Preparation method of BiOBr/RGO nanometer composite and application thereof in reaction of degrading rhodamine

A technology of nanocomposite materials and composite materials, which is applied in the field of photocatalysts, can solve the problems of different preparation methods, and achieve the effects of low preparation temperature, good catalytic stability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

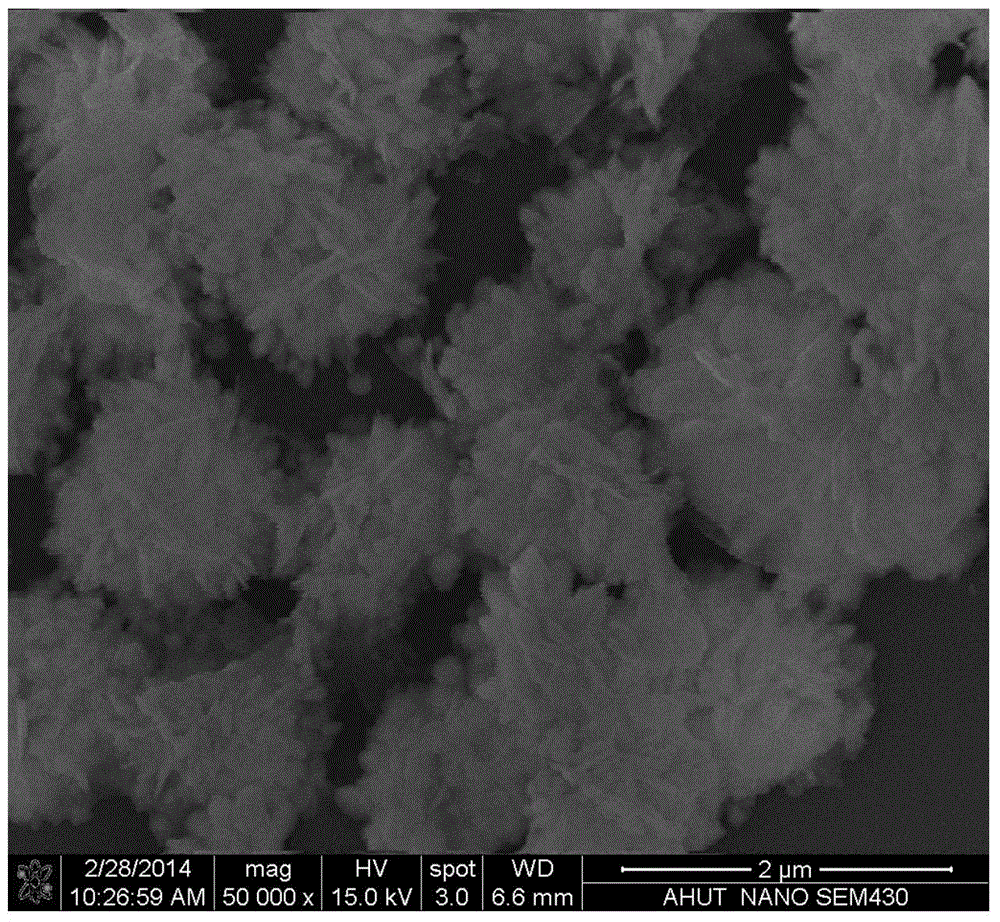

[0034] The specific preparation steps of 1#BiOBr / GO nanocomposite are as follows:

[0035] (1) Preparation of GO

[0036] 0.5g graphite powder and 1.5g KMnO 4 Add it into a round-bottomed flask containing 12 mL of concentrated sulfuric acid, stir magnetically for 4 h under ice-water bath conditions, heat to 35 ° C, stir at constant temperature for 30 min, add 23 mL of distilled water dropwise, raise the temperature to 98 ° C, stir for 15 min, and transfer the mixture to ice In a water bath, add 70 mL of distilled water to dilute, then add 10 mL of 30% hydrogen peroxide, stir for 30 min, the solution turns yellow, centrifuge, wash thoroughly until the pH of the supernatant is 7, and dry the lower precipitate to obtain GO.

[0037] (2) Preparation of BiOBr / GO nanocomposites

[0038] Measure 20 mL of toluene into a round bottom flask, stir at 60 °C for 30 min, add 50 mg of CTAB and 0.4 mL of OA, continue stirring until the two are completely dissolved, then add 3 mg of GO prepa...

Embodiment 2

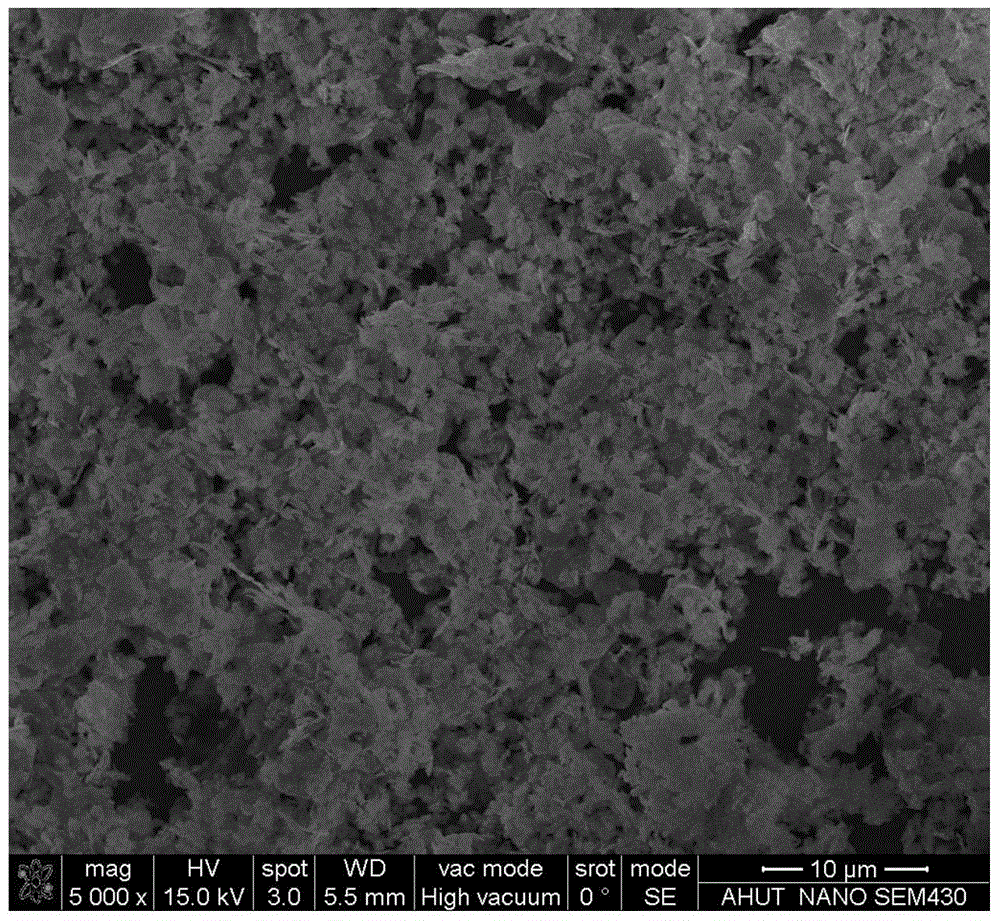

[0040] The specific preparation steps of 2#BiOBr / GO nanocomposite are as follows:

[0041] (1) Preparation of GO

[0042] Same as the preparation method of GO in Example 1.

[0043] (2) Preparation of BiOBr / GO nanocomposites

[0044] Measure 20 mL of toluene into a round bottom flask, stir at 60 °C for 30 min, add 73 mg of CTAB and 0.4 mL of OA, continue stirring until the two are completely dissolved, then add 3 mg of GO prepared above, stir for 2 h to completely disperse, and the suspension The solution is called A. In addition, measure 190mL H at room temperature 2 O, add 10 mL of 65% HNO 3 , weighed 1.96g Bi(NO 3 ) 3 ·5H 2 O, stirred with a glass rod to dissolve completely, called solution B. Measure 1.0 mL of solution B and drop it into the suspension A under stirring, continue to stir for 12 hours, raise the temperature to 85°C for reflux, and keep it at 85°C for 12 hours, and the reaction ends. The reactants were cooled to room temperature, centrifuged, washed,...

Embodiment 3

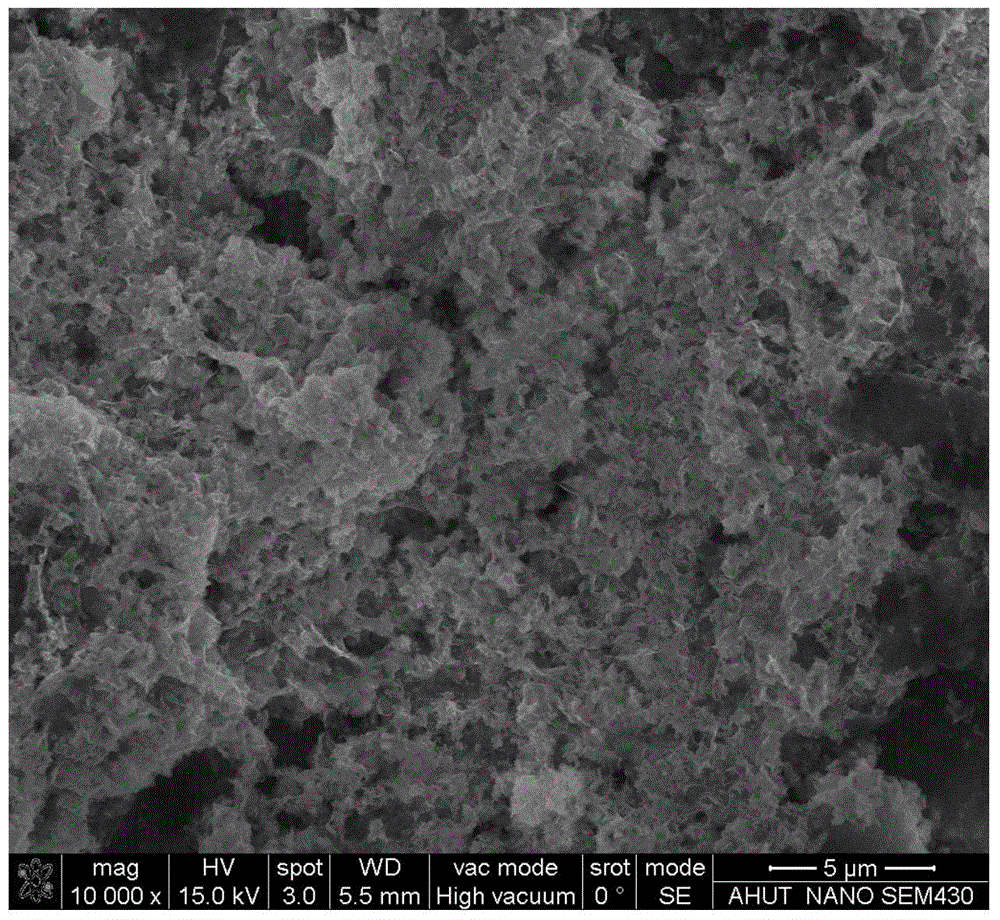

[0046] The specific preparation steps of 3#BiOBr / GO nanocomposite are as follows:

[0047] (1) Preparation of GO

[0048] Same as the preparation method of GO in Example 1.

[0049] (2) Preparation of BiOBr / GO nanocomposites

[0050] Measure 20 mL of toluene into a round-bottomed flask, stir at 60 °C for 30 min, add 90 mg of CTAB and 0.4 mL of OA, continue stirring until the two are completely dissolved, then add 3 mg of GO prepared above, and stir for 2 h to completely disperse it. The suspension is called A. In addition, measure 190mL H at room temperature 2 O, add 10 mL of 65% HNO 3 , weighed 1.96g Bi(NO 3 ) 3 ·5H 2 O, stirred with a glass rod to dissolve completely, called solution B. Measure 1.0 mL of solution B and drop it into the suspension A under stirring, continue to stir for 12 hours, raise the temperature to 85°C for reflux, and keep it at 85°C for 12 hours, and the reaction ends. The reactants were cooled to room temperature, centrifuged, washed, and dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com