Patents

Literature

249results about How to "Reduce degradation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

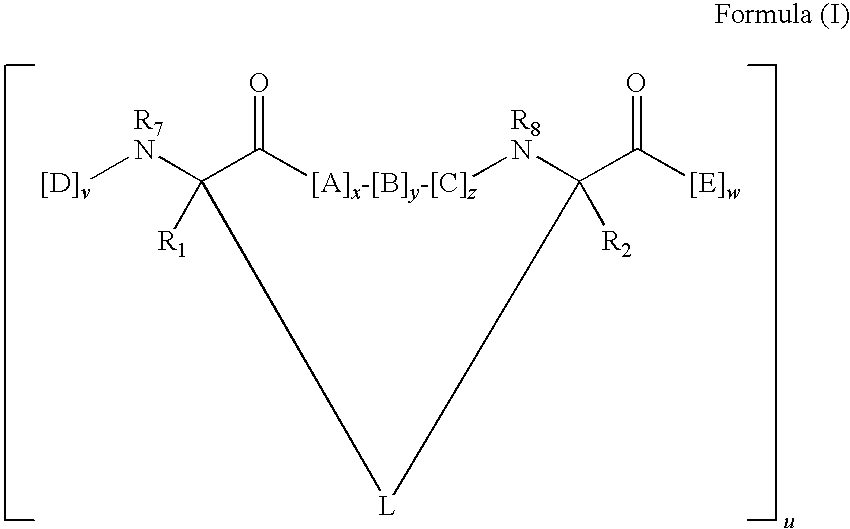

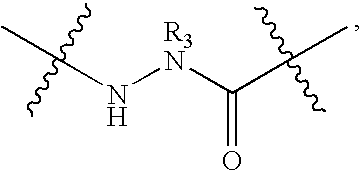

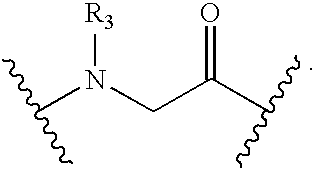

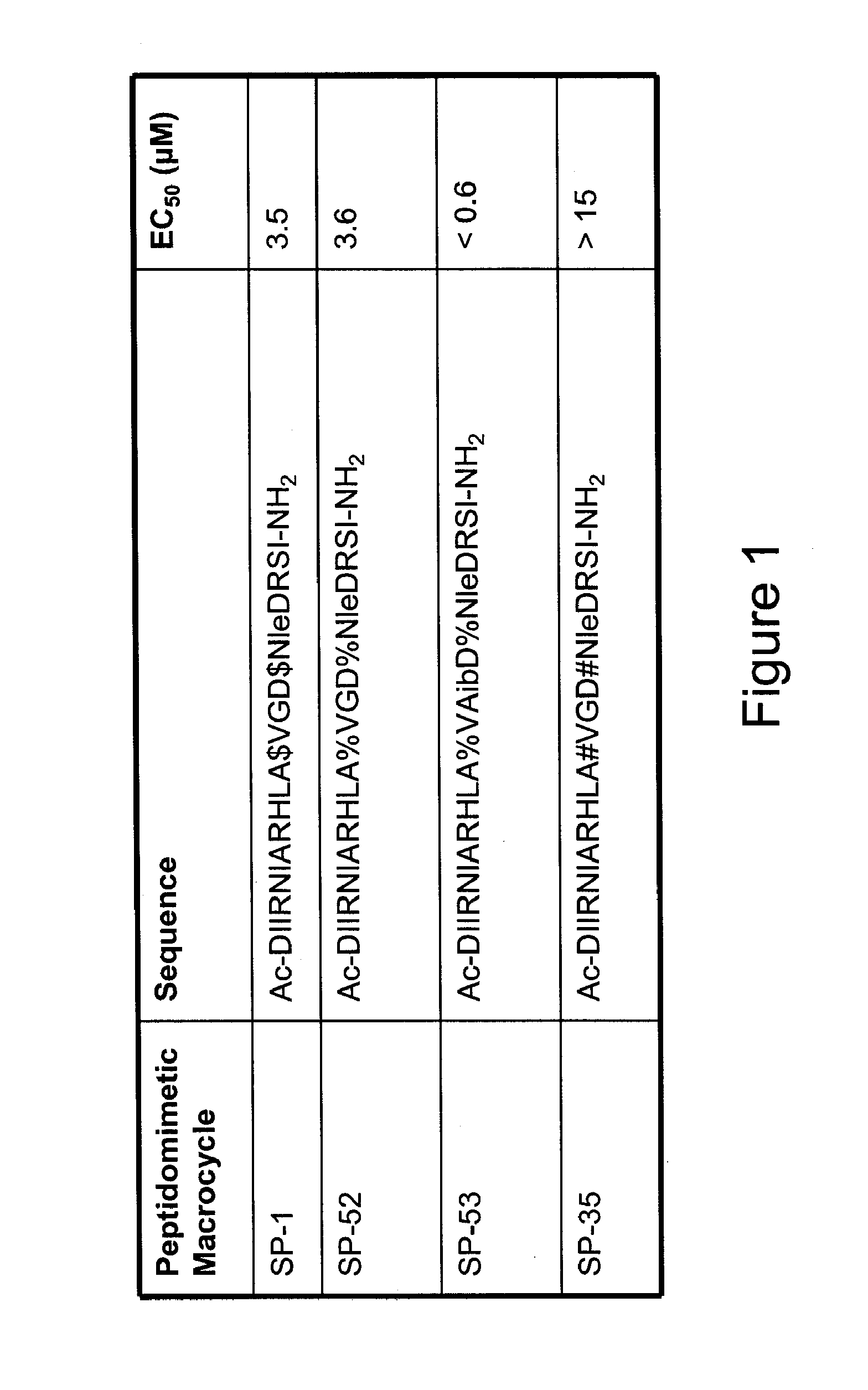

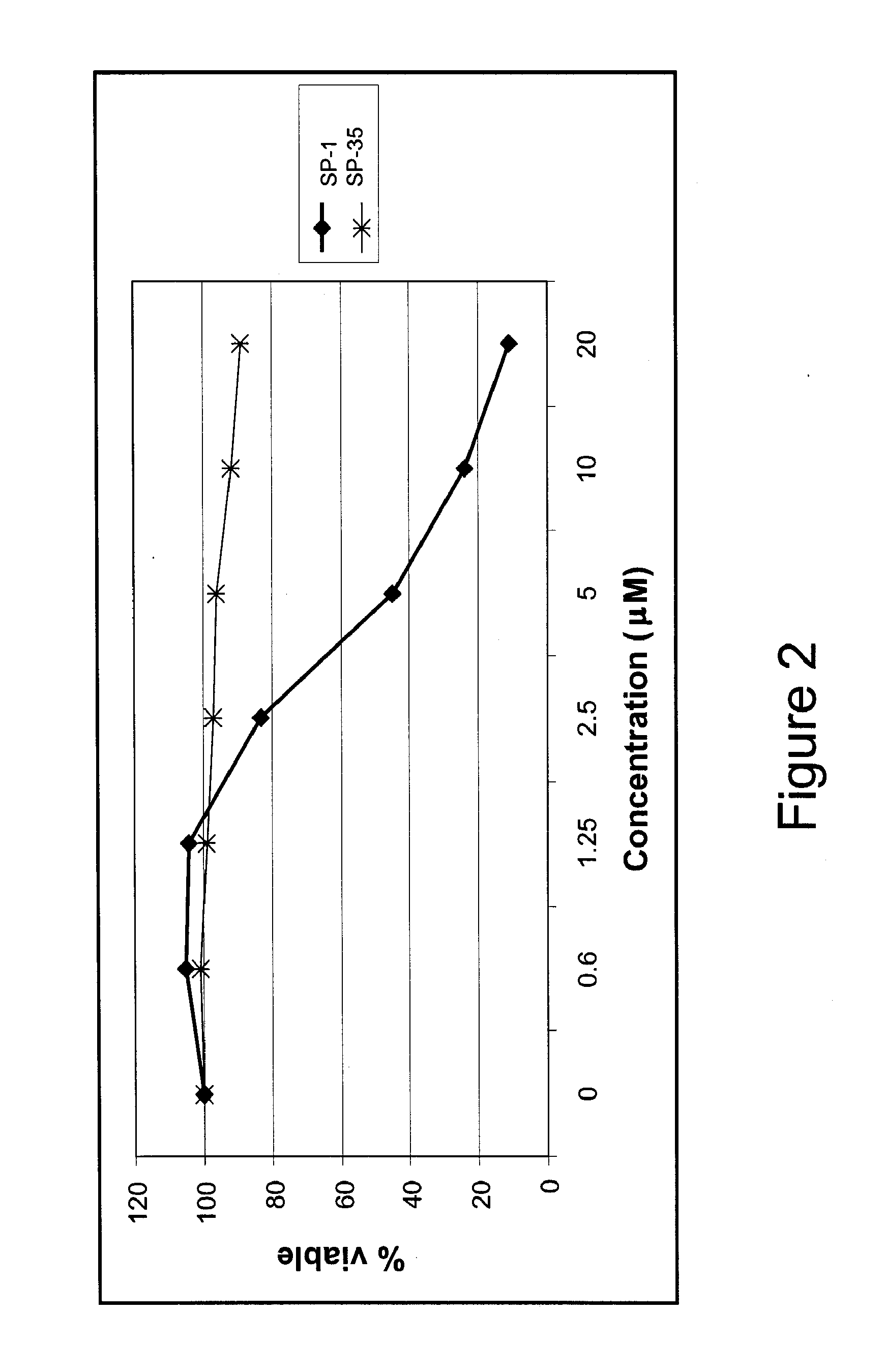

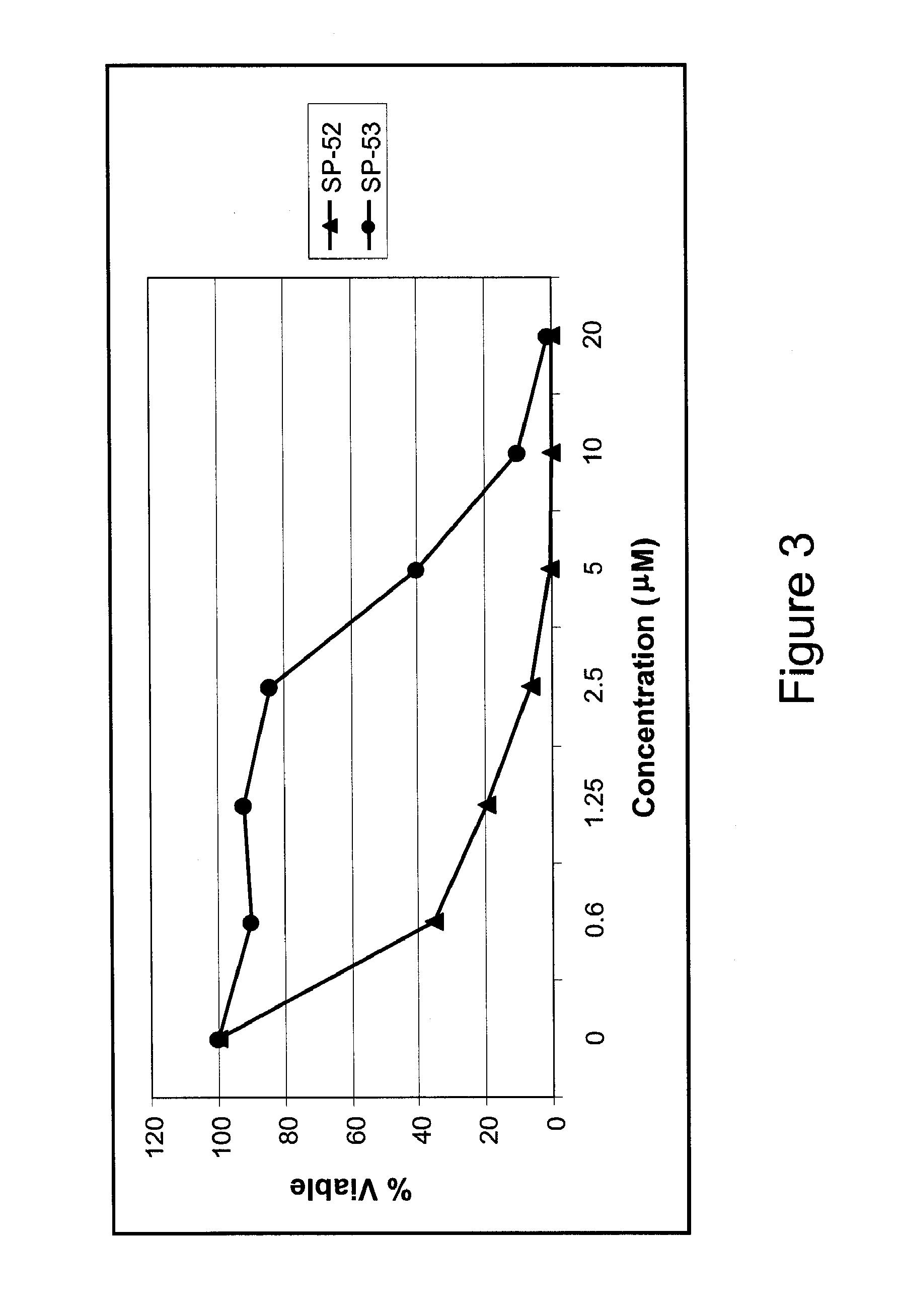

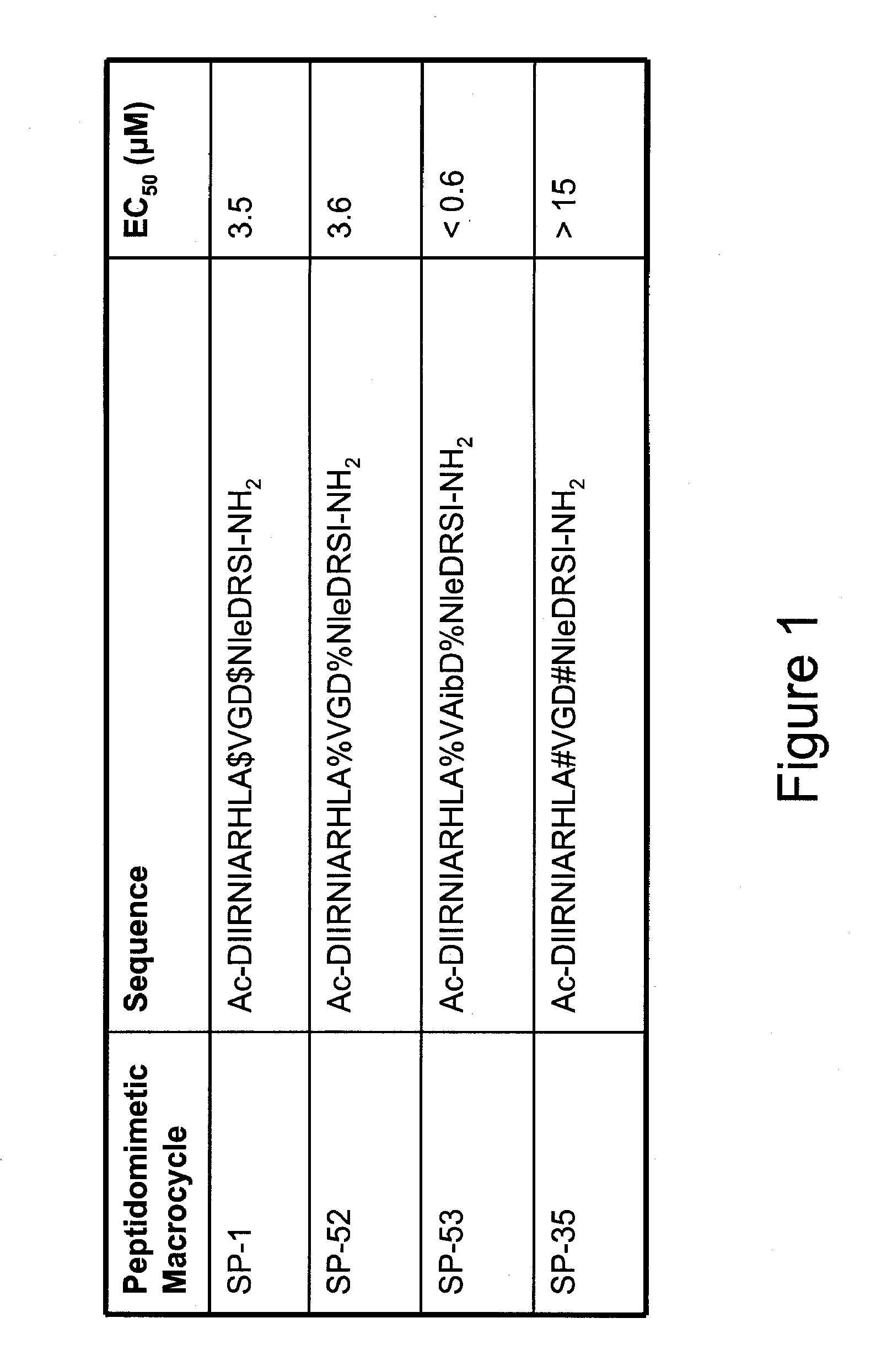

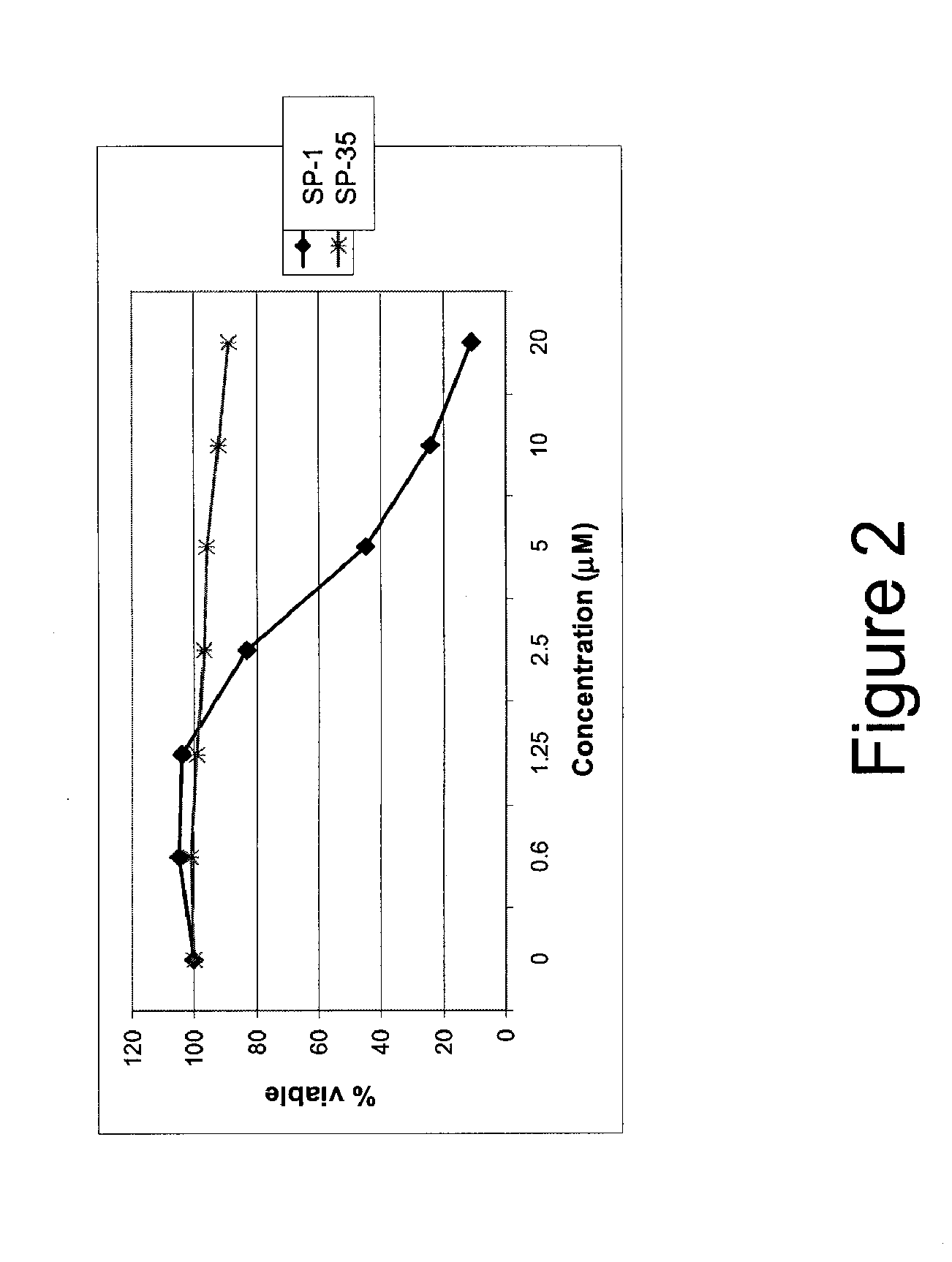

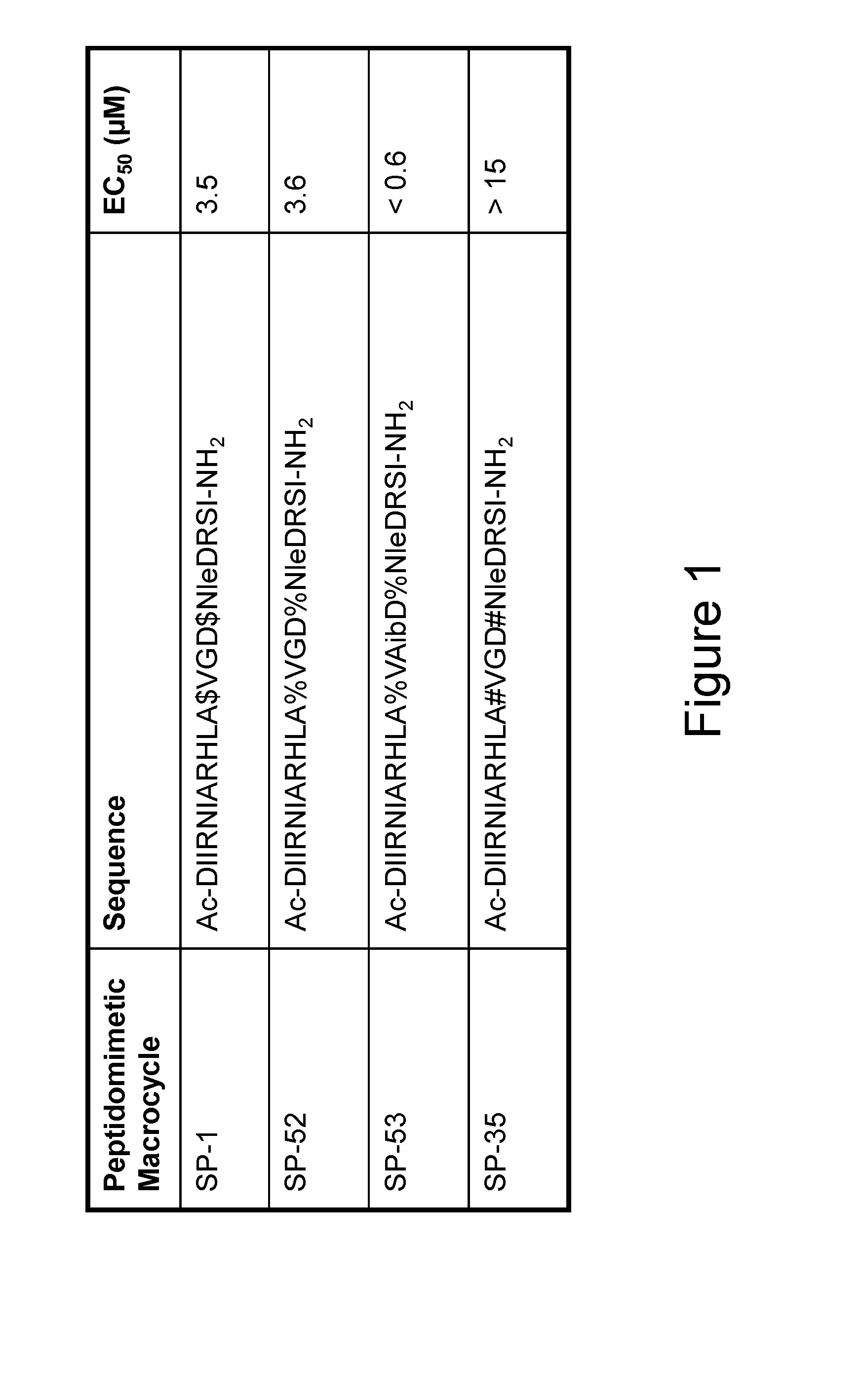

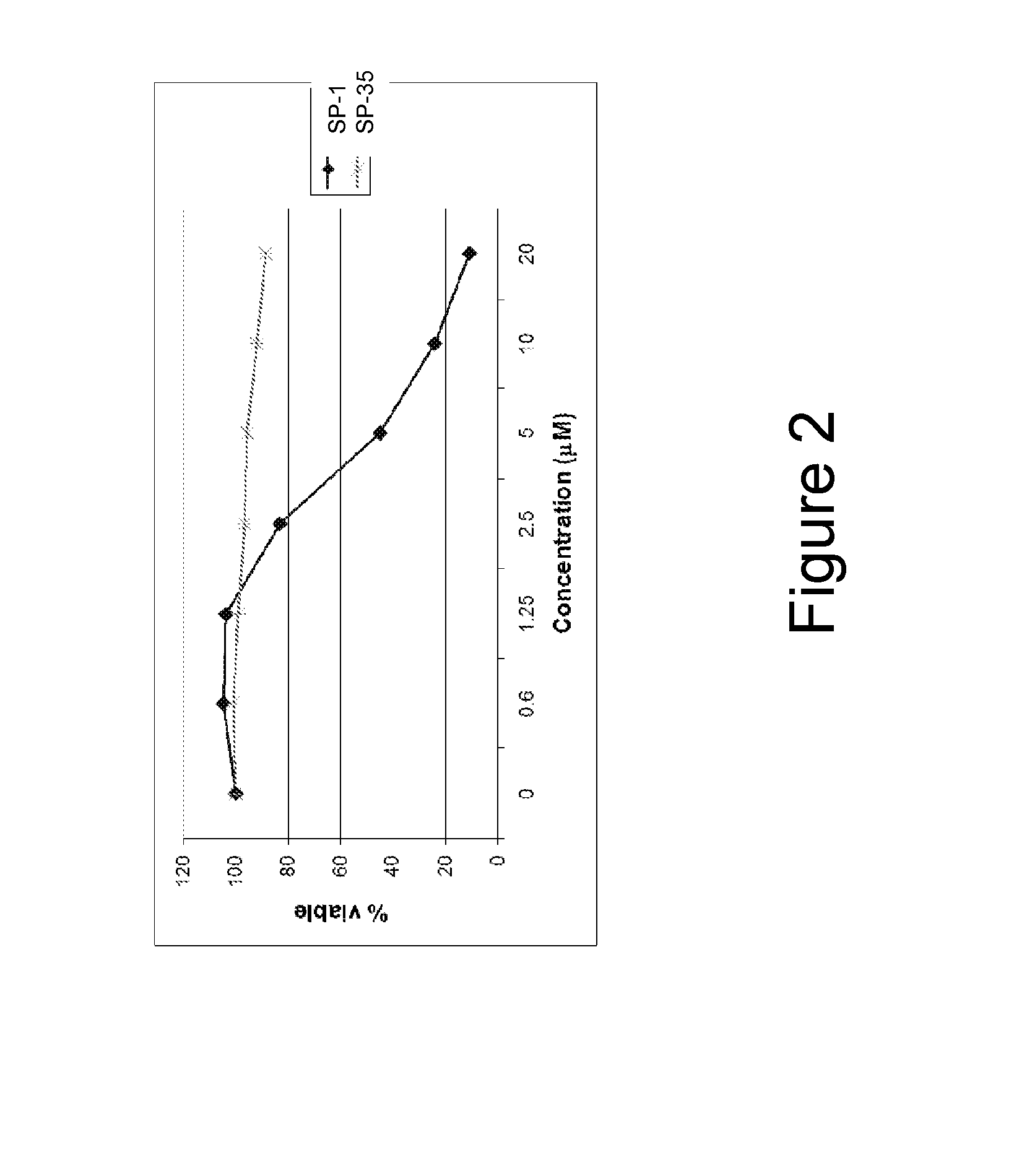

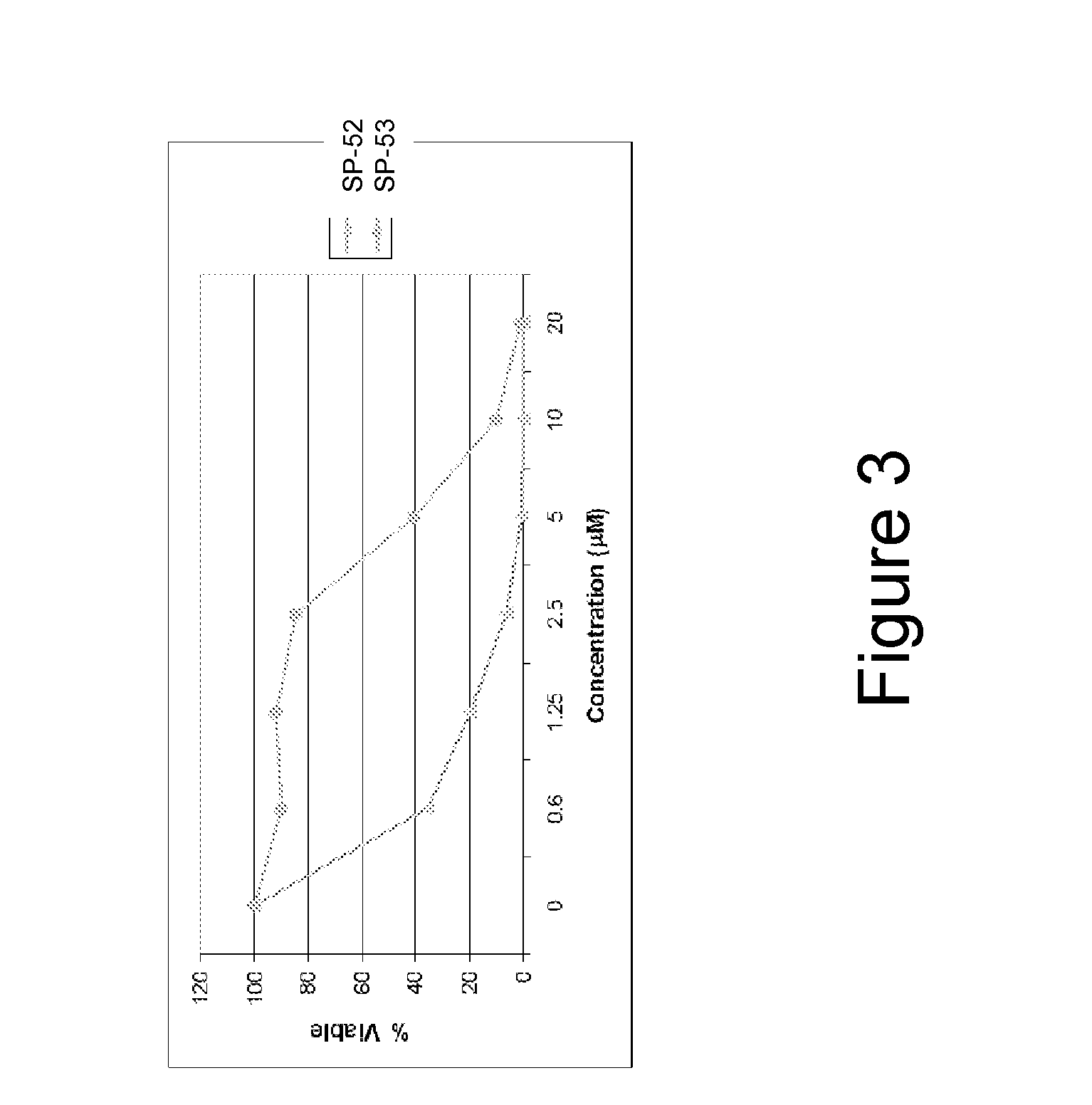

Biologically active peptidomimetic macrocycles

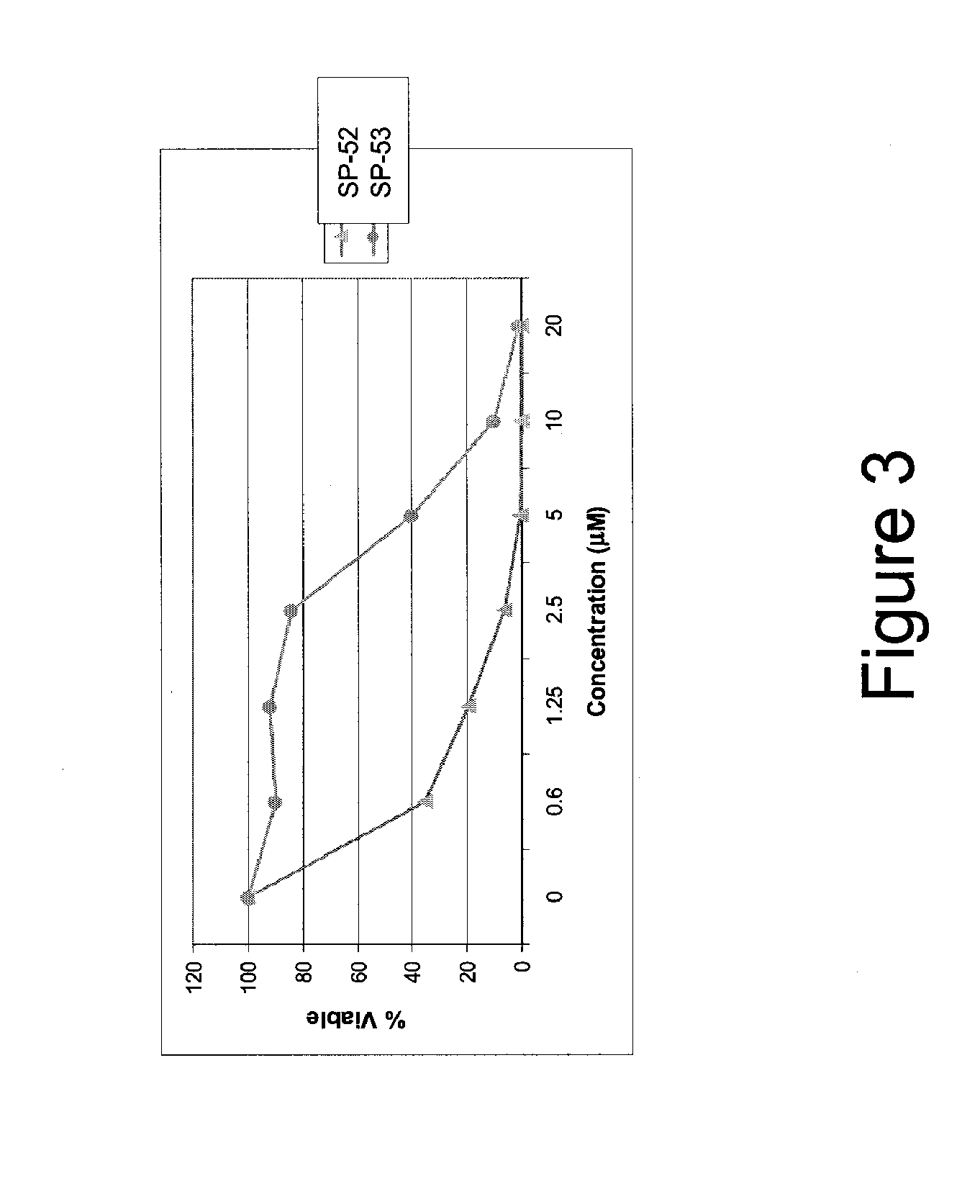

InactiveUS20090326192A1Strong penetrating powerImprove biological activityCompound screeningApoptosis detectionBioactive peptideMacrocycle Compounds

The present invention provides biologically active peptidomimetic macrocycles with improved properties relative to their corresponding polypeptides. The invention additionally provides methods of preparing and using such macrocycles, for example in therapeutic applications.

Owner:AILERON THERAPEUTICS INC

Biologically Active Peptidomimetic Macrocycles

InactiveUS20110144303A1Strong penetrating powerImprove biological activityPeptide/protein ingredientsPeptide preparation methodsBioactive peptideBiological activity

The present invention provides biologically active peptidomimetic macrocycles with improved properties relative to their corresponding polypeptides. The invention additionally provides methods of preparing and using such macrocycles, for example in therapeutic applications.

Owner:AILERON THERAPEUTICS INC

Biologically active peptidomimetic macrocycles

InactiveUS20130023646A1Improve biological activityReduced activityCompound screeningApoptosis detectionBioactive peptideMacrocycle Compounds

The present invention provides biologically active peptidomimetic macrocycles with improved properties relative to their corresponding polypeptides. The invention additionally provides methods of preparing and using such macrocycles, for example in therapeutic applications.

Owner:AILERON THERAPEUTICS INC

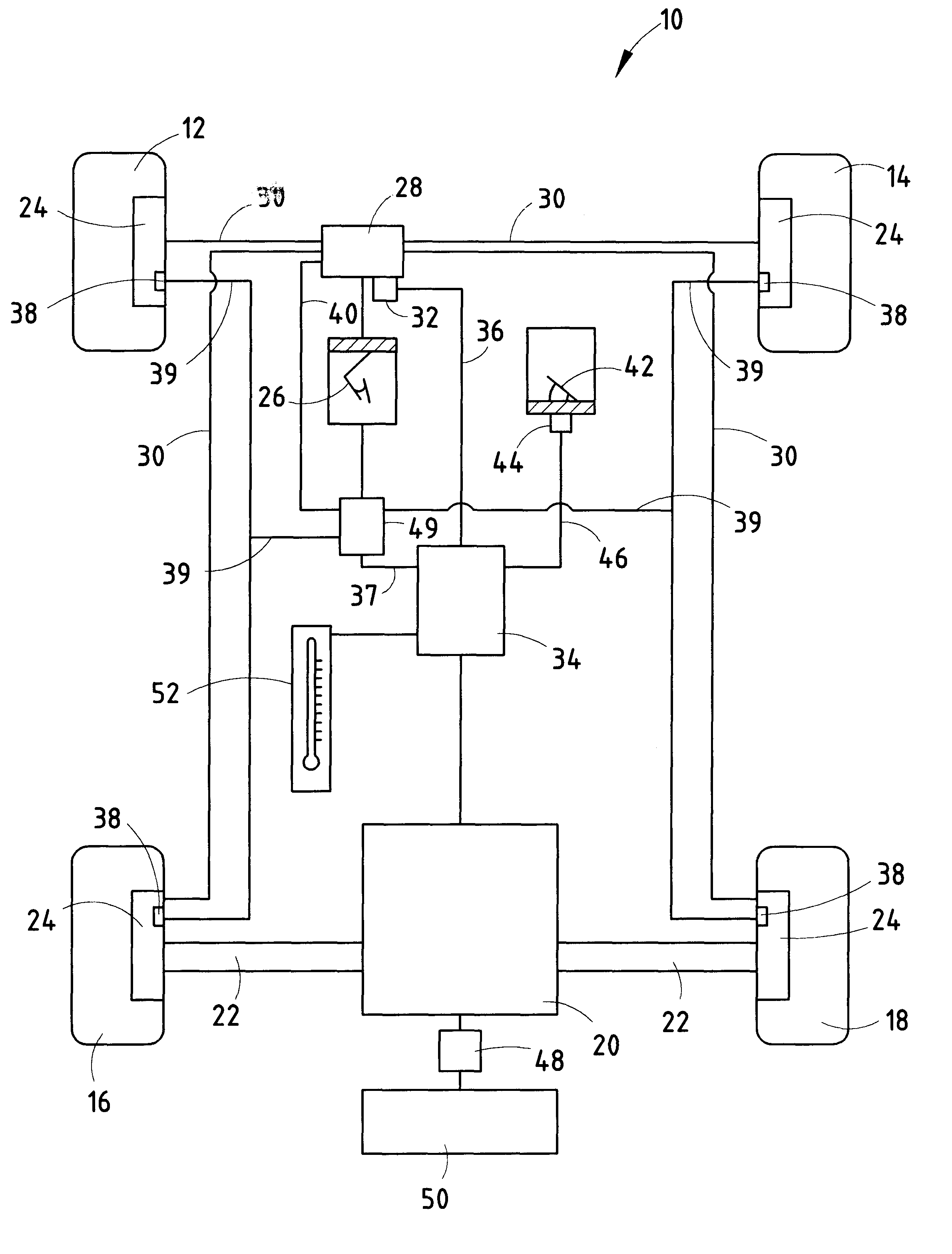

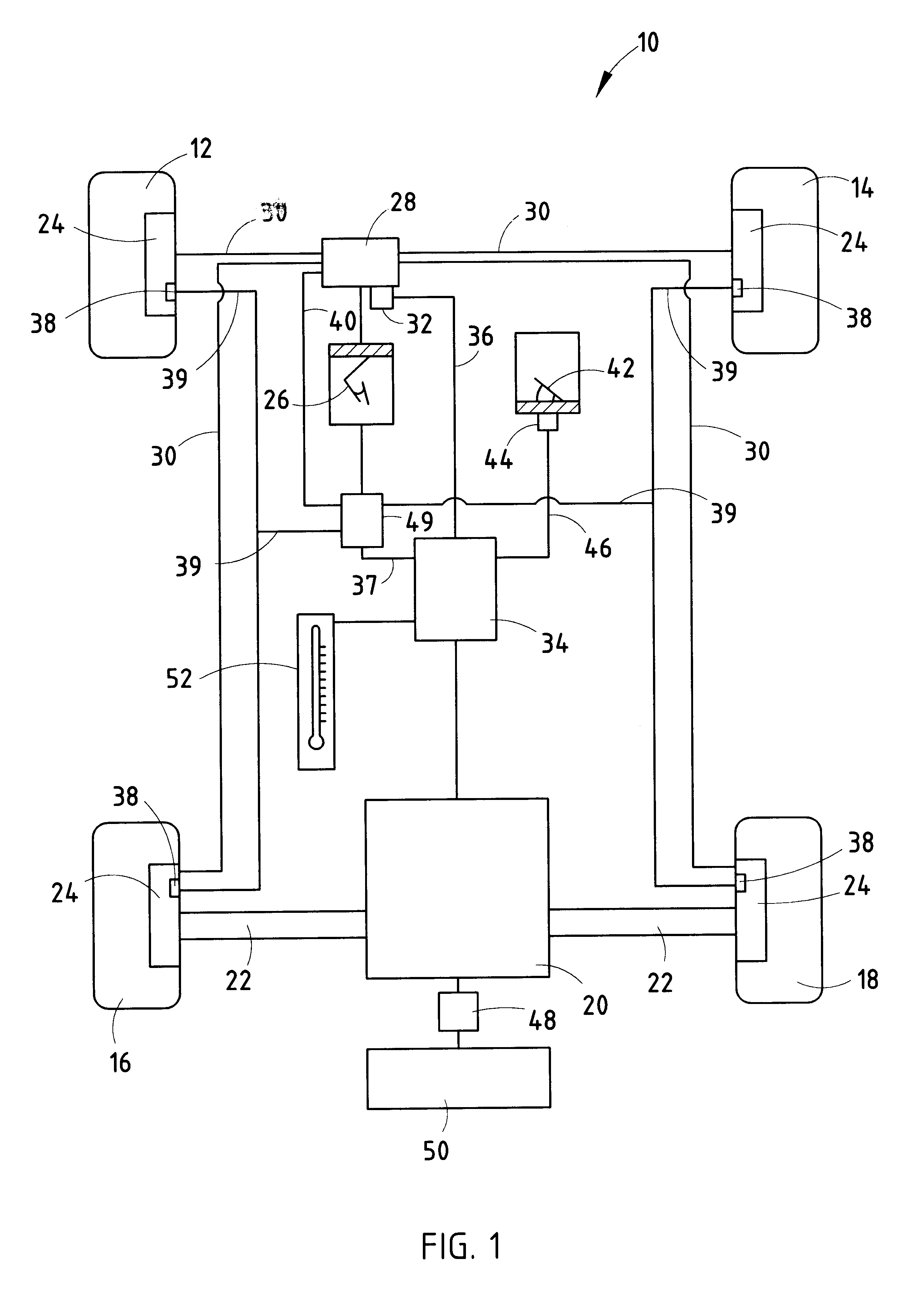

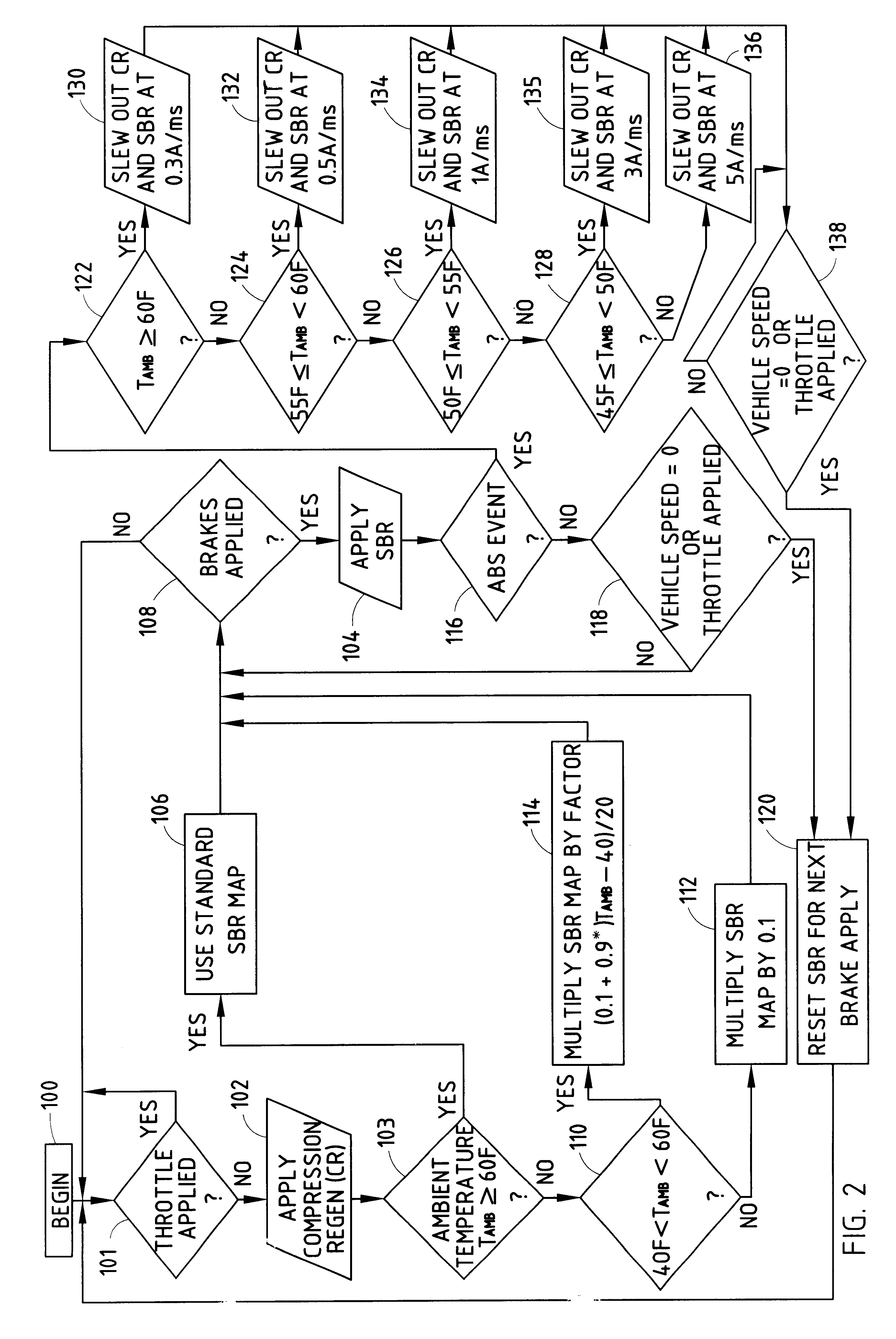

Temperature dependent regenerative brake system for electric vehicle

InactiveUS6275763B1Increase chanceReduce degradation rateAuxillary drivesBraking element arrangementsMobile vehicleRegenerative brake

A braking system for a motor vehicle having braking wheels 16, 18, a service brake pedal, a friction braking system operative upon the braking wheels 16, 18 in response to actuation of the vehicle brake pedal 26, an anti-lock braking system cooperative with the friction braking system to control the friction braking force applied to the braking wheels 16, 18 upon detection of slippage of the braking wheels 16, 18, a regenerative braking system operative upon the braking wheels 16, 18 in response to actuation of the vehicle brake pedal 26 for selectively generating an applied regenerative braking force through the braking wheels 16, 18, and an ambient temperature sensor 52. The regenerative braking system operates at a first effective rate of applied regenerative braking force upon application of the brake pedal 26 at an ambient temperature above a desired temperature, and the regenerative braking system operates at a second, lower effective rate of applied regenerative braking force at an ambient temperature below a desired temperature. Upon activation of the anti-lock braking system, the applied regenerative braking force is reduced at a first predetermined rate when the ambient temperature is above a desired temperature and the regenerative braking force is reduced at a second, faster predetermined rate when the ambient temperature is below a desired temperature.

Owner:FORD GLOBAL TECH LLC +1

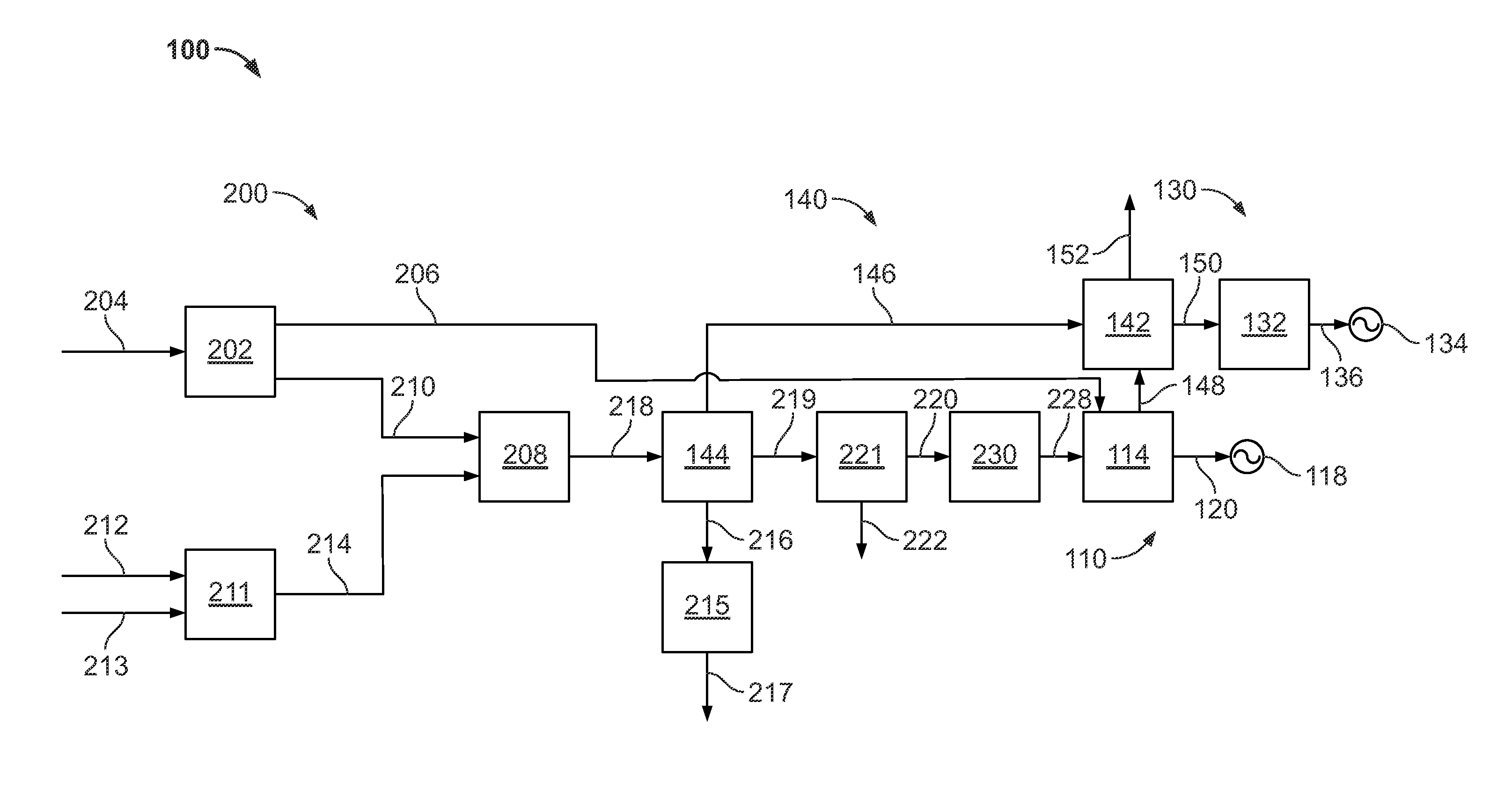

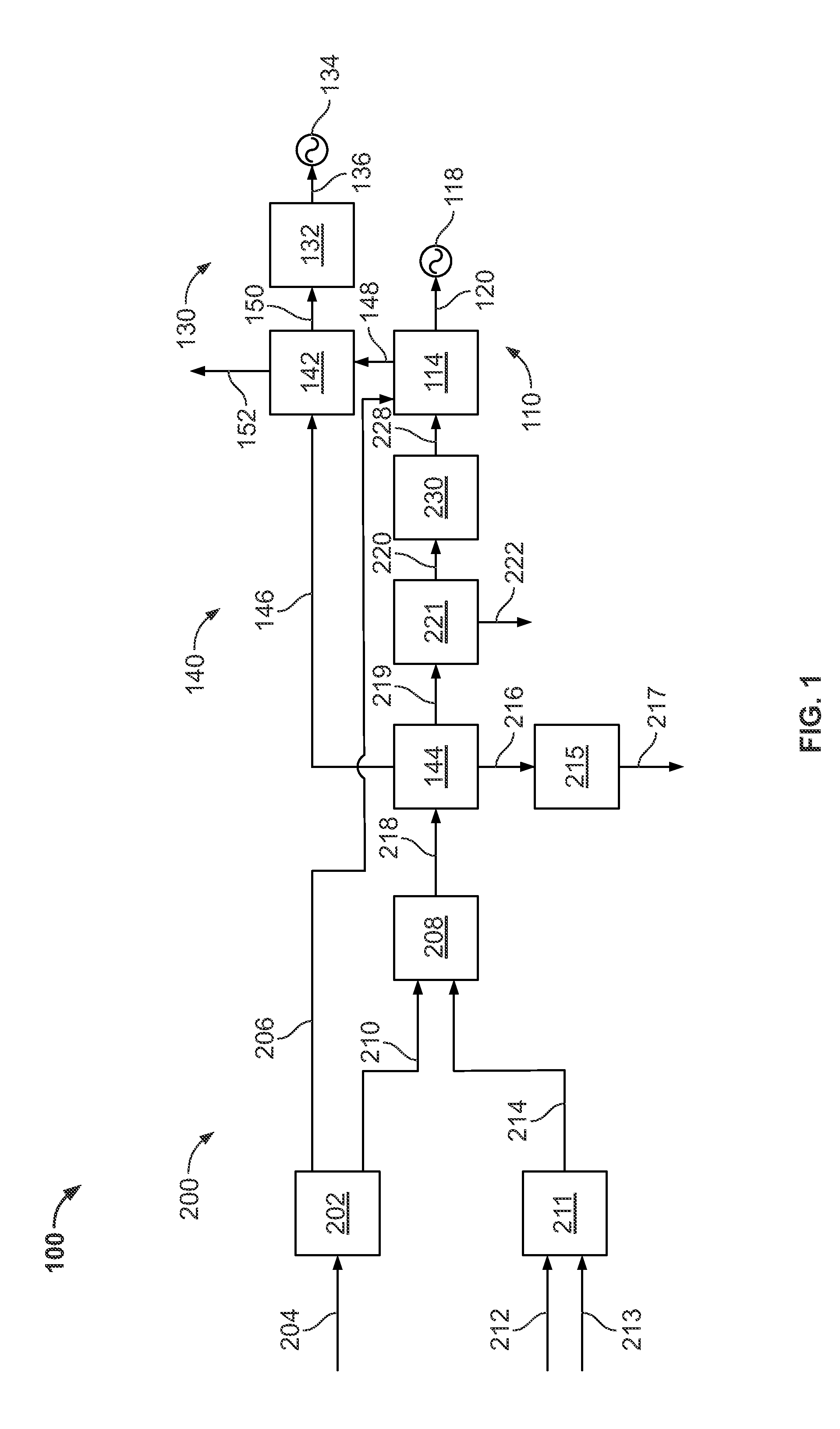

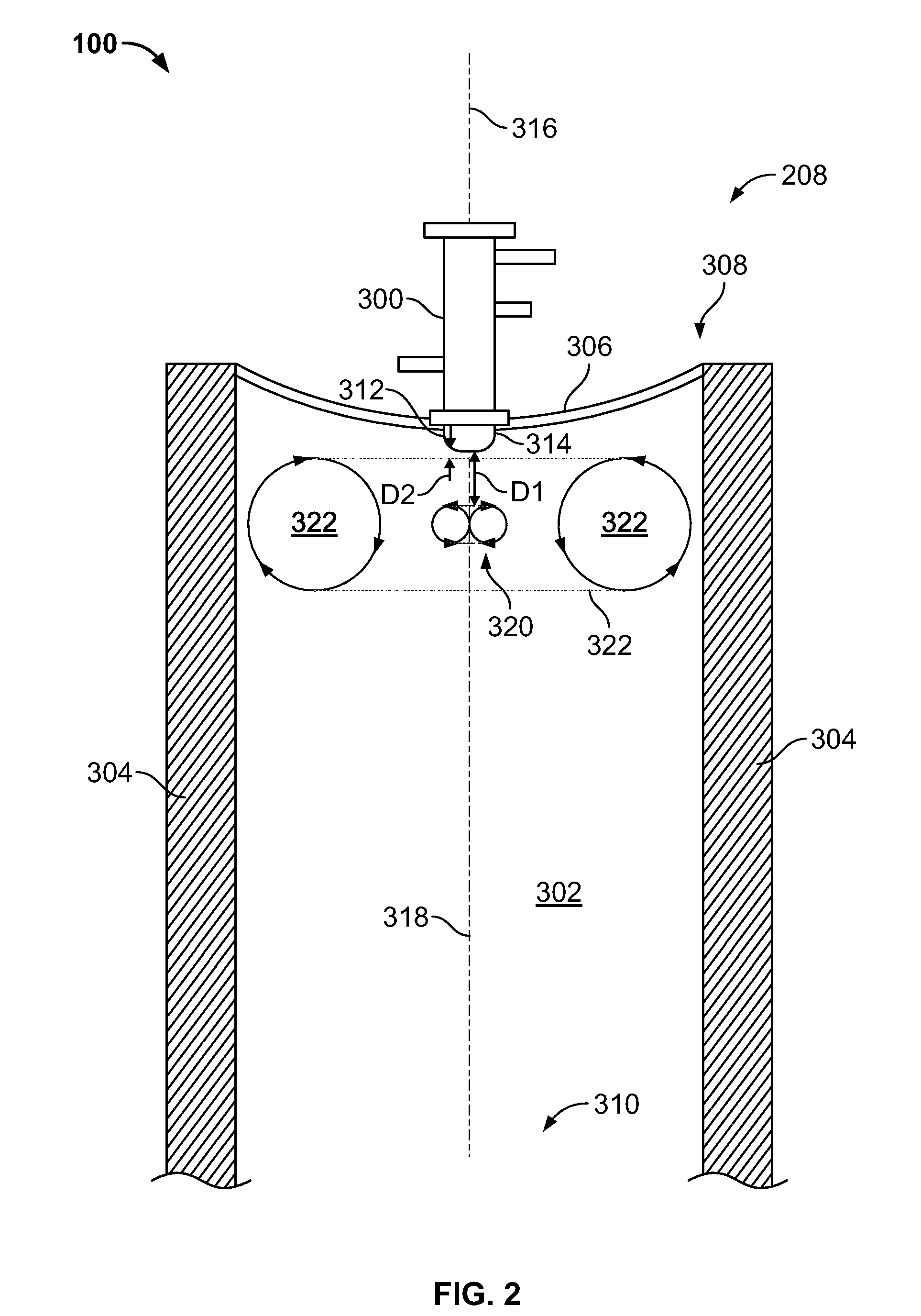

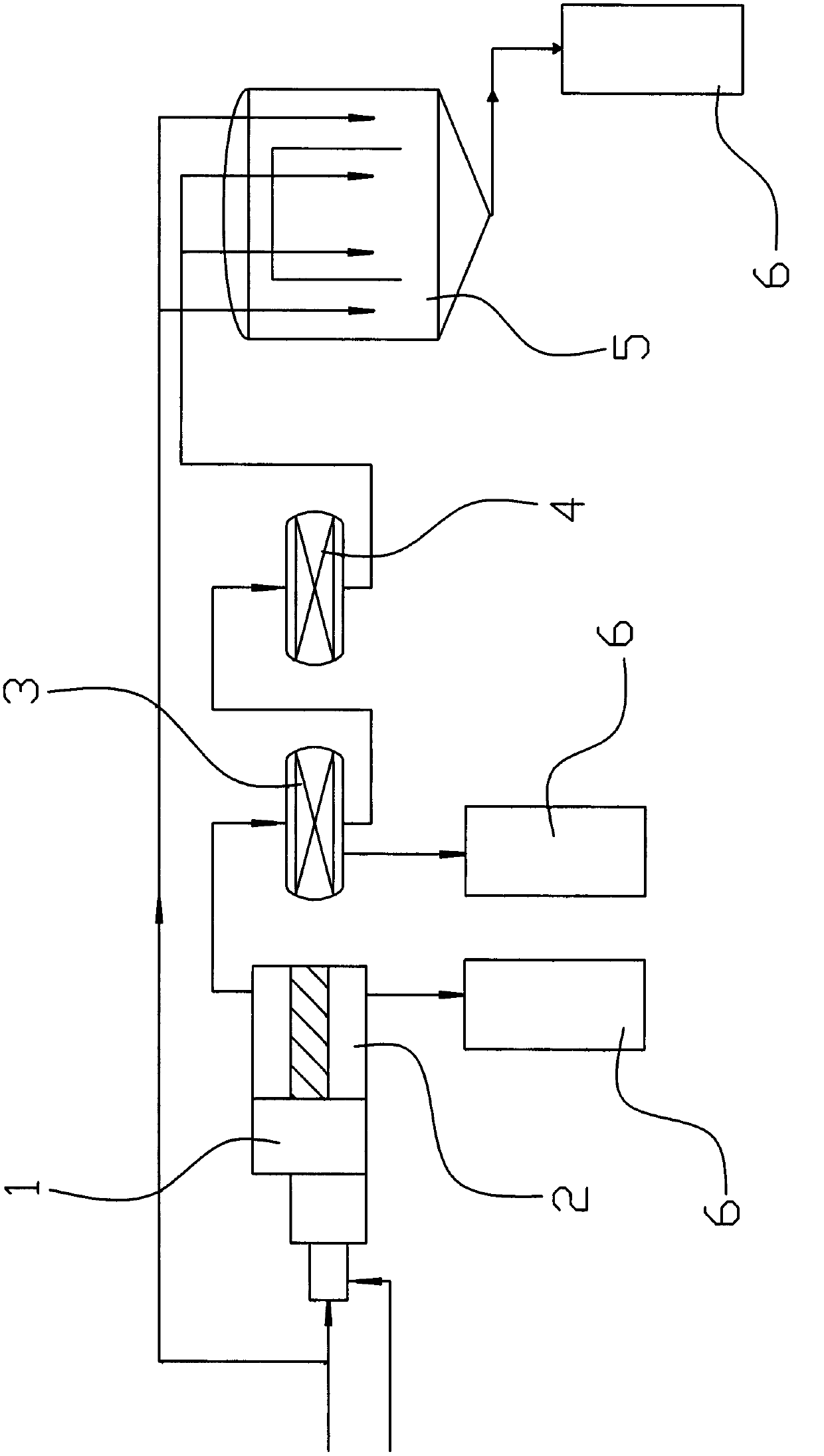

Method and apparatus to produce synthetic gas

ActiveUS20110036011A1Easy to operateEasy to evaporateValve members for heating/coolingPipe heating/coolingSyngasForming gas

A method of producing a synthetic gas (syngas) includes injecting a plurality of reactant streams into a gasification reactor via at least one injection device having a plurality of injection annuli, an inner portion that extends annularly about a centerline extending through the at least one injection device, and an outer portion extending substantially annularly about the inner portion. At least a portion of the outer portion is oriented obliquely with respect to the at least one injection device centerline. The method also includes mixing at least a portion of each of the streams together such that a plurality of recirculation zones is defined by the streams. The method further includes producing a syngas within the recirculation zones via mixing at least a portion of each of the streams. The injection device includes an inner portion that extends annularly about a centerline extending through the injection device. The device also includes an outer portion extending substantially annularly about the inner portion that includes at least one of at least one carbonaceous reactant injection port oriented obliquely with respect to the injection device centerline and at least one outer face oriented obliquely with respect to the injection device centerline.

Owner:AIR PROD & CHEM INC

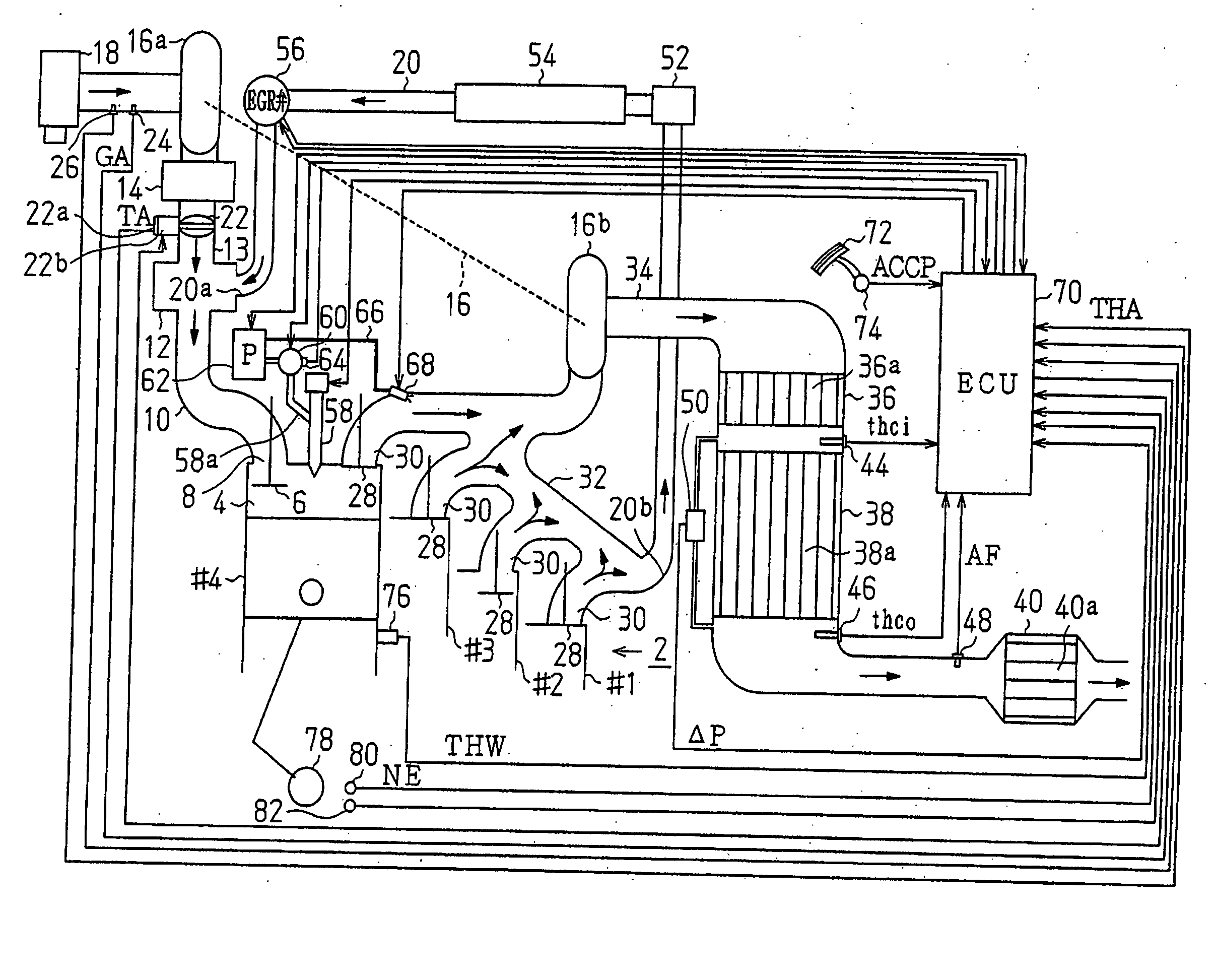

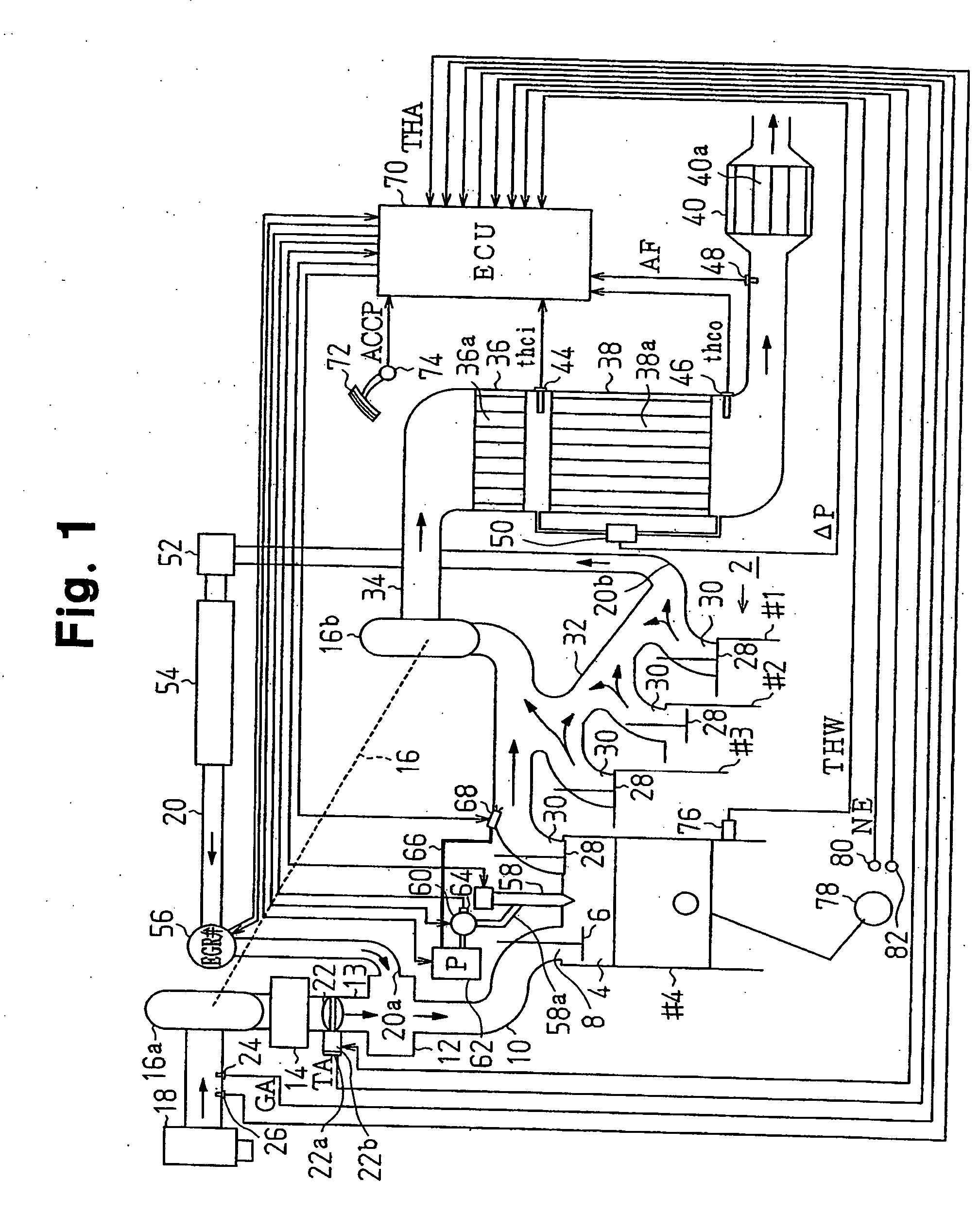

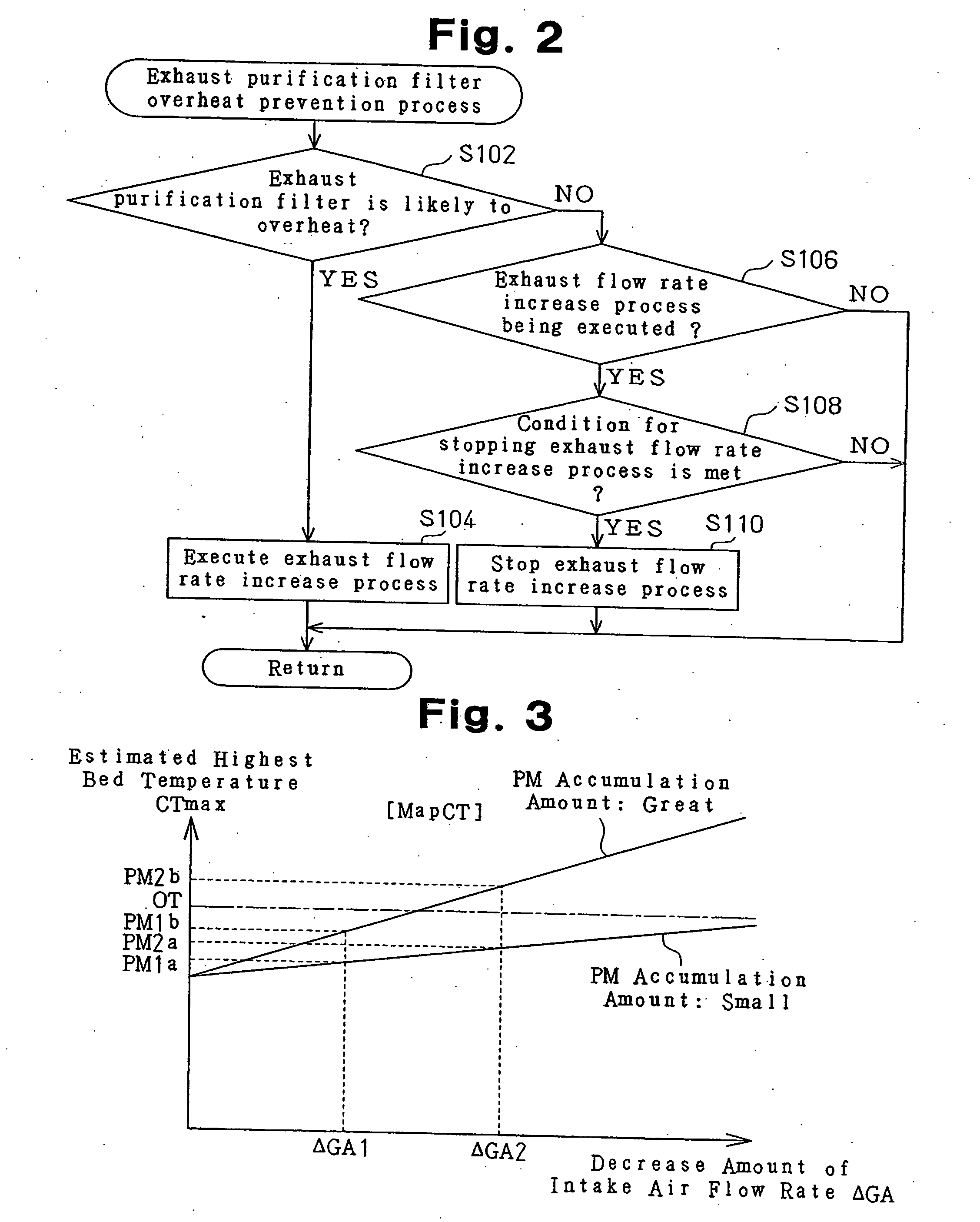

Apparatus and method for preventing overheating of exhaust purification filter

InactiveUS20060016180A1Avoid purificationReduce degradation rateElectrical controlNon-fuel substance addition to fuelParticulatesExhaust fumes

An apparatus for preventing a filter for purifying exhaust gas emitted by a vehicle diesel engine from overheating is provided. The filter filters particulate matter in exhaust gas. Particulate matter that is accumulated in the filter through filtering is burned and purified by executing a temperature increase process in which the filter is heated. The apparatus includes an electronic control unit as overheat prevention means. During the temperature increase process, the overheat prevention means executes an increase process for increasing the flow rate of exhaust gas when the filter is likely to overheat. As a result, the filter is effectively prevented from overheating.

Owner:TOYOTA JIDOSHA KK

Biologically active peptidomimetic macrocycles

InactiveUS20140323701A1Improve biological activityReduced activityCompound screeningApoptosis detectionBioactive peptideMacrocycle Compounds

The present invention provides biologically active peptidomimetic macrocycles with improved properties relative to their corresponding polypeptides. The invention additionally provides methods of preparing and using such macrocycles, for example in therapeutic applications.

Owner:AILERON THERAPEUTICS INC

Method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur

ActiveCN104208992AHigh activityReduce energy consumptionDispersed particle separationSulfur preparation/purificationCombustionLiquid state

The invention discloses a method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur sequentially comprises the following steps: introducing the acid gas into a combustion furnace to be mixed with air introduced by the other pipeline so as to carry out a combustion reaction; introducing the gas reacted in the combustion furnace into a cooler to be cooled to 230-250 DEG C, after cooling, separating the cooled liquid sulfur at a liquid outlet, introducing mixed gas in the combustion furnace into a catalyst reactor, enabling hydrogen sulfide to react with sulfur dioxide in the catalyst reactor so as to generate sulfur and water, and separating the generated liquid sulfur at the liquid outlet of the catalyst reactor; introducing the mixed gas in the catalyst reactor into a hydrogenation reactor and enabling the sulfur dioxide to react with hydrogen in the hydrogenation reactor; introducing the gas in the hydrogenation reactor into a hydrogen sulfide absorption device and preparing the hydrogen sulfide into elemental sulfur under the action of an alkaline solution, a complex catalyst and the introduced air. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur has the advantages of short process route, high quality of produced sulfur and low energy consumption, is capable of fully removing SO2 gas and is green and environmentally friendly.

Owner:NINGBO RES & DESIGN INST OF CHEM IND

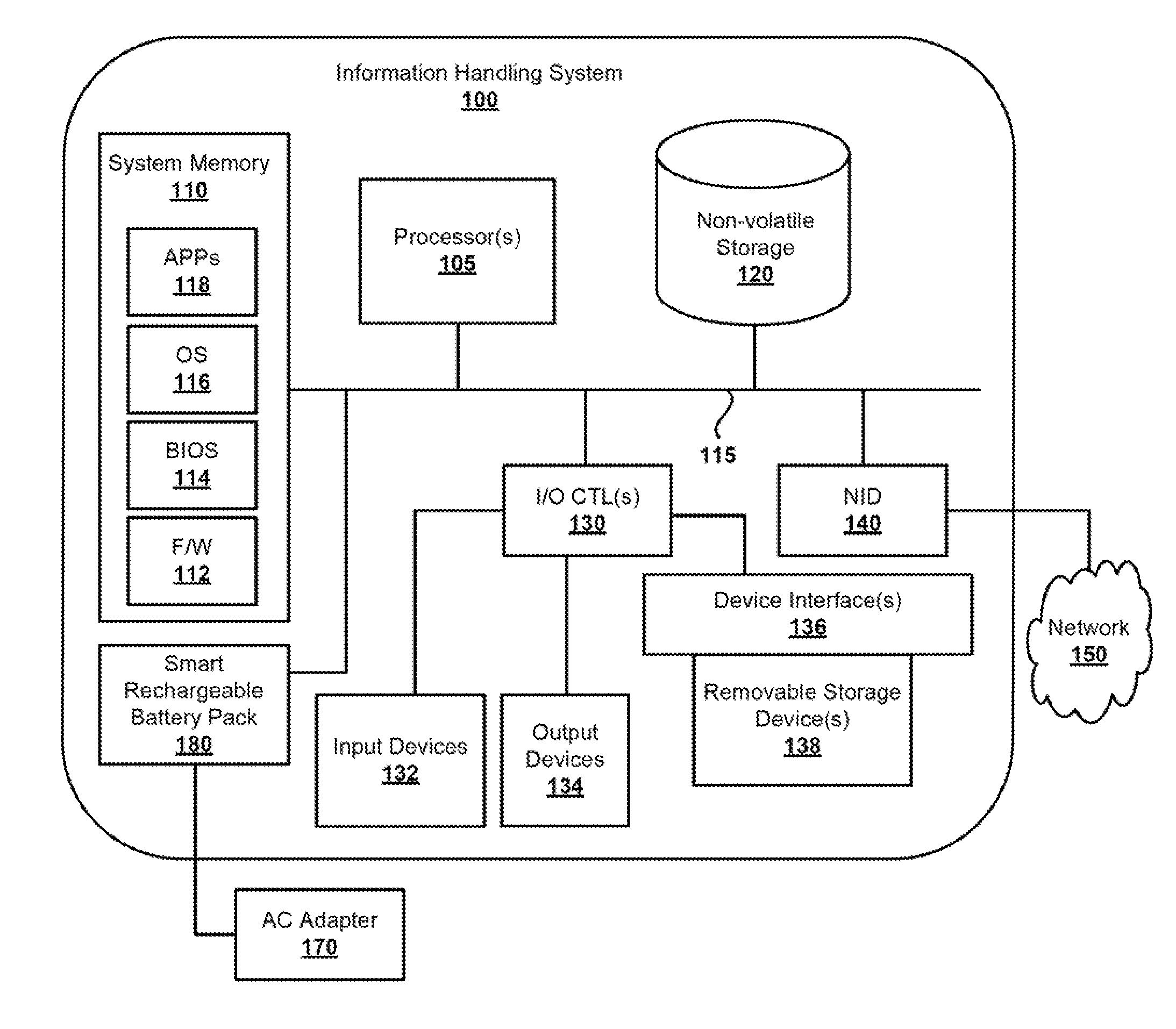

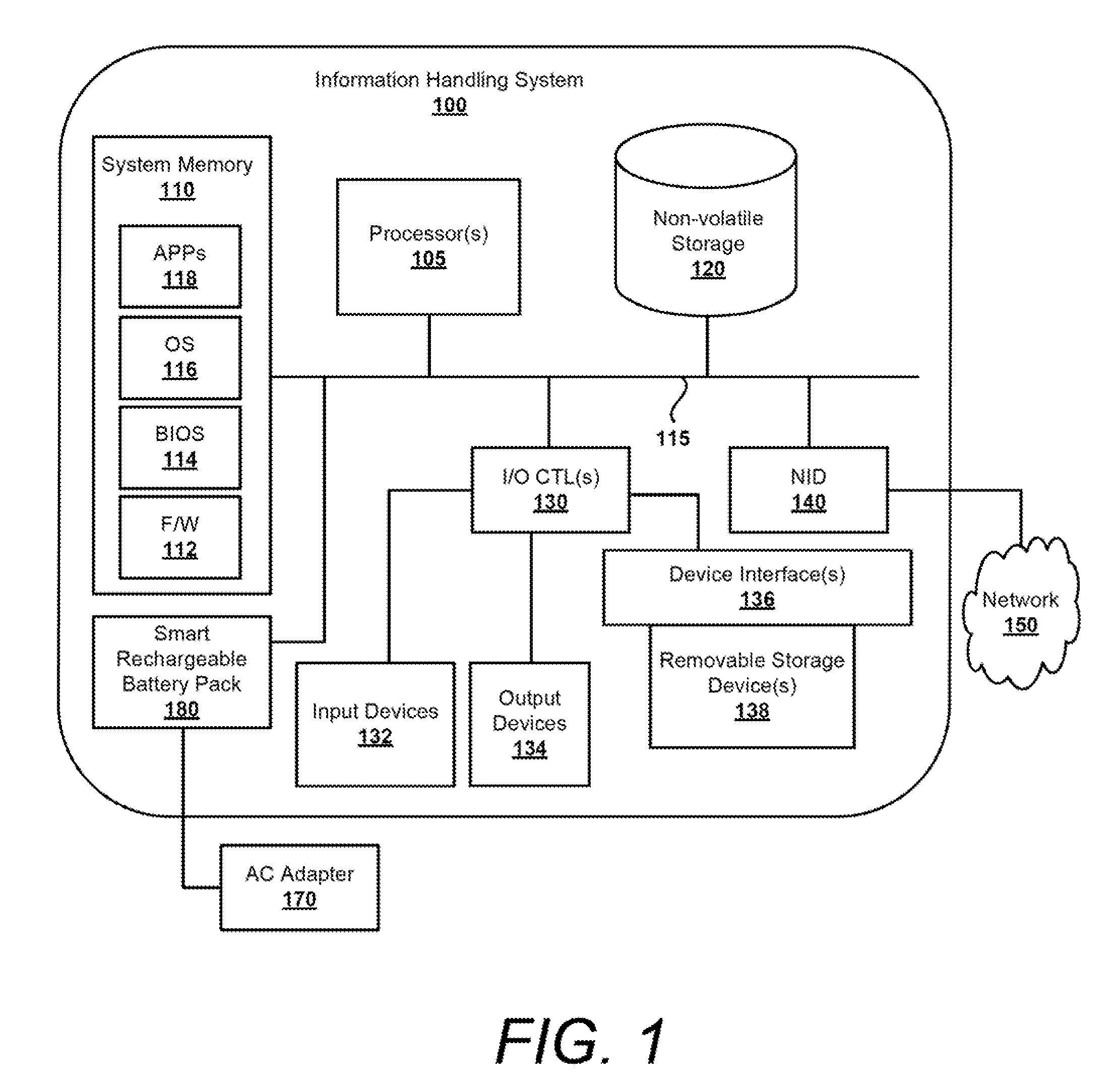

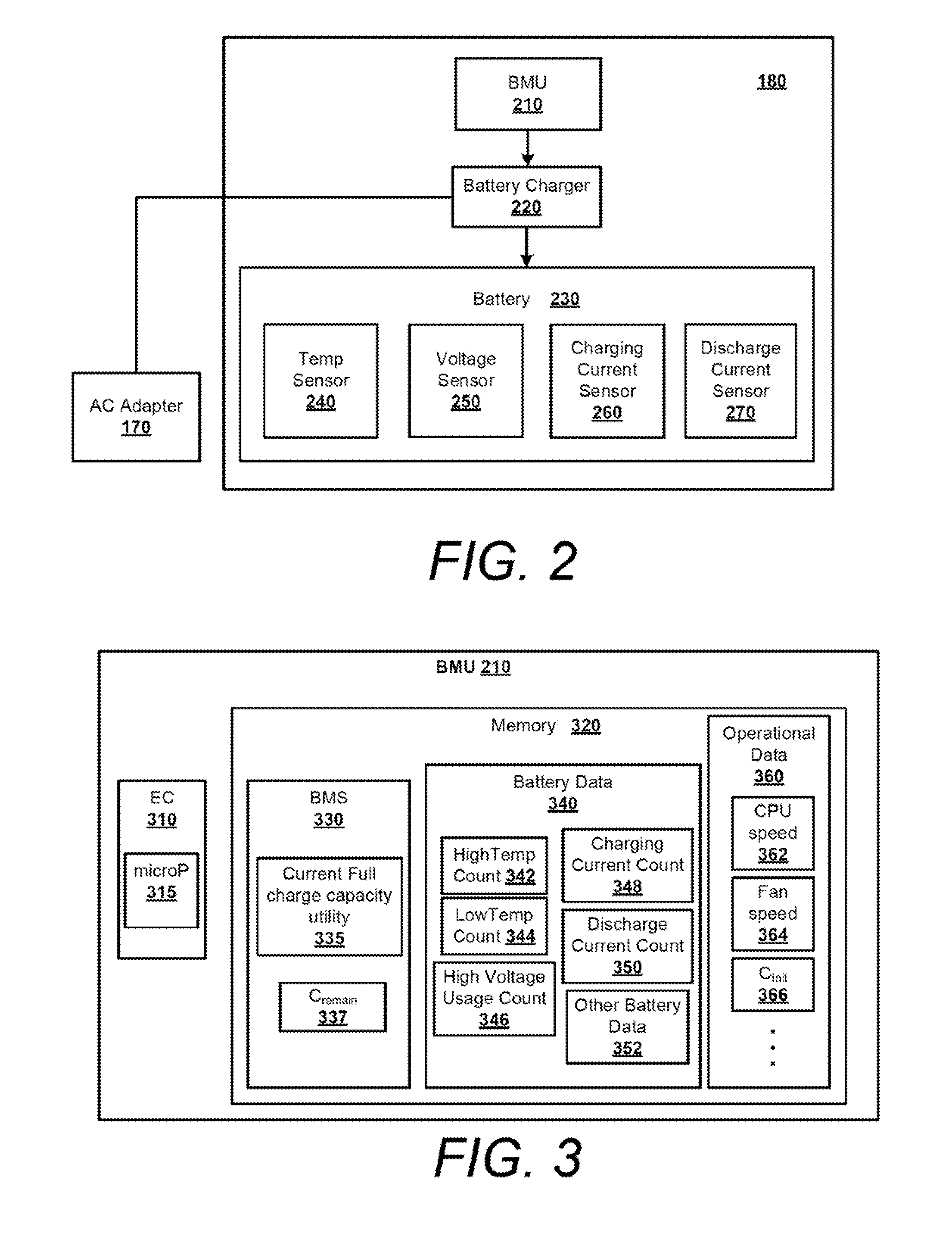

Mitigating premature wear out of a rechargeable battery

ActiveUS9263912B2Reduce degradation rateEnd of lifeElectrical testingElectric powerElectrical batteryRechargeable cell

Owner:DELL PROD LP

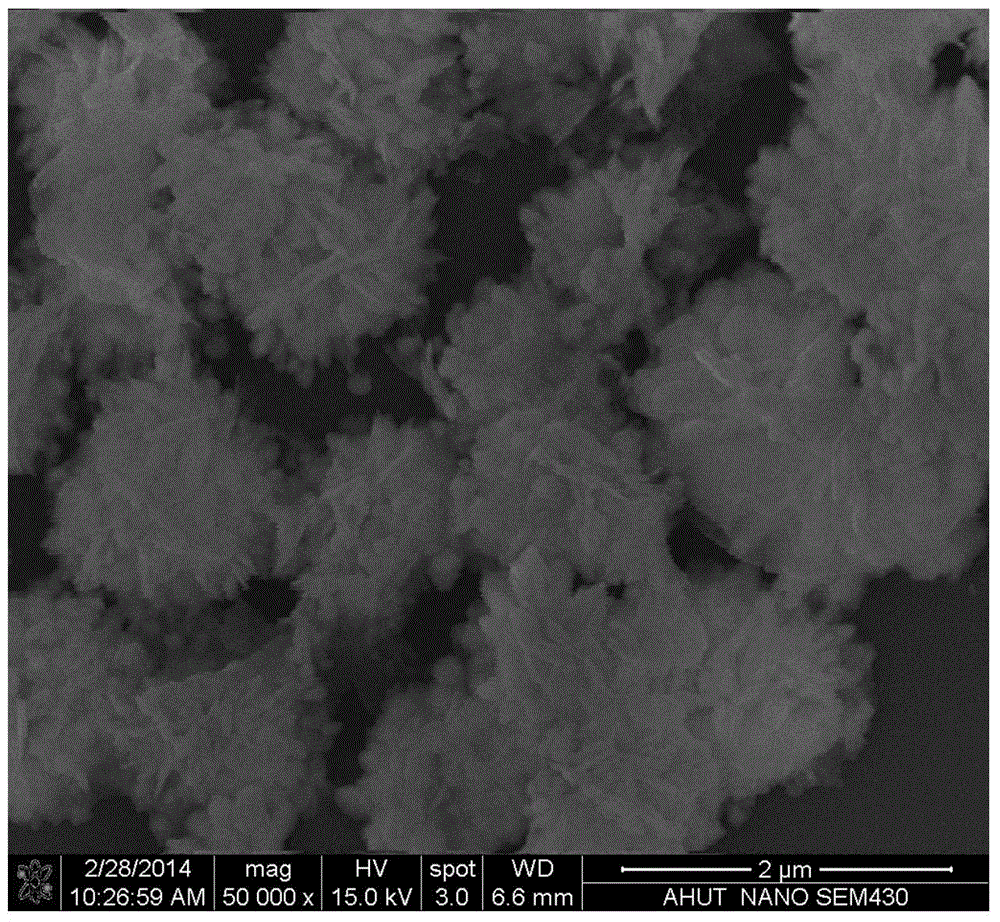

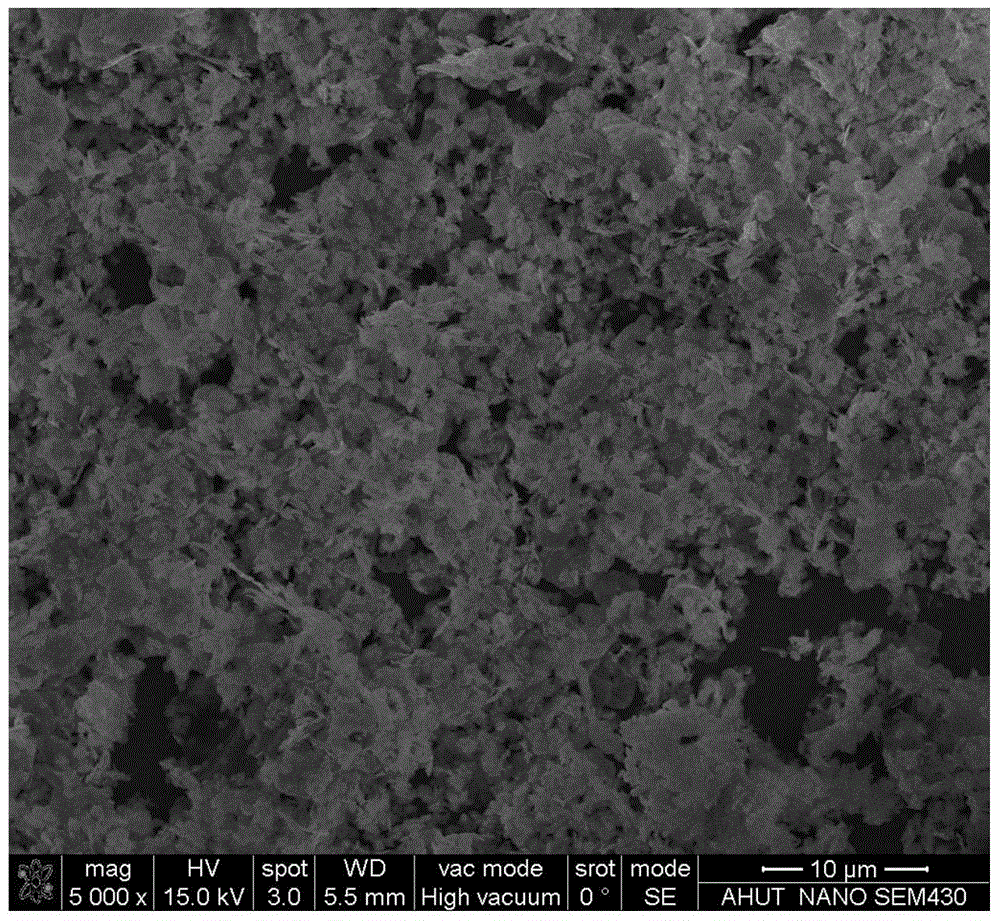

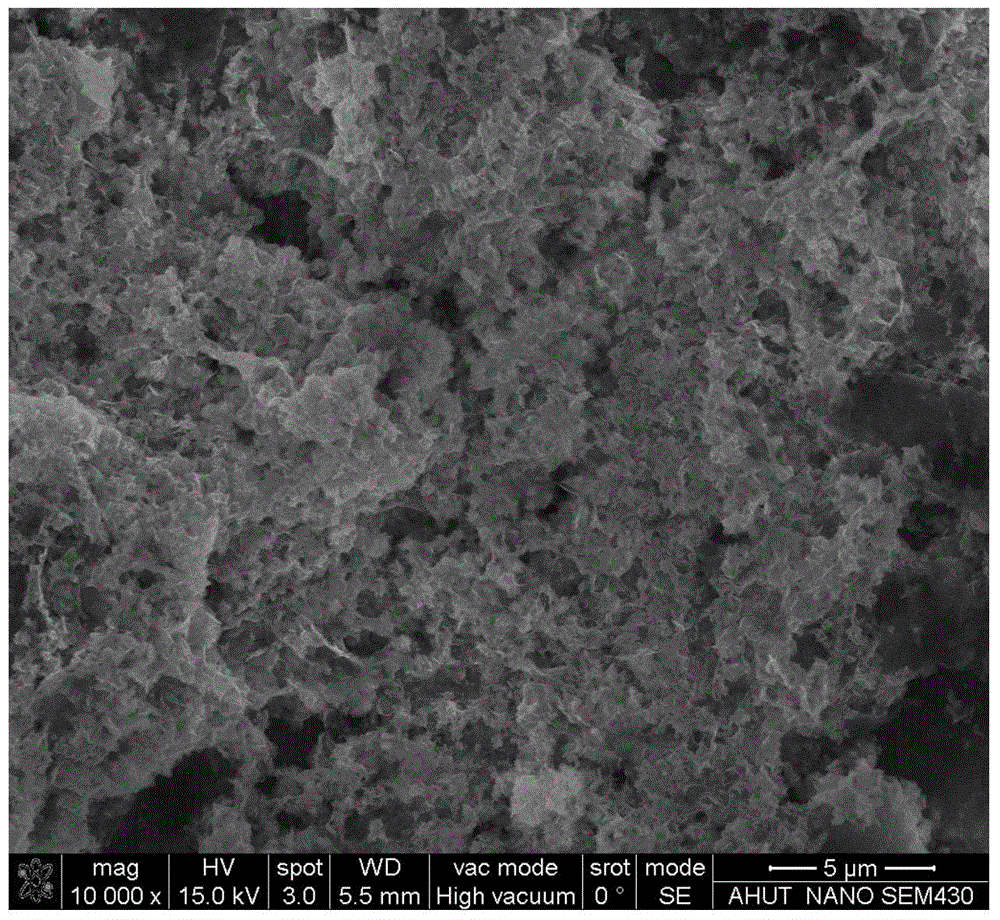

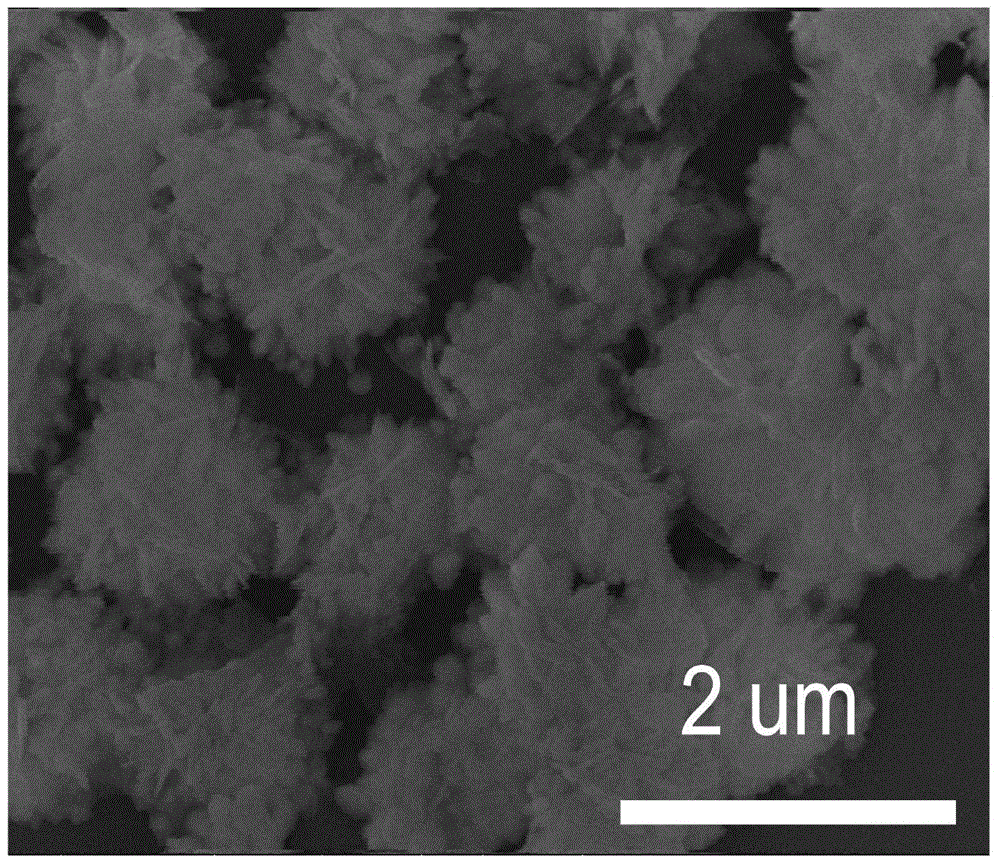

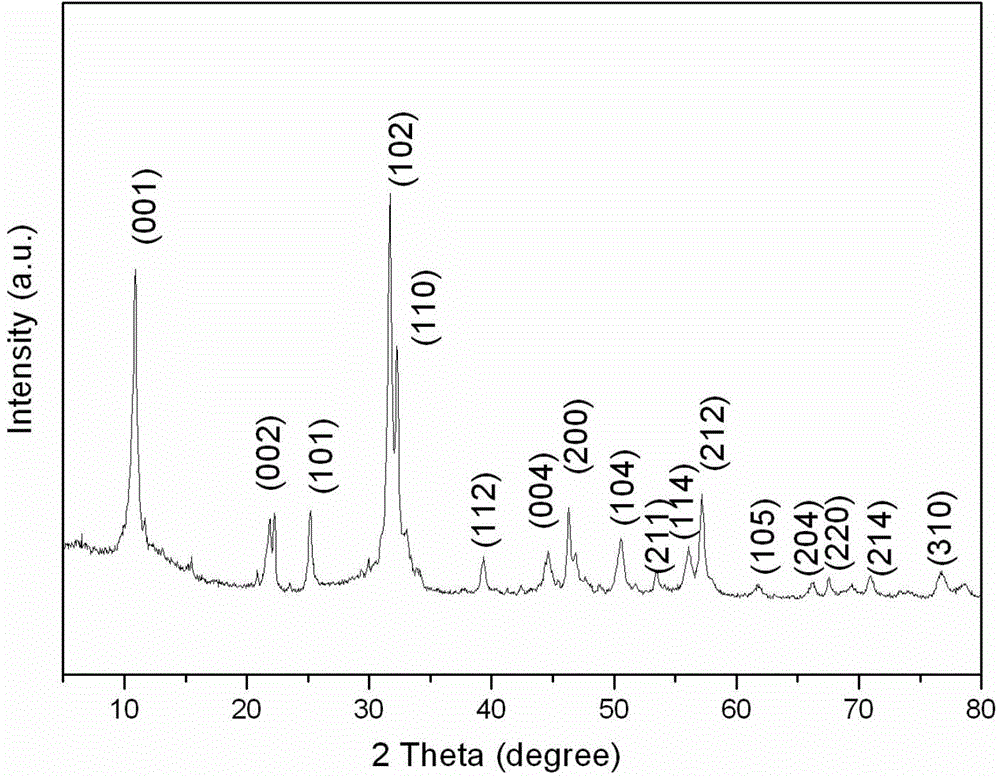

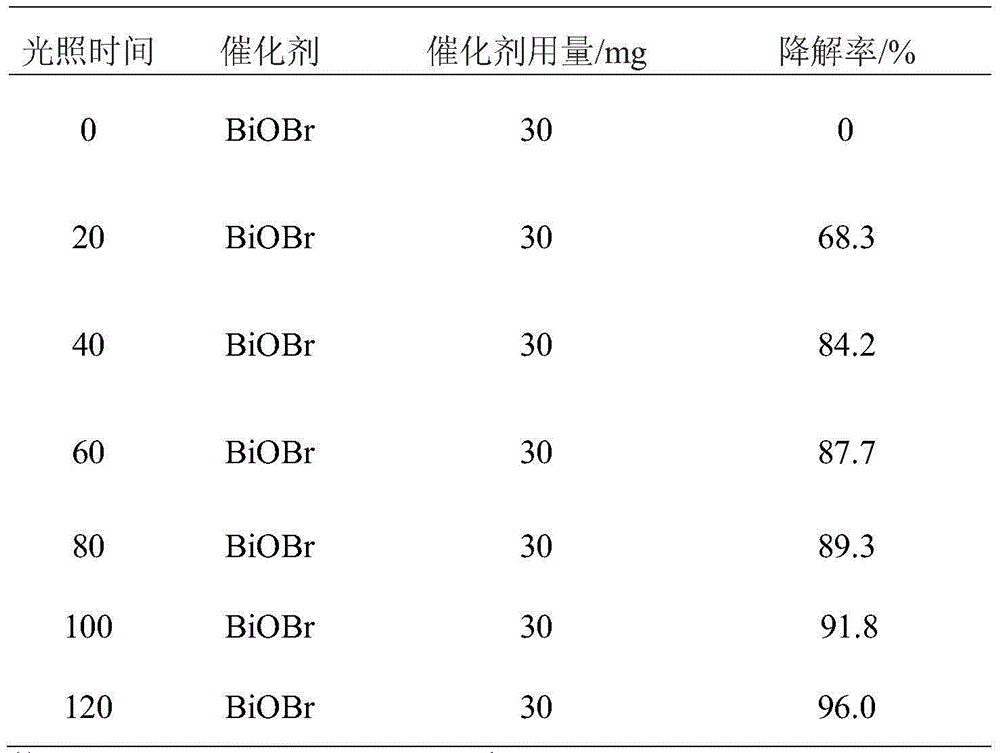

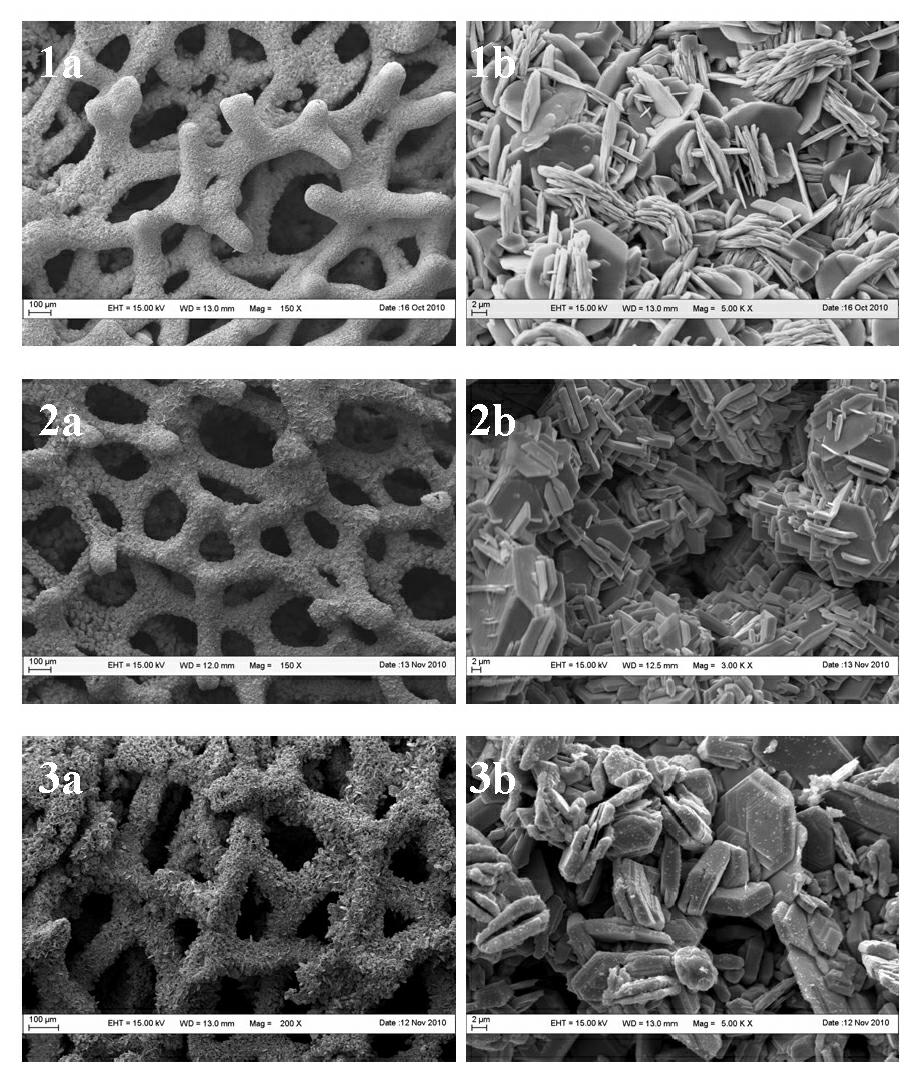

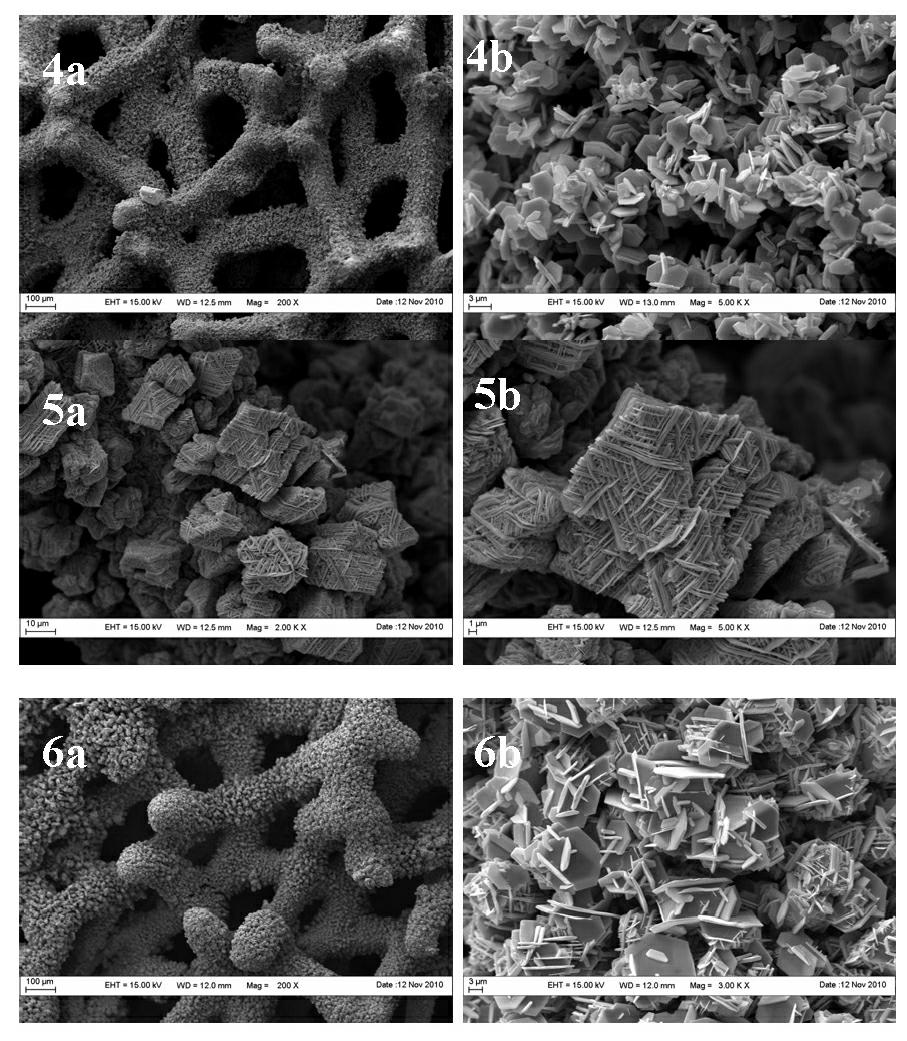

Preparation method of BiOBr/RGO nanometer composite and application thereof in reaction of degrading rhodamine

ActiveCN104353472AImprove stabilityGood catalyticPhysical/chemical process catalystsWater/sewage treatment by irradiationGrapheneBULK ACTIVE INGREDIENT

The invention discloses a preparation method of a BiOBr / RGO nanometer composite and application thereof, belonging to the field of photocatalysts. The BiOBr / RGO nanometer composite has an active ingredient of BiOBr / RGO, and is characterized in that floriform BiOBr and laminar RGO are interweaved together to form a special three-dimensional structure. The preparation method comprises the following steps: weighing a certain amount of methylbenzene, hexadecyl trimethyl ammonium bromide and oleic acid, mixing at a constant temperature, adding oxidized graphene to obtain a solution A; weighing a certain amount of H2O, adding HNO3 and Bi(NO3)3.5H2O to obtain a solution B; dropping the solution B in the solution A under a mixing state, raising the temperature to 85 DEG C and reflowing for 12h; and then, cooling, washing and drying to obtain a target product. The BiOBr / RGO nanometer composite prepared by adopting the preparation method can be used as a photocatalyst for a reaction of degrading rhodamine, and has good catalysis effect and stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Cultivation method of Gastrodia elata Bl.

InactiveCN105660136AGuaranteed normal growthUniform sizeBiocideFungiArmillariella melleaArmillaria mellea

The invention discloses a cultivation method of Gastrodia elata Bl., and belongs to the technical field of Gastrodia elata Bl. planting. The method comprises the steps of preparation of an armillaria mellea culture medium, preparation of fungus sticks, inoculating, Gastrodia elata Bl. cultivation, management and the like. Due to control of an armillaria mellea culture process, and improvement of a Gastrodia elata Bl. cultivation method, the cultivation method provided by the invention has the advantages that the Gastrodia elata Bl. productivity is improved; Gastrodia elata Bl. cultivated according to the cultivation method is uniform in size, full, and good in appearance.

Owner:赵志鑫

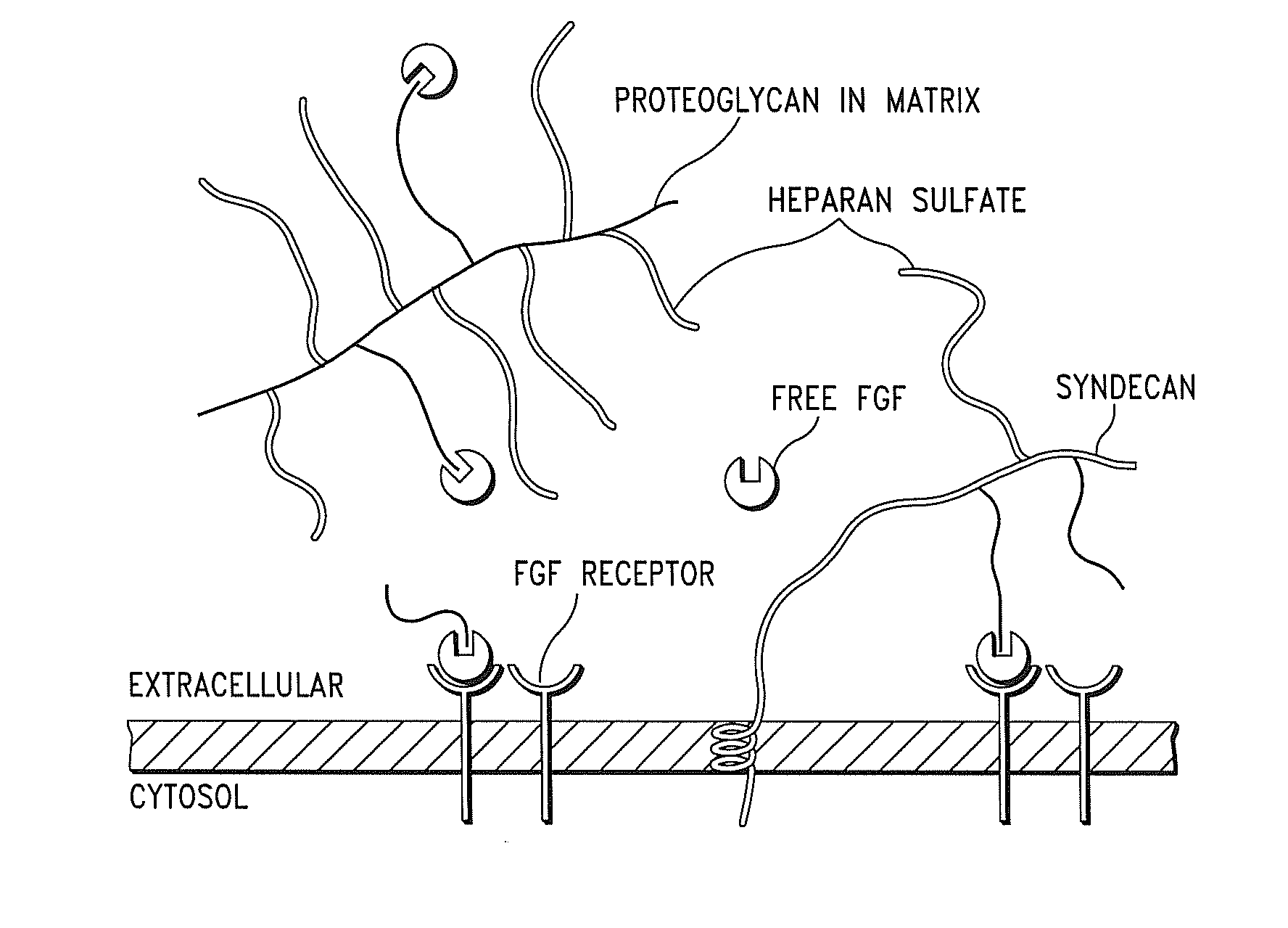

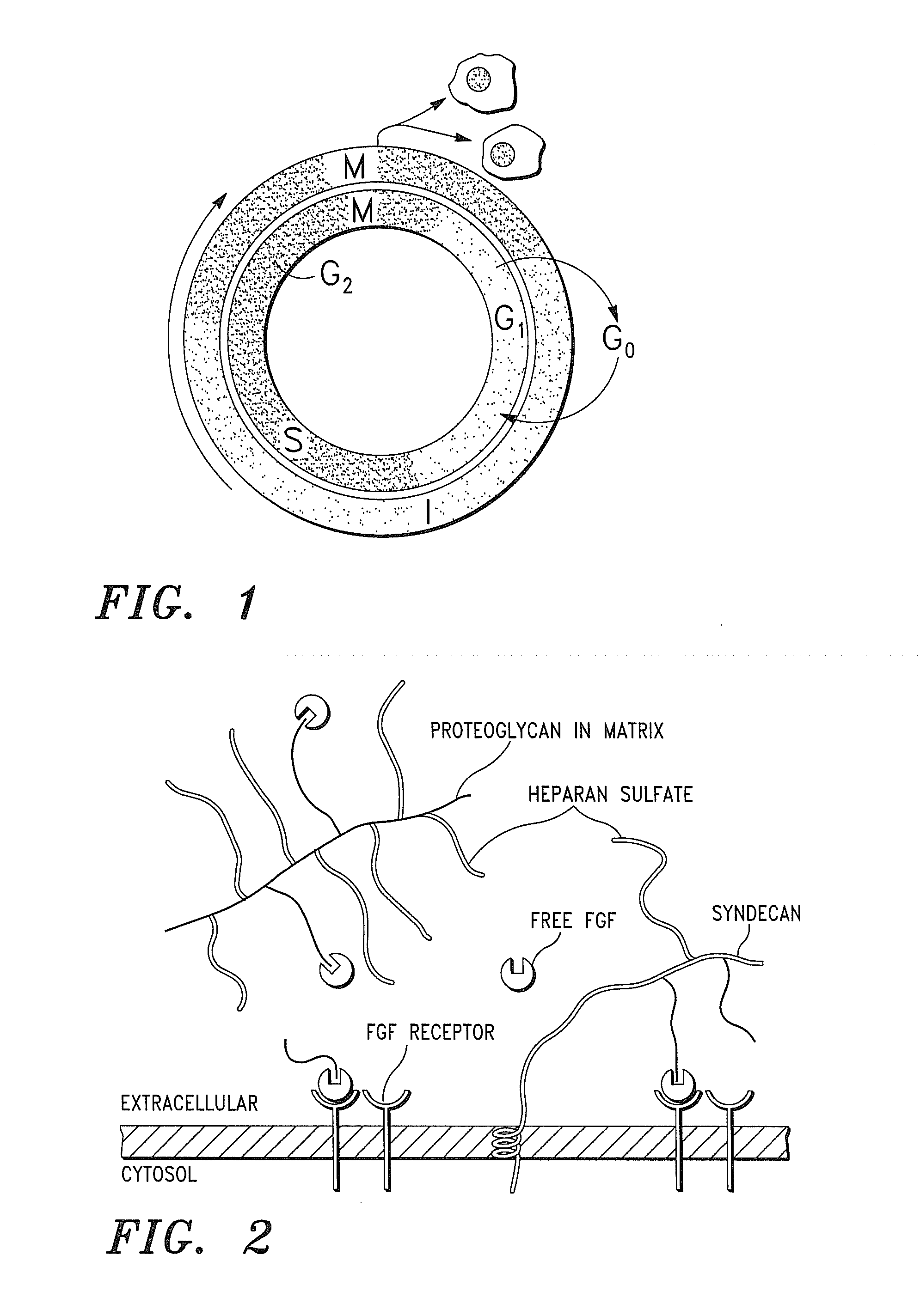

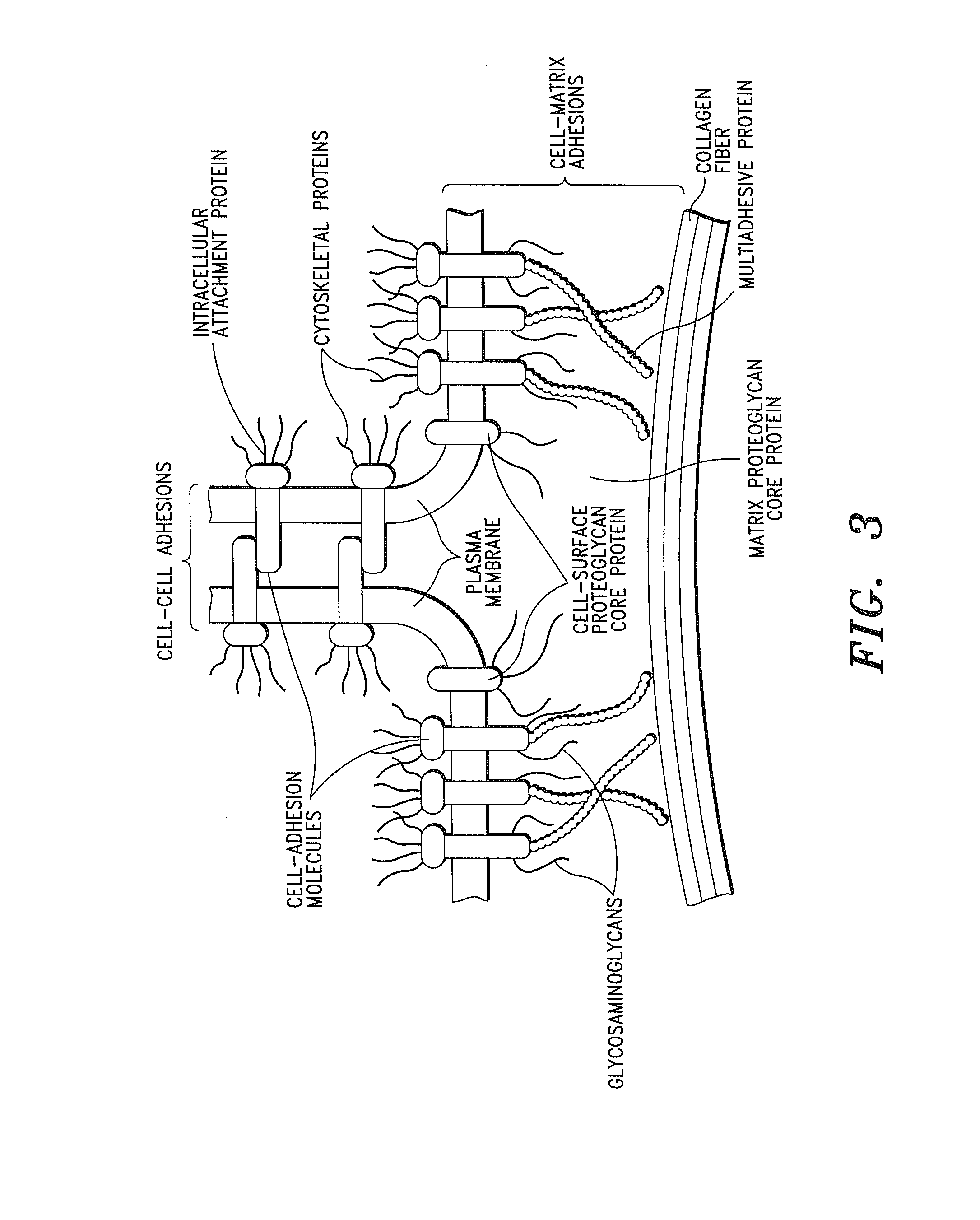

Compositions and Methods for Treating Organ Dysfunction

ActiveUS20140205565A1Increasing and extending lifespanReduce degradation ratePeptide/protein ingredientsGenetic material ingredientsCell-Extracellular MatrixECM Protein

A method of retarding cellular senescence comprising (i) providing an extracellular matrix (ECM) composition comprising ECM from an adolescent tissue source, the ECM comprising an exogenously added cytokine, and (ii) administering ECM composition to an organ with cells exhibiting cellular senescence, wherein, the cytokine interacts with at least one molecule in the ECM composition and modulates ROS production of the cells, whereby, the cellular senescence is abated.

Owner:CORMATRIX CARDIOVASCULAR INC

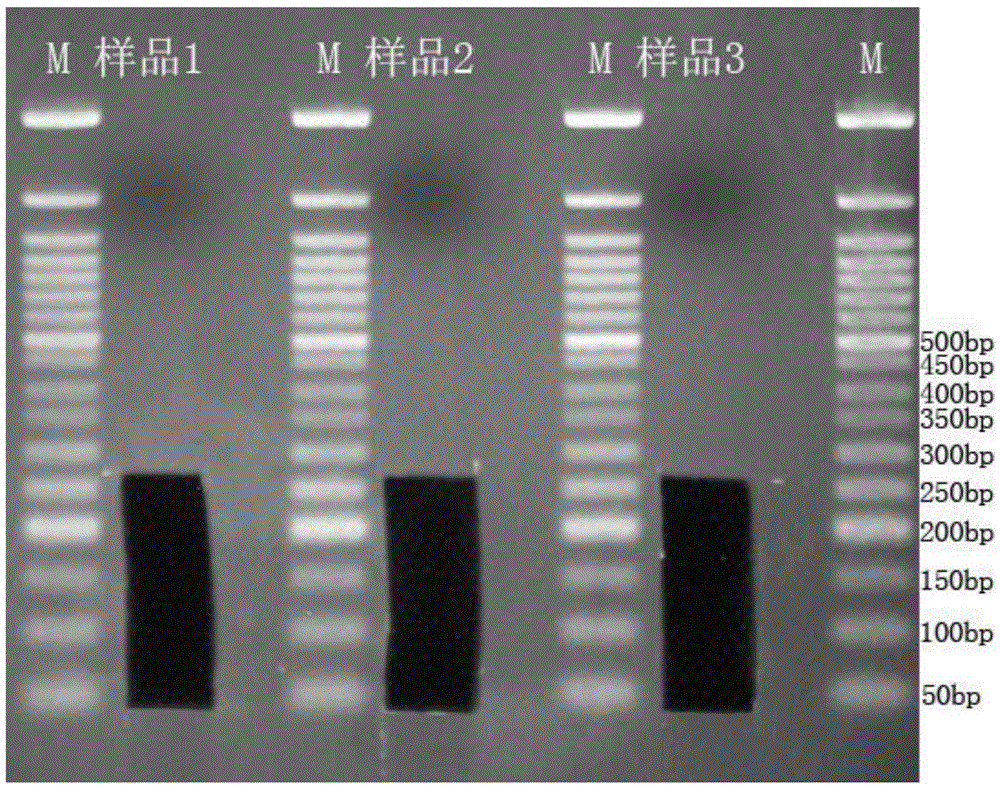

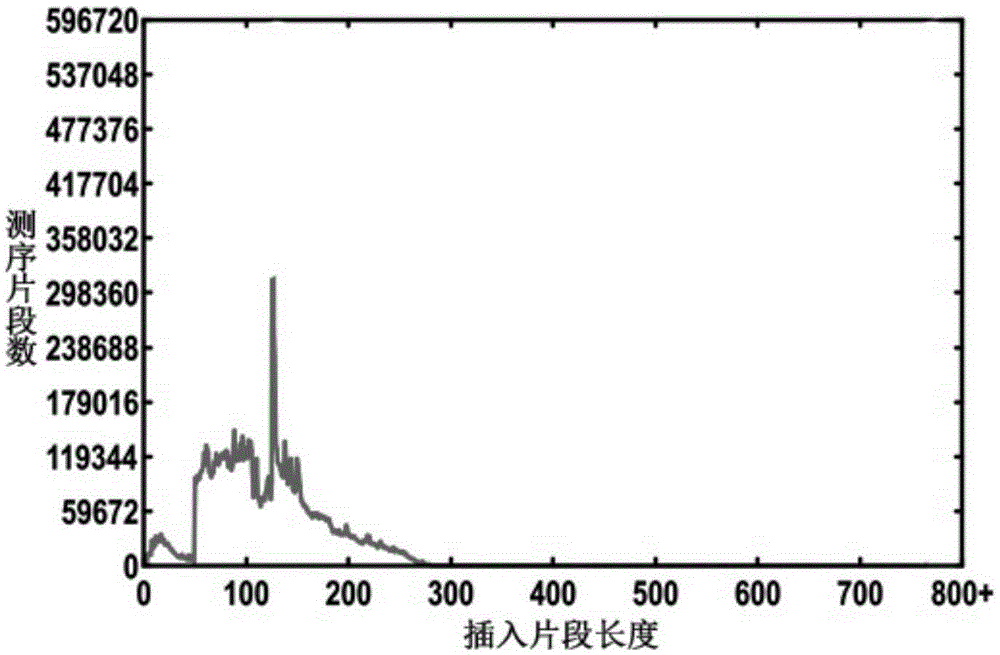

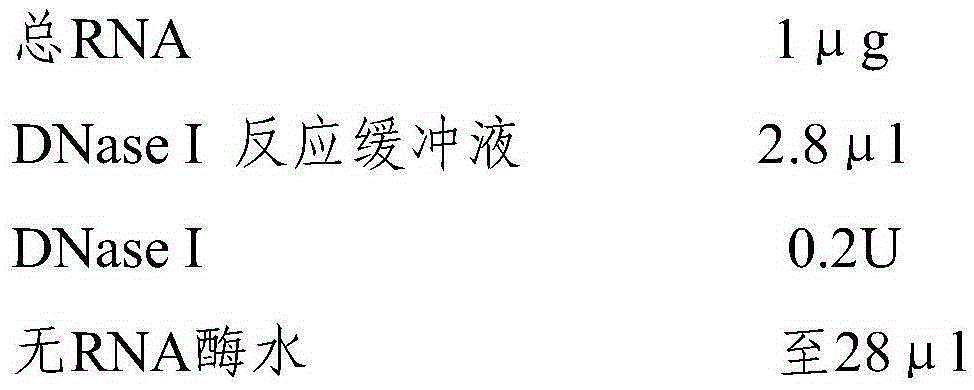

High throughput library construction method for small RNA of prokaryote

InactiveCN105297144AReduce purification operationsReduce the probability of RNA degradationLibrary creationDNA preparationSequencing dataRna degradation

The invention provides a high throughput library construction method for small RNA of prokaryote. The construction method includes the following steps of 1, digesting DNA in total RNA; 2, removing rRNA; 3, using random primers to synthesize a first chain of cDNA; 4, synthesizing a second chain of the cDNA; 5, screening the small RNA of the prokaryote in an electrophoresis mode through cutting gel; 6, repairing the tail end, adding A, carrying out purifying after linker adding, carrying out PCR amplification on a purified product, purifying a computer library, and constructing the computer library. According to the high throughput library construction method, after separation of the small RNA of the prokaryote is adjusted to the fact that the two chains are combined and converted into the cDNA, RNA degradation caused by separation on the RNA level can be avoided, the proportion of rRNA in sequencing data is greatly reduced, and the complete sequence of the small RNA of the prokaryote is obtained.

Owner:BIOMARKER TECH

Formula and production process of dairy cow protein particle feed

InactiveCN101731485AImprove utilization efficiencyIncrease expansionAnimal feeding stuffFiberAntioxidant

The invention relates to a formula of dairy cow protein particle feed which comprises the following components by weigh percent: 15-40 percent of energy feed, 40-80 percent of protein feed, 0-9 percent of oil and fat, 0-18 percent of amino acid, 0-2.3 percent of vitamin, 1.6-2 percent of calcium carbonate, 0-1 percent of adhesive, 0-0.1 percent of antioxidant and 0-0.3 percent of antimold agent. The production process of the dairy cow protein particle feed comprises the following steps: a, weighting the components according to the weight percent thereof; b, grinding the components; c, mixing the ground components; d, tempering the mixture; e, granulating the mixture; f, post-curing the granules; g, drying the granules; and h making the granules into the dairy cow protein particle feed which has the diameter of less than 4 mm and the length of 1 to 2 times of the diameter and contains the dry matter of more than 88 percent. The dry matter contains the crude protein of more than 20 percent and the crude fiber of less than 18 percent. The dairy cow protein particle feed can be kept stable in water for more than 5 min and has the dispersion rate of less than 12 percent in water. The protein in the dairy cow protein particle feed is less degraded by the rumen microorganisms, the rumen bypass efficiency of the protein is improved, the need of the essential amino acids in the nutrient of protein in the dairy cow body is balanced, the efficiency of using the dairy cow protein particle feed by the dairy cow is increased, the health status of the dairy cow body is improved and the pollution of the nitrogen in the excrement of the dairy cow to the environment is reduced.

Owner:ZHEJIANG KESHENG FEED CO LTD

Preparation method of flower-like BiOBr and application of flower-like BiOBr in rhodamine degradation reaction

ActiveCN104475132AEasy to prepareLow preparation temperaturePhysical/chemical process catalystsWater/sewage treatment by irradiationDispersityCatalytic effect

The invention discloses a preparation method and application of flower-like BiOBr, belonging to the field of photocatalysts. The BiOBr has flower-like structure, and has favorable dispersity; and the petal thickness is 20-40nm, and the corolla diameter is 1-1.5 mu m. The preparation method comprises the following steps: measuring toluene, putting the toluene into a round-bottom flask, stirring at constant temperature, adding cetyl trimethylammonium bromide and oleic acid, and stirring for dissolution to obtain a solution A; measuring a certain amount of water, and adding HNO3 and Bi(NO3)3.5H2O to obtain a solution B; and while stirring, dropwisely adding the solution B into the solution A, continuing stirring for 12 hours, heating to 85 DEG C, refluxing for 12 hours, cooling the reaction product, separating, washing, and drying to obtain the flower-like BiOBr. The flower-like BiOBr can be used as a photocatalyst for degrading the organic pollutant rhodamine in water, and has favorable catalytic effect and high stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

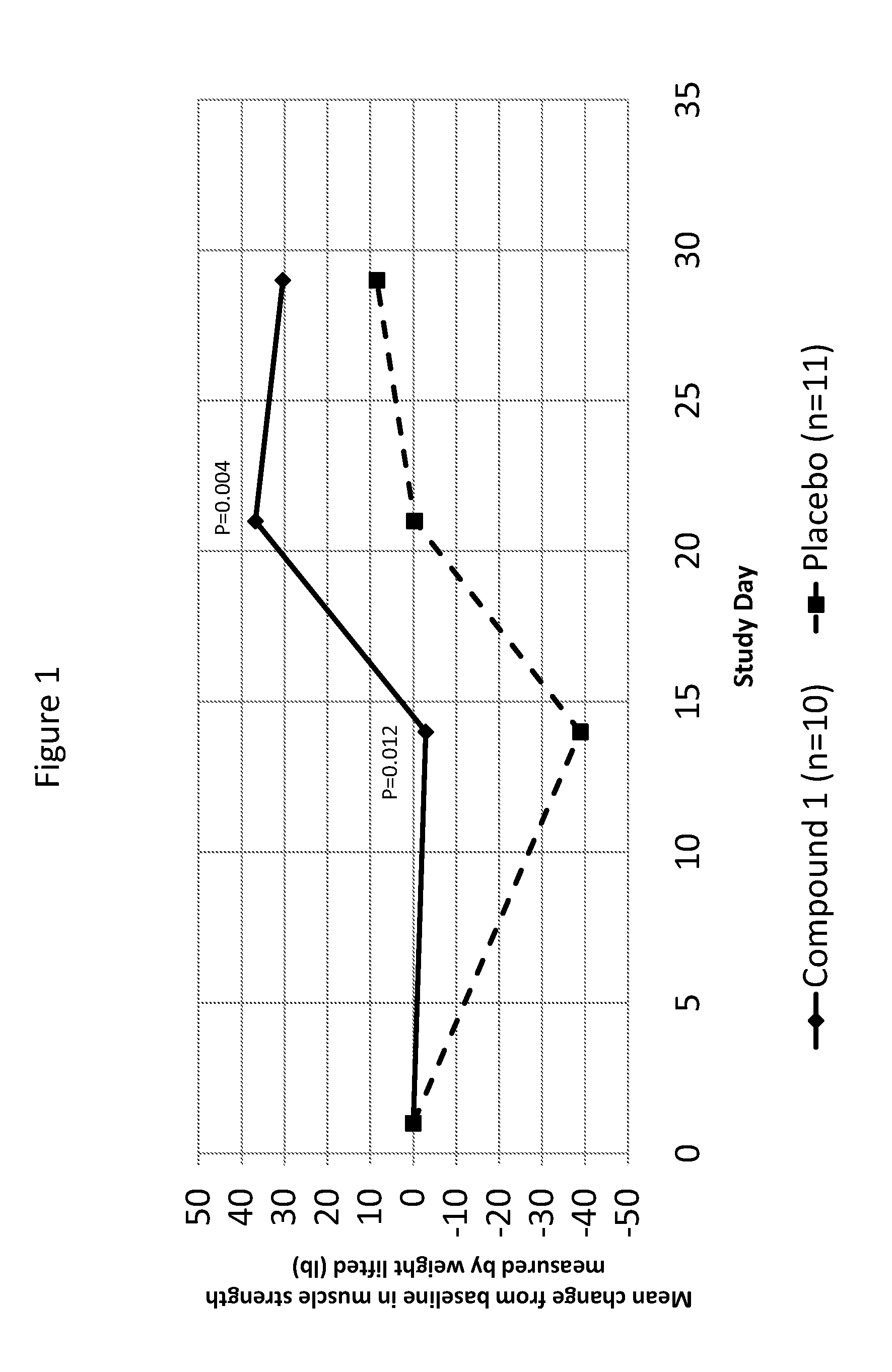

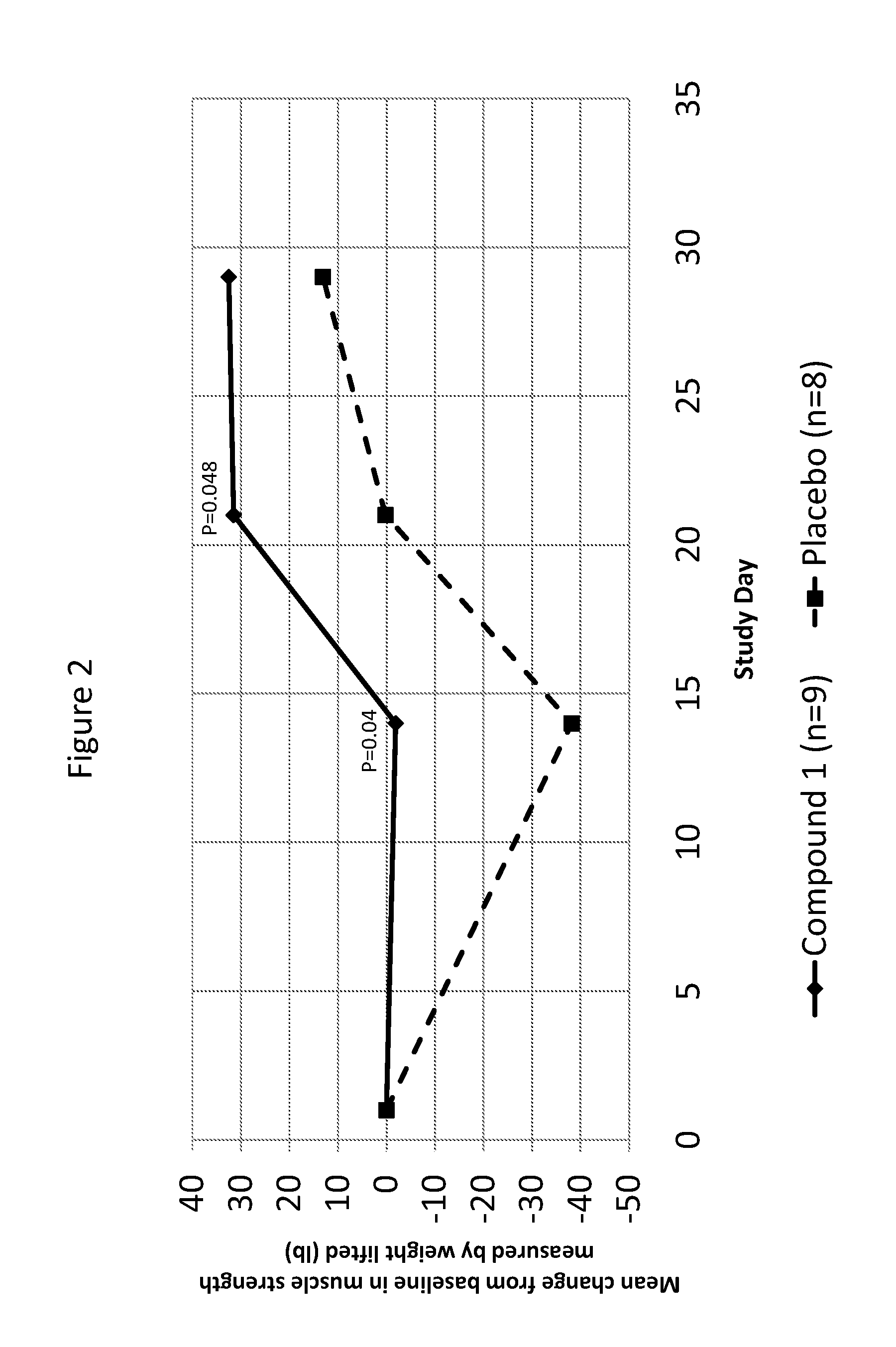

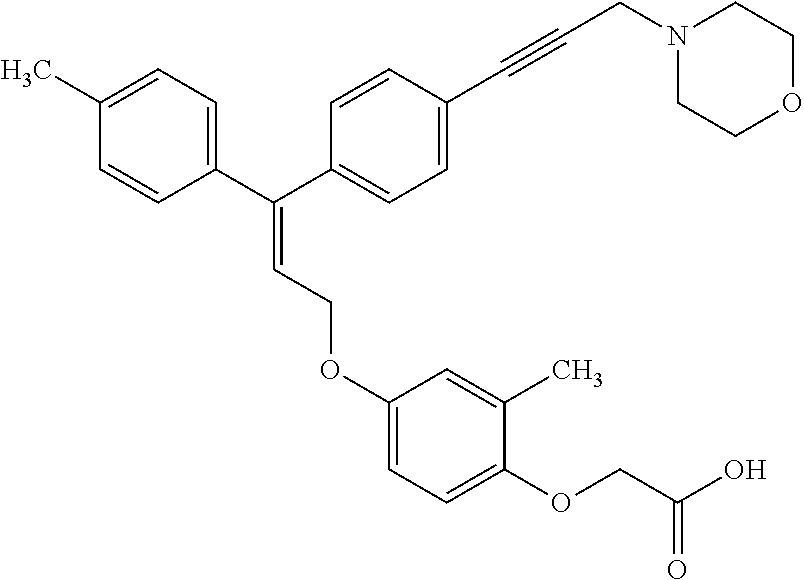

Use of a PPAR-delta agonist for treating muscle atrophy

ActiveUS9487493B2Convenient treatmentReducing disuse-associated muscle atrophyOrganic active ingredientsOrganic chemistryAgonistPPAR-delta Agonists

Owner:VTV THERAPEUTICS LLC

Method for desulfurizing acid gas containing hydrogen sulfide and recovering sulfur

ActiveCN104208992BHigh activityReduce energy consumptionDispersed particle separationSulfur preparation/purificationCombustionSulfur

Owner:NINGBO RES & DESIGN INST OF CHEM IND

Method for producing glutamic acid through double-feeding fermentation optimization of corn steep liquor and glucose

ActiveCN103243132AFast growthImprove adaptabilityMicroorganism based processesFermentationBiotechnologyDouble-time

The invention discloses a method for producing glutamic acid through double-feeding fermentation optimization of corn steep liquor and glucose, which comprises the following steps of: in fermentation culture of glutamic acid, initially adding 1-10g / L of glucose to a fermentation culture medium, and initially adding 1-10g / L of corn steep liquor; after the fermentation culture starts, starting feeding the corn steep liquor and glucose at the same time, wherein 5-19g / L of corn steep liquor is fed and completely added within 5-10 hours since the fermentation starts, and the total amount of the corn steep liquor is 15-20g / L; feeding the concentrated solution of glucose until the fermentation is over; maintaining the amount of residual sugar in the fermentation culture medium at 0.05-10g / L; and controlling the pH value of the liquid ammonia in the whole process of fermentation to 6.8-7.3. The method disclosed by the invention effectively increases the growth speed of thalli and shortens the adaptation period in the initial stage of thallus fermentation and the thallus doubling time, thus shortening the overall fermentation time and reducing the overall production cost of glutamic acid.

Owner:山东祥维斯生物科技股份有限公司

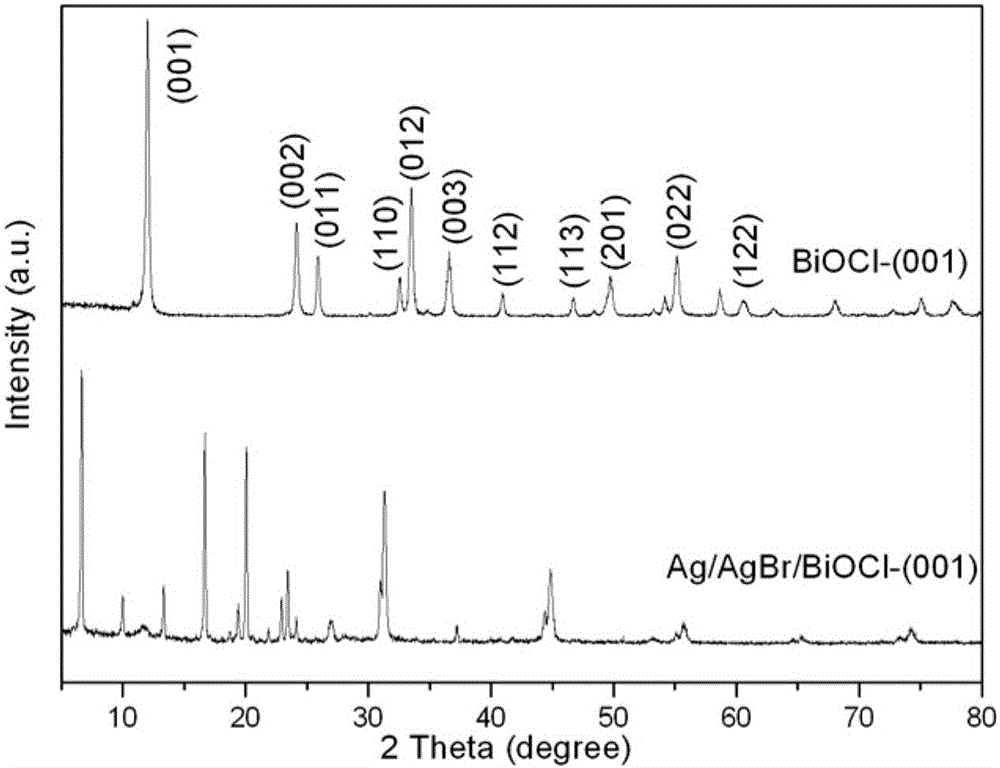

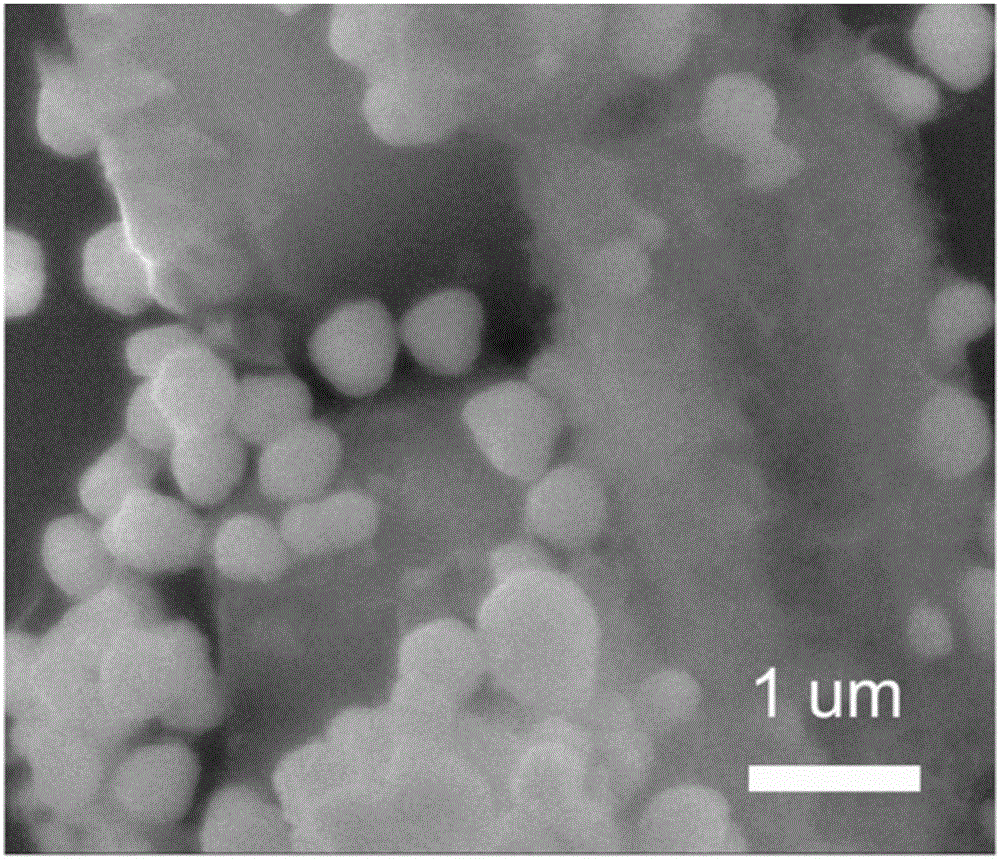

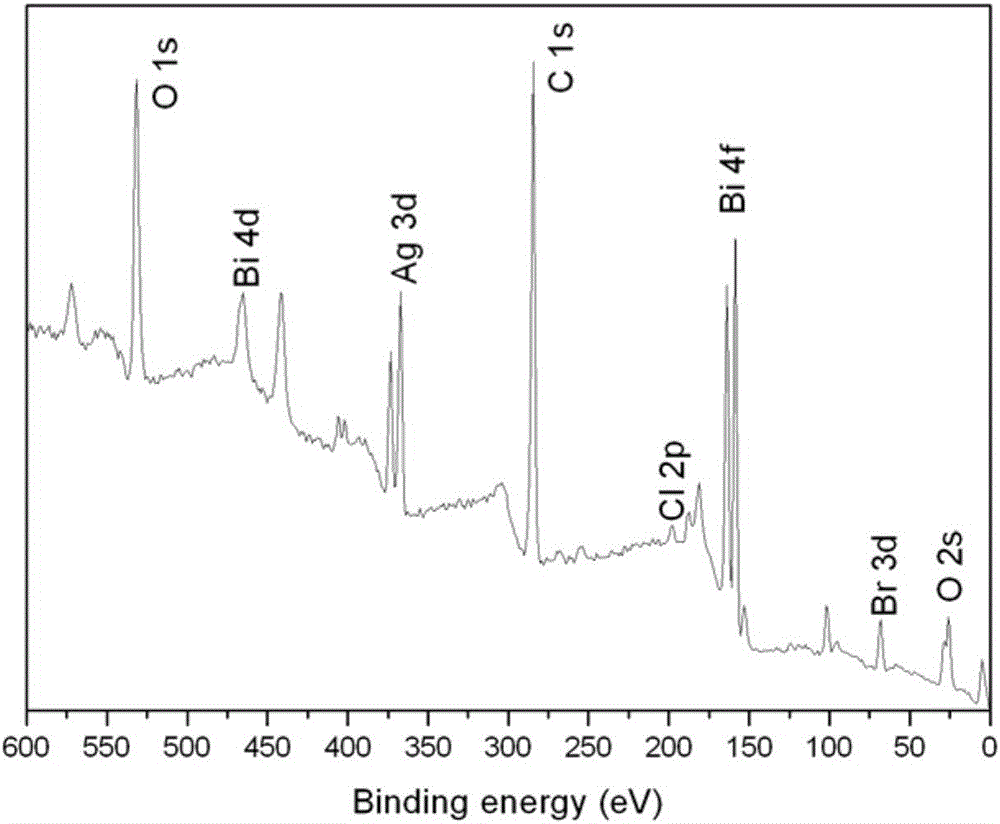

Preparing method and application of Ag/AgBr/BiOCl-(001) nanometer composite material

ActiveCN105709782AHigh catalytic efficiencyImprove catalytic stabilityPhysical/chemical process catalystsSurface engineeringActive component

The invention discloses a preparing method and application of an Ag / AgBr / BiOCl-(001) nanometer composite material, and belong to the field of photocatalysts. The active component of the composite material is Ag / AgBr / BiOCl-(001). The material is characterized in that based on the combination of the crystal surface engineering technology and the surface plasmon resonance effect, Ag / AgBr colloidal spheres and (001)-surface-exposed BiOCl nanometer sheets (BiOCl-(001)) are composited to prepare the three-component composite photocatalyst Ag / AgBr / BiOCl-(001) is prepared. The preparing method includes the steps that ethylene glycol serves as a solvent, a certain amount of PVP and a certain amount of CTAB are weighed and put into a round-bottom flask, the mixture is fully stirred at the certain temperature to be fully dissolved, a proper amount of BiOCl-(001) is added, stirring is carried out at the constant temperature, then a proper quantity of ethylene-glycol Ag (NO3)3 solutions is slowly added, and the mixture is reacted at the temperature of 155 DEG C for 15 min, and is cooled, washed, dried to obtain the target product. The prepared Ag / AgBr / BiOCl-(001) nanometer composite material can serve as a photocatalyst to be used for the degrading reaction of methyl orange, and has the good catalytic effect and the stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

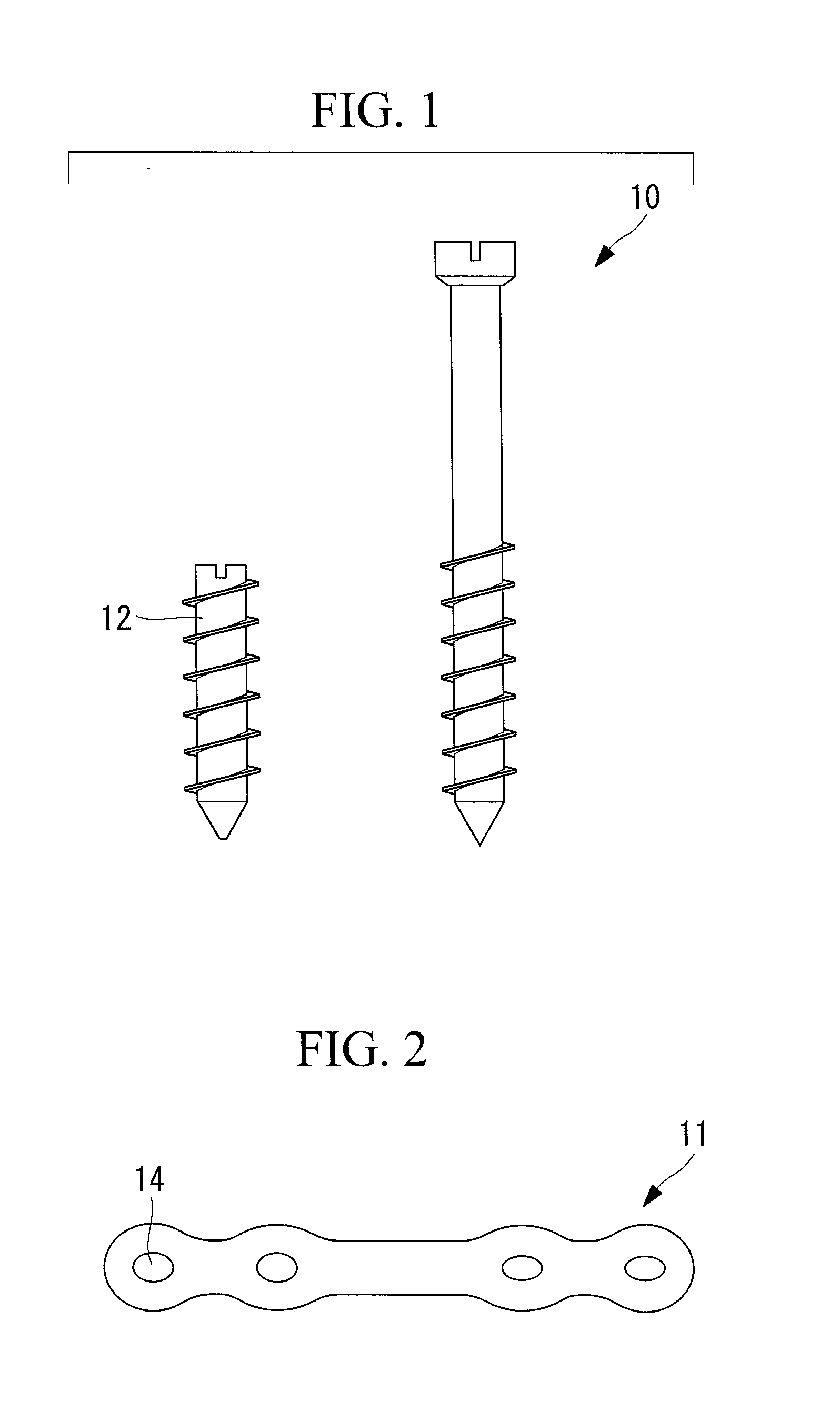

Biodegradable implant and fabrication method thereof

ActiveUS20130304134A1Reduce degradation rateReduces degradation rateSuture equipmentsImpression capsBiodegradable implantsBony Tissues

The present invention can suitably be used even in a site where hydrogen gas is metabolized slowly, such as the osseous tissue. Provided is a biodegradable implant including a biodegradable magnesium member formed of a magnesium alloy and coating layers that coat the biodegradable magnesium member, thereby reducing the degradation rate thereof in a living organism, wherein a depression to be infiltrated by an osteoblast is formed in a surface of the biodegradable magnesium member.

Owner:OLYMPUS CORP

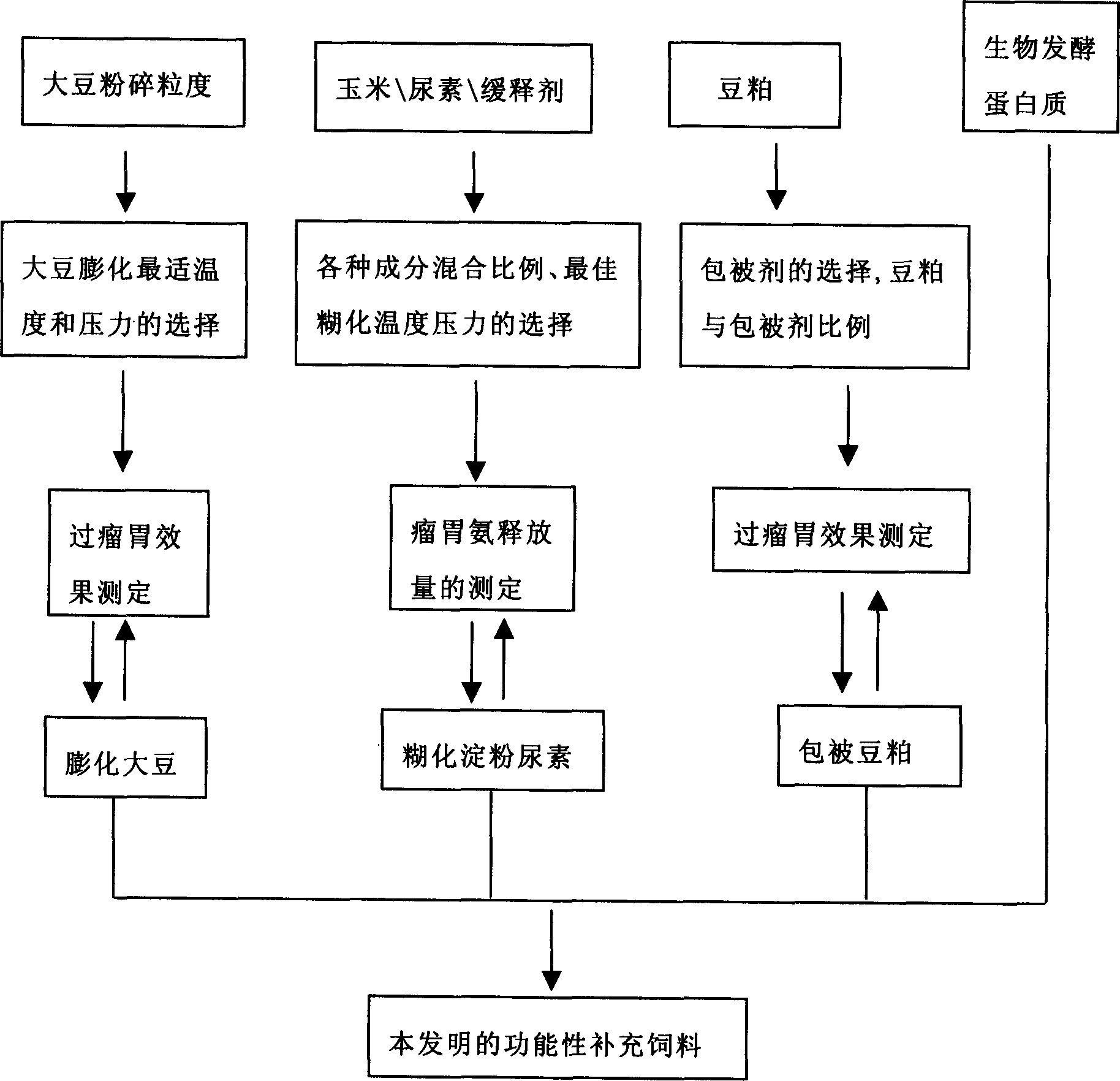

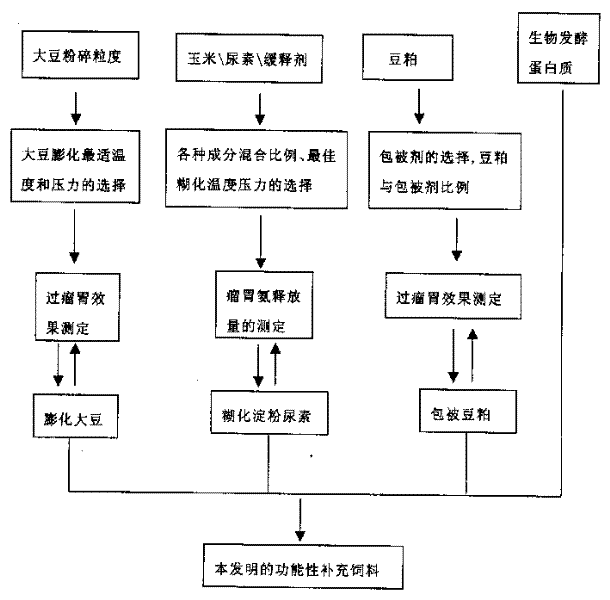

Functional supplementary feed for feednig cow, preparing method and use thereof

InactiveCN1552238AReduced white matter degradationImprove utilization efficiencyFood processingAnimal feeding stuffSoybean mealMilk secretion

A functional feed for the milk cow is prepared from soybean, soybean dregs, corn, urea, ruminal slow-releasing agent and fermented biological protein through conventionally puffing soybean, pulverizing corn and mixing with urea and ruminal slow-releasing agent to obtain gelatinized starch urea, pulverizing soybean dregs, coating and drying to obtain coated soybean dregs, screening the fermented biological protein, and proportional mixing. It can increase the milk output per day by 1.52-2.85 kg and elongate the peak period of milk secretion by 26-35 days.

Owner:北京东方联鸣科技发展有限公司

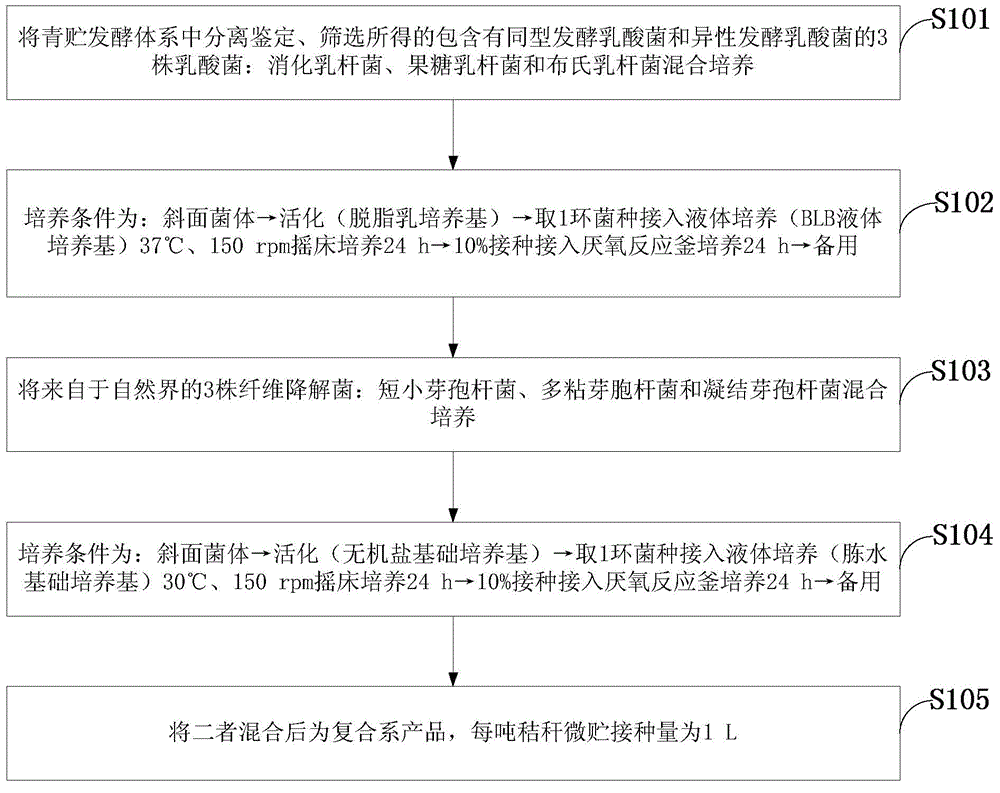

Straw treatment microecological preparation and preparation method thereof

InactiveCN104450566AImproves aerobic stabilityPromote generationBacteriaAnimal feeding stuffLactobacillus alimentariusLactobacillus fructivorans

The invention discloses a straw treatment microecological preparation and a preparation method thereof. The straw treatment microecological preparation comprises digestive lactobacillus, lactobacillus fructivorans, lactobacillus buchneri, bacillus pumilus, bacillus polymyxa and bacillus coagulans. The preparation method comprises the following steps of carrying out mixed culture on three lactic acid bacteria: the digestive lactobacillus, the lactobacillus fructivorans and the lactobacillus buchneri which are separated, identified and screened from a silage fermentation system and contain homofermentative lactic bacteria and heterofermentative lactic bacteria; carrying out the mixing culture on three fibrolytic bacteria: the bacillus pumilus, the bacillus polymyxa and the bacillus coagulans which are from the nature; mixing two mixtures into a composite product, wherein the microbial storage inoculation amount of every ton of straws is 1 L. The straw treatment microecological preparation disclosed by the invention can be used for enhancing the silage quality and the aerobic stability and reducing the loss of weight in a fermentation process by reducing pH and protein degradation rate and is very significant to animal husbandry production by reducing the decomposing speed of a silage after the silage is fed by opening a cellar.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY SCI SHANXI ACAD OF AGRI SCI SAAS

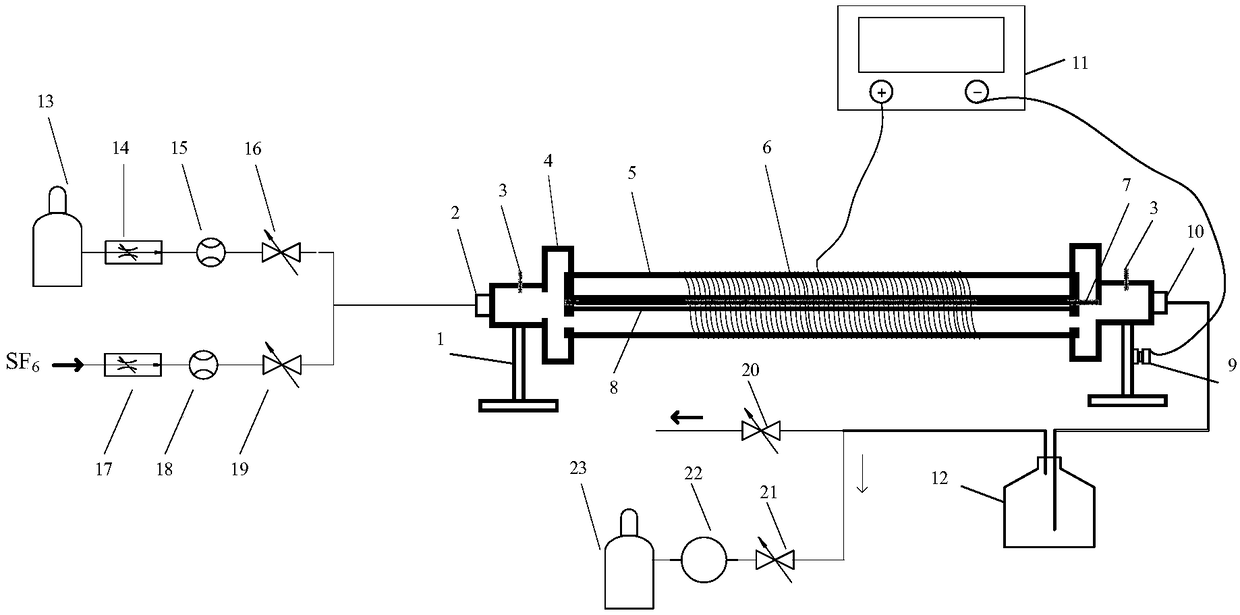

Treatment device and treatment method for degrading sulfur hexafluoride based on dielectric barrier discharge

PendingCN108273366AEfficient decompositionSimple plasma conditionsGas treatmentDispersed particle separationSulfur hexafluorideProduct gas

The invention discloses a treatment device and a treatment method for degrading sulfur hexafluoride based on dielectric barrier discharge. The treatment device comprises a dielectric barrier dischargereactor, wherein a high-voltage electrode end of a high voltage source (11) is connected with an outer electrode of the dielectric barrier discharge reactor; a ground electrode end of the high voltage source is connected with a ground electrode connection post (9) of the dielectric barrier discharge reactor; a gas inlet joint (2) is arranged at one end of the dielectric barrier discharge reactor;a gas outlet joint (10) is arranged at the other end of the dielectric barrier discharge reactor and is connected with a tail gas absorption tank (12) through a pipeline. Through the treatment deviceand the treatment method, the technical problems that the treatment amount is extremely low, the degradation rate is low, the SF6 gas cannot be effectively degraded, and the degraded tail gas is noteffectively recycled when only sulfur hexafluoride gas is collected, purified, stored and decomposed in the prior art are solved.

Owner:GUIZHOU POWER GRID CO LTD

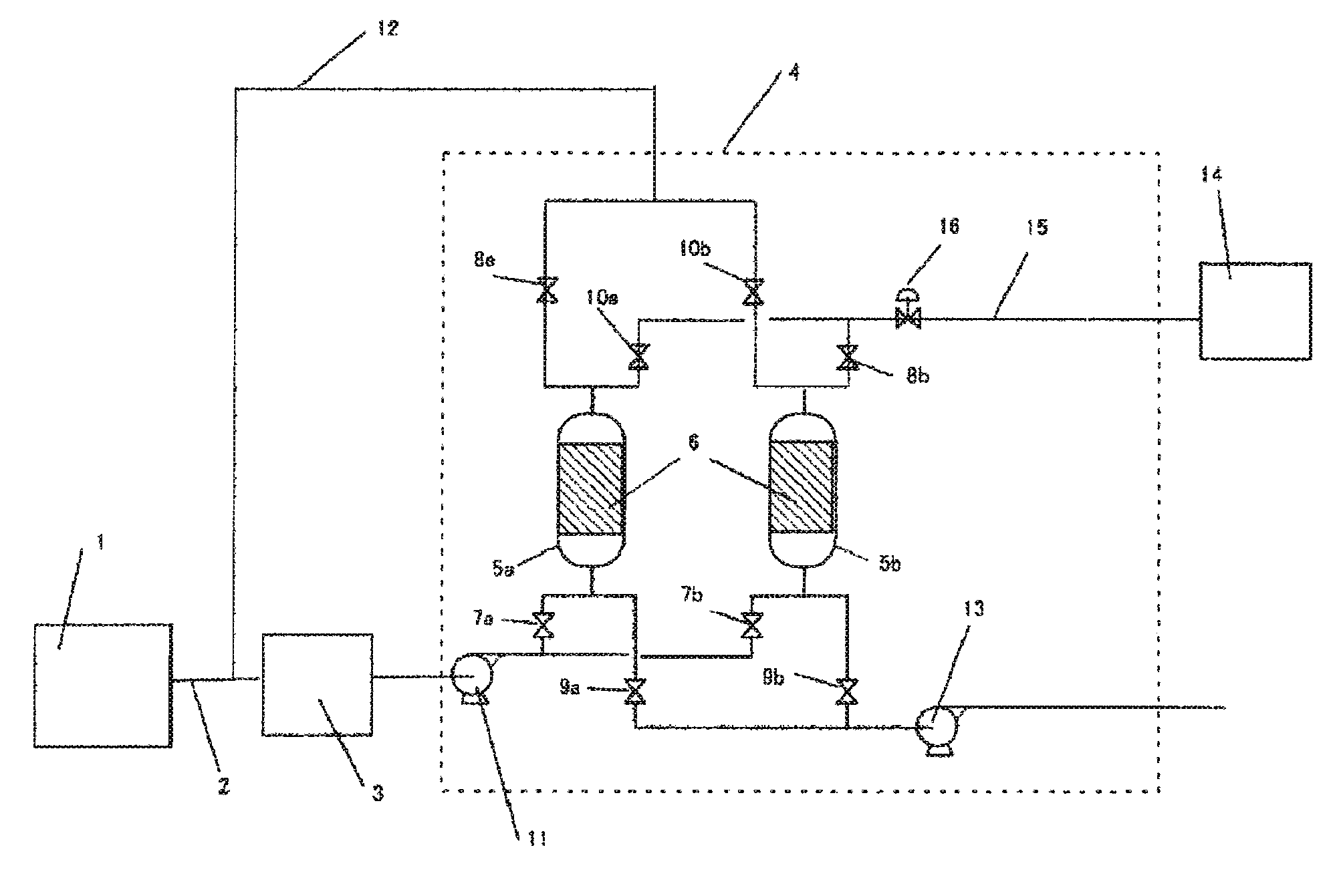

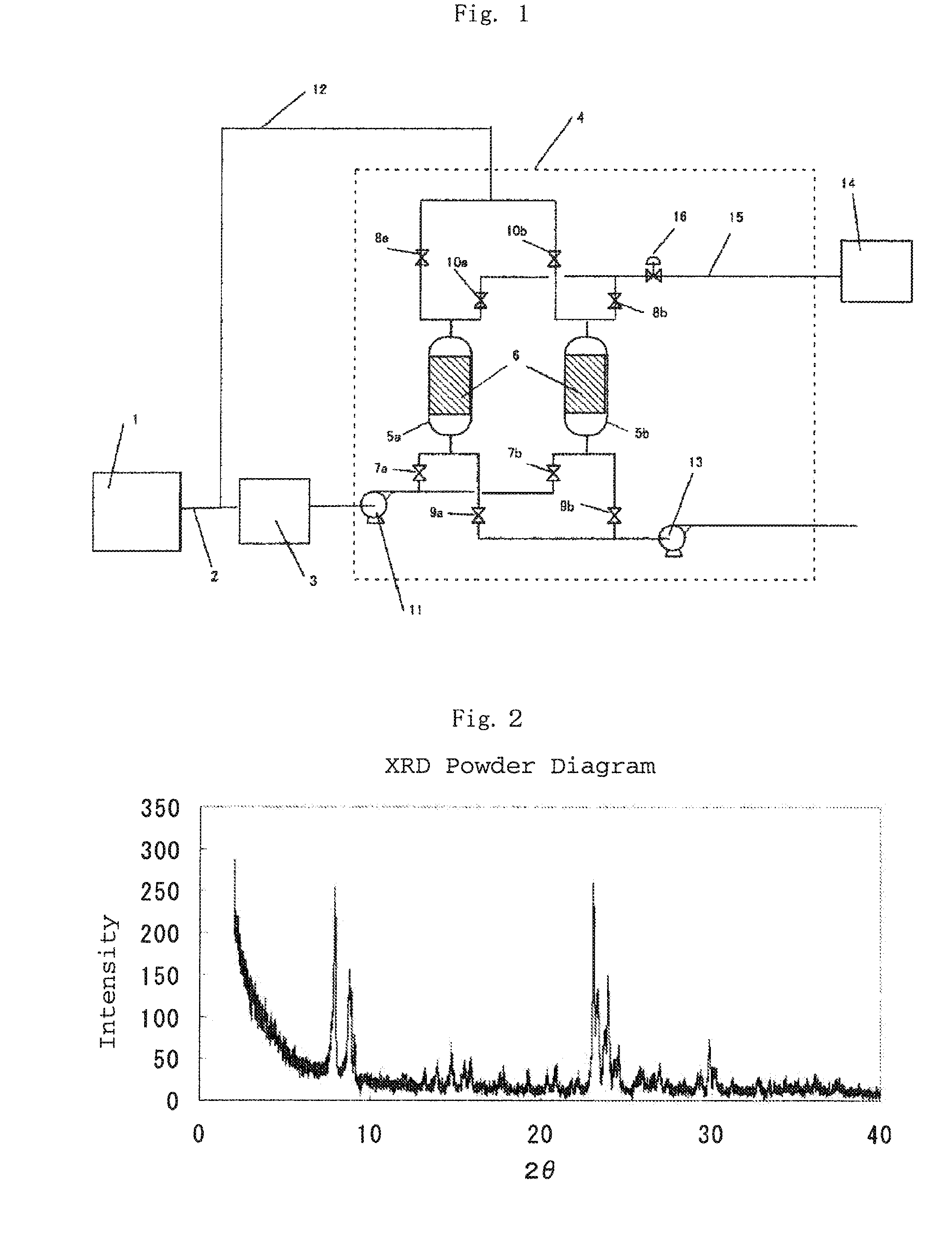

Method and apparatus for producing and storing ozone using adsorbent

InactiveUS20090293717A1Reduce production cost and run costGood adsorption capacityGas treatmentDispersed particle filtrationChemistryProduct gas

The present invention provides a low-cost ozone production method and apparatus for carrying out ozone / oxygen separation using an ozone adsorbent, that re-uses the recovered oxygen as a feed for ozone production, and that desorbs and recovers the adsorbed ozone using dry air. In the method and apparatus, a gas containing an ozone and oxygen two-component gas supplied from an ozone generator is pressurized, introduced into an ozone adsorbent-packed adsorption column, and brought into contact with the adsorbent to adsorb the ozone to the adsorbent. Using dry air as a counterflow purge gas for the adsorbed ozone, the ozone is desorbed from the ozone adsorbent-packed adsorption column loaded with adsorbed ozone by depressurizing the adsorption column or air is introduced as a purge gas from the rear of the column into the adsorbent bed, whereby an ozone and air two-component gas is recovered. The method and apparatus use, as the ozone adsorbent, at least one selected from the group consisting of (1) pentasil-type zeolites, (2) acid-treated pentasil-type zeolites, (3) mesoporous silica, and (4) acid-treated mesoporous silica.

Owner:ADSORPTION TECH INDS

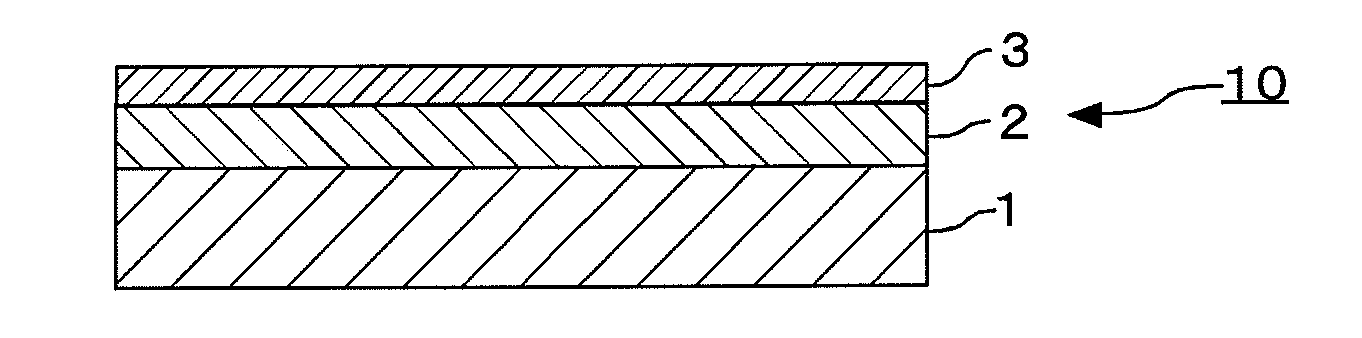

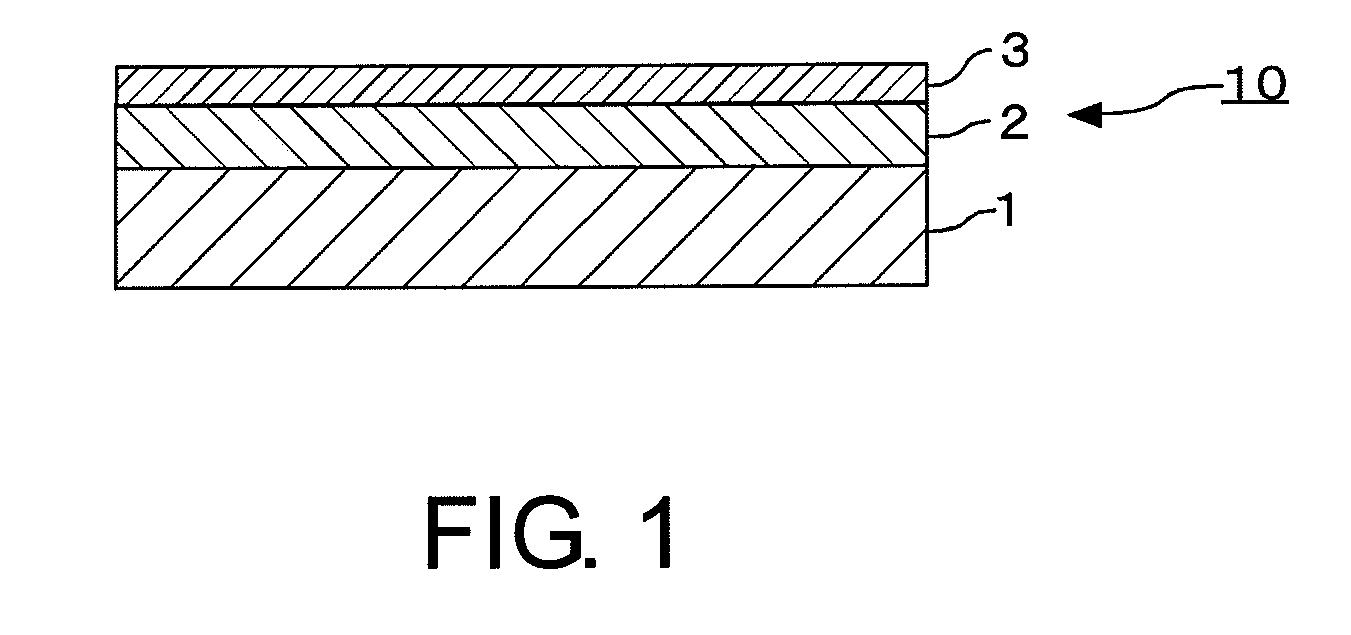

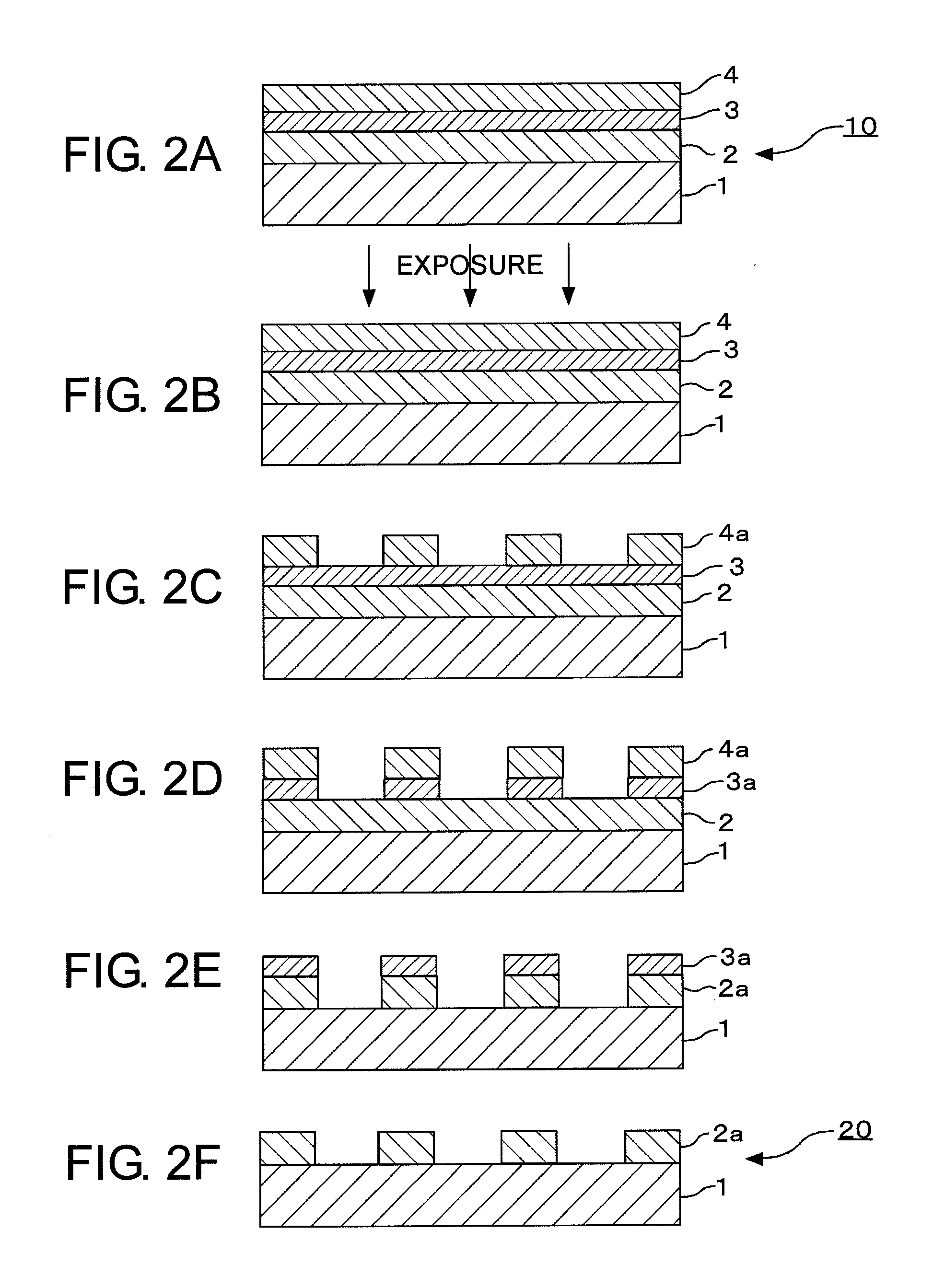

Mask blank, transfer mask, method of manufacturing a transfer mask, and method of manufacturing a semiconductor device

ActiveUS20120156596A1Small biasSuppress surface reflectionLayered productsPhotomechanical apparatusSurface layerRefractive index

A mask blank for use in the manufacture of a transfer mask adapted to be applied with ArF excimer laser exposure light is disclosed. The mask blank has, on a transparent substrate, a light-shielding film for forming a transfer pattern. The light-shielding film has an at least two-layer structure including a lower layer and an upper layer from the transparent substrate side. The lower layer is made of a material composed of a transition metal, silicon, and nitrogen and having a nitrogen content of 21 at % or more and a refractive index n of 1.9 or less. The upper layer is made of a material composed of a transition metal, silicon, and nitrogen and having a refractive index n of 2.1 or less. A surface layer of the upper layer contains oxygen and has a nitrogen content of 14 at % or more.

Owner:HOYA CORP

Preparation method and application of CuS catalyst with three-dimensional framework structure

InactiveCN102133534AEasy to handleHigh catalytic efficiencyPhysical/chemical process catalystsHigh concentrationIndustrial waste water

The invention discloses a preparation method and application of a CuS catalyst with a three-dimensional framework structure. In the invention, CuS crystalline materials in four shapes including hexagonal phase shape, three-dimensional shape, plate shape and flower shape are synthesized by adopting a solvothermal method, and a catalytic degradation experiment is carried out by taking azo dye (methyl orange) as a research object. The catalyst does not need light and has more than 85% of degradation rate to high-concentration industrial waste water within 60 minutes. The CuS catalyst prepared by the preparation method disclosed by the invention has the advantages of effective treatment on methyl orange dye waste water, low operation cost, requirements for normal temperature and normal pressure, simple process, no need of light, simplicity and convenience for operation, no secondary pollution, high catalytic efficiency, no influence on catalytic efficiency in the recycling process as well as very high actual application and theoretical research values.

Owner:XUCHANG UNIV

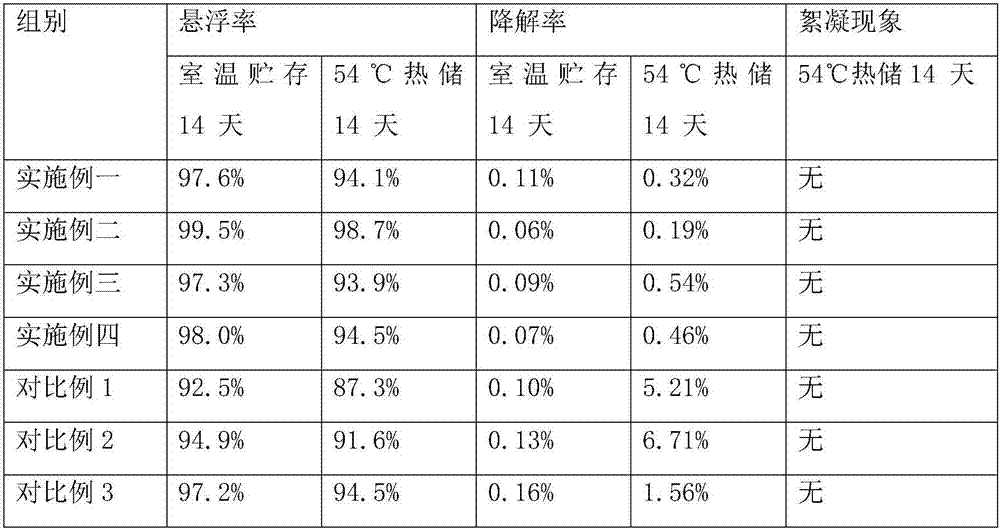

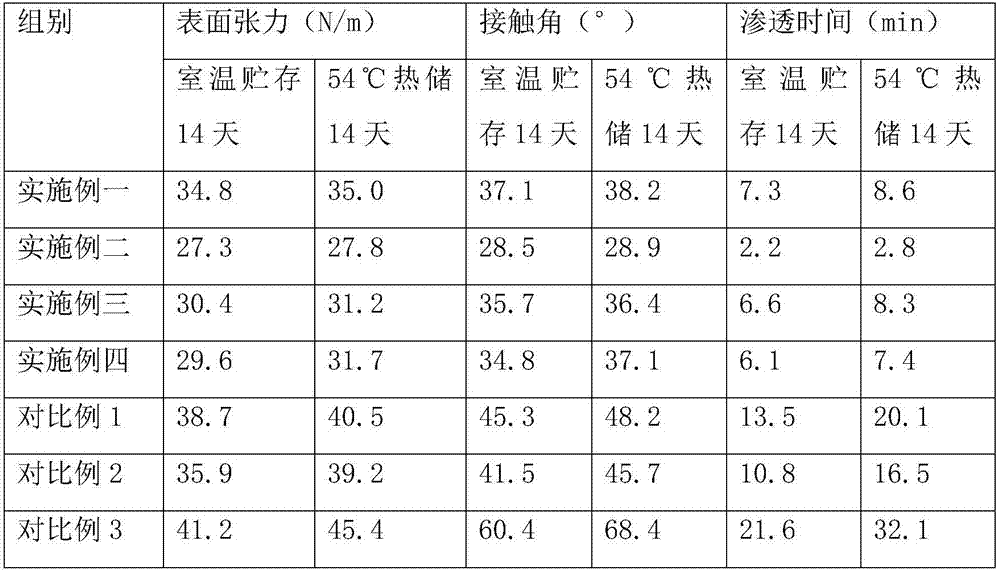

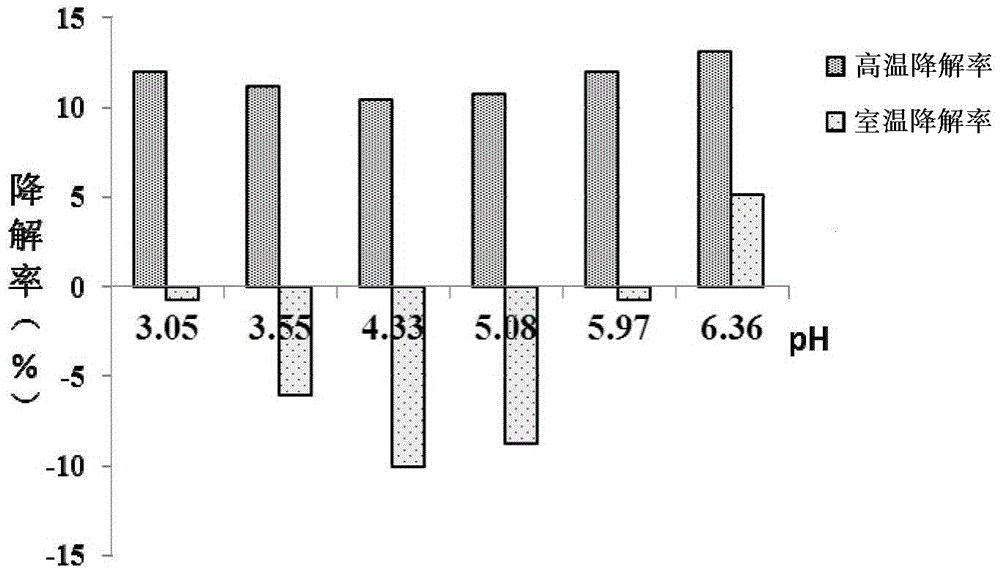

Thiacloprid aqueous suspension agent and preparation method thereof

ActiveCN107439540AImprove anti-coalescence stabilityExcellent long-term storage stabilityBiocideAnimal repellantsChemistryPesticide

The invention provides a thiacloprid aqueous suspension agent. The thiacloprid aqueous suspension agent comprises the following components by mass percent: 35-50% of thiacloprid, 3-10% of a wetting dispersant, 2-5% of a synergist, 0.05-2% of a thickener, 0-1% of a preservative, 2-6% of an antifreezing agent, 0.1-1% of a defoaming agent and the balance of water, wherein the wetting dispersant is selected from one or more of a polycarboxylate dispersant sp-2700, a gemini-like type dispersant sp-sc3, a phosphate ester type dispersant PEAS03, a carboxylate type dispersant CP9 and a non-ionic hydroxyl polyethylene oxide block copolymer dispersant 500LQ. The invention belongs to the technical fields of pesticides. The thiacloprid aqueous suspension agent provided by the invention has good anti-coalescence stability, is difficult to be oxidized or decomposed, strong in persistent effect, good in quality stability and enhanced in pharmaceutical effect and has lower surface tension and a smaller contact angle, good permeability, properties such as rain wash resistance and spreadability are obviously enhanced, and insects can be killed with strong effect.

Owner:HUIZHOU YINNONG TECH

Chemical looping system

InactiveUS20130125462A1Easy to separateIncrease generationFluidized bed combustionGaseous fuelsNuclear engineeringCompound (substance)

A chemical looping system and a method of transferring oxygen therein are provided. The system has an air reactor adapted to receive air for oxidizing an oxygen carrier, a fuel reactor adapted to receive a fuel and the oxidized oxygen carrier for at least partially oxidizing the fuel by reducing the oxygen carrier to produce a gas. The oxygen carrier has oxide-dispersion-strengthened alloy particles.

Owner:SIEMENS AG

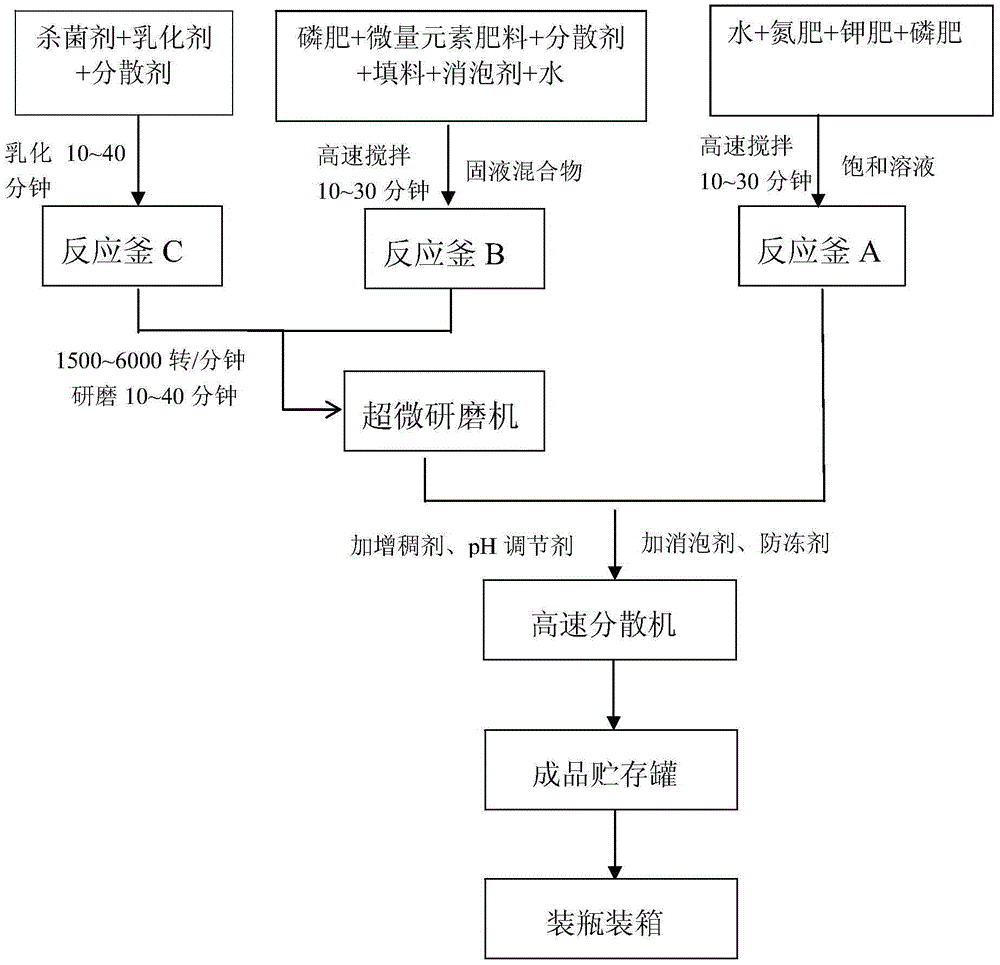

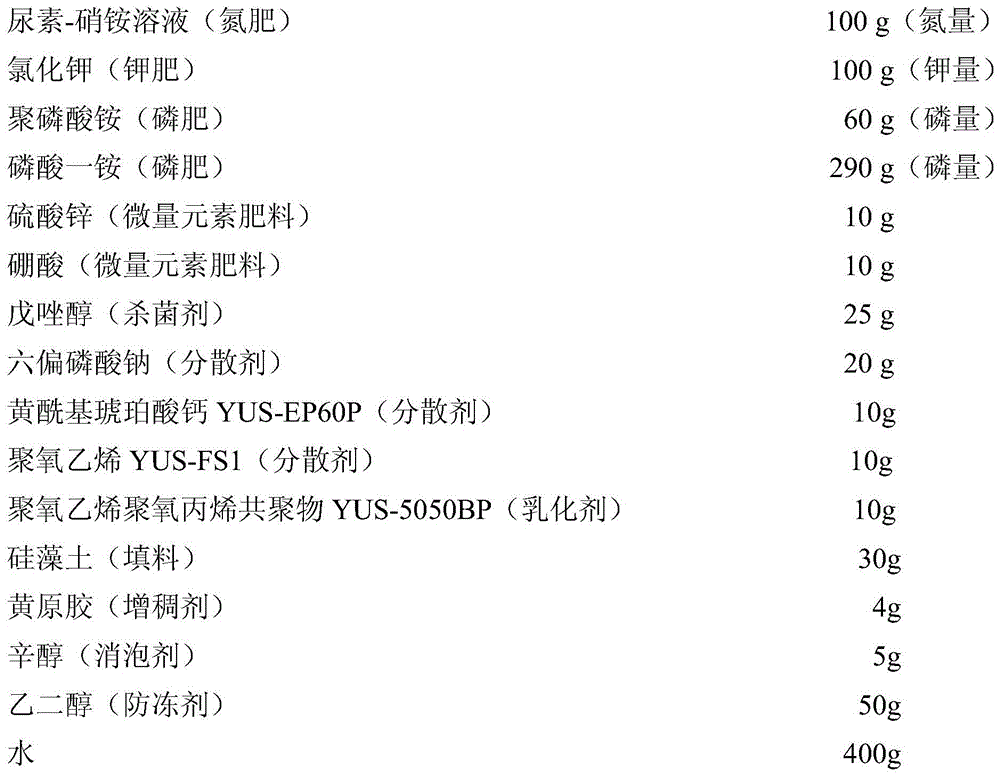

Suspension-type bactericide liquid medicine fertilizer and preparation method thereof

InactiveCN105622272AImprove stabilityImprove uniformitySuperphosphatesAlkali orthophosphate fertiliserTrace elementPotassium

The invention discloses suspension-type bactericide liquid medicine fertilizer and a preparation method thereof. The suspension-type bactericide liquid medicine fertilizer comprises nitrogen fertilizer, phosphorous fertilizer, potassium fertilizer, trace element fertilizer, bactericide, emulsifier, dispersant, filler, defoamer, antifreezing agent, thickener and water and further comprises pH regulator. Medicine and fertilizer are combined in a form of a suspending agent; through joint action of reasonable formulation, proper auxiliary and good processes of an ultramicro grinding machine and a high-speed dispersing machine, stability, uniformity and fluidity of the medicine fertilizer are high, degradation rate is low, and the medicine fertilizer can be maintained being free of layering and precipitating for half a year; the process is simple and reasonable, material grinding size is shortened as much as possible, energy consumption is low, and the medicine fertilizer is suitable for industrialized production.

Owner:CHINA AGRI UNIV

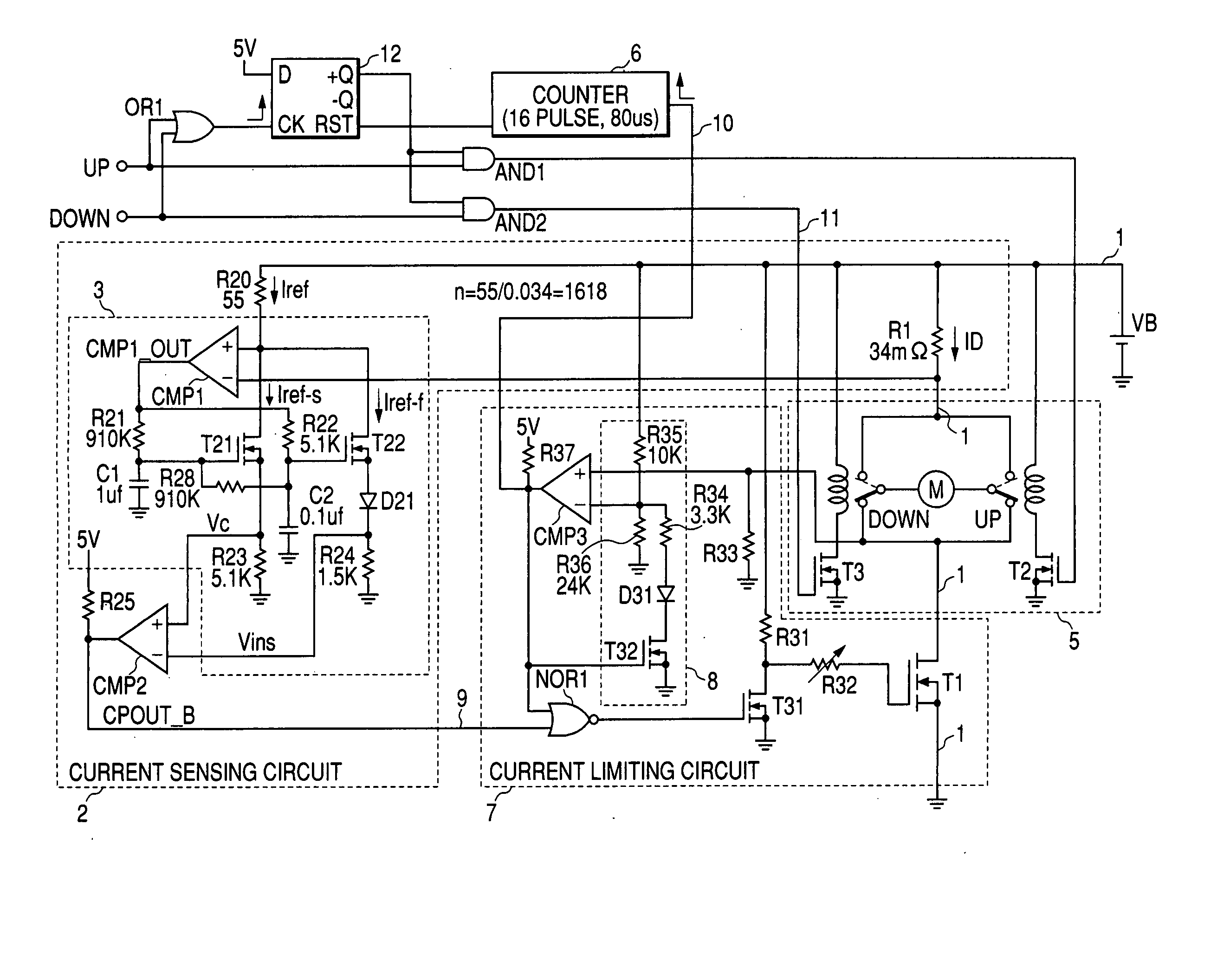

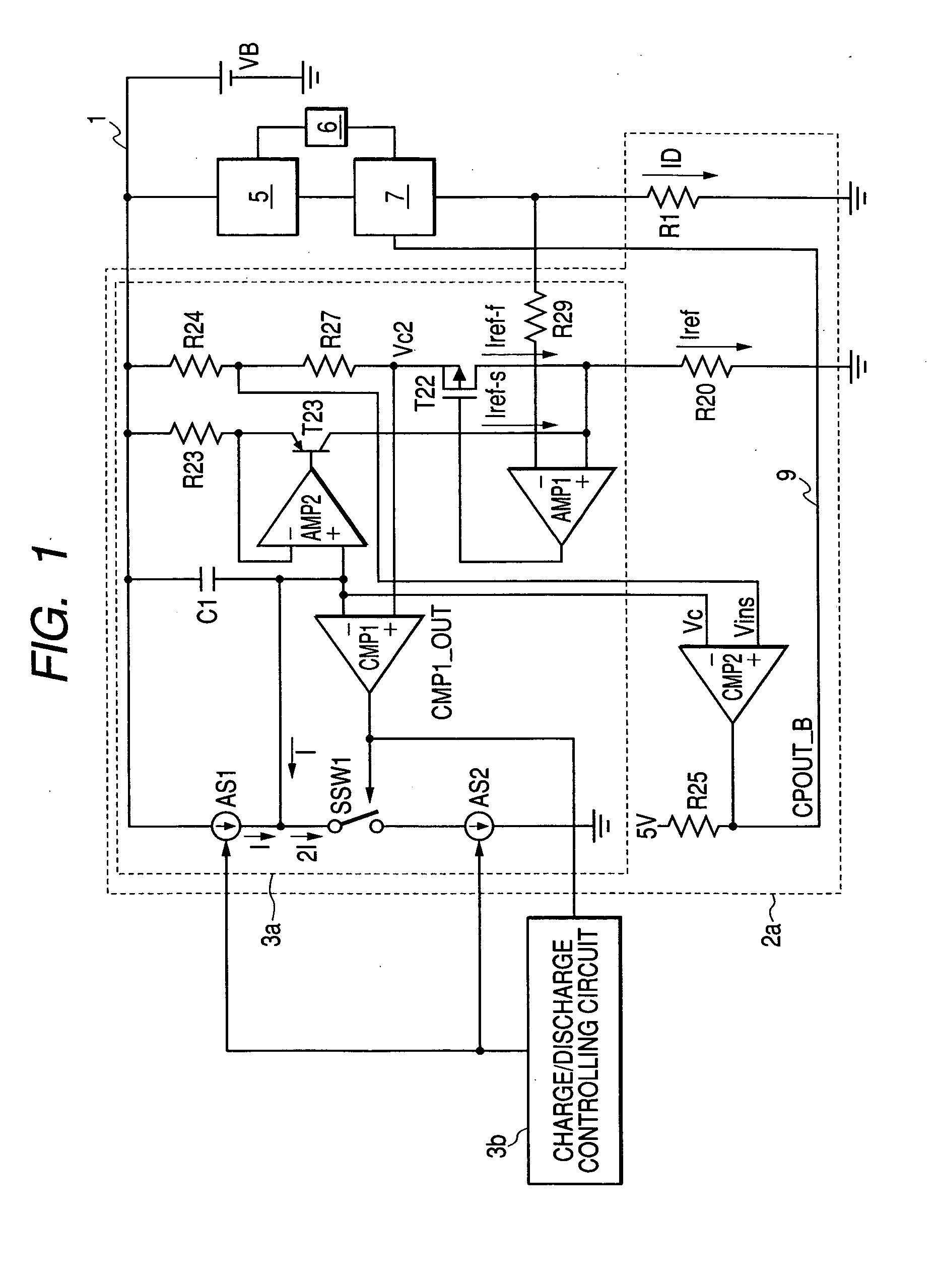

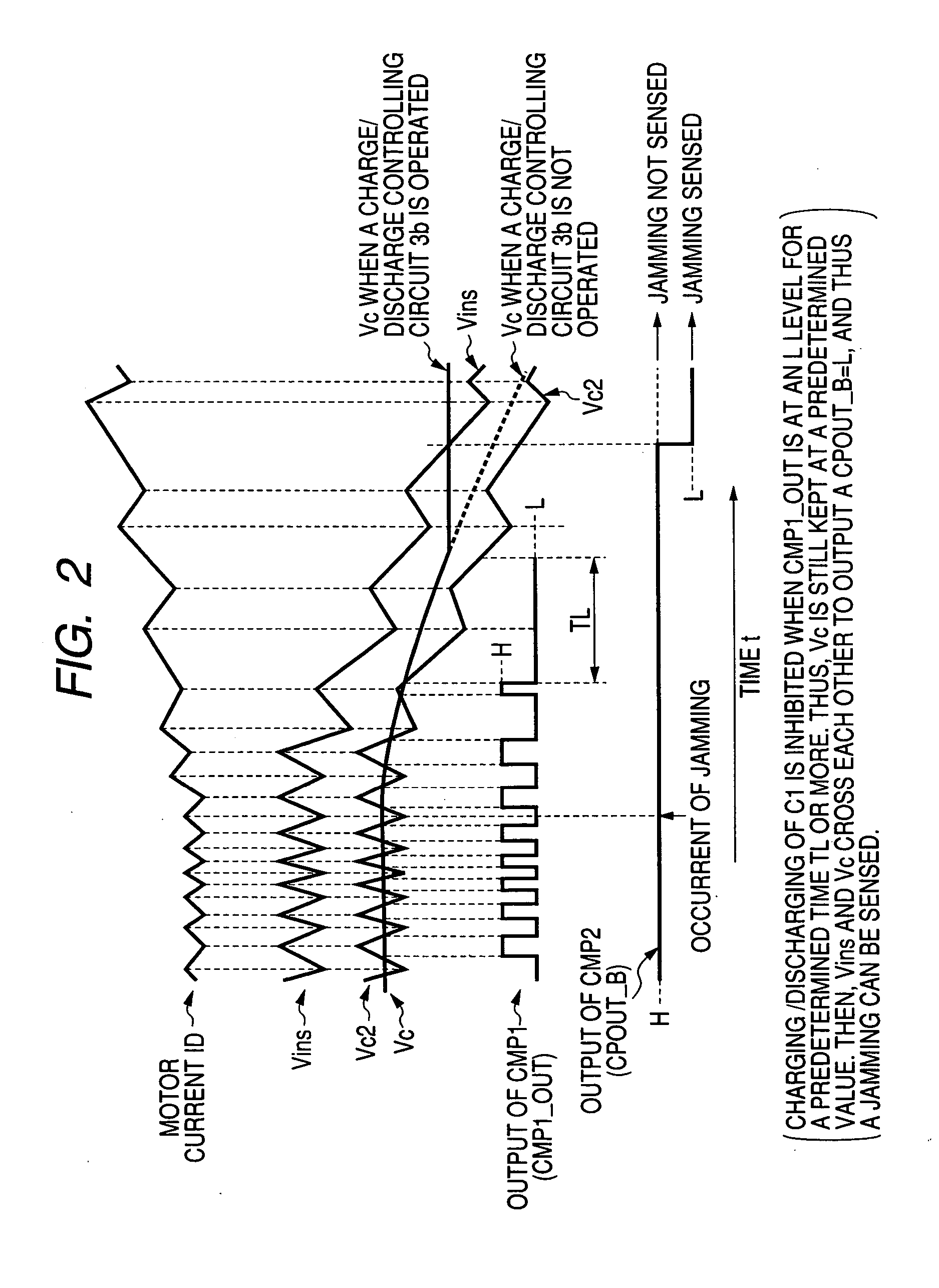

Power-window jamming preventing apparatus

ActiveUS20050067987A1Increase currentIncrease probabilityParameter calibration/settingAsynchronous induction motorsForeign matterCurrent limiting

A power-window jamming preventing apparatus, includes a current sensing circuit, which senses a motor current flowing through a motor for driving a window glass; a current limiting circuit, which increases and decreases the motor current based on a current-limitation control signal outputted from the current sensing circuit when an amount of increase of the motor current exceeds a predetermined vale; a jamming determining circuit, which determines a jamming of a foreign matter in the window glass based on increase of the motor current to reverse a rotation of the motor; and a charge / discharge controlling circuit which monitors a voltage level of a charge / discharge controlling signal, and controls a charging / discharging circuit to keep a third reference voltage constant when the charge / discharge controlling signal having one of voltage levels is continuously outputted for a predetermined time.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com