Production process of pure linen cheese

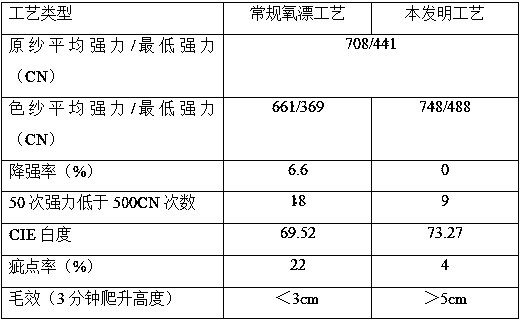

A production process and cheese yarn technology, applied in the field of flax cheese yarn production technology, can solve the problems affecting production efficiency and product quality, yarn strength damage, yarn breakage, etc., to improve hand feel, reduce strength reduction rate, control The effect of fabric defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] One, 21 S The inherent qualities of pure linen bobbins:

[0016] The average yarn strength is ≥700CN, the minimum strength is ≥500CN, and the strength CV value is ≤20.

[0017] 2. Enzyme refining:

[0018] 1. Refining mixture formula:

[0019] Water is mixed with pectinase, scouring agent and chelating agent to form a scouring mixture, wherein the content of pectinase is 3g / L, the content of scouring agent is 1g / L, and the content of chelating agent is 1g / L.

[0020] 2. Refining process parameters:

[0021] The heating rate is 3°C / min, the temperature is kept at 60°C for 60 minutes, the liquor ratio is 7-9, and the dyeing pump speed is 100%.

[0022] 3. Oxygen bleaching:

[0023] 1. Oxygen bleach formula:

[0024] Mix water with hydrogen peroxide (27.5%), multifunctional compound enzyme, scouring agent, yarn protectant and chelating agent to form an oxygen bleaching solution, wherein the content of hydrogen peroxide (27.5%) is 2g / L, and the content of multifunctio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com