Preparation method and application of nano material monolithic column immobilized enzyme biological micro-reactor

A technology of nanomaterials and microreactors, applied in enzyme production/bioreactors, methods of supporting/immobilizing microorganisms, biochemical equipment and methods, etc., can solve slow mass transfer rate, low catalytic efficiency, poor service life, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the synthesis of nano gold

[0027] (1) Synthesis of gold nanoparticles with different particle sizes

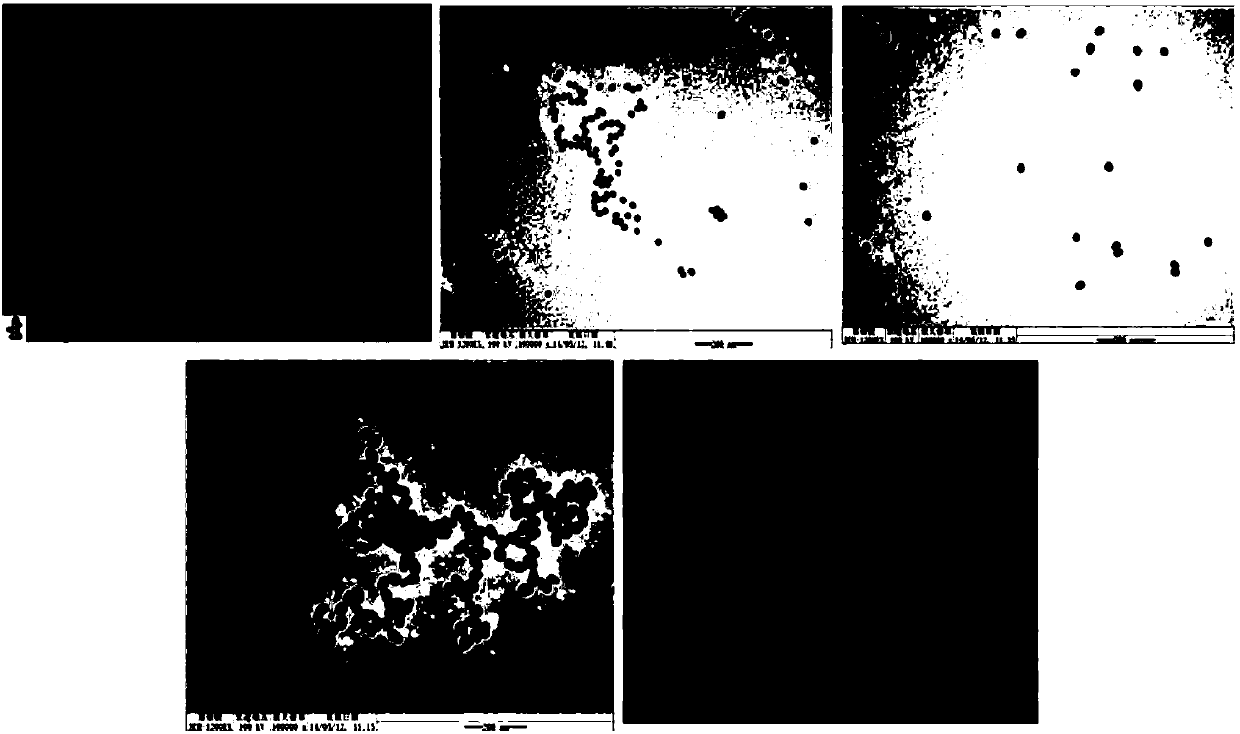

[0028] Add 50mg of chloroauric acid and 500mL of ultrapure water into a 2000mL Erlenmeyer flask, heat to 98°C under magnetic stirring, then add a certain amount of sodium citrate, keep the temperature at 98°C for reaction, and the color of the reaction solution will last for a few seconds Turn blue, then black, then red, continue heating for 10 min, stop heating, continue stirring for 0.5 h, prepare nano-gold colloid solution, cool at room temperature, high-speed centrifugal purification, save for later use. The particle size of the synthesized gold nanoparticles was changed by changing the amount of sodium citrate, as shown in Table 1. The particle size and morphology of the synthesized gold nanocolloids were studied by transmission electron microscopy (TEM) ( figure 1 ).

Embodiment 2

[0029] Example 2: Fe 3 o 4 SiO 2 -NH 2 Synthesis of Magnetic Nanoparticles

[0030] (1) Solvothermal Synthesis of Magnetic Fe 3 o 4 nanoparticles

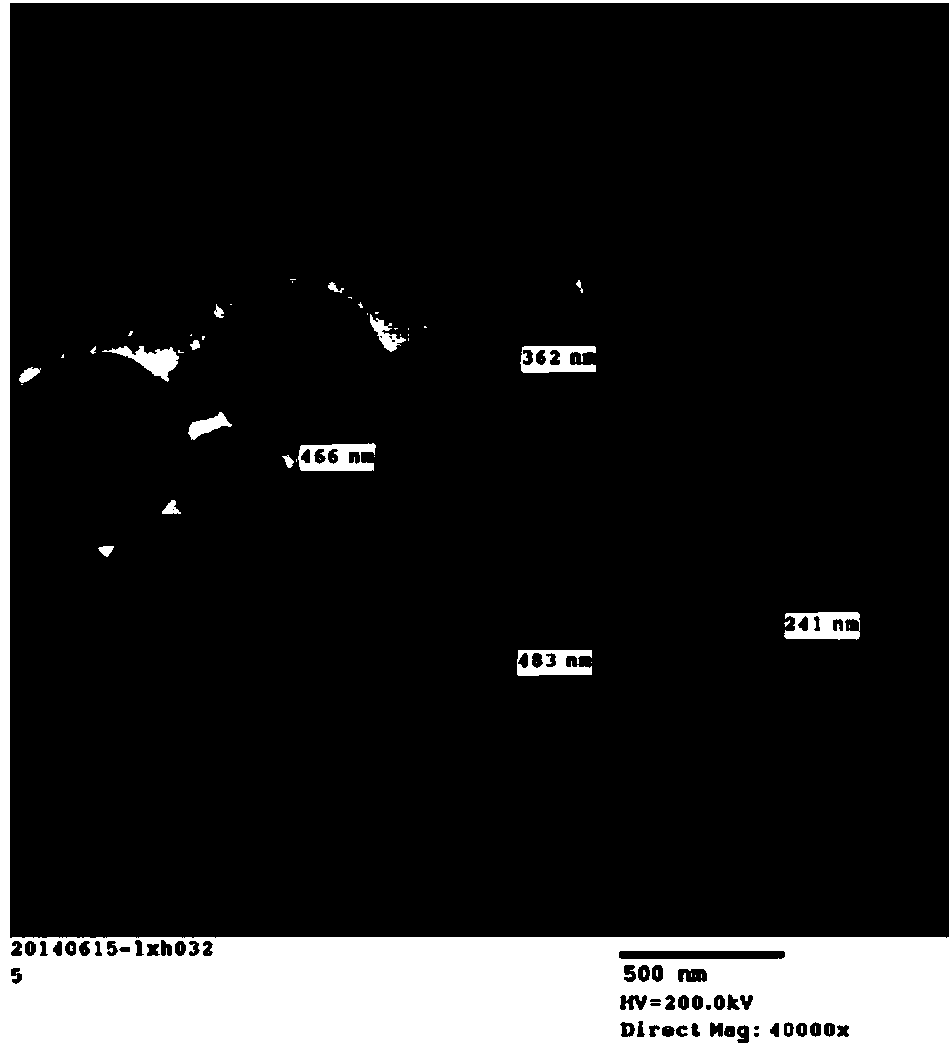

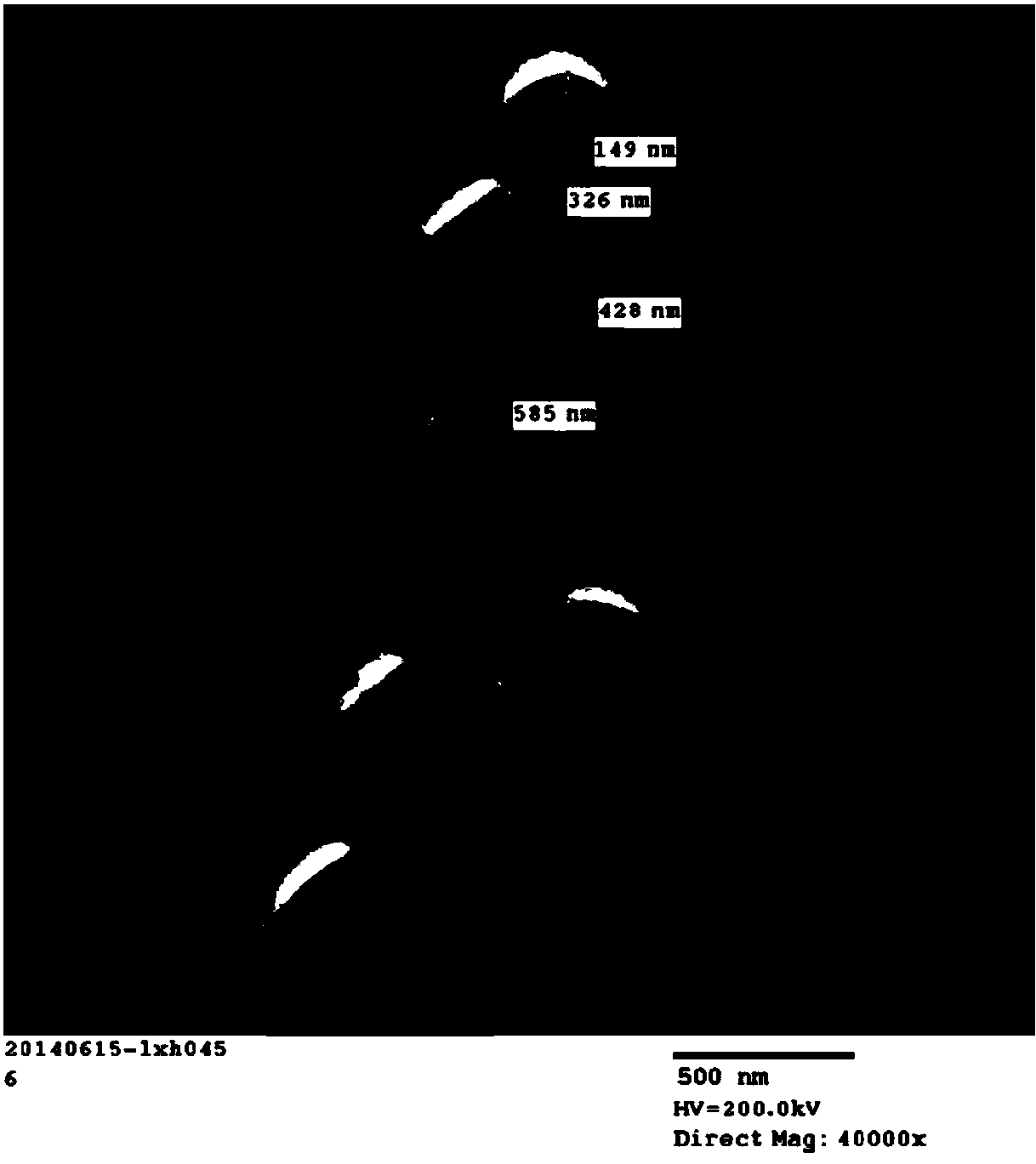

[0031] FeCl 3 .6H 2 O (1.35g, 5mmol) and NaAc (3.6g) were dissolved in ethylene glycol (50mL), sonicated for 30min to fully dissolve and disperse the solid, and the dispersion was transferred to a stainless steel autoclave lined with polytetrafluoroethylene and sealed. React at 200°C for 8 hours, cool naturally after the reaction, wash 4 times alternately with absolute ethanol and water with the help of a magnet, and dry in vacuum at 60°C for 6 hours to obtain magnetic Fe 3 o 4 Nanoparticles, whose transmission electron micrographs are shown in figure 2 shown.

[0032] (2) Fe 3 o 4 SiO 2 Synthesis of Core-Shell Structured Nanoparticles

[0033] The magnetic Fe prepared in (1) 3 o 4 350 mg of nanoparticles were dispersed in 160 mL of ethanol, and ultrasonically treated for 0.5 h. Add 1mL ammonia water (25wt%), 40m...

Embodiment 3

[0036] Example 3: Synthesis of metal organic framework material MIL-101

[0037] Utilize the hydrothermal method to synthesize MIL-101, the specific steps are as follows: Weigh 2.0g of Cr(NO 3 ) 3 .6H 2 O was dissolved in 25 mL of deionized water, and after fully dissolved, 0.83 g of terephthalic acid was added, followed by 410 μL of hydrofluoric acid. Then the mixed solution was transferred into a 100 mL stainless steel autoclave lined with polytetrafluoroethylene, and placed in an oven at 220° C. for 8 h. After cooling, the product was filtered, washed, and vacuum-dried at 60°C to obtain a mixture of green powder and white needle-like crystals. The product uses N,N'-dimethylformamide, chloroform and absolute ethanol in sequence to remove white needle-like crystals and unreacted inorganic and organic impurities blocked in the pores to obtain MIL with a particle size of about 500nm -101. Using the BET method to measure the specific surface area of MIL-101, it is 3000m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com