Patents

Literature

146results about How to "Control heating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heating control method of power battery pack of electric vehicle

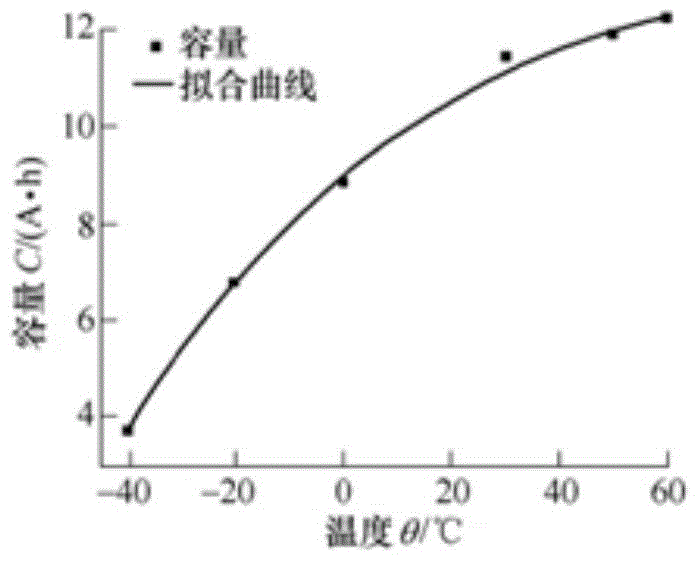

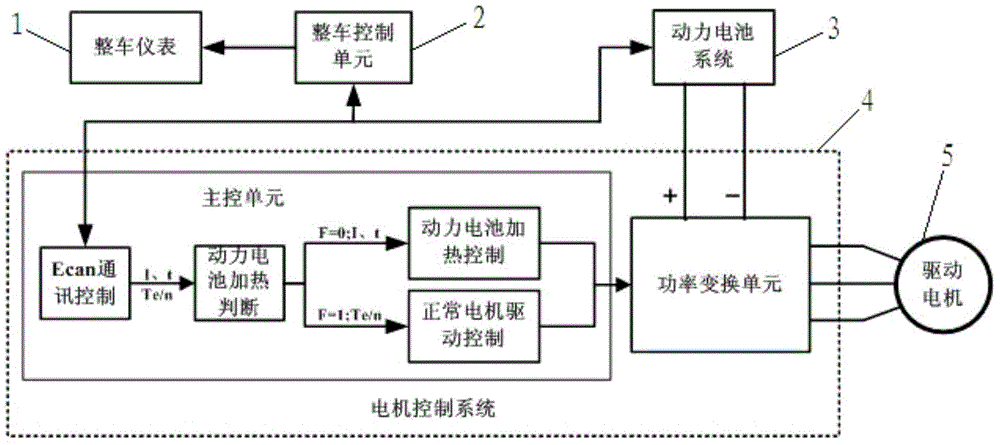

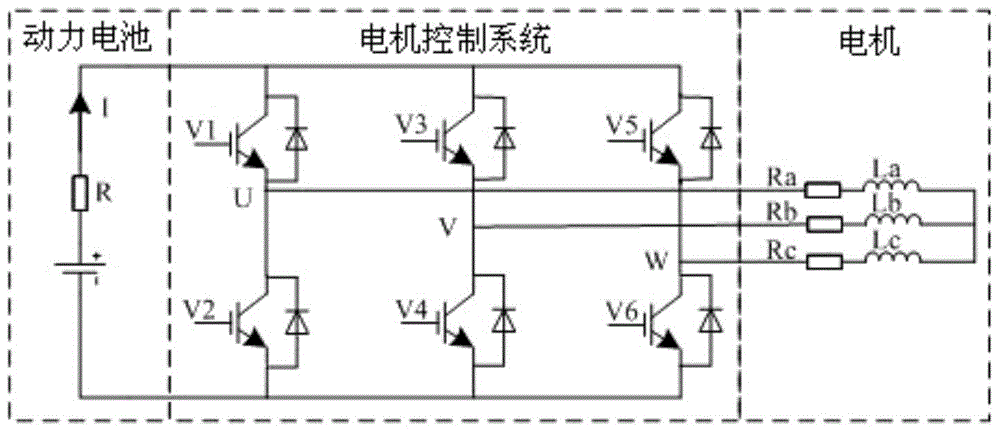

ActiveCN103560304AIncrease temperatureControl heating rateCell temperature controlElectrical batteryEngineering

The invention belongs to the technical field of power batteries of vehicles, and particularly relates to a heating control method of a power battery pack of an electric vehicle. The heating control method is implemented by a whole vehicle instrument, a whole vehicle control unit, a power battery system, a motor control system and a driving motor, wherein the whole vehicle instrument is connected with the whole vehicle control unit, the whole vehicle control unit is connected with the power battery system and the motor control system respectively, and the motor control system is connected with the power battery system and the driving motor respectively. According to the method, power batteries are heated by virtue of an original electric drive system of the electric vehicle, the energy of the power batteries is mainly used for the self heating of the power batteries, so that the temperature of the power batteries can be rapidly raised without extra cost, and the heating efficiency is high.

Owner:DONGFENG MOTOR CORP HUBEI

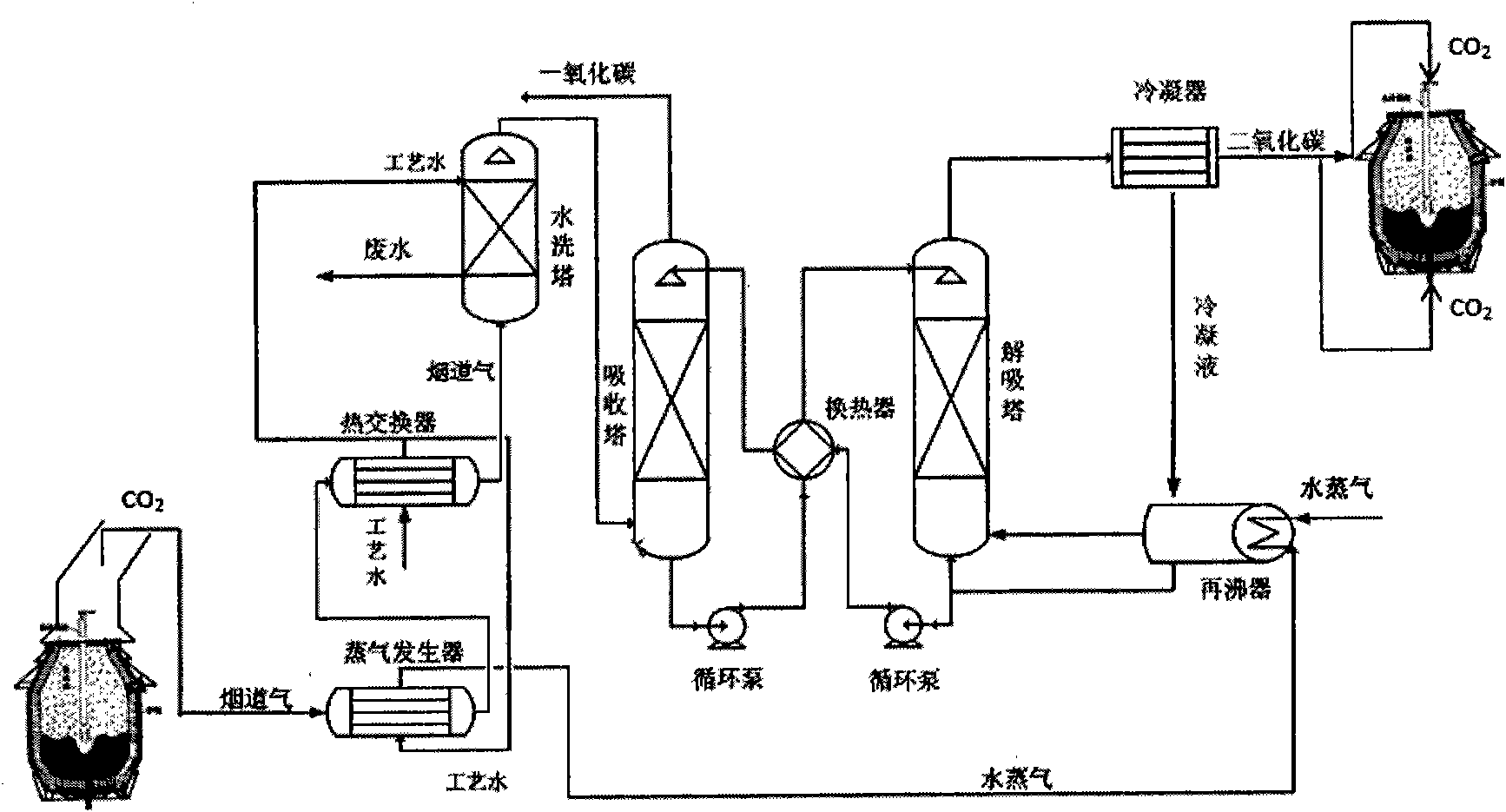

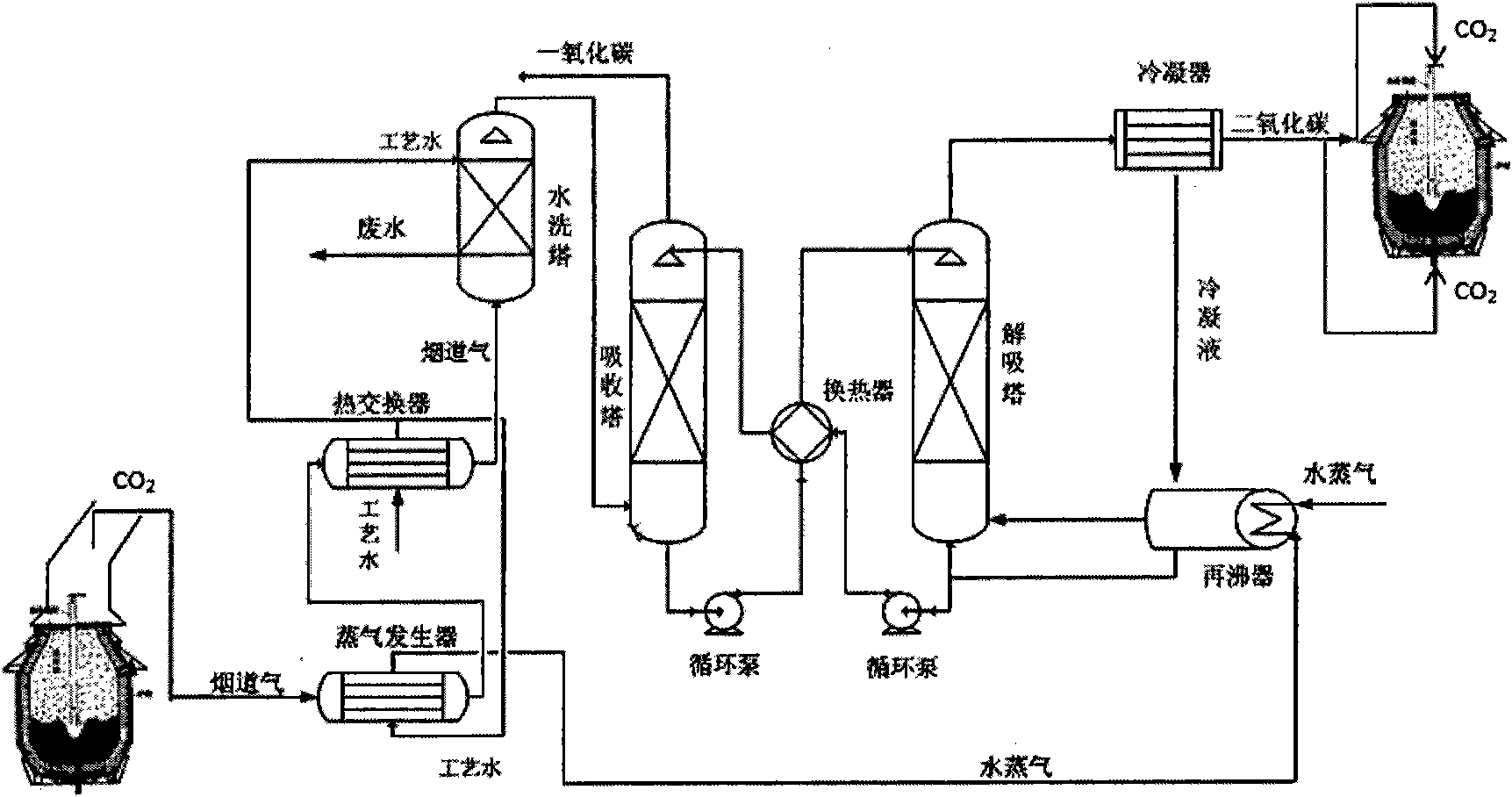

Method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing

InactiveCN101818227AHigh carbon contentControl heating rateManufacturing convertersGas emission reductionProduct gasProcess engineering

The invention discloses a method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing and belongs to the fields of ferrous metallurgy, energy conservation and environment protection. In the invention, the CO2 in the converter steel-making gas is separated and recycled after being cooled and dedusted; the recovery is 100 to 15,000Nm<3> / h; and the concentration of CO in the converter gas is improved by 5 to 20 percent at the same time. The CO2 serves as a gas source for the top blowing and the bottom blowing of a top and bottom combined blown converter. A chemical absorption separation method is adopted to separate the CO2; steam added with rich liquid is generated by using the residual heat of the converter gas; and almost no additional energy is consumed in the process for separating the carbon dioxide. 1 to 30 percent of the CO2 and 99 to 70 percent of O2 are blown from the top part; pure CO2 or a mixture of the CO2 and N2 or Ar or O2 or gas and the like is adopted in the whole process of the bottom blowing; and the amount of the CO2 is 100 to 3,000Nm<3> / h. The method is applicable to a steel-making process for a 30 to 350 ton converter. By adopting the method, for each ton of steel, 1 to 20 m3 of CO2 emission is reduced synthetically; the soot amount is reduced by 1 to 30 percent; and the content of the CO in the gas is improved to more than 2 to 15 percent.

Owner:UNIV OF SCI & TECH BEIJING

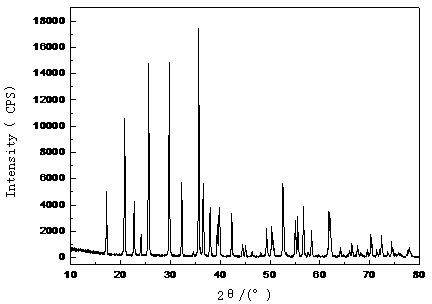

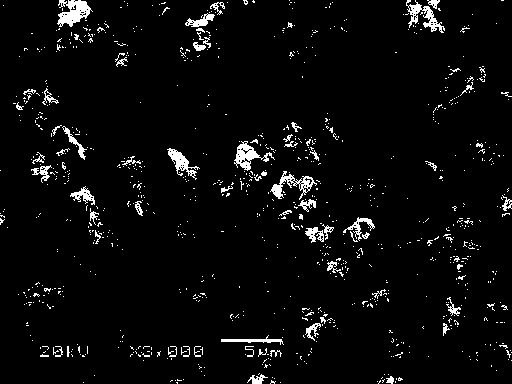

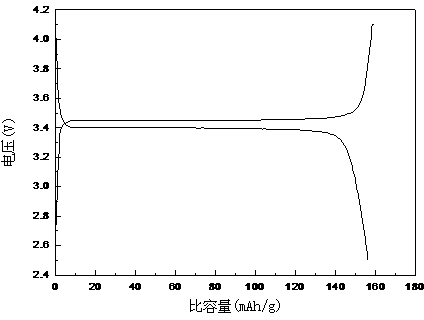

Multi-ion-doped carbon-coated lithium iron phosphate battery material and preparation method thereof

InactiveCN103367746AGuaranteed uniformityImprove electronic conductivityCell electrodesChemistryCrystal

The invention discloses a multi-ion-doped carbon-coated lithium iron phosphate battery material and a preparation method thereof. The material has a structure of Li1-x M'x Fe1-y My (PO4)1-zFz / C, wherein x is more than or equal to 0.001 and less than or equal to 0.1, y is more than or equal to 0.001 and less than or equal to 0.1, z is more than or equal to 0.001 and less than or equal to 0.1, M' and M are respectively metal ions doped at the lithium position and the iron position, C is organic matter pyrolysis carbon covered on the surface of lithium iron phosphate, and M' and F come from fluoride M' Fn (n is equal to 1, 2, 3 or 4). The preparation method comprises the steps of: (1) preparing doped iron phosphate containing crystal water by a coprecipitation method; (2) carrying out heat treatment on the iron phosphate containing the crystal water, and removing the crystal water; and (3) mixing the doped iron phosphate, lithium source, the fluoride M' Fn and organic carbon source, carrying out ball-milling, drying and roasting to obtain the multi-ion-doped carbon-coated lithium iron phosphate battery material. The preparation method is simple and easy in technology, and the prepared lithium iron phosphate is high in specific discharge capacity and excellent in rate capability, thus having application prospect in the field of a power battery.

Owner:YANTAI ZHUONENG BATTERY MATERIAL

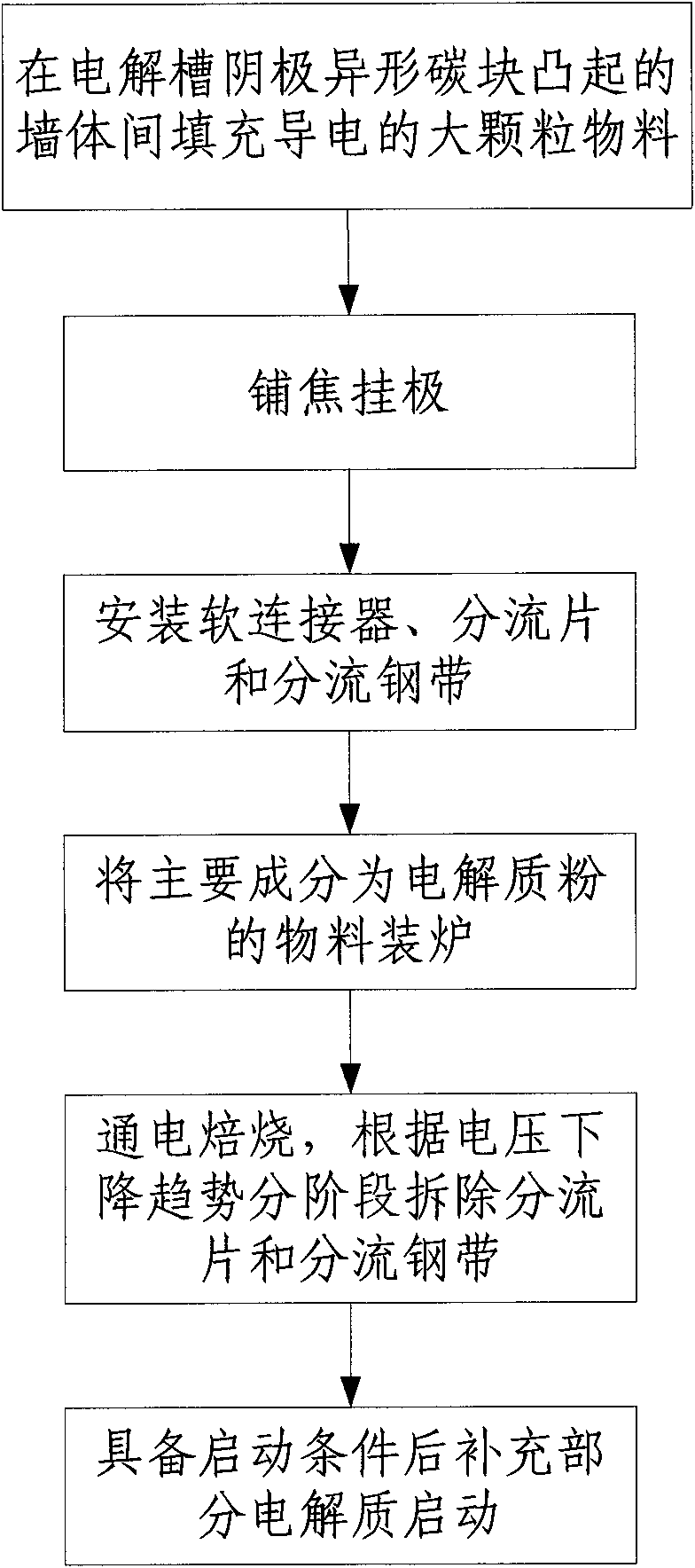

Method for roasting and starting aluminum electrolytic cell

The invention discloses a method for roasting and starting an aluminum electrolytic cell. The method comprises the following steps: firstly, evenly and compactly filling conductive bulky grain materials among wall bodies which are projected on cathode abnormal carbon blocks of the electrolytic cell; using coke grains for pouring cracks and filling gaps among the bulky grain materials; laying cokegrains on upper surfaces of the abnormal carbon blocks and the filled bulky grain materials; after laying coke grains of a group of anodes, placing a group of anodes thereon; then installing a soft connector, a current-dividing sheet and a current-dividing steel belt; filling the materials which takes electrolyte powder as the main component in a furnace and evenly laying the materials around theelectrolytic cell; detaching the current-dividing plate and the current-dividing steel belt by phases through electrifying and roasting according to the downtrend of voltage; and when most materials in the gaps of the anodes are smelted and communicated and both the electrolyte height and the roasting temperature meet requirements, supplementing part of electrolyte to the electrolytic cell and then starting the electrolytic cell. The method has the advantages of short roasting time, less electricity consumption, safe and reliable control of roasting process, low producing cost, and the like.

Owner:YANKUANG GRP CO LTD +1

Carboxylated styrene-butadiene latex

ActiveCN104628953AStable molecular structureMolecular weight controllableButadiene-styrene rubberMechanical property

The invention relates to a carboxylated styrene-butadiene latex. High-speed steam is utilized to provide reaction heat energy for the reaction of the carboxylated styrene-butadiene latex, and the cooled steam is converted into high-temperature deionized water; the high-speed steam also drives the liquid in the reaction vessel to rotate, and the liquid in the reaction vessel is dispersed by the steam flow to form abundant micro steam-water combinations so as to push the material in the reaction vessel to quickly flow; and the substances and temperature in the reaction vessel are uniformly distributed, the polymerization reaction is uniform, and thus, the carboxylated styrene-butadiene latex has the advantages of stable molecular structure, controllable molecular weight and more centralized size distribution, has balanced and excellent mechanical properties, and enhances the qualification rate and quality of the product.

Owner:宁波卫山多宝建材有限公司

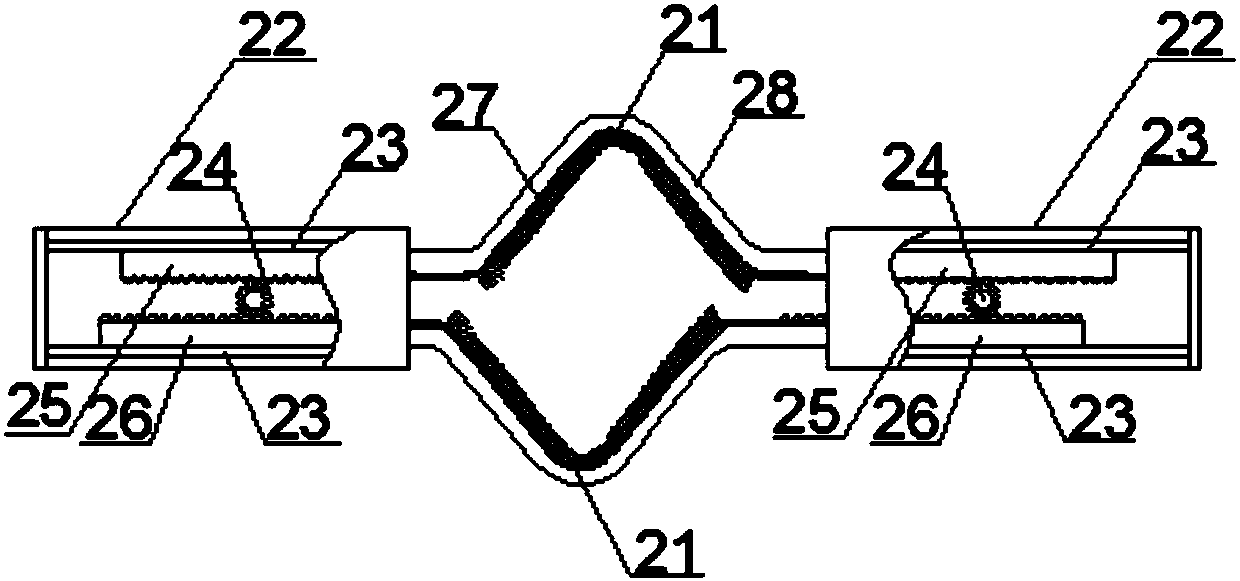

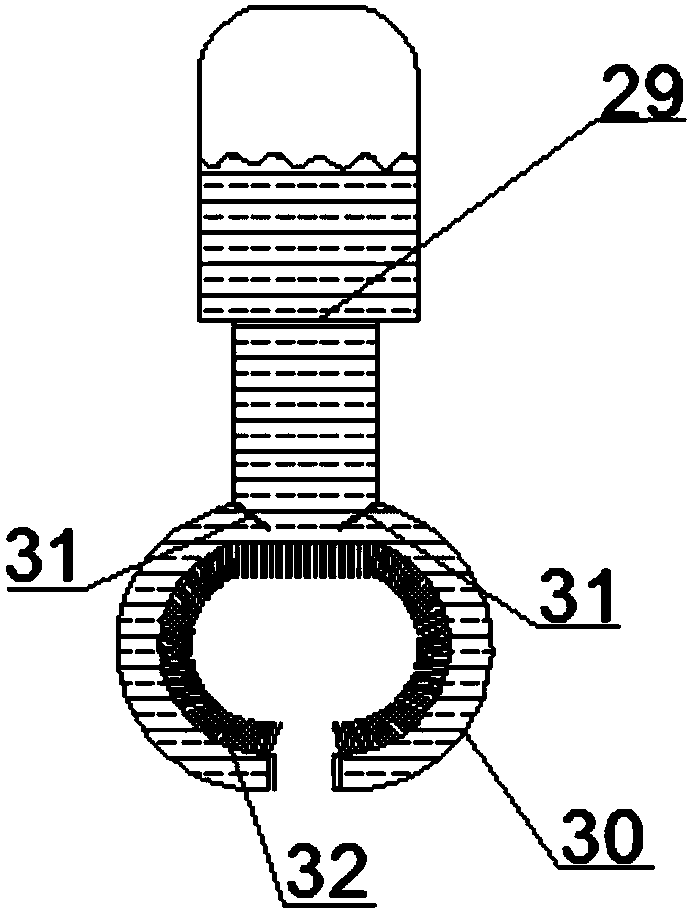

Deicing robot based on automatic tensioning type U-shaped heating mechanism

InactiveCN107834485AImprove bindingEfficient removalOverhead installationDrive wheelElectric machine

The invention discloses a deicing robot based on an automatic tensioning U-shaped heating mechanism, relates to the technical field of protection equipment for overhead power transmission cables, and solves the problem of deicing the existing deicing mechanism with strong binding force and thick ice layer. The problem of limited ice capacity, including the casing, on which the driving wheel and the driven wheel are installed, the driving motor and the worm gear mechanism are arranged inside the casing, the worm gear is arranged above the worm and meshed with the worm, and the worm wheel and the driving wheel pass through the transmission belt A Transmission connection, the front end of the worm sticks out of the casing and is connected with a rotating body that rotates with the rotation of the worm. The rotating body is equipped with a mechanical deicing mechanism, including a thermal deicing mechanism. The thermal deicing mechanism includes a stepping motor, a transmission belt B, The U-shaped heating plate and the shells symmetrically arranged on both sides of the transmission line can effectively remove the icing with strong binding force and thick ice layer, such as rain rime and mixed rime, and avoid thermal De-icing mechanisms are prone to damage to the interior of power lines due to sustained heat.

Owner:弘毅天承知识产权股份有限公司

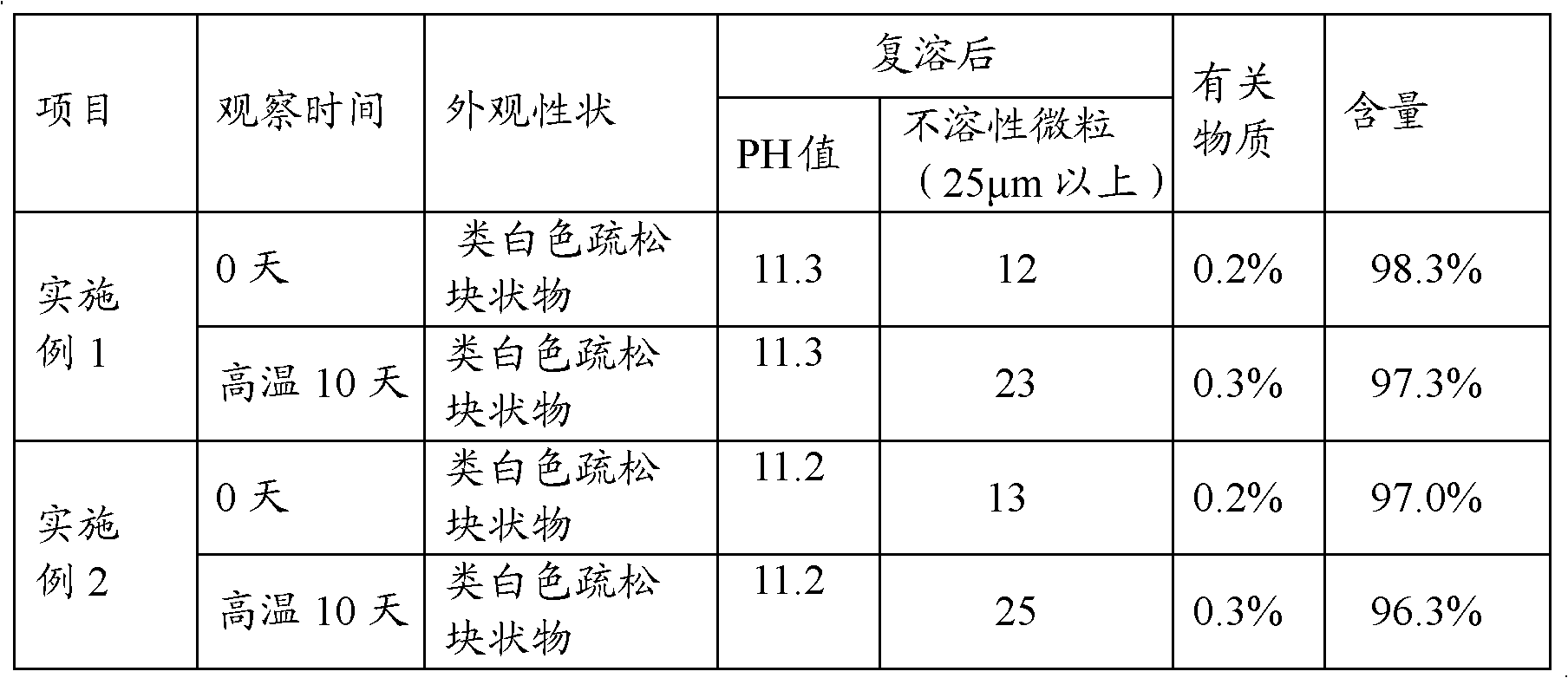

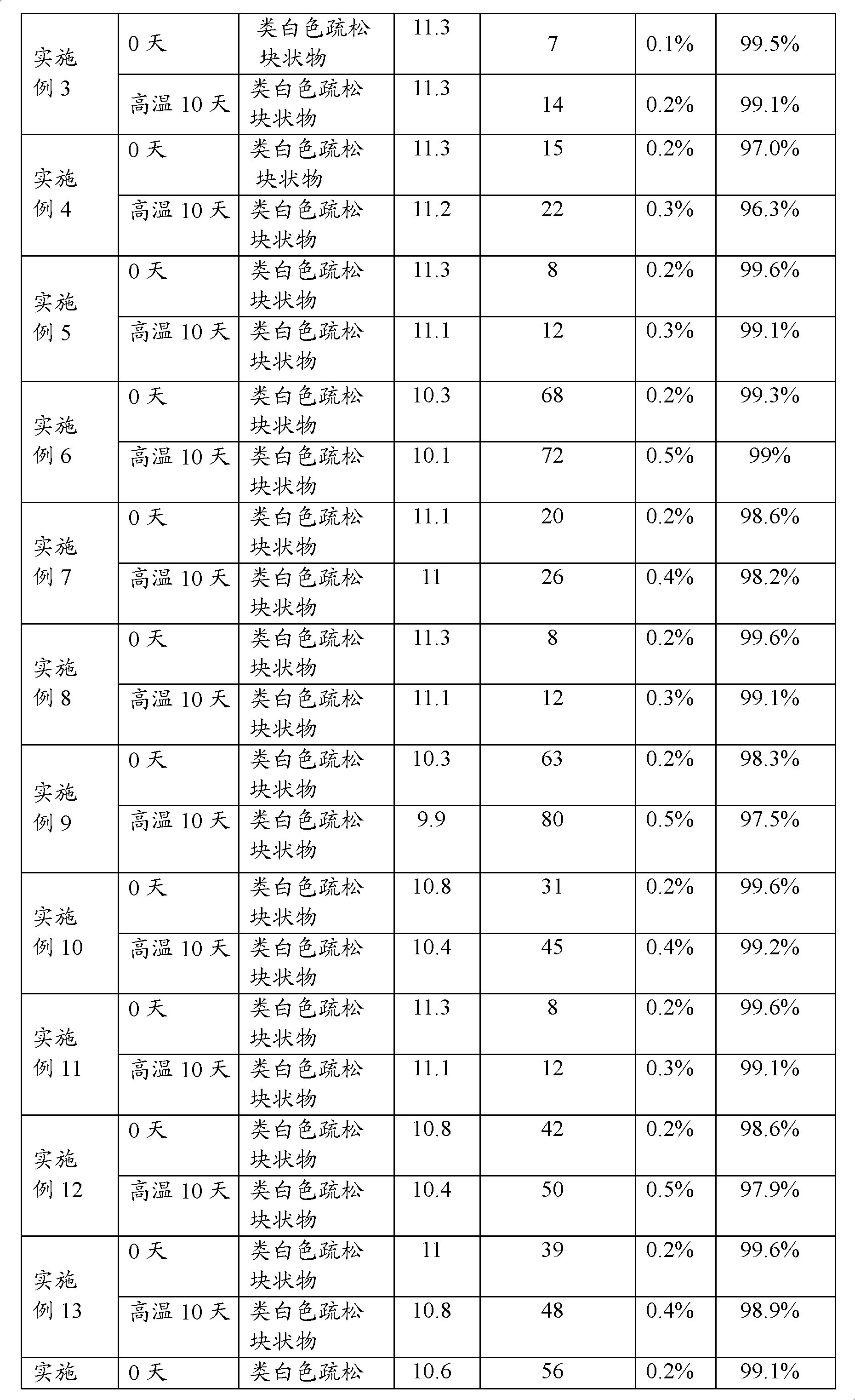

Lansoprazole lyophilized powder injection preparation and its preparing method

ActiveCN102552181AStable pHStable contentOrganic active ingredientsPowder deliveryLansoprazoleMedicine

The invention provides a Lansoprazole lyophilized powder injection preparation and its preparing method. The preparation is used for treating peptic ulcer and belongs to the field of medicines. The Lansoprazole lyophilized powder injection preparation provided in the invention comprises Lansoprazole, a chemical stabilizing agent, a physical form stabilizing agent and a pH conditioning agent; and through quantified proportioning and synergism of the above-mentioned components, stability of the preparation can be effectively improved. According to the invention, the preparation has stable quality and is safe to use; and the preparation method is simple and is convenient for industrial large-scale production.

Owner:SUZHOU SIXTH PHARMA PLANT OF JIANGSU WUZHONG PHARMA GROUP

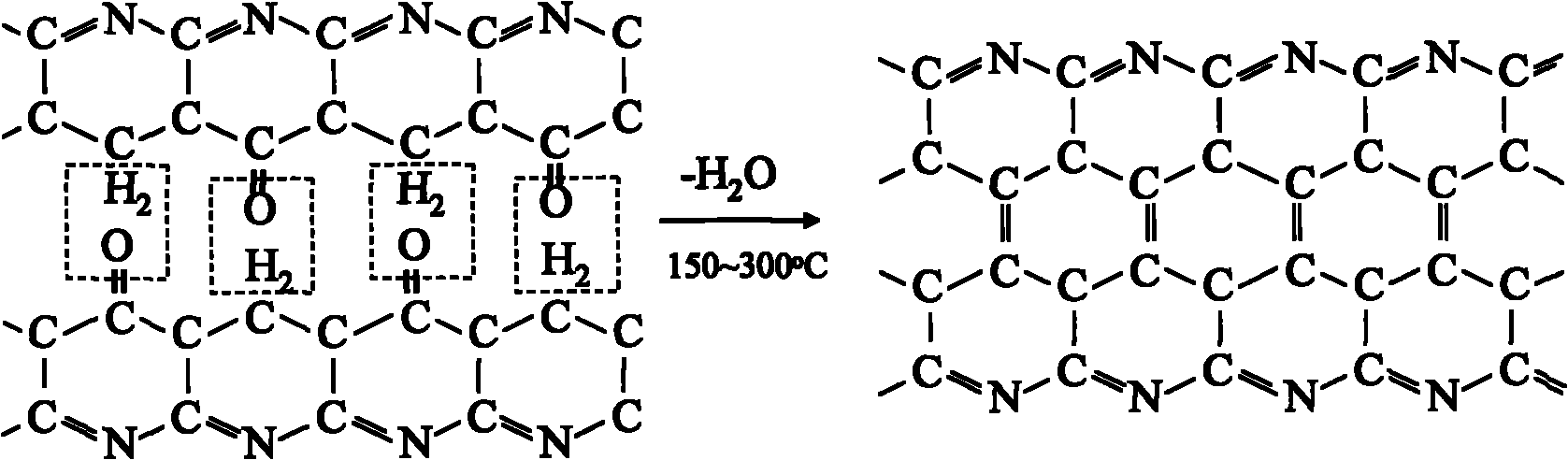

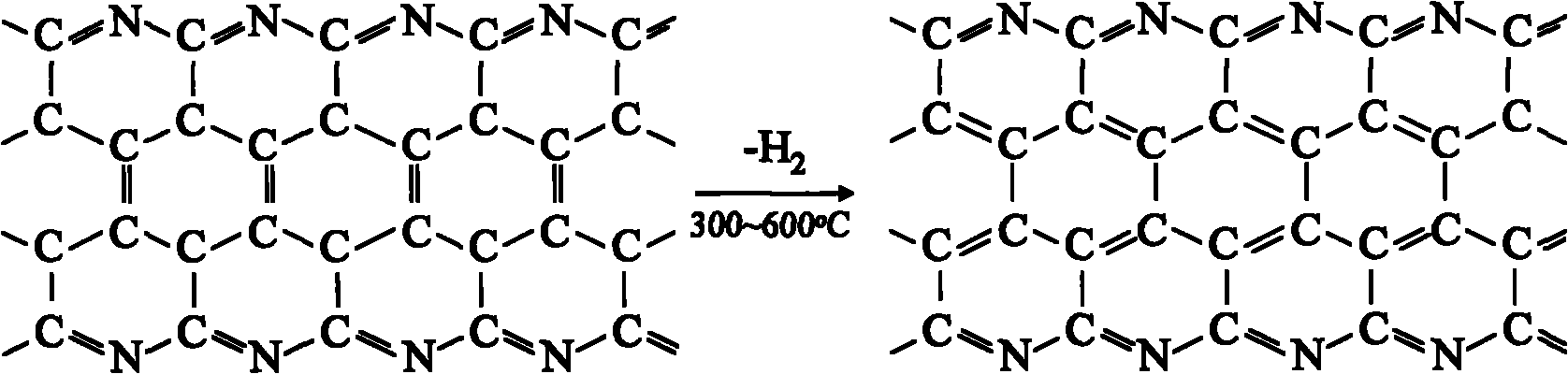

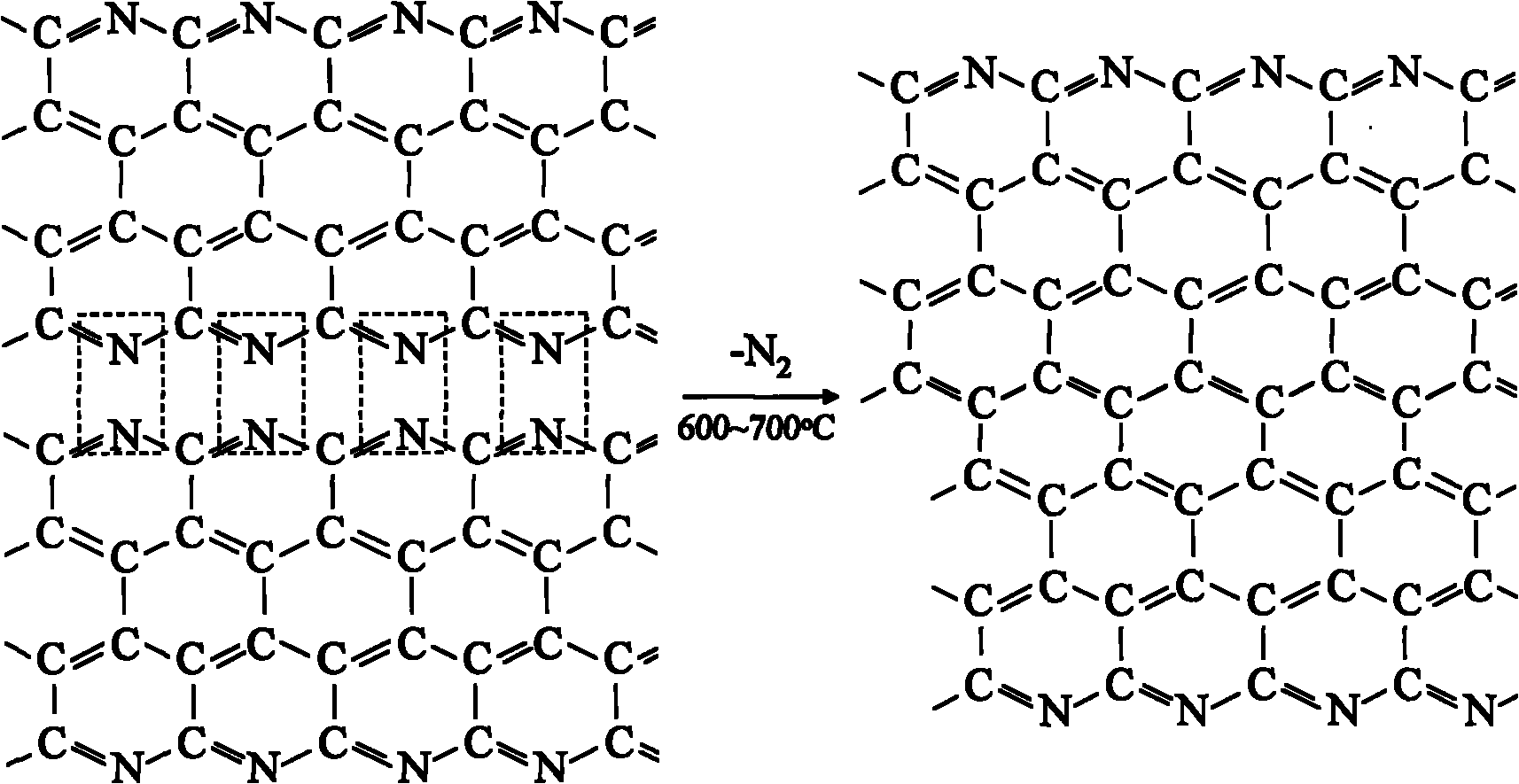

Method for preparing conducting film LiFePO4 cladding material containing nitrogen

InactiveCN101924204AImplementation of the problem of non-uniform growth rateEliminate the problem of non-uniform growth rateCell electrodesPhosphorus compoundsCarbon filmReaction temperature

The invention relates to a preparation method of a lithium ion battery anode material, aiming to provide a method for preparing a conducting film LiFePO4 cladding material containing nitrogen. The method comprises the following steps of: ball milling and mixing FePO4.4H2O, LiOH.H2O and a polyacrylonitrile emulsion, blending into a paste and putting the paste into a quartz reactor; regulating and controlling the microwave output power and controlling the reaction temperature to be at 150 DEG C; raising the microwave output power in an oxygen atmosphere and heating up to 300 DEG C from 150 DEG C; switching to a highly pure nitrogen atmosphere, raising the microwave output power and heating up to 600 DEG C from 300 DEG C; and continuously raising the microwave output power under the highly pure nitrogen atmosphere and annealing at 700-800 DEG C for denitrifying. Nitrogen atoms remain on the conducting carbon film formed by the invention, and lone pair electrons of the nitrogen atoms can effectively improve the conductivity of the carbon film so as to improve electrochemical and dynamic properties of the anode, reduce the electrode polarization and improve the velocity volume of the lithium cell, thus the invention can be applied to power cells of electric vehicles.

Owner:ZHEJIANG UNIV

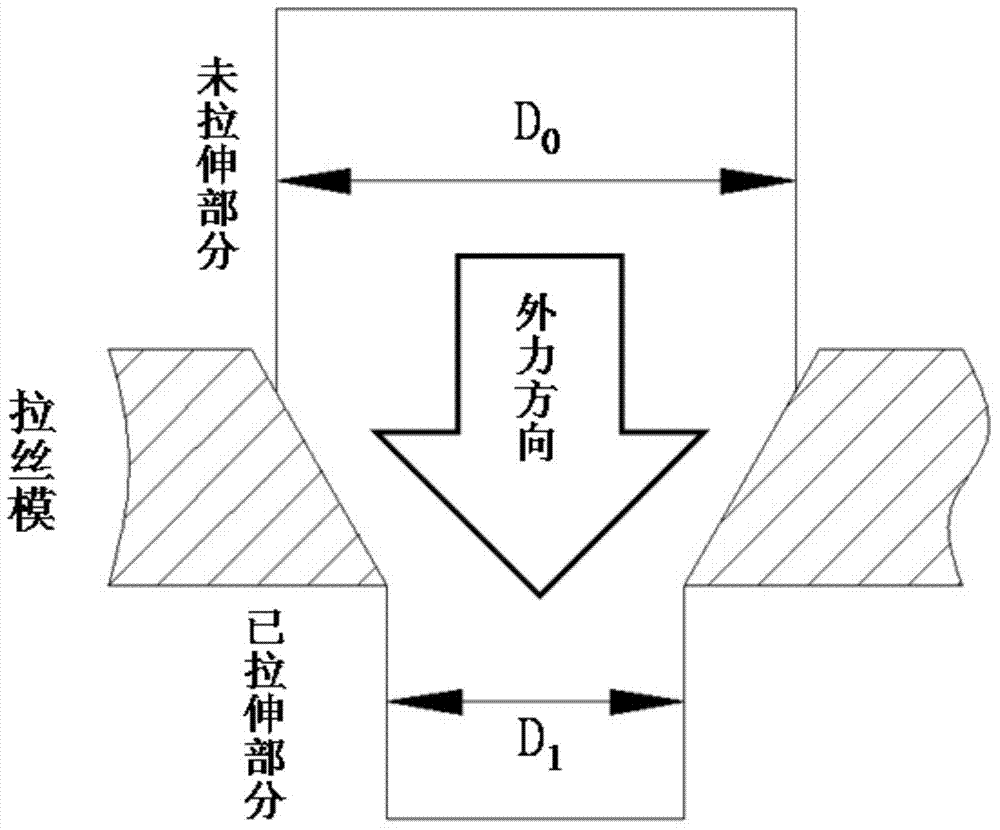

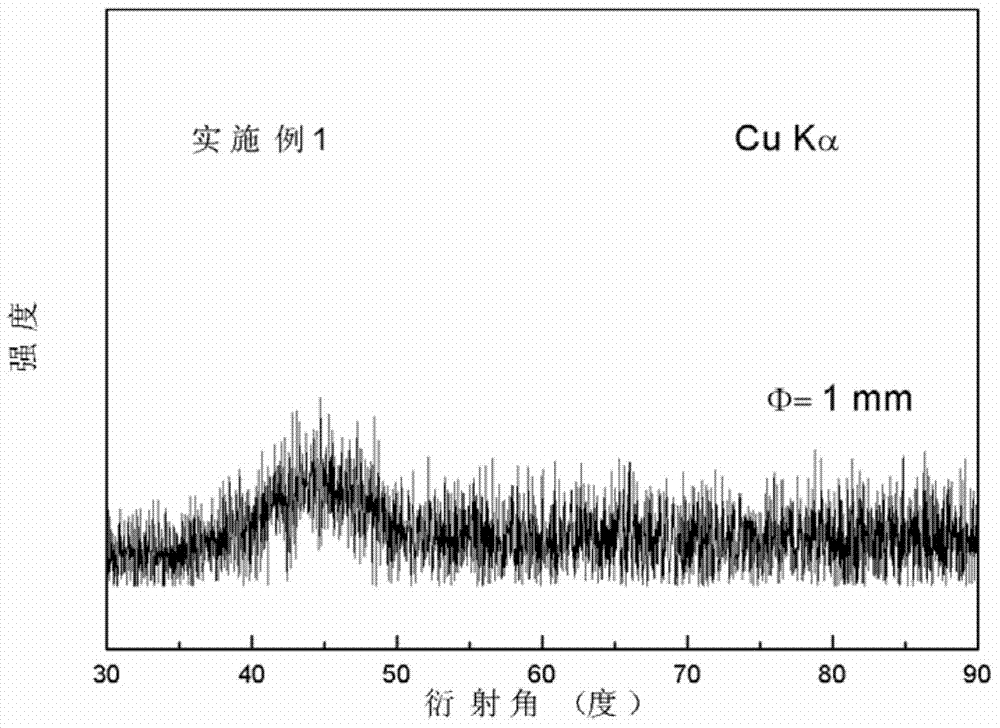

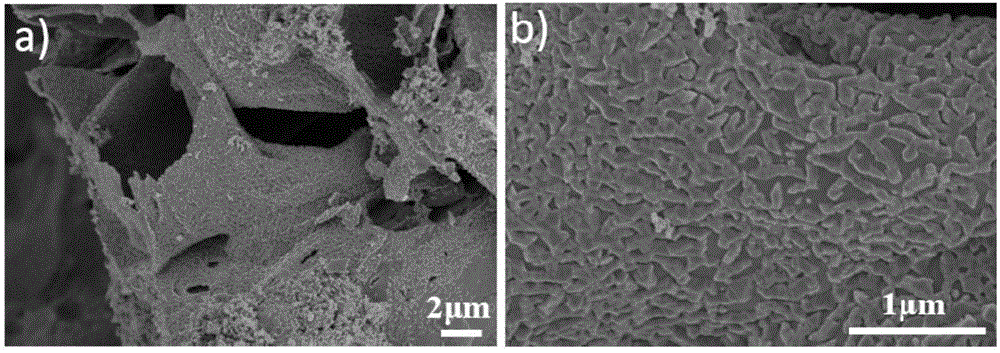

Preparation method of amorphous alloy fiber and device for implementing the preparation method

The invention provides a preparation method of an amorphous alloy fiber and a device for implementing the preparation method. The preparation method utilizes superplasticity of an amorphous alloy material. The preparation method comprises the following steps of fixing one end of an amorphous alloy material such as a bar, a wire or a band, connecting the other free end of the amorphous alloy material to an external force supplement device, arranging a heater for heating the amorphous alloy material between the two ends, when the temperature of the amorphous alloy material is in a sub-cooled liquid phase region range from a glass transition temperature to an initial crystallization temperature and is increased to a softening temperature, starting the external force supplement device, and slowly drawing the free end by the external force supplement device so that the amorphous alloy material produces plastic deformation and forms amorphous alloy fibers. The preparation method is simple and feasible, has a low cost, can prepare the amorphous alloy fibers with small diameters and can widen an amorphous alloy fiber application scope.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

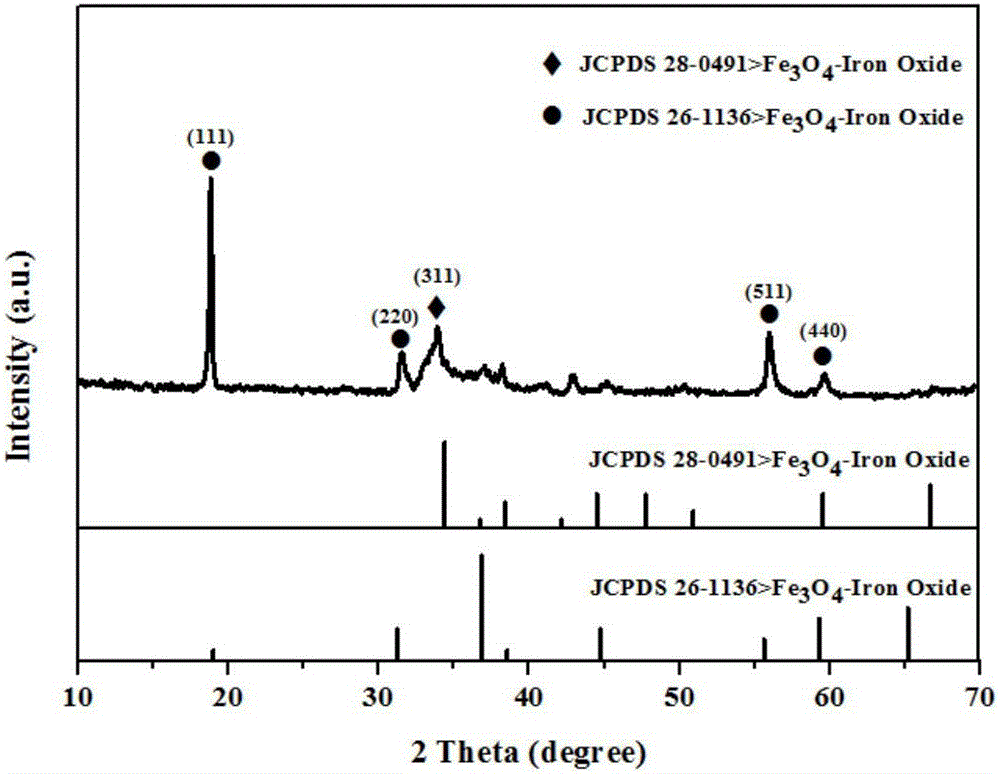

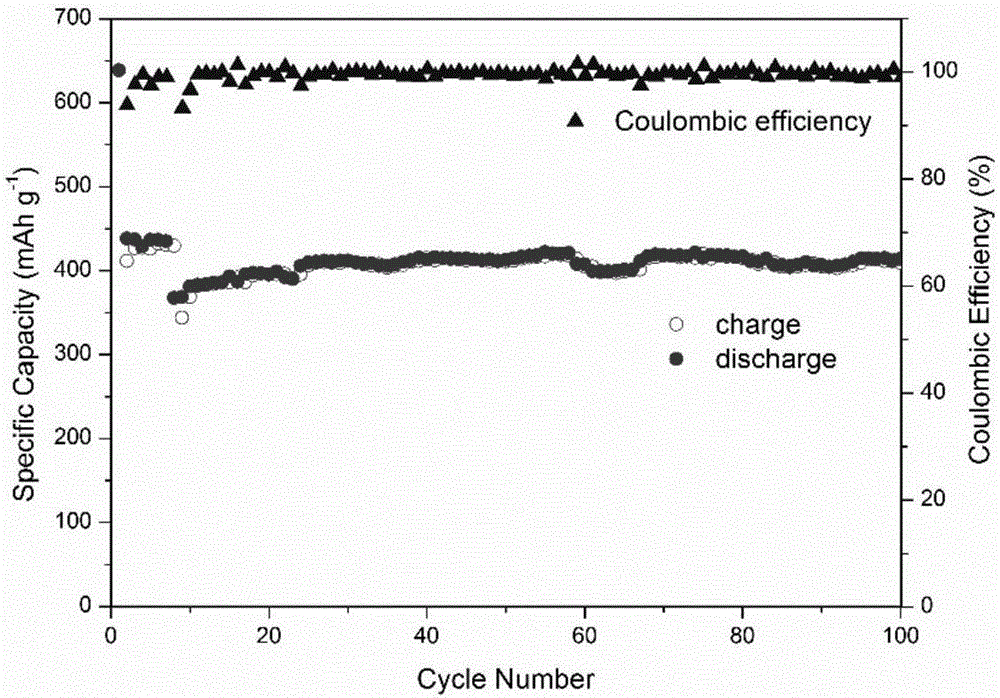

Preparation method of nitrogen-doping carbon substrate-supported Fe3O4 composite material sodium-ion battery negative electrode material

ActiveCN106532001AEnvironmentally friendlyWide variety of sourcesCell electrodesSecondary cellsSodium-ion batteryRaw material

A preparation method of a nitrogen-doping carbon substrate-supported Fe3O4 composite material sodium-ion battery negative electrode material comprises the steps of dissolving urea and a soluble trivalent complexing ferric salt in deionized water according to a mass ratio being (4:1)-(4:4), and uniformly mixing the urea and the soluble trivalent complexing ferric salt to prepare a solution A; freezing the solution A to obtain a solid B after a pH value of the solution A is adjusted to 3-7; and pyrolyzing the solid B under a temperature of 400-700 DEG C after the solid B is frozen and dried. The raw material adopted by the preparation method has the advantages of environmental friendliness, wide source, low cost and the like, and the preparation method is easy to operate; the trivalent ferric salt is used as an iron source and a nitrogen-doping nitrogen source, active sites on a Fe3O4 electrode material are increased due to nitrogen doping, and intercalation and de-intercalation of sodium ions are facilitated; any surfactant is not added, reaction is completed at one time, and subsequent processing is not needed; and the nitrogen-doping carbon substrate-supported Fe3O4 composite material prepared according to the method is stable in cycle performance, and the conductivity of the nitrogen-doping carbon substrate-supported Fe3O4 composite material is improved.

Owner:SHAANXI UNIV OF SCI & TECH

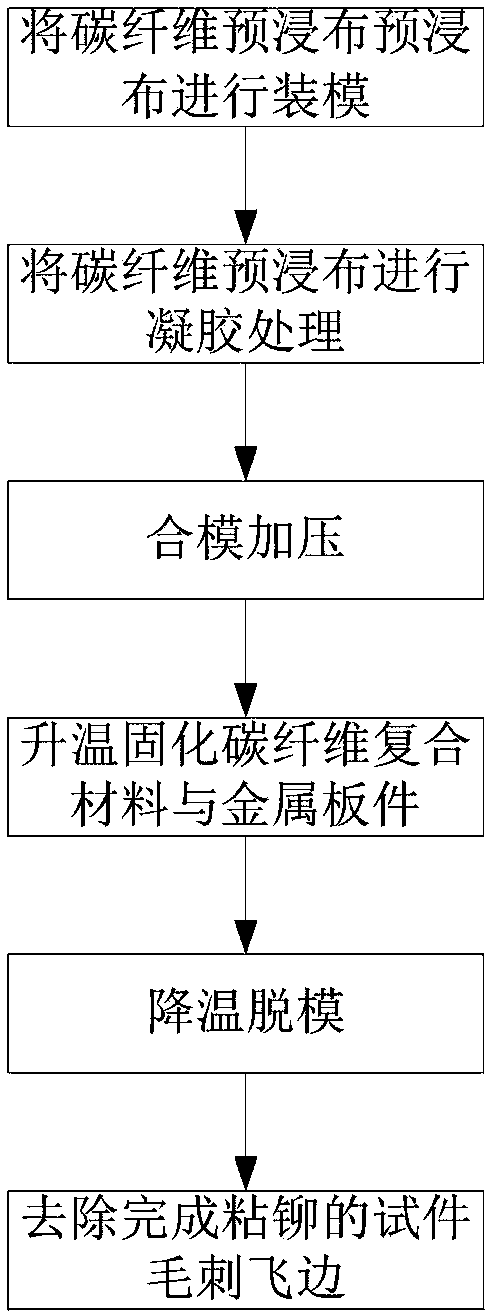

Integrated device and method for forming of carbon fiber composite material and sticky-riveting of carbon fiber composite material and metal sheet piece

PendingCN108297458ALow investment costReduced production footprintDomestic articlesWeight reductionCarbon fiber compositeBond properties

The invention relates to an integrated device and method for forming of a carbon fiber composite material and sticky-riveting of the carbon fiber composite material and a metal sheet piece, and belongs to the technical field of composite riveting. The technical problems that gaps exist in connecting of the composite material and a metal material, the composite material and an adhesive layer are damaged due to riveting, and the technology procedure is complicated exiting in the prior art are solved. The carbon fiber composite material and metal material sticky-riveting method applying the device comprises the following steps that a carbon fiber prepreg is subjected to die-filling; the carbon fiber prepreg is subjected to gelling; the gelled carbon fiber prepreg and a metal sheet are subjected to die-closing and pressurizing; the carbon fiber prepreg and the metal sheet piece are subjected to heating curing; cooling and die-releasing are conducted; and burrs and flashings at the edge parts when a carbon fiber composite material plate and a metal sheet sticky-riveting test piece are formed are removed. According to the integrated device and method for forming of the carbon fiber composite material and sticky-riveting of the carbon fiber composite material and the metal sheet piece, the effect that bonding can be completed while the carbon fiber composite material is subjected to die-pressing forming is achieved; and the bonding property is effectively improved, and the bonding strength is improved.

Owner:JILIN UNIV

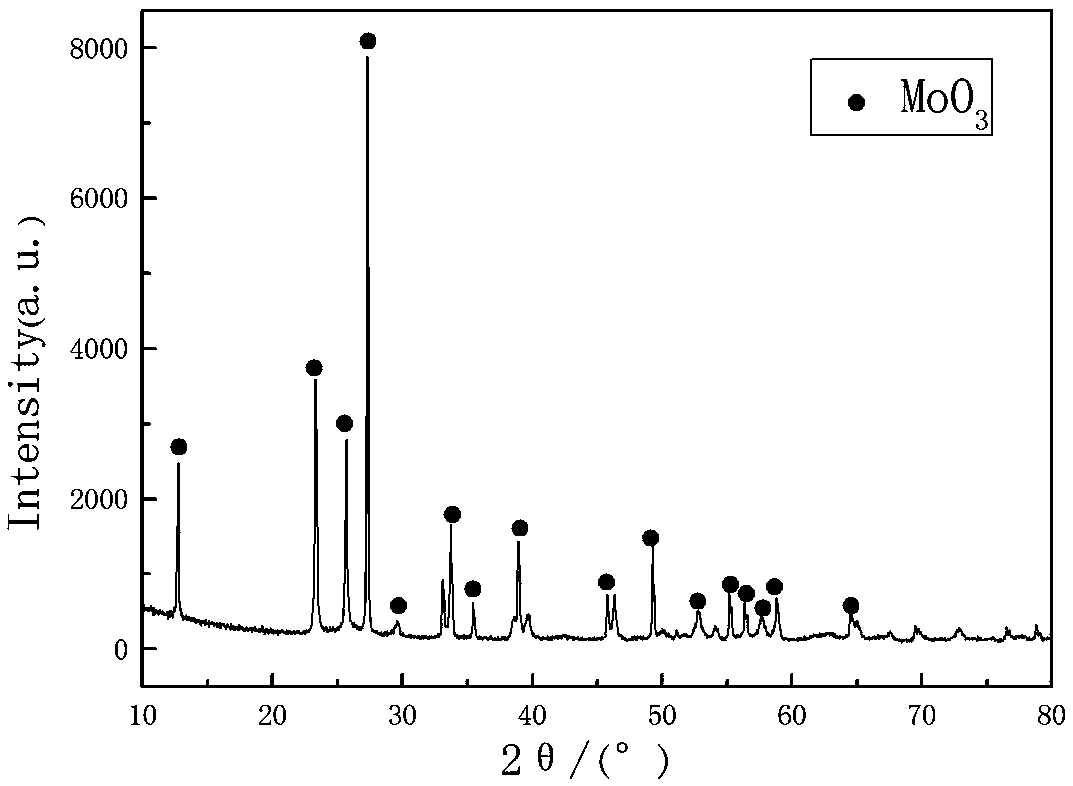

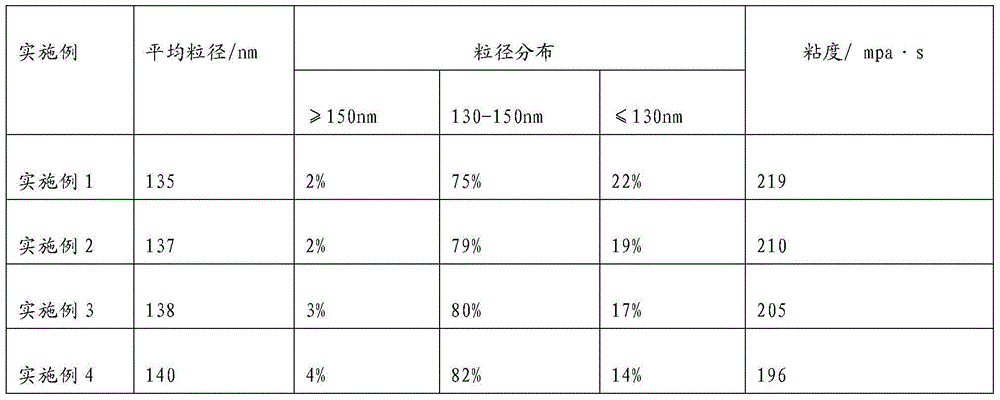

Preparation method of nano MoO3 powder for photocatalytic degradation

ActiveCN108786786AImprove catalytic performanceSimple stepsMaterial nanotechnologyWater/sewage treatment by irradiationPhotocatalytic degradationNanometre

The invention provides a preparation method of sheet-shaped agglomerated-state spherical nano MoO3 powder and belongs to technical application of preparation of nano powder through a wet chemical method. The preparation method of the MoO3 composite powder comprises the following steps: after mixing and stirring ammonium tetramolybdate and a graphene oxide solution, placing for a period of time invacuum; continually quickly freezing with liquid nitrogen and freezing and drying; finally, calcining in the air to obtain the sheet-shaped agglomerated-state spherical nano molybdenum trioxide powder. The preparation method provided by the invention has the advantages that the shape of the powder is unique and the granularity of the powder is uniform; raw materials are easy to obtain and a technology is simple and convenient; the preparation method also has the advantages of simplicity in operation, controllable process, stable product and the like. Prepared nano spherical MoO3 grains are uniformly arrayed to form a large sheet shape, and the powder has extremely excellent photocatalytic performance.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of carboxylic butadiene-styrene latex

ActiveCN104592447AStable molecular structureConcentrated particle size distributionThermal energyMechanical property

The invention relates to a preparation method of a carboxylic butadiene-styrene latex; reaction thermal energy is provided for reaction of the carboxylic butadiene-styrene latex through high-speed water vapour; after being cooled, the water vapour is converted into high-temperature deionized water; furthermore, the high-speed water vapour is also used for driving liquid in a reaction container to rotate; the liquid in the reaction container is dispersed by a water vapour flow to form a lot of tiny steam and water mixtures; a material in the reaction container is driven to flow rapidly; substances and temperature in the reaction container are uniform to distribute; the polymerization reaction is also uniform; therefore, the final product, namely the carboxylic butadiene-styrene latex, is steady in molecular structure, easy in molecular weight control and more centralized in particle diameter distribution; the balanced and good mechanical property can be obtained; and the yield and quality of the product are increased.

Owner:NANTONG TENGLONG CHEM TECH CO LTD

Welding method of super-thick steel casting

InactiveCN109108431AEliminate welding residual stressReduces the chance of weld cracksArc welding apparatusFurnace typesLayer removalWelding deformation

The invention discloses a welding method of a super-thick steel casting. Process steps include S1, preparing a joint: an asymmetric X-type groove is adopted; S2, preheating: the front side and the reverse side are uniformly heated, the preheating temperature is set within the range of 150-160 DEG C, and the heating rate does not exceed 100 DEG C / h; S3, back welding: gas shielded welding backingis carried out on flux-cored welding wires for three layers, and fire warming is carried out to remove stress after each weld seam is welded; S4, reverse side air gouging: air gouging back chipping and carburized layer removal are carried out; S5, reverse side back welding: back welding is carried out by three layers after the temperature of the steel casting reaches a preheating temperature according to the method described in the step 2, and fire warming is performed on each weld seam to remove stress; S6, filling and cover surface welding: the front side and the reverse side are welded respectively by one welder simultaneously and symmetrically, and hammering is carried out layer by layer after each layer of weld beads of each weld seam is welded; and S7, 550 DEG C *2h heat treatment after stress removal is carried out immediately after the completion of welding. By means of the method, welding stress and welding deformation can be significantly reduced, and the probability of generating steel casting welding cracks is greatly reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

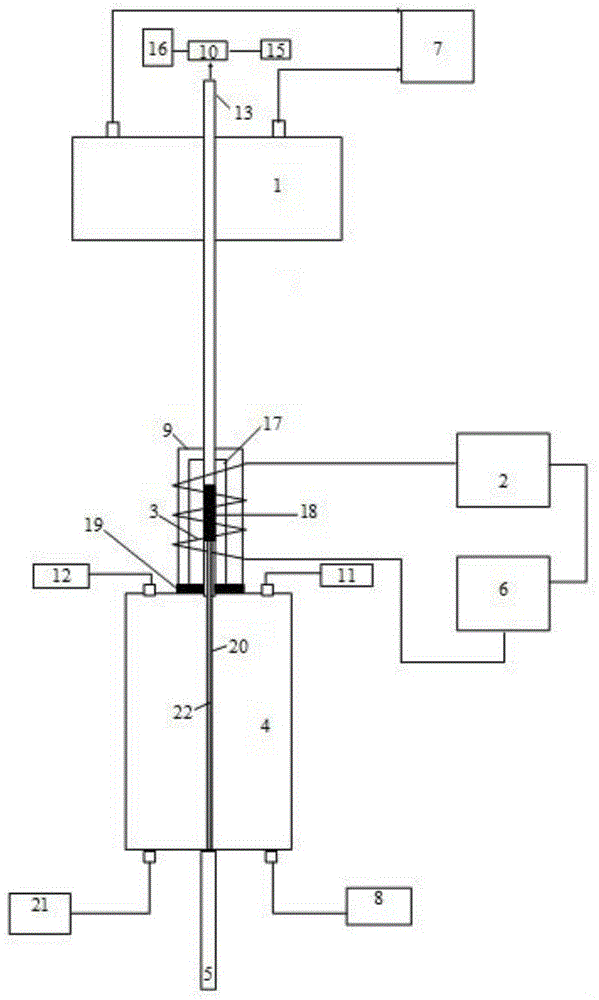

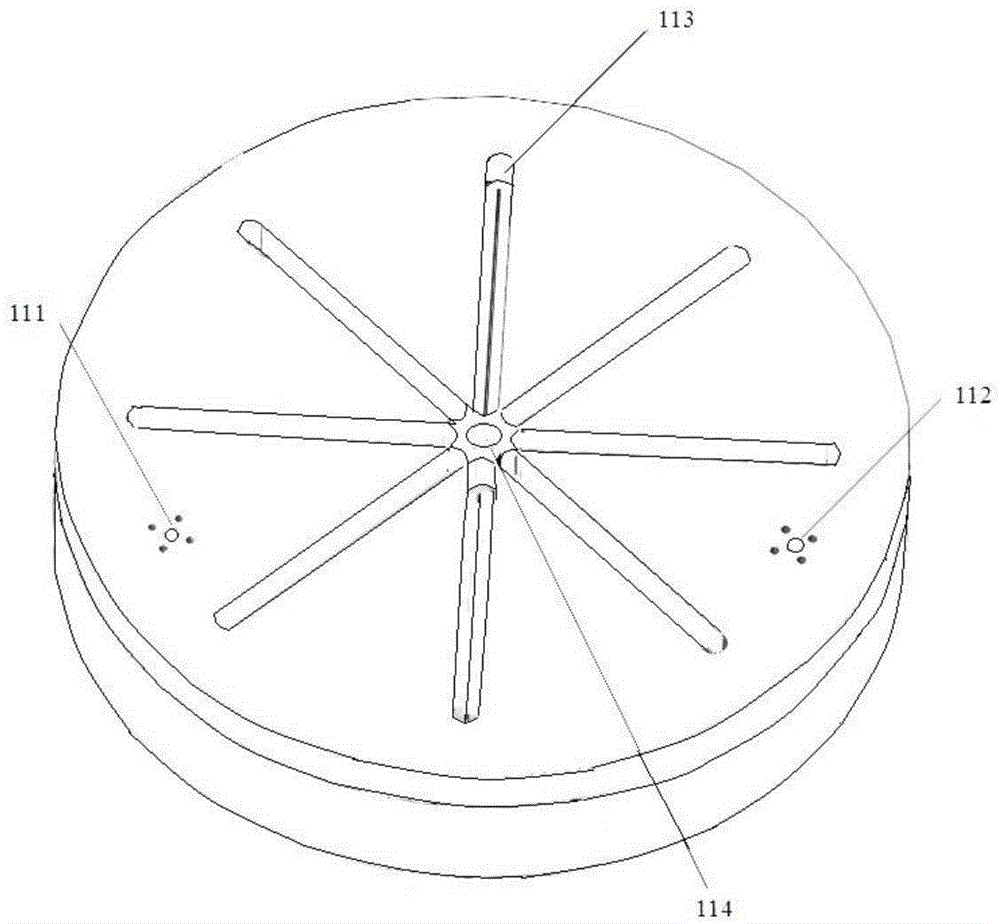

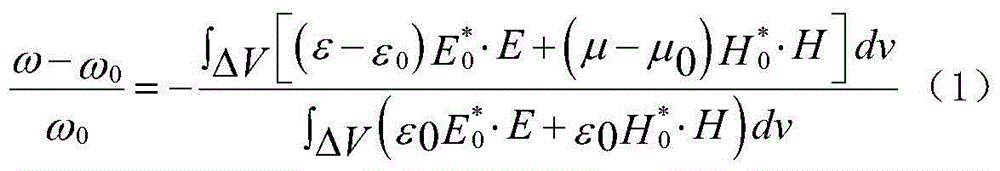

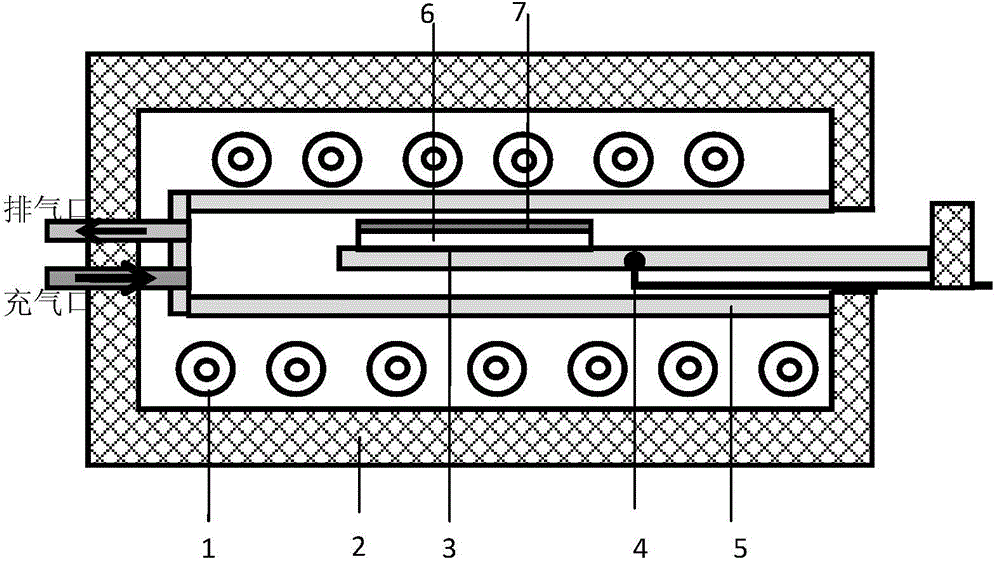

System and method for high-temperature testing of complex permittivity in oxygen-deficient environment

InactiveCN104360172AOxygen-poor environmentHeating fastResistance/reactance/impedencePermittivityEngineering

The invention provides a system and method for high-temperature testing of complex permittivity in an oxygen-deficient environment. The system comprises a testing portion, a pneumatic portion, a sample guiding portion, a heating and cooling temperature control portion and a concentration pressure and temperature control portion. The method comprises the steps that the resonant frequency and the quality factor of a cavity are tested, a rod-shaped sample is placed in the cavity, vacuumizing is conducted on a reservoir firstly, and after vacuumizing, nitrogen and oxygen are fed into the reservoir; an induction heating device is started; when the temperature is raised to a needed temperature through heating, the pneumatic device is started instantly, the heated sample is rapidly ejected into a cylinder resonant cavity through a metal supporting rod, and testing is conducted; the resonant frequency and the quality factor of the resonant cavity and the complex permittivity and the loss tangent value of the sample are tested through a vector network analyzer. By the adoption of the system and method for high-temperature testing of complex permittivity in the oxygen-deficient environment, variable-temperature testing can be conducted on the dielectric property of a material in the oxygen-deficient environment, the heating power can be controlled through the external induction heating device, the testing temperature is higher than 1500 DEG C, and the testing pressure ranges from 0.02 MPa to 0.1 Mpa.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

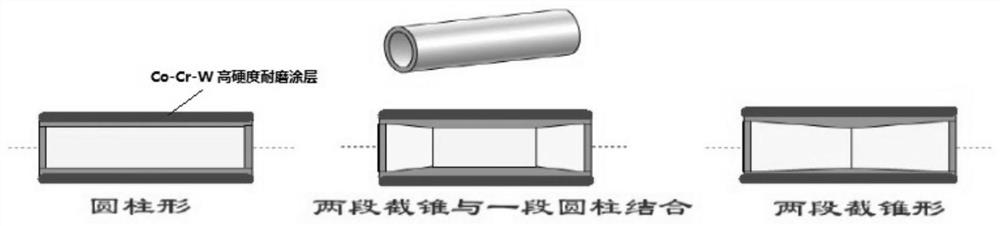

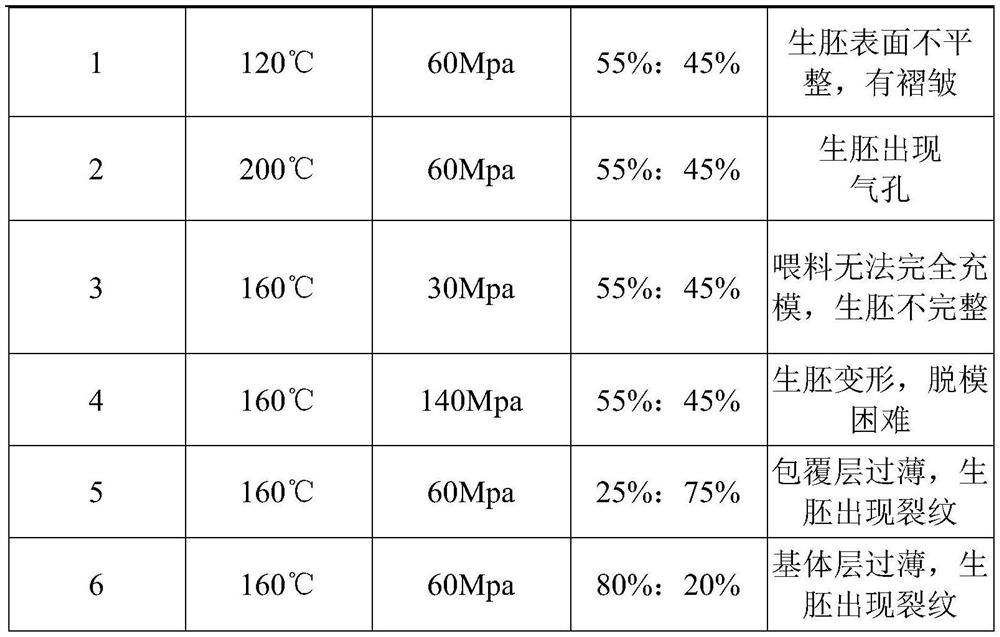

High-hardness wear-resistant piston pin and preparation method thereof

The invention discloses a high-hardness wear-resistant piston pin and a preparation method thereof. The preparation method comprises the following steps of firstly, respectively mixing matrix material powder and Co-Cr-W alloy powder with a binder, and performing granulation to obtain a matrix material feed and a high-hardness wear-resistant coating material feed; then, sequentially injecting the matrix material feed and the Co-Cr-W alloy coating material feed into a mold cavity by using an injection molding technology to obtain a product green body; removing the binder in the green body through catalytic debinding and thermal debinding processes; and finally, performing co-sintering densification to obtain the Co-Cr-W series high-hardness wear-resistant piston pin. The process is simple, the bonding performance of a coating layer and a matrix is good, and the piston pin has the characteristics of high hardness and wear resistance.

Owner:湖南英捷高科技有限责任公司

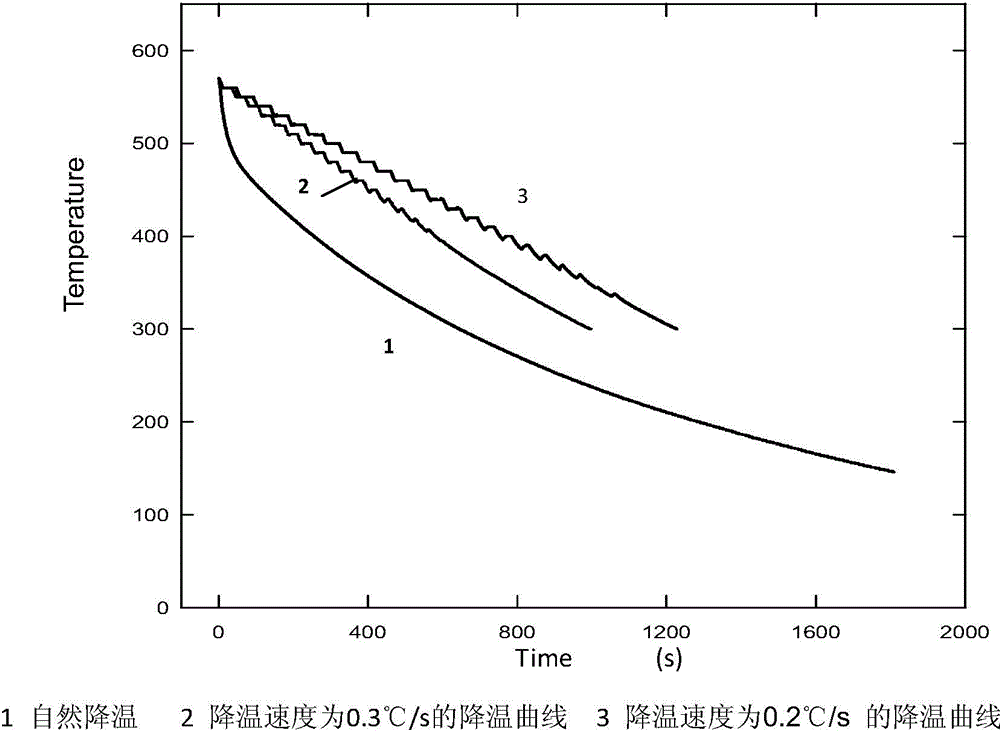

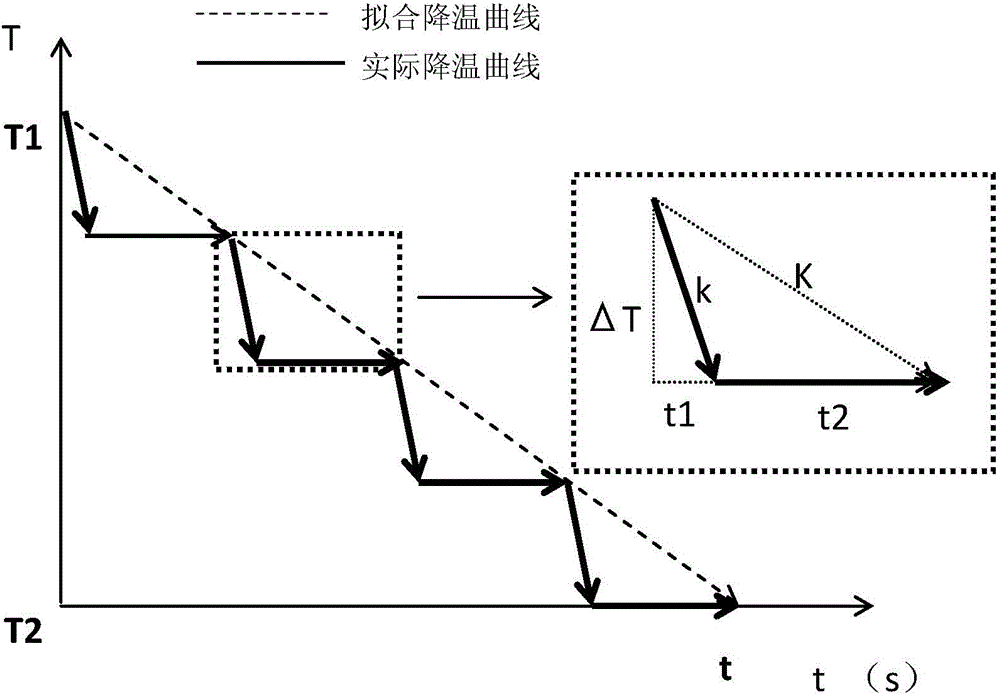

Temperature rise and fall control method in rapid temperature rise treatment process

InactiveCN104465370AControl heating rateControl cooling rateSemiconductor/solid-state device manufacturingPhotovoltaic energy generationManufacturing technologyHalogen

The invention discloses a temperature rise and fall control method in the rapid temperature rise thermal treatment process of Cu, In, Ga and Se solar cell sample pieces and a setting method of temperature rise and fall control and belongs to the field of conductor material thermal treatment manufacturing technologies. The speed of temperature rise and fall of a vacuum heating chamber is controlled by controlling the power-on / off time of a halogen tungsten lamp (in other words, the temperature rise time, the temperature fall time and the temperature maintaining duration are controlled by setting a program). Through the method, the limit that the temperature rise in the RTP is controllable while control over the temperature fall process is simplex is broken through, and the temperature rise and fall control method is a diversified thermal treatment process capable of simply achieving temperature rise and slow temperature fall.

Owner:SUZHOU RUISHENG SOLAR ENERGY TECH

Preparation method of non-metal-doped titanium dioxide porous film with ordered pores

The invention relates to a preparation method of a non-metal-doped titanium dioxide porous film with ordered pores. The preparation method comprises the following steps of: uniformly dispersing a reagent which is completely decomposed into gaseous substances NH3 and(or) CO and CO2 and titanium dioxide nano-particles or titanium dioxide soil into water or alcohol to prepare a dispersion system; preparing titanium dioxide slices by the prepared dispersion system through methods such as spin-coating, lifting, scraping or tabletting, and drying under a certain temperature; and thermally treating the dried titanium dioxide slices in a certain vacuum degree to control heat-up velocity to prepare the non-metal-doped titanium dioxide porous film with ordered pores. According to the preparation method disclosed by the invention, effective control of order and pore diameter of pores of the titanium dioxide porous film as well as effective doping of non-metal materials (N and C) is realized at the same time by controlling the amount of the reagent, the vacuum degree and the heat-up velocity during thermal treatment.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Glass heating furnace and heating method

InactiveCN105936586AReduce energy consumptionHeating fastGlass tempering apparatusGlass productionTemperature controlHeating time

The invention discloses a glass heating furnace and a heating method. A ceramic roller way for heating glass is arranged in a furnace. Glass is placed on the ceramic roller way. A radiation type air heater is arranged above the glass. A forced convection device is also arranged above the glass and is used to make hot air around the radiation type air heater carry out internal thermal circulation; during the circulation process, the force convection device can control the flowing speed and flow of hot air and is used to heat the upper surface of glass, thus the upper surface of glass can be uniformly heated relative to the lower surface, and the temperature of the upper surface of glass can be controlled. The high temperature convection device makes the idle hot air above the heater carry out forced internal thermal circulation so as to further reduce the energy consumption, moreover, the heating speed is increased, the heating becomes more uniform, and the heating time is shortened.

Owner:GUANGDONG FUSHAN GLASS MACHINERY

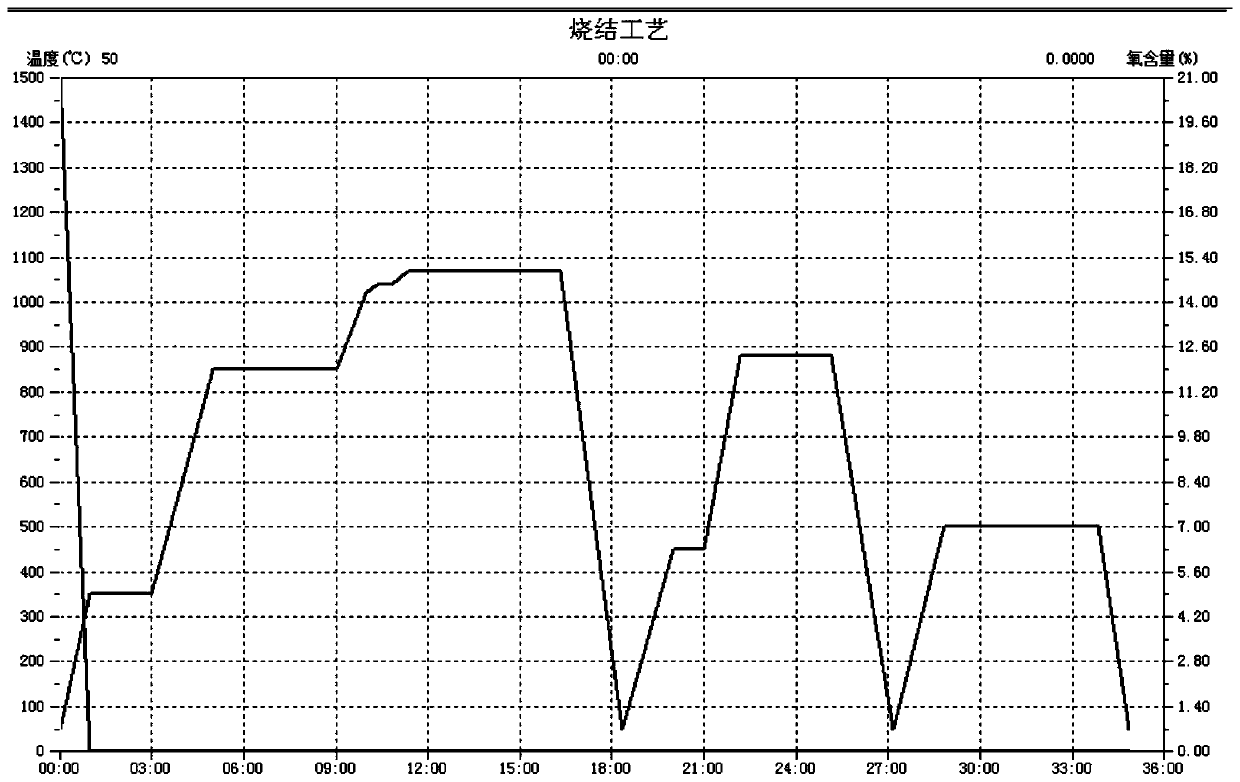

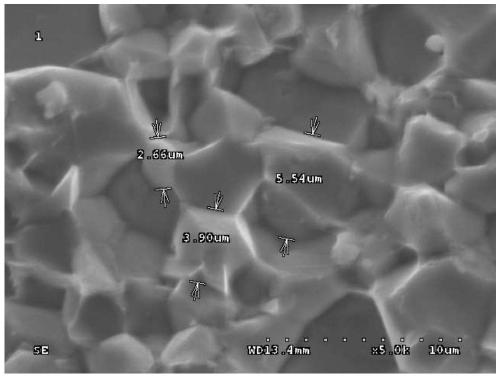

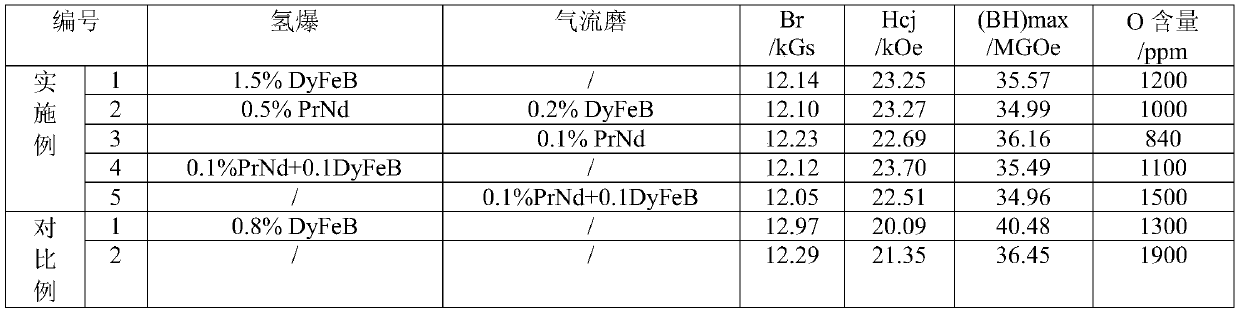

Sintered neodymium iron boron magnet

ActiveCN109732046AEvenly distributedImprove effective utilizationInductances/transformers/magnets manufactureMagnetic materialsHydrogenRare earth

The invention relates to the technical field of rare earth permanent magnets, in particular to a sintered neodymium iron boron magnet and a preparation method thereof. The sintered neodymium iron boron magnet is characterized in that according to the mass percentage composition, the general formula of the sintered neodymium iron boron magnet is ReaDybFe100-a-b-c-dBcMd; Re is one or more of Pr, Nd,La, Ce, Gd and Ho; M is one or more of Co, Cu, Al, Nb, Ga, Zr, Ti and Cr; and a is larger than or equal to 27 and smaller than or equal to 33, b is larger than or equal to 1.0 and smaller than or equal to 2.0, c is larger than or equal to 0.9 and smaller than or equal to 1.1, and d is larger than or equal to 0 and smaller than or equal to 5. Through the optimized process, smelting, single hydrogen breaking and powder making are not needed, and the using amount of heavy rare earth can be reduced to 1.5wt% or even 1.2wt%, so that rare earth is more uniformly distributed in the grain boundary, and the effective utilization ratio of the rare earth is improved; and according to the sintered neodymium iron boron magnet prepared through the process, while cost is reduced, the excellent magneticproperties are achieved.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

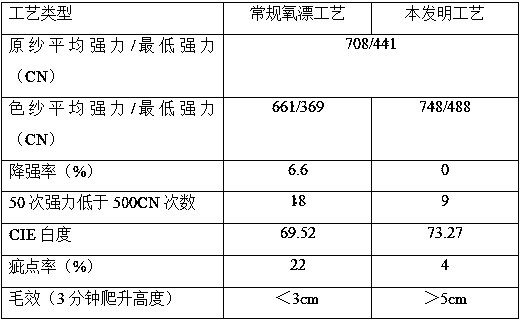

Production process of pure linen cheese

InactiveCN109295735AFeel goodReduce degradation rateBiochemical treatment with enzymes/microorganismsVegetal fibresYarnPectinase

The invention relates to a production process of pure linen cheese. Pure linen cheese which has undergone chlorite bleaching is then subjected to oxygen bleaching, dyeing, softening and yarn drying processes. The invention is characterized in that pure linen cheese is subjected to bio-enzyme scouring treatment before oxygen bleaching, and a mixed solution for the bio-enzyme scouring is mainly composed of pectinase, scouring agent and chelating agent; the heating rate of a rinsing liquid used in the oxygen bleaching is 1-1.5 DEG C / min; during the softening process, a hydrophilic softener is adopted; and the moisture content of the cheese obtained after the yarn drying is 6-8%. By the process, hydrophilicity of the fiber can be enhanced and hand feeling of the yarn can be improved, strengthreduction rate of the yarn is reduced, rewinding is promoted for the linen yarn, capillary effect of the yarn is improved, and the soft hand feeling is beneficial to subsequent weaving.

Owner:JIANGSU LIANFA TEXTILE

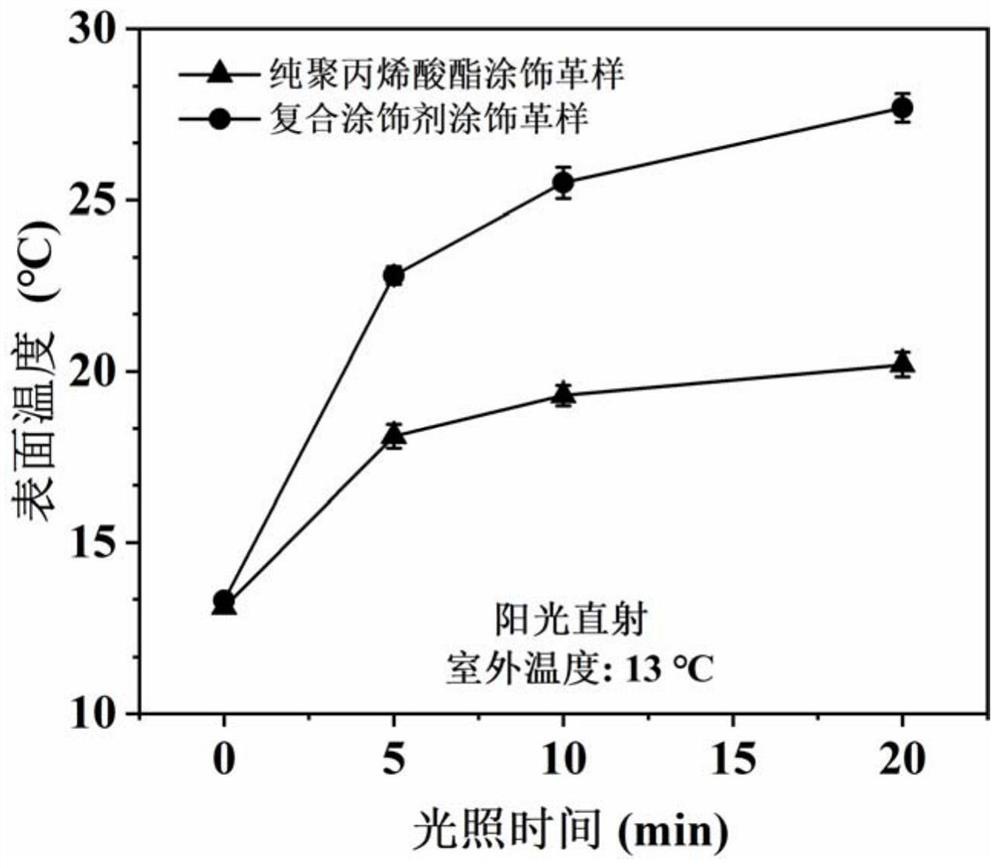

Photo-thermal heat preservation type composite leather finishing agent based on Pickering emulsion polymerization method and preparation method thereof

ActiveCN111748255AGood dispersionReduce temperature differenceCoatingsLeather surface finishingPolymer scienceUltrasonic emulsification

The invention discloses a photo-thermal heat preservation type composite leather finishing agent based on a Pickering emulsion polymerization method, a preparation method and application thereof, andbelongs to the technical field of leather finishing agent preparation. According to the preparation method, the amphipathy is regulated and controlled through polydopamine modified Ti3C2; ultrasonic emulsification is carried out on the obtained amphiphilic polydopamine modified Ti3C2 nanosheet, a co-emulsifier, a vinyl monomer and water to obtain a pre-emulsion, and polymerization of the pre-emulsion is initiated by using a Pickering emulsion polymerization method to obtain the photo-thermal heat preservation type composite leather finishing agent. The photo-thermal heat preservation type composite leather finishing agent prepared by the method contains amphiphilic polydopamine modified Ti3C2 nanosheet with a synergistic photo-thermal conversion effect, the problem of sedimentation and agglomeration when Ti3C2 is introduced by a blending method is avoided, then the obtained photo-thermal heat preservation type composite leather finishing agent is applied to a leather finishing process,and a leather product capable of rapidly and spontaneously heating under natural illumination can be obtained, so that the total heat dissipation amount of a human body is reduced by reducing the temperature difference between the human body and the leather product, and the heat retention property of the leather product is improved.

Owner:杭州棕榈地科技开发有限公司

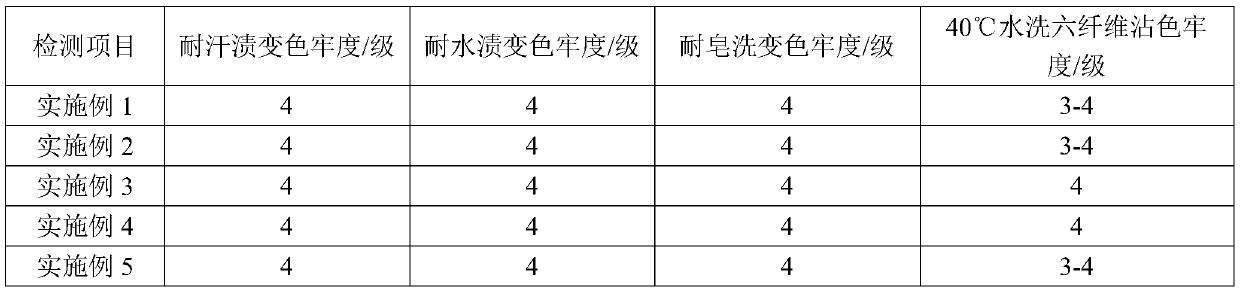

Dyeing method of polyester-polyamide composite silk fabric

The invention relates to a dyeing method of a polyester-polyamide composite silk fabric and belongs to the technical field of fabric dyeing. The method comprises the steps of treatment before cold piling, open-width vibrated rinsing based on a rotating drum, preshrinking in an overflow vat, pre-setting treatment, dyeing with dispersed dyes, acid overdyeing and setting treatment. According to the method, by utilizing the synergic action of working solutions in each step and the synergic action among the processes in each step, the fabric shows high color fastness to sweat stains, water stains and soaping, so that the fabric has the advantages of high color fastness and full and rich colors.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

Brazing method for SiC particle-reinforced aluminum matrix composite

InactiveCN106735667AImprove weld bonding strengthSimple processWelding/cutting media/materialsSoldering mediaAluminum matrix compositesSurface grinding

The invention discloses a brazing method for a SiC particle-reinforced aluminum matrix composite. The brazing method comprises the following steps that S1, the SiC particle-reinforced aluminum matrix composite is put into water, grinding and ultrasonic washing are conducted, room temperature drying under the vacuum condition is conducted, and a pre-welding base material is obtained; S2, surface grinding and washing are conducted on aluminum-silicon-magnesium brazing filter metal, and welding brazing filter metal is obtained after drying; S3, a vacuum brazing furnace is vacuumized, and the pre-welding base body and the welding brazing filter metal are assembled and then put into the vacuum brazing furnace; and S4, the vacuum brazing furnace is heated to 580-600 DEG C, the temperature is kept for 25-35 min, cooling along with the furnace is conducted, welding is completed, and the welding piece is obtained. According to the brazing method, for the characteristic of the SiC particle-reinforced aluminum matrix composite, by the adoption of the vacuum brazing welding manner, the aluminum-silicon-magnesium brazing filter metal is used, the Ti active ingredient is added, the contact surface tension of the flux and the composite is improved, and the weld seam bonding force is improved. The brazing method has the beneficial effects of being excellent in shear strength, simple in process and easy to implement.

Owner:天长市通联焊业有限公司

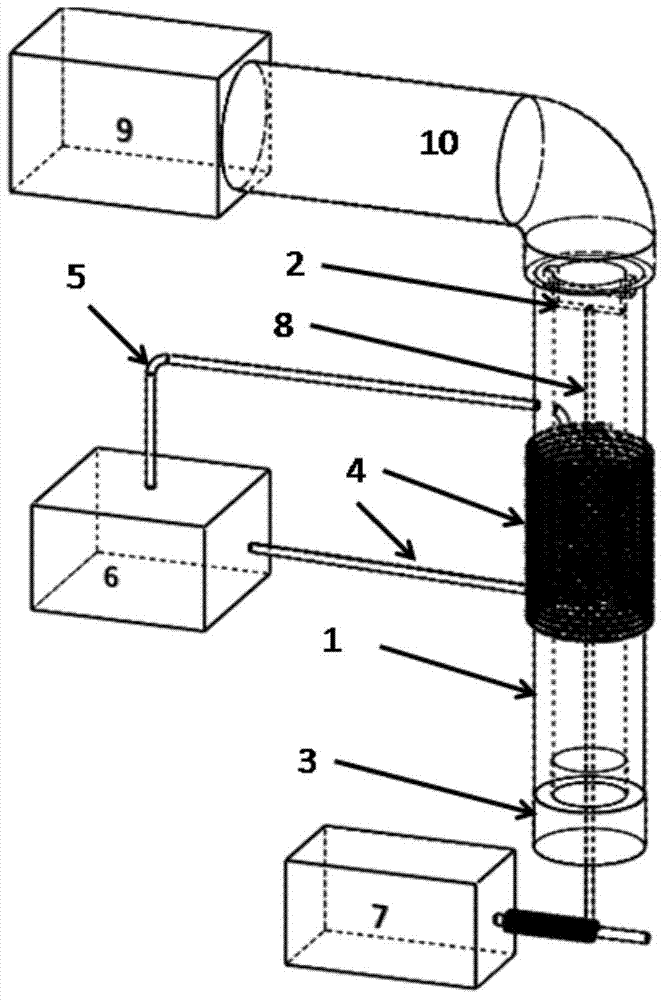

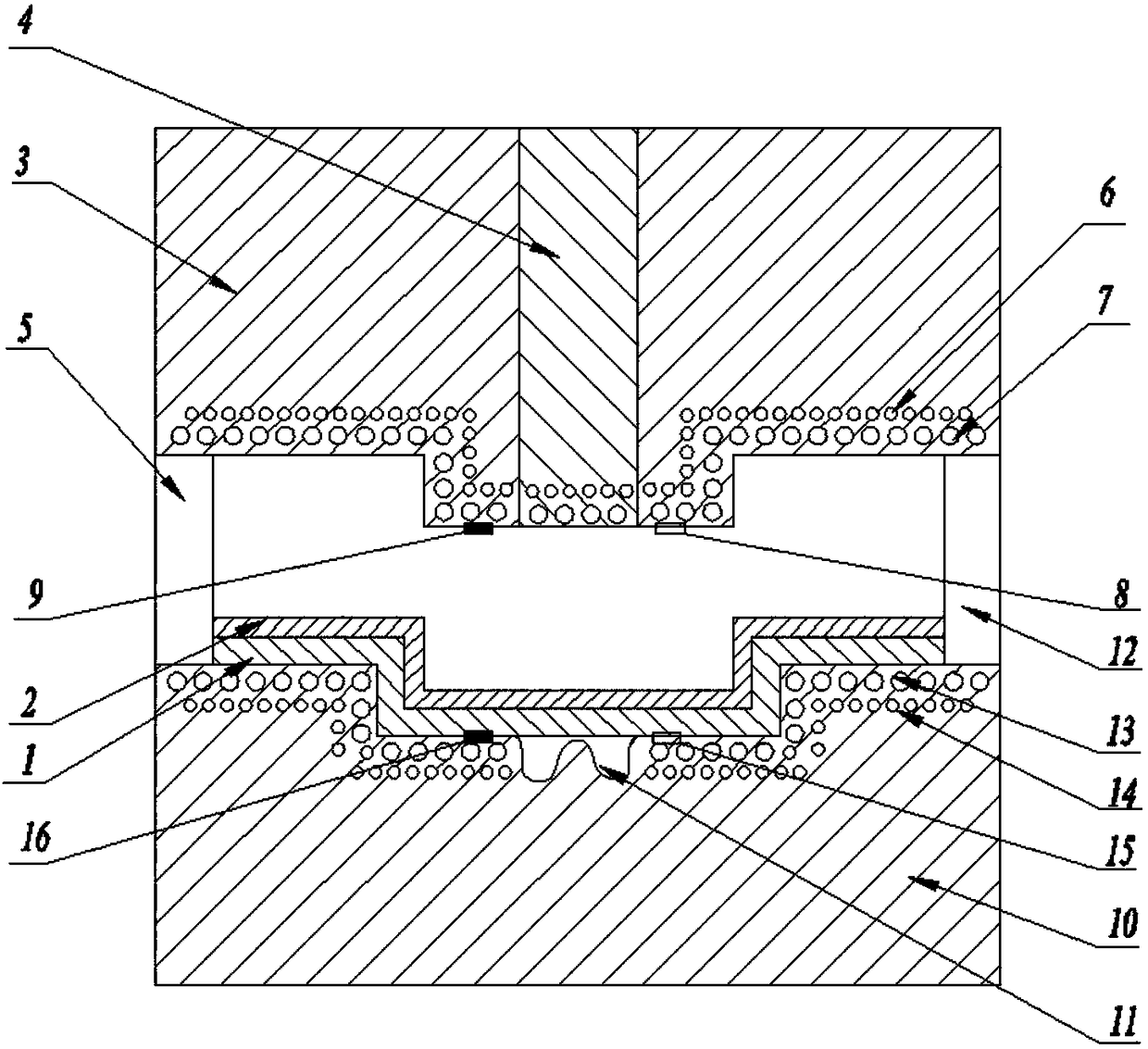

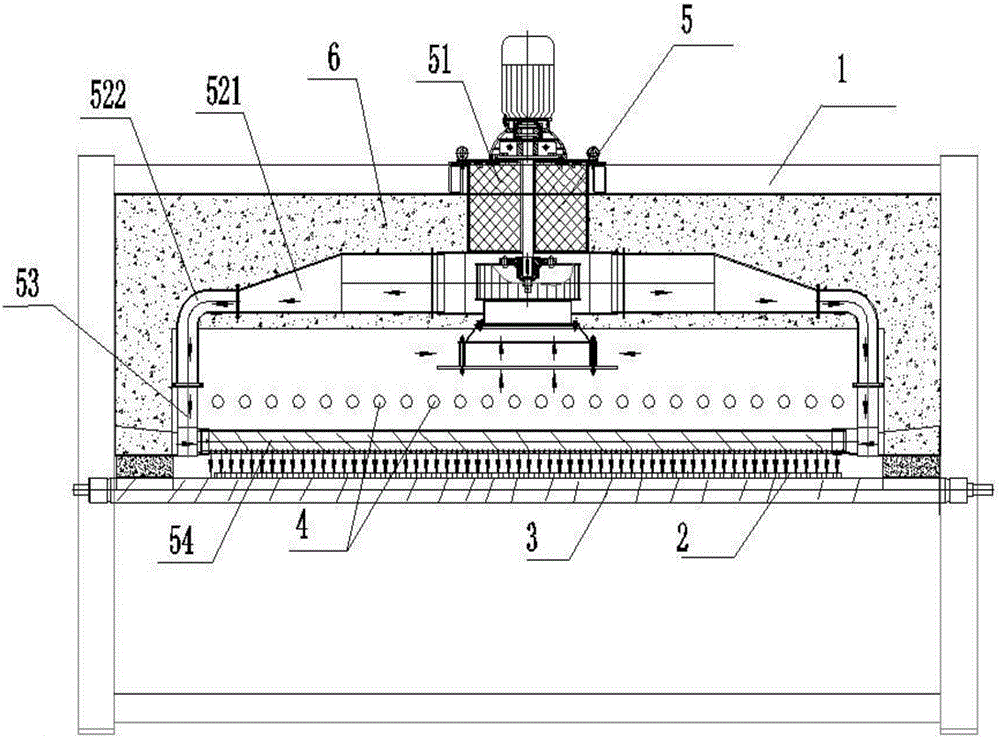

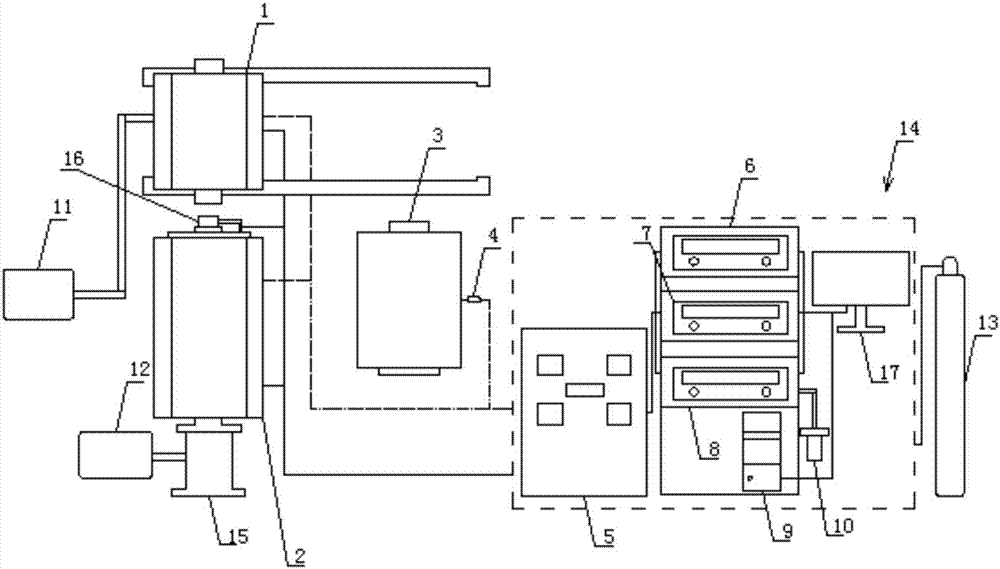

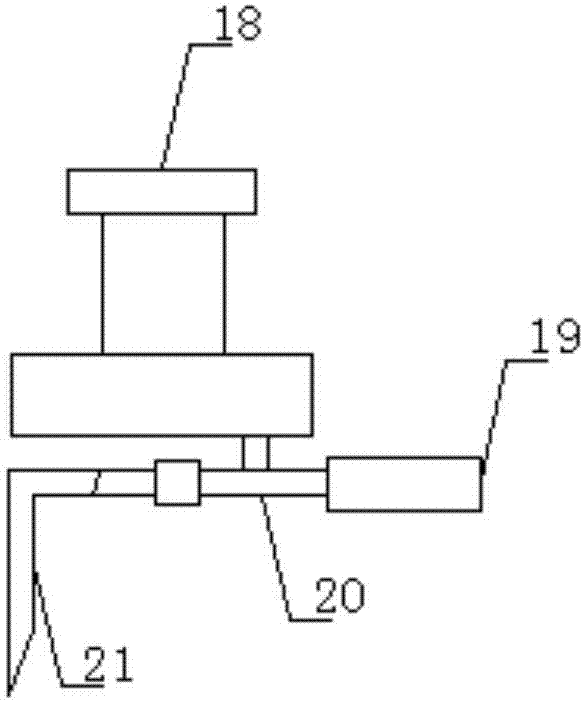

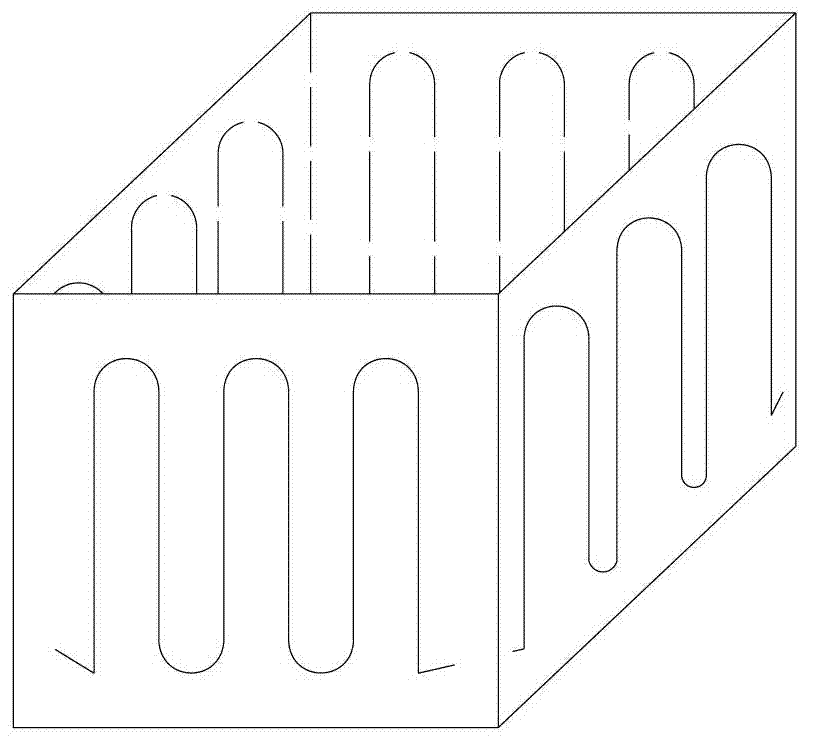

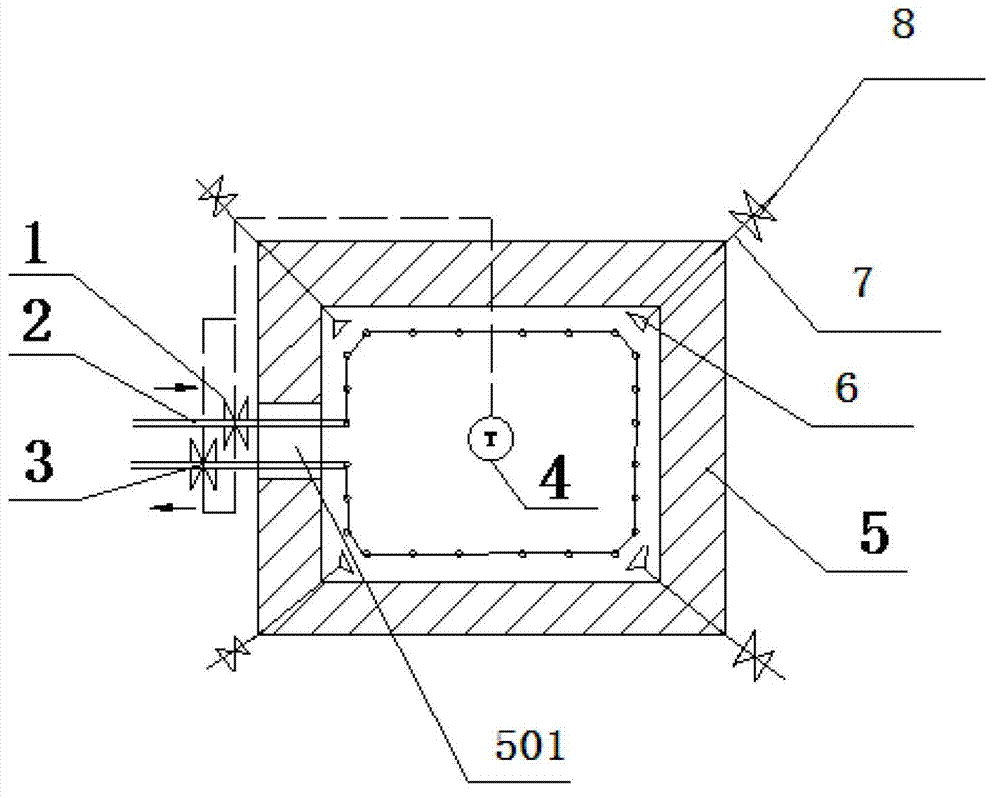

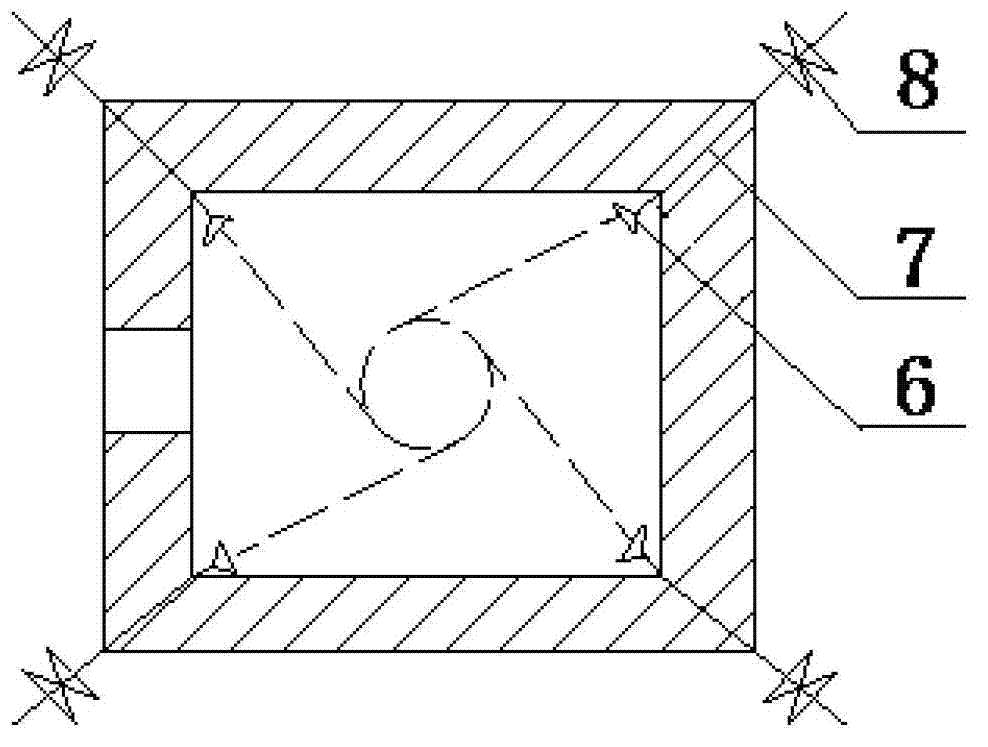

Blast furnace coal spraying-iron ore sintering experiment simulation device

ActiveCN107190113AControl heating rateImprove accuracyBlast furnace detailsCombustionIron ore sintering

The invention belongs to the technical field of metallurgy chemical engineering and particularly relates to a blast furnace coal spraying-iron ore sintering experiment simulation device. The blast furnace coal spraying-iron ore sintering experiment simulation device comprises a coal powder combustion furnace, a sintering furnace, a hot air furnace communicating with the coal powder combustion furnace or the sintering furnace, a support moving the hot air furnace to communicate with the coal powder combustion furnace or the sintering furnace, a control and data collection system connected with the coal powder combustion furnace, the sintering furnace and the hot air furnace, and an air cylinder supplying air to the control and data collection system. Through the blast furnace coal spraying-iron ore sintering experiment simulation device provided by the invention, the function that coal powder-hot air continuous combustion and iron ore hot air sintering are simulated simultaneously is achieved, the experiment device utilization ratio is increased, device cost is lowered, and the practical application problems that the occupied area is large, the area of a laboratory is limited, and an experimental device is inconvenient to move are solved.

Owner:WUHAN UNIV OF SCI & TECH

Multi-ion co-doping lithium iron phosphate material and preparation method thereof

InactiveCN105845913AGuaranteed uniformityImprove rate discharge performanceCell electrodesChemistryIron phosphate

The invention provides a multi-ion co-doping lithium iron phosphate material and a preparation method thereof. The chemical formula of the multi-ion co-doping lithium iron phosphate material is Li<1-z>M<2>Fe<1-y>V<y>(PO<4>)<1-x>F<x> / C, wherein x is more than or equal to 0.001 but less than or equal to 0.1, y is more than or equal to 0.001 but less than or equal to 0.1, z is more than or equal to 0.001 but less than or equal to 0.1, and M is lithium position doping metal ion. The preparation method comprises the following steps of firstly, preparing vanadium ion doping iron phosphate Fe<1-y>V<y>PO<4>.2H<2>O containing crystal water; secondly, obtaining vanadium doping iron phosphate Fe<1-y>V<y>PO<4> which does not contain the crystal water by thermal processing; and finally, adding a ball-milling medium, carrying out ball-milling mixing, carrying out pre-sintering and then calcination in a high temperature, and cooling and grinding the mixture to obtain the multi-ion co-doping lithium iron phosphate powder material. The method is simple in process, energy consumption is relatively low, the raw material is low in cost, and industrial production at a large scale is facilitated.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Boiler drying temperature control module and its control method

InactiveCN102767957AAvoid temperature fluctuationsEvenly distributedLinings repairGas emission reductionTemperature controlEngineering

The invention relates to a boiler drying temperature control module. The control module comprises a temperature measurement unit arranged at an inner side of a boiler wall. The control module is characterized in that a vapor heat dissipation pipe and a burner nozzle are arranged at the inner side of the boiler wall, and the vapor heat dissipation pipe is provided with a first flow control valve at an inlet end and a second flow control valve at an outlet end. Meanwhile, the invention also provides a method for controlling a boiler drying temperature by using the boiler drying temperature control module. The control module and method carry out drying by using vapor produced by a boiler without using novel special drying apparatus, simplify a drying process, ensure uniform distribution of a temperature field, achieve online regulation of a heating rate, and guarantee a boiler drying effect.

Owner:BAOSTEEL STAINLESS STEEL

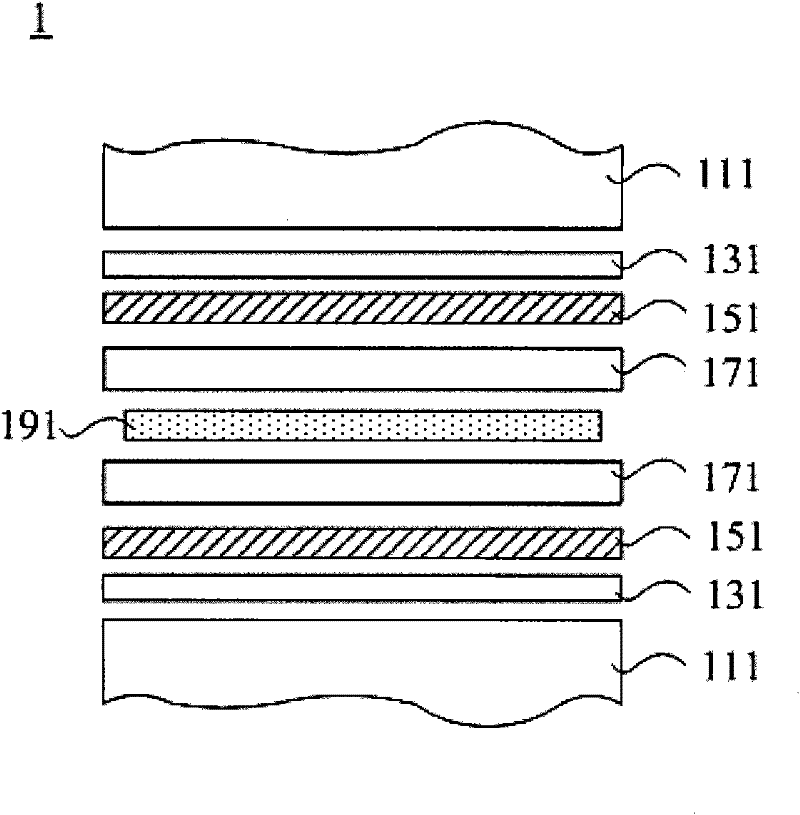

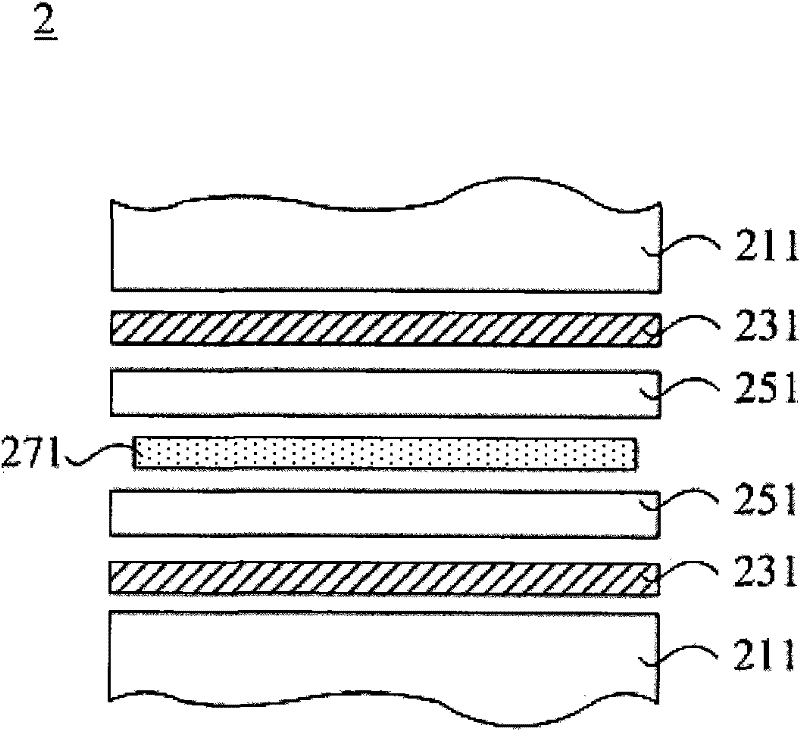

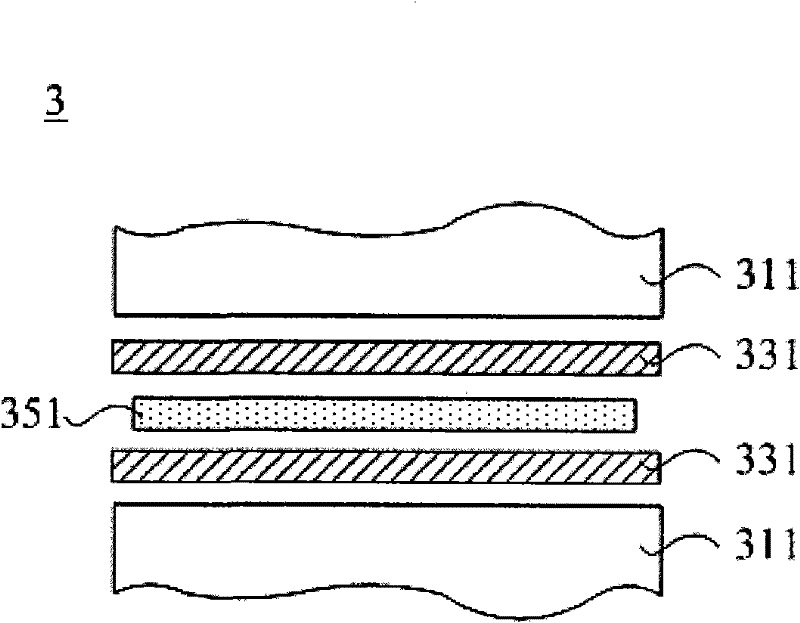

Buffer material for hot press and application of buffer material

The invention discloses a buffer material for a hot press. The buffer material comprises a base layer, a fixing line and first fibers consisting of a single component substantially. The buffer material has reversible deformation capacity under the operating conditions of the hot press. The first fibers are fixed on the base layer in a knitting mode by means of the fixing line, and nonwoven cloth with the density of about 0.1-3.0 grams per cubic centimeter is formed; the base layer and the fixing line respectively independently consist of one or more kinds of fibers of which the glass transition temperature is more than or equal to that of the first fibers; and the first fibers account for more than or equal to 70 weight percent of the buffer material. The invention also provides application of the buffer material for the hot press.

Owner:TECH ADVANCE IND

Multiple ions co-doped lithium iron phosphate material and preparation method thereof

InactiveCN105152155AHigh crystallinityImprove uniformityPhosphatesHybrid capacitor electrodesLithium iron phosphateVanadium doping

The invention provides a multiple ions co-doped lithium iron phosphate material and a preparation method thereof. This material has a chemical general formula: Li1-zMzFe1-yVy(PO4)1-xFx / C, wherein 0.001< / =x< / =0.1, 0.001< / =y< / =0.1, 0.001< / =z< / =0.1, and M is lithium-doped metal ions. The preparation method includes: preparing vanadium ion doped iron phosphate Fe1-yVyPO4.2H2O containing crystal water, and performing thermal treatment to obtain vanadium doped iron phosphate Fe1-yVyPO4 not containing crystal water; adding a ball-milling medium, allowing ball milling and mixing, performing pre-sintering, performing calcining at high temperature, and performing grinding after cooling to obtain multiple ions co-doped lithium iron phosphate powdered material. The preparation method is simple, energy consumption is low, raw materials are low in price, and industrial production of the material is facilitated.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Faint nutrition and healthcare instant chrysanthemum tea electuary and its preparation method

InactiveCN107258992AEnhance anti-inflammatoryInhibitory activityPre-extraction tea treatmentIntestinal structureCodonopsis pilosula

The invention discloses a faint nutrition and healthcare instant chrysanthemum tea electuary, which is prepared from, by weight, 40-50 parts of dry chrysanthemum, 5-7 parts of radix paeoniae alba, 3-5 parts of cyathula prostrate, 3-5 parts of liquorice, 2-4 parts of aloe, 5-7 parts of honeysuckle, 2-4 parts of hawthorn, 1-3 parts of Codonopsis pilosula, 2-4 parts of red jujube, 3-5 parts of medlar, 7-9 parts of fresh tea leaf, 2-4 parts of polyphenol additive, 0.5-1.5 parts of compound vitamin additive, and 0.8-1.4 parts of compound prebiotics. The chrysanthemum tea electuary is quick in dissolving speed in water, faint in smell, and has the functions of boosting immunity, clearing away heat and toxic materials, and coordinating intestines and stomach; after brewing, the taste is mellow, the nutrition value is high, and the expiration date is long; the electuary is convenient to use; meanwhile, the preparation method adopts toxic-free and harm-free raw materials, so the electuary is suitable for long-term drinking; moreover, materials are convenient to take, and the raw material cost is low, and technique is simple and clear; the faint nutrition and healthcare instant chrysanthemum tea electuary has high practical value and good application prospect.

Owner:金寨县秉诚农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com