Rubber modified asphalt waterproof coating as well as preparation method and use method thereof

A bitumen waterproof coating and rubber modification technology, which is applied to asphalt coatings, carboxyl rubber coatings, chloroprene homopolymer coatings, etc., can solve the problems of long drying time, slow water volatilization speed, and low solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: the preparation of rubber modified asphalt waterproof coating of the present invention

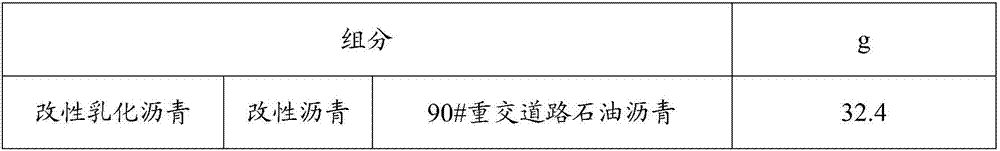

[0084] Table 1: Component A raw materials

[0085]

[0086]

[0087] Table 2: B component raw materials

[0088] components g calcium chloride 9 Sodium chloride 1 Deionized water 90

[0089] The preparation of rubber modified asphalt waterproof paint of the present invention:

[0090] 1. The modified asphalt is prepared by the following preparation method:

[0091] (a) Add the asphalt heated to 130°C into the mixing pot, raise the temperature to 160°C, and start the electric mixer at a speed of 100-200rpm;

[0092] (b) Add modifier and tackifying resin to the system obtained in step (a), heat at 170°C, stir at 50-100rpm, until there are no infusible particles;

[0093] (c) Emulsify the system obtained in step (b) with a high-speed shear emulsifier at a rotational speed of 1000-2000 rpm for about 30 minutes, discharge, and obt...

Embodiment 2

[0103] Embodiment 2: the preparation of rubber modified asphalt waterproof coating of the present invention

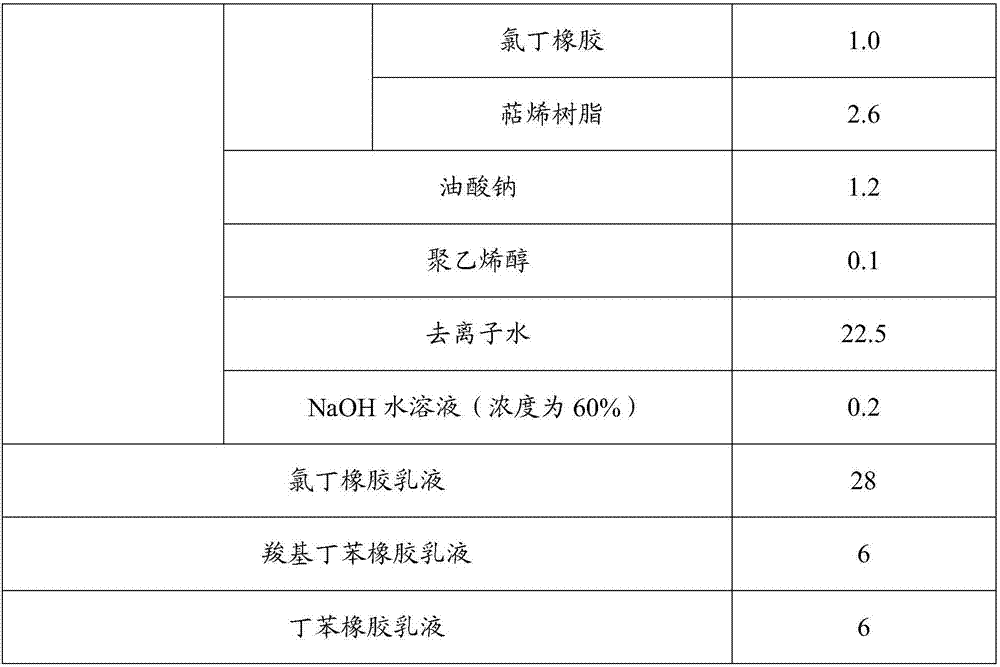

[0104] Table 3: A component raw materials

[0105]

[0106]

[0107] Table 4: Component B Raw Materials

[0108] components g calcium nitrate 9 Sodium chloride 1 Deionized water 90

[0109] The preparation of rubber modified asphalt waterproof paint of the present invention:

[0110] 1. The modified asphalt is prepared by the following preparation method:

[0111] (a) Add the asphalt heated to 130°C into the mixing pot, raise the temperature to 160°C, and start the electric mixer at a speed of 100-200rpm;

[0112] (b) Add modifier and tackifying resin to the system obtained in step (a), heat at 170°C, stir at 50-100rpm, until there are no infusible particles;

[0113](c) Emulsify the system obtained in step (b) with a high-speed shear emulsifier at a rotational speed of 1000-2000 rpm for about 30 minutes, discharge, and obta...

Embodiment 3

[0123] Embodiment 3: the preparation of rubber-modified asphalt waterproof coating of the present invention

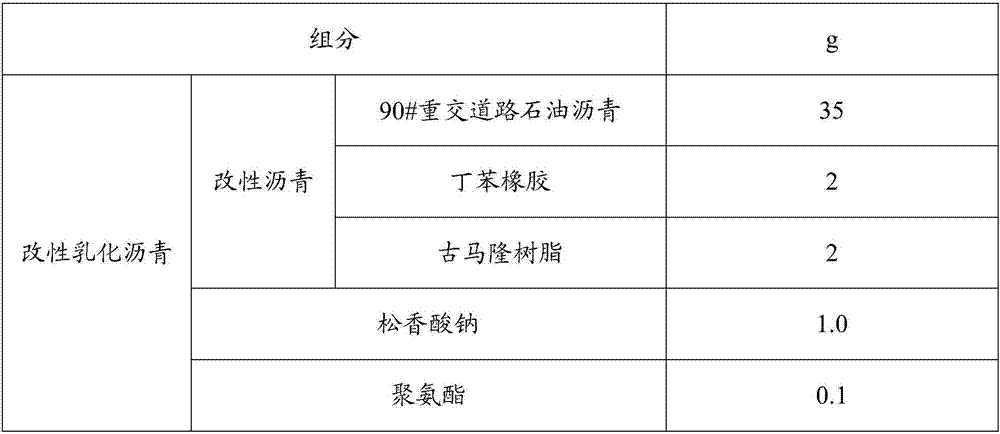

[0124] Table 5: Component A Raw Materials

[0125]

[0126]

[0127] Table 6: B component raw materials

[0128] components g calcium nitrate 8 Sodium chloride 1 Deionized water 91

[0129] The preparation of rubber modified asphalt waterproof paint of the present invention:

[0130] 1. The modified asphalt is prepared by the following preparation method:

[0131] (a) Add the asphalt heated to 130°C into the mixing pot, raise the temperature to 160°C, and start the electric mixer at a speed of 100-200rpm;

[0132] (b) Add modifier and tackifying resin to the system obtained in step (a), heat at 170°C, stir at 50-100rpm, until there are no infusible particles;

[0133] (c) Emulsify the system obtained in step (b) with a high-speed shear emulsifier at a rotational speed of 1000-2000 rpm for about 30 minutes, discharge, and obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com