Patents

Literature

272results about "Fusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

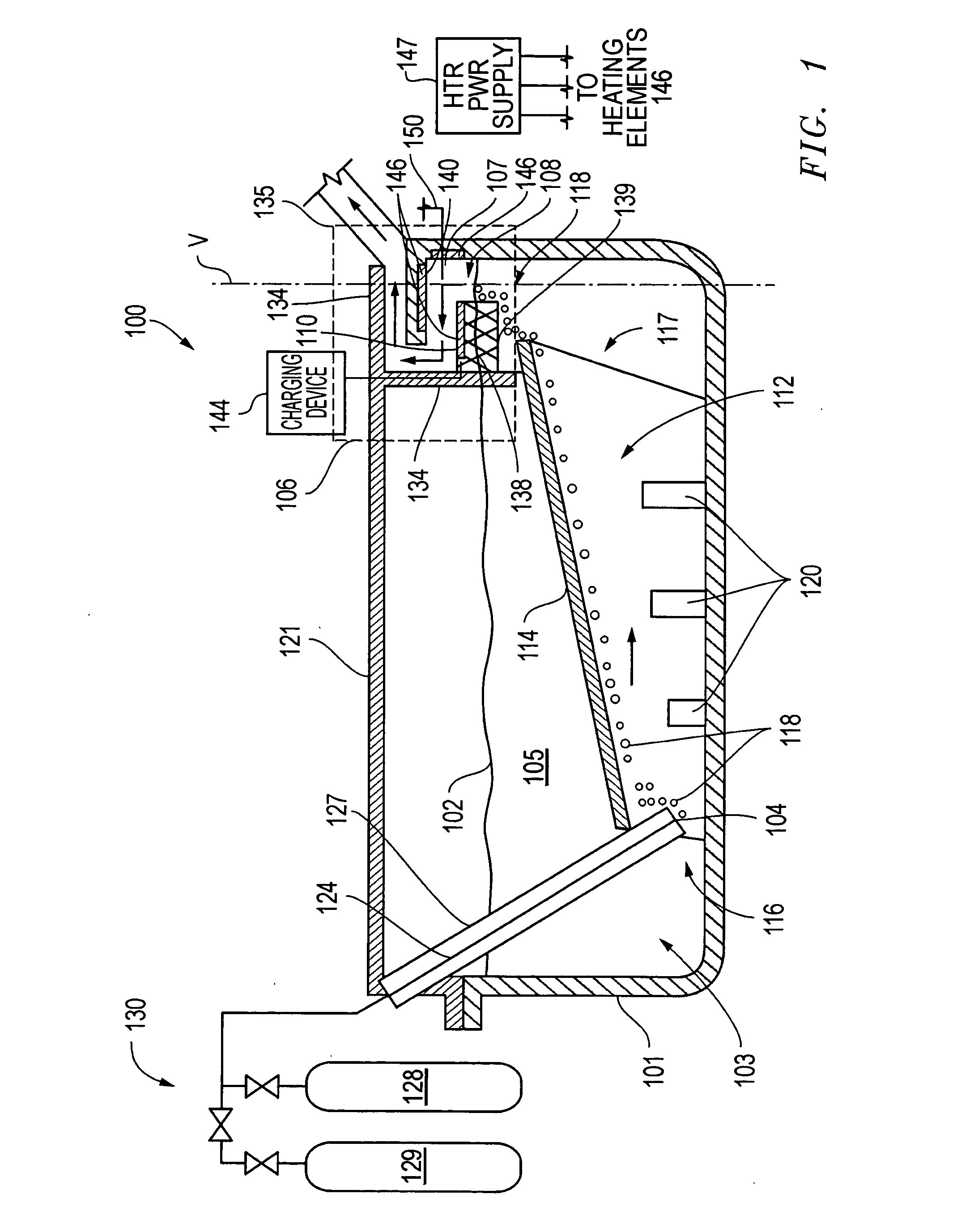

Fused glassy particulates obtained by flame fusion

InactiveUS6254981B1Efficient meltingFast heat transferSynthetic resin layered productsCellulosic plastic layered productsParticulatesSuspended particles

The disclosure describes methods for producing bulk, particulate material that includes solid, generally ellipsoidal particles. Irregularly shaped feed particles with average particle sizes of up to 25 microns on a volume basis are dispersed in at least a portion of a combustible gas mixture by application of force and / or fluidizing agents. The combustible mixture with particles in suspension is then delivered, while controlling agglomeration or re-agglomeration of the particles, to at least one flame front. There, the mixture and suspended particles are uniformly distributed across the surface(s) of and passed through the flame front(s) with a high concentration of particles in the mixture. This flame front and the resultant flame(s) with suspended particles are located in at least one "wall free" zone. In such zone(s) the flame(s) may expand while the particles are maintained in dispersion and heated, with controlled and highly efficient application of heating energy. At least partial fusion occurs within at least the surfaces of the particles at high thermal efficiencies, while agglomeration of particles during fusion is inhibited.

Owner:3M CO

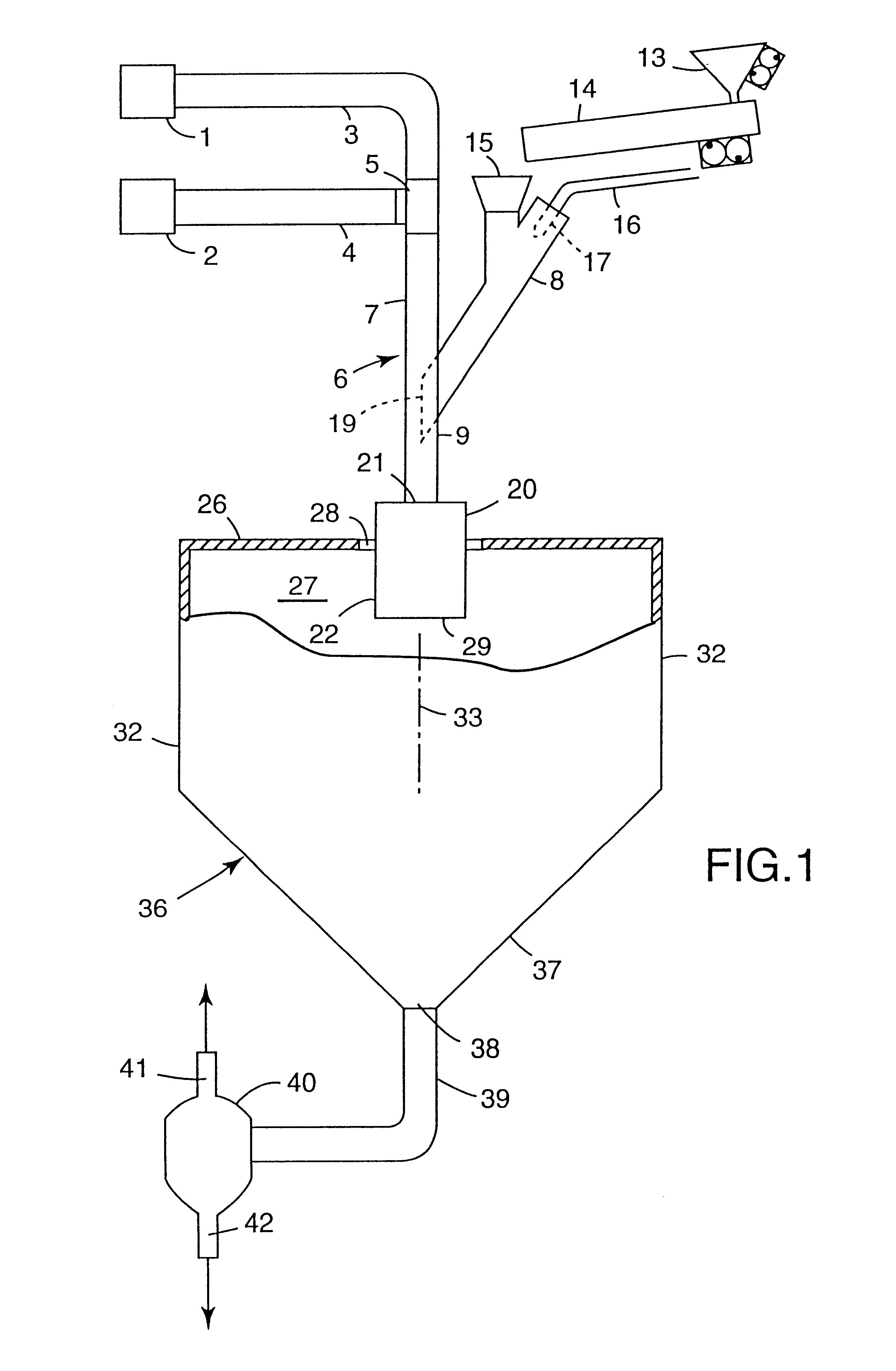

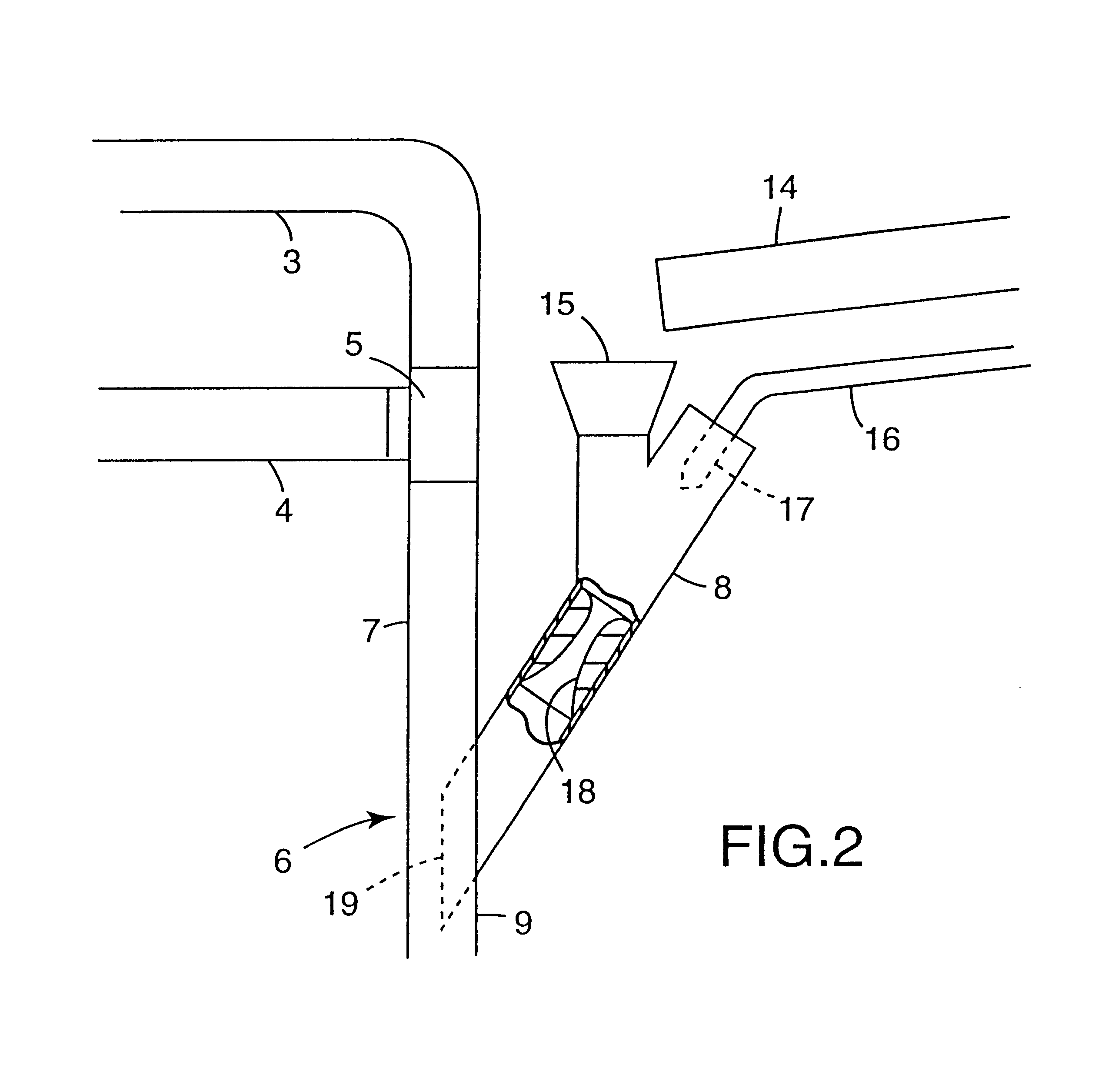

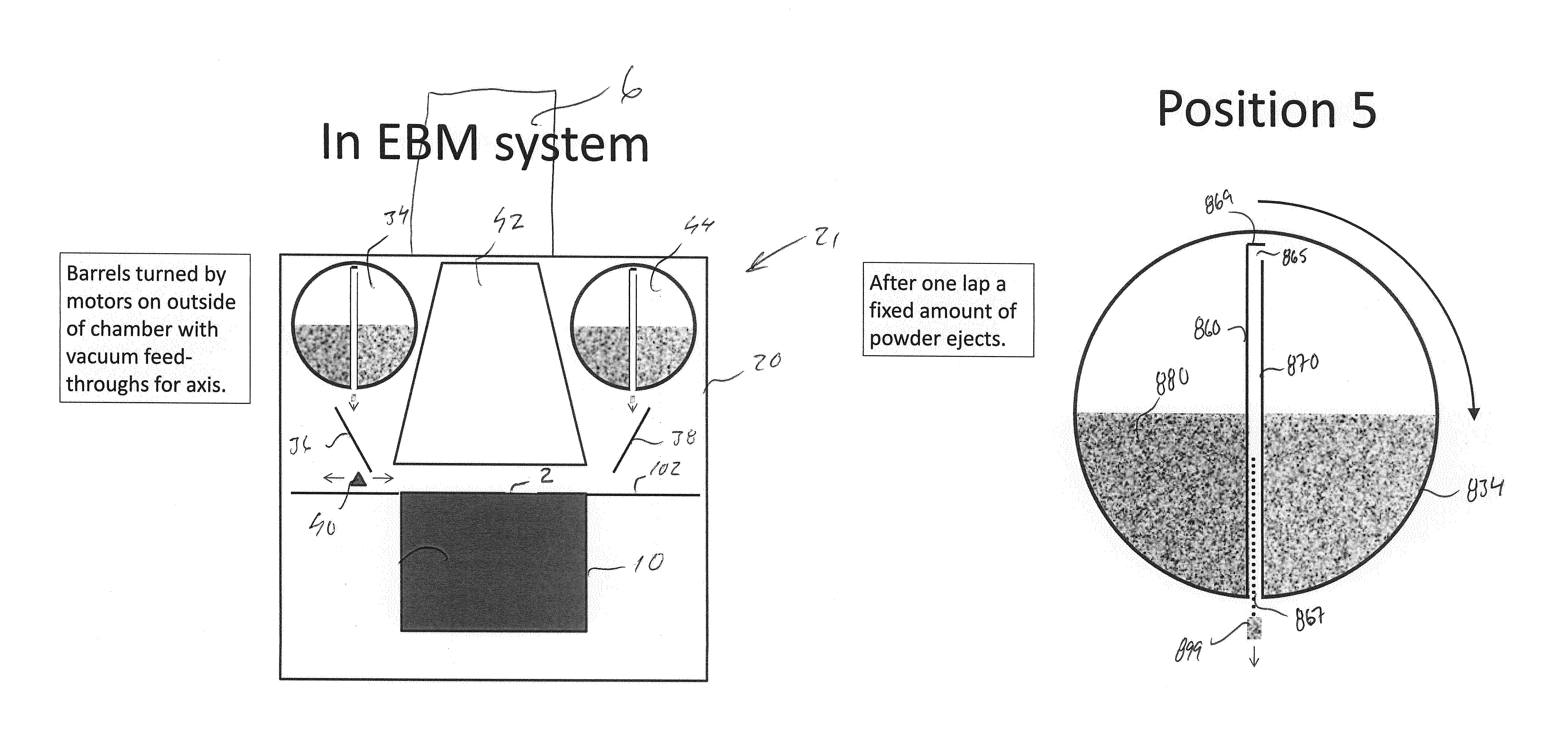

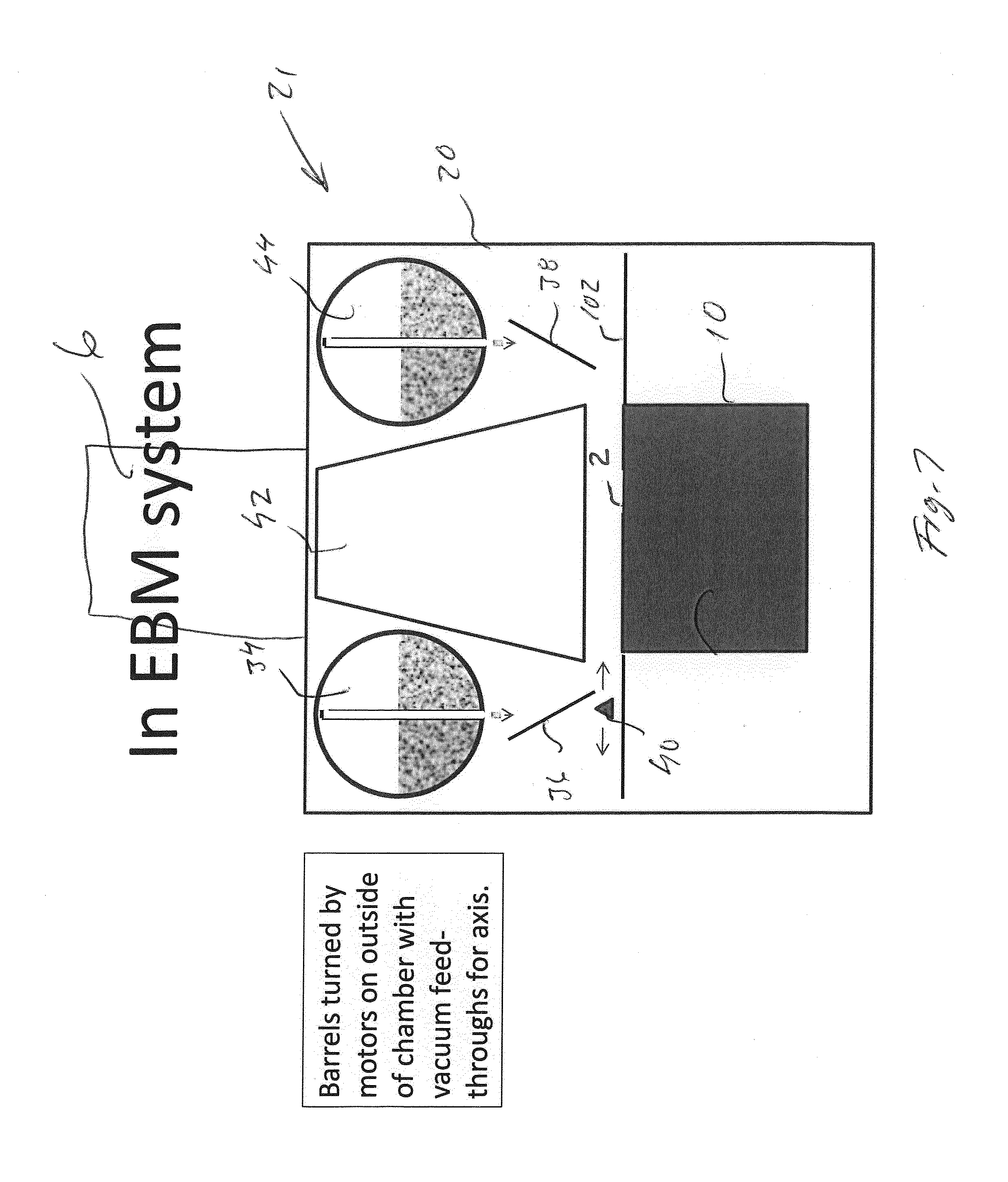

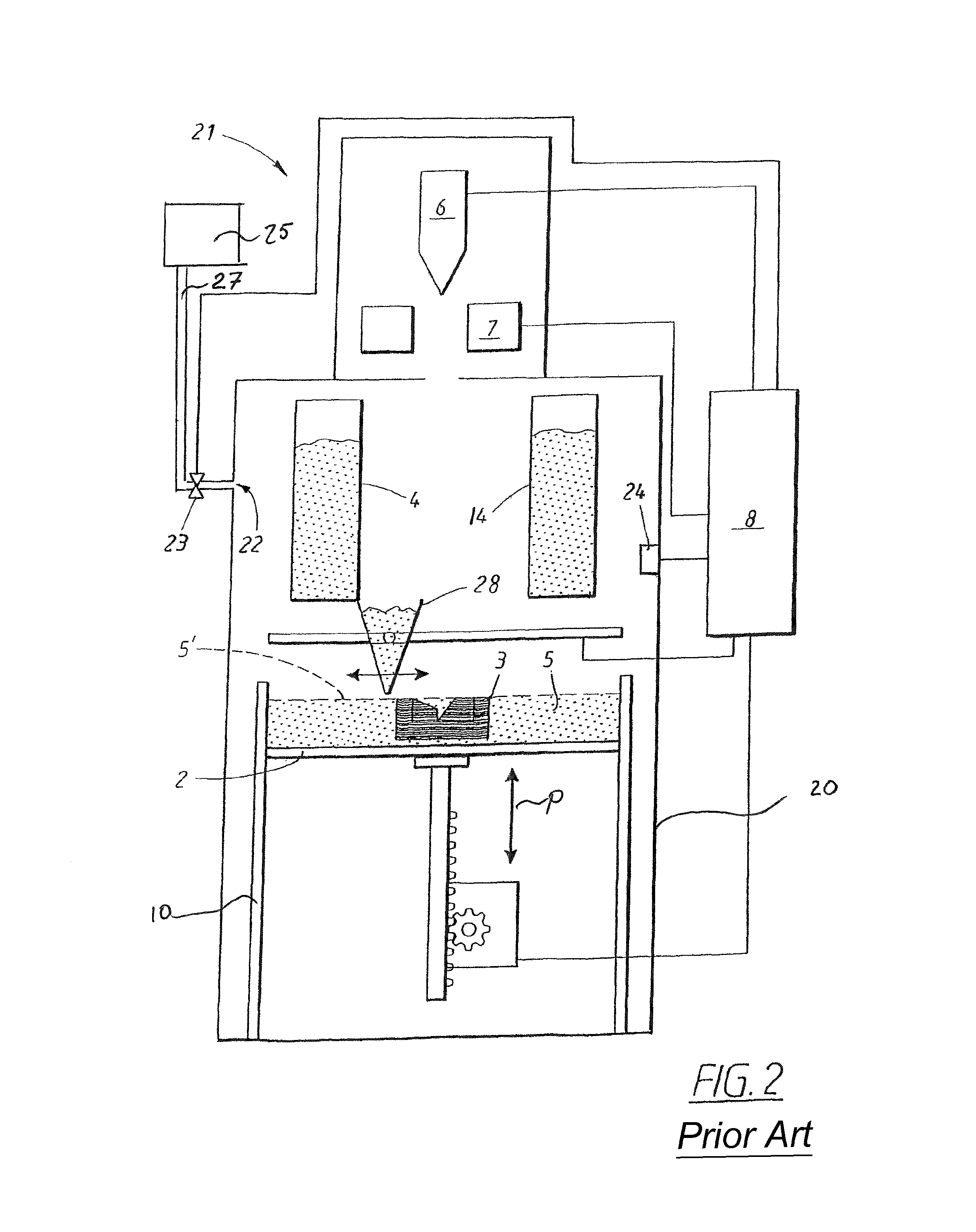

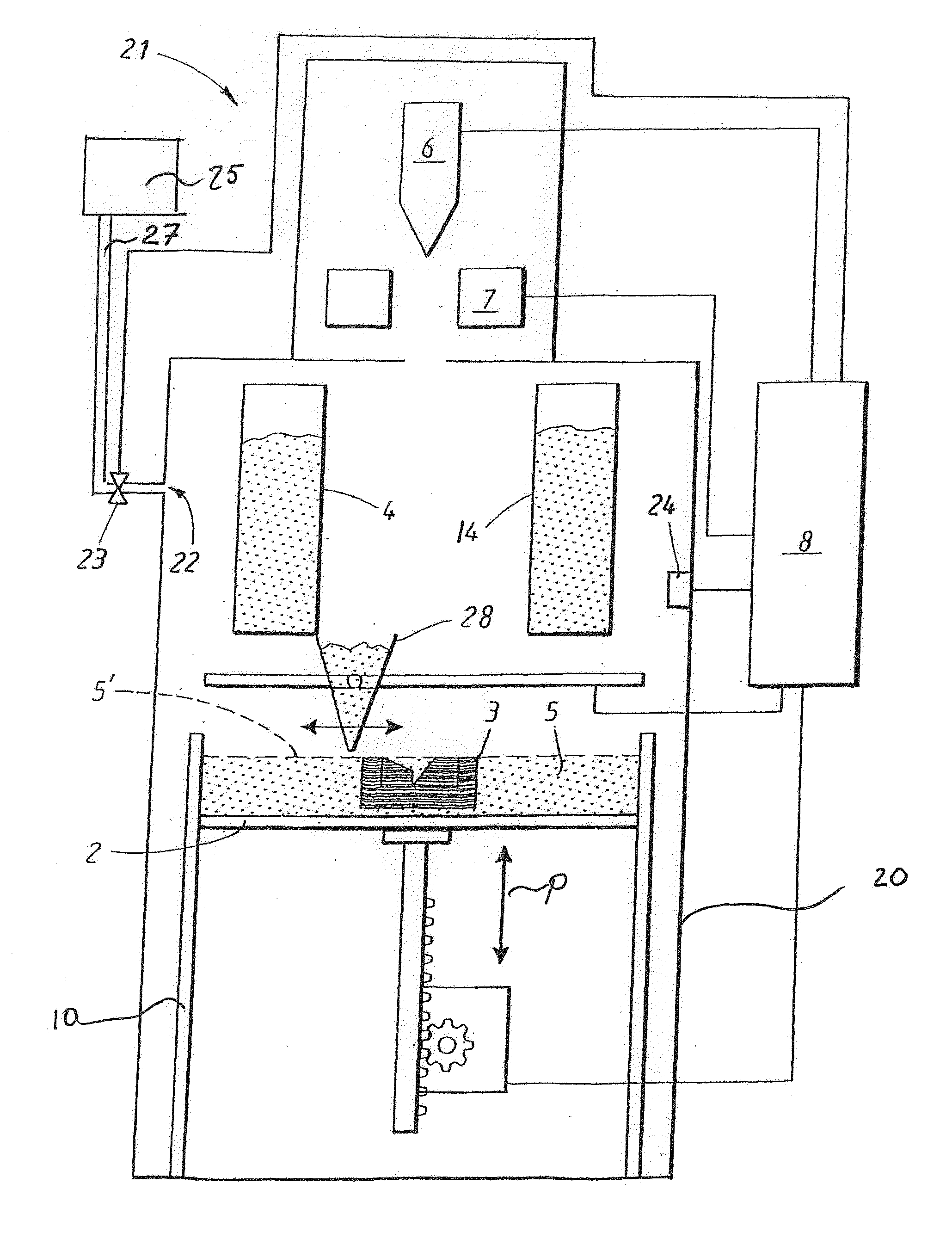

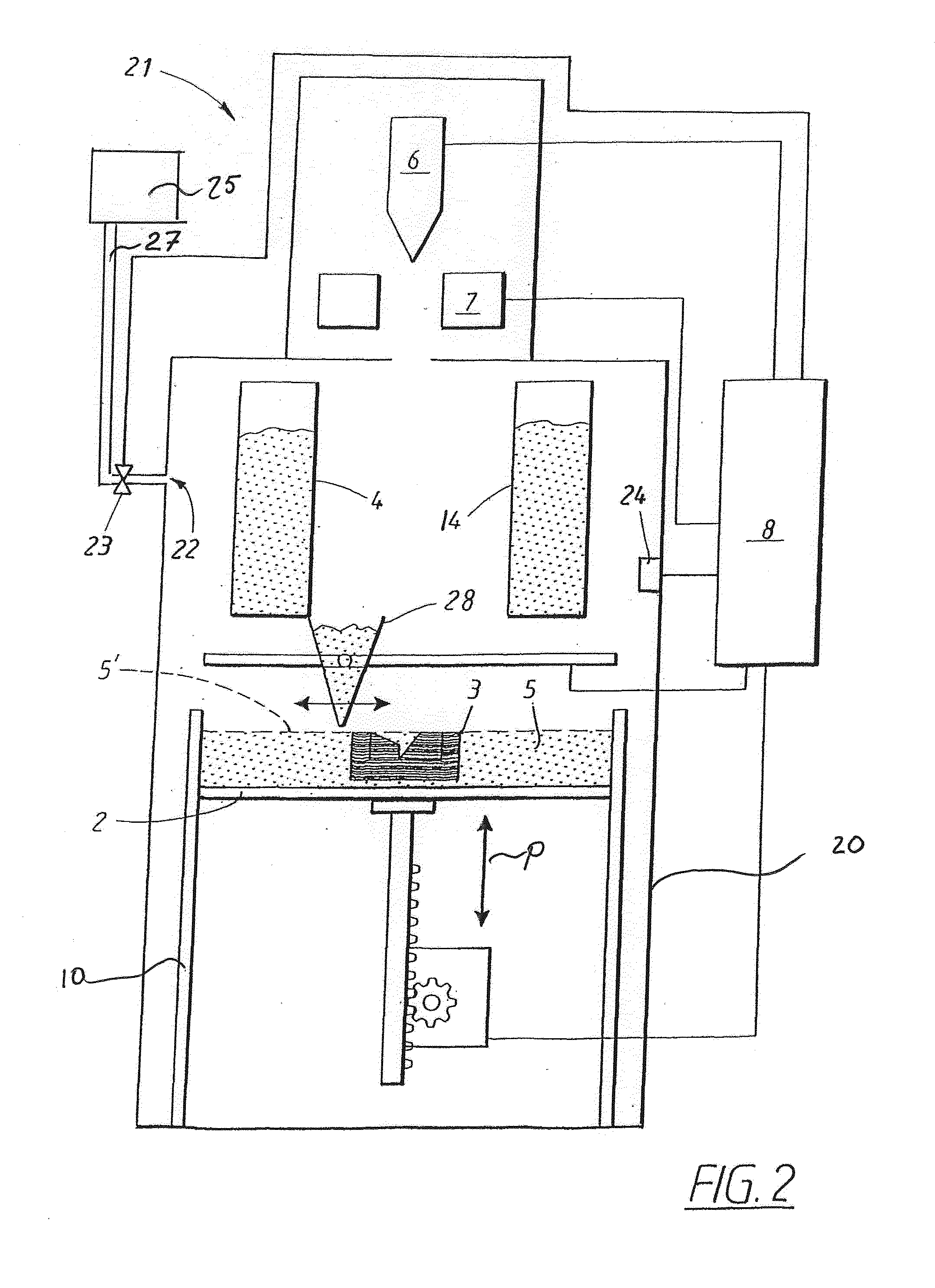

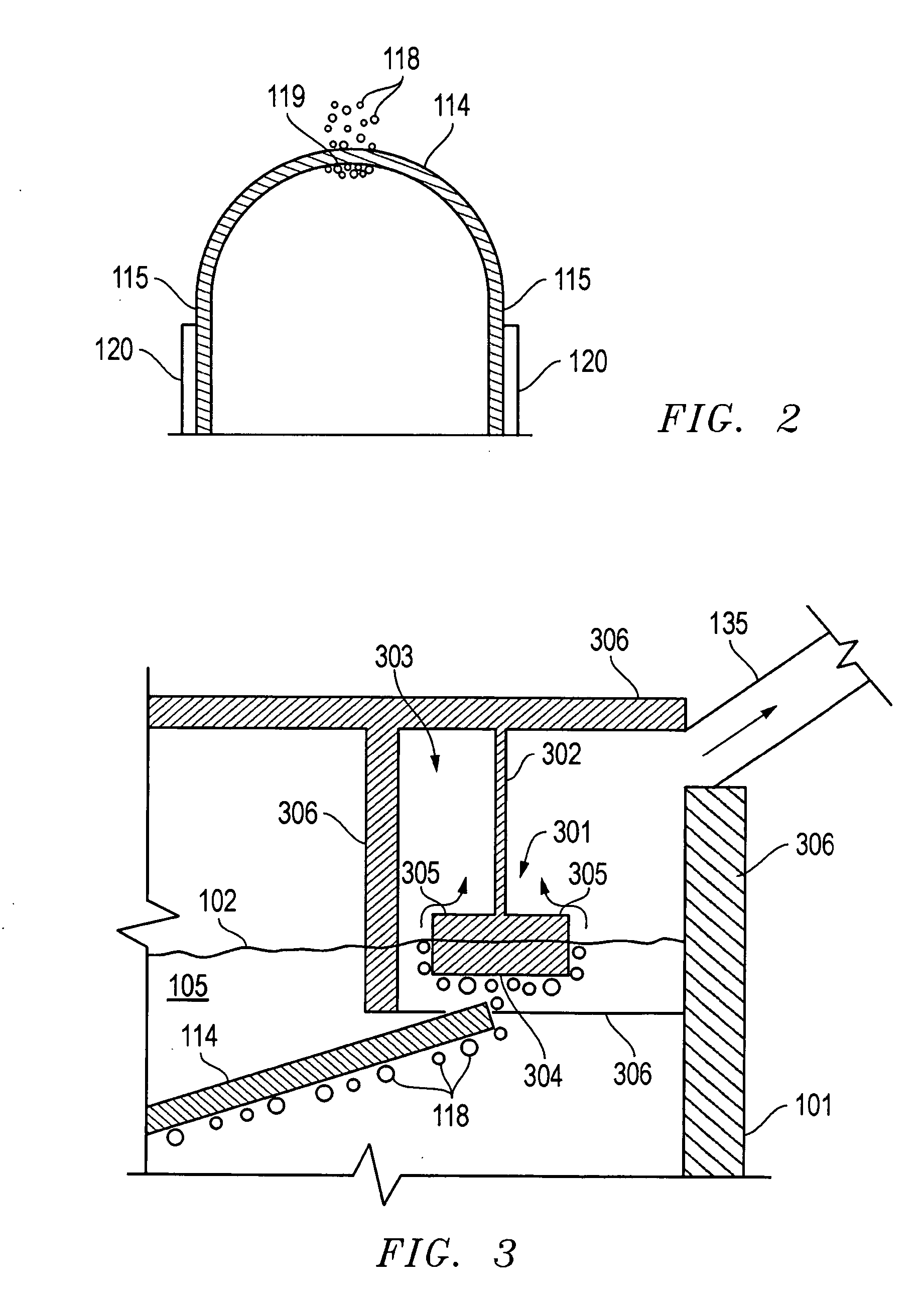

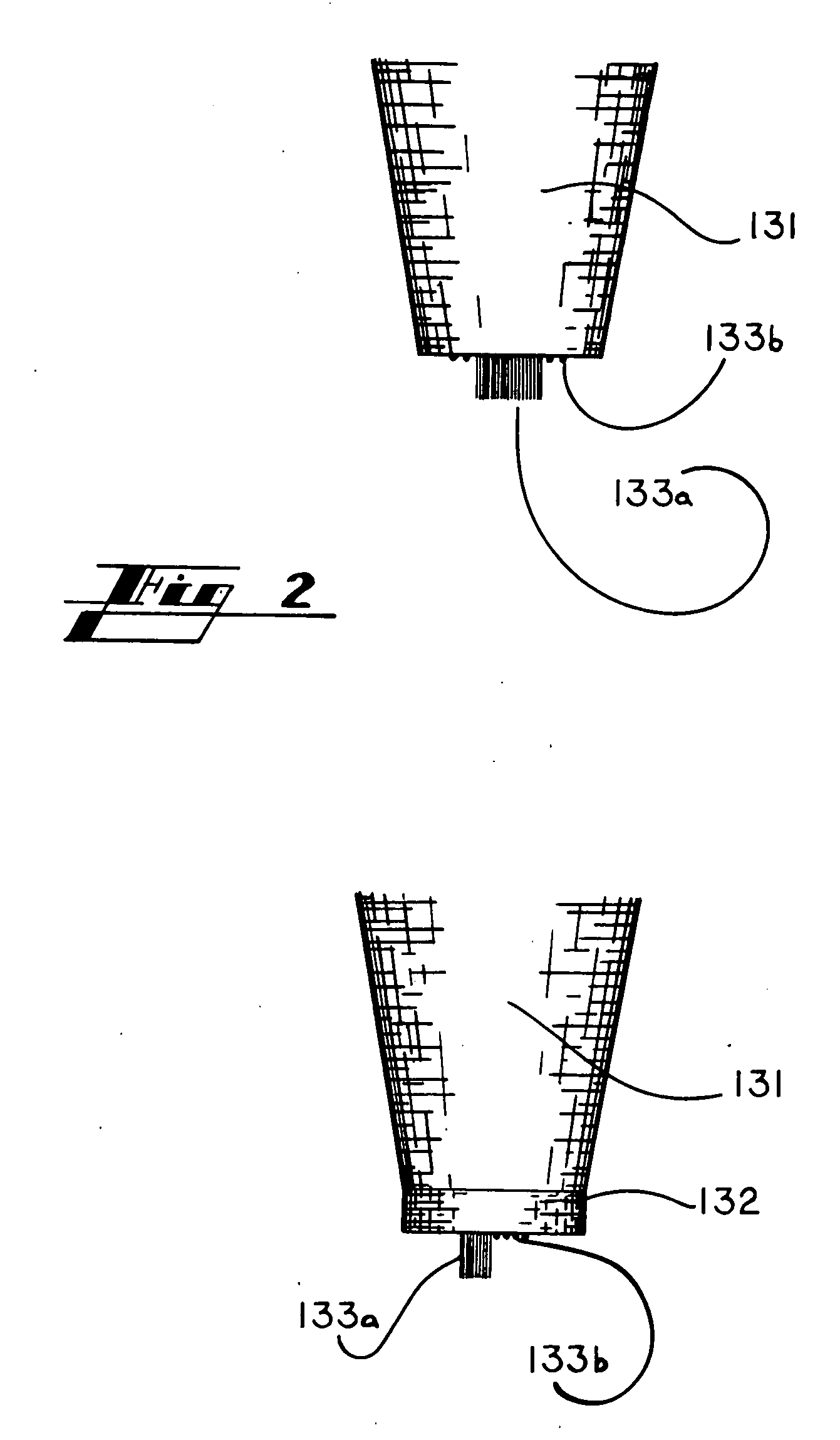

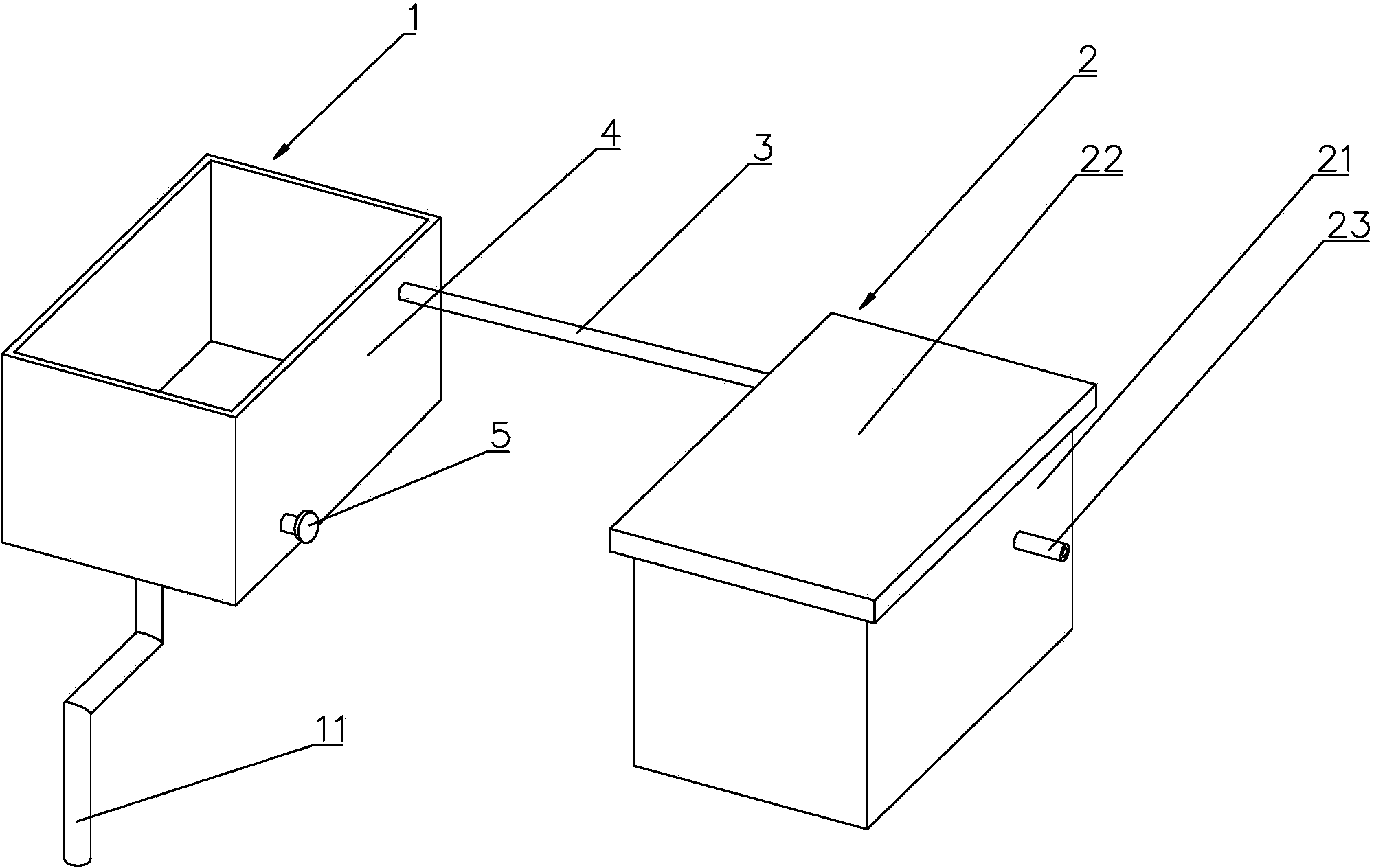

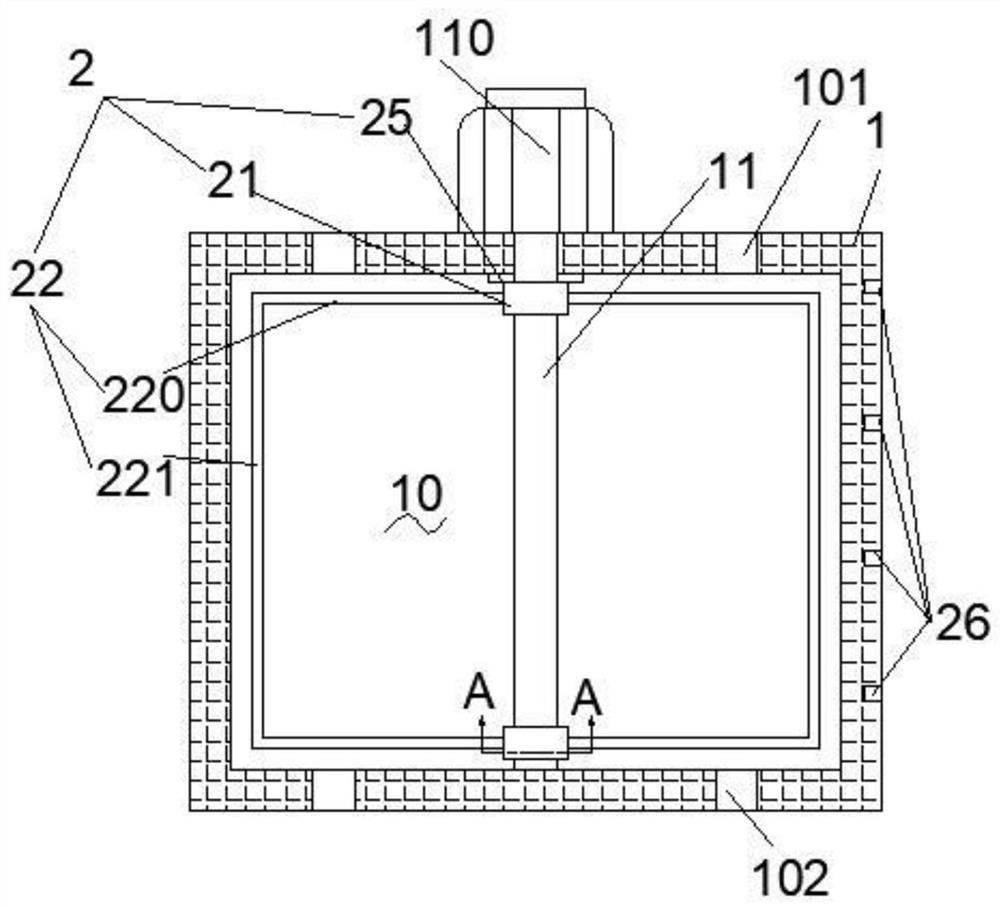

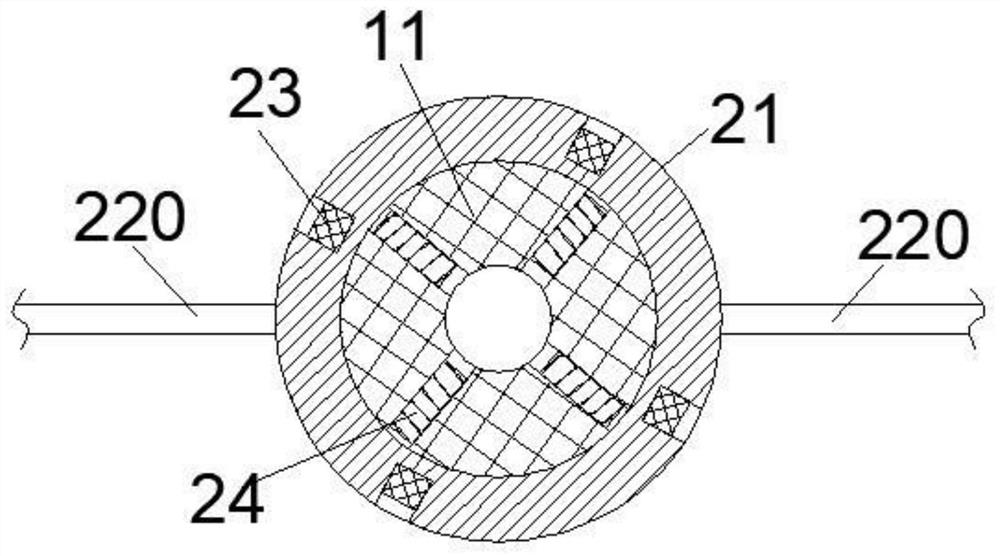

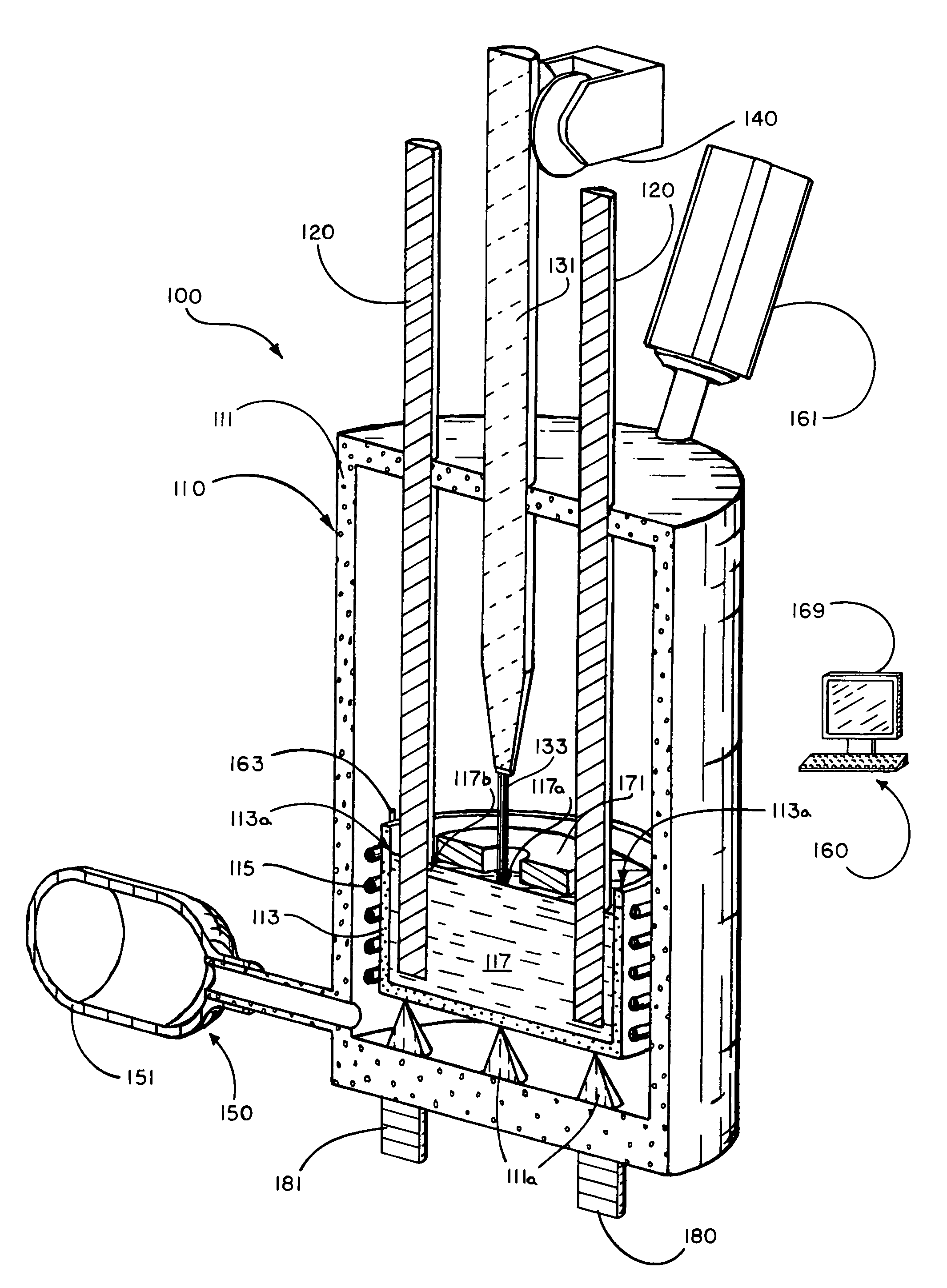

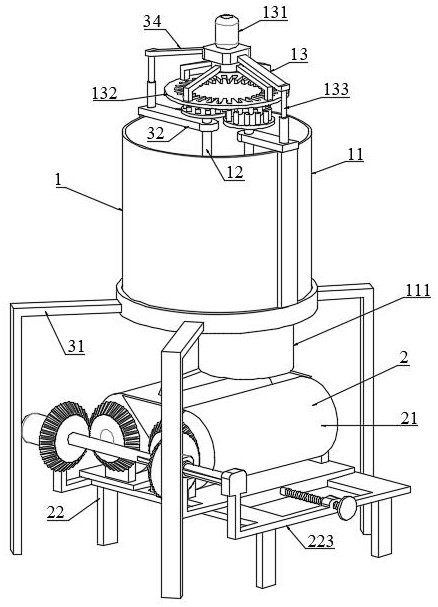

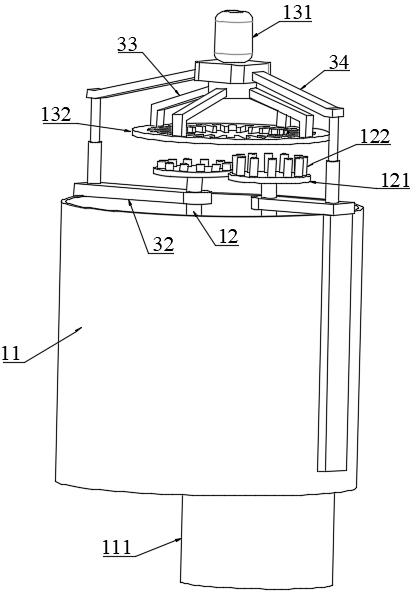

Powder distribution in additive manufacturing

ActiveUS9126167B2Good repeatabilityManufacturing heating elementsIncreasing energy efficiencyMetallurgyDistributor

An additive manufacturing method for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table. Providing at least one rotatable powder container above said work table, said powder container comprising at least one exit for providing powder to a powder table arranged beside said work table, at least one opening inside said container is spatially separated from and connected to said at least one exit. Ejecting a fixed amount of powder from said powder container during at least one predetermined segment of rotational angles of said powder container, from the exit of said powder container onto said powder table, wherein said fixed amount is determined by the shape and size of the at least one opening inside said container. Distributing said powder onto said work table with a powder distributor.

Owner:ARCAM AB

Powder distribution in additive manufacturing

ActiveUS20150054191A1Good repeatabilityConfectioneryManufacturing heating elementsMetallurgyDistributor

An additive manufacturing method for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table. Providing at least one rotatable powder container above said work table, said powder container comprising at least one exit for providing powder to a powder table arranged beside said work table, at least one opening inside said container is spatially separated from and connected to said at least one exit. Ejecting a fixed amount of powder from said powder container during at least one predetermined segment of rotational angles of said powder container, from the exit of said powder container onto said powder table, wherein said fixed amount is determined by the shape and size of the at least one opening inside said container. Distributing said powder onto said work table with a powder distributor.

Owner:ARCAM AB

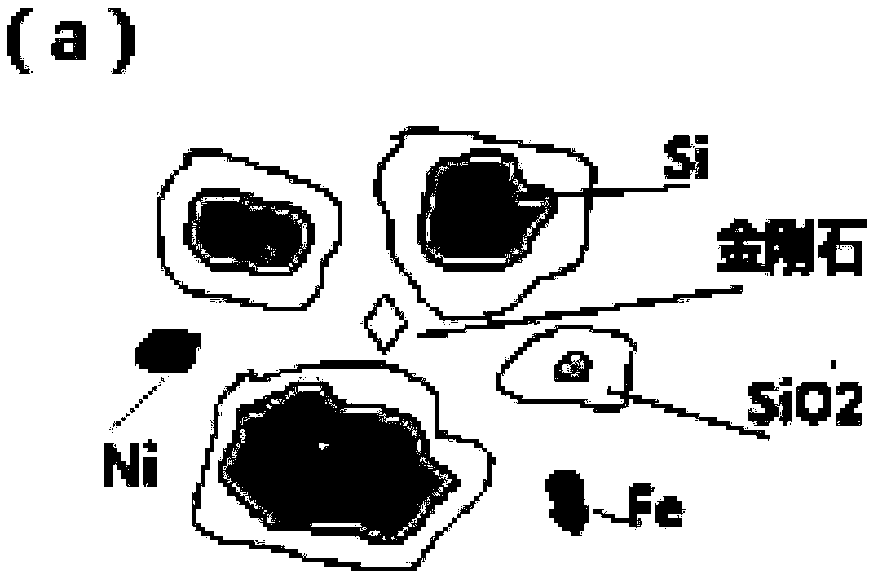

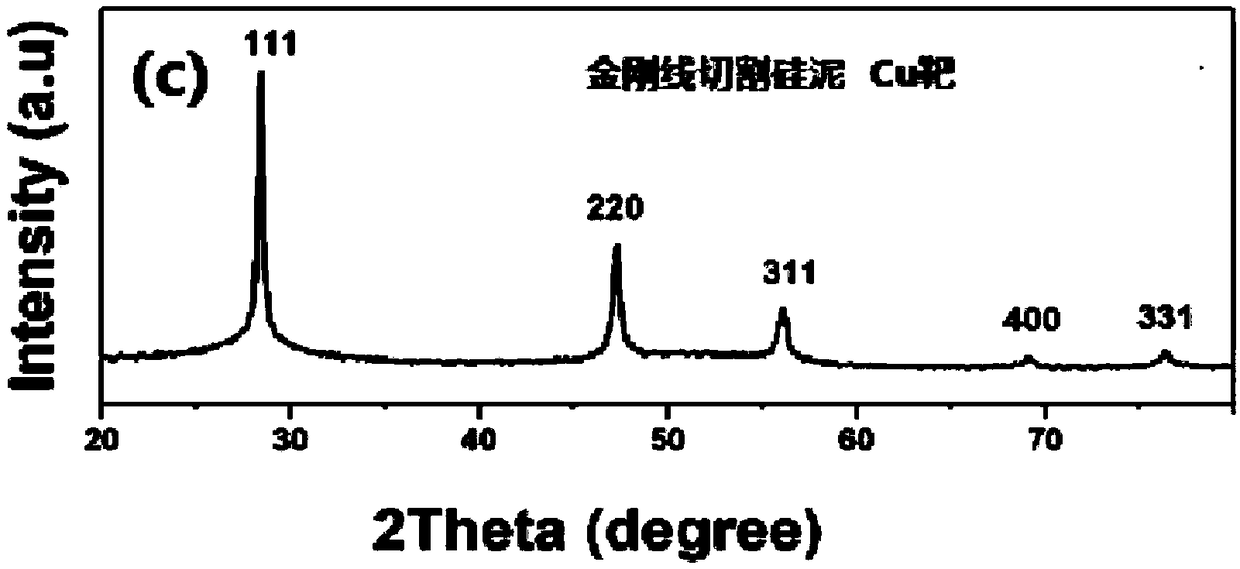

Method and device for producing silicon monoxide

ActiveCN108821292ASimple processShort processSilicon oxidesPressure vessel componentsSilicon monoxideSilicon oxygen

The invention provides a method and device for producing silicon monoxide. The method disclosed by the invention is mainly characterized in that a silicon-containing substance such as silicon oxide, monatomic silicon, silicon-containing gas (liquid) , and non-completely oxidized silicon, particularly dried solid silicon powder separated from diamond wire silicon cutting waste slurry is subjected to further oxidation (including incomplete oxidation), reduction or addition of silicon dioxide to approach to an ideal ratio of generation of silicon monoxide, and then a silicon monoxide gas is formed under a condition facilitating overflow of silicon monoxide, and then the gas is condensed into rod-shaped, plate-shaped, granular or powdery silicon monoxide. In one embodiment, an oxide layer (SiO2) on the surface of silicon particles (Si) is controlled, so that a silicon monoxide precursor can be prepared, and the preparation process can be oxidization of the silicon or reduction of overly-oxidized silicon-oxygen compounds, and optionally, in another embodiment of the present application, a silicon monoxide powder can be directly produced by utilizing incomplete oxidation of a silicon-containing gas.

Owner:储晞

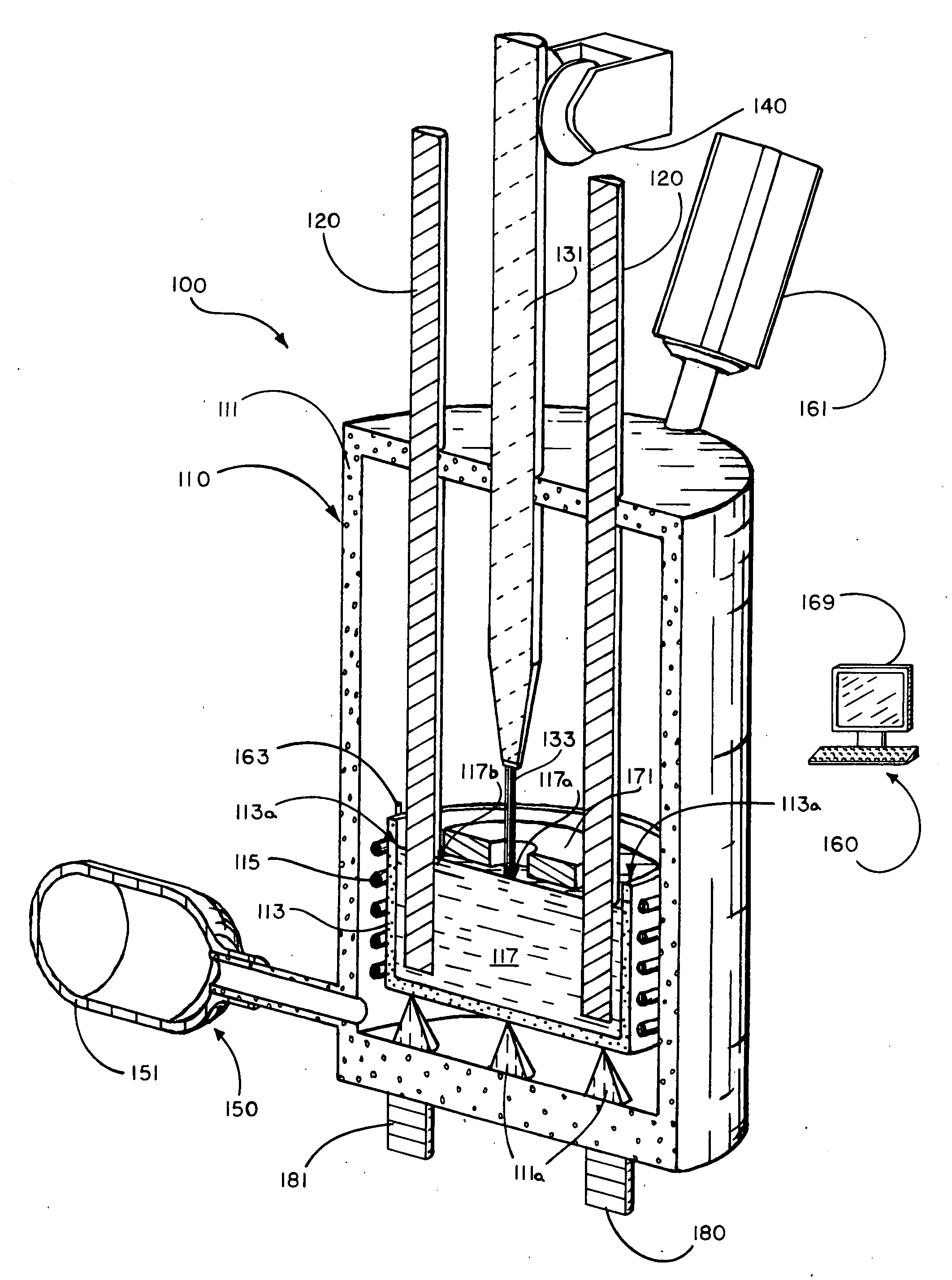

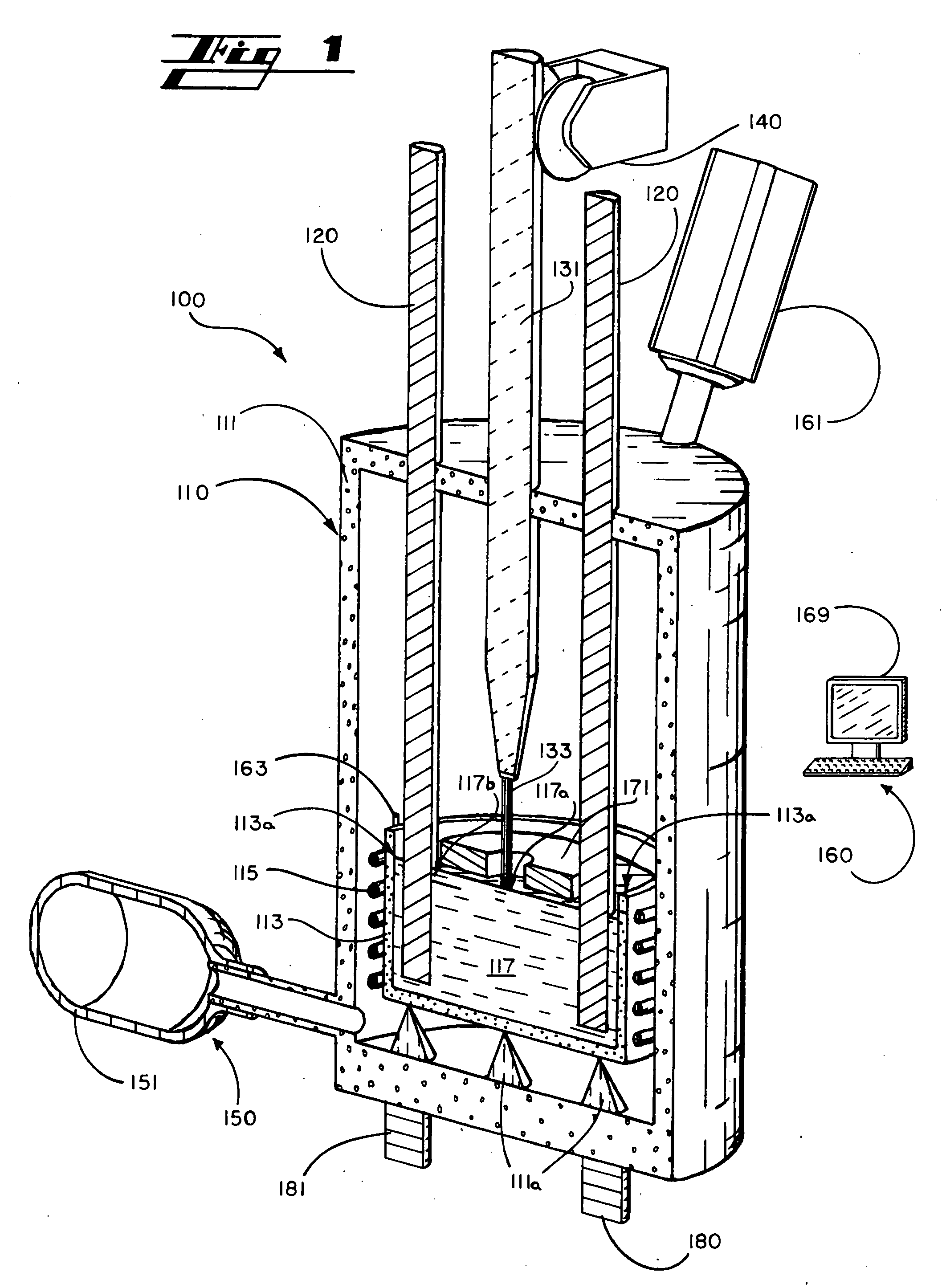

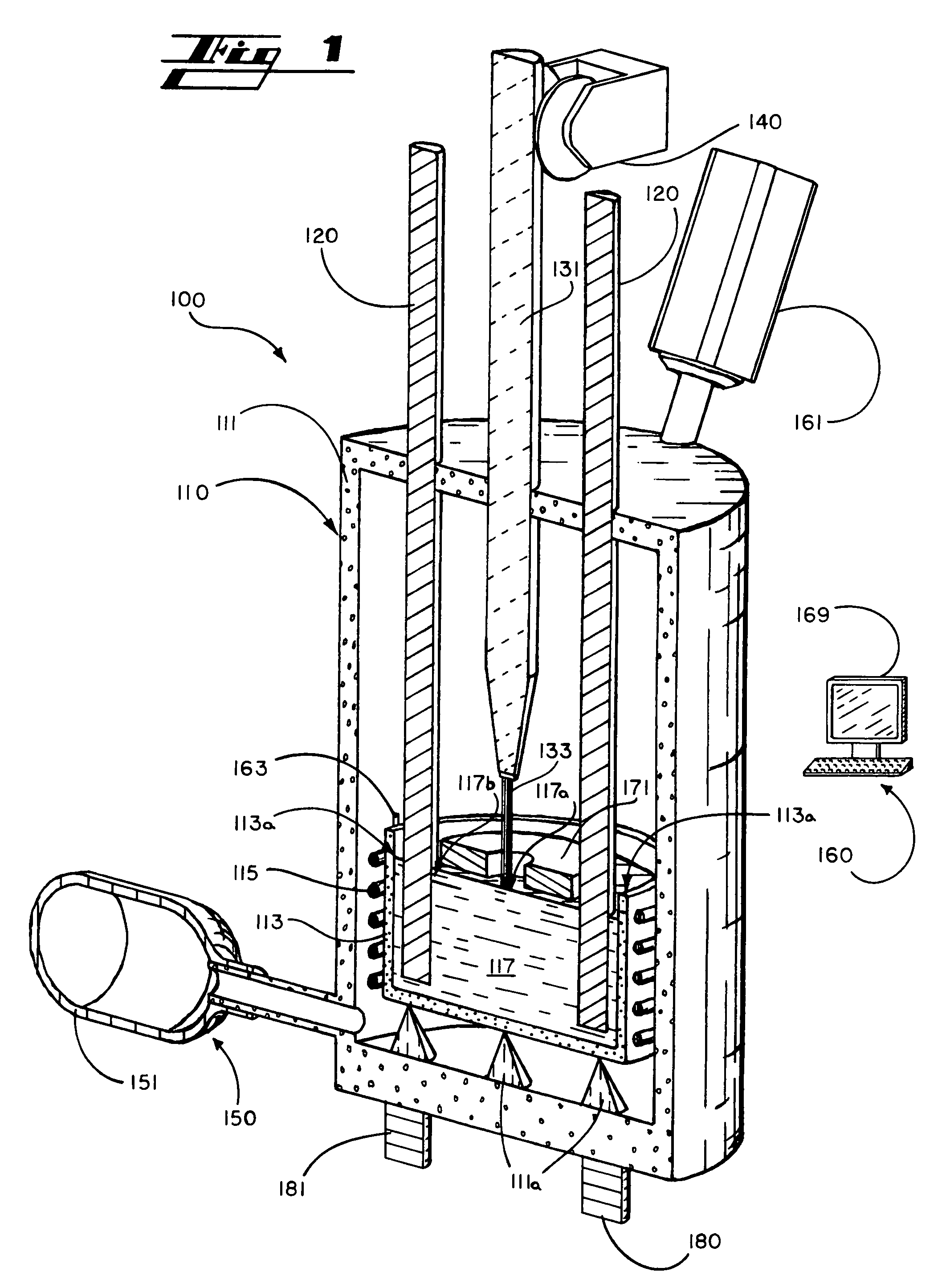

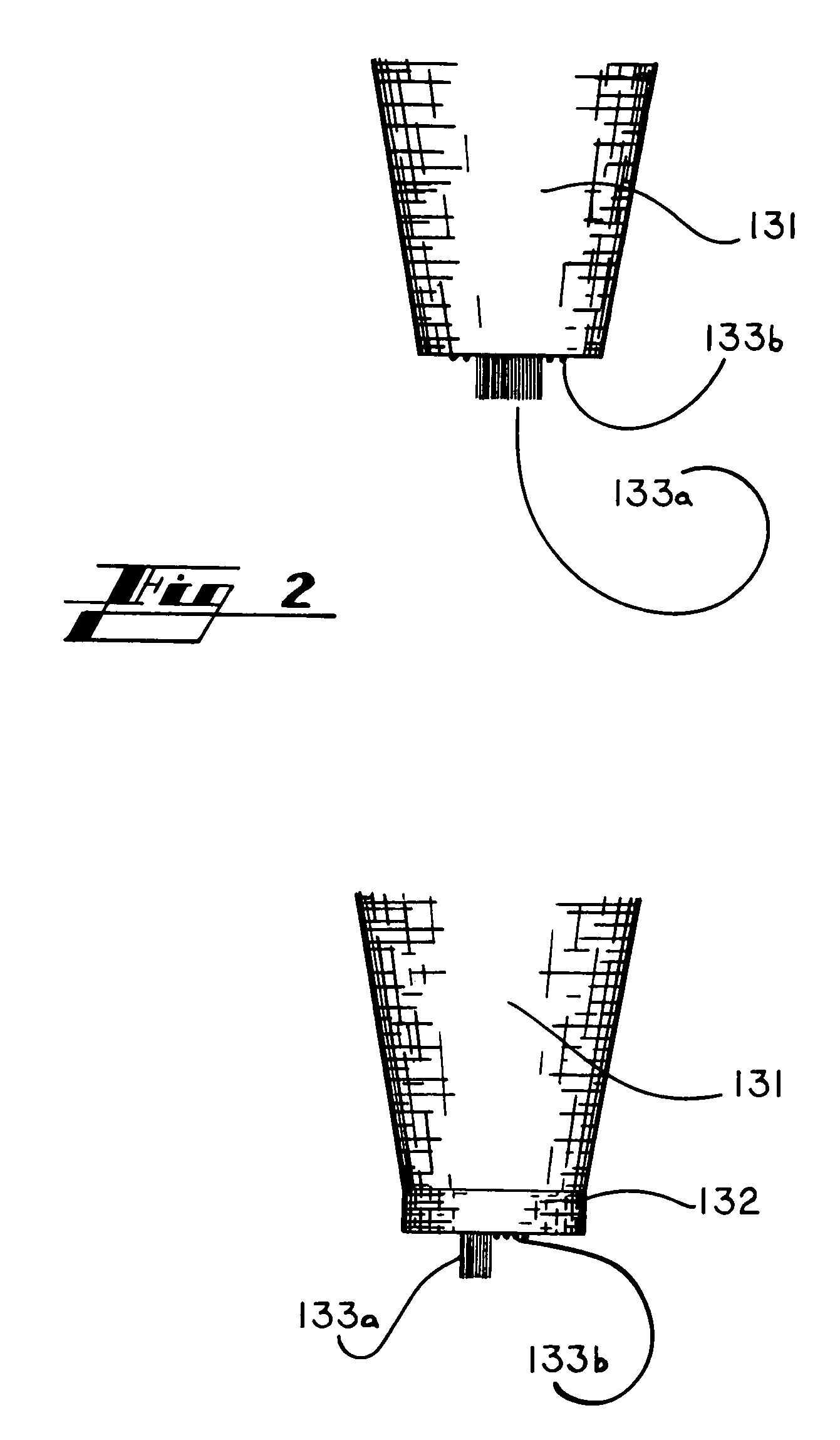

Method and apparatus for preparing a collection surface for use in producing carbon nanostructures

A method includes producing deposition conditions in a collection area above a reactant liquid containing one or more catalyst metals. The reactant liquid is maintained under conditions in which atoms of the catalyst metal may escape from the reactant liquid into the collection area. A suitable carrier gas is directed to traverse a surface of the reactant liquid and flow along a collection path that passes over a collection surface in the collection area. This flow of carrier gas is maintained so that escaped atoms of catalyst metal are entrained in the gas traversing the surface of the reactant liquid and are deposited on the prior to or concurrently with nanocarbon structure formation at the collection surface.

Owner:CLEAN TECH INT

System and method for manufacturing carbon nanotubes

InactiveUS20090311168A1Allow for manufactureLow costMaterial nanotechnologyNanostructure manufactureMulti-Walled NanotubeBCN nanotube

Owner:DUVALL GIDEON

Method and apparatus for preparing a collection surface for use in producing carbon nanostructures

A method includes producing deposition conditions in a collection area above a reactant liquid containing one or more catalyst metals. The reactant liquid is maintained under conditions in which atoms of the catalyst metal may escape from the reactant liquid into the collection area. A suitable carrier gas is directed to traverse a surface of the reactant liquid and flow along a collection path that passes over a collection surface in the collection area. This flow of carrier gas is maintained so that escaped atoms of catalyst metal are entrained in the gas traversing the surface of the reactant liquid and are deposited on the collection surface prior to or concurrently with nanocarbon structure formation at the collection surface.

Owner:CLEAN TECH INT

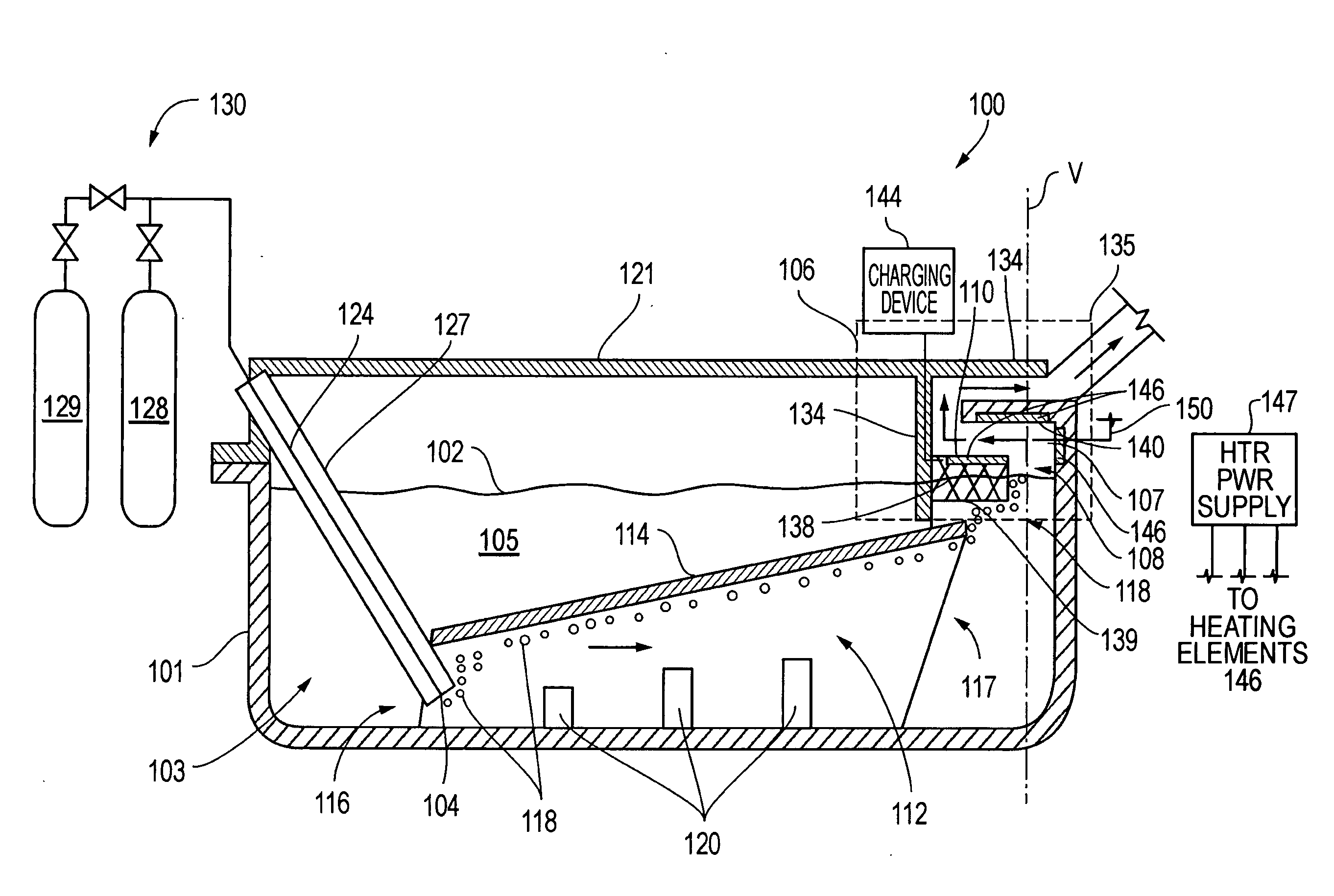

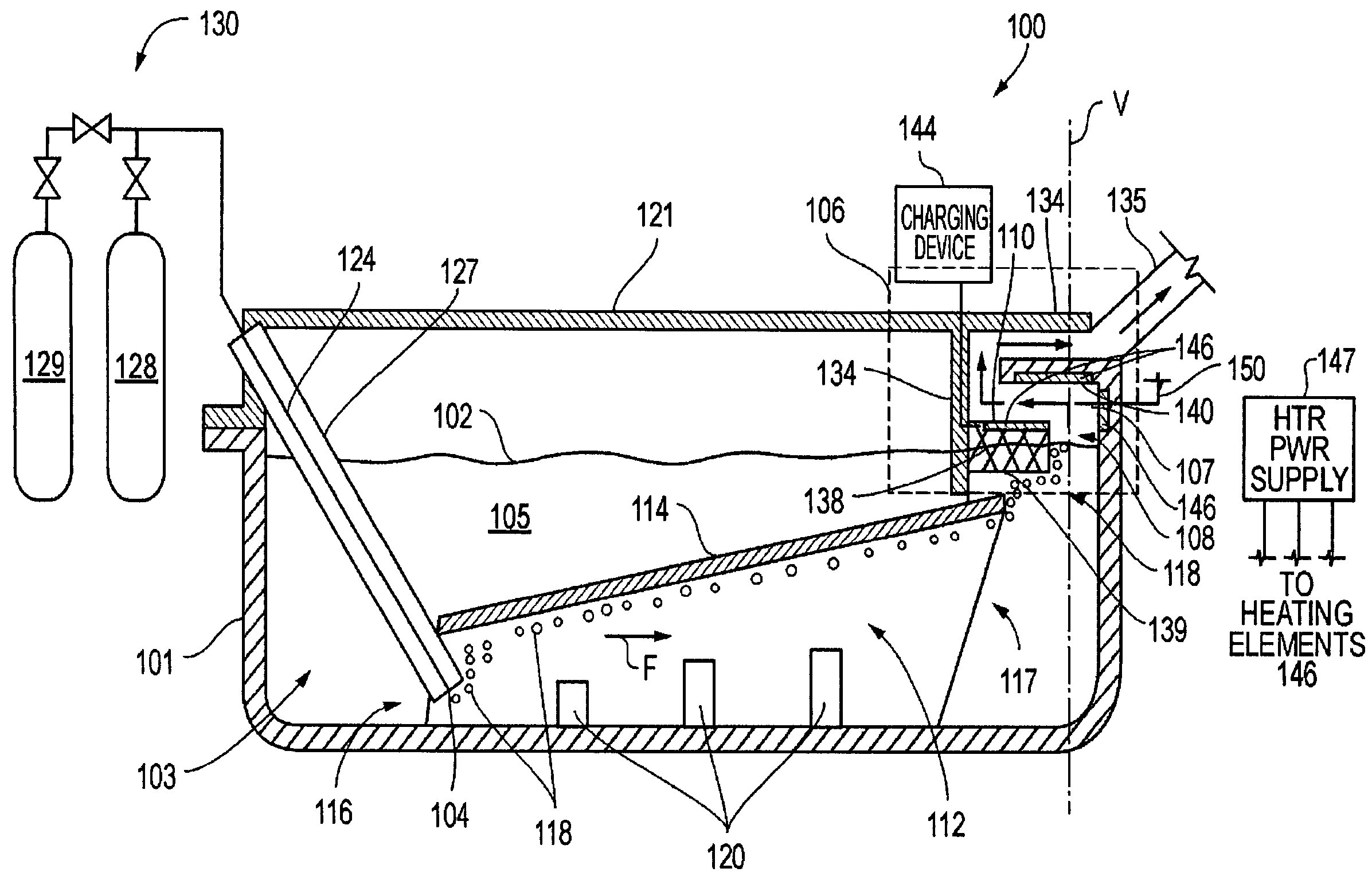

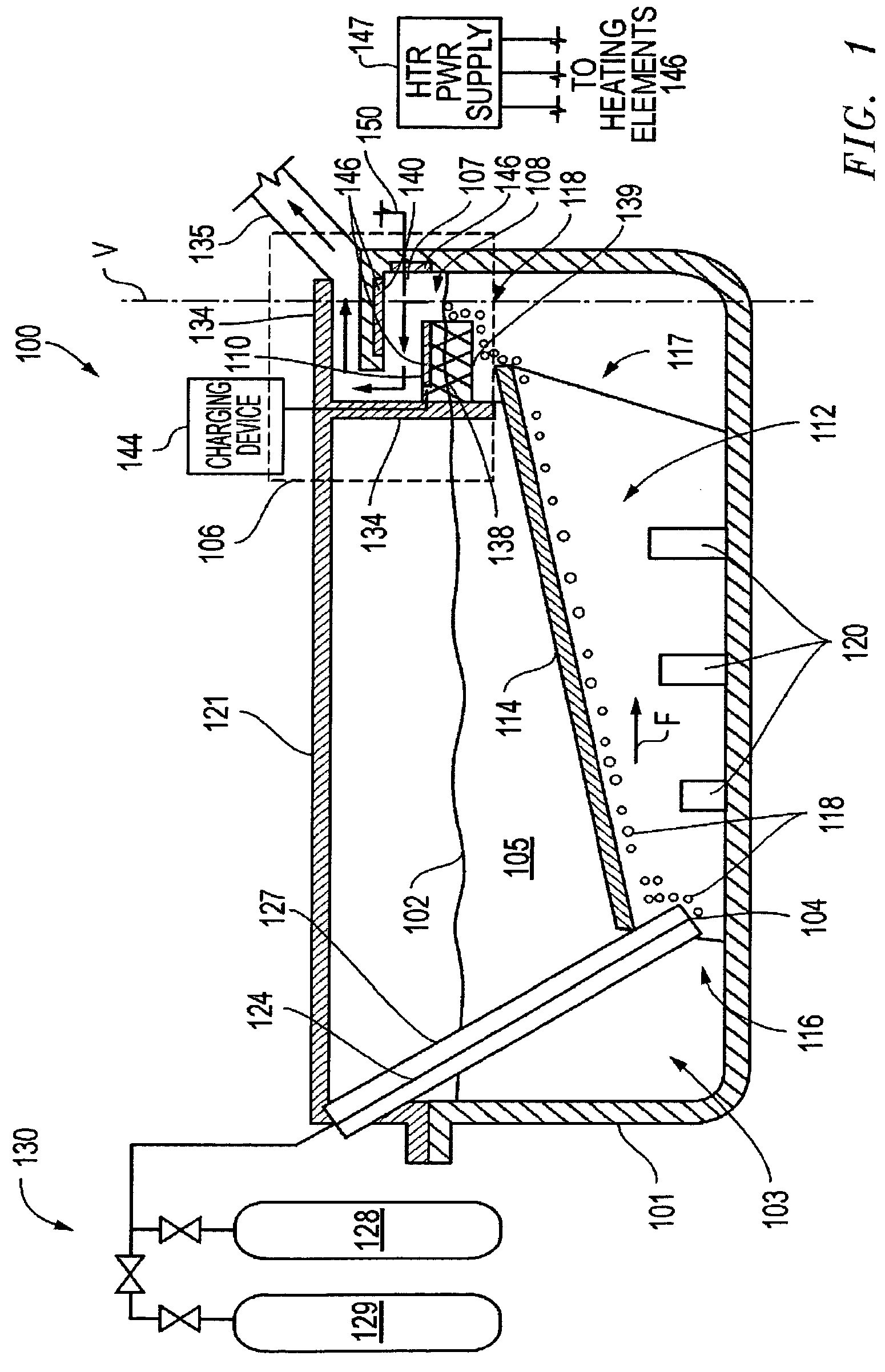

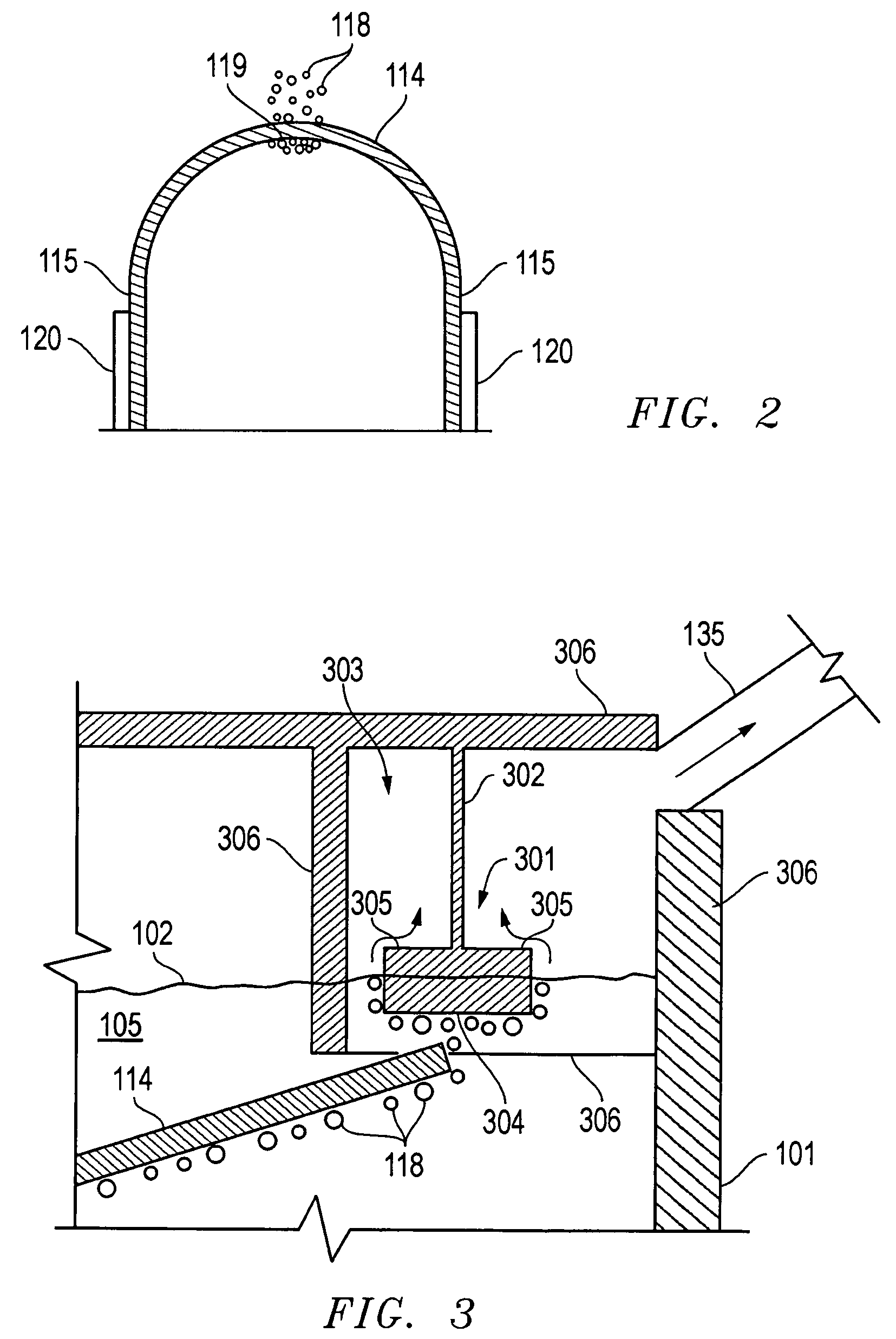

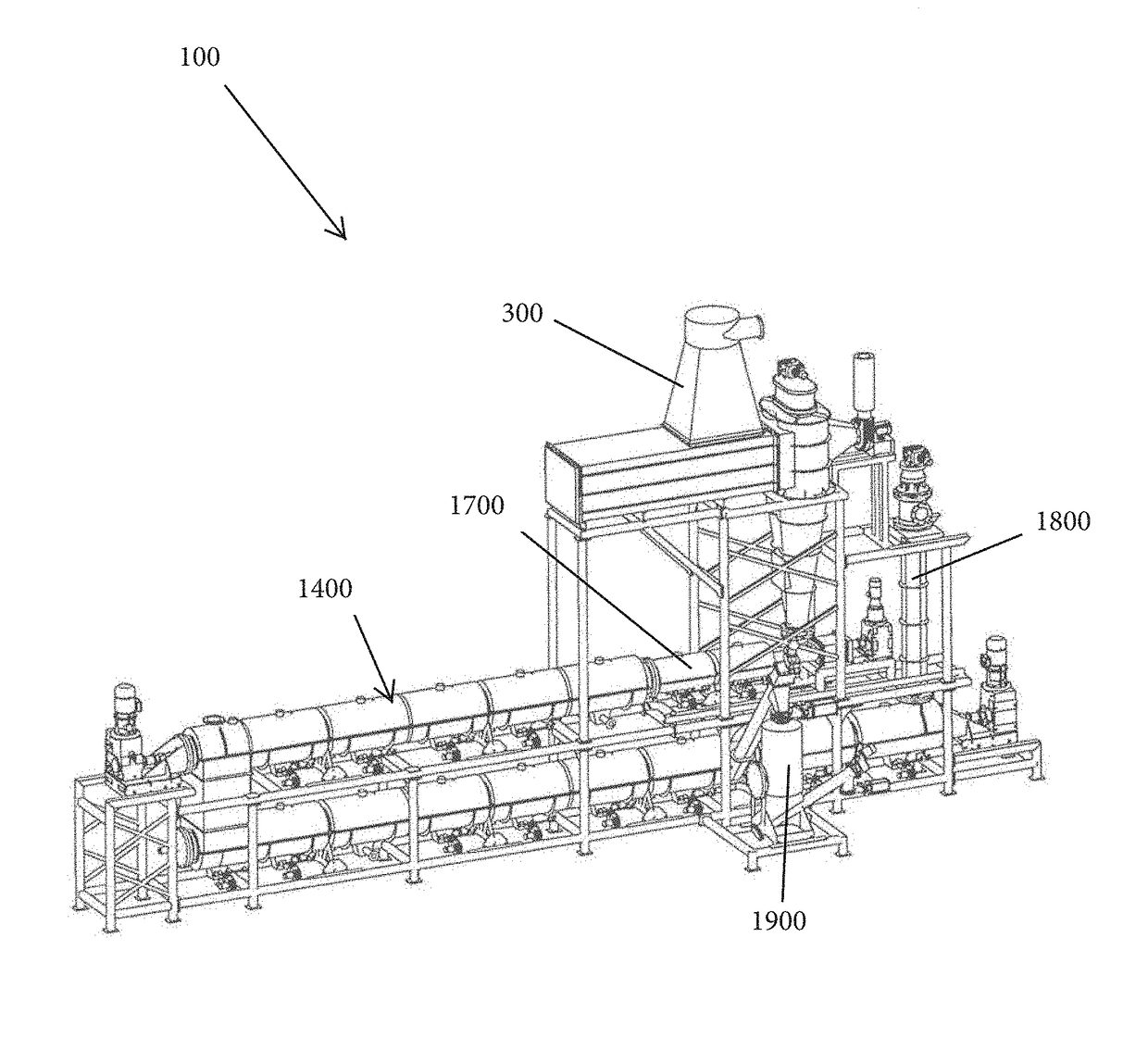

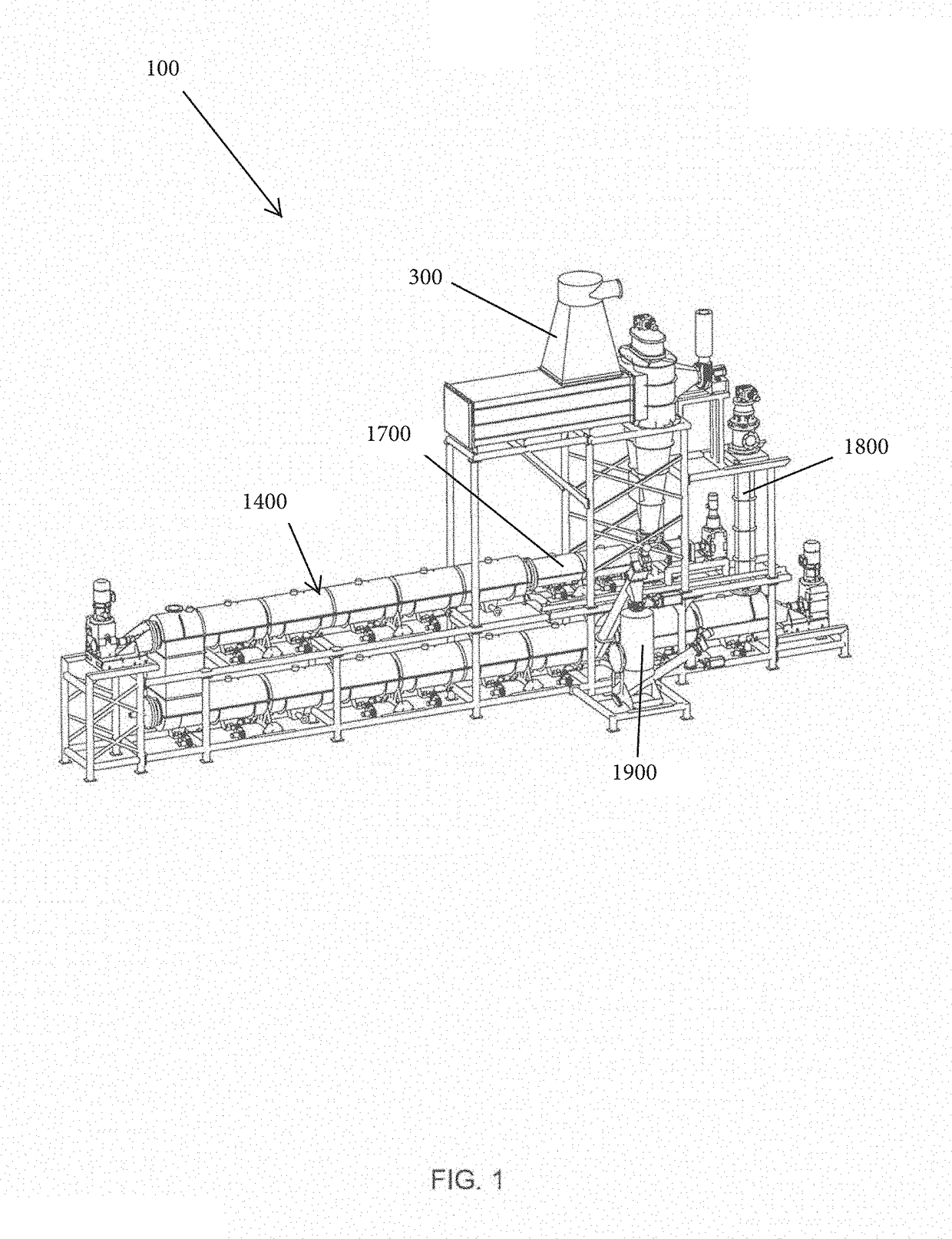

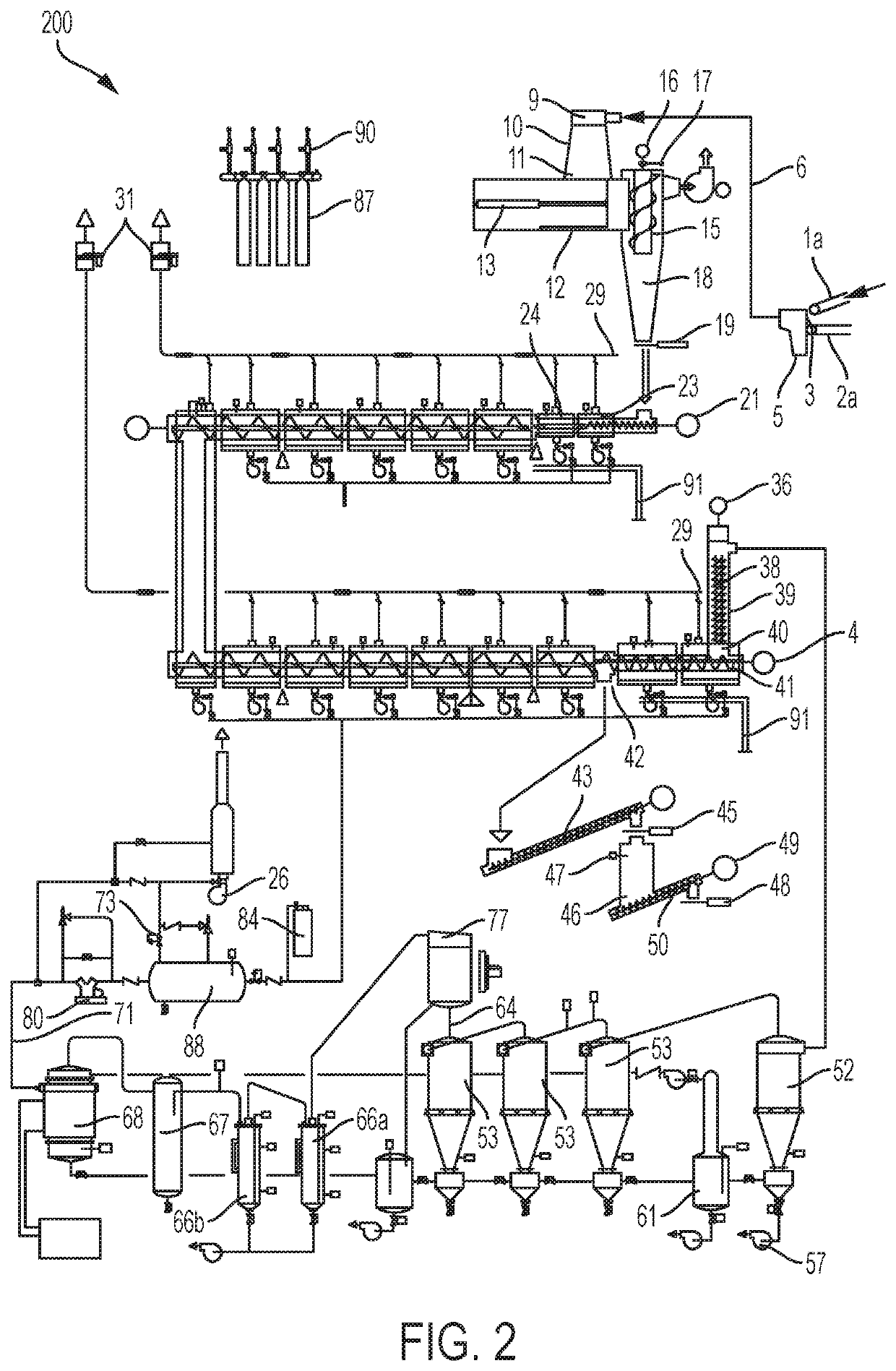

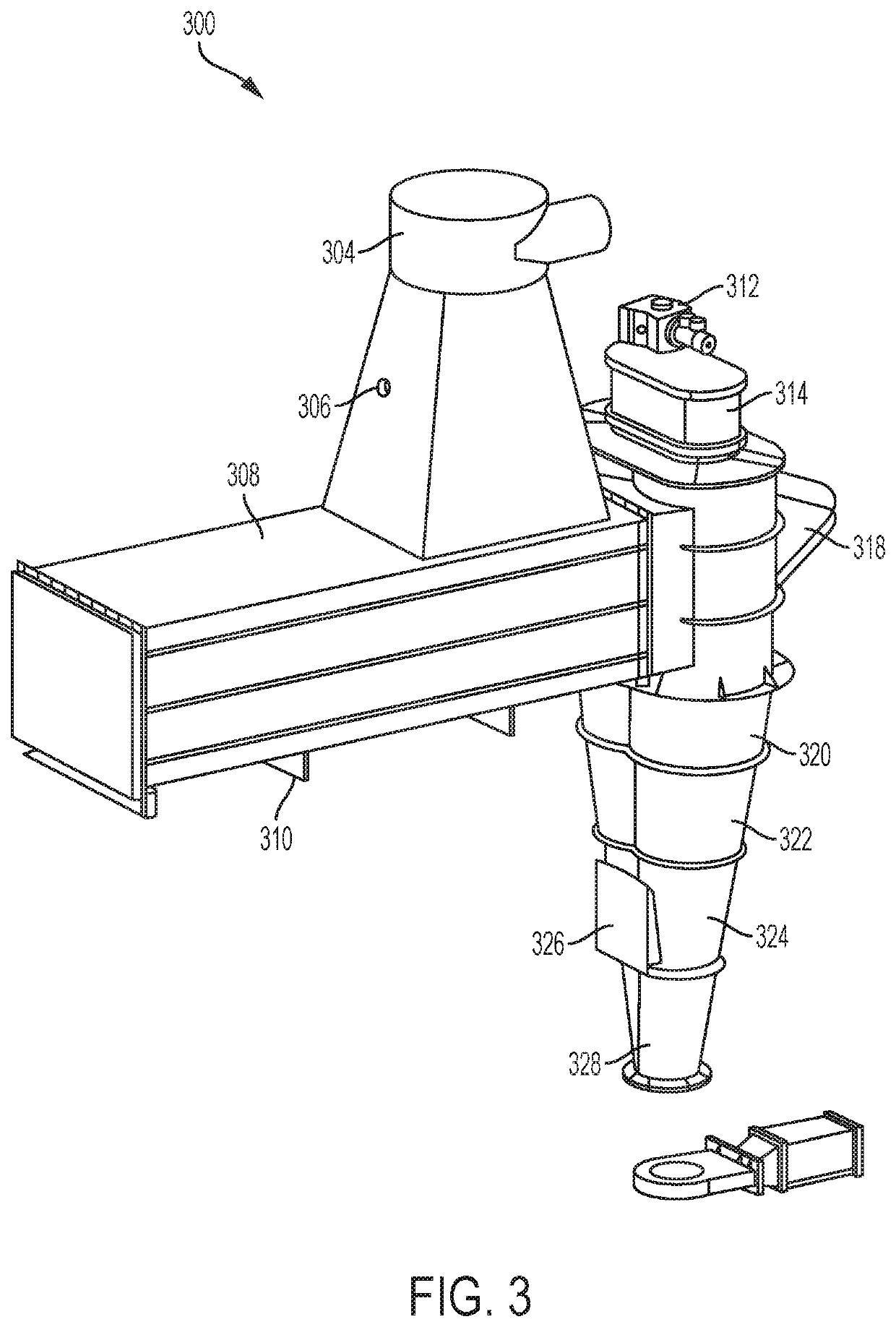

System and process for converting waste plastic into fuel

ActiveUS20180010049A1Liquid hydrocarbon mixture productionIndirect heating destructive distillationThermal expansionProcess engineering

An apparatus is provided for processing reusable fuel comprising: a continuous material supply assembly; a heated airlock feeder configured to continuously receive and process the material supply received therein; a reactor configured to receive the processed material from the heated airlock feeder; and a vapor refining system configured to process vapor supplied by the reactor. The apparatus may comprise a char disposal system configured to eliminate char from the reactor. The apparatus may also comprise a thermal expansion system configured to allow thermal expansion of the reactor. A cooling system may be configured to receive processed fuel from the reactor.

Owner:BRAVEN ENVIRONMENTAL LLC

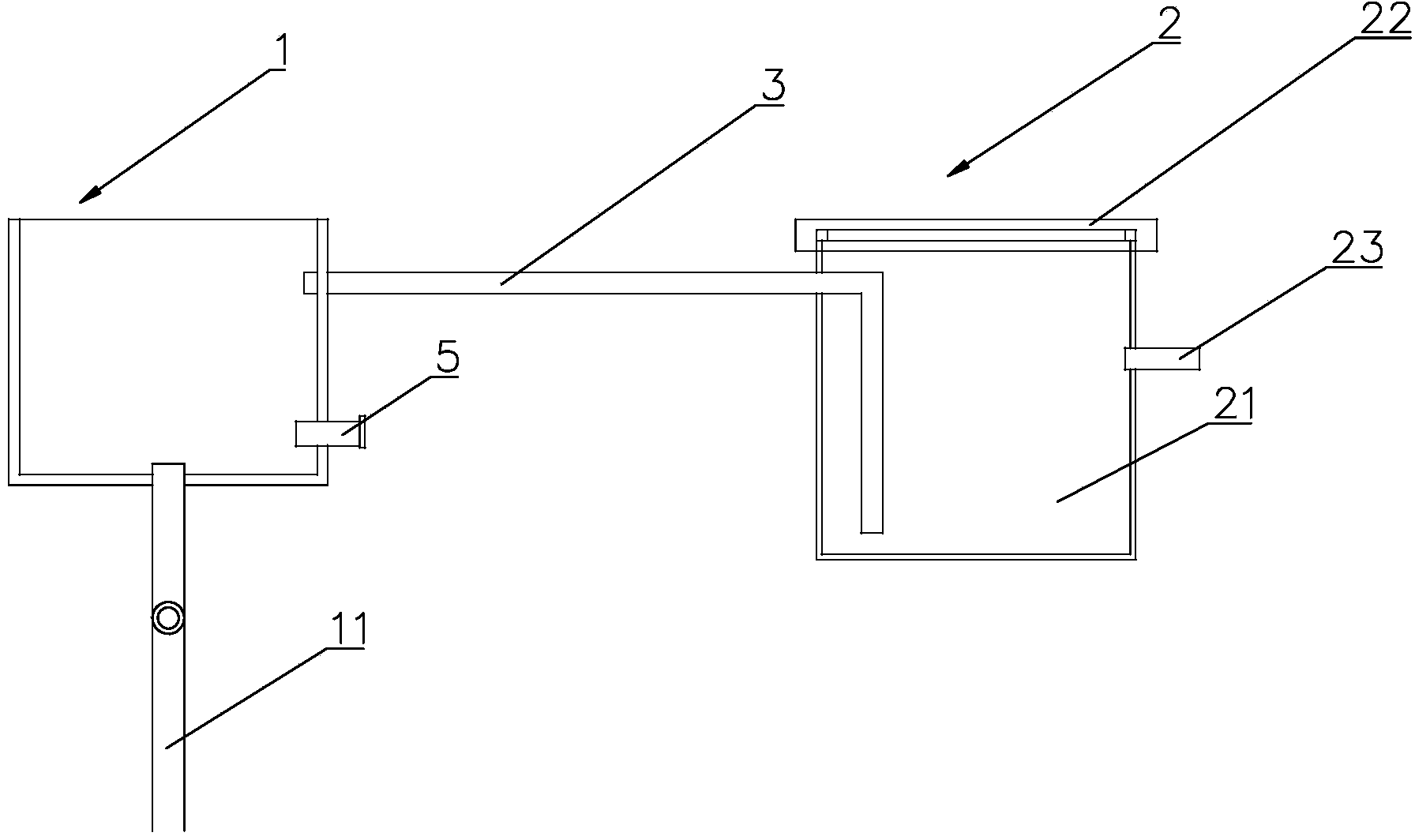

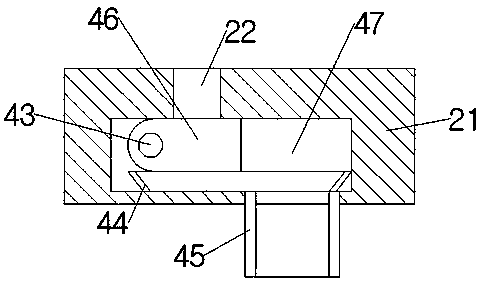

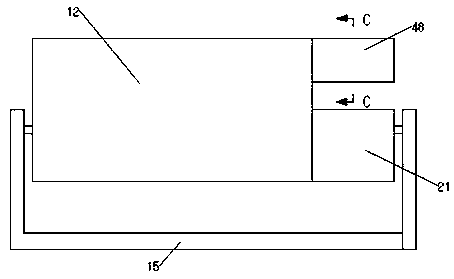

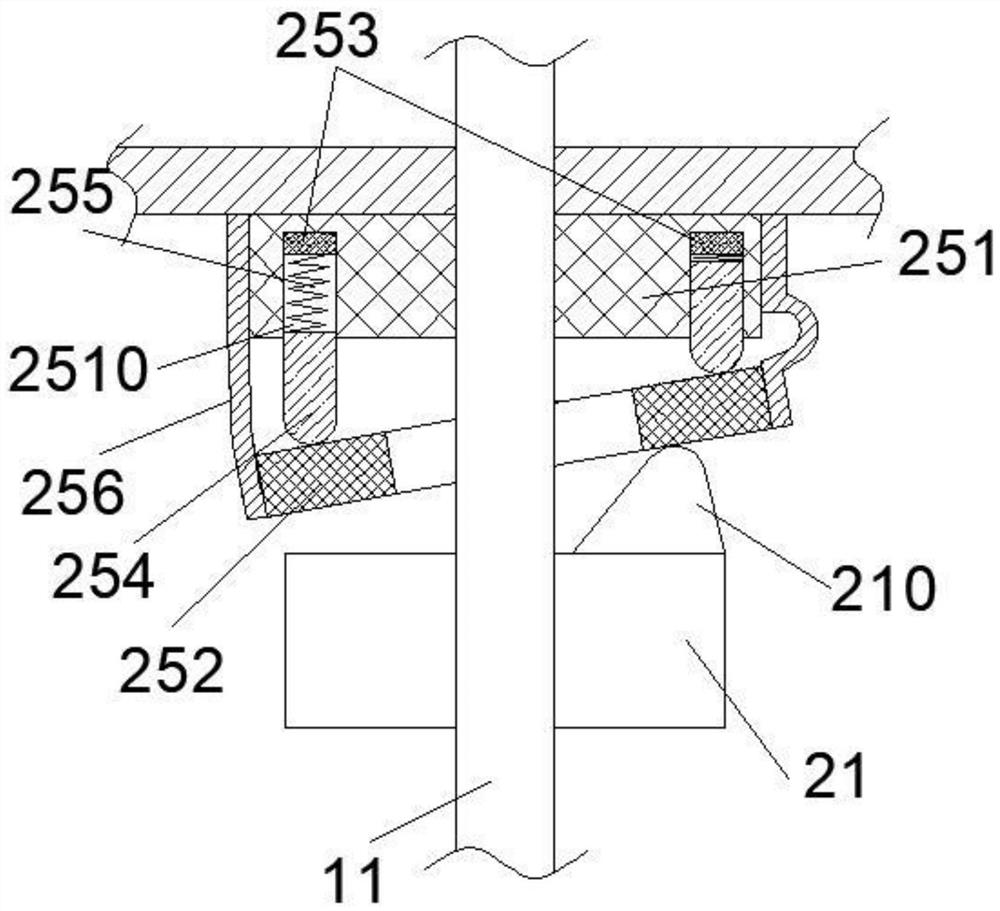

Dewaxing device of tissue embedding machine

ActiveCN104324668AEnsure uninterrupted supplyPrevent cooling hardeningPreparing sample for investigationFusionParaffin waxTissue Embedding

The invention provides a dewaxing device of a tissue embedding machine; the dewaxing device is capable of continuously discharging wax, and comprises a main dewaxing cylinder and an auxiliary dewaxing cylinder, wherein the auxiliary dewaxing cylinder is provided with a first heating device; the bottom of the main dewaxing cylinder is provided with a wax outlet pipe; a wax conveying pipe is arranged between the main dewaxing cylinder and the auxiliary dewaxing cylinder; the auxiliary dewaxing cylinder is provided with a wax feeding hole and an air inlet; the auxiliary dewaxing cylinder is hermetically arranged; a second heating device is arranged at the pipe orifice of the wax outlet pipe. The dewaxing device of the tissue embedding machine has the beneficial effects that the auxiliary dewaxing cylinder can be used for providing standby wax for the main dewaxing cylinder in time, so that the liquid paraffin wax is continuously supplied without waiting; the heating device arranged at the pipe orifice of the wax outlet pipe can be used for separately heating paraffin wax at the pipe orifice, so that the paraffin wax is prevented from being cooled and hardened, the wax is smooth in flow, and wax blockage is avoided; the wax conveying pipe is controlled to convey the liquid paraffin wax by enabling the air inlet to be filled with high-pressure air, and a control valve is not arranged in the wax conveying pipe, so that wax leakage is avoided.

Owner:福建启盛实验设备科技有限公司

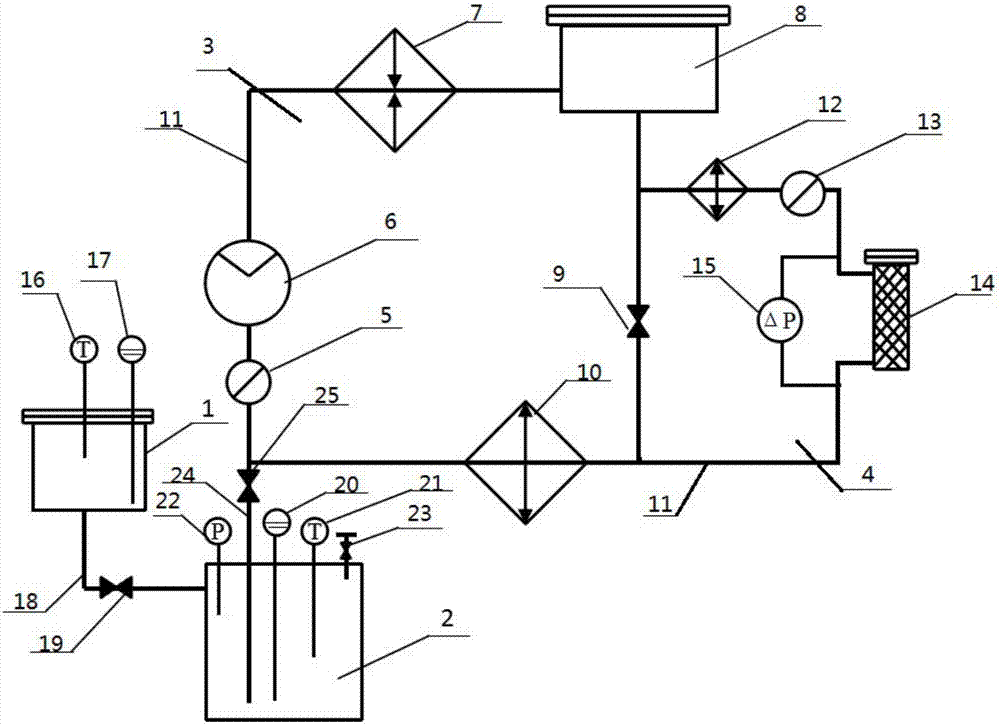

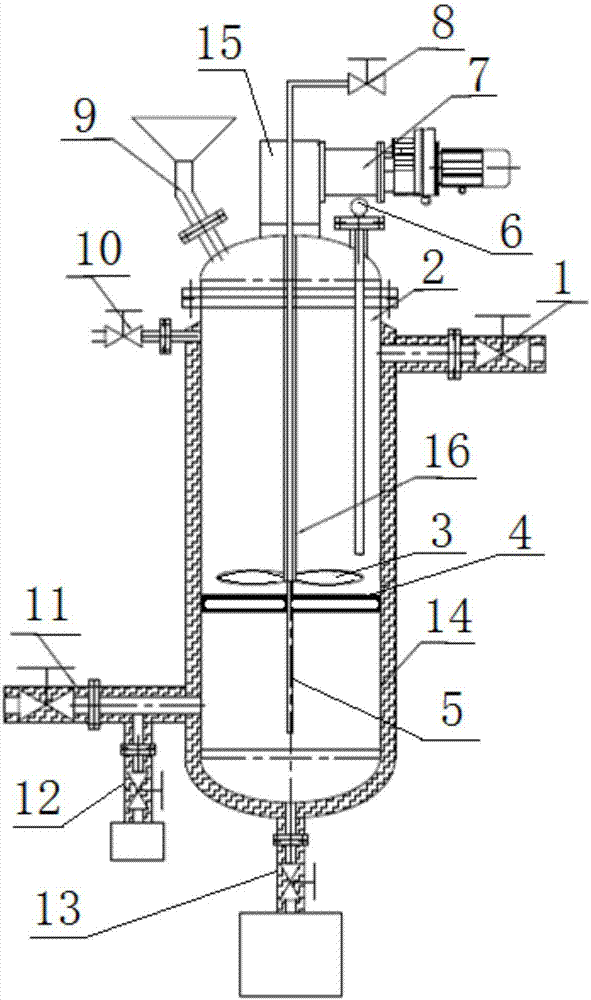

Liquid metal purification experiment loop system and application method thereof

ActiveCN107315068AShorten purification experiment timeImprove the efficiency of purification experimentsNuclear energy generationFusionMelting tankLiquid state

The invention belongs to the technical field of liquid metal purification and discloses a liquid metal purification experiment loop system. The liquid metal purification experiment loop system comprises a melting tank, a storage tank and a loop body; the loop body comprises a main loop unit and a purification branch unit; the main loop unit comprises a first flowmeter, a pump, a heater, an expansion box, a first valve and a first cooler which are sequentially connected to form a loop, the purification branch unit comprises a second cooler, a second flowmeter and a purification experiment device which are serially connected in sequence, a first thermocouple and a first liquidometer are arranged at the top of the melting tank, the bottom of the melting tank is connected with the upper portion of the storage tank through a first connecting pipe, and a second valve is arranged on the first connecting pipe; a second liquidometer, a second thermocouple, a pressure meter and a gas circuit interface are arranged at the top of the storage tank. By the arrangement, purification experiments can be carried out, and true working condition can be simulated by adding impurities to the expansion box; in addition, operation cost is low, experiment efficiency is high, convenience in use is achieved, and the experiments on various filter cores can be performed.

Owner:BAISE UNIV

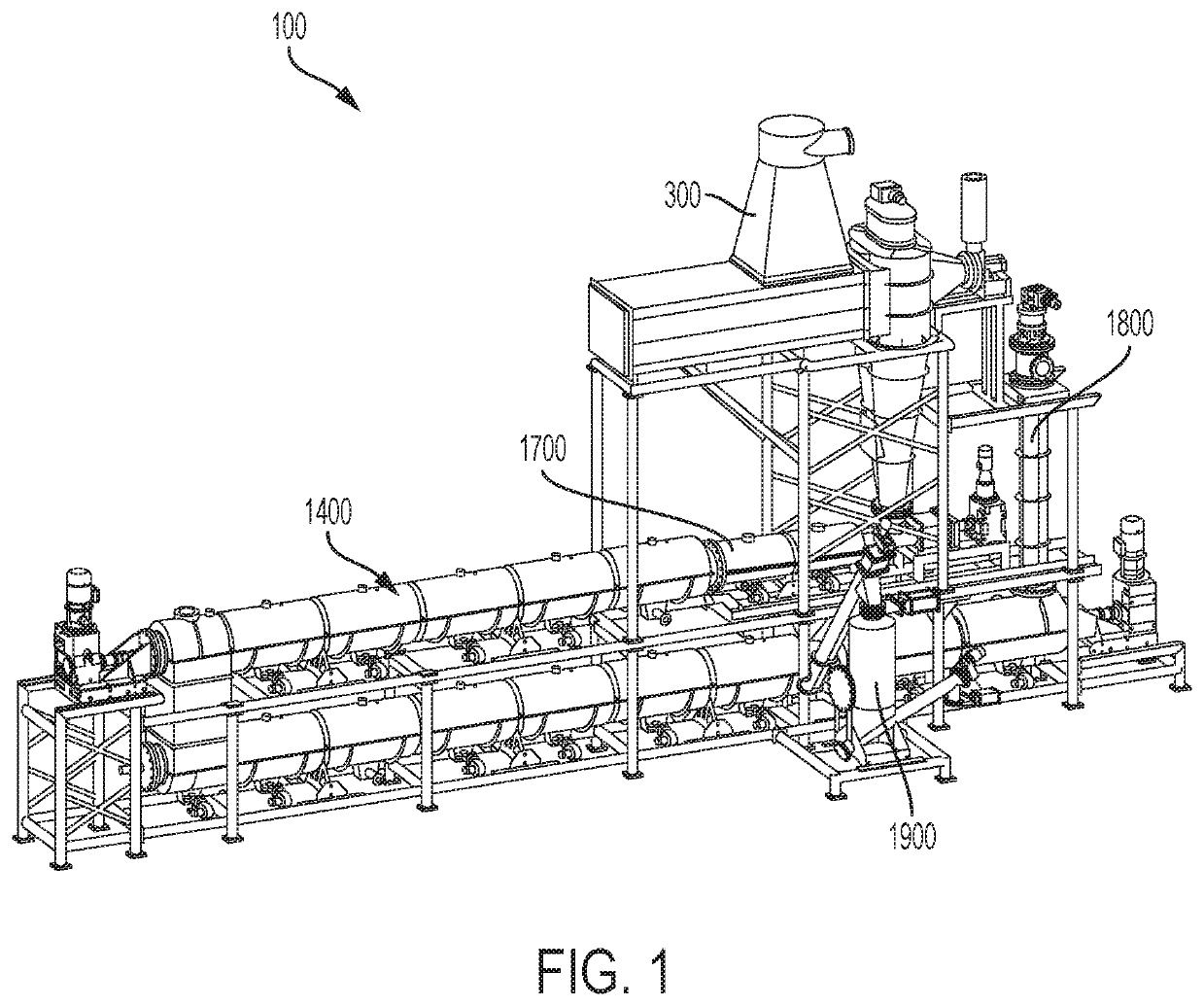

System and process for converting waste plastic into fuel

ActiveUS10731082B2Liquid hydrocarbon mixture productionIndirect heating destructive distillationThermal dilatationThermodynamics

An apparatus is provided for processing reusable fuel comprising: a continuous material supply assembly; a heated airlock feeder configured to continuously receive and process the material supply received therein; a reactor configured to receive the processed material from the heated airlock feeder; and a vapor refining system configured to process vapor supplied by the reactor. The apparatus may comprise a char disposal system configured to eliminate char from the reactor. The apparatus may also comprise a thermal expansion system configured to allow thermal expansion of the reactor. A cooling system may be configured to receive processed fuel from the reactor.

Owner:BRAVEN ENVIRONMENTAL LLC

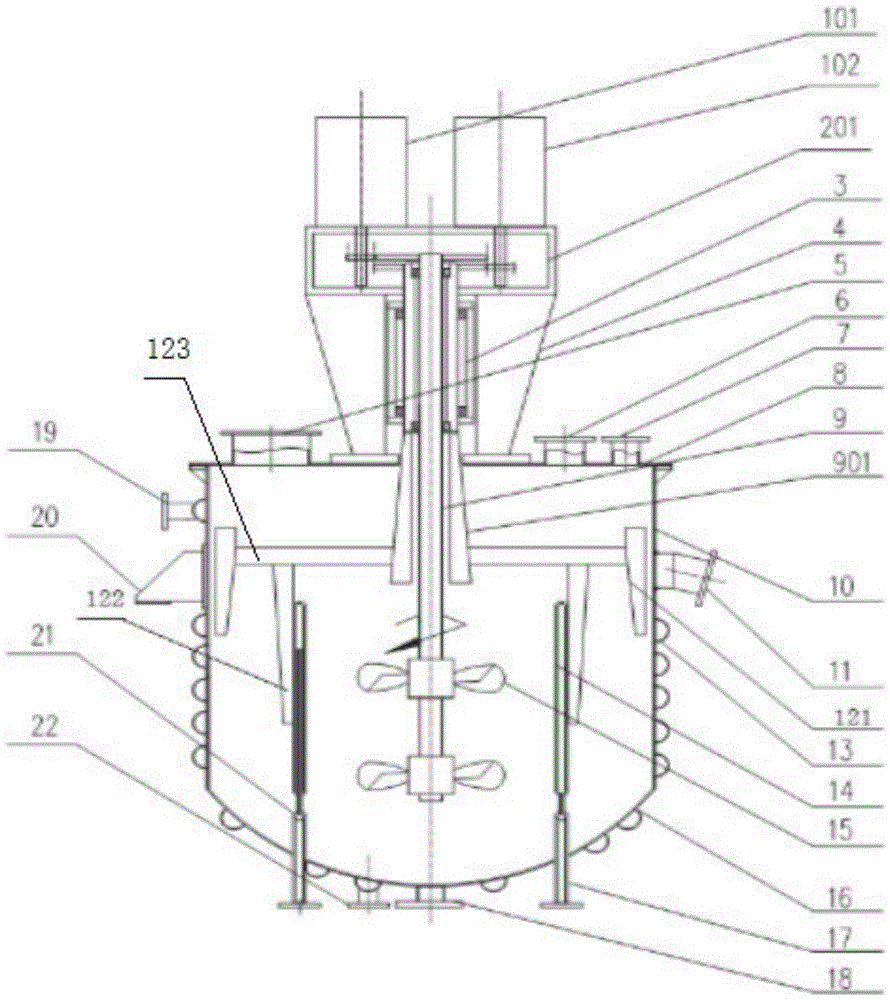

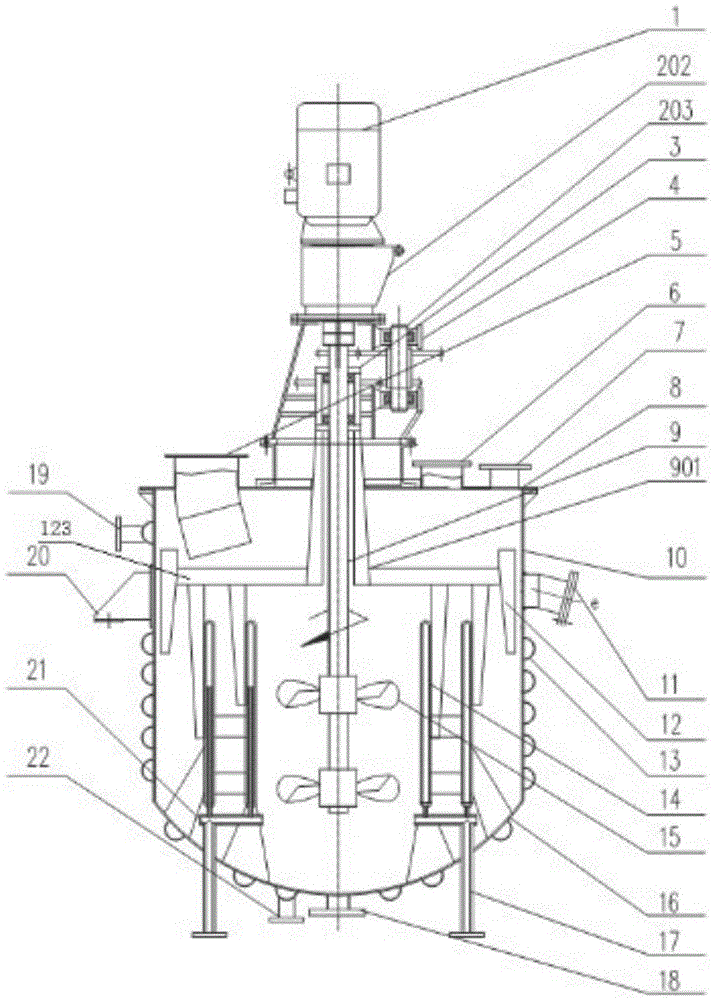

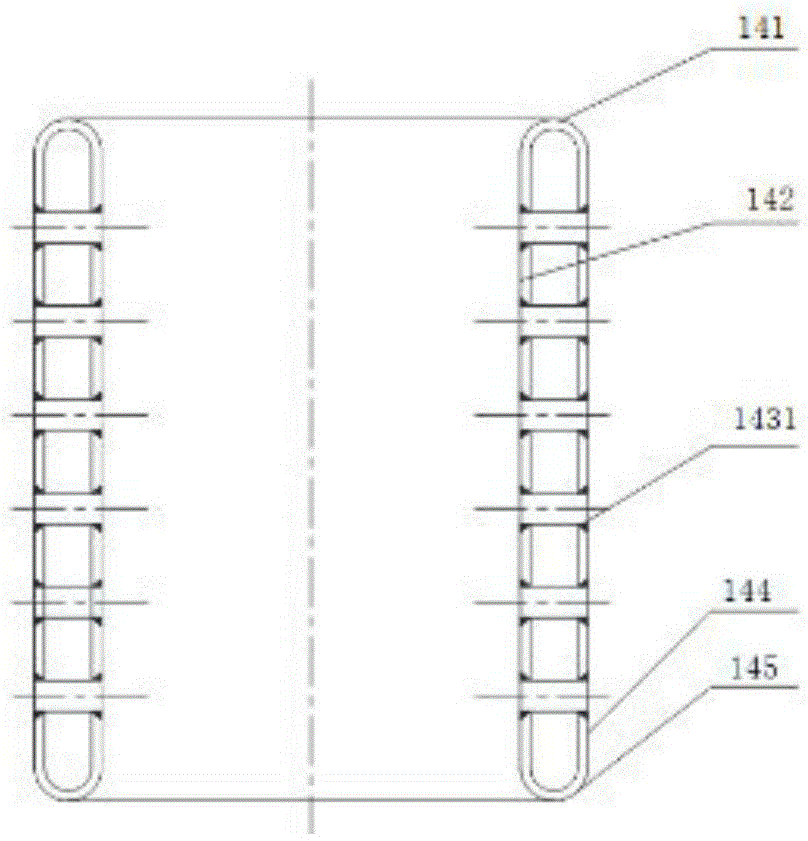

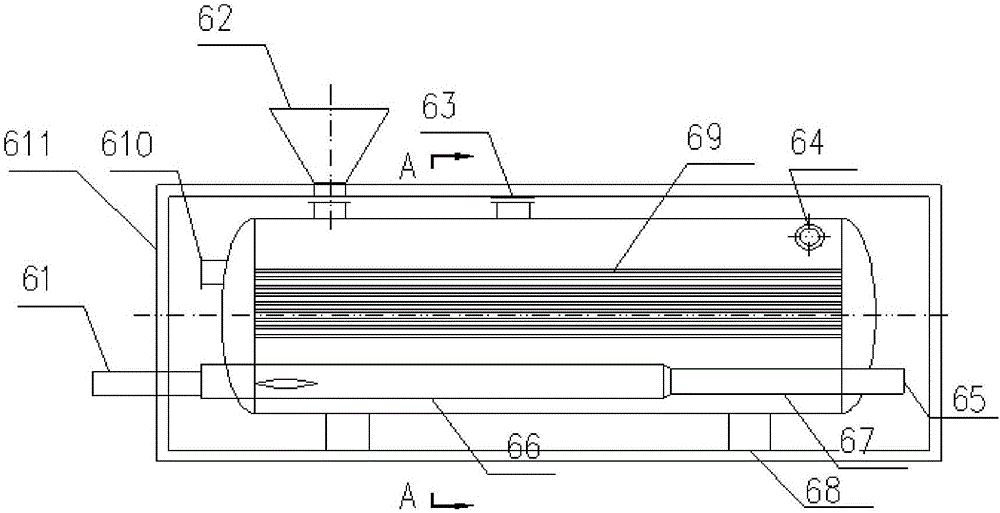

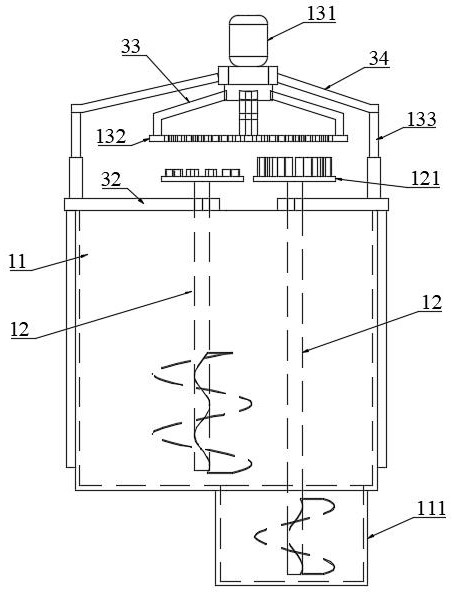

A fusing and mixing device for treating high viscosity materials

InactiveCN105536653AImprove thermal efficiencyAvoid stickingChemical/physical/physico-chemical stationary reactorsFusionEngineeringThick wall

The invention provides a fusing and mixing device for treating high viscosity materials. The device is formed by mounting scraping plates to positions near the inner wall of the internal-jacket fusing and mixing device provided with a stirring gear and to positions near vertical walls of inside and outside cylinders of internal jackets. Each of the internal jackets is formed by connecting inside and outside cylinders with annular semicircle pipes and welding with round steel or thick-wall tubes for connection and reinforcement. The internal jacket close to the stirring gear can be adopted as a stream guiding cylinder of the stirring gear. The scraping plates and stirring blades can be driven by one motor and can be separately driven by two motors. By adoption of the internal jackets, materials are not liable to adhere to the internal surface of the fusing and mixing device. Material adhesion phenomena are completely avoided by adoption of the scraping plates. The fusing and mixing device is low in thermal resistance, high in thermal efficiency, low in energy consumption and operating cost and less in exhaust emission in a heating process. A problem of a high-tower composite fertilizer granulation device that normal production cannot be continued due to material adhesion in a first mixing tank and a second mixing tank is overcome.

Owner:JANGSU RIGHT HEAVY MACHINERY CO LTD

Solid salt heating and melting device and method

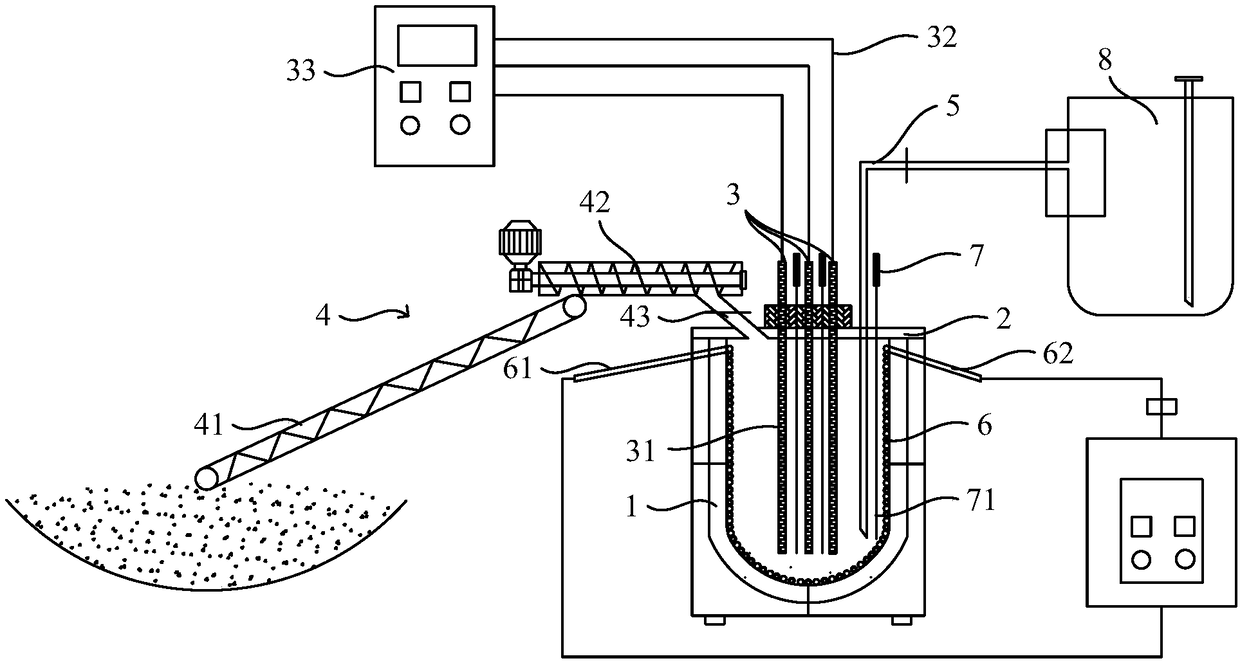

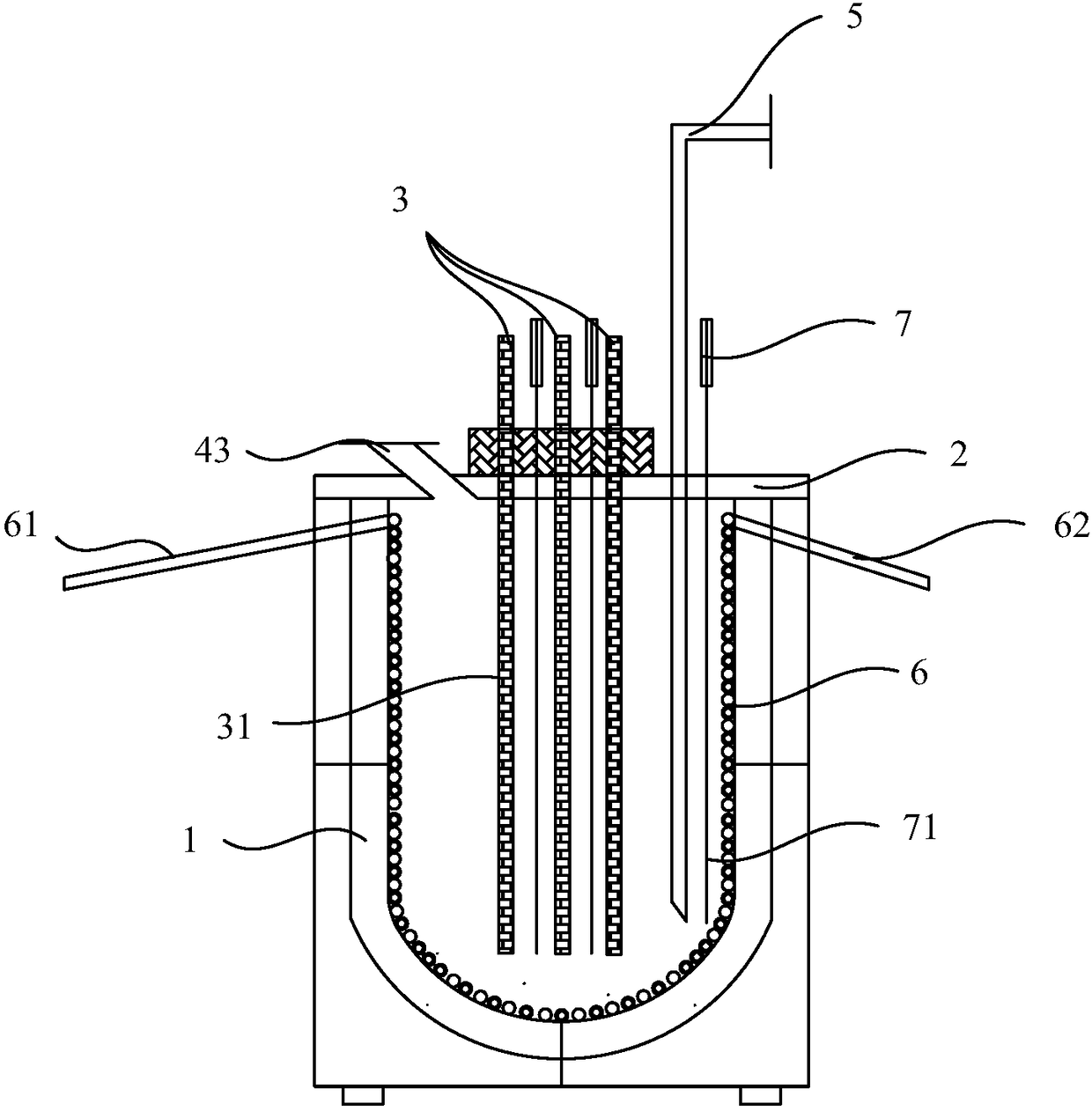

ActiveCN108295776ARandom combinationHeating fastHeat storage plantsFusionMechanical engineeringElectrode

The invention discloses a solid salt heating and melting device and method. The solid salt heating and melting device comprises a container body, a container cover and an electrode group. The lower portion of the container body is closed, and the upper portion is opened. The container cover seals the upper portion of the container body. The electrode group is fixed to the container cover. The container body is a heat exchange jacket and is used for cooling the inner wall of the container body so as to form a frozen salt wall. The solid salt heating and melting device further comprises a continuous heating device and a discharge pipe. The continuous heating device penetrates through the container cover. The discharge pipe is fixed to the container cover. The electrode group and the discharge pipe extend to the bottom of the container body. The electrode group comprises a plurality of bar-shaped electrodes. The electrodes are arrayed to form a polygonal prism. The distances between the lower ends of the electrodes can be adjusted.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

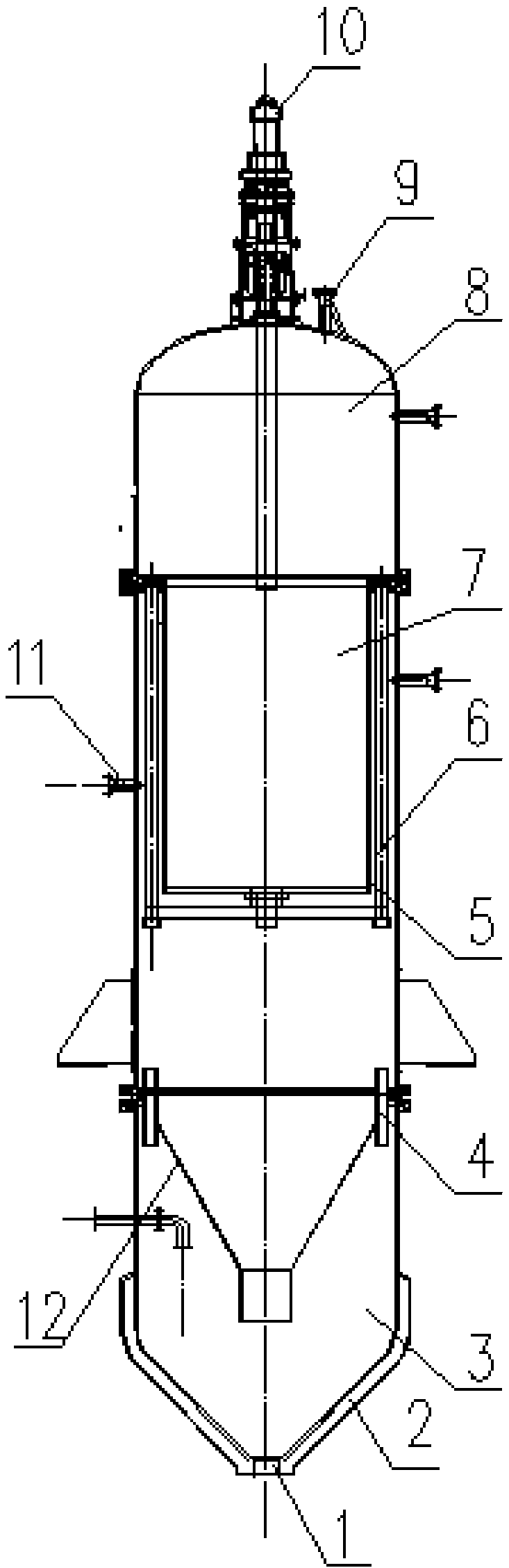

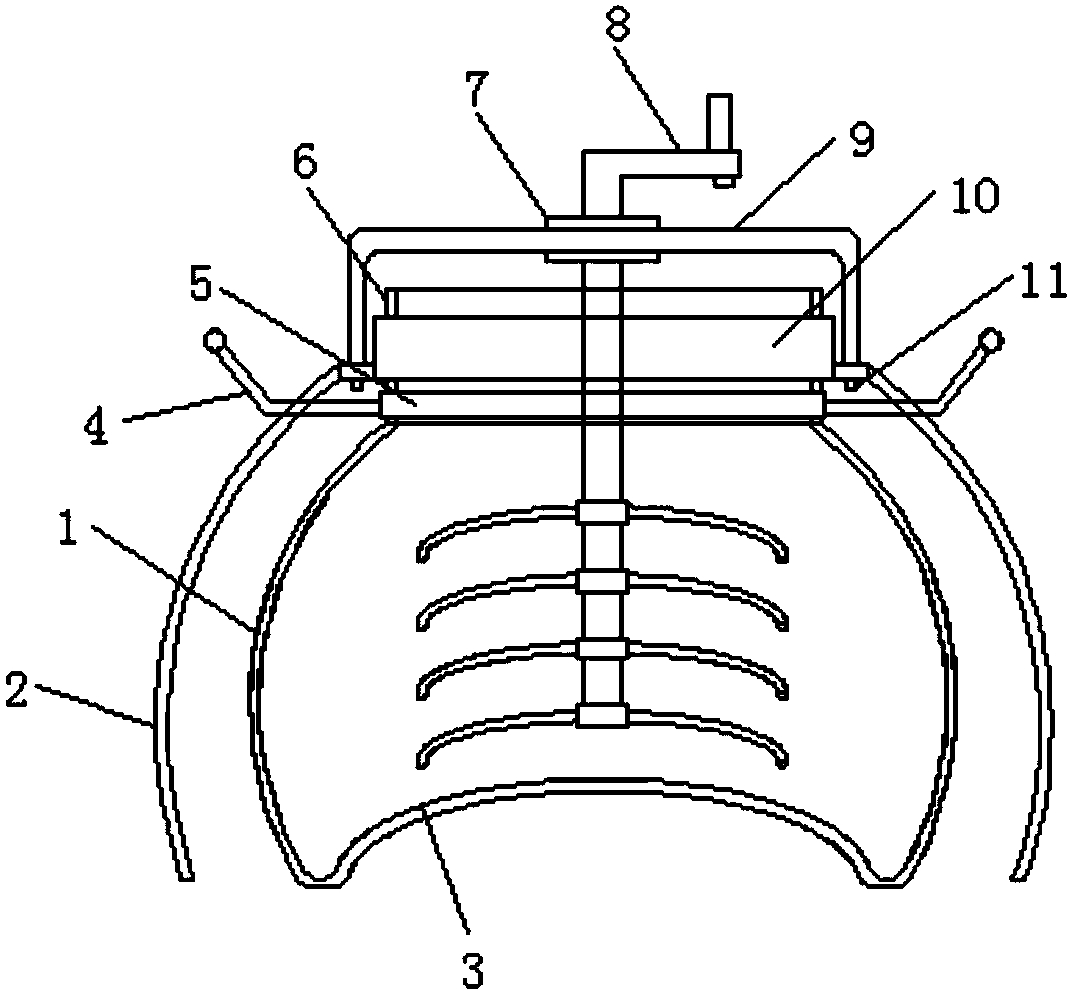

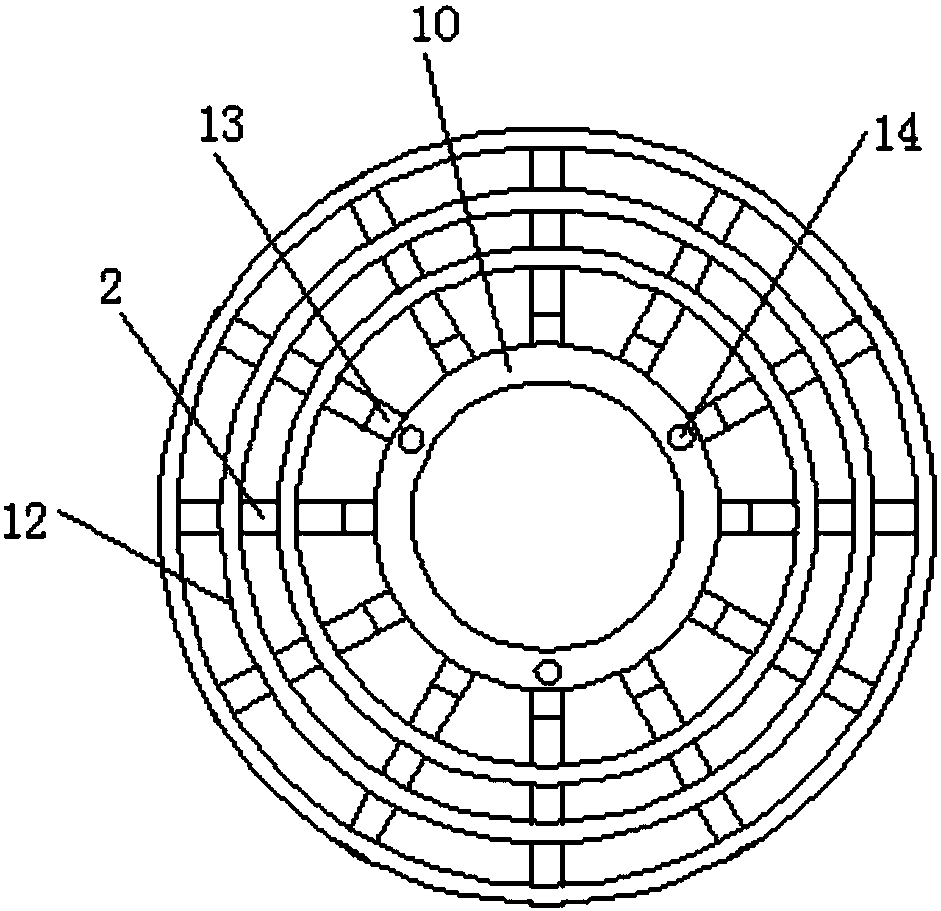

Filter type sulfur melting kettle

The invention relates to a filter type sulfur melting kettle. The filter type sulfur melting kettle comprises a clear liquid section, a filter section and a sulfur melting section, all of which are orderly arranged from top to bottom, wherein a revolving filter screen is arranged in the filter section and driven by a driving device arranged at the top of the kettle; the clear liquid section is provided with a clear liquid outlet, while the filter section is provided with a sulfur foam inlet and the sulfur melting section is provided with a sulfur outlet. The revolving filter screen is a cage type filter screen and capable of rotating around an axis; a fixed scraper plate is arranged on the kettle body outside the revolving filter screen. Compared with the prior art, the filter type sulfur melting kettle has the following beneficial effects: 1) the revolving filter screen is capable of separating the clear liquid and the elemental sulfur in sulfur foam from each other, the sulfur is scraped into the sulfur melting section by use of the scraper plate, and the sulfur product is good in quality and high in recovery rate; 2) slag is not easy to accumulate on the wall of the kettle, the kettle body of the three-section design is easy to clear and convenient to repair and replace, and the equipment utilization rate is high; 3) the sulfur content in the clear liquid is low, and a pipeline is not prone to block, and the clear liquid can be directly returned to the system for utilization; 4) the equipment controllability is high, the production process is stable, the energy consumption is low and the production cost can be reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

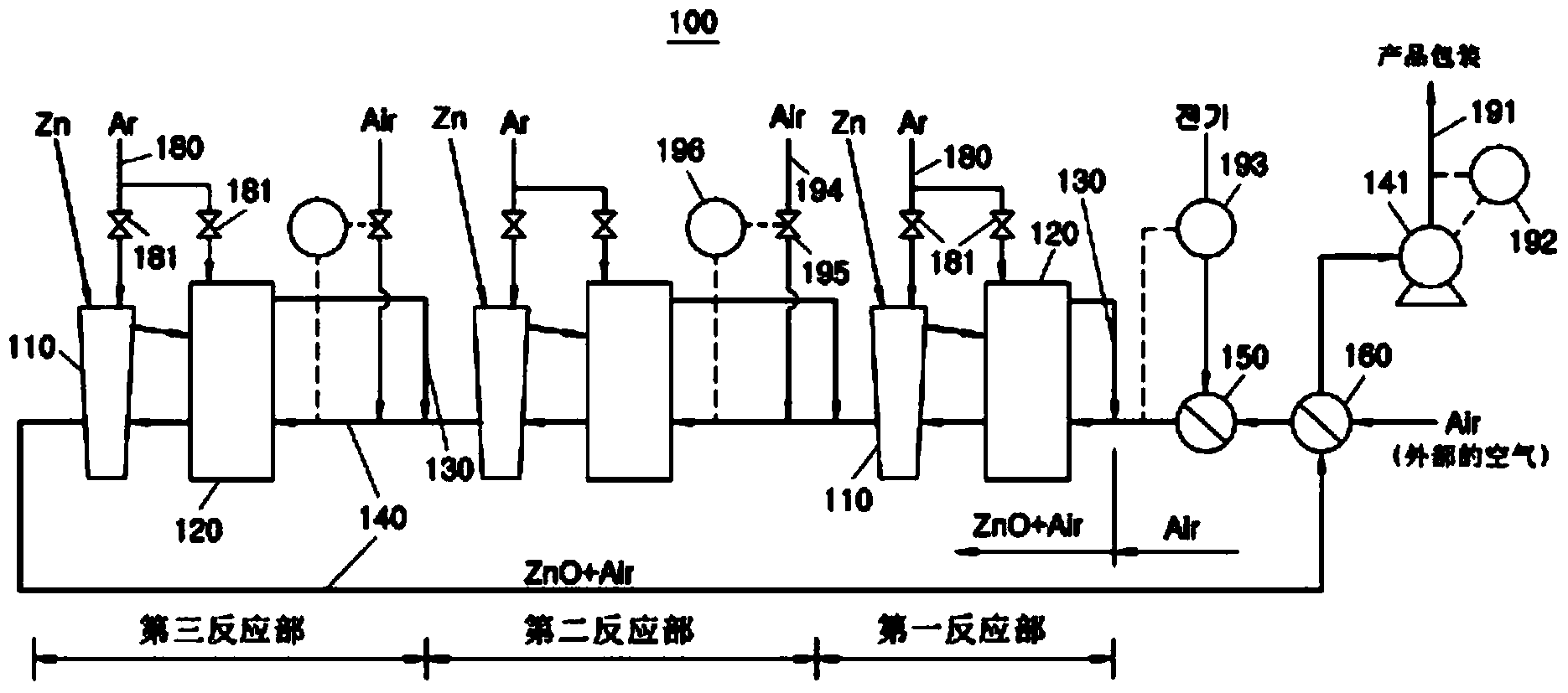

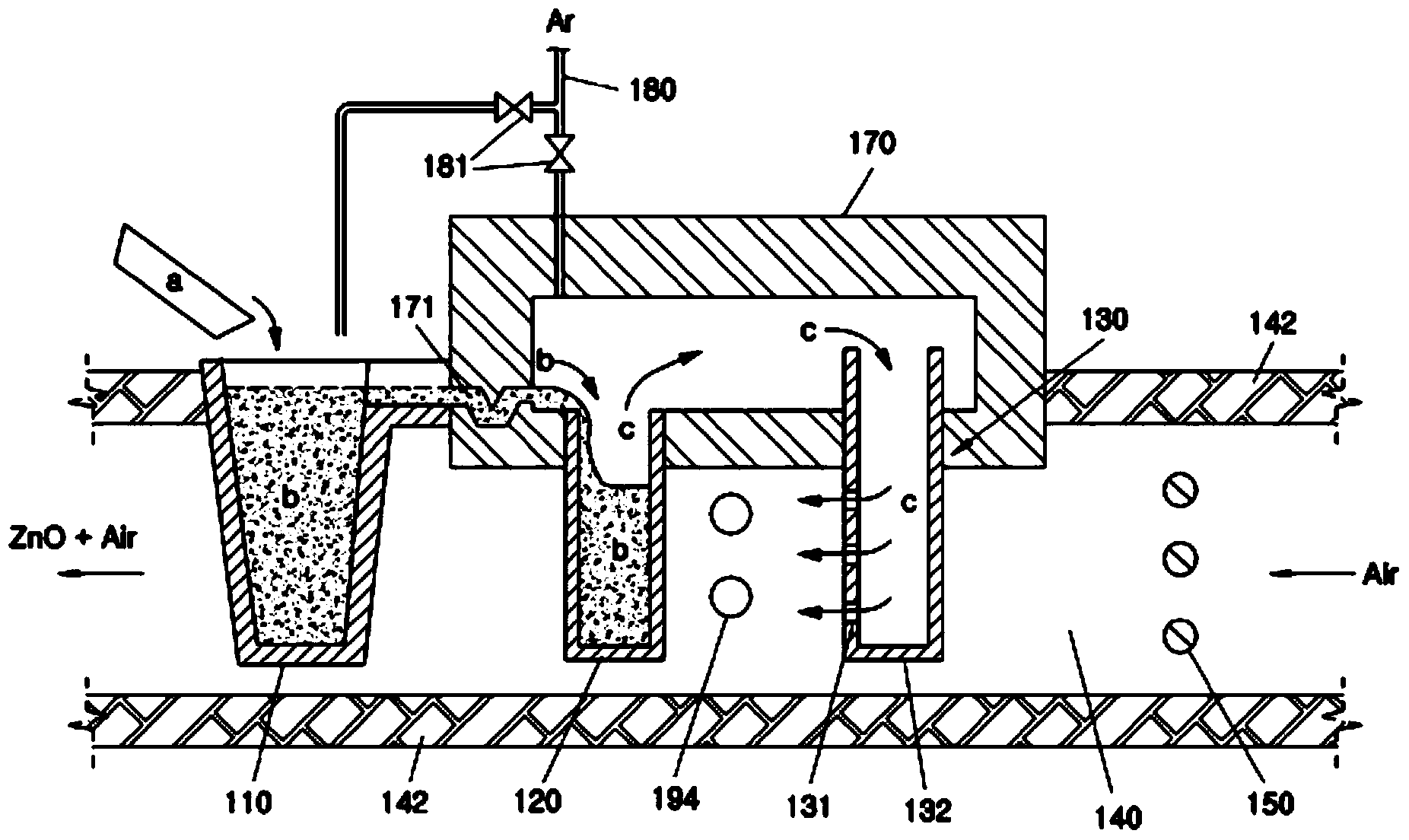

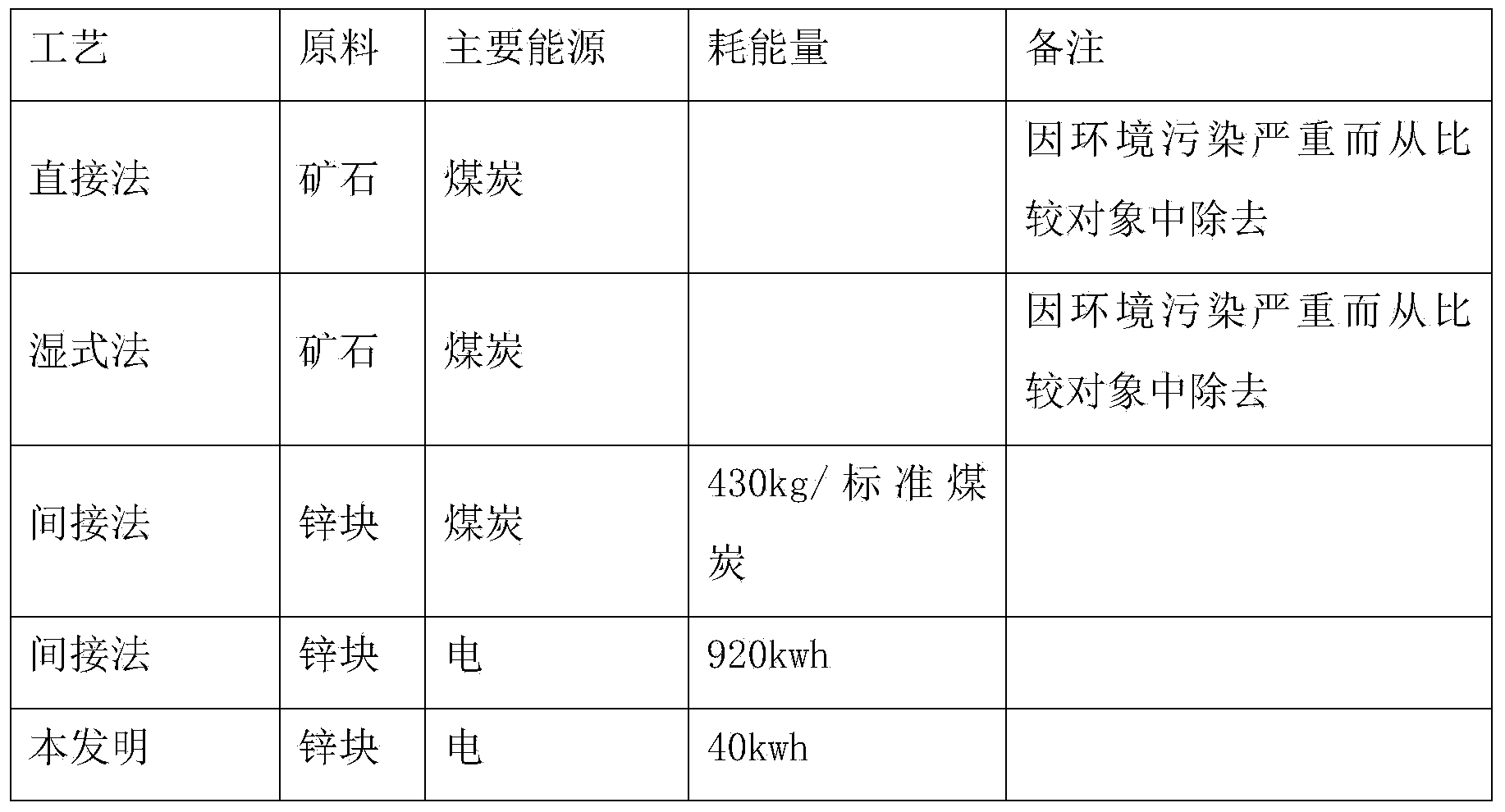

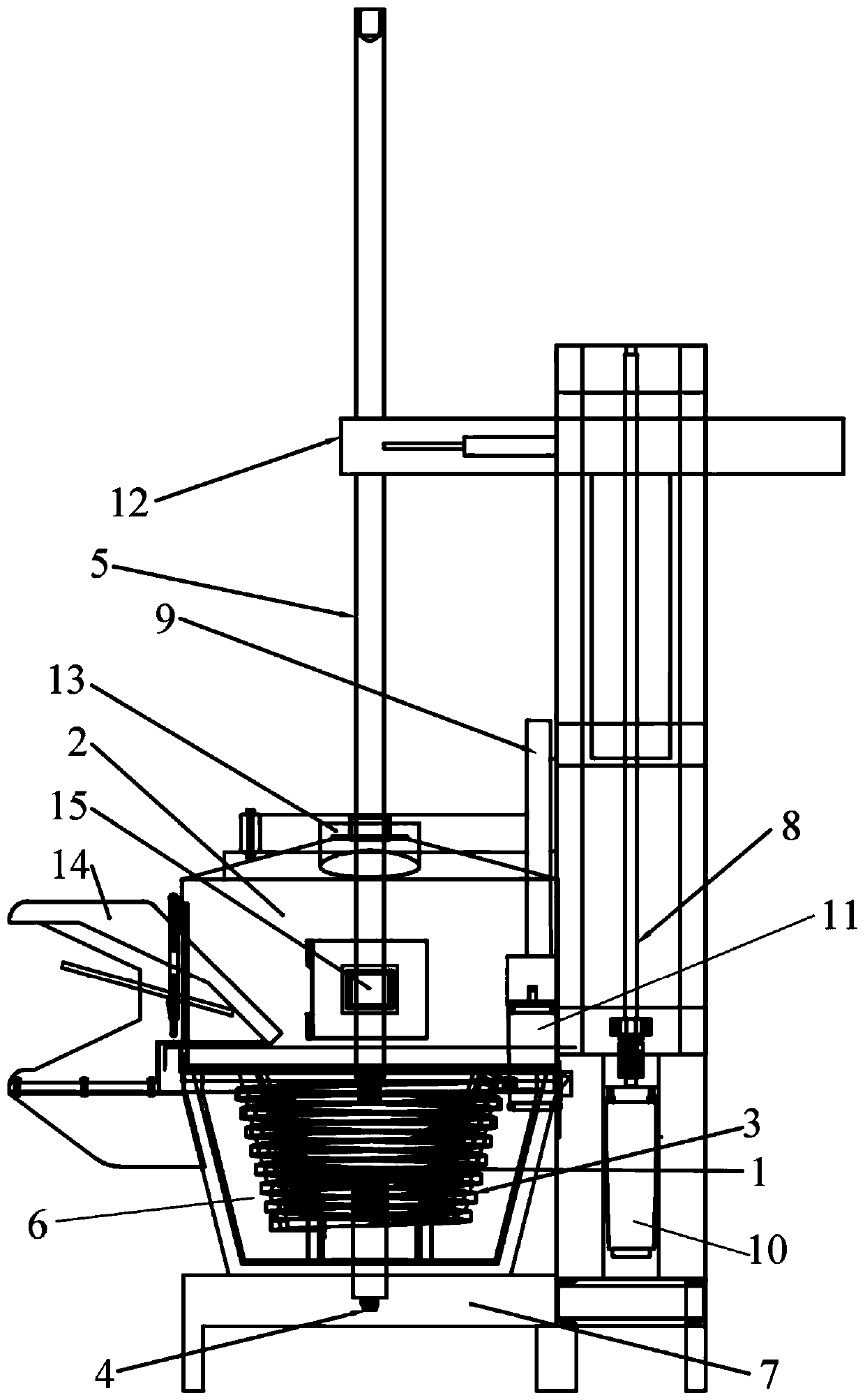

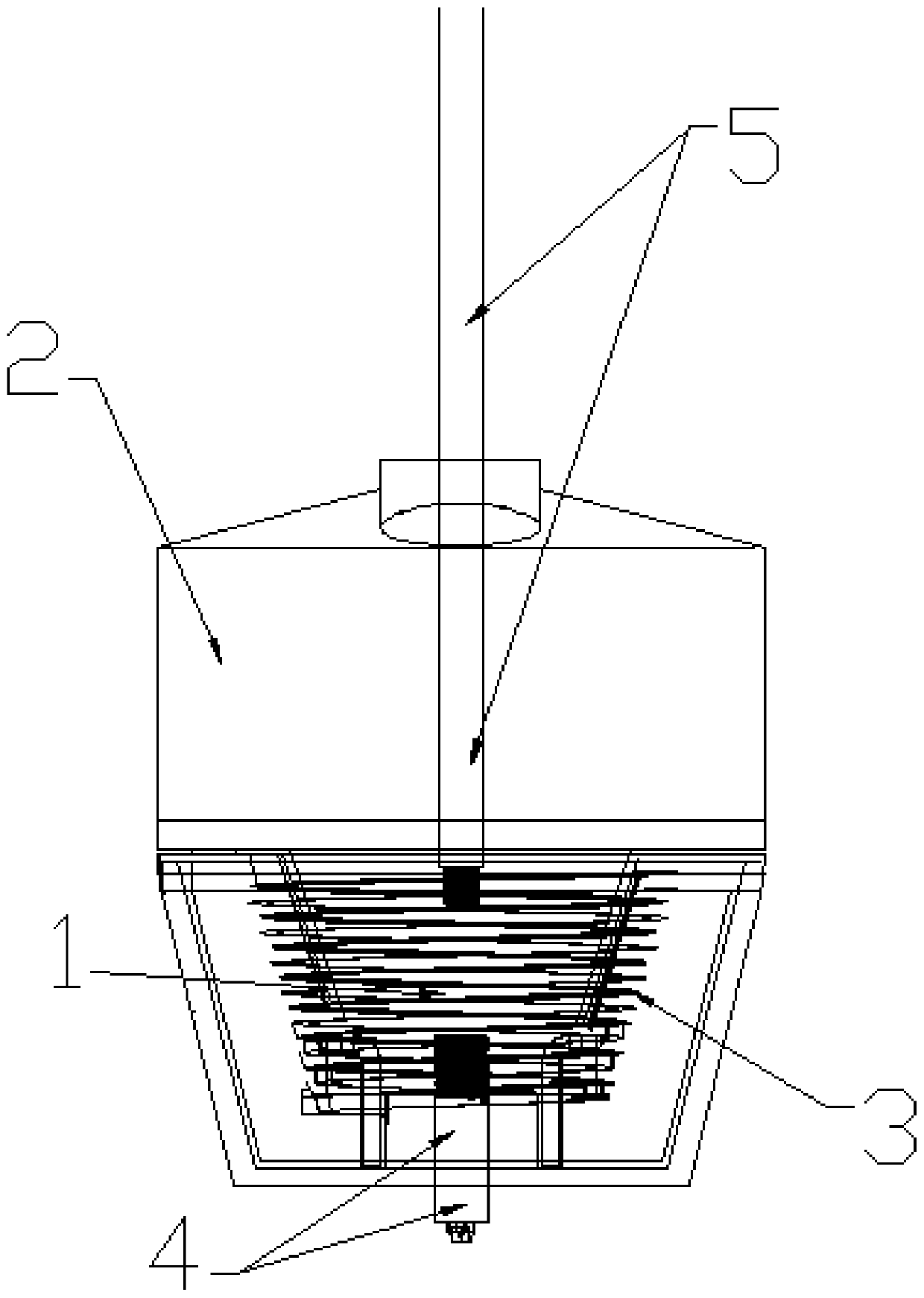

System for producing zinc oxide

ActiveCN104245590AAvoid generatingReduce pollutionZinc oxides/hydroxidesChemical industryEvaporationOxygen

The present invention relates to a system for producing zinc oxide, comprising: a zinc melting unit for melting zinc to produce molten zinc; a zinc evaporation pipe for receiving the molten zinc from the zinc melting unit and generating zinc vapor; a zinc vapor supply line for supplying the zinc vapor discharged from the zinc evaporation pipe; an air transport line for providing an air flow path by the blowing force of a blower and having an interior to which the zinc vapor is supplied by the zinc vapor supply line, wherein the air transport line enables the zinc oxides generated by the reaction between the oxygen contained in the air and zinc vapor to be discharged together with the air; and a heating unit installed in the air transport line to heat the air to be mixed with the zinc vapor. The system for producing zinc oxide is installed in the air transport line in such a manner that a portion or the whole of the zinc melting unit, the zinc evaporation pipe and the zinc vapor supply line uses the heat contained in the air in the air transport line or the heat of the reaction caused by the generation of zinc oxide when melting or evaporating the zinc. The system of the present invention utilizes the heat recovered from the heated air and the reaction heat generated during the production of zinc oxide.

Owner:姜景皓 +1

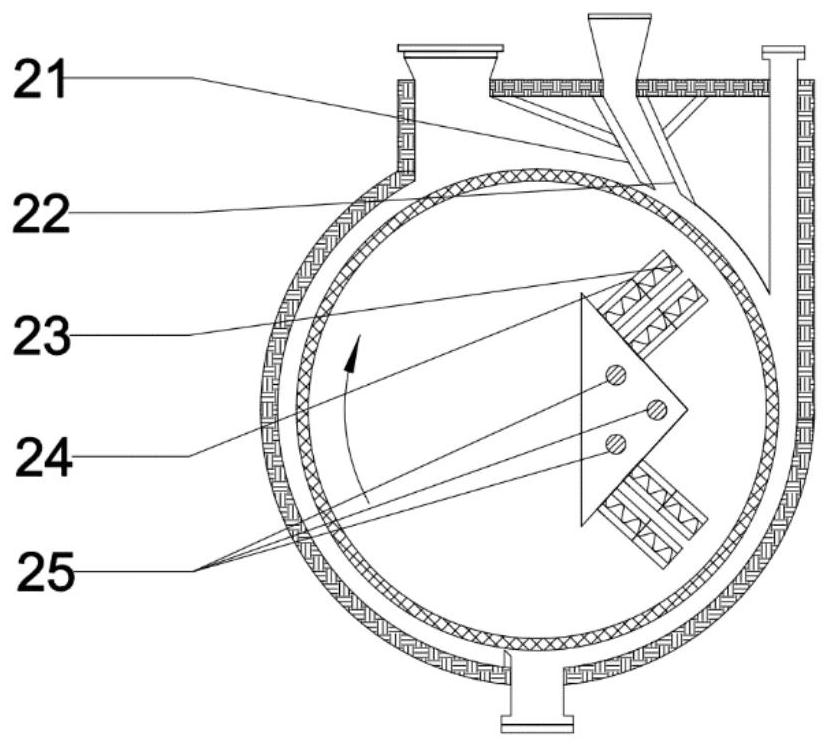

Plasma arc magnetic rotary gasification pulverizing furnace

PendingCN111495298AImprove product qualityReduce spreadOxygen/ozone/oxide/hydroxideNanotechnologyGraphite electrodeSlag

The invention provides a plasma arc magnetic rotary gasification pulverizing furnace. The plasma arc magnetic rotary gasification pulverizing furnace comprises a crucible, a dust collection cover, a magnetic coil, a first electrode, a second graphite electrode, a direct-current voltage output device and an air draft device, and the dust collection cover is arranged on one side of the opening of the crucible; the dust collection cover is communicated with the air draft device through a pipeline; a gap is reserved between the dust collection cover and the opening of the crucible; and the first electrode and the second graphite electrode are arranged on one side of the concave surface of the dust collection cover and in a space surrounded by the crucible, the first electrode and the second graphite electrode are electrically connected with the direct-current voltage output device, the magnetic coil surrounds the outer side of the crucible, and a circuit formed by the first electrode and the second graphite electrode is connected with the magnetic coil in series or in parallel. According to the pulverizing furnace, the magnetic coil is arranged outside the crucible, the generated rotating magnetic field enables plasma electric arcs to be more stable and energy to be more concentrated, the influence of an oxidation layer and oxidation slag on the product quality is effectively avoided, and the uniformity of the particle size of nanoscale oxidation powder is improved.

Owner:昆明先导新材料科技有限责任公司

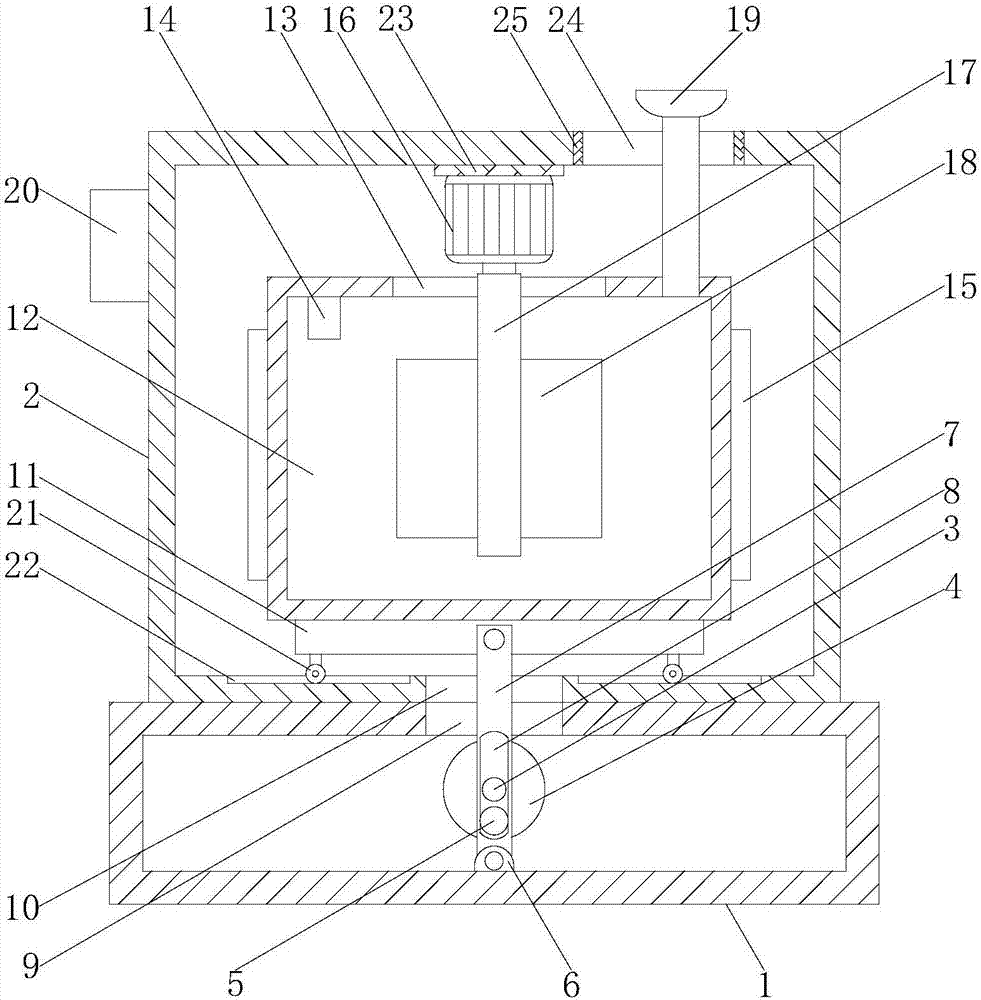

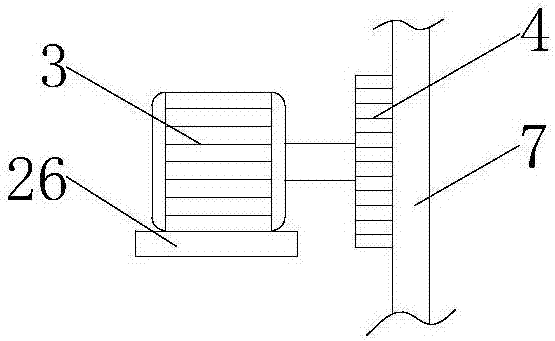

Melting device for new materials

InactiveCN107051335AAchieve the effect of rotationEfficient and uniform meltingFusionRotational axisDrive wheel

The invention discloses a melting device for new materials. The melting device comprises a base, the top of the base is fixedly connected with a box, the inner wall of the base is fixedly connected with a first motor, the output end of the first motor is fixedly connected with a driving wheel, the surface of the driving wheel is fixedly connected with a sliding block, the axial center of the inner cavity of the base is fixedly connected with a connecting block, and the top of the connecting block is movably connected with a long plate through a hinge. According to the melting device for the new materials, the effect of driving the driving wheel to rotate is achieved through the arrangement of the first motor, the effect of driving the long plate to move is achieved through the rotation of the driving wheel, the effect of driving a support plate to move is achieved through the long plate, the effect of driving a melting box to move is achieved through the support plate, the effect of driving a rotating shaft to rotate is achieved through a second motor, the effect of driving stirring blades to rotate is achieved through the rotating shaft, the new materials can be effectively and uniformly melted, and the working efficiency of a user is greatly improved.

Owner:FOSHAN FEISHIDA NEW MATERIAL TECH CO LTD

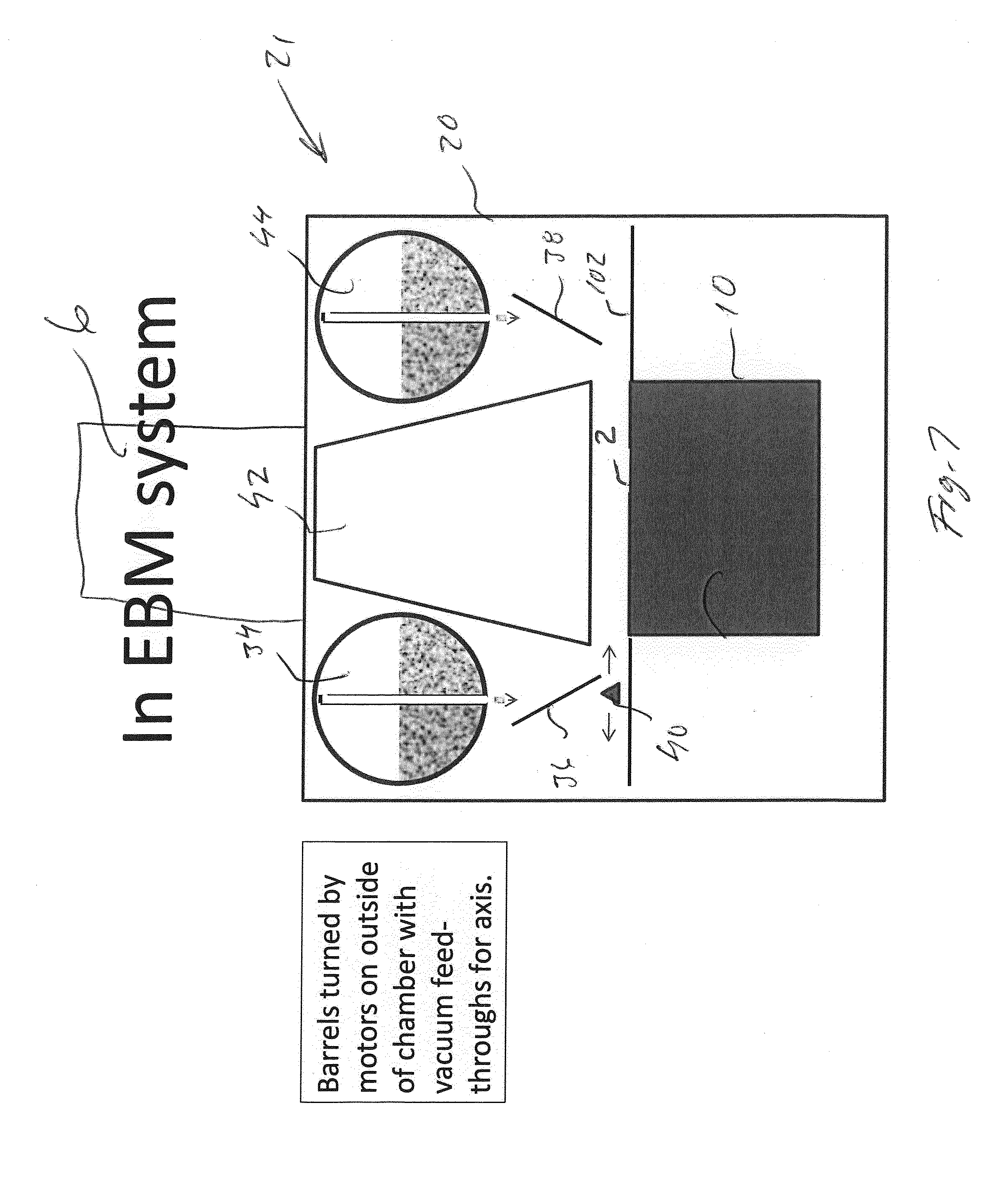

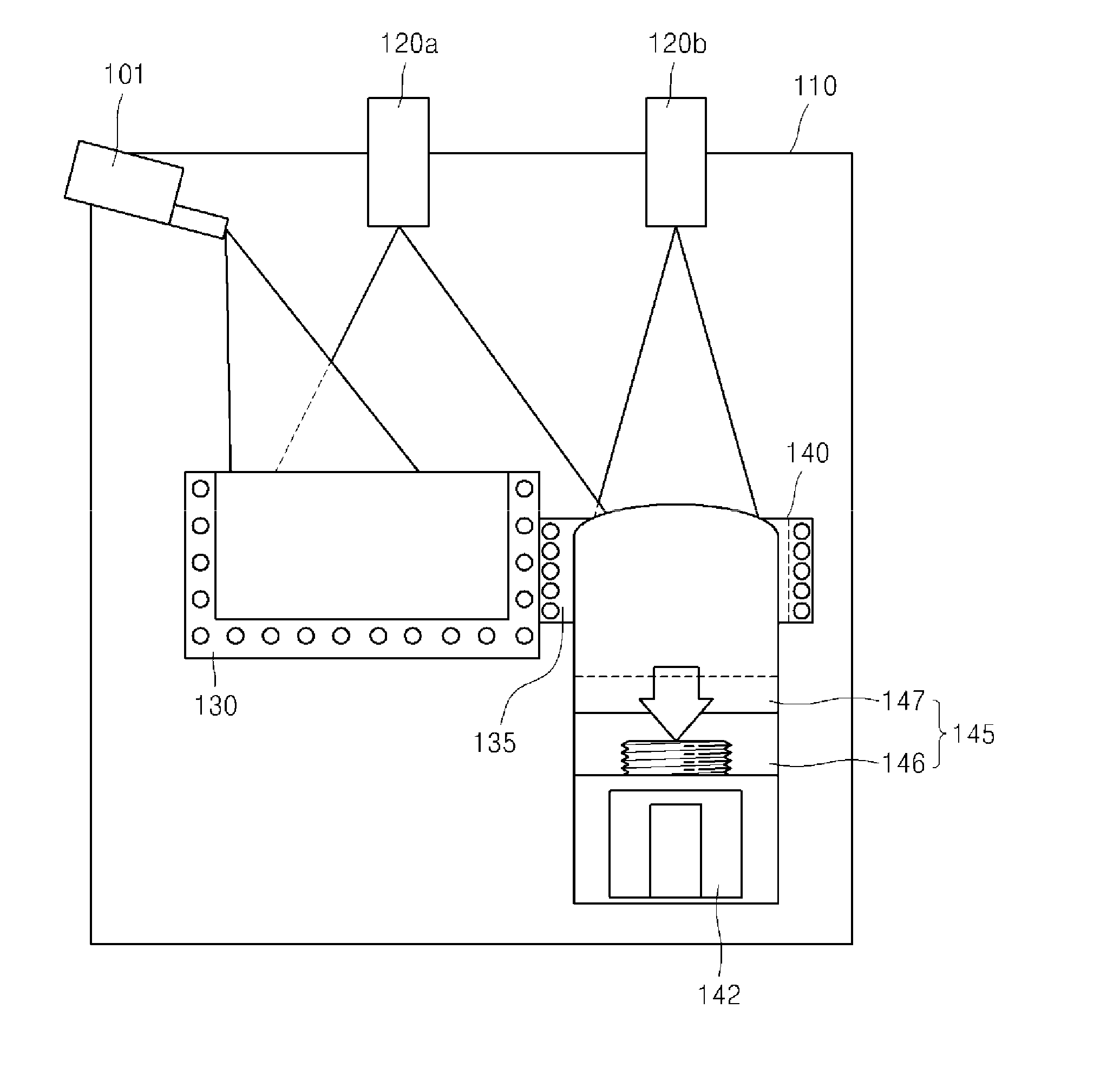

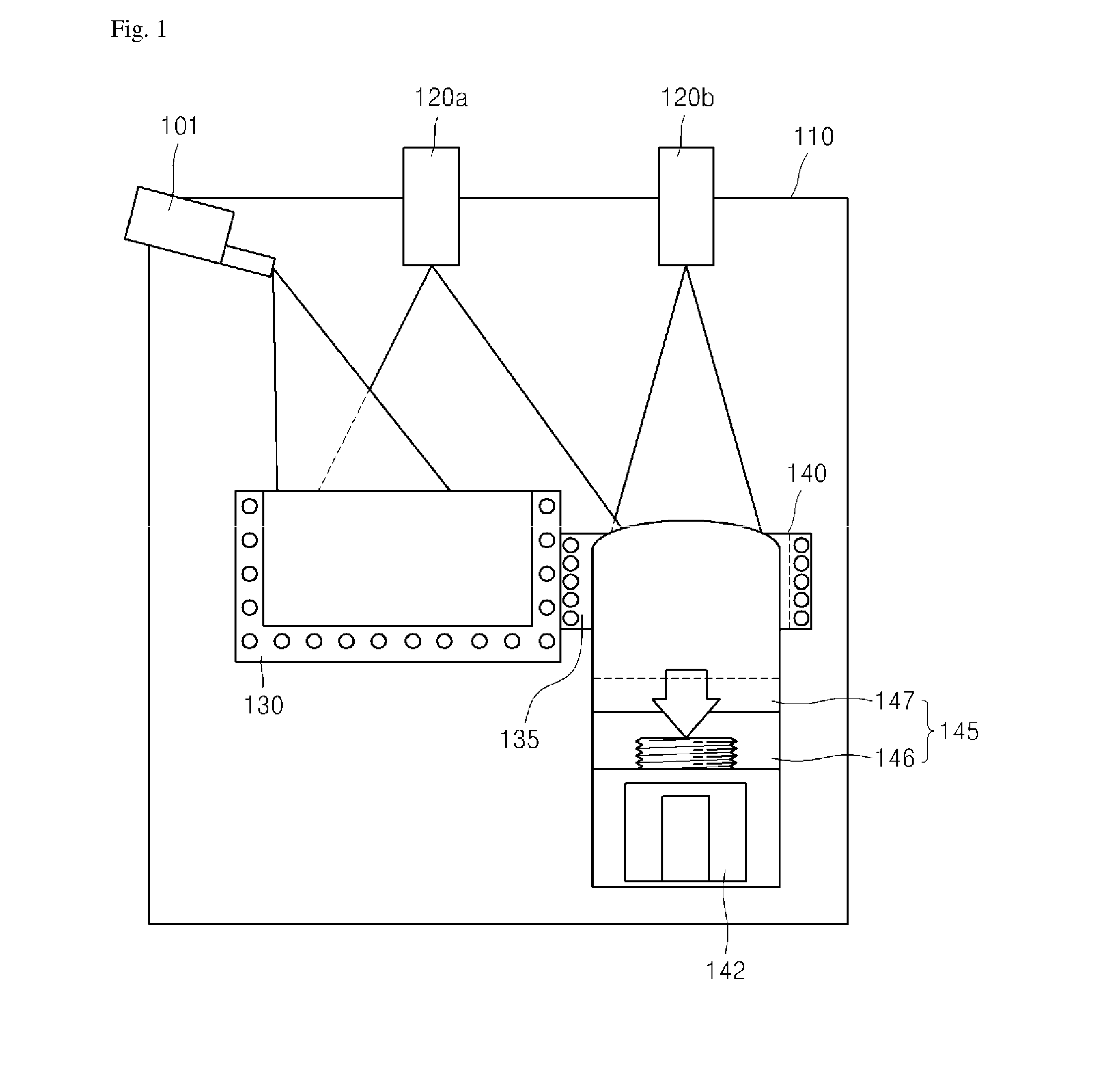

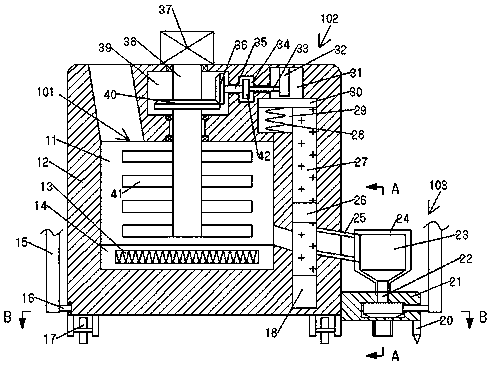

Apparatus for manufacturing polysilicon based electron-beam melting using dummy bar and method of manufacturing polysilicon using the same

ActiveUS20130291596A1Improve silicon refining efficiencyHigh puritySiliconBy zone-melting liquidsVacuum chamberElectron

Methods and apparatus for manufacturing high purity polysilicon. The apparatus includes a vacuum chamber; first and second electron guns disposed at an upper side of the vacuum chamber to irradiate electron beams into the vacuum chamber; a silicon melting unit which is placed on a first electron beam-irradiating region corresponding to the first electron gun and to which powdery raw silicon is fed and melted by the first electron beam; and a unidirectional solidification unit placed on a second electron beam-irradiating region corresponding to the second electron gun. The unidirectional solidification unit is provided therein with a start block driven in a downward direction to transfer molten silicon in the downward direction and is formed at a lower side thereof with a cooling channel. The start block includes a dummy bar having a silicon button joined to an upper portion of the dummy bar.

Owner:KOREA INST OF ENERGY RES

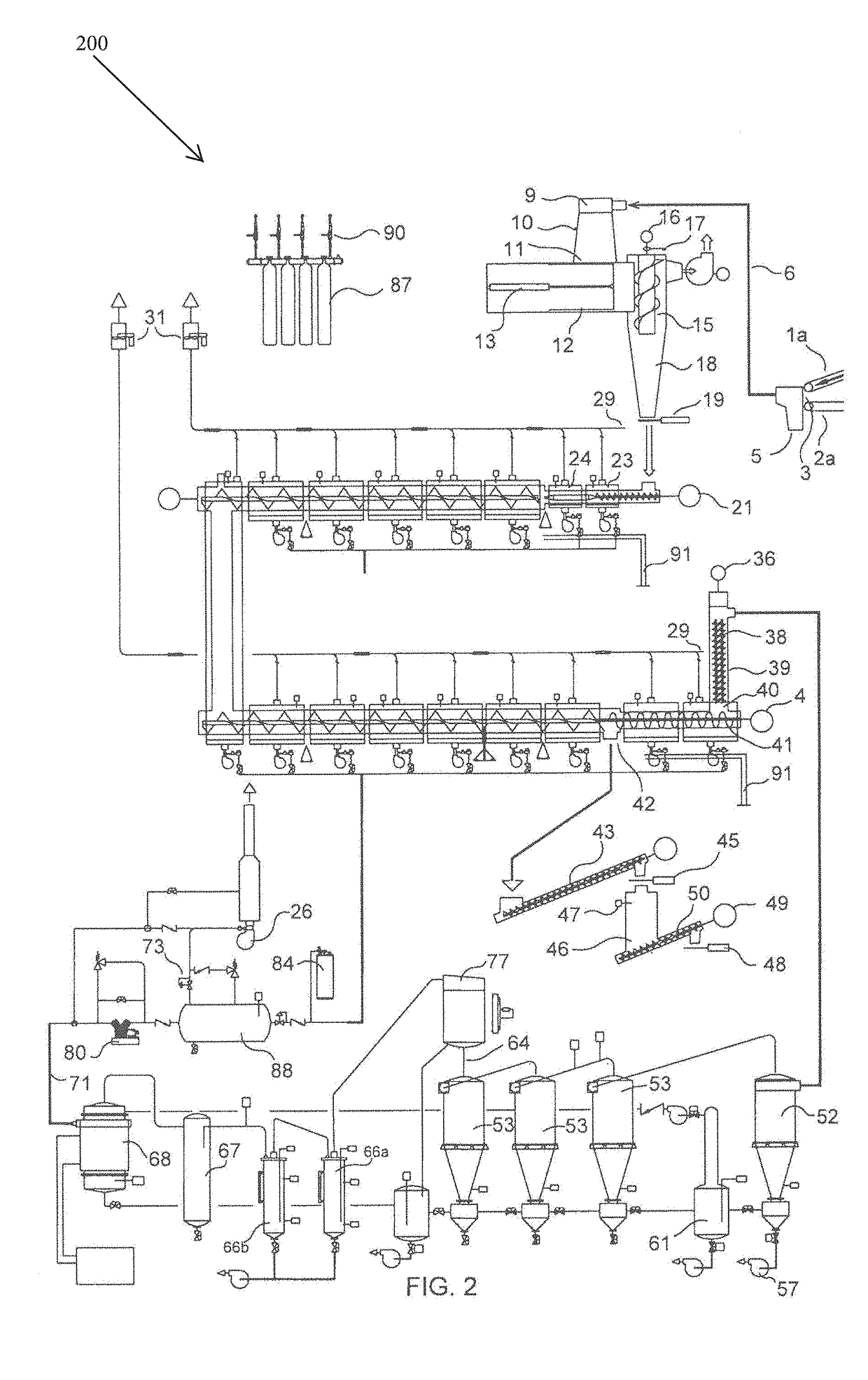

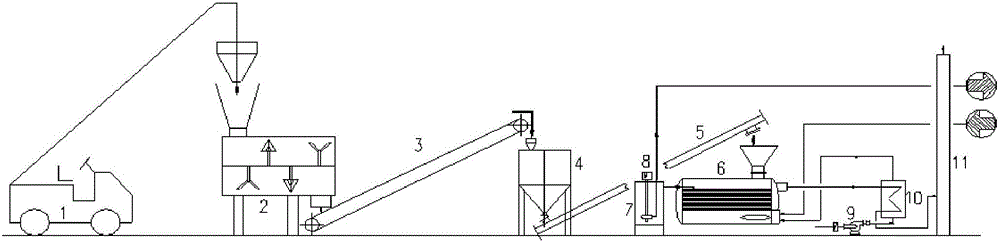

Skid-mounted fused salt pre-mixing and salt dissolving system

InactiveCN106362650AEasy to operateQuick disassemblyCombustion processFurnace typesAir preheaterMolten salt

The invention discloses a skid-mounted fused salt pre-mixing and salt dissolving system. The skid-mounted fused salt pre-mixing and salt dissolving system is composed of a mixer, a mixing groove, a fire tube salt fusing furnace, a buffering groove, an air pre-heater and a chimney. According to the skid-mounted fused salt pre-mixing and salt dissolving system, a few of sets of equipment are arranged, are simple to operate and are of a skid-mounted form; the skid-mounted fused salt pre-mixing and salt dissolving system is convenient to transport, has no foundation and is rapid to mount and dismount; investment and occupied land are saved.

Owner:EAST CHINA ENG SCI & TECH

Road engineering construction marking device for road zebra crossings

The invention discloses a road engineering construction marking device for road zebra crossings. The road engineering construction marking device for the road zebra crossings comprises a marking vehicle, wherein the marking vehicle is internally provided with a stirring cavity with an upward opening, and the stirring cavity is internally provided with a fusing mechanism capable of fusing a coating; a first bevel gear meshes with a second bevel gear to drive a rotating rod to rotate, when marking is carried out after the coating is fused by the fusing mechanism, a power mechanism drives a moving block to reciprocate up and down so that the fused coating can enter a coating cavity through a through hole and a connecting pipe, the coating cavity is filled with the coating continually, the coating can be enabled to exist in the coating cavity all the time when a marking mechanism performs marking, when each road zebra crossing is marked, the road zebra crossing cannot be broken off, and no overlapped part occurs; and in addition, a cleaning mechanism can clean a bottom surface to be marked, so that garbage and impurities are not mixed with the coating.

Owner:TAIZHOU JIAOJIANG YUTI AUTOMATION EQUIP CO LTD

Plastic modification device and method

InactiveCN113368785ATo achieve the purpose of data monitoringProcess control/regulationPlastic recyclingEngineeringMixing effect

The invention provides a plastic modification device and method. The plastic modification device comprises a stirring device, the stirring device comprises a stirring cavity and a stirring shaft rotationally arranged in the stirring cavity, the stirring shaft is provided with a viscosity detection device, and the stirring cavity is provided with a temperature detection device; the viscosity detection device can be used for detecting the viscosity of the current molten plastic in the stirring cavity when the stirring shaft is used for stirring; the plastic modification device further comprises a control device, and when the viscosity of molten plastic in the stirring cavity reaches a preset value, the control device controls the stirring shaft and the viscosity detection device to stop working. By using the plastic modification device to process the plastic according to the method, the real-time viscosity value of the molten plastic in the stirring cavity can be detected through the viscosity detection device, the current mixing effect of the plastic and the modifier in the stirring cavity can be judged by monitoring the viscosity value of the plastic in the stirring cavity, and the purposes of scientific monitoring and datamation monitoring are achieved.

Owner:深圳市三工色彩科技有限公司

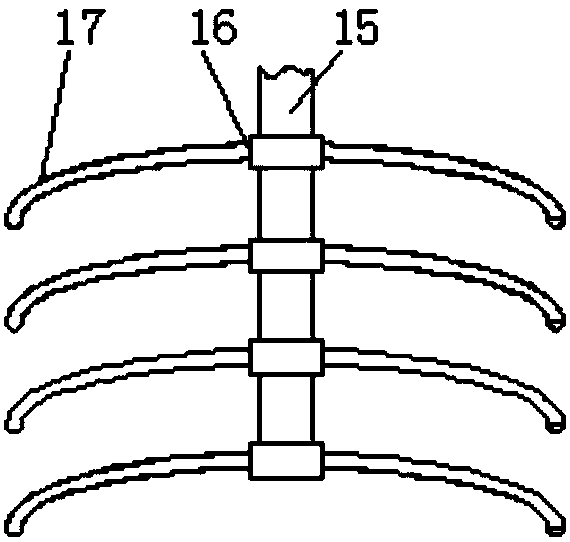

High-temperature liquid-state nitrate purification and performance enhancement fusing tank

ActiveCN106861582AImprove high temperature thermal stabilityLess corrosiveNitrogen compoundsChemical/physical/physico-chemical stationary reactorsNitratePerformance enhancement

The invention relates to a high-temperature liquid-state nitrate purification and performance enhancement fusing tank. A filtering plate (4) is horizontally arranged inside a tank body (2), a hollow stirring rod (16) is arranged in the middle of the top of the tank body (2) towards the tank body (2), the lower end of the hollow stirring rod (16) is positioned on the upper side of the filtering plate (4), a stirring paddle (3) is arranged on the lower end of the hollow stirring rod (16), the lower end of the hollow stirring rod (16) is connected with a bubbler (5) which downwards penetrates through the filtering plate (4). Dry air, carbon dioxide and nitrogen gas are sequentially fed, the stirring paddle (3) is used for stirring while the bubbler (5) conducts gas introduction, and through the coordinated and reasonable structure arrangement of the stirring paddle and the bubbler and by bubbling, stirring, filtering, additive addition and the like under the high-temperature melting state, the purification function of high nitrate can be realized, the impurity removal and purification rate of the fused salt is up to 97%, the high-temperature thermal stability of nitrate can be enhanced, and the corrosivity of nitrate can be reduced. The stirring and homogenization time is short, and the high-temperature liquid-state nitrate purification and performance enhancement fusing tank is energy-saving, environment-friendly, safe and high in efficiency.

Owner:上海煜志科技有限公司

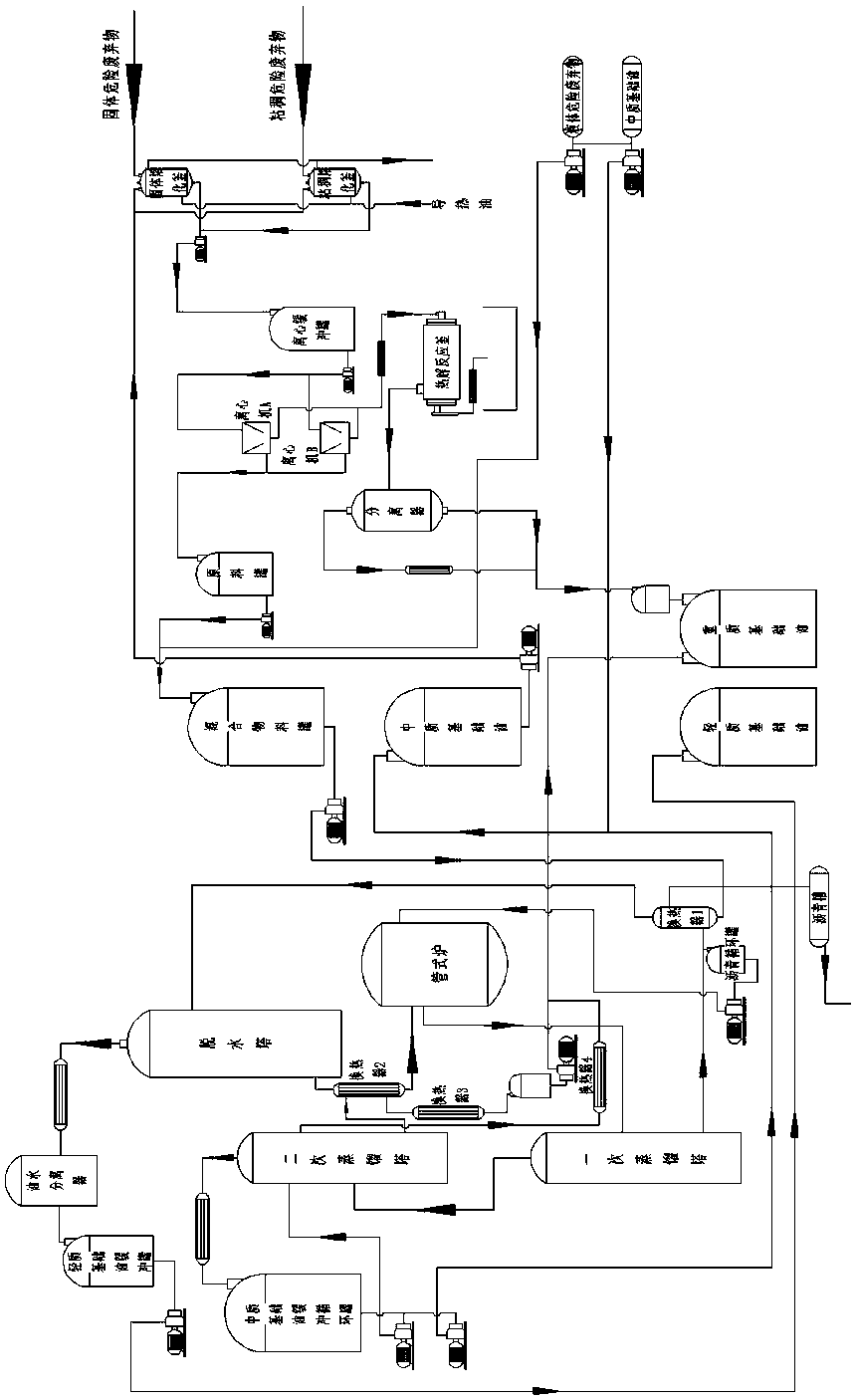

Industrial HW11 and HW08 hazardous waste treatment method

ActiveCN109456785AStrengthen the whole process supervisionSolving Disposal ProblemsLiquid hydrocarbon mixture productionSpecial form destructive distillationMixed materialsBase oil

The invention belongs to the technical field of industrial hazardous waste treatment, particularly relates to an industrial HW11 and HW08 hazardous waste treatment method and aims to provide a treatment method for pyrolyzing HW11 and HW08 hazardous wastes by indirect heating. The technical scheme includes that the HW11 and HW08 hazardous wastes are classified into solid hazardous wastes, viscous hazardous wastes and liquid hazardous wastes, the solid hazardous wastes and the viscous hazardous wastes are added into a melting kettle, extraction agents are added into the melting kettle, indirectheating extraction is performed, the wastes are centrifugally separated to obtain filtrate and filter residues, the solid hazardous wastes, the viscous hazardous wastes and the liquid hazardous wastesare mixed to obtain mixed materials, the mixed materials are dewatered and distilled to obtain light base oil, medium base oil, heavy base oil and maltha, and the solid hazardous waste filter residues and the viscous hazardous waste filter residues are pyrolyzed to obtain pulverized coal.

Owner:山西洪旭环保科技有限公司

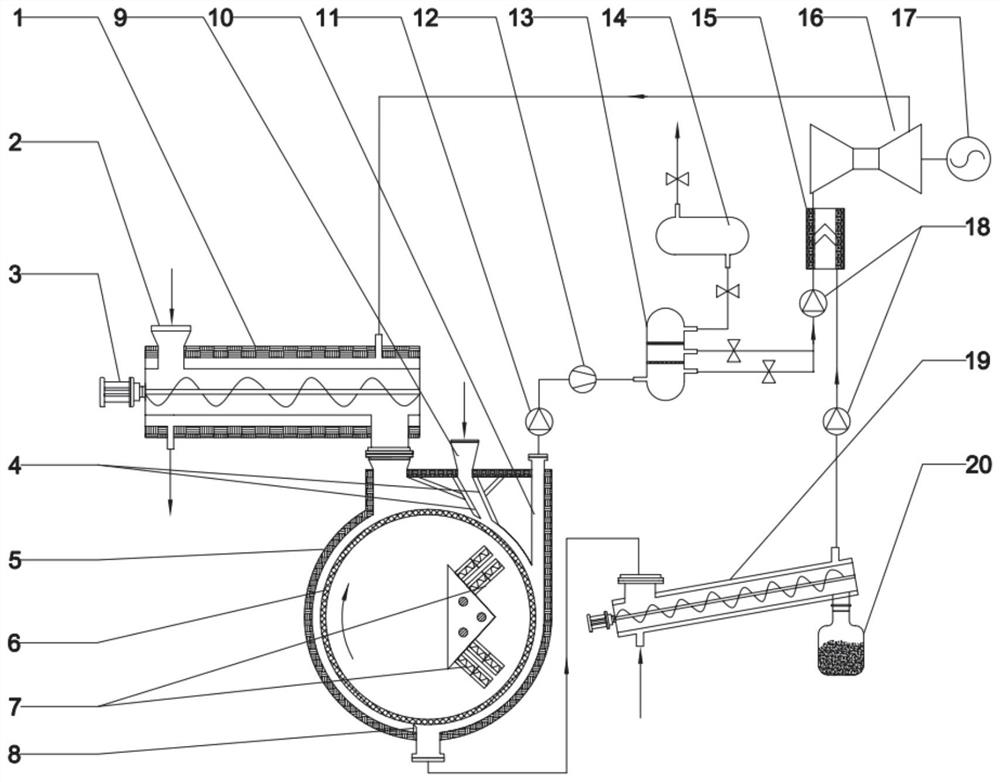

System and method for preparing carbon nanofiber and hydrogen through microwave continuous pyrolysis

ActiveCN113457575AIncrease profitShort processCombustion enginesCarbon nanotubesCatalytic pyrolysisPlastic waste

The invention relates to a system and method for preparing carbon nanofibers and hydrogen through microwave continuous pyrolysis. The system comprises a melting feeding device used for carrying out heating melting treatment on materials, a microwave pyrolysis device used for carrying out catalytic pyrolysis on materials, a pyrolysis gas purification and utilization device and a power generation device; the microwave pyrolysis device comprises a material inlet, a pyrolysis gas outlet and a carbon product outlet, and the material inlet is connected with the material outlet of the melting feeding device; the pyrolysis gas purification and utilization device is connected with the pyrolysis gas outlet and is used for carrying out hydrogen purification and residual gas separation on the pyrolysis gas generated by catalytic pyrolysis; and the power generation device comprises a small internal combustion engine and a power generator, and the small internal combustion engine uses residual gas as fuel and conveys flue gas generated by combustion to the melting feeding device to serve as a heat source for material melting. The poly-generation system for co-producing the high-performance carbon material and the hydrogen from the plastic waste is formed, the technical problems that a traditional pyrolysis method is low in product yield and high in energy consumption are solved, and the energy utilization rate is greatly increased.

Owner:SOUTHEAST UNIV

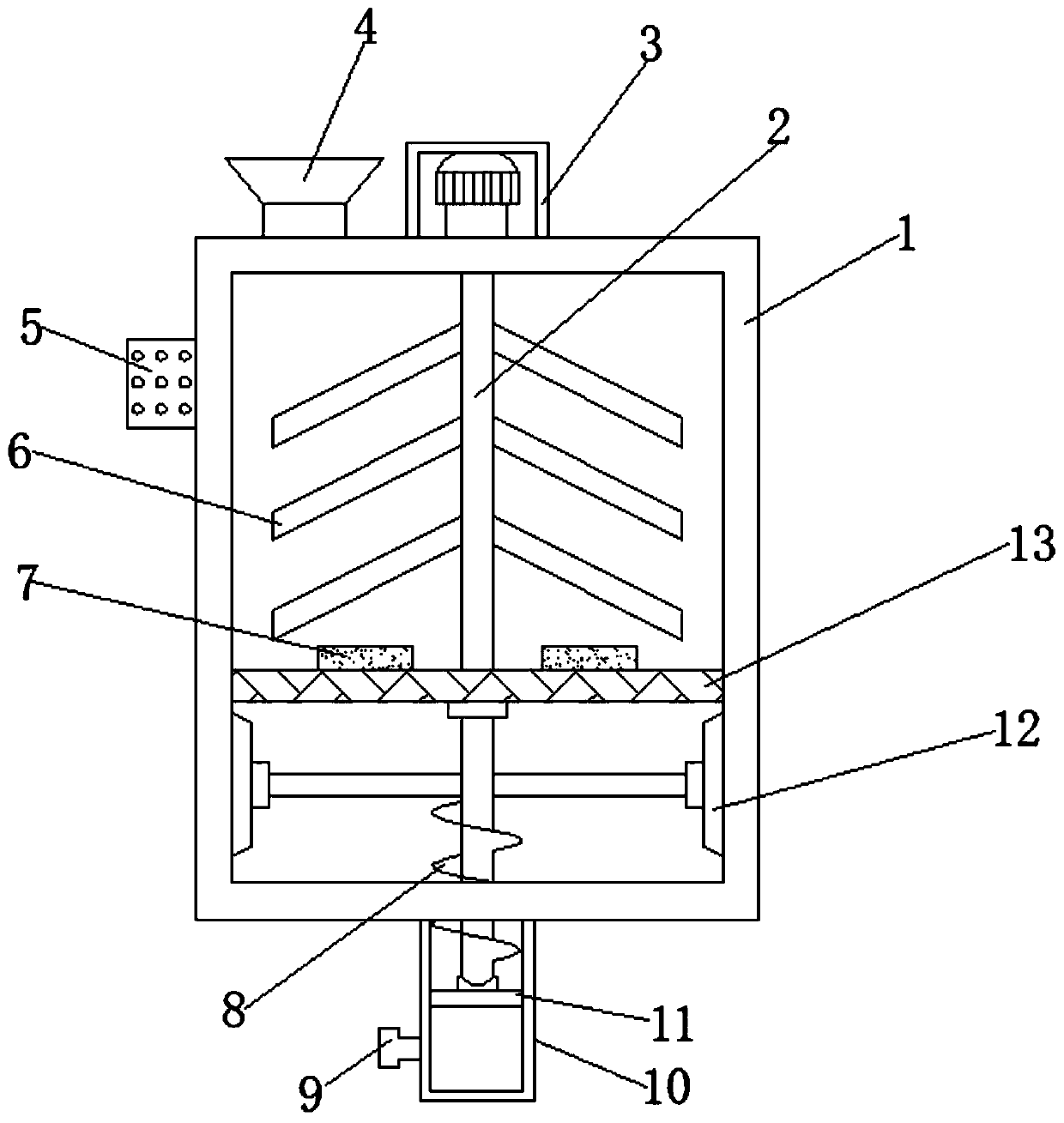

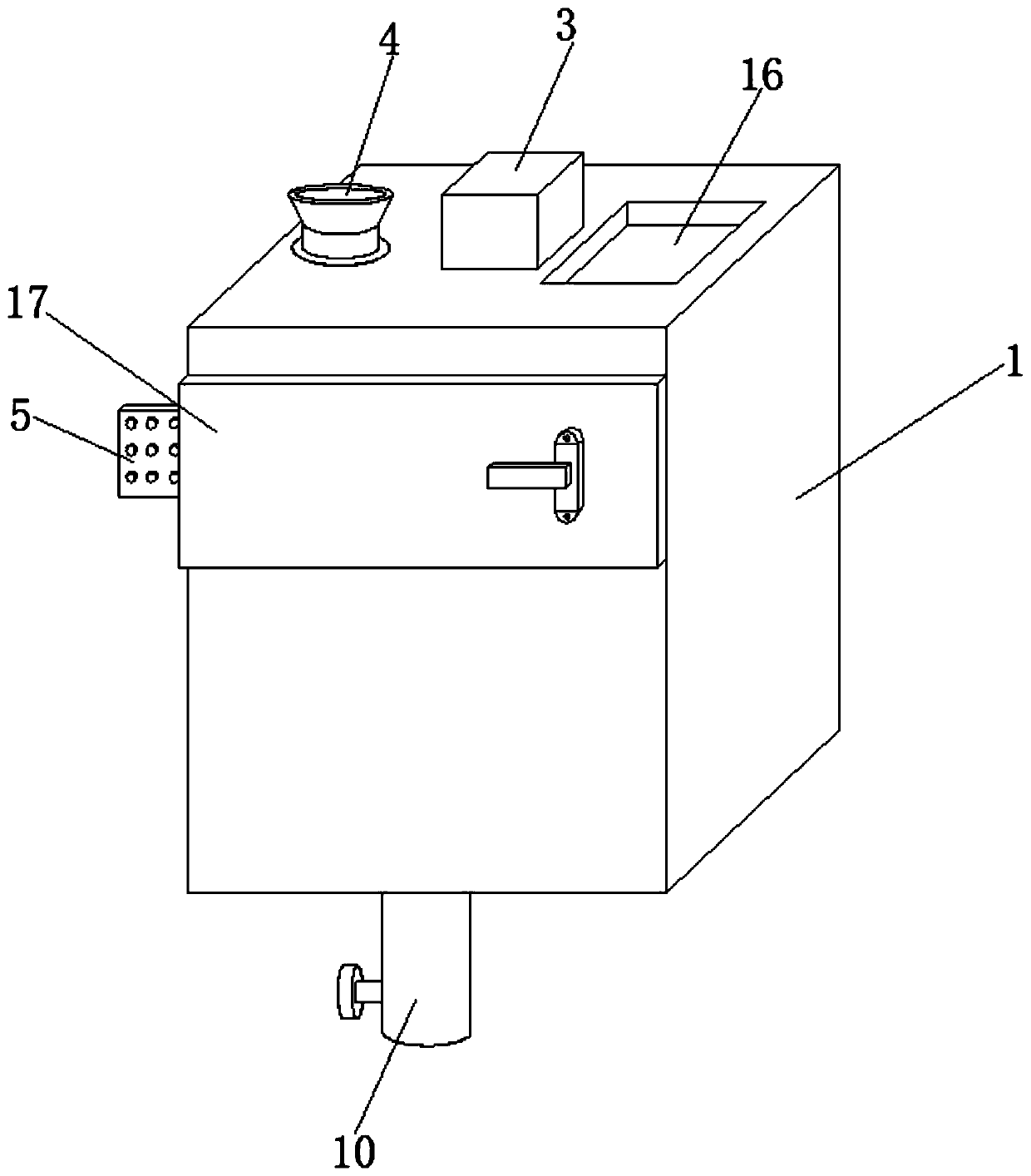

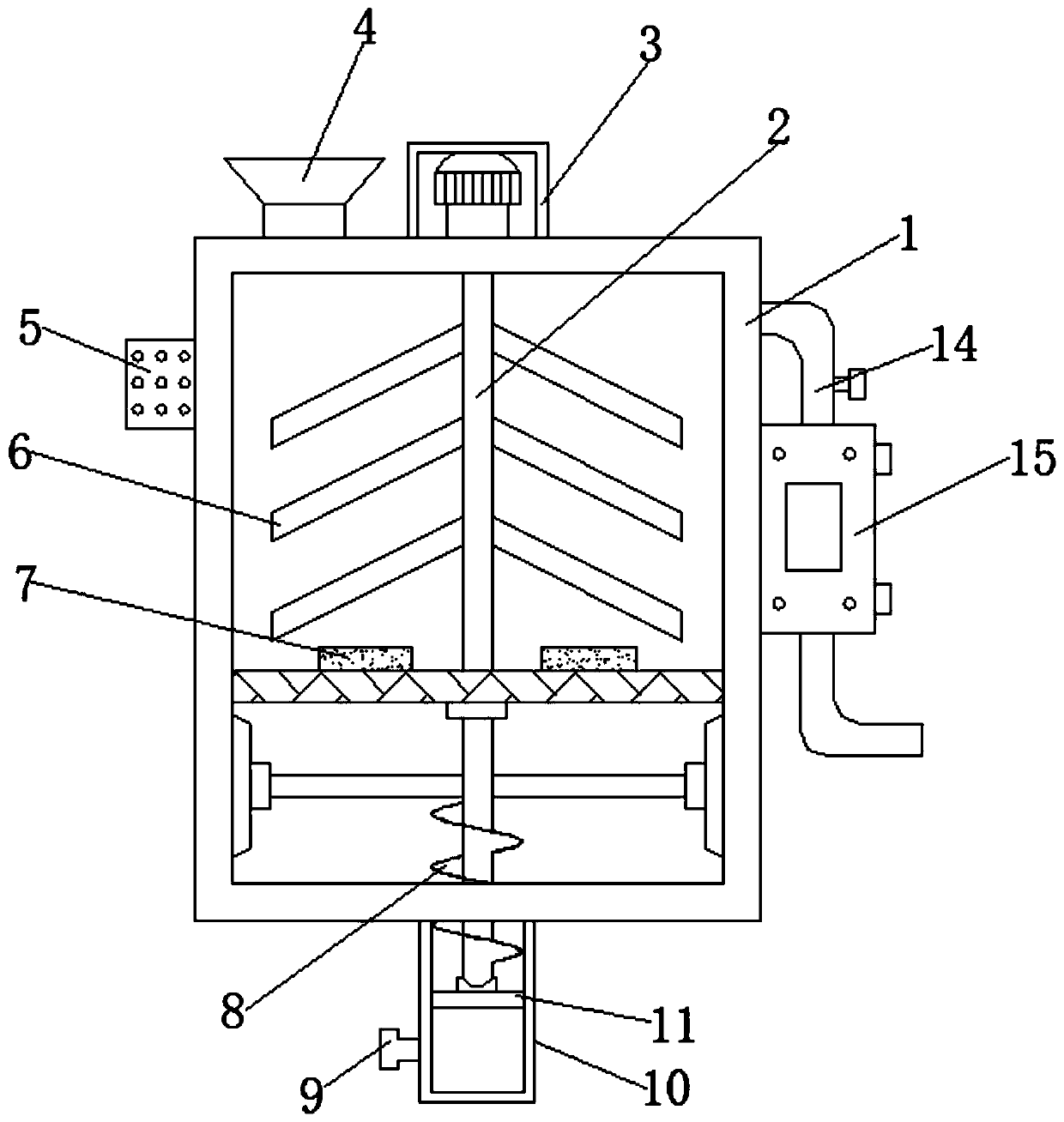

Melting device for curing agent coating producion

InactiveCN110665439AImprove filtering effectIncrease melting rateFusionElectric machineFirming agent

The invention discloses a melting device for curing agent coating production, which comprises a box body, wherein filter screens are arranged on the inner walls of two sides of the box body, heating blocks are arranged on the outer wall of the top of the filter screens, a fixing hole is formed in the outer wall of the top of the box body, a feed hopper is arranged in the fixing hole, a protectiveshell is arranged on the outer wall of the top of the box body, a motor is arranged on the inner wall of the top of the protective shell, a rotating column is arranged on the outer wall of one end ofan output shaft of the motor, stirring rods are arranged on the outer walls of two sides of the rotating column, and a discharging pipe is inserted into the inner wall of the bottom of the box body. According to the invention, when the rotating column rotates, a propeller is driven to rotate, and materials in the box body can be discharged through the discharging pipe at this time, so that discharging work of people is facilitated, blockage of the discharging pipe is avoided, and materials adhered to the inner wall of the box body can be scraped off through the scraper, so that cleaning of workers is facilitated, and waste of resources is avoided.

Owner:湖北汉耐尔新材料科技有限公司

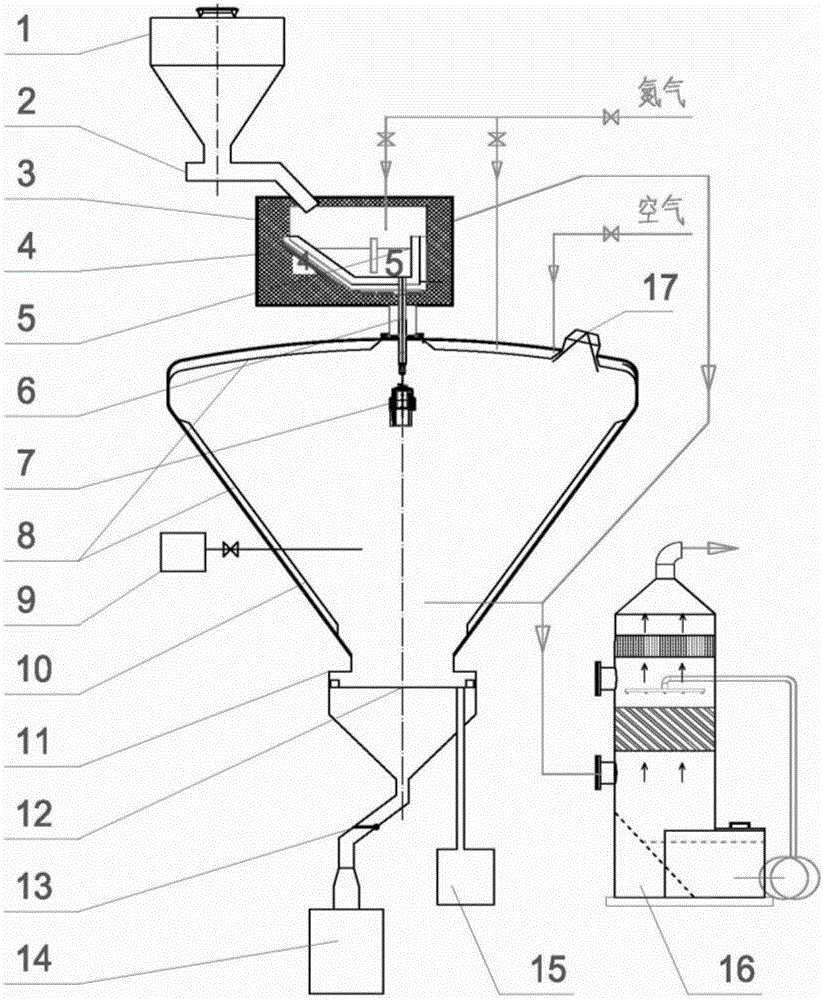

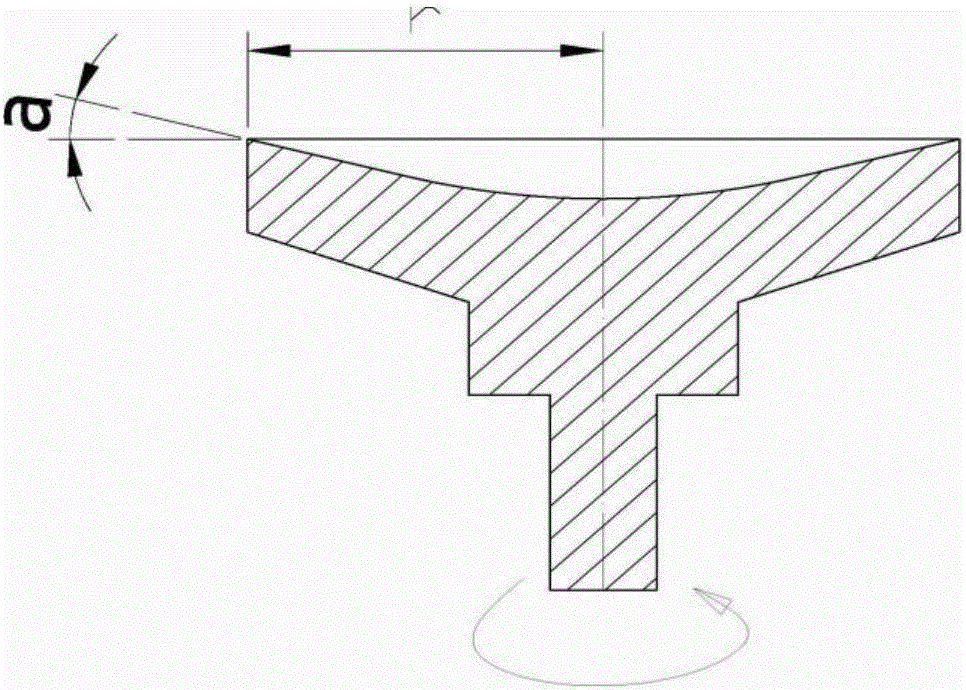

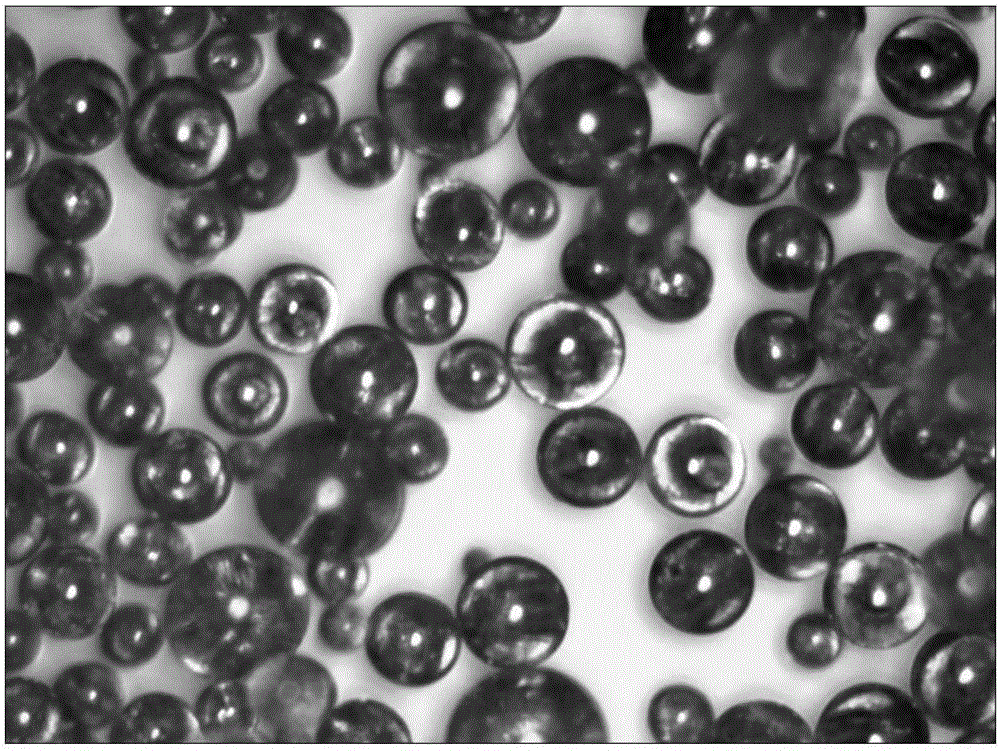

Melting atomization system, high-activity spherical cuprous chloride catalyst prepared through system and preparation method of high-activity spherical cuprous chloride catalyst

ActiveCN105817178AChange or increase catalytic activityChange or increase activityCatalyst activation/preparationGranulation by liquid drop formationDispersityGranularity

The invention relates to a melting atomization system, a high-activity spherical cuprous chloride catalyst prepared through the system and a preparation method of the high-activity spherical cuprous chloride catalyst.The melting atomization system comprises a material storage barrel, a conveying feeder, a melting furnace, an atomizing tank and a screening mechanism which are sequentially connected.A rapid melting device and an atomizing tundish furnace are arranged in the melting furnace.An atomizing plate is arranged in the atomizing tank.The atomizing tundish furnace is connected with the atomizing plate through a flow guide pipe.A screen is built in the screening mechanism.The bottom of the screening mechanism is connected with a finished product package machine through a pipeline which is provided with a power discharge valve.The upper portion of the screen is connected with a rough powder collecting tank through a collecting pipeline.The melting furnace rapidly melts a cuprous chloride raw material, then the temperature is raised and kept through the atomizing tundish furnace, and molten liquid is continuously atomized.Spherical cuprous chloride powder can be continuously and industrially produced, the sphericity degree of CuCl powder is good, granularity is quite concentrated, granule dispersity is good, catalysis activity is good, and consistency of catalysis quality is high.

Owner:HUIJIN ATOMIZING SCI

System and method for manufacturing carbon nanotubes

InactiveUS7985394B2Allow for manufactureLow costMaterial nanotechnologyCarbon compoundsMulti-Walled NanotubeMaterials science

Owner:DUVALL GIDEON

Powder coating processing device

The invention discloses a powder coating processing device which comprises a melting mechanism and a tabletting mechanism. The melting mechanism comprises a melting tank, two stirring rods and a rotating part, the melting tank is arranged on the supporting frame, a pre-melting tank is arranged at the eccentric position of the bottom of the melting tank, the bottoms of the two stirring rods are located in the melting tank and the pre-melting tank respectively, the tops of the two stirring rods penetrate through the horizontal plate, a rotating disc is arranged at the tops of the stirring rods, and a plurality of columns are sequentially arranged at the top of the rotating disc in the circumferential direction; the rotating part comprises a first motor and an annular plate, a plurality of U-shaped notches are sequentially formed in the inner wall of the annular plate in the circumferential direction, the column bodies are matched with the U-shaped notches, a support is arranged at the top of the annular plate, and an output shaft of the first motor is connected with the support; the tabletting mechanism comprises two rollers and a displacement part, and the displacement part is used for adjusting the distance between the two rollers. Part of the raw materials can be pre-melted in a small melting tank, and then all the raw materials are melted and mixed in a large melting tank.

Owner:成都瑞德琅科技有限公司

Chemical experiment crystal melting device

InactiveCN108479642AIncrease the heating areaEvenly heatedHeating or cooling apparatusFusionCompound (substance)Thermal energy

The invention discloses a chemical experiment crystal melting device which comprises a crystal melting device body, wherein a top opening is integrally cast at the top of the crystal melting device body, a first annular fixed frame is in sleeve connection to the bottom of the outer side of the top opening, heat-insulation handles are symmetrically welded to the two sides of the first annular fixedframe, a second annular fixed frame is in sleeve connection to the outer side of the top opening and at the top of the first annular fixed frame, an arc heat-insulation frame is connected to the outer side of the second annular fixed frame through a connection frame at the annular same angle, three clamping connection holes are formed in the second annular fixed frame at the annular same angle, and the clamping connection holes are connected with a protection cover plate through connection pins. In the chemical experiment crystal melting device disclosed by the invention, a heating base is designed as an arc structure, so that a heating area of the crystal melting device body is obviously enlarged, a thermal energy utilizing rate is improved, thermal energy loss is reduced, and a heatingefficiency is improved.

Owner:长沙亚斯智能科技有限公司

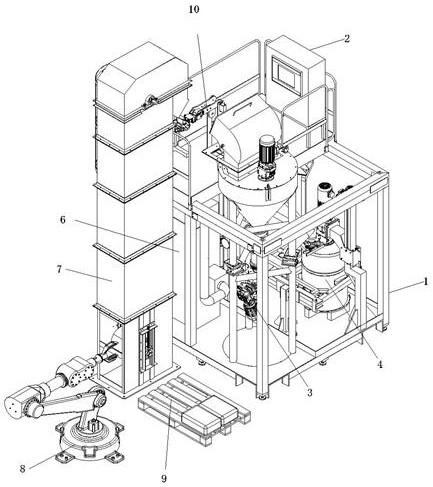

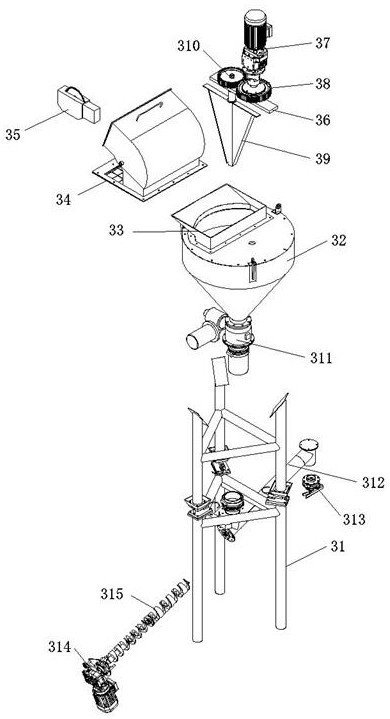

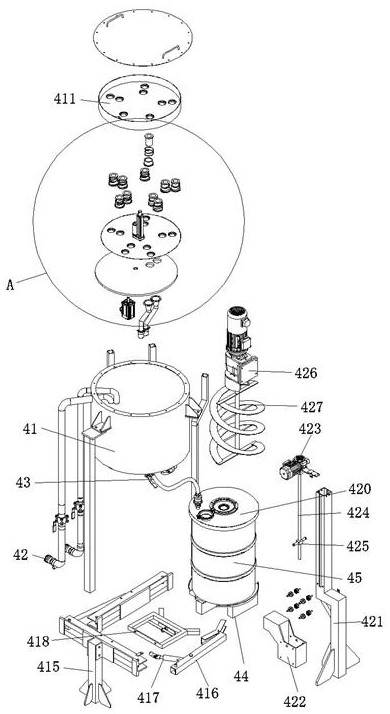

Intelligent efficient semi-solid molecule pulping device

ActiveCN113244875AEasy to take outAchieving Quantitative ControlTransportation and packagingRotary stirring mixersMetal machiningProcess engineering

The invention discloses an intelligent efficient semi-solid molecule pulping device which comprises a mounting platform, a control box, a pulping mechanism, a mixing mechanism, a heating device, an elevator, a transfer mechanical arm, a material tray and a carrying mechanical arm. The control box is arranged at the top end of the mounting platform; the pulping mechanism is arranged at the front end of the inner side of the mounting platform; the mixing mechanism is arranged at the rear end of the inner side of the mounting platform; the heating device is mounted at the left end of the inner side of the mounting platform; and the material tray is arranged on the rear side of the transfer mechanical arm. According to the intelligent efficient semi-solid molecule pulping device, high-molecular compound pulping assembly line automatic operation in the metal processing process can be achieved, automatic feeding of bagged raw materials and compound mixing pulping are achieved, manual operation items of workers are reduced, the automation degree is high, quantitative control over compound adding is achieved, and the staff can change in time according to needs.

Owner:江苏固家智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com