Patents

Literature

98results about How to "Solve the sticky problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

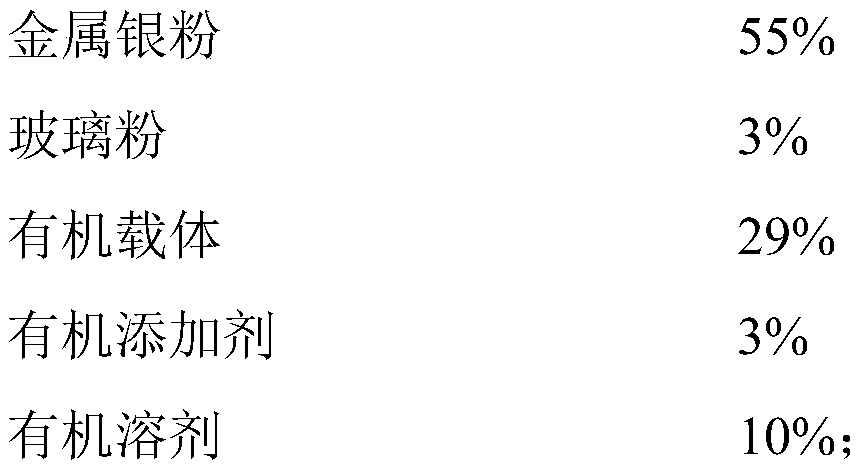

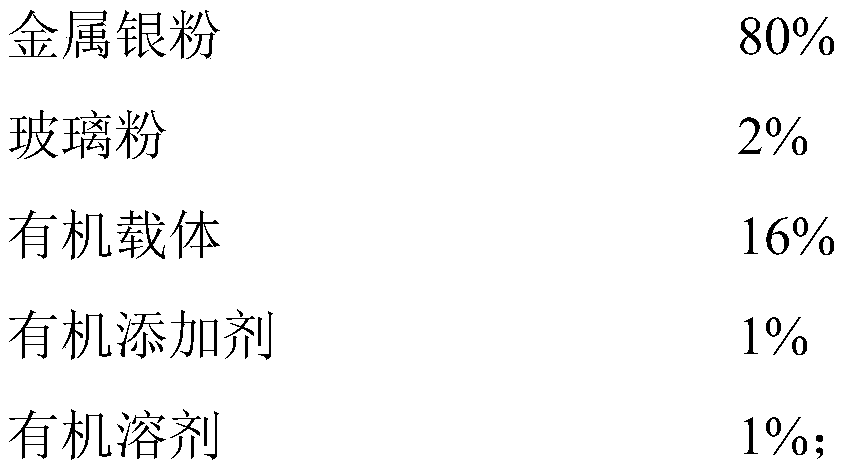

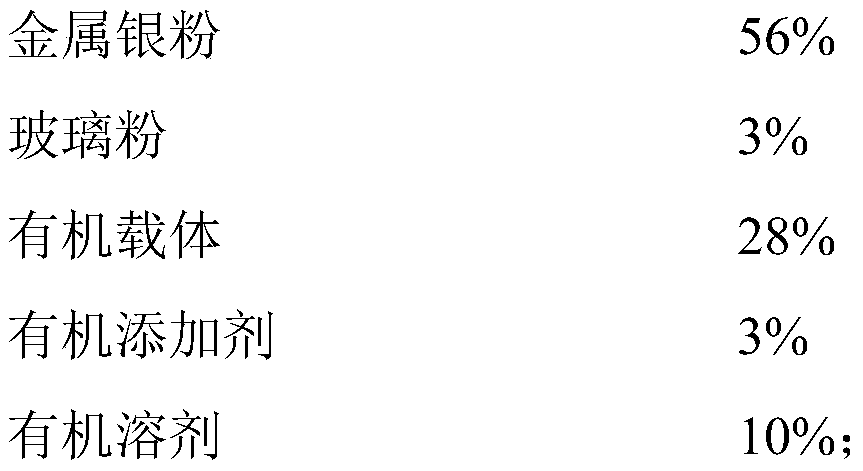

Conductive silver paste for ceramic filter and preparation method thereof

PendingCN111489848ASolve conductivity problemsSolve solder performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteThermal dilatation

The invention relates to conductive silver paste for a ceramic filter and a preparation method of the conductive silver paste. The conductive silver paste comprises the following components in parts by weight: 50-80 parts of metal silver powder, 2-5 parts of glass powder, 10-30 parts of an organic carrier, 1-3 parts of an organic additive and 1-10 parts of an organic solvent, wherein the glass powder is lead-free glass powder, the coefficient of thermal expansion is 110-120*10<-7> / DEG C, and the sintering temperature is 550-750 DEG C. The preparation method comprises the following steps: adding the organic carrier and the organic solvent into a mixer, adding the metal silver powder, the glass powder and the organic additive, fully mixing, transferring a mixture into a high-speed dispersionmachine, and uniformly dispersing at a high speed to obtain a conductive silver paste; and grinding the prepared conductive silver paste in a three-roller mill, and finely adjusting a roller to enable the fineness of the conductive silver paste to be less than 10mu m and the viscosity to be 30-50Pa.S, thereby obtaining the conductive silver paste for the ceramic filter. The conductive silver paste for the filter can form a conductive silver layer which is high in compactness, high in adhesive force, high in conductivity, good in weldability and stable in performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

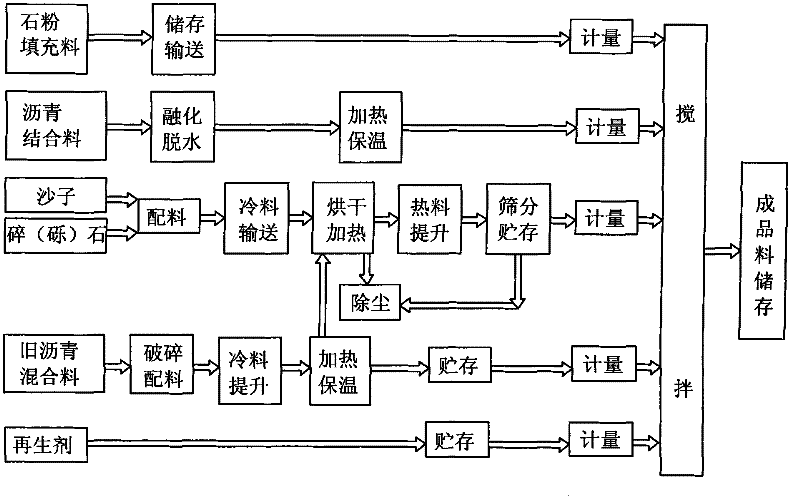

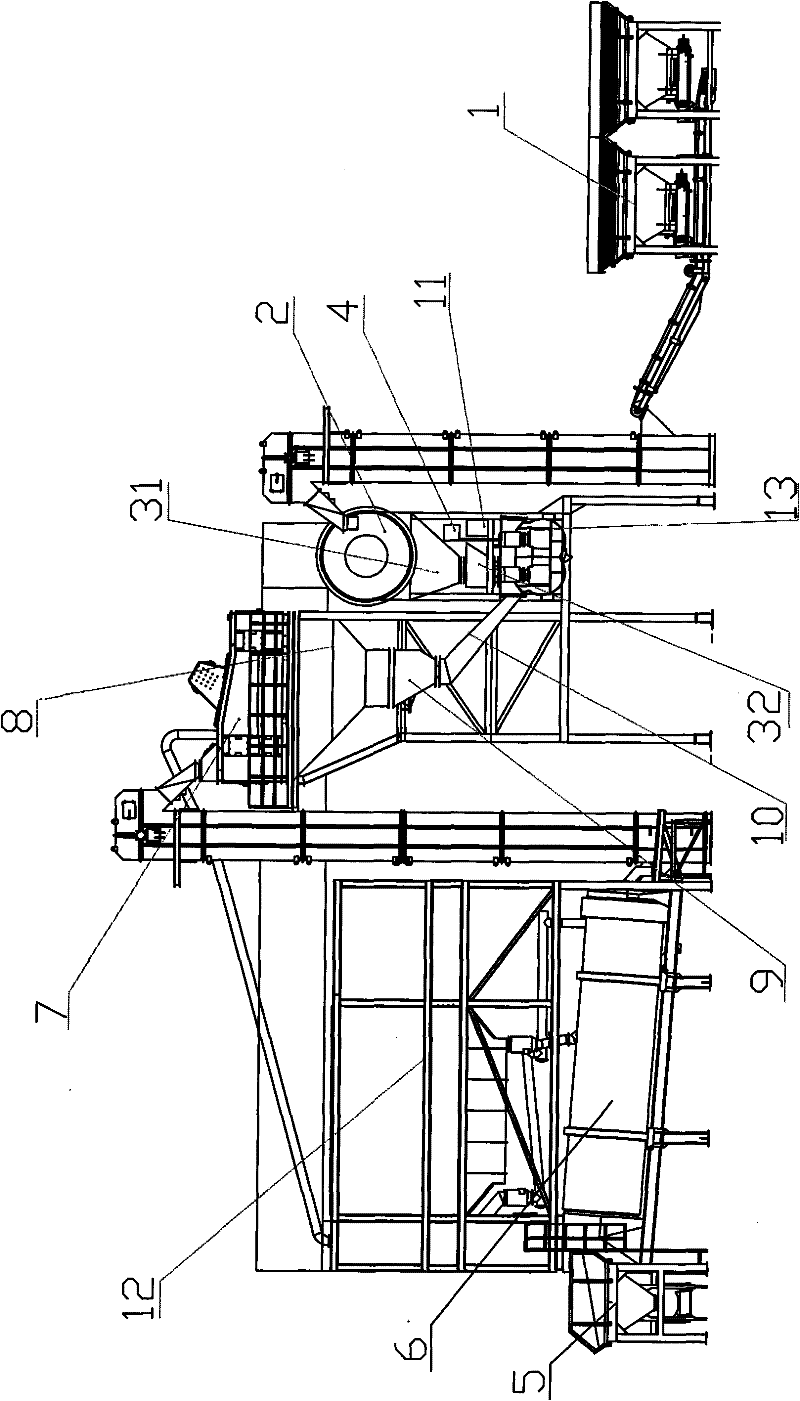

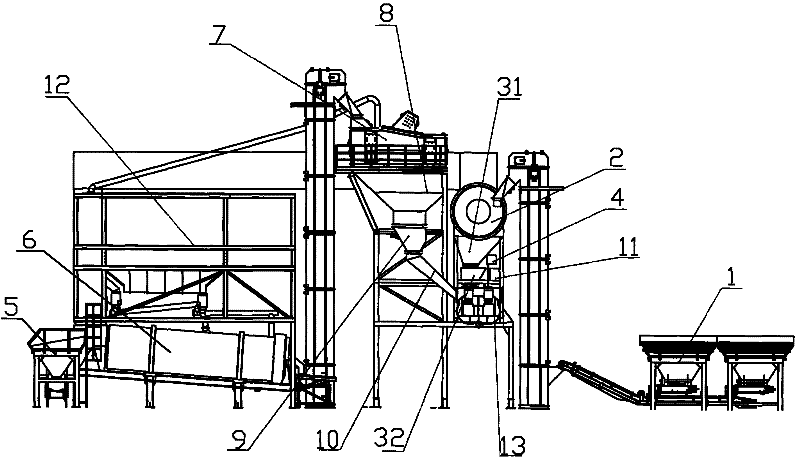

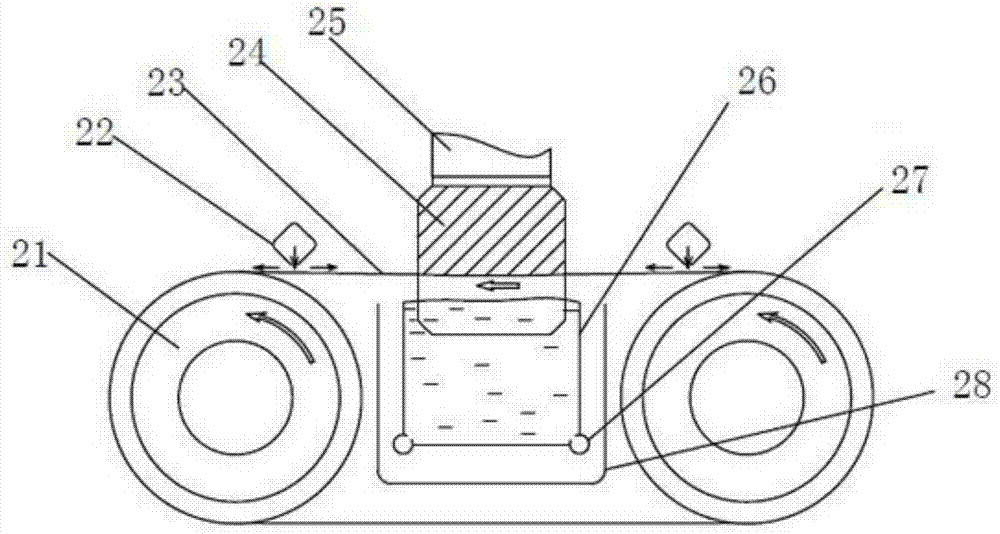

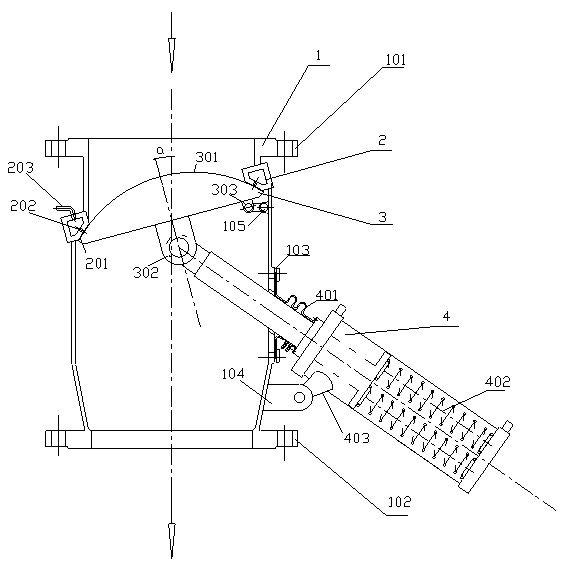

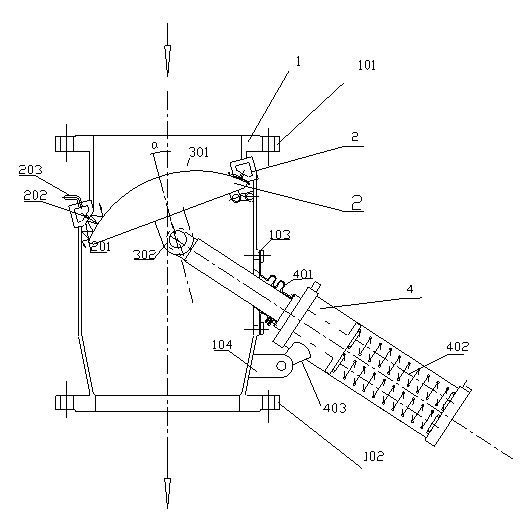

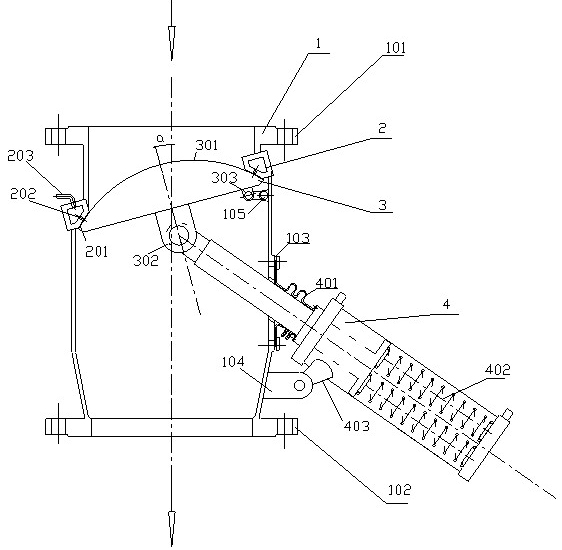

Asphalt concrete plant-mix hot recycling equipment with improved structure

InactiveCN102127893ASolve the sticky problemLow failure rateRoads maintainenceFailure rateMaterials science

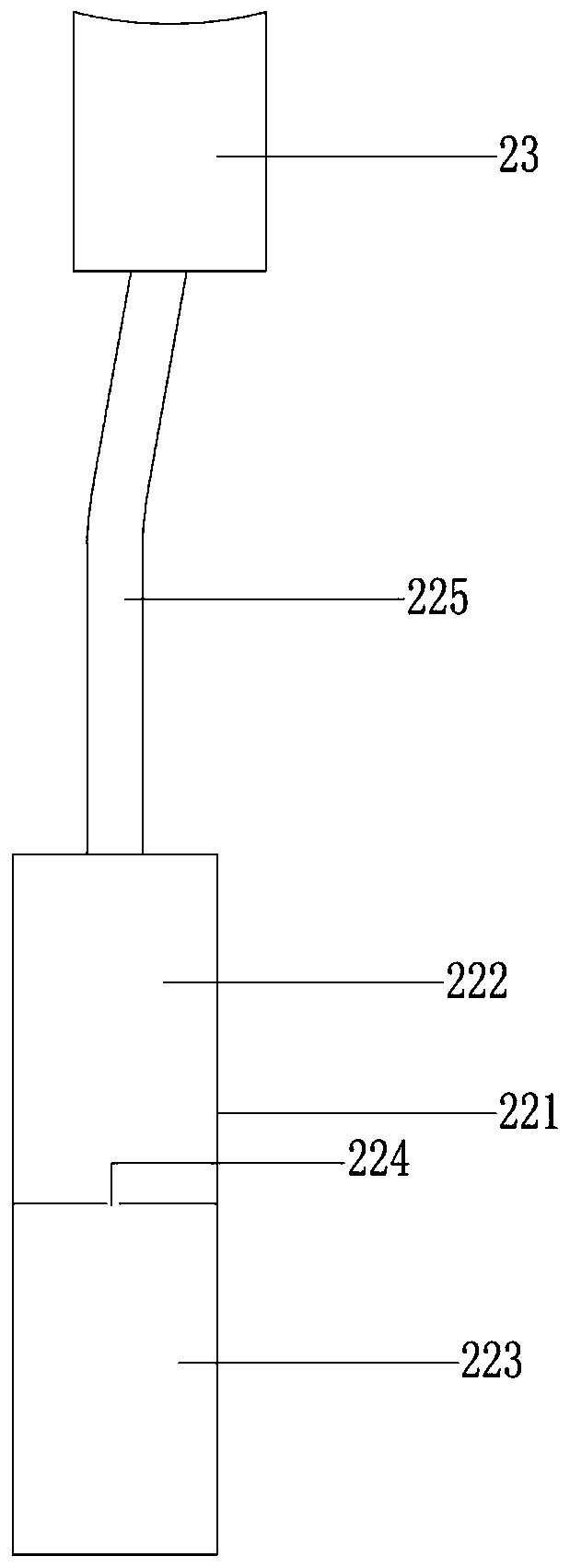

The invention discloses asphalt concrete plant-mix hot recycling equipment with an improved structure. The equipment comprises an old asphalt mixture treatment system, a new aggregate treatment system, a new asphalt material treatment system, an additive treatment system and a stirring device, and is characterized in that: the old asphalt mixture treatment system comprises an old hot reclaimed asphalt storing and metering device for storing and metering old hot reclaimed asphalt, and the device is arranged above the stirring device and is arranged in the way of directly putting the old hot reclaimed asphalt into the stirring device below the device; the new aggregate treatment system comprises a new aggregate storing and metering device and a new aggregate conveying device; the new aggregate storing and metering device is used for storing dried, heated and sieved new aggregate and metering the new aggregate; and the new aggregate conveying device is connected with the new aggregate storing and metering device and the stirring device and is used for conveying the new aggregate to the stirring device. By using the structure, the problem of material sticking brought by conveying the old hot reclaimed asphalt can be solved, and the failure rate of the equipment can be reduced.

Owner:FUJIAN TIETUO MACHINERY

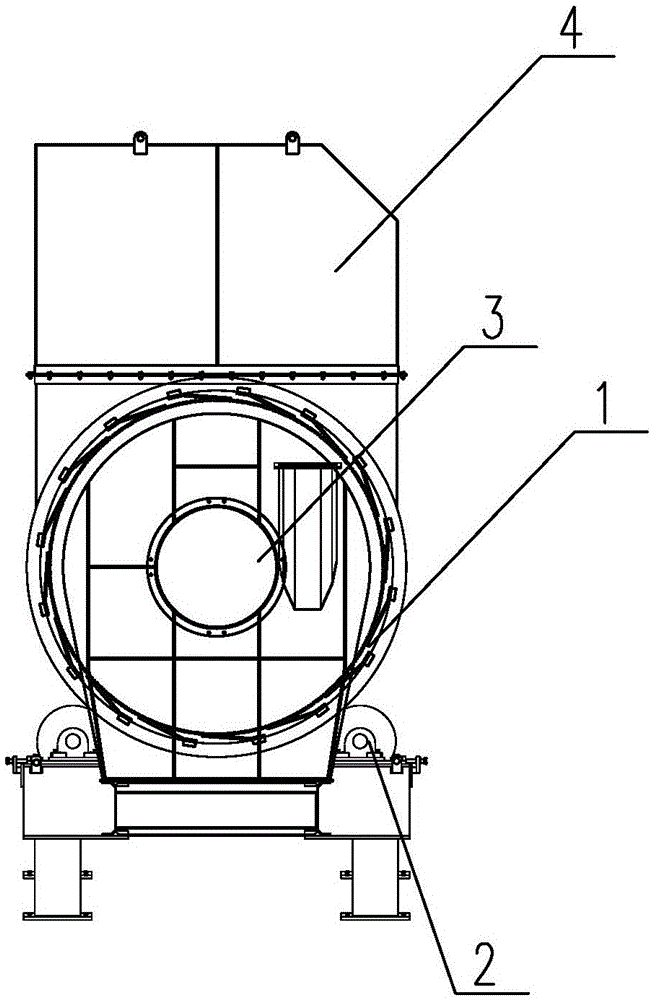

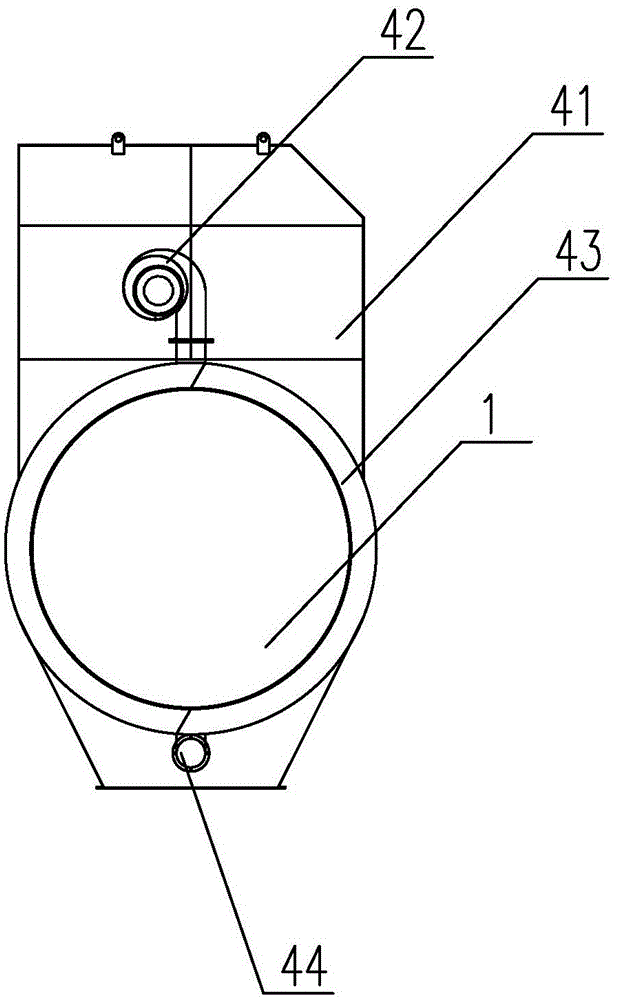

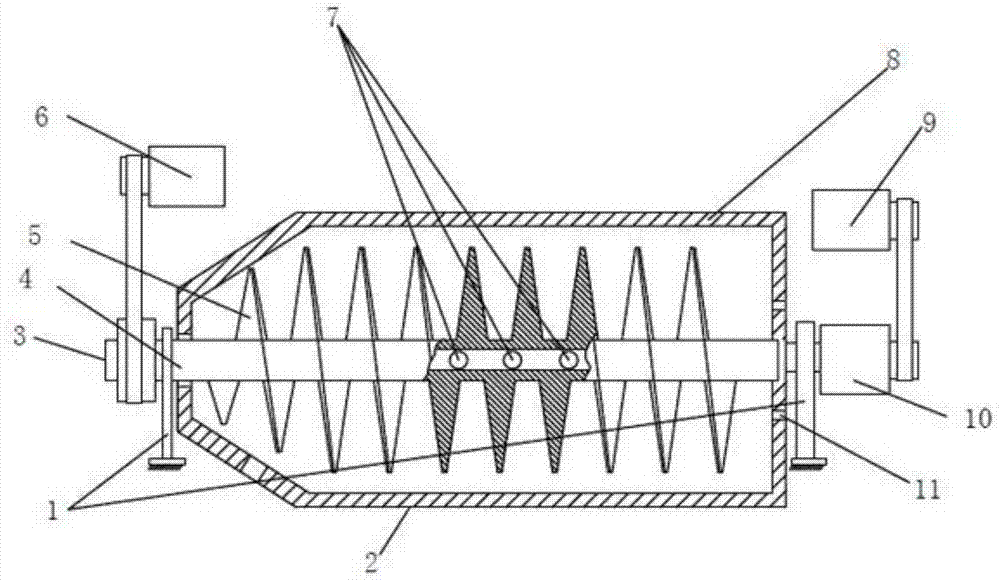

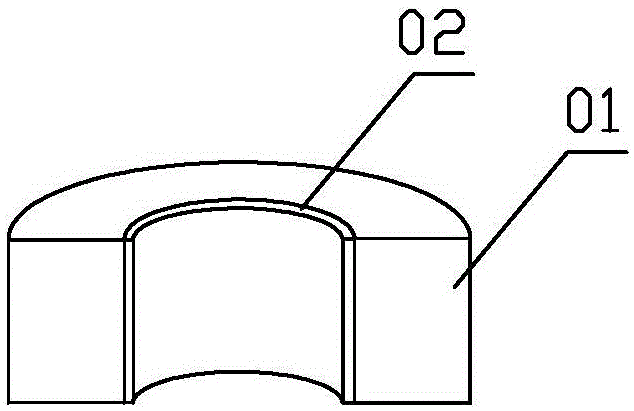

Asphalt regeneration roller and method for preventing materials from being stuck on roller inner wall

InactiveCN105040555AGuaranteed uptimeSolve the sticky problemRoads maintainenceCombustorPulp and paper industry

The invention relates to the technical field of stirring equipment, and especially relates to an asphalt regeneration roller and a method for preventing materials from being stuck on the roller internal wall. The asphalt regeneration roller comprise a roller body, a roller driving device, and a baking material combustor; the roller driving device is connected to the roller body to drive the roller body to rotate; and the baking material combustor is connected to the front end of the roller body and is used to heat the regenerated asphalt in the roller body. The asphalt regeneration roller also comprises a roller wall heating device, and the roller wall heating device is connected to the roller body and is capable of heating the wall of the roller body to a temperature at which the asphalt in the roller body can be converted into a fluid. In the conventional method, the materials stuck on the wall are removed by blades; while in the provided asphalt regeneration roller, a roller wall heating device is used to heat the inner wall of a dry roller so as to convert the stuck asphalt into fluid, thus the roller inner wall material sticking problem can be radically solved; the cleaning efficiency is high, the stable operation of the roller body can be guaranteed, and thus the production and maintenance costs are reduced.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

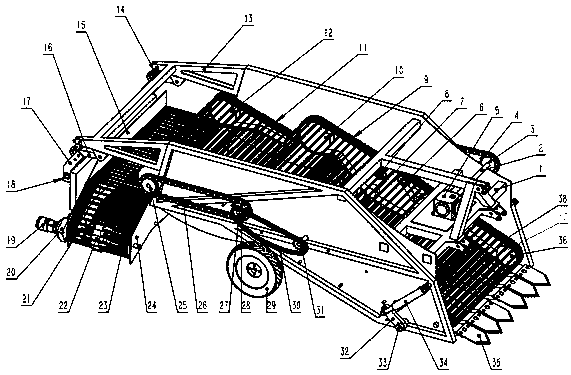

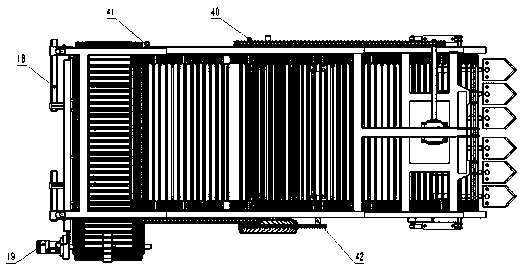

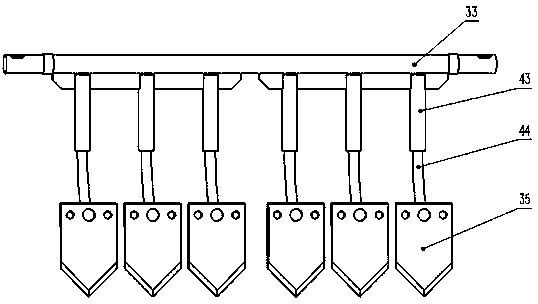

Potato harvesting machine for hilly and mountains regions

The invention relates to a potato harvesting machine for hilly and mountains regions, and belongs to the field of agricultural harvesting machinery and equipment. An excavating device digs up soil andpotato mixtures; power is transmitted to a power transmission system through a power output shaft of a tractor, is outputted to drive shafts in a gear box to rotate, and is transmitted to a driving wheel through a chain to drive vibration separating devices to rotate; the primary vibration separating device is rotated to vibrate and separate the soil and potato mixtures which are then conveyed tothe secondary vibration separating device; potatoes with less soil are subjected to vibration separating again by the secondary vibration separating device, and then conveyed to a lateral conveying system. The potato harvesting machine has the advantages that the angle of the excavating device is adjusted through a hydraulic cylinder to achieve stepless angle adjustment; the two-stage vibration separating devices are applied to solve the problem of high soil stickiness of the hilly and mountains regions, and the separation frequency is high; the potatoes are piled up in strips through a lateral conveying device, the rate of visible potatoes is increased, and the potato burry rate and damage rate are decreased.

Owner:KUNMING UNIV OF SCI & TECH

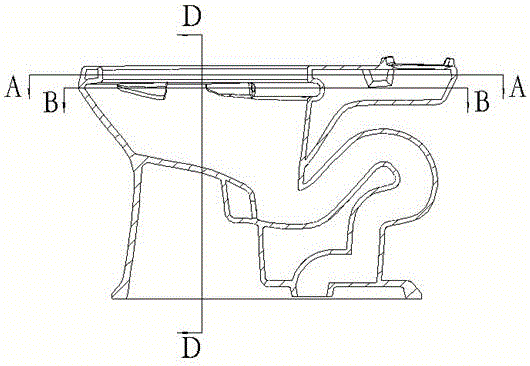

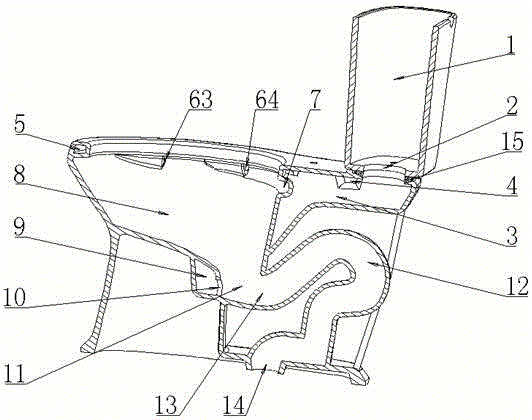

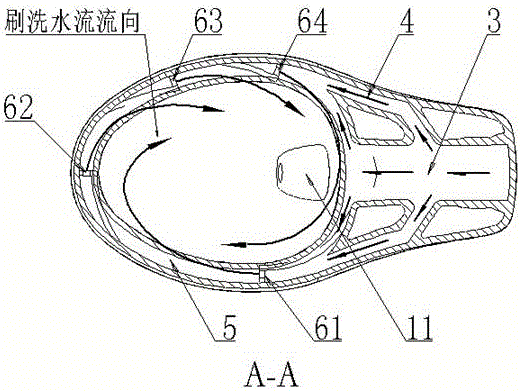

Cross flow siphon toilet bowl

The invention relates to a toilet bowl, in particular to a cross flow siphon toilet bowl. The cross flow siphon toilet bowl comprises a toilet bowl body. The toilet bowl body comprises a pot. A ring way is arranged on an opening of the pot. A water tank is arranged above the position behind the toilet bowl body, a water inlet is formed in the middle of the bottom of the water tank, and the toilet bowl body is connected with the water tank through a sealing rubber ring. A main water way is arranged on the upper portion of the rear in the toilet bowl body, an auxiliary water way for spraying supplied water is arranged below the position in front of the main water way, a cap head is arranged at the bottom of the pot, and the tail end of the auxiliary water way stretches to the front of the cap head. The auxiliary water way is connected with the cap head through a spray hole, a blow-off pipeline is arranged behind the cap head, and multiple cross flow spray nozzles are arranged below the ring way and connected with the ring way. Flow diversion water ways are arranged on the two sides of the main water way. By means of the cross flow siphon toilet bowl, the toilet bowl flushing mode and the water flow distribution proportion are improved by improving the overall structure of the toilet bowl, and the effects of efficiently saving water, being silent and achieving super-strong washing are achieved.

Owner:TANGSHAN MONOPY CERAMIC +1

Composite solid sweetener

The invention discloses a composite solid sweetener, scientific compounding is carried out on sucralose and stevioside by adopting a physical method, one or a plurality of synergists in carriers and a small amount of an anti-caking agent are taken as auxiliary materials for preparation, and the composite solid sweetener mainly comprises three forms, namely, granules, powder and tablets, and comprises the following components according to parts by weight: 0.5-98 of sucralose, 0-3 of stevioside, 0-35 of maltodextrin, 0-80 of mannitol, 0-80 of isomalt, 0-80 of isomaltooligosaccharide, 0-1.5 of silicon dioxide, 0-20 of microcrystalline cellulose and 0-6 of magnesium stearate. The composite solid sweetener has the advantages of high sweetness, good taste, good stability, high safety, high temperature resistance, acid resistance and wide range of application.

Owner:章裕兵

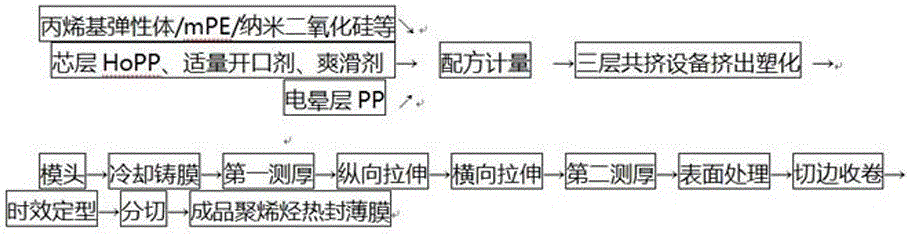

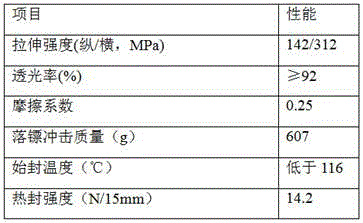

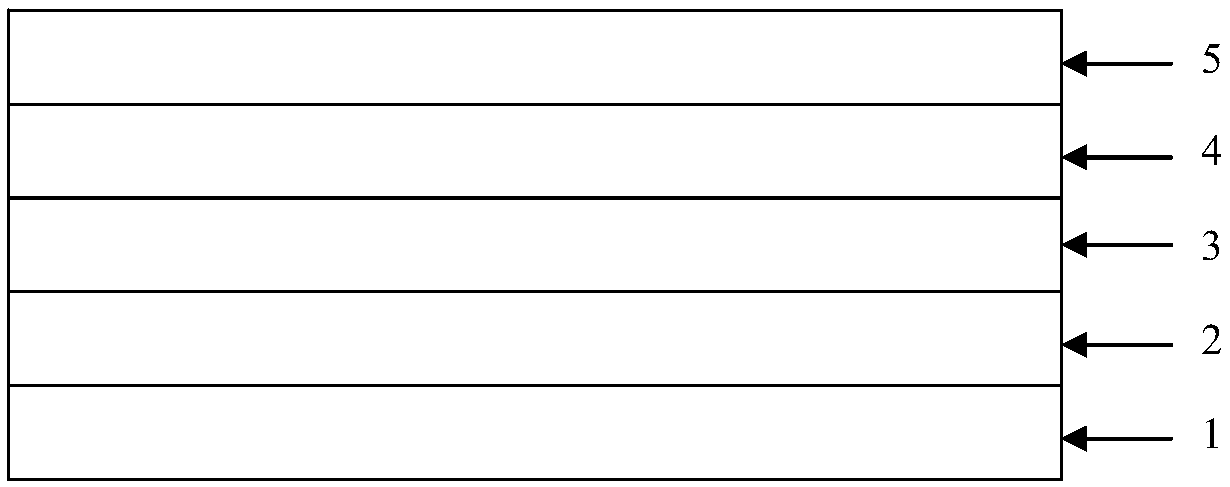

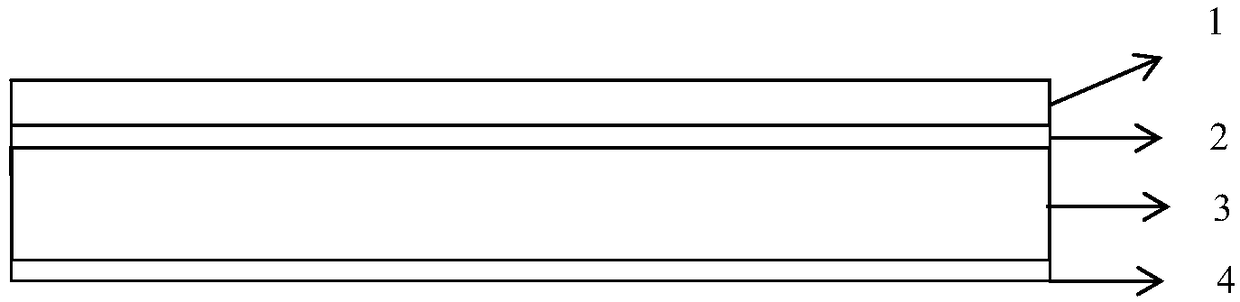

Low-temperature heat sealing polyolefin thin film and preparation method thereof

ActiveCN106240099ASolve the sticky problemPlay a reinforcing roleSynthetic resin layered productsLow-density polyethyleneElastomer

The invention belongs to the field of preparation of heat sealing thin films, and particularly relates to a low-temperature heat sealing polyolefin thin film and a preparation method thereof. The low-temperature heat sealing polyolefin thin film comprises a corona layer, a core layer and a heat sealing layer from top to bottom, wherein the heat sealing layer is a composite material prepared from a PBE elastomer, metallocene linear low-density polyethylene, LDPE, nanosilicon dioxide and a smooth agent. According to the low-temperature heat sealing polyolefin thin film and the preparation method thereof, by the adding of the nanosilicon dioxide and the smooth agent into the heat sealing layer, the problem of adhesion caused by the adding of the PBE elastomer is solved, and the intensity and the stiffness of the thin film cannot be reduced; by the adding of the proper amount of LDPE, the processing flowability is improved; an elastomeric state drawing molding technology is combined with crystallite nucleation, so that the transparent polyolefin heat sealing thin film with ultralow start-sealing temperature and high heat sealing intensity is prepared.

Owner:福融新材料股份有限公司 +1

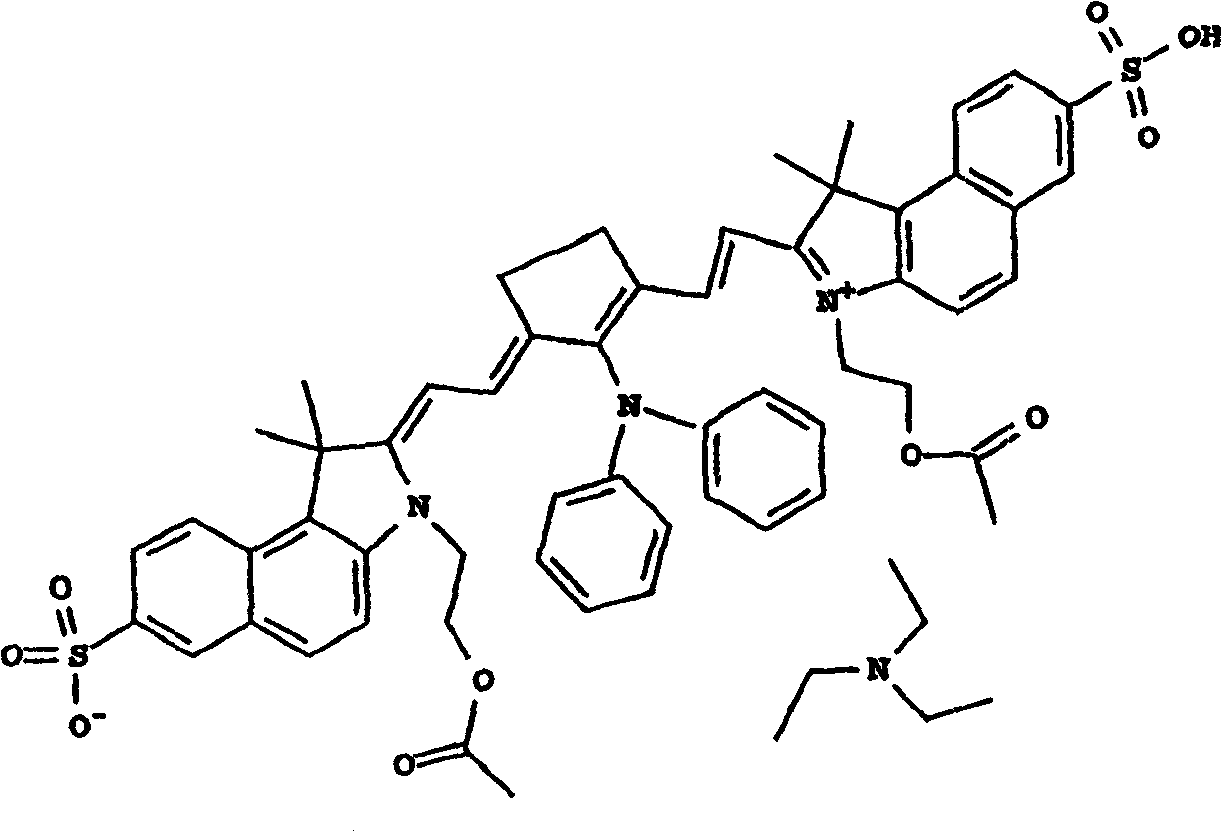

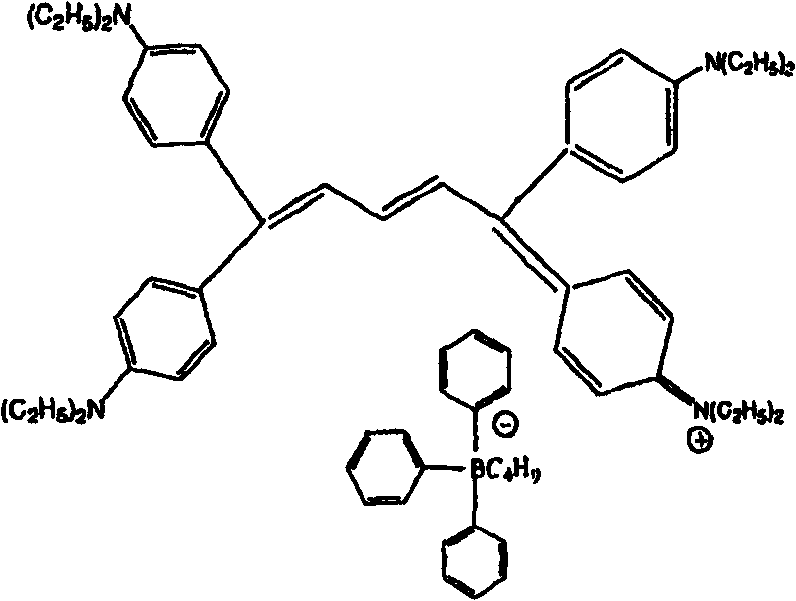

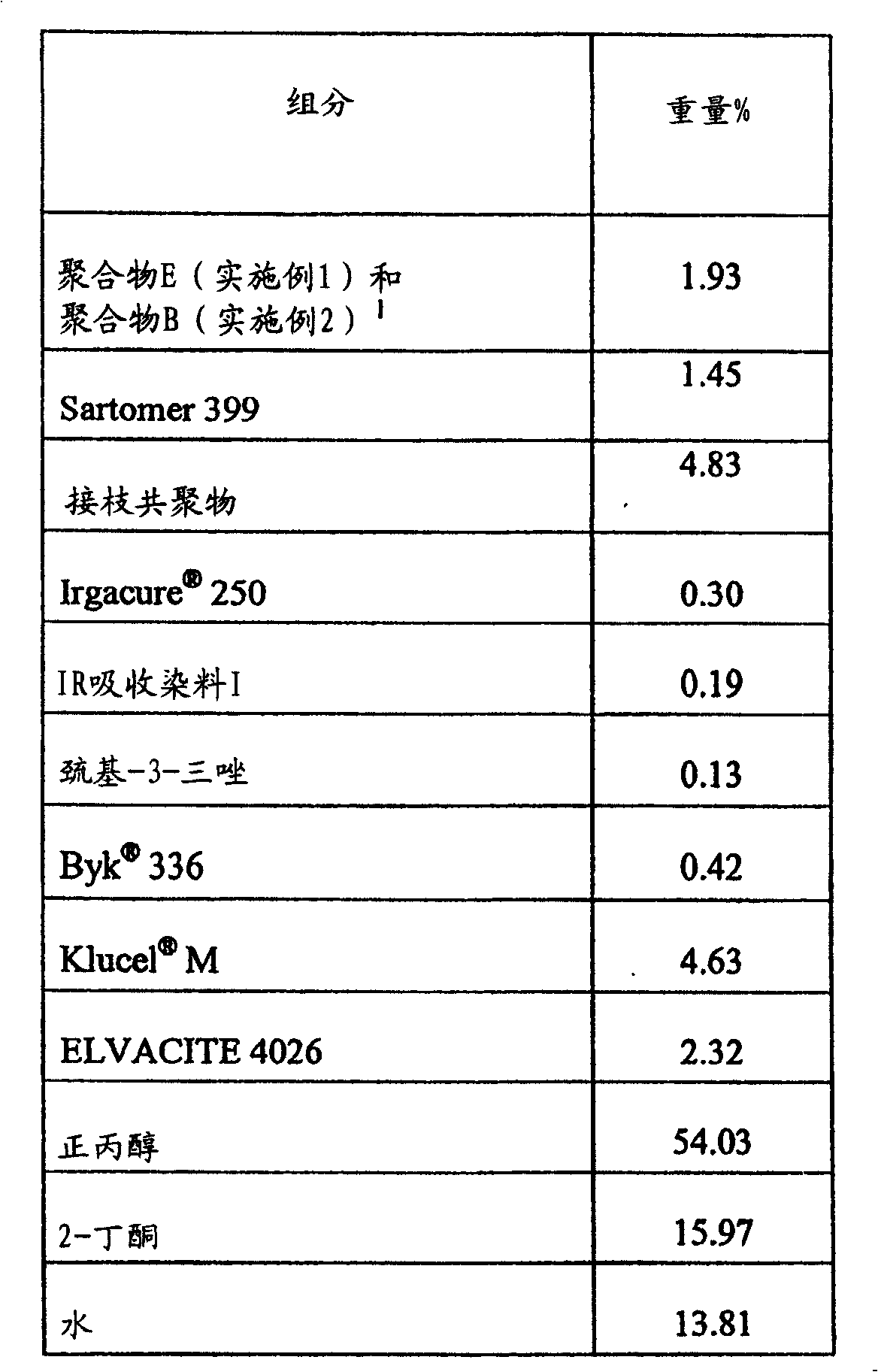

Radiation-sensitive compositions and imageable materials

InactiveCN101283311ANo need to reduce actual coat weightSolve the sticky problemRadiation applicationsPhotomechanical apparatusChemistryRadiation

A radiation-sensitive composition includes a radically polymerizable component that comprises carboxy groups, an initiator composition to generate radicals, and a polymeric binder comprising poly(alkylene oxide) segments and optionally pendant cyano groups. This composition can be used to prepare imageable elements such as negative-working, on-press developable printing plate precursors.

Owner:EASTMAN KODAK CO

High-viscosity mortar cutting process for cutting silicon chip

InactiveCN104493988AImprove cutting efficiencyImprove sand carrying capacityWorking accessoriesCentrifugesSilicon chipSingle crystal

The invention discloses a high-viscosity mortar cutting process for cutting a silicon chip and belongs to the technical field of cutting of a solar cell silicon chip. The high-viscosity mortar cutting process comprises the following steps: a, preparing mortar by adopting cutting fluid and green silicon carbide sand particles and continuously stirring to prevent sedimentation; b, separating high-density mortar and low-density mortar out of the mortar by a centrifugal separator and continuously stirring the separated high-density mortar and low-density mortar to prevent sedimentation; c, feeding the high-density mortar into a cutting seam to participate in cutting for single crystal cutting and using the low-density mortar for jetting chips in a knife edge after cutting so as to solve the problem of an adhesion phenomenon; d, recovering the high-density mortar and the low-density mortar which are used in the step c together and feeding the recovered high-density mortar and low-density mortar into centrifugal separator again for repeated use. According to the high-viscosity mortar cutting process, high-viscosity mortar can be used in the cutting of the silicon chip so as to promote cutting capacity of the silicon chip and improve a finished product ratio of products and working efficiency.

Owner:YANGGUANG GUIFENG ELECTRONICS SCI & TECH CO LTD

Tunnel waterproof board bonding and laying process

InactiveCN105840215ASimple and fast constructionSolve the sticky problemUnderground chambersTunnel liningGeotextileAdhesive glue

The invention provides a tunnel waterproof board bonding and laying process. The process comprises the following steps: step 1, treatment of the fundamental plane of a primary support; step 2, manufacturing of a water drainage blind pipe; step 3, laying of geotechnical cloth; step 4, annular bonding and laying of waterproof boards; step 5, lap-joint of edges of the waterproof boards; step 6, checking and local treatment; step 7, pouring of second lining; step 8, forming of a skin-type waterproof layer through concrete and self-adhesive glue. The major innovative point of the system is that the problem of adhesion between the waterproof boards and the geotechnical cloth is systematically solved by optimizing the formula of adhesive glue and the structure of the geotechnical cloth. The waterproof boards are bonded with the geotechnical cloth on the primary support through the adhesive glue; compared with a suspending and washer welding construction manner, the process has the construction characteristics of simplicity and rapidness; the coiled materials can be closely attached to the primary support, and the problem that a cavity is formed at the top of the secondary lining due to insufficient reservation of traditional coiled materials is solved well.

Owner:SICHUAN HAODESI NEW MATERIAL TECH CO LTD

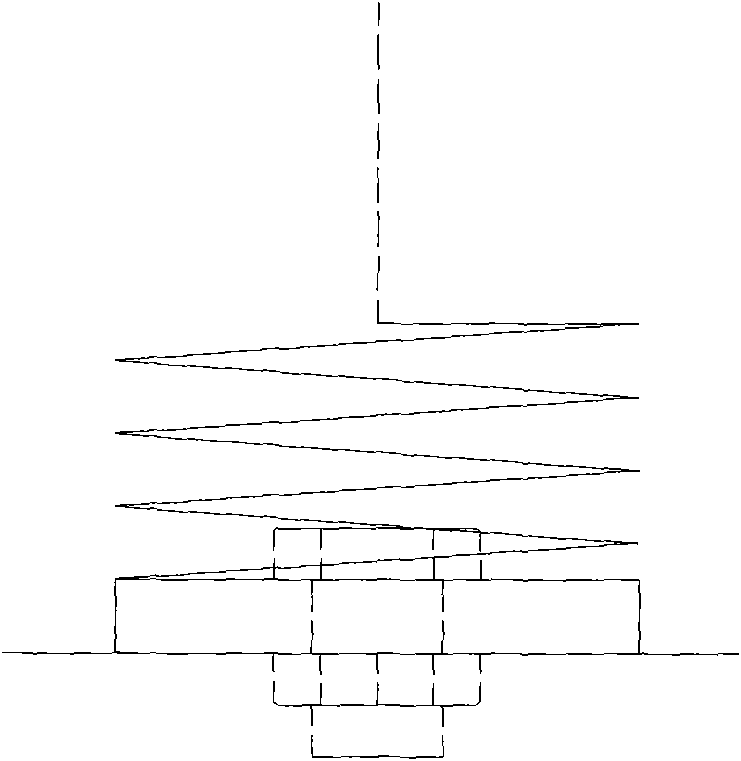

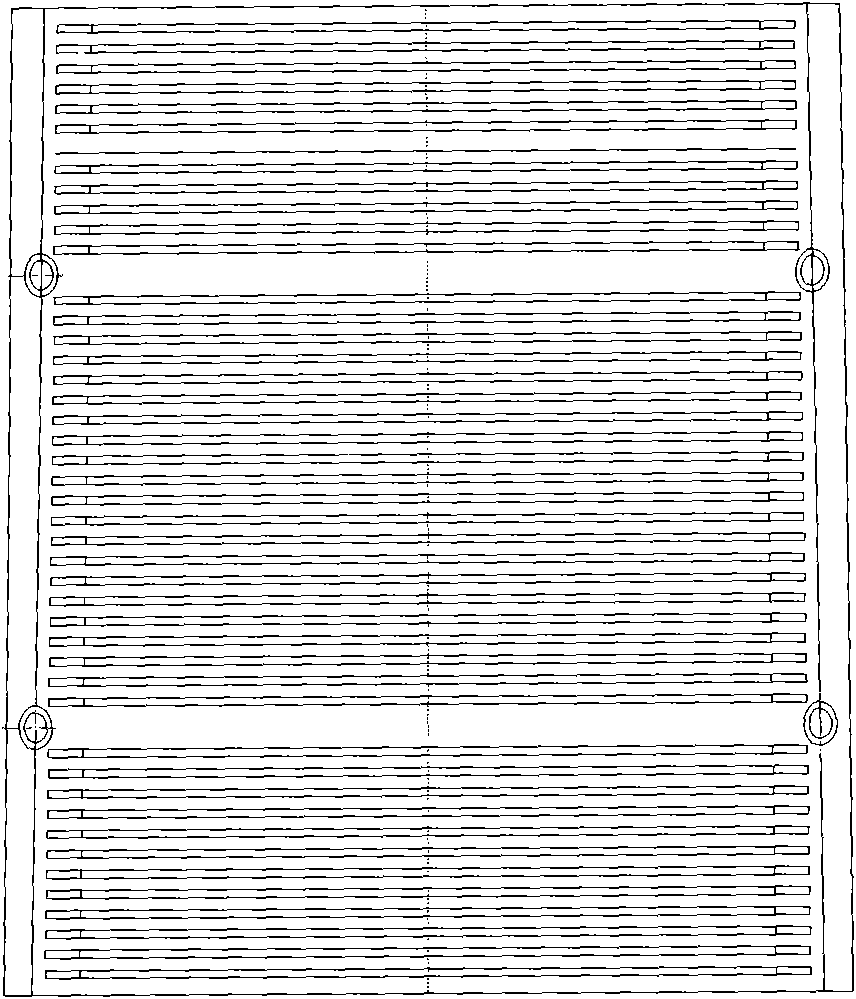

High-efficient sticking-blocking resistant wear-resistant round roller screen

InactiveCN101837343ASolve the sticky problemSolve the blocking phenomenonSievingScreeningWear resistantEngineering

The invention discloses a high-efficient sticking-blocking resistant wear-resistant round roller screen which mainly comprises a screen frame, a screen plate, elastic brushes, brush plates, and the like. The screen plates are in arc shapes, are casted by wear-resisting steel, and are combined in parallel by a plurality of groups of screen teeth in a shape similar to a V shape, and screen cuts are striped arcs, are axially vertical to the roller screen, are in a shape similar to the V shape, and are gradually enlarged from the inside to the outside in size, therefore, the material is not easy to be blocked. One end of each elastic brush is in a spring shape, and the other end is in a straight line shape; during screening, the straight line ends of the elastic brushes extend into the screen cuts to clean off sticking and blocking material on the roller screen by stabbing, stirring and scraping and the like; the plurality of elastic brushes are regularly fixed on the arc-shaped brush plates through bolts and pressure pads, which ensures that each screen cut basically has a plurality of elastic brushes; and the brush plates can move horizontally, when the elastic brushed are worn seriously, the distance between every two brush plates can be adjusted horizontally to ensure that the elastic brushes are reused. The invention fundamentally solves the problems of material sticking and blocking in the process of material screening can completely overcome the defect that lump ore, coke, and the like stick and block screen pores due to high dust content, humid dust, and the like. The invention realizes the self-cleaning function of materials in the screening process, not only can screen out dust in the materials, but also can completely clear sticky materials away from the surfaces of the materials.

Owner:陈卫 +1

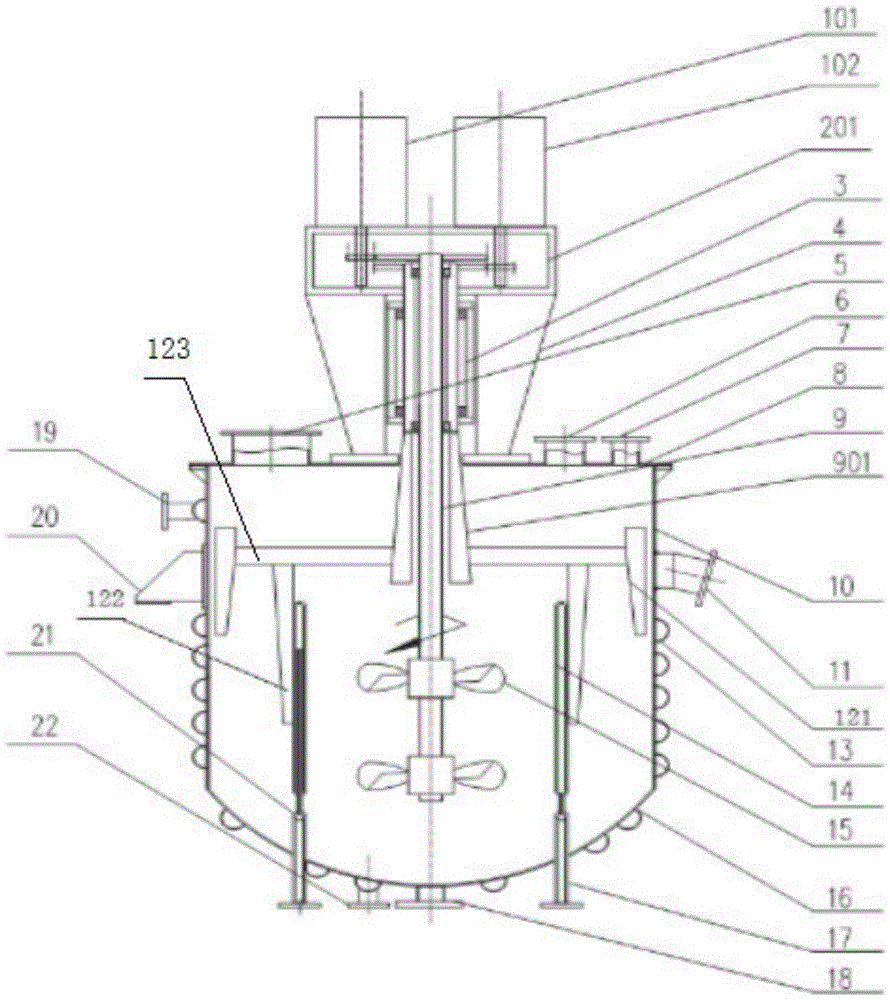

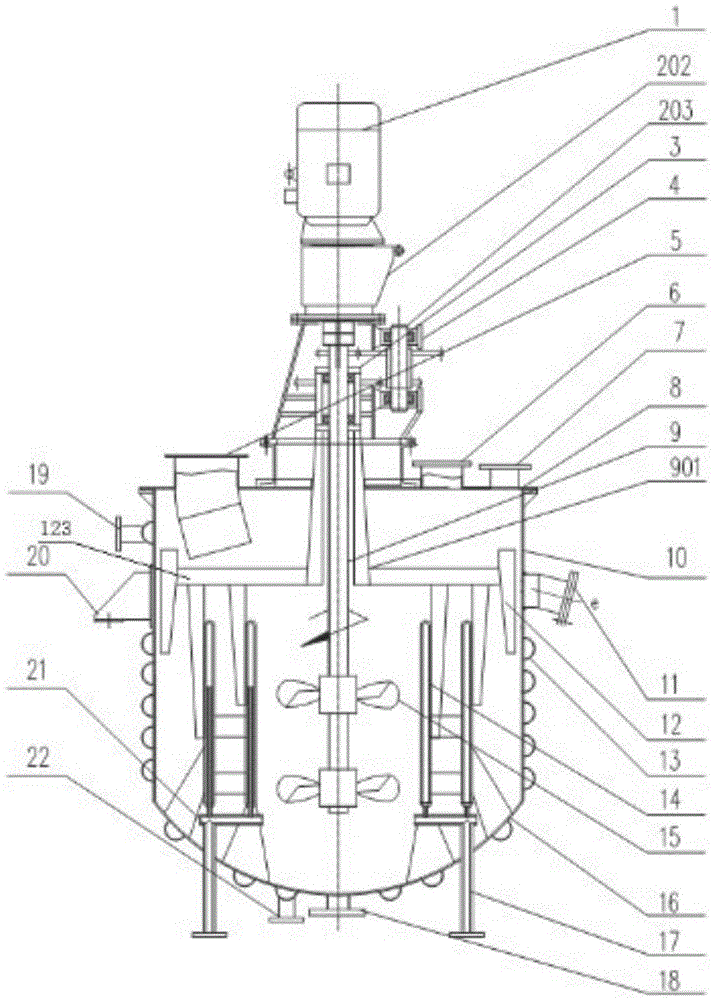

A fusing and mixing device for treating high viscosity materials

InactiveCN105536653AImprove thermal efficiencyAvoid stickingChemical/physical/physico-chemical stationary reactorsFusionEngineeringThick wall

The invention provides a fusing and mixing device for treating high viscosity materials. The device is formed by mounting scraping plates to positions near the inner wall of the internal-jacket fusing and mixing device provided with a stirring gear and to positions near vertical walls of inside and outside cylinders of internal jackets. Each of the internal jackets is formed by connecting inside and outside cylinders with annular semicircle pipes and welding with round steel or thick-wall tubes for connection and reinforcement. The internal jacket close to the stirring gear can be adopted as a stream guiding cylinder of the stirring gear. The scraping plates and stirring blades can be driven by one motor and can be separately driven by two motors. By adoption of the internal jackets, materials are not liable to adhere to the internal surface of the fusing and mixing device. Material adhesion phenomena are completely avoided by adoption of the scraping plates. The fusing and mixing device is low in thermal resistance, high in thermal efficiency, low in energy consumption and operating cost and less in exhaust emission in a heating process. A problem of a high-tower composite fertilizer granulation device that normal production cannot be continued due to material adhesion in a first mixing tank and a second mixing tank is overcome.

Owner:JANGSU RIGHT HEAVY MACHINERY CO LTD

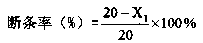

Preparation method of rice flour with low strip breaking rate

ActiveCN110477275ALow sliver breakage rateSolve the problem of high strip breakage rateFood preservationFood shapingToughnessViscosity

The invention relates to a preparation method of rice flour with the low strip breaking rate. The technological process of the preparation method comprises the steps of rice cleaning, soaking, grinding into thick liquid, adding chitosan and protein, adjusting the water content, steaming, flour mixing, extrusion molding, aging, re-steaming, cooling and product finishing. According to the preparation method, a chitosan and protein composite system is added in the preparation process of the rice flour, the chitosan and corn starch are fully mixed first then to be added to rice milk, and the problems of uneven dispersion and easy caking of the chitosan added to the rice milk are solved; and at the same time, due to cross-linking between chitosan molecules with hydrogen bonds of the chitosan molecules into a net structure, entanglement is high, a chitosan solution has a certain viscosity, when added to the rice flour, the chitosan solution can improve toughness of the rice flour, the stripbreaking rate is reduced, the cooking loss of the rice flour can be reduced, at the same time, the shelf life of the rice flour can be prolonged, and nutritional value of the rich flour is improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

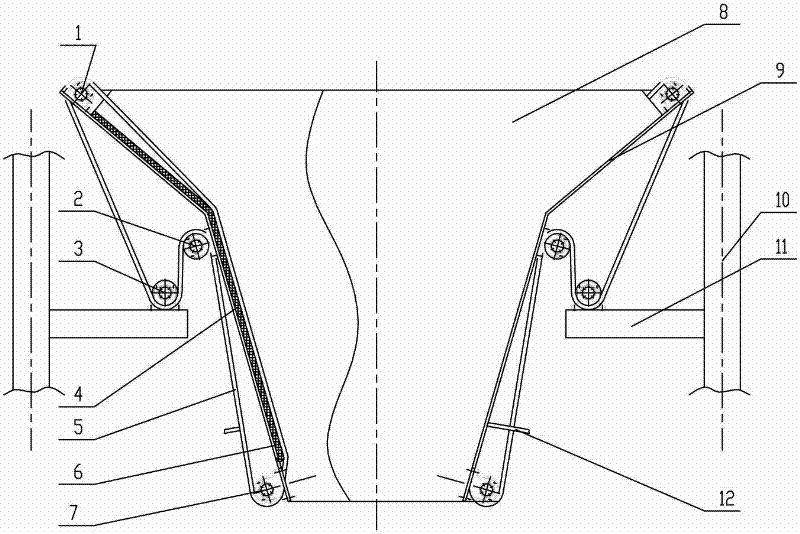

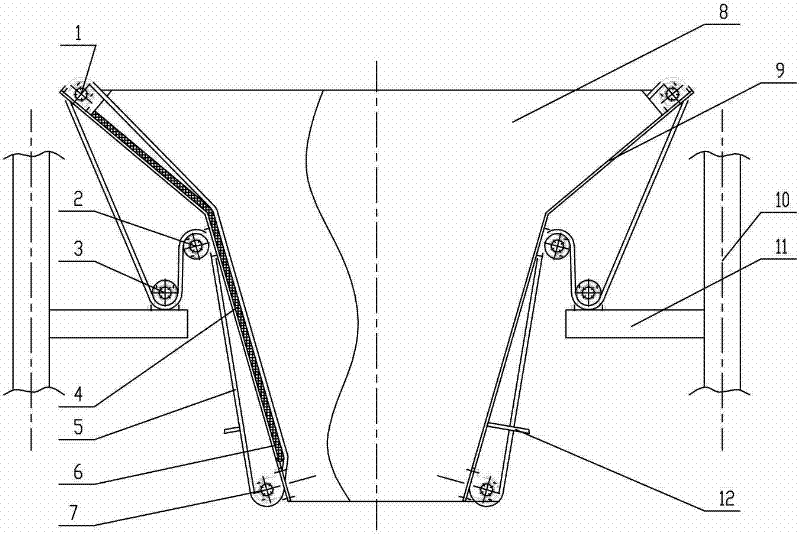

Anti-sticking material bulk cargo storage bin

ActiveCN102491015AGuaranteed cleanlinessAvoid direct abrasionLarge containersBulk cargoDevice breakage

The invention relates to an anti-sticking material bulk cargo storage bin. The storage bin is characterized in that two corresponding side plates of the bulk cargo storage bin are such side plates that the lower part gradient is 70 degrees, and the upper part gradient is 50 degrees; the top ends and the bottom ends of the two side plates are respectively provided with a top guide hole and a bottom guide hole, the inner walls of the two side plates are provided with lining boards, and the outer walls of the two side plates are provided with wing plates; the two side plates are respectively provided with an anti-sticking material mechanism; and each anti-sticking material mechanism comprises a support, a tension roller arranged on the support, a top guide roller arranged on the top of each wing plate, a bottom guide roller arranged on the bottom of each wing plate, a bearing base arranged on the middle of each wing plate, a driving roller rotatably connected with the bearing base, a motor connected with the driving roller, a strap which can pass through the top guide hole and the bottom guide hole and is respectively connected with the top guide roller, the tension roller, the driving roller and the bottom guide roller, and a U-shaped scraper arranged on the lower part of each wing plate. The bulk cargo storage bin provided by the invention has the advantages of reducing the labour intensity of workers, and avoiding occurrence of accident of next stage equipment damage caused by bulk dropping due to excessive sticky materials.

Owner:NORTHERN ENG & TECH CORP MCC

Transfer platinum cat eye positioning paper and preparation process thereof

PendingCN109440534ASolve the sticky problemStrong lusterSpecial visual effect coatingsFlexible coversWater basedPlatinum

The invention provides and particularly relates to transfer platinum cat eye positioning paper and a preparation process thereof, and relates to the technical field of printing. The preparation process of the transfer platinum cat eye positioning paper comprises the following work procedures of a UV coating molding pressing work procedure, an aluminum plating work procedure, back glue and cuttingwork procedure, a compounding work procedure, a connecting line peeling and surface coating work procedure and a transverse cutting work procedure. The transfer platinum cat eye positioning paper comprises a bottom paper layer, a transfer glue water layer, a water-based back glue layer, a platinum cat eye aluminum plating layer and a water-based surface coating layer, wherein the transfer glue water layer, the water-based back glue layer, the platinum cat eye aluminum plating layer and the water-based surface coating layer are sequentially compounded onto the bottom paper layer. The aluminum layer of the paper prepared by the preparation process realizes the firm combination with the paper; the positioning precision is high; the problem of poor combination firmness of a UV layer and an aluminum layer of a conventional transfer process is solved; the process of only transferring the platinum cat eye aluminum layer and not transferring the UV coating is realized; in addition, the platinum luster is better than that of a film coating card; the efficiency is higher; the production cost is reduced; the application is not limited; the application of the platinum positioning paper in thepackaging industry can be greatly promoted.

Owner:绍兴虎彩激光材料科技有限公司

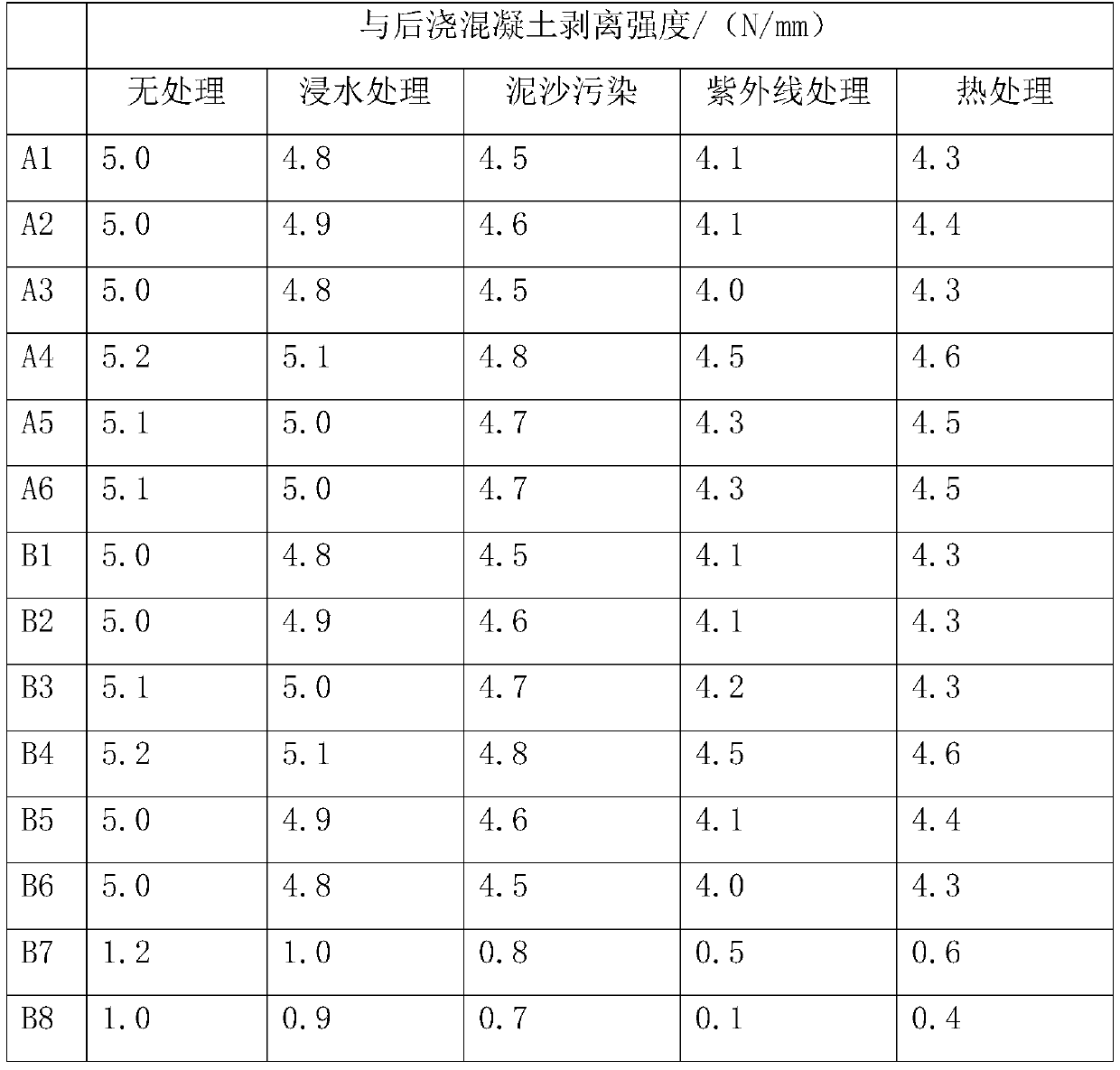

Asphalt-based pre-coating waterproof system

ActiveCN111546717ALow viscosityImprove permeabilitySynthetic resin layered productsLaminationCross linkerPolymer emulsion

The invention discloses an asphalt-based pre-coating waterproof system. A building surface to be pre-coated is used as a base surface and comprises a first modified asphalt layer, a base layer, a second modified asphalt layer, a protective layer and a functional layer in sequence from bottom to top; the protective layer is used for protecting an asphalt coating; the functional layer and post-castconcrete realize mutual adhesion of a body; the first modified asphalt layer and the second modified asphalt layer comprise the following components in parts by weight: 35 to 65 parts of asphalt, 5 to30 parts of a modifier, 15 to 30 parts of mineral powder, 0.01 to 0.1 part of a cross-linking agent, 0.01 to 0.1 part of a heat stabilizer and 0.01 to 0.1 part of a viscosity regulator; the modifiercomprises SBS, SBR, IIR and SIS. The protective layer and the functional layer take a polymer emulsion and a cement component as base materials, compounding of the same material is ensured, the integrity is good, a cement-based sand-containing coating layer is used as the functional layer, the weight ratio of the polymer emulsion to the cement component to graded sand is optimized, bonding with apost-cast concrete body is achieved, the bonding effect is remarkably improved, and the waterproof effect is more reliable.

Owner:SHENZHEN ZHUOBAO TECH

Processing method for packing tape

ActiveCN105017981AWill not affect normal useNo extra weightFilm/foil adhesivesEngineeringPlastic film

The invention provides a processing method for a packing tape with better user experience. No right-angled corners are available at the upper and lower ends of a produced tape, so that a user is not cut, and meanwhile, the end face of a tape coil is not sticky, so that the tape is more convenient to take and use. The processing method comprises the following main steps: adding a tape raw material acrylic acid into an emulsification tank for emulsification; then putting the emulsified raw material into a reaction pot to be heated to prepare glue; then adding the glue into a coating machine; mounting a plastic thin film coil on the coating machine and smearing the glue to a plastic thin film through the coating machine to prepare a mother coil; pipe-cutting the mother coil through a pipe cutter; stripping the successfully pipe-cut tape through a stripping machine to obtain coils of tapes; polishing the upper and lower inner corners of a paper element of the stripped tape by using a polishing machine; polishing the right-angled corners with the inner corners to bevels or arc-shaped faces; and uniformly adhering paper element powder left when the right-angled corners are polished to the end face of the tape coil of the tape to prepare a finished product packing tape.

Owner:广东宝兰山新材料科技有限公司

Solid fermentation culture method of paecilomyces lilacinus

ActiveCN113215003AInhibit bacterial growthHigh purebred rateFungiMicroorganism based processesPaecilomyces spChemistry

The invention discloses a solid fermentation culture method of paecilomyces lilacinus, and belongs to the technical field of bioengineering. The invention discloses a solid fermentation culture method of paecilomyces lilacinus. The solid fermentation culture method comprises the following steps: test tube activation of paecilomyces lilacinus, preparation of a primary seed solution of paecilomyces lilacinus, preparation of a secondary seed solution of paecilomyces lilacinus, and solid fermentation culture of paecilomyces lilacinus. According to the invention, millet and rice are used as main culture materials; the acidity and a nitrogen source of a fermentation culture medium are adjusted through a corn steep liquor paste acidic material; the material viscosity in the fermentation culture process is reduced by adding white carbon black and silicon dioxide superfine water retention materials; the content of live bacteria in paecilomyces lilacinus cultured in a foam box is very high; the prepared microbial inoculum is high in purity; the subsequent preservation survival rate of the microbial inoculum is high; and the field application effect in several years is very good.

Owner:HEBI HESHENG BIO TECH CO LTD

Powder sealing valve

InactiveCN102042417AGuaranteed cleanlinessSolve the sticky problemCleaning using gasesLift valveEngineeringNitrogen gas

The invention discloses a powder sealing valve comprising a valve body, a sweeping mechanism, a valve core and an executing mechanism; the valve core is arranged in the valve body to open and close the valve under the effect of the executing mechanism; the sweeping mechanism is an annular gas chamber; the annular gas chamber is also arranged in the valve body; the valve core is in sealed contact with the gas chamber; the sealing surfaces of the valve core and the gas chamber are both spherical surfaces; the annular gas chamber is provided with a gas inlet and a gas outlet; and the gas outlet is arranged on the sealing surfaces of the gas chamber and the valve core. In the invention, the annular gas chamber is arranged in the valve body, the gas inlet is arranged outside the gas chamber, the gas outlet is arranged on the sealing surfaces of the interior of the gas chamber and the valve core, and dry gas (compressed gases of air and nitrogen can be selected according to conditions for use) is injected between the sealing surfaces to keep the sealing surfaces clean by means of the sweeping of gas flow, thereby solving the problem of material sticking, realizing reliable sealing and achieving zero leakage.

Owner:LIMIN CHEM CO LTD

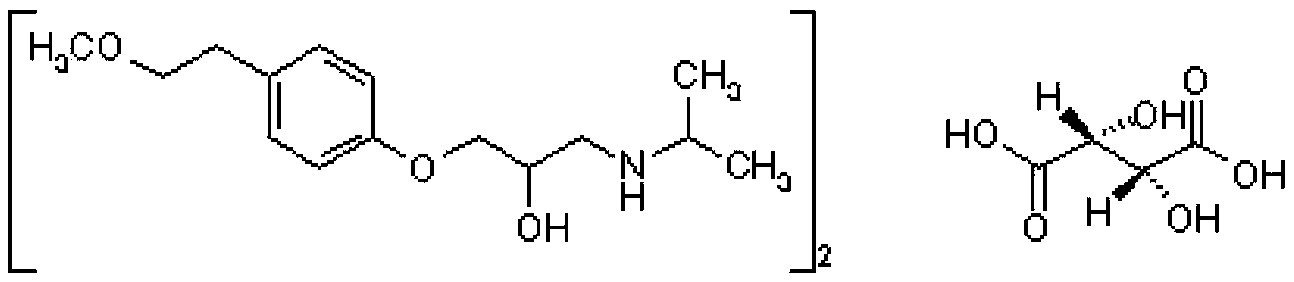

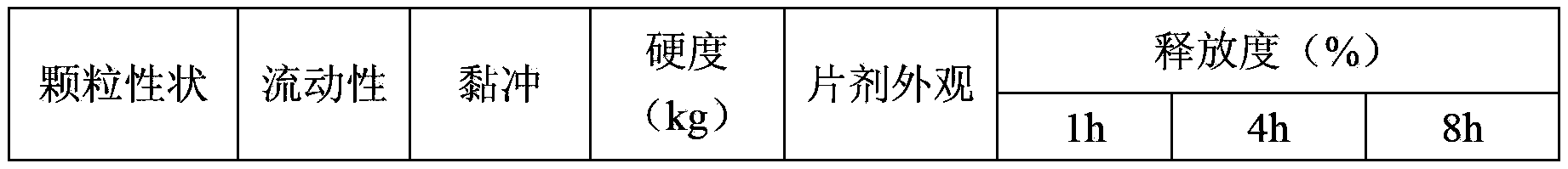

Metoprolol tartrate sustained release tablet and preparation method thereof

InactiveCN103405394AFacilitated releaseRelease rate has no effectOrganic active ingredientsNervous disorderAdhesiveFiller Excipient

The invention provides a metoprolol tartrate sustained release tablet. The metoprolol tartrate sustained release tablet is prepared from the following components in percentage by mass: 100 of metoprolol tartrate, 60-80 of retardant, 20-40 of filling agent, 2-10 of lubricating agent, 50-90 of adhesive and 2.5-4 of film coating powder. Aiming at the problem that adhesive brewing is easily caused in production because the metoprolol tartrate is easy to dissolve in water, the invention provides a two-step granulation method comprising the steps of respectively preparing medicine contained granules and blank granules, drying the medicine contained granules and the blank granules, totally mixing the medicine contained granules and the blank granules and tabletting, so that the problem of adhesive brewing in tabletting is solved. In addition, the metoprolol tartrate is strong in moisture absorption property and bitter in taste, and a coating layer can be used for improving the stability of the metoprolol tartrate and masking the bitter taste of the metoprolol tartrate. The metoprolol tartrate sustained release tablet has the advantages that the components of the auxiliary materials are simple, the operation is convenient, the prepared granules are good in flowability, strong in adhesive resistance and incapable of causing adhesive brewing during tabletting, and the coating layer can be used for improving the stability of a drug and masking the bitter tastes of active ingredients and has no affect to the release rate of the tablet. The metoprolol tartrate sustained release tablet is suitable for industrial production and relatively high in application value.

Owner:SHANGHAI SINE PROMOD PHARMA

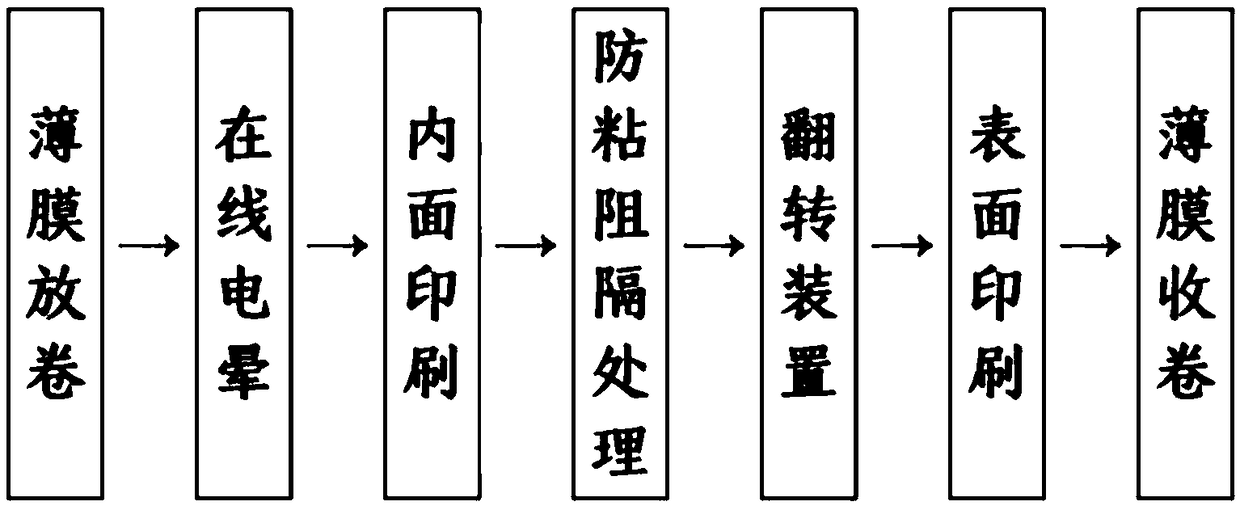

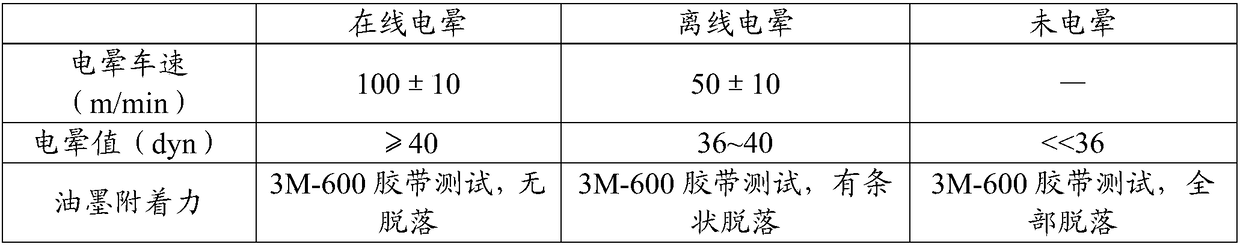

Double-sided printing method for plastic film

InactiveCN109177557AGuaranteed fastnessReduce surface tensionOther printing apparatusPrinting after-treatmentBarrier treatmentEngineering

The invention relates to a double-sided printing method for a plastic film. The method includes the steps that (1) a first surface of the plastic film is subjected to online corona treatment; (2) a second surface of the plastic film is subjected to printing treatment; (3) after the printing treatment, the second surface of the plastic film is subjected to adhesion prevention and barrier treatment;(4) the plastic film is overturned, so that the first surface of the plastic film is to be printed; and (5) the first surface of the plastic film is subjected to printing treatment and precisely aligned at printed images of the second surface. According the double-sided printing method for the plastic film, a traditional gravure inner printing technology is broken, and by adoption of overturningprinting technology through a gravure printer, precise alignment of printed images on the positive and negative surfaces is completed; through the online corona treatment, the synchronism of corona and printing and the stability of corona are greatly ensured; and through online coating adhesion prevention and barrier materials, the problem of ink adhering back is solved without affecting the strength of the composite.

Owner:三樱包装(江苏)有限公司

Continuous type phosphating production process of sleeve material

InactiveCN103924233AShorten the timeIncrease productivityMetallic material coating processesConductor CoilSaponification

The invention belongs to the technical field of production of chain sleeve materials, and particularly relates to a continuous type phosphating production process of a sleeve material. The invention discloses a packaging continuous type phosphating production process of a flat filament. The continuous type phosphating production process comprises the following steps: A: releasing; B: hardening and tempering; C: clarifying water, namely the flat filament taken out of a hardening and tempering tank enters a clear water tank for cleaning, the cleaned flat filament is subjected to immersion cleaning twice by using clear water, and the clear water inside the clear water tank is kept overflowing; D: saponifying, namely the flat filament passes through the clear water tank and then enters a saponification tank for saponification, a heating steam pipe is arranged at the bottom inside the saponification tank, the clear water tank is divided into a plurality of working areas, and the clear water tank is internally provided with a temperature sensor; and E: winding. According to the continuous type phosphating production process disclosed by the invention, the continuous type phosphating production process of the sleeve material can be optimized and improved, so that the integral phosphating production process realizes the automatic production.

Owner:ZHEJIANG JIANHONG CHAIN PASSING MATERIAL

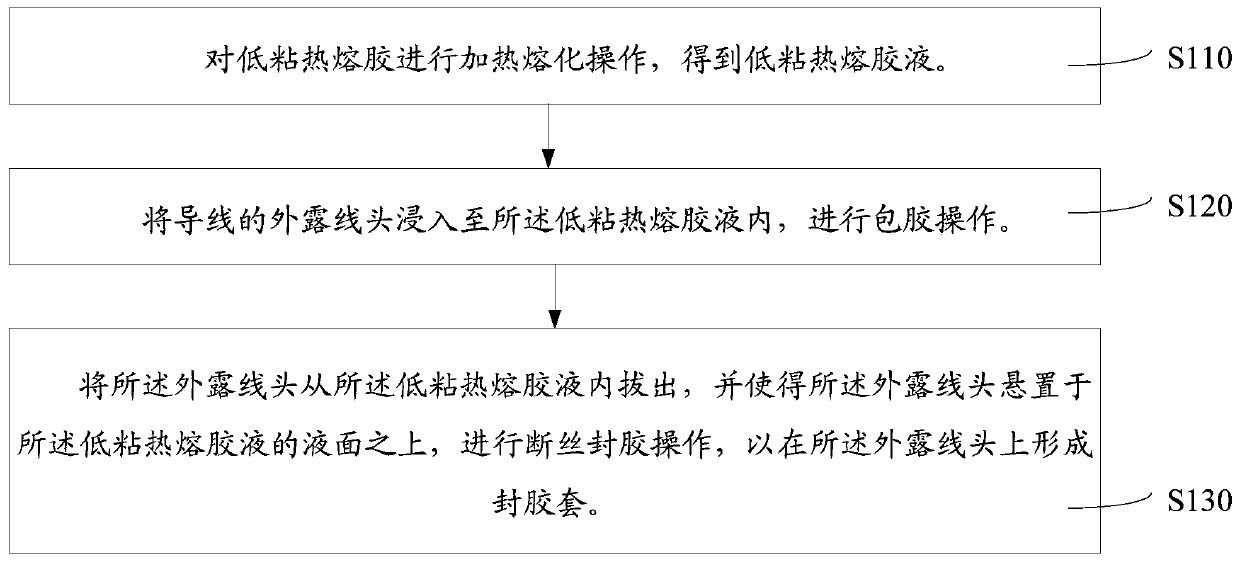

Lithium battery wire exposed wire end insulation production process

ActiveCN110649444ALow costAvoid short circuit problemsContact member cases/bases manufactureNon-macromolecular adhesive additivesHot meltElectrical tape

The invention relates to the field of wire end insulation treatment process and discloses a lithium battery wire exposed wire end insulation production process. The production process comprises stepsof heating and melting a low-viscosity hot melt adhesive to obtain low-viscosity hot melt adhesive solution; immersing an exposed wire end of a wire into the low-viscosity hot melt adhesive solution,and carrying out adhesive coating operation; pulling out the exposed wire end from the low-viscosity hot melt adhesive liquid, suspending the exposed wire end above a liquid level of the low-viscosityhot melt adhesive liquid, and carrying out wire breaking and adhesive sealing operation so as to form an adhesive sealing sleeve on the exposed wire end. The production process is advantaged in thatthe low-viscosity hot melt adhesive is used for forming the adhesive sealing sleeve on the exposed wire end, insulation operation is simple and convenient, residual adhesive is not easy to generate, sealing coating property of the exposed wire end is better, a problem of short circuit of the exposed wire end of the wire is solved, a problem of damp oxidation of the exposed wire end is solved, thetin-absorbing effect of the exposed wire end is good, cost of the low-viscosity hot melt adhesive is far lower than that of insulating tape and a sleeve, and the production benefit can be increased bymore than 300%.

Owner:HUIZHOU HENGTAI TECH

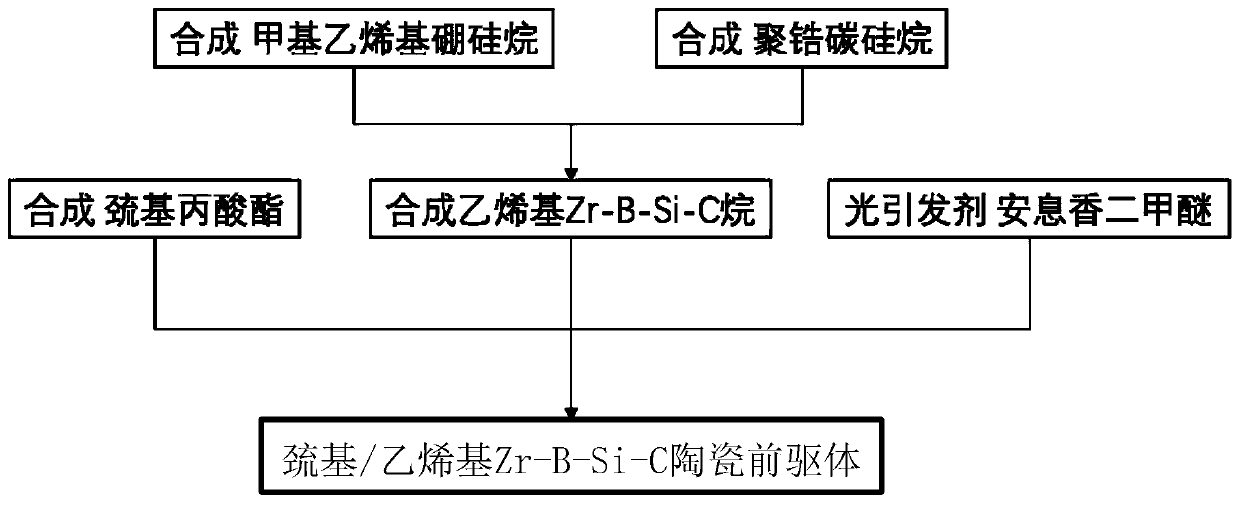

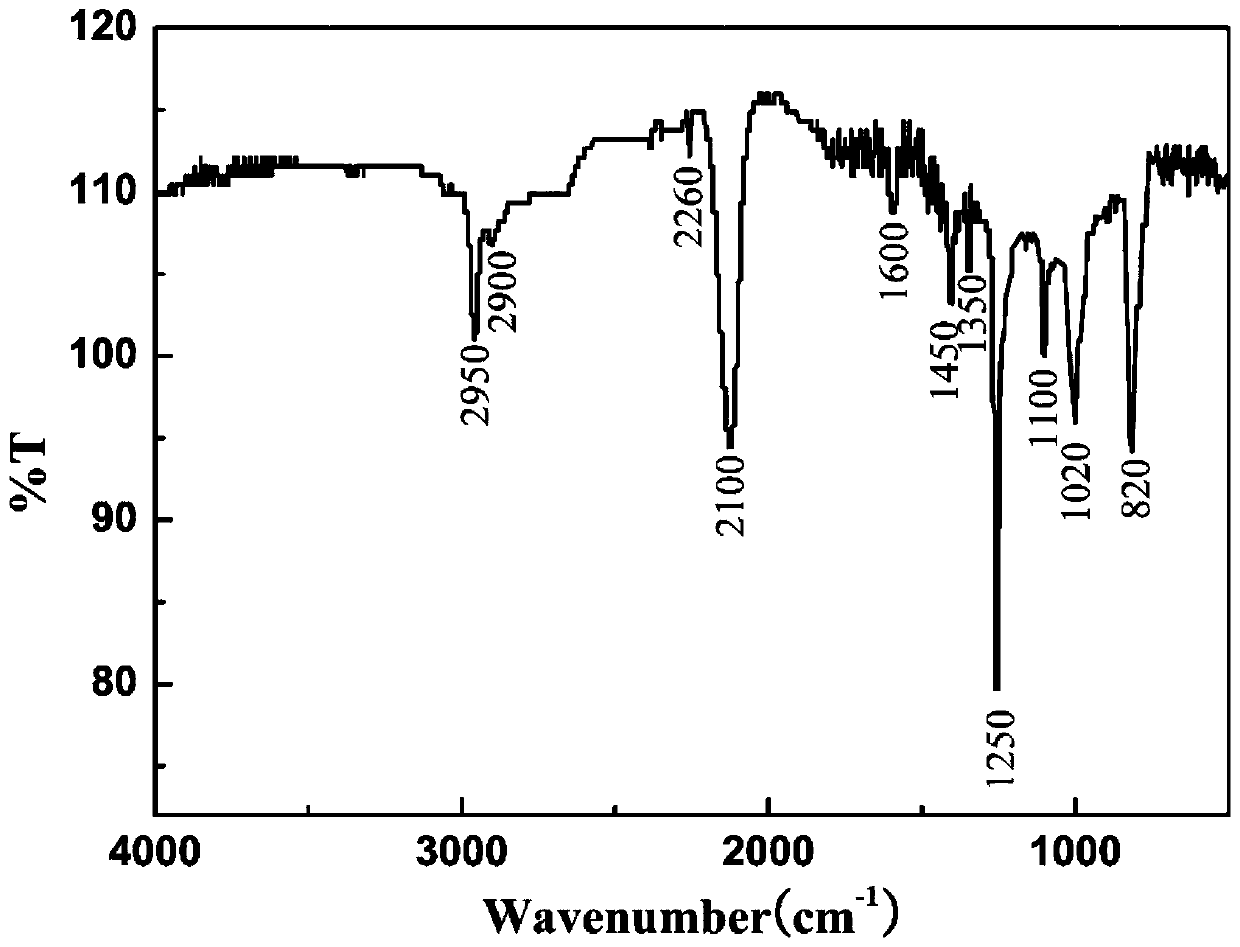

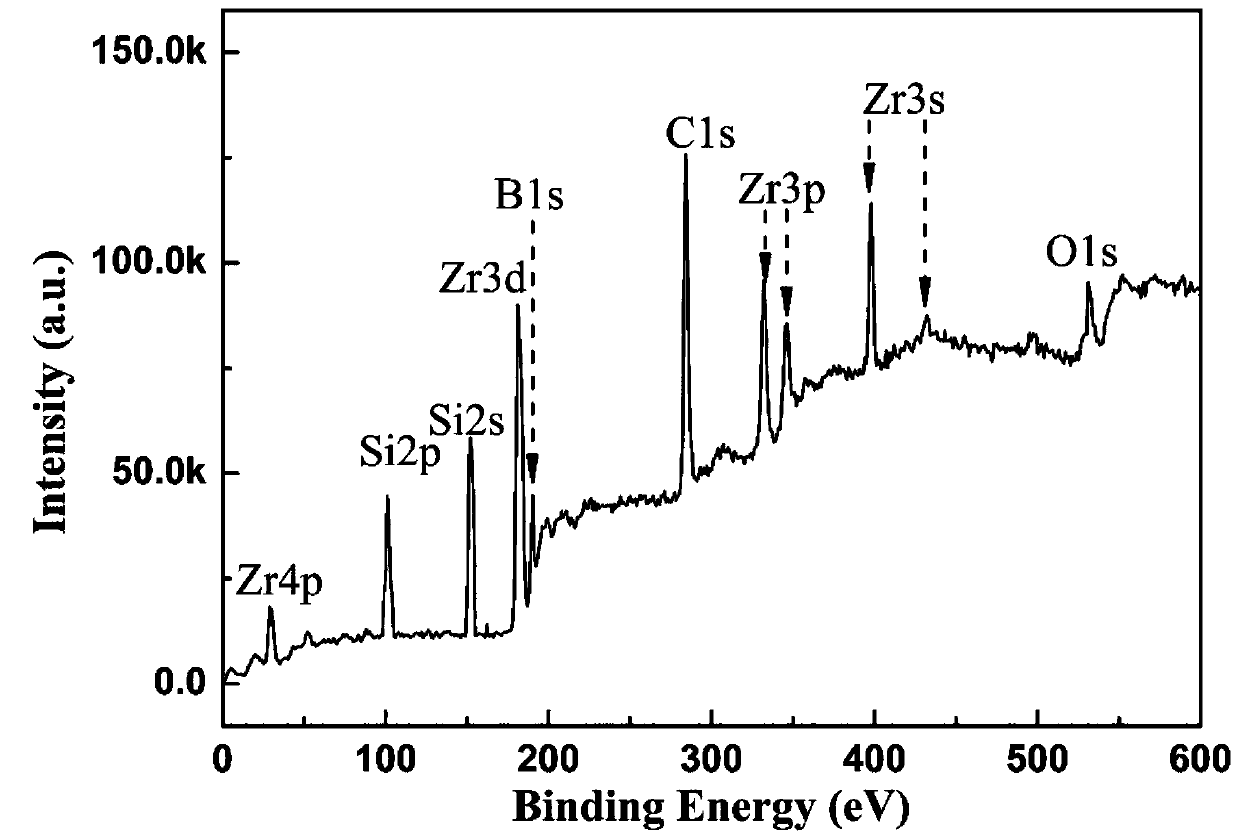

Light-sensitive Zr-B-Si-C ceramic precursor and in-situ preparation method thereof

The invention relates to a light-sensitive Zr-B-Si-C ceramic precursor and an in-situ preparation method thereof. The method comprises the following steps: uniformly mixing methylvinyldichlorosilane and a borane dimethyl sulfide complex, and then adding metal sodium for dechlorination to obtain methylvinyl borosilane; uniformly mixing chloromethyltrichlorosilane, methylchloromethyldichlorosilane and bis(cyclopentadienyl)zirconium dichloride, then adding metal magnesium to carry out a first heat preservation reaction, and then adding a reducing agent to carry out a second heat preservation reaction to obtain polyzirconocarbosilane; uniformly mixing methylvinyl borosilane and polyzirconocarbosilane to obtain vinyl Zr-B-Si-C alkane; and uniformly mixing the vinyl Zr-B-Si-C alkane with mercaptopropionate, and then adding a photoinitiator to initiate a polymerization reaction to prepare the ceramic precursor. The problems of high viscosity, high thermal stress, structural member mechanicalproperty attenuation and the like of a traditional photocuring system are solved, and a high-quality raw material is provided for photocuring 3D printing of an ultrahigh-temperature ceramic structuralmember.

Owner:XIAMEN UNIV OF TECH

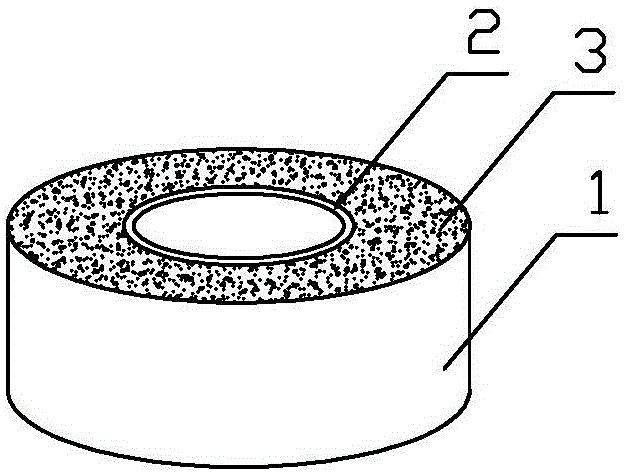

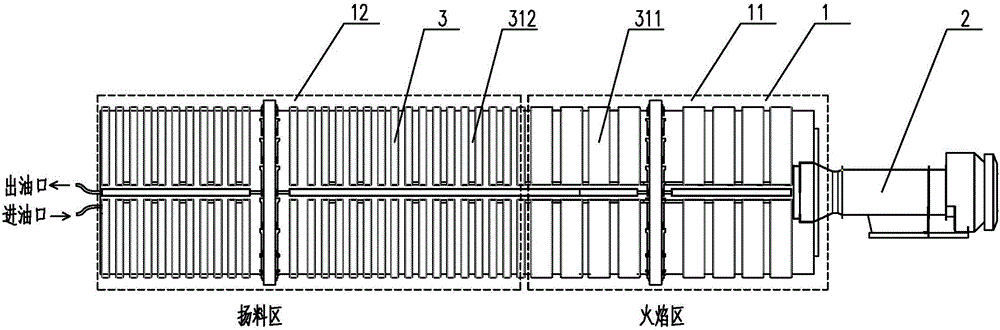

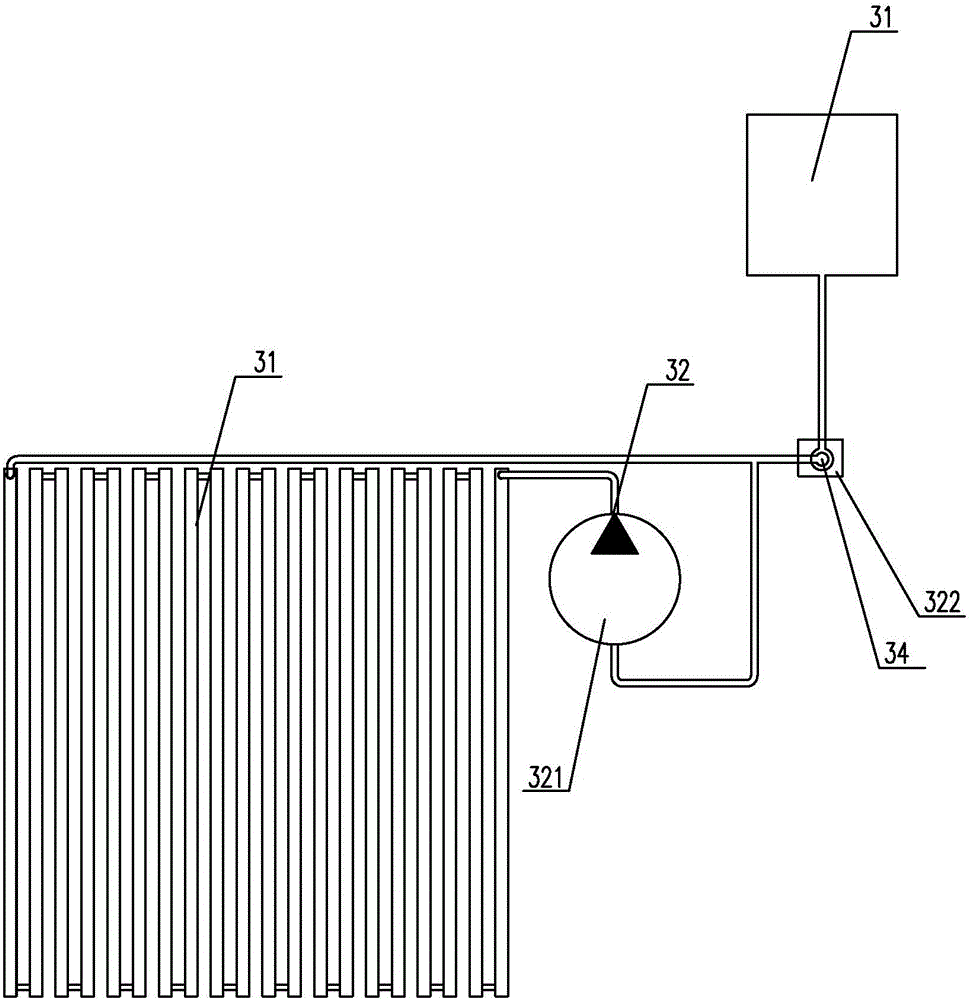

Asphalt regenerating roller with anti-adhesion heating device and anti-adhesion method

ActiveCN105696443AIncrease temperatureSolve the sticky problemRoads maintainenceCombustionOil transportation

The invention relates to the technical field of stirring devices, particularly to an anti-adhesion heating device capable of solving the problem that materials adhere to an inner wall inside an asphalt regenerating roller and an anti-adhesion method. The asphalt regenerating roller with the anti-adhesion heating device comprises the anti-adhesion heating device, wherein the anti-adhesion heating device comprises a heat conduction oil pipeline and a heat conduction oil transportation device; the heat conduction oil pipeline is arranged on the outer wall of a roller body from a combustion zone to a material dispersing zone; and the heat conduction oil transportation device communicates with the heat conduction oil pipeline and is used for transporting heat conduction oil to the heat conduction oil in the heat conduction oil pipeline. According to the asphalt regenerating roller with the anti-adhesion heating device and the anti-adhesion method, the heat conduction oil in the heat conduction oil pipeline is heated through directly utilizing the heat energy of the combustion zone of the roller body, the temperature of the material dispersing zone of the roller body is increased, and the roller wall of the roller body is heated to the temperature capable of enabling the asphalt material to be molten to be liquid; and the regenerated material adhesive property is reduced through the asphalt regenerating roller and the anti-adhesion method, the material sticking problem of the roller wall of a currently existing roller is completely solved, the integral energy consumption of the device is reduced, and energy saving and environmental protection are realized.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

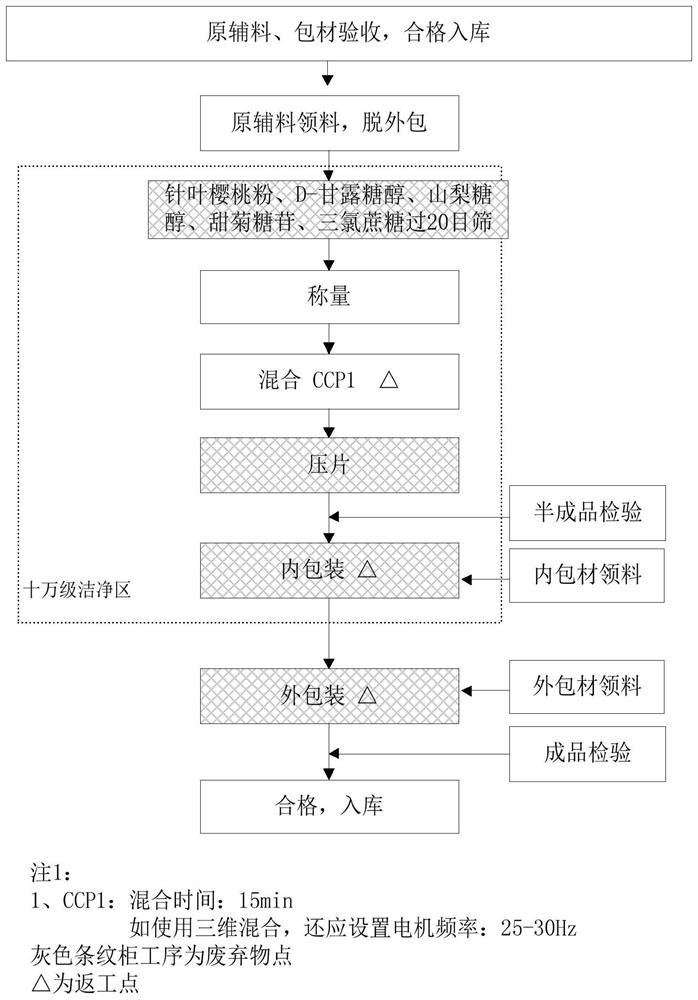

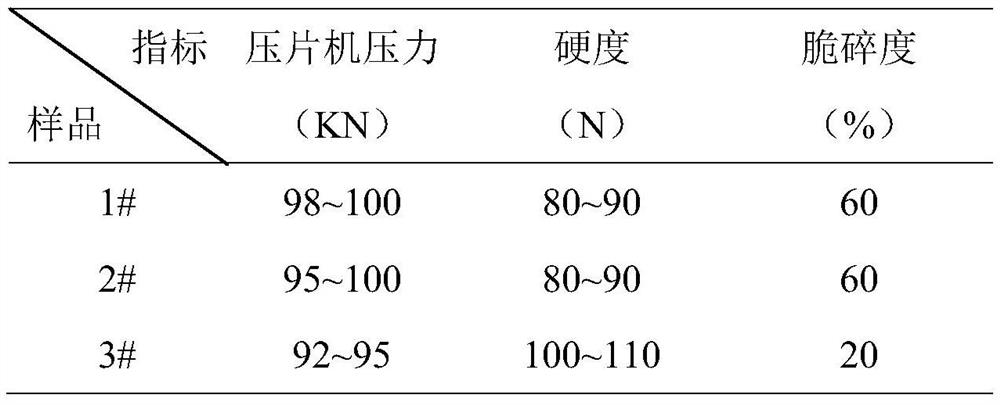

Acerola cherry tabletted candies and preparation method thereof

PendingCN113973964AImprove fluidity and compressibilityImproves hardness and friabilityConfectionerySweetmeatsSucroseMagnesium stearate

The present invention relates to acerola cherry tabletted candies and a preparation method thereof. The candies consist of cherry powder, an excipient, a sweetening agent, an adhesive and a lubricant; the acerola cherry tabletted candies specifically comprise 25-33.35% of acerola cherry powder, 28.6-29.3% of sorbitol, 15-25% of microcrystalline cellulose, 1-8% of D-mannitol, 0.1-1% of stevioside, 10.65-20% of blueberry powder, 0.01-0.05% of sucralose and 0.3-1% of magnesium stearate. The tabletted candies are obtained by adopting the technologies of sieving, weighing, premixing, total mixing and direct pressing. The acerola cherry tabletted candies are simple in preparation process, stable in hardness, friability and taste, have blueberry flavor, are moderate in sourness and sweetness and convenient to eat, and have the beneficial effects of enhancing immunity, improving skin state, whitening, regulating intestinal flora and the like.

Owner:富诺健康股份有限公司

Metoprolol tartrate tablet and preparation method thereof

InactiveCN108553430ASolve the sticky problemSolving Dissolution ProblemsOrganic active ingredientsNervous disorderChemistryMagnesium Sterate

The invention relates to the field of pharmaceutic preparations, in particular to a metoprolol tartrate tablet and a preparation method thereof. The provided metoprolol tartrate tablet is prepared from, by weight, 0.45-0.56 part of metoprolol tartrate, 0.2-0.4 part of lactose, 0.5-0.7 part of microcrystalline cellulose, 0.02-0.04 part of povidone K30, 0.06-0.12 part of sodium carboxymethyl starch,0.008-0.012 part of colloidal silicon dioxide and 0.016-0.024 part of magnesium stearate. The formula of an existing metoprolol tartrate tablet is optimized, and it is accidentally found that under the condition of not needing to add resin, surprisingly technical effects on overcoming sticky dissolution and dissolution rate are achieved.

Owner:GRAND PHARM (CHINA) CO LTD

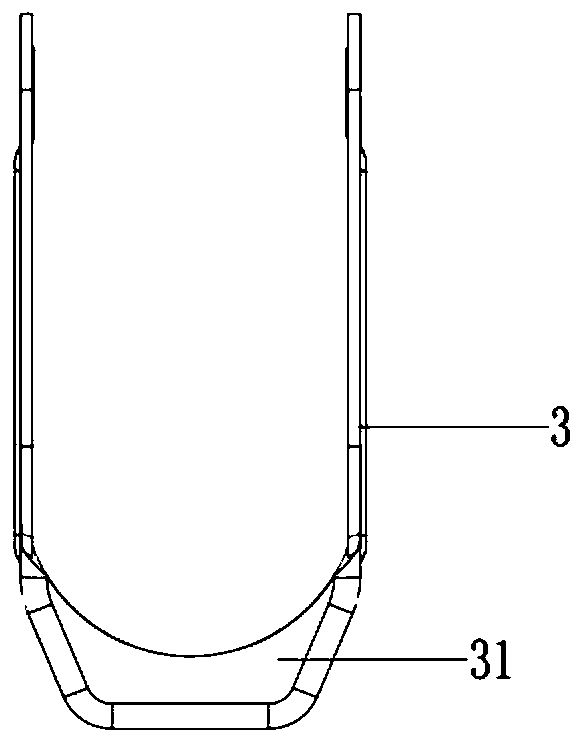

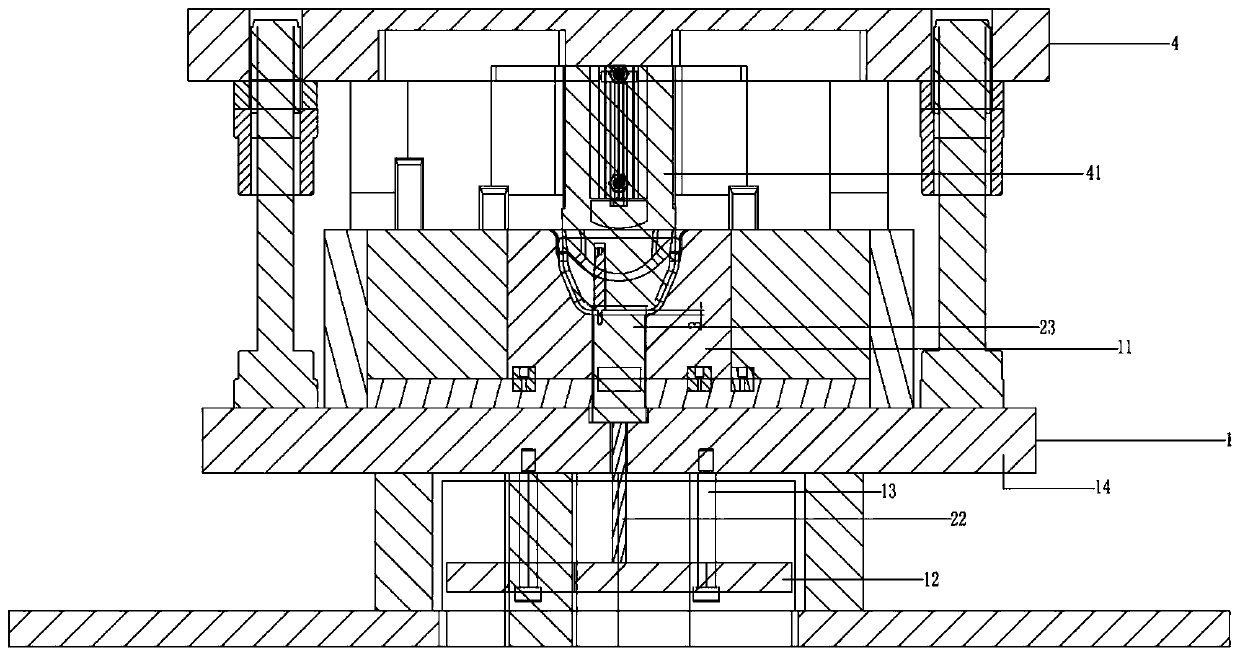

Profiling stripping structure applied to die opening engineering of U-shaped workpiece drawing die

PendingCN110496919ASolve the problem of damaged skirtImprove yield rateShaping toolsEjection devicesEngineeringDrive shaft

The invention provides a profiling stripping structure applied to die opening engineering of a U-shaped workpiece drawing die. According to the structure, skirt edges are arranged on the two sides ofthe width direction of a U-shaped workpiece, the profiling stripping structure comprises a profiling stripping mechanism arranged on a lower die mechanism, wherein the profiling stripping mechanism comprises an upward ejection driving part and a profiling stripping block, the profiling stripping block is located in a preset space in a male die of the lower die mechanism in an initial state, a driving shaft of the upward ejection driving part is connected with the profiling stripping block, the driving shaft is of a V-shaped bending structure, and the upward ejection driving part drives the profiling stripping block to move upwards and ejects the U-shaped workpiece in the direction deviated from a male die of an upper die mechanism during die opening. Compared with the prior art, the structure can be used for effectively solving the problem that an ejection block damages the skirt edges during auxiliary stripping, so that the product yield is improved.

Owner:YIHE PRECISION IND SUZHOU

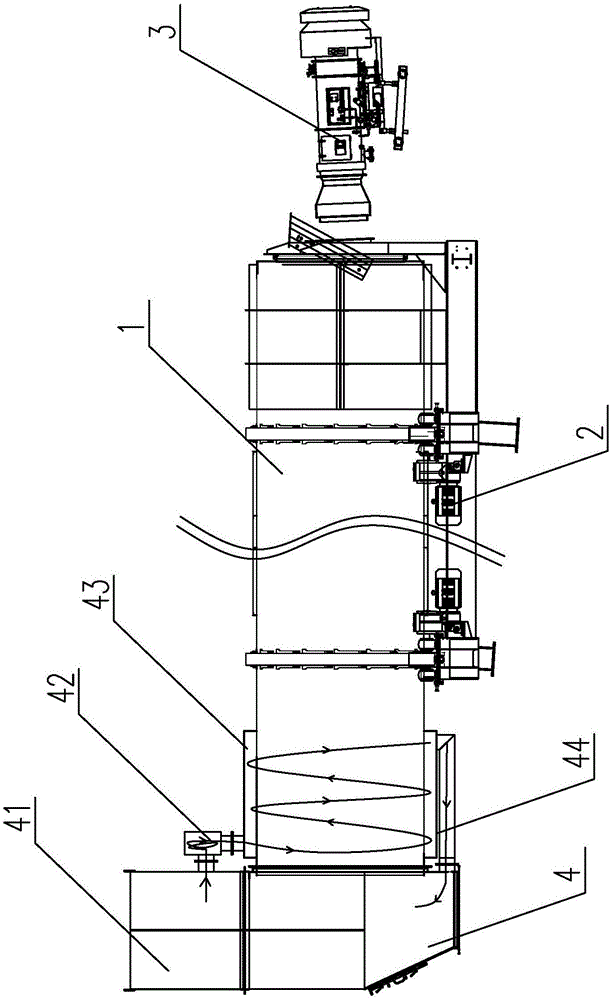

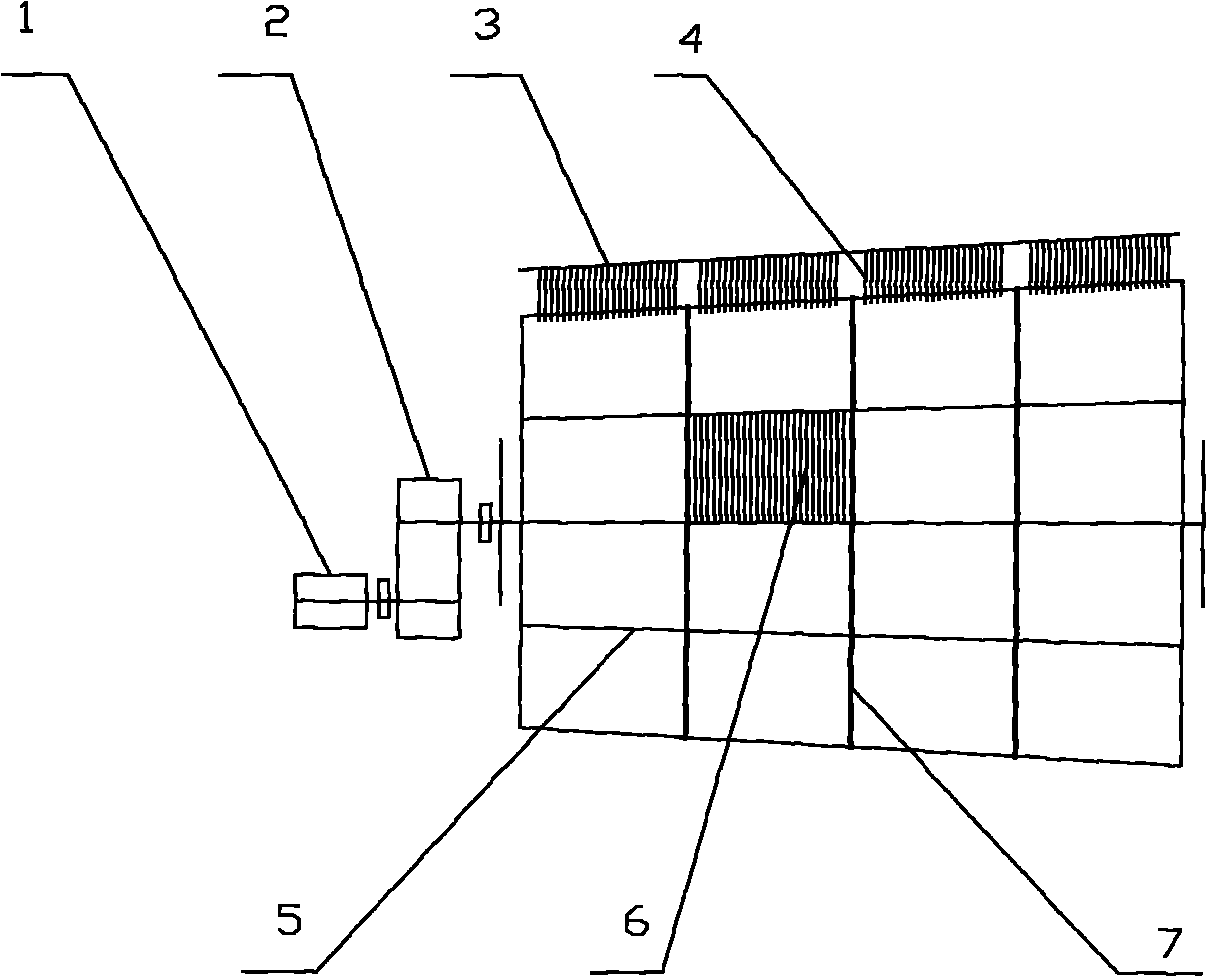

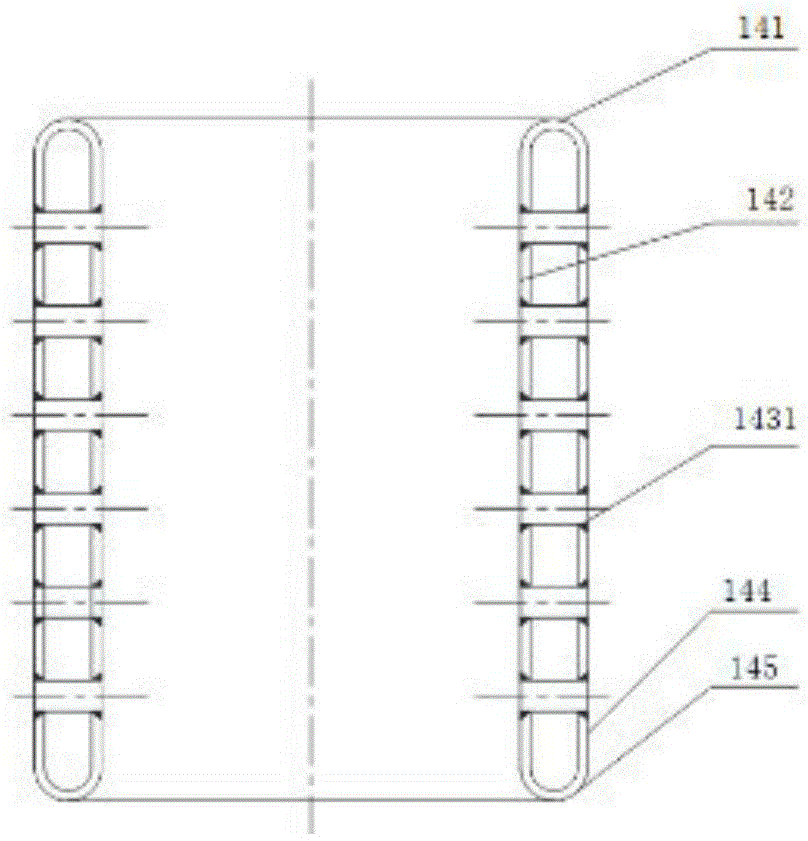

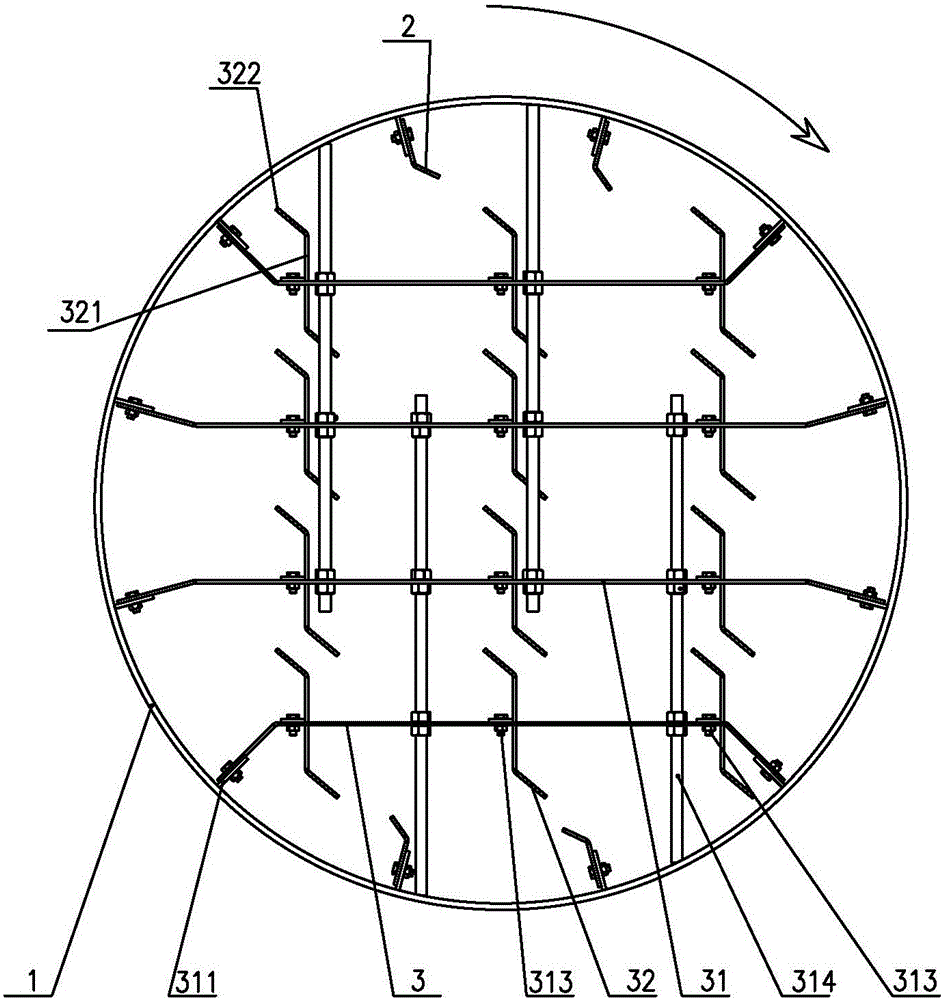

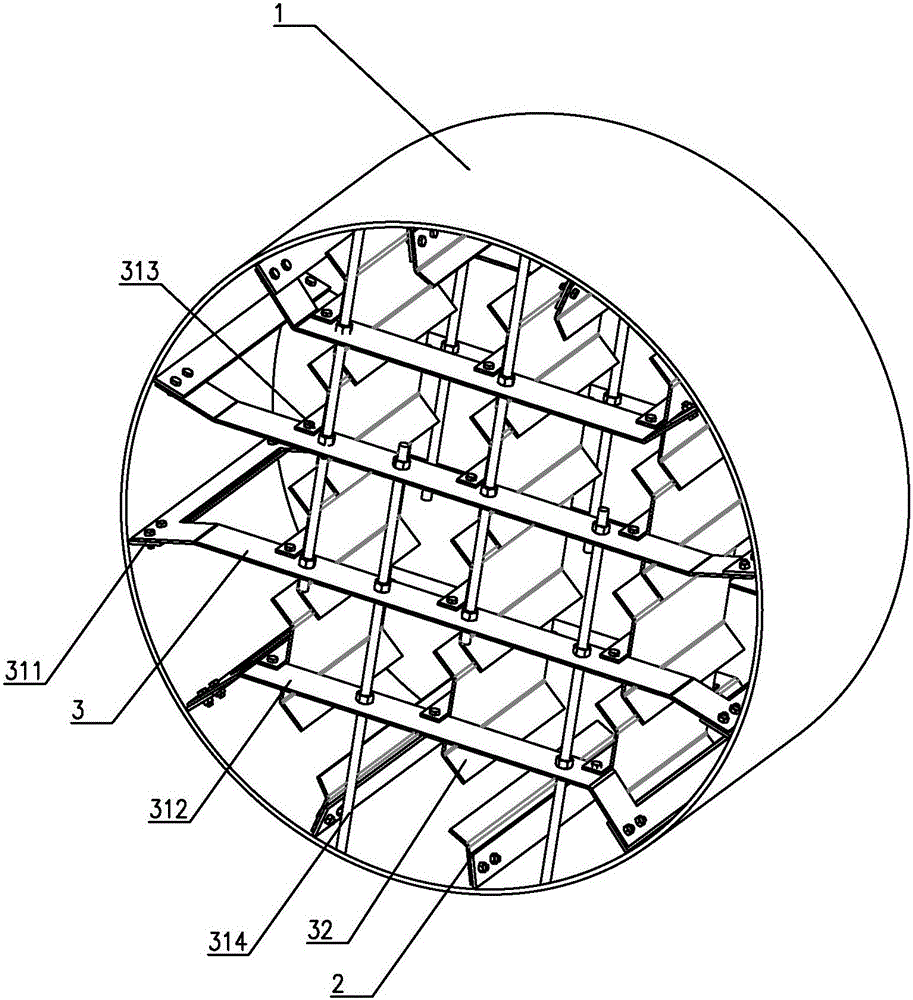

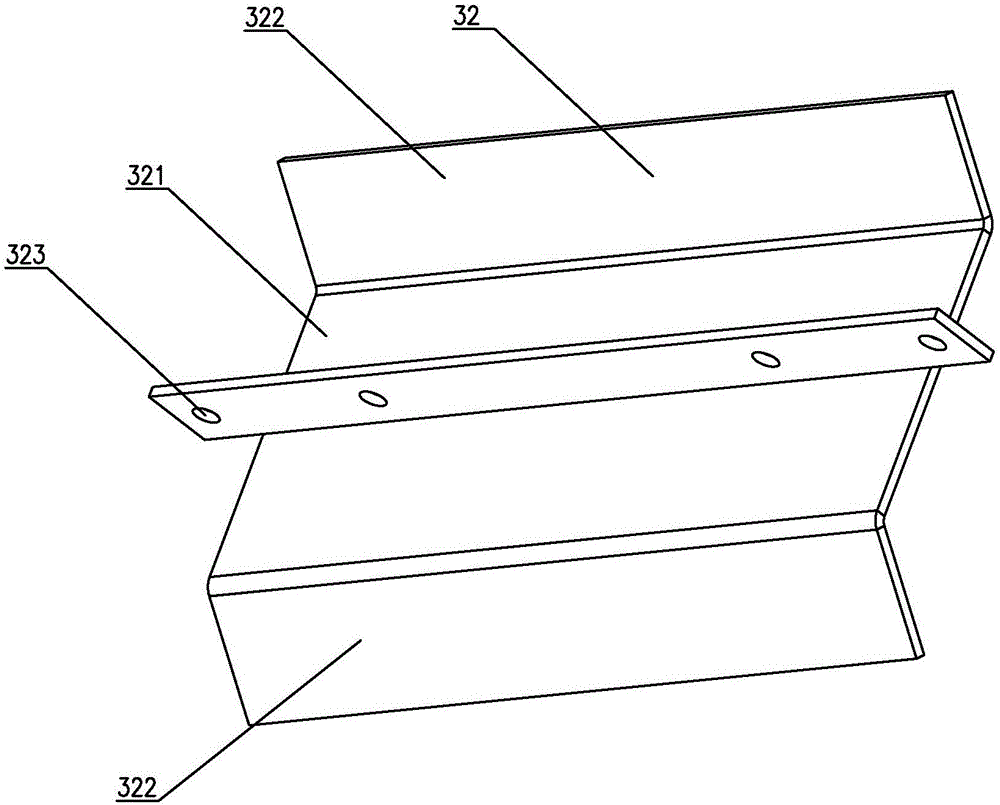

Aggregate drying drum and drying method for dry-mixed mortar production line

ActiveCN104990380AReduce moistureAvoid stickingDrying solid materialsDrying machines with non-progressive movementsProduction lineEngineering

The invention relates to the technical field of stirring equipment, in particular to an aggregate drying drum and a drying method. The aggregate drying drum for a dry-mixed mortar production line comprises a rotating cylinder and a lifting blade arranged on the inner wall of the rotating cylinder, and further comprises an aggregate scattering device, wherein the aggregate scattering device comprises a support component and multiple bent blades; the multiple bent blades are uniformly distributed on the peripheral section of the rotating cylinder by the support component; and each bent blade performs holding and lifting actions along with the rotation of the cylinder, so that the peripheral section of the whole rotating cylinder is uniformly distributed with curtains. The aggregate drying drum enables aggregate moisture to be quickly reduced, quickens the temperature rise to prevent materials from being bonded on the drum, improves the use effect of subsequent lifting blades, radically solves the problem of bonding the materials on the drum, improves the curtain effect in the drum, improves the heat efficiency of the drum, and can reduce the heat source consumption.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

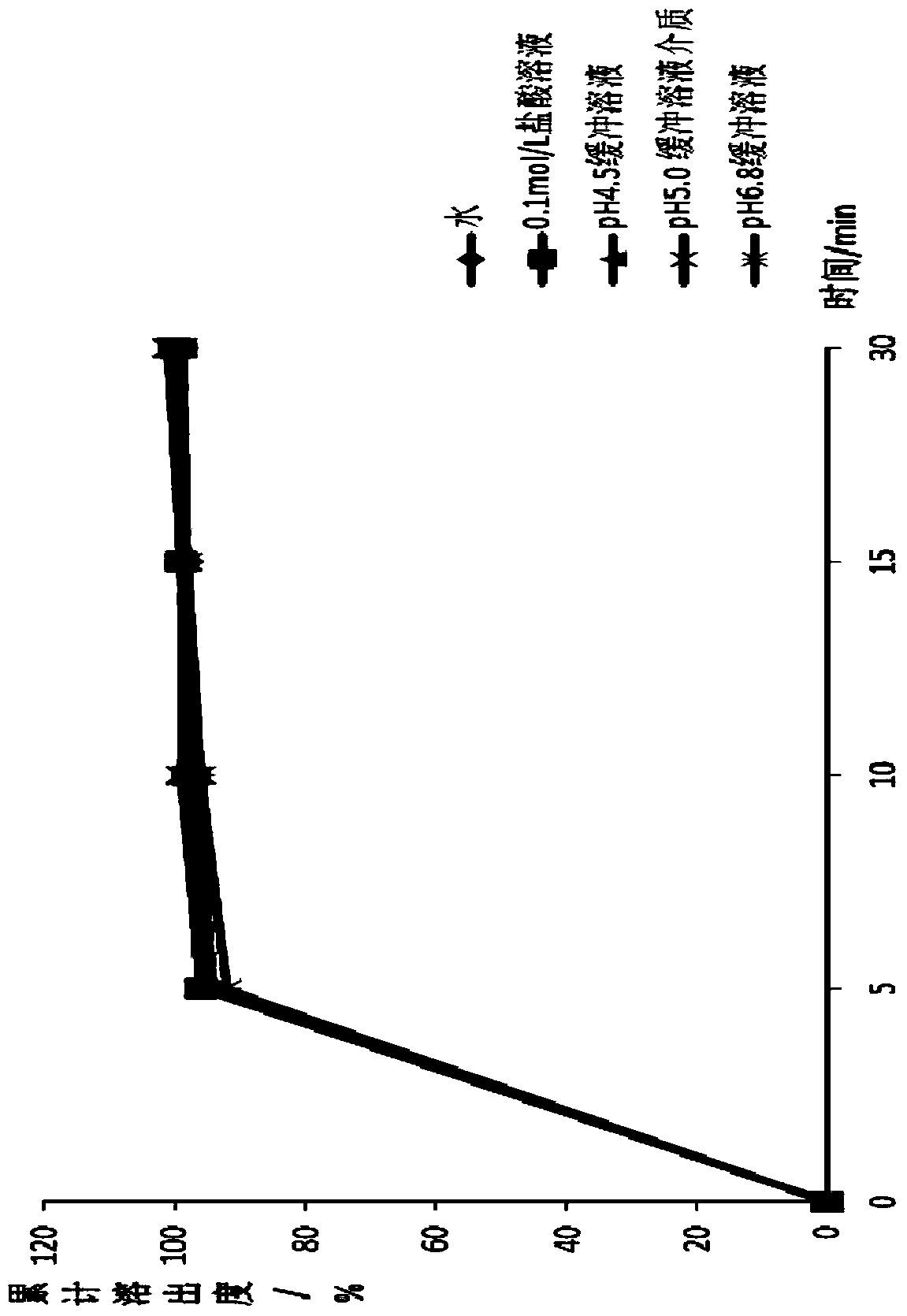

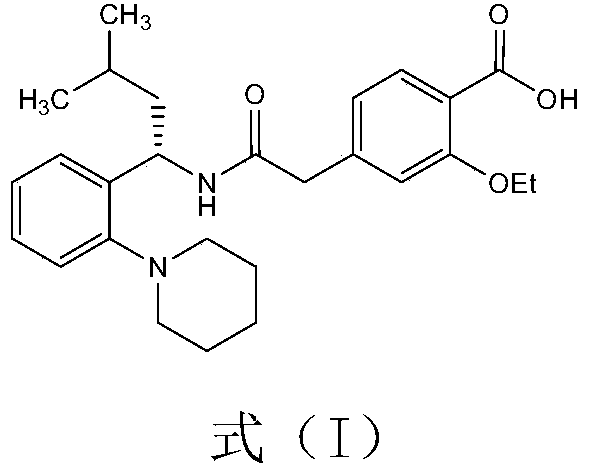

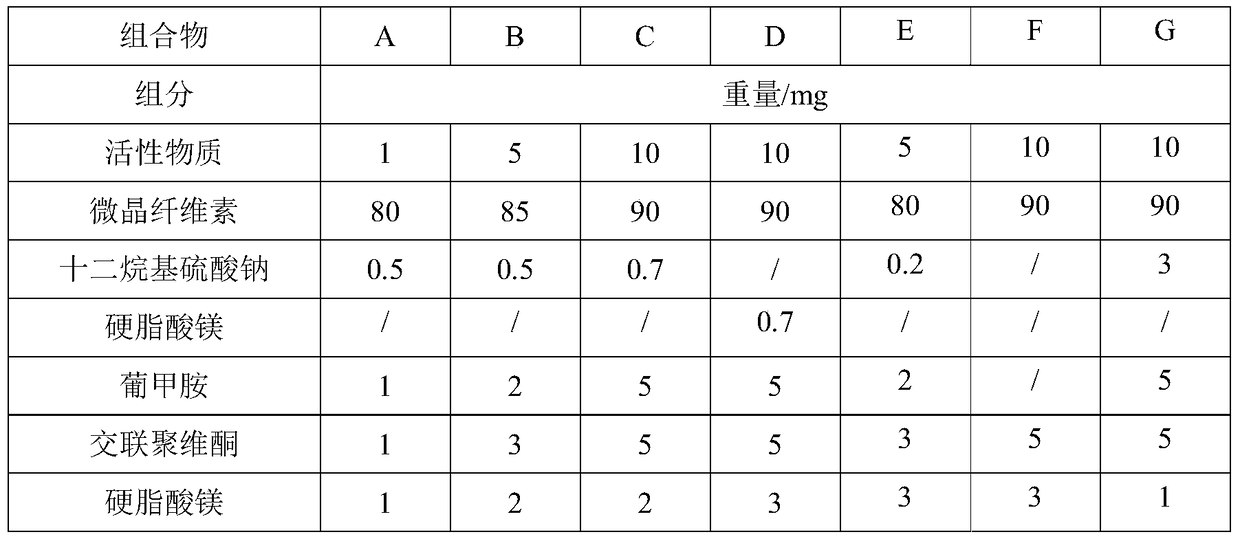

Stable repaglinide pharmaceutical composition and preparation method thereof

ActiveCN105535980BImprove mixing uniformityHigh dissolution rateOrganic active ingredientsMetabolism disorderBenzoic acidDissolution

The invention relates to a stable repaglinide drug composition and a preparation method thereof. The composition is prepared from an active material S(+)-2-ethyoxyl-4-{2-[(3-methyl-1(2-(1-piperidyl) phenyl) butyl) amino]-2-oxo ethyl}benzoic acid, a surfactant, a stabilizer, a carrier, a disintegrating agent and a lubricant. The invention also discloses a solid preparation prepared from the composition. The preparation is uniform in content uniformity, quick in dissolution and good in stability, realizes consistent dissolution in various dissolution media, and is controllable in product production process, thus comprehensively ensuring end product quality.

Owner:JIANGSU HANSOH PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com