Skid-mounted fused salt pre-mixing and salt dissolving system

A technology of molten salt and chemical salt, applied in the direction of melting, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large heating furnace and complicated disassembly and assembly, and achieve the effect of saving investment, occupying land, and quickly disassembling and assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

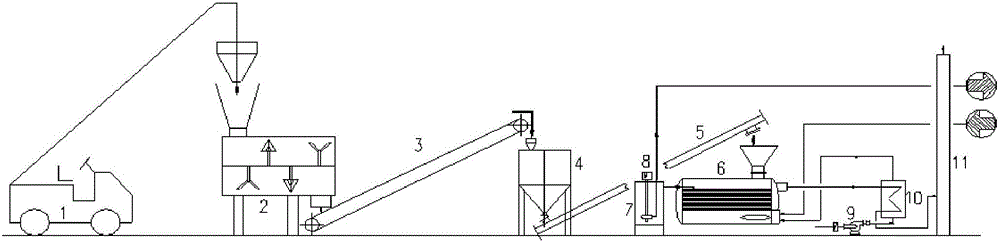

[0030] Such as figure 1 , figure 2 As shown, a skid-mounted molten salt premixing and salt melting system includes:

[0031] Mixer 2 is used to accommodate the sodium nitrate, potassium nitrate or other salts suspended by crane 1, sodium nitrate, potassium nitrate or other salts, and the above salts can be proportioned according to technical requirements (such as sodium nitrate 60%+potassium nitrate 40% %, potassium nitrate 53%+sodium nitrite 40%+sodium nitrate 7%) are mixed in mixer 2;

[0032] Mixing tank 4, the top of which is connected to the bottom of mixer 2 through belt conveyor 3, and the mixed sodium nitrate, potassium nitrate or other salts in mixer 2 are sent to mixing tank 4 by belt conveyor 3;

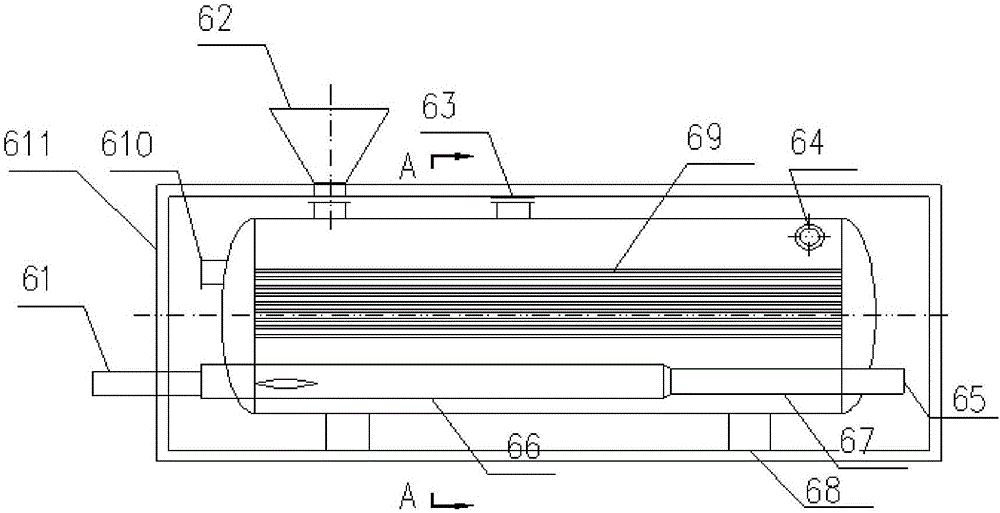

[0033] The fire tube molten salt furnace 6 has a horizontal furnace structure. The inside of the fire tube molten salt furnace 6 is heated by burners. The side wall of the furnace body is provided with an overflow port, and the end of the furnace body is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com