Composite carbon dioxide fracturing fluid and preparation method thereof

A technology of carbon dioxide and gaseous carbon dioxide, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of poor temperature resistance and shear resistance of fracturing fluid, reduced oil and gas stimulation effect, and the existence of more insolubles and other problems, to achieve the effect of improving fluidity, easy toxicity, solubility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

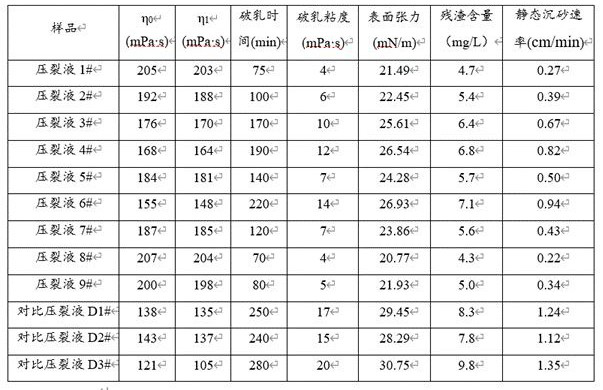

Examples

Embodiment 1

[0053] (1) Preparation of the first monomer: Dissolve 90.0g N,N-diethyl-2-chloroacetamide in 150.0g pyridine to obtain solution I, then dissolve 100.0g 4-hydroxybutyl vinyl ether in 200.0g Solution II was obtained in pyridine, and solution I was added dropwise to solution II, and reacted in an ice-water bath for 4 hours. After purification and drying, intermediate A was obtained. Weighed 100.0g intermediate A and 150.0g 1,4-butane sultone Dissolve in a mixture of 300.0g methanol and acetone, the weight ratio of methanol and acetone is 1:1, react at 80°C for 6h to obtain the first monomer;

[0054] (2) Preparation of the second monomer: Dissolve 120.0g of 9-decenal and 100.0g of phenylamine in 300.0g of isopropanol, add glacial acetic acid and react at 30°C for 3 hours to obtain the second monomer;

[0055] (3) Preparation of thickener: Dissolve 40.0g of the first monomer and 10.0g of the second monomer in 50.0g of dimethyl sulfoxide, raise the temperature to 85°C, add 0.5g of ...

Embodiment 2

[0058] (1) Preparation of the first monomer: Dissolve 100.0g N,N-diethyl-2-chloroacetamide in 150.0g pyridine to obtain solution I, then dissolve 100.0g 4-hydroxybutyl vinyl ether in 200.0g Solution II was obtained in pyridine, and solution I was added dropwise to solution II, and reacted in an ice-water bath for 4 hours. After purification and drying, intermediate A was obtained. Weighed 100.0g of intermediate A and 150.0g of 1,4-butane sultone In a mixed solution of 300.0g methanol and acetone, the weight ratio of methanol and acetone is 1:1, react at 80°C for 6h to obtain the first monomer;

[0059] (2) (3) (4) The same as in Example 1 to obtain fracturing fluid 2#.

Embodiment 3

[0061] (1) Preparation of the first monomer: Dissolve 90.0g N,N-diethyl-2-chloroacetamide in 150.0g pyridine to obtain solution I, then dissolve 100.0g 4-hydroxybutyl vinyl ether in 200.0g Solution II was obtained in pyridine, and solution I was added dropwise to solution II, and reacted in an ice-water bath for 4 hours. After purification and drying, intermediate A was obtained. Weighed 100.0g intermediate A and 120.0g 1,4-butane sultone Dissolve in a mixture of 300.0g methanol and acetone, the weight ratio of methanol and acetone is 1:1, react at 80°C for 6h to obtain the first monomer;

[0062] (2) (3) (4) The same as in Example 1 to obtain fracturing fluid 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com