Alcohol-containing fracturing fluid and preparation method and application thereof

An alcohol pressure and ethanol technology, which is applied in chemical instruments and methods, earthwork drilling, and production fluids, etc., can solve the problem of inability to take into account solubility and fracturing performance, precipitation of thickeners, and inability to form stable fracturing fluid base fluid, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] In the second aspect of the present invention, the present invention proposes a method for preparing alcohol-containing fracturing fluid, which is characterized in that, comprising:

[0071] Weigh the thickener, water, ethanol and ethylene glycol, add the thickener while stirring in the water until the thickener dissolves, then add the ethanol and ethylene glycol, and continue stirring to obtain a mixed solution. Seal the mixture and keep it warm;

[0072] Weighing the cross-linking agent, adding the cross-linking agent to the heat-preserved mixed solution while stirring, stirring and standing still to obtain alcohol-containing fracturing fluid.

[0073] In one or more embodiments of the present invention, during the process of adding the thickener, the speed of the mixer is constantly adjusted to keep the bottom of the vortex just to see the top of the central axis of the blade;

[0074] Further, after adding the thickener, stir for 3-8 minutes, preferably 5 minutes; ...

Embodiment 1

[0090] Example 1 Optimum preparation method of alcohol-containing fracturing fluid base fluid

[0091] In the experiment, two addition sequences were used to prepare alcohol-containing fracturing fluid base fluid. One method is to dissolve guar gum in water first, and then add alcohol after the guar gum is fully dissolved (method 1#); the other method is, Mix the alcohol and water well first, then add guar gum to the mixed solution (method 2#). In order to determine the preparation method, two methods were used to conduct the solubility experiment of the selected guar gum in ethanol solution.

[0092] Hydroxypropyl guar gum (HPG) and carboxymethyl hydroxypropyl guar gum (CMHPG) were selected to carry out the experiment, the addition amount was 0.4%, and the volume concentration of ethanol was changed from 0% to 60%. The experimental results are shown in Table 1.

[0093] Table 1 Guar Gum Alcohol Solubility Experiment Result

[0094]

[0095] From the experimental results,...

Embodiment 3

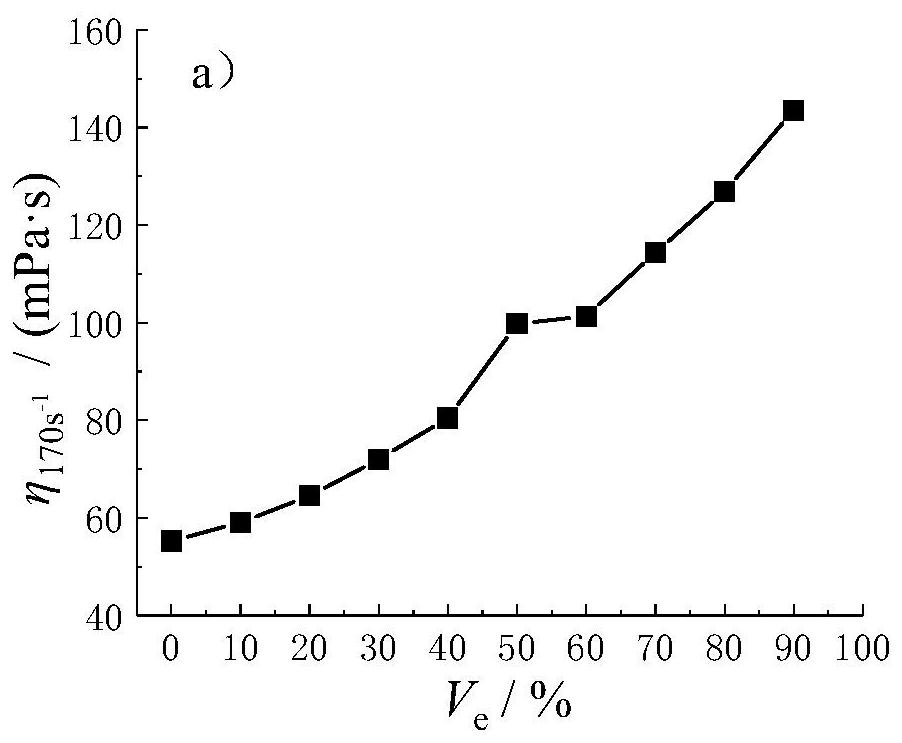

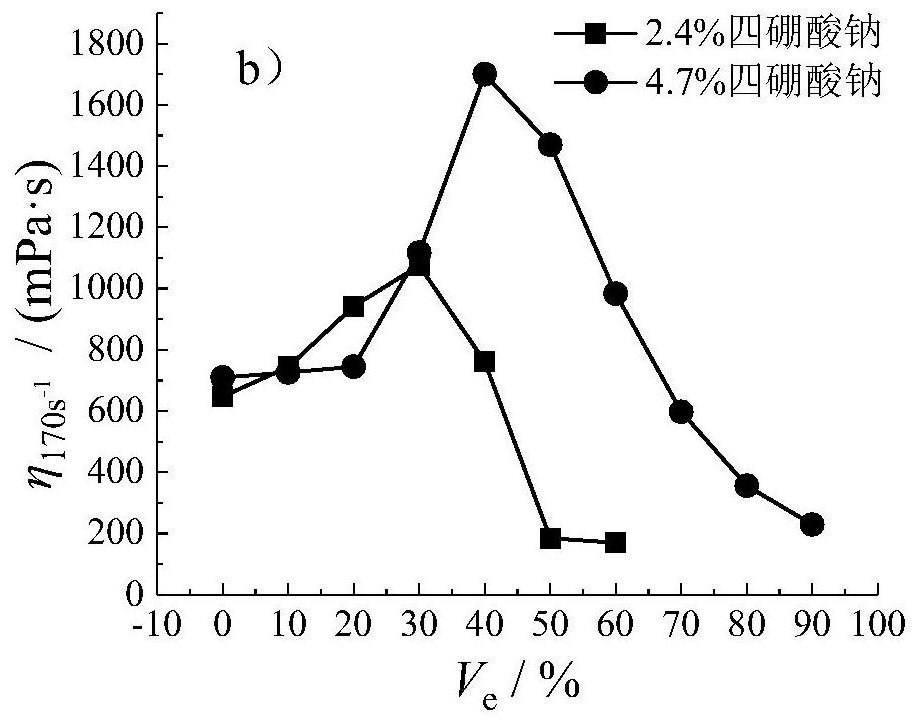

[0112] Example 3 Ethylene Glycol-Water Fracturing Fluid Performance Research

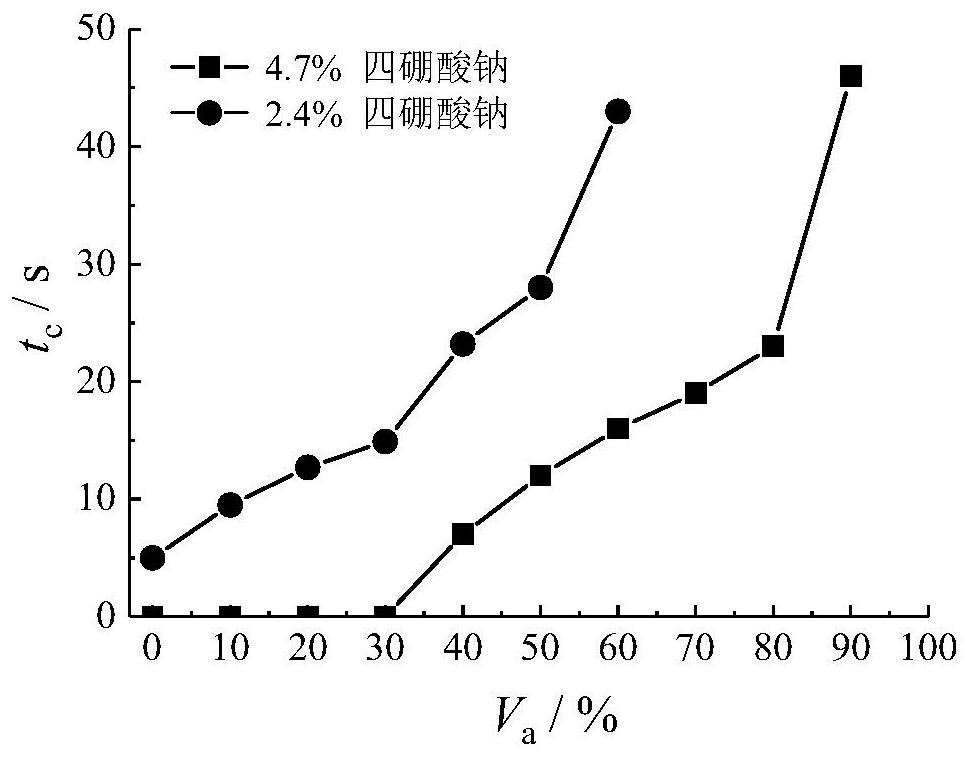

[0113] As a monohydric alcohol, the addition of ethanol can greatly improve the performance of fracturing fluid. However, modified guar gum can only be dissolved in systems with ethanol content below 60%. The ethylene glycol molecule contains two hydroxyl molecules, and its molecular structure is similar to that of water molecules. Low concentration of water reduces water-sensitive water lock damage during fracturing.

[0114] The solution was prepared by adding water-guar gum-ethylene glycol in order to test the solubility of two modified guar gums in ethylene glycol solution. The mass fraction of guar gum was tested at 0.4%, 0.8% and 1.2%, and the experimental results showed , within the normal scope of application, the solubility of the two kinds of guar gum in ethylene glycol solution does not change with the change of the mass fraction of guar gum added. Solubility.

[0115] The solubility ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com