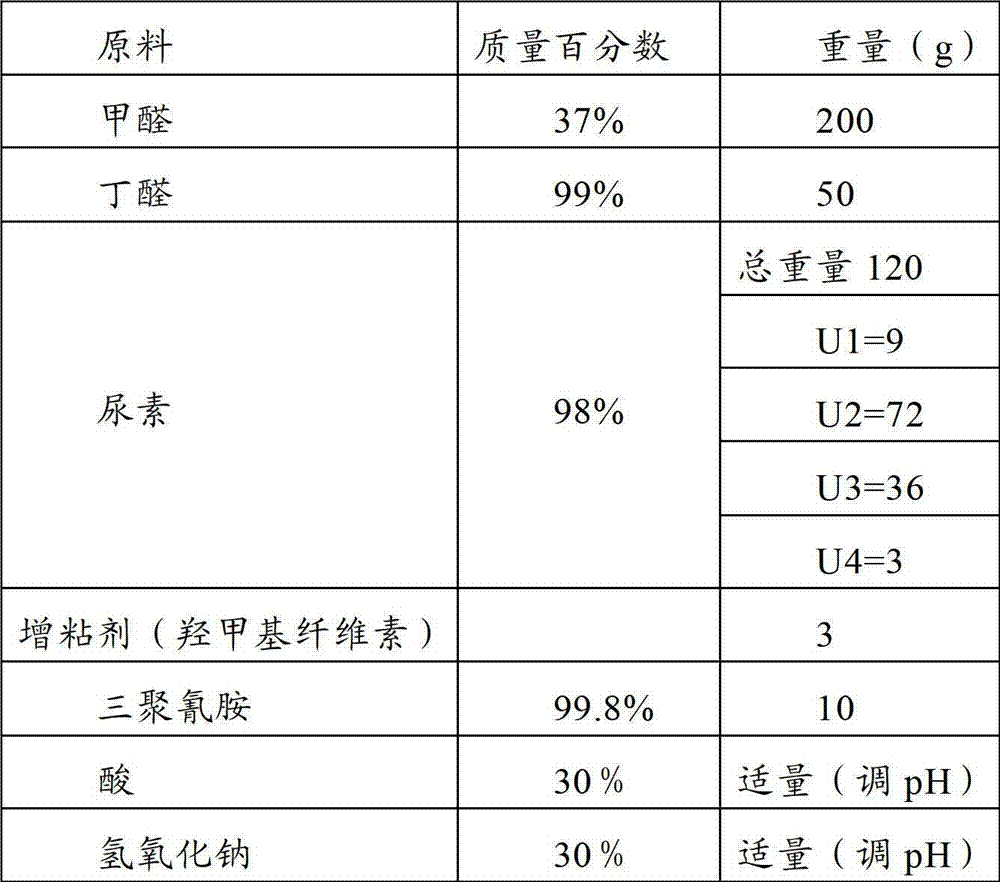

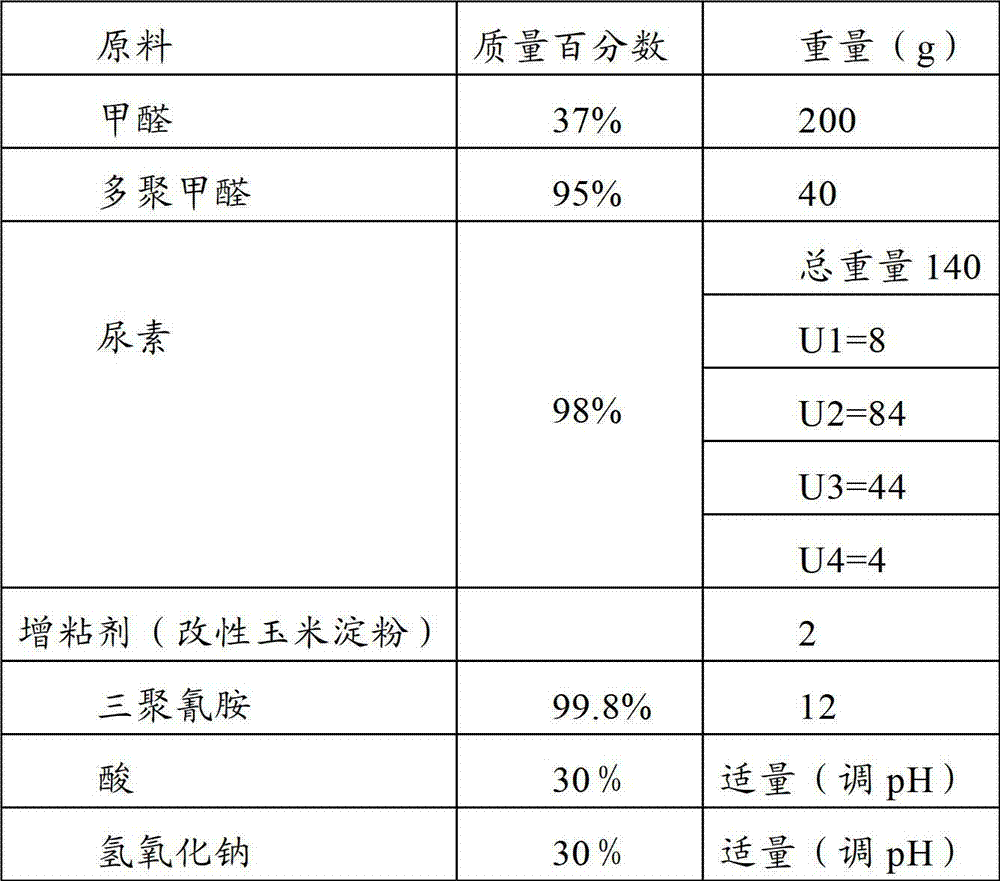

Adhesive for veneering of artificial board and preparation method of adhesive

InactiveCN103031095AReduce penetrationReduce generationMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSolubilityAdhesive

The invention relates to an adhesive for a veneering of an artificial board and a preparation method of the adhesive. The adhesive comprises the components in parts by weight: 200 parts of formaldehyde, 20-50 parts of a modifier, 110-140 parts of urea, 5-15 parts of tripolycyanamide, and 1-10 parts of a tackifier. By addition of appropriate parts of modifier, on the one hand, the high solid content adhesive can be prepared without dehydration, moisture brought to a base material during coating is reduced, permeation of the adhesive is reduced, and glue penetration is reduced. In addition, through addition of the modifier, the molar ratio of formaldehyde and urea in the polycondensation phase in the urea resin synthetic process can be greatly reduced, so that hydrophilic radicals in the resin structure are greatly decreased. Meanwhile, tripolycyanamide in appropriate parts is added to modify, so that the water-solubility of the adhesive is reduced, the hydrophobicity of the adhesive is enhanced, and glue penetration is beneficially reduced. The tackifier in appropriate parts is added to improve the initial adhesion of the adhesive and reduce malposition of a veneer on the base material, so that the product quality is improved.

Owner:EVERFIRST WISEFUND TECH BEIJING

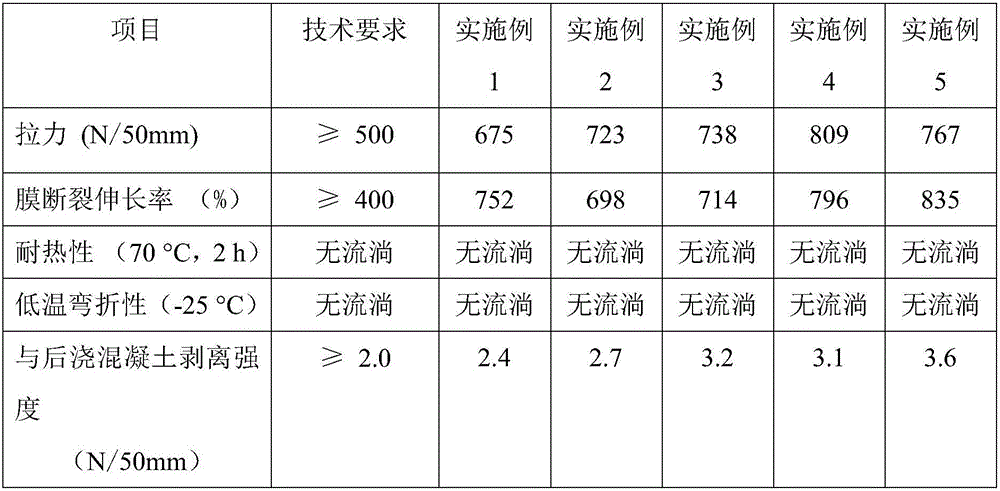

Pre-paved type polyolefin self-adhering film waterproof sheet and preparation method thereof

InactiveCN106543914AGood flexibilityModerate softnessFilm/foil adhesivesRailway tunnelEnvironmental resistance

The invention discloses a pre-paved type polyolefin self-adhering film waterproof sheet and a preparation method thereof. The pre-paved type polyolefin self-adhering film waterproof sheet is composed of two layers of structures, namely, a polyolefin waterproof sheet and a self-adhering glue layer, wherein the polyolefin sheet is prepared from the following raw materials in parts by weight: 65-85 parts of polyethylene, 10-25 parts of thermoplastic elastomer, 5-10 parts of polyethylene grafting materials, 3-8 parts of a modified tackifier, 0.2-0.6 part of titanium dioxide and 0.1-0.5 part of an antioxidant. The preparation method comprises the following steps: mixing according to the raw material ratio of the polyolefin waterproof sheet, fusing, extruding and forming the polyolefin sheet, and then compounding one self-adhering glue layer onto the sheet. The polyolefin self-adhering film waterproof sheet prepared according to the method has the advantages of excellent physical and mechanical properties, excellent waterproof property, moderate softness, excellent workability, safety, environmental protection and excellent peeling strength of self-adhering glue layer and post-poured concrete. The pre-paved type polyolefin self-adhering film waterproof sheet prepared according to the method provided by the invention can be used for waterproof purpose of railway tunnels.

Owner:广州大禹防漏技术开发有限公司

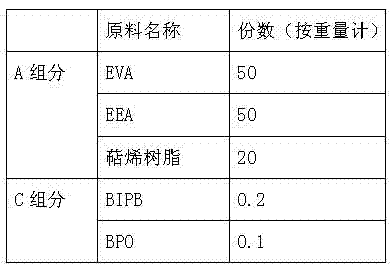

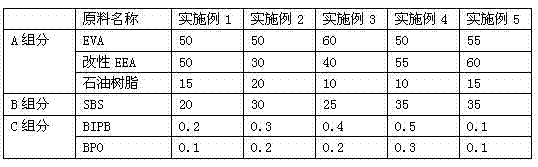

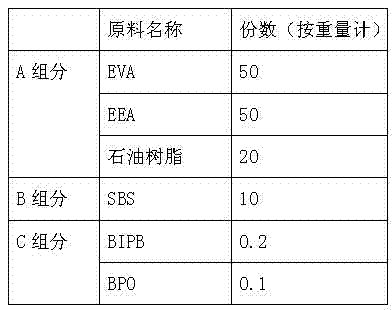

Hot melt adhesive film for adhering sole, and preparation method thereof

ActiveCN103756576APolymerization ControlImproved color stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceBenzoyl peroxide

The present invention relates to a hot melt adhesive film for adhering a sole. The hot melt adhesive film comprises the following raw materials by weight: 50-60 parts of ethylene-vinyl acetate (EVA), 30-60 parts of modified ethylene-ethyl acrylate (EEA), 15-35 parts of a styrene-butadiene block copolymer (SBS), 5-20 parts of a terpene resin, 0.1-0.5 part of bis-(tertbutylperoxy isopropyl)benzene (BIPB), and 0.1-0.5 part of benzoyl peroxide (BPO). According to the present invention, the hot melt adhesive film does not contain benzene, toluene, xylene and other harmful solvents, the sole does not require the primer treatment, the operation process is simple, and the environmental requirement requirements are met.

Owner:江阴伟韬塑料新材料有限公司

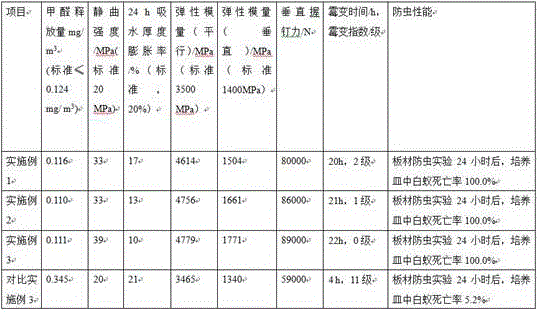

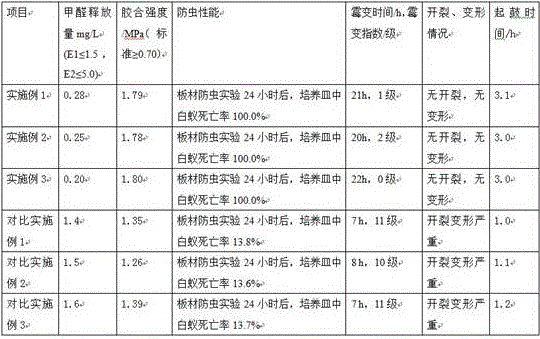

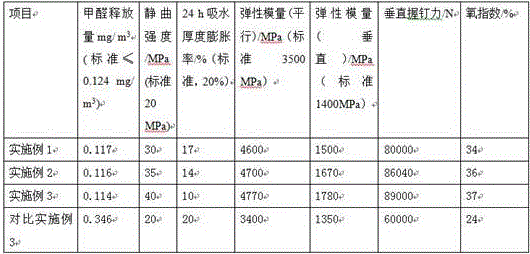

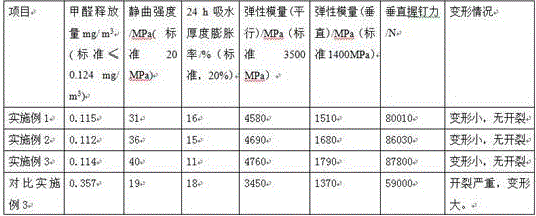

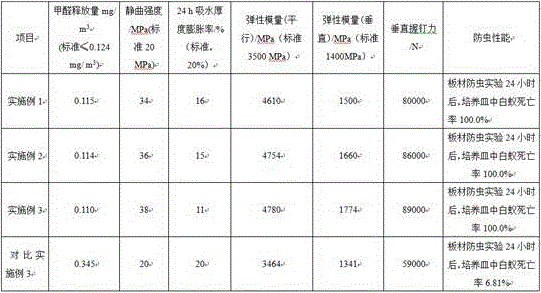

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

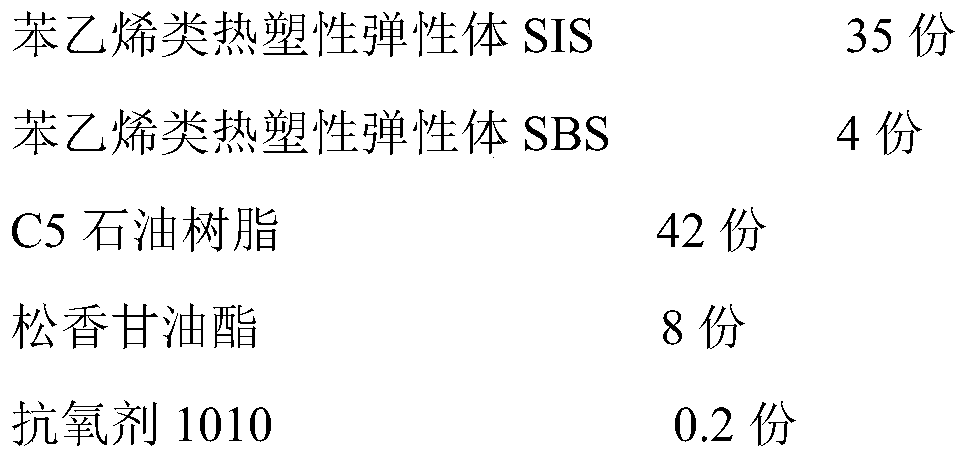

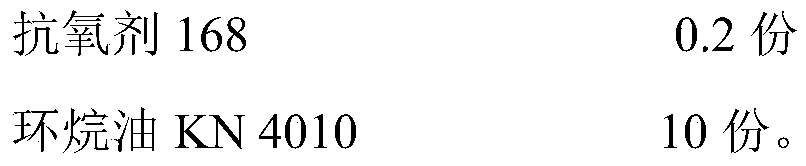

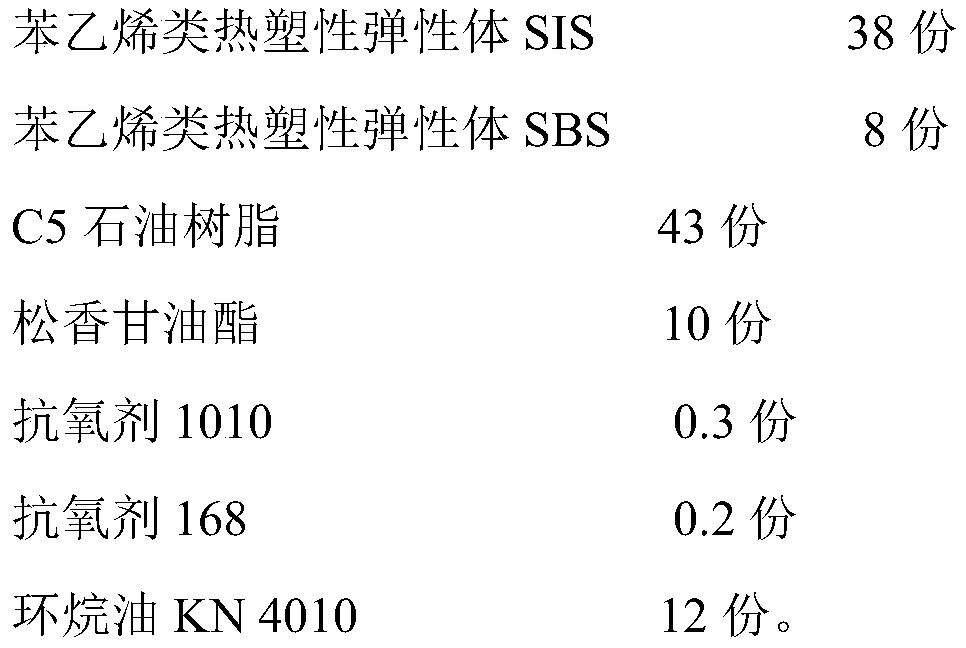

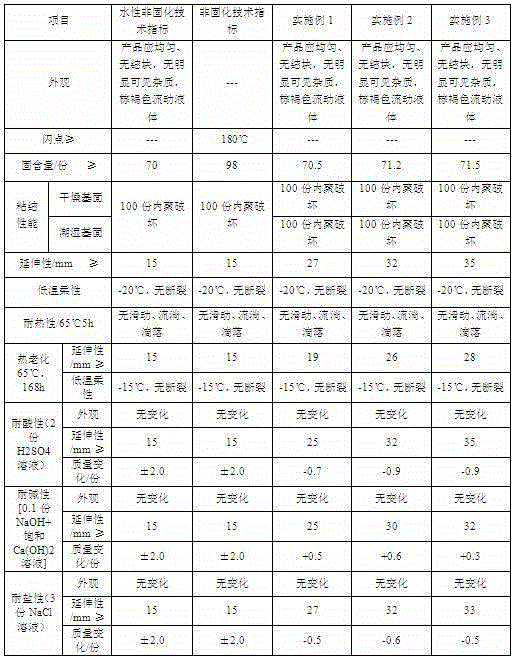

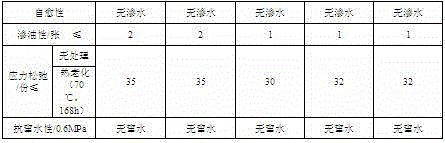

Hot-melt pressure sensitive adhesive for adhesive tapes, and preparation method thereof

InactiveCN110437778AImprove ring tackImprove peel forceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPetroleum resinAntioxidant

The invention relates to a hot-melt pressure sensitive adhesive, and concretely relates to a hot-melt pressure sensitive adhesive for adhesive tapes, and a preparation method thereof. The hot-melt pressure sensitive adhesive comprises a styrenic thermoplastic elastomer SIS, a styrenic thermoplastic elastomer SBS, petroleum resin, rosin glyceride, a primary antioxidant, an auxiliary antioxidant anda softener, wherein the styrenic thermoplastic elastomer SIS is a linear structure, the styrene content is 20-28%, and the diblock content is 20-28%; and the styrenic thermoplastic elastomer SBS is astar structure, the styrene content is 28-32%, and the diblock content is 12-18%. The purpose of the invention is to solve the problem of poor use performance of the adhesive tapes, caused by failedcombination of the initial adhesion, the permanent adhesion and the aging resistance of existing hot-melt pressure sensitive adhesives for adhesive tapes. The initial adhesion (the initial adhesion includes ring initial adhesion and 180 DEG peel strength) of the hot-melt pressure sensitive adhesive of the invention meets use requirements, and has a high adhesion and a good aging resistance. The present invention also provides the preparation method of the hot-melt pressure sensitive adhesive for adhesive tapes.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

Water-based non-curable rubber asphalt coating and preparation method thereof

ActiveCN105038593ASolve the problem of heating to constructionSimple construction processConjugated diene hydrocarbon coatingsBituminous coatingsWater basedBituminous waterproofing

The invention discloses a water-based non-curable rubber asphalt coating and a preparation method thereof and belongs to the field of coatings. Modified rubber asphalt and mixed tackifying resin are emulsified, and a self-adhesive additive, an interface additive, an anti-freezing agent and an anti-ageing agent are compounded. The problem that the non-curable rubber asphalt waterproof coating cannot be applied until the coating is heated is solved, a process is simplified, and the application range of a product is widened. The initial adhesivity and persistent adhesivity of the coating are improved by using a tackifying resin emulsion. The problem that the non-curable rubber asphalt waterproof coating cannot be fully spread on a damp interface due to poor adhesivity is solved by using a silane interface agent, full-spreading seamless construction can be achieved, the hidden danger of water leakage or seepage is completely eradicated, and the permeation resisting performance meets the industrial standard. The water-based non-curable rubber asphalt coating is cured no longer by innovatively using the self-adhesive additive after coating construction is completed, and is good in puncture resistance and self-curing performance. Quick demulsification of the water-based non-curable rubber asphalt coating is achieved by adopting a double-component spraying technology.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

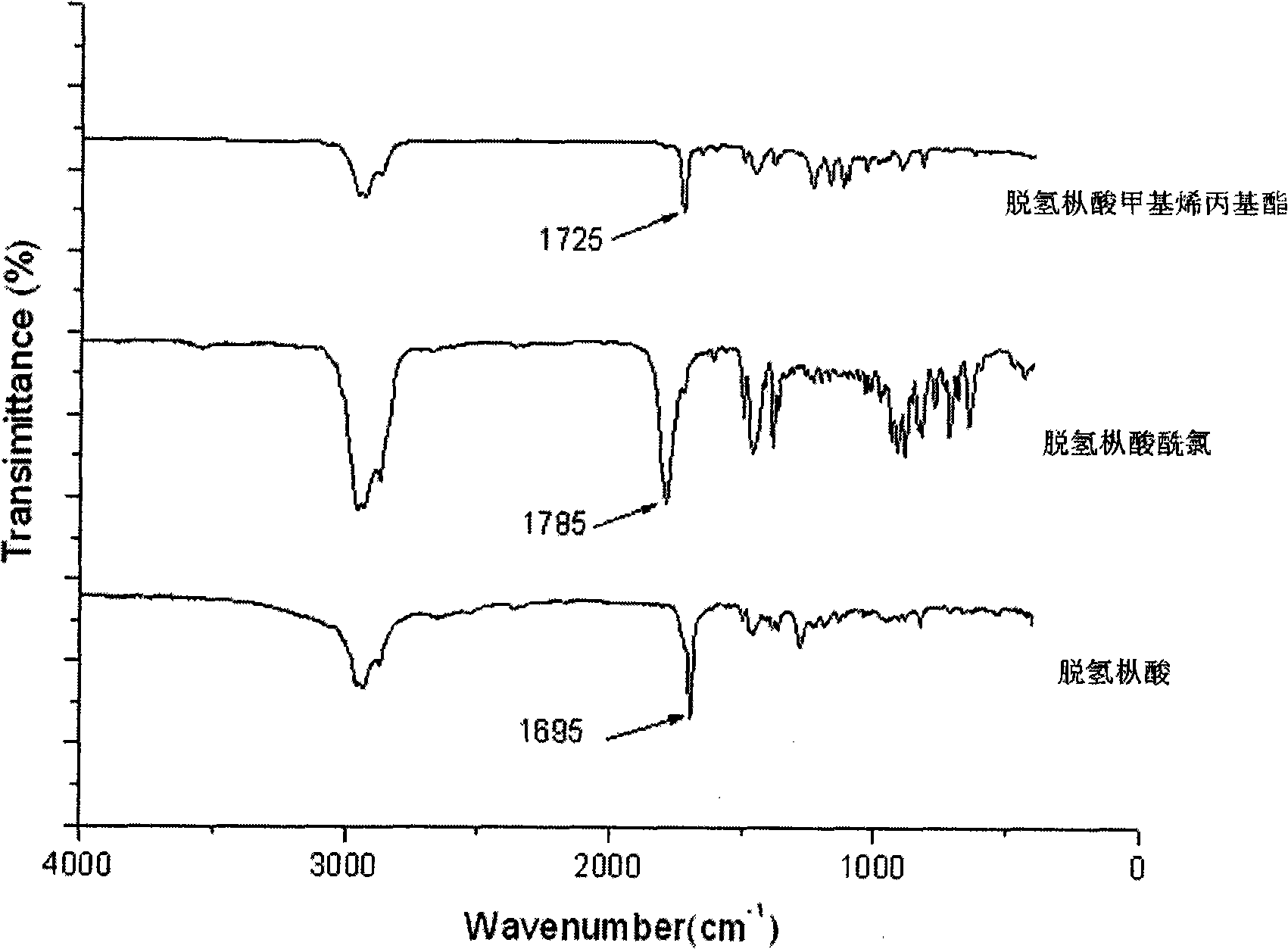

Method for synthesizing rosin or rosin derivatives methacrylic ester

InactiveCN101265392AImprove stabilityHigh purityNatural resin chemical modificationAdhesiveReaction temperature

The invention discloses a synthetic method of colophony or vinsol methyl allyl ester. The synthetic method comprises the following steps: the colophony or one kind of the vinsol is dissolved in aprotic solvent, is added with an acyl chlorination reagent and is heated to ensure the temperature to be 0 to 85 DEG C, the reaction time is 0.5 to 5 hours, acyl chlorination is performed to the carboxyl in the colophony or the vinsol, an acid-binding agent, a polymerization retarder and methally alcohol are added into the reaction product in the first step, and are reacted for 2 to 5 hours under 10 to 80 DEG C, the aprotic solvent is removed, the colophony or the vinsol methyl allyl ester can be acquired, the dosage of the acid-binding agent is 100 to 500 percent of the molar mass of the carboxyl in the colophony or the vinsol, and the dosage of the polymerization retarder is one thousandth of the mass of the methally alcohol. The synthetic colophony (vinsol) methyl allyl ester can perform free radical polymerization, and can be applied to the fields of paint, adhesives, oil ink, paper making, etc. The process efficiency of the method is high, and the product stability is good.

Owner:JIANGSU QIANGLIN BIO ENERGY

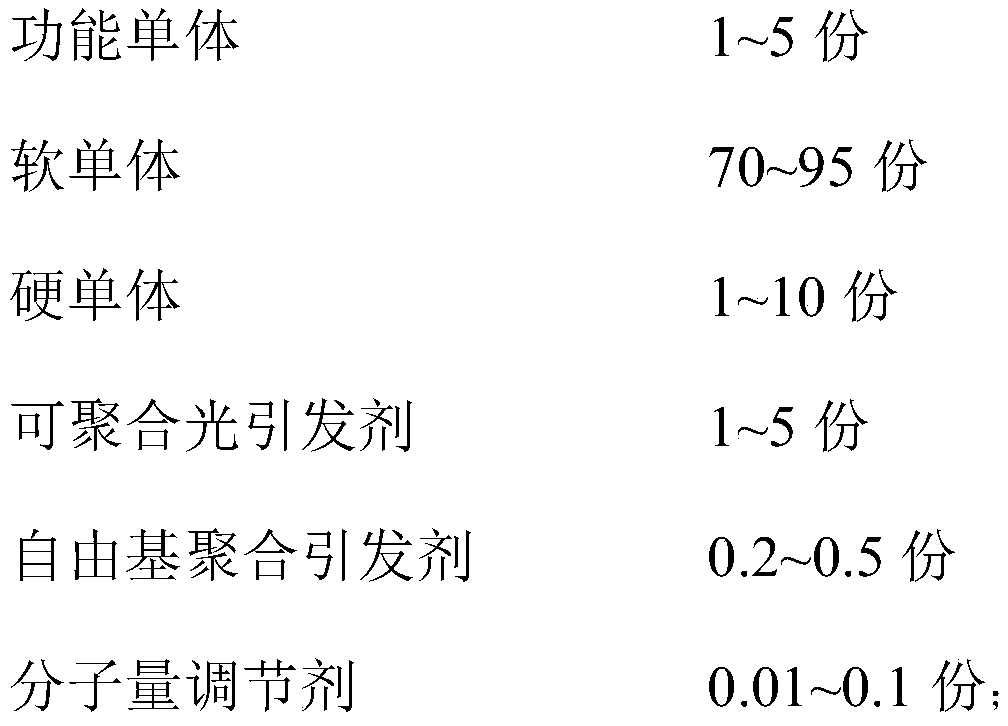

Environmentally-friendly hot-melt pressure sensitive adhesive and preparation method thereof

PendingCN110093128AUniform molecular weightGood solubilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEnvironmental resistanceAntioxidant

The invention discloses an environmentally-friendly hot-melt pressure sensitive adhesive. The environmentally-friendly hot-melt pressure sensitive adhesive is prepared from, by weight, 25-35 parts ofa thermoplastic elastomer, 28-36 parts of modified petroleum resin, 6-10 parts of natural tackifying resin, 12-20 parts of a plasticizer, 2-3 parts of a modifying filler, 0.2-0.3 part of a coupling agent and 0.2-0.3 part of an antioxidant. The present invention also discloses preparation method of the hot-melt pressure sensitive adhesive. The thermoplastic elastomer is used as a matrix for the hot-melt pressure sensitive adhesive, the modified petroleum resin and the natural tackifying resin are used as tackifying resins, and no organic solvent is needed, so the raw materials are safe and environmentally friendly; the petroleum resin is modified, so the compatibility of the petroleum resin and the thermoplastic elastomer is improved, and the thermal stability of the hot-melt pressure sensitive adhesive is improved; and the reinforcing effect of the modifying filler improves the initial viscosity, the glass strength and the thermal stability of the hot-melt pressure sensitive adhesive are improved, so the environmentally-friendly hot-melt pressure sensitive adhesive with excellent performances is prepared.

Owner:黄敏

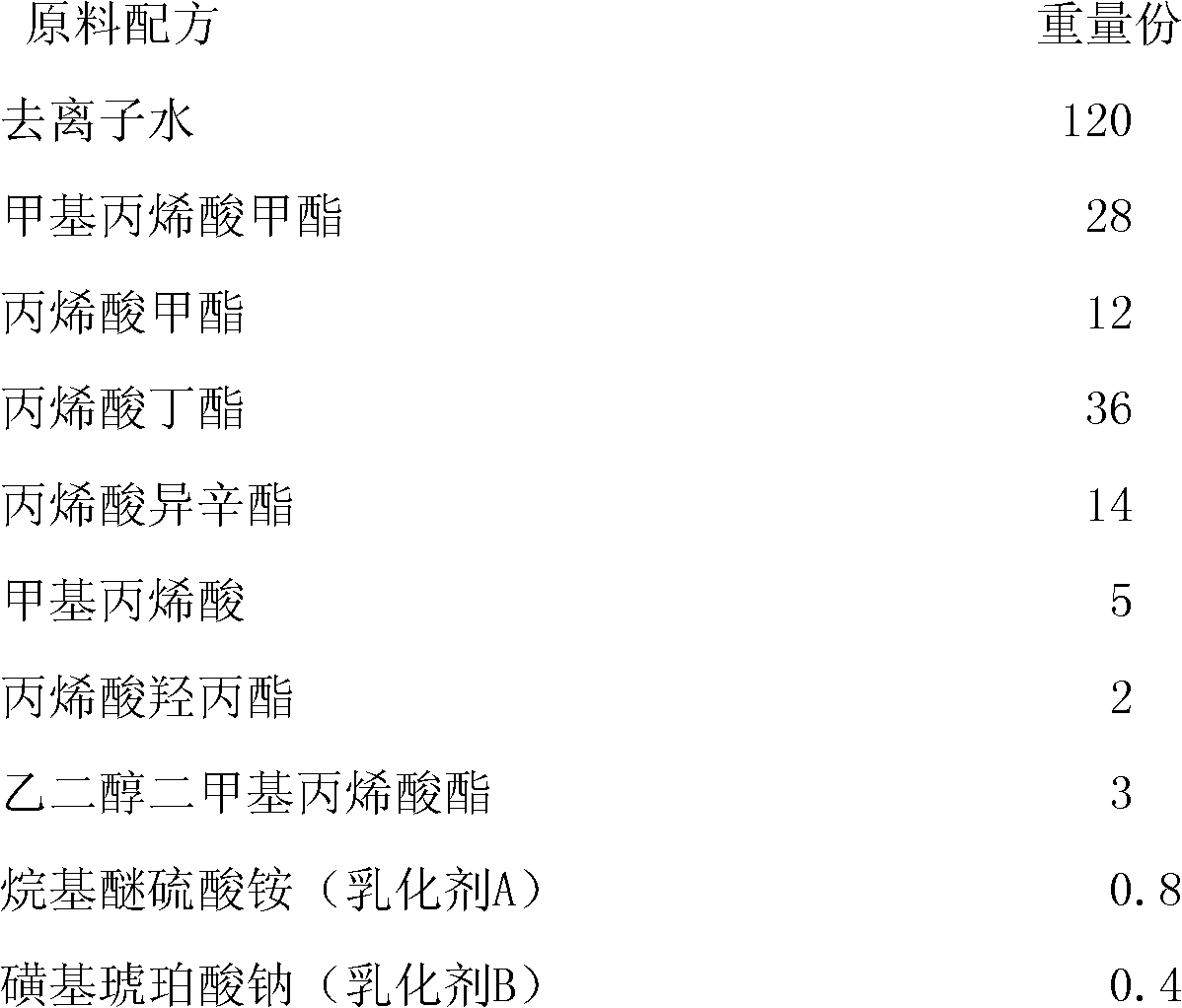

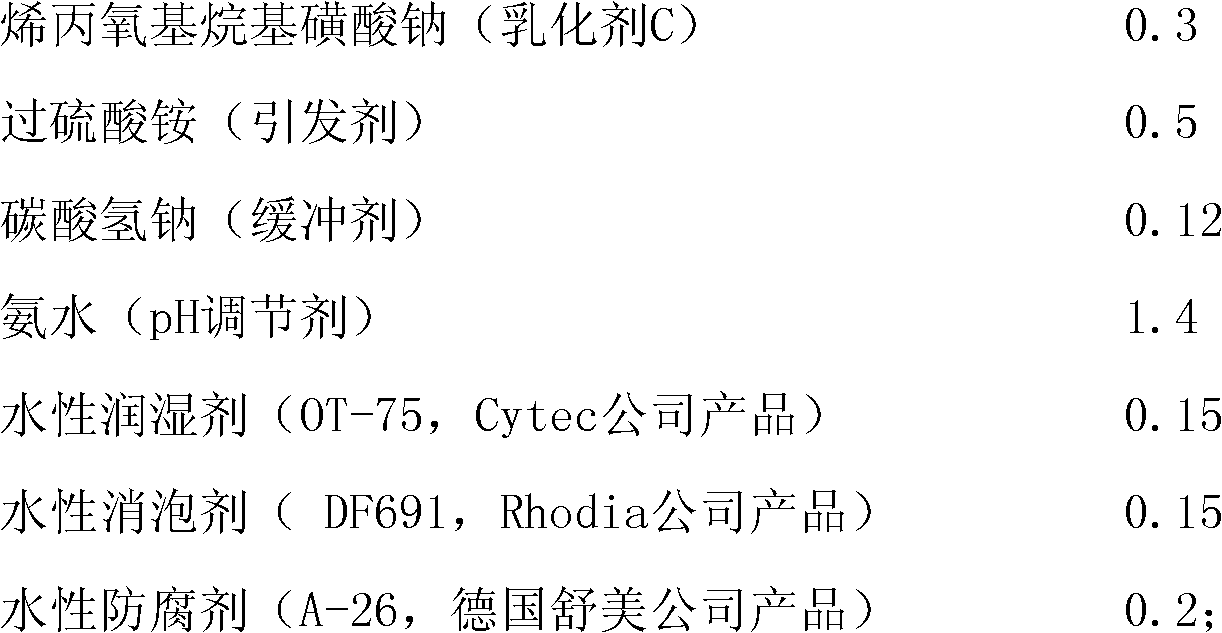

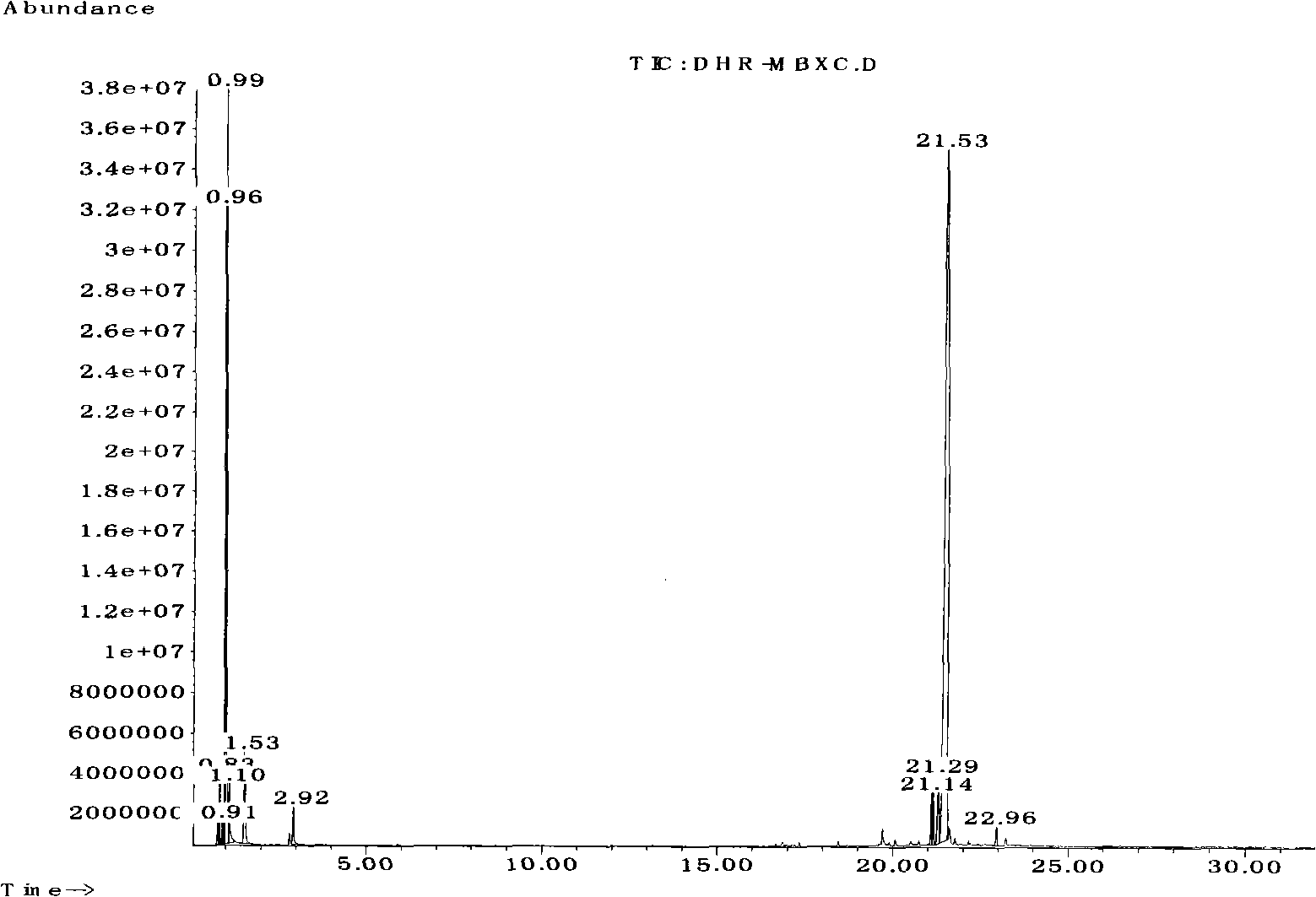

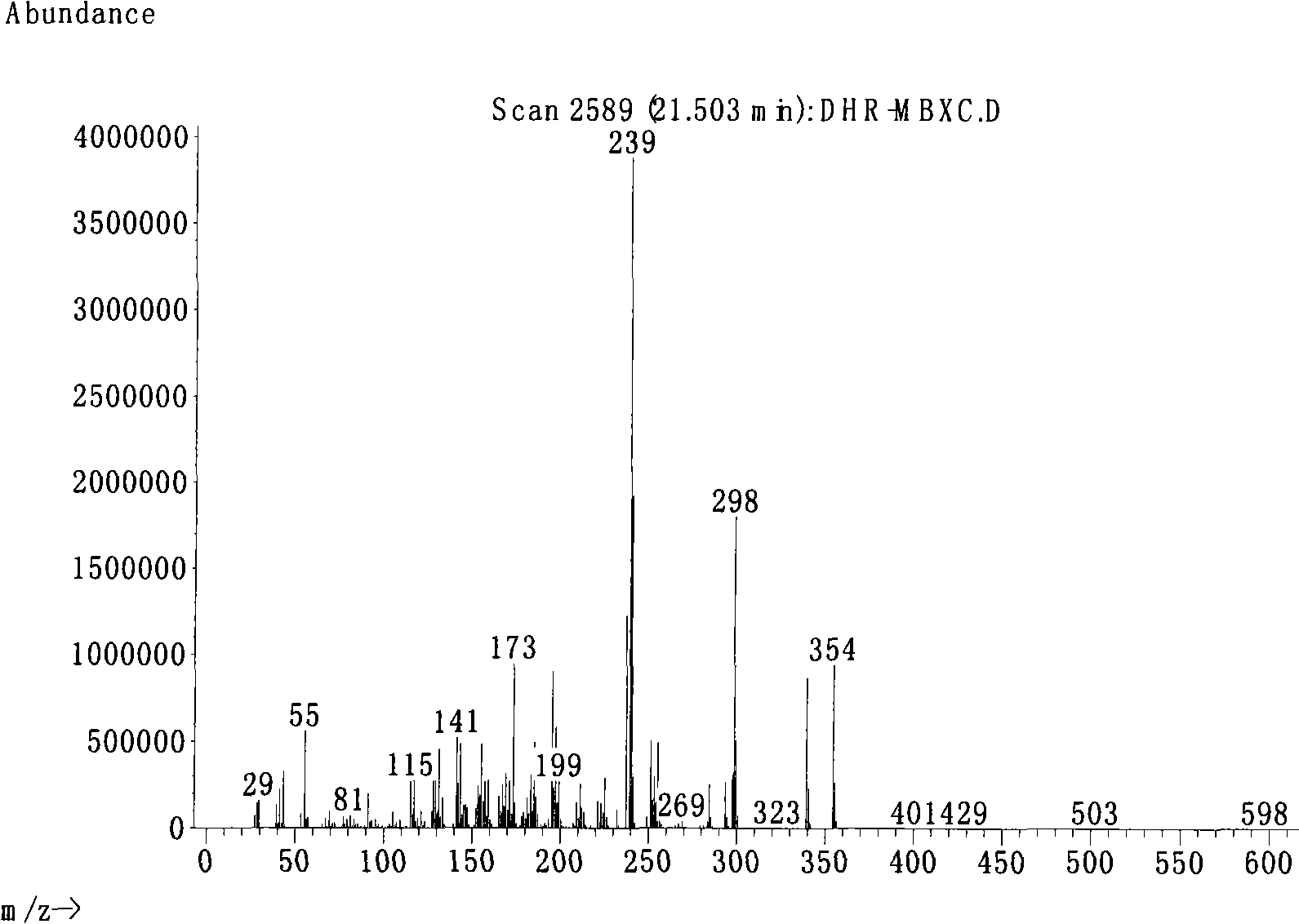

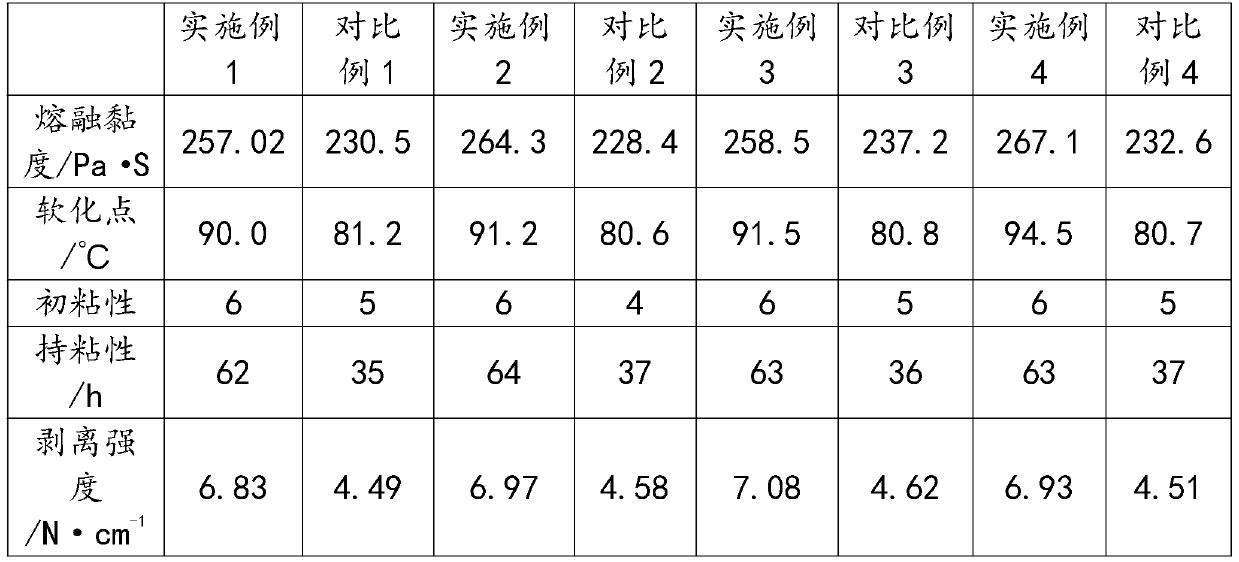

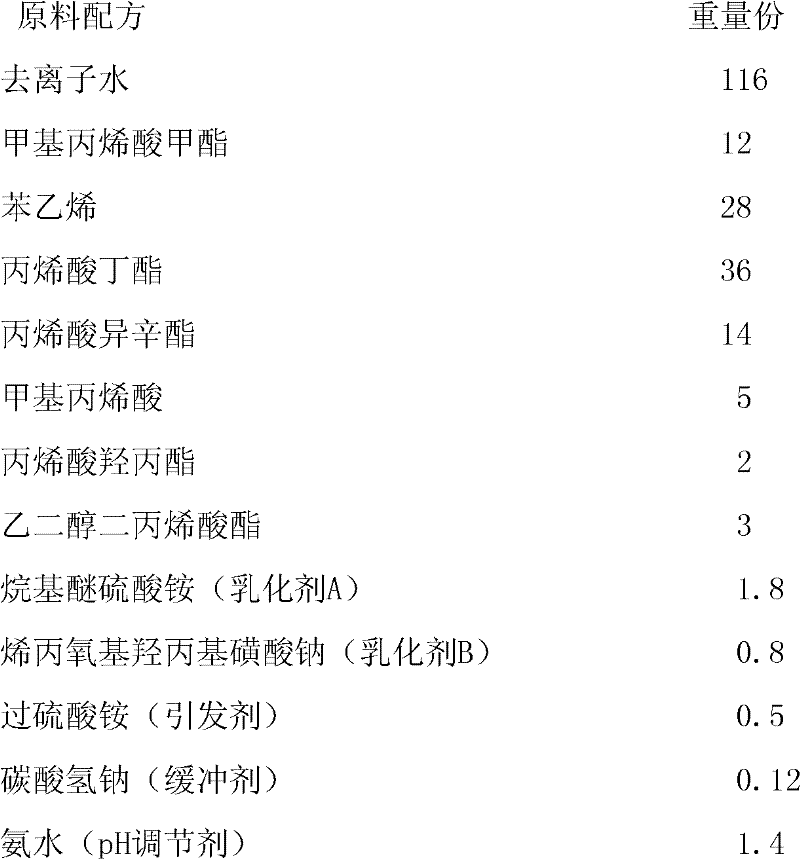

Aqueous laminating adhesive for gold and silver cards and preparation method thereof

InactiveCN102229789AImprove initial tack performanceHigh bonding strengthEster polymer adhesivesHydrocarbon polymer adhesivesIsooctyl acrylateFunctional monomer

Belonging to the field of aqueous binder preparation, the invention discloses an aqueous laminating adhesive for gold and silver cards and a preparation method thereof. With a solid content of 45-55%, the laminating adhesive is an aqueous laminating adhesive employing monomers, an emulsifier, an initiator, a buffering agent, a pH conditioning agent, aqueous auxiliary agents and deionized water asthe raw materials, which undergo the steps of pre-emulsification, seed reaction, polymerization and complex formulation. Wherein, the monomers include hard monomers, soft monomers and functional monomers containing -COOH and -OH groups; the hard monomers consist of methyl methacrylate and styrene; the soft monomers consist of butyl acrylate monomer and enthyl hexyl acrylate; the functional monomers containing -COOH and -OH groups are composed of any of methacrylic acid and acrylic acid, any of hydroxyethyl acrylate and hydroxypropyl acrylate, and ethylene glycol diacrylate; the emulsifier is composed of alkyl ether ammonium sulfate and KD AHPS with a ratio of 1:0.4-0.8 by weight.

Owner:BEIJING COMENS YANSHAN TECH

Method for producing particle board by adopting moisture-proof composite urea resin

ActiveCN106313205AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesWear resistantAdhesive

The invention discloses a method for producing particle board by adopting moisture-proof composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a moisture-proof agent is also added to prepare the moisture-proof composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced particle board is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage. The particle board produced by the method disclosed by the invention is low in formaldehyde residual volume, also stable in quality, hard to damage, good in water resistance and good in moisture resistance.

Owner:广西横县新威林板业有限公司

Corn starch adhesive and preparation method thereof

InactiveCN101885952ANo over-oxidationNo excessive gelatinizationNon-macromolecular adhesive additivesStarch derivtive adhesivesWater bathsSodium Bentonite

The invention discloses a corn starch adhesive and a preparation method thereof. The corn starch adhesive is prepared from corn starch, potassium permanganate, sodium hydroxide, borax, sodium thiosulfate, sodium bentonite and water. The preparation method comprises the following steps of: grinding and screening the sodium thiosulfate; preparing pasty corn starch in a constant-temperature water bath; mixing the water, the potassium permanganate and the screened sodium bentonite in the constant-temperature water bath, and pouring into the pasty corn starch to prepare mixed solution; adding water to dissolve the sodium hydroxide, the borax and the sodium thiosulfate, and pouring into the mixed solution to prepare the finished product. The preparation process is simple, and the conventional equipment is not needed to be changed; during production, the temperature is low, and the energy consumption is low; and the produced starch adhesive has the advantages of good liquidity, strong adhesiveness, quick drying, high stability, no pollution, and can greatly improve the ring crush compression resistance and the tension strength of corrugated paper.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

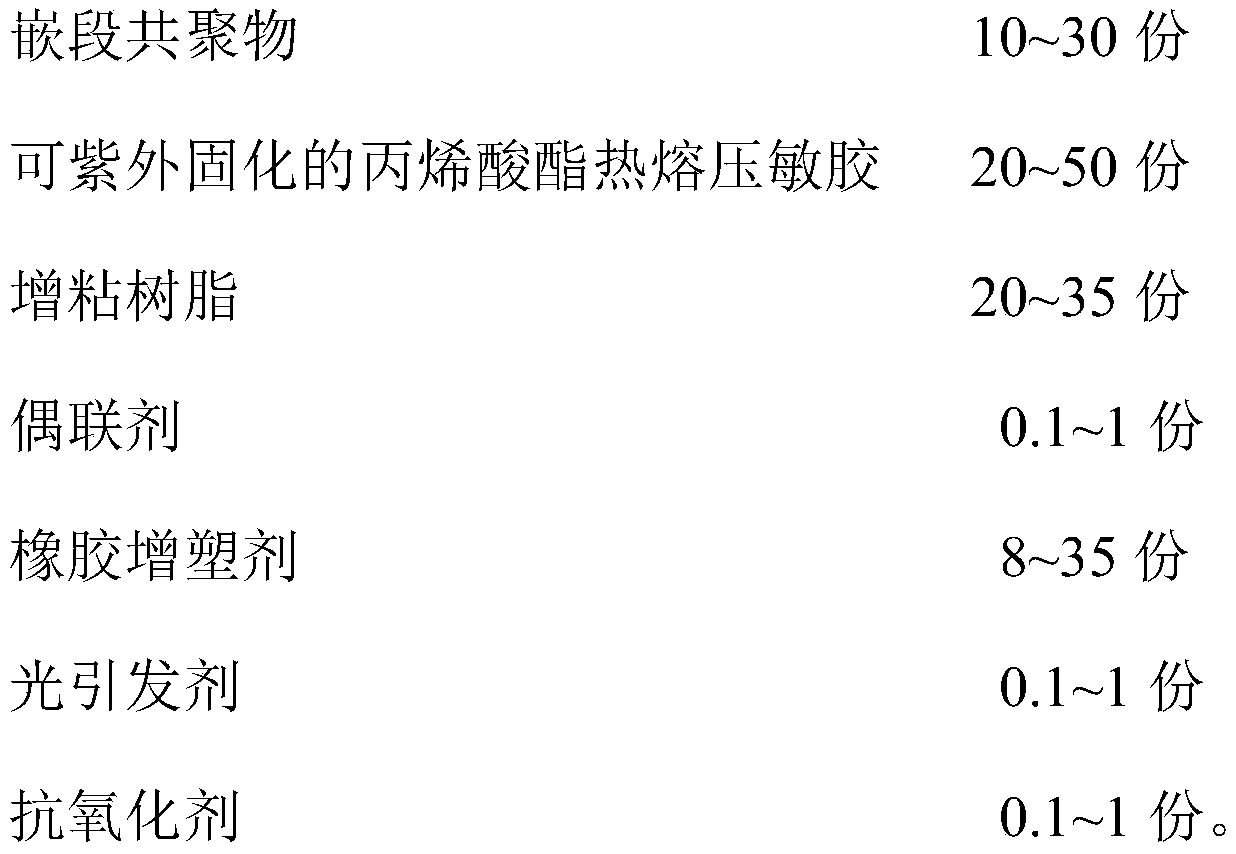

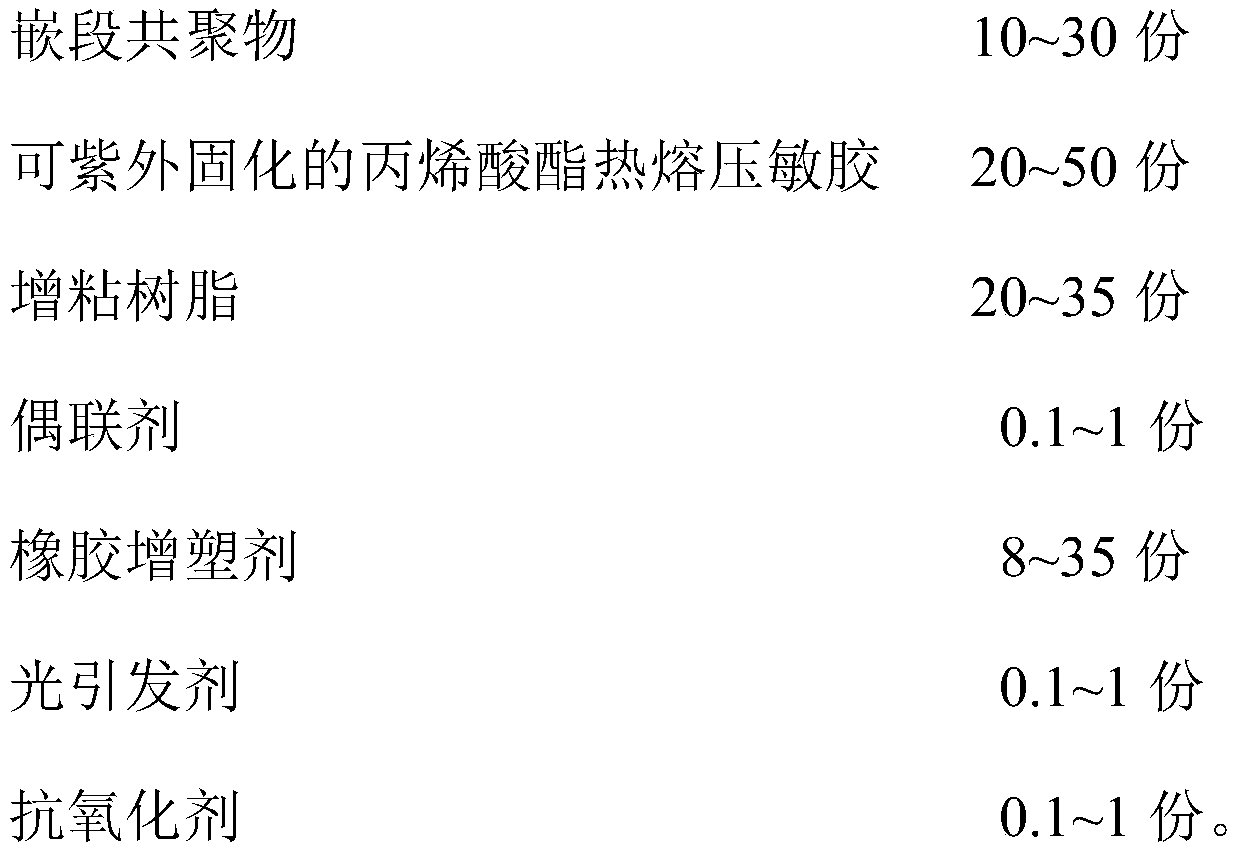

Ultraviolet-curing hot-melt pressure-sensitive adhesive high in peeling strength, and preparation method and applications thereof

ActiveCN110467893AGood compatibilityImprove stabilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantPlasticizer

The invention discloses an ultraviolet-curing hot-melt pressure-sensitive adhesive high in peeling strength, and a preparation method and applications thereof. The ultraviolet-curing hot-melt pressure-sensitive adhesive high in peeling strength comprises, by weight, 10 to 30 parts of a segmented copolymer, 20 to 50 parts of a UV-curable acrylic ester hot-melt pressure-sensitive adhesive, 20 to 35parts of a tackifying resin, 0.1 to 1 part of a coupling agent, 8 to 35 parts of a rubber plasticizer, 0.1 to 1 part of a photoinitiator, and 0.1 to 1 part of an antioxidant. The peeling strength, theprimary viscosity, and the applying effect on nonpolar base materials of the ultraviolet-curing hot-melt pressure-sensitive adhesive are improved obviously; the ultraviolet resistance and the high temperature resistance are also improved greatly.

Owner:KUNSHAN JIUQING PLASTIC

Method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin

ActiveCN106182218AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantAdditive ingredient

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

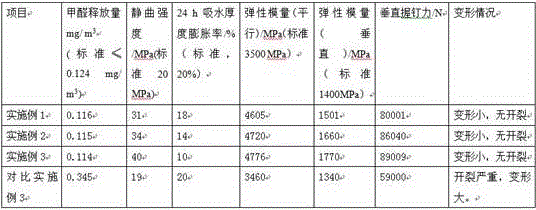

Method for producing high-temperature-resisting oriented particle board by using total-eucalyptus leftover material

ActiveCN106313265AWhite colorGood film formingNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesParticle boardImpurity

The invention provides a method for producing a high-temperature-resisting oriented particle board by using a total-eucalyptus leftover material. The method comprises the steps of material preparation, drying, debarking, impurity removing, sorting, storage, respective gluing of a surface layer and a core layer, classified paving, pre-hot-pressing molding, sanding of an overcoating and the like, wherein the surface layer is coated with an isocyanate sawdust powder composite adhesive; the core layer is coated with a high-temperature-resisting composite urea resin adhesive; the core layer wood shaving is of a three-layer structure which comprises a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer; the core layer middle layer is paved longitudinally; the core layer upper surface layer, the core layer lower surface layer and the surface layer are paved horizontally. The oriented particle board prepared by the method provided by the invention is 31MPa to 40MPa in parallel static bending intensity, 4605MPa to 4776MPa in parallel elasticity modulus, 1501MPa to 1770MPa in vertical elasticity modulus, 10% to 18% in thickness swelling rate of 24-h water absorption and as high as 89009N in vertical nail-holding power, and is good in dimensional stability and reliability. Moreover, the oriented particle board prepared by the method provided by the invention is also excellent in heat resistance.

Owner:广西横县新威林板业有限公司

Method for producing flame-retardant oriented strand boards with full eucalyptus wood scraps

InactiveCN106182316AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScrapElastic modulus

The invention provides a method for producing flame-retardant oriented strand boards with full eucalyptus wood scraps. The method comprises the working procedures of material preparation, drying, debarking and impurity removal, sorting and storage, respective gluing on surface layers and a core layer, graded laying, preheating pressing molding, sanding and finishing, and the like, wherein the surface layers are coated with isocyanate sawdust powder compound adhesive, the core layer is coated with flame-retardant compound urea-formaldehyde resin adhesive, core layer shavings are divided to form a three-layer structure which includes a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer, vertical laying is adopted for the core layer middle layer, and transverse laying is adopted for the core layer upper surface layer, the core layer lower surface layer and the surface layers. According to the oriented strand boards produced with the method, the static bending intensity in the parallel direction ranges from 30 MPa to 40 MPa, the parallel elasticity modulus ranges from 4600 MPa to 4770 MPa, the vertical elasticity modulus ranges from 1500 MPa to 1780 MPa, the thickness swelling rate of water absorption of 24 hours ranges from 10% to 17%, the vertical nail-holding power is as high as 89000 N, and the dimensional stability and reliability are good. In addition, the oriented strand boards produced with the method further have the excellent effect of flame retardance.

Owner:广西横县新威林板业有限公司

Method for producing weather-resistant oriented strand board by using full-eucalyptus leftover material

ActiveCN106272865AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesOptoelectronicsImpurity

The invention provides a method for producing a weather-resistant oriented strand board by using a full-eucalyptus leftover material. The method includes material preparation, drying, peel and impurity removing, sorting storage, gluing of a surface layer and core layer, classified pavement, pre-hot pressing forming, facing sanding and other working procedures. The surface layer is coated with isocyanate sawdust powder composite adhesives, and the core layer is coated with weather-resistant composite urea-formaldehyde resin adhesives. Core layer wood shavings are divided into three layers of structures and comprise a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer. The core layer middle layer is longitudinally laid, and the core layer upper surface layer, the core layer lower surface layer and a surface layer are transversely laid. According to the oriented strand board prepared through the method, the static bending intensity in the parallel direction is 31-40MPa, and the parallel elasticity modulus is 4580-4760MPa; and the vertical elasticity modulus is 1510-1790MPa, the 24 h thickness swelling rate of water absorption is 11%-16%, vertical nail-holding ability reaches up to 87800N, and the dimensional stability and reliability are good. Moreover, the oriented strand board prepared through the method has excellent weather resistance.

Owner:广西横县新威林板业有限公司

Polyurethane adhesive and preparation method thereof

ActiveCN107858133AExcellent reworkabilityReduce tanglingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane elastomerMasterbatch

The invention provides a polyurethane adhesive and a preparation method thereof. The polyurethane adhesive is prepared from the following components in percentage by mass: 1.6 to 11.4 percent of hydroxyl polyurethane elastomer, 0 to 3.5 percent of flexibilizer, 0 to 2.8 percent of polymer modifier, 0.1 to 2.8 percent of reinforcing agent, 0 to 1.5 percent of aid and 88 to 97 percent of organic solvent. The adhesive has the advantages of low solid content, good rework ability, high initial viscosity, high peel strength, high shearing strength, good wettability and low cost of a substrate and the like; in addition, the adhesive has good high-temperature washing resistance, bending resistance and heat-resisting aging when being used for adhering shoe soles to vamps. The invention also provides the preparation method of the polyurethane adhesive; the preparation method comprises the steps of preparing polyurethane elastomer masterbatch, dissolving and the like; the process is simple.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Method for producing antiseptic oriented strand board through full-eucalyptus leftover materials

InactiveCN106239689AWhite colorGood film formingWood veneer joiningDomestic articlesDusting powdersOptoelectronics

The invention provides a method for producing an antiseptic oriented strand board through full-eucalyptus leftover materials. The method comprises the procedures of material preparing, drying, peel and impurity removing, sorting and storing, surface layer and core layer gluing, classified paving, preheating press forming, sanding facing and the like. A surface layer is coated with an isocyanate wood dust powder composite adhesive, a core layer is coated with an antiseptic composite urea-formaldehyde resin adhesive, and core layer wood shavings are of three-layer structures including a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer. The core layer middle layer is longitudinally laid, and the core layer upper surface layer, the core layer lower surface layer and the surface layer are transversely laid. According to the oriented strand board prepared through the method, the static bending intensity in the parallel direction ranges from 34 MPa to 38 MPa, and the parallel elasticity modulus ranges from 4,610 MPa to 4,780 MPa; and the vertical elasticity modulus ranges from 1,500 MPa to 1,774 MPa, the water absorption thickness swelling rate in 24 h ranges from 11% to 16%, and the vertical nail holding force reaches up to 89,000 N. Meanwhile, through adding of an antiseptic agent, the problem that panels are prone to suffering from corrosion of wood-destroying fungi, moulds and white ants is thoroughly solved, and the service life of the panels is prolonged.

Owner:广西横县新威林板业有限公司

Method for producing cabinet board by adopting flame-retardant composite urea resin

InactiveCN106333530AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesBuilding materialUrea

The invention relates to home building materials, in particular to a method for producing a cabinet board by adopting flame-retardant composite urea resin. The cabinet board structurally comprises decorative paper, a cunninghamia lanceolata veneer, a shaving board and a back board from top to bottom, wherein the periphery of the cabinet board is edged with aluminium alloy; a flame-retardant composite urea resin adhesive is applied between the cunninghamia lanceolata veneer and the shaving board; a flame-retardant composite urea resin adhesive is applied between the shaving board and the back board; a flame-retardant composite urea resin adhesive is also adopted for the shaving board in the cabinet board. The cabinet board manufactured by the method has the advantages of strong water resistance, high bonding strength, low formaldehyde residue and a flame-retardant function. The shaving board in production of the cabinet board is made of waste materials and leftover materials which can not be utilized in the process of manufacturing a multilayered eucalyptus board after rotary cutting of eucalyptus boards, and the leftover materials are utilized, so that the woods can be saved and the production cost of an enterprise can be reduced.

Owner:广西横县正林木业有限公司

Two-component solvent-free plant oil-based adhesive

ActiveCN105969293AImprove initial tack performanceHigh strengthMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesAdhesiveHeat resistance

The invention provides a two-component solvent-free plant oil-based adhesive, which comprises components A and B, wherein component A comprises modified plant oil, tackifying resin, a coupling agent, a filler, microencapsulated microspheres and a chain extender; component B comprises isocyanate or a mixture of isocyanate and modified plant oil. The two-component solvent-free plant oil-based adhesive with high comprehensive performance is safe in use, economical, moderate in curing speed, adjustable in hardness, high in initial cohesiveness, water resistance and heat resistance, strong in adhesive strength, wide in application range, green and environment-friendly.

Owner:福建省南平星源辉生物科技有限公司

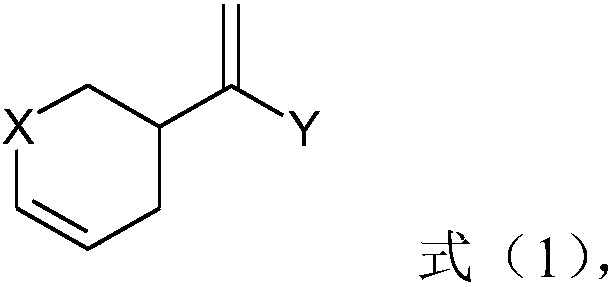

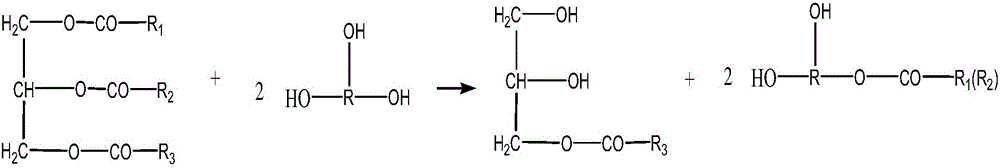

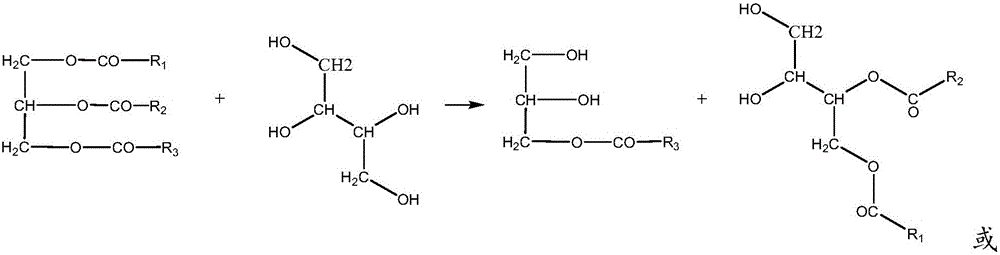

Actinic radiation curable resin composition containing polyfunctional acrylate compound

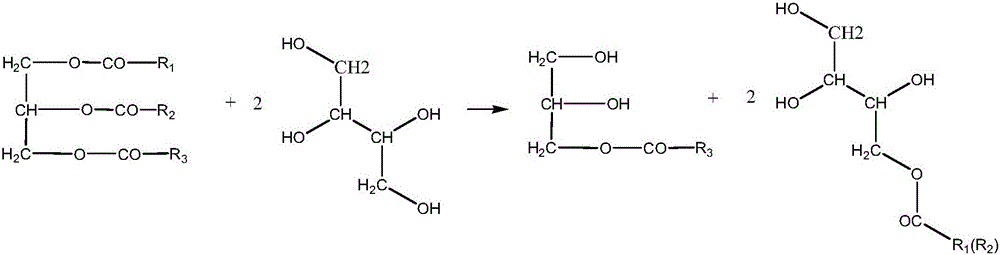

ActiveCN103314023AImprove initial tack performancePrevent movementNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveDendrimerGlycerol Derivatives

The present invention provides a resin composition which serves as an adhesive for accurately fixing a component made of a material such as metal or plastic. This resin composition exhibits high initial adhesion to the material. In the durability tests including high-temperature and high-humidity test, the resin composition exhibits high holding power, and is rarely deformed even when heated under loading as well as when heated, thus inhibiting the movement of the part. An actinic radiation curable resin composition characterized by comprising (A) a polyfunctional acrylate compound having four or more (meth)acryloyl groups in the molecule, (B) a photocurable prepolymer, (C) a mono- or bi-functional (meth)acryloyl -containing monomer and (D) a photopolymerization initiator, said polyfunctional acrylate compound (A) being selected from the group consisting of (a1) glycerol derivatives, and linear or branched polymers thereof which each comprise ether skeletons as the connecting functional groups, (a2) trimethylolpropane derivatives, and linear or branched polymers thereof which each comprise ether skeletons as the connecting functional groups, (a3) monomeric pentaerythritol derivatives, and linear or branched polymers thereof which each comprise ether skeletons as the connecting functional groups, and (a4)dendrimers which contain ether or ester bonds and in which (meth)acryloyl groups are present at four or more terminals.

Owner:KYORITSU KAGAKU SANGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com