Patents

Literature

2084 results about "Thermal power station" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermal power station is a power station in which heat energy is converted to electric power. In most of the places in the world the turbine is steam-driven. Water is heated, turns into steam and spins a steam turbine which drives an electrical generator. After it passes through the turbine, the steam is condensed in a condenser and recycled to where it was heated; this is known as a Rankine cycle. The greatest variation in the design of thermal power stations is due to the different heat sources; fossil fuel dominates here, although nuclear heat energy; solar heat energy, biofuels and waste incineration are also used. Some prefer to use the term energy center because such facilities convert forms of heat energy into electrical energy. Certain thermal power stations are also designed to produce heat energy for industrial purposes, or district heating, or desalination of water, in addition to generating electrical power.

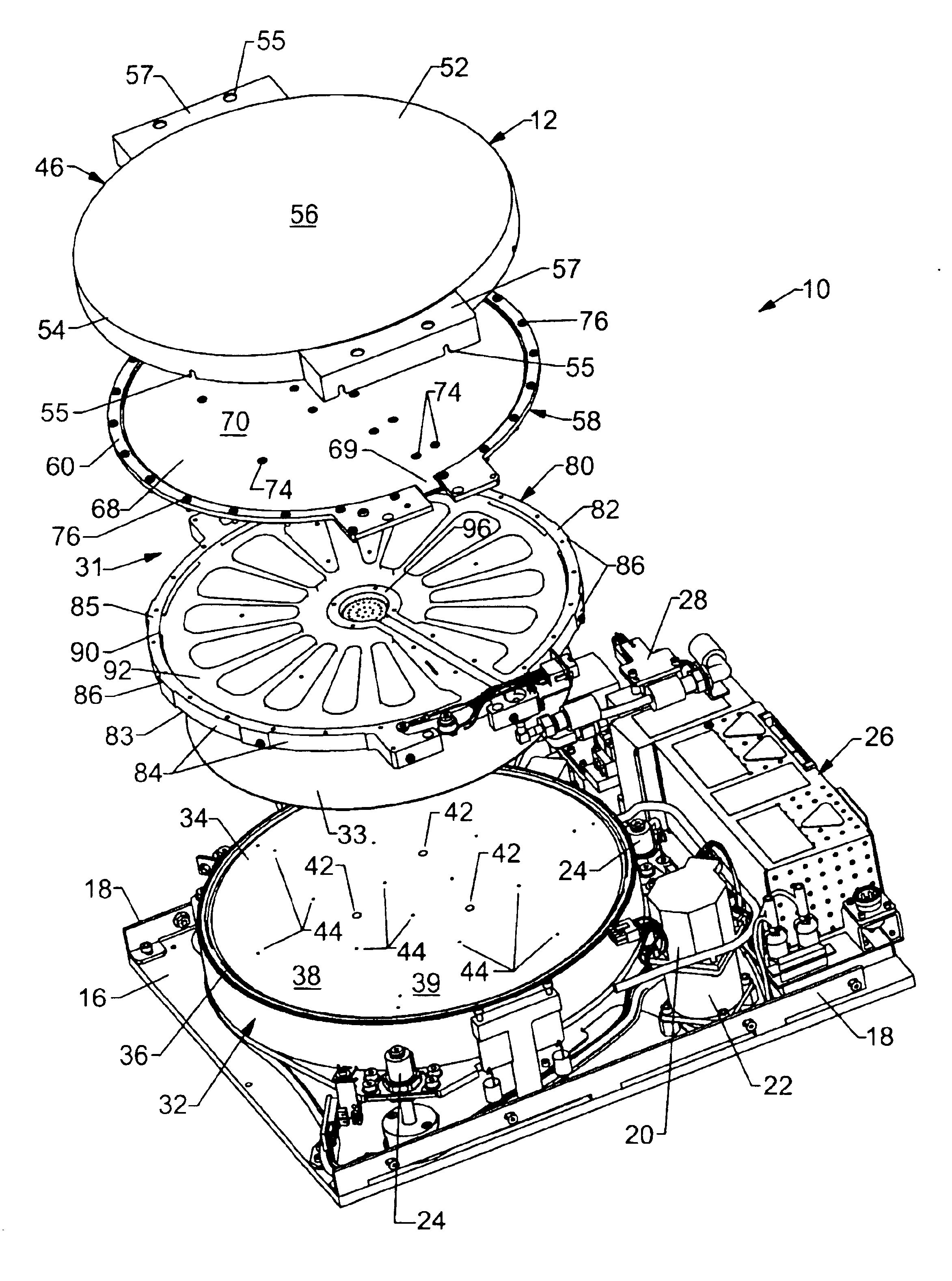

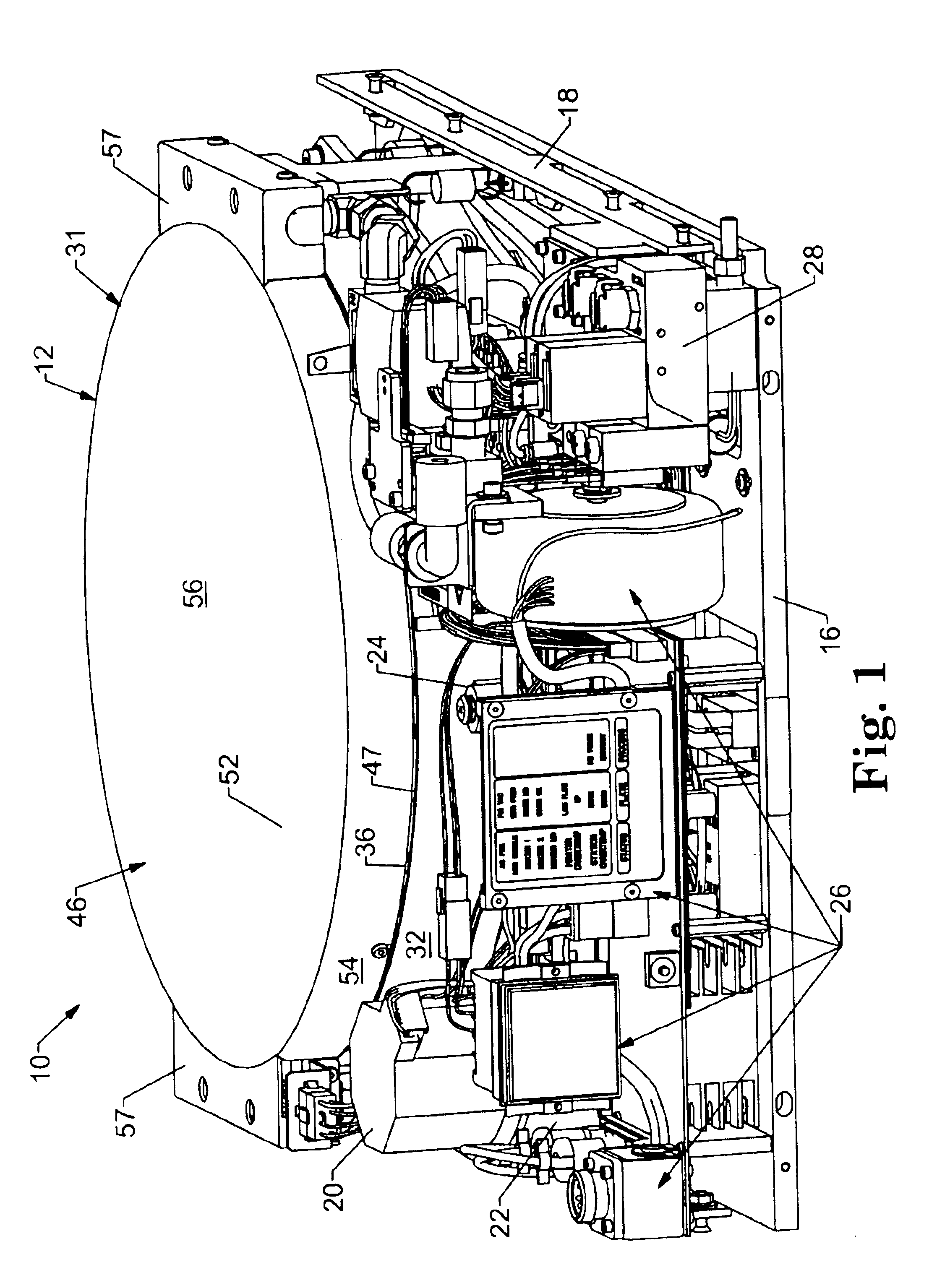

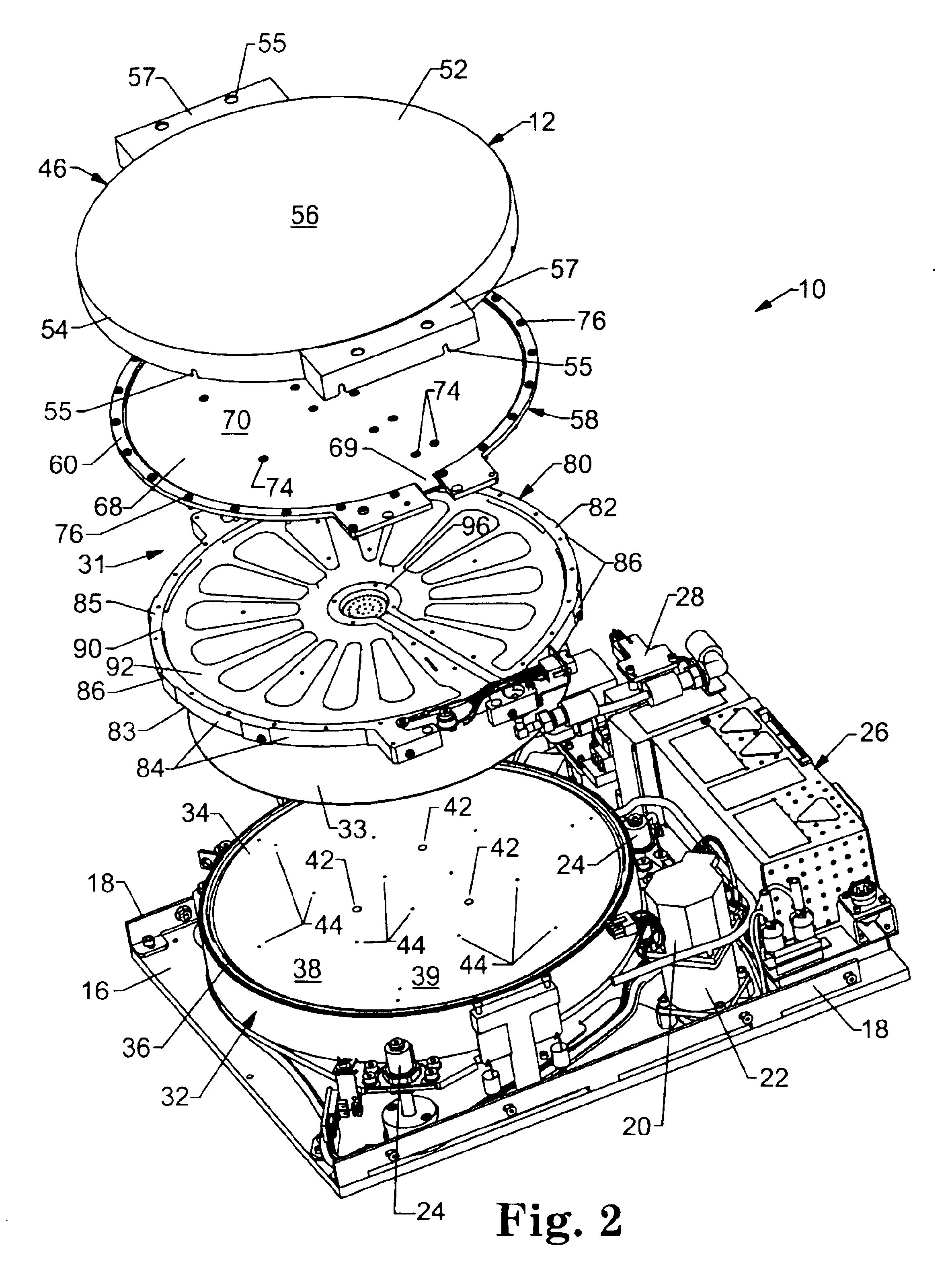

Thermal process station with heated lid

ActiveUS6884066B2Improve thermal uniformityImprove temperature uniformityCharge supportsSemiconductor/solid-state device manufacturingResistThermal energy

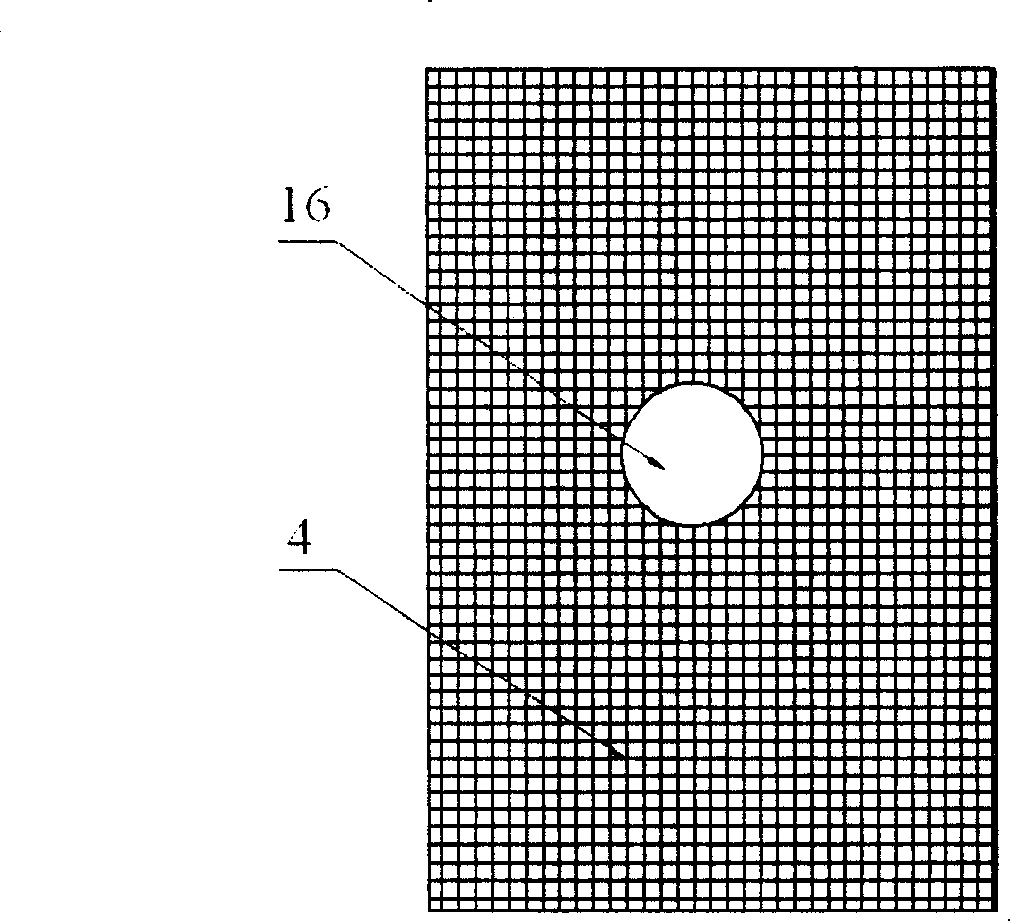

Methods and apparatuses to improve the temperature uniformity of a workpiece being processed on a heated platen of a thermal processing station. A heated platen is enclosed in a housing incorporating an additional heat source that uniformly outputs thermal energy into the process chamber in which the heated platen is positioned. In preferred embodiments, this heat source is positioned in the lid of the housing. It is additionally preferred that the heated lid includes features that provide a gas flow path to introduce to and / or purge gas from the process chamber. In terms of photoresist performance, the improved thermal uniformity provided by using such an additional heat source in the housing, e.g., in the lid, offers improved line width control and line uniformity across a wafer.

Owner:TEL EPION

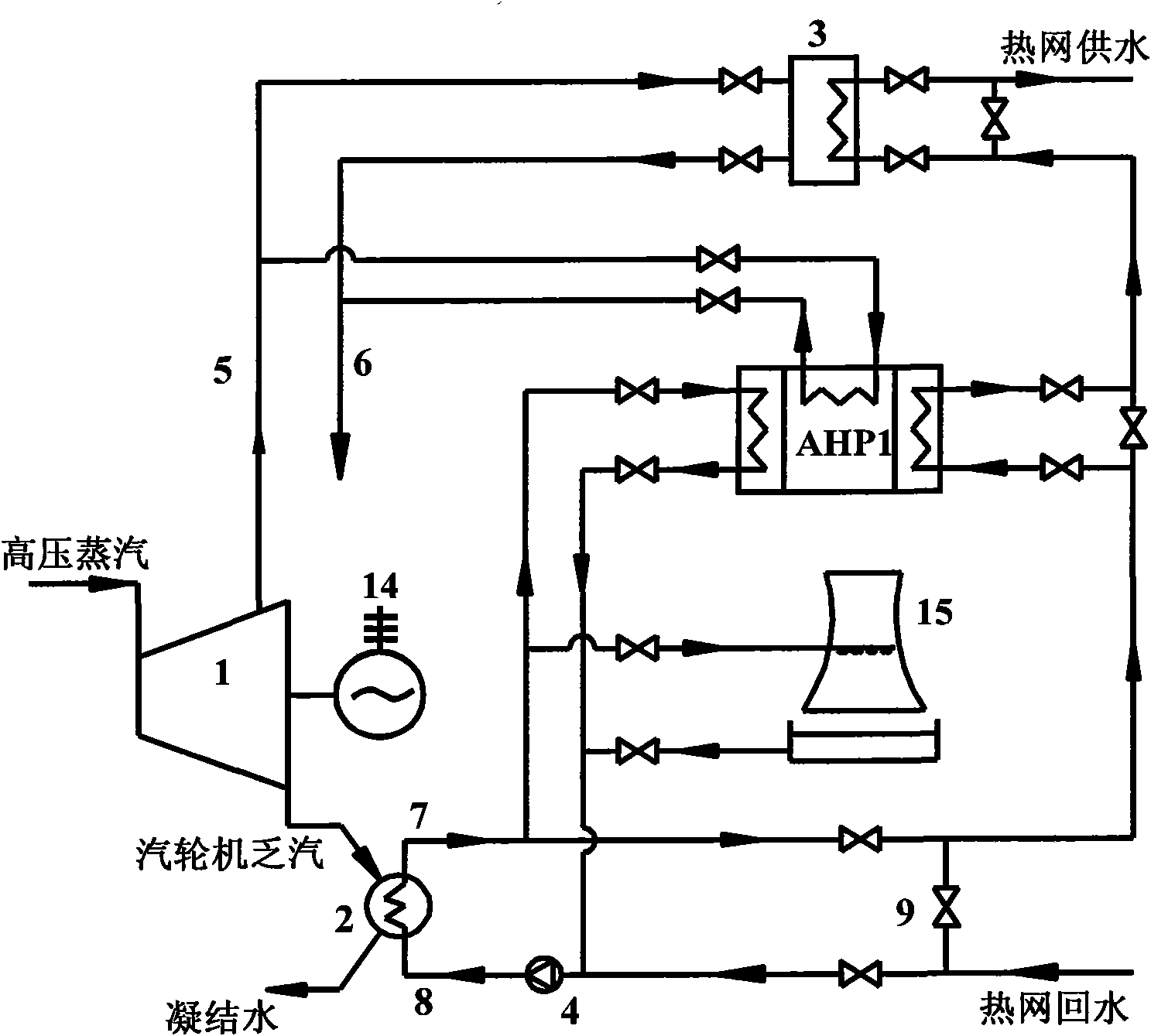

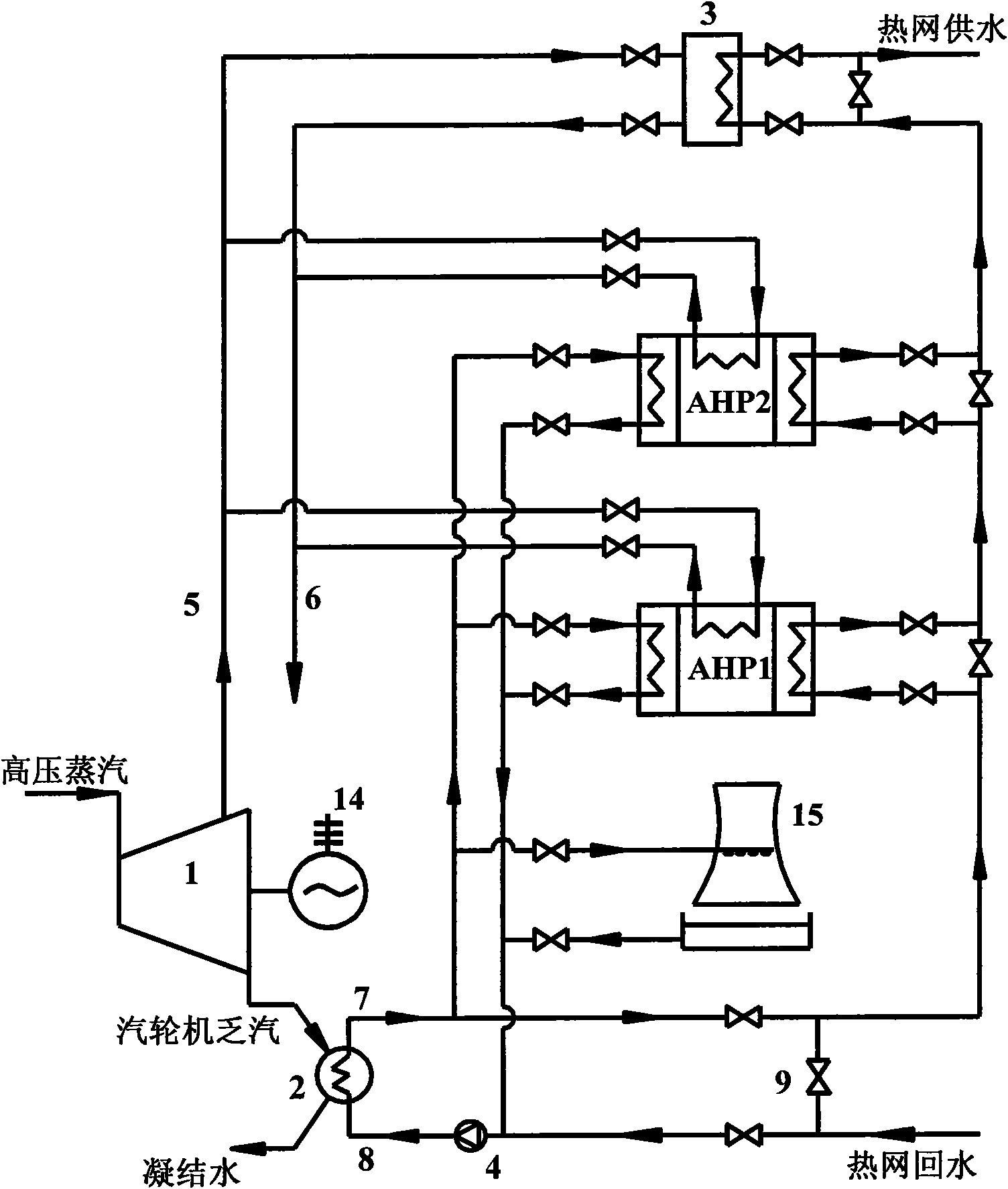

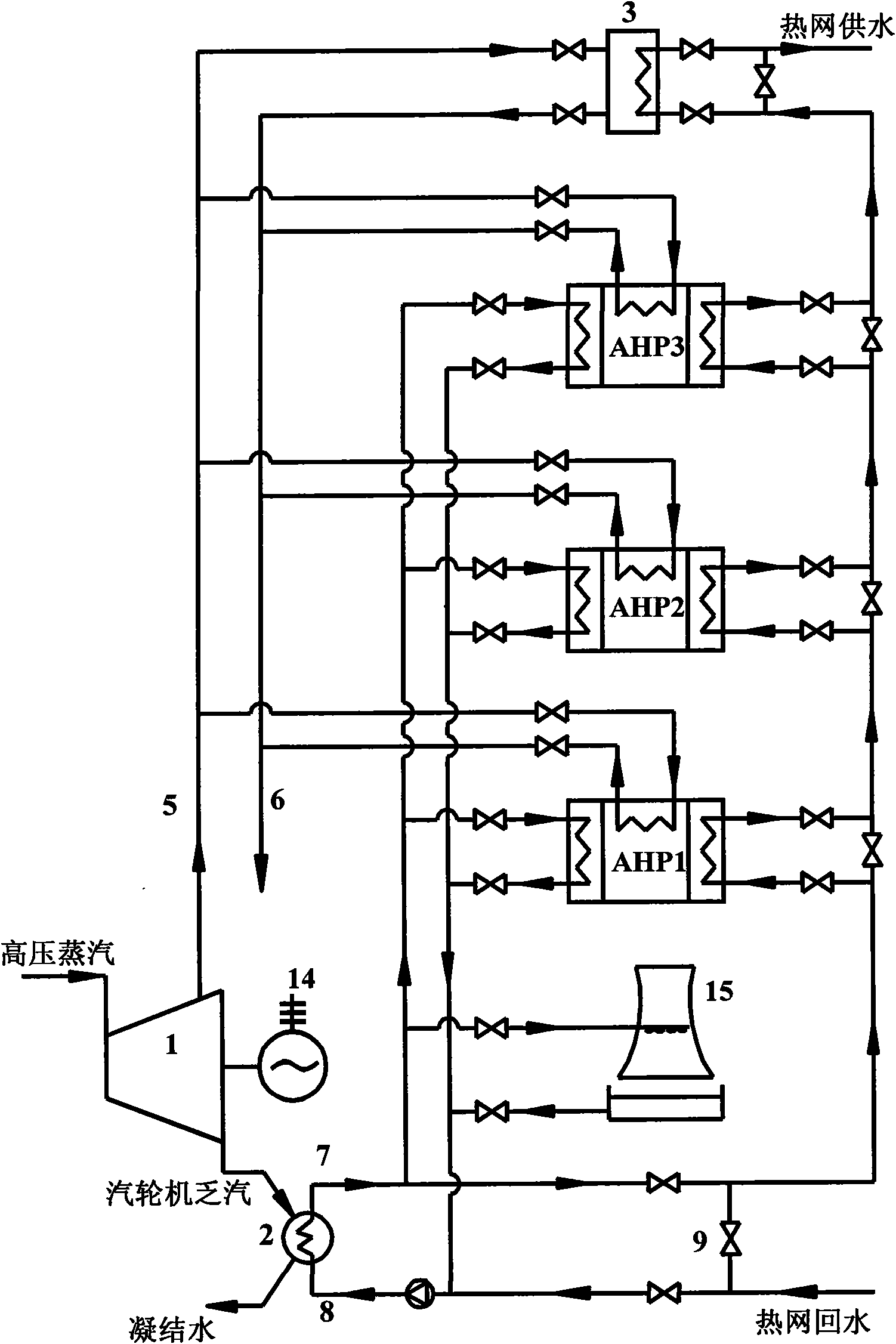

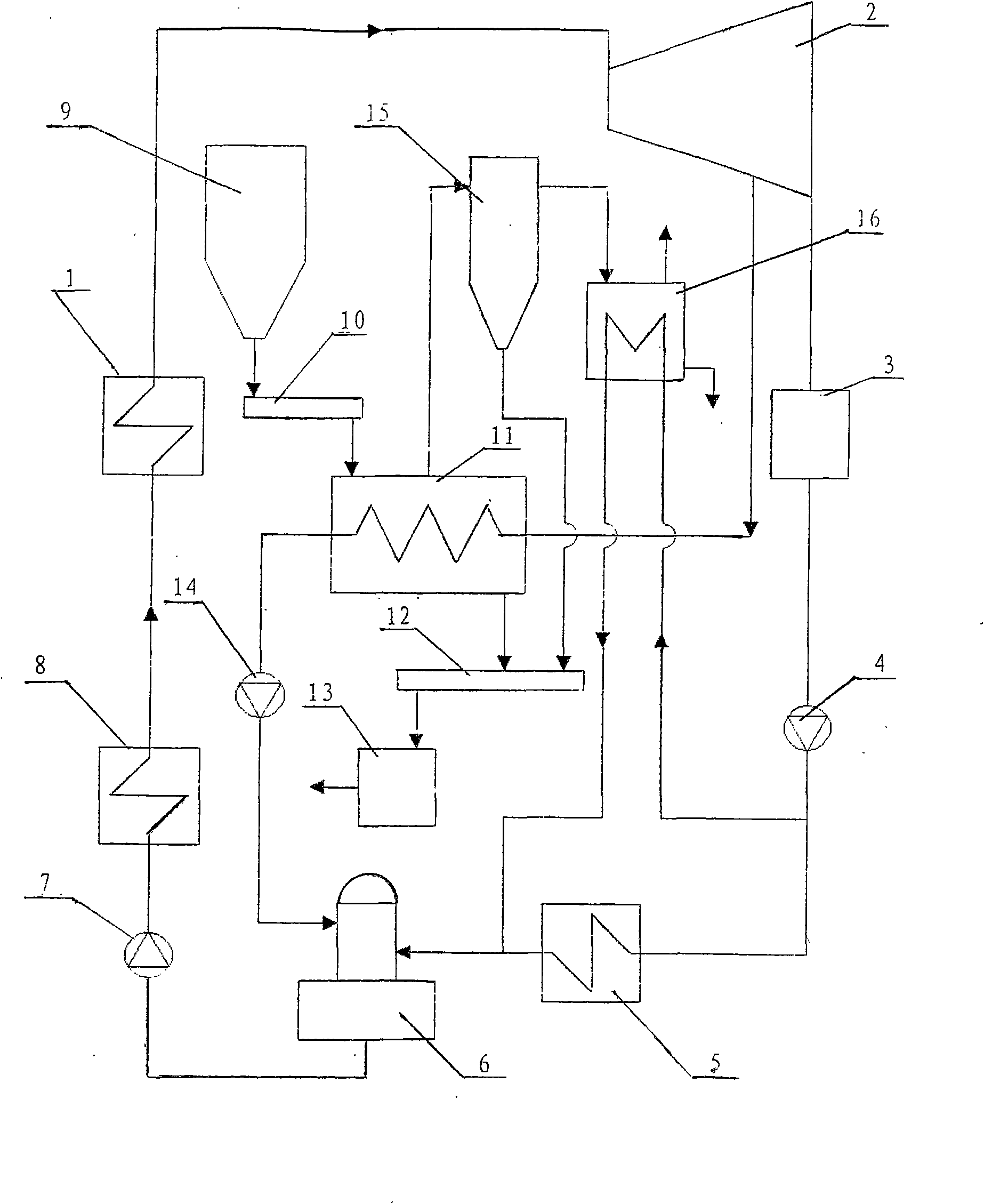

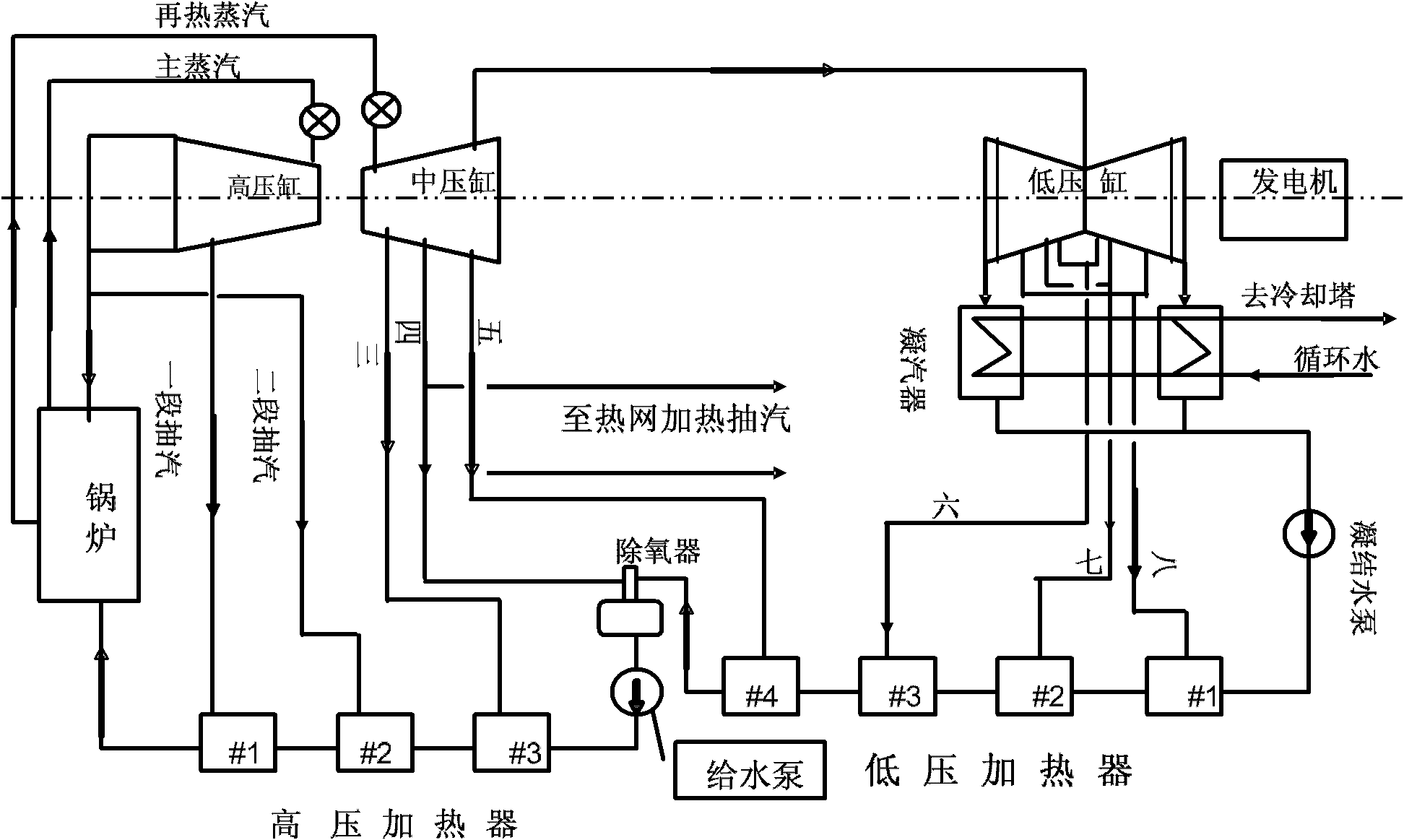

Method for recovering waste heat of thermal power plant and heating and supplying heat to hot water in a stepping way

ActiveCN101619662AImprove utilization efficiencyReduce exergy lossSteam useCombined combustion mitigationCooling towerSteam condensation

The invention discloses a method for recovering the waste heat of a thermal power plant and heating and supplying heat to hot water in a stepping way. In the method, low-temperature heat-net return water is firstly mixed with circulating cooling water positioned on an outlet of a cooling condenser or exchanges heat with the circulating cooling water positioned on the outlet of the cooling condenser to be increased in temperature and then sequentially delivered into an each-step vapour absorption type heat pump and a vapor-water heat exchanger in a series connection way to be gradually heated to be increased in temperature to heat supplying temperature and finally discharged through a water supplying pipeline; the circulating cooling water absorbs the waste steam condensation heat of a steam turbine in the cooling condenser, then one path of the circulating cooling water is directly mixed with the low-temperature heat-net return water or heats the low-temperature heat-net return water through the heat changer, the other path of the circulating cooling water is delivered into an each-step absorption type heat pump unit to be used as a low-order heat source of the absorption type heat pump unit, and the redundant heat of the circulating cooling water is discharged to the environment through a cooling tower. The invention uses the steam extraction of the steam turbine as a driving heat source of the absorption type heat pump so that the low-temperature heat-net return water is heated in a stepping way, thereby reducing the effective energy loss; the waste heat of the discharged steam of the steam turbine is sufficiently recovered in a direct heating way and an absorption type heat pump temperature increasing heating way, therefore, the comprehensive energy usage efficiency of the thermal power plant is enhanced.

Owner:TSINGHUA UNIV +1

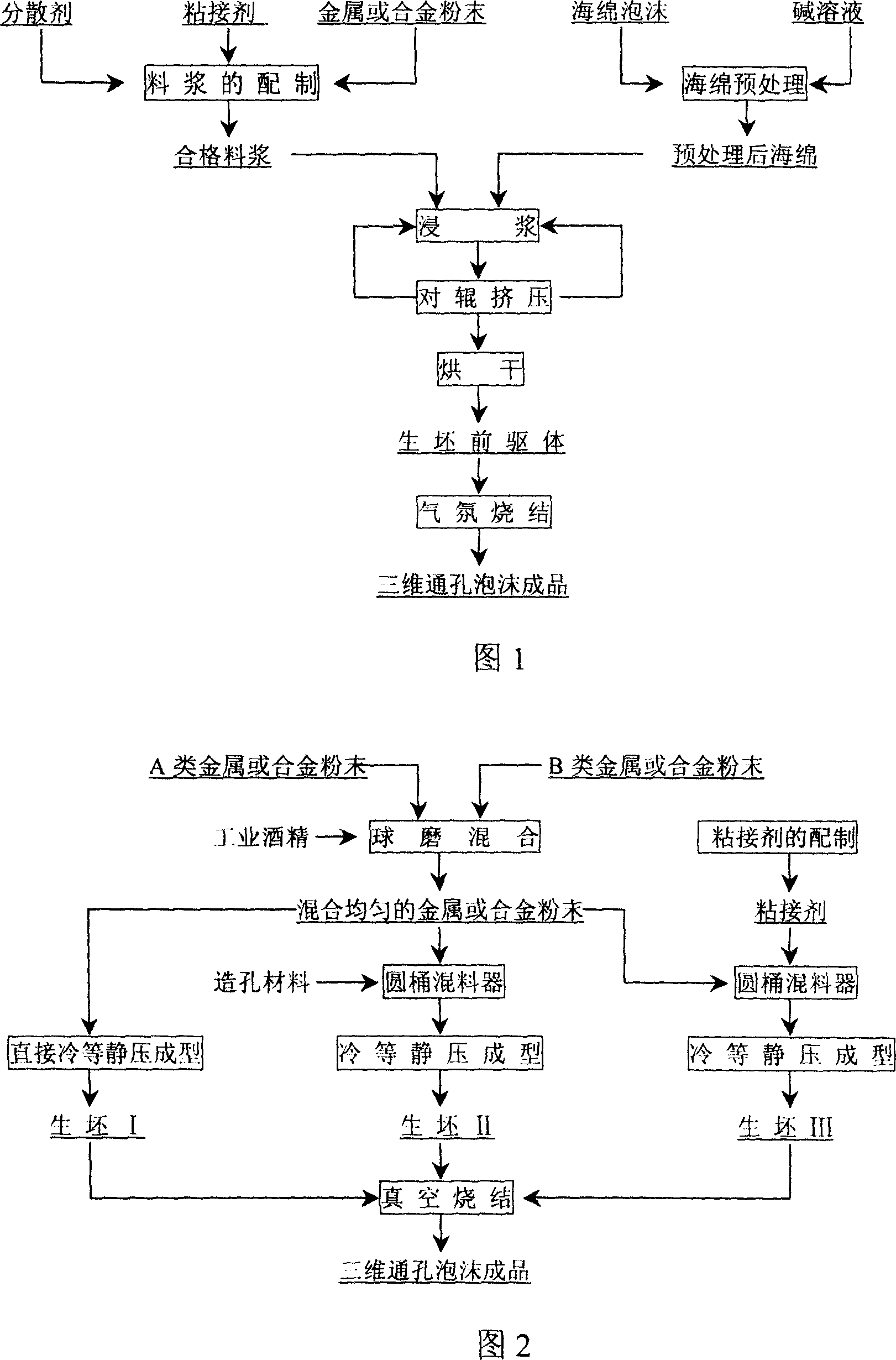

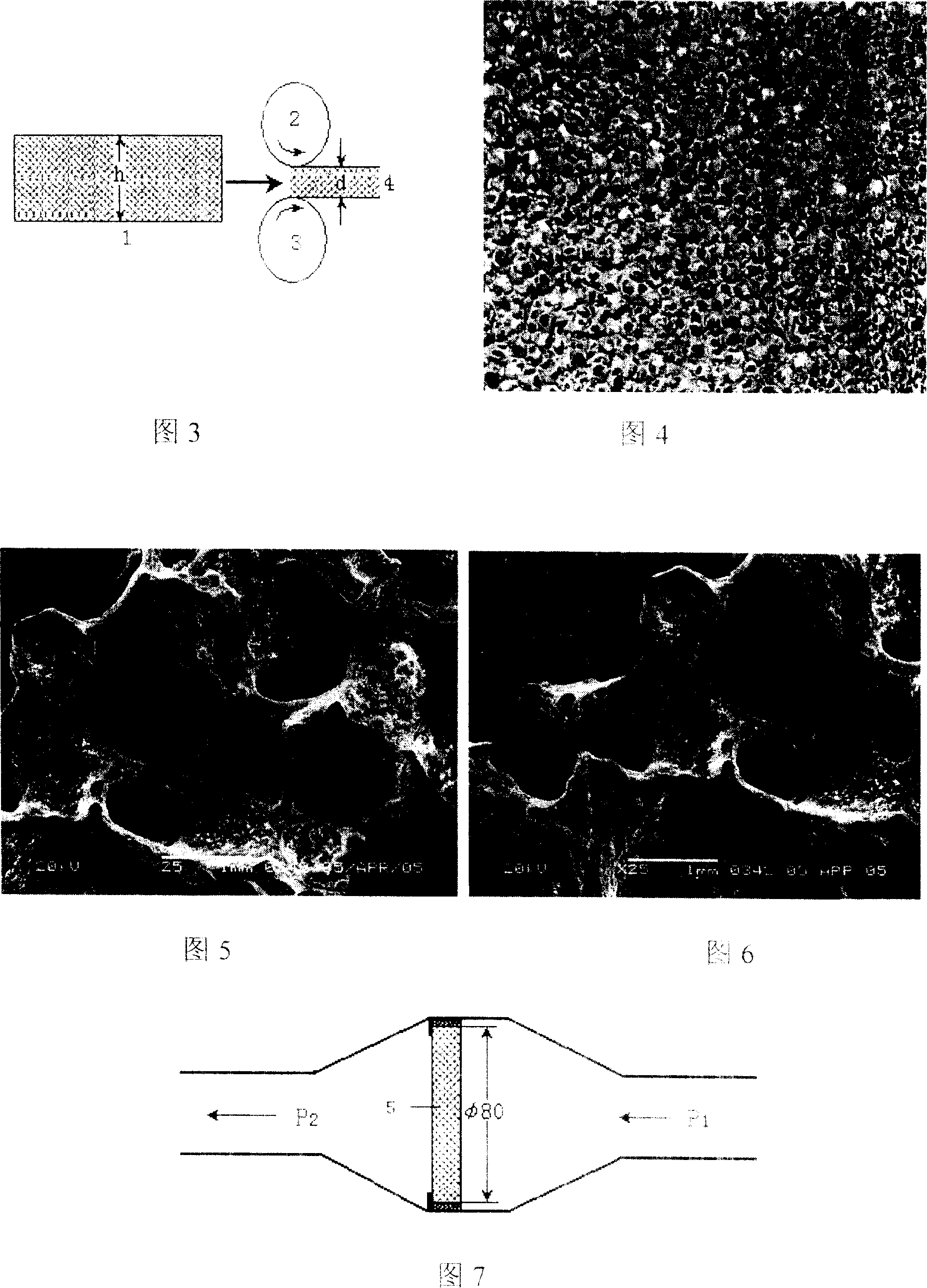

Three-dimensional through-hole or part-hole interconnecting porous metal foam and its preparing method

The invention relates to a multi-hole foamed metal material and the manufacturing method. It includes the following steps: equally dispersing metal or alloy powder that has the particle diameter at 1-100um into solution contains adhesive agent to make slime, pouring the slime into through-hole polyurethane sponge foam, after taking drying and sintering, the material would be gained. It also could be make by the method of directly isostatic cool pressing one or more metal or alloy powder, isostatic cool pressing after mixing with pore forming material or isostatic cool pressing after mixing with adhesive agent solution to gain green pressing that would be sintered in vacuum furnace to make the material. The invention could be used to process vehicle tail gas and could also be used to filter the smoke form thermal power station or metallurgical furnace.

Owner:CENT SOUTH UNIV

Purification works for thermal power plant

InactiveUS7559977B2Reduce heat lossIncrease energy yieldUsing liquid separation agentCombustion enginesCombustion chamberExhaust fumes

A method for separation of CO2 from the combustion gas from a thermal power plant fired with fossil fuel, wherein the combustion gas from the thermal power plant is used as cooled, compressed and reheated by combustion of natural gas in a combustion chamber to form an exhaust gas, where the exhaust gas is cooled an brought in contact with an absorbent absorbing CO2 from the exhaust gas to form a low CO2 stream and an absorbent with absorbed CO2, and where the low CO2 stream is heated by means of heat exchanges against the hot exhaust gas leaving the combustion chamber before it is expanded in turbines, is described. A plant for performing the method and a combined plant is also described.

Owner:CO2 CAPSOL

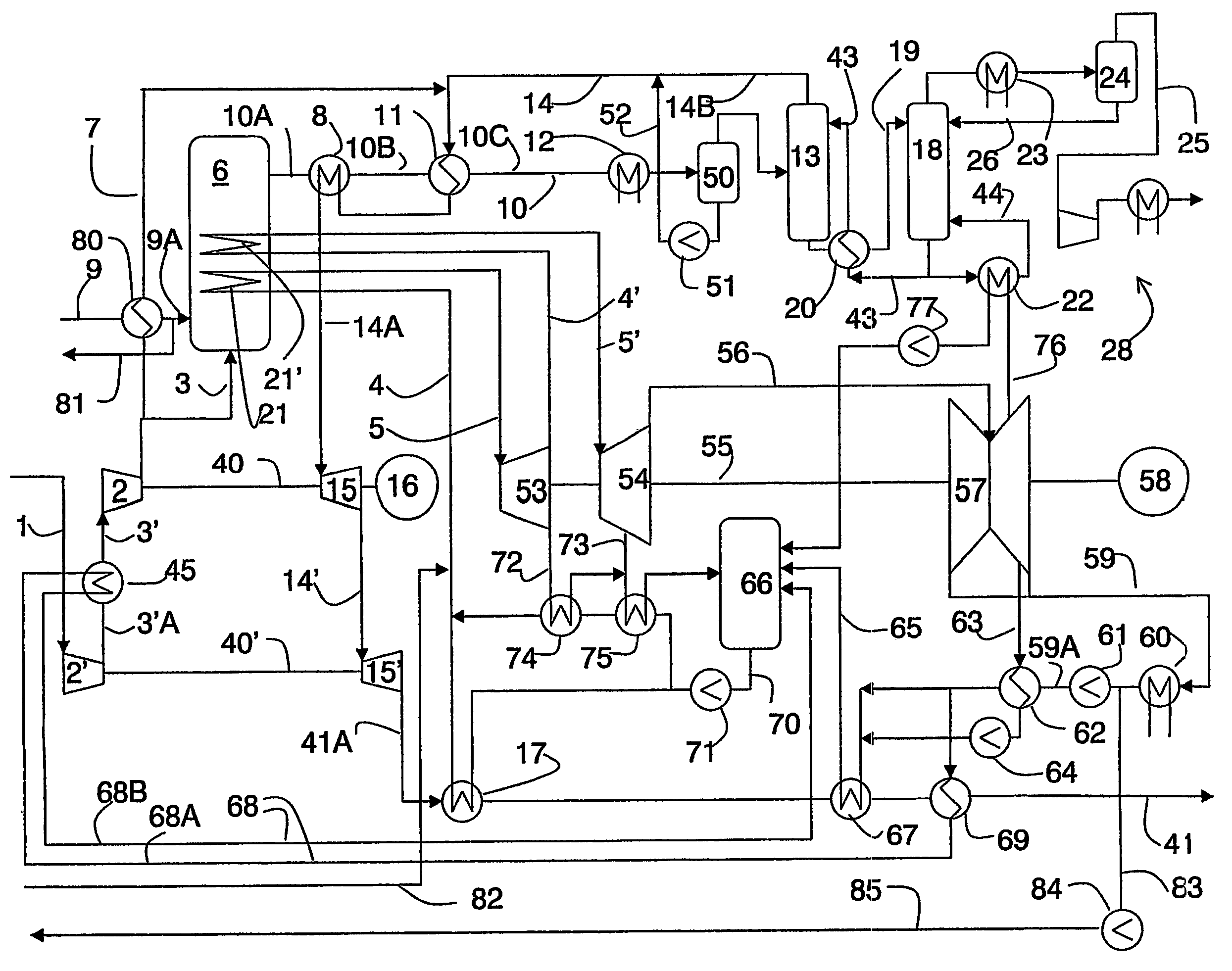

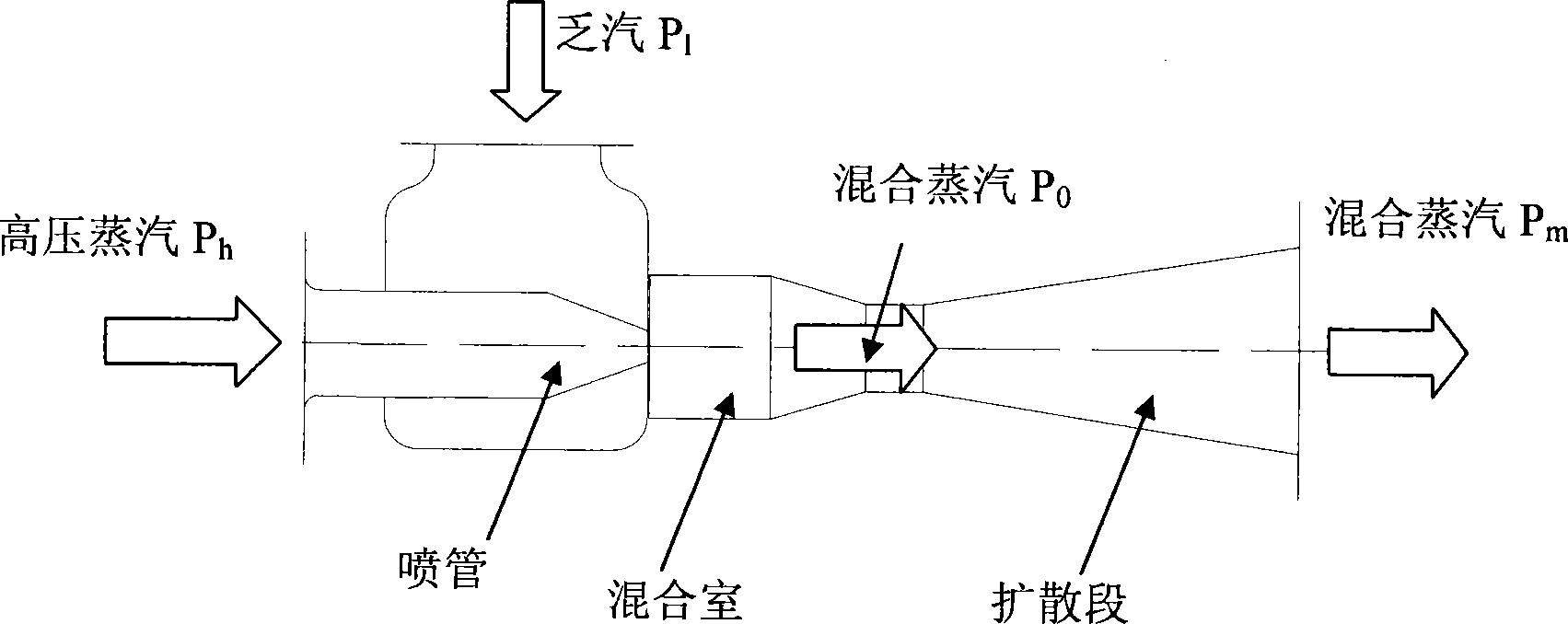

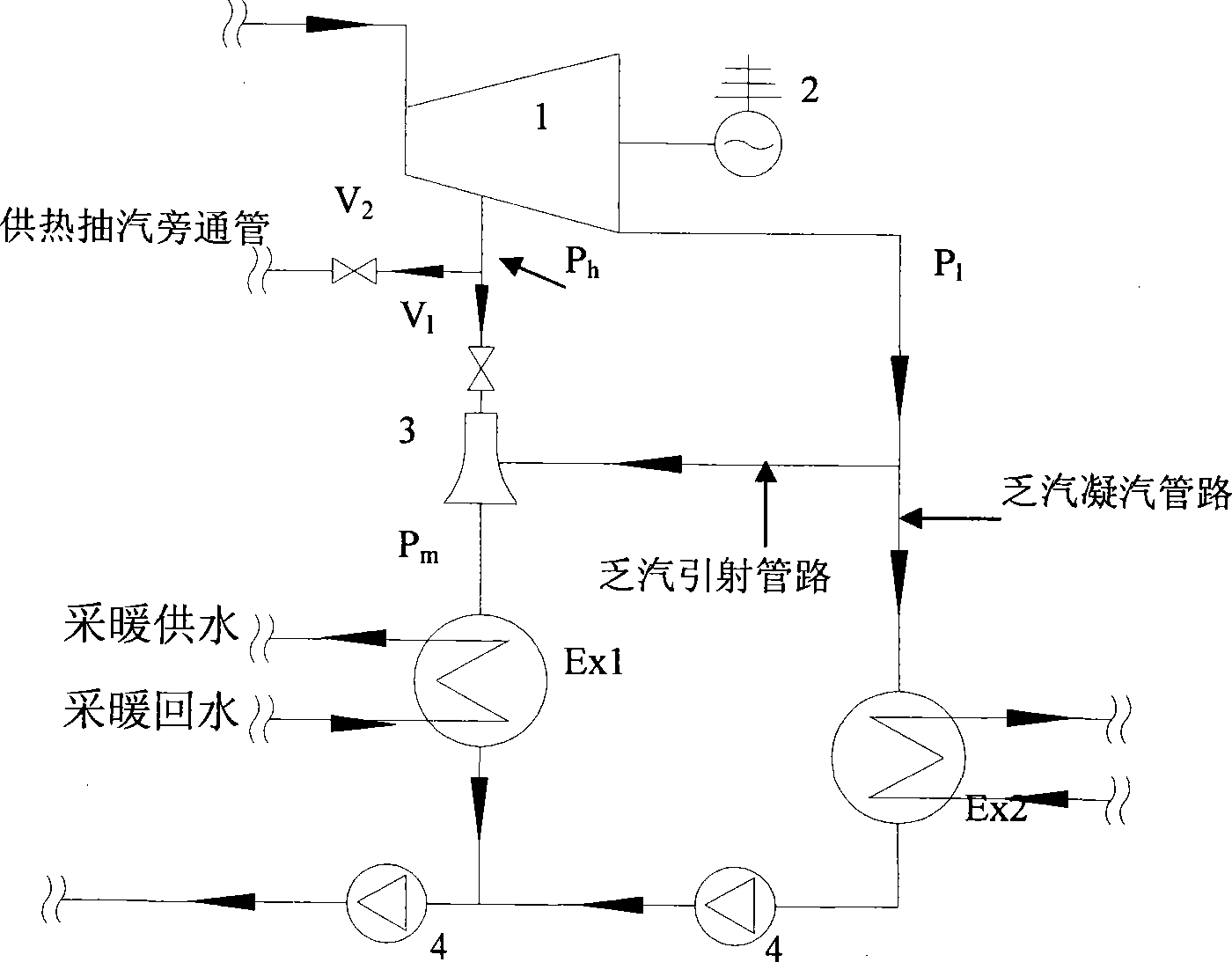

Steam jet type heat pump heat distribution system for recovering thermal power plant condensing residual heat

InactiveCN101240909AEasy to manufactureImprove heat transfer effectFeed water supplyEnergy efficient heating/coolingLow voltageCore component

The present invention provides a steam injection heatpump heating system. The technical solution is that the system is composed of a steam injector, a high voltage steam pipeline, a low voltage steam pipeline, a throttling gear and a bypass connecting pipe. The high voltage steam enters in the heat exchanger heaing backwater after injecting lower steam turbine voltage condensing in low temperature, this realises waste heat recovery in low temperature condensing steam of the steam turbine. The core component is the steam injector, the high voltage heat supplying pumping is used as high-velocity jet acceleratively formed in the injecting tube of the working steam, and lower voltage steam turbine is rolled in the mixing room as injected flow, mixing steam in the expanding section of the steam injector is decelerately compressed in a certain back pressure, then sending to the heat interchanger for heating backwater, a certian back pressure mixing steam condenses to water after heat releasing in the exchanger, returning to the backwater system of electrical factory, completing thermal circuit of the combined heat and power generation set.

Owner:TSINGHUA UNIV

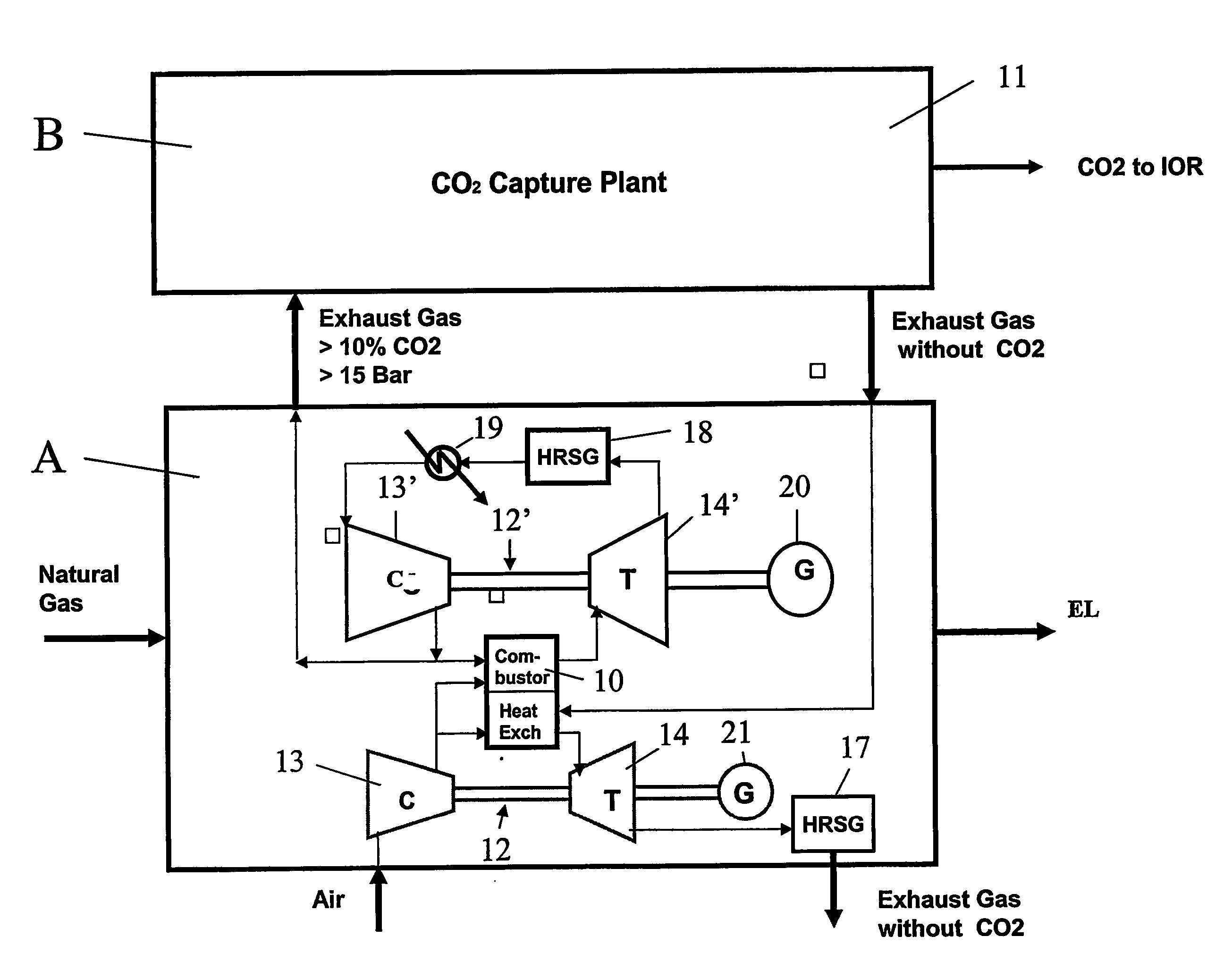

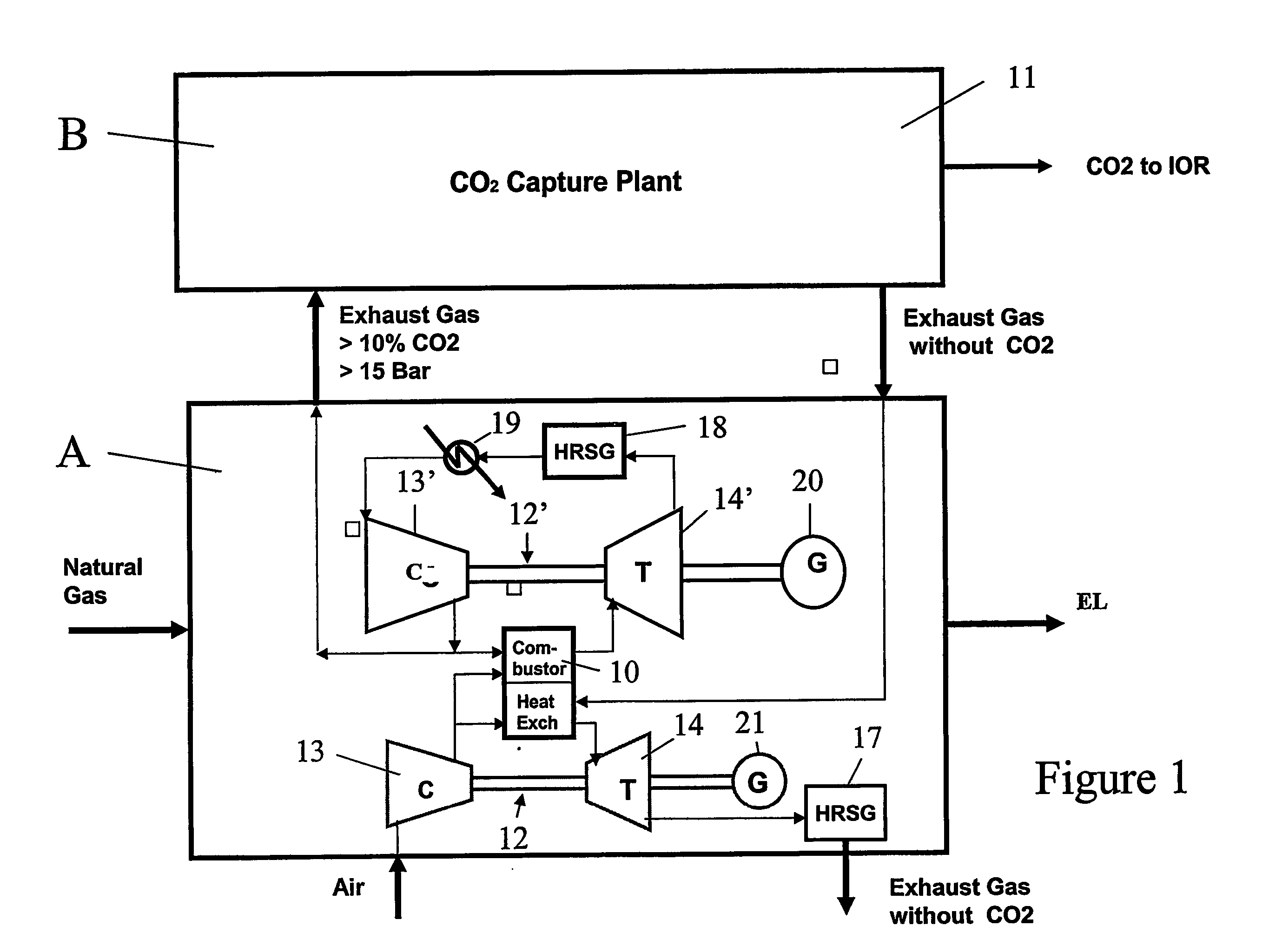

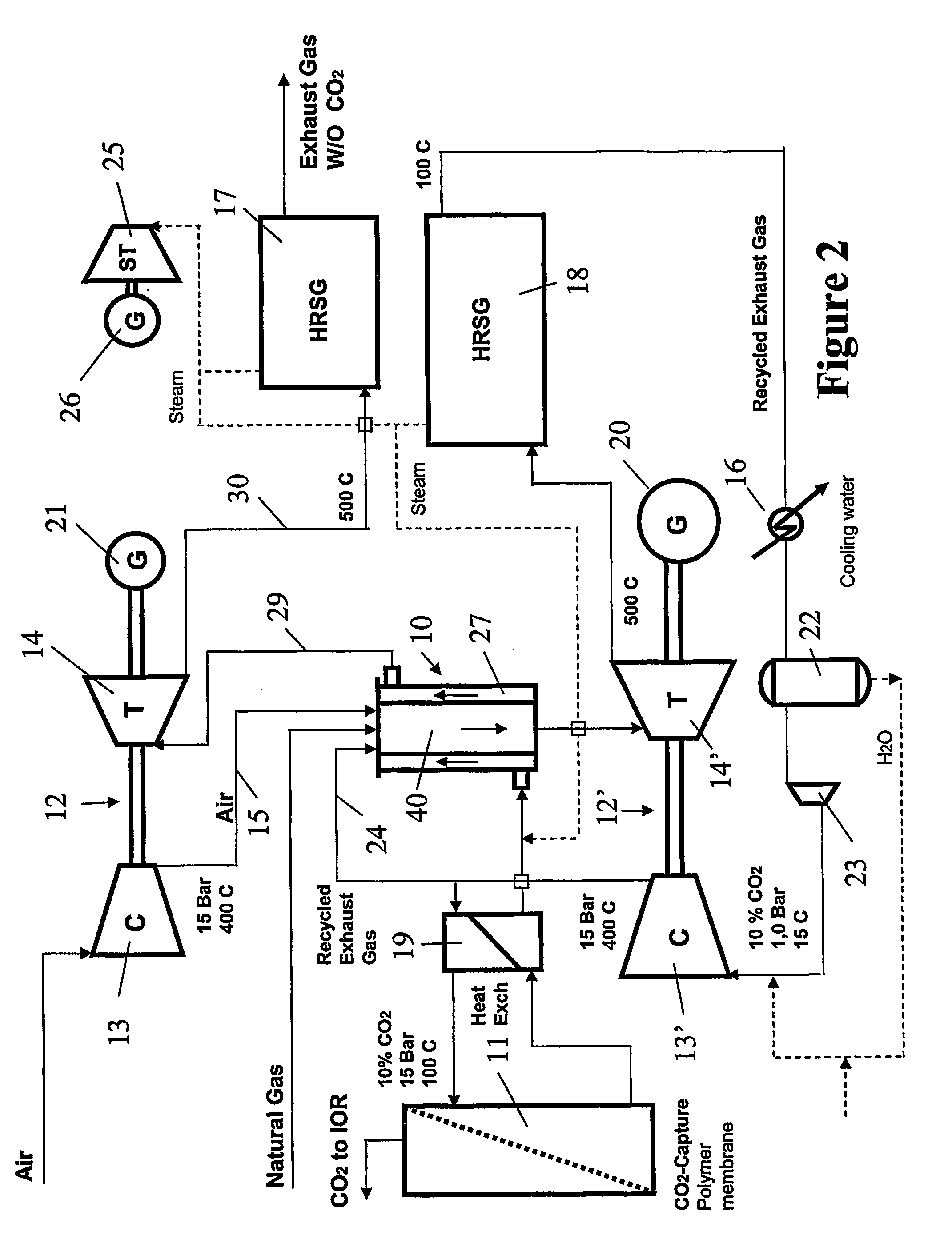

Efficient combined cycle power plant with co2 capture and a combustor arrangement with separate flows

ActiveUS20060112696A1Favourable and improved heat transferMore energyTurbine/propulsion engine coolingDispersed particle separationCombustion chamberCombustor

The invention relates to a method for inter alia to increase the energy and cost efficiency of a gas power plant or a thermal heat plant with CO2 capturing. The power plant comprises gas turbine plants (12,12′) comprising compressor units (13,13′) and turbine units (14,14′) and further comprises a combustor (10). The combustor (10) is working in principle with to separate gas part streams where one gas part stream flows internally through the flame tube (40) of the combustor (10), while the other gas part stream is flowing along the exterior of the flame tube (40). The first gas part stream comprises additional air and re-circulated, un-cleaned flue gas from the combustor (10), said gases being combusted together with fuel inside the flame tube (40). The second gas part stream comprises cleaned flue gas which is heated up at the exterior of the flame tube (40) while the flame tube (40) is cooled down. The invention comprises also a power plant, a combustor and a CO2 capture plant.

Owner:STATOIL ASA PETRO SA (NO)

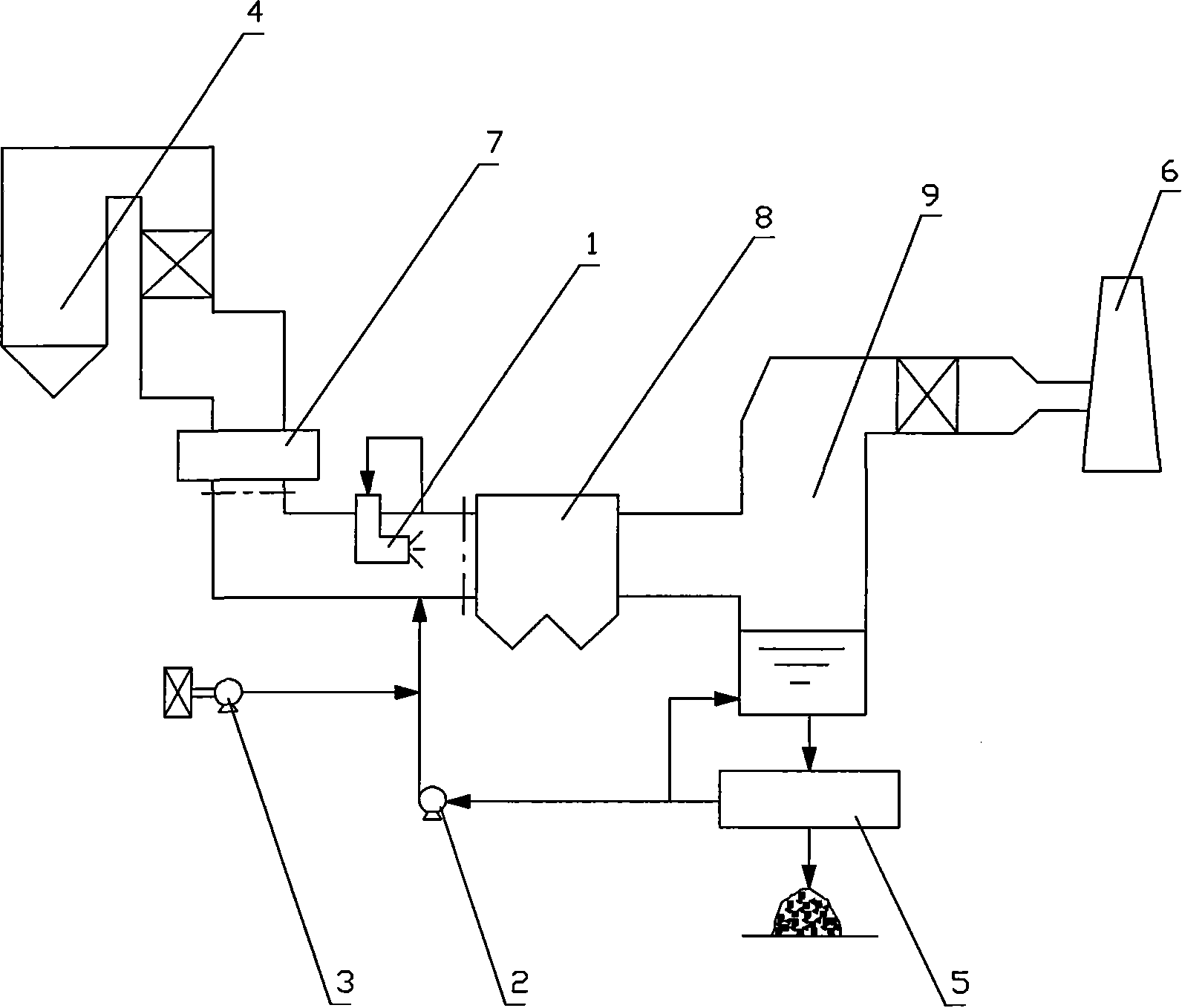

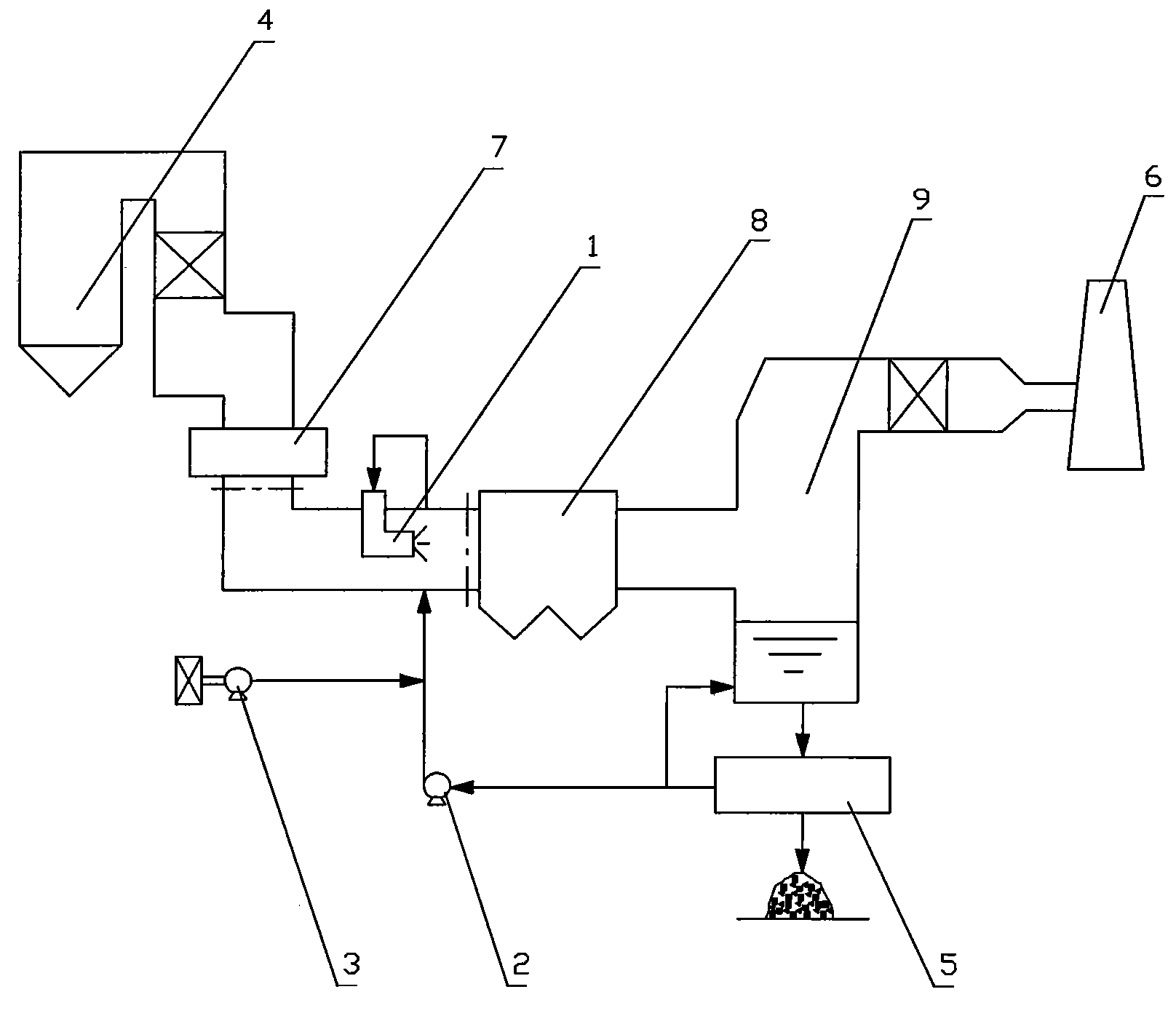

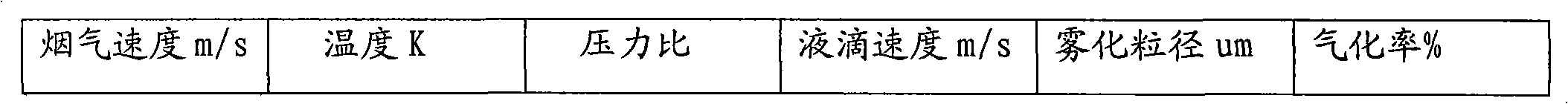

Spray evaporation treatment method of wet method flue gas desulfurization wastewater in thermal power station

ActiveCN101844819AOvercoming multiple configuration devicesSmall investmentDispersed particle separationWater/sewage treatmentEvaporationTreatment system

The invention discloses a spray evaporation treatment method of the wet method flue gas desulfurization wastewater in a thermal power station. In the method, an atomizing nozzle is arranged in the region with the temperature at 413-470 K and the flue gas speed of 5-11 m / s in a flue of the boiler tail part; desulfurization wastewater is pumped by utilizing a water pump, air is compressed by a compressor, and the pressure ratio of the compressed air to the desulfurization wastewater entering into the atomizing nozzle is 0.25-0.6; the speed of liquid droplets atomized by the atomizing nozzle is 50-80 m / s, and particle diameters of the liquid droplets are less than 50 mu m; and the liquid droplets are evaporated and then exhausted out of a chimney together with the flue gas. The invention can save chemical drugs utilized in the conventional wastewater treatment method; overcome the defects of many apparatuses, large investment, high running cost and heavy apparatus repair and maintenance load of a wastewater treatment system in the prior art, overcome the great corrosion influence of chlorine ions in water meta-acidity environment, reduce the specific resistance of ashes in a dust collector and improve the dust collector efficiency through increasing the flue gas humidity and properly lowering the flue gas temperature.

Owner:WUHAN TIANHE TECH

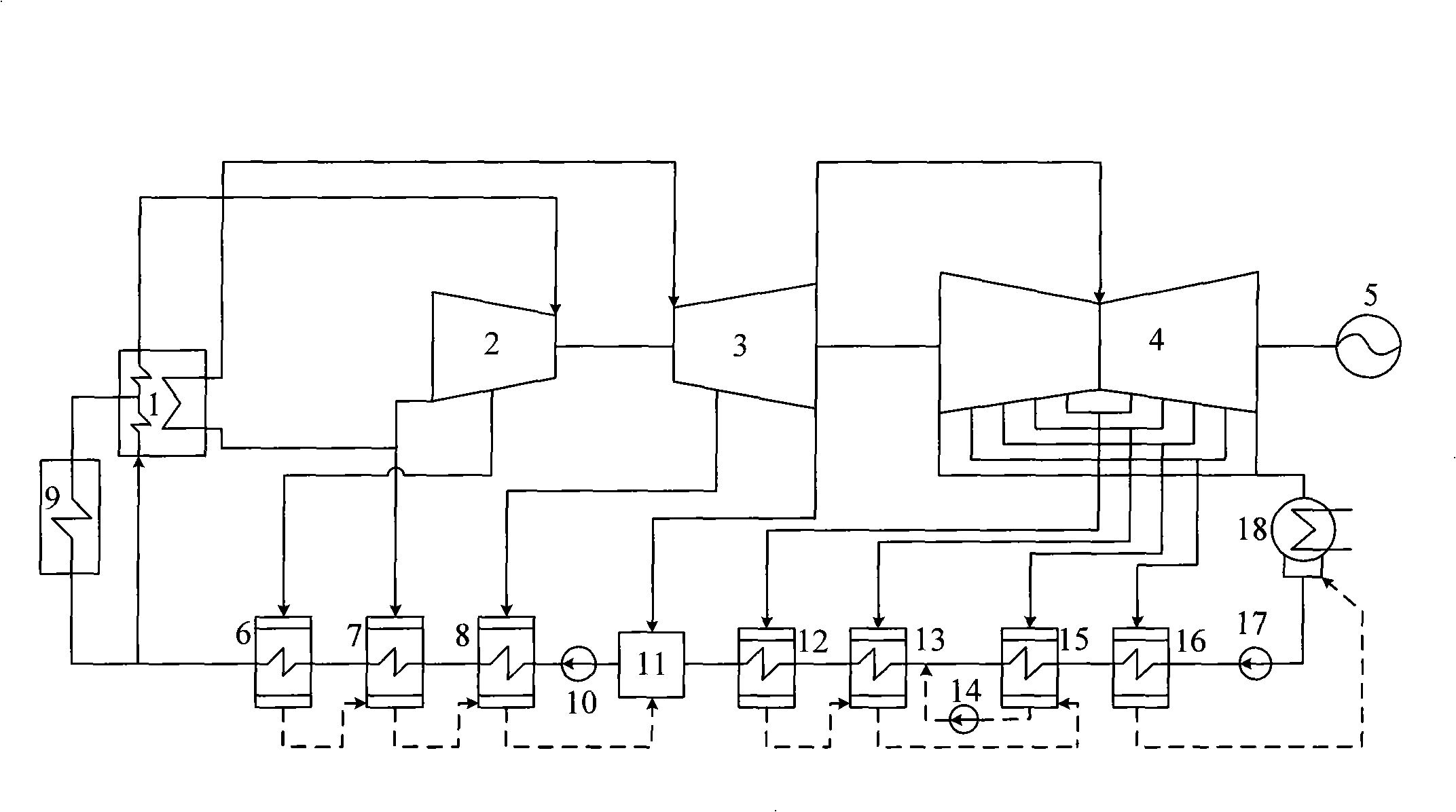

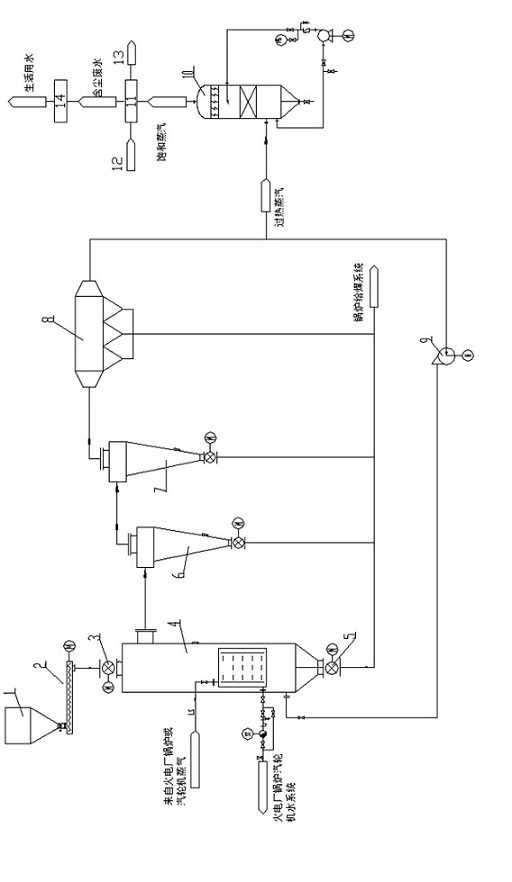

Solar energy and coal-burning unit combined thermal power generation system

InactiveCN101270675AHigh thermal efficiencyImprove thermal efficiencySteam engine plantsDeaeratorEngineering

The invention relates to a generating system, in particular to the heat generating system consisting of a solar heat collector and a coal-fired unit. The heat generating system adopts solar energy to take the place of the partial coal-fired heat energy of a coal-fired unit boiler. A condenser, an extraction pump, a low pressure heater, a deaerator, a water-feeding pump, a high pressure heater and the heat collector, a coal burning boiler and a steam turbine that are connected in parallel are connected in series. The steam turbine drives the generator and discharges gas into the condenser. Condensed water flows into a heater from the condenser to be heated up and pressurized, is deoxidized by the deaerator, then goes through the solar heat collector to be heated to be saturated vapor and goes into the coal burning boiler or directly goes into the coal burning boiler to become the steam with high temperature and high pressure. And then the steam goes into the steam turbine for applying work to drive the generator to generate electricity. The extracted steam of the steam turbine goes into each heater to finish thermodynamic cycle. The thermal efficiency of solar thermal power generation is improved, investment in the trough solar electrical energy generation of single paraboloid is reduced and the coal consumption of the coal-fired unit is decreased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

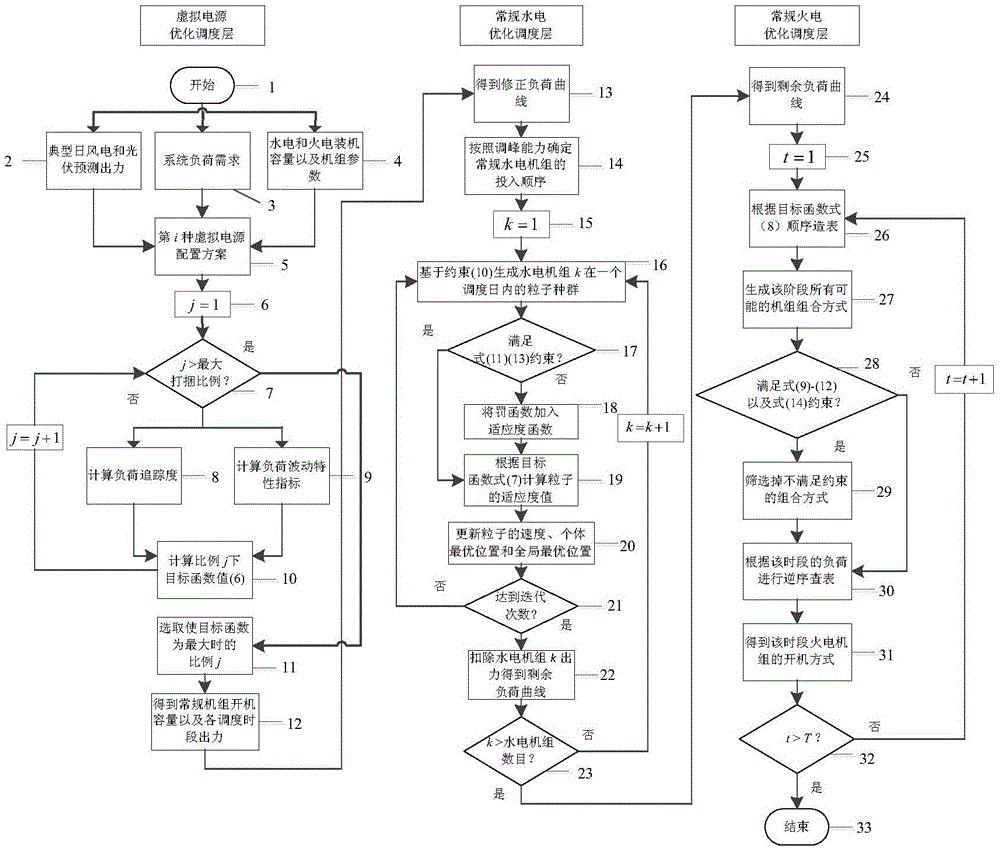

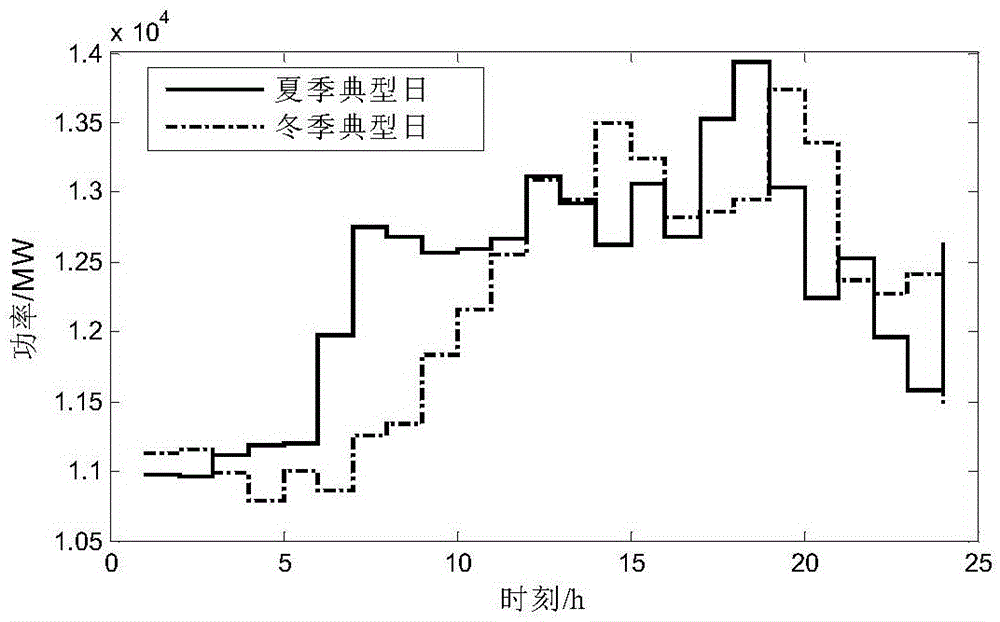

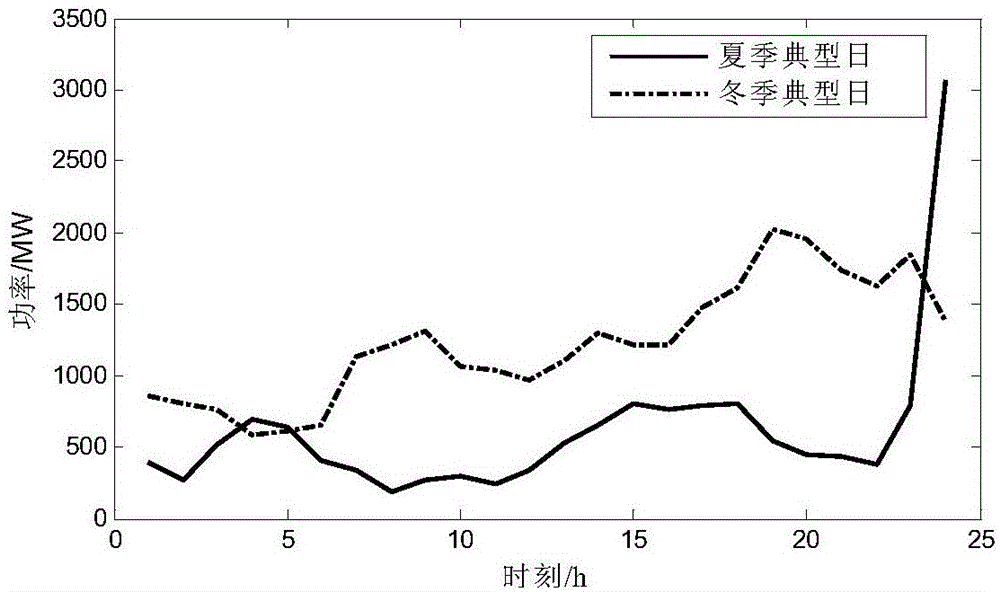

Wind-light-water-fire multi-source complementary optimization scheduling method

InactiveCN105048516AExcellent peak shaving benefitsPeak-shavingSingle network parallel feeding arrangementsHybrid systemNew energy

The invention discloses a wind-light-water-fire multi-source complementary optimization scheduling method. The method is characterized in that an optimum bundling proportion coefficient of new energy and conventional energy can be obtained by using a load tracking index based on the complementary characteristic of power supplies; and then the conventional hydropower station and the thermal power station, together with the coefficient, are involved into the system scheduling operation. The constructed scheduling module enables the complementary effect of the power supplies to be realized fully; and the optimum peak regulation benefit, economic benefit, and environment-friendly benefit of the multi-source mixing system can be realized.

Owner:SICHUAN UNIV

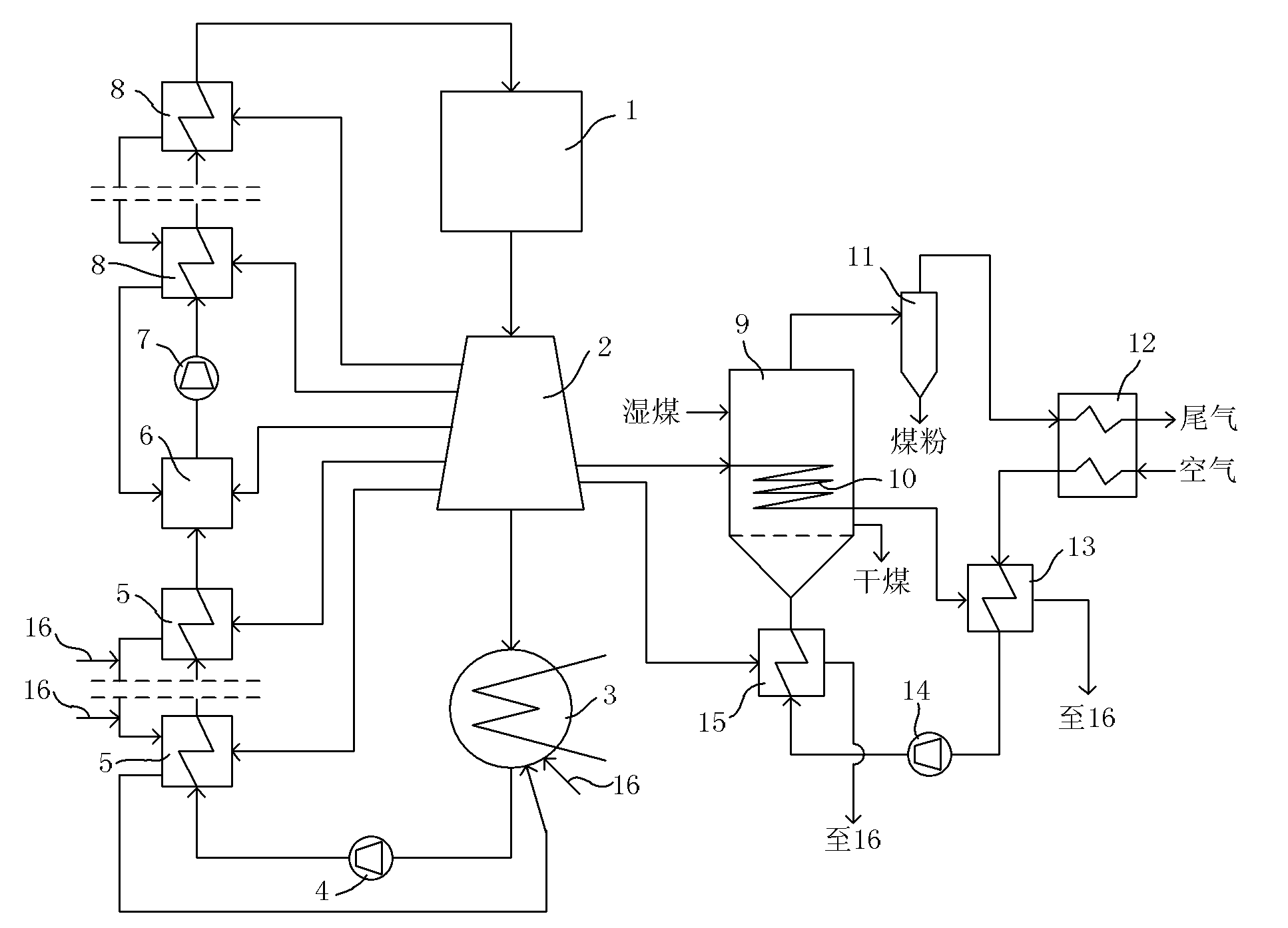

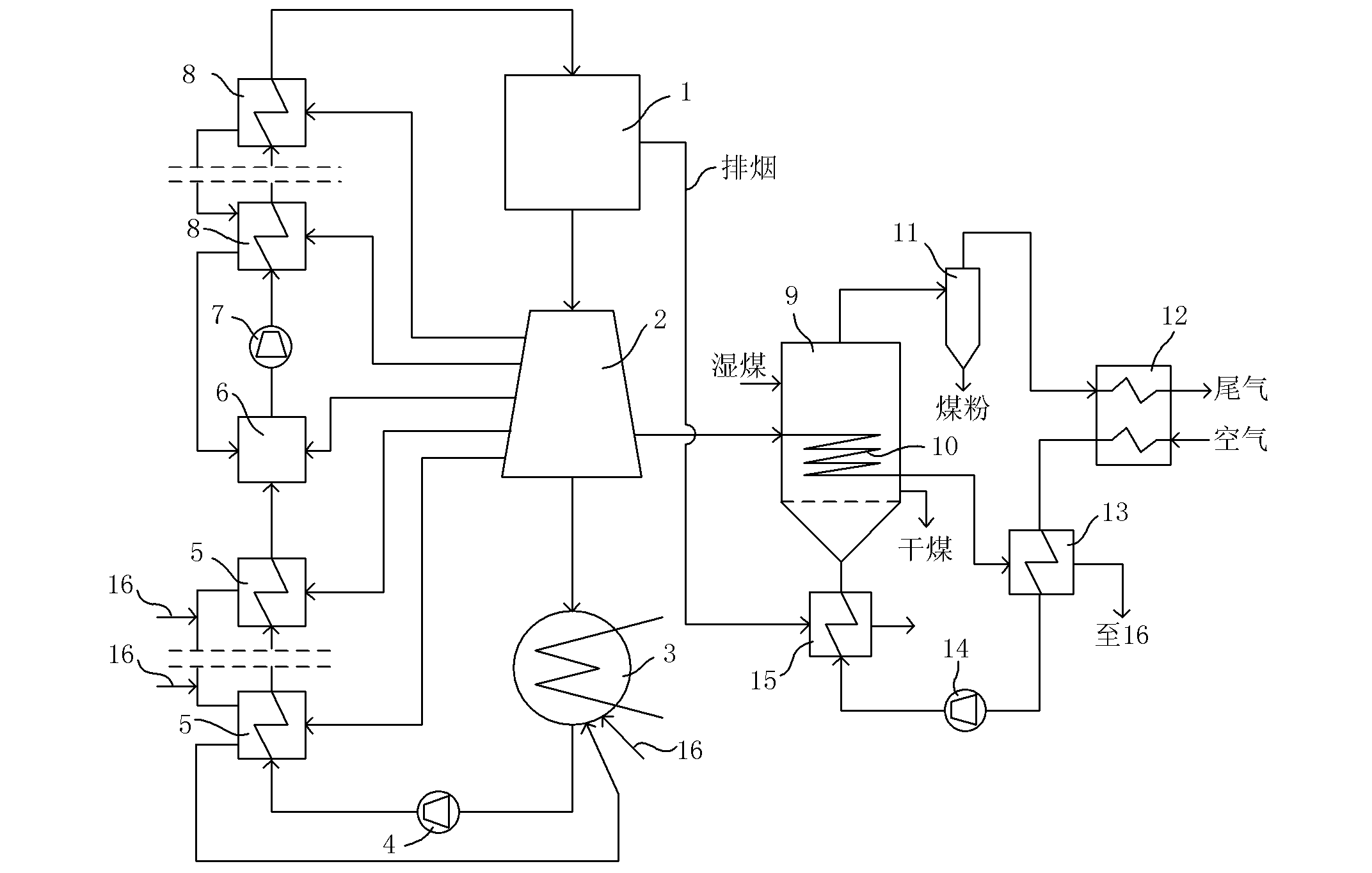

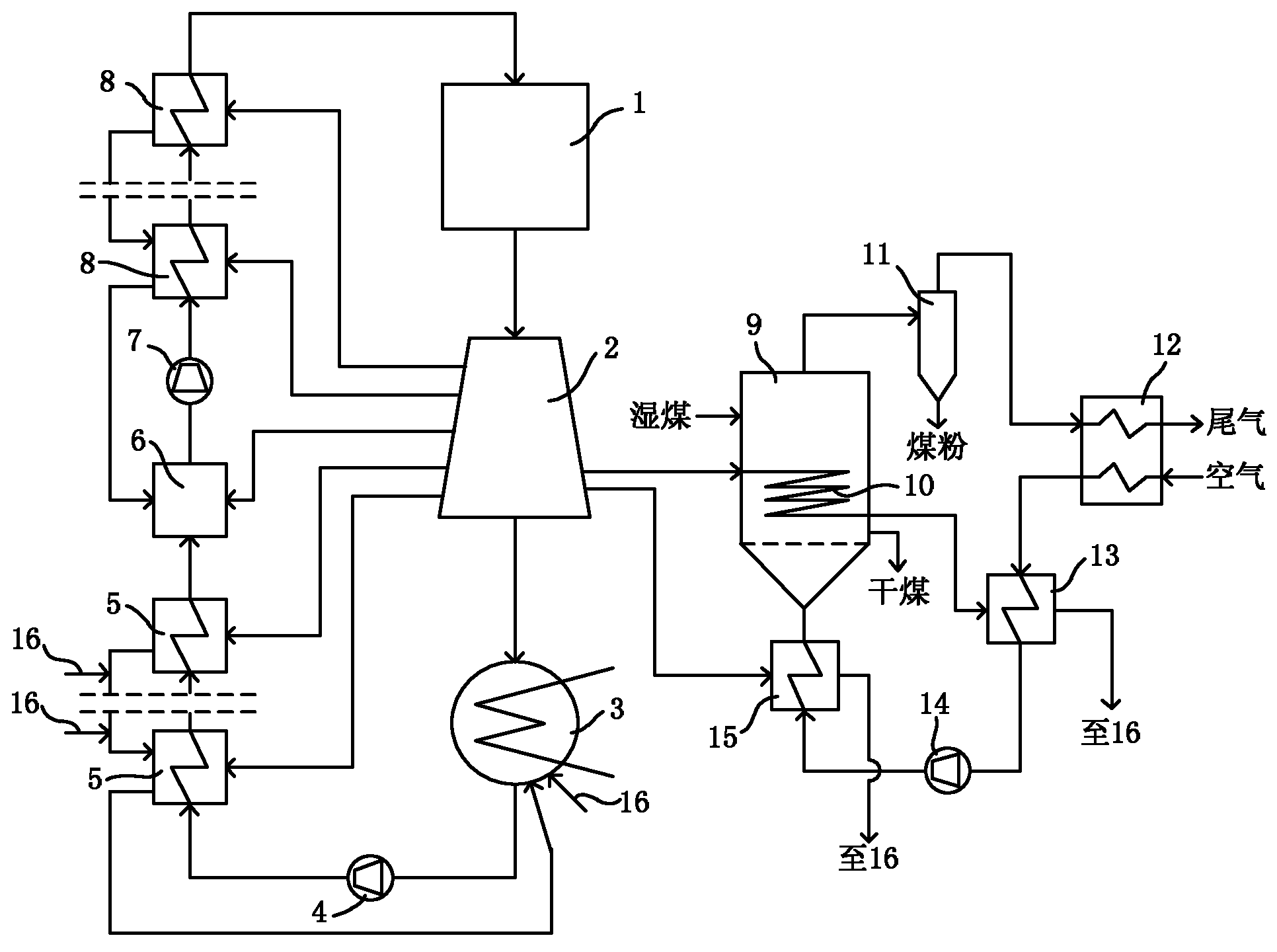

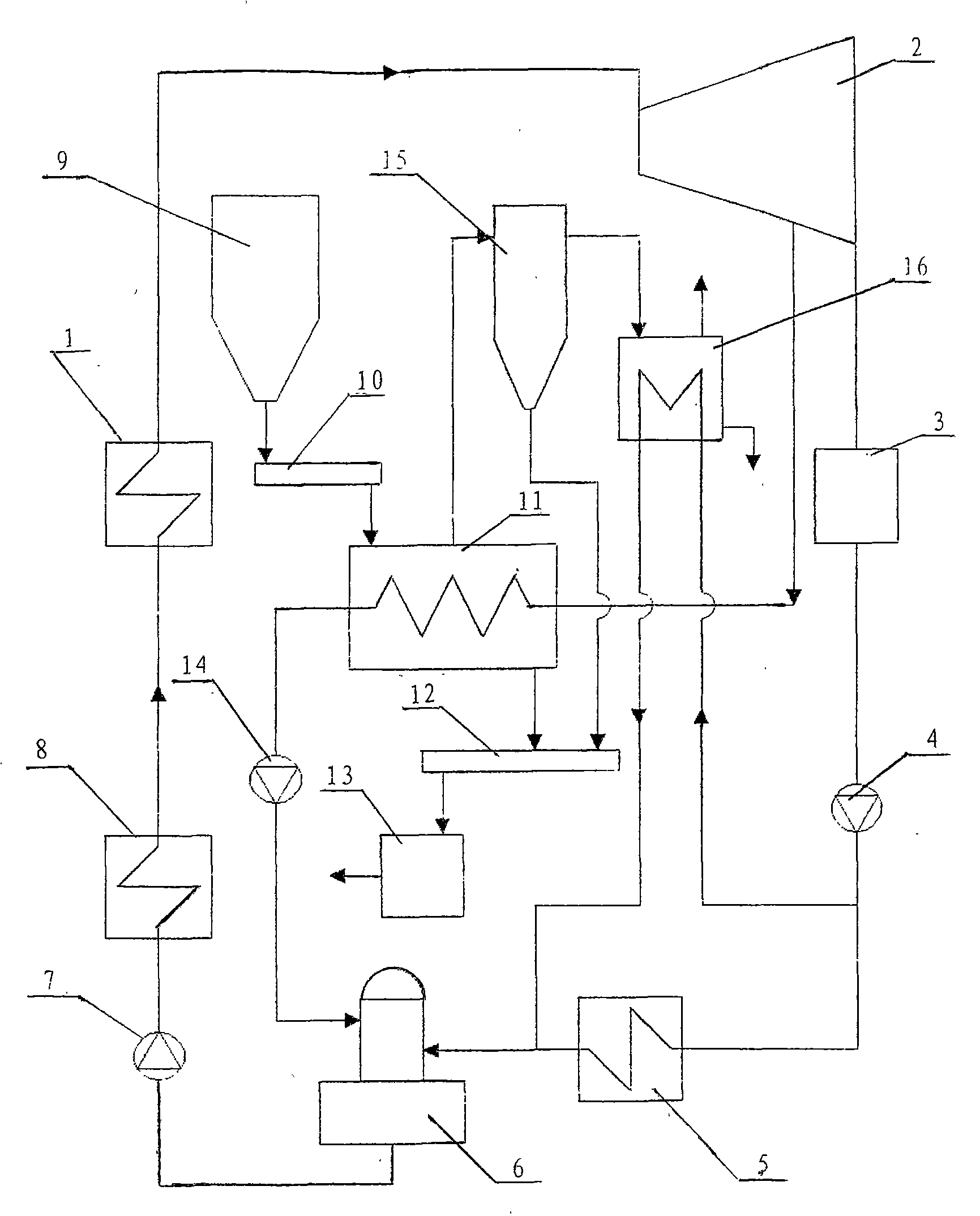

High-moisture-content lignite predrying method and system integrated with thermal power plant

InactiveCN102353237AWith drying capacityKeep dryDrying solid materials with heatFeed water supplyThermal energyFluidized bed drying

The invention discloses a high-moisture-content lignite predrying method and system integrated with a thermal power plant. In the method, lignite is dried by using hot air as a fluidizing agent and a drying medium in a fluidized bed dryer; and a heater is built in the fluidized bed dryer to supply partial heat for drying. The lignite predrying system integrated with the thermal power plant comprises the fluidized bed dryer, the heater built in the dryer, a deduster, a gas-gas heat exchanger, a gas-water heat exchanger, an air heater and a fan. According to the system, waste heat in the system and low-grade heat energy in the power plant are fully utilized to dry the lignite. By applying the method and the system disclosed by the invention, the moisture content of the lignite fed into a furnace can be reduced, the heat loss of a boiler due to exhaust gas can be reduced, and the efficiency of the lignite boiler is increased; the low-grade heat energy and waste heat resources in the thermal power plant are fully utilized, so that the consumption of high-grade energy sources in a drying process is reduced, and the power generation efficiency of a lignite power plant is increased.

Owner:XI AN JIAOTONG UNIV

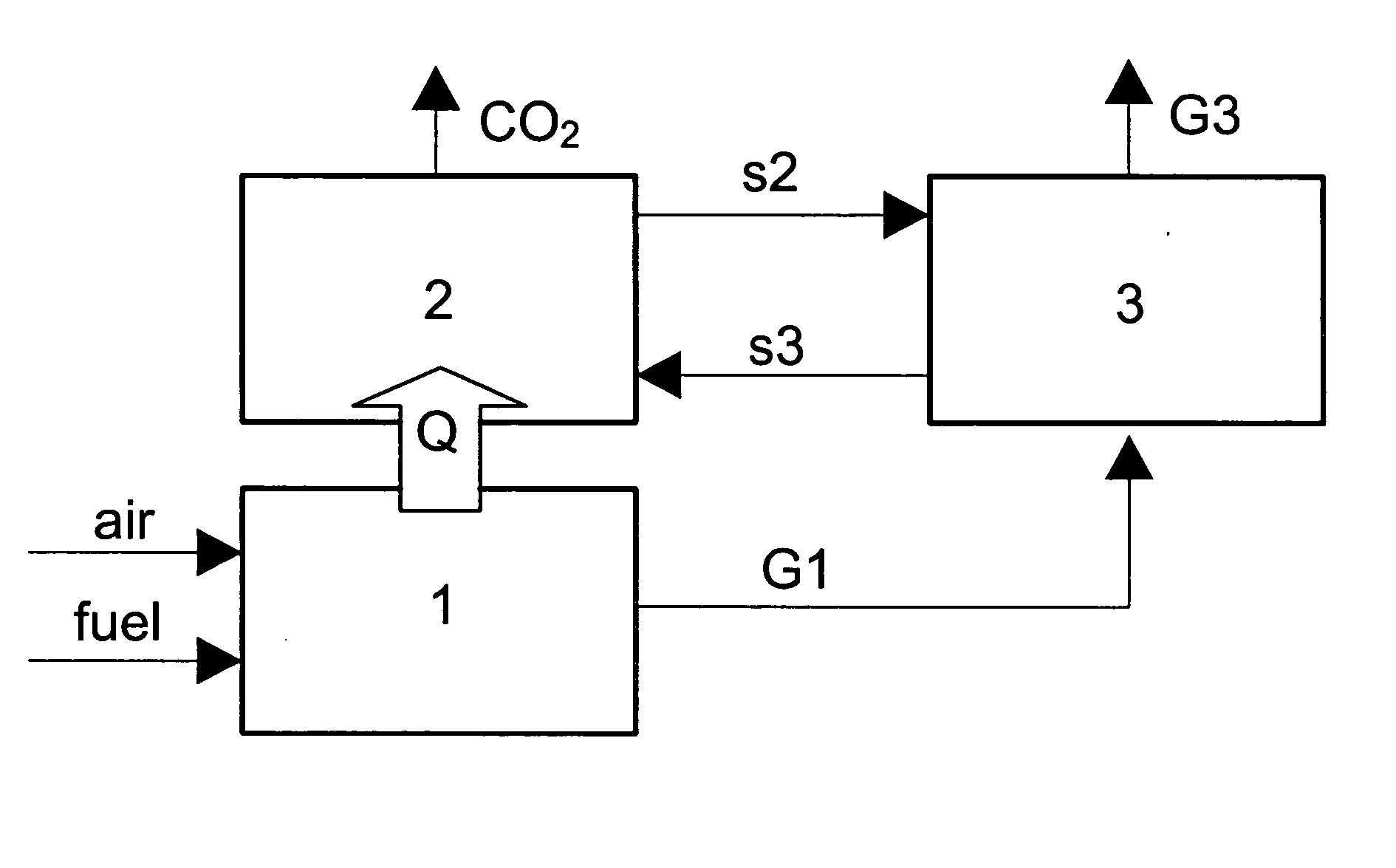

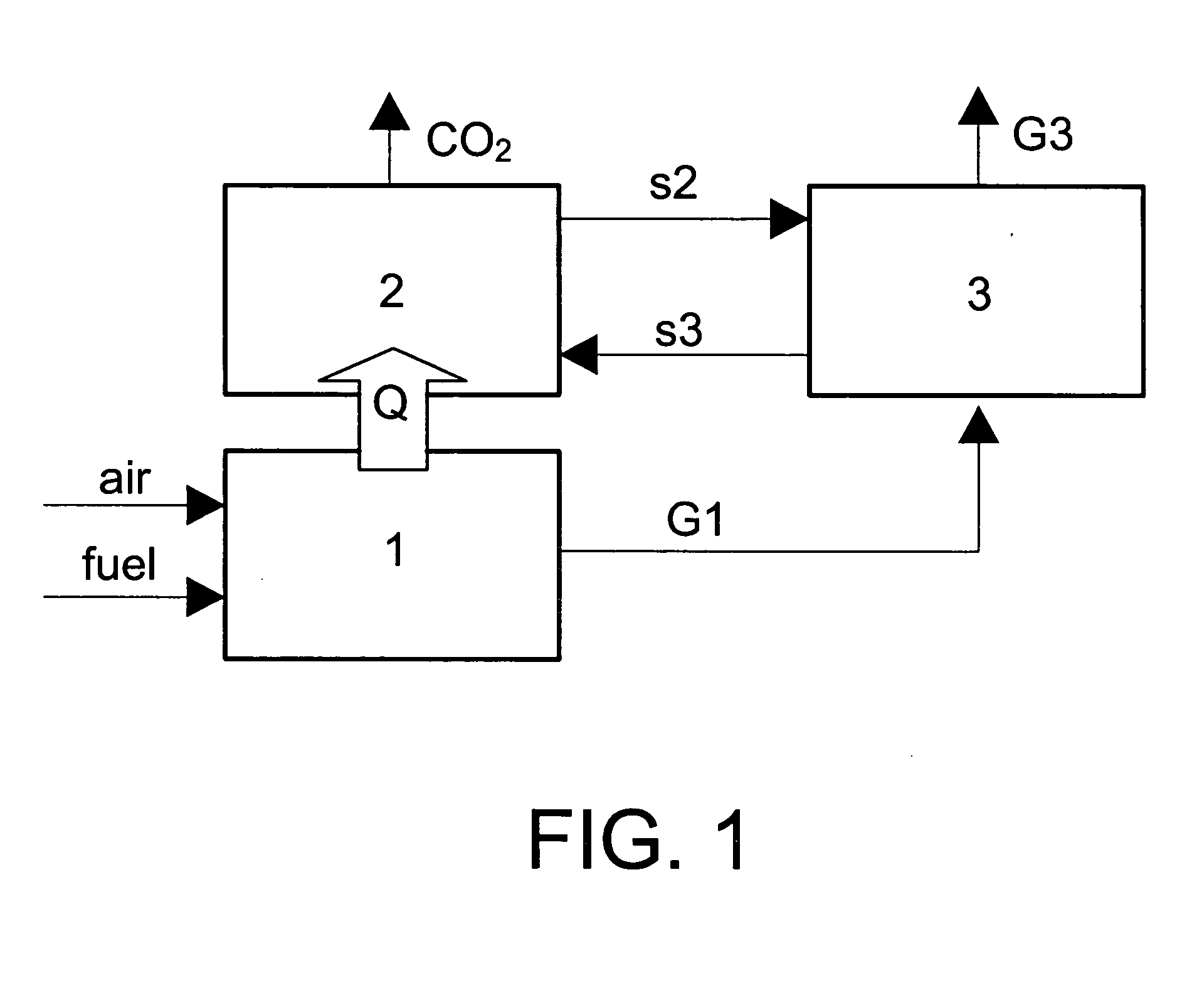

Combustion method with integrated CO2 separation by means of carbonation

InactiveUS20050060985A1Easy to separateReduce the temperatureGas treatmentOther chemical processesCalcium in biologyCombustion

The invention relates to a method for separating CO2 from combustion gases, which can be used at areas with large emissions (thermal power stations using any carbonaceous fuel). The separated CO2 stream can be used and / or contained in geological formations. The inventive method aims to reduce the high costs involved in CO2 separation which prevent large-scale use of the CO2 confinement options included in the UN's IPCC reports. Said method consists of bringing the combustion gases into contact with a calcareous sorbent (limestone, calcined dolomite) at 650-750° C., thereby producing the CO2 capture reaction by means of the rapid carbonation of the sorbent. The sorbent is regenerated in another reactor (calciner) which operates in CO2 or CO2 / H2O atmospheres.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

Thermal power generation system based on high-moisture lignite pre-drying upgrading and recovering technology

ActiveCN101881191AIncrease energy densityReduce smoke lossDrying solid materials with heatSteam regenerationDeaeratorHigh pressure

The invention relates to a thermal power generation system based on a high-moisture lignite pre-drying upgrading and recovering technology. The thermal power generation system comprises a boiler, a turbine, a condenser, a condensation pump, a low pressure heater, a deaerator, a water feed pump, a high pressure heater, a wet coal bin, a wet coal feeder and a coal mill and is characterized in that a lignite pre-drying device, a drain pump, a dry coal feeder, a dust remover and a heat energy and waste water recovering device are additionally arranged in the power generation system. The invention improves the energy density of fire coal and accordingly increases the efficiency of the boiler, and is capable of reducing the investment of the boiler and a milling system by a larger extent, simultaneously reducing the plant power utilization ratio, further improving the energy source comprehensive utilization efficiency of a thermal power generation plant, recovering a great deal water by using coal to produce water and saving precious water resources. The invention achieves the effects of high efficiency, energy saving, water saving and emission reduction and accords with the industrial policy of developing the low-carbon economy in China.

Owner:CHINA POWER ENG CONSULTING GRP +1

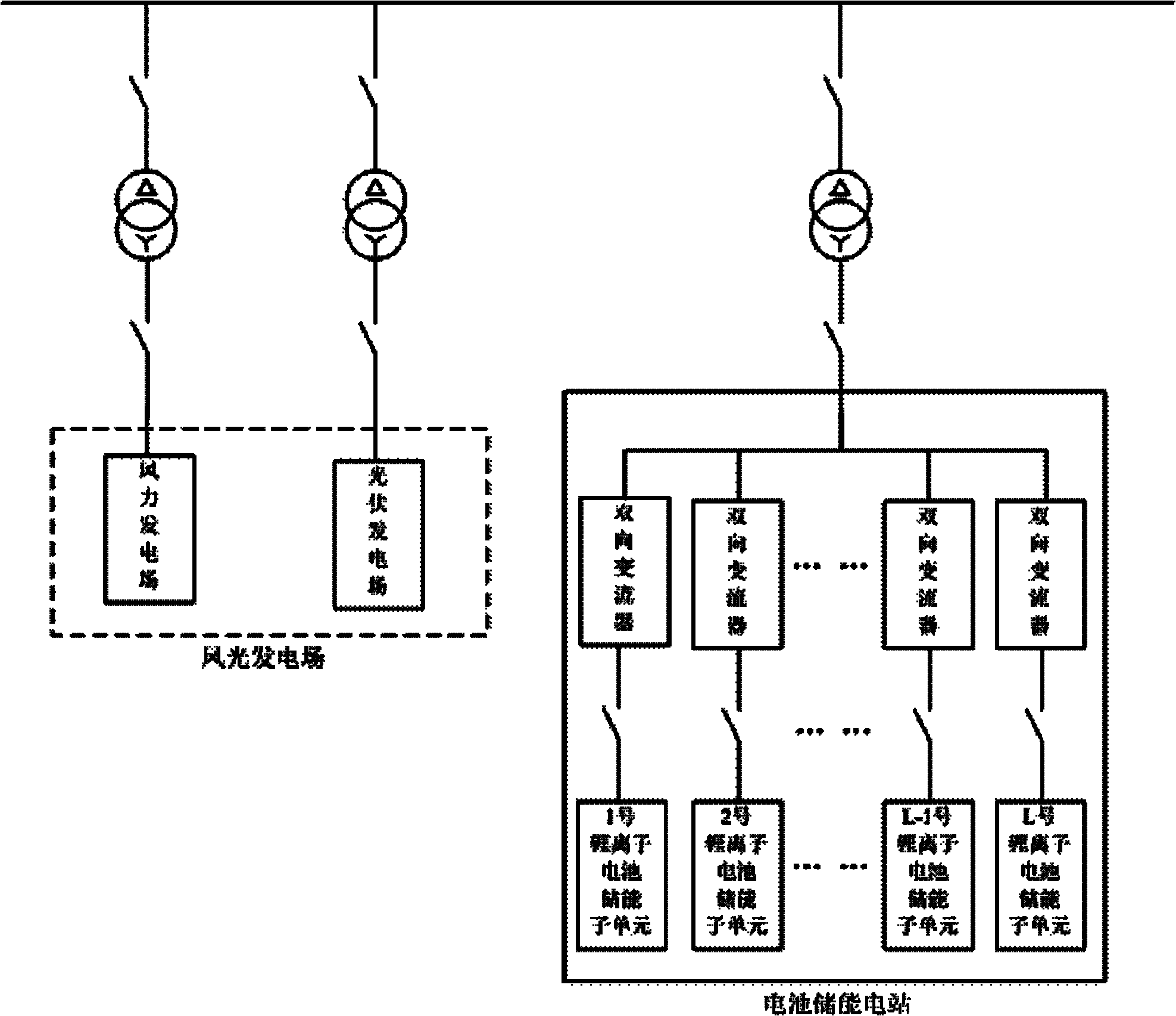

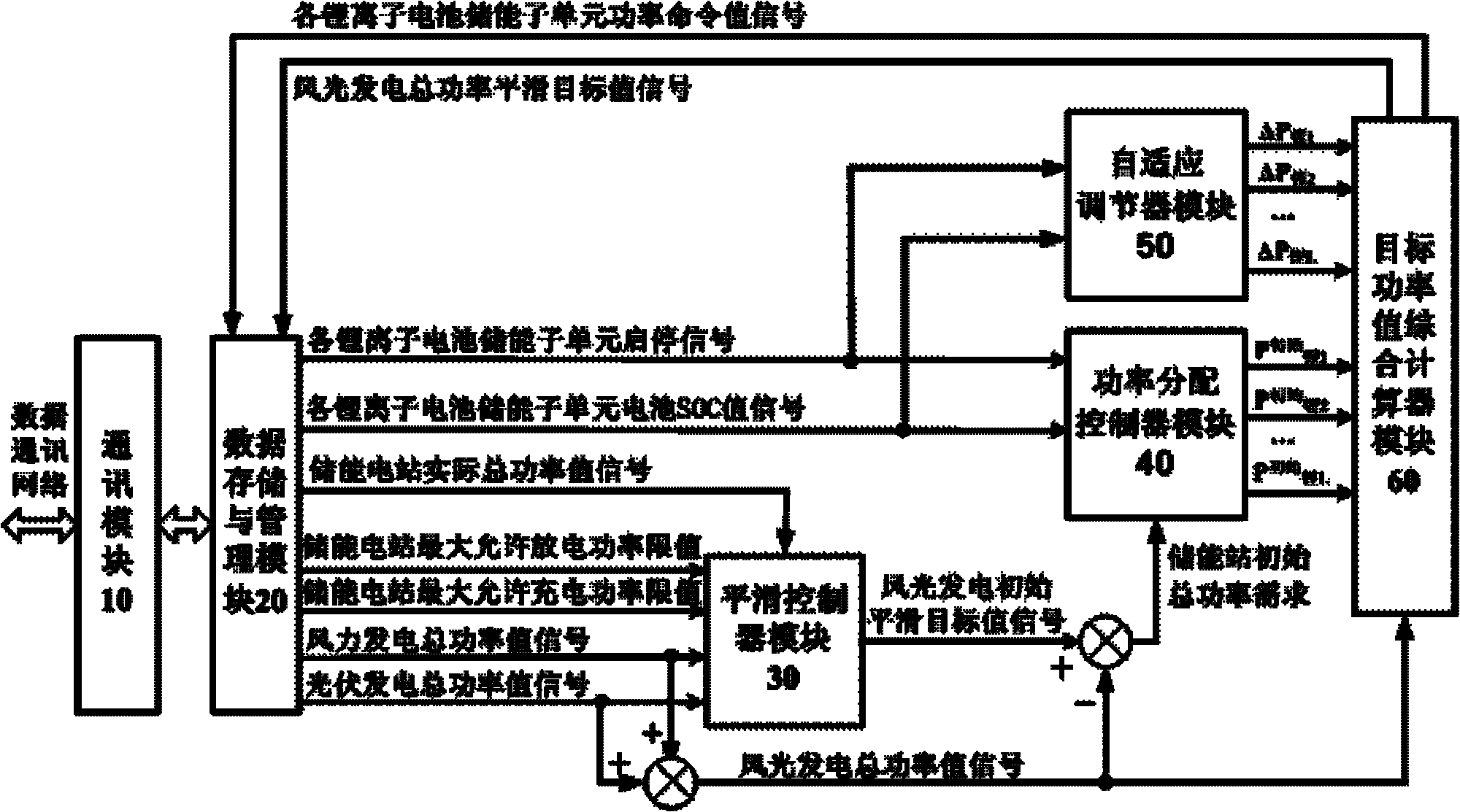

Smooth wind-optical generated output control method based on megawatt-grade battery energy-storage power station

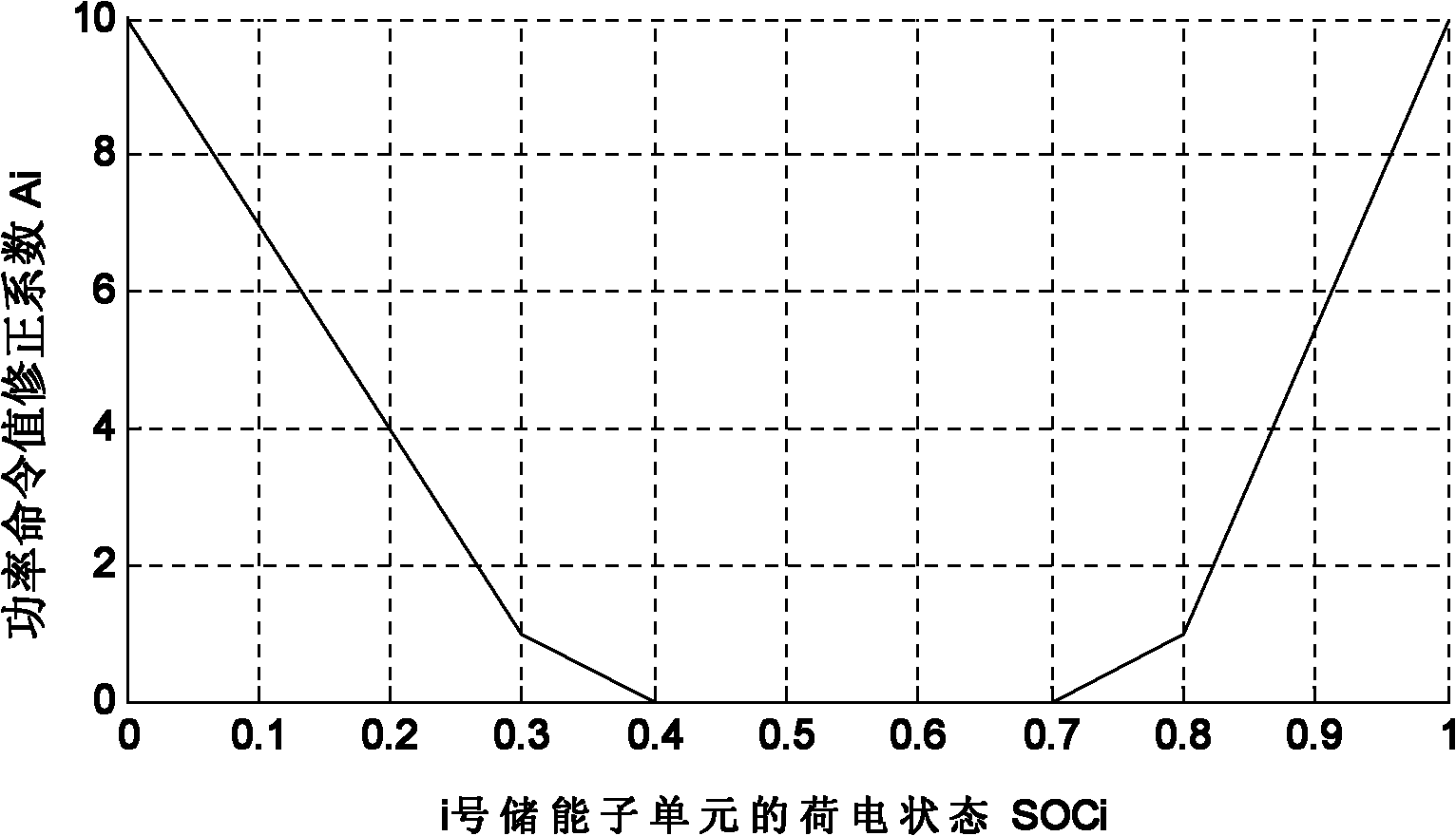

ActiveCN102214934AEasy to manageEffective controlSingle network parallel feeding arrangementsWind energy generationBattery storage power stationPower station

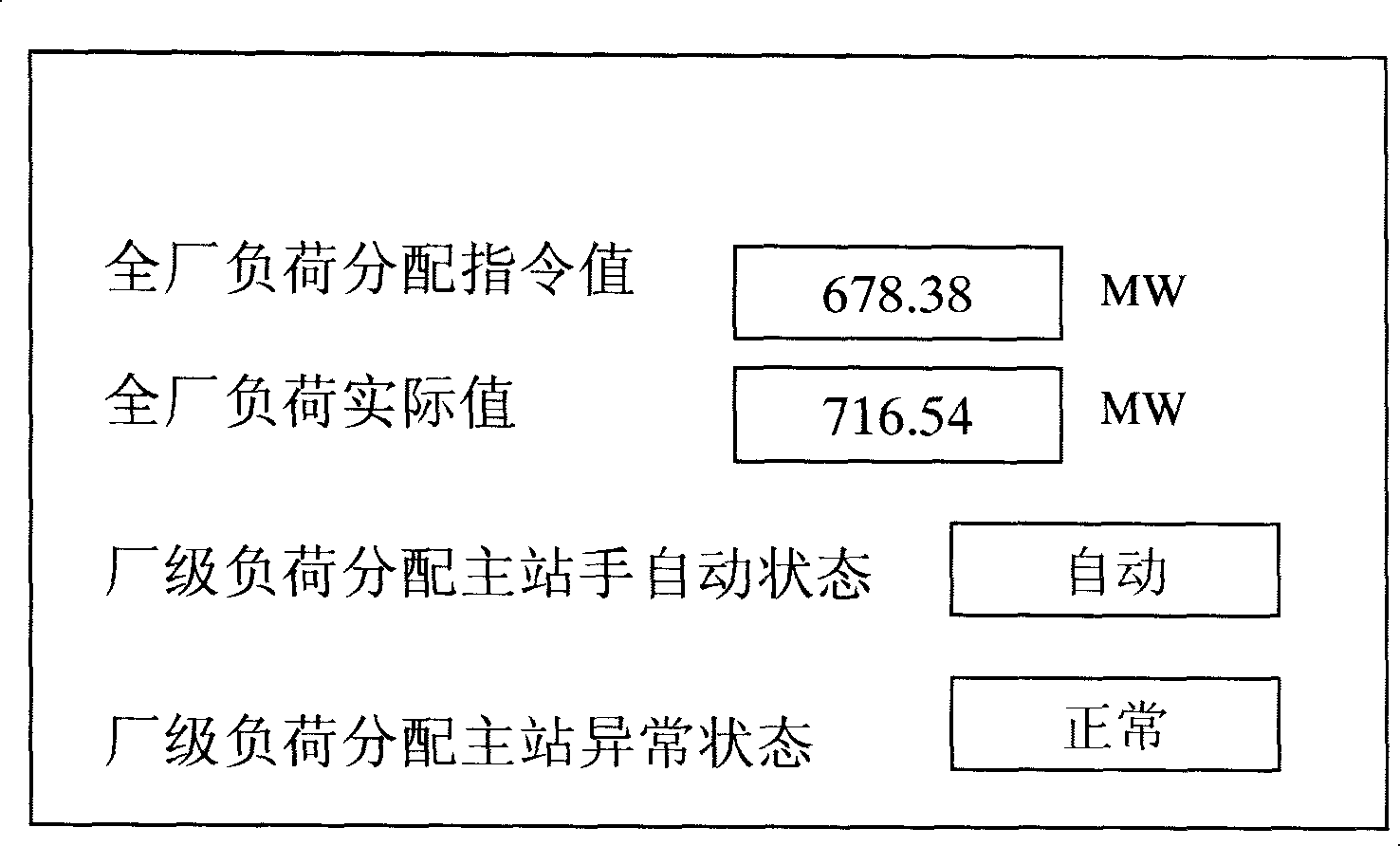

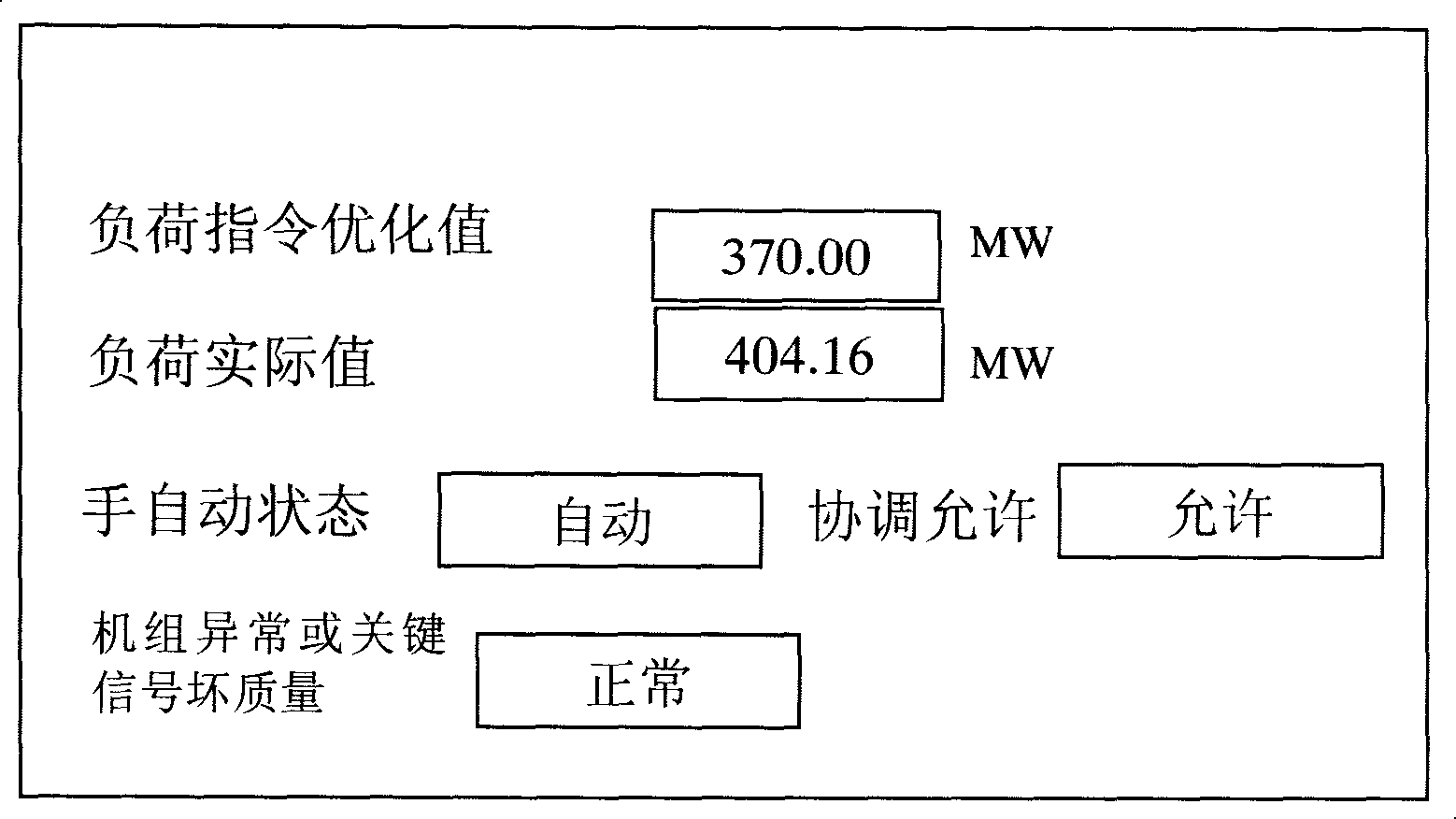

The invention relates to a smooth wind-optical generated output control method based on a megawatt-grade battery energy-storage power station. The method comprises the following steps: A. reading, storing and managing data; B. determining the initial total power requirement according to the initial smooth target value of wind-optical power generation and the total power value of wind-optical power generation; C. calculating the initial target power value of a battery energy-storage subunit; D. calculating the initial power command corrected value of each battery energy-storage subunit in real time; E. calculating the power command value of each battery energy-storage subunit and the total power smooth target value of the wind-optical generation; and F. outputting the data. According to the invention, the smooth wind-optical generated output control method based on the megawatt-grade battery energy-storage power station is implemented through an industrial personal computer and a communication platform, the real-time effective control on the megawatt-grade battery energy-storage power station can be realized, and the purpose of controlling the smooth wind-optical generated output can be realized.

Owner:许昌许继电科储能技术有限公司

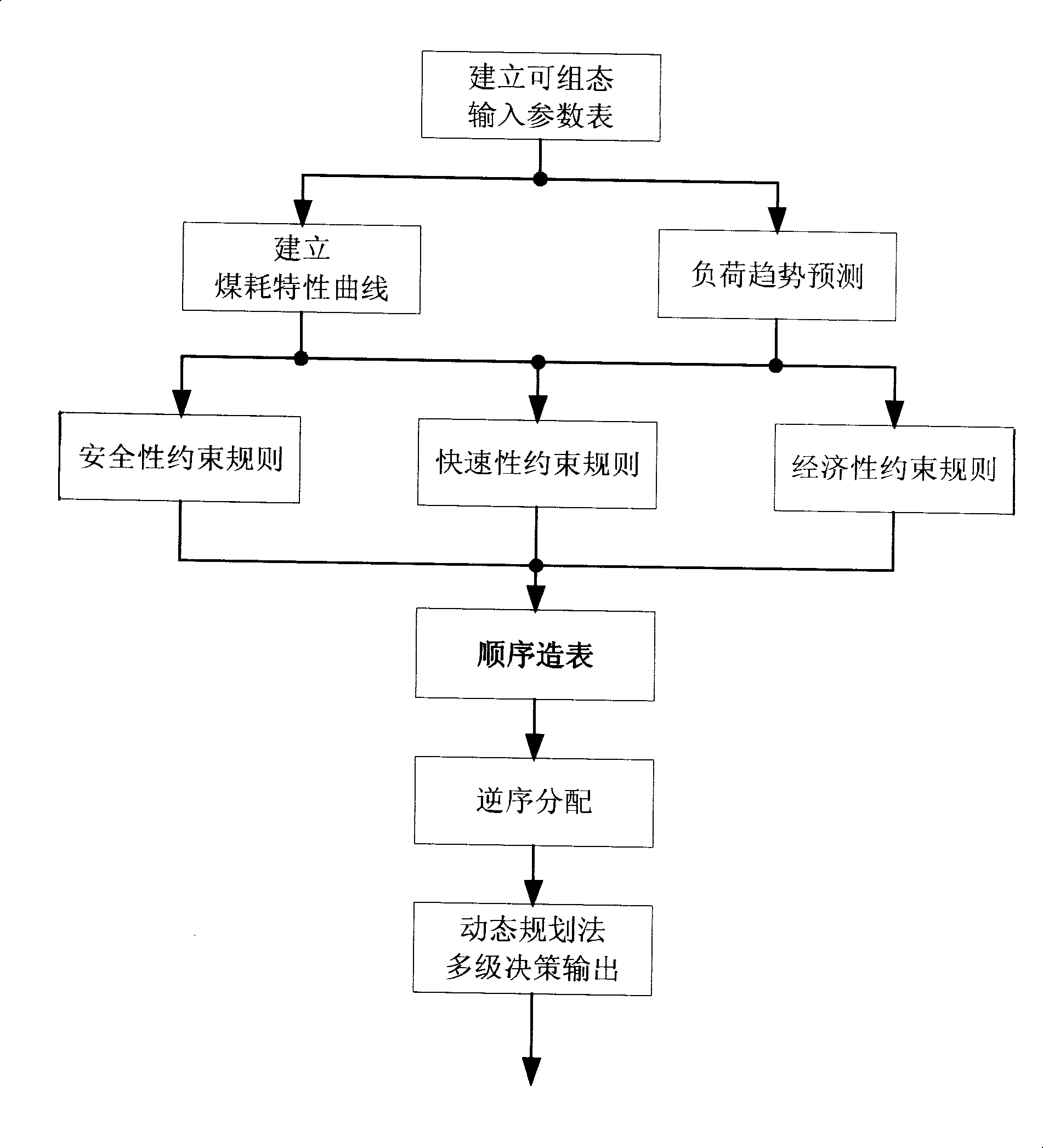

Method for optimizing distribution of thermal power station load based on a plurality of restriction rules

ActiveCN101206754AImprove economyAbility to increase load demandForecastingInformation technology support systemDistribution methodProcess engineering

The invention relates to the energy saving technology field, in particular to a multi-constraint rule based thermal power plant load optimal allocation method which comprises the following steps of: 1) building a configurable input parameter table; 2) building a coal consumption characteristic curve; 3) performing the load tendency prediction; 4) guaranteeing the safety constraint rules; 5) implementing the rapid constraint rules; 6) optimizing the economy constraint rules; 7) implementing the dynamic programming method under multi-constraint rules. The invention mainly aims to the power plants provided with at least two thermal power generating units, assists in shift supervisors perform the load maximizing and adjusting, and has the advantages of reducing equipment consumption and coal consumption, and improving performing economy.

Owner:BEIJING HUADIAN TIANREN ELECTRIC POWER CONTROL TECH

Real-time issuing method and system of safe and economic operation state of thermal power plant

InactiveCN104616124AGuaranteed uptimeImprove management levelTechnology managementResourcesVideo monitoringReal time messaging protocol

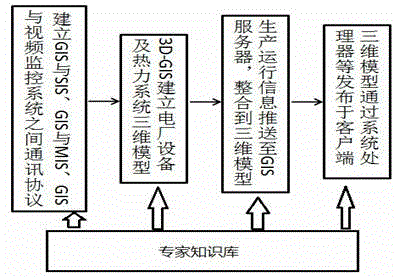

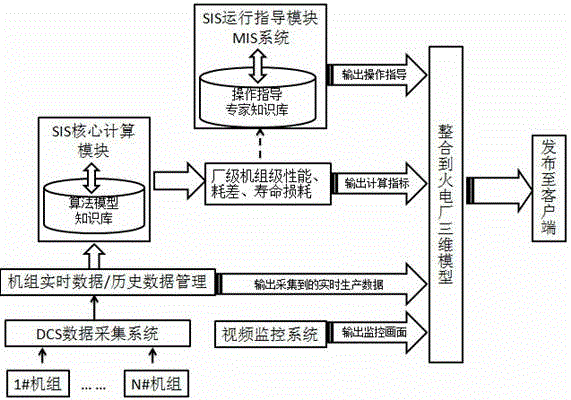

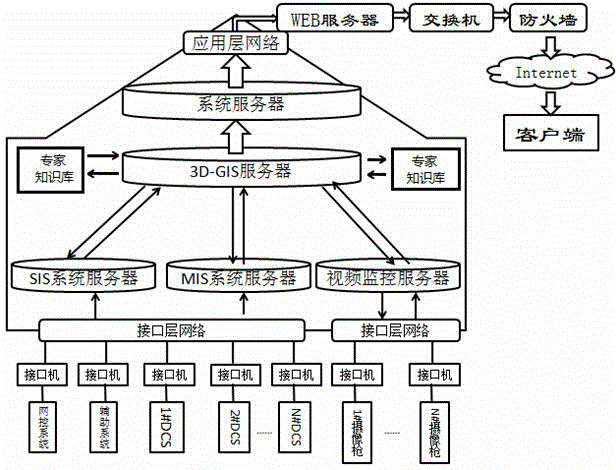

The invention provides a real-time issuing method and a real-time issuing system of a safe and economic operation state of a thermal power plant. The method comprises the following steps: building a real-time communication protocol among SIS, MIS, a video monitoring system and 3D-GIS; building a three-dimensional model indicating a production area view of the thermal power plant by utilizing a 3D-GIS technology to ensure that the three-dimensional model corresponds to equipment, heat distribution pipelines, valves and the like in a real production environment; processing data, video pictures, expert knowledge bases and the like pushed by the SIS, 3D-GIS and the video monitoring system by a GIS server and integrating to three-dimensional model corresponding positions; supplying the safe and economic operation state and fault solution strategies of location point equipment or systems. According to the real-time issuing method and the real-time issuing system, the complete coverage of the safe and economic operation state monitoring requirements and fault solution strategies of the unit are achieved, so that the occurrence of major accidents caused by ignorance of data abnormity due to human factors can be greatly reduced, and the safe and economic operation and the management level of the thermal power plant are effectively improved.

Owner:CHONGQING UNIV

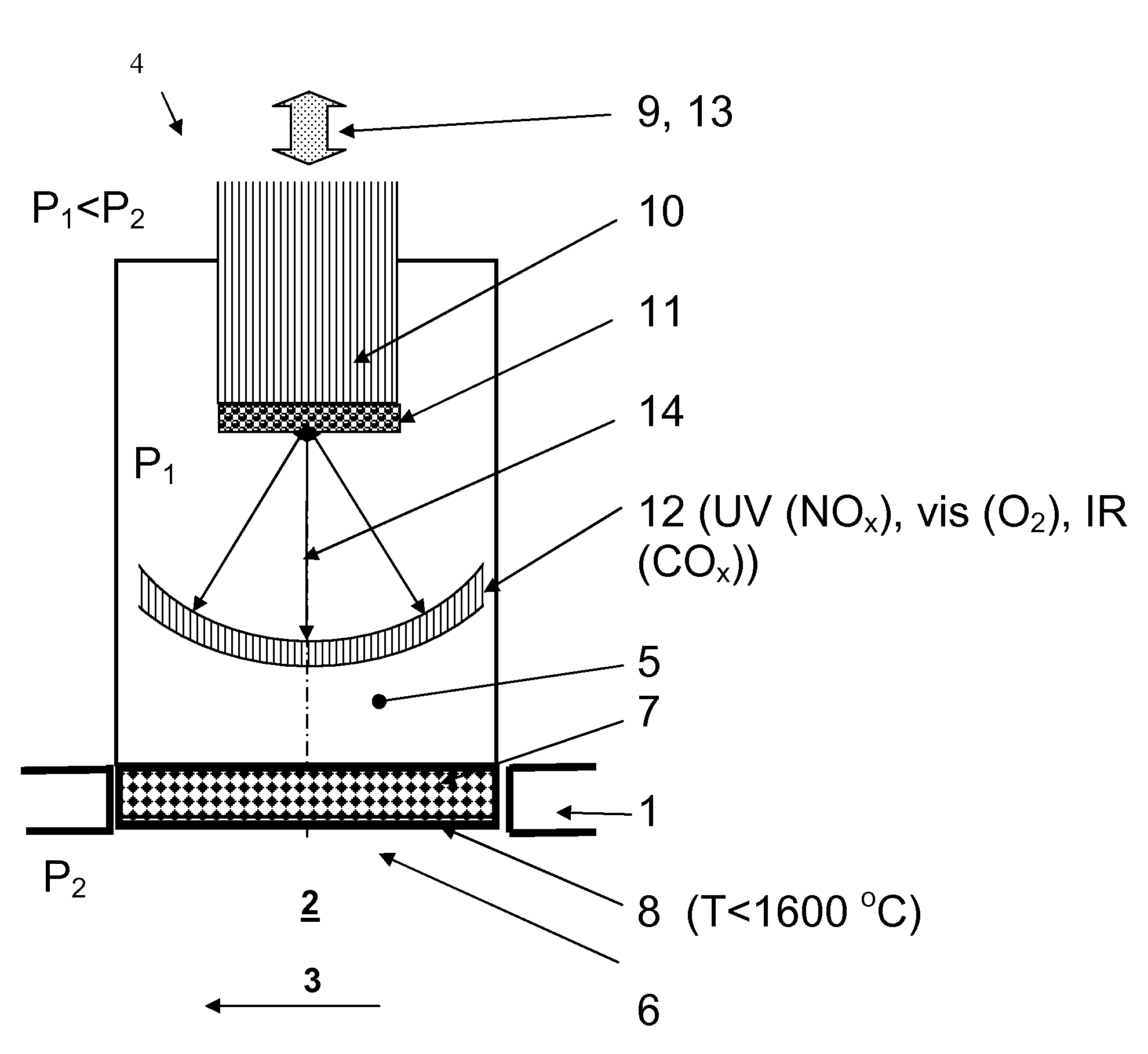

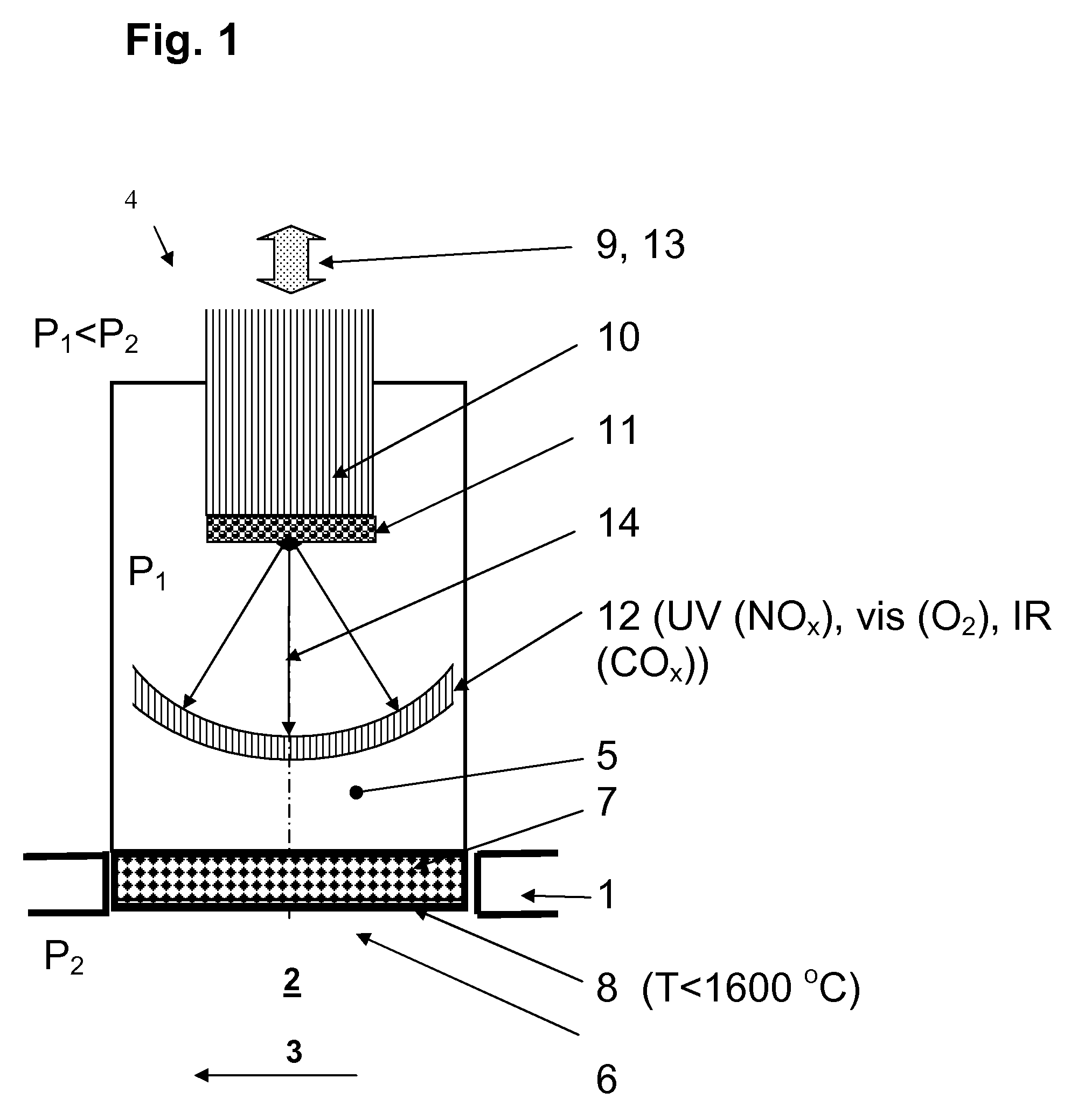

Optical sensor device for local analysis of a combustion process in a combustor of a thermal power plant

InactiveUS7650050B2Easy constructionInexpensive to fabricatePhotometryMaterial analysis by optical meansCombustorEngineering

Owner:ANSALDO ENERGIA IP UK LTD

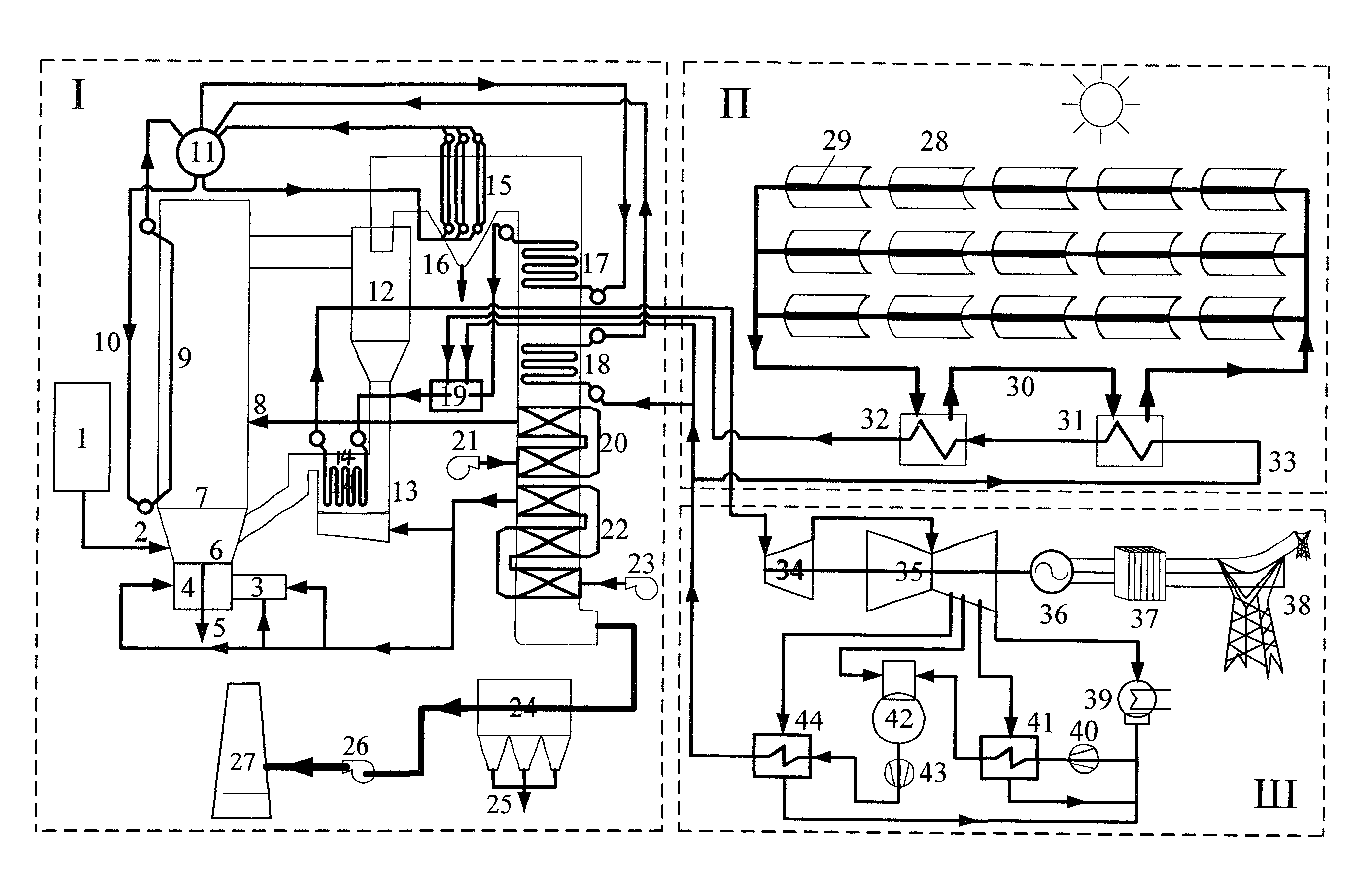

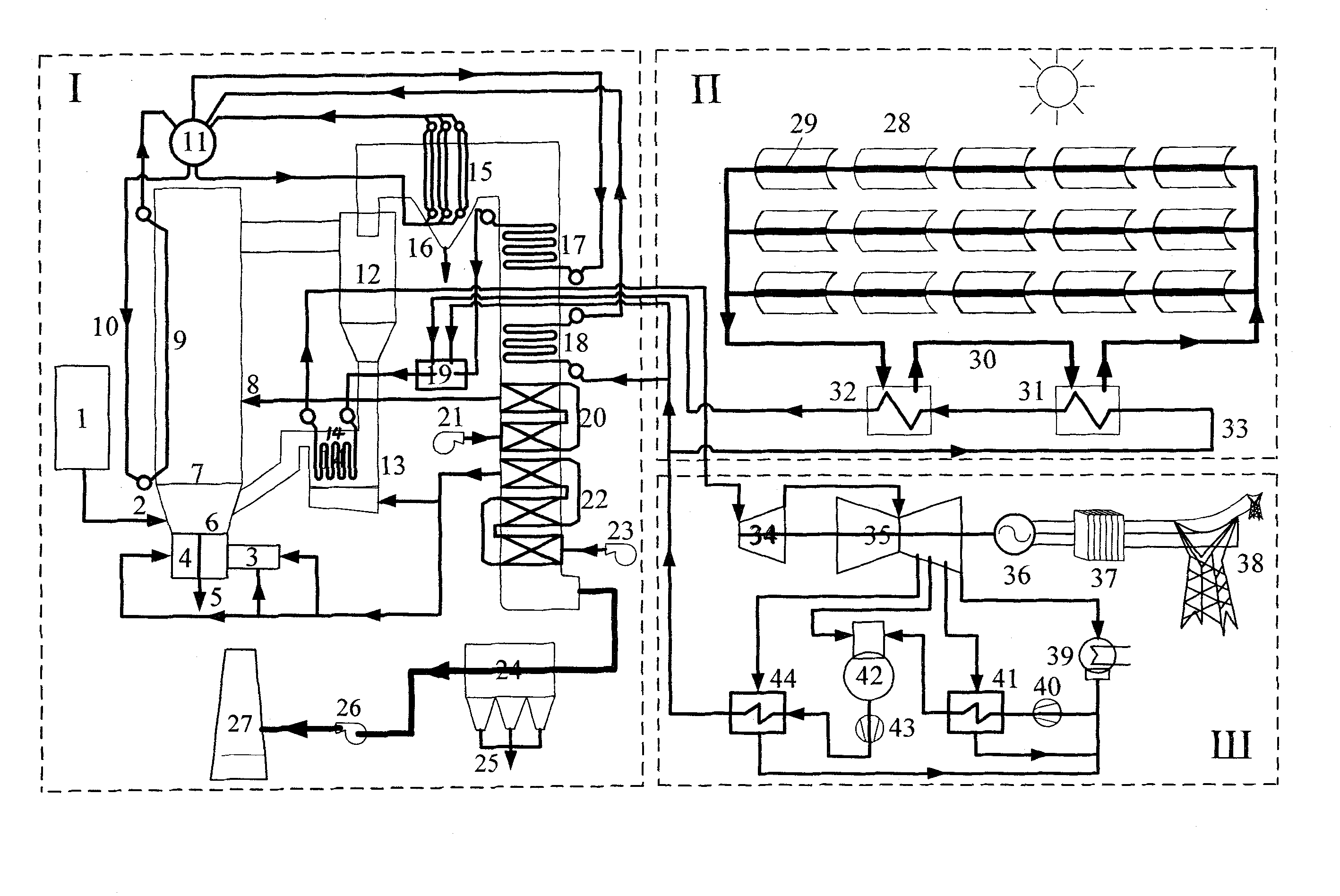

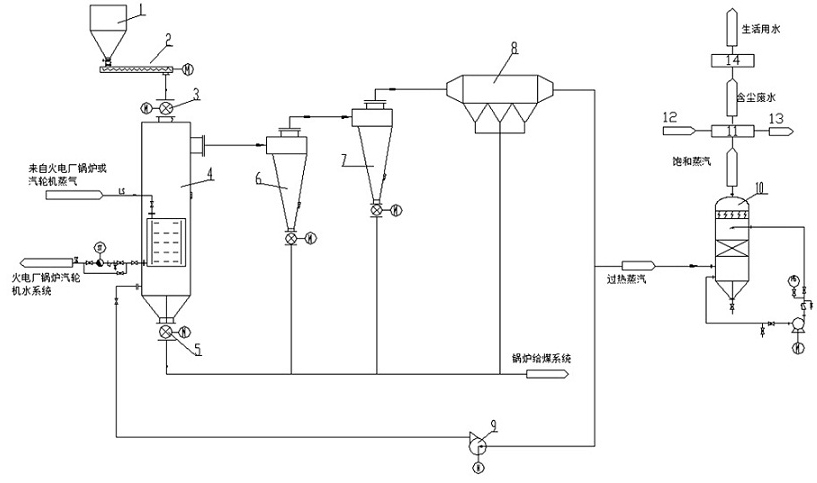

Solar energy and biomass energy integrated complementary combined thermal power generating system

ActiveCN101787906ARealize rationalityRealize comprehensive utilizationSteam generation heating methodsFrom solar energyEngineeringSystem stability

The invention discloses a solar energy and biomass energy integrated complementary combined thermal power generating system, which comprises a biomass circulating fluidized bed combustion boiler system, a solar heat absorption conversion system and a team turbine power generating system, wherein under the condition of the sun radiation, the biomass circulating fluidized bed combustion boiler system and the solar heat absorption conversion system are combined with the steam turbine power generating system to run, so the solar energy radiation heat is converted to the heat energy to be used for heating water, and finally the steam is heated to be the middle-temperature middle-pressure or the high-temperature high-pressure steam so as to drive the steam turbine unit to generate power; and under the condition that no sun radiation exists or the solar heat absorption conversion system has malfunction and is required to be examined, the solar heat absorption conversion system is disconnected, but the biomass circulating fluidized combustion boiler system and the steam turbine power generating system are still maintained to run normally. The solar heat utilization system is reasonably integrated into the biomass power generating system; and moreover, the combined power generating system has the advantages of low investment cost, high power generation efficiency, good system stability and the like.

Owner:SOUTHEAST UNIV

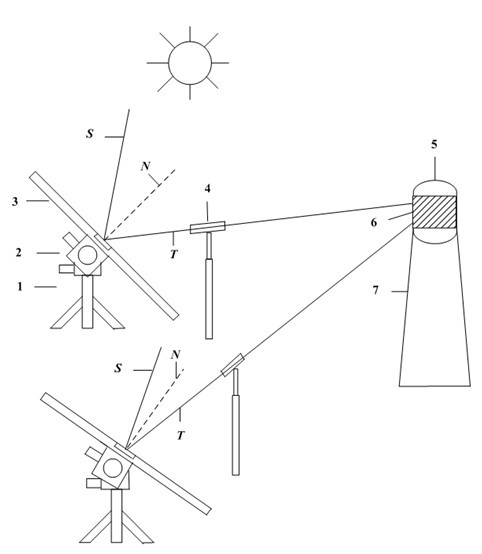

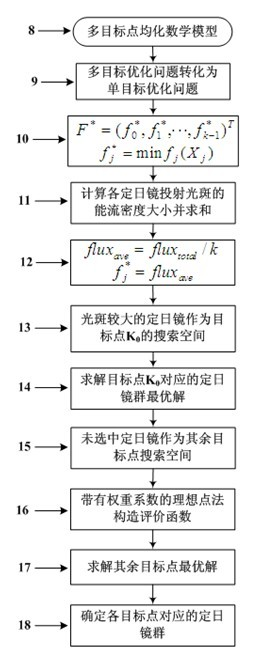

Method for scheduling heliostat field in tower solar thermal power station

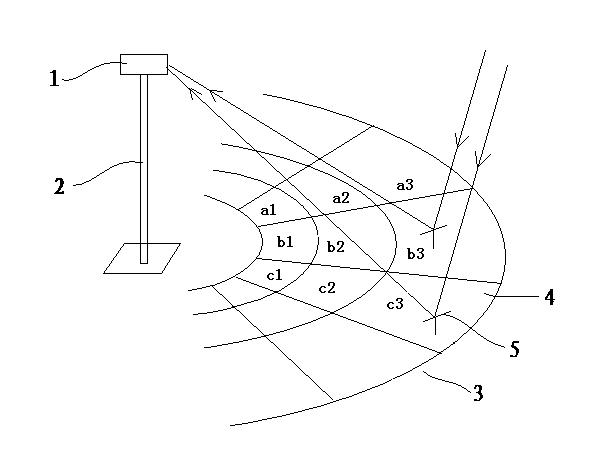

InactiveCN102331793AOvercome densityOvercome the shortcomings that cannot be corrected by themselvesControl using feedbackHeliostatLoop control

The invention discloses a method for scheduling a heliostat field in a tower solar thermal power station. In the method, an open-closed loop combined control mode is adopted; in open loop control, the control direction and position of a heliostat are computed in real time according to the running rule of the sun, the latitude and longitude of the heliostat as well as the geometric relationship between the positions of the heliostat and a heat absorber; and in closed loop control, a target position corresponding to each heliostat is determined through a closed loop sensor, and the heliostat is accurately tracked according to a real-time angle value of the heliostat fed back by the closed loop sensor, so that the energy-flux density of the heliostat field is homogenized and scheduled. According to the method, automatic homogenizing and scheduling of the energy-flux density projection of the heliostat field are realized, and the defects of poor energy-flux density homogenizing effect and unavailable self-correction caused by a large tracking error existing in open loop control are overcome effectively; and moreover, the method is easy to implement and is convenient to operate.

Owner:NANJING SCIYON AUTOMATION GRP

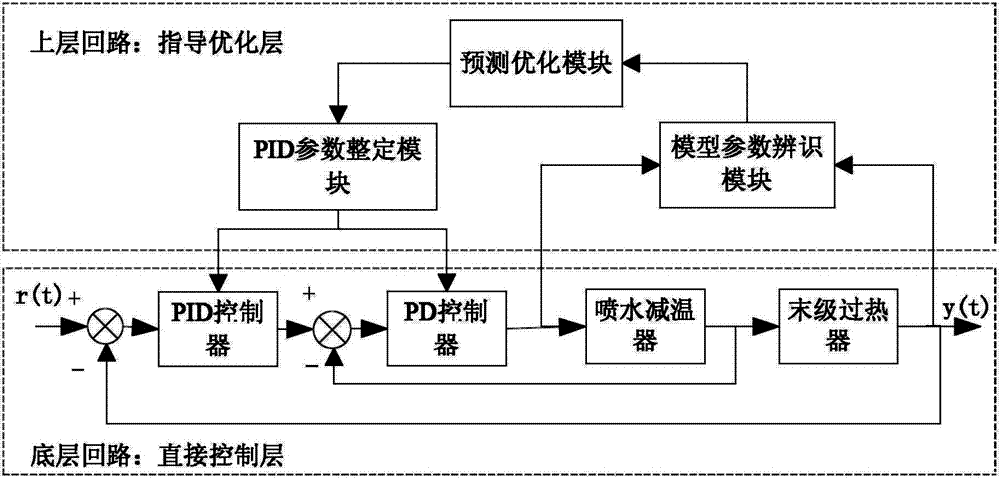

Main steam temperature predictive control method of ultra supercritical unit of thermal power plant

ActiveCN102777879ATo achieve the purpose of adaptive control of main steam temperatureImprove stabilityBoiler controlAdaptive controlComponent Object ModelOnline model

The invention relates to a main steam temperature predictive control method of an ultra supercritical unit of a thermal power plant. A layered control structure is arranged, the layered control structure consists of a bottom direct control layer and an upper guide optimization layer, and the upper guide optimization layer realizes model parameter identification, prediction optimization and PID (Proportion Integration Differentiation) parameter setting control; and the bottom direct control layer is in a cascade system structure and comprises main loop control and assistant loop control, and a PID controller orienting a DCS (distributed control system) is directly controlled. The control method can be used for replacing a control engineer to set PID parameters, on-line model identification and control parameter setting methods are directly adopted to achieve the purpose of main steam temperature self-adaptive control, the application of an advanced control technology and an intelligent optimization technology under a DCS is realized, the stability and the robustness are stronger, and a changing process of a controlled object model of the main steam temperature under a variable load can be adapted.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

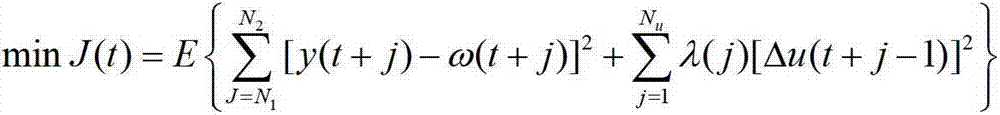

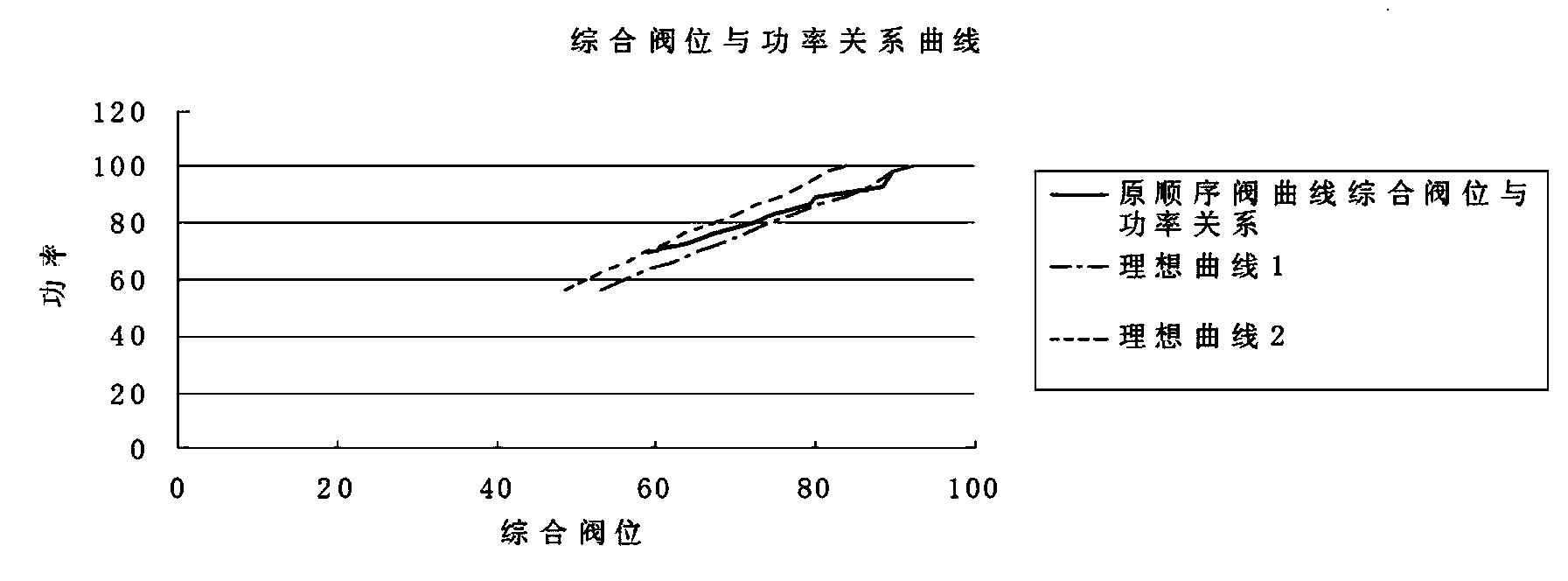

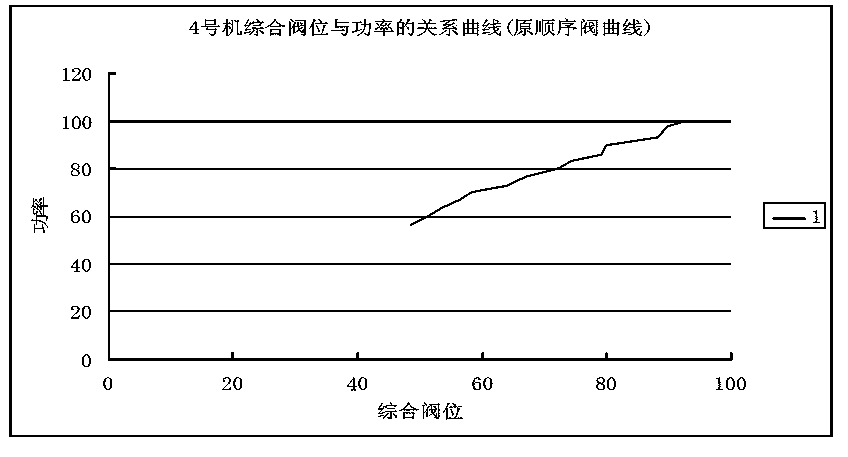

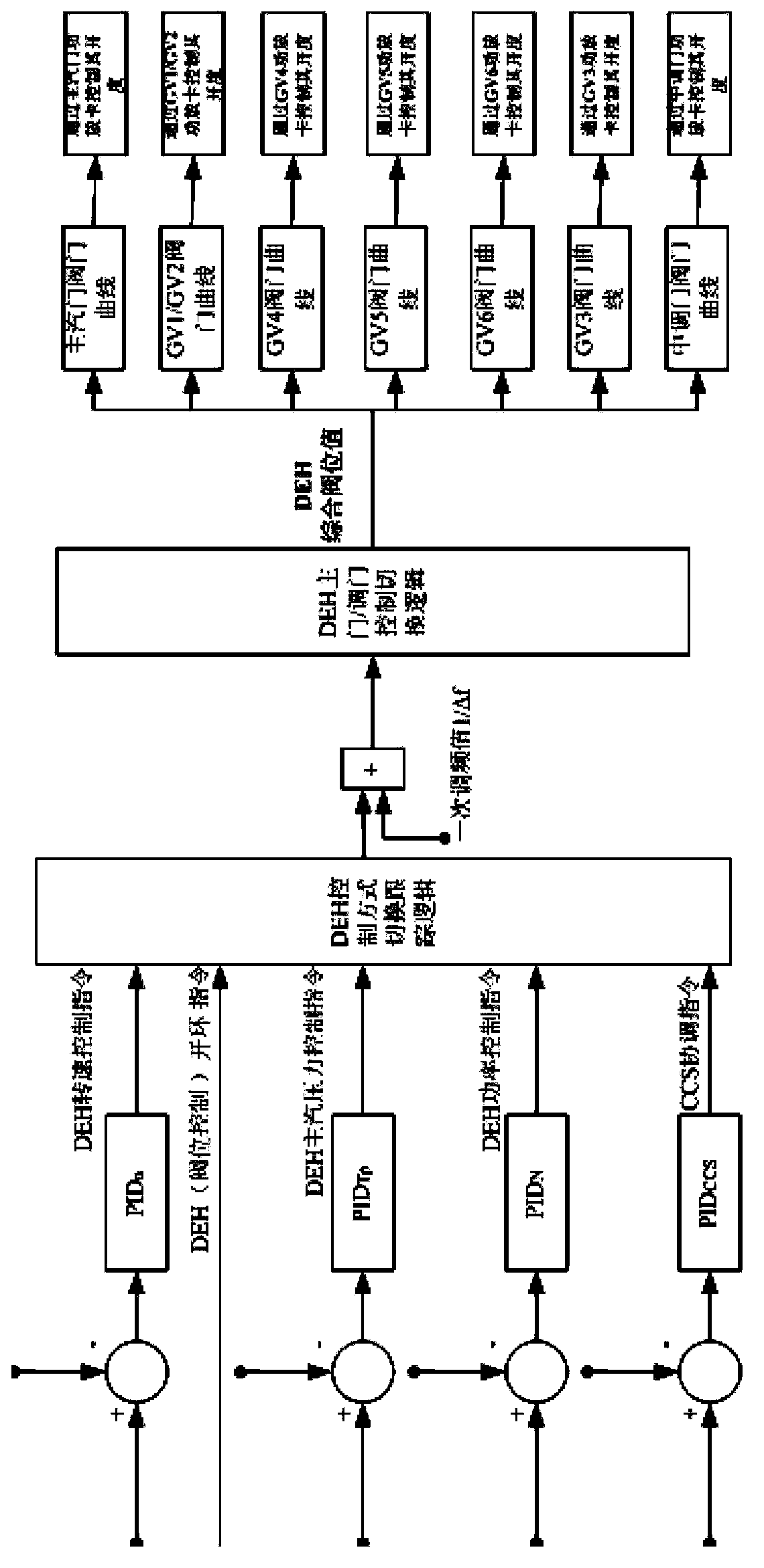

Adjustment method for steam turbine control valve flows in thermal power plant

InactiveCN103670536AAvoid swingingImprove linearizationMachines/enginesEngine componentsFlow curveEngineering

The invention provides an adjustment method for steam turbine control valve flows in a thermal power plant. The adjustment method includes the following steps that step1, a control valve optimization experiment is performed, all experimental data are determined, and a load up-and-down experiment needing to be performed for a current valve curve linear relation, a high control valve flow characteristic experiment, and determining on maximum strokes and sequence valve curves of all high control valve equalizing valves, sequence valve curves after on-line inspection and modification and maximum flow point positions of intermediate control valves are sequentially performed; step2, a control valve flow curve optimization scheme is obtained through calculation and analysis performed on control valve flow curve experimental data. The adjustment method can effectively improve the flow characteristic of steam turbine control valves, improve load variation and primary frequency modulation performance of a generator set, effectively improve adjustment quality of the generator set, and improve running safety and service life of high control valves and the intermediate control valves and economy of the set.

Owner:GANSU DATANG INT LIANCHENG POWER GENERATION

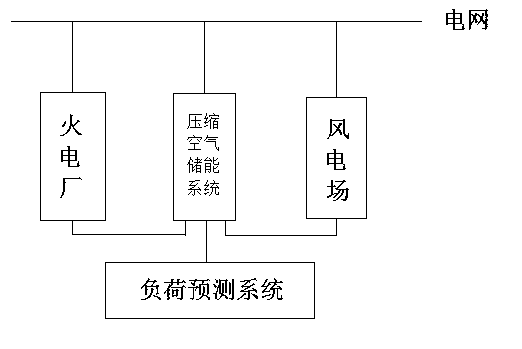

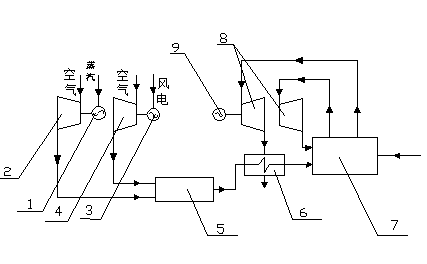

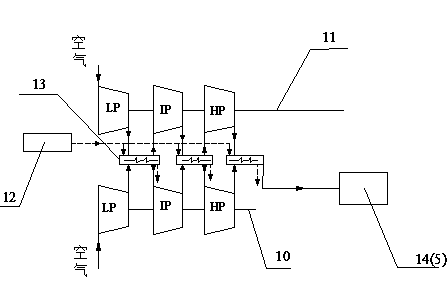

Wind power generation, thermal power generation and compressed air energy storage integrated power generation system

InactiveCN103644081AGood environmental benefitsRotary/oscillating piston combinations for elastic fluidsWind motor combinationsThermal energy storageEngineering

The invention discloses a wind power generation, thermal power generation and compressed air energy storage integrated power generation system. The integrated system is mainly composed of a wind power plant, a thermal power plant and a compressed air energy storage power station. The wind power plant and the thermal power plant are connected through a compressed air system to form a wind power, thermal power and energy storage integrated power generation system. The compressed air energy storage system adjusts power output according to a grid load requirement and the output condition of the wind power plant and the thermal power plant to achieve linkage of the wind power plant and the thermal power plant and improve grid load response capability. Under the condition that grid safety is ensured, more clean energies can be connected into a grid. The compressed air energy storage system utilizes high temperature slag generated by the thermal power plant to generate power and replaces the traditional way that a traditional compressed air energy storage system utilizes natural gas to generate power. Therefore, the system has high environment benefit. Meanwhile, the system is high in peak load adjustment capability. By means of the system, the grid can receive wind power in a large scale, and the peak adjustment capability can be improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Thermal power plant main operating parameter target value determining method based on association rule mining

ActiveCN106094744AImprove robustnessImprove accuracyTotal factory controlProgramme total factory controlData setRule mining

The invention provides a thermal power plant main operating parameter target value determining method based on association rule mining. The rule knowledge of a unit under certain operating conditions is acquired by using steady operating data stored in a historical operating database through an association rule mining technology, and finally the knowledge is used to guide the unit optimization operating. The method comprises the steps that the steady operating data are extracted from a unit historical operating data set through a data preprocessing technology; discretization of continuous attributes is carried out on a specific condition data set through a condition dividing result to complete data set preparation of association rule mining; and rule knowledge extraction is carried out on a discretized data set through an association rule mining technology to acquire a unit historical operating knowledge database. The knowledge database can assist an operator or a control system to make relevant decisions. According to different target attributes, the economy, stability and environment protection of unit operating can be improved, and a unit is under an excellent operating condition for a long time.

Owner:SHANGHAI UNIV

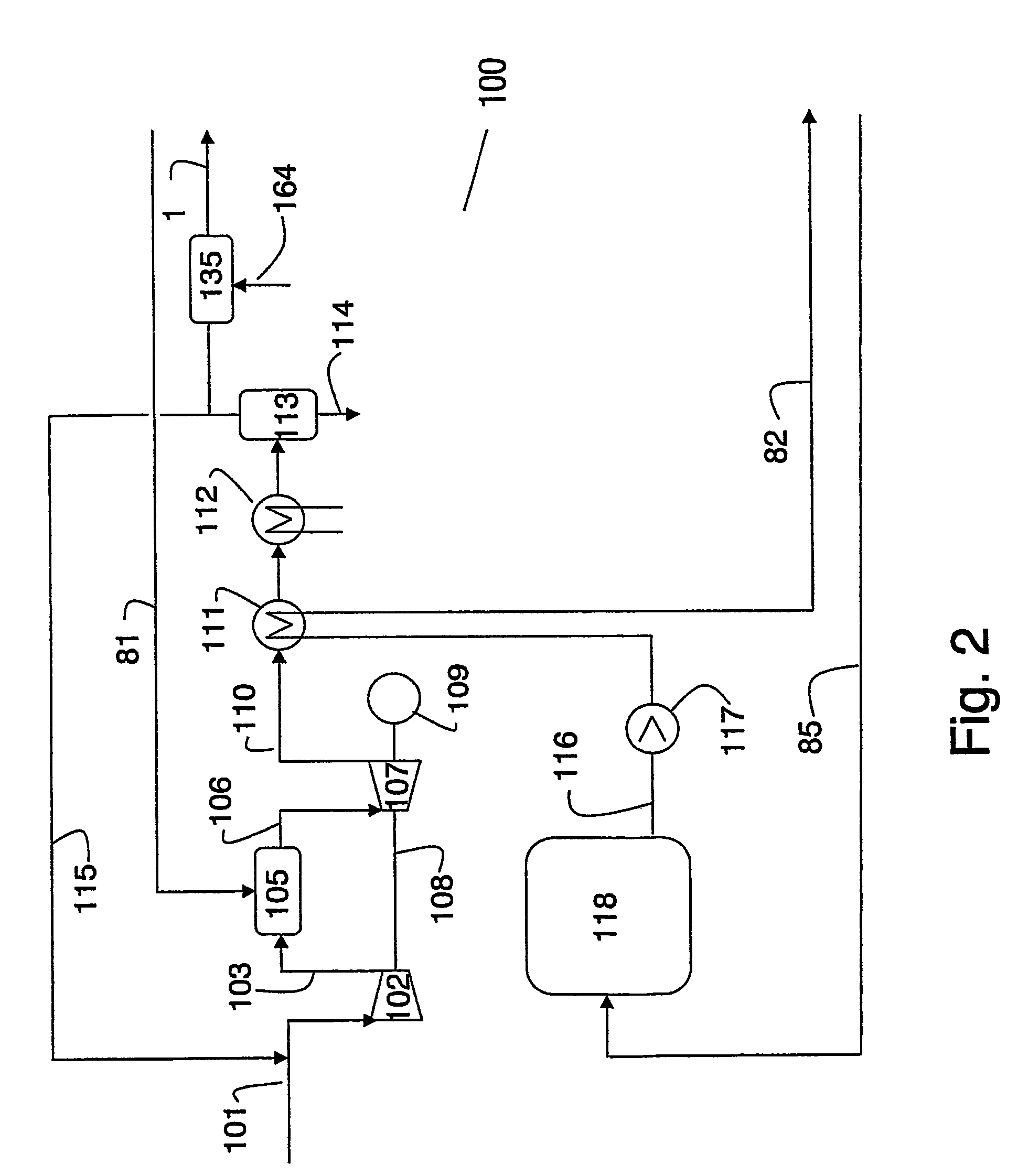

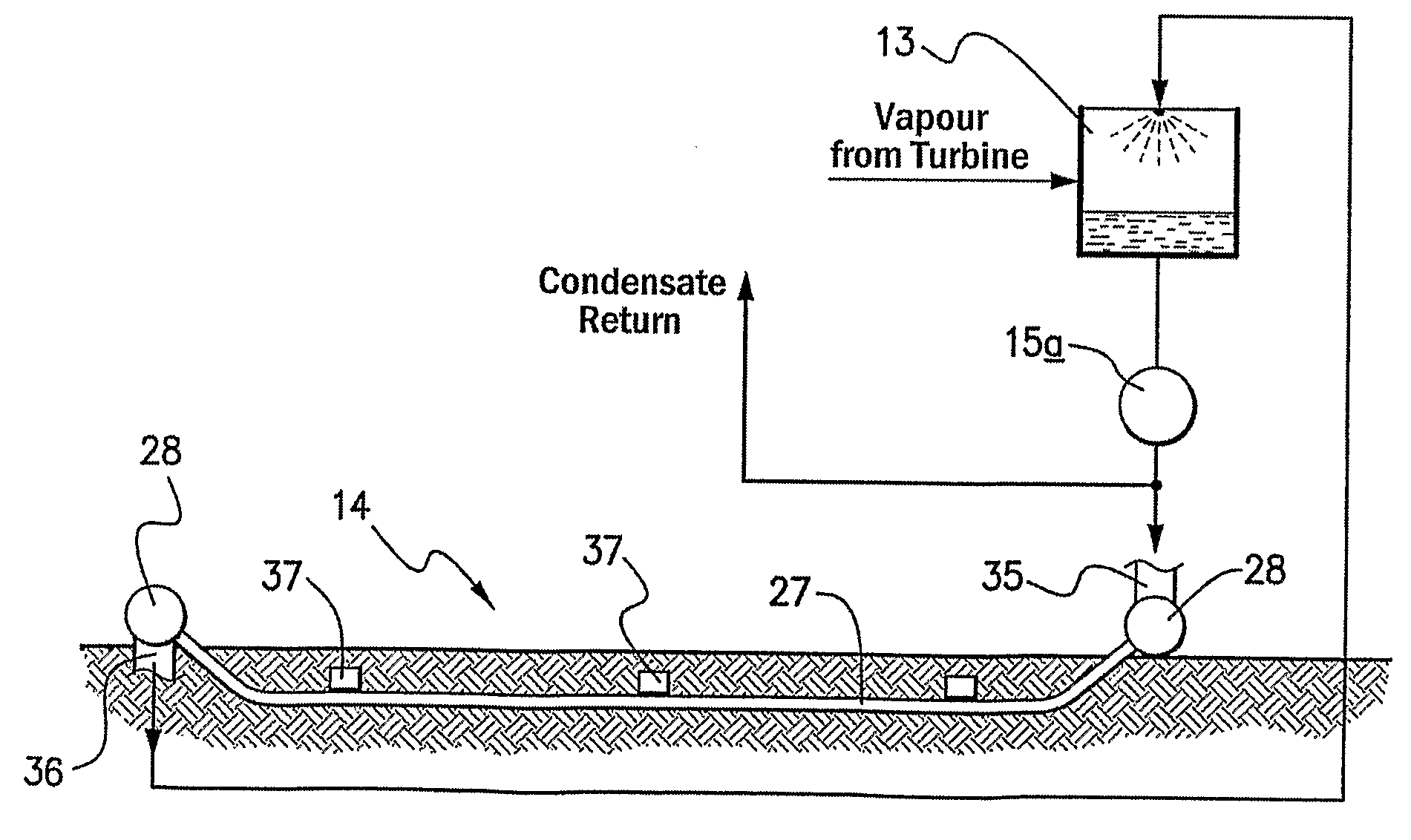

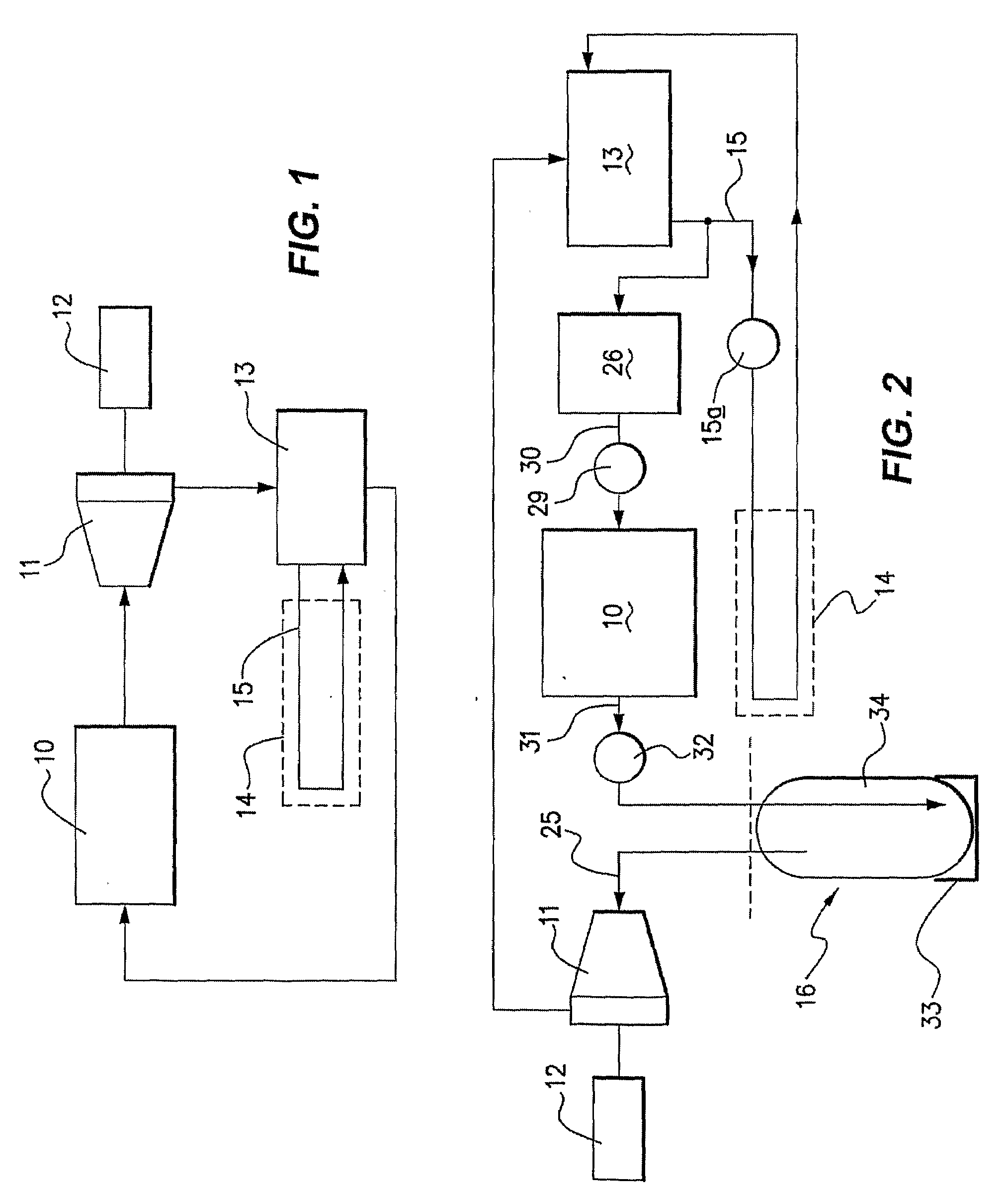

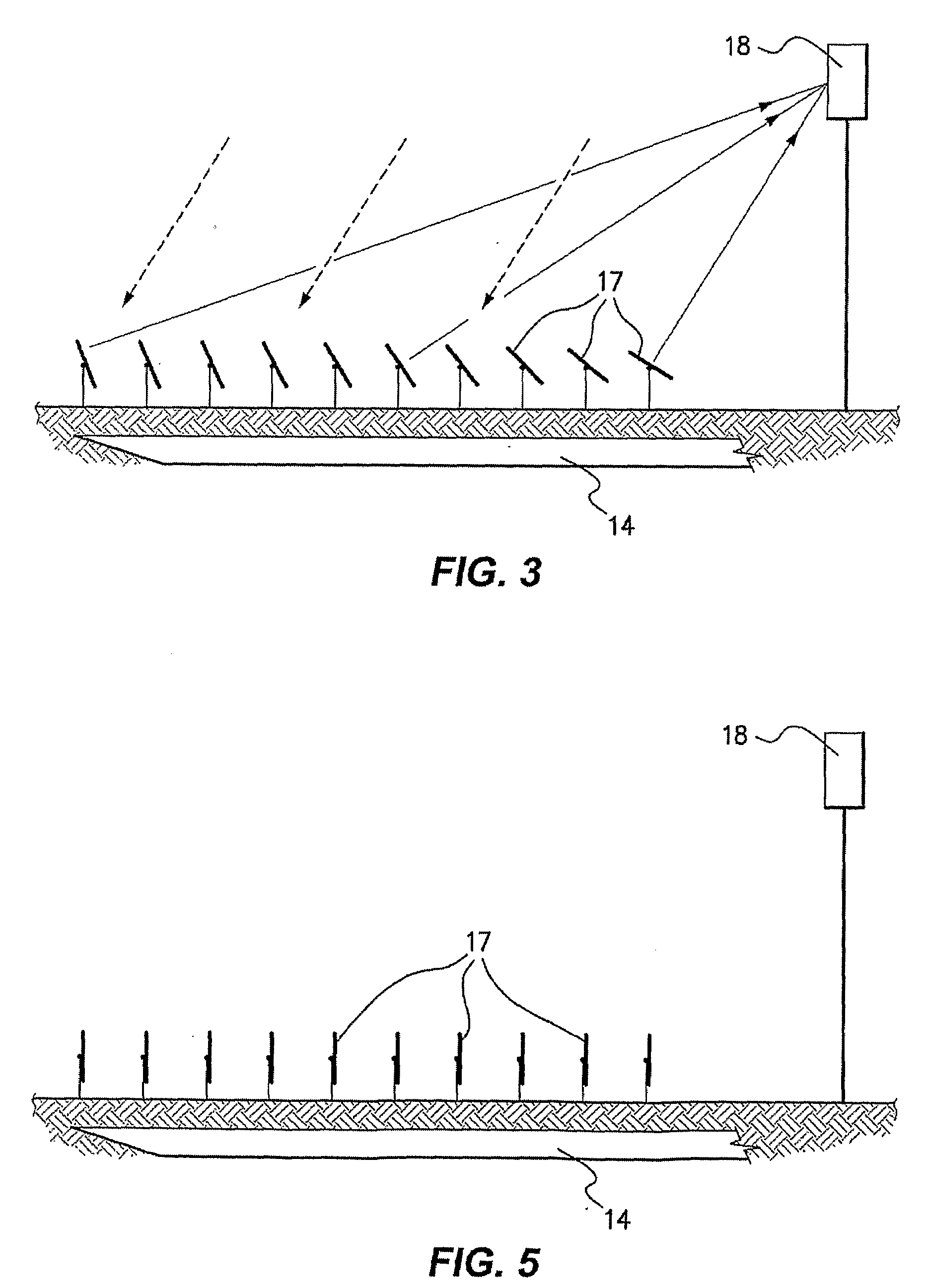

Thermal power plant incorporating subterranean cooling of condenser coolant

InactiveUS20090158736A1Facilitate maximum heat dissipationMaximize shadeSolar heating energyAuxillary drivesPower stationSteam condensation

A thermal power plant is disclosed that comprises a heating system (10) that utilizes solar radiation for heating a working fluid, a turbine (11) to which, in operation, the working fluid is delivered, a condenser (13) located downstream from the turbine and arranged for condensing vapour exhausted from the turbine, and a cooling system (14) associated with the condenser. The heating system comprises a field of reflectors (17) that, during diurnal periods, are arranged (for example by pivoting) to reflect incident solar radiation to a receiver (18) for heating the working fluid. The cooling system (14) is arranged in operation of the power plant to transport a coolant fluid to which heat is transferred during vapour condensing and it comprises a subterranean heat exchanger incorporating conduits (27) through which the coolant is recirculated when cycling through the condenser. In one embodiment of the power plant the cooling system / subterranean heat exchanger (14) is positioned within ground that is located at least in part below the field of reflectors (17). Also disclosed is a method of operating a thermal power plant.

Owner:AREVA SOLAR

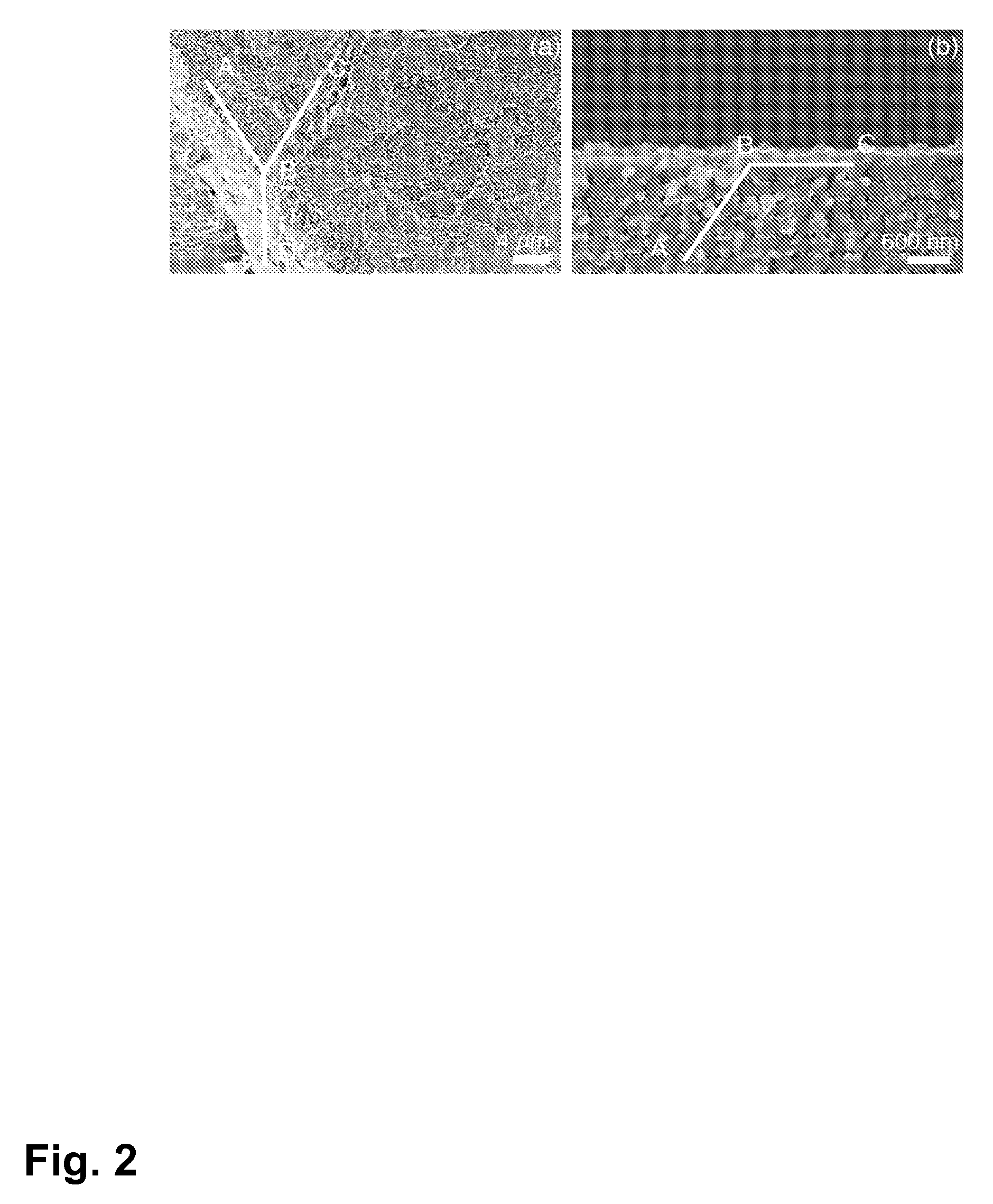

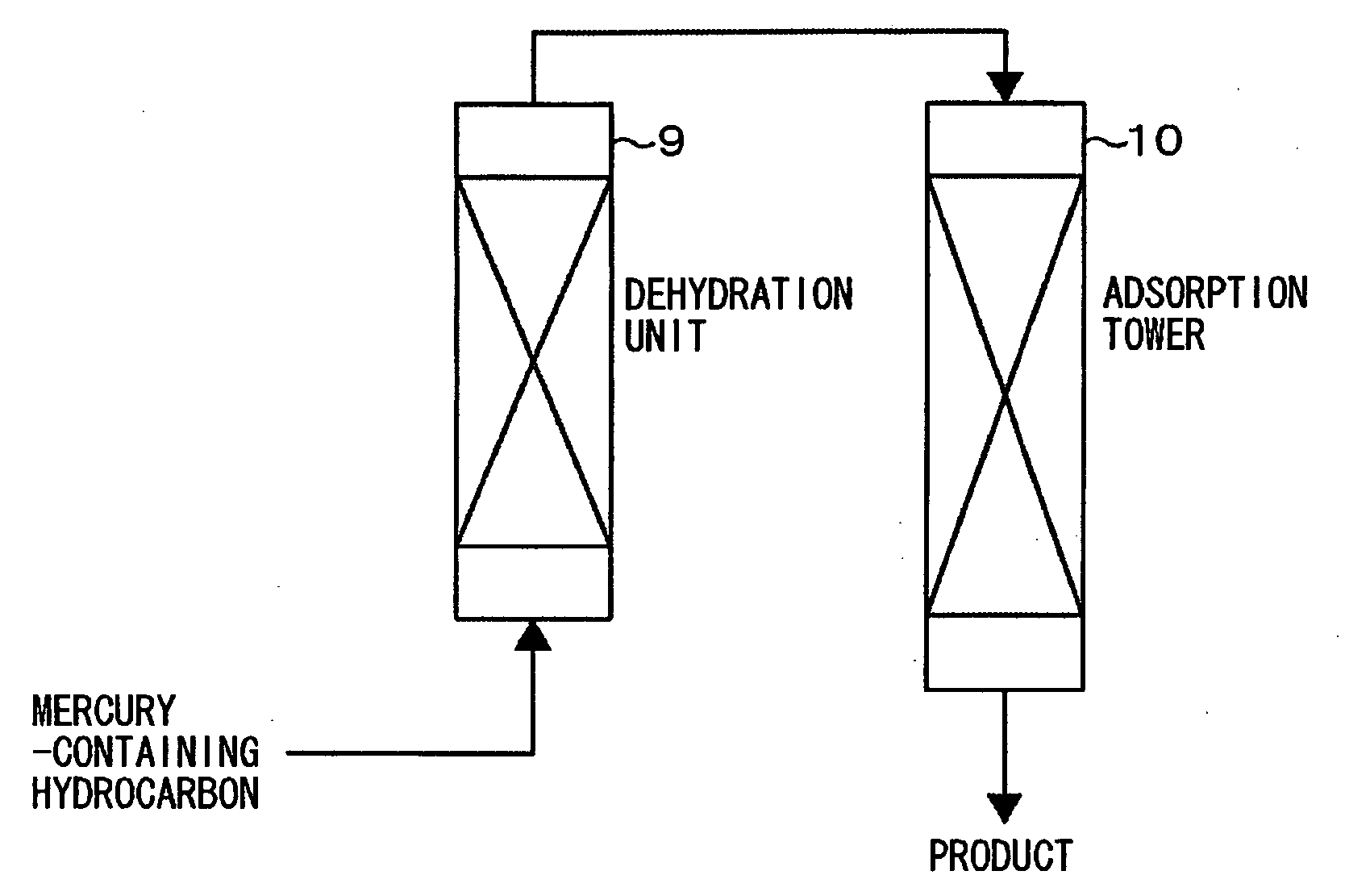

Mercury-removal adsorbent ,method of producing mercury-removal adsorbent, and method of removing mercury by adsorption

InactiveUS20100025302A1Reduce concentrationIncrease volumeGas treatmentOther chemical processesSorbentPotassium iodine

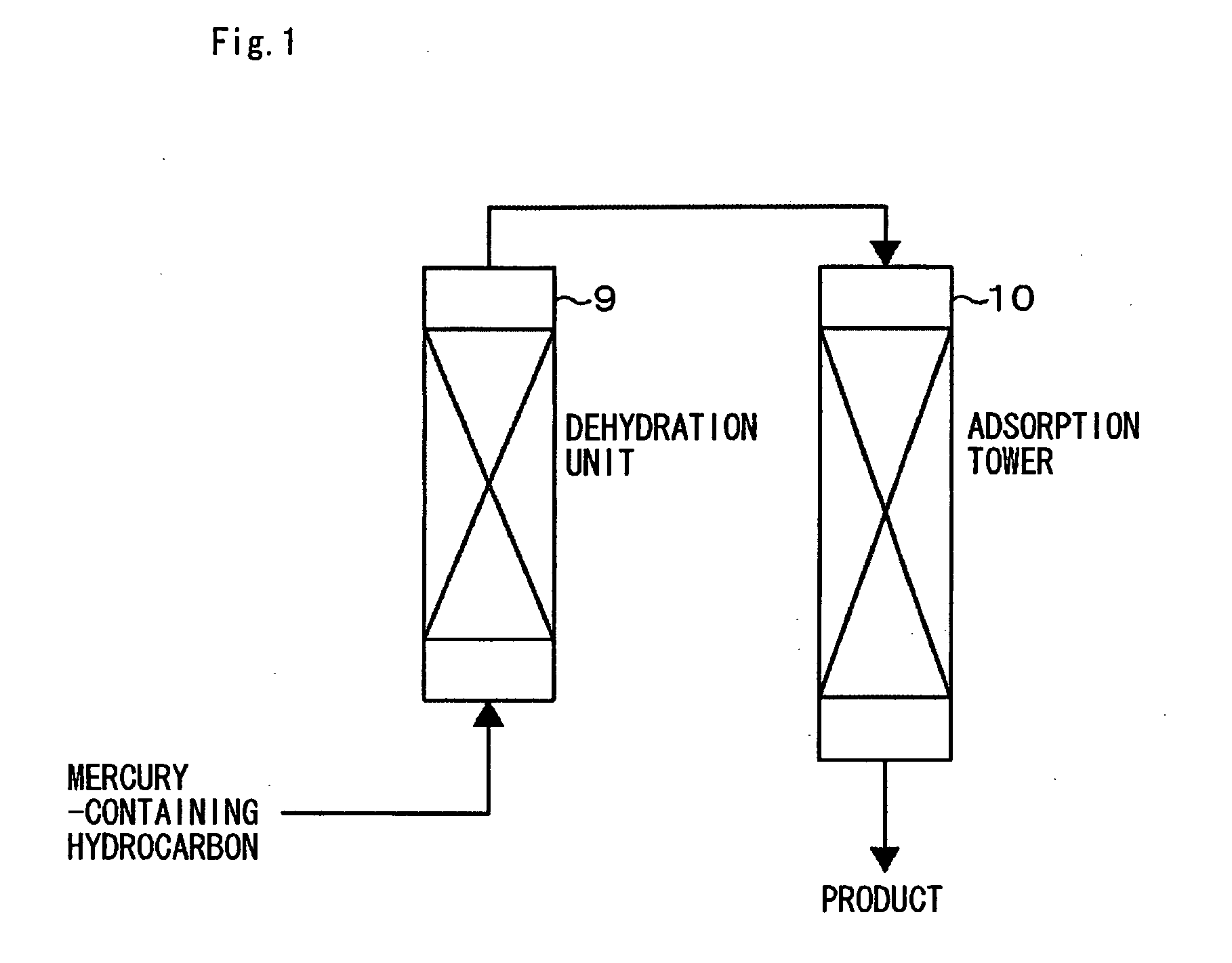

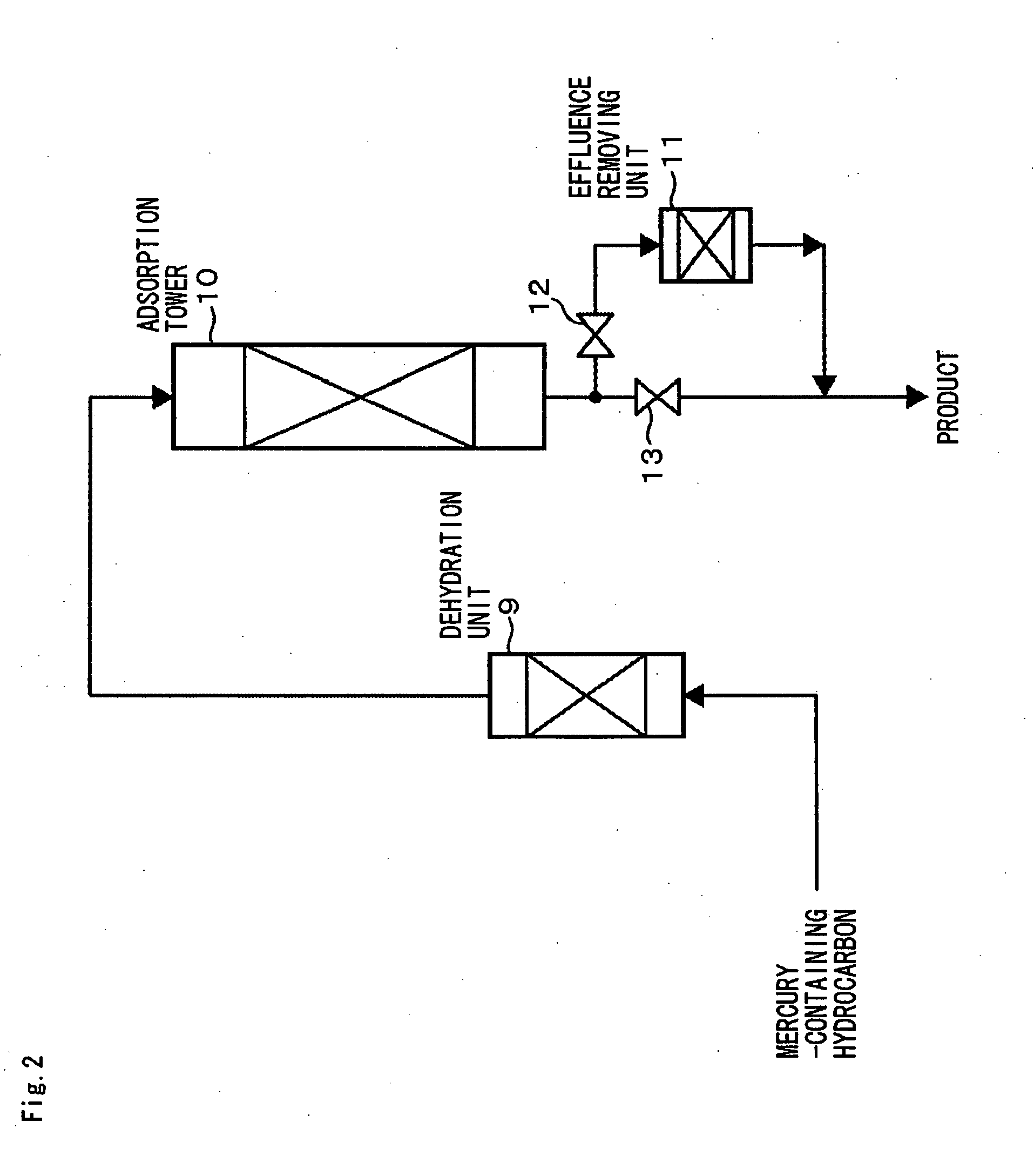

To provide mercury-removal adsorbents, a method of producing mercury-removal adsorbents, and a method of removing mercury by adsorption which are capable of realizing efficient removal of mercury by adsorption from liquid hydrocarbon, thermal power station exhaust combustion gas, natural gas, off gas of various process plants, and so on which contain mercuries in various forms such as elemental mercury, ionic mercury, and organic mercury, and a concomitant hindering mercury adsorption.Mercury-removal adsorbents carrie potassium iodide in an amount of 27 to 70% of a total adsorbent weight, and a volume of pores with a 1 μm pore diameter or more in the mercury-removal adsorbents is 0.6 mL / g or more. These mercury-removal adsorbents are filled in, for example, an adsorption tower 10, and a hydrocarbon liquid is passed therethrough (mercury removal step). In a case where the hydrocarbon liquid contains saturated water, a dehydration unit 9 or the like is installed on a preceding stage of the adsorption tower 10 to dehydrate the hydrocarbon liquid (dehydration step).

Owner:JGC CORP

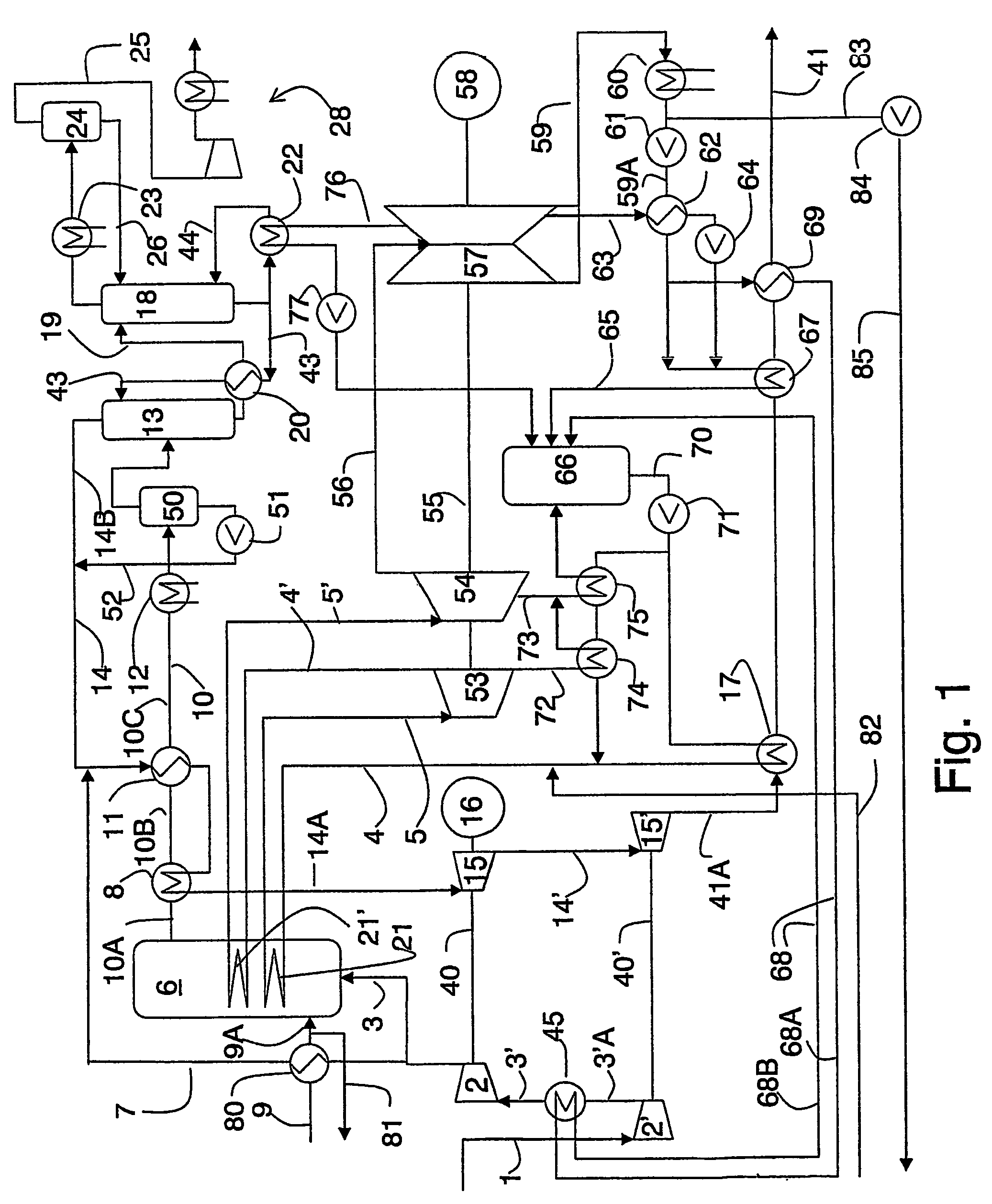

Method and system for recovering circulating water residual heat of thermal power plants

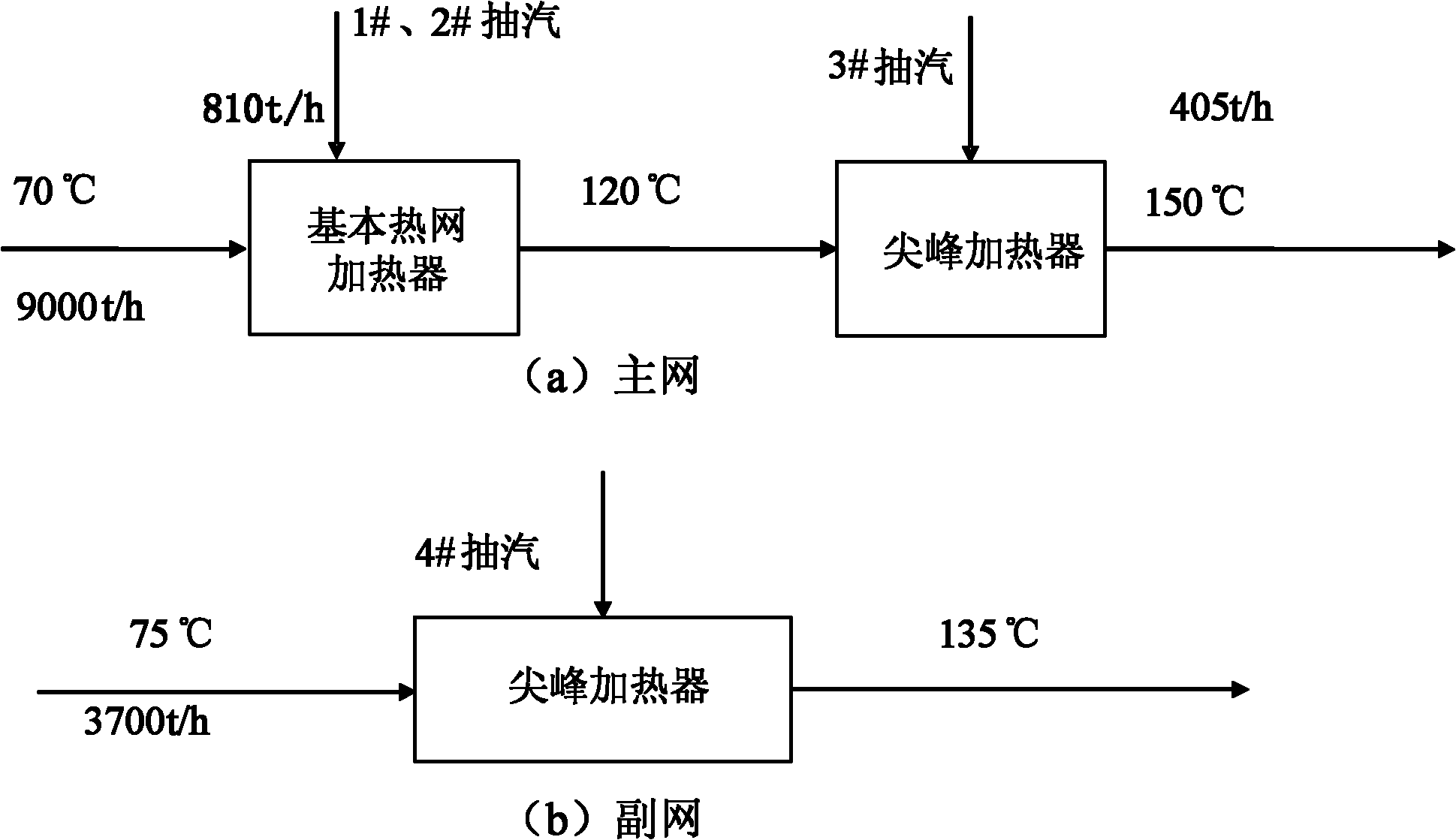

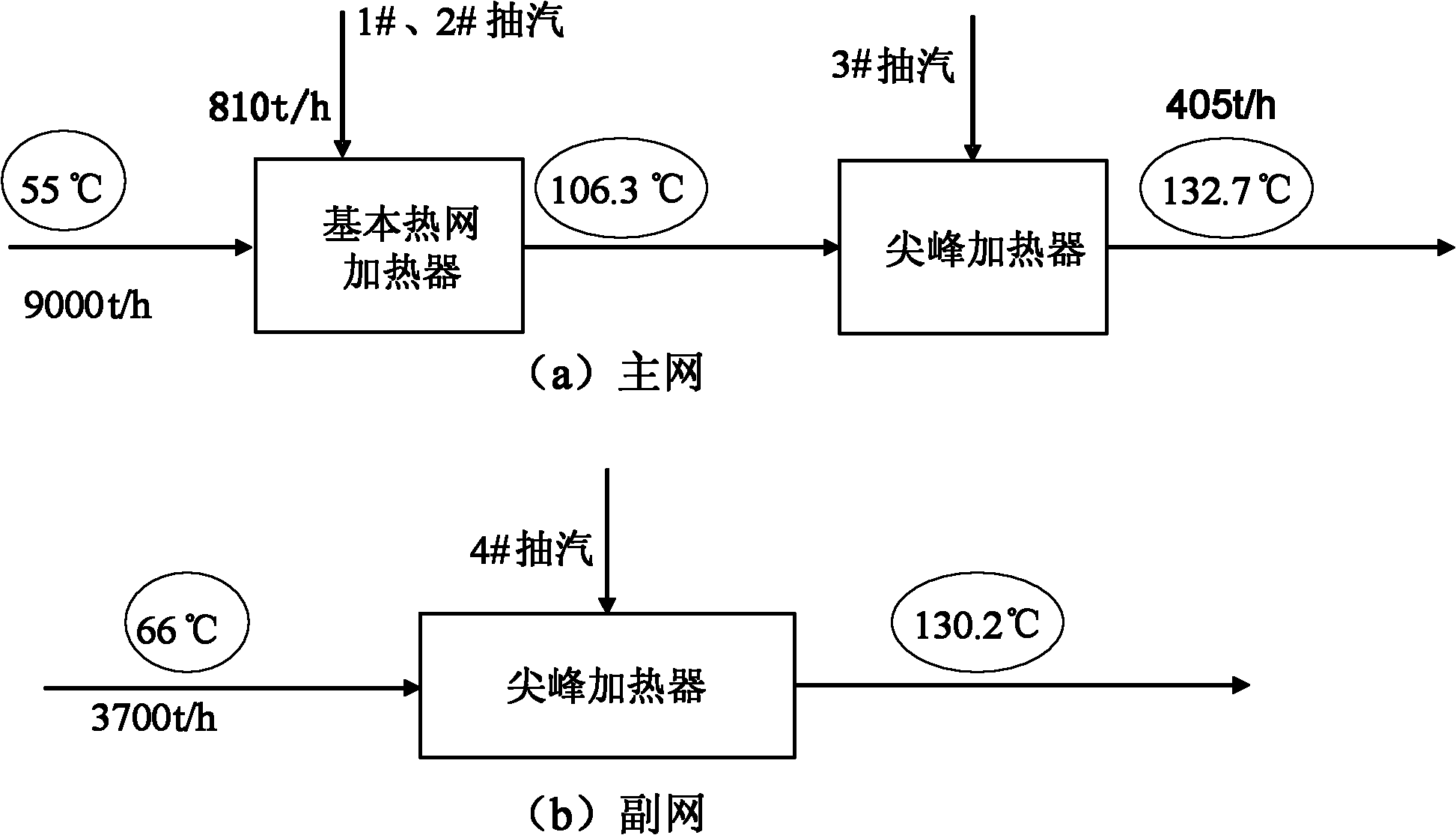

ActiveCN102220888AIncrease heating capacityImprove economyHeat pumpsHeat recovery systemsAbsorption heat pumpEngineering

The invention provides a method and system for recovering the circulating water residual heat of thermal power plants. The system comprises an absorption type heat pump, a turbine, a condenser, a basic heat supply network heater, a peak heater, an auxiliary pipe, auxiliary equipment and a coordination control and protection system, wherein the absorption type heat pump is used for recovering the residual heat of circulating water of the condenser and heating return water of a main heat supply network; the basic heat supply network heater is used for heating the return water of the main heat supply network, which is heated by the absorption type heat pump; the peak heater is used for heating the return water of the main heat supply network, which is heated by the basic heat supply network heater and conveying the return water to users of the heat supply network; the auxiliary pipe is connected with the turbine, the condenser, the absorption type heat pump, the basic heat supply network heater, the peak heater and the auxiliary equipment; and the running and the safety of all equipment in the system are controlled by the coordination control and protection system. The invention has the advantages that heat which is discharged by the circulating water of the condenser to the air is recovered by the absorption type heat pump, the heating and steam extraction energy level of the thermal power plants is integrated, the energy of the thermal power plants is saved, and the heat supply capability and economy of the thermal power plants are improved.

Owner:BEIJING CHUANGSHI ENERGY

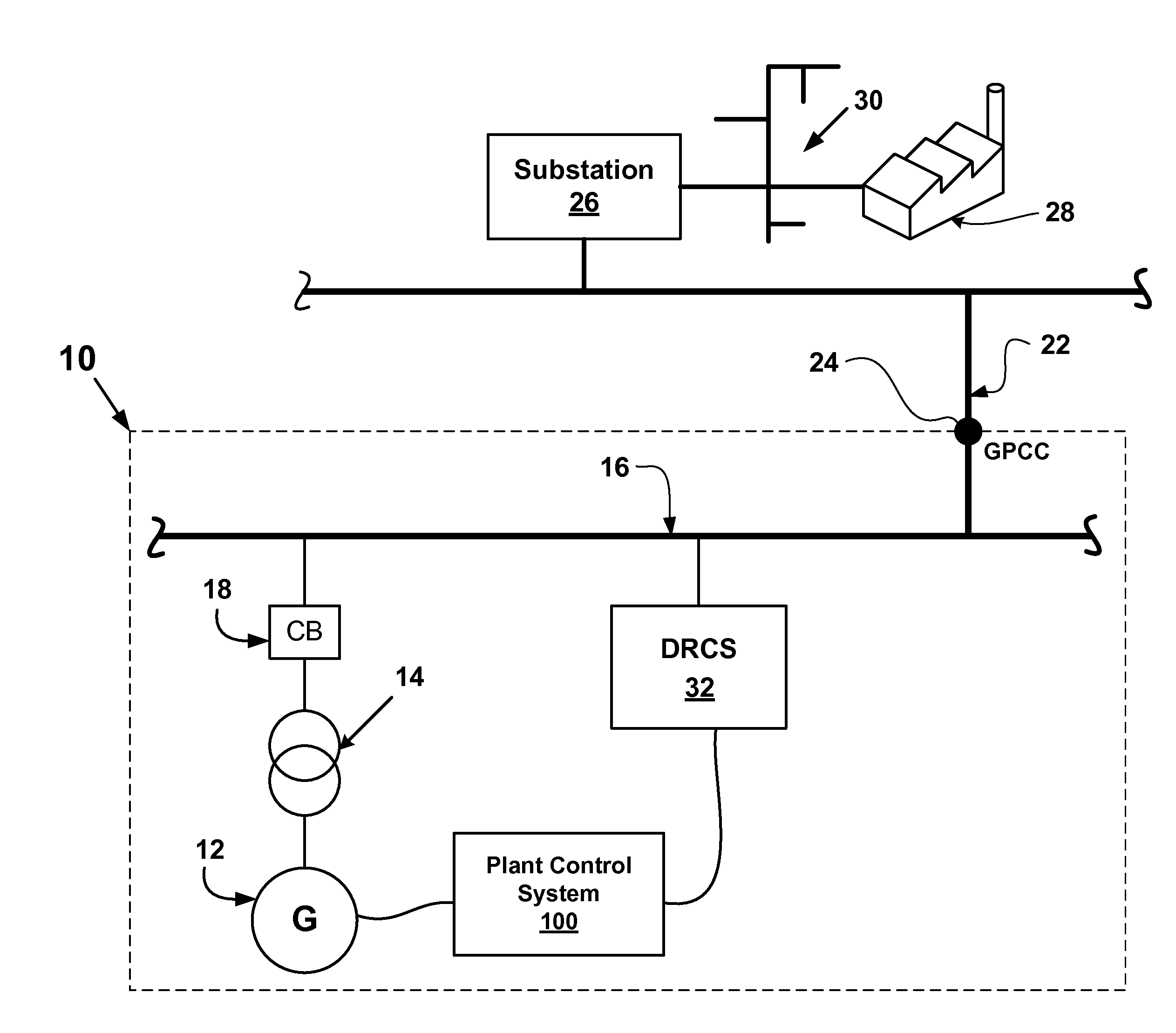

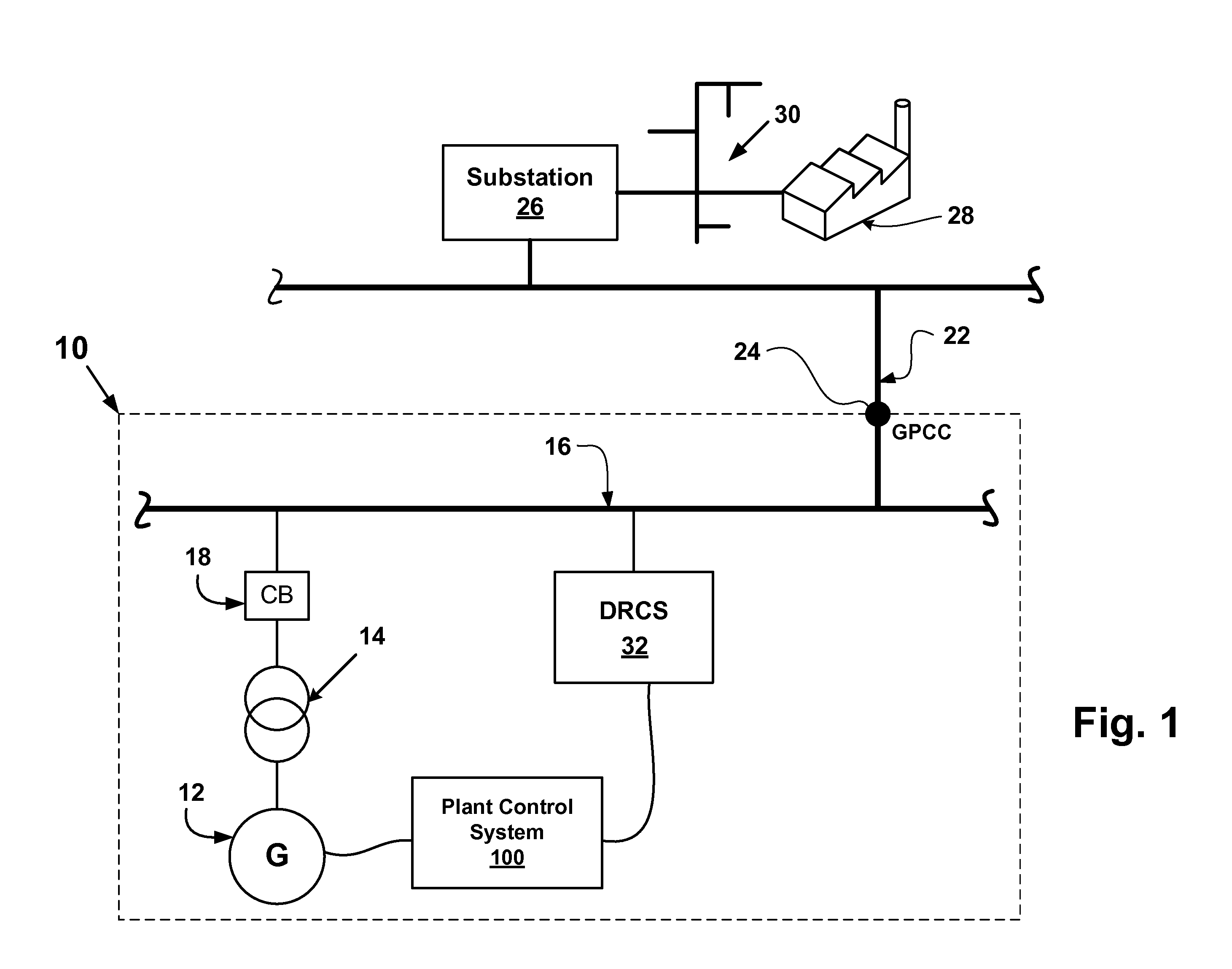

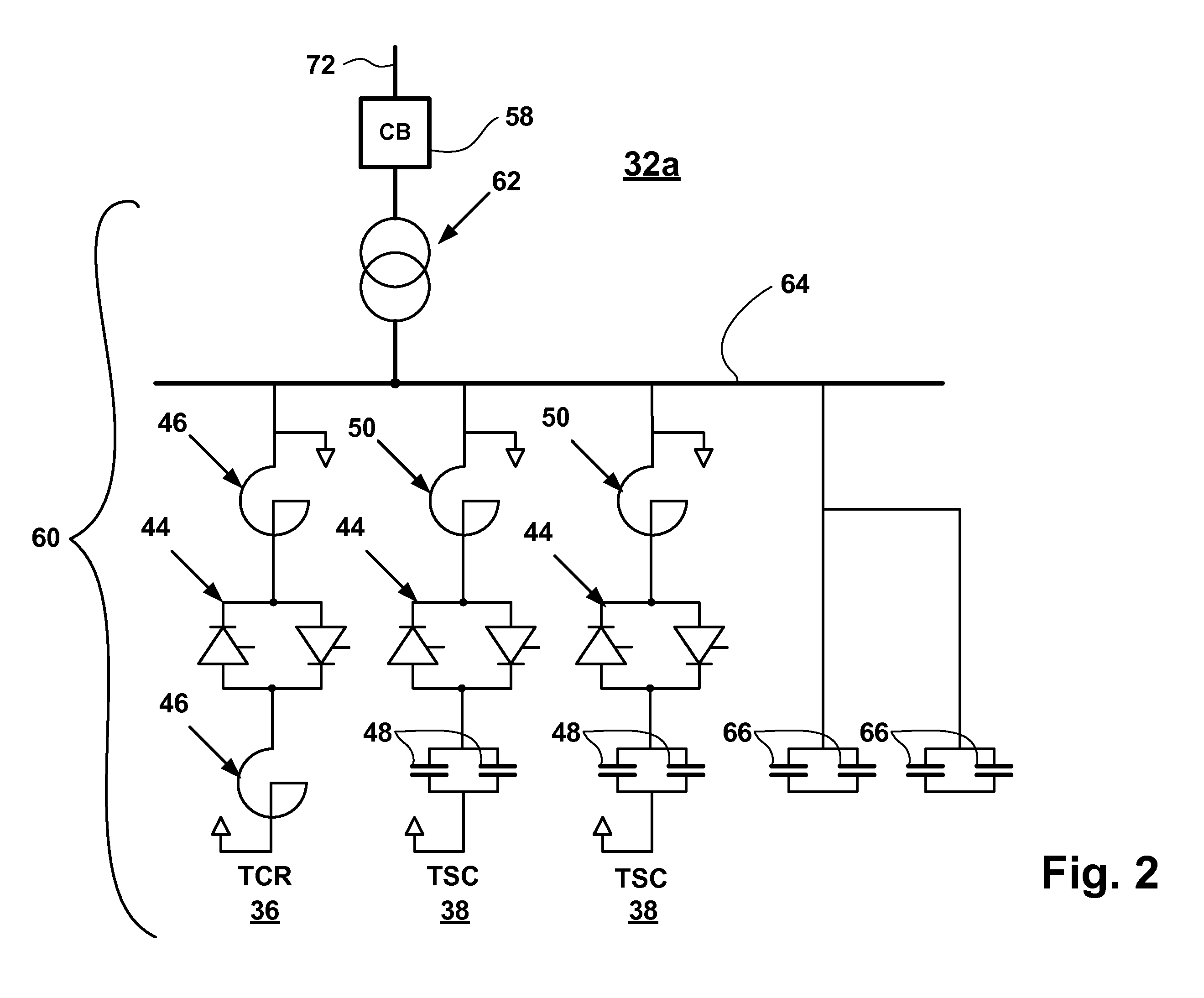

Method and apparatus for improving power generation in a thermal power plant

InactiveUS20110181044A1Increase power generationFlexible AC transmissionEngine controllersPower stationEngineering

A method and apparatus for improving power generation in a thermal power plant. A dynamic reactive compensation system is provided and is connected to a high voltage bus or a generator bus of the power plant. The dynamic reactive compensation system comprises power electronic devices and is operable to provide most of the reactive power that is required from the power plant.

Owner:ABB POWER GRIDS SWITZERLAND AG

Comprehensive utilization system for drying low-order coal of thermal power plant in steam pumping and indirect heat exchanging way and process thereof

The invention relates to a comprehensive utilization system for drying low-order coal of a thermal power plant in a steam pumping and indirect heat exchanging way and a process thereof. The system comprises an indirect-heat-exchange low-order coal predrying device using a steam pipeline of a boiler or a steam turbine of the thermal power plant as a heat source, wherein tail steam obtained by the drying low-order coal of the device is connected with a secondary steam heat insulating and washing device; the secondary steam heat insulating and washing device is connected with a secondary steam recycling device; and the secondary steam recycling device is connected with a dust-containing waste water purifying and utilizing device. In the invention, the steam pumped by the boiler or the steam turbine is used as the drying heat source, high-moisture low-order coal (brown coal) is dewatered and dried through an indirect-heat-exchange drier, and secondary steam generated by dewatering the low-order coal (brown coal) is butt jointed with a steam-water system of the power plant, thereby the operating condition of the boiler is improved, the CO2 emission and fuel consumption are obviously reduced, the loss of a coal mill and matched systems is reduced, the generating efficiency of the power plant is improved, and the blank of the drying and the comprehensive utilization of the low-order coal (brown coal) of the thermal power plant in China is filled.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Thermal control method and system based on capillary slot group and thermal power combination

InactiveCN101242729ATimely deliveryHigh strengthIndirect heat exchangersSemiconductor lasersEvaporationEngineering

The invention is a capillary microgrooves and thermoelectric combined heat control method and system, relates to a heat dissipation and heat controlling method and device used in laser, electronic and electric apparatus. Liquid are heated for evaporation and boiling in capillary microgroove evaporator by heat member, steam flows into condensator through heat preservation flexible pipe, coagulates and heat releases in coagulating microgrooves in condensator under function of thermoelectric cooler on exine of condensator, and meanwhile thermoelectric cooler transmit heat from heat surface to heat dissipation elements (heat dissipation board or water-cooling heat radiator), and finally dissipate heat by air-cooling or water-cooling; coagulated liquid flows back to capillary microgroove evaporator through liquid return flexible pipe and connector to drain microgrooves, so that a circulation of heat extracting and releasing is completed, and components are cooled and heat controlled. Device adopting the inventive method includes a vacuum capillary microgroove evaporator, heat preservation flexible pipe, condensator, thermoelectric cooler, heat dissipation element, liquid return flexible pipe, connector to drain microgrooves.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

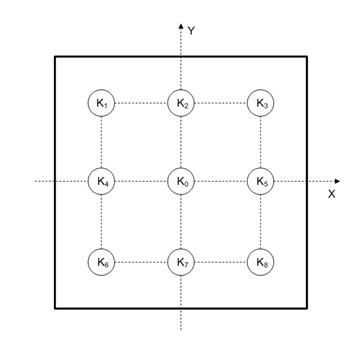

Method for scheduling heliostat of tower type solar energy thermal power station

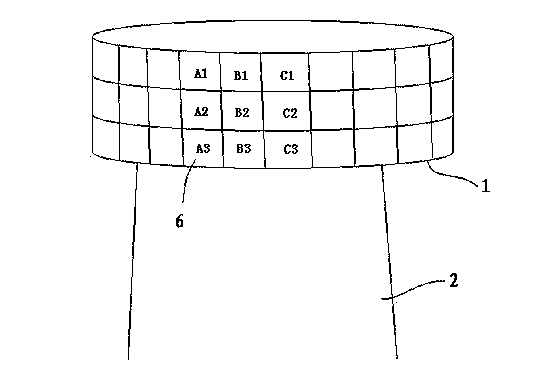

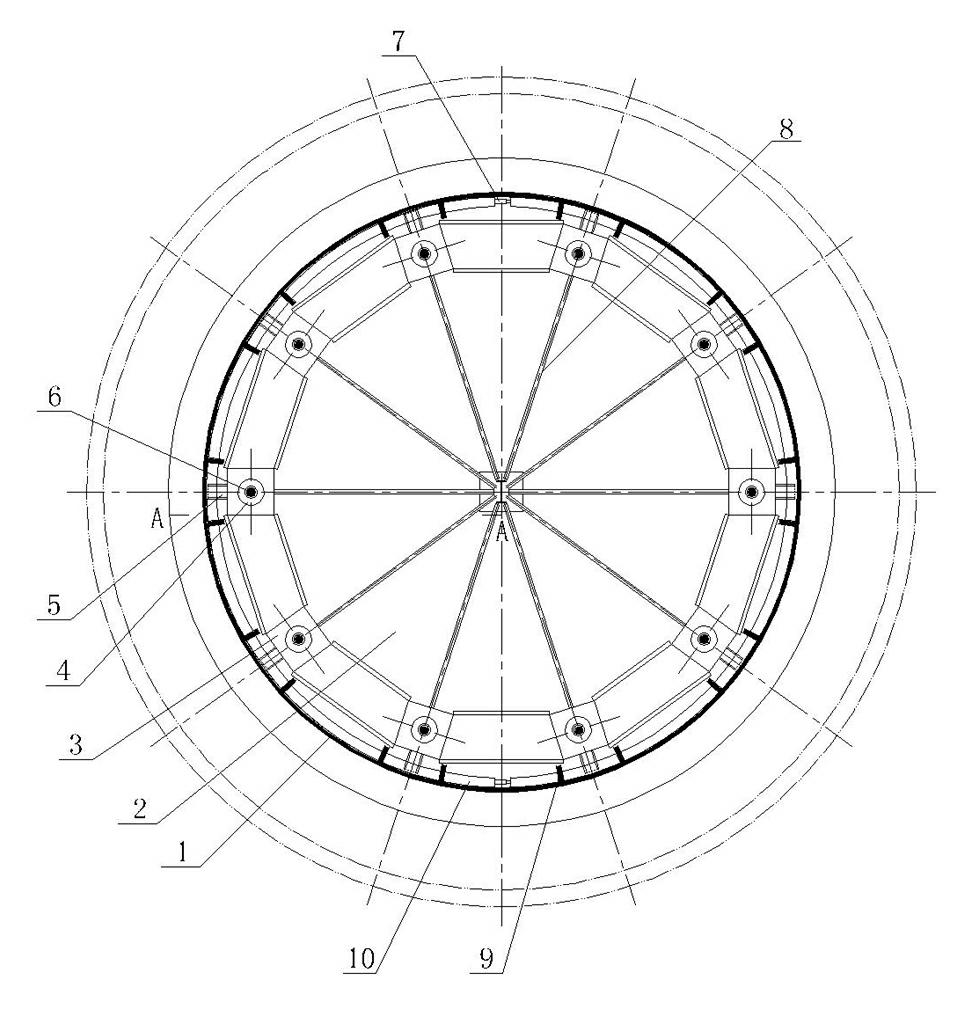

ActiveCN103838251AAvoid overheatingEvenly distributedControl using feedbackAdaptive controlTemperature controlHeliostat

The invention relates to a method for controlling a heliostat in a tower type solar energy thermal power station, for solving the problem of local overheating of the surface of a heat absorber in the prior art. An apparatus comprises a thermal collector tower. The top portion of the thermal collector tower is provided with a heat absorber. A plurality of heliostats which reflect sun light to the surface of the heat absorber are arranged around the thermal collector tower to form a heliostat field. The apparatus is characterized in that the surface of the heat absorber is divided into a plurality of cancellate heat absorption areas, the heliostat field is divided into a plurality of heliostat groups, each heliostat group comprises a plurality of heliostats, the heat absorption areas on the surface of the heat absorber are in one-to-one correspondence with the heliostat groups, the reflection target of the heliostats in each heliostat group is the geometric center of a corresponding heat absorption area, each heat absorption area is provided with an independent temperature control device, and when a temperature control device in a certain heat absorption area monitors that a signal exceeds a set value, the reflection target of the plurality of heliostats in the heliostat group corresponding to the heat absorption area is scheduled to a neighboring heat absorption area within a set scope. The method provided by the invention can ensure that energy on the surface of the heat absorber is uniformly distributed to the maximum, and the situation of local overheating of the surface of the heat absorber is prevented.

Owner:上海联和投资有限公司

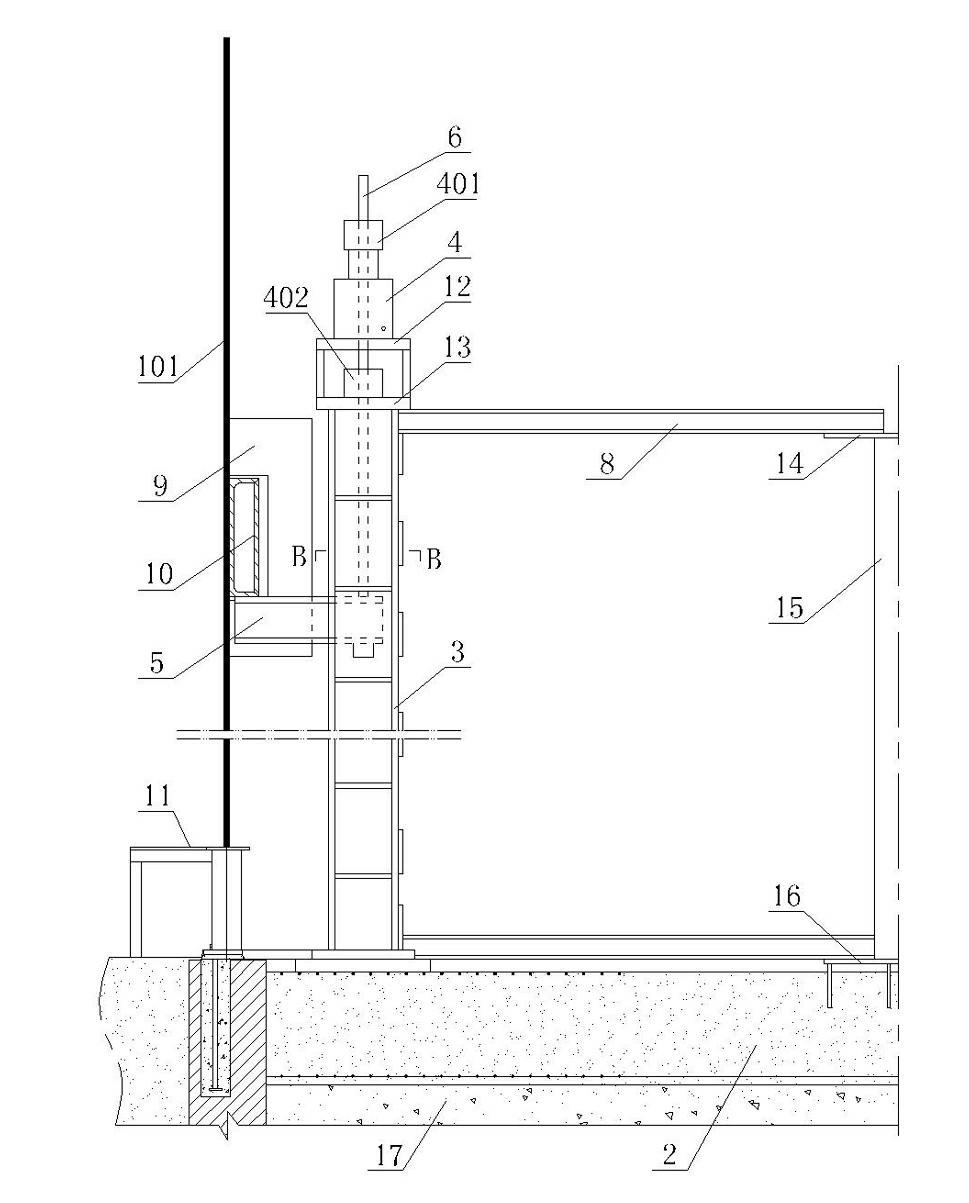

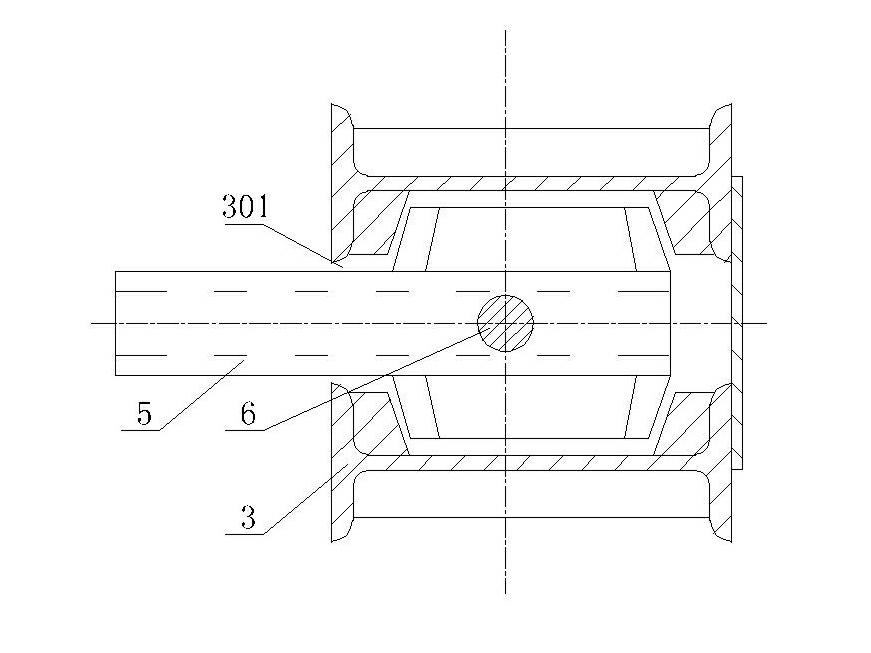

Hydraulic lifting inverted construction method for steel inner cylinder of chimney in thermal power plant

InactiveCN102108737AReduce investmentReduce construction costsBuilding constructionsTowersAnnular beamHydraulic pressure

The invention discloses a hydraulic lifting inverted construction method for a steel inner cylinder of a chimney in a thermal power plant, which comprises the following steps: (1) dividing the steel inner cylinder into a plurality of cylinder sections, and dividing each cylinder section into a plurality of cylinder sheets; (2) manufacturing a jack stand base in the steel inner cylinder, and mounting a hydraulic lifting device and a construction platform on the jack stand base; (3) beginning to assemble the first cylinder section of the steel inner cylinder, welding a plurality of sets of door-shaped clips on the inner wall of the first cylinder section along a circumferential direction, and clipping the horizontal annular beam by the door-shaped clips; (4) lifting the assembled cylinder section to the height of the first cylinder section by using the hydraulic lifting device, assembling a next cylinder section and welding the next cylinder section with the previous cylinder section; (5) cutting off the door-shaped clips and transferring and mounting the door-shaped clips and the horizontal annular beam to the corresponding position of the next cylinder section; and (6) repeatedly circulating the steps (4) and (5), and mounting the subsequent cylinder sections in turn. The method has the advantages that: the construction cost is low; the stress is definite, the operation is simple and convenient, and the safety factor is high; and the construction period is short and the project quality is high.

Owner:DONGDIAN YANTA ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com