Preparation method and application of CuS catalyst with three-dimensional framework structure

A three-dimensional framework, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of complex stoichiometric composition of CuS crystals, achieve high practical application and theoretical research value, convenient The effect of cheap operation and raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 0.0803g of copper foam and elemental sulfur powder (molar ratio 1:2) into a 20 mL hydrothermal reactor (polytetrafluoroethylene liner), add 12 mL of ethylenediamine and 4 mL of ethylene glycol as a mixture solvent, at 160 o C for 24 hours, the product was washed with 0.5 mol / L dilute hydrochloric acid for 2 to 5 times, and deionized water for 2 to 5 times, and at 80 o C was dried for 5 hours to obtain CuS catalyst 1 with a three-dimensional skeleton structure.

[0033] in 1 mL H 2 o 2 With the assistance of , take 0.02 g of CuS catalyst to catalyze the degradation of methylene blue aqueous solution, the concentration of methylene blue aqueous solution is 10 mg / L, and the volume is 100 mL. After reacting for 100 minutes, the removal rate of methylene blue was 98.82%.

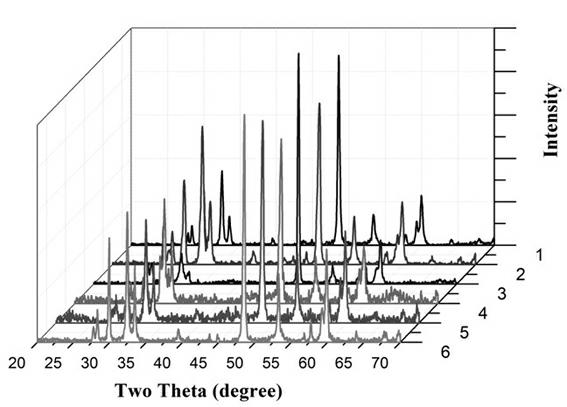

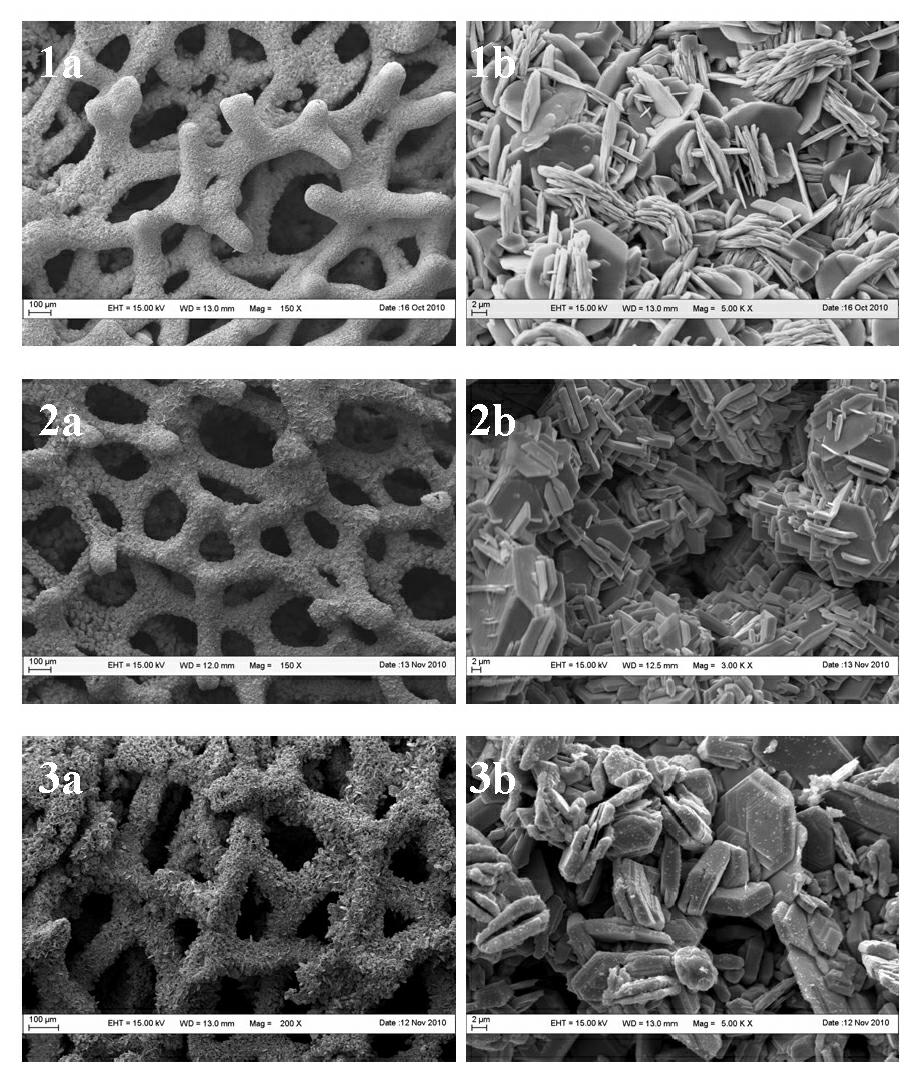

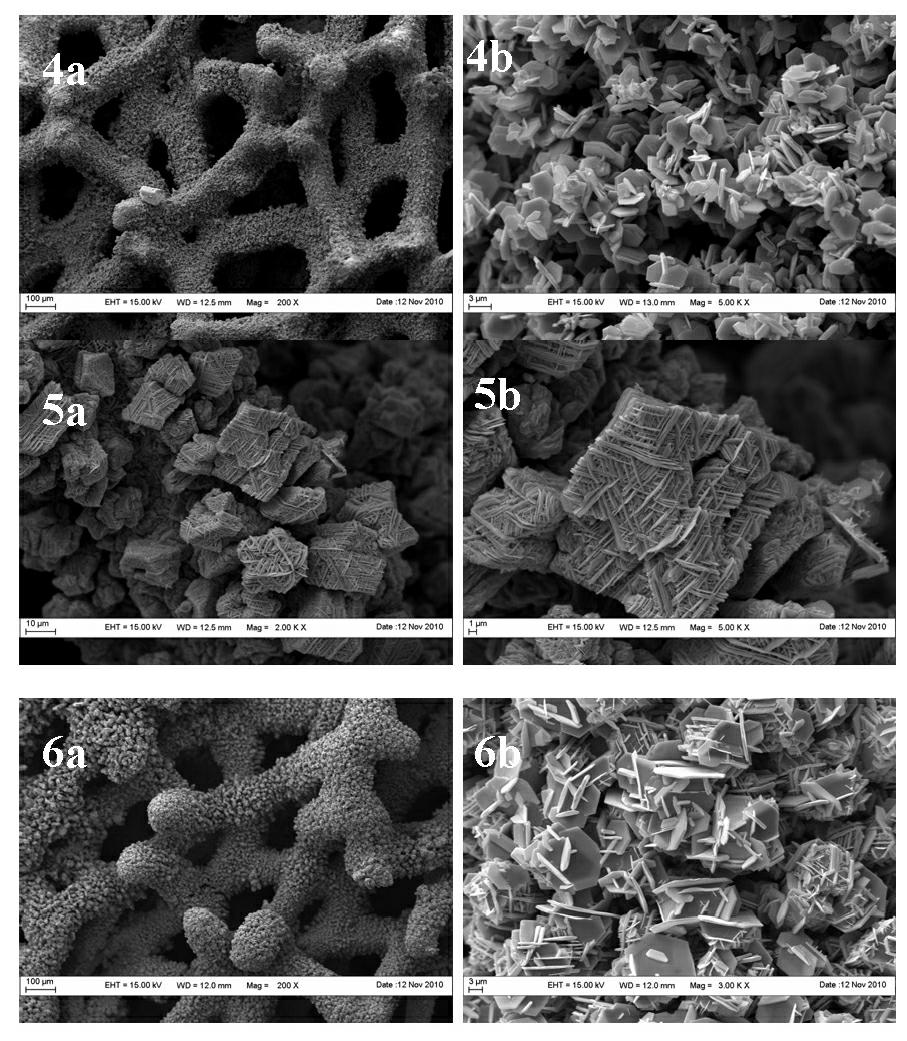

[0034] figure 1 (1) It is the XRD pattern of the prepared micron particles. It can be seen from the figure that the prepared CuS corresponds to the JCPDS card number 6-464; figure 2 (1a, 1b) ar...

Embodiment 2

[0036] Take 0.0835 g copper foam and elemental sulfur powder (molar ratio 1:2) into a 20 mL hydrothermal reaction kettle (polytetrafluoroethylene liner), add 13 mL ethylenediamine and 3 mL ethylene glycol as a mixture solvent, at 120 o C for 36 hours, the product was washed 2 to 5 times with 0.5 mol / L dilute nitric acid, and 2 to 5 times with deionized water, and the product was washed at 50 o C was dried for 36 hours to obtain CuS catalyst 2 with a three-dimensional skeleton structure.

[0037] in 1.5 mL H 2 o 2 With the assistance of , 0.02 g CuS catalyst was used to catalyze the degradation of methylene blue aqueous solution, the concentration of methylene blue aqueous solution was 20 mg / L, and the volume was 100 mL. After 60 minutes of reaction, the removal rate of methylene blue was 97.19%.

[0038] figure 1 (2) It is the XRD pattern of the prepared micron particles. It can be seen from the figure that the prepared CuS corresponds to the JCPDS card number 6-464; fi...

Embodiment 3

[0040] Take 0.0964 g of copper foam and elemental sulfur powder (molar ratio 1:2) into a 20 mL hydrothermal reactor (polytetrafluoroethylene liner), add 9 mL of L ethylenediamine and 3 mL of water as a mixed solvent, at 180 o C for 6 hours, the product was washed 2 to 5 times with 1.5 mol / L dilute sulfuric acid, and 2 to 5 times with deionized water, and the product was washed at 50 o C was dried for 11 hours to obtain CuS catalyst 3 with a three-dimensional skeleton structure.

[0041] in 2 mL H 2 o 2 With the assistance of , take 0.02 g of CuS catalyst to catalyze the degradation of methylene blue aqueous solution, the concentration of methylene blue aqueous solution is 10 mg / L, and the volume is 100 mL. After reacting for 80 minutes, the removal rate of methylene blue was 95.93%.

[0042] figure 1 (3) It is the XRD pattern of the prepared micron particles. It can be seen from the figure that the prepared CuS corresponds to the JCPDS card number 6-464; figure 2 (3a, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com