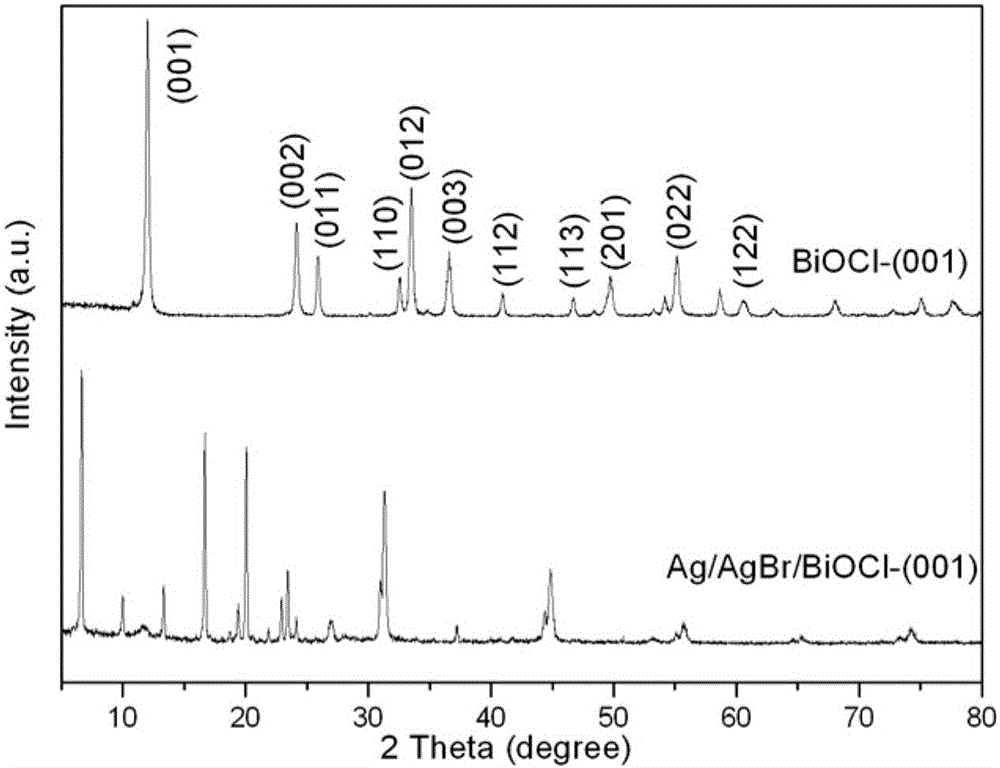

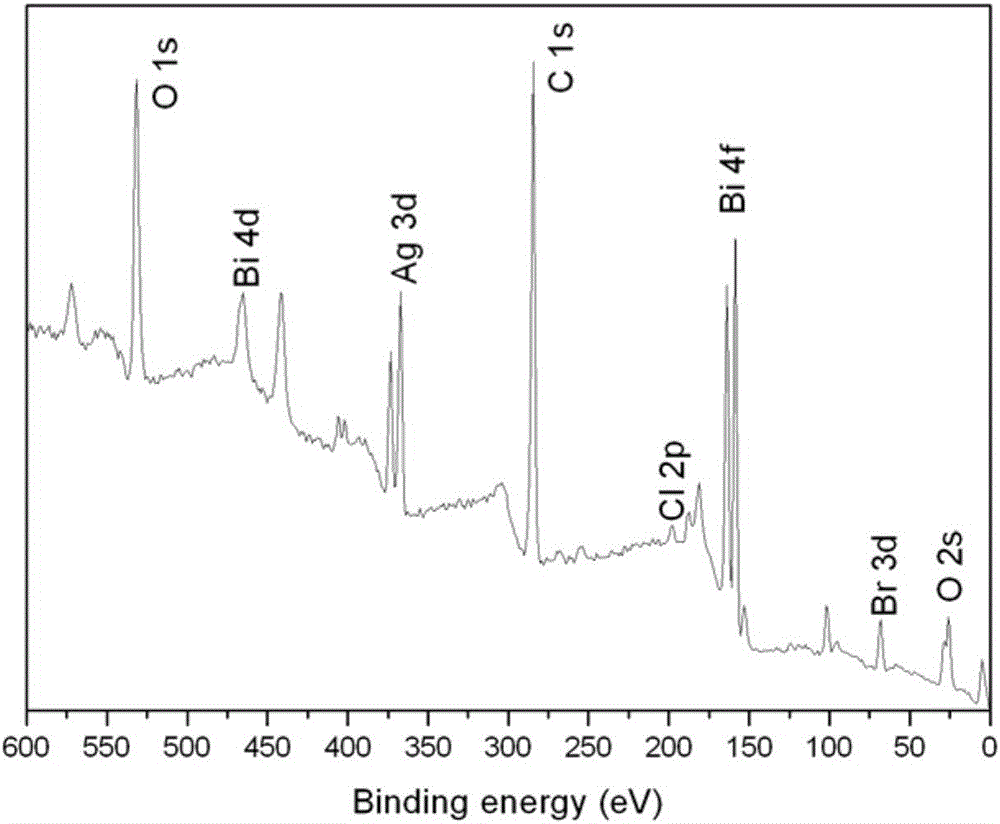

Preparing method and application of Ag/AgBr/BiOCl-(001) nanometer composite material

A nanocomposite material and reaction temperature technology, applied in chemical/physical processes, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of weakening the magnetic field potential difference of nanocrystals, unfavorable electron-hole separation, etc., to achieve The preparation method is simple, the catalytic efficiency is high, and the catalytic stability is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

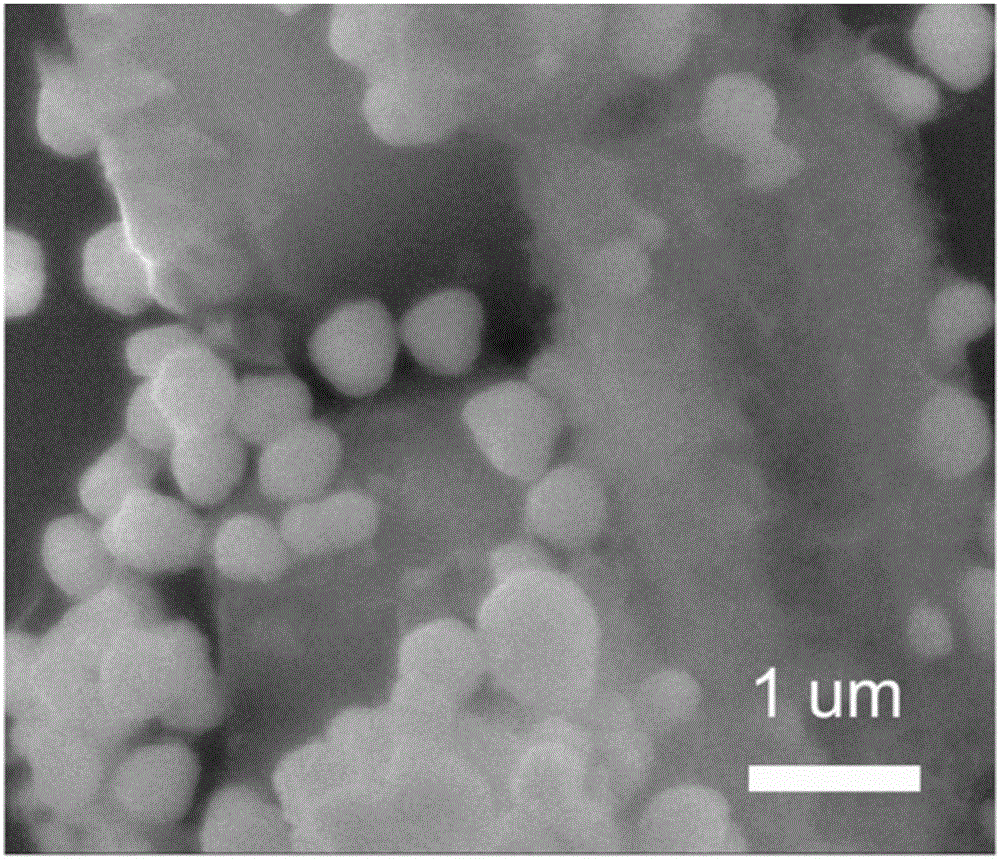

[0038] The specific preparation steps of 1#Ag / AgBr / BiOCl‐(001) nanocomposite are as follows:

[0039] (1) Preparation of BiOCl‐(001)

[0040] Weigh 146mgNaCl, 100mgNaOA, add 30mL deionized water, stir at 75°C for 30min to fully dissolve NaOA and NaCl, slowly add 2mL of 0.5mol / LBi(NO 3 ) 3 , and reacted at 95°C for 3 hours, cooled the reactant to room temperature, centrifuged, washed, and dried to obtain a solid product, which was BiOCl‐(001) single crystal nanosheets.

[0041] (2) Measure 12mL of ethylene glycol into a round bottom flask, stir at 105°C for 30min, add 95mg of PVP and 120mg of CTAB, continue stirring until the two are completely dissolved, then add 30mg of BiOCl-(001) prepared in step (1) , continue to stir for 5h, so that BiOCl‐(001) is evenly distributed in the above solution, and the suspension at this time is called A. In addition, weigh 100mgAgNO at room temperature 3 , which was dissolved in 3.0 mL of ethylene glycol, called solution B. While stirring...

Embodiment 2

[0043] The specific preparation steps of 2#Ag / AgBr / BiOCl‐(001) nanocomposites are as follows:

[0044] (1) Preparation of BiOCl‐(001)

[0045] With the preparation method of BiOCl-(001) among the embodiment 1.

[0046] (2) Preparation of Ag / AgBr / BiOCl‐(001) nanocomposites

[0047] Measure 12mL of ethylene glycol into a round bottom flask, stir at 60°C for 30min, add 95mg of PVP and 120mg of CTAB, continue to stir until the two are completely dissolved, then add 30mg of BiOCl-(001) prepared in step (1), and continue to stir 5h, so that BiOCl‐(001) is evenly distributed in the above solution, and the suspension at this time is called A. In addition, weigh 100mgAgNO at room temperature 3 , which was dissolved in 3.0 mL of ethylene glycol, called solution B. While stirring, drop solution B into suspension A with a plastic dropper, stir for 30 minutes, raise the temperature to 155°C, keep it for 15 minutes, and the reaction ends. The reactant was cooled to room temperature, ce...

Embodiment 3

[0049] The specific preparation steps of 3#Ag / AgBr / BiOCl‐(001) nanocomposite are as follows:

[0050] (1) Preparation of BiOCl‐(001)

[0051] With the preparation method of BiOCl-(001) among the embodiment 1.

[0052](2) Preparation of Ag / AgBr / BiOCl‐(001) nanocomposites

[0053] Measure 12mL of ethylene glycol into a round bottom flask, stir at 120°C for 30min, add 95mg of PVP and 120mg of CTAB, continue to stir until the two are completely dissolved, then add 30mg of BiOCl-(001) prepared in step (1), and continue to stir 5h, so that BiOCl‐(001) is evenly distributed in the above solution, and the suspension at this time is called A. In addition, weigh 100mgAgNO at room temperature 3 , which was dissolved in 3.0 mL of ethylene glycol, called solution B. While stirring, drop solution B into suspension A with a plastic dropper, stir for 30 minutes, raise the temperature to 155°C, keep it for 15 minutes, and the reaction ends. The reactant was cooled to room temperature, cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com