Thermal control method and system based on capillary slot group and thermal power combination

A technology of micro-groove group and thermal control, applied in the direction of circuits, electrical components, indirect heat exchangers, etc., can solve the problems of low efficiency, insufficient heat dissipation, large lasers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

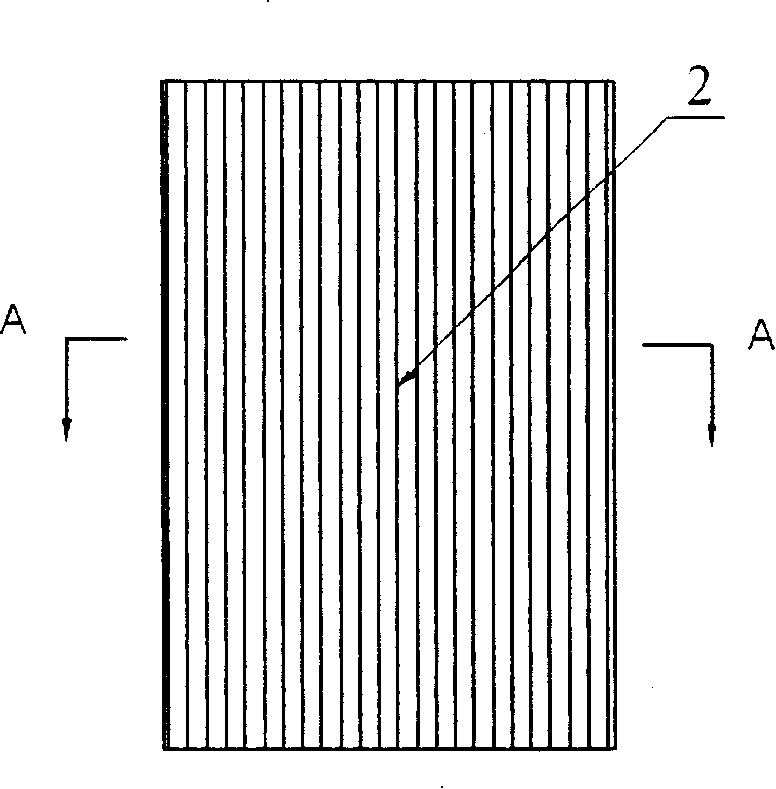

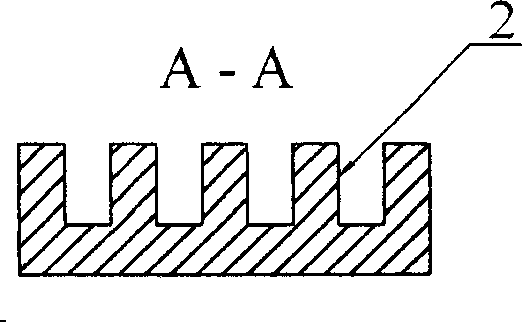

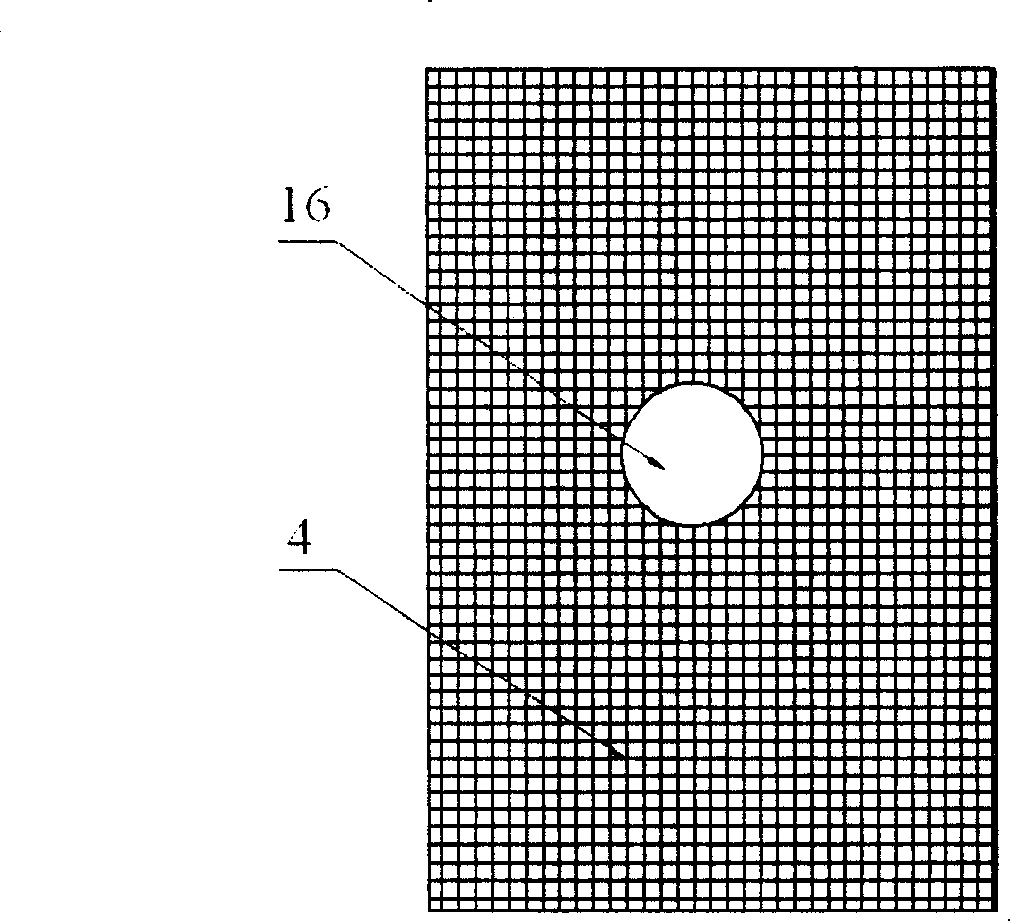

[0073] see Figure 5 , to make a water-cooled heat dissipation capillary microgroove group and thermoelectric cooler (TEC) combined heat dissipation and thermal control system. It includes a micro-groove group evaporator 3 with a rectangular sealed cavity made of metal copper with good thermal conductivity, which can also be called a heat-taking element. The inner wall of the micro-groove group evaporator 3 cavity has a rectangular micro-groove 2 to form a micro-groove group. The spacing of the micro-groove 2 is 0.4mm, the width of the micro-groove 2 is 0.3mm and the groove The depth is 0.8mm. The size of described rectangular micro-channel 2 is suitable for forming stronger capillary force, so that dehydrated alcohol or distilled water etc. in the micro-groove group evaporator 3 have higher vaporization latent heat liquid working medium through micro-channel ...

Embodiment 2

[0078] see Figure 6, to make a combined heat dissipation and thermal control system of air-cooled heat dissipation capillary microgroove group and thermoelectric cooler (TEC). The water-cooled radiator in Embodiment 1 is replaced by a radiator plate 8 with fin groups. The hot surface of the thermoelectric cooler is in close contact with the bottom surface of the heat sink plate 8 with fins through the heat conducting silicone grease, and a fan 9 is installed on the top of the heat sink plate 8. The height of the rectangular fins is 20 mm, and the thickness of the fins is 1 mm. , the fin spacing is 1.5mm, the power of the fan 9 is 30W, the heat released by the condensation of the steam is conducted from the inner wall of the condenser 6 to the outer surface of the condenser 6, and is absorbed by the cold surface of the thermoelectric cooler. While performing temperature control, the heat and the heat generated by the thermoelectric cooler itself are conducted from the hot sur...

Embodiment 3

[0079] Embodiment 3: In this embodiment, a capillary wick is installed in the liquid return hose 10 along the direction of the tube axis to increase the capillary force for the condensate to quickly flow back to the evaporator. The capillary core is a 2-layer 250-mesh stainless steel wire mesh core. Other parts of this embodiment are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com