Preparation of silane coupling agent-modified SiO2 loaded rhodium catalyst and selective hydrogenation application of catalyst to butadiene-acrylonitrile rubber

A silane coupling agent, rhodium catalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, sustainable manufacturing/processing, etc. It is easy to adsorb polymer molecules and reduce the efficiency of the catalyst, so as to achieve the effect of improving the catalytic efficiency, simplifying the preparation process and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

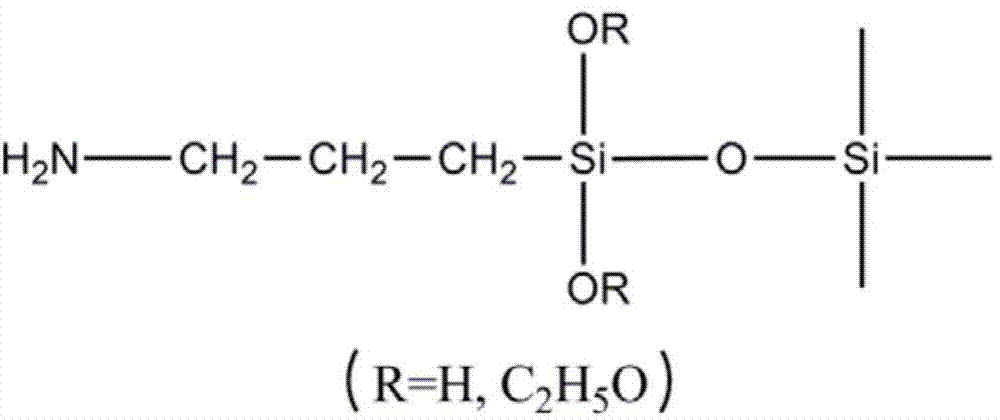

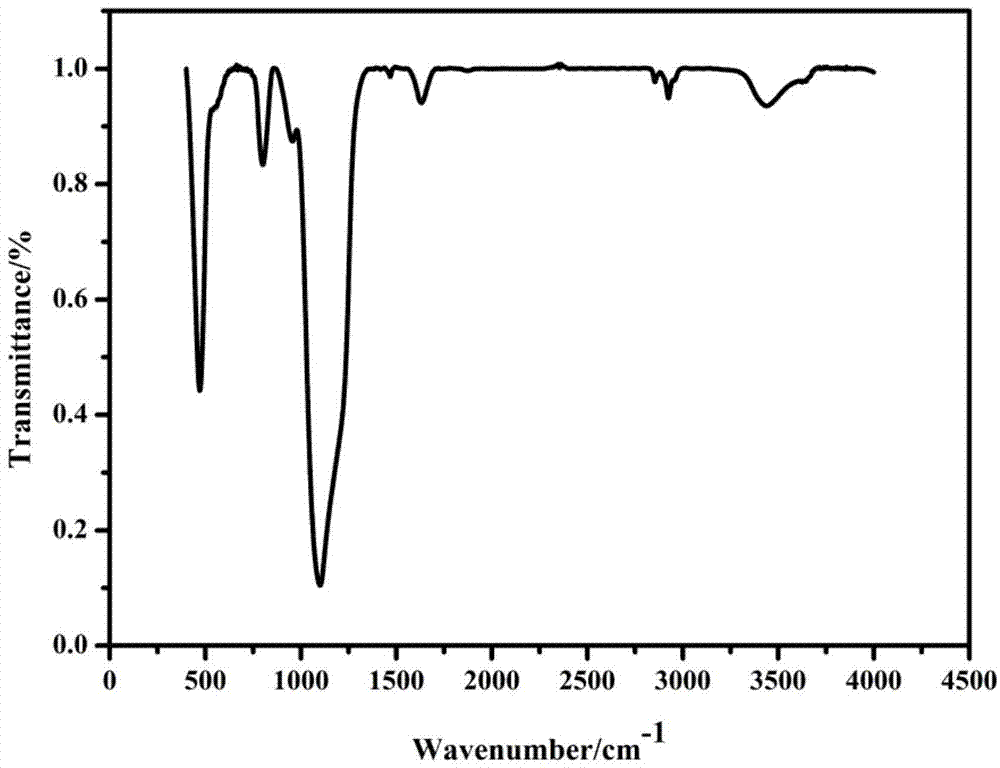

[0024] APTS modified SiO 2 The process of the preparation method is as follows:

[0025] Add 300ml deionized water to a three-neck flask, weigh 5g of SiO 2 Import into the bottle, add 4ml of APTS, stir and react for 2 hours at 40°C, add dropwise 8ml of ammonia water (w25%), react for 4 hours, filter and dry to obtain APTS modified SiO 2 .

[0026] Supported Catalyst APTS-SiO 2 -RhCl 3 The preparation method steps are as follows:

[0027]Immersion method, take by weighing 1.0g rhodium chloride, be mixed with the rhodium chloride solution that concentration is 1g / L, drop 20ml rhodium chloride solution in 2.0g APTS modified SiO 2 Add it dropwise evenly, let it stand for 10h, wash it, and dry it in an oven to get APTS-SiO 2 -RhCl 3 catalyst.

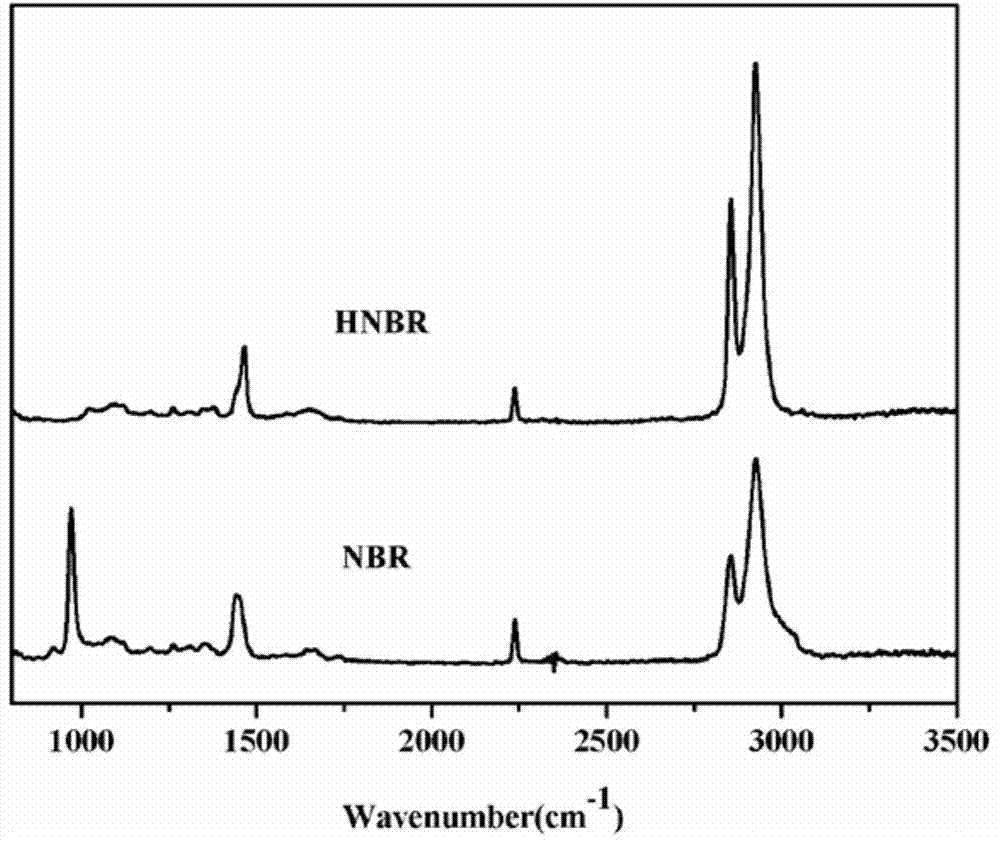

[0028] APTS-SiO 2 -RhCl 3 The general steps of carrying out solution method catalytic hydrogenation to nitrile rubber with supported catalyst are as follows:

[0029] Prepare nitrile rubber into a solution with a certain concentra...

example 1

[0031] According to the above-mentioned general steps of hydrogenation, measure 120ml of the prepared nitrile rubber chlorobenzene glue with a graduated cylinder, the concentration of the glue is 3%, and add it to a 0.5L high-pressure reactor, APTS modified SiO 2 Post-prepared supported catalyst APTS-SiO 2 -RhCl 3 The mass is 0.6g, triphenylphosphine (PPh 3 ) dosage is 0.6g. Under the conditions of reaction temperature of 120°C and hydrogen pressure of 3.0 MPa, react for 8 hours, cool to obtain the product, condense with ethanol, dry in a vacuum oven, and measure the degree of hydrogenation. The experimental results are shown in Table 1

example 2

[0037] Modified SiO by APTS above 2 In the modification process, the deionized water is replaced with ethanol, water-ethanol (volume ratio is 1:1) mixed solution. Preparation of Supported Catalyst APTS-SiO 2 -RhCl 3 The process of hydrogenation is the same, and the hydrogenation step is also the same. To study the influence of different modified solvents on the degree of hydrogenation of NBR. The experimental results are shown in Table 2

[0038] Table 2 The influence of different modified solvents on the degree of hydrogenation of NBR

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com