Water-based non-curable rubber asphalt coating and preparation method thereof

A technology for non-curing rubber and asphalt coatings, applied in the field of coatings, can solve the problems of asphalt smoke pollution, poor adhesion of wet interfaces, heating construction of non-curing rubber asphalt coatings, etc. Effects of aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

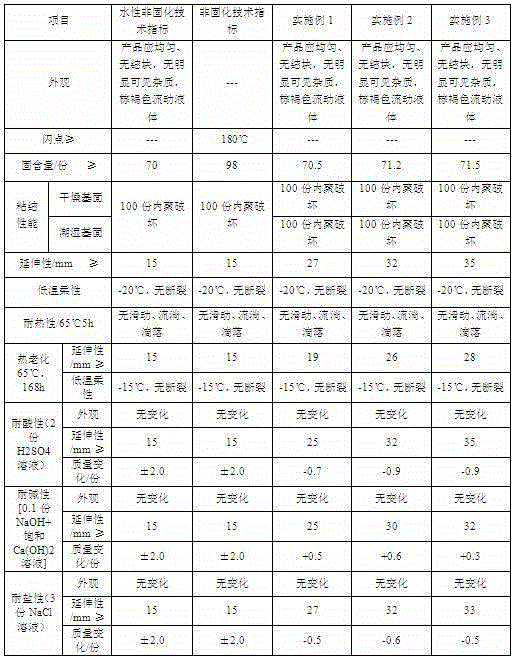

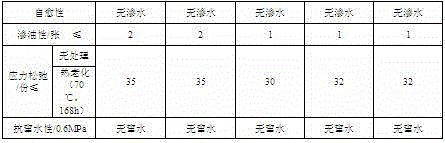

Examples

Embodiment 1

[0028] A water-based non-curing rubber asphalt coating is composed of component A and component B; component A is composed of 75 parts of cationic rubber modified emulsified asphalt, 10 parts of tackifying resin emulsion, 3 parts of self-adhesive additive, 2 parts of interface agent, Composed of 2 parts of antifreeze and 1 part of anti-aging agent; component B is composed of 10 parts of inorganic salt, 5 parts of buffer and 60 parts of water; the mass ratio of component A to component B is 25:1.

[0029] Among them component A:

[0030] Cationic rubber modified emulsified asphalt is composed of base asphalt, mixed rubber, vulcanizing agent, stabilizer, deionized water and cationic emulsifier, the mass ratio of base asphalt, mixed rubber, vulcanizing agent, stabilizer, deionized water and cationic emulsifier 100:11:0.1:0.1:30:6. The base asphalt is 70# base asphalt; the mixed rubber is composed of carbon black reinforced SBR rubber, SBS rubber and SIS rubber, and the mass rati...

Embodiment 2

[0046] A water-based non-curing rubber asphalt coating is composed of component A and component B; component A is composed of 85 parts of cationic rubber modified emulsified asphalt, 15 parts of tackifying resin emulsion, 5 parts of self-adhesive additive, 3 parts of interface agent, Composed of 3 parts of antifreeze and 2 parts of anti-aging agent; component B is composed of 30 parts of inorganic salt, 15 parts of buffer and 80 parts of water; the mass ratio of component A to component B is 30:1.

[0047] Among them component A:

[0048] Cationic rubber modified emulsified asphalt is composed of base asphalt, mixed rubber, vulcanizing agent, stabilizer, deionized water and cationic emulsifier, the mass ratio of base asphalt, mixed rubber, vulcanizing agent, stabilizer, deionized water and cationic emulsifier 100:20:0.2:0.2:60:9.

[0049] The mixed rubber is composed of carbon black reinforced SBR rubber, SBS rubber and SIS rubber, and the mass ratio of carbon black reinforce...

Embodiment 3

[0065] A water-based non-curing rubber asphalt coating is composed of component A and component B; component A is composed of 80 parts of cationic rubber modified emulsified asphalt, 12 parts of tackifying resin emulsion, 4 parts of self-adhesive additive, 2.5 parts of interface agent, 2.5 parts of antifreeze and 1.5 parts of anti-aging agent; component B is composed of 20 parts of inorganic salt, 10 parts of buffer and 70 parts of water; the mass ratio of component A to component B is 28:1.

[0066] Among them component A:

[0067] Cationic rubber modified emulsified asphalt is composed of base asphalt, mixed rubber, vulcanizing agent, stabilizer, deionized water and cationic emulsifier, the mass ratio of base asphalt, mixed rubber, vulcanizing agent, stabilizer, deionized water and cationic emulsifier 100:15:0.15:0.15:45:8.

[0068] The mixed rubber is composed of carbon black reinforced SBR rubber, SBS rubber and SIS rubber, and the mass ratio of carbon black reinforced SB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com