Drilling method and drill pipe for rotary cutting of soft coal seams to reduce resistance and protect holes

A technology for soft coal seam and hole protection, applied in drilling equipment and methods, drill pipes, drill pipes, etc., can solve the problems of shallow drilling depth, low drilling efficiency, and large drilling resistance, and reduce rotation and propulsion. Resistance, reasonable matching, and the effect of reducing confining pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

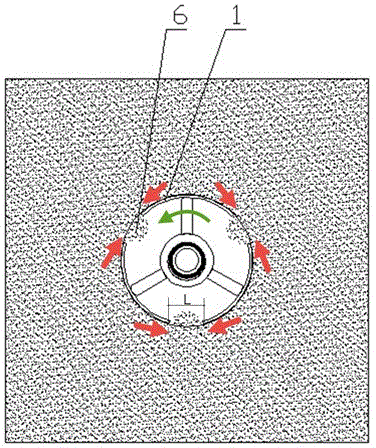

[0035] Embodiment 1: Used in soft coal seam rotary cutting method to reduce resistance and protect holes, and evaluate the drilling shrinkage ratio d according to the geological conditions of the coal seam c And determine the rotary cutting depth, drilling speed and air supply air volume, and use the rotary cutting resistance reducing drill pipe to drill the hole. The drill pipe rotates and continuously cuts the coal body that expands and deforms in the drilling hole, and realizes the integration of rotary cutting resistance reduction and hole protection Drilling, the method comprises the steps of:

[0036] ①. Take coal samples at the construction site, test the uniaxial compressive strength of the coal samples in the laboratory, apply the geological strength index method, evaluate the mechanical parameters of the coal body, and calculate the drilling shrinkage ratio d c , the drilling shrinkage ratio d c is the maximum displacement u of the borehole wall deformation p Ratio...

Embodiment 2

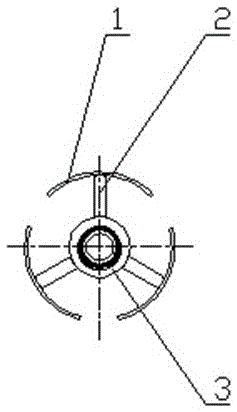

[0044] Embodiment two: if Figure 4 , Figure 5 As shown, the difference from Embodiment 1 is that the open space L between the blades 1 of the rotary-cutting protection hole becomes larger, and the slag feeding capacity of the rotary-cutting resistance-reducing protection hole drill pipe along the open space L increases, but the rotary-cutting protection hole The hole protection space formed between the blade 1 and the supporting blade 2 is reduced. Therefore, this type of rotary cutting drill pipe for reducing resistance and protecting holes is suitable for drilling shrinkage ratios of 20≤d c ≤40% coal seam drilling.

Embodiment 3

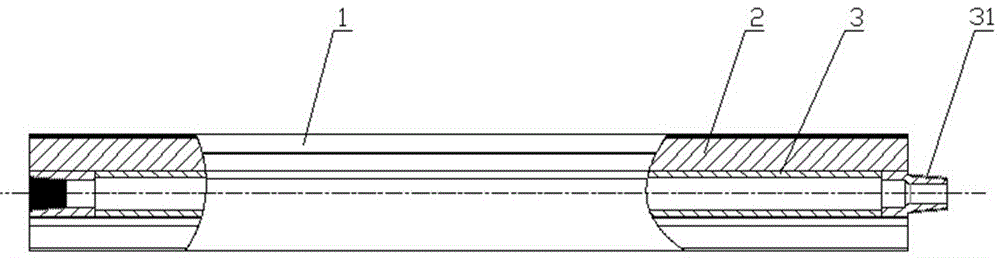

[0045] Embodiment three: as Image 6 , Figure 7 As shown, the difference from Embodiment 1 and Example 2 is that the drill pipe joints of Embodiment 1 and Example 2 adopt threaded connection 31, while the drill pipe joint of Embodiment 3 adopts plug-in connection 32, and the plug-in connection, The drill pipe can be reversed, but the installation and removal of the drill pipe is not as convenient as threaded connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com