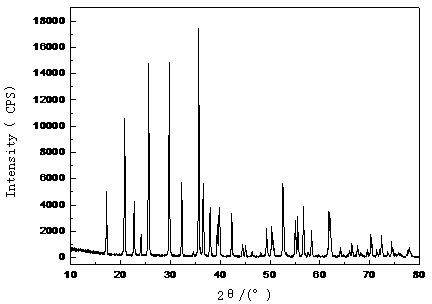

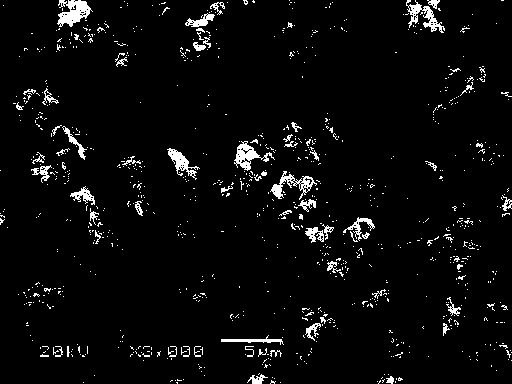

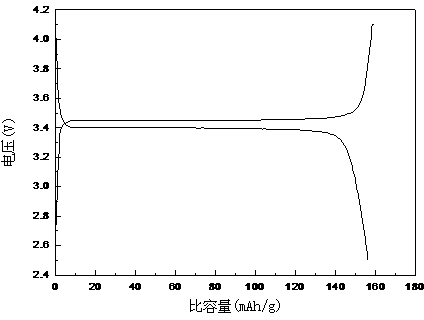

Multi-ion-doped carbon-coated lithium iron phosphate battery material and preparation method thereof

A carbon-coated technology for lithium iron phosphate and battery materials, which is applied to battery electrodes, circuits, electrical components, etc. Electrical properties and other issues, to ensure uniformity, high specific capacity, and improve the effect of electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Weigh 259.49g FeCl 3 ·6H 2 O, 10.51g NiSO 4 ·6H 2 O was added to 20L deionized water to prepare a mixed solution A with a total metal ion concentration of 0.05mol / L; weigh 115.03g NH 4 h 2 PO 4 Add it into 0.2L deionized water to make solution B with a concentration of 5mol / L; prepare an ammonia solution with a concentration of 10mol / L; pump solution A and solution B into a rapidly stirring reaction kettle with a peristaltic pump, and control the reaction temperature to 40°C, the stirring speed is 1200rpm, adjust the pH value to 2.4 with ammonia solution, react for 0.5h, then filter the reaction liquid, wash and dry to obtain Ni-doped iron phosphate containing crystal water, expressed as Fe 0.96 Ni 0.04 PO 4 2H 2 O.

[0028] 2, the Fe obtained in step 1 0.96 Ni 0.04 PO 4 2H 2 O was heat-treated from room temperature to 300°C for 10 hours at a heating rate of 5°C / min, and then cooled naturally to obtain Ni-doped iron phosphate without crystal water, expre...

Embodiment 2

[0033] 1. Weigh 403.62g Fe(NO 3 ) 3 9H 2 O, 0.24g CoCl 2 ·6H 2 O was added to 1L deionized water to prepare a mixed solution A with a total metal ion concentration of 1mol / L; weigh 131.05g (NH 4 ) 2 HPO 4 Add it into 1L of deionized water to prepare a solution B with a concentration of 1mol / L; prepare an aqueous ammonia solution with a concentration of 8mol / L; use a peristaltic pump to pump solution A and solution B into a rapidly stirring reactor, and control the reaction temperature to 80 ℃, the stirring speed is 800rpm, adjust the pH value to 3 with ammonia solution, react for 1.5h, then filter the reaction liquid, wash and dry to obtain Co-doped iron phosphate containing crystal water, expressed as Fe 0.999 co 0.001 PO 4 2H 2 O.

[0034] 2, the Fe obtained in step 1 0.999 co 0.001 PO 4 2H 2 O was heat-treated from room temperature to 450 °C for 6 hours at a heating rate of 1 °C / min, and the temperature was naturally lowered to obtain Co-doped iron phosphate ...

Embodiment 3

[0038] 1. Weigh 264.89g FeCl 3 ·6H 2 O, 5.00g Mn(NO 3 ) 2 4H 2 O was added to 4L deionized water to prepare a mixed solution A with a total metal ion concentration of 0.25mol / L; weigh 131.05g (NH 4 ) 2 HPO 4 Add it into 2L deionized water to prepare solution B with a concentration of 0.5 mol / L; prepare an aqueous ammonia solution with a concentration of 3 mol / L; pump solution A and solution B into a rapidly stirring reactor with a peristaltic pump, and control the reaction temperature to 65°C, the stirring speed is 2500rpm, adjust the pH value to 2.7 with ammonia solution, react for 3h, then filter, wash and dry the reaction liquid to obtain Mn-doped ferric phosphate containing crystal water, expressed as Fe 0.98 mn 0.02 PO 4 2H 2 O.

[0039] 2, the Fe obtained in step 1 0.98 mn 0.02 PO 4 2H 2 O was heat-treated from room temperature to 400 °C for 10 h at a heating rate of 10 °C / min, and the temperature was naturally lowered to obtain Mn-doped iron phosphate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com