High-viscosity mortar cutting process for cutting silicon chip

A silicon wafer cutting and cutting process technology, applied in the direction of fine working devices, working accessories, manufacturing tools, etc., can solve the problems that the viscosity of mortar can no longer be improved, the line marks, and the processing efficiency cannot be improved, so as to achieve the improvement of silicon The effect of increasing sheet cutting ability, reducing loss, and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

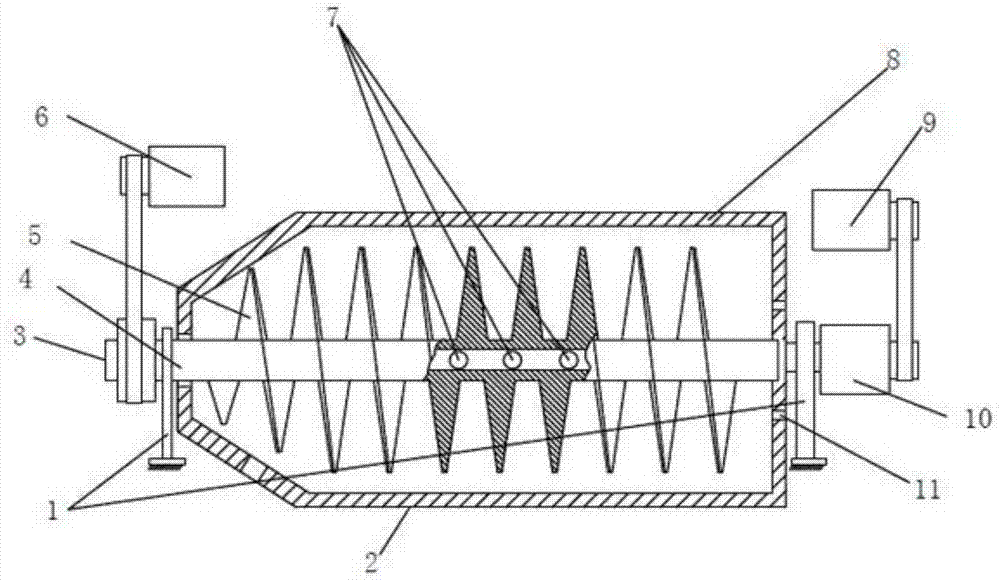

[0027] The following will combine figure 1 , figure 2 The present invention is described in further detail with specific examples.

[0028] A high-viscosity mortar cutting process for cutting silicon wafers, the specific steps are as follows:

[0029] a. Use cutting fluid with a viscosity of 60-65mPa.s and green silicon carbide sand to prepare a density of 1.48±0.02g / cm 3 , mortar with a viscosity of 150±10mPa.s and constantly stirred to prevent precipitation;

[0030] b. Separate the high-density mortar and low-density mortar from the above-mentioned mortar through a centrifugal screw separator, and stir to prevent sedimentation; among them, the high-density mortar has a density of 1.68g / cm 3 , the viscosity is 280±10mPa.s, and the density of low-density mortar is 1.35g / cm 3 , the viscosity is 100±10mPa.s;

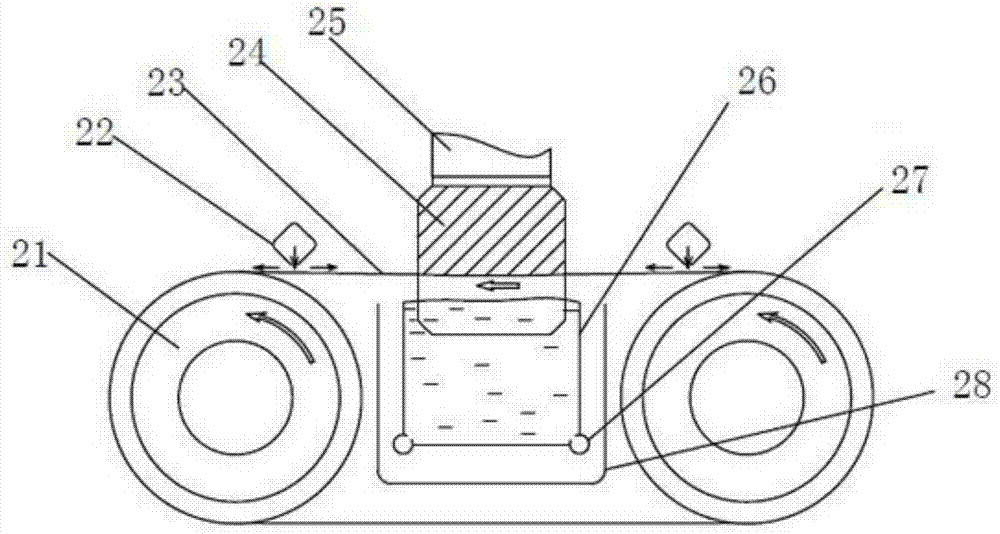

[0031] c. Send the high-density mortar separated in step b to the mortar nozzle, and then spray it onto the steel wire mesh for cutting through the mortar nozzle fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com