Functional supplementary feed for feednig cow, preparing method and use thereof

A functional, dairy technology, applied in animal feed, animal feed, applications, etc., can solve the balance problem of energy and protein that does not involve added energy and biologically fermented protein, does not involve high nutrient concentration and high rumen rate, single Add and other issues to achieve the effect of easy promotion and industrial production, good palatability, and reduced body condition loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The functional supplementary feed material for feeding dairy cows provided by the present embodiment comprises the following composition:

[0043] Full-fat puffed soybean: 60wt% Coated soybean meal: 20wt%

[0044] Gelatinized starch urea: 20wt% Bio-fermentation protein: 0.6wt%;

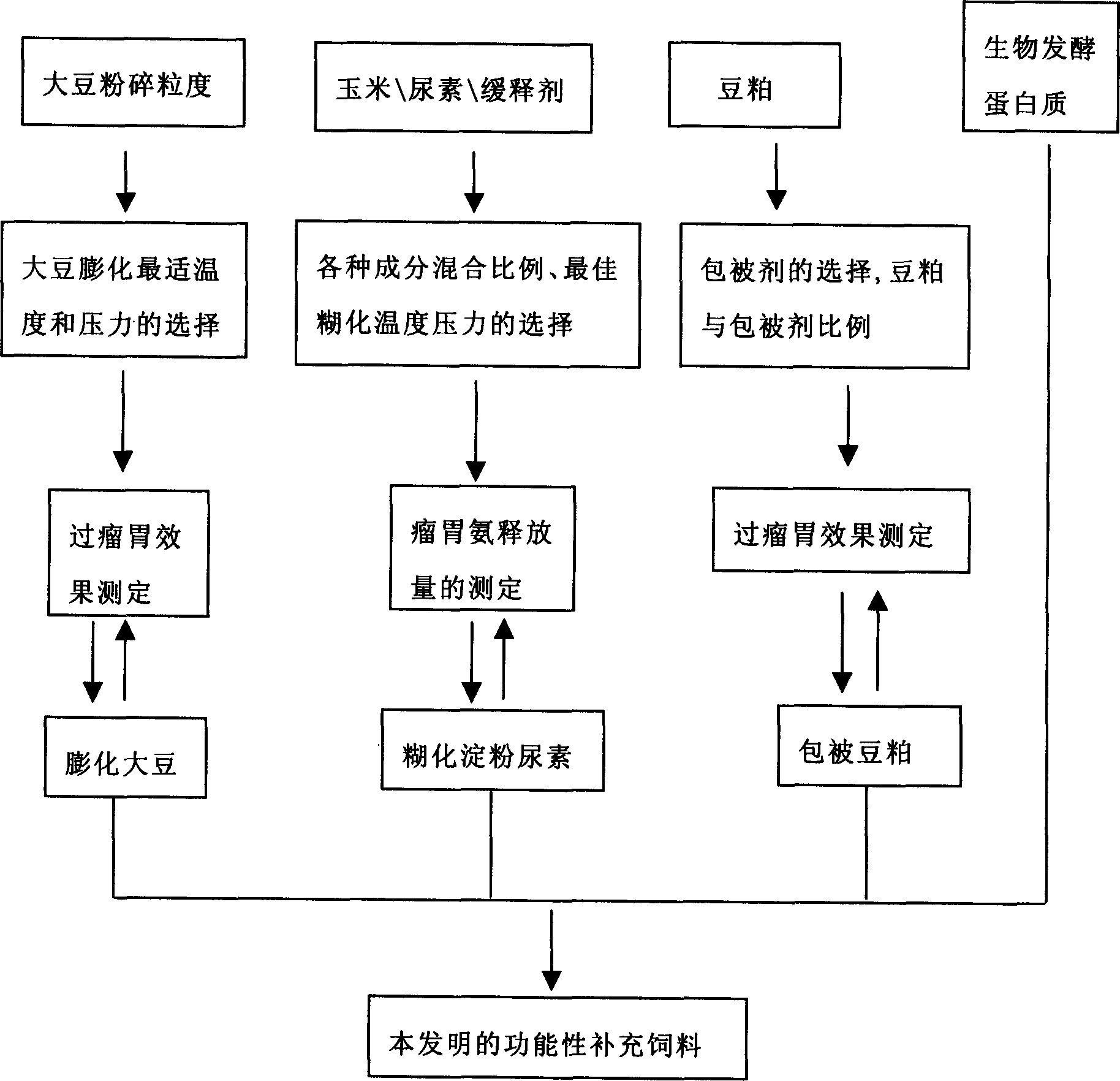

[0045] Attached below figure 1 The supplementary feed material of the present invention and purposes are described in detail with the preparation method of embodiment:

[0046] 1. The processing flow of full-fat puffed soybeans: First, crush the soybeans with a 5mm die-hole sieve → puff the soybeans with a conventional feed extruder unit, wherein the puffing temperature: 130 degrees Celsius; puffing pressure: 4.5 kg → cooling to room temperature → sieving , to achieve the 10mm sieve hole rate of not more than 20%, to realize the control of puffed soybean particle size → using conventional artificial rumen technology to pass the rumen rate to reach more than 65%;

[0047] 2. The processing te...

Embodiment 2

[0055] The preparation method of this embodiment is described in detail below:

[0056] 1. The processing flow of puffed soybeans: first crush soybeans with a 5mm die hole sieve → puff them (using a conventional feed puffing unit), where puffing temperature: 130 degrees Celsius; puffing pressure: 4.5 kg → cooling to room temperature → sieving ( Particle size control is achieved by using a 10mm sieve with a mesh rate of no more than 20%) → using conventional artificial rumen technology to measure the rumen-passing effect; the rumen-passing rate reaches more than 65%;

[0057] 2. Processing technology of gelatinized starch urea: crush corn with 2.5-3mm die hole sieve → add urea and rumen slow-release agent after crushing, rumen slow-release agent uses magnesium oxide; wherein corn: urea: rumen slow-release agent is mixed The ratio is 60:35:1→expand the mixed corn, urea and magnesium oxide with a conventional feed extruder unit, the extruding temperature is 140 degrees Celsius, t...

Embodiment 3

[0064] The feed material that present embodiment provides has the composition of table 3:

[0065] puffed soybeans

gelatinized starch urea

Coated soybean meal

bio-fermented protein

salt

80wt%

10wt%

10wt%

-

0.6wt%

[0066] Below in conjunction with embodiment the preparation method of the present invention is described in detail:

[0067] 1. The processing flow of puffed soybeans: first crush soybeans with a 5mm die-hole sieve → puff them (using a conventional feed puffing unit), where puffing temperature: 130 degrees Celsius; puffing pressure: 4.5 kg → cooling to room temperature → sieving ( Particle size control is achieved by using a 10mm sieve with a mesh rate of no more than 20%) → Use conventional artificial rumen technology to measure the rumen passing effect; the rumen passing rate must reach more than 65%))

[0068] 2. The processing technology of gelatinized starch urea: crushing of corn (crushing with a 2.5-3m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com