Foam-assisted hydraulic sandblasting perforating technique pipe string and method

A technique of pipe string and sandblasting perforation, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problems of poor sand carrying capacity, increased perforation depth, liquid infiltration, etc., and achieves improved carrying capacity. sand capacity, reducing the penetration into the formation, and reducing the effect of confining pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

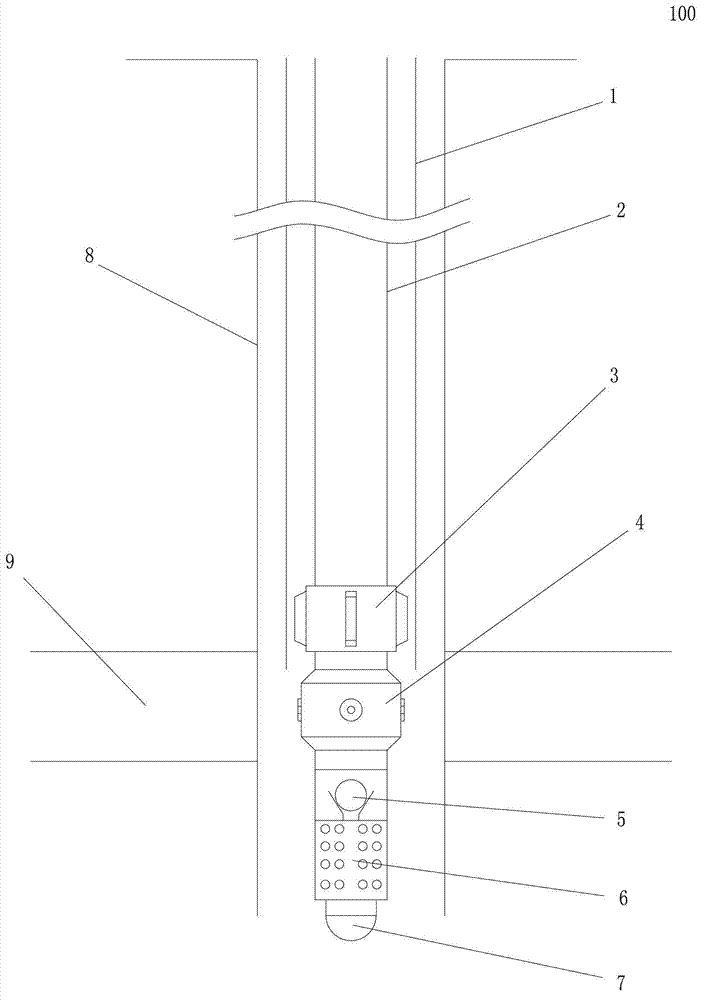

[0025] Such as figure 1 As shown, the present invention proposes a foam-assisted hydraulic sand blasting perforation process string 100, the process string 100 includes an outer oil pipe 1 lowered into the wellbore 8 and a sandblasting pipe installed in the outer oil pipe 1 column; the sand blasting string is composed of inner oil pipe 2, centralizer 3, hydraulic injector 4, one-way valve 5, screen pipe 6 and plug 7 in order from top to bottom; the hydraulic injector 4 is located in the oil layer 9; the total length of the inner oil pipe 2 is 1-2m shorter than the total length of the outer oil pipe 1, so as to ensure that the inner oil pipe 2 and the centralizer 3 are located inside the outer oil pipe 1, while the hydraulic injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com