Treatment device and treatment method for degrading sulfur hexafluoride based on dielectric barrier discharge

A dielectric barrier discharge, sulfur hexafluoride technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of inability to degrade SF6 gas, no effective recovery of exhaust gas, low degradation rate, etc. The effect of mild discharge environment and efficient decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

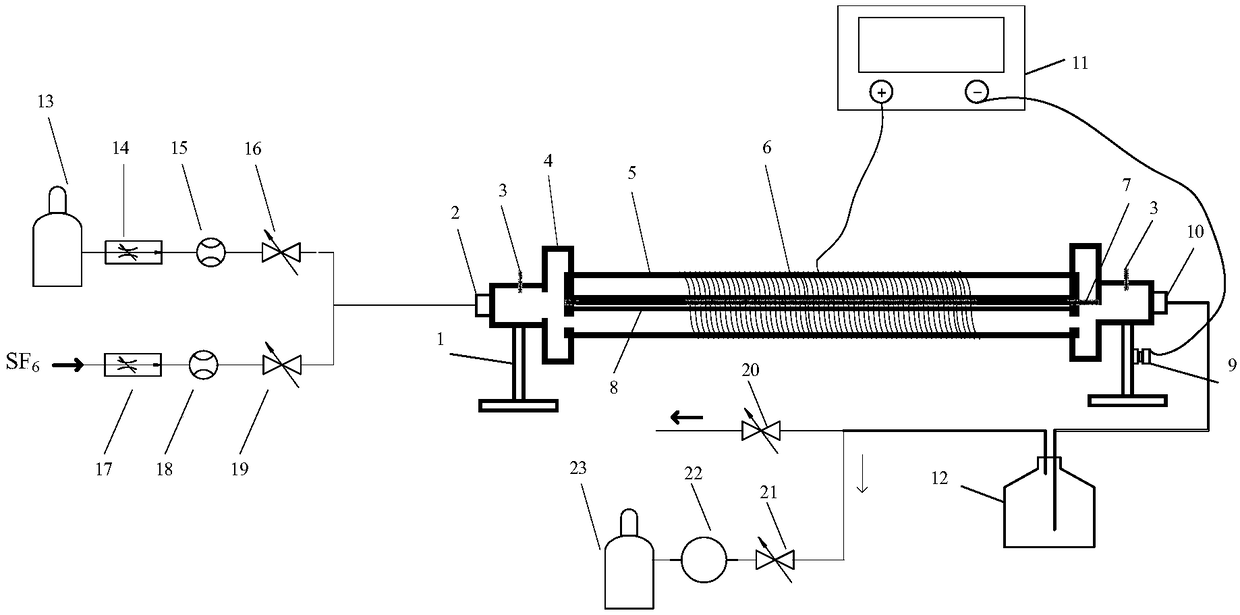

[0026] A device for degrading sulfur hexafluoride based on dielectric barrier discharge, which includes a dielectric barrier discharge reactor, the high voltage electrode terminal of the high voltage voltage source 11 is connected to the external electrode of the dielectric barrier discharge reactor; the ground electrode terminal of the high voltage voltage source It is connected with the ground electrode terminal 9 of the dielectric barrier discharge reactor; one end of the dielectric barrier discharge reactor is provided with an air inlet joint 2; .

[0027] The high-voltage voltage source 11 is an AC voltage source, which provides a high-frequency voltage with a positive and negative amplitude of 13kV and a frequency of 8.7kHz for the dielectric barrier discharge reactor. Connect to the high-voltage electrode and the ground electrode of the dielectric barrier reactor through wires; under this voltage condition, the high-frequency AC voltage source has the highest input powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com