Patents

Literature

3170 results about "Heat control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanotube/metal substrate composites and methods for producing such composites

InactiveUS20050238810A1Simplified and advantageous mannerReduce productionMaterial nanotechnologyIndirect heat exchangersHydrogen fuel cellChemical vapor deposition

Carbon nanotubes are grown directly on metal substrates using chemical vapor deposition. Metal substrates are comprised of catalysts which facilitate or promote the growth of carbon nanotubes. The nanotube coated metal substrates have applications including, but not limited to, heat transfer and thermal control, hydrogen storage, fuel cell catalytic reformers, electronics and semiconductors, implantable medical devices or prostheses, and tribological wear and protective coatings.

Owner:MAINSTREAM ENG

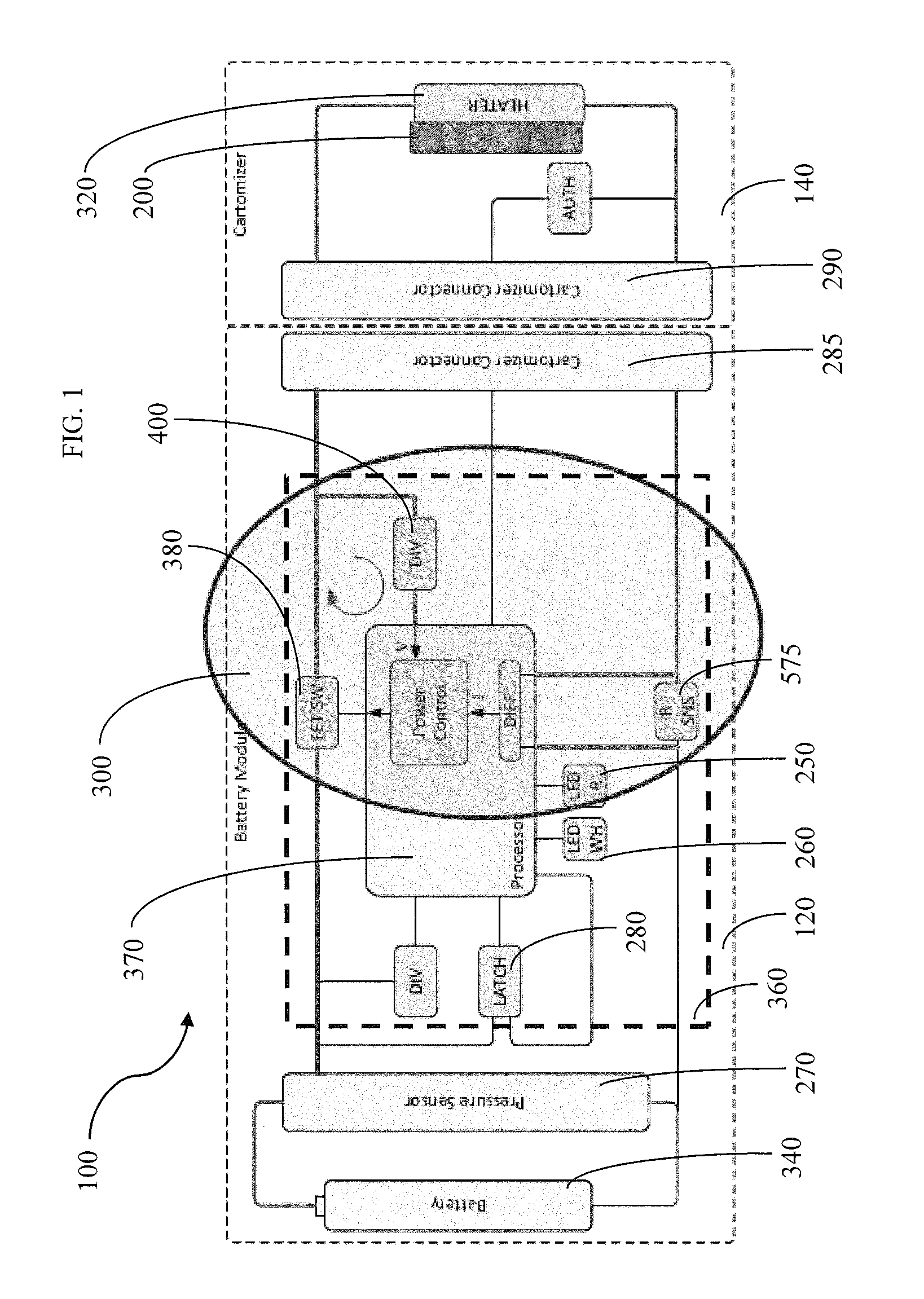

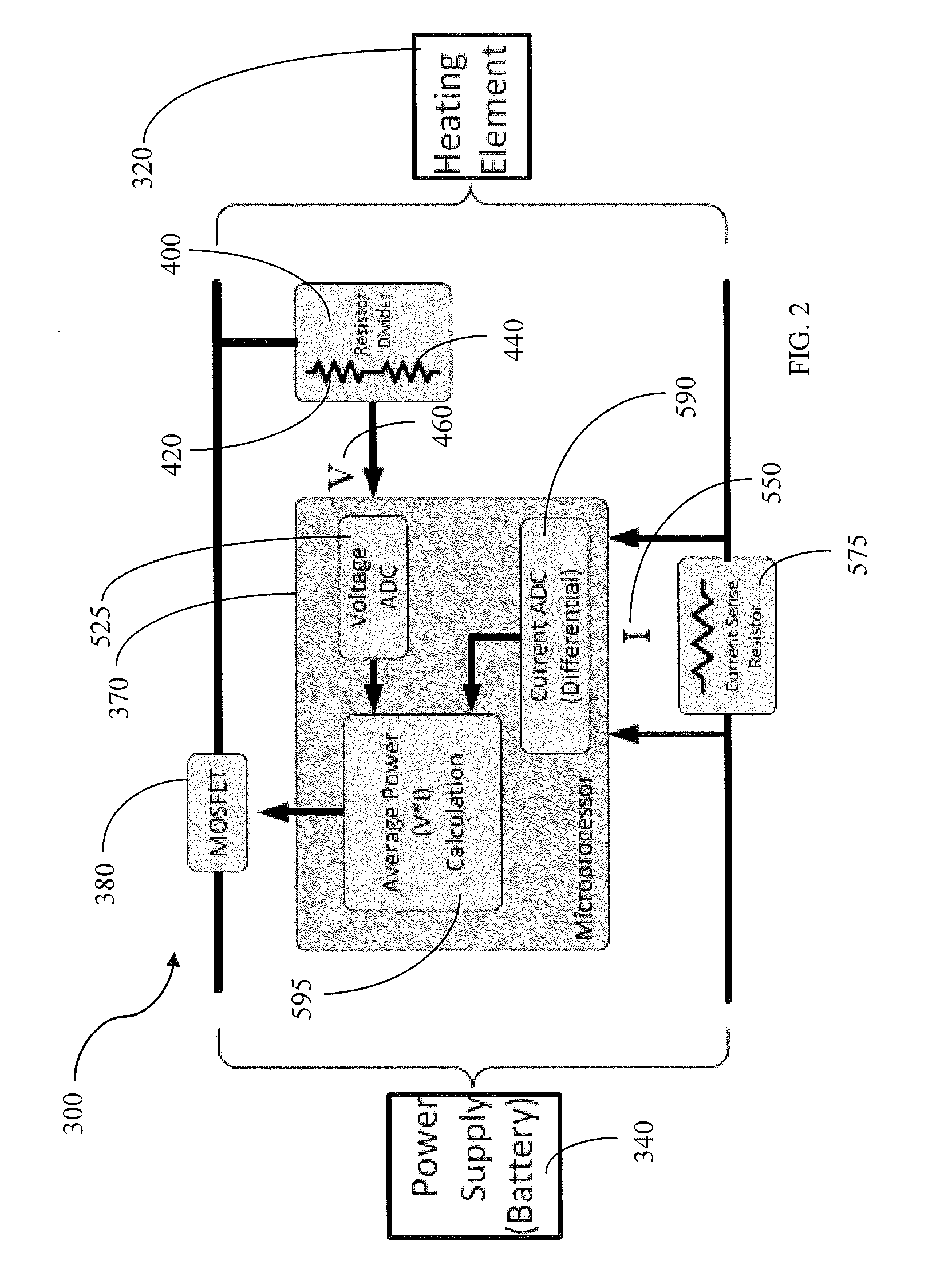

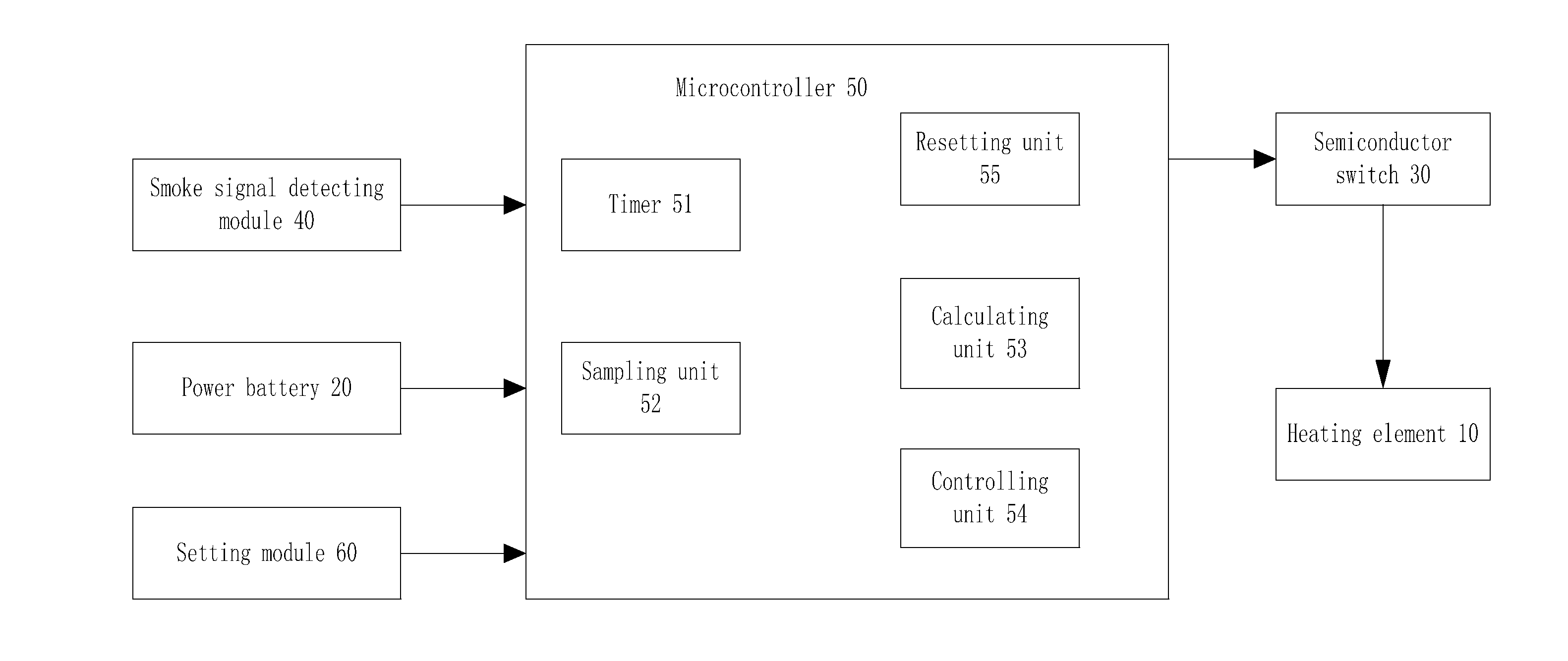

Heating control arrangement for an electronic smoking article and associated system and method

Owner:RAI STRATEGIC HLDG INC

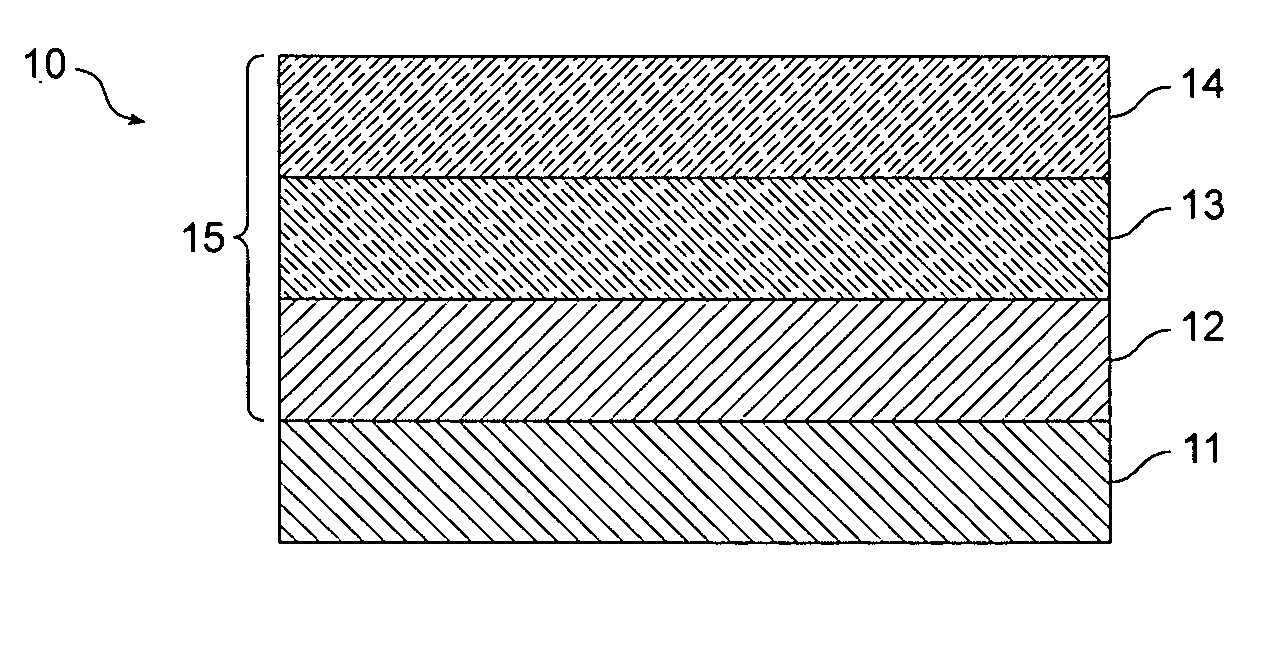

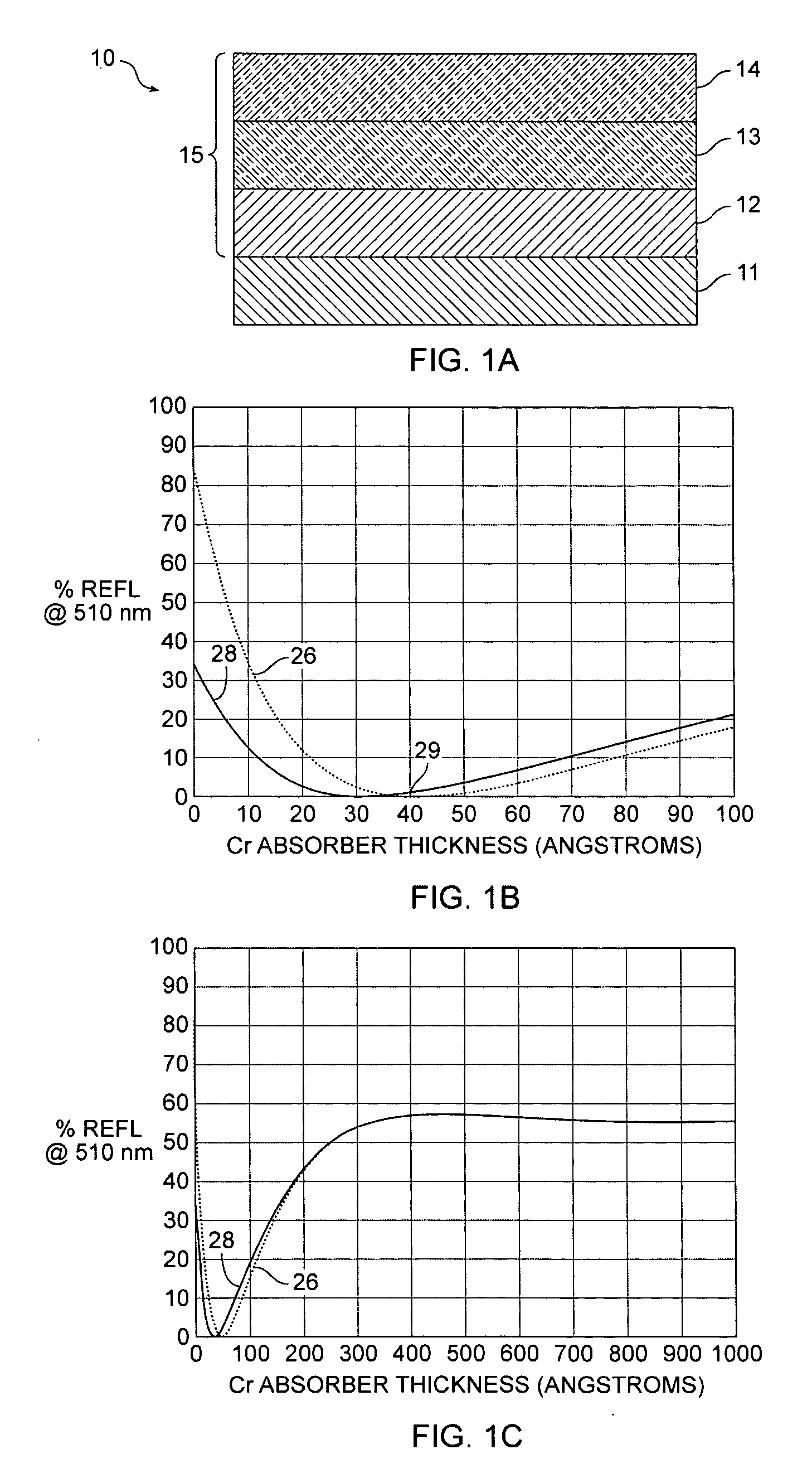

Thermal control interface coatings and pigments

The invention provides an optical structure with low chroma and brightness in the visible region and low emissivity in the infrared region. The optical structure includes an interference structure having an infrared reflective layer and an infrared absorbing thin film layer. These layers are in turn separated by a thin film spacer of a dielectric or semiconductor material. The reflectivity and transmission of the layers are selectively controlled through the thickness of the layers such that the visual reflectivity and color is independent of the infrared properties of the absorber and reflector layers.

Owner:JDS UNIPHASE CORP +1

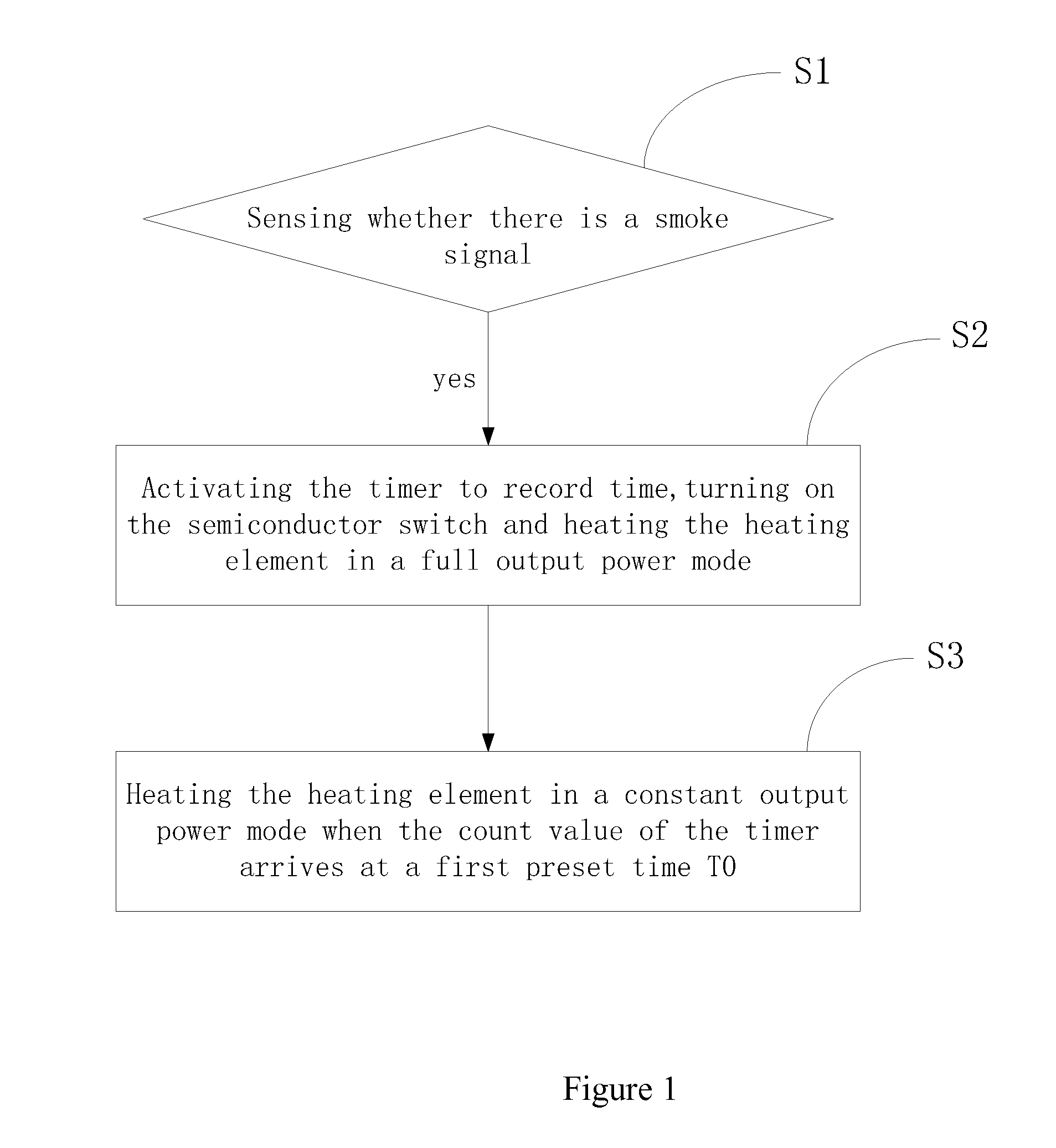

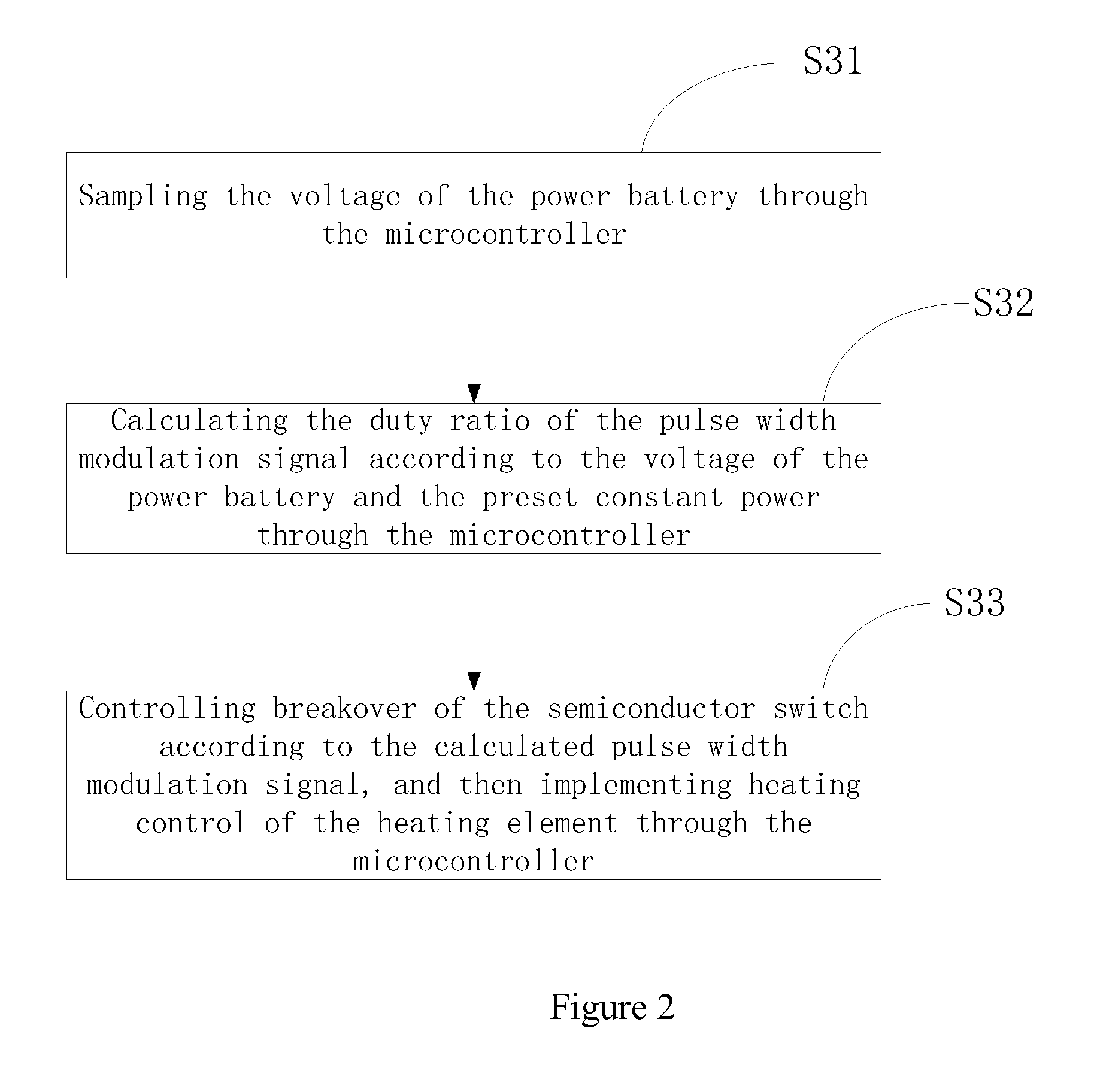

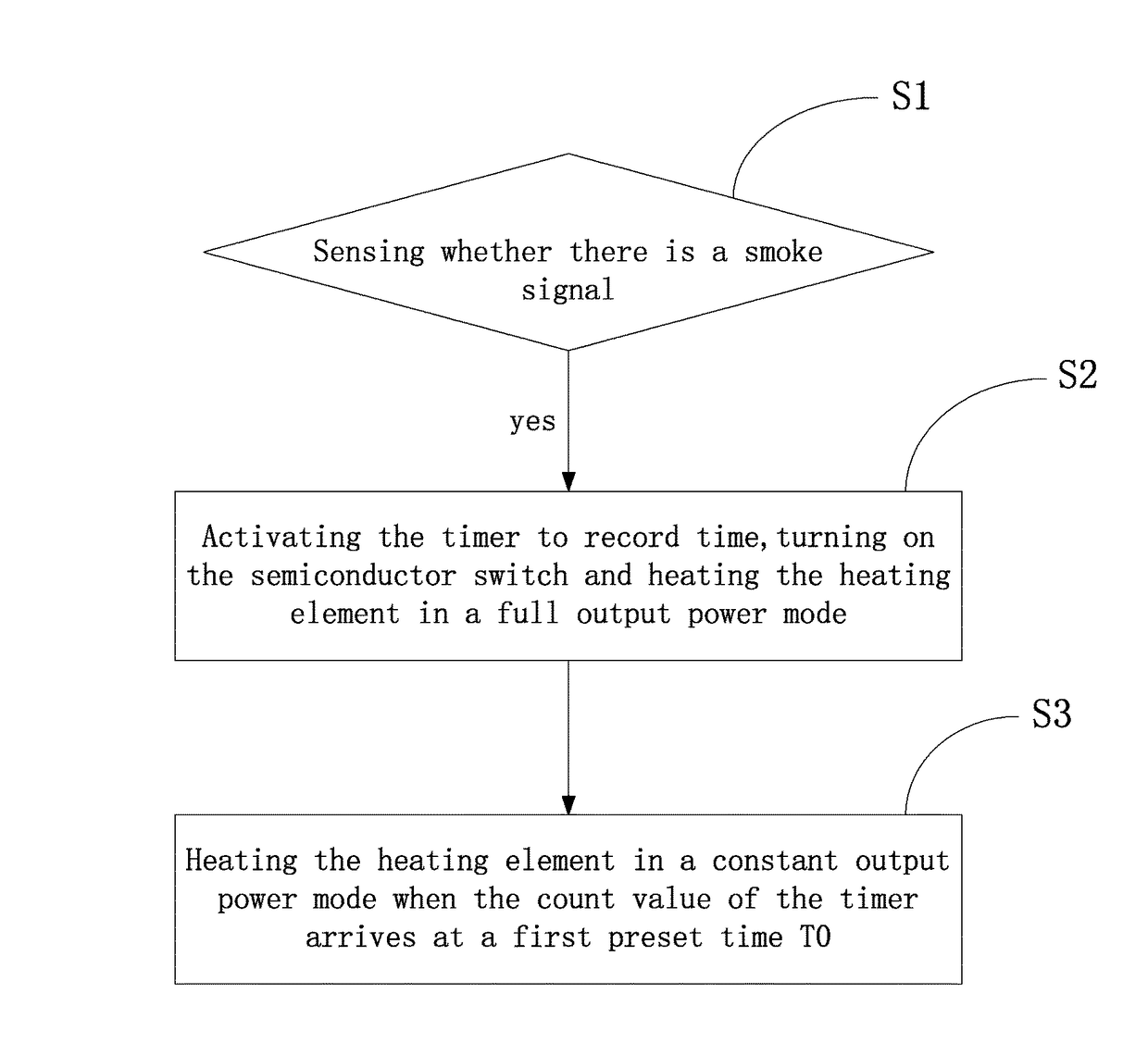

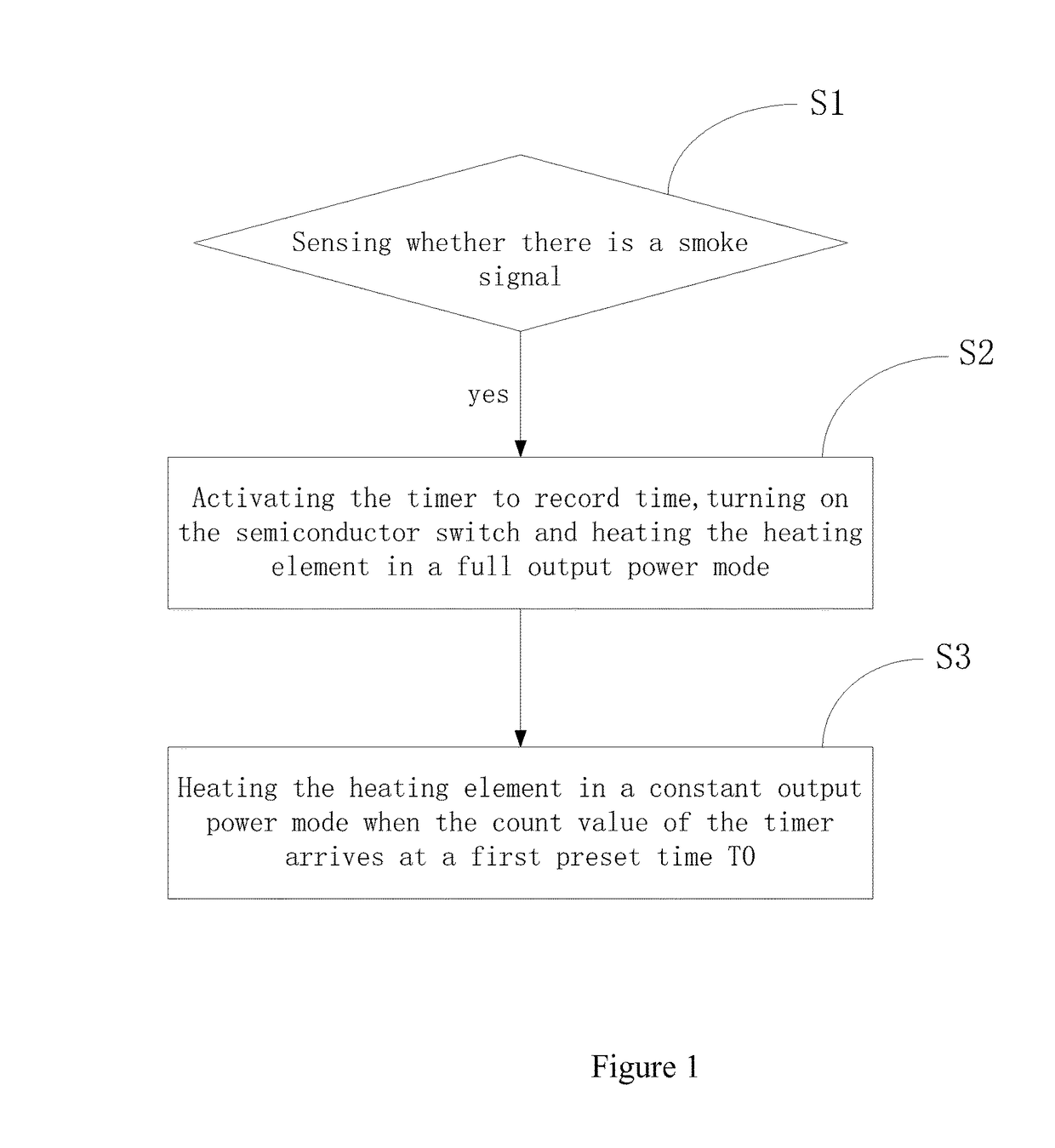

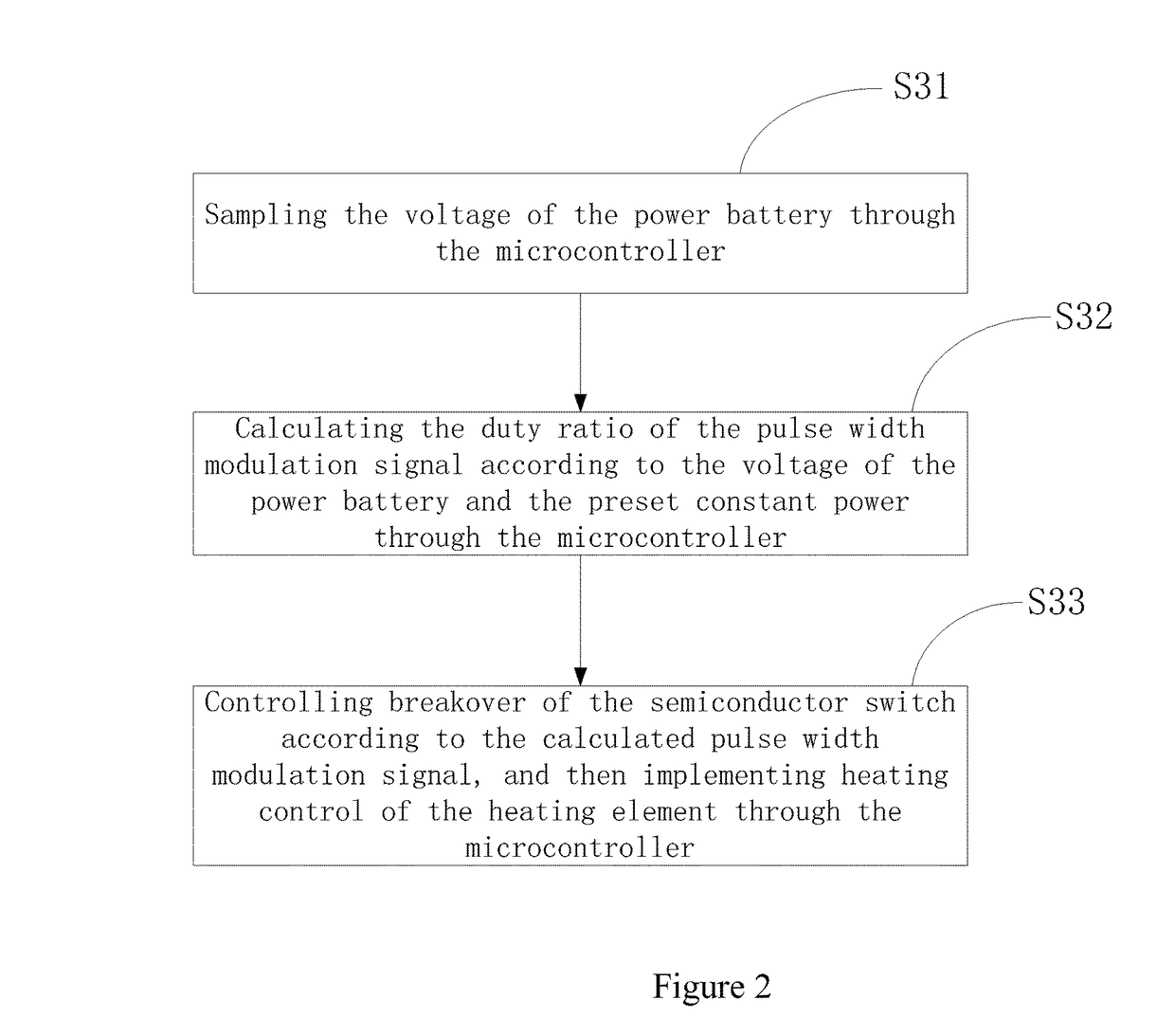

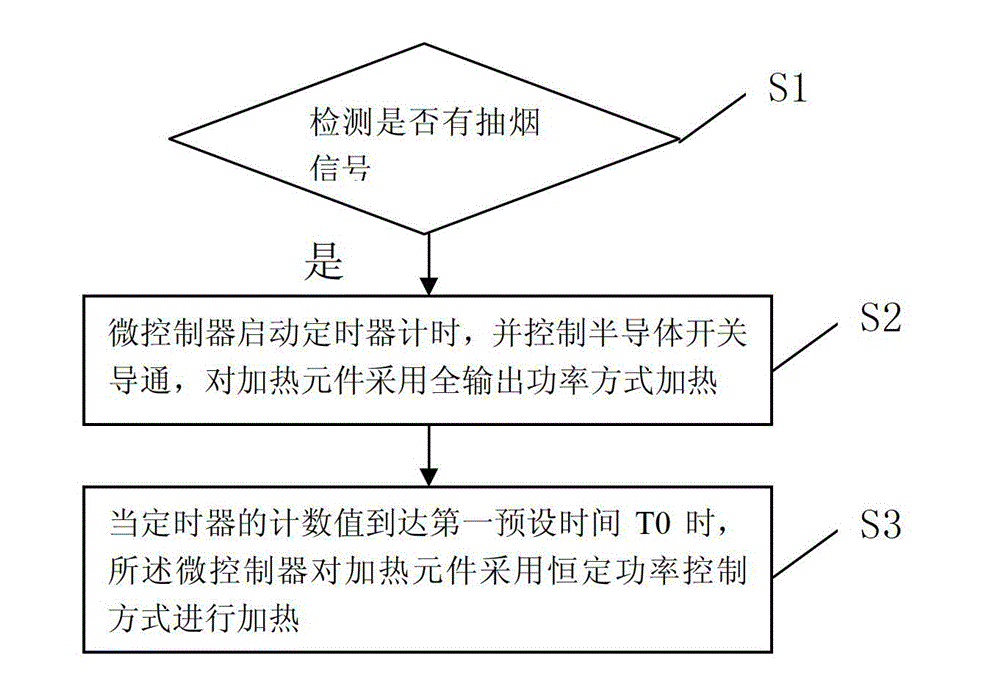

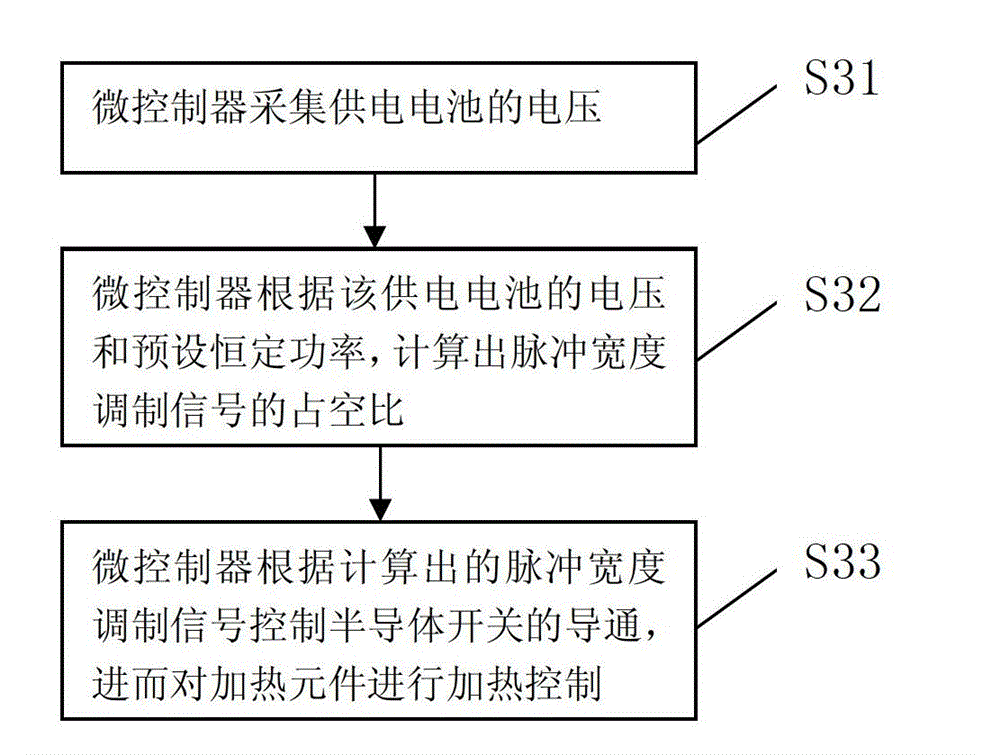

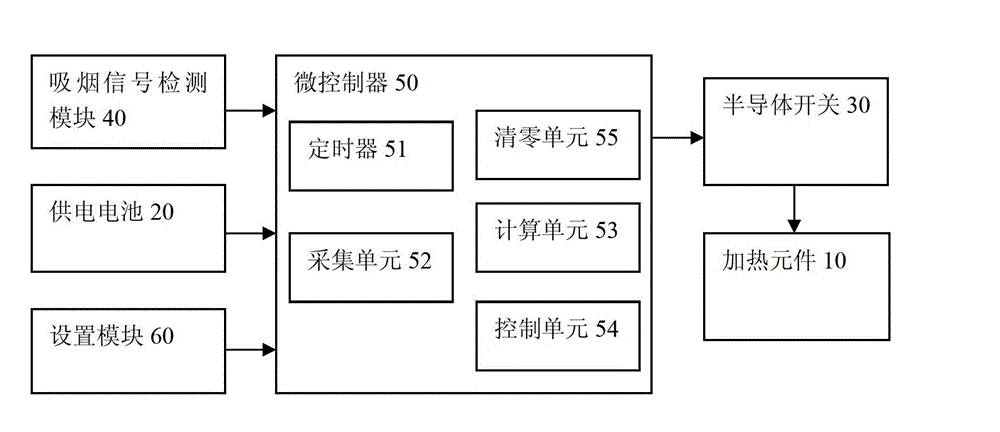

Method and device for heating control of an electronic cigarette

A method and device for heating control of an electronic cigarette are provided, wherein, the method includes steps as below: S1. sensing whether there is a smoke signal via a sensor or a switch, if yes, executing step S2; S2. activating a timer to record time and turn on a semiconductor switch so as to heat the heating element in a full output power mode; S3. heating the heating element in a constant power mode when the recording time of the timer arrives at a first preset time T0. When implementing the present invention, the adoption of the two heating methods for heating element makes an optimized atomization effect and an excellent taste of smoking possible, which is not affected by the changeable voltage of the battery.

Owner:HUIZHOU KIMREE TECH

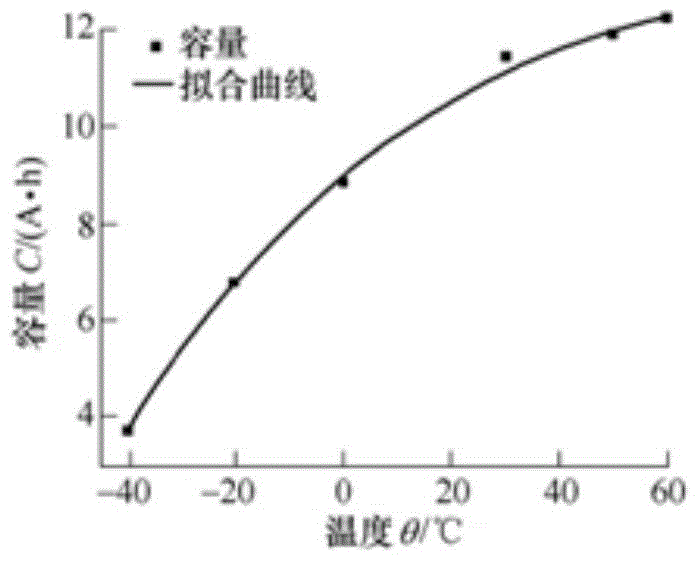

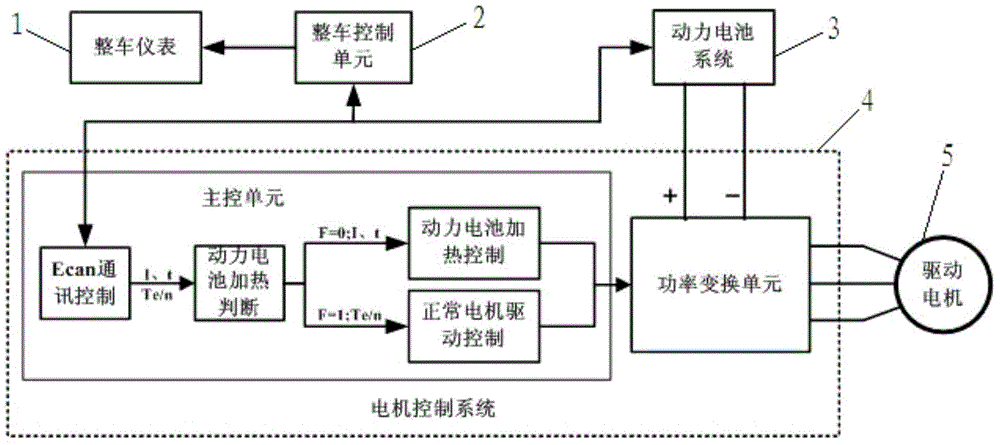

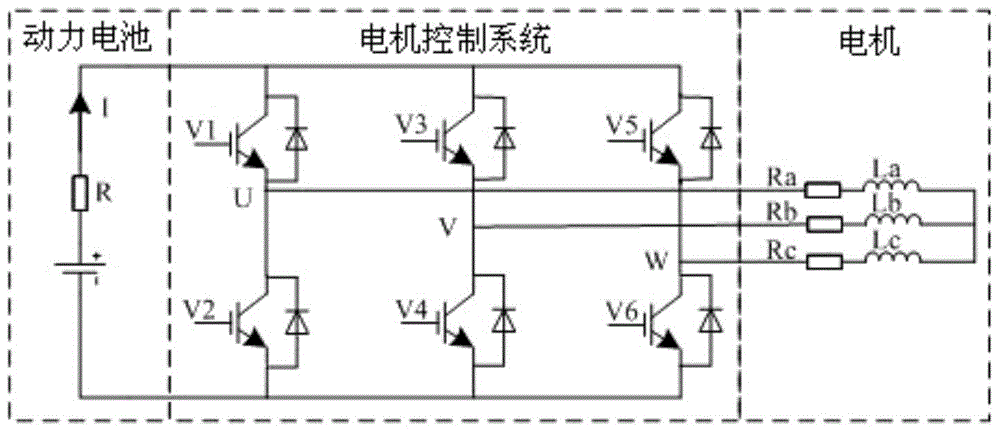

Heating control method of power battery pack of electric vehicle

ActiveCN103560304AIncrease temperatureControl heating rateCell temperature controlElectrical batteryEngineering

The invention belongs to the technical field of power batteries of vehicles, and particularly relates to a heating control method of a power battery pack of an electric vehicle. The heating control method is implemented by a whole vehicle instrument, a whole vehicle control unit, a power battery system, a motor control system and a driving motor, wherein the whole vehicle instrument is connected with the whole vehicle control unit, the whole vehicle control unit is connected with the power battery system and the motor control system respectively, and the motor control system is connected with the power battery system and the driving motor respectively. According to the method, power batteries are heated by virtue of an original electric drive system of the electric vehicle, the energy of the power batteries is mainly used for the self heating of the power batteries, so that the temperature of the power batteries can be rapidly raised without extra cost, and the heating efficiency is high.

Owner:DONGFENG MOTOR CORP HUBEI

Method and device for heating control of an electronic cigarette

A method and device for heating control of an electronic cigarette are provided, wherein, the method includes steps as below: S1. sensing whether there is a smoke signal via a sensor or a switch, if yes, executing step S2; S2. activating a timer to record time and turn on a semiconductor switch so as to heat the heating element in a full output power mode; S3. heating the heating element in a constant power mode when the recording time of the timer arrives at a first preset time T0. When implementing the present invention, the adoption of the two heating methods for heating element makes an optimized atomization effect and an excellent taste of smoking possible, which is not affected by the changeable voltage of the battery.

Owner:HUIZHOU KIMREE TECH

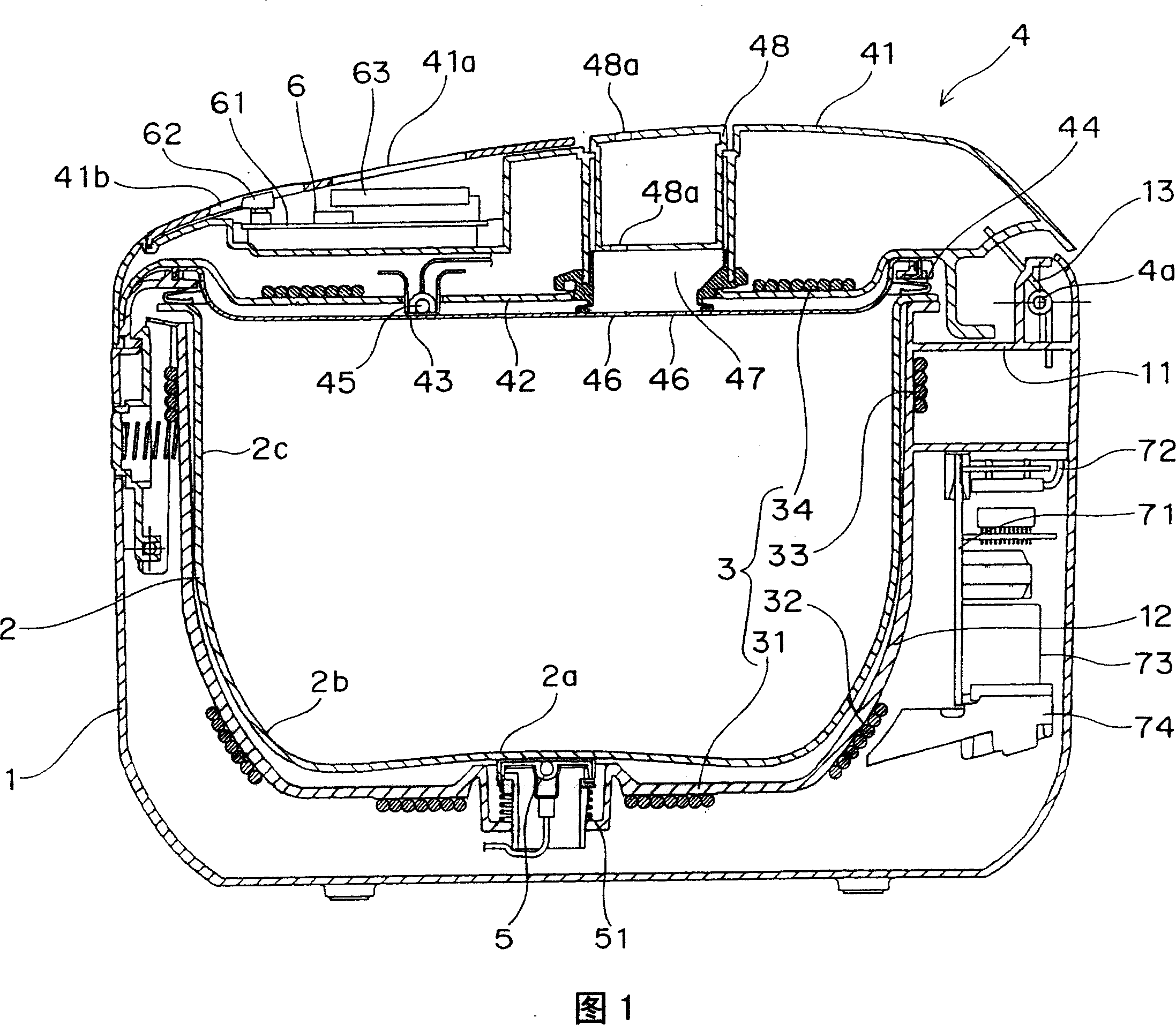

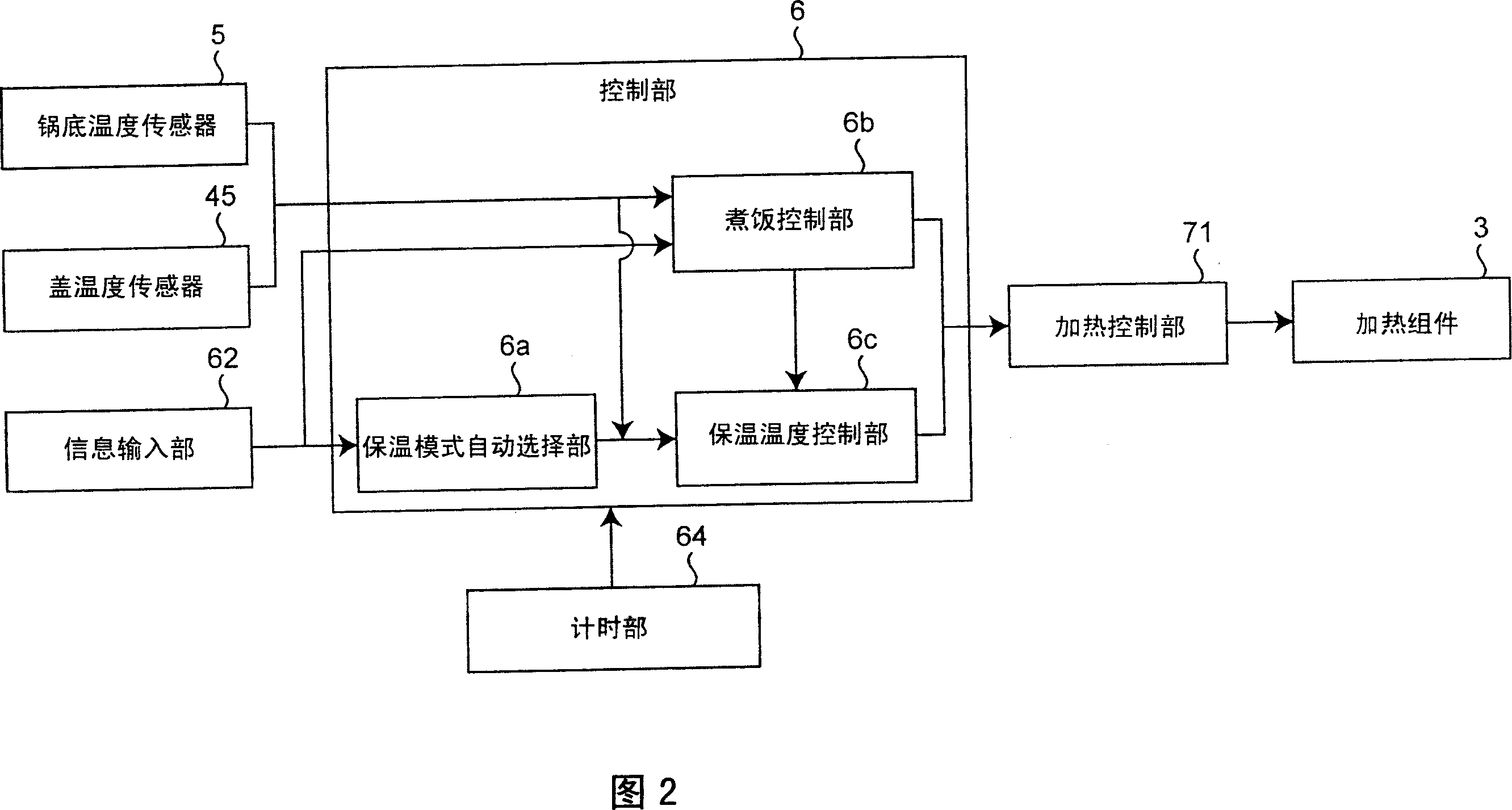

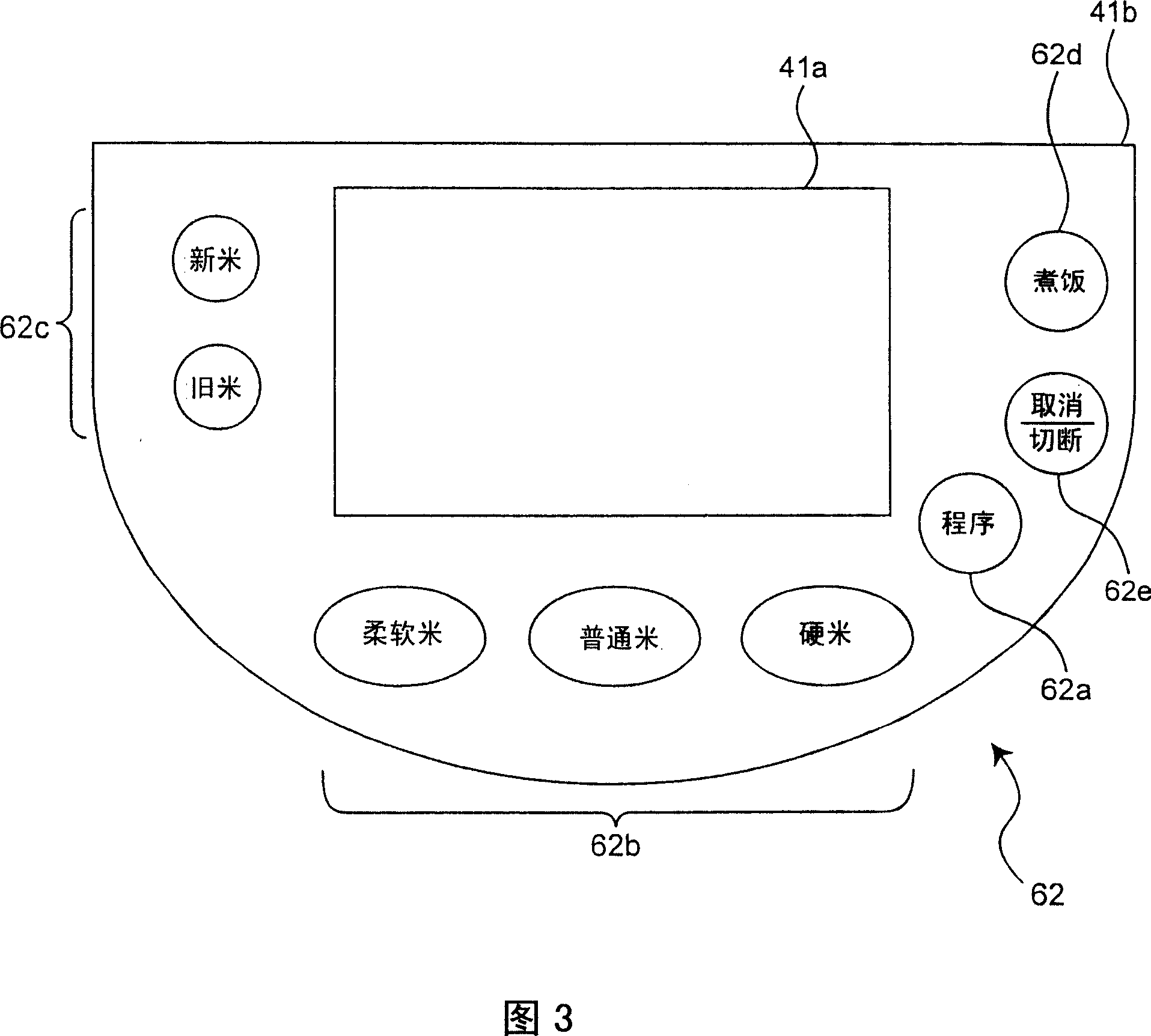

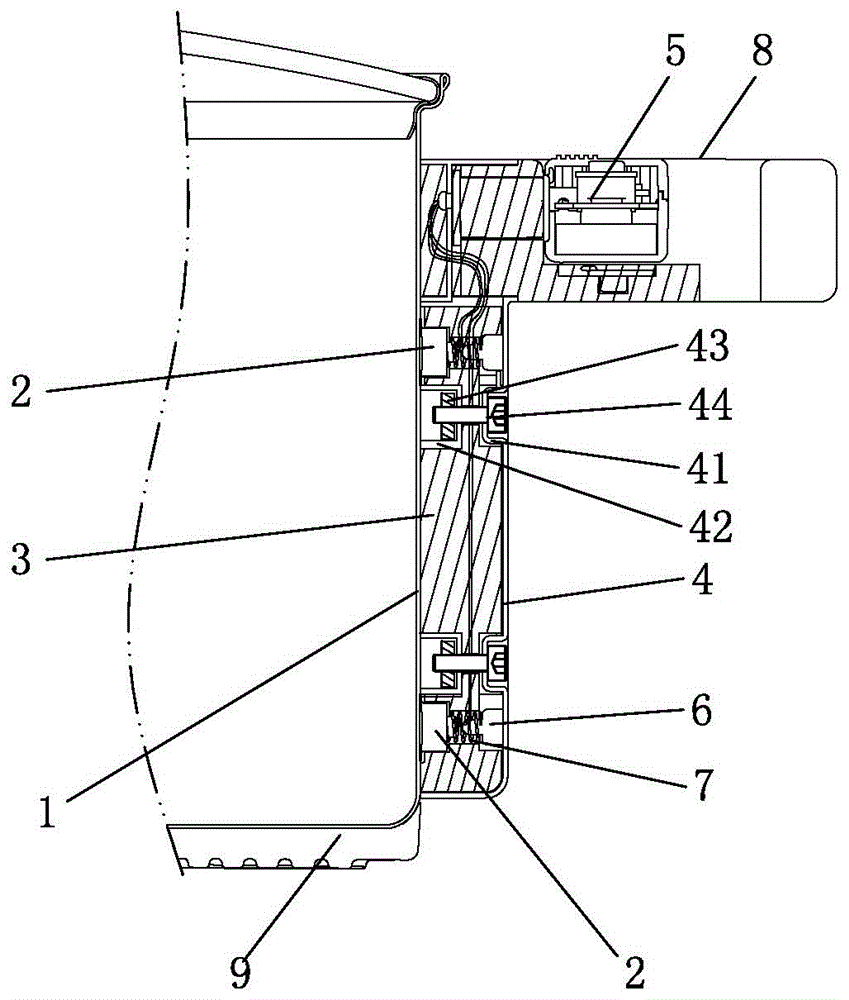

Electric cooker

ActiveCN101023842AReduce the burden onReduce rotBoiling over preventionCooking insertsTemperature controlThermal insulation

The invention provides an electric cooker capable of relieving the burden of user and more effectively depressing the decay of rice and deterioration of edible flavour induced by heat preservation. The electric cooker comprises boiler holding rice inside the electric cooker body; cover easily openned and closed for covering the peristome of upside of the cooker; heating arrangement for heating the pan bottom; cooker temperature test sensor for detecting temperature; heat control section for controlling the heating action of heating arrangement of the pan bottom; cook information input part for inputting the cook information related with cooking rice; automatic selection part of thermal insulation mode for automatically selecting the corresponding thermal insulation mode from many thermal insulation modes based on the cook information input by cook information input part before cooking; holding temperature control section for controlling temperature, based on thermal insulation mode selected by the automatic selection part of thermal insulation mode and controlling the heat control section by temperature detected by cooker temperature test sensor.

Owner:PANASONIC CORP

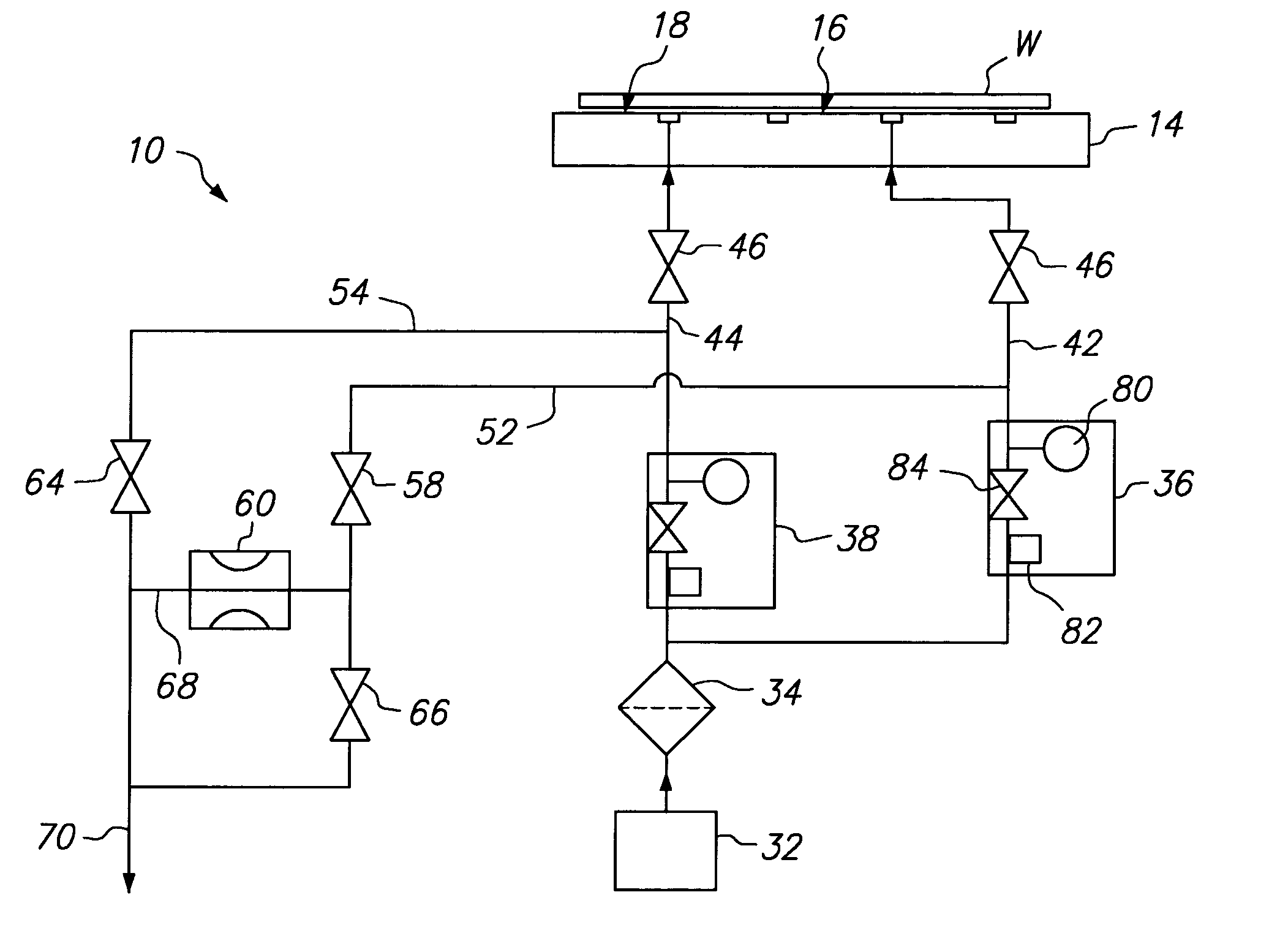

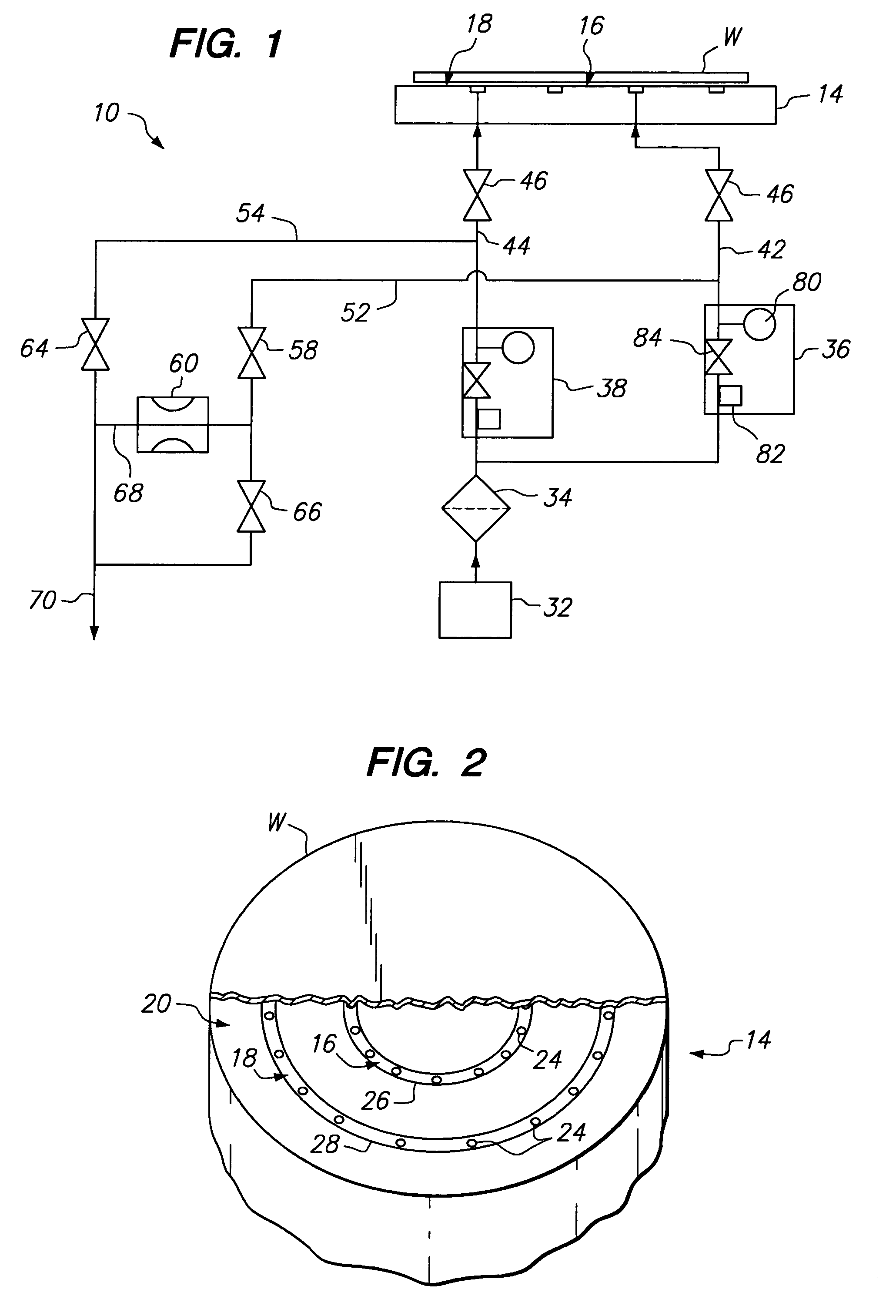

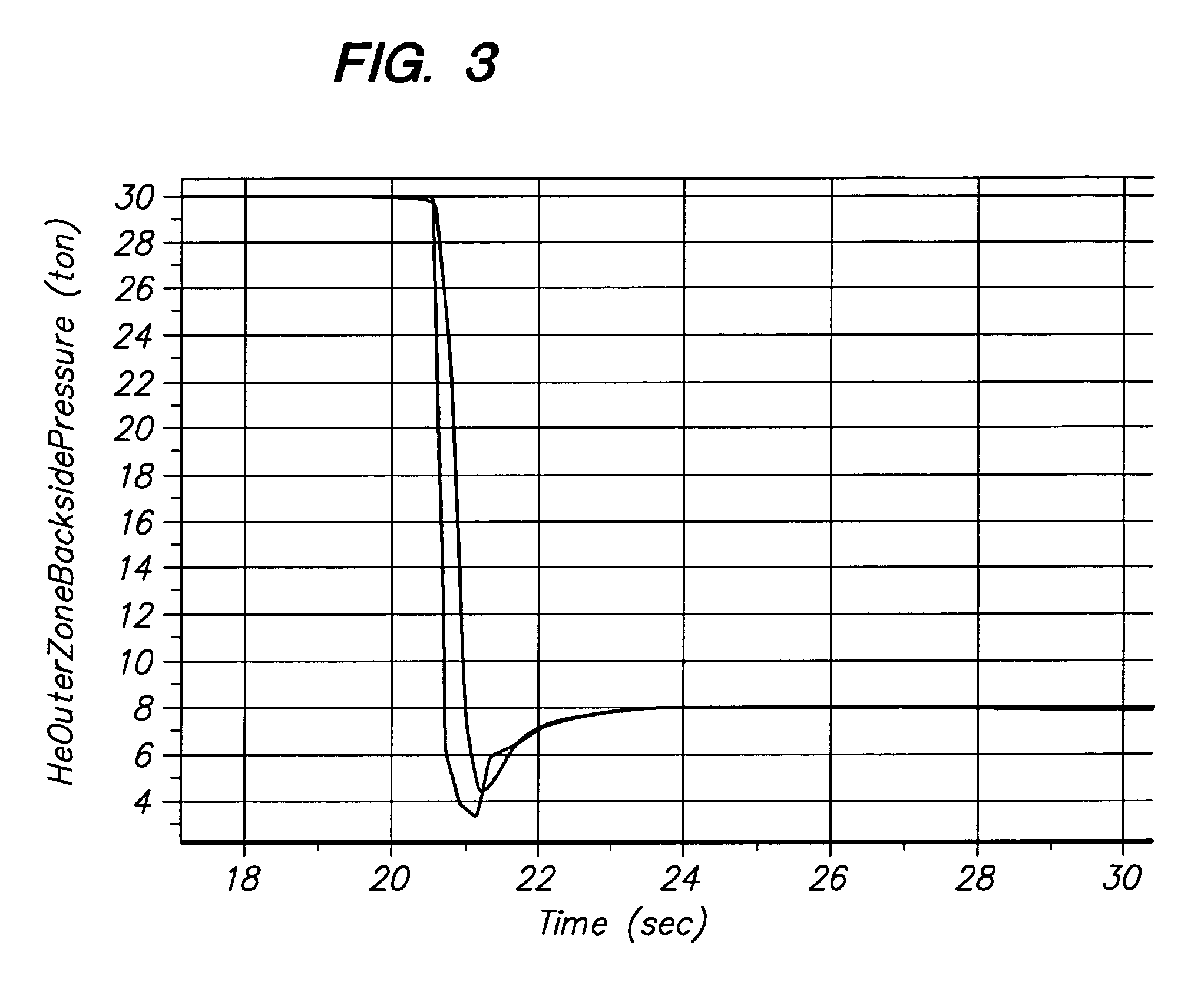

Multiple zone gas distribution apparatus for thermal control of semiconductor wafer

ActiveUS7156951B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingControl systemProduct gas

A gas distribution apparatus delivers a coolant gas, such as helium, to an upper surface of a chuck for controlling a temperature of a wafer placed on the chuck. The gas distribution apparatus allows first and second zones, such as an inner zone and an outer zone of the chuck, to be supplied with a coolant gas at different pressures for control of the temperature across the wafer. The gas distribution apparatus includes a pressure and flow control system for supplying the coolant gas at selected pressures and bleed lines which provide the dual function of allowing rapid evacuation of the inner and outer zones and preventing excess pressure from one zone from migrating to another zone.

Owner:LAM RES CORP

Electrophoretic display with thermal control

An electrophoretic display (EPD) with thermal control is disclosed for controlling and maintaining an image in extreme temperature environments. Techniques are also disclosed for maintaining the EPD cell threshold voltage for EPD cells comprising an EPD display media at or above a desired level in an environment in which the EPD may be subjected to an extreme temperature. The techniques comprise sensing a sensed temperature associated with the EPD display media, determining whether the sensed temperature satisfies a criterion established to ensure that the display media temperature remains at a level associated with an acceptable EPD cell threshold voltage, and in the event it is determined that the sensed temperature does not satisfy the criterion, controlling the EPD display media temperature as required to bring the sensed temperature to a level that satisfies the criterion.

Owner:E INK CORPORATION

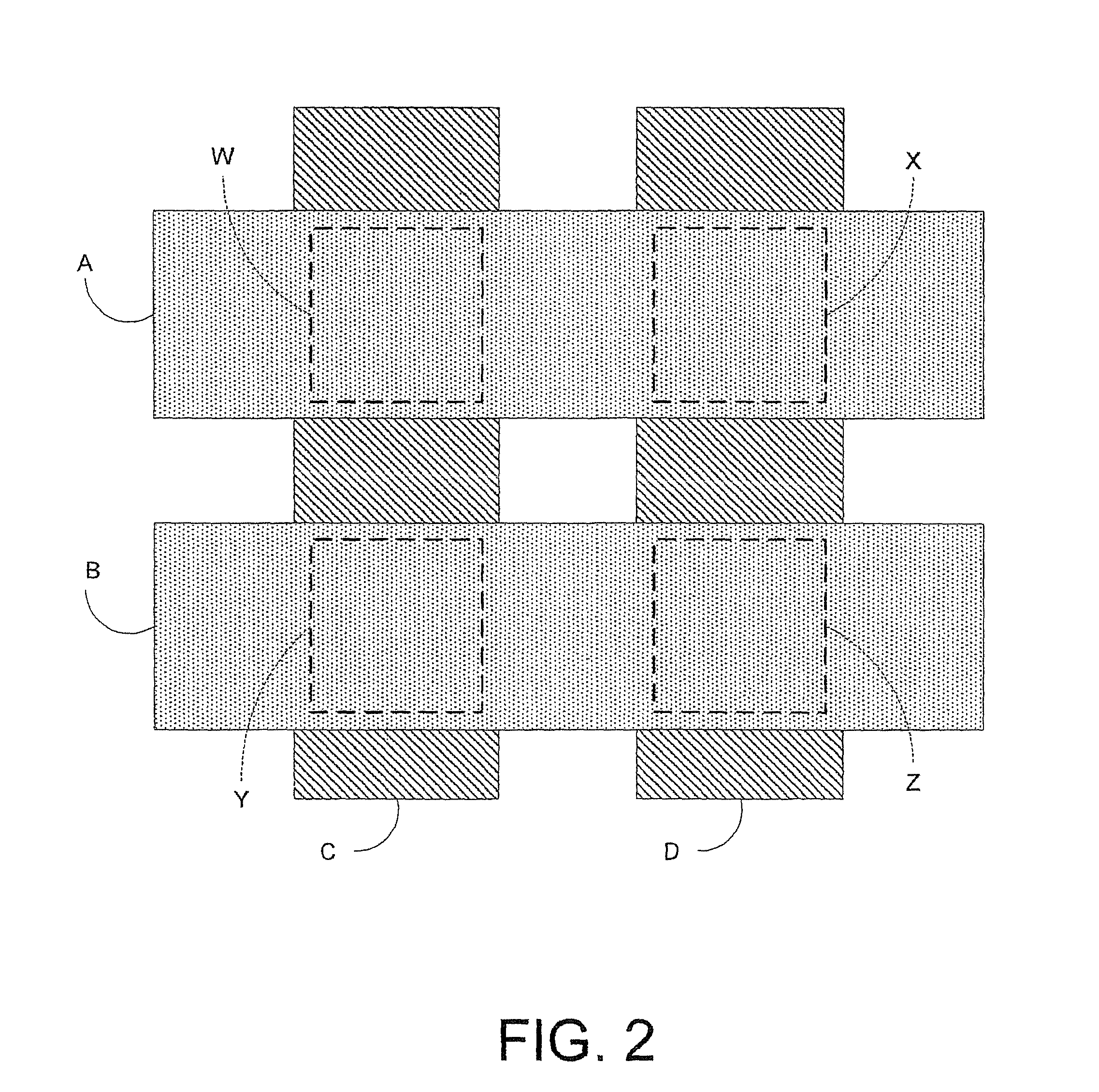

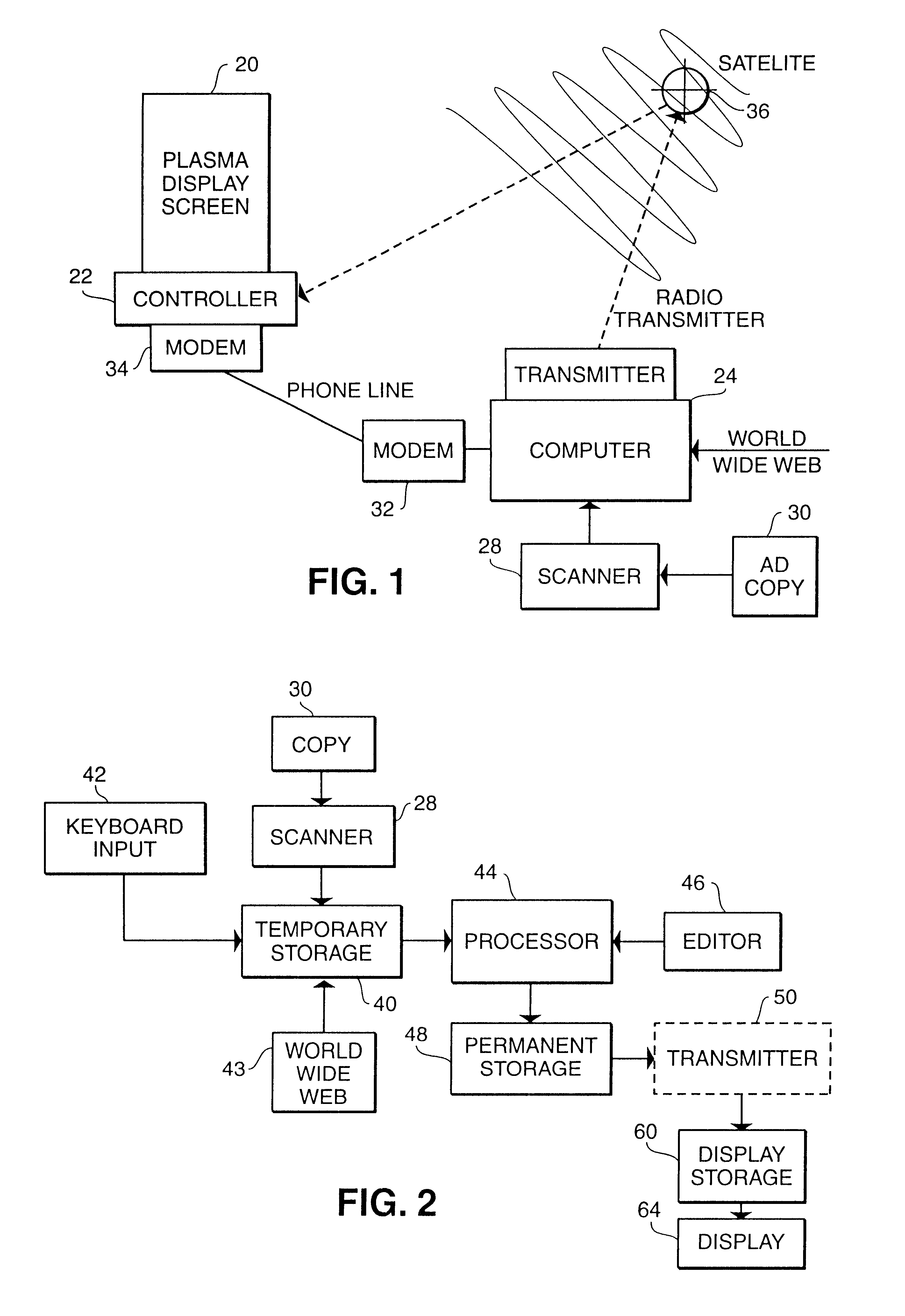

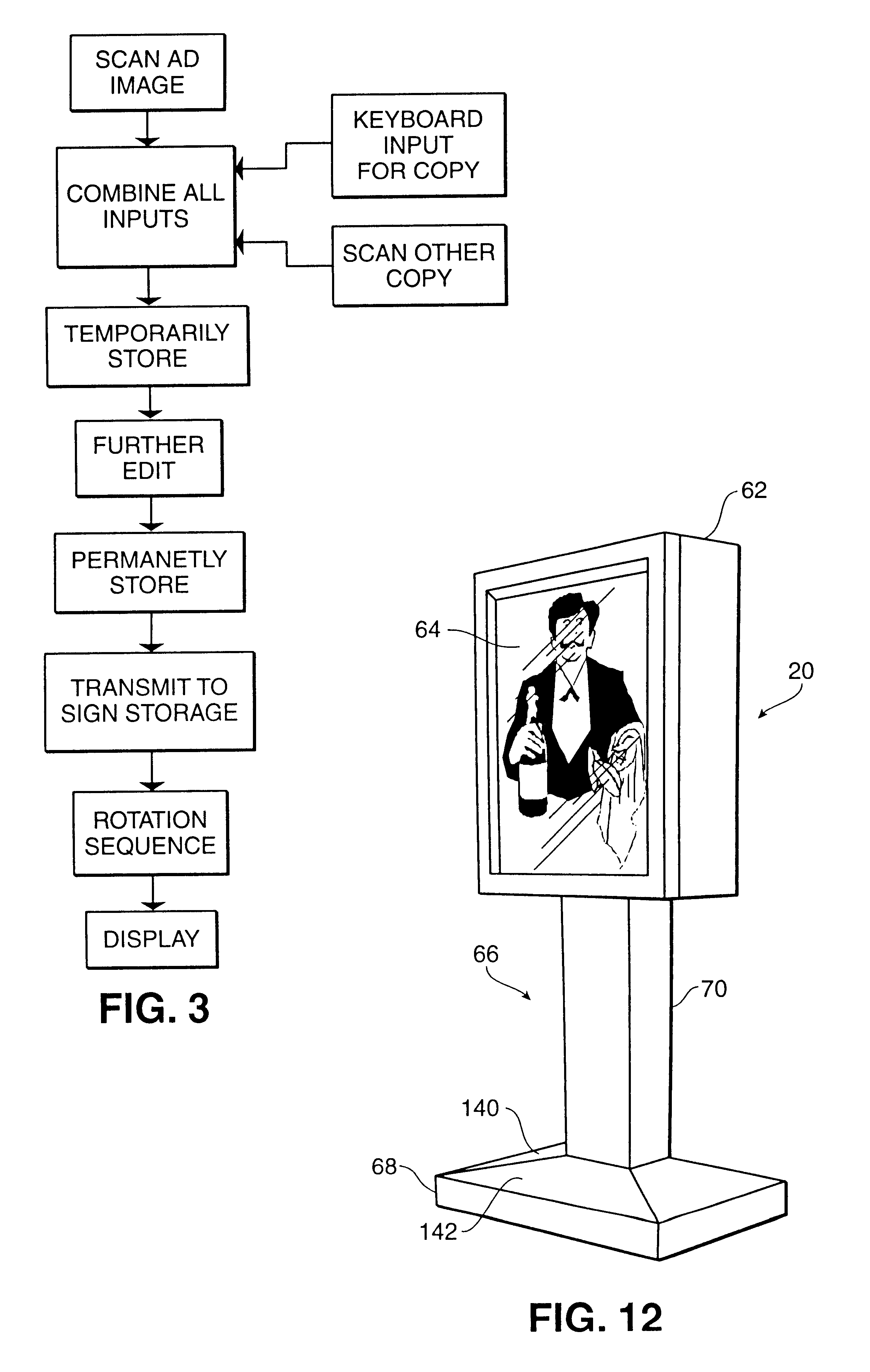

Remote control electronic display system

InactiveUS6384736B1Easy to changeEliminate needSnap fastenersElectric signal transmission systemsGraphicsWireless transmission

A remotely controlled electronic display sign which operates with a plasma display and which provides for humidity and heat control and the like allowing the sign to be used in various environments. The sign is essentially self-contained and includes those components necessary for enabling a display of desired material from a remote control source or one located at the sign. A controller in or associated with the sign is accessible either electrically, or through satellite transmission or other wireless transmission from the remote source which allows the display of the sign to be changed at will. Thus, an operator at a remote source may, with the aid of a pre-prepared graphic design, transmit that design to the controller at or associated with the sign for display of that graphic information and potentially with sound.

Owner:ACTIVELIGHT +2

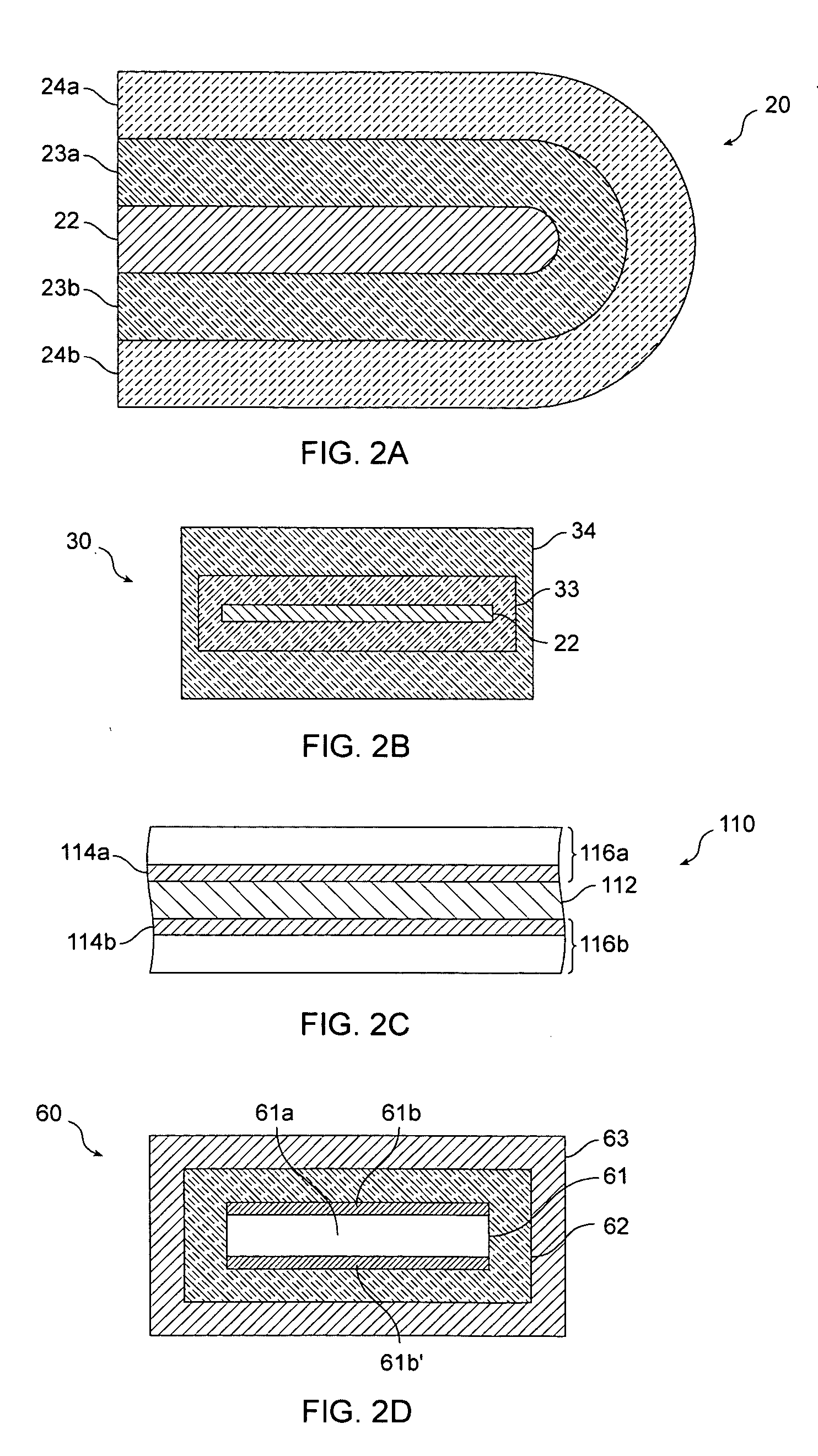

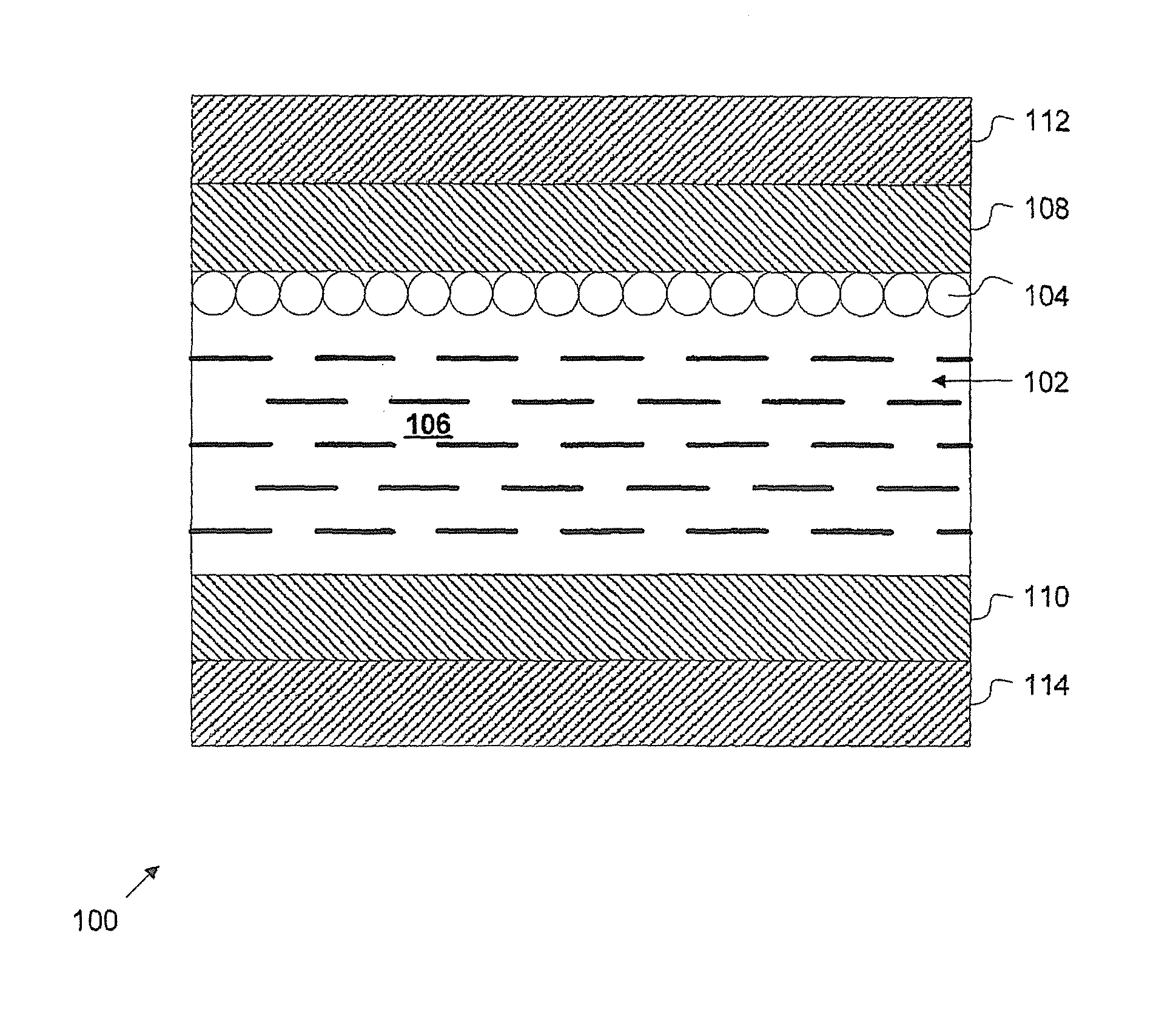

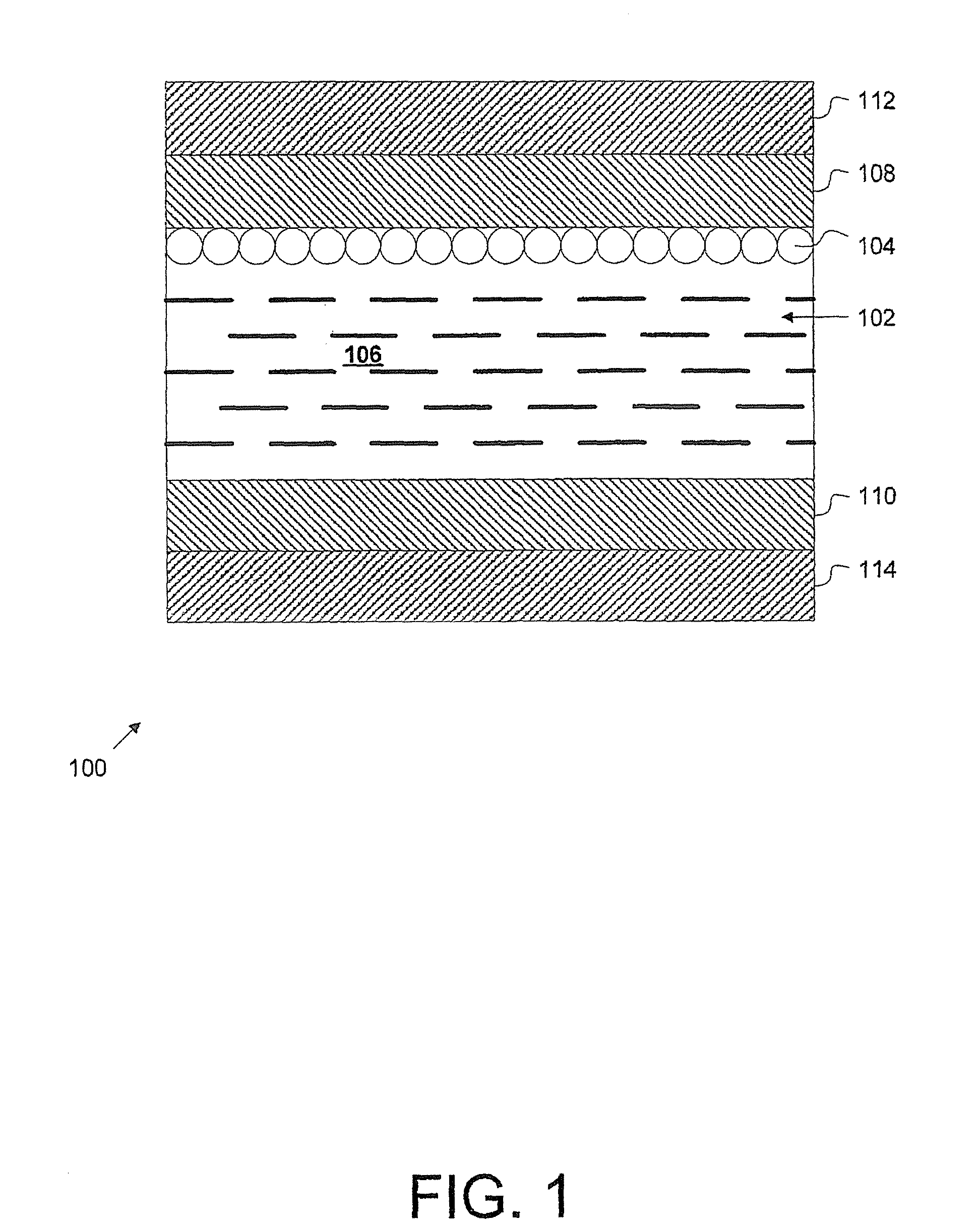

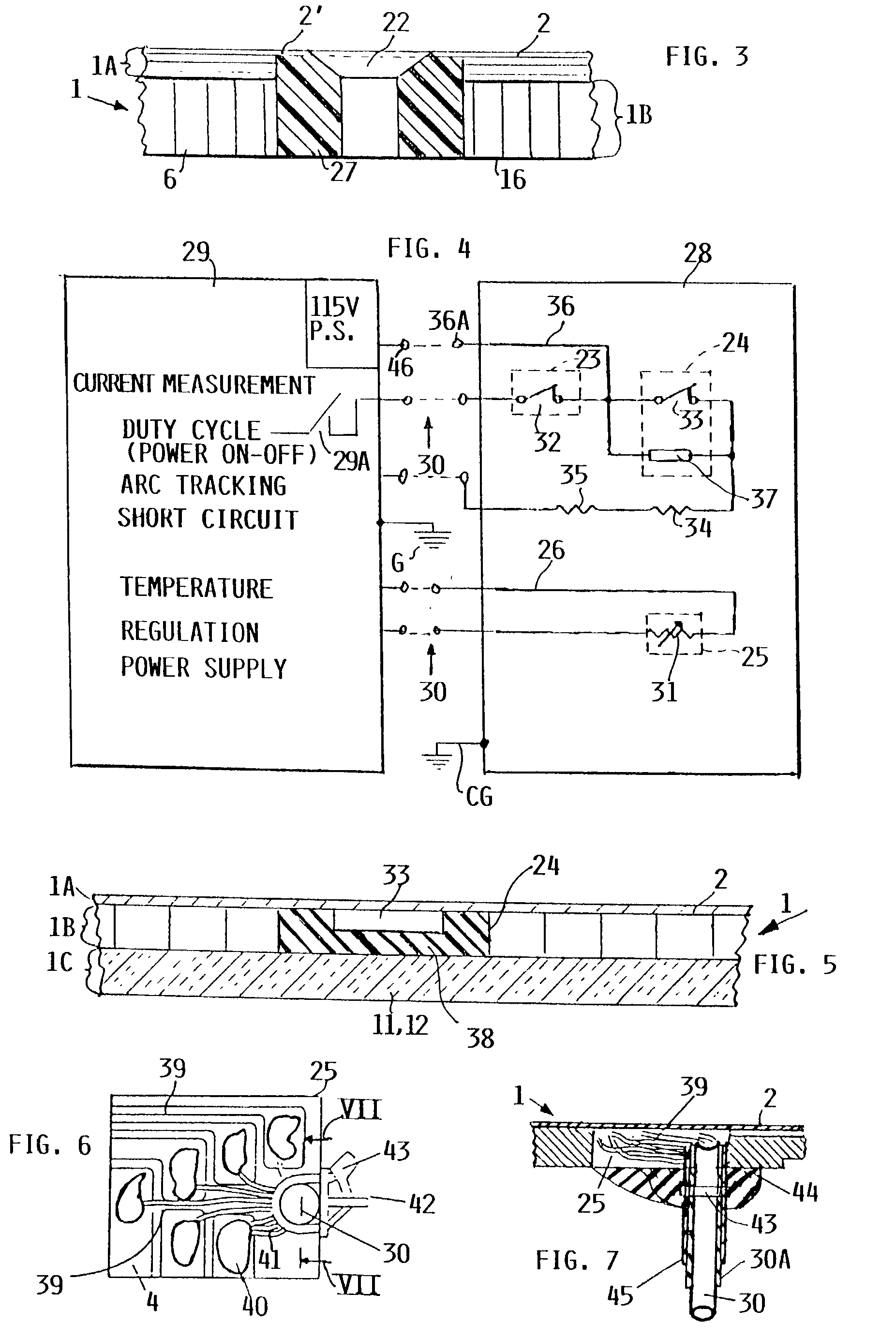

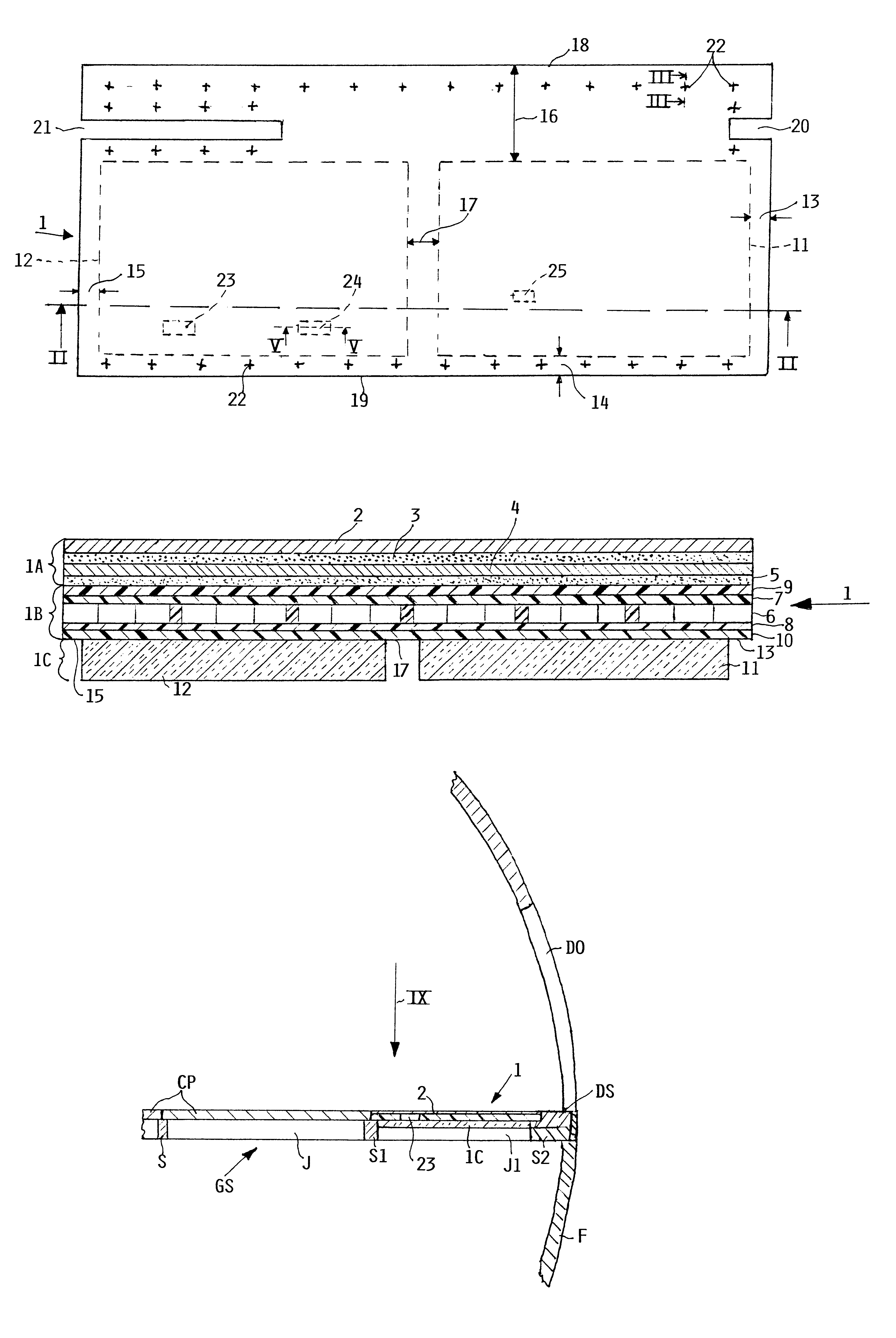

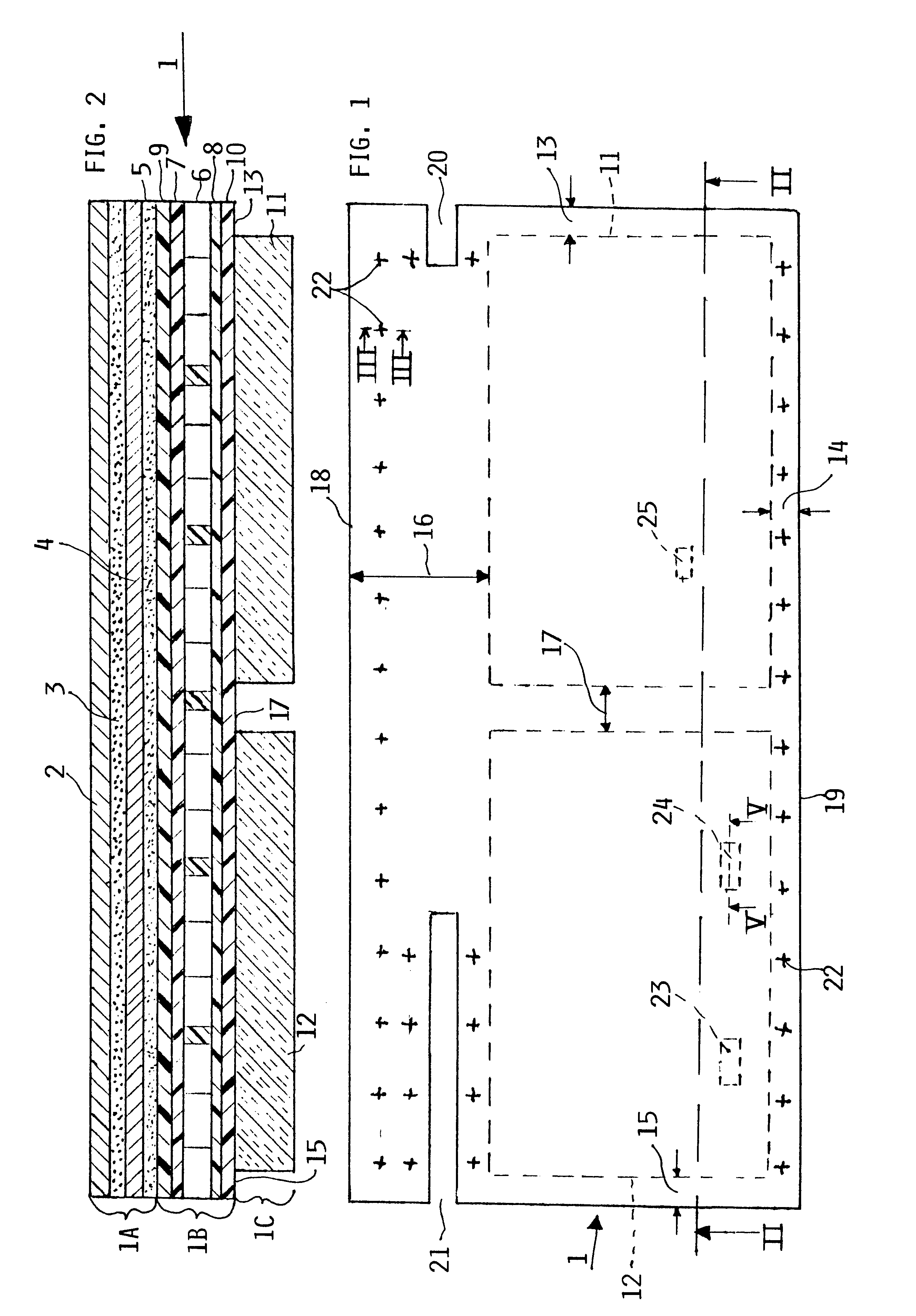

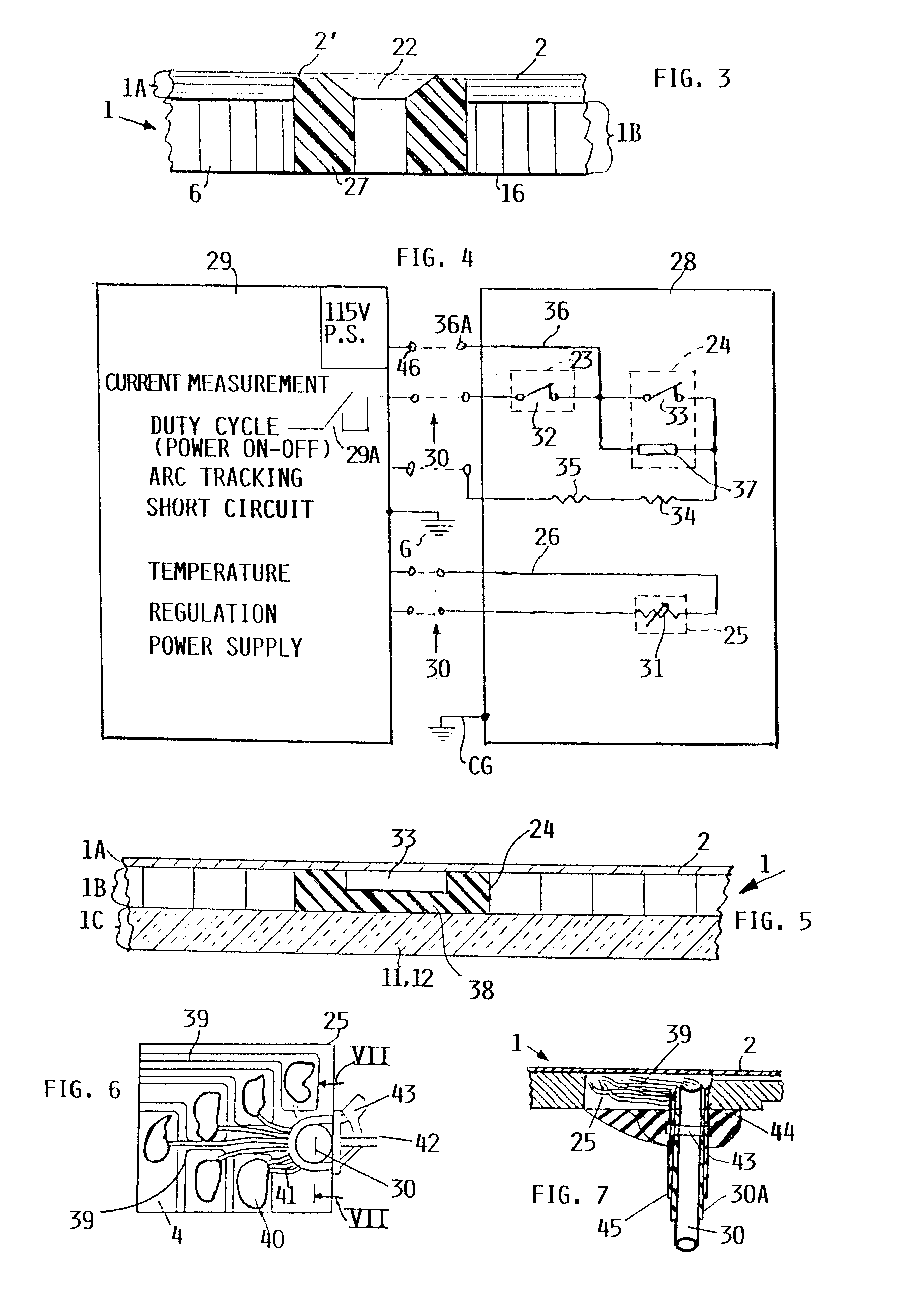

Electrically heated aircraft composite floor panel

InactiveUS20020168184A1Avoid temperature riseReduce consumptionFluid heatersElectric heating systemGlass fiberFiber-reinforced composite

An aircraft floor heating panel is constructed for mechanical strength and to meet special heating requirements next to a door in an aircraft. The panel has a lightweight core. Each surface of the core is first covered with at least one carbon-fiber reinforced composite layer for protection against deterioration. Each carbon fiber layer in turn is covered by a glass fiber reinforced composite layer for mechanical strength. A foil heater is arranged inside the composite panel coextensive with at least a portion of the panel area. A heat distributing metal plate covers the panel as an upper step-on surface. A heat insulating layer is bonded to the panel opposite the heat distributing metal plate. A triple heat control is provided for an increased safety against fire hazards.

Owner:AIRBUS OPERATIONS GMBH

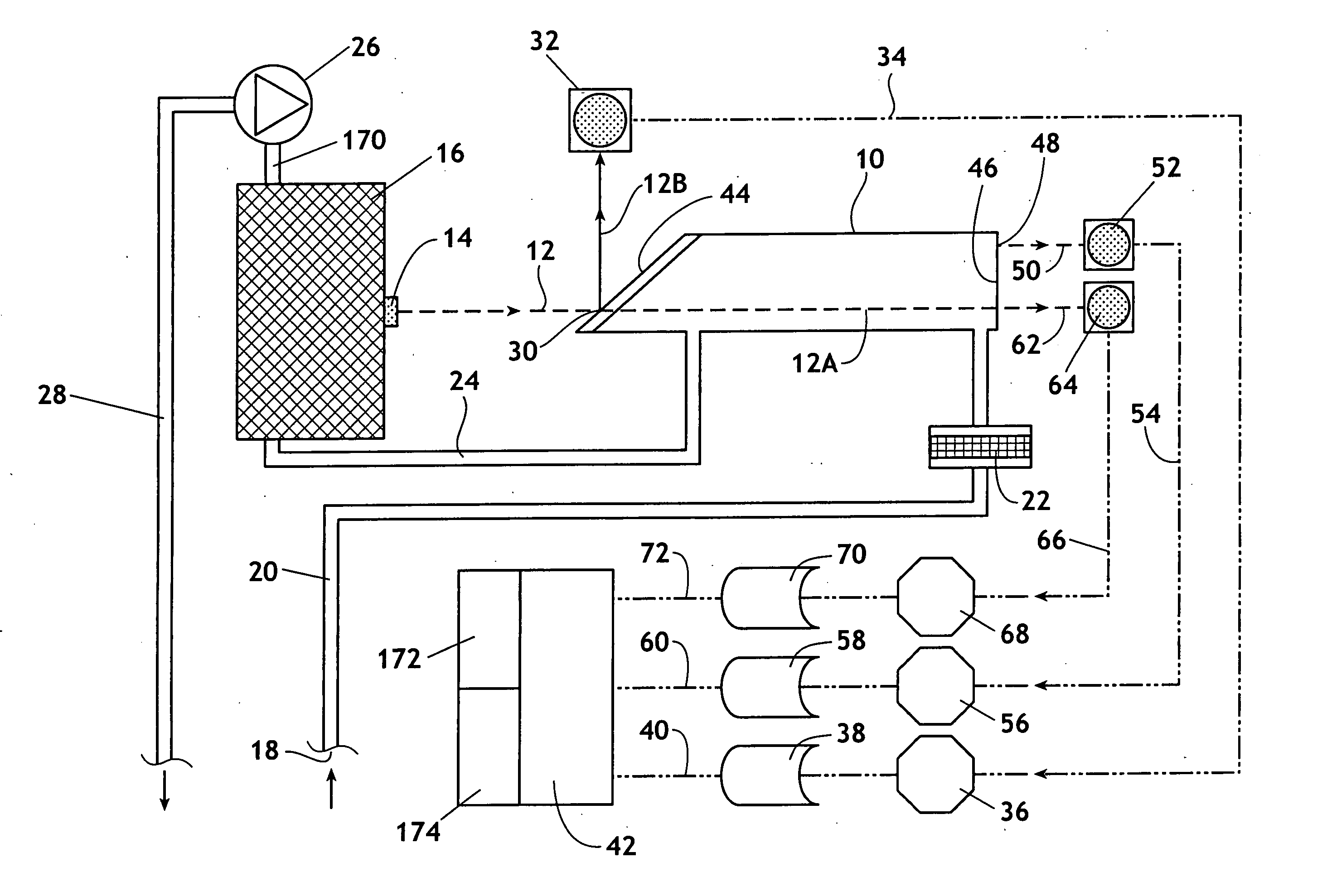

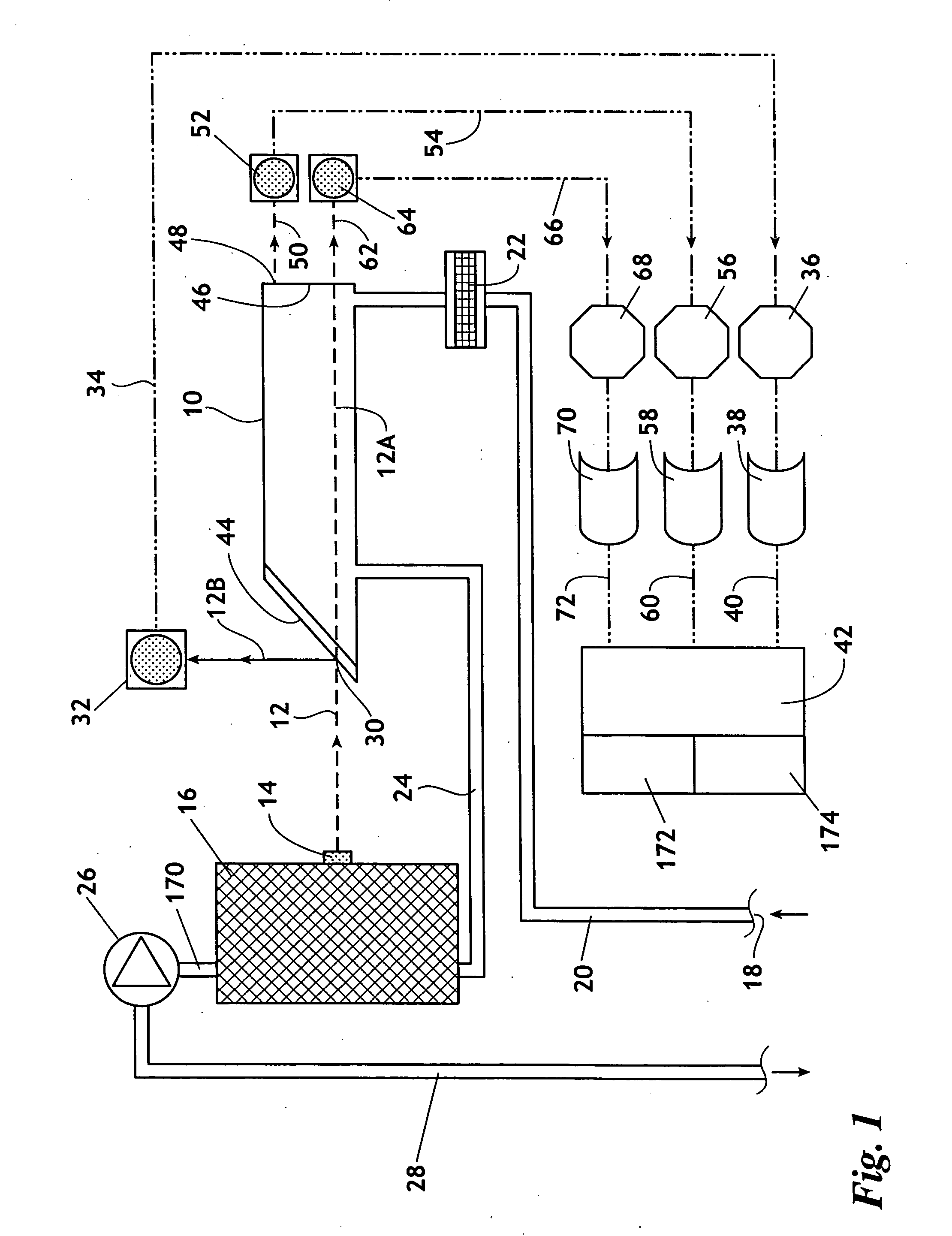

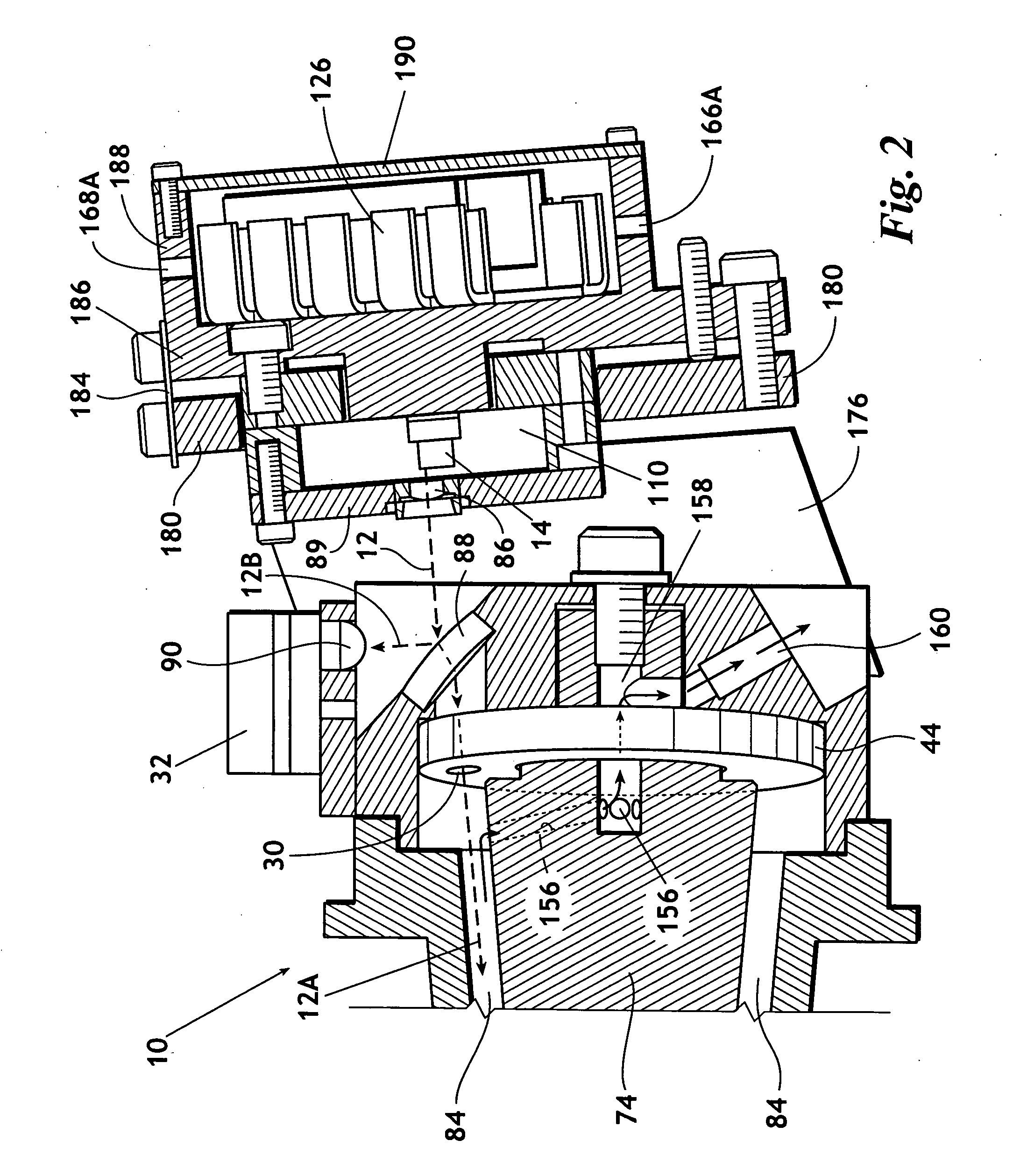

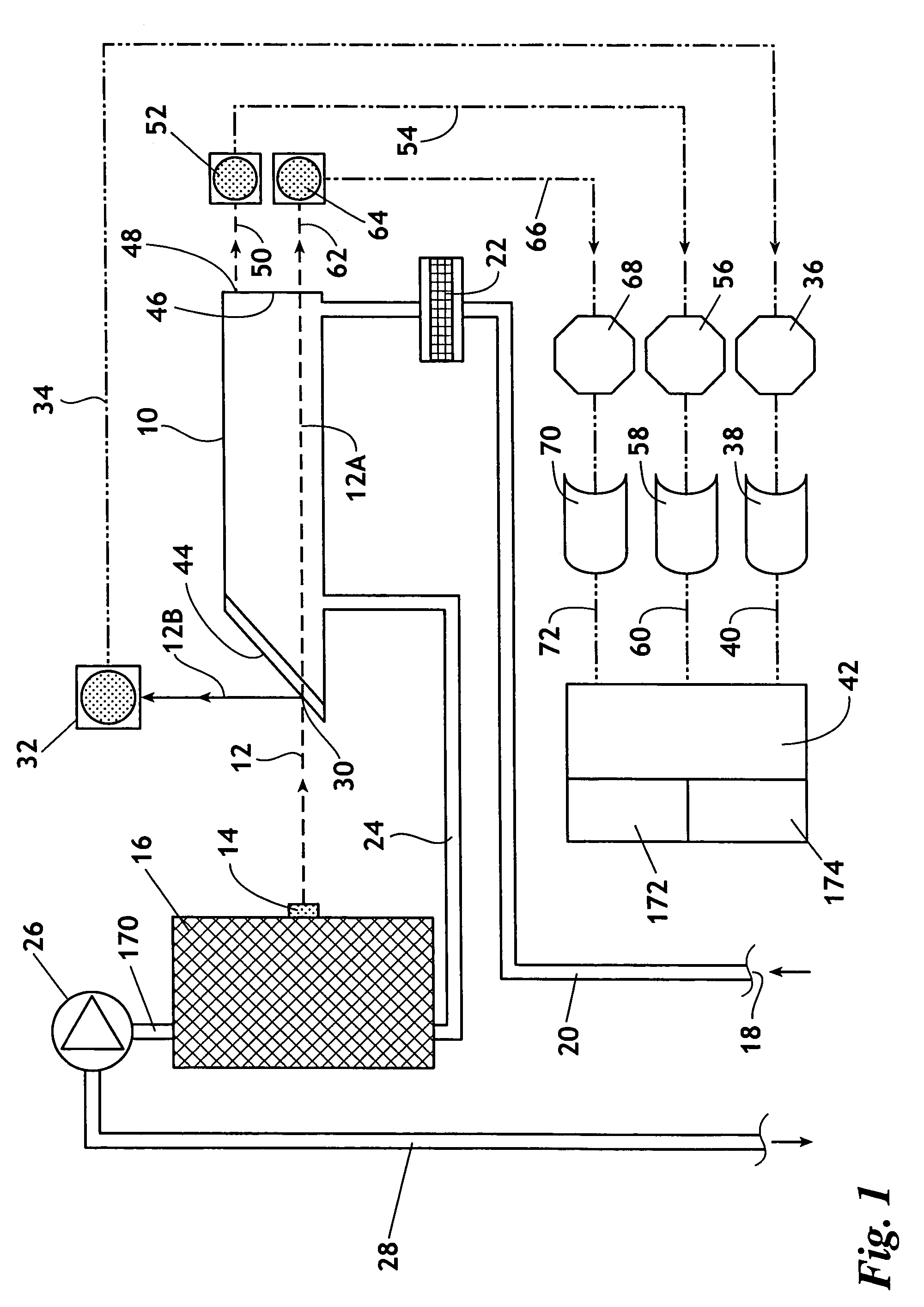

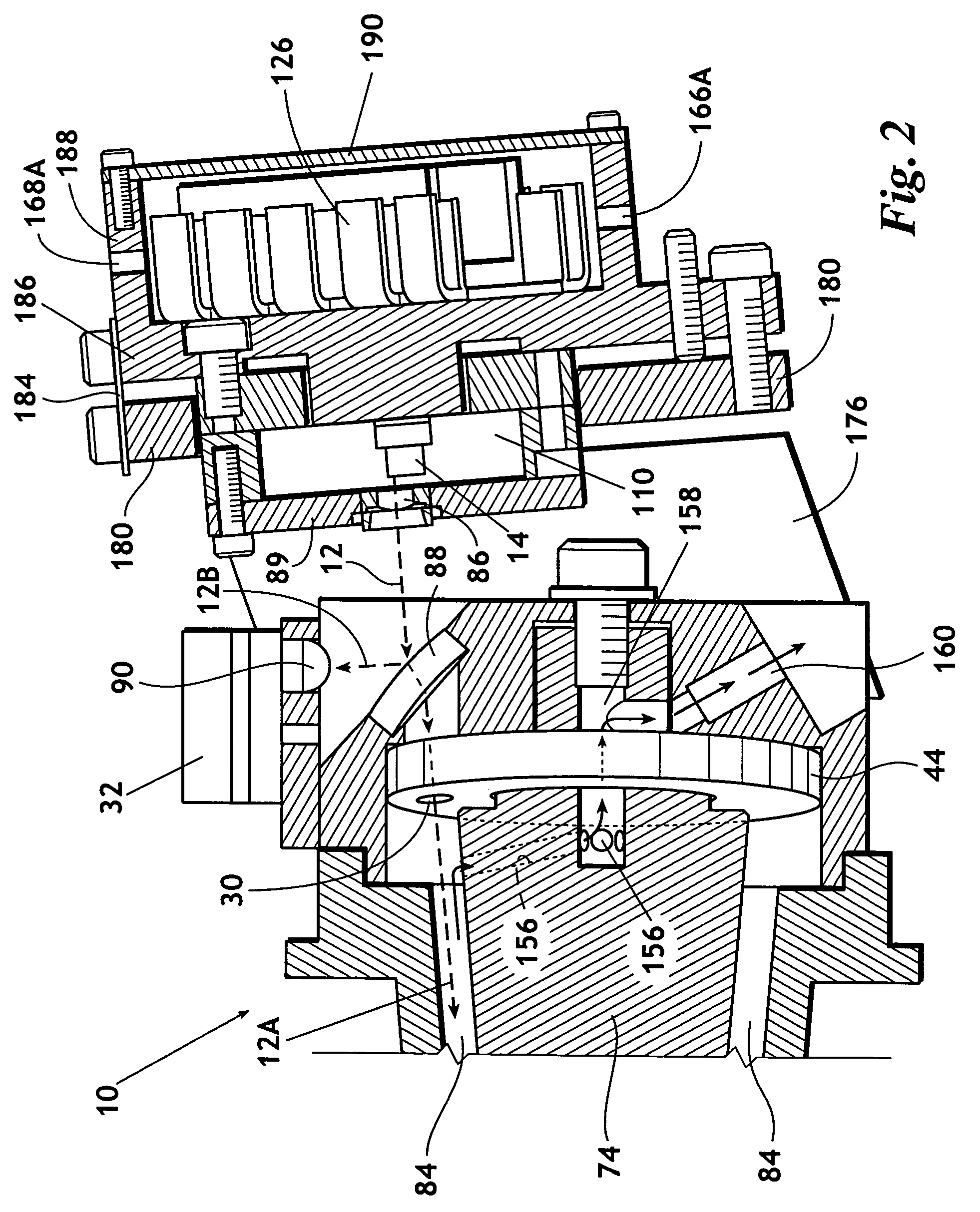

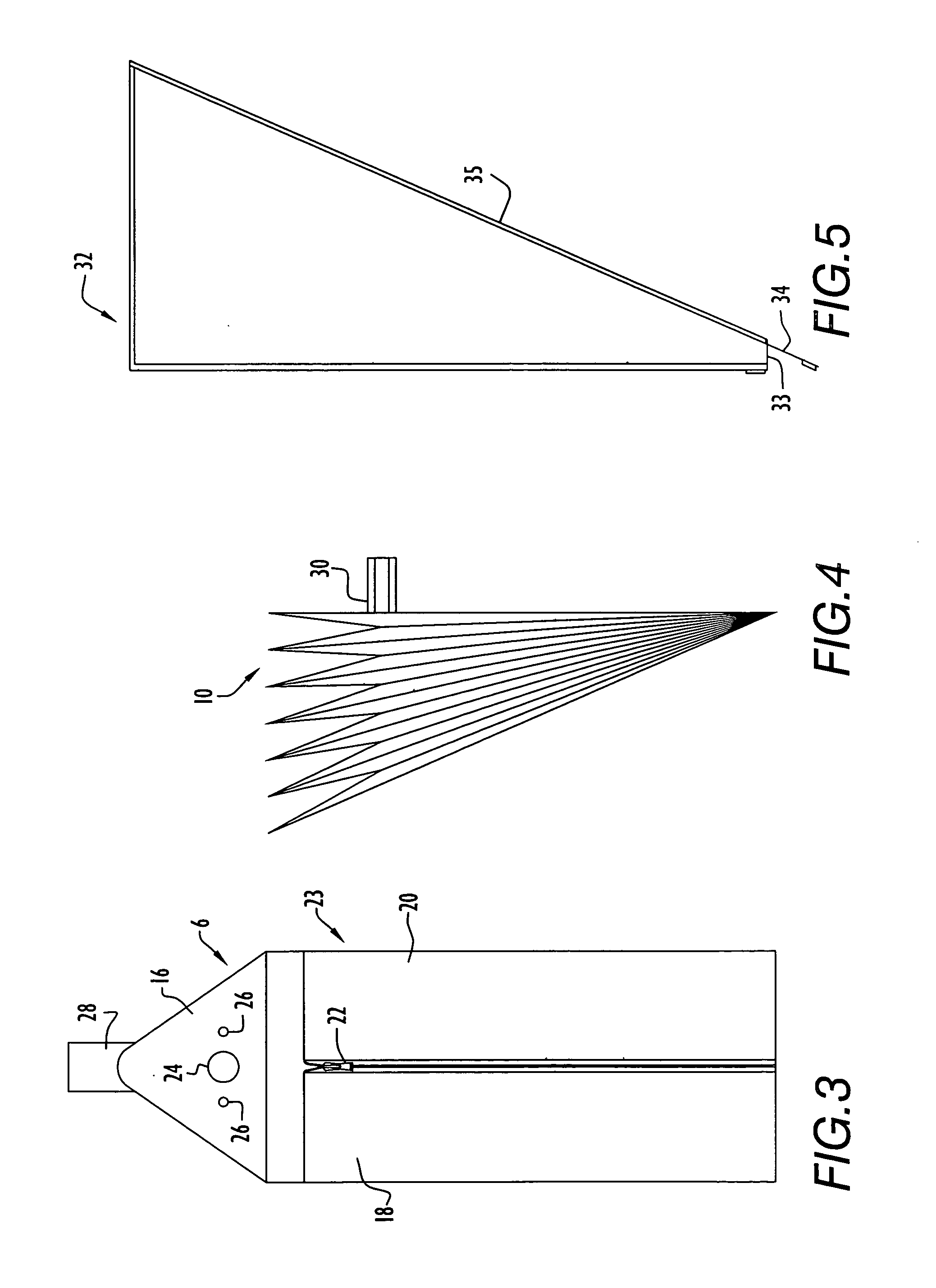

Method and device for detecting gases by absorption spectroscopy

ActiveUS20060119851A1Increase the itineraryImprove portabilityTransmissivity measurementsWavelengthAbsorption spectroscopy

A method and device for measuring a concentration of a preselected gas in a gas sample are disclosed. The device comprises a Herriott type multipass cell (10) having a center axle (74) and a housing (80A, 80B) surrounding and spaced from the axle to provide a tubular sample cavity (84). The gas sample is pumped through the sample cavity via apertures (154, 156) provided in opposed ends of the axle. A first mirror (44) and a second mirror (46) are supported at opposed ends of the axle. A light source, e.g. a laser or LED, is provided for emitting a light beam into the sample cavity via an entry aperture (30) in the first mirror, the light beam having a wave length at which the preselected gas strongly absorbs. The beam is reflected between the mirrors for a number of times before exiting the cell via an exit aperture (48) in the second mirror and impinging on a detector (52). The device further comprises a reference detector (32) for monitoring the intensity of the unattenuated light beam and a detector for detecting the intensity of light transmitted through the second mirror after a single pass through the cell. The light source is operatively connected to a heat control assembly having a heat sink and the gas sample is passed said heat sink to augment temperature control of the light source.

Owner:ECOTEC INT HLDG LLC

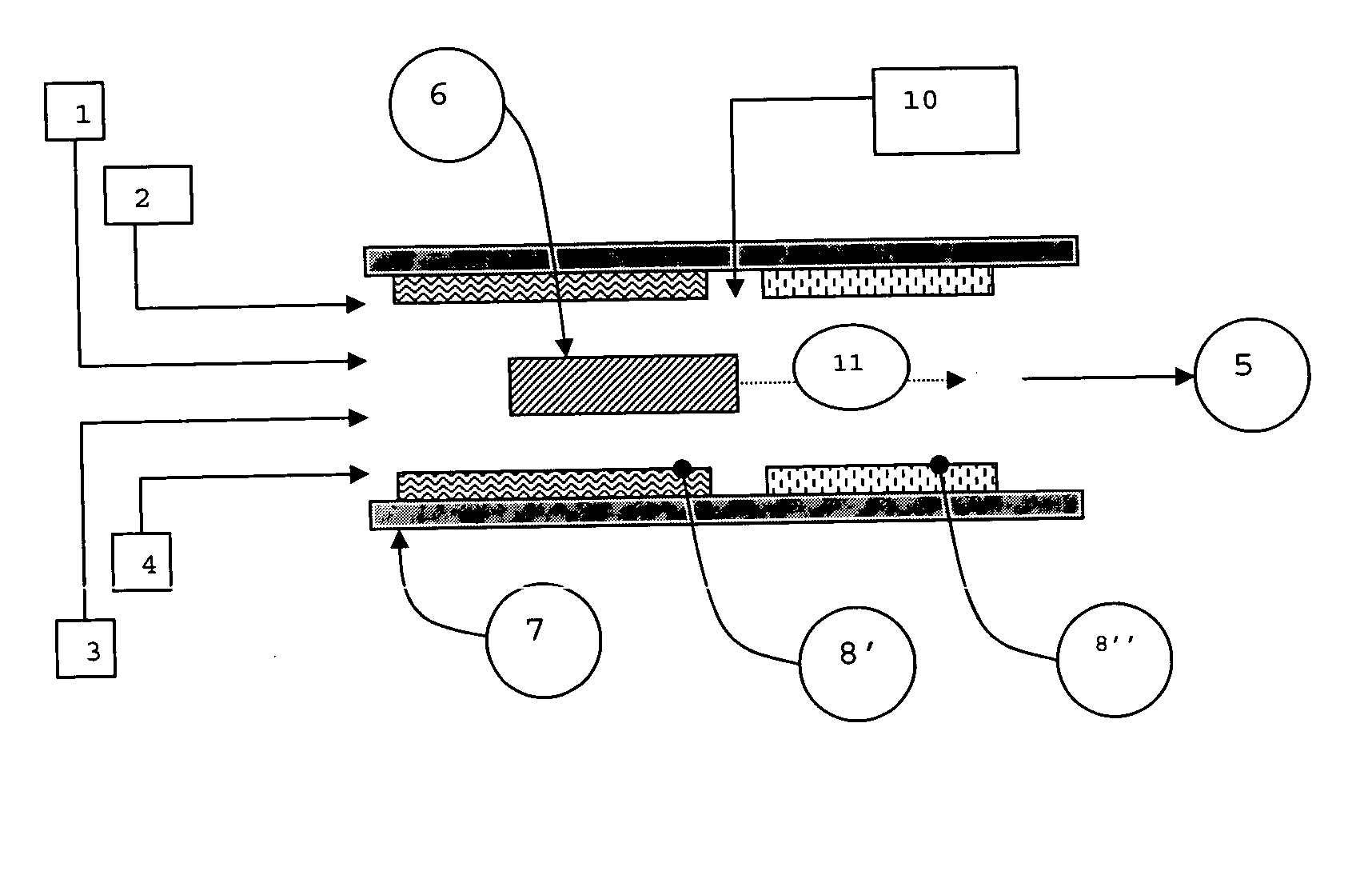

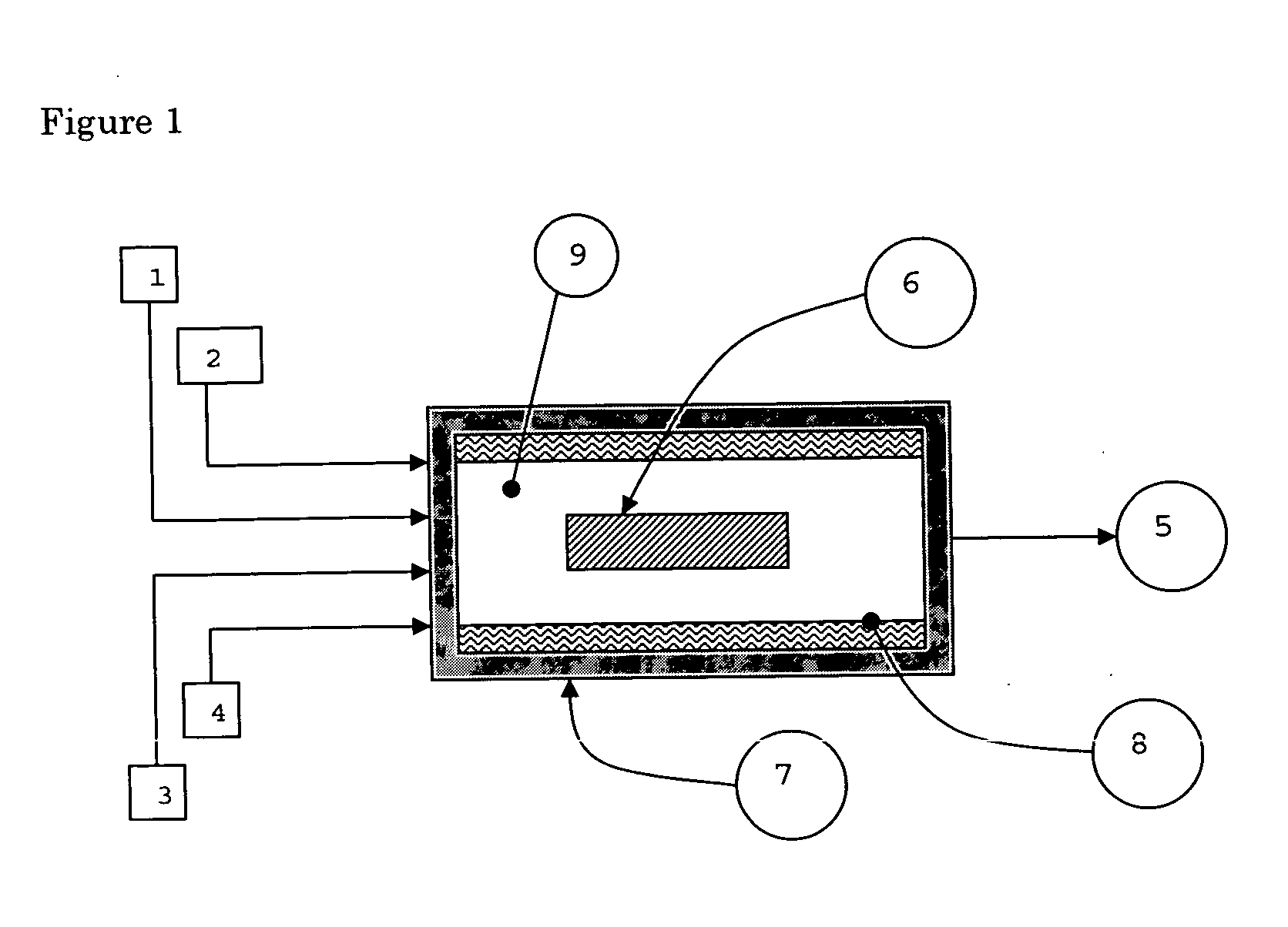

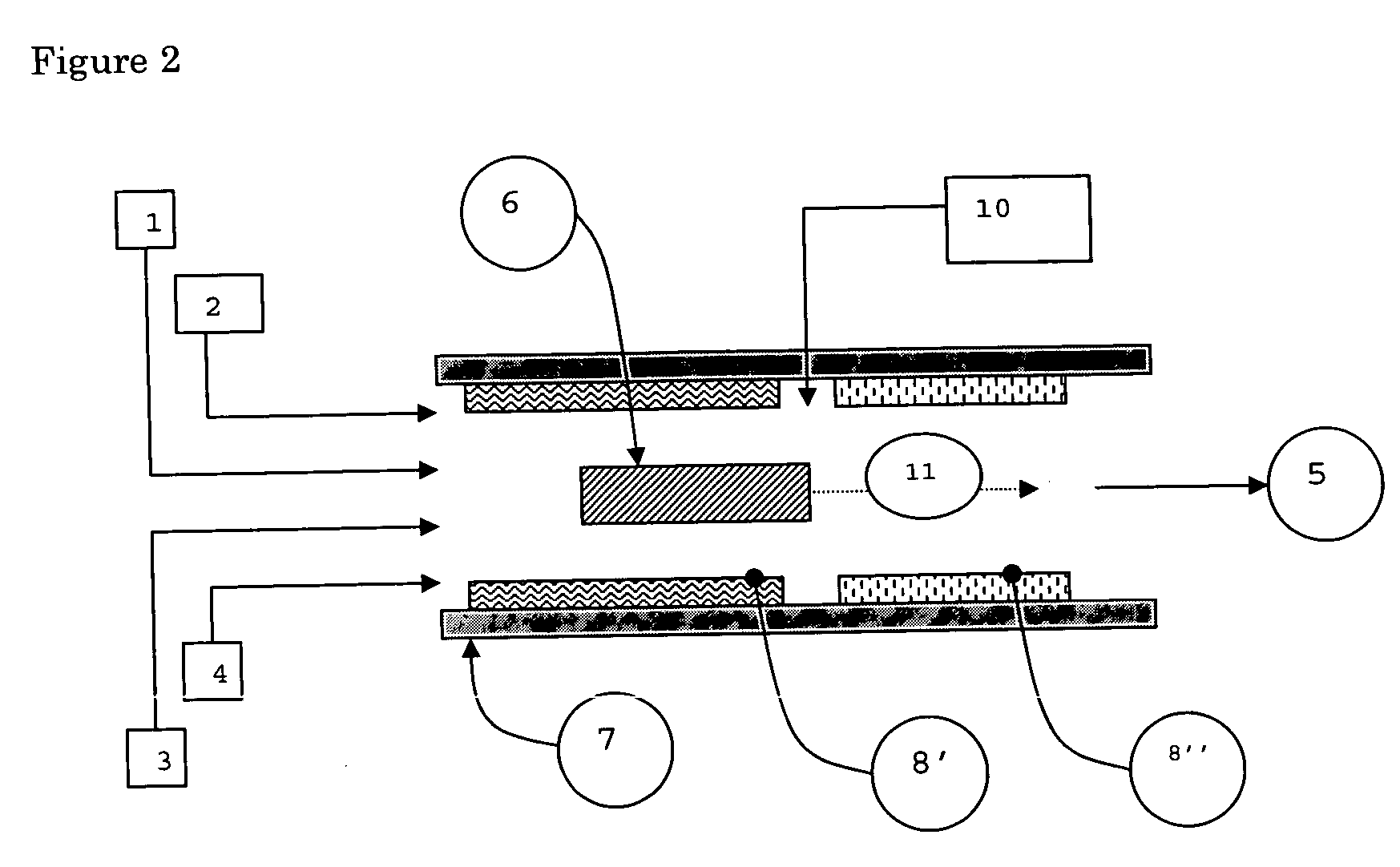

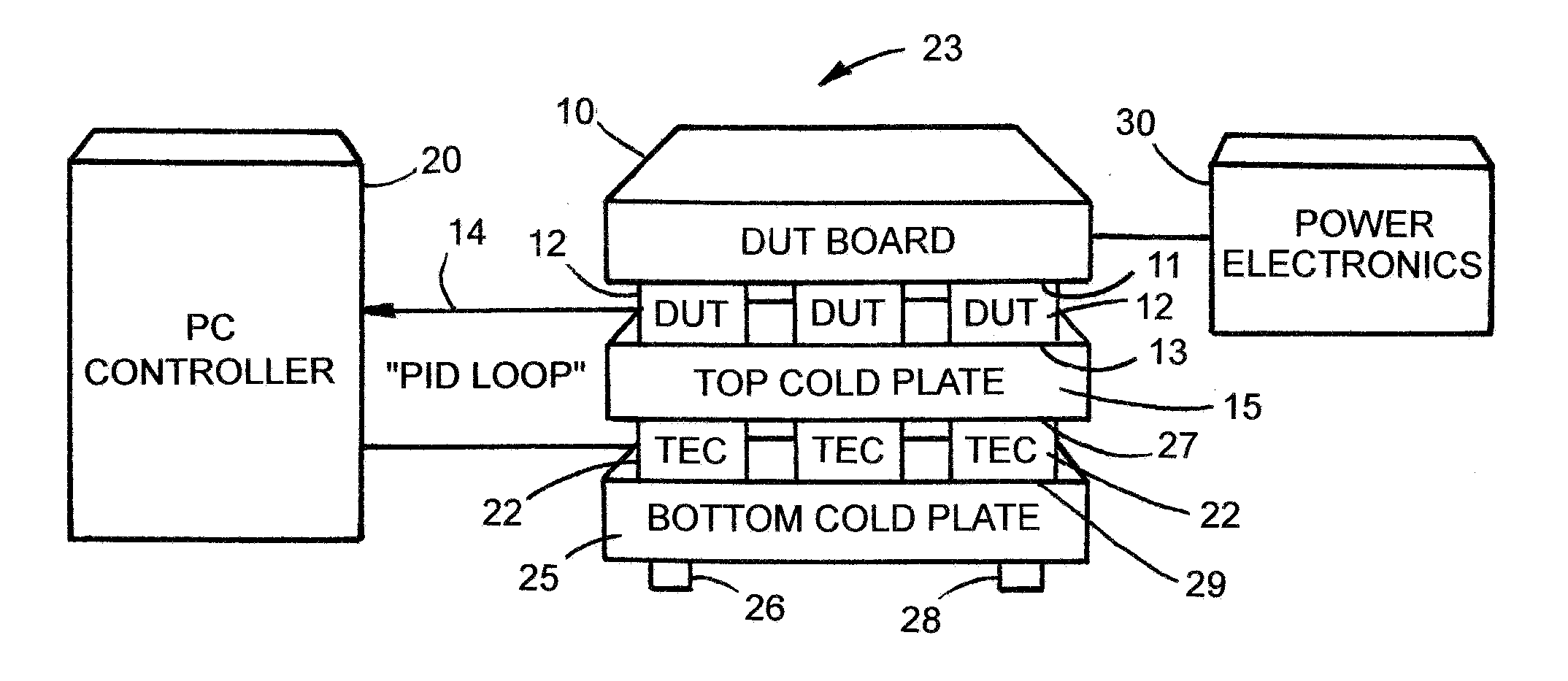

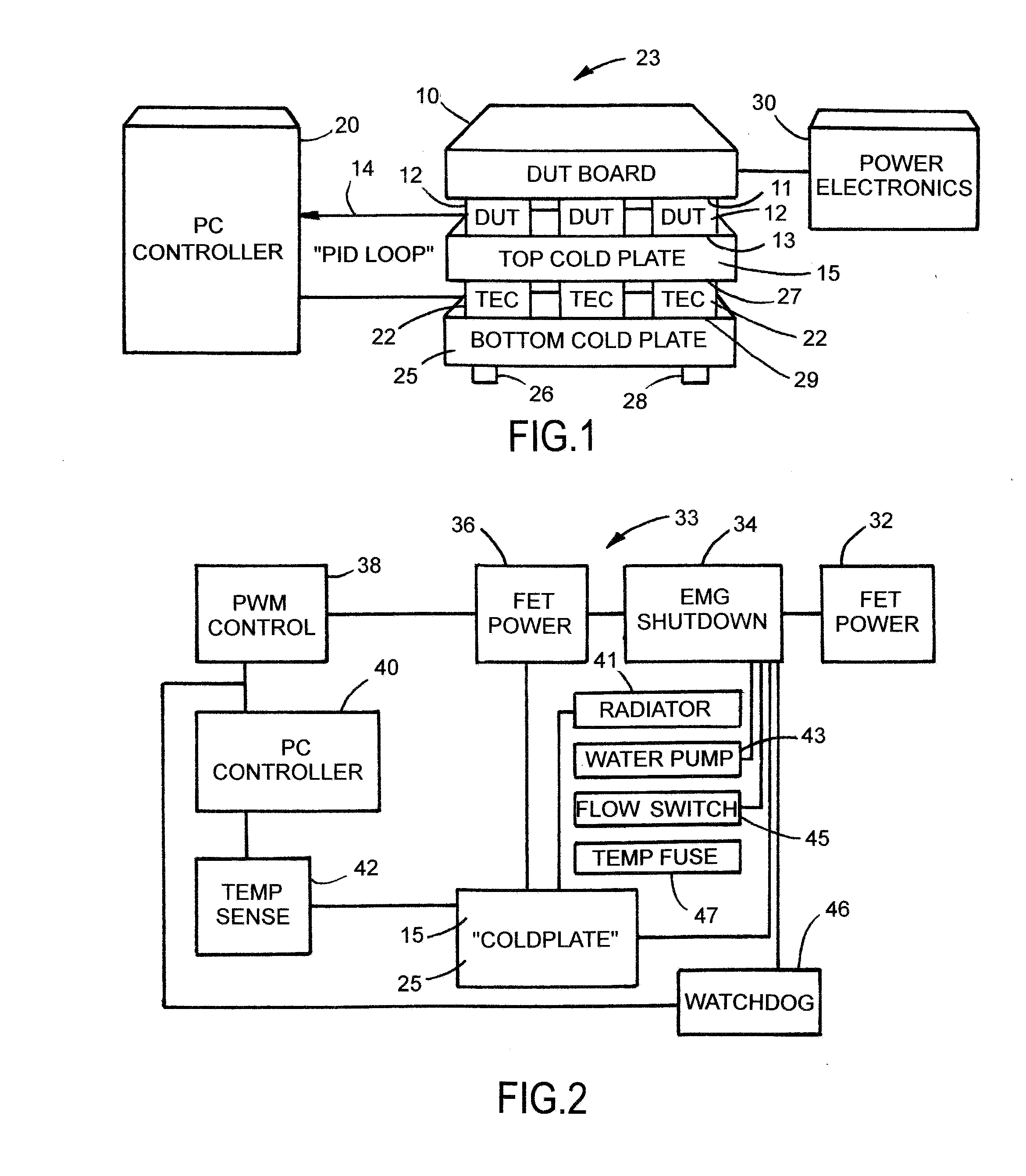

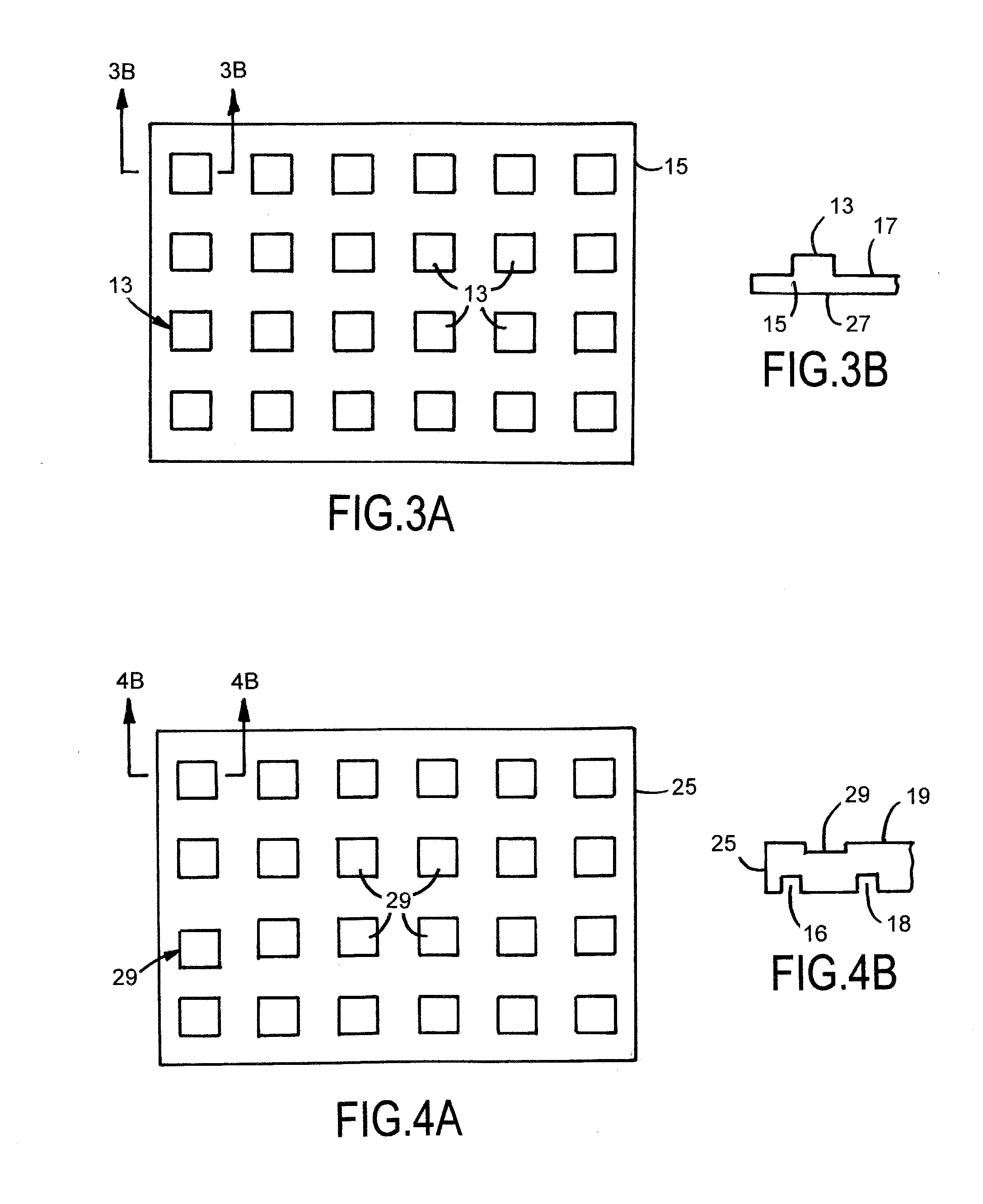

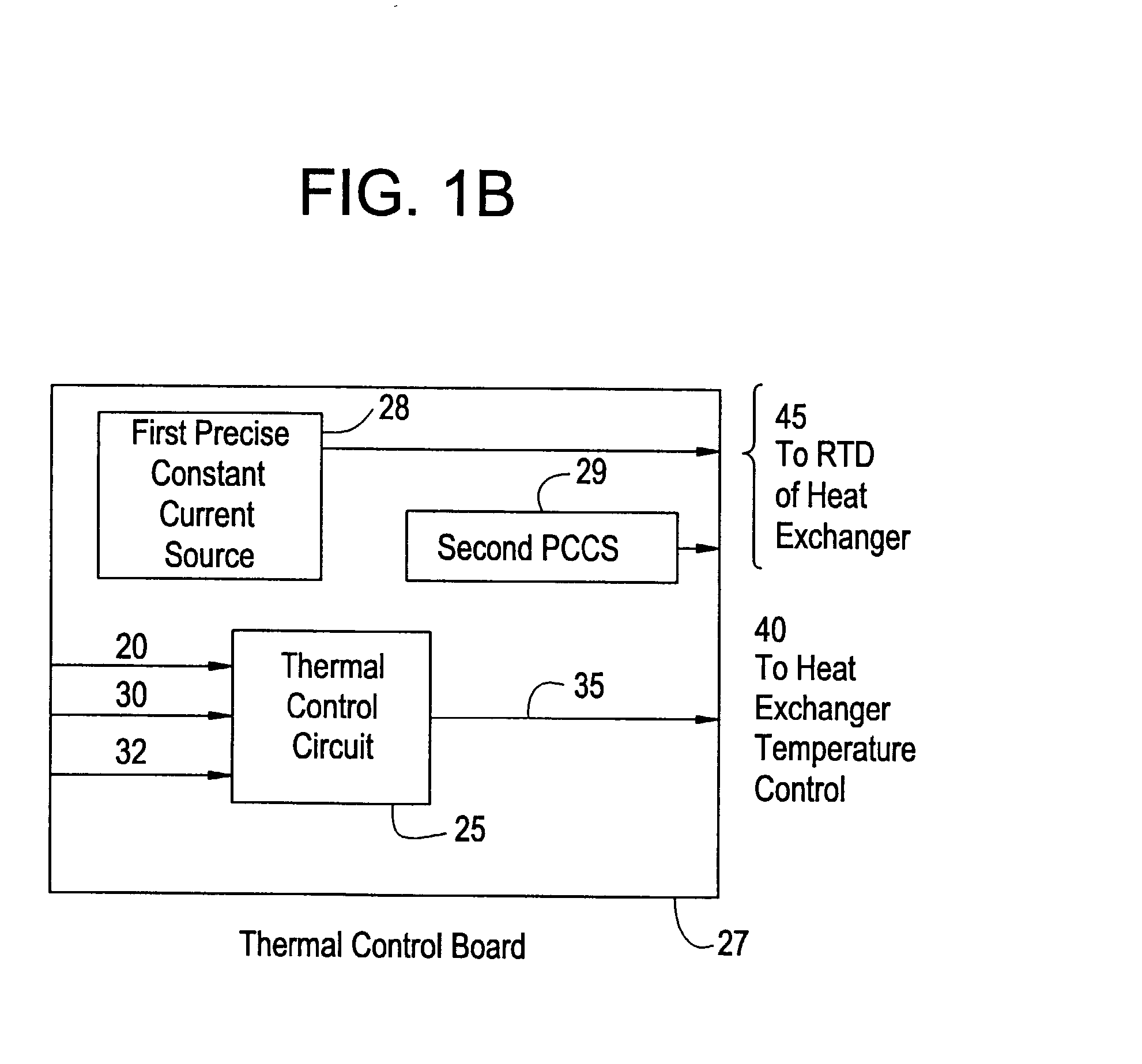

Systems and Methods for Thermal Control

ActiveUS20130285686A1Electronic circuit testingFault location by increasing destruction at faultDevice under testThermoelectric element

The present invention relates generally to a system and a method for thermal control. More particularly, the invention encompasses an apparatus for thermal control and management of at least one device under test (DUT). The inventive thermal control and management apparatus also allows for the management of a plurality of devices under test, and with each device under test having its own testing regimen. The thermal control and management of the device under test (DUT) is managed using at least one thermoelectric element or cooler (TEC), which can be used to either heat or cool the corresponding device under test (DUT).

Owner:SILICON TURNKEY SOLUTIONS

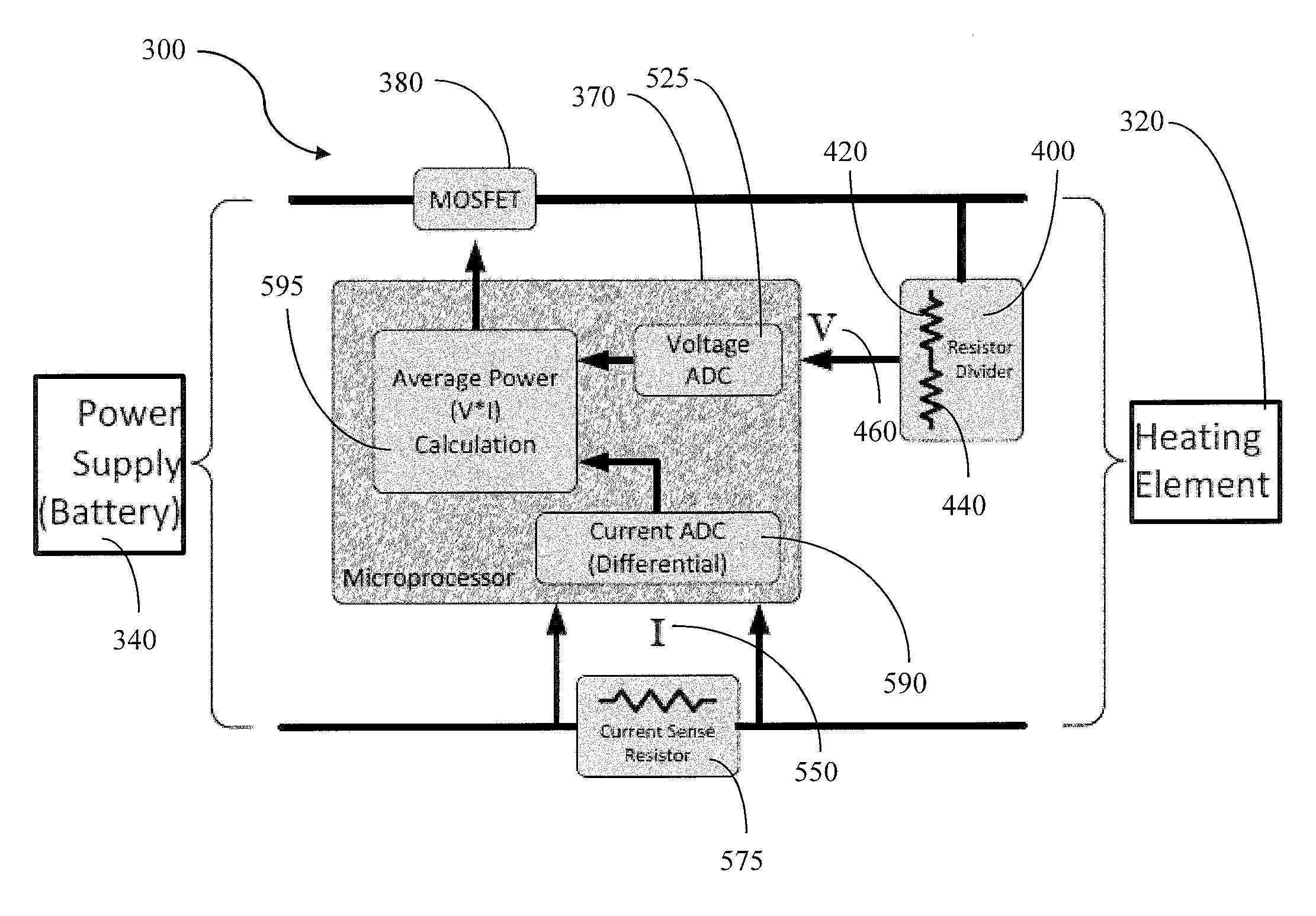

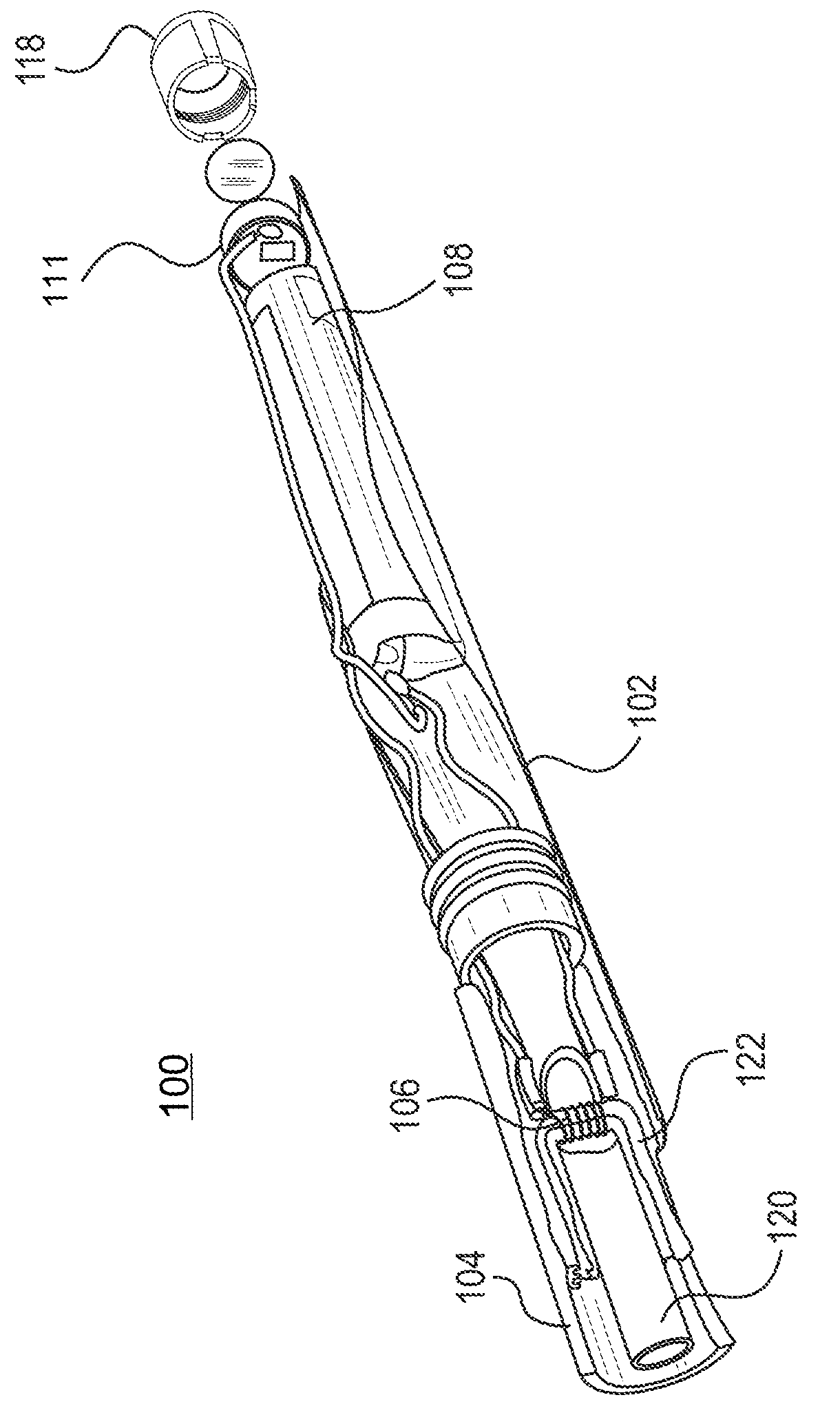

Heating control for vaporizing device

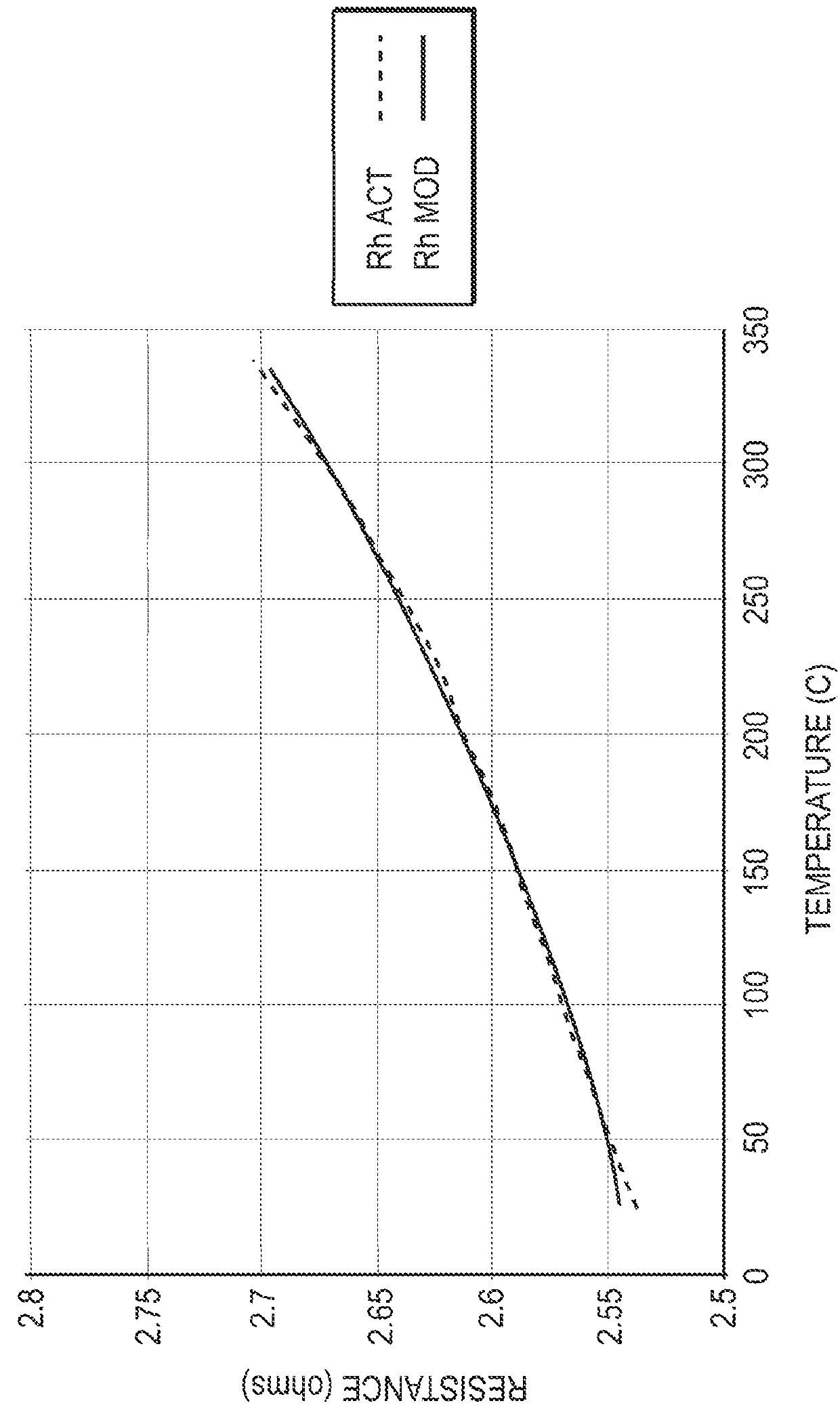

ActiveUS20160053988A1Machines/enginesGaseous substancesElectrical resistance and conductanceElectronic communication

The temperature of a vaporizing device, e.g., the temperature of a heating element of the vaporizing device, may be controlled according to various aspects of the present disclosure. The vaporizing device may comprise a heating element, a power source, at least one sensor in electronic communication with the heating element and the power source, and a processor configured to control the temperature of the heating element. The method of controlling the temperature may comprise receiving a resistance measurement of the heating element from the at least one sensor, determining the temperature of the heating element based on the resistance measurement, and adjusting the amount of power supplied to the heating element based on the determined temperature of the heating element.

Owner:NJOY LLC

Cooker provided with multiple temperature-sensing probes and food cooking method

InactiveCN103948308AThe connection is tight and firmUndisturbedSteam cooking vesselsFood scienceThermal insulationTwo temperature

The invention relates to the technical field of cookware, in particular to a cooker provided with multiple temperature-sensing probes and a food cooking method. More than two temperature-sensing probes are arranged at different-height positions of a cooker wall, the lowest end temperature-sensing probe is arranged on the cooker wall close to the bottom of the cooker, thermal insulation materials are arranged the peripheries of the temperature-sensing probes, metal protective layers cover the outer sides of the thermal insulation materials, and the temperature-sensing probes are connected tightly, so that the interference of the outside temperature is prevented, and the sensing precision is improved; the temperature-sensing probe conductors are connected to a temperature displaying unit; through the temperature displaying unit, the temperature of the interior of the cooker is immediately known, the accurate heat control is carried out, and the scientific cooking is carried out. The invention further relates to a food cooking method by utilizing the intelligent cooker. The cooking method comprises the following steps of heating at an approximate boiling point; continuously heating till the cooker senses a set temperature t1 of temperature T1; after the temperature of the boiling point is closed, cooking on soft fire on time, so as to avoid the energy consumption waste.

Owner:GUANGDONG MASTER GROUP

Method and device for detecting gases by absorption spectroscopy

InactiveUS7352463B2Increase the itineraryImprove portabilityTransmissivity measurementsWavelengthAbsorption spectroscopy

A method and device for measuring a concentration of a preselected gas in a gas sample are disclosed. The device comprises a Herriott type multipass cell (10) having a center axle (74) and a housing (80A, 80B) surrounding and spaced from the axle to provide a tubular sample cavity (84). The gas sample is pumped through the sample cavity via apertures (154, 156) provided in opposed ends of the axle. A first mirror (44) and a second mirror (46) are supported at opposed ends of the axle. A light source, e.g. a laser or LED, is provided for emitting a light beam into the sample cavity via an entry aperture (30) in the first mirror, the light beam having a wave length at which the preselected gas strongly absorbs. The beam is reflected between the mirrors for a number of times before exiting the cell via an exit aperture (48) in the second mirror and impinging on a detector (52). The device further comprises a reference detector (32) for monitoring the intensity of the unattenuated light beam and a detector for detecting the intensity of light transmitted through the second mirror after a single pass through the cell. The light source is operatively connected to a heat control assembly having a heat sink and the gas sample is passed said heat sink to augment temperature control of the light source.

Owner:ECOTEC INT HLDG LLC

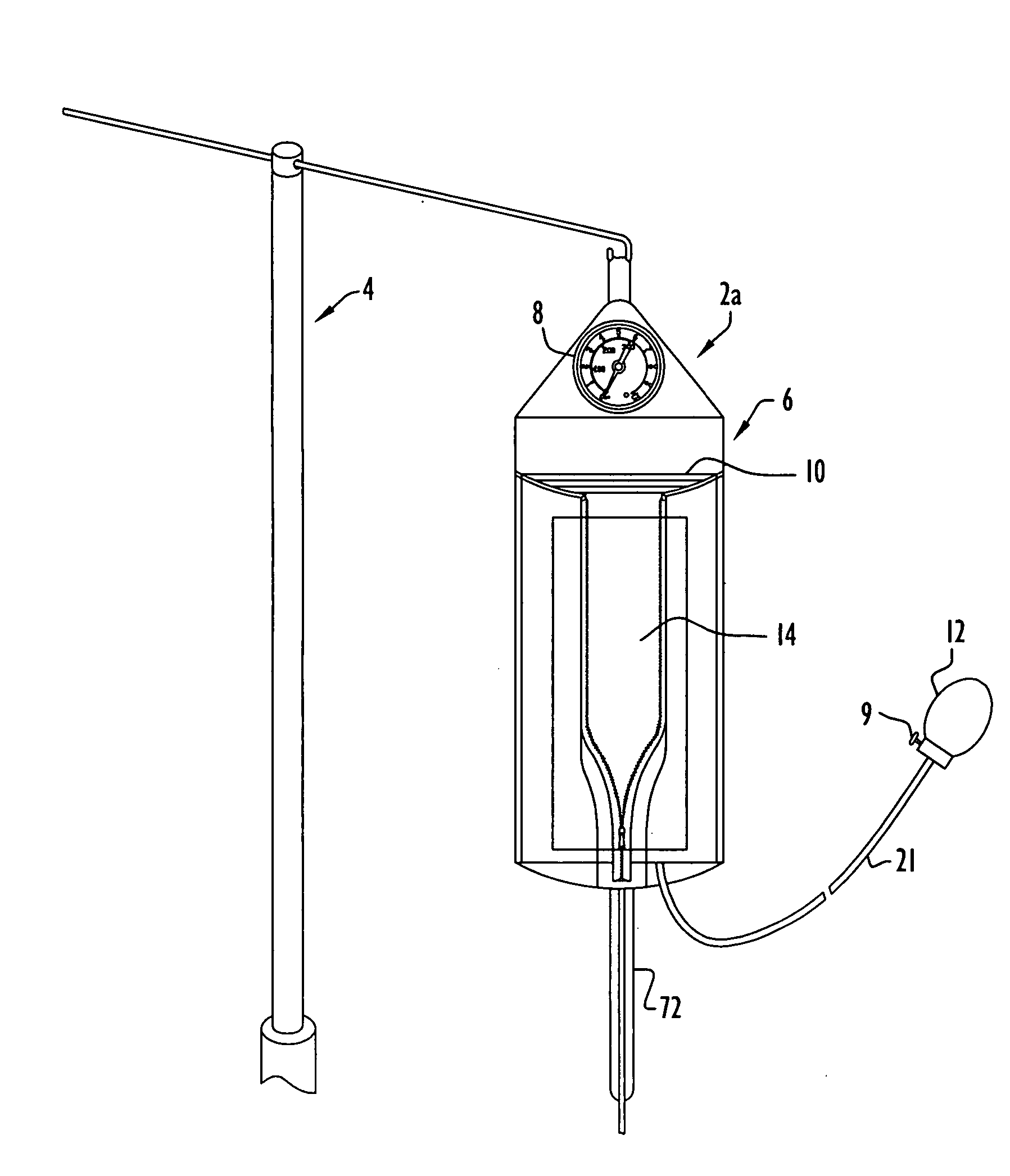

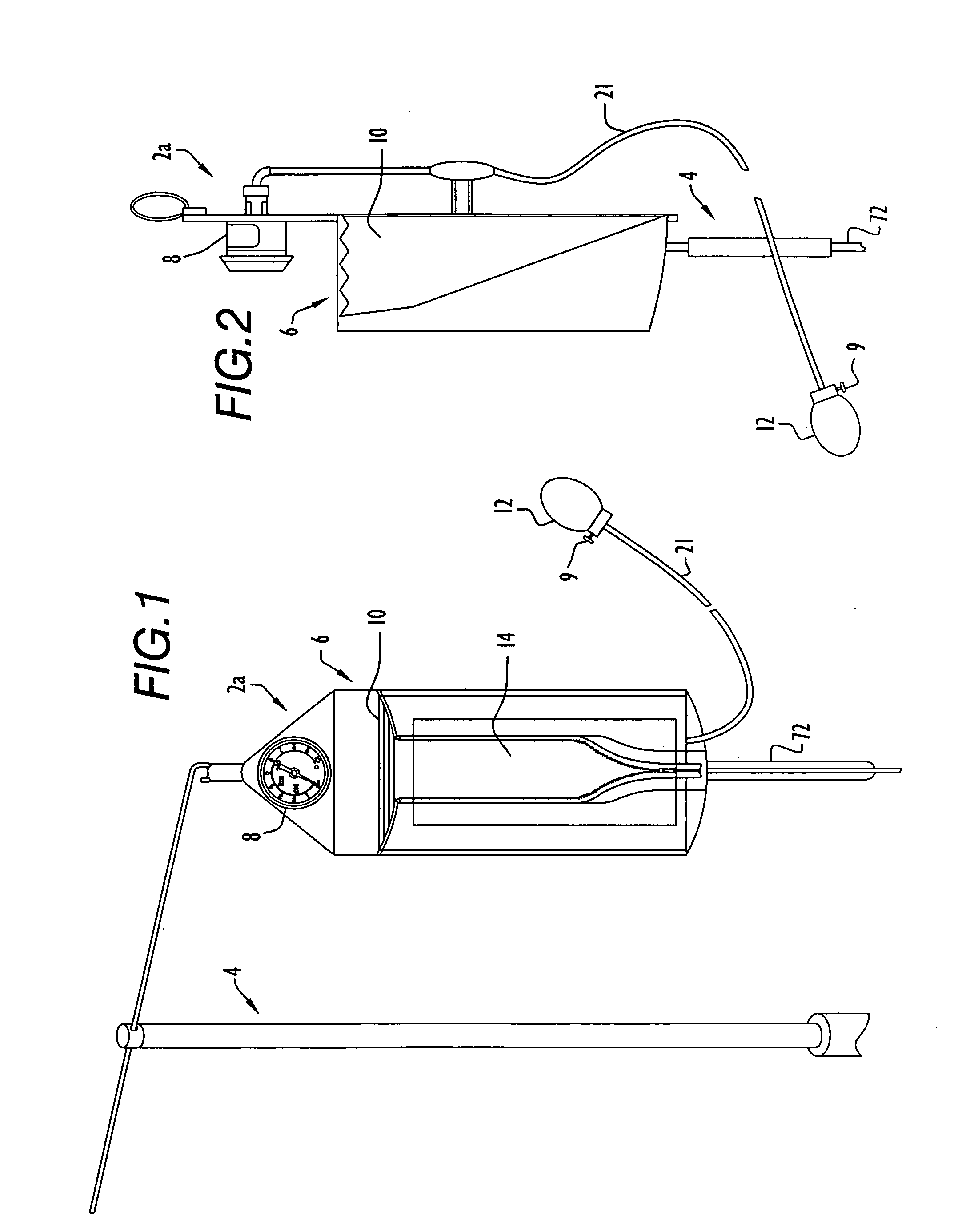

Method and apparatus for pressure infusion and temperature control of infused liquids

A method and apparatus for pressure infusion and temperature control of infused liquids includes a receptacle for receiving a liquid-filled bag containing intravenous solution or other liquid and an inflatable pressure device. The inflatable pressure device is disposed within a pressure device bag and is positioned proximate the liquid-filled bag in the receptacle. The inflatable pressure device expands within the pressure device bag upon inflation and exerts pressure on the liquid-filled bag. A heating element may be disposed on the inflatable pressure device bag to heat the liquid-filled bag to a desired temperature. The liquid may alternatively be maintained at a desired temperature, while flowing to a patient via a heating assembly disposed along a tube. The heating assembly includes a sleeve having a slot for receiving the tube and a plurality of individually controlled heaters. An infrared sensing device is mounted proximate a drip chamber to ascertain a drip count, while a temperature sensor is disposed within a holder that is positioned toward the entry site on a patient. A heat controller controls the heaters based on a drip count, while a safety controller disables heater operation in response to liquid temperature exceeding the desired temperature. Thus, the safety controller and heat controller, in combination, control the heating assembly heaters based on liquid temperature and flow rate, respectively. Alternatively, the liquid-filled bag may be heated to a desired temperature whereby the heating assembly includes a single heater controlled by a controller to maintain the liquid at the desired temperature during infusion of the liquid into a patient.

Owner:MEDICAL SOLUTIONS INC

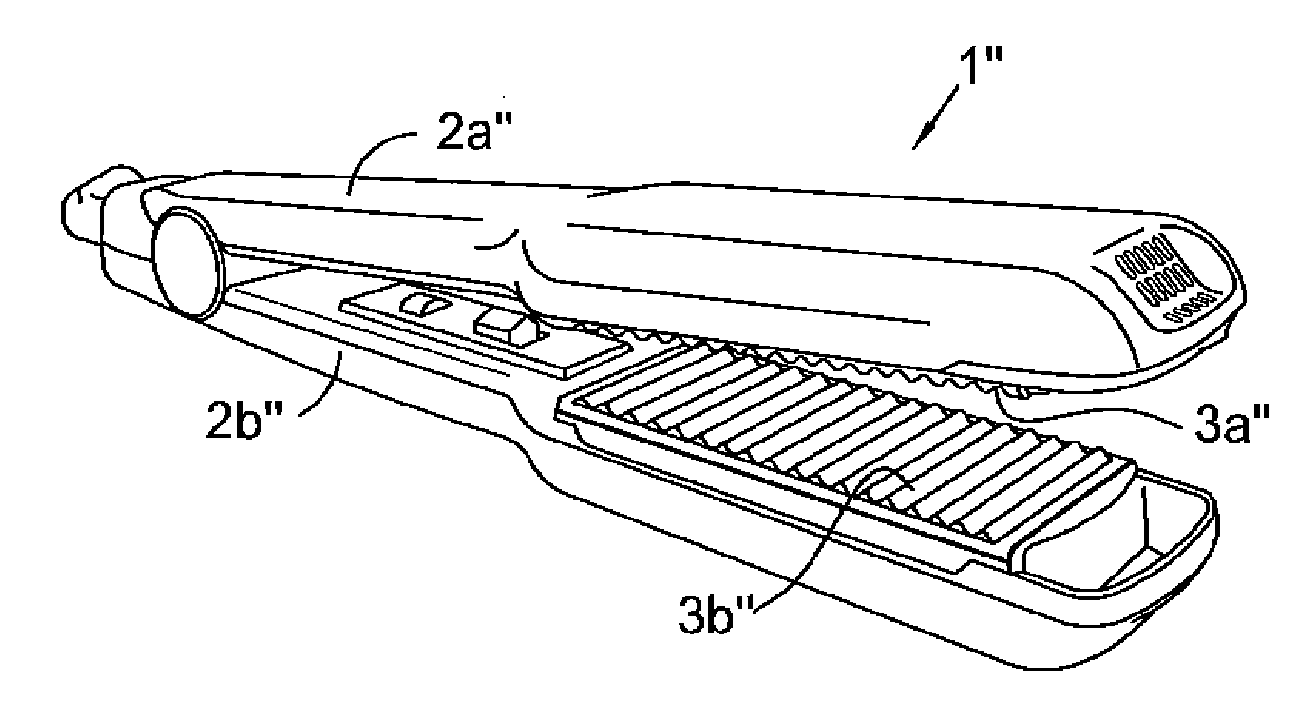

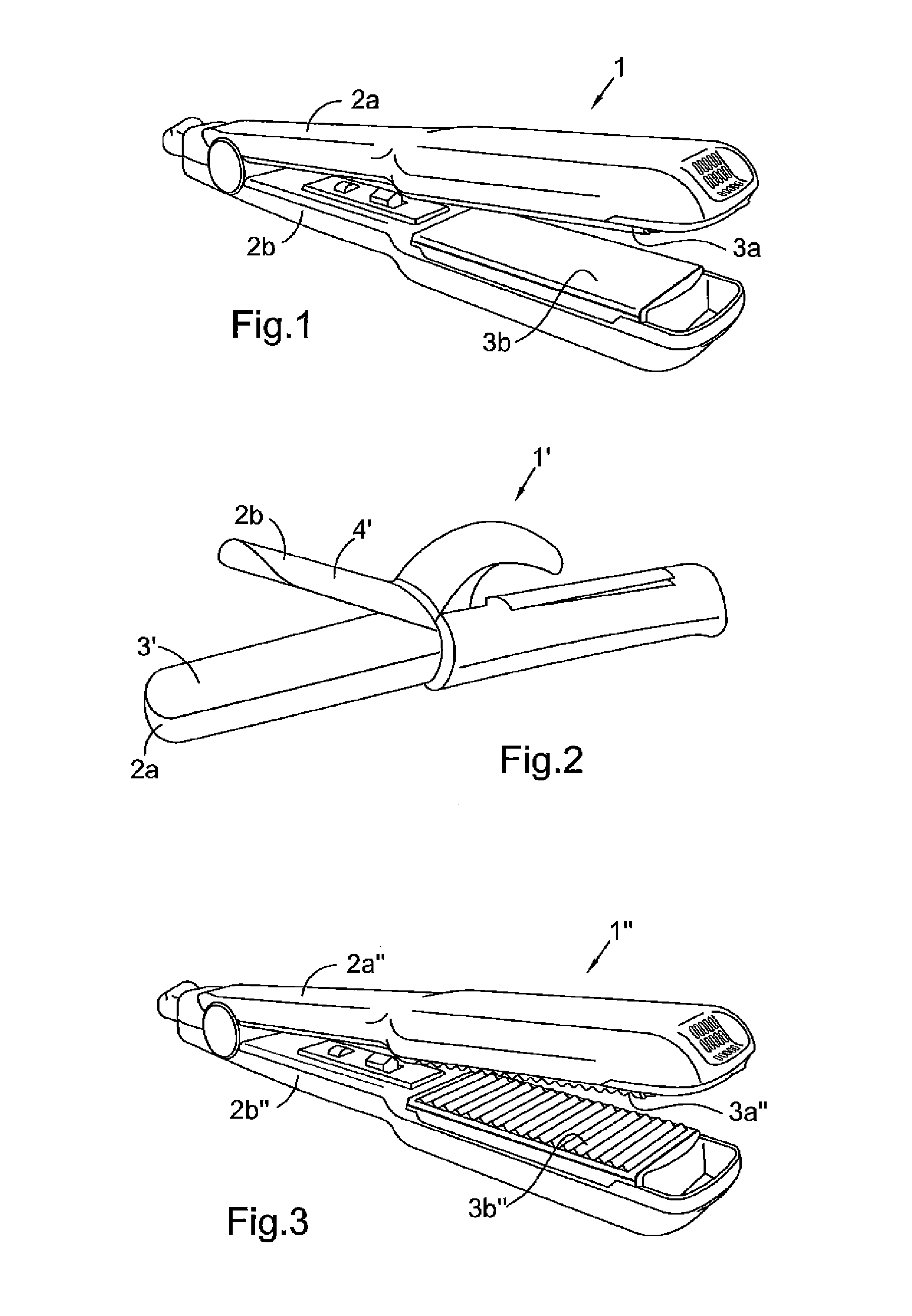

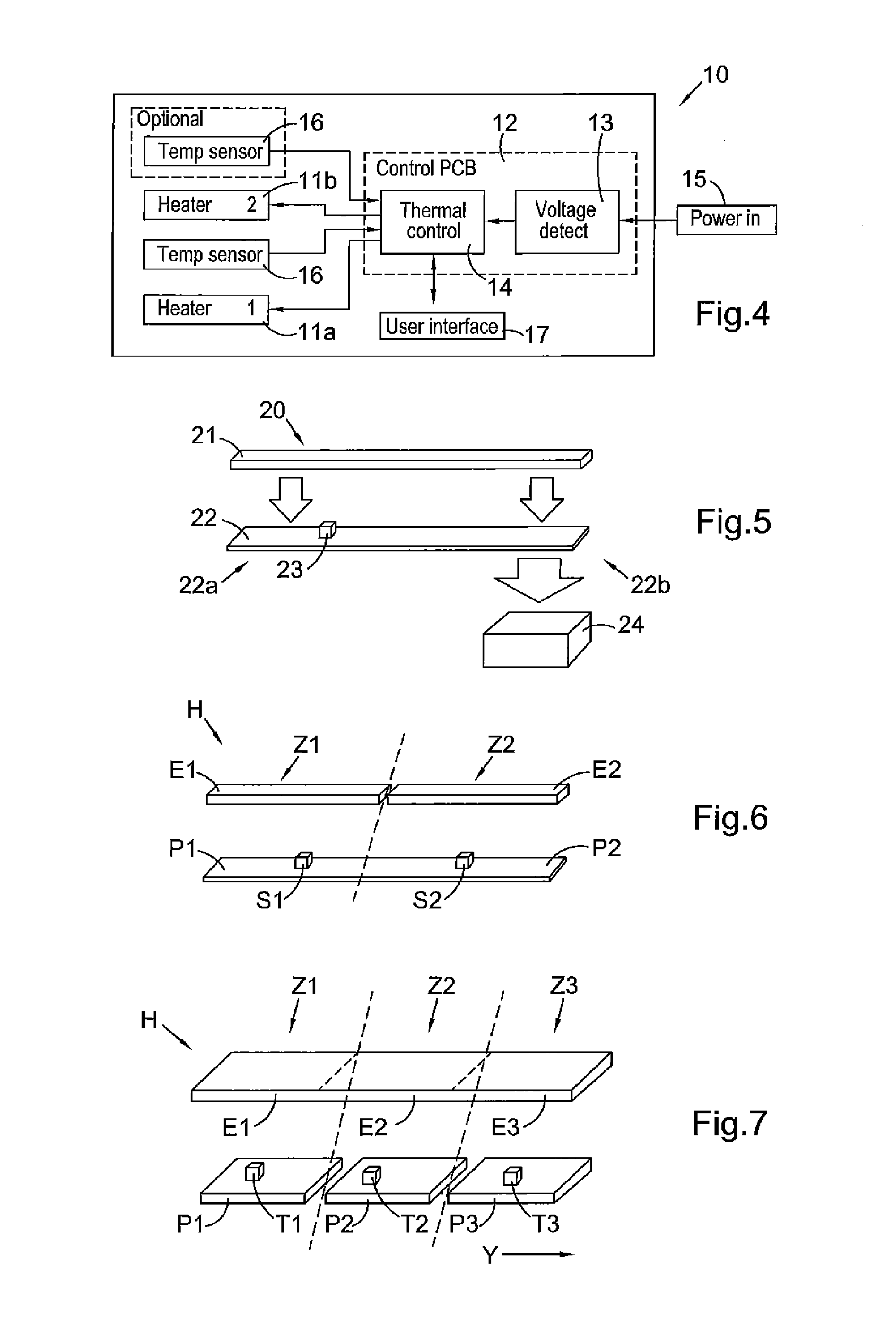

Hair styling appliance

ActiveUS20120227758A1Improve thermal controlUniform heating effectCurling-ironsCurling-tongsEngineeringThermal control

The invention relates to a hair styling appliance (100, 100′, 100″) comprising at least one heater (103, 104) having plurality of heating zones (Z1-Z5). The heating zones are independently operable arranged along the length of the heater. The sequential arrangement of the independently operable heating zones helps to improve the thermal control of the hair styling appliance. The hair styling appliance may be a hair straightener, curling tong, curling wand or a crimping iron.

Owner:JEMELLA

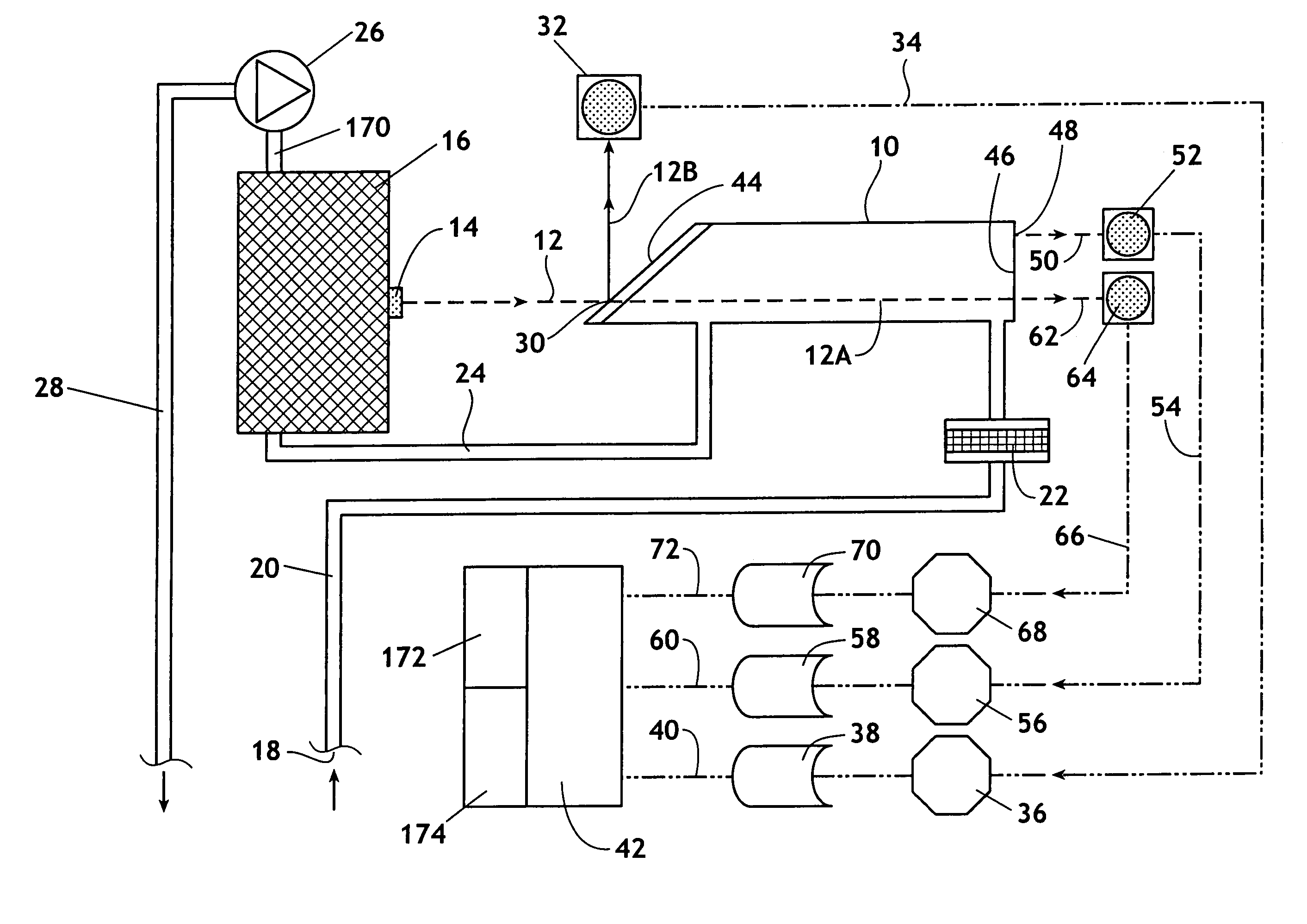

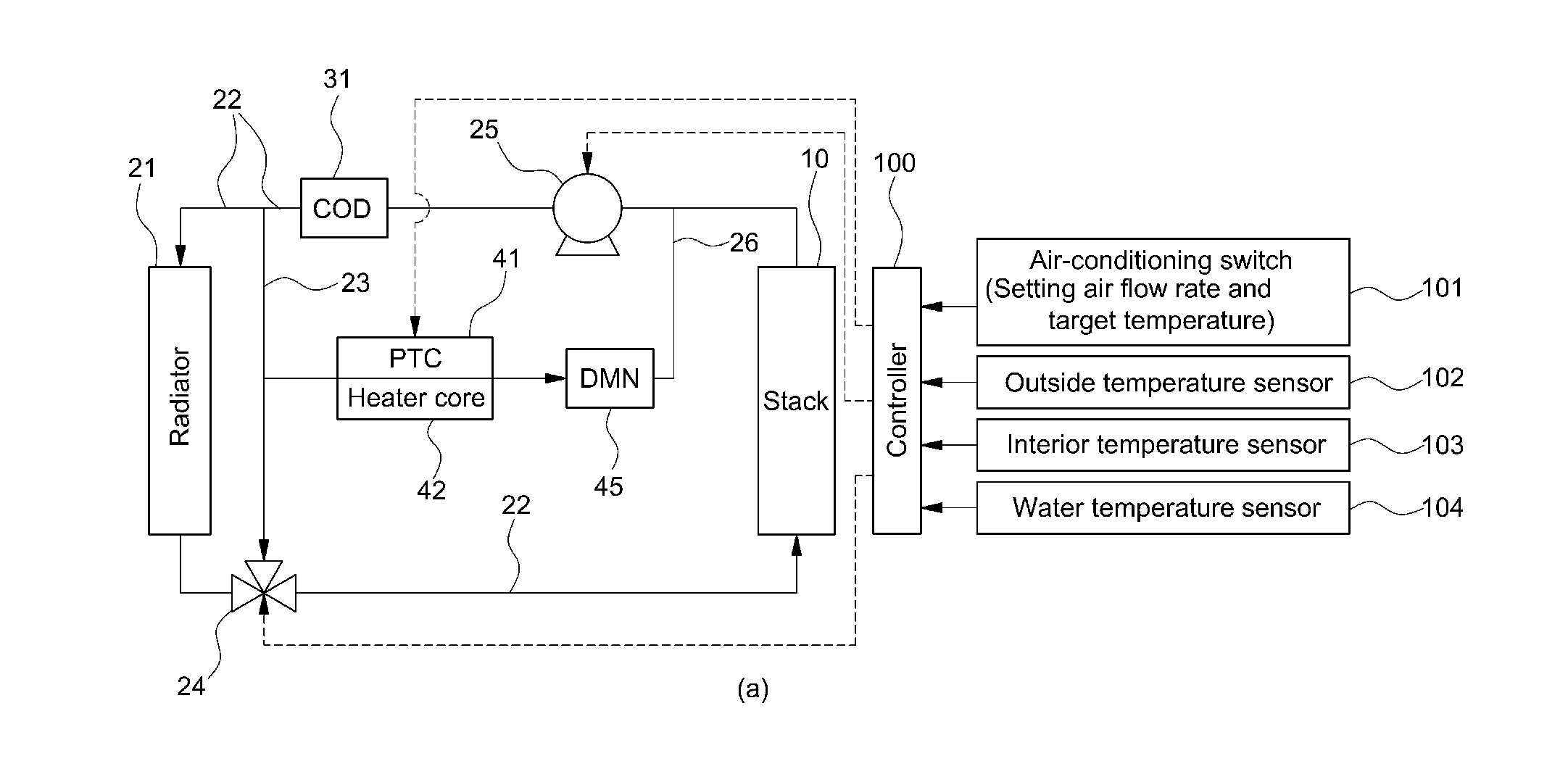

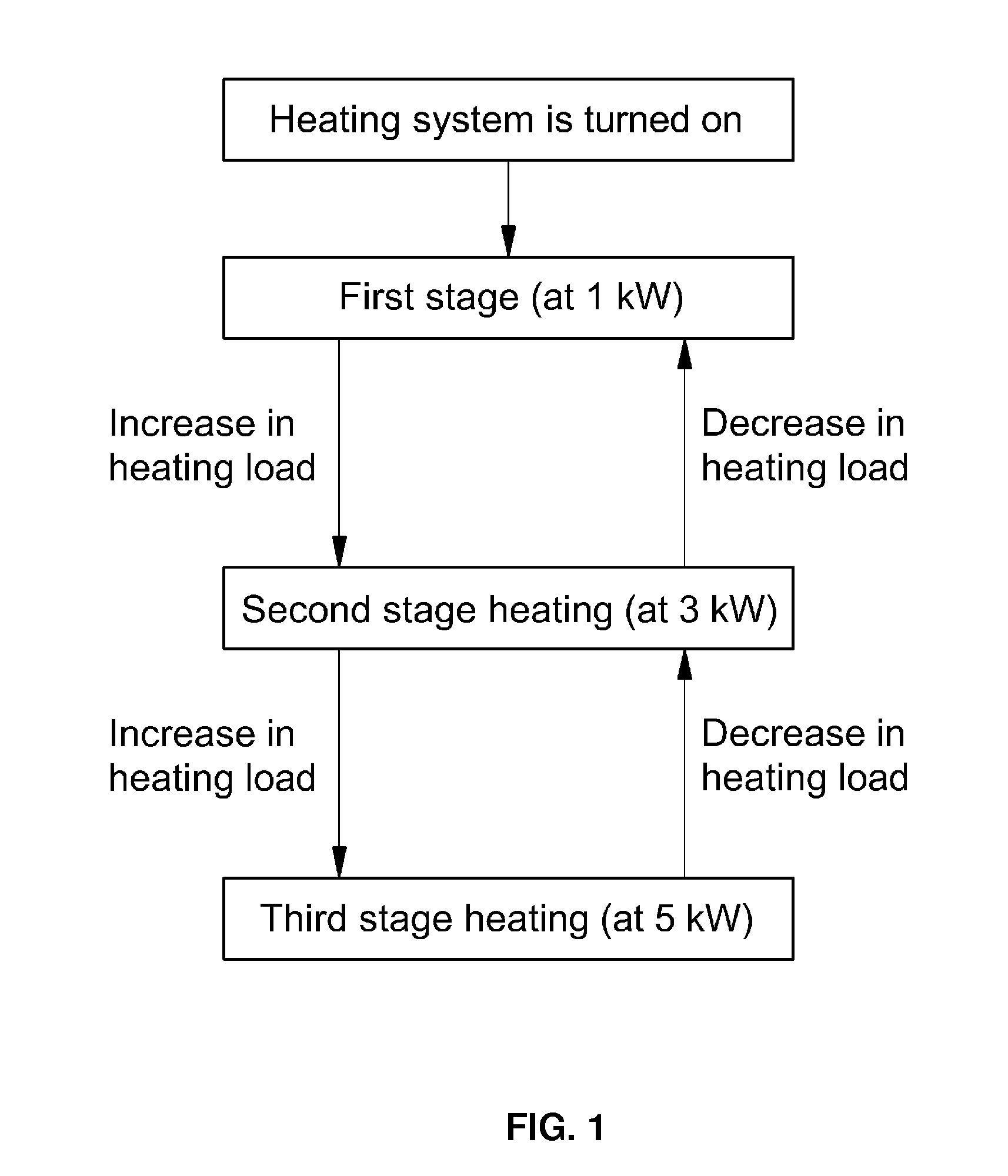

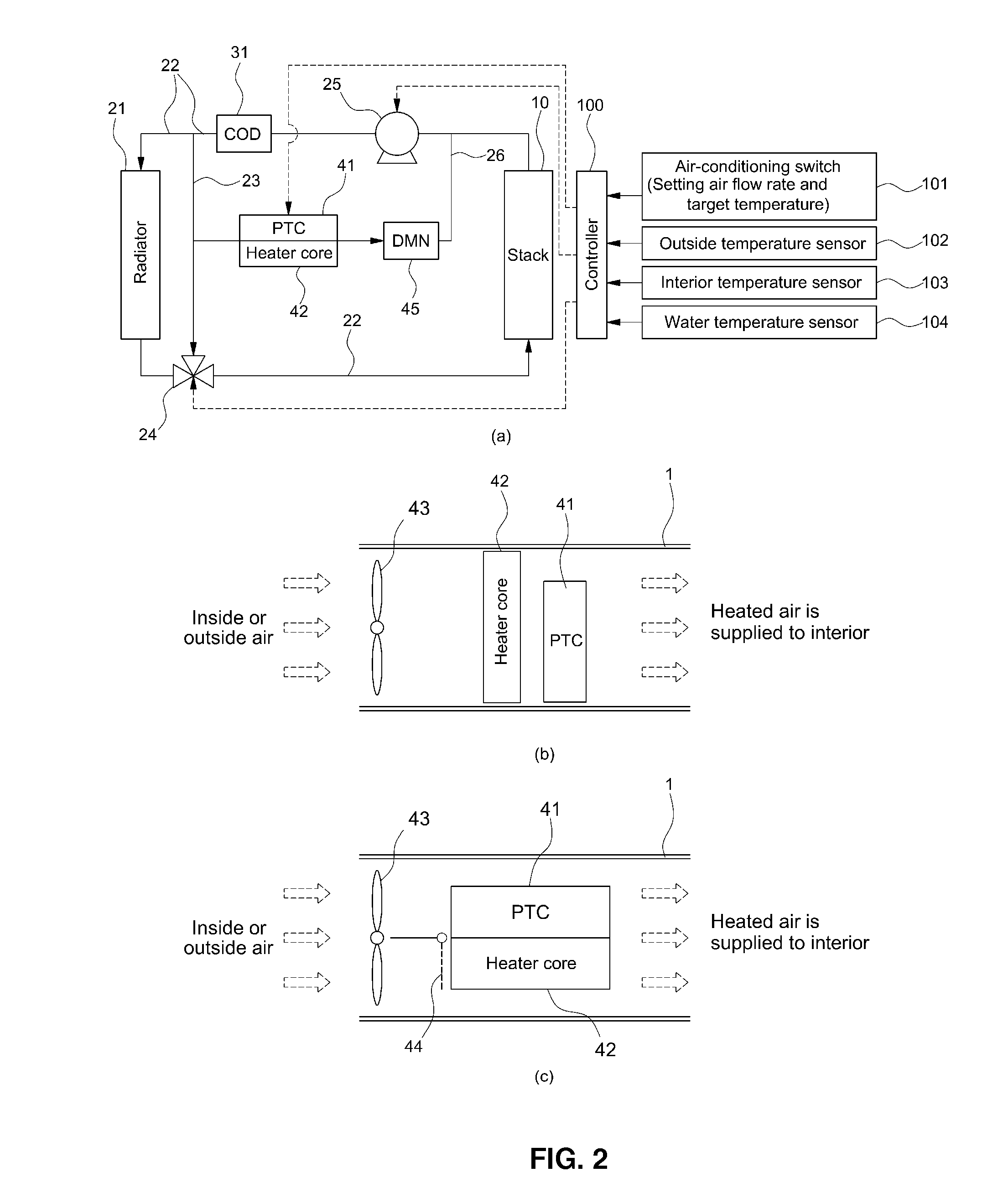

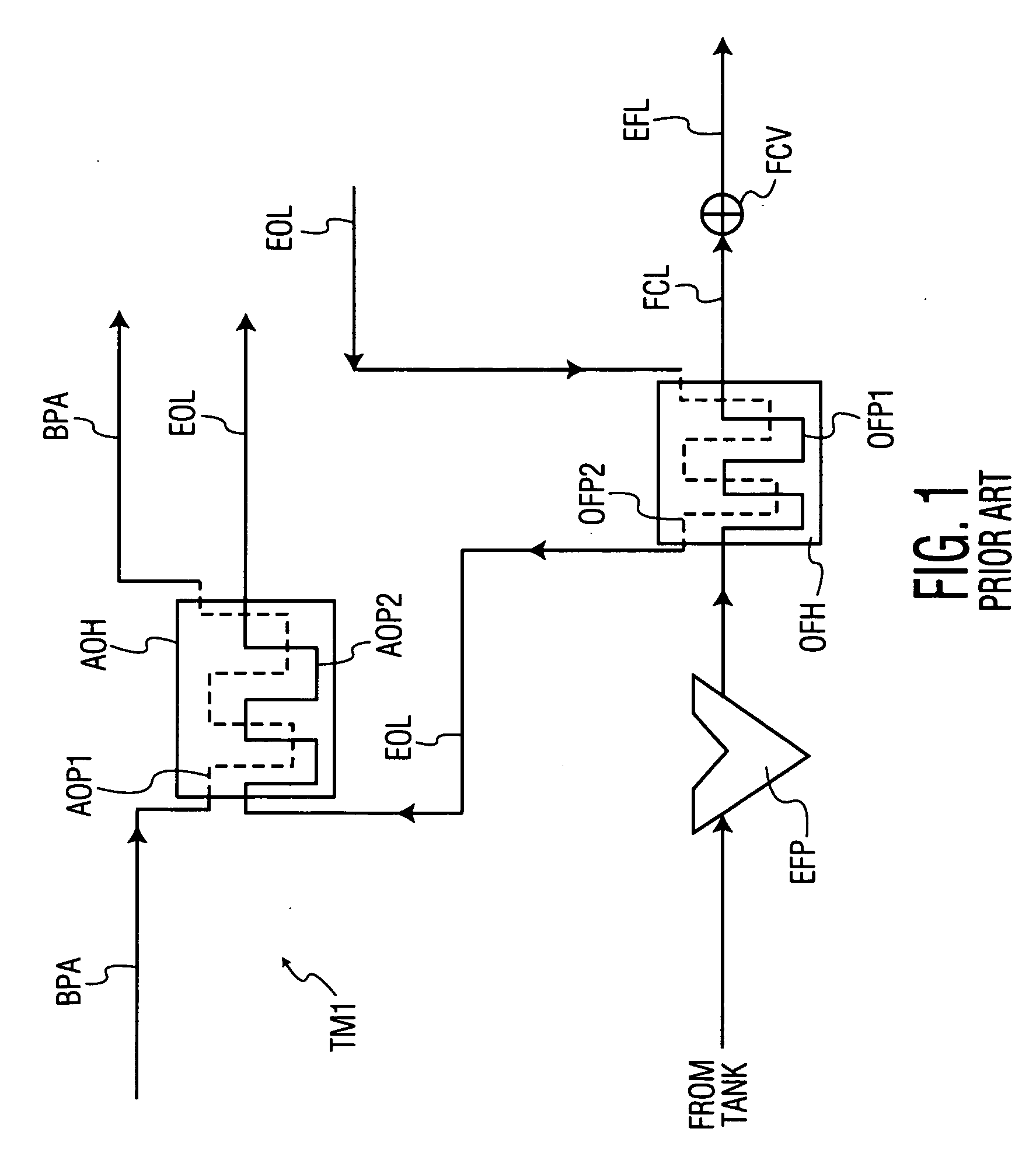

Heating control method for fuel cell vehicle

ActiveUS20120122000A1Reduce power consumptionImprove fuel efficiencyAir-treating devicesFuel cell auxillariesLower limitFuel cells

The present invention provides a heating control method for a fuel cell vehicle, in which an additional heating source is used together with a typical electric heater to reduce power consumption and increase fuel efficiency as compared to the sole use of the electric heater. For this purpose, the present invention provides a heating control method for a fuel cell vehicle which comprises an electric heater for heating air supplied to the interior of the vehicle, and a heater core provided in a coolant line for cooling a fuel cell stack and heating the air supplied to the interior of the vehicle by heat exchange with the coolant discharged from the fuel cell stack. The method comprises: detecting a state of charge (SOC) of a battery when the interior temperature is lower than a predetermined temperature set by a driver and, if the SOC of the battery is above a predetermined lower limit, heating the interior of the vehicle by operating the electric heater by the power of a battery; heating the interior of the vehicle by operating the electric heater by the power generated by the fuel cell stack, if the SOC of the battery is below the lower limit; heating the interior of the vehicle using both the heater core and the electric heater, if the temperature of the coolant is above a predetermined temperature at which the fuel cell stack does not reach a normal operating temperature; and heating the interior of the vehicle using only the heater core while turning off the electric heater, if the temperature of the coolant is increased above a normal operating temperature of the fuel cell stack.

Owner:HYUNDAI MOTOR CO LTD +1

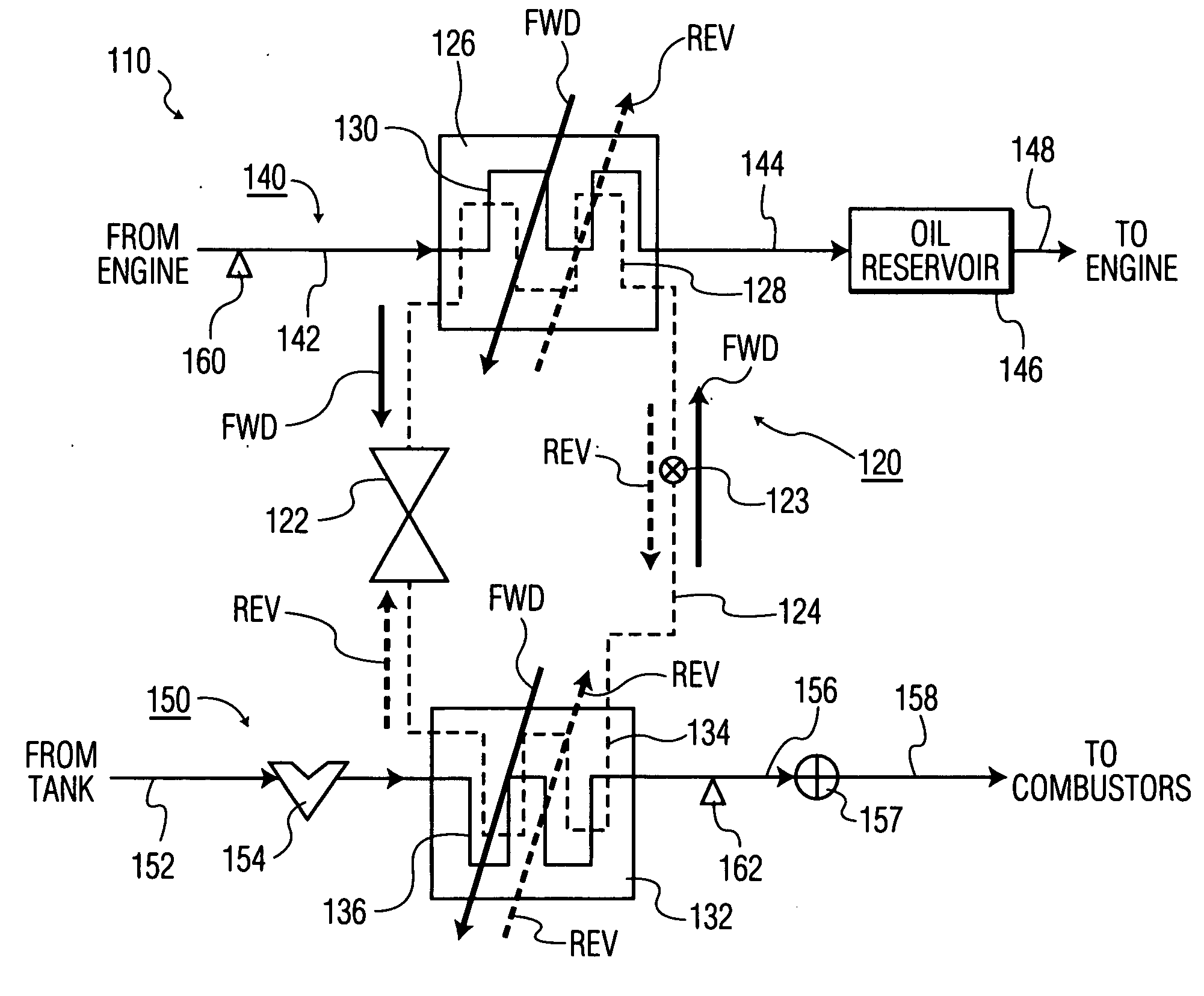

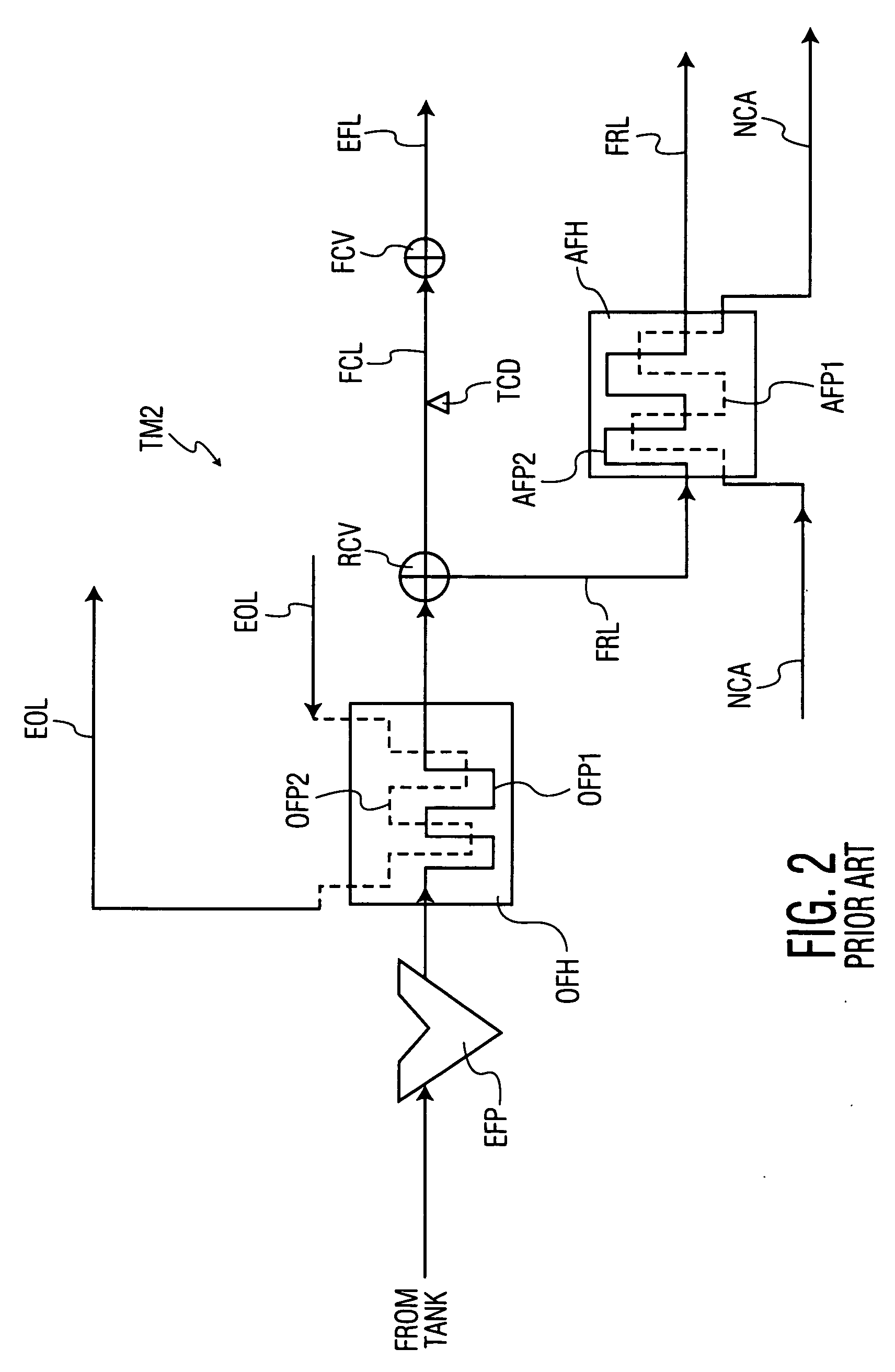

Systems and methods for thermal management in a gas turbine powerplant

InactiveUS20100107603A1Minimize impactReduce coke depositionAnalogue computers for vehiclesTurbine/propulsion engine coolingWorking fluidThermal management system

A thermal management system for a gas turbine powerplant with an engine oil line and an engine fuel line incorporates a heat transfer control module that includes a reversible heat pump with a heat pump compressor for circulating working fluid in forward and reverse directions through a working fluid line of the heat pump. The heat control module also includes a first heat exchanger having a heat exchange path for the working fluid between the compressor and a heat pump expansion valve and another heat exchange path for the engine oil. A second heat exchanger has a heat exchange path for the working fluid between the compressor and the expansion valve and another heat exchange path for the engine fuel. The heat pump can be operated in forward or reverse directions depending on whether heat is to be transferred from the engine oil or the fuel to the heat pump working fluid. In another embodiment an engine oil reservoir located between the first heat exchanger and the engine collects the oil before it is introduced to the engine and thus acts as a heat capacitor for the system.

Owner:PROPULSION GAS TURBINE & ENERGY EVALUATIONS

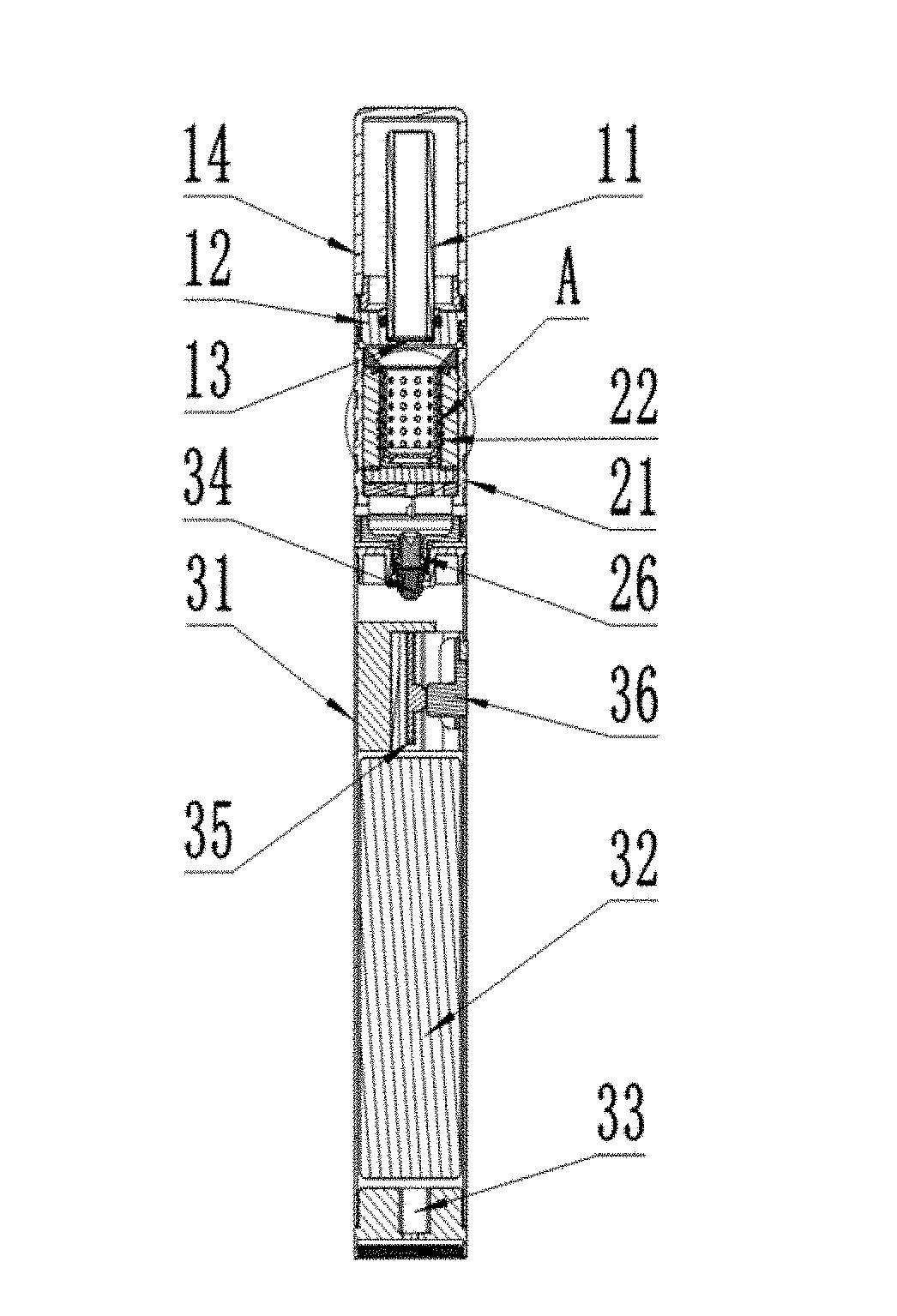

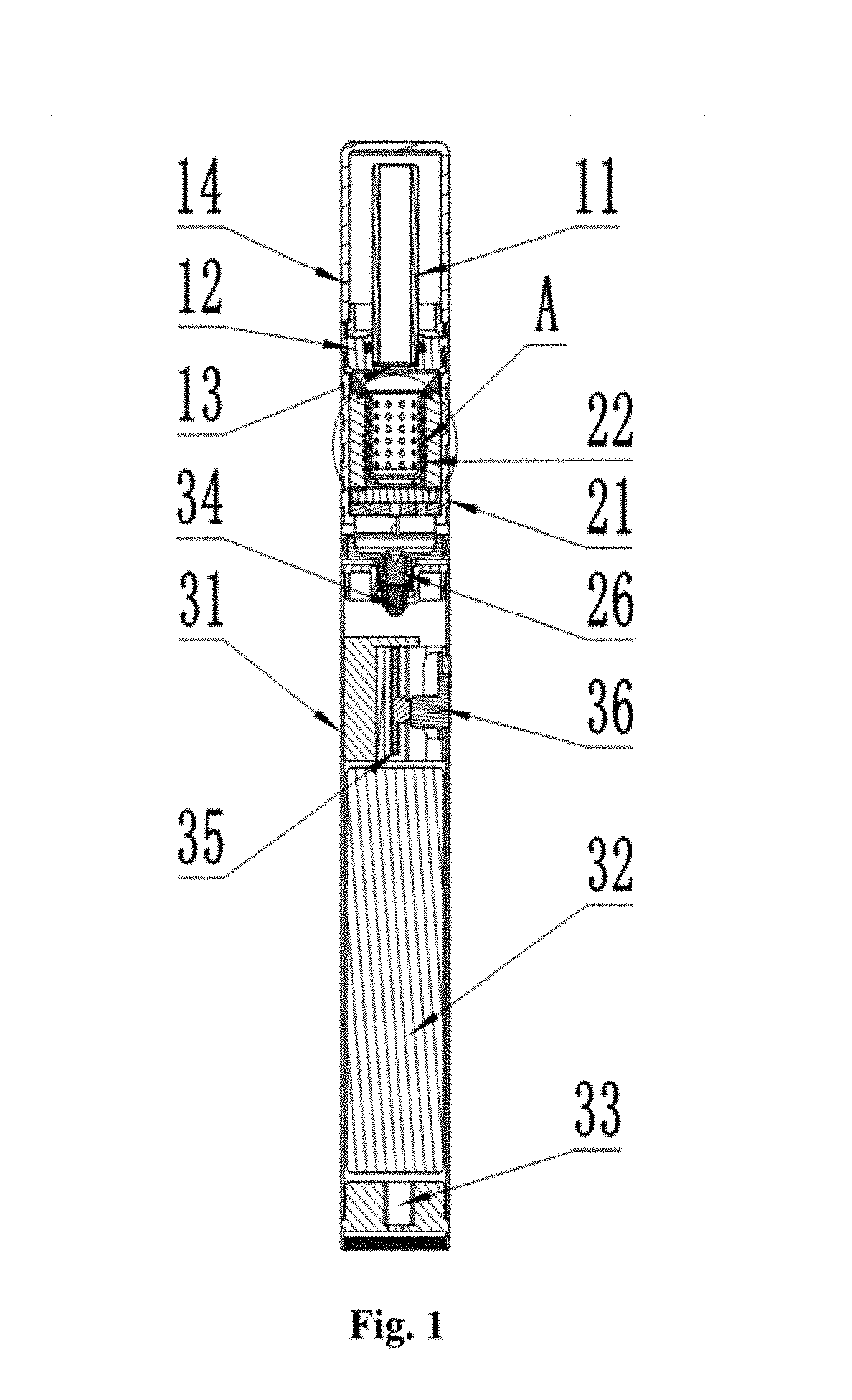

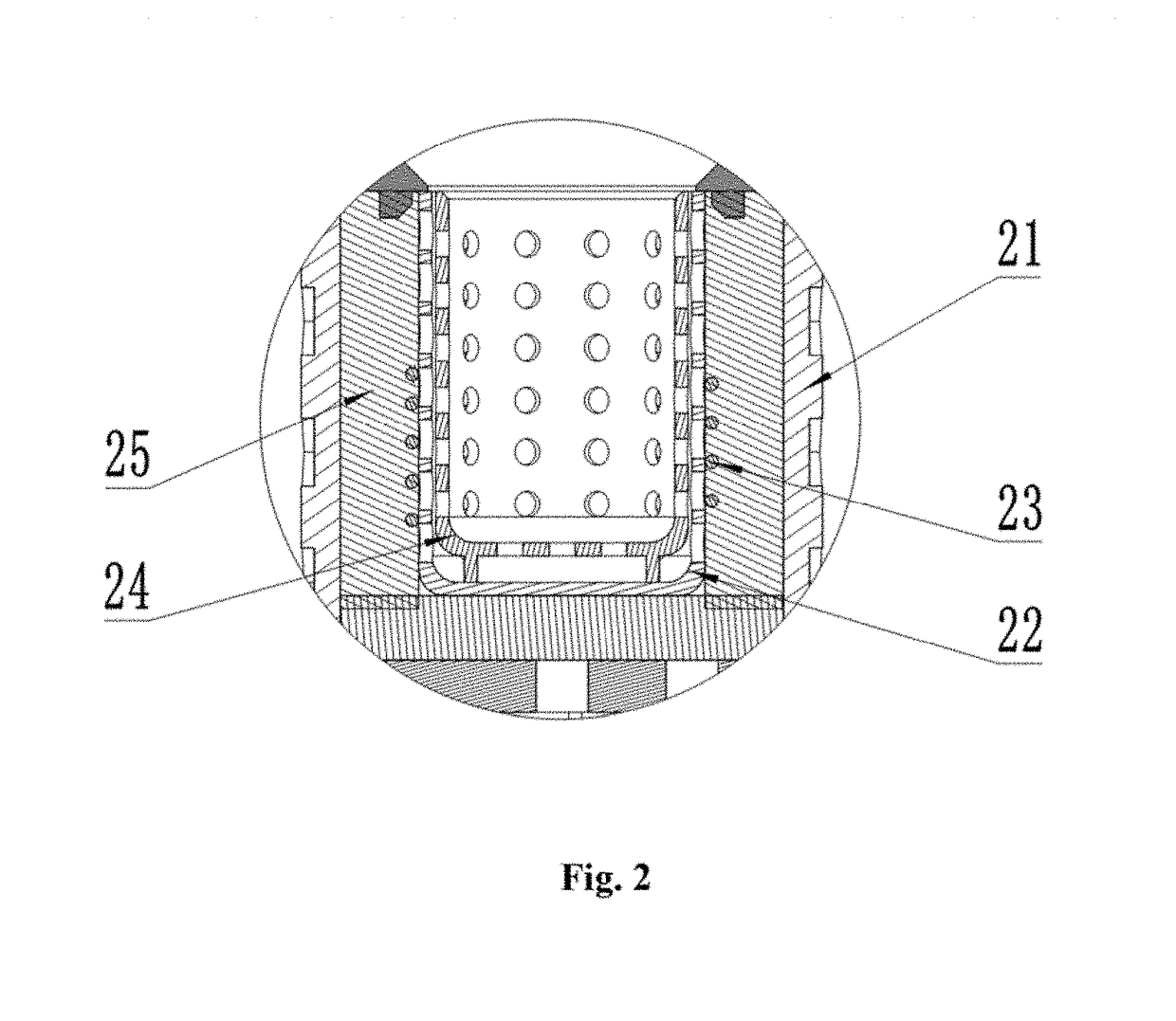

Annular stereoscopic-heating electronic cigarette with replaceable inner container

InactiveUS20170215474A1Evenly heatedProlonging smoking timeProgramme controlTobacco pipesNickel cadmiumEngineering

This invention provides an annular stereoscopic-heating electronic cigarette with replaceable inner container, comprising: a cylindrical electronic cigarette body; the electronic cigarette body comprises a smoke-filtering member, an annual stereoscopic-heating member and a heat-controlling member; wherein: the annual stereoscopic-heating member comprises an annual stereoscopic-heating casing, and an openwork member for conducting heat. A nickel cadmium (Ni-Cd) heating coil is spirally wind around and firmly contacts the exterior surface of the open member. A replaceable shredded tobacco inner container is sleeved within the openwork member. The exterior of the Ni-Cd heating coil and the bottom of the openwork member are respectively wrapped around by an asbestos heat-insulating layer. A short-circuit contactor is set at the bottom of the annular stereoscopic-heating casing and connects to the Ni-Cd beating coil.

Owner:LRIDER TECH CO LTD

Heating control method and device for electronic cigarette

InactiveCN104026742AAffect the taste of smokingDoes not affect the atomization effectTobacco devicesConstant powerProcess engineering

Owner:HUIZHOU KIMREE TECH

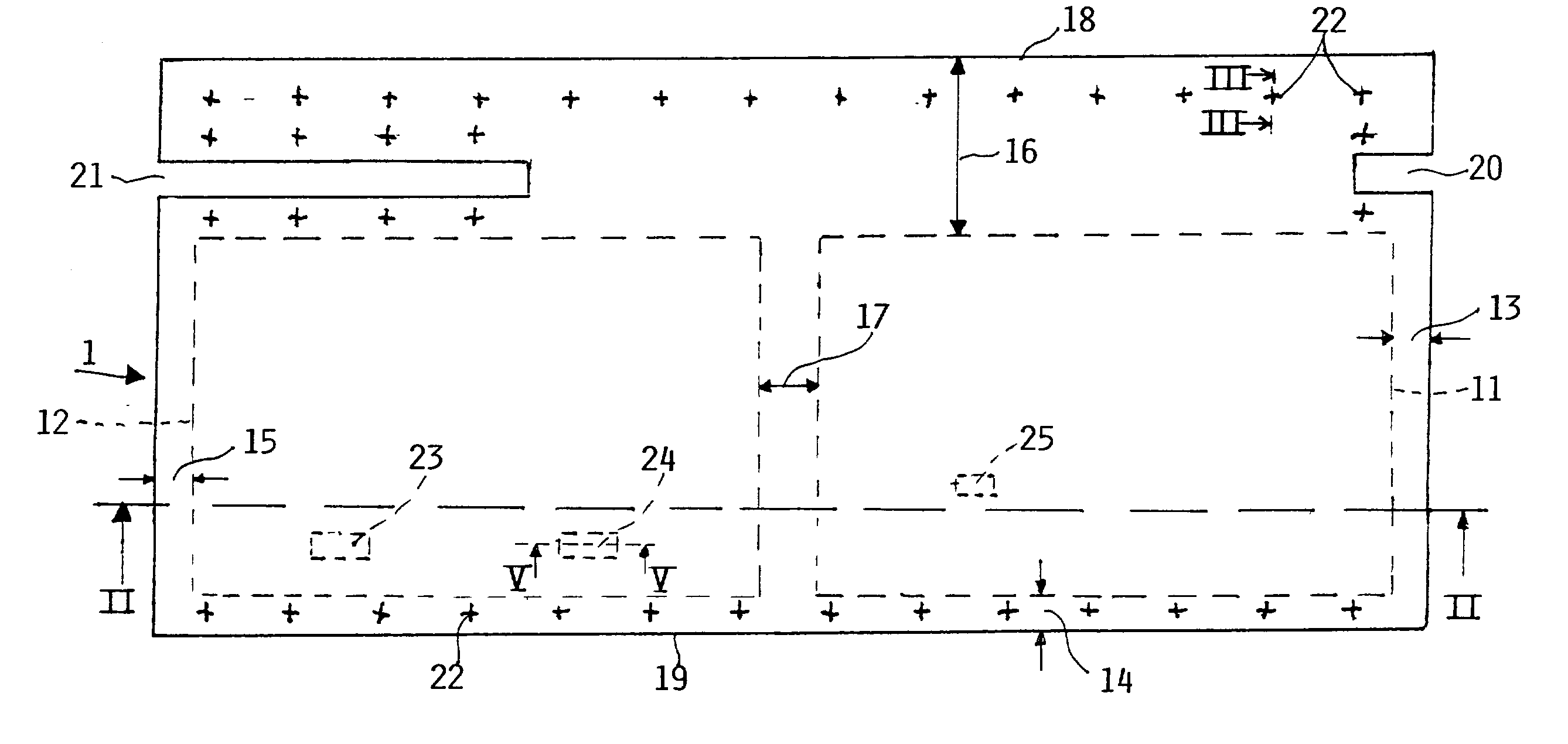

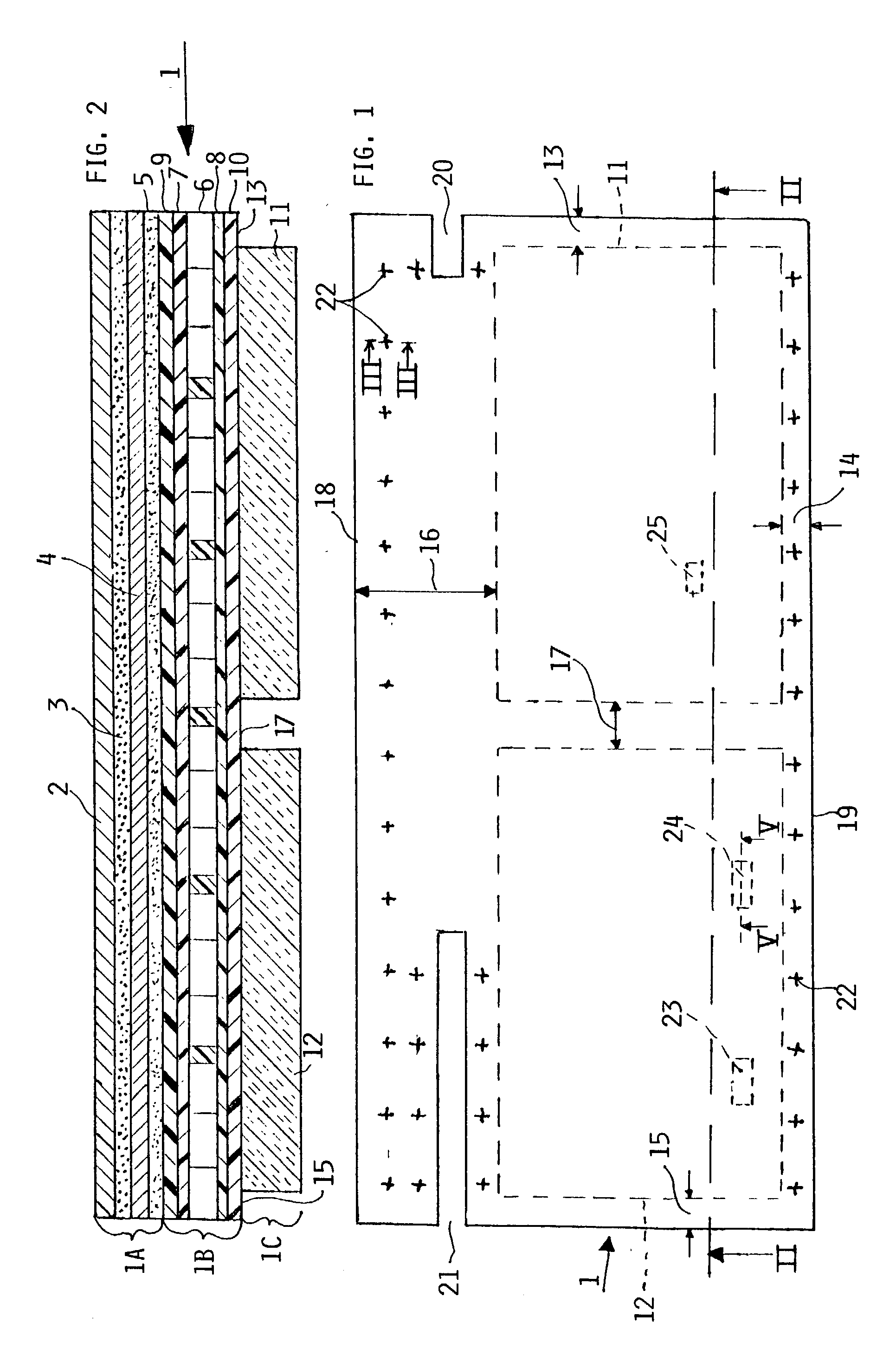

Electrically heated aircraft composite floor panel

InactiveUS6611659B2Reduce consumptionReduce weightFluid heatersElectric heating systemGlass fiberFiber-reinforced composite

An aircraft floor heating panel is constructed for mechanical strength and to meet special heating requirements next to a door in an aircraft. The panel has a lightweight core. Each surface of the core is first covered with at least one carbon-fiber reinforced composite layer for protection against deterioration. Each carbon fiber layer in turn is covered by a glass fiber reinforced composite layer for mechanical strength. A foil heater is arranged inside the composite panel coextensive with at least a portion of the panel area. A heat distributing metal plate covers the panel as an upper step-on surface. A heat insulating layer is bonded to the panel opposite the heat distributing metal plate. A triple heat control is provided for an increased safety against fire hazards.

Owner:AIRBUS OPERATIONS GMBH

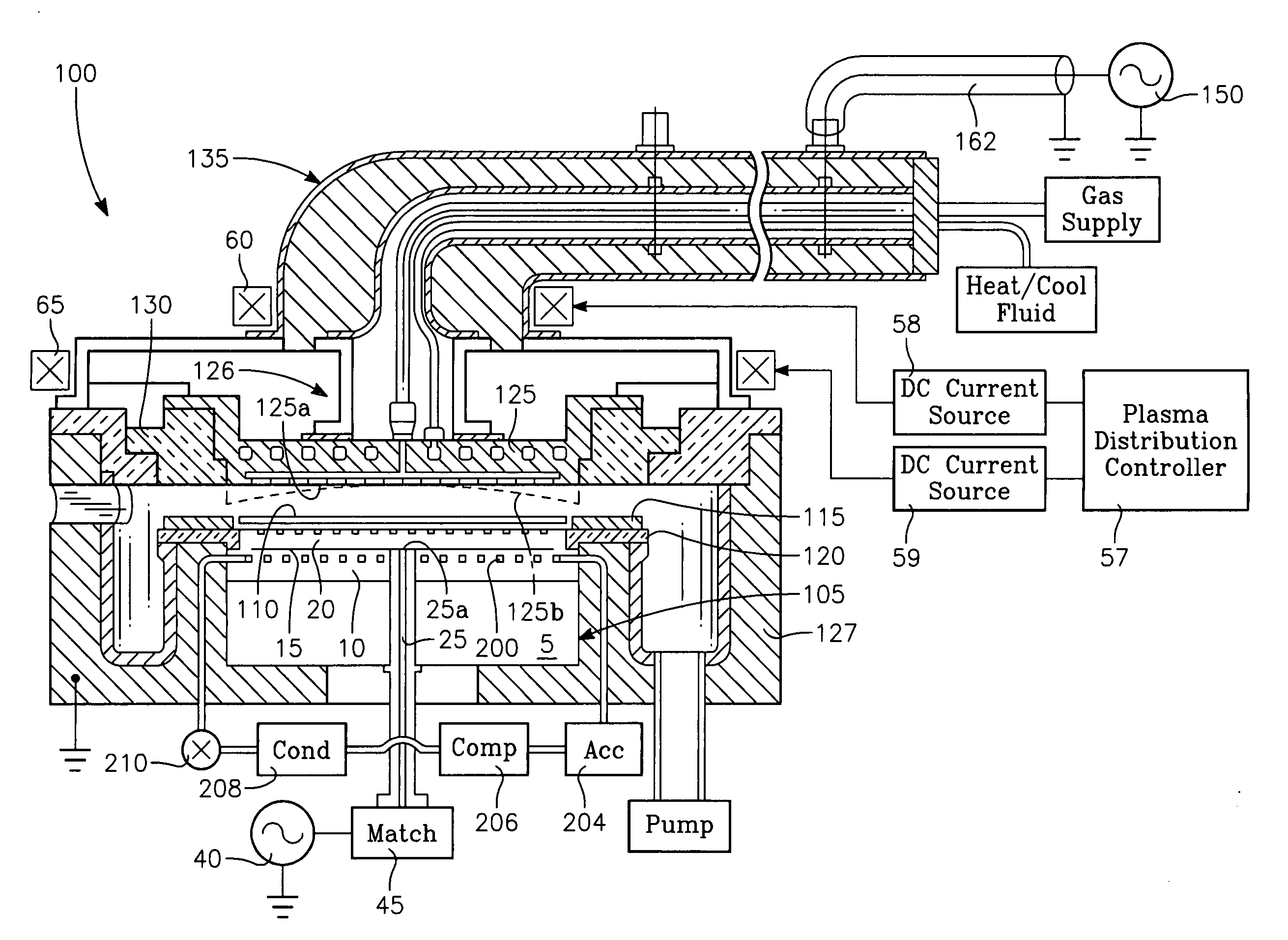

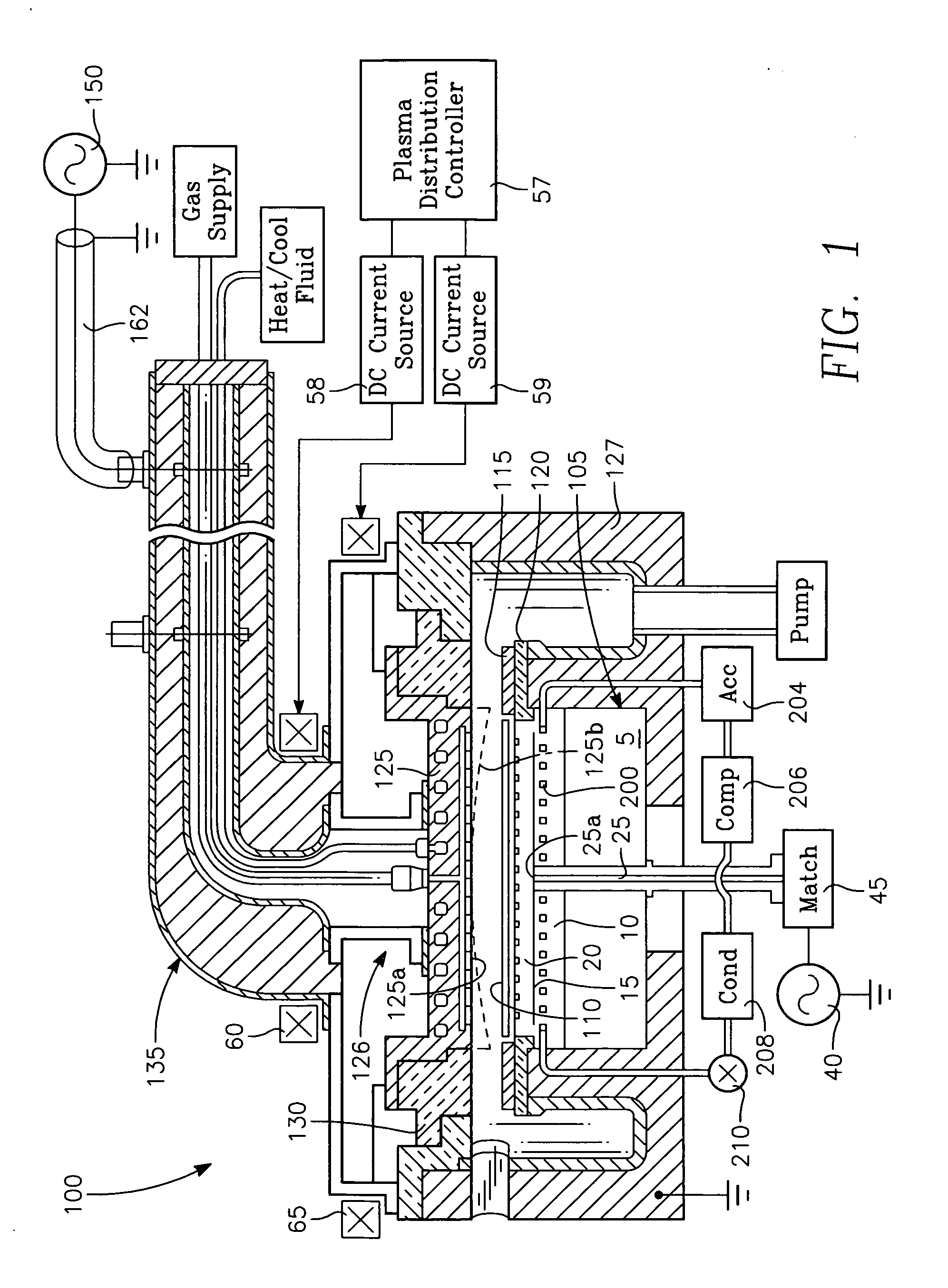

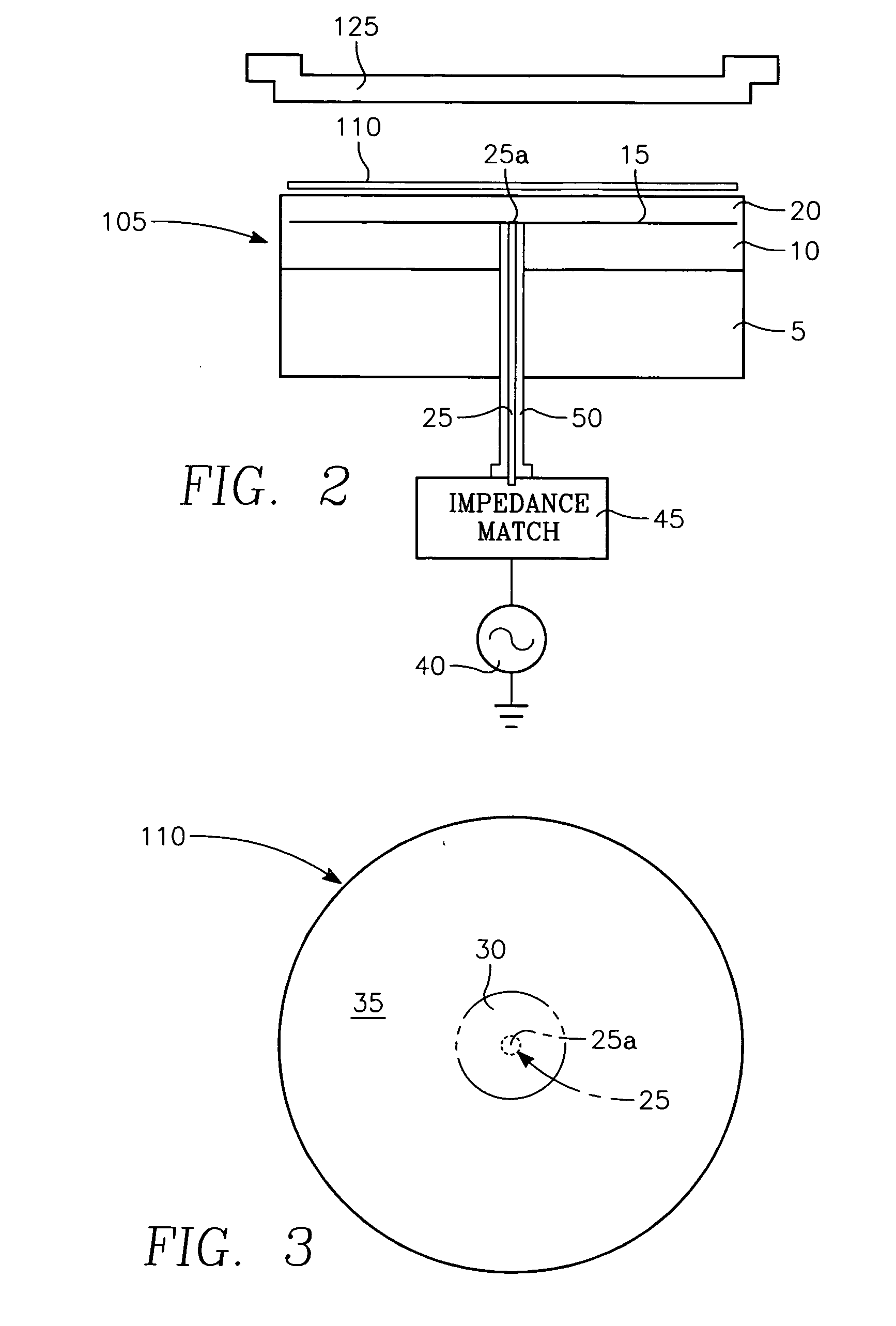

Capacitively coupled plasma reactor having very agile wafer temperature control

ActiveUS20070081294A1Promote fillingLiquid surface applicatorsSemiconductor/solid-state device manufacturingCapacitanceProcess engineering

A plasma reactor for processing a workpiece includes a reactor chamber, an electrostatic chuck within the chamber having a top surface for supporting a workpiece and having indentations in the top surface that form enclosed gas flow channels whenever covered by a workpiece resting on the top surface. The reactor further includes thermal control apparatus thermally coupled to the electrostatic chuck, an RF plasma bias power generator coupled to apply RF power to the electrostatic chuck, a pressurized gas supply of a thermally conductive gas, a controllable gas valve coupling the pressurized gas supply to the indentations to facilitate filling the channels with the thermally conductive gas for heat transfer between a backside of a workpiece and the electrostatic chuck at a heat transfer rate that is a function of the pressure against the backside of the workpiece of the thermally conductive gas. The reactor further includes an agile workpiece temperature control loop including (a) a temperature probe in the electrostatic chuck, and (b) a backside gas pressure controller coupled to an output of the temperature probe and responsive to a specified desired temperature, the controller governing the gas valve in response to a difference between the output of the temperature probe and the desired temperature.

Owner:BE AEROSPACE INCORPORATED

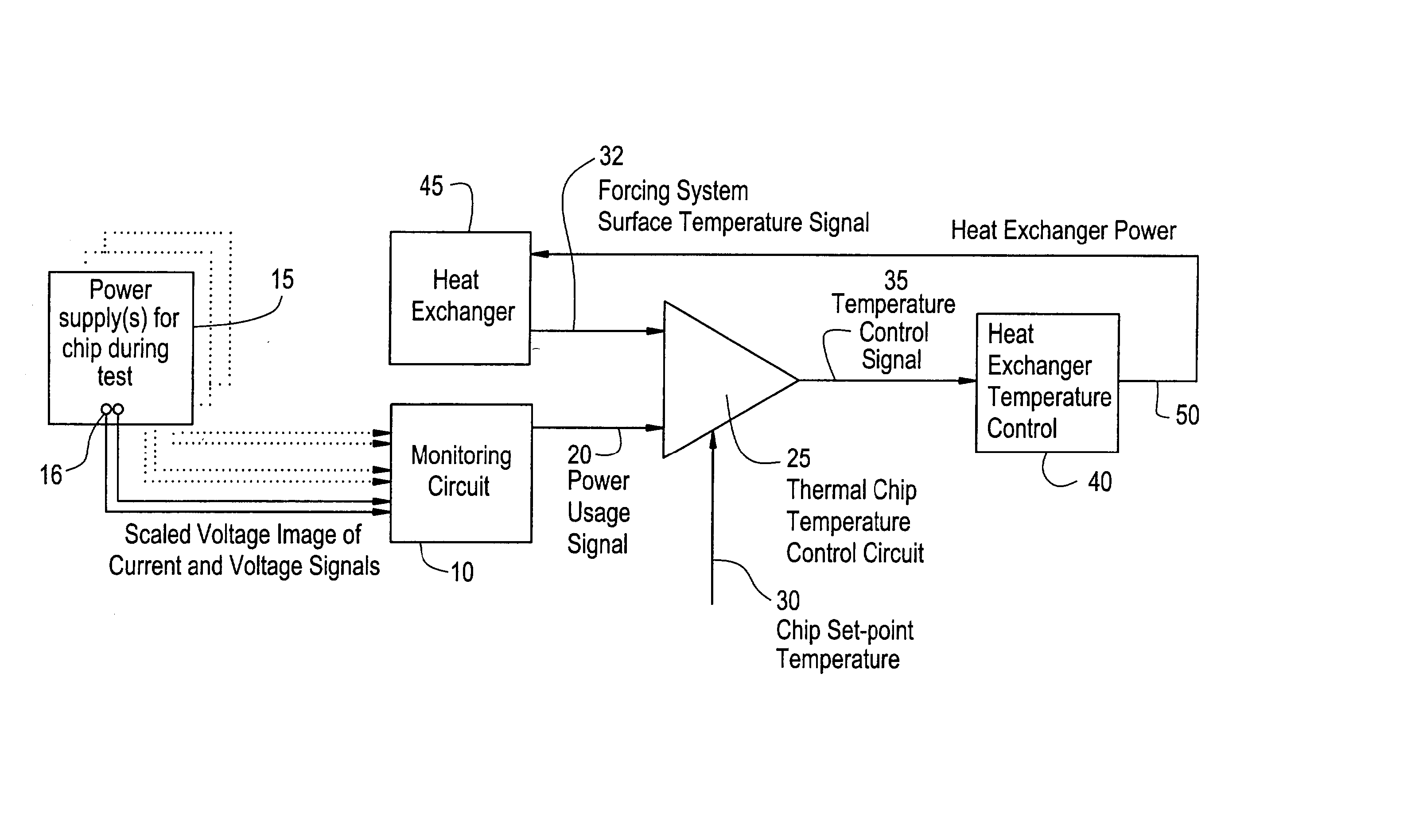

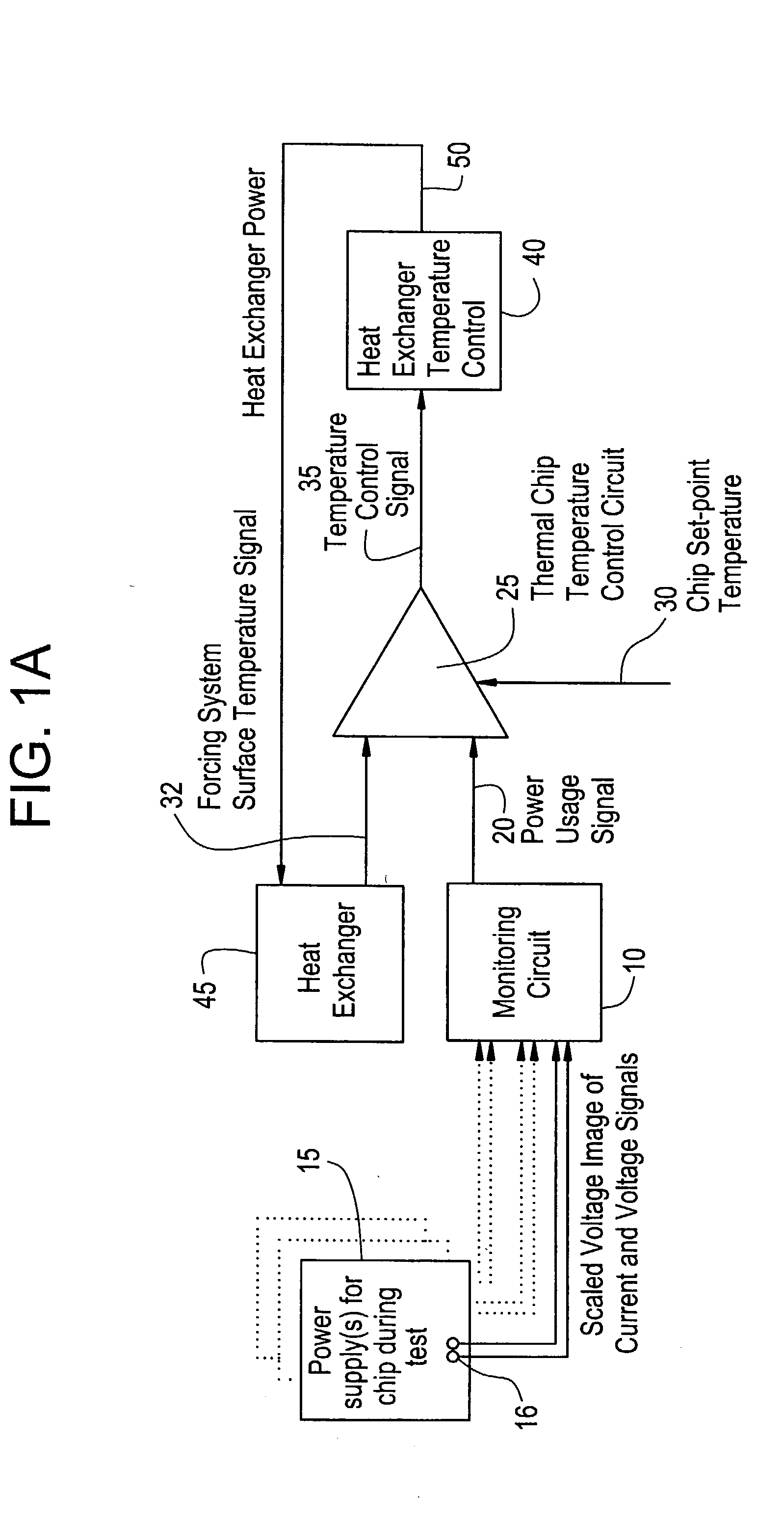

Temperature control of electronic devices using power following feedback

InactiveUS20030001605A1Temperatue controlSemiconductor/solid-state device detailsTemperature controlEquipment temperature

A system and method for controlling a temperature of a device during testing with a thermal controller and a heat exchanger includes measuring an instantaneous power consumption of the device during testing. The heat exchanger is controlled with the thermal controller using the measured instantaneous power consumption by the device to regulate the temperature of the device during testing, wherein the heat exchanger is in conductive contact with the device.

Owner:DELTA DESIGN

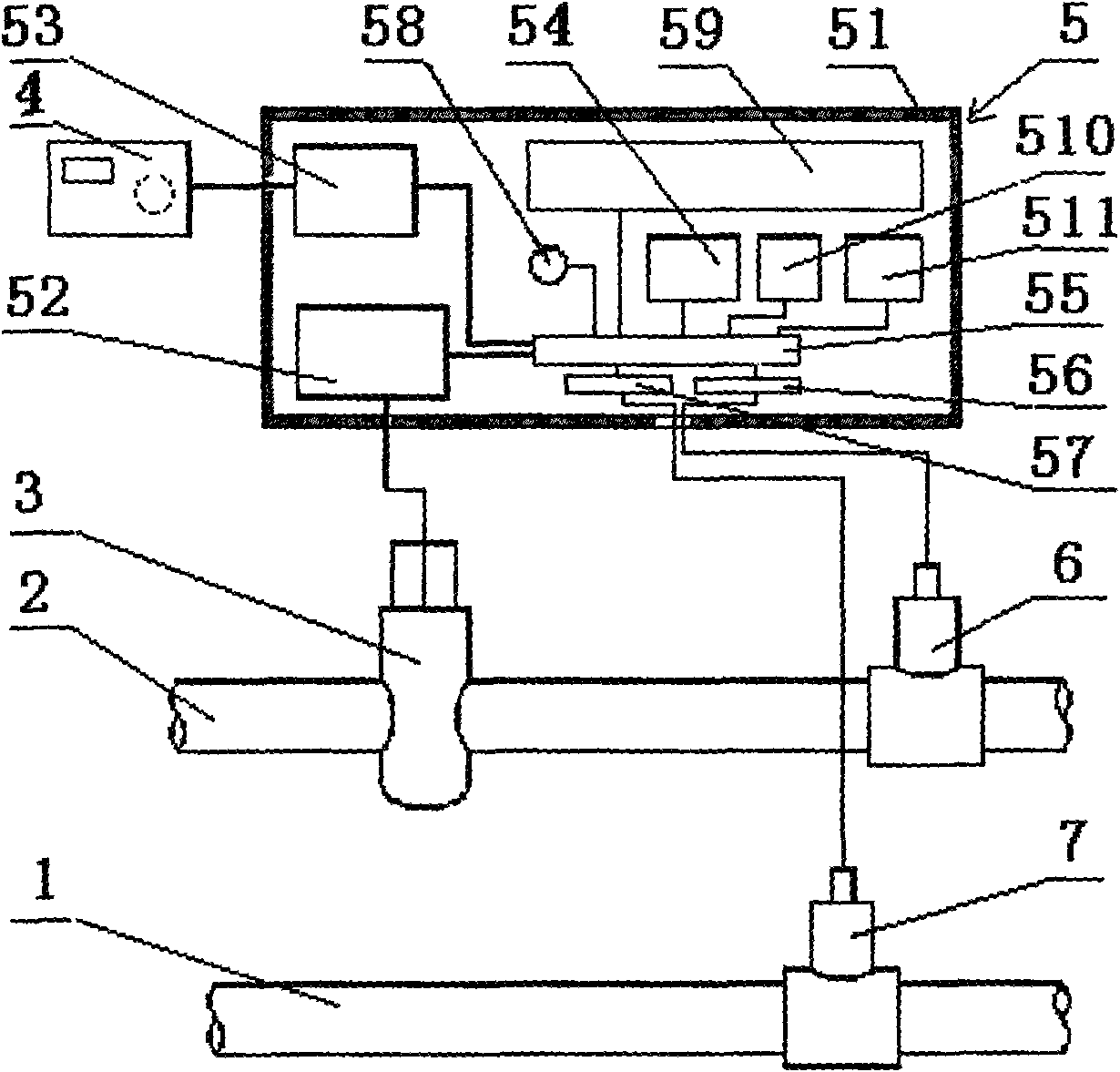

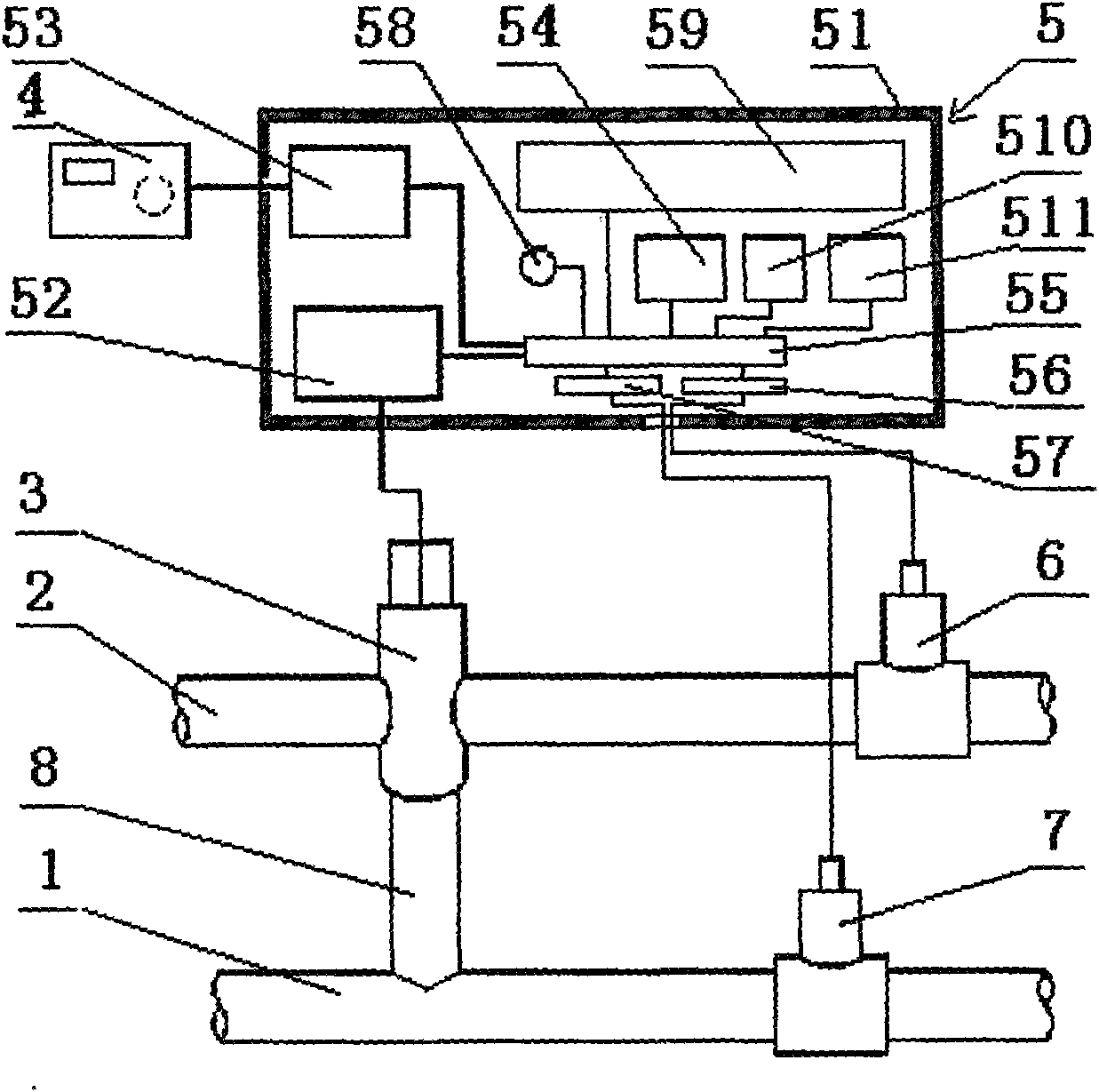

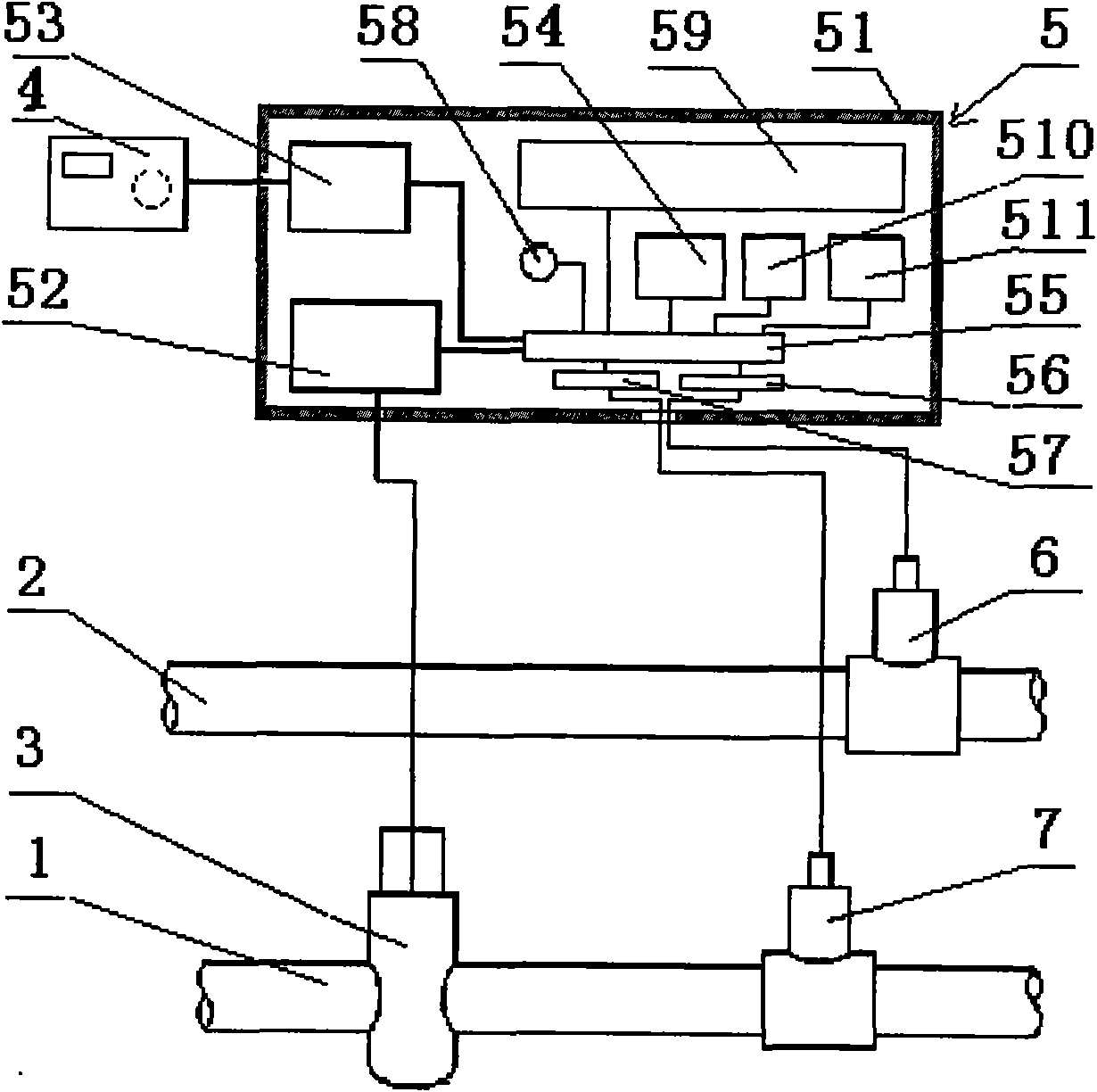

Heat quantity apportionment measuring method and device for central heating

ActiveCN101598611ASolve the real problemAddressing deviations in heat allocationTariff metering apparatusCalorimeterRoom temperatureEngineering

The invention relates to a heat quantity apportionment measuring method and a device for central heating. In the method, aiming at a heating system of a switching-on / switching-off type heat supply control mode, the apportionment measurement of the heating heat consumption is carried out according to a switching-on / switching-off time area method, modification with the time is carried out on the opening time of a switching-on / switching-off valve according to an built-in special modification computation program by the real-time measurement of the water supply and return water temperature values of heating users, and accumulation is carried out to calculate a modified opening specific value; when the heating season is over, the final modified opening ratio and the heating area of each user are used for apportioning the total heat quantity to determine heating charge which needs to be charged by each user; and the special modification computation program is designed in such a way that under the opening state of the switching-on / switching-off control valve, the water supply temperature value and the return water temperature value are read, the modified opening ratio is calculated, so the apportionment of the heat quantity used by the users is calculated. The device is suitable for the heat quantity apportionment measuring method for central heating and comprises a room temperature controller, the switching-on / switching-off control valve, a water supply temperature sensor, a return water temperature sensor, a heat supply control / opening time modification integrating instrument and the special modification computation program.

Owner:HEBEI GONGDA KEYA ENERGY TECH

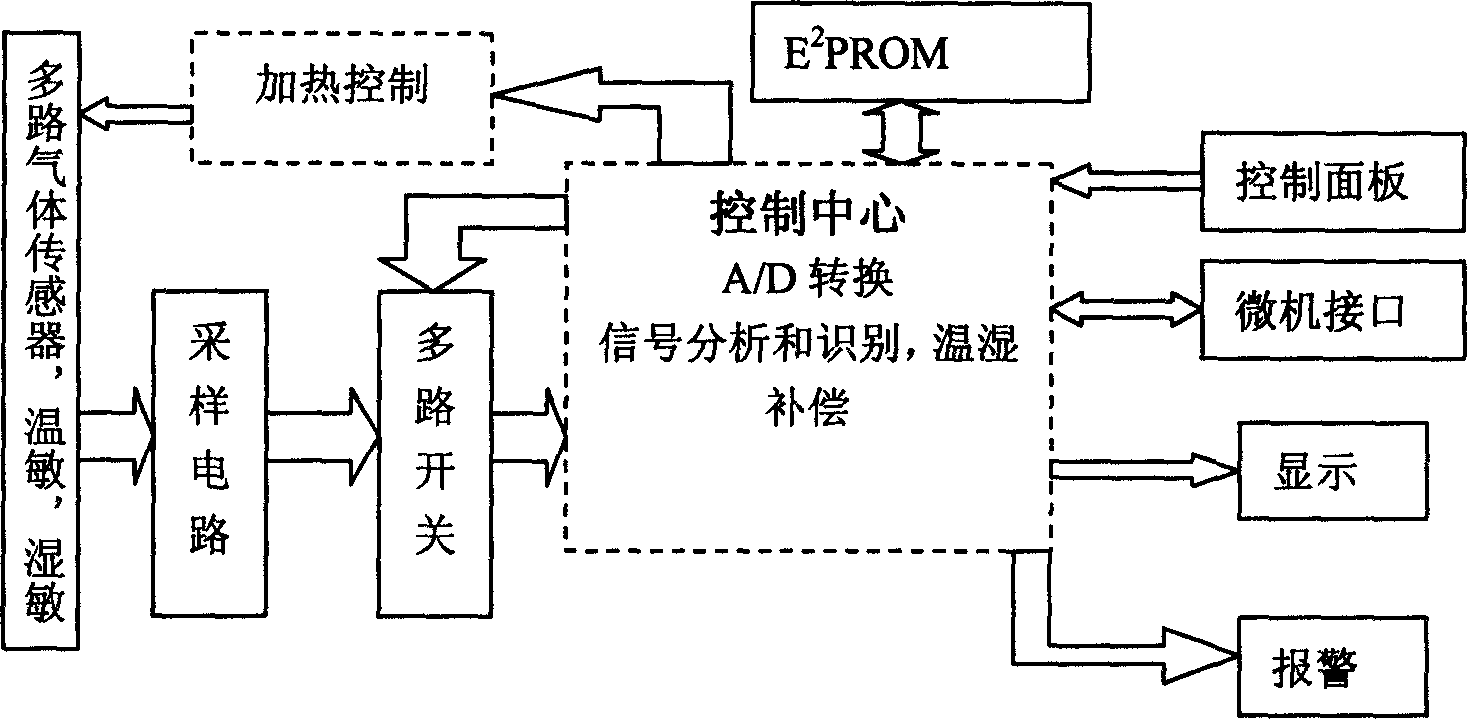

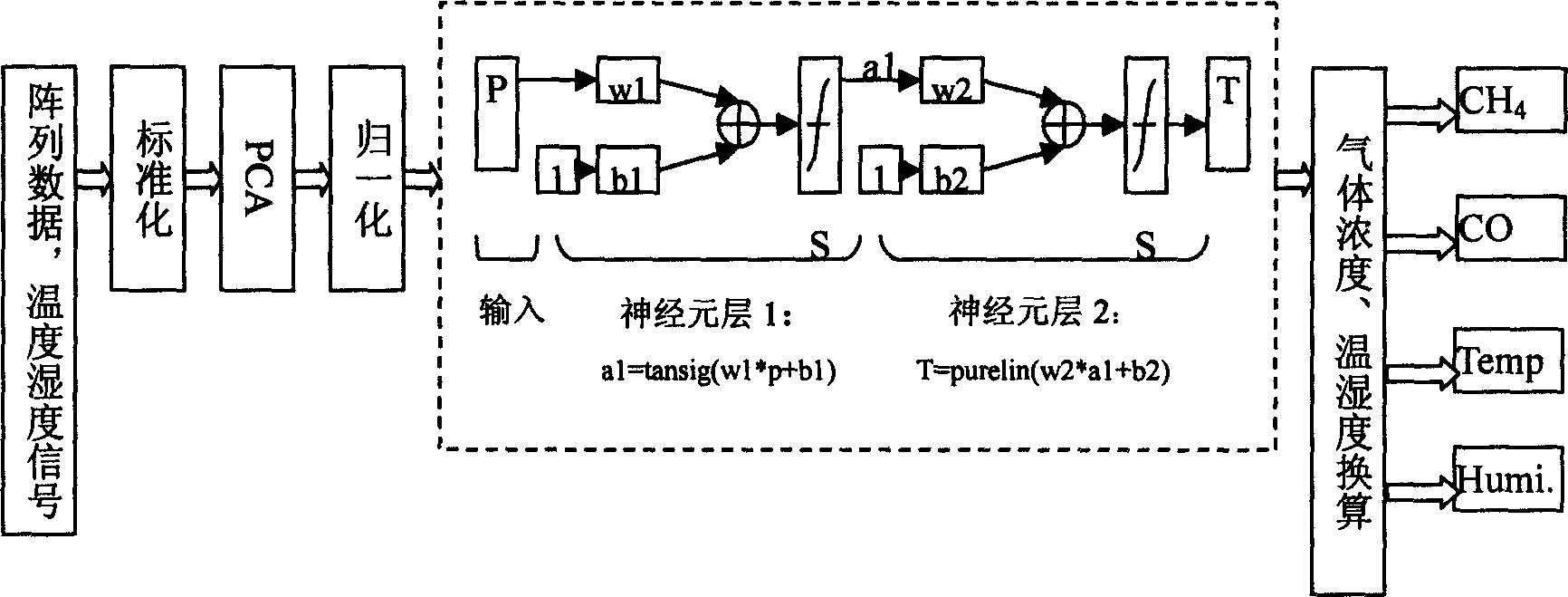

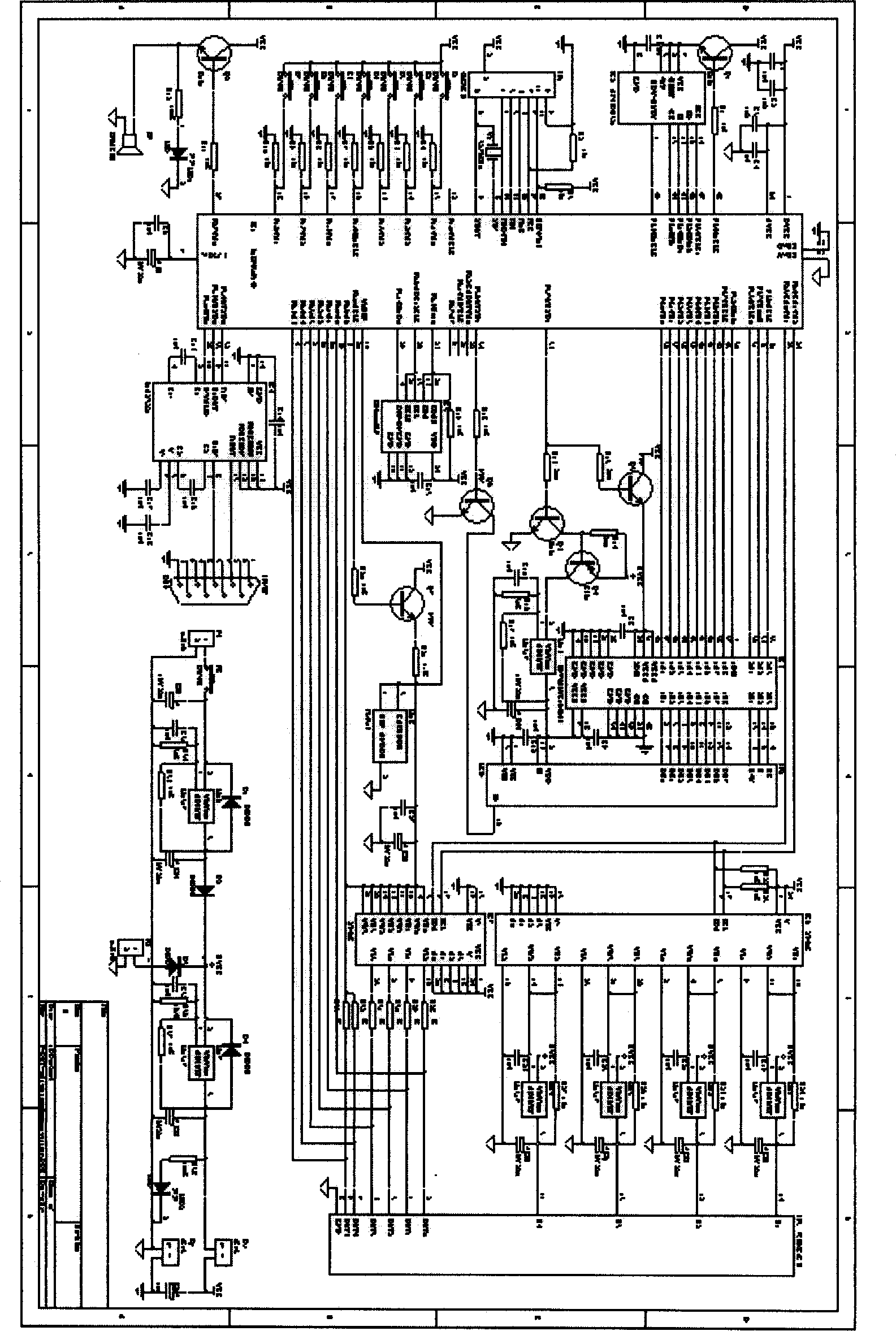

Portable gas detection analyzer with temperature and humidity compensation function

InactiveCN1588030AReal-time temperature and humidity compensationReal-time monitoring of temperature and humidity changesMaterial analysis by electric/magnetic meansInstrumental componentsEngineeringAnalytical technique

The invention provides a portable gas detecting and analysing instrument with temperature and humidity compensation function, which belongs to gas detecting and analysing field. It discloses a portable CO and CH4 gas detecting analysing instrument with a temperature and humidity compensation function. The instrument includes a control circuit and the circuits connected with it including the gas sensor detecting circuit, temperature detecting circuit, humidity detecting circuit, LCD circuit, acousto -optical alarming circuit, data storing circuit, PC communication interface circuit, timing circuit, heating control circuit and the power circuit. The gas detecting instrument in the invention can real-time detecte CO and CH4 content in the detected gas and the change of the environmental temperature and humidity and store the test data, time and environmental information into the memory for further analysis with computer and make the temperature and humidity compensation, collect, manage and keep the test information for retrieving. The instrument can be applied to detection of environment and gas content in mine and regions abundant of fuel gas such as CO and CH4, etc.

Owner:DALIAN UNIV OF TECH +1

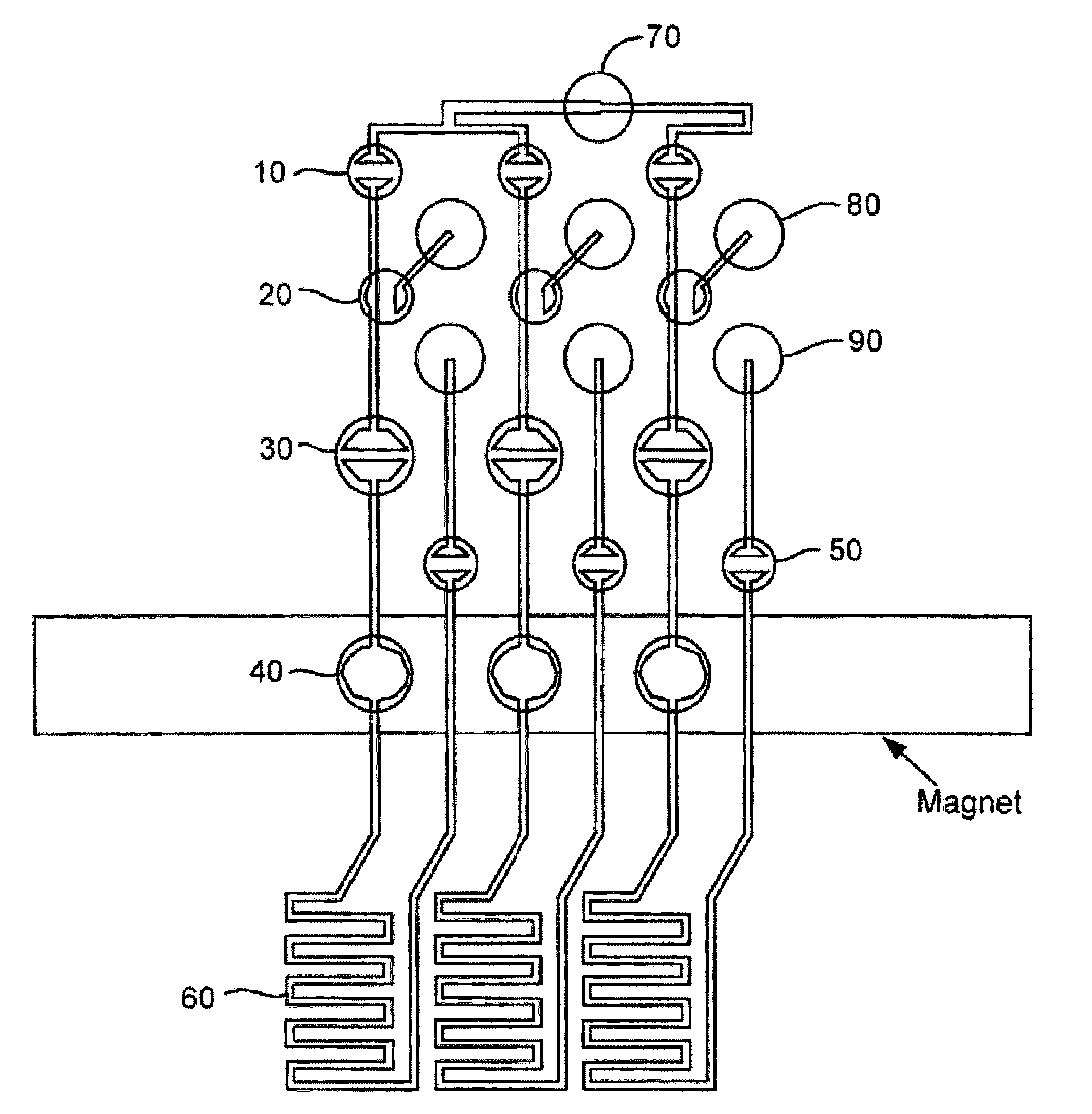

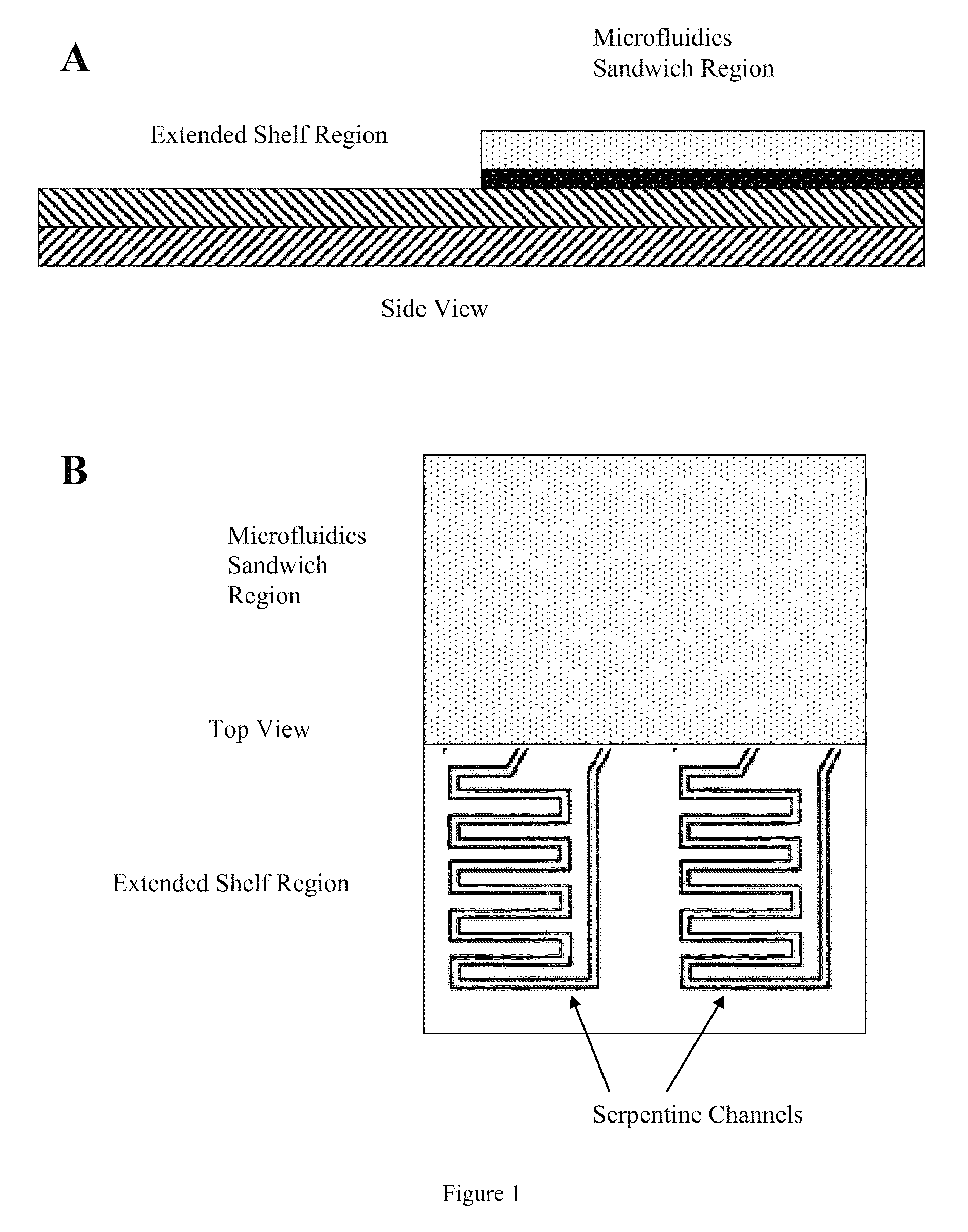

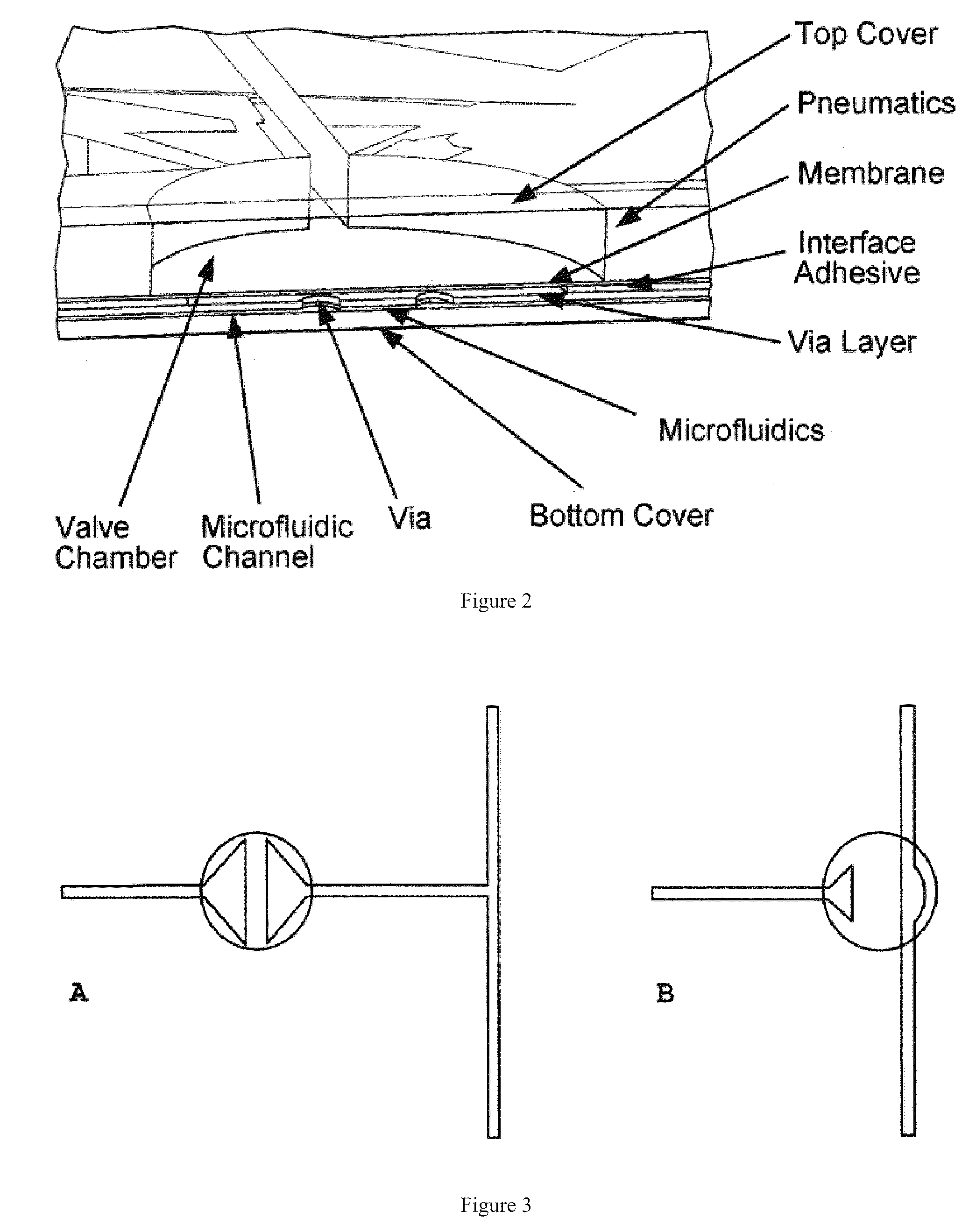

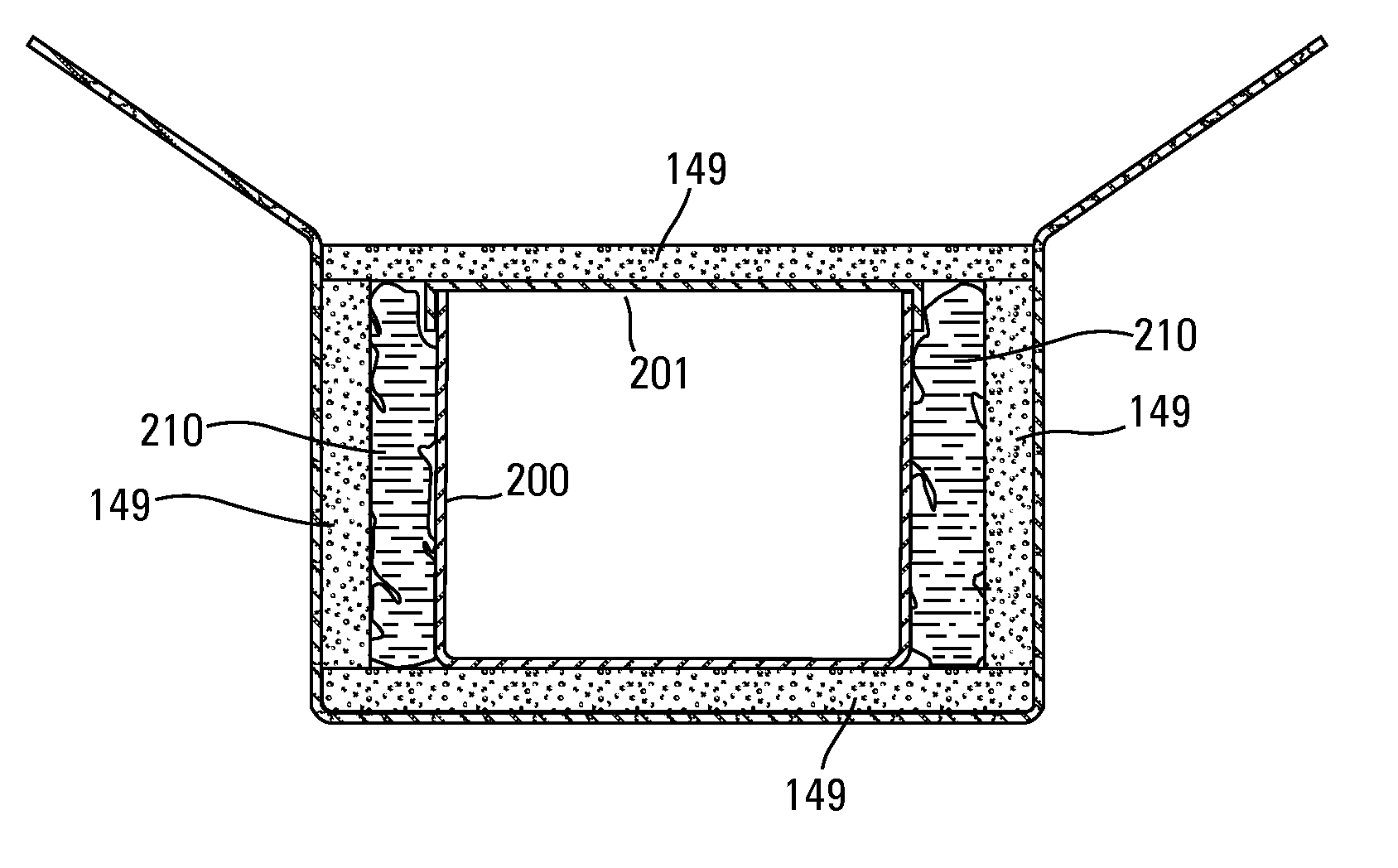

Microfluidic methods

This invention provides microfluidic devices that comprise a fluidics layer having microfluidic channels and one or more regulating layers that regulate the movement of fluid in the channels. The microfluidic devices can be used to mix one or more fluids. At least a portion of the fluidics layer can be isolated from the regulating layer, for example in the form of a shelf. Such isolated portions can be used as areas in which the temperature of liquids is controlled. Also provided are instruments including thermal control devices into which the microfluidic device is engaged so that the thermal control device controls temperature in the isolated portion, and a movable magnetic assembly including magnets with shields so that a focused magnetic field can be applied to or withdrawn from the isolated portion or any other portion of the microfluidic device. Also provided are methods of mixing fluids. The methods include stacking a plurality of alternating boluses of different liquids in a microfluidic channel, and moving the stacked boluses through the channel. In another method, the boluses are moved into a diaphragm valve having a volume able to accommodate several boluses, and then pumping the liquids out of the valve.

Owner:INTEGENX

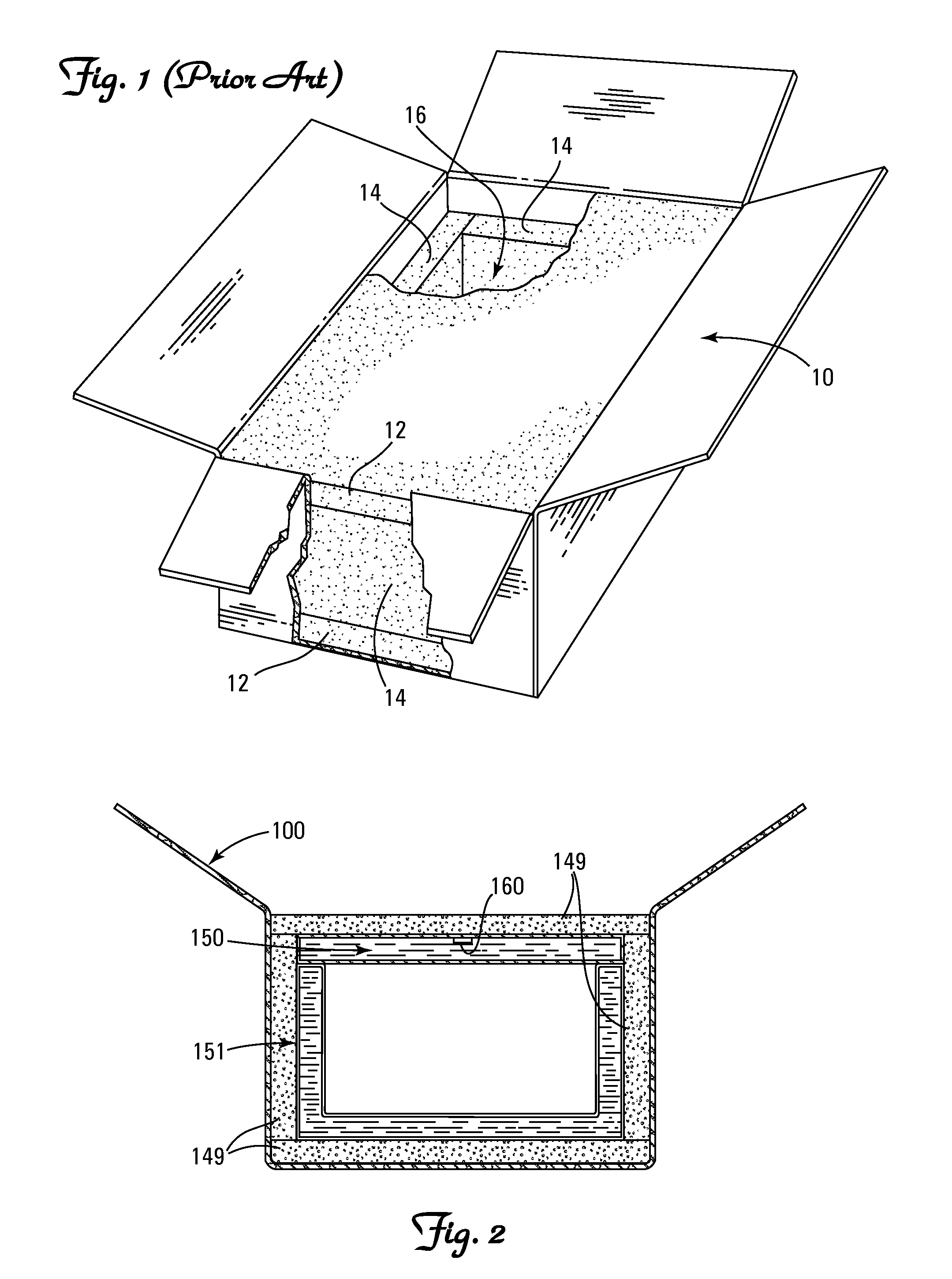

Travel container with passive thermal control and a flexibile outer shell

InactiveUS20080099492A1Cheap to makeClose temperature controlDomestic cooling apparatusLighting and heating apparatusEngineeringPhase-change material

An apparatus for shipping articles under controlled temperature conditions, having a metallic article enclosure surrounded by a set of insulating panels, with a predetermined volume separation between the enclosure and the insulating panels, and the predetermined volume being filled with phase change material.

Owner:MINNESOTA THERMAL SCI

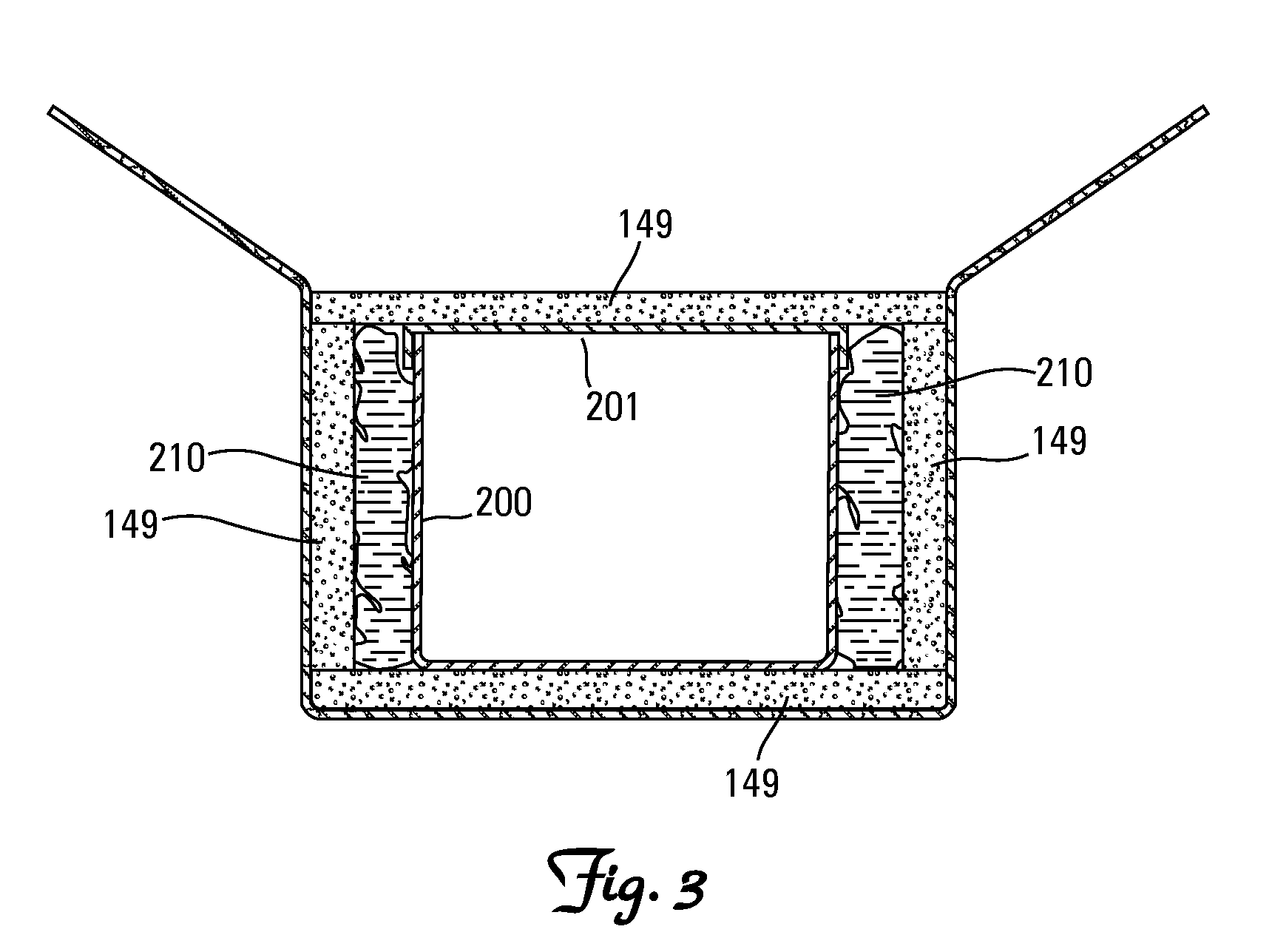

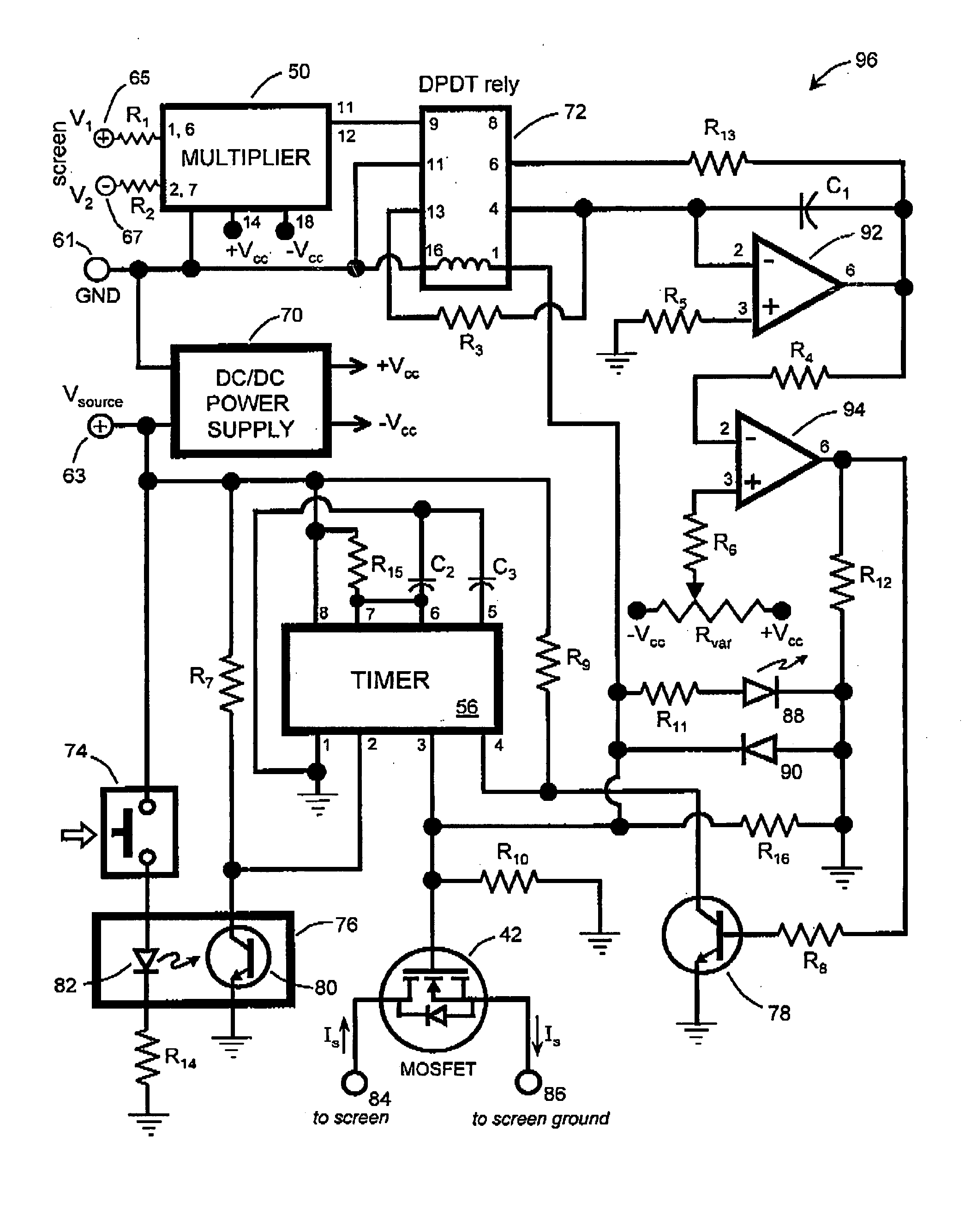

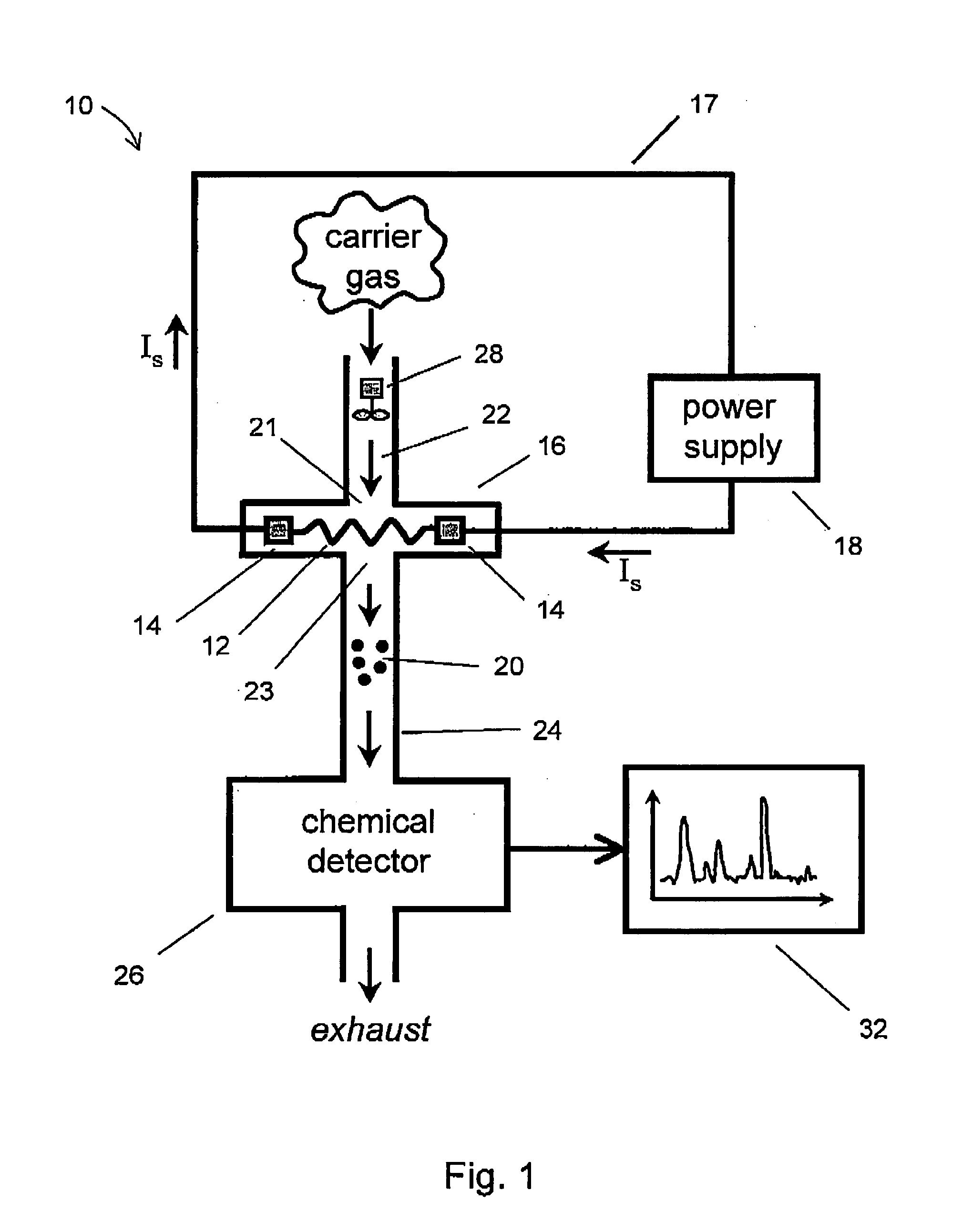

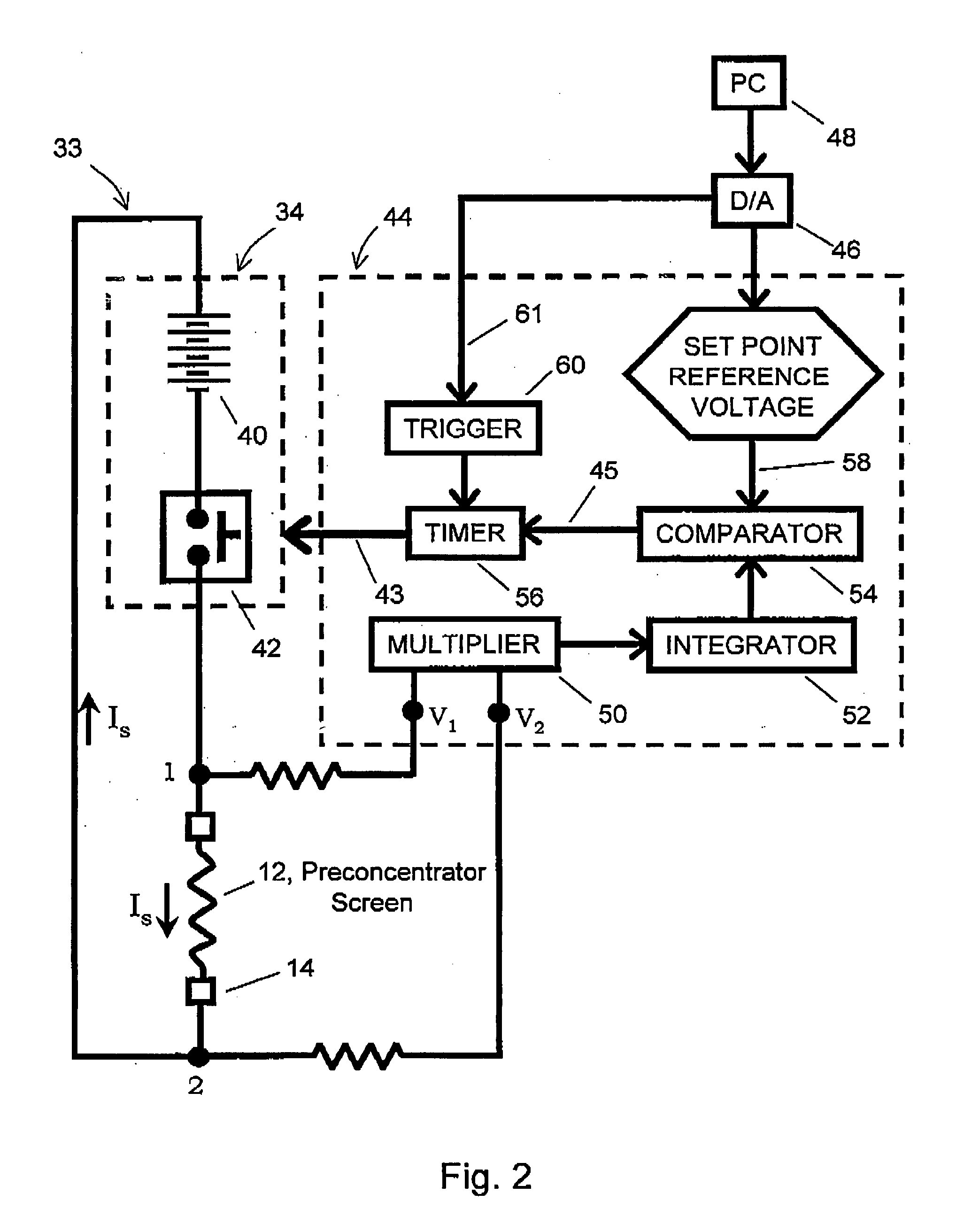

Integrating preconcentrator heat controller

A method and apparatus for controlling the electric resistance heating of a metallic chemical preconcentrator screen, for example, used in portable trace explosives detectors. The length of the heating time-period is automatically adjusted to compensate for any changes in the voltage driving the heating current across the screen, for example, due to gradual discharge or aging of a battery. The total deposited energy in the screen is proportional to the integral over time of the square of the voltage drop across the screen. Since the net temperature rise, ΔTs, of the screen, from beginning to end of the heating pulse, is proportional to the total amount of heat energy deposited in the screen during the heating pulse, then this integral can be calculated in real-time and used to terminate the heating current when a pre-set target value has been reached; thereby providing a consistent and reliable screen temperature rise, ΔTs, from pulse-to-pulse.

Owner:SANDIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com