Patents

Literature

74 results about "Catalytic rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic rate constant (kcat) The first-order rate constant that describes the rate-limiting step in enzyme catalysis, usually the conversion of the enzyme-substrate complex into the enzyme-product complex; the maximal velocity divided by the enzyme concentration.

Hydrogen storage material hydrolysis and hydrogen releasing system taking monodispersed or supported phosphorus-containing metal compound as catalyst

ActiveCN108525685ASave raw materialsHigh catalytic efficiencyPhysical/chemical process catalystsHydrogen productionHydrolysisAqueous solution

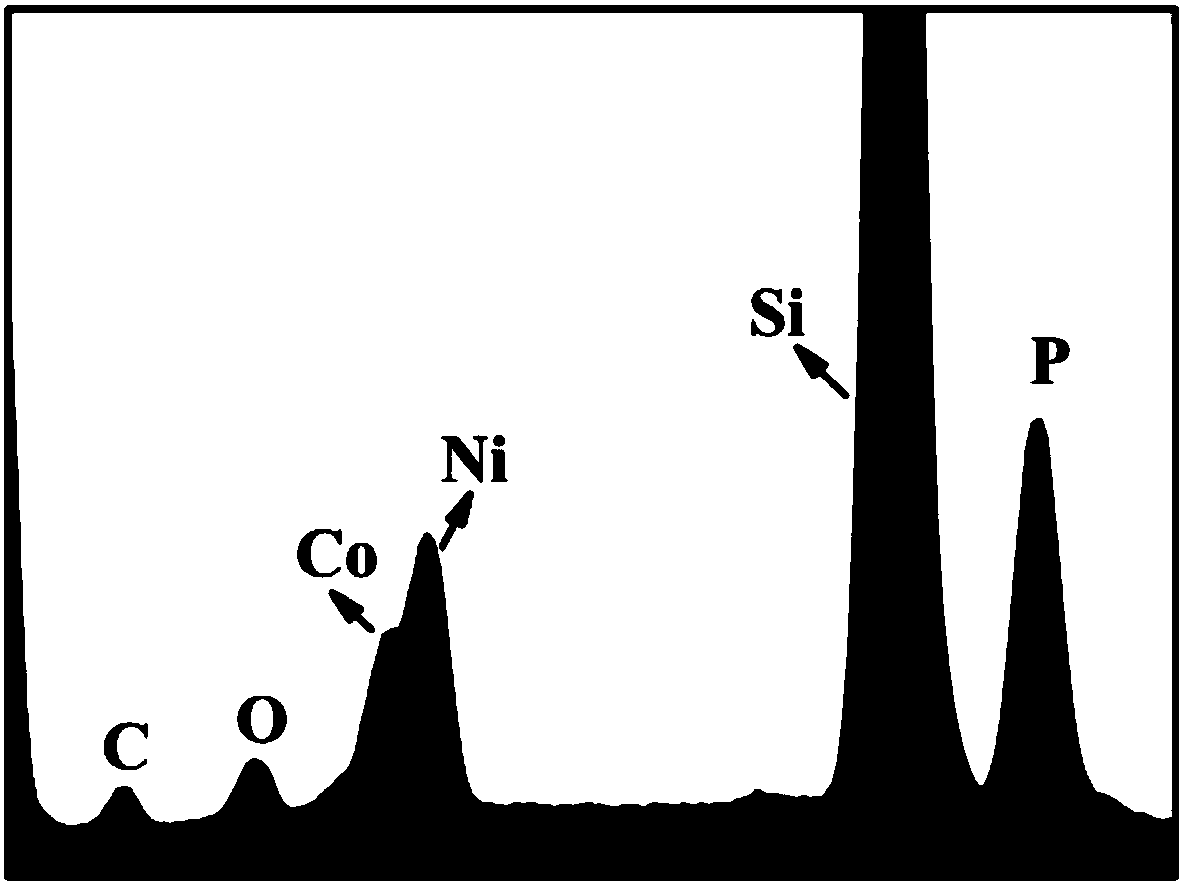

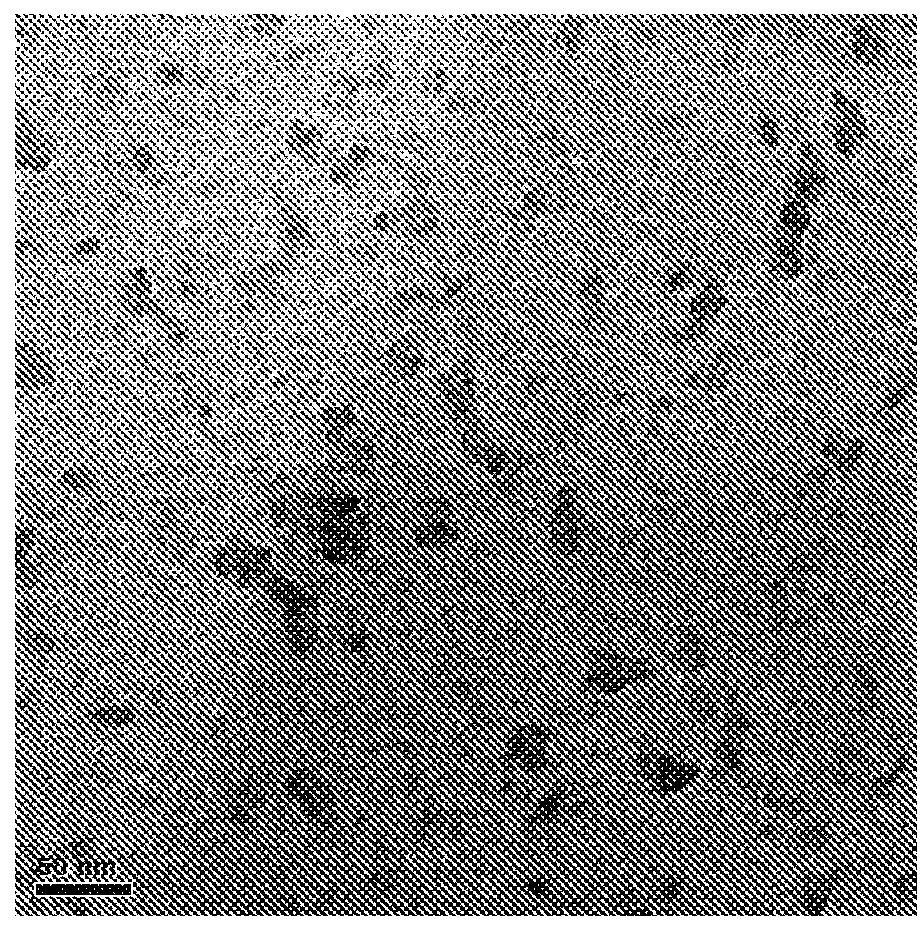

The invention discloses a hydrogen storage material hydrolysis and hydrogen releasing system taking a monodispersed or supported phosphorus-containing metal compound as a catalyst. The system comprises a hydrogen storage material and water, and further comprises a catalyst, wherein the catalyst is one or multiple of a monodispersed multi-metal phosphide, a supported multi-metal phosphide, a monodispersed single-metal and multi-non-metal phosphorus-containing compound, a supported single-metal and multi-non-metal phosphorus-containing compound, a monodispersed multi-metal multi-non-metal phosphorus-containing compound and a supported multi-metal multi-non-metal phosphorus-containing compound. Alkali is added into an aqueous solution of the monodispersed or supported phosphorus-containing metal to improve the catalytic rate of the catalyst and shorten the induction period. The catalysis efficiency of the supported catalyst is higher than that of the monodispersed catalyst. The system provides a batch of efficient novel catalysts for hydrolysis and hydrogen releasing of the hydrogen storage material, and provides a method for increasing the hydrolysis rate of the hydrogen storage material under the catalysis of the phosphorus-containing metal compound.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A composite photocatalyst, preparation method hereof and use thereof

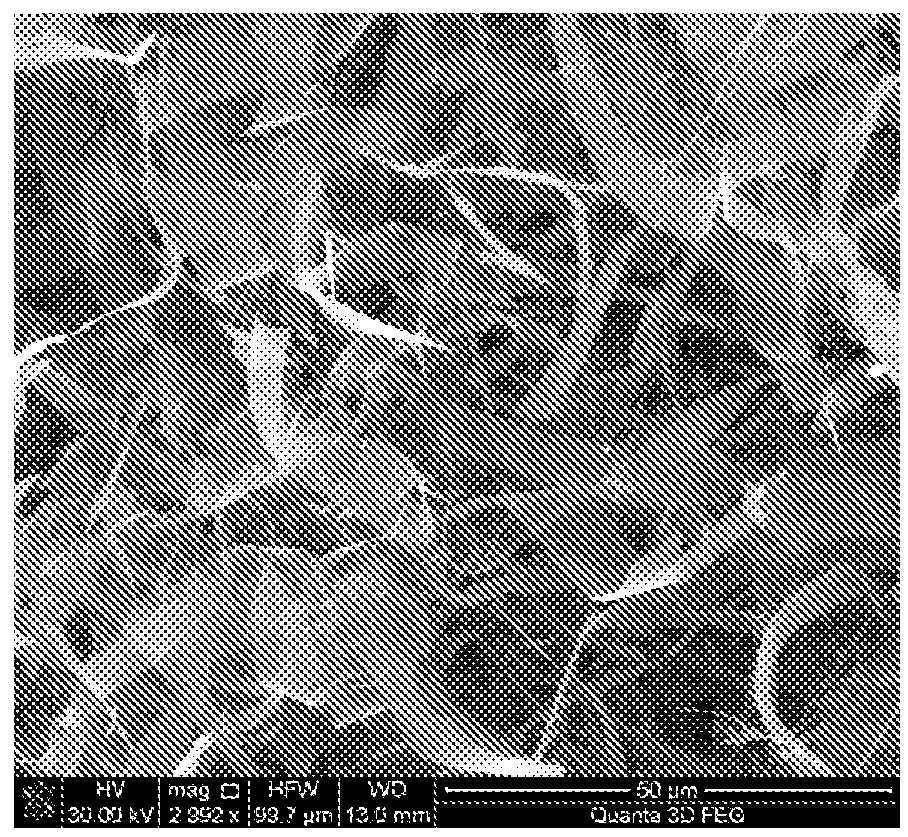

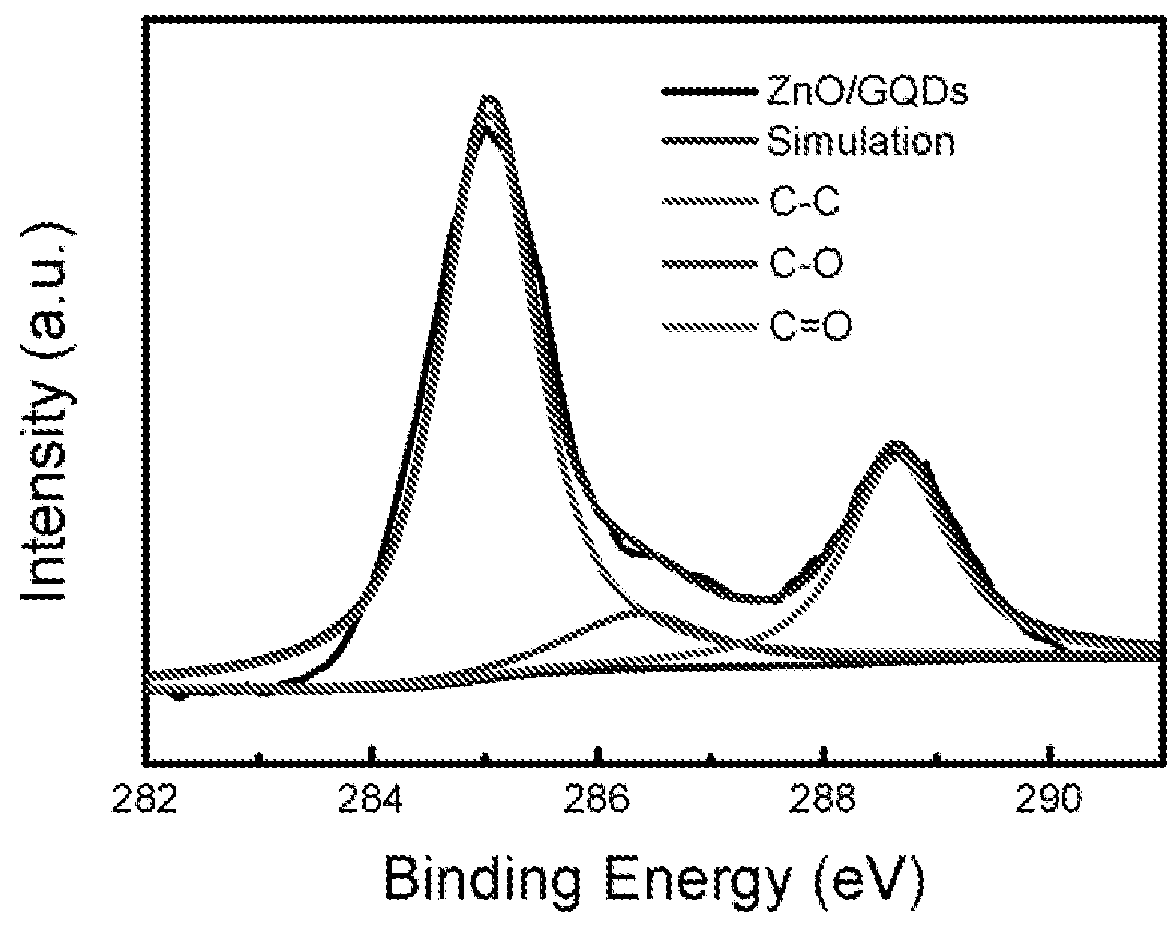

InactiveUS20180264440A1Improve photoelectric conversion efficiencyEasy to getWater/sewage treatment by irradiationWater treatment compoundsZincCvd graphene

A composite photocatalyst, preparation and use thereof are disclosed. The composite photocatalyst is composed of metal oxide and quantum dot material. Based on the photocatalyst, the percentage content of the metal oxide is from 80 to 99.99% by mass, and the percentage content of the quantum dot material is form 0.01 to 20% by mass. The metal oxide is zinc oxide or titanium oxide. The quantum dot material is graphene quantum dot or carbon quantum dot. The preparation is that the metal oxide and quantum dot material are stirred, mixed, ultrasonicated and dried in sequence, and the photocatalyst is obtained. Compared with other photocatalysts, the catalyst has higher catalytic efficiency and faster catalytic rate for Rhodamine B and provides more sufficient and more comprehensive utilization of sunlight.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

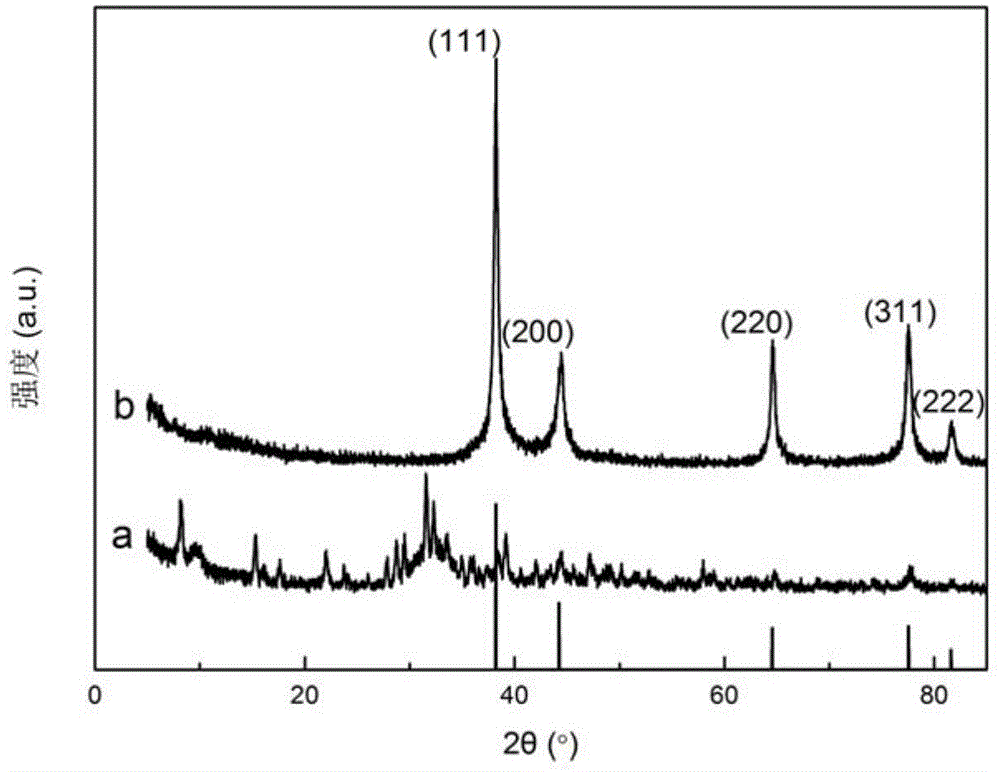

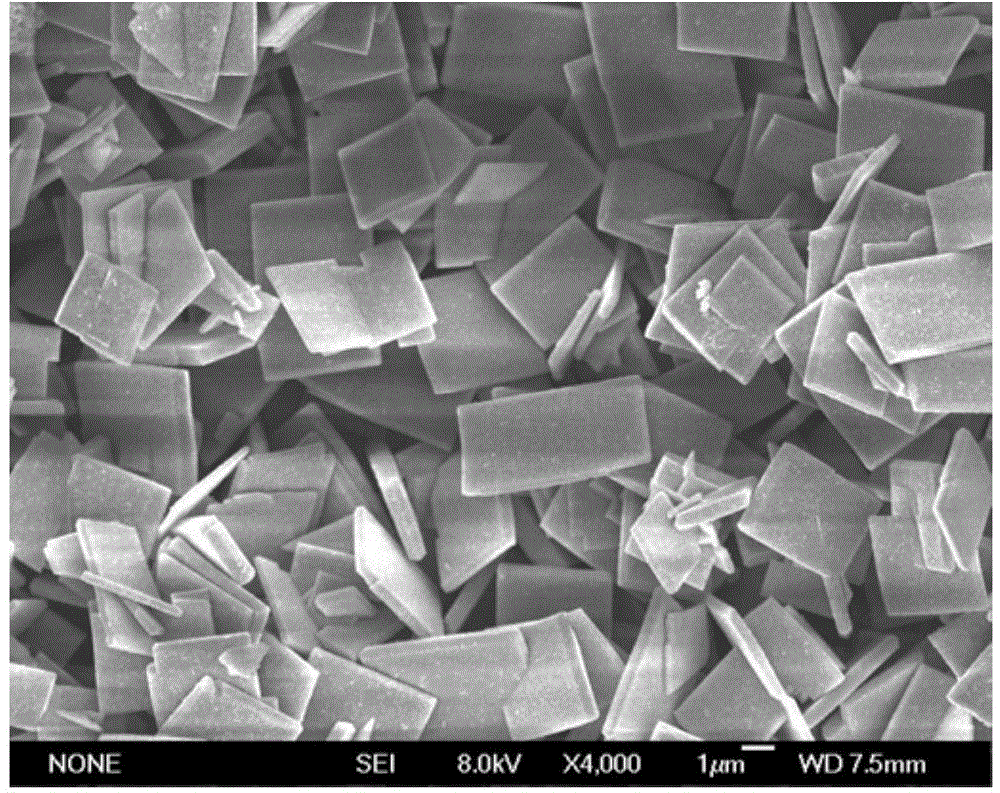

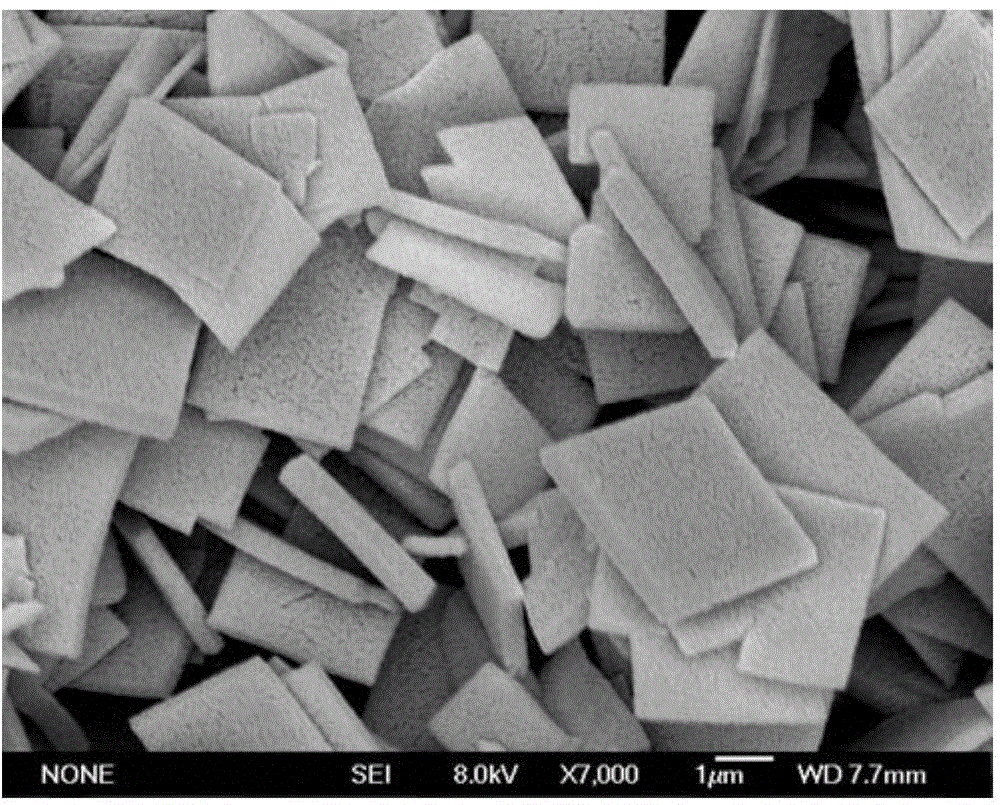

Porous silver micro-nano structure and shape and size controllable preparation method thereof

InactiveCN104525937ABreakthrough hazardReduce post processingMaterial nanotechnologyMicro nanoMaterials science

The invention provides a porous silver micro-nano structure and a shape and size controllable preparation method of the porous silver micro-nano structure, and belongs to the technical field of precious metal porous nano-crystalline structures. The overall appearance shape of the porous silver micro-nano structure is a hexagonal sandwich shape or a quadrilateral shape or a strip shape and is formed by stacking 30-50-nanometer silver basic composition units, and multiple pores are formed by stacking silver basic composition units. The preparation method includes the steps that sodium citrate, sodium carbonate and citric acid are dissolved in deionized water, a silver nitrate solution and a D-glucose solution are added in sequence, the mixture is stirred and sinks, and a precursor is obtained after centrifugal drying; the porous silver micro-nano structure is obtained after heat treatment is conducted on the precursor. The method is simple, environmentally friendly and controllable in shape and size; the prepared porous silver micro-nano structure is uniform in size distribution, large in specific surface area, good in permeability and higher in catalytic rate for p-nitrophenol, and has potential application in the precious metal catalytic aspect.

Owner:JILIN UNIV

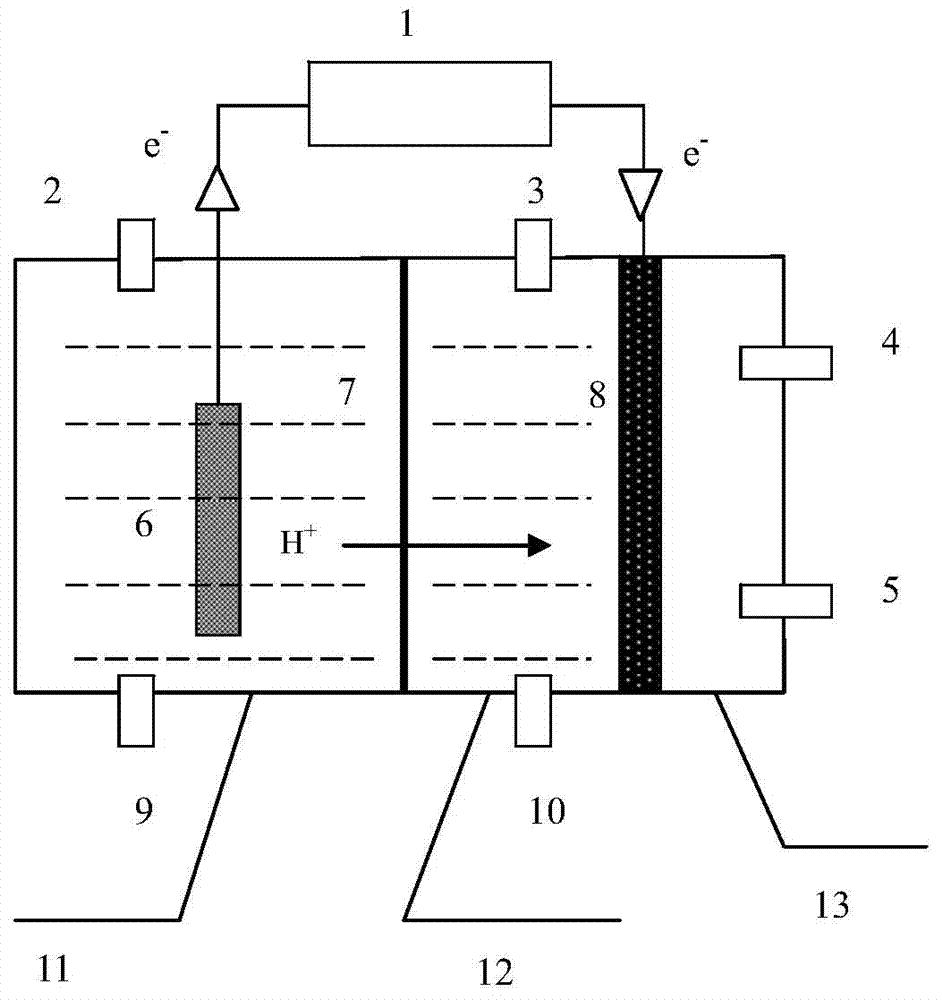

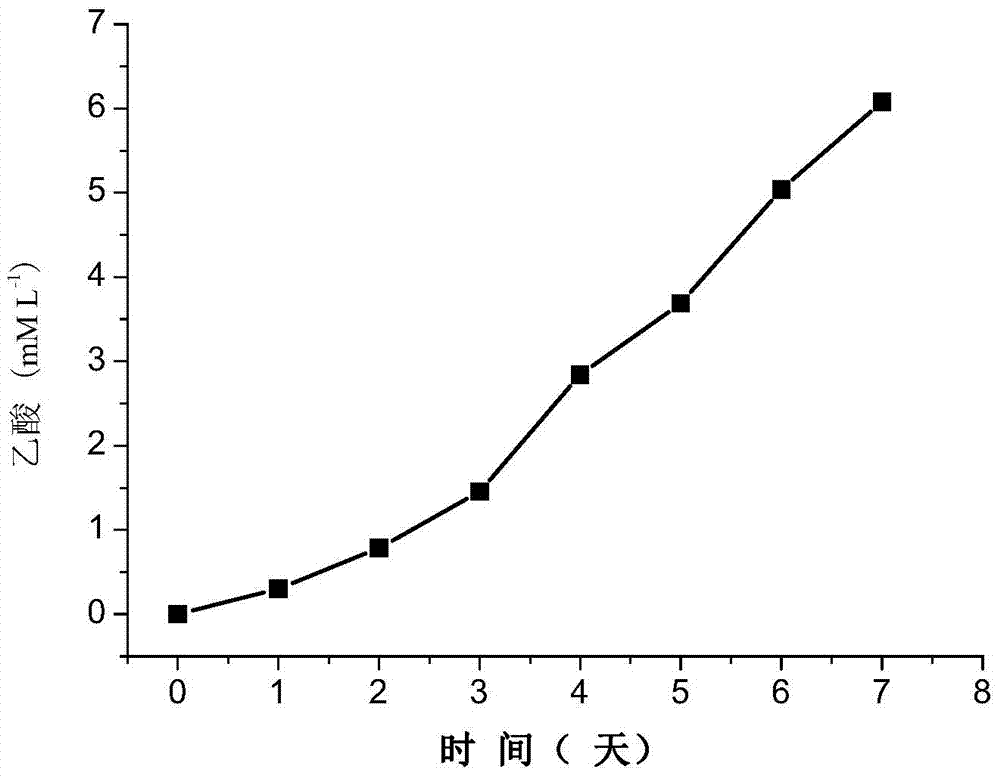

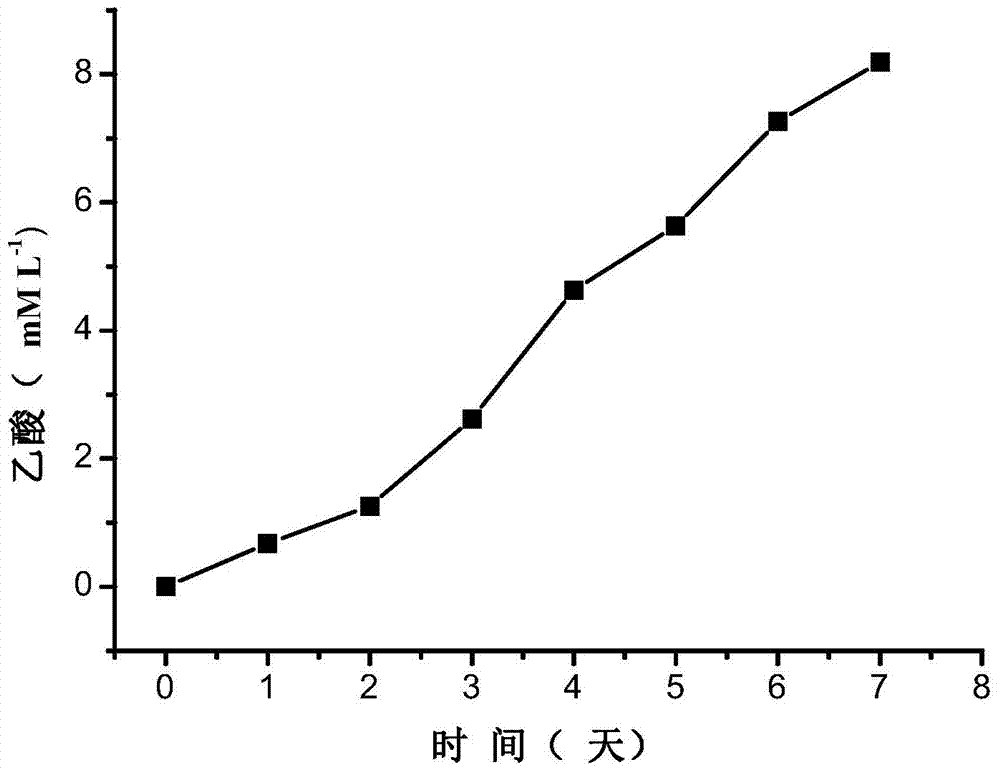

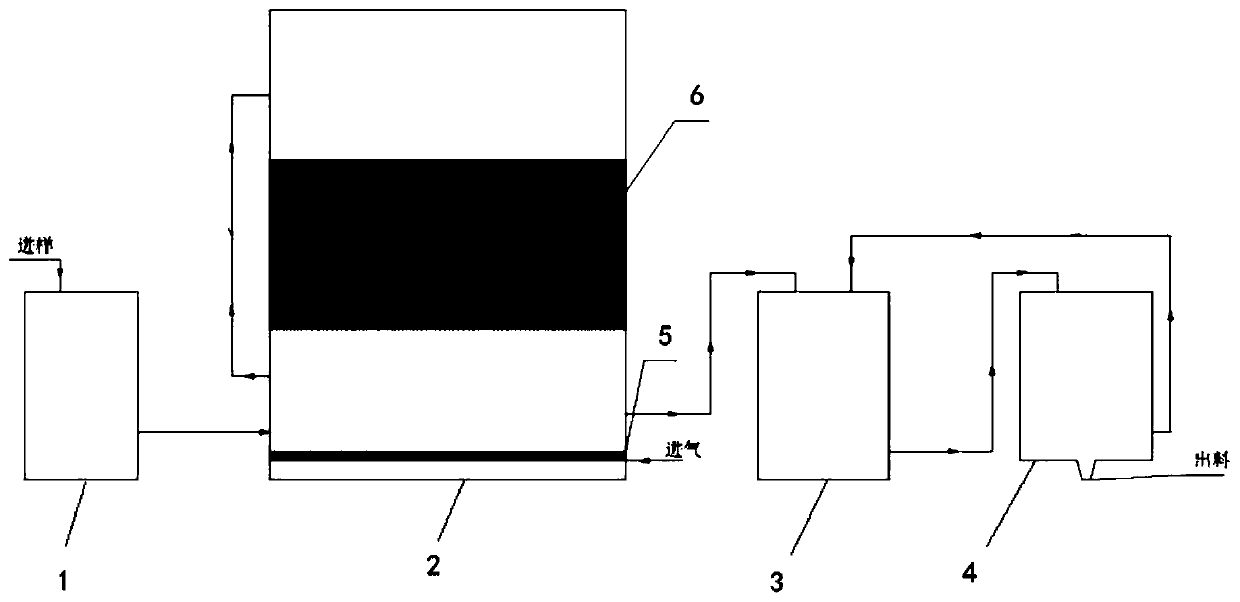

Apparatus and method for producing acetic acid by reducing carbon dioxide through microbial-electrochemical system

ActiveCN104328046ALow costIncrease mass transfer rateProductsElectrolysis componentsElectrochemical responseAcetic acid

The invention provides an apparatus and a method for producing acetic acid by reducing carbon dioxide through a microbial-electrochemical system. The apparatus includes an anode chamber and a cathode chamber, wherein the anode chamber and the cathode chamber separated by a separator. An anode is arranged inside the anode chamber and a cathode is arranged inside the cathode chamber. The anode and the cathode are connected in series outside the anode chamber and the cathode chamber through a power supply to form a loop. The cathode divides the cathode chamber into a cathode liquid chamber and a cathode gas chamber and is a gas diffusion electrode. The invention also discloses a method for producing acetic acid by reducing carbon dioxide through the apparatus. In the invention, the cathode is in the structure of a gas diffusion electrode so that a mass transfer rate and a catalytic rate of carbon dioxide in an electrochemical reaction. An acetic acid generating rate is higher. The apparatus and the method have an important application prospect in fixation and conversion of carbon dioxide.

Owner:NANJING UNIV OF TECH

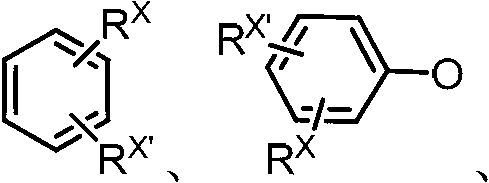

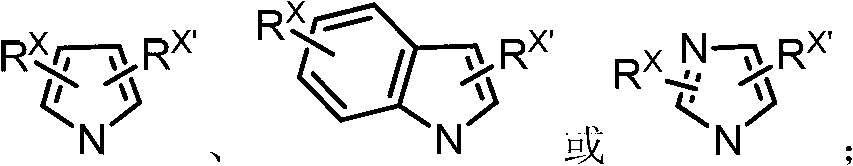

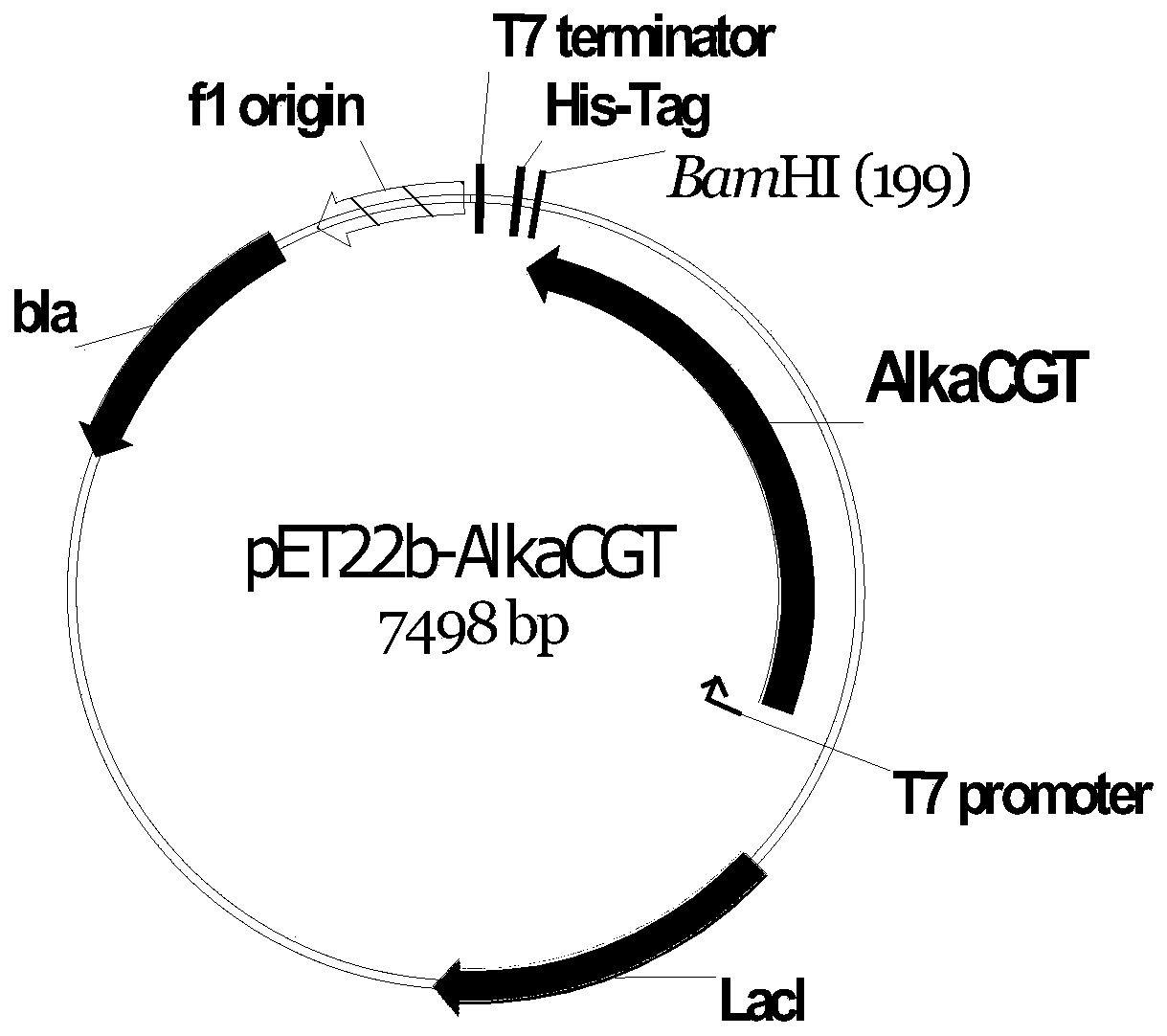

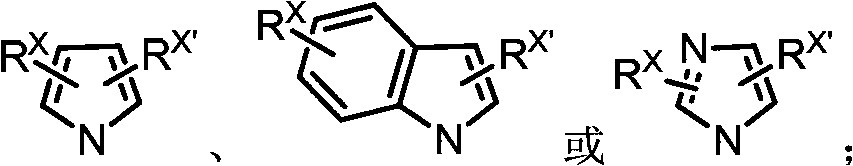

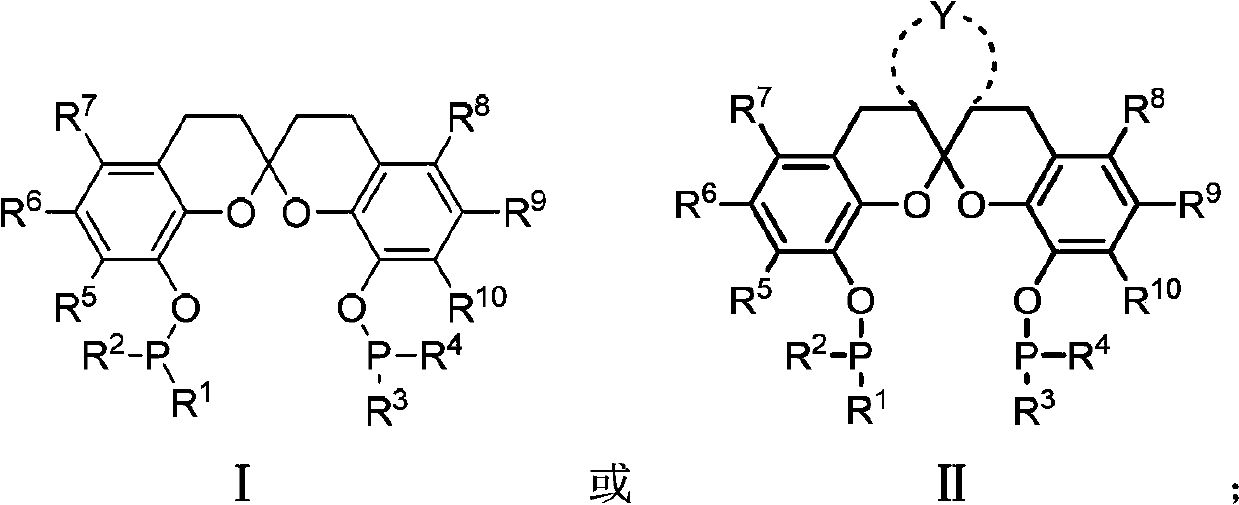

Spiroketal frame bidentate phosphoramidite ligand as well as preparation method and application thereof

ActiveCN102746338AHigh mole percentageIncrease catalytic rateOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsIsomerizationDiastereomer

The invention discloses a spiroketal frame bidentate phosphoramidite ligand as well as a preparation method and an application thereof. The ligand is the compound shown in a formula I or II or the enantiomer, racemate or diastereoisomer of the compound; and the ligand is prepared by condensation reaction of the compound in the formula I or II, and phosphorus-chlorine compounds. The spiroketal frame bidentate phosphoramidite ligand disclosed by the invention and transition metal salt form a complex, and the complex can be used for terminal olefine hydroformylation or isomerization-hydroformylation of internal olefins; and moreover, the spiroketal frame bidentate phosphoramidite ligand has high catalytic rate, good selectivity and practical value.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Preparation method of silicane gas

ActiveCN101671028AResolve failureSolve the problem of product hydrolysisSilicon hydridesCatalyst activation/preparationSolar batterySilicon thin film

A preparation method of silicane gas relates to a preparation method of electronic gas. The preparation method solves the problems that in the existing technology for preparing silicane gas, catalyticrate is difficult to be controlled, catalytic agent feeding is difficult, recycling difficulty is big, copper silicon contacts have slow productivity and low reactive activity in the preparation process of trialkoxysilanesby, the catalytic agent easily loses effectiveness after meeting water, the products are easily hydrolyzed, and the utilization rate of alcohol is low. The preparation method ofsilicane gas comprises the following steps: 1. preparing trialkoxysilanesby by using silicon powder and alcohol; 2. preparing catalytic controlled release formulations; and 3. using trialkoxysilanesby obtained in the step one to prepare silicane gas by reaction under the action of the catalytic controlled release formulations. The selectivity of trialkoxysilanesby prepared by the method reaches 95% and transformation ratio thereof reaches 90%; in the preparation method, the resolution ratio of the trialkoxysilanesby is 99.8%, silicane productivity is 90-93% and the purity is 99%; and silicanecan be used for preparing noncrystalline silicon thin film solar batteries and used in LED, LCD industries.

Owner:HARBIN INST OF TECH

Water treatment method for ultrasonically improving oxidation of pollutant with permanganate

InactiveCN102173524AEnhanced ability to catalyze permanganate oxidationImprove oxidation capacityMultistage water/sewage treatmentTreatment effectDecomposition

The invention relates to a water treatment method, particularly a water treatment method for ultrasonically improving oxidation of pollutants with permanganates, and aims to solve the problems in the prior art the speed of oxidation with permanganates is slow, the treatment effect is not stable, the dispersion of produced manganese dioxide nanoparticles is poor and the catalytic rate is low. The method has three forms. The first form comprises the following steps of: pre-treating water; feeding the effluent into a mixing pond, a flocculation pond and a precipitation pond in sequence; filtering the effluent; feeding to a clear water pond and sterilizing. The second form comprises the following steps of: feeding the water into a mixing pond and then pre-treating the water, feeding the effluent to a flocculation pond and then a precipitation pond, filtering the effluent, feeding to a clear water pond and sterilizing. The third form comprises the following steps of: feeding the water into a mixing pond; adding permanganates, inducers and coagulants under ultrasonic action; feeding the effluent to a flocculation pond and then a precipitation pond; filtering the effluent; feeding to a clear water pond and sterilizing. The method has stable operating effects, is favorable for the dispersion of manganese dioxide nanoparticles which are used as the reduction product of permanganates, improves the catalytic ability of manganese dioxide in oxidation of permanganates, and promotes the decomposition of permanganates to produce highly-active intermediate-state manganese.

Owner:HARBIN INST OF TECH

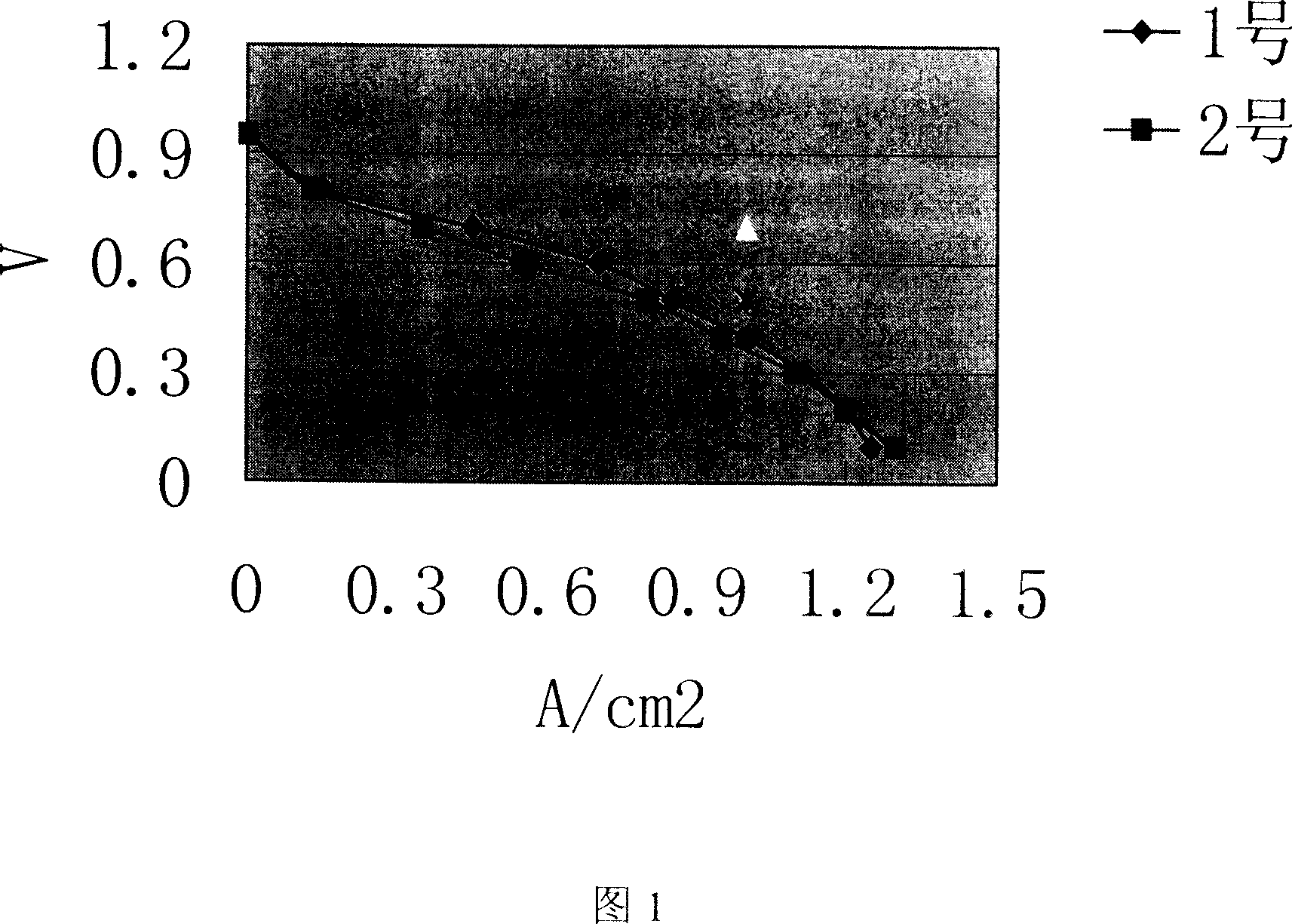

Manufacturing method of membrane electrode of fuel cell

InactiveCN101000963AIncrease profitSimplicity guaranteedCell electrodesFinal product manufactureFuel cellsProton

This invention provides a fuel cell membrane electrode preparation method, including two major steps of producing the catalytic layer membrane and membrane electrode. The catalyst layer membrane is produced by impregnating the catalyst dispersed liquid onto the microporous membrane. The membrane electrode is produced by pressing the catalyst layer membrane, carbon paper and proton exchange membrane together. Comparing with the existing technology, the invention improves the utilization of catalytic rate, saves the process of removing media without holes during preparing the catalytic layer membrane by thermal transfer print. In addition, it also plays a certain role in enhancing catalytic layer and membrane structure, regulating fuel cell catalyst water balance, and maintaining the stability of electrode operation.

Owner:SHANGHAI HORIZON FUEL CELL TECH

Mg/Al/X ternary composite metal oxide catalyst and preparation method thereof

InactiveCN101559361AGood shape selective catalytic functionIncrease active centerCatalyst activation/preparationEther preparation from oxiranesPhosphateCalcination

The invention relates to an Mg / Al / X ternary composite metal oxide catalyst and a preparation method thereof. The catalyst is characterized in that the catalyst consists of magnesium, aluminum and ternary metal elements, and the surface of a catalyst product is distributed with an aperture of which diameter is 1 to 20mu m and a protrusion of which height is 0.1 to 10mu m; and the ternary metal elements contain Ce, Dy, Fe, Mn, Co, Cd, Zn or Ni soluble salt comprising nitrate, hydrochloride, sulfate, phosphate or perchlorate. The preparation method for the catalyst comprises the following processes in turn: precursor preparation, crystallization, secondary crystallization, molding and calcination. The catalyst is applicable to the production process of the conventional kettle-type or intermittent polyether product, has good narrow molecular-weight distribution effect for the synthesis of the polyether product, has high catalytic rate, and can be recycled.

Owner:TIANJIN POLYTECHNIC UNIV

Metal composite in-situ nitrogen-doped carbon microsphere catalyst and application thereof

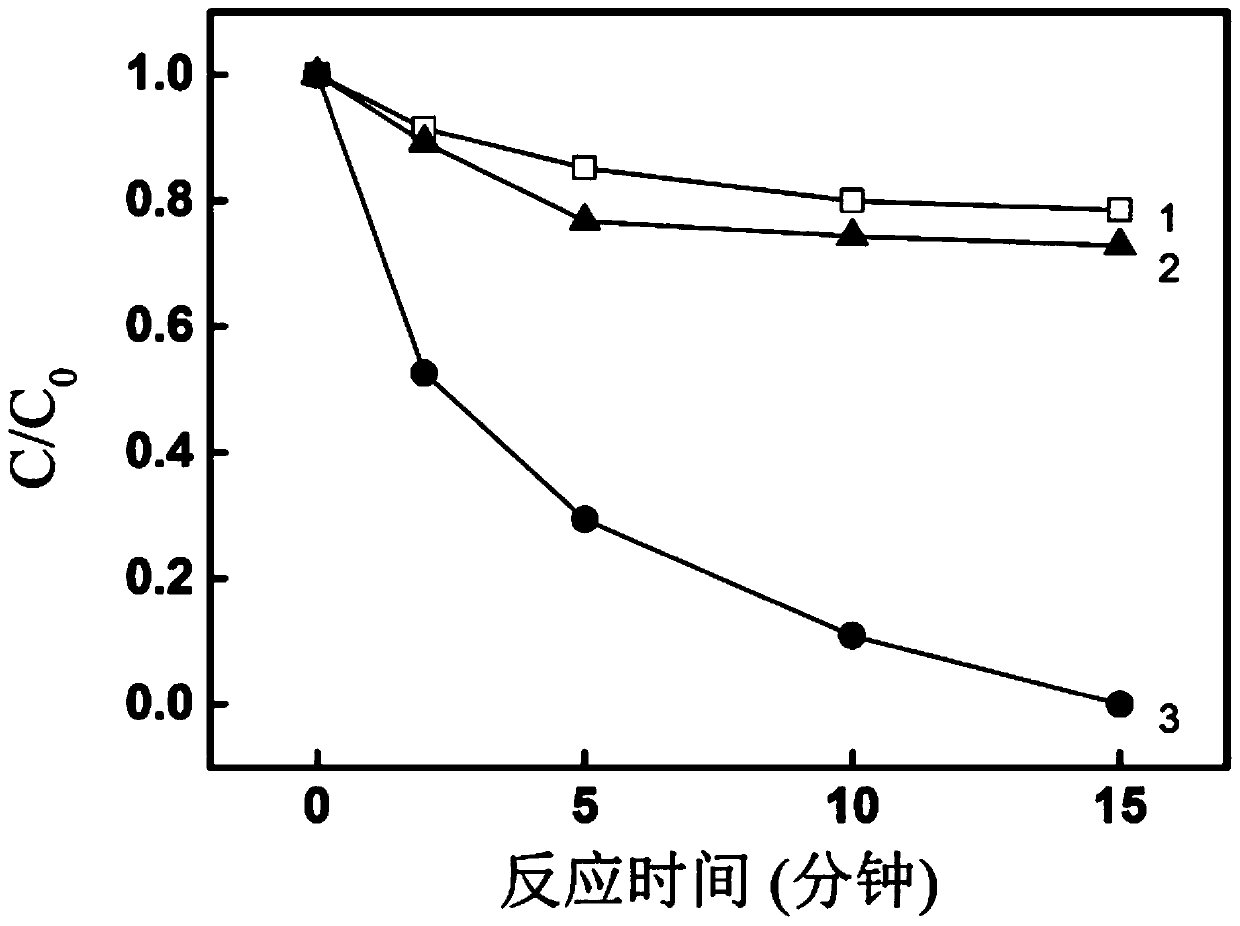

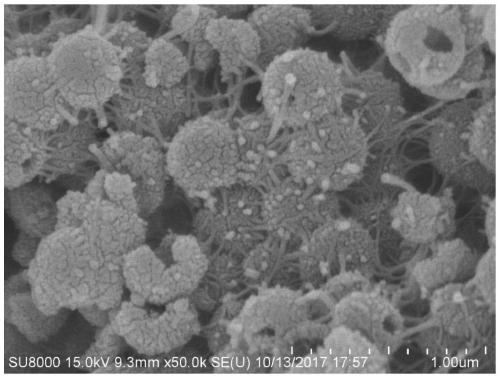

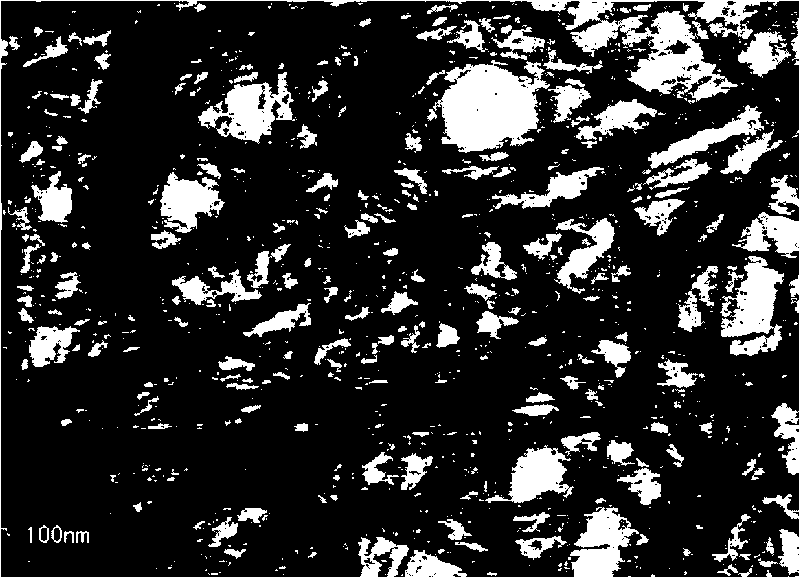

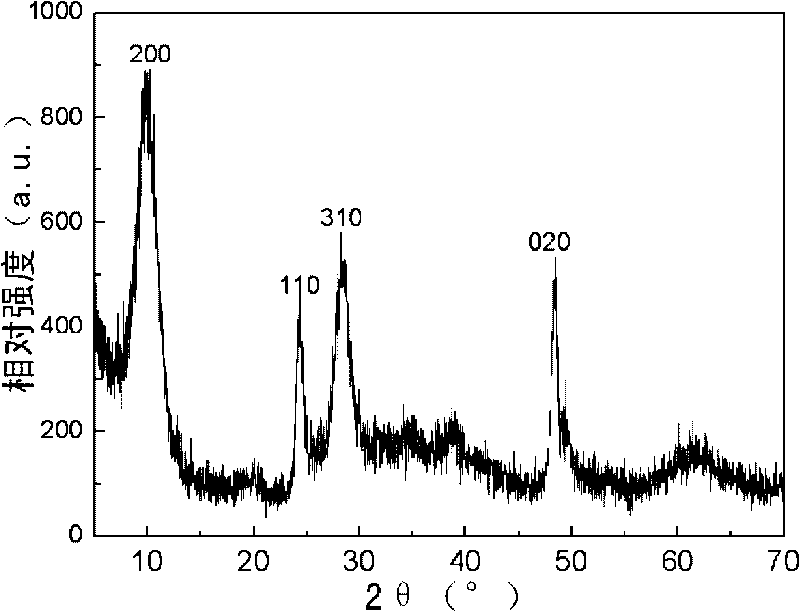

ActiveCN109731605AImprove performanceIncrease the rate of catalytic reactionsPhysical/chemical process catalystsWater contaminantsHigh rateTreatment effect

The invention relates to application of a catalyst to water treatment, in particular to a metal composite in-situ nitrogen-doped carbon microsphere catalyst and application thereof and aims to solve problems of low catalytic rate, high feeding quantity and poor treatment effects in application of a carbon material prepared according to an existing preparation method to catalytic oxidation treatment of polluted water. A method includes: firstly, preparing in-situ nitrogen-doped carbon microspheres; secondly, modifying the in-situ nitrogen-doped carbon microspheres to obtain the metal compositein-situ nitrogen-doped carbon microsphere catalyst. The metal composite in-situ nitrogen-doped carbon microsphere catalyst has advantages of high rate and effectiveness in degradation of organic pollutants; in degradation of atrazine, complete reaction can be realized by catalyzing of persulfate for 15min. The metal composite in-situ nitrogen-doped carbon microsphere catalyst is obtained.

Owner:HARBIN INST OF TECH

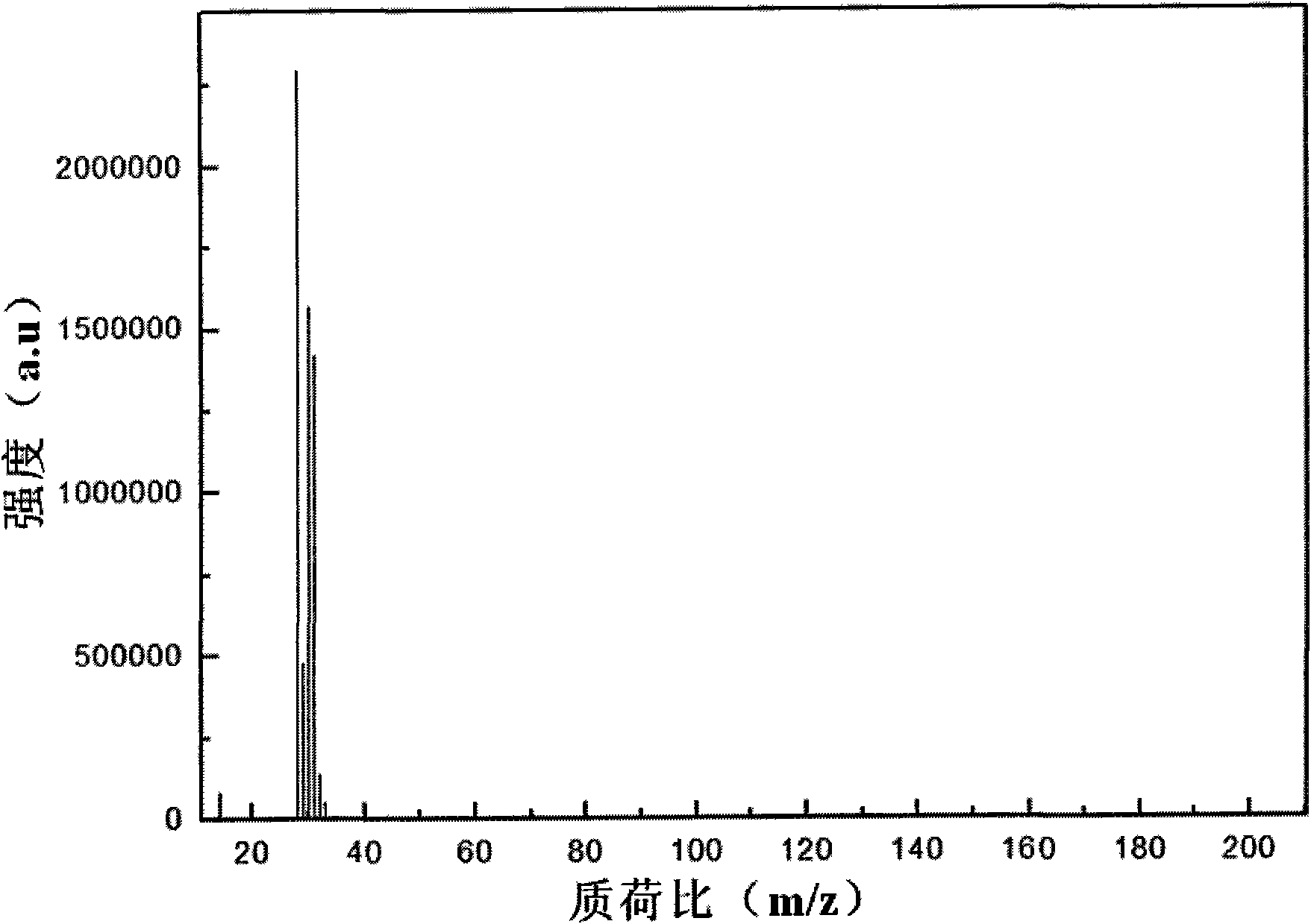

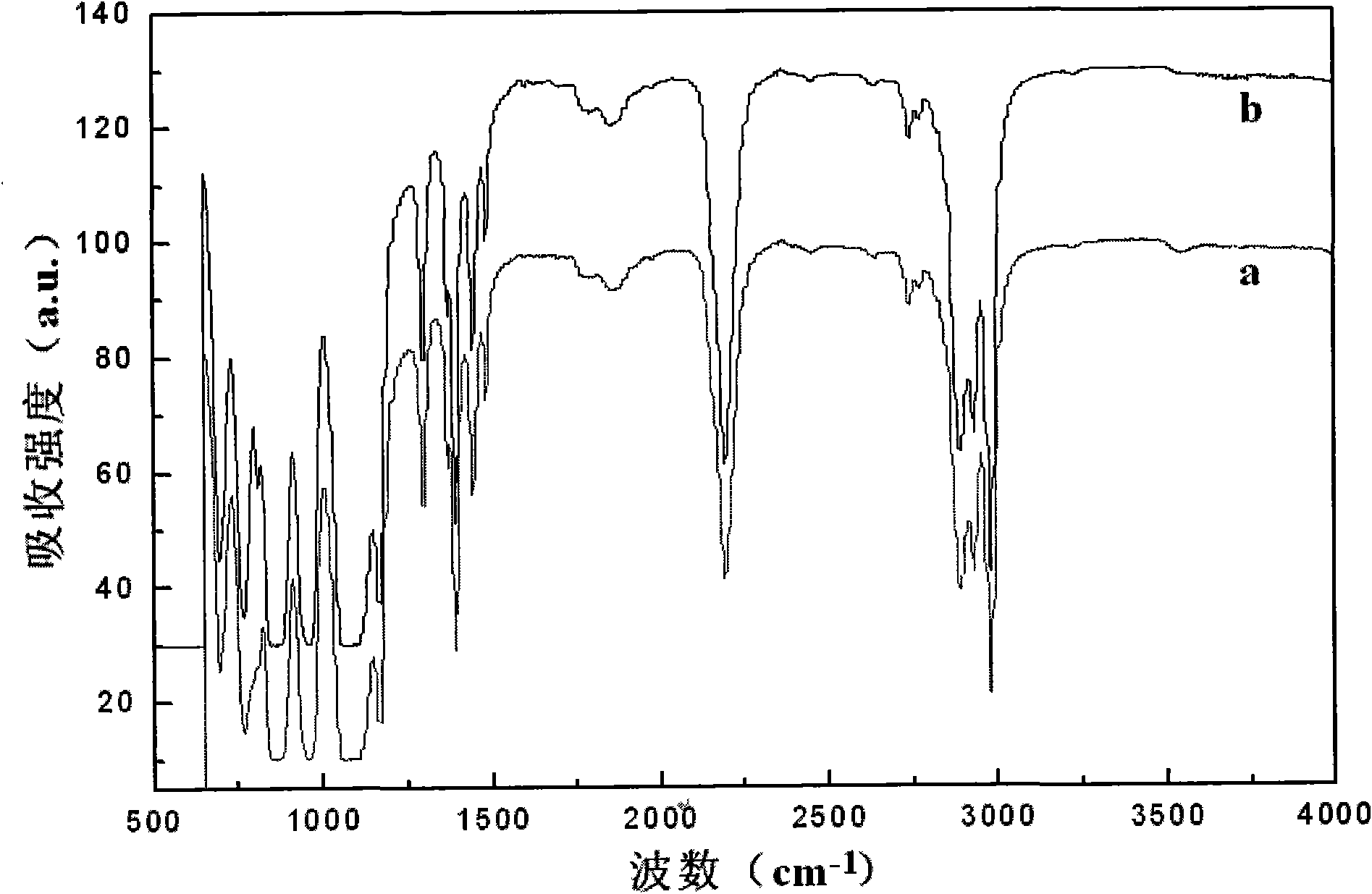

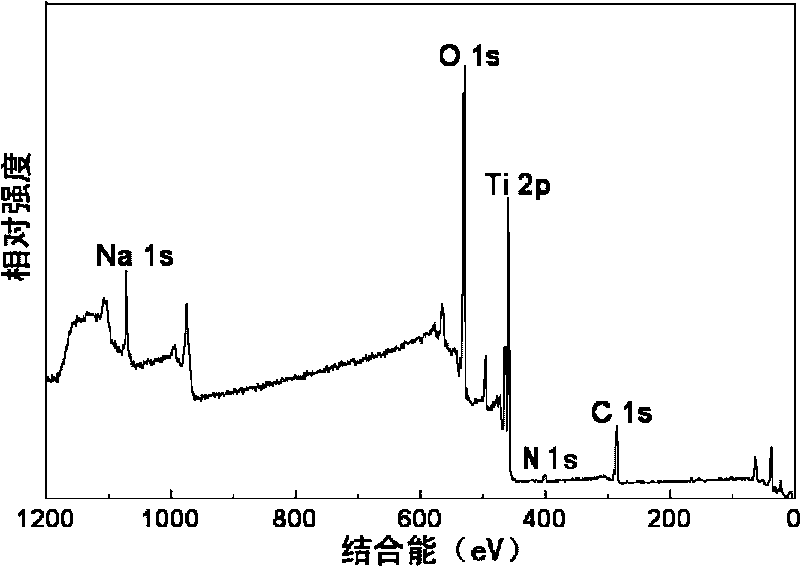

Method for preparing nitrogen-doped titanic acid nano tube by hydrothermal cosolvent method

InactiveCN101723442AImprove thermal stabilityImprove stabilityNanostructure manufactureEnergy inputMethyl orangeTitanic acid

The invention discloses a method for preparing a nitrogen-doped titanic acid nano tube by a hydrothermal cosolvent method, which relates to a method for preparing a nitrogen-doped titanic acid nano tube. The method solves the problems of poor stability of the titanic acid nano tube obtained by the conventional hydrothermal synthetic method and poor effect of degrading organic pollutants through photocatalysis. The method comprises the following steps: firstly, putting titanium dioxide into sodium hydroxide solution and triethanolamine to perform hydrothermal reaction so as to obtain a reaction product; secondly, cleaning the reaction product, and then drying the reaction product in vacuum; and thirdly, thermally treating the reaction product in a muffle furnace to form the nitrogen-doped titanic acid nano tube. The method adopts the triethanolamine as a reaction raw material to generate the nitrogen-doped titanic acid nano tube having good thermal stability and complete tube wall and containing an H2Ti2O5H2O crystalline substance; and the catalytic rate constant shown by the nitrogen-doped titanic acid nano tube for degrading methyl orange is 0.00921, which is 9 times of the catalytic rate constant (0.00109) shown by the nano titanium dioxide for degrading the methyl orange.

Owner:NORTHEAST FORESTRY UNIVERSITY

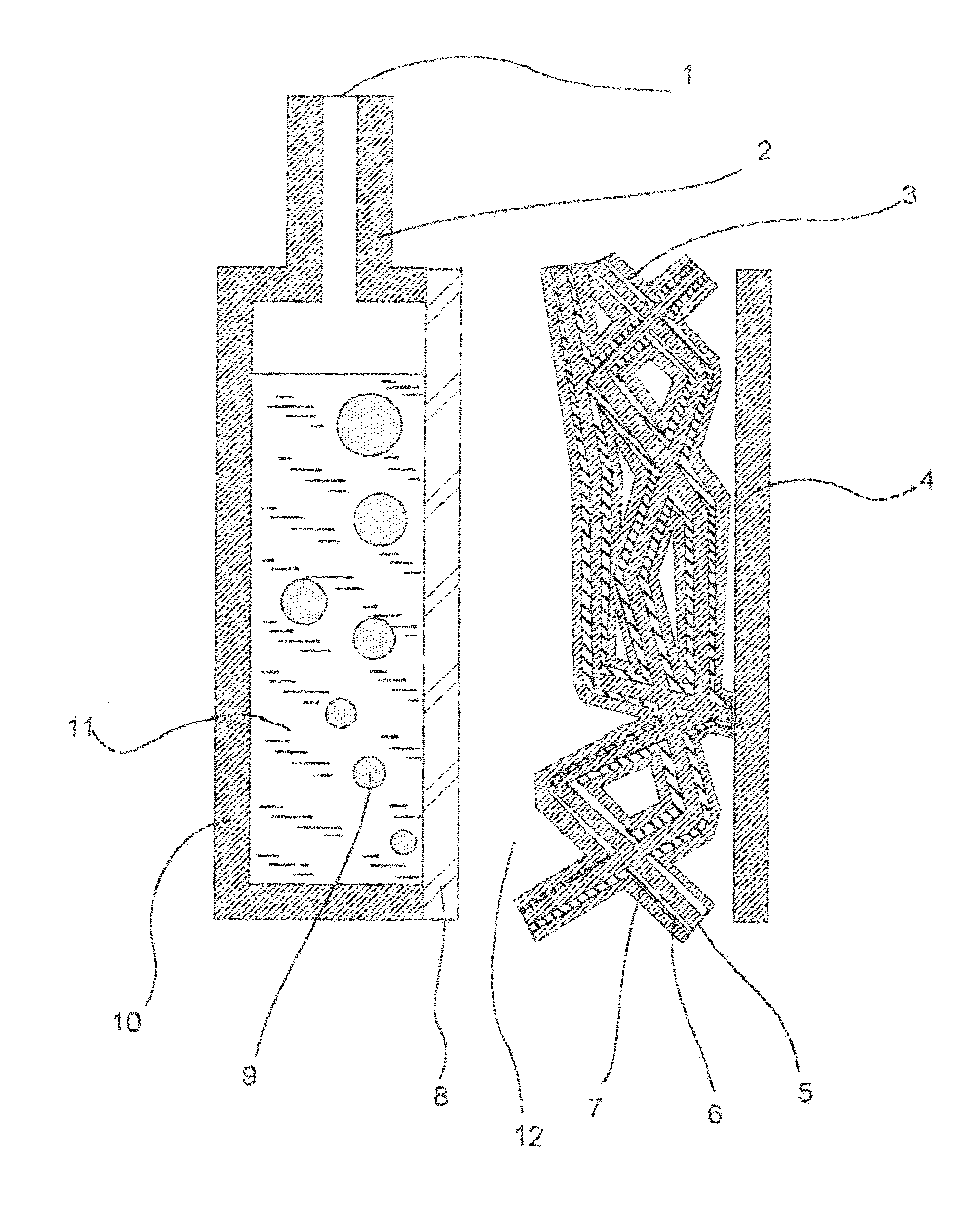

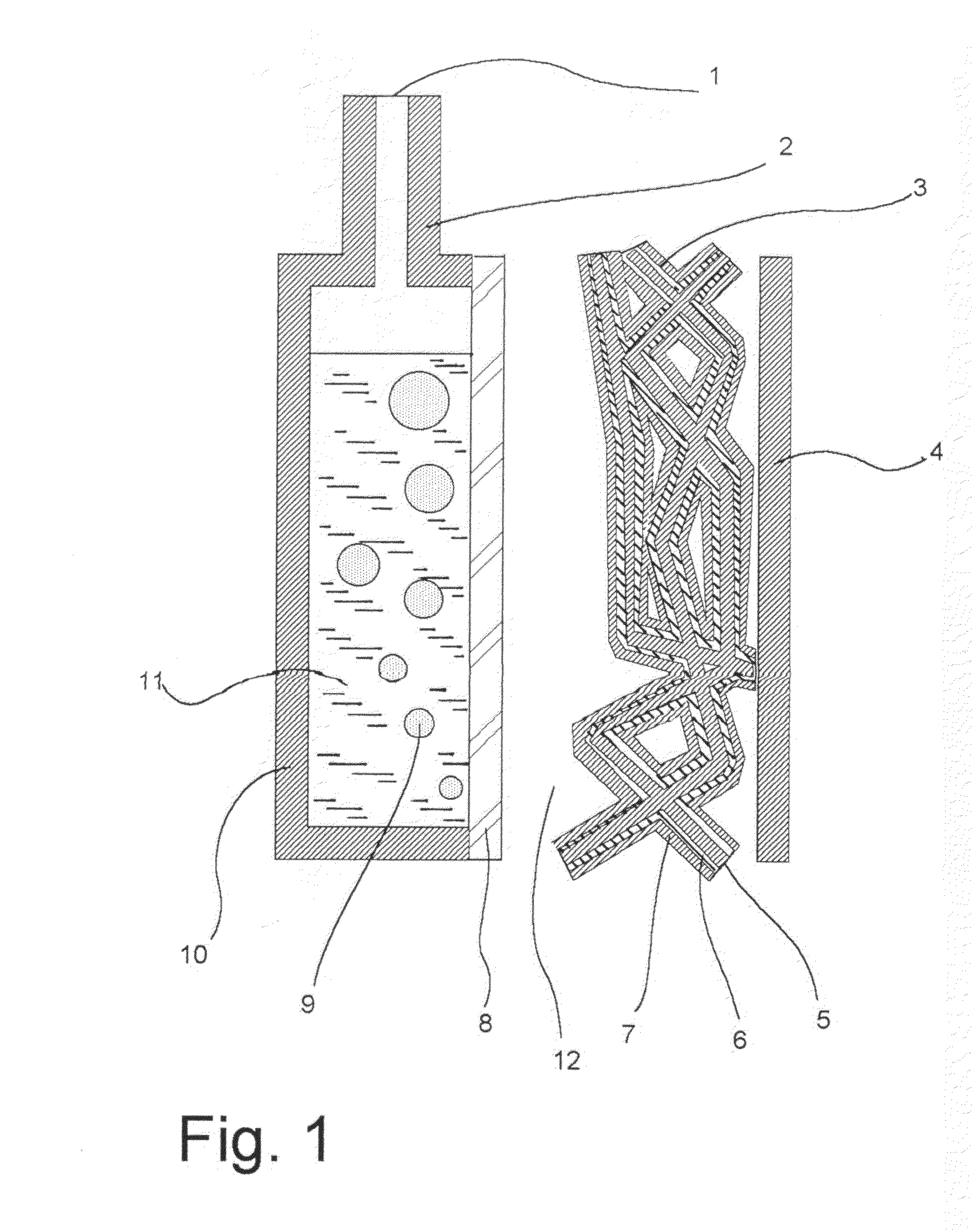

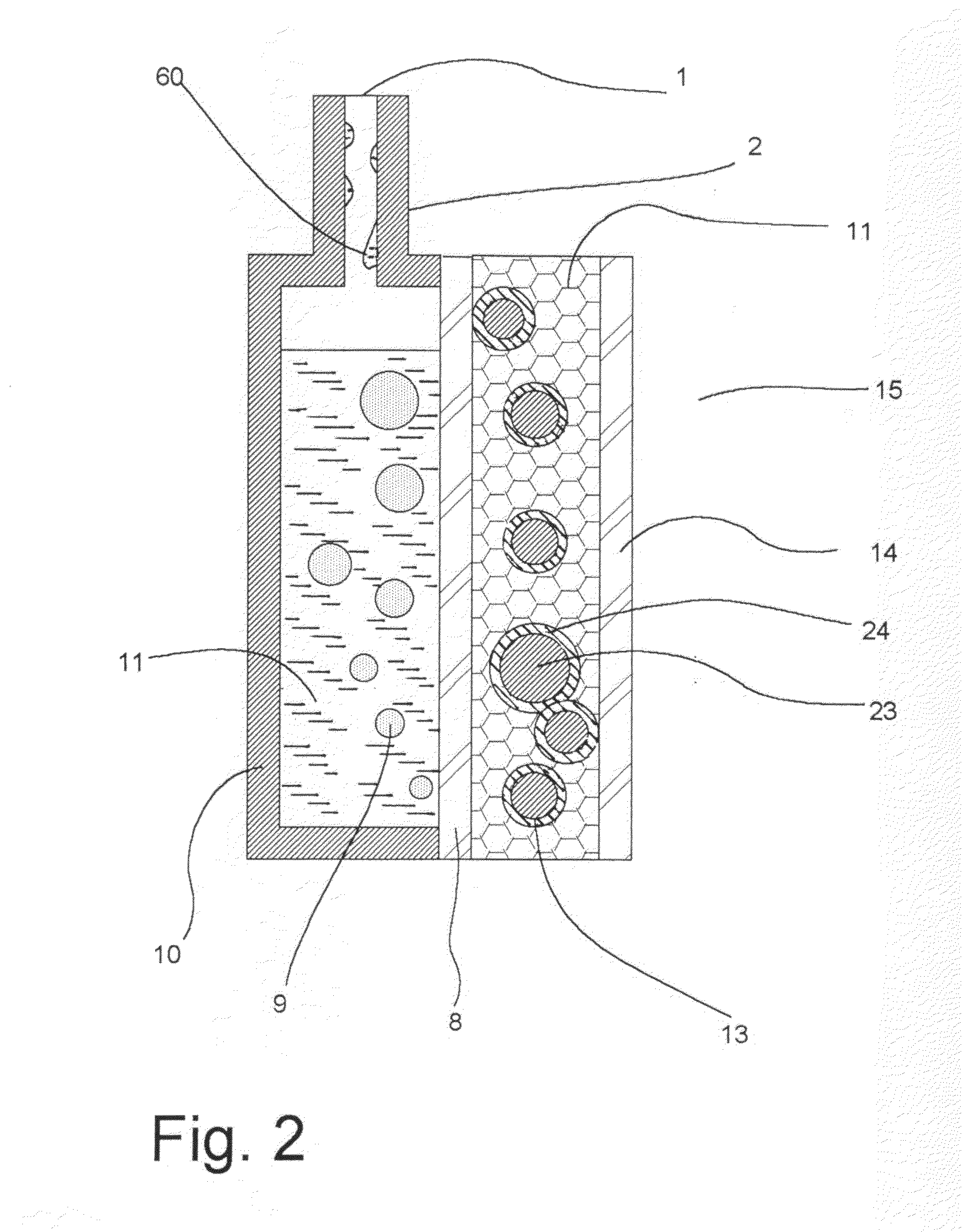

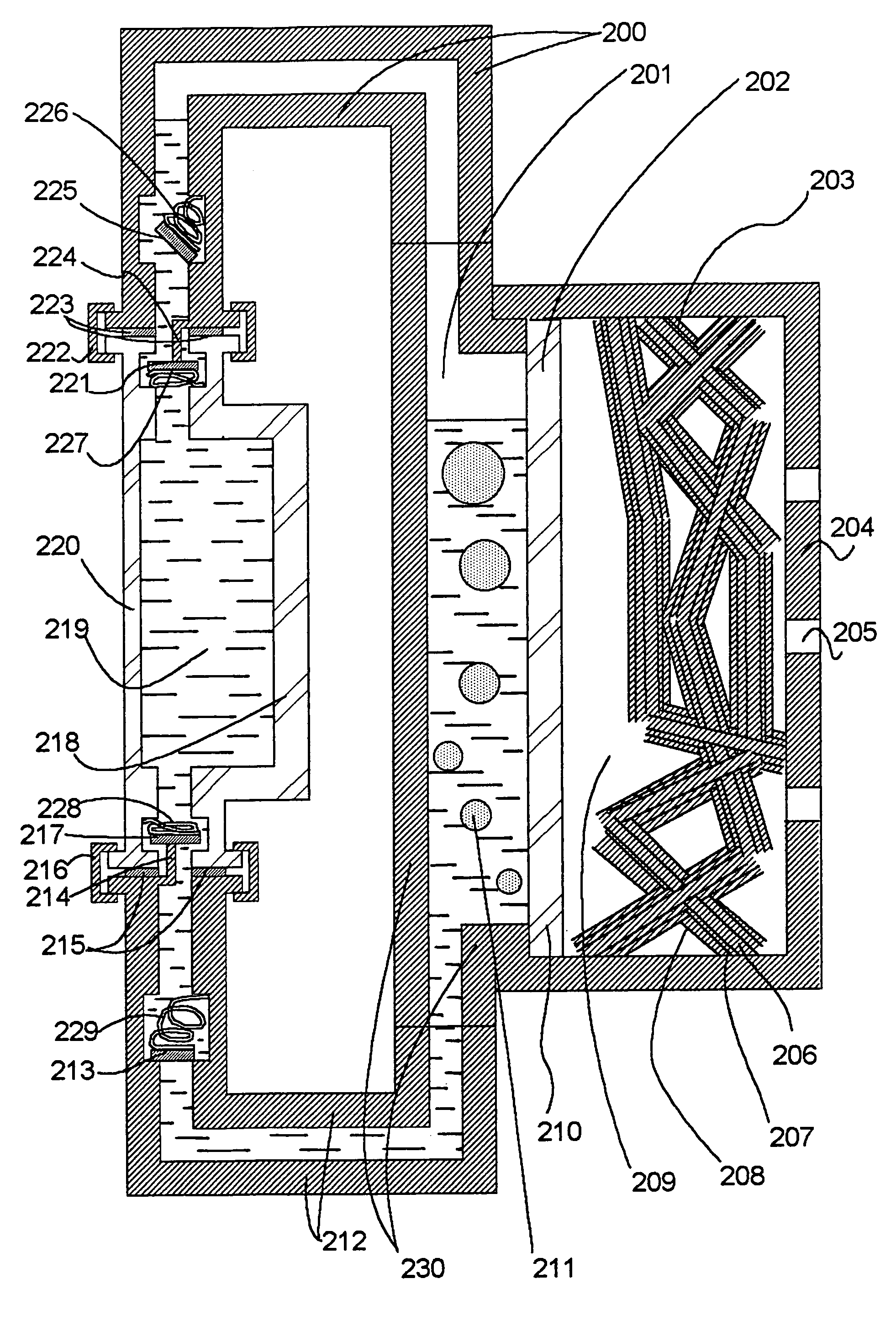

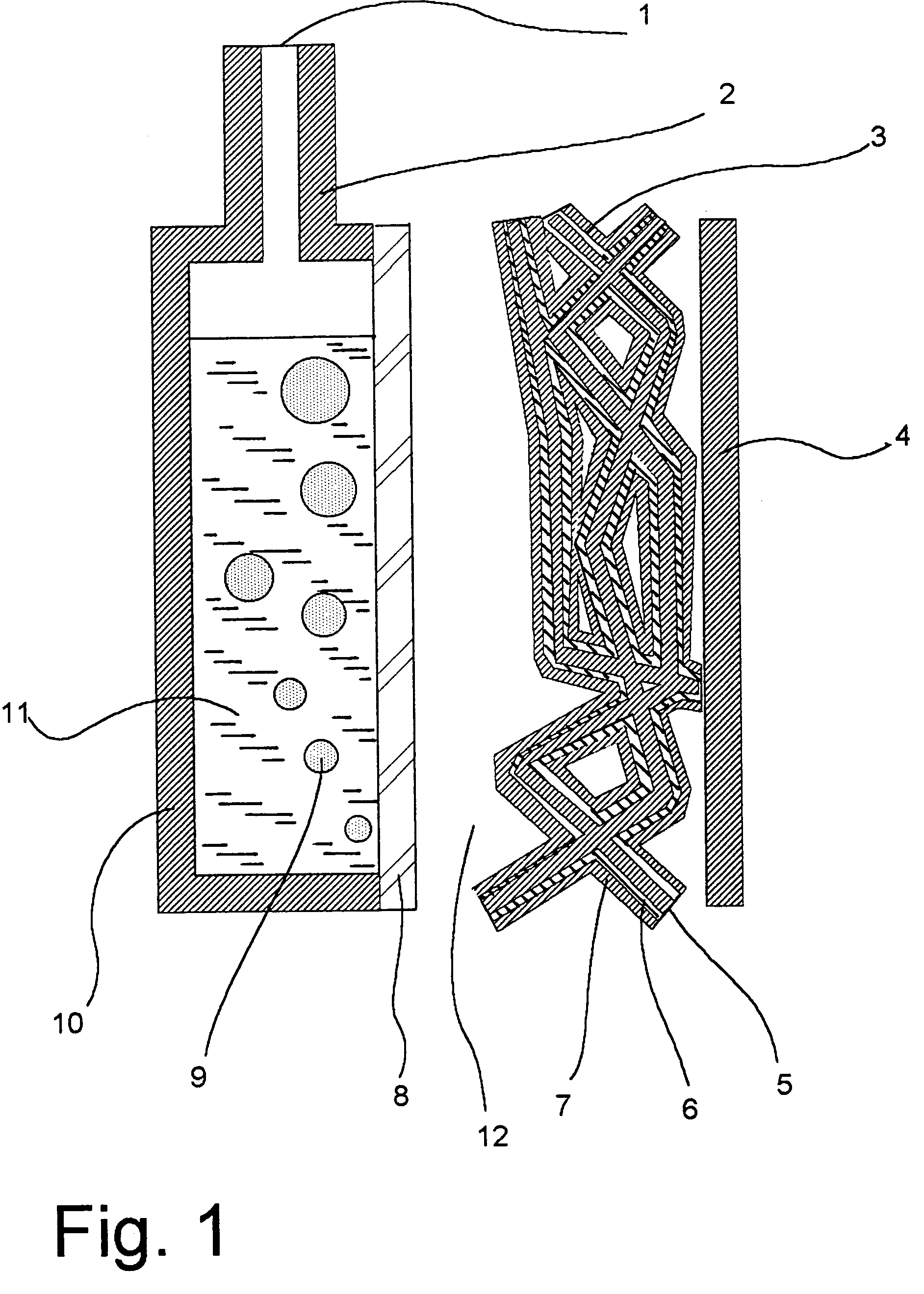

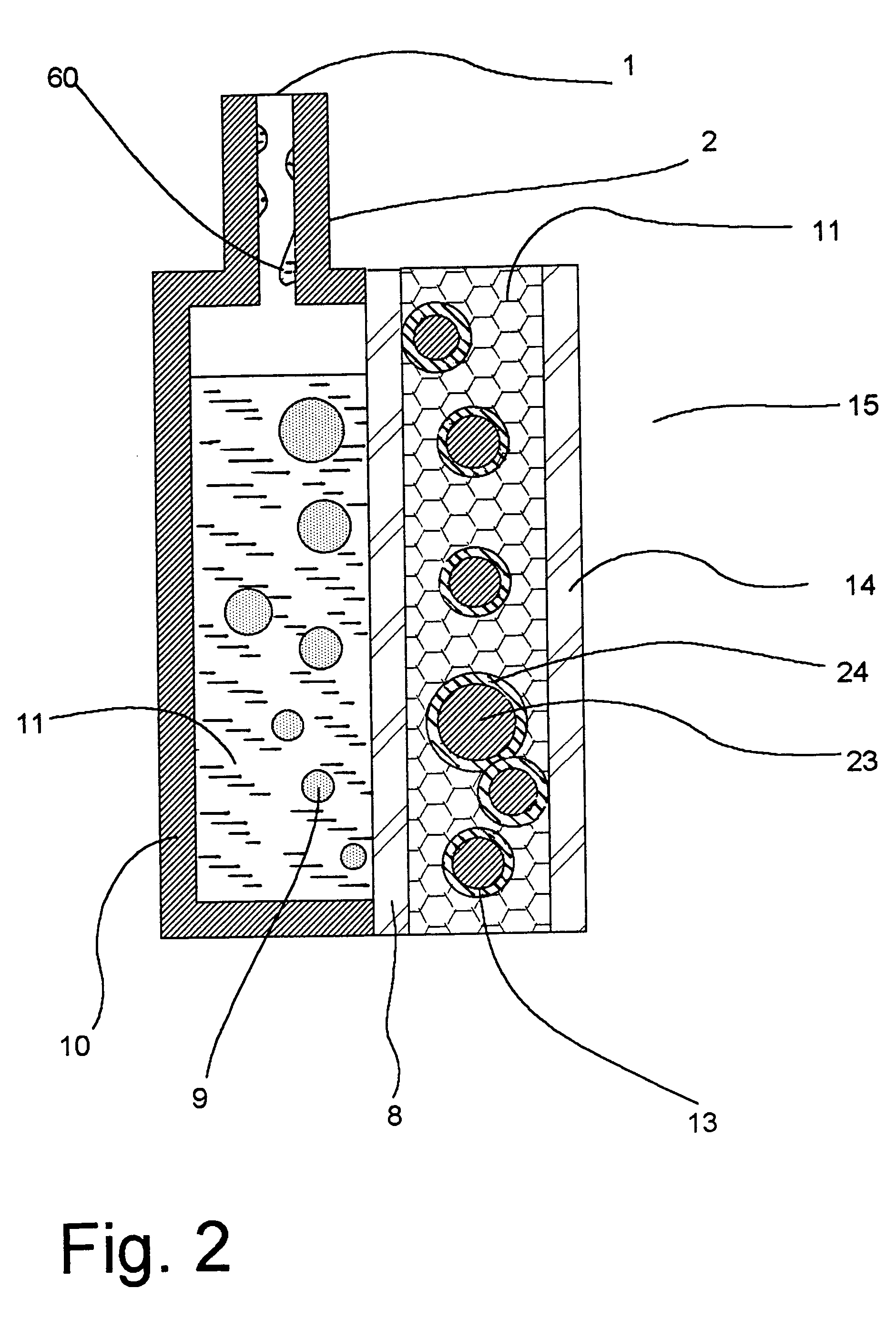

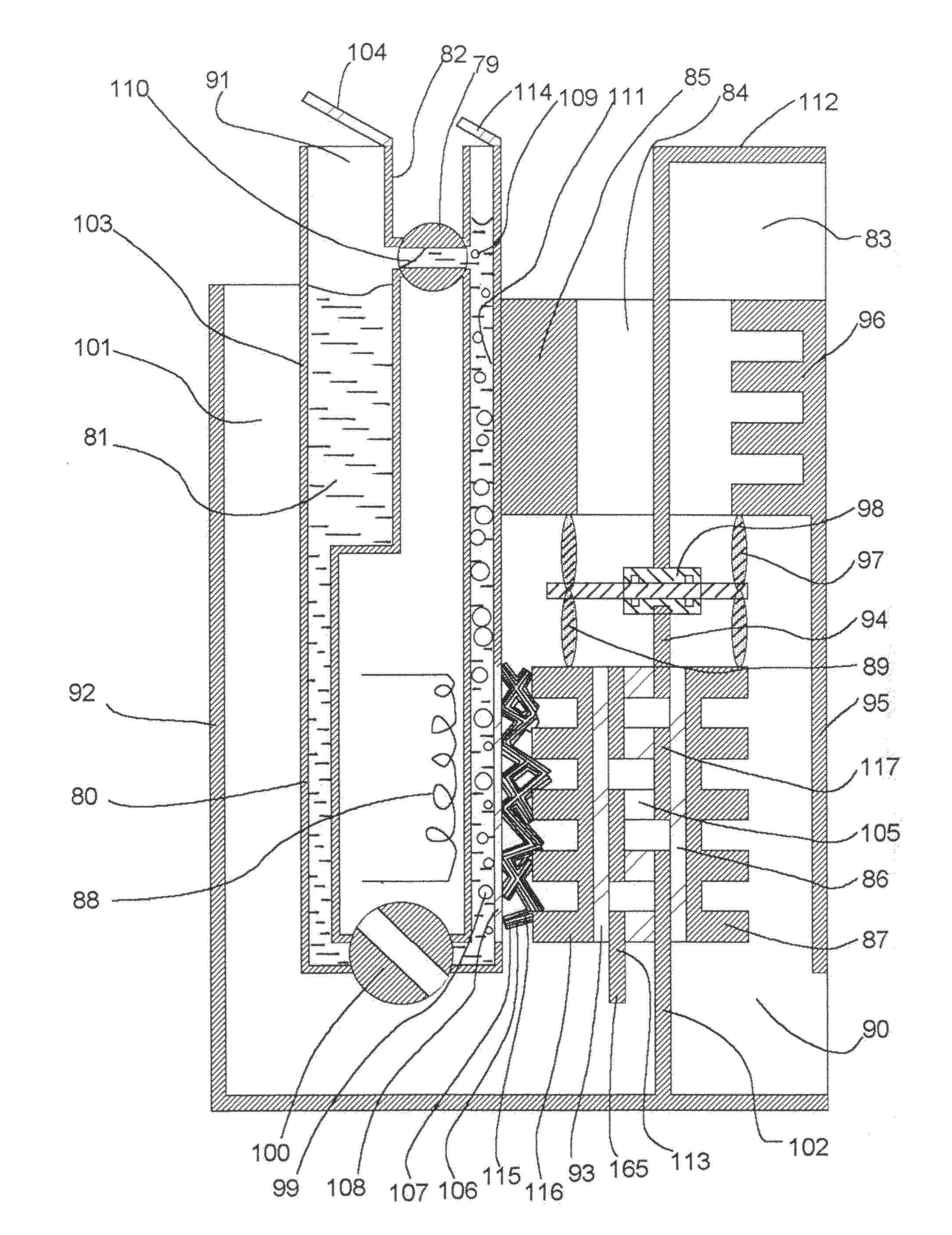

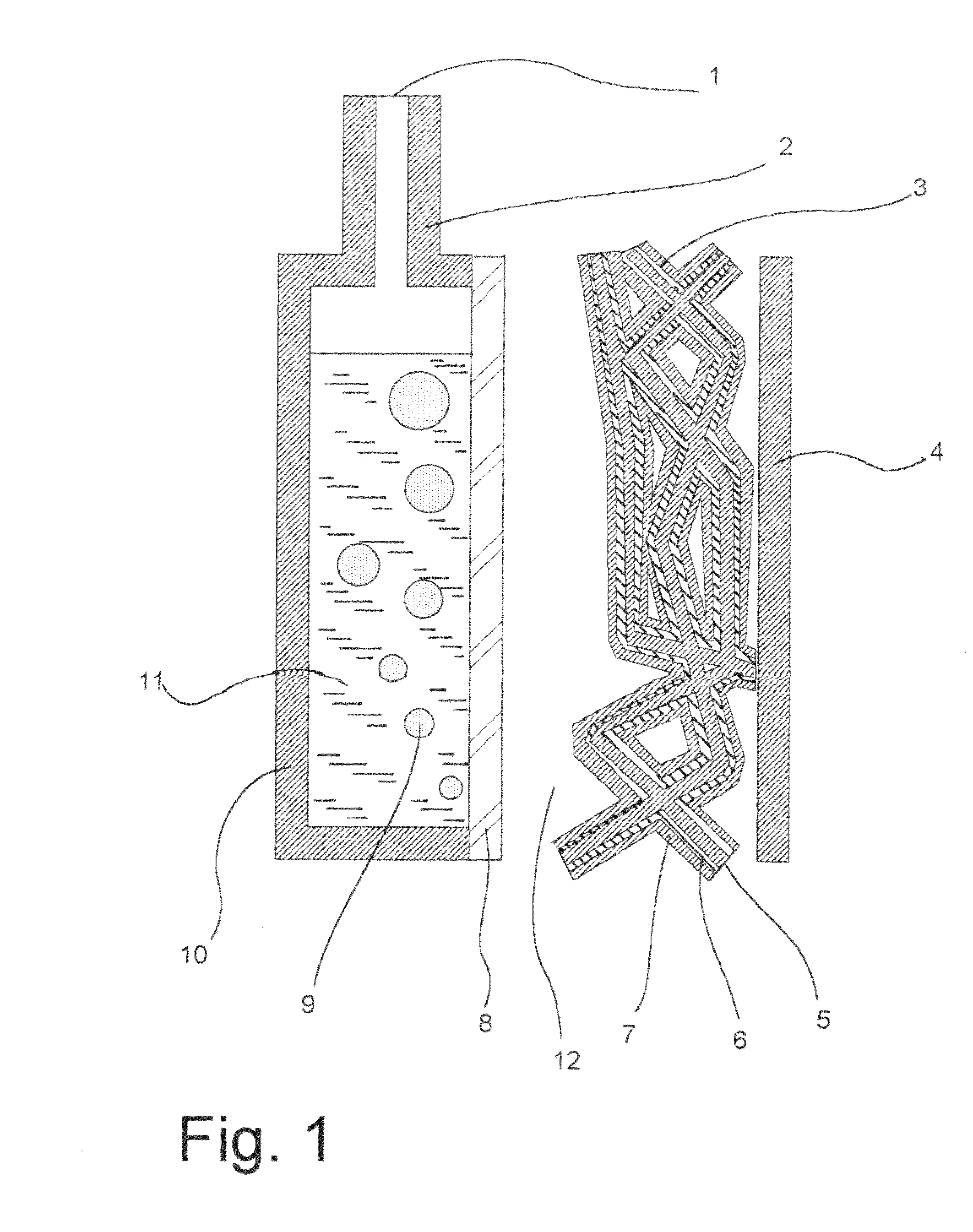

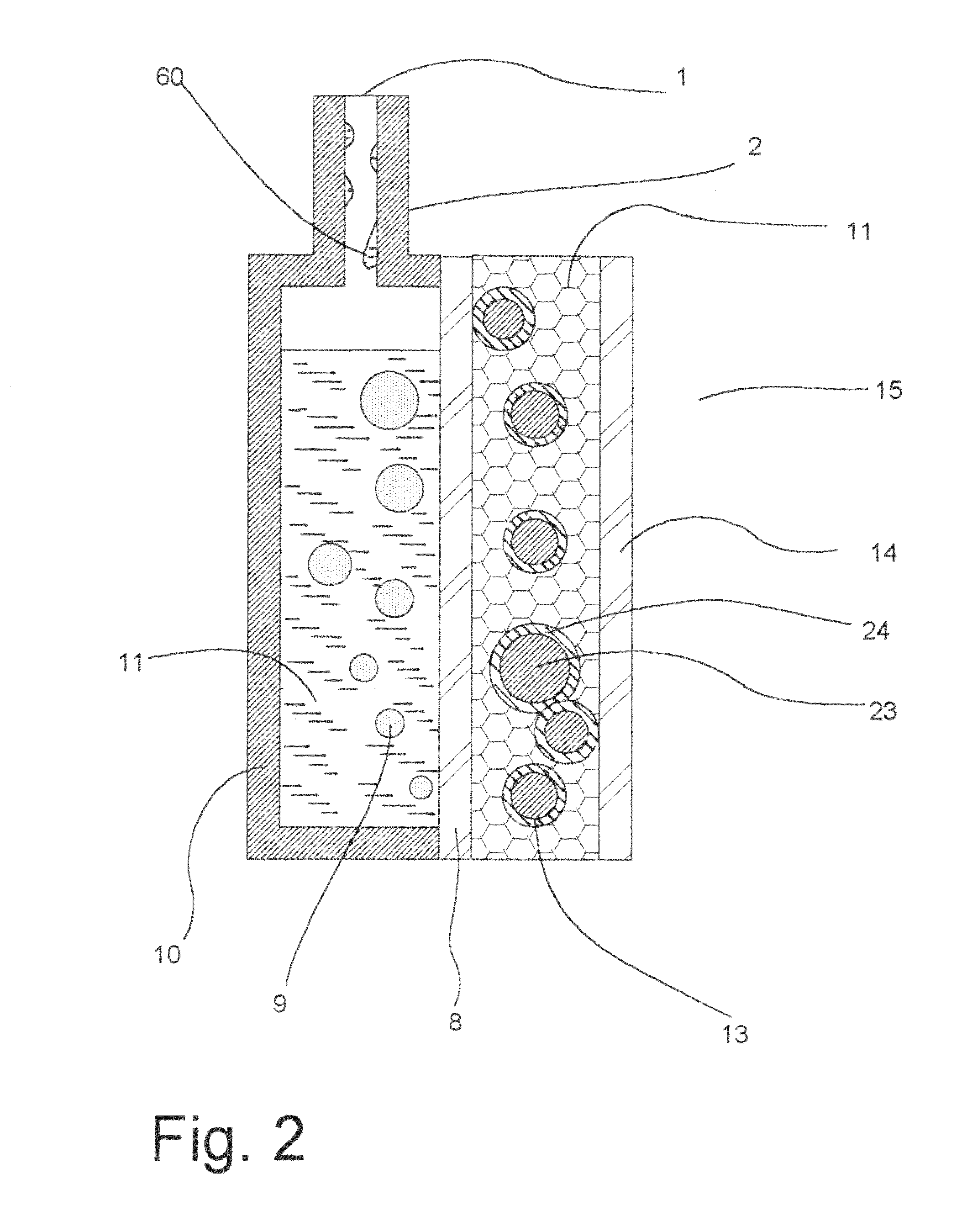

Membrane catalytic heater

InactiveUS20100227286A1Stable rateImprove efficiencyFurnace componentsCapillary burnersProcess engineeringPermselective membrane

A portable catalytic combustion heater, wherein fuel vapor (11) and air (10) are supplied to a catalyst (6) which promotes the flameless combustion of fuel and releases that. The fuel is supplied as a liquid, passes through a selectively permeable membrane (8) such as fuel vapor exits the membrane and is fed to the catalyst (6). Additional features include porous supports and means of enhancing and diminishing the catalytic rate of combustion and controlling the heat output.

Owner:GHT GLOBAL HEATING TECH

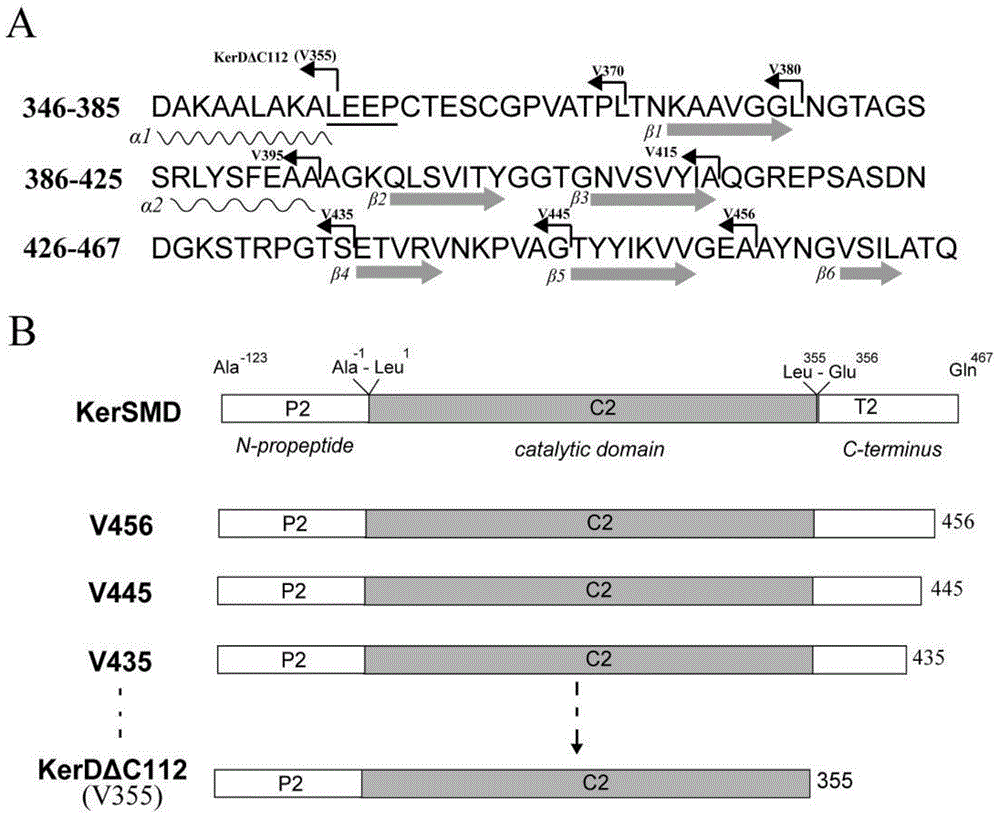

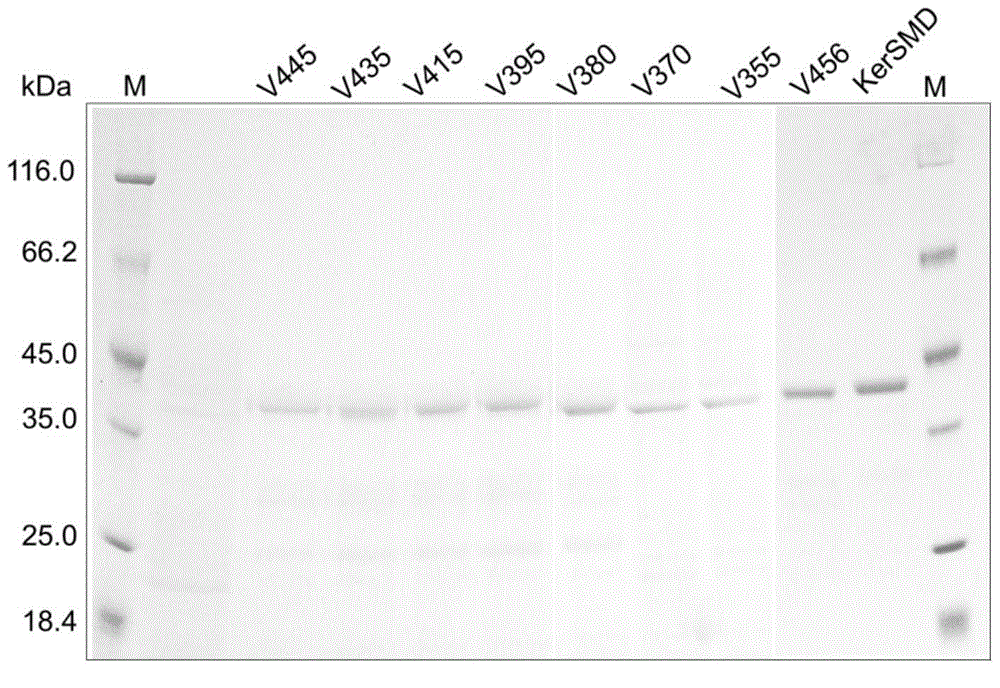

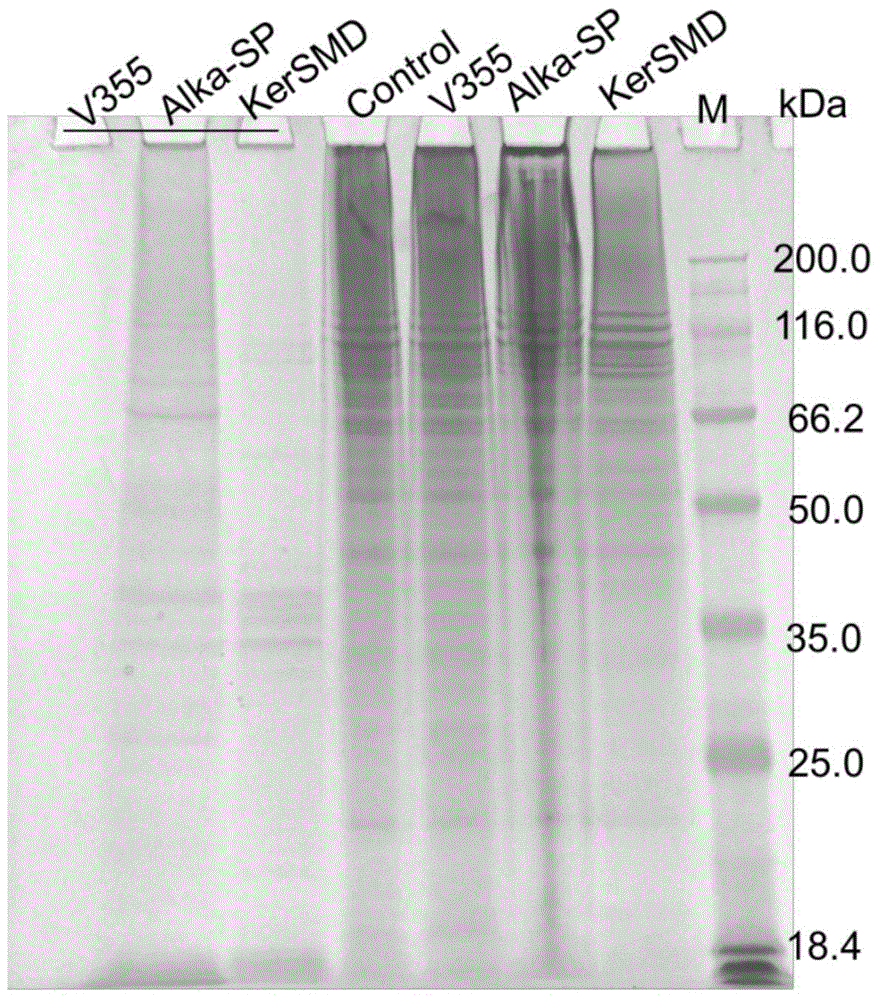

Catalytic rate improving keratinase mutants and preparation method thereof

ActiveCN105002152AEnhanced ability to resist detergent SDSIncrease catalytic rateBacteriaHydrolasesCollagenase activityMutant

The present invention discloses catalytic rate improving keratinase mutants and a preparation method thereof, and belongs to the field of enzyme engineering. According to the present invention, the C terminal structure of keratinase KerSMD is sheared to obtain a series of keratinase mutants, wherein the catalytic rate of the keratinase mutants on the casein substrate is significantly improved and is increased by 33-103%, particularly the mutant V355 has effects of significantly improved catalytic rate, significantly improved enzyme activity, enhanced salt tolerance and enhanced detergent resistance, the characteristics of no collagenase activity and salt tolerance of the V355 can be used in the leather processing industry, the catalytic rate on the substrate is rapid, and the V355 has the characteristic of detergent resistance so as to be subjected to laundry additive production application.

Owner:JIANGNAN UNIV

Allosteric Control of Proteins by Manipulating Mechanical Tension

InactiveUS20080311592A1Reduced binding affinityHigh binding affinitySugar derivativesMicrobiological testing/measurementPolynucleotideMechanical tension

A method of altering the conformation of a polypeptide having a known three-dimensional structure is described. The method comprises attaching a first end of a polymer to a first portion of the polypeptide, attaching a second end of the polymer to a second portion of the polypeptide, and altering the mechanical tension of the polymer, thereby altering the conformation of the polypeptide. The alteration of the conformation of the polypeptide may increase or decrease the binding affinity of the polypeptide for a substrate bound by the polypeptide, or alter the catalytic rate of an enzyme. Typically, the polymer is a polynucleotide or polypeptide.

Owner:RGT UNIV OF CALIFORNIA

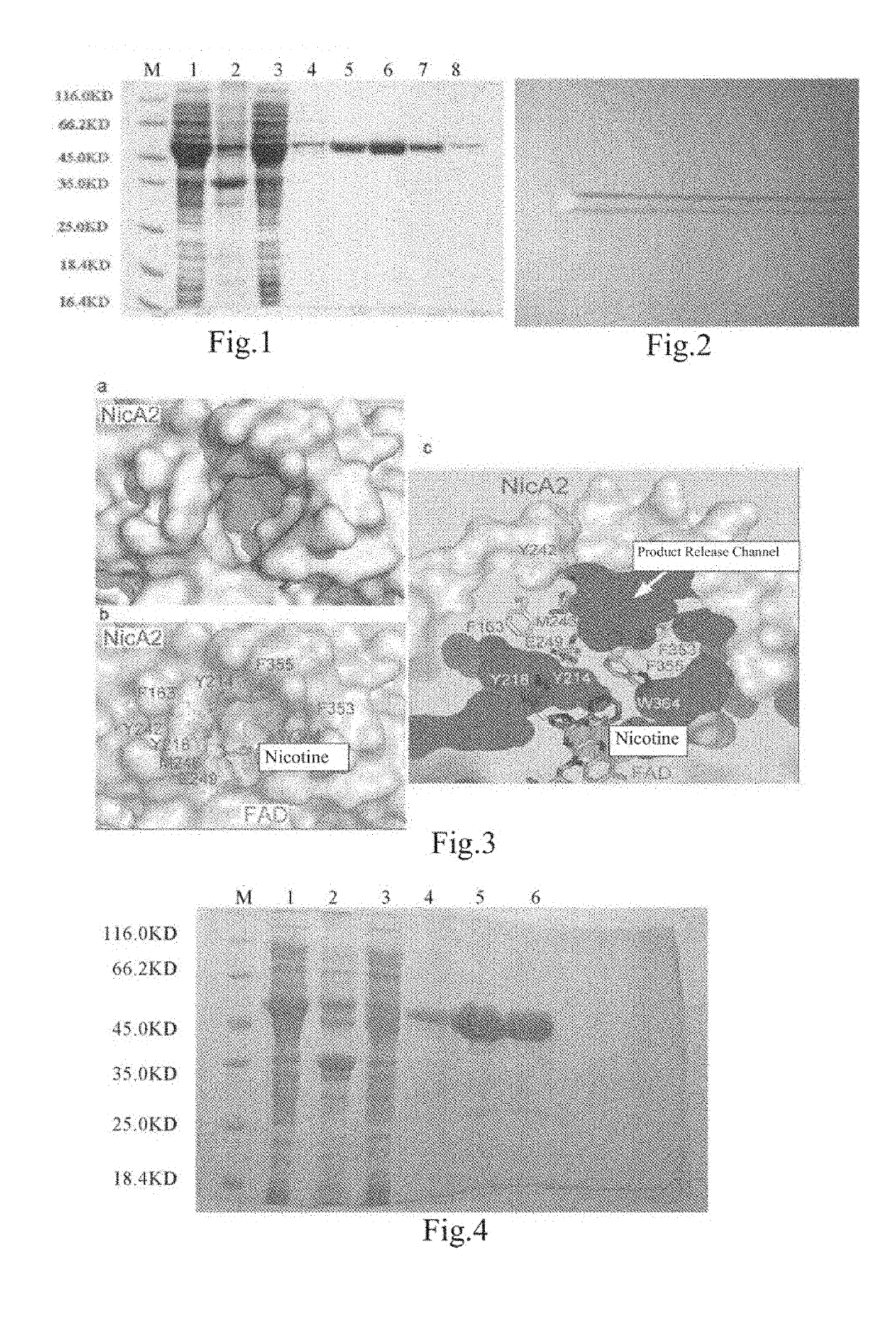

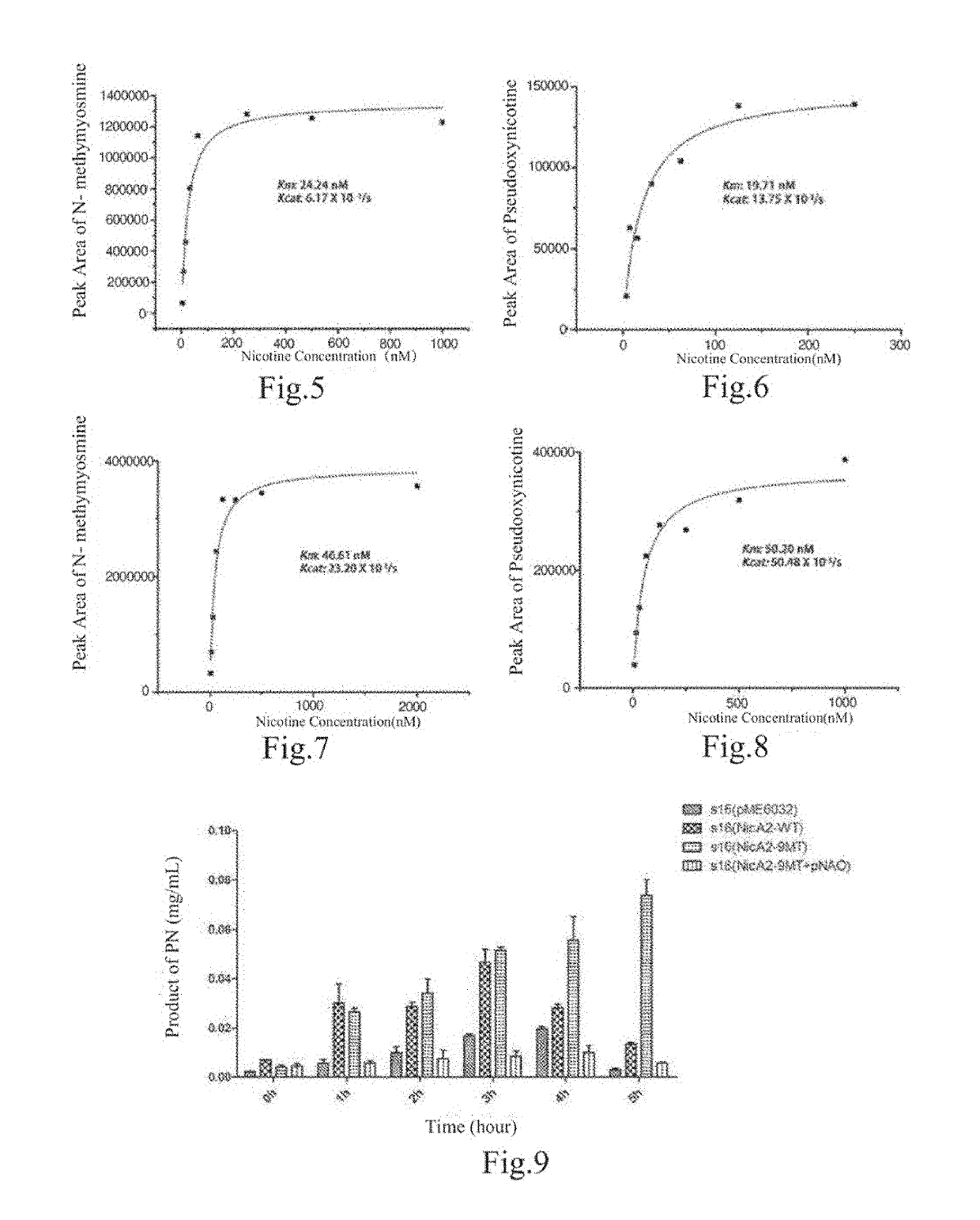

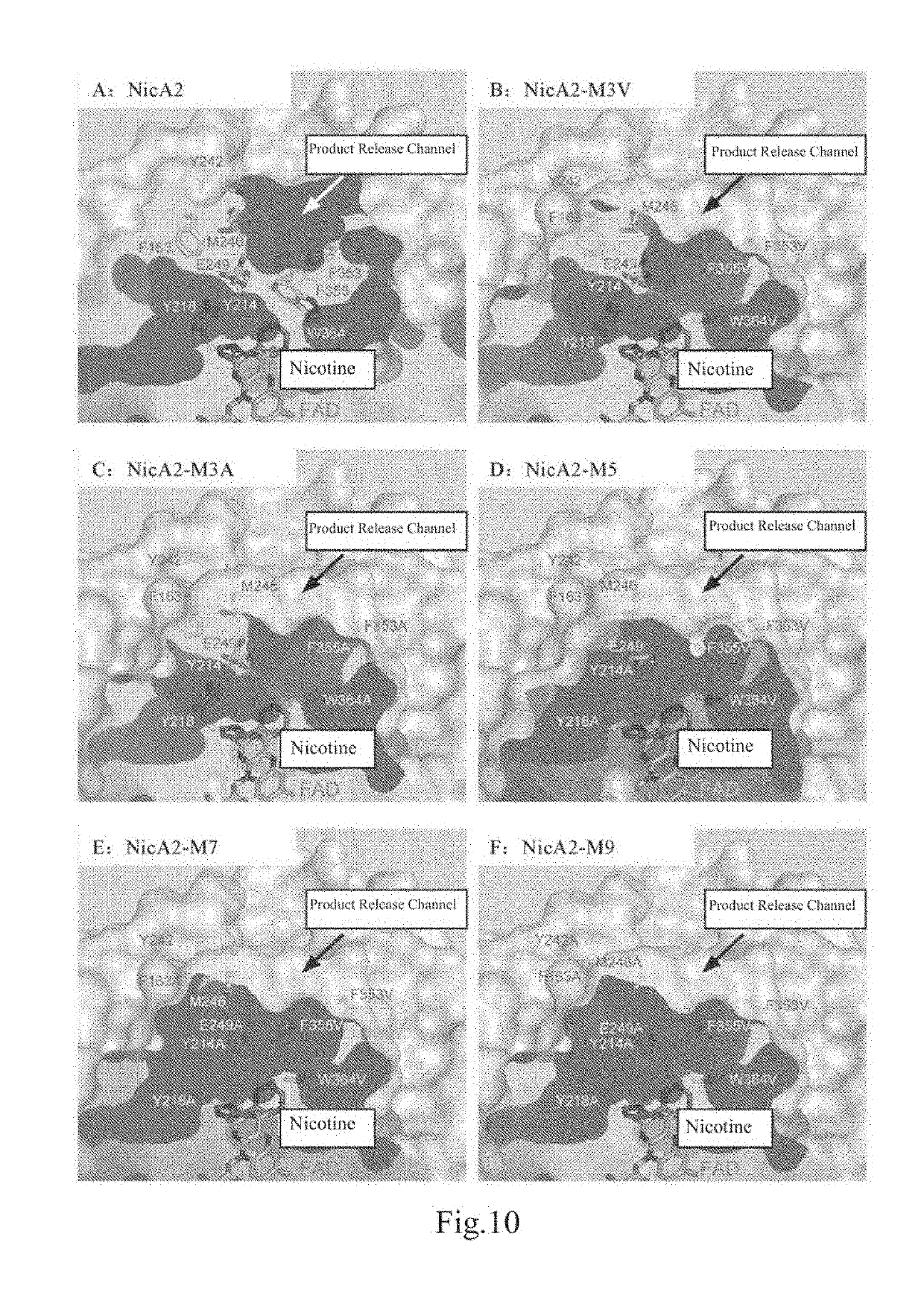

Enzyme and application thereof

ActiveUS20190153403A1High catalytic efficiencyImprove nicotine transformation abilityNervous disorderPeptide/protein ingredientsArtificial enzymeSide chain

Provides an artificial enzyme obtained by improving upon a sequence of a natural nicotine dehydrogenase, wherein the improvement comprises replacing at least one amino acid hindering product release with an amino acid with smaller side chains, thereby improving a catalytic rate.

Owner:SHANGHAI JIAO TONG UNIV

Membrane catalytic heater

InactiveUS7708553B2Stable rateImprove efficiencyFurnace componentsOrganic-compounds/hydrides/coordination-complexes catalystsProcess engineeringEngineering

This invention discloses a portable catalytic combustion heater. Fuel vapor and air are supplied to a catalyst which promotes the flameless combustion of the fuel, releasing heat. The fuel is supplied as a liquid, passes through a selectively permeable membrane such that fuel vapor exits the membrane and is fed to the catalyst. Additional features such as porous supports and means of enhancing and diminishing the catalytic rate of combustion and controlling the heat output are also shown. This invention can be used to heat apparel, blankets, food, dwellings, containers, machinery, insect attractants, humidifiers, and perfume generators.

Owner:GHT GLOBAL HEATING TECH

Preparation method of inorganic biological composite nano-catalyst Au@A beta 2535

ActiveCN107175129AHas catalytic propertiesOptimal Control StructureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystCatalytic effect

The invention provides a preparation method of inorganic biological composite nano-catalyst Au@A beta 2535. The preparation method includes steps of 1, preparing polypeptide solution dispersed by hexafluoroisopropanol; 2, preparing polypeptide powder; 3, preparing polypeptide solution; 4, preparing catalyst Au@A beta 2535. The preparation method is simple and moderate; the prepared gold / polypeptide inorganic biological composite nano-catalyst is uniform and controllable in structure, and good in catalytic effect; meanwhile, the solution and polypeptide form can be changed; different forms of catalysts with different catalytic rates can be prepared.

Owner:JIANGSU UNIV

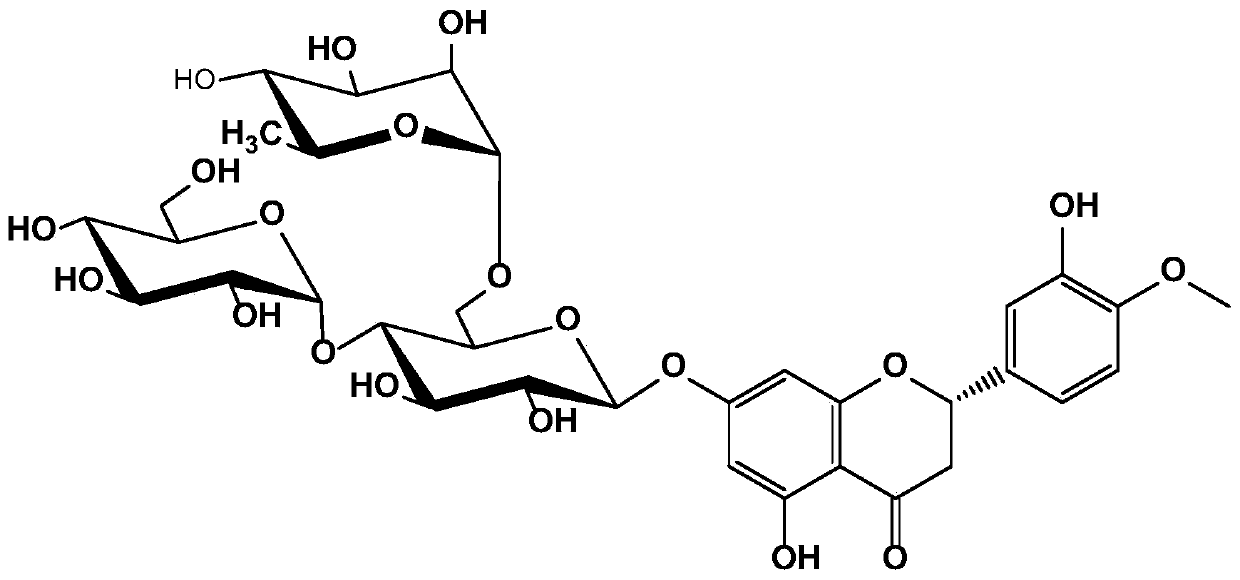

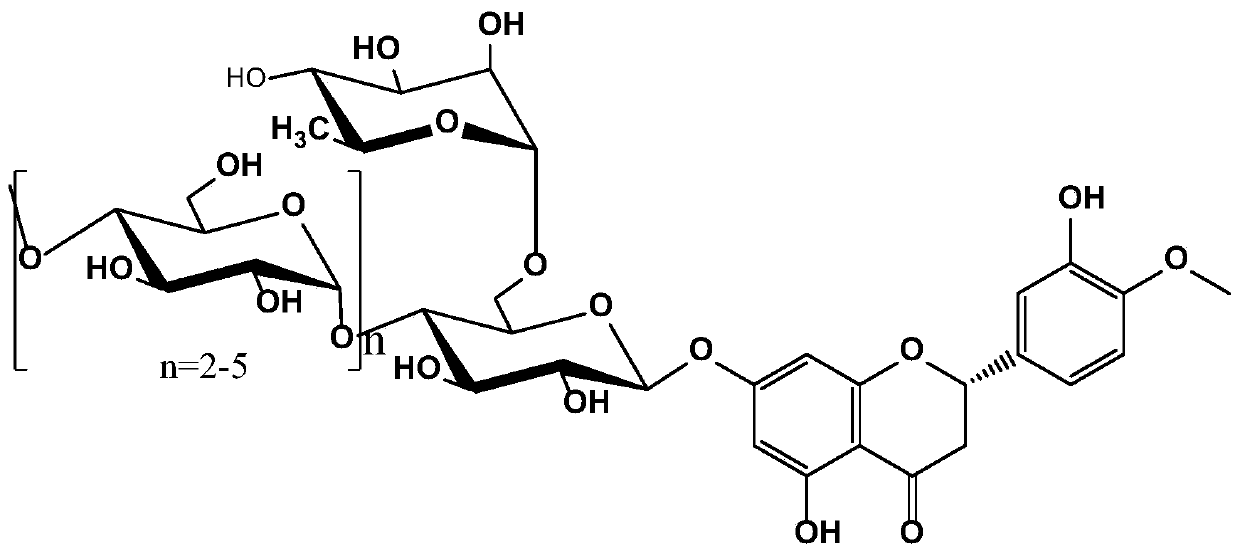

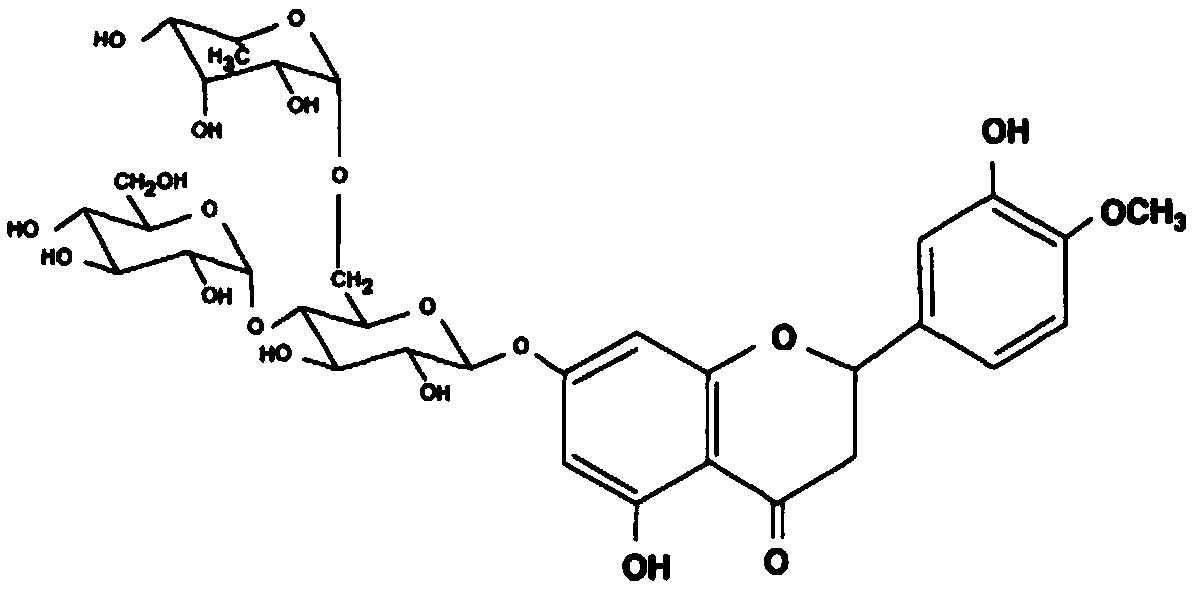

Application of alkaline cyclodextrin glucosyltransferase in production of alpha-glucosylhesperidin

InactiveCN110982865AEfficient preparationIncrease the amount of feedBacteriaMicroorganism based processesBiotechnologyEscherichia coli

The invention discloses application of alkaline cyclodextrin glucosyltransferase in production of alpha-glucosylhesperidin. The amino acid sequence of the alkaline cyclodextrin glucosyltransferase isas shown in SEQ ID NO. 2. The alkaline cyclodextrin glucosyltransferase disclosed by the invention can realize high-level secretory expression in escherichia coli, so efficient preparation of the alkaline cyclodextrin glucosyltransferase is realized; the conversion rate of hesperidin with a concentration of 0.5-15% can reach 58-88% within 16 hours; and the alkaline cyclodextrin glucosyltransferasehas the characteristics of high substrate feeding amount, high catalytic rate and high substrate conversion rate and is suitable for industrial production of alpha-glucosylhesperidin.

Owner:ZHEJIANG UNIV OF TECH

Spiroketal frame bidentate phosphoramidite ligand as well as preparation method and application thereof

ActiveCN102746338BHigh mole percentageIncrease catalytic rateGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsIsomerizationDiastereomer

The invention discloses a spiroketal frame bidentate phosphoramidite ligand as well as a preparation method and an application thereof. The ligand is the compound shown in a formula I or II or the enantiomer, racemate or diastereoisomer of the compound; and the ligand is prepared by condensation reaction of the compound in the formula I or II, and phosphorus-chlorine compounds. The spiroketal frame bidentate phosphoramidite ligand disclosed by the invention and transition metal salt form a complex, and the complex can be used for terminal olefine hydroformylation or isomerization-hydroformylation of internal olefins; and moreover, the spiroketal frame bidentate phosphoramidite ligand has high catalytic rate, good selectivity and practical value.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

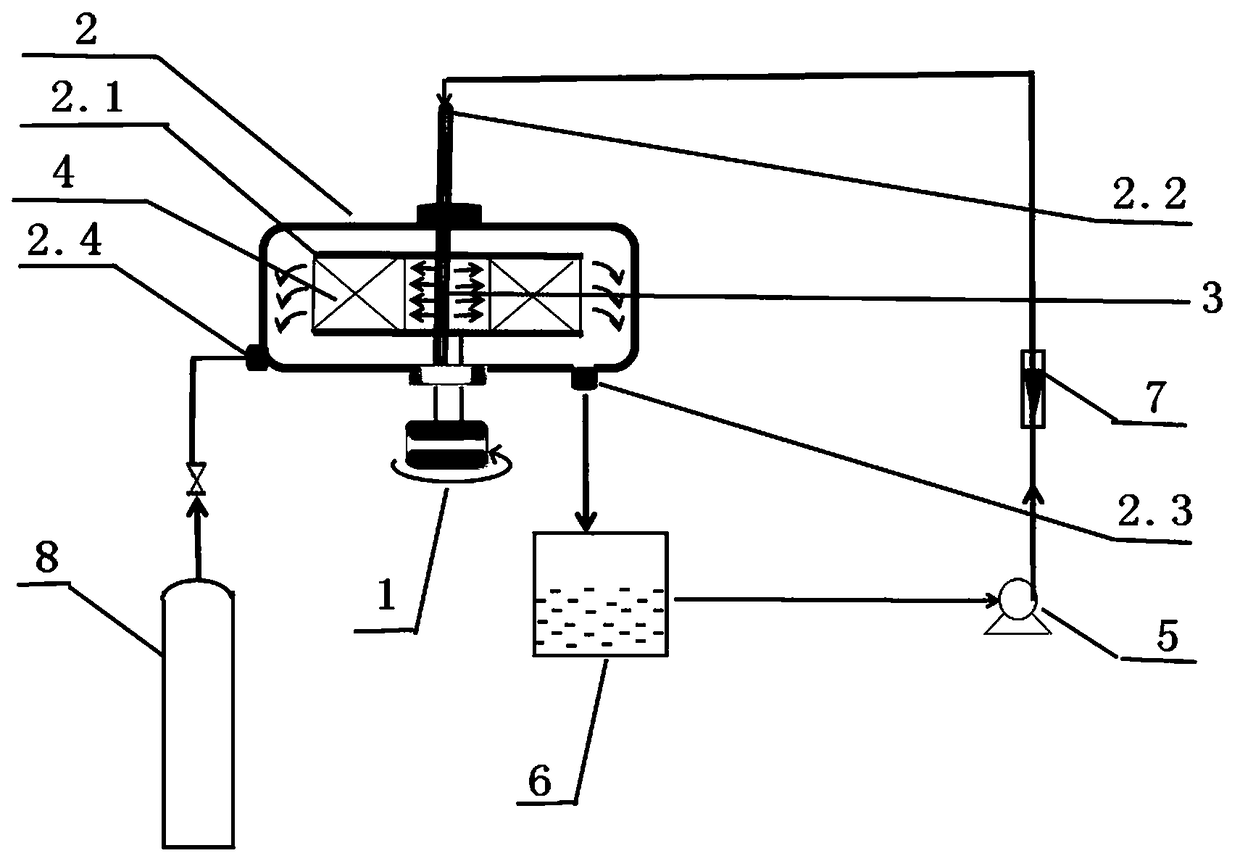

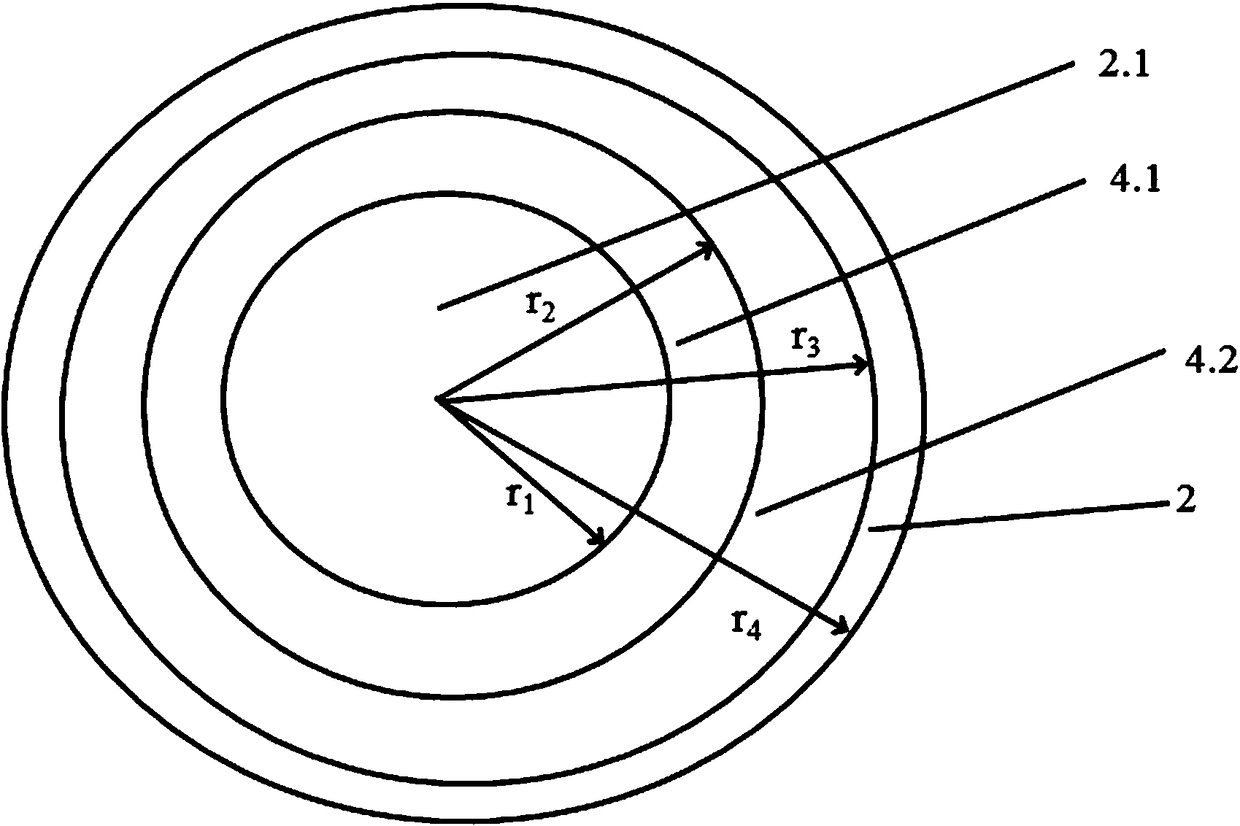

Method and device for ultra-gravity catalytic wet oxidation of phenolic wastewater

ActiveCN108341478AImprove purification effectHelp removeWater contaminantsWater/sewage treatment by sorptionSorbentDual action

The invention belongs to the technical field of phenolic wastewater treatment. In order to solve the problems of slow adsorption rate of adsorption materials on the surface of an adsorbent, slow catalytic rate, difficult removal of products and the like during the prior catalytic wet oxidation process of phenolic wastewater, the invention provides a method and device for ultra-gravity catalytic wet oxidation of the phenolic wastewater. The phenolic wastewater is fed into an ultra-gravity rotary packing bed by a liquid inlet pipe; initial distribution is carried out under the action of a liquiddistributor; then the phenolic wastewater is driven by a rotor to enter an adsorbent surface supporting a catalyst; simultaneously, the phenolic wastewater is degraded with an oxidizing agent under the dual action of the catalyst and ultra gravity; and finally the degraded wastewater is discharged into a liquid storage tank through a liquid outlet pipe. The process has the advantages of large processing capacity and small device volume, the integration of adsorption and degradation is realized, and the problems of transmission resistance, low catalytic rate and the like in a conventional wetoxidation method are greatly reduced. The method and device provided by the invention are suitable for treating various phenolic wastewater, such as coking wastewater, gasification waste water and thelike.

Owner:ZHONGBEI UNIV

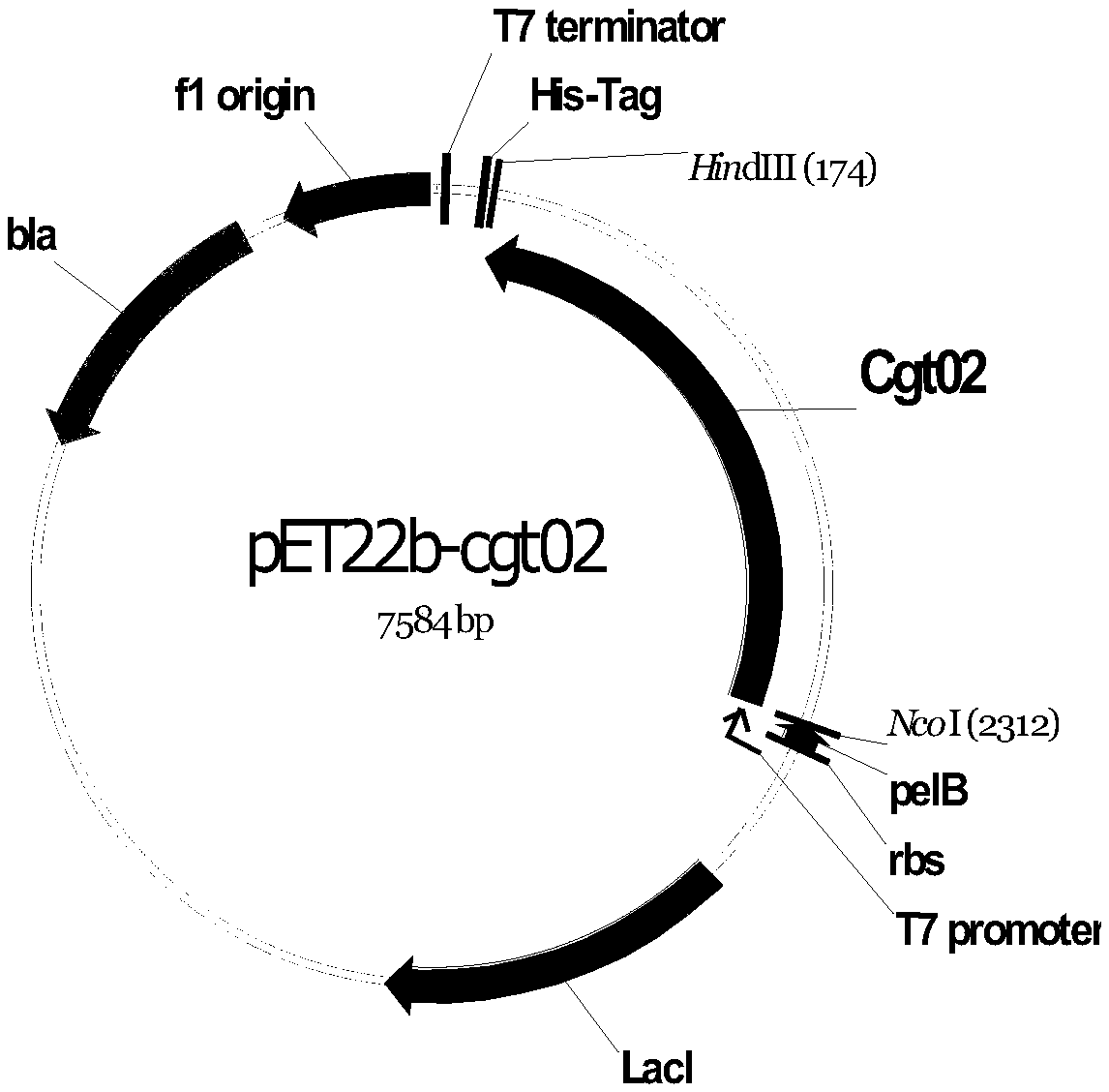

Application of cyclodextrin glycosyltransferase in production of alpha-glycosyl hesperidin

InactiveCN109652481AEfficiently catalyzes glycosylation reactionsHigh substrate dosageMicroorganism based processesFermentationActive componentThermal stability

The invention discloses application of cyclodextrin glycosyltransferase in production of alpha-glycosyl hesperidin. An active component of a bacterial agent for producing alpha-glycosyl hesperidin isescherichia coli IEF-cgt02, the cyclodextrin glycosyltransferase with high thermal stability can be efficiently synthesized in cells, and dextrin is adopted as a glycosyl donor to efficiently catalyzea glycosylation reaction of hesperidin. 2-15% of alpha-glycosyl hesperidin is produced by biocatalysis of the bacterial agent, the reaction time is controlled within 24 hours, and the conversion rateof hesperidin reaches 70% or above. The cyclodextrin glycosyltransferase has the advantages of high substrate feeding amount, catalysis rate and substrate conversion rate and is suitable for industrial production of alpha-glycosyl hesperidin.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of platinum catalyst for liquid silicone rubber

The invention provides a preparation method of a platinum catalyst for liquid silicone rubber. The preparation method comprises the following steps: S1, adding sodium bicarbonate into an alcohol solvent to be dissolved; S2, under anaerobic condition, adding chloroplatinic acid, vinyl tetramethyl disiloxane and maleate compound into S1 to react; S3, after reaction of S2 is finished, filtering solid out, washing for many times, combining filtrate, and removing low molecules in the filtrate to obtain the platinum catalyst for the liquid silicone rubber. The prepared platinum catalyst for the liquid silicone rubber disclosed by the invention is applied to the liquid silicone rubber, can effectively adjust activity and speed of addition reaction between vinyl polysiloxane and hydrogen polysiloxane, has excellent catalytic rate, obviously improves operable time of addition type silicone rubber and normal-temperature storage time of the single-component addition type liquid silicone rubber, obviously improves flatness and smoothness of the surface of a cured part after curing and is suitable for single-component or double-component organic silicone adhesives. The preparation method disclosed by the invention has the advantages of simple operation technology, high product yield and suitability for being popularized and applied in industry.

Owner:江苏矽时代材料科技有限公司

Water treatment method for ultrasonically improving oxidation of pollutant with permanganate

InactiveCN102173524BEnhanced ability to catalyze permanganate oxidationImprove oxidation capacityMultistage water/sewage treatmentDecompositionManganese

The invention relates to a water treatment method, particularly a water treatment method for ultrasonically improving oxidation of pollutants with permanganates, and aims to solve the problems in the prior art the speed of oxidation with permanganates is slow, the treatment effect is not stable, the dispersion of produced manganese dioxide nanoparticles is poor and the catalytic rate is low. The method has three forms. The first form comprises the following steps of: pre-treating water; feeding the effluent into a mixing pond, a flocculation pond and a precipitation pond in sequence; filtering the effluent; feeding to a clear water pond and sterilizing. The second form comprises the following steps of: feeding the water into a mixing pond and then pre-treating the water, feeding the effluent to a flocculation pond and then a precipitation pond, filtering the effluent, feeding to a clear water pond and sterilizing. The third form comprises the following steps of: feeding the water intoa mixing pond; adding permanganates, inducers and coagulants under ultrasonic action; feeding the effluent to a flocculation pond and then a precipitation pond; filtering the effluent; feeding to a clear water pond and sterilizing. The method has stable operating effects, is favorable for the dispersion of manganese dioxide nanoparticles which are used as the reduction product of permanganates, improves the catalytic ability of manganese dioxide in oxidation of permanganates, and promotes the decomposition of permanganates to produce highly-active intermediate-state manganese.

Owner:HARBIN INST OF TECH

Membrane catalytic heater

InactiveUS8585396B2Stable rateImprove efficiencyFurnace componentsCapillary burnersProcess engineeringPermselective membrane

A portable catalytic combustion heater, wherein fuel vapor (11) and air (10) are supplied to a catalyst (6) which promotes the flameless combustion of fuel and releases that. The fuel is supplied as a liquid, passes through a selectively permeable membrane (8) such as fuel vapor exits the membrane and is fed to the catalyst (6). Additional features include porous supports and means of enhancing and diminishing the catalytic rate of combustion and controlling the heat output.

Owner:GHT GLOBAL HEATING TECH

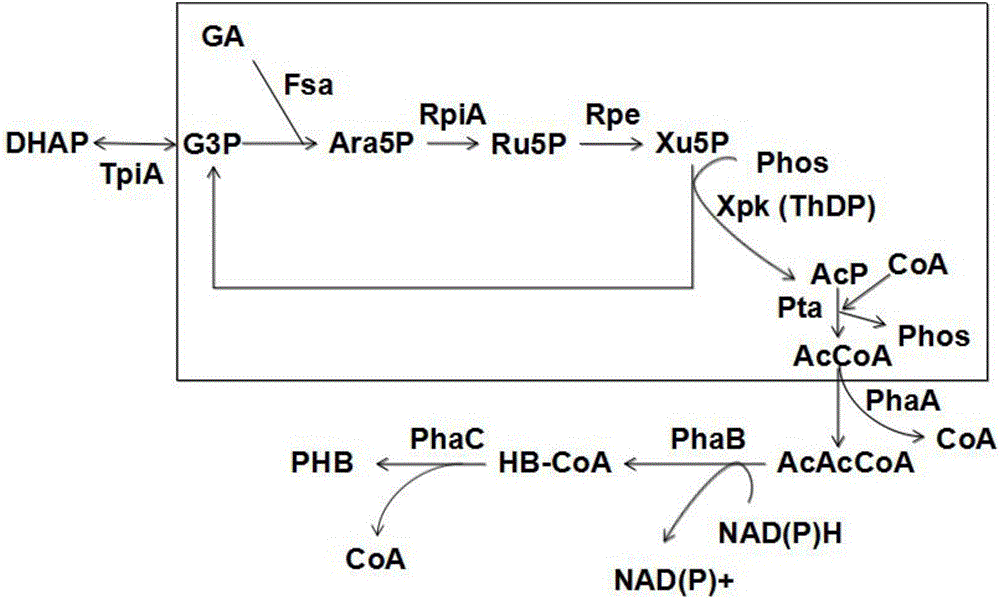

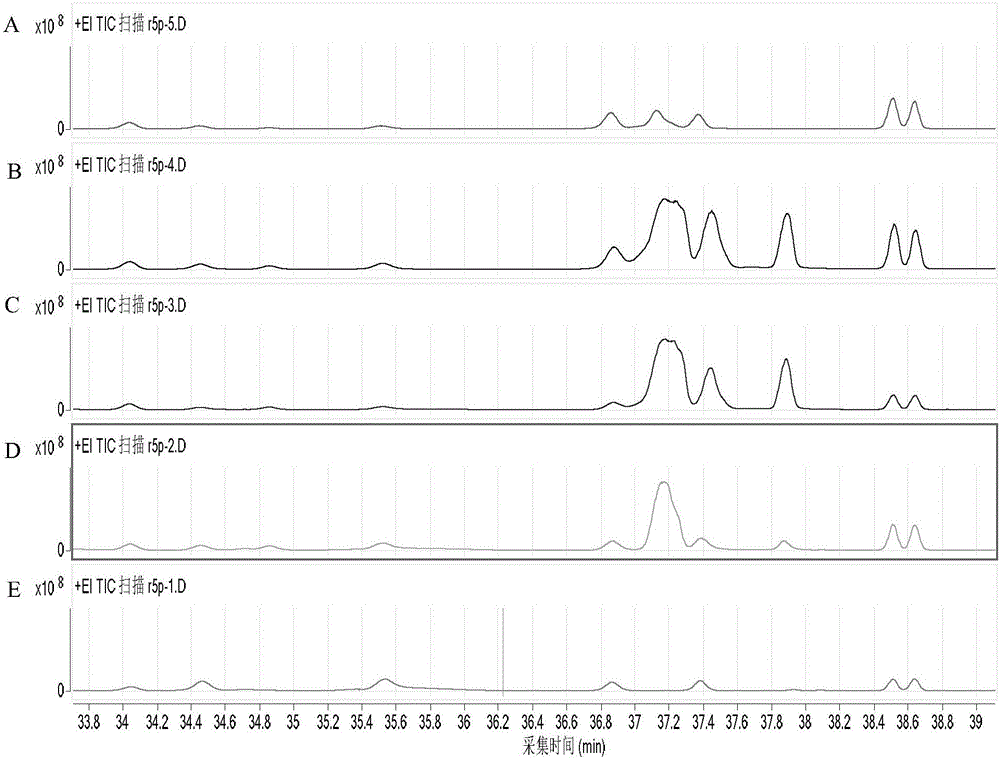

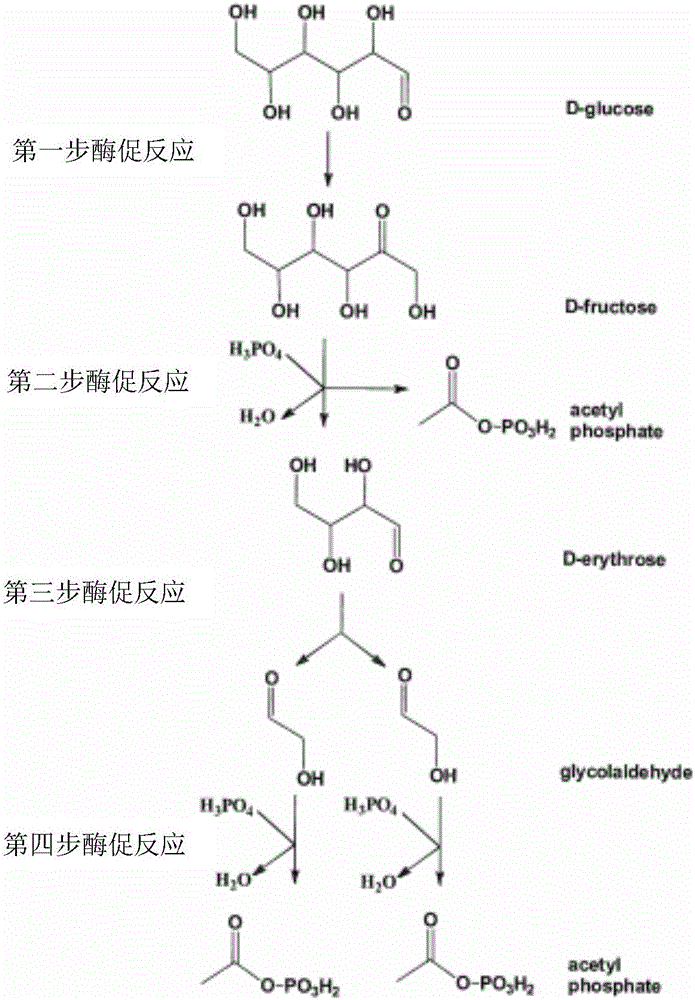

New way for synthesizing acetyl coenzyme A and derivative product thereof using glycolic aldehyde

ActiveCN106755172AHigh affinityIncrease enzyme activityFermentationPhosphoric acidBatch fermentation

The invention discloses a new way for synthesizing acetyl coenzyme A and a derivative product thereof using glycolic aldehyde. The method comprises reaction that glycolic aldehyde reacts with 3-glyceraldehyde phosphate under enzyme catalysis to generate 5-phosphoric acid arabinose, wherein the enzyme is selected from aldolase, transaldolase and isozyme thereof and mutate enzyme. The method is relatively high in catalytic rate; the theoretical yield of carbon of a reaction route is 100%; the carbon loss avoided; G3P, an enzyme and a coenzyme all can be recycled; the reaction efficiency is relatively high; and the cost is reduced. In addition, the coenzymes RpiA and Rpe from a pentose phosphate pathway are high in affinity with a substrate and high in catalytic activity. According to the method, more obvious advantages are developed in the production processes, of in vitro continuous polyenzyme catalysis, fed-batch fermentation and continuous fermentation, capable of controlling the substrate level.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Apparatus and method for catalytic oxidation of magnesium sulfite, and cobalt nitrate/ZSM-5 molecular sieve catalyst and preparation method thereof

ActiveCN110420659AAchieve crystallization recoveryNo pollution in the processMolecular sieve catalystsCatalyst activation/preparationCatalytic oxidationMagnesium sulfite

The invention provides an apparatus and method for catalytic oxidation of magnesium sulfite, and a cobalt nitrate / ZSM-5 molecular sieve catalyst and a preparation method thereof, belonging to the technical field of flue gas desulphurization. According to the invention, a preparation box is utilized to pretreat a magnesium sulfite raw material; a reaction box is used for performing a catalytic oxidation reaction; an evaporator is employed for concentrating magnesium sulfate slurry obtained after catalytic oxidation; a cooling and crystallization box is used for cooling and crystallizing the concentrated slurry; an obtained solid is discharged directly as a product; and remaining slurry is returned to the evaporator for further concentration. The apparatus provided by the invention is a continuous reaction device, can realize continuous catalytic oxidation of magnesium sulfite, has high production efficiency and low cost, and produces no waste residues or waste liquid in the whole catalytic oxidation process; the cobalt nitrate / ZSM-5 molecular sieve catalyst used in the apparatus of the invention is a solid catalyst, has high catalytic rate and long service life, and can avoid contamination of an oxidation product by a homogeneous catalyst.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

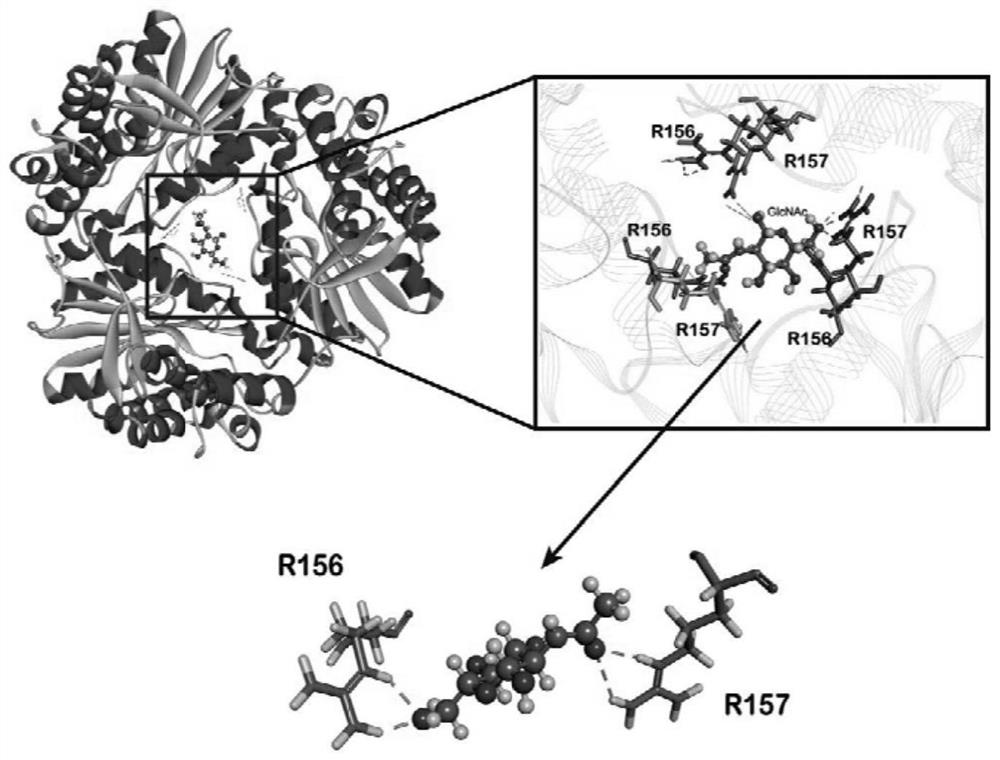

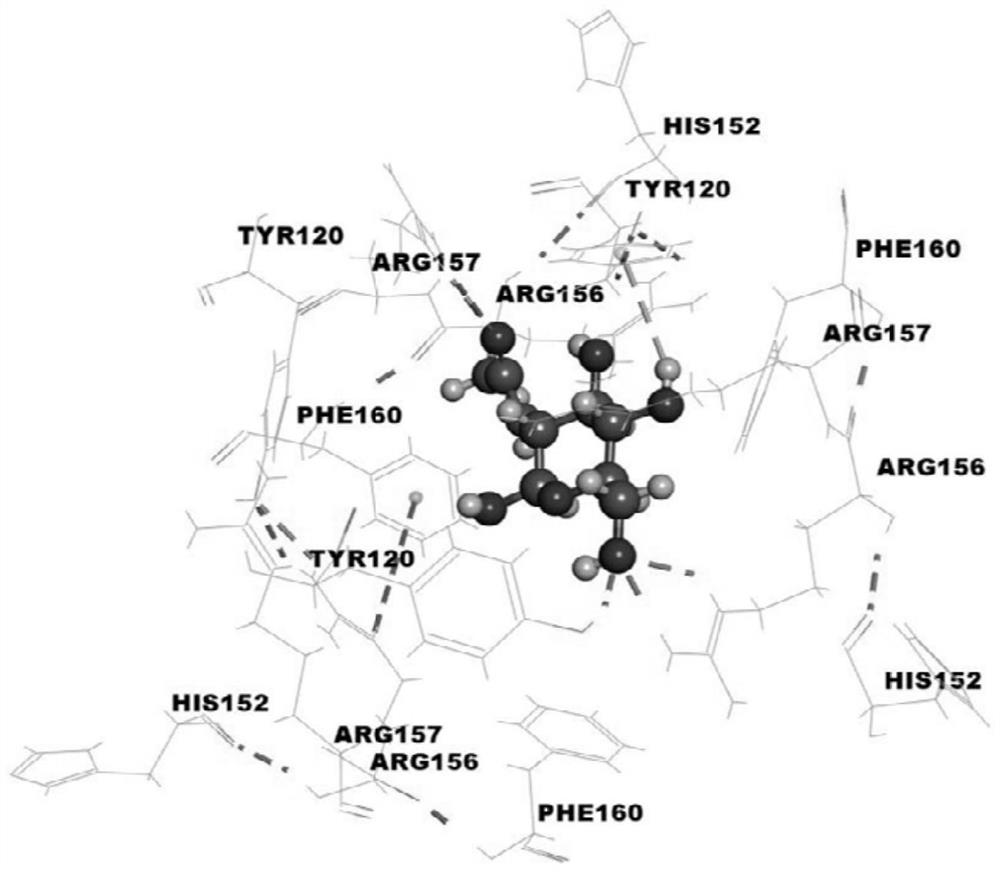

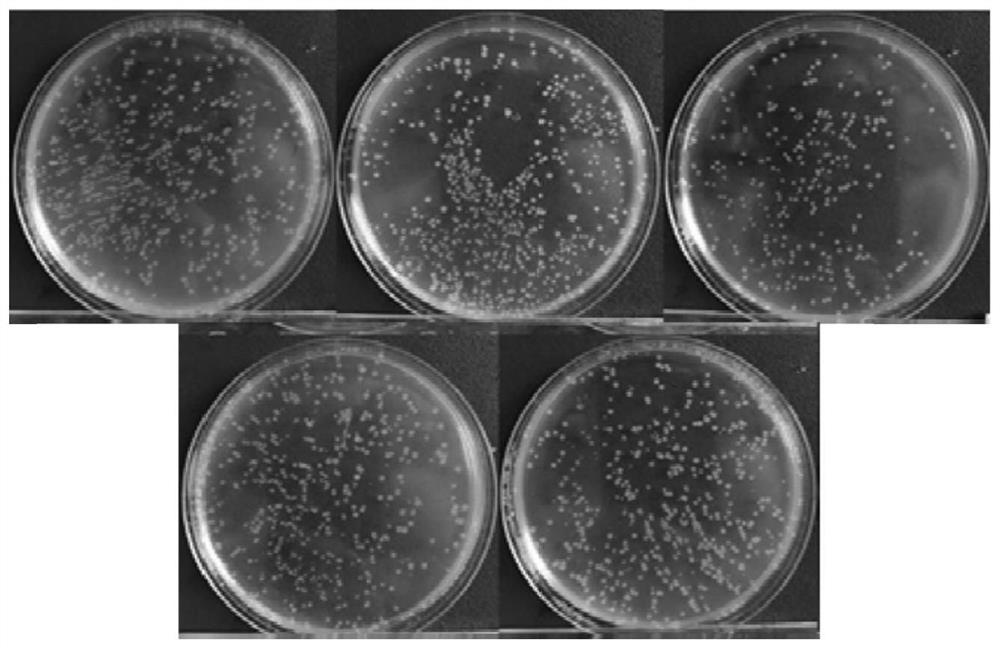

Bacillus subtilis for efficient secretory expression of diacetylchitobiose deacetylase and application thereof

ActiveCN112961850AIncrease speedHigh selectivityPolypeptide with localisation/targeting motifBacteriaChemical synthesisSecretion expression

The invention discloses a bacillus subtilis for efficient secretory expression of diacetylchitobiose deacetylase and application thereof. The molecular structure of the diacetylchitobiose deacetylase Dac and the RBS sequence of an expression vector pP43mut-N1-yncM-Dac are modified, so that the catalytic rate and translation expression rate of the diacetylchitobiose deacetylase Dac are increased, the enzyme activity is improved, and the bacillus subtilis capable of producing glucosamine GlcN at high yield is constructed. Compared with the prior art, the extracellular enzyme activity of the diacetylchitobiose deacetylase can reach 3769.5 U / mL. The conversion method is mild in condition, small in environmental pollution, high in substrate selectivity, specific in target product, high in reaction rate and high in product yield. The method is beneficial to solving the problems of serious pollution, tedious steps and the like in a chemical synthesis method, and is simple in process, easy to control and convenient to popularize and apply.

Owner:SHANDONG RUNDE BIOTECH CO LTD +1

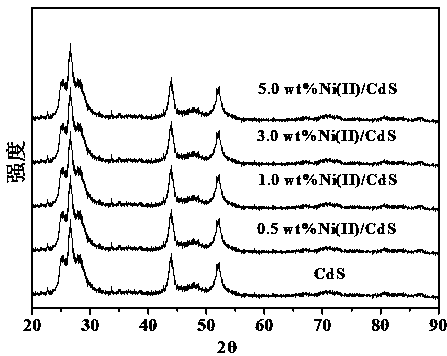

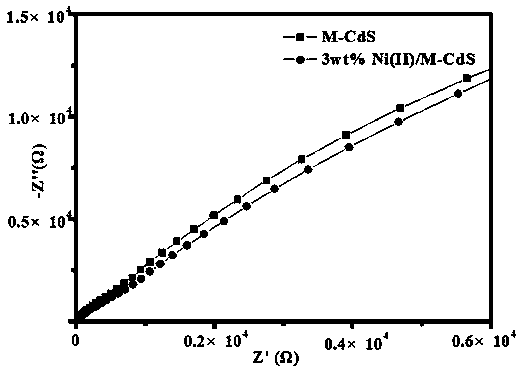

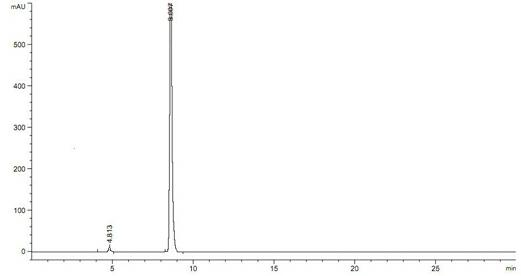

Preparation of nickel (II) supported mixed phase cadmium sulfide material and application of photocatalytic activation saturated hydrocarbon bonds

InactiveCN108786851AImprove photocatalytic performanceImprove conversion ratePhysical/chemical process catalystsOrganic compound preparationBenzaldehydeCatalytic oxidation

The invention discloses a nickel (II) supported mixed phase cadmium sulfide composite material Ni(II) / CdS. The preparation method comprises the following steps: respectively and uniformly dispersing cadmium sulfide and nickel chloride into deionized water, mixing the two solutions after dissolving, namely respectively and uniformly dispersing cadmium sulfide (CdS) and nickel chloride (NiCl2.6H2O)into deionized water, mixing the two solutions after dissolving, stirring and reacting at a temperature of 40-80 DEG C for 0.5-3 hours, washing with deionized water after the reaction is completed, and drying, so as to obtain the target product Ni(II) / CdS. The product Ni(II) / CdS obtained after modifying the mixed crystal CdS by Ni(II) in the invention has excellent photocatalytic performance, is used for a reaction for catalytically oxidizing the toluene into benzaldehyde, has a high catalytic rate (can reach 216.70umolh<-1>g<-1> and high toluene conversion rate (can reach 8.8%), and has highactivation selectivity (can reach 78.8%) on saturated C-H (sp3) in the toluene.

Owner:NORTHWEST NORMAL UNIVERSITY

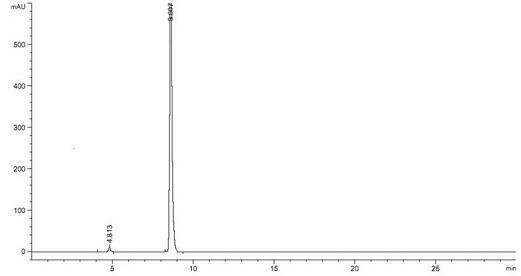

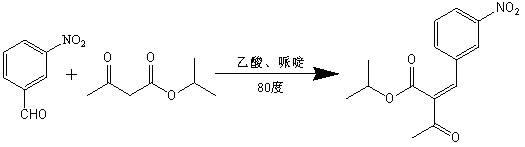

Preparation method of isopropyl 2-(3-nitrobenzylidene)acetoacetate

InactiveCN102491902AIncrease concentrationShort reaction timeOrganic chemistryOrganic compound preparationChromatographic separationSolvent

The invention provides a preparation method of isopropyl 2-(3-nitrobenzylidene)acetoacetate, which comprises the following steps: carrying out condensation reaction on 3-nitrobenzaldehyde and isopropyl acetoacetate as initial raw materials by using an organic solvent as a solvent in the presence of catalysts acetic acid and piperidine for 2-8 hours; after carrying out vacuum concentration on the filtrate at 80 DEG C to 2 / 3-3 / 4 by volume, cooling to -5-5 DEG C while stirring to crystallize over night; and filtering, and recrystallizing with isopropanol to finally obtain the isopropyl 2-(3-nitrobenzylidene)acetoacetate. The invention shortens the reaction time; the isopropanol, which has lower toxicity than methylbenzene and can enhance the product yield and purity, is utilized as the reaction solvent; the catalytic rate of the catalysts is very high, the reaction is quicker and more thorough, and thus, the catalysts can enhance the yield; the invention enhances the yield and saves the cost; and since the refinement method of column chromatography separation, the technique is easy to operate, has the advantage of cheap and accessible raw materials, and thus, is suitable for industrial production.

Owner:QINGDAO HUANGHAI PHARM CO LTD

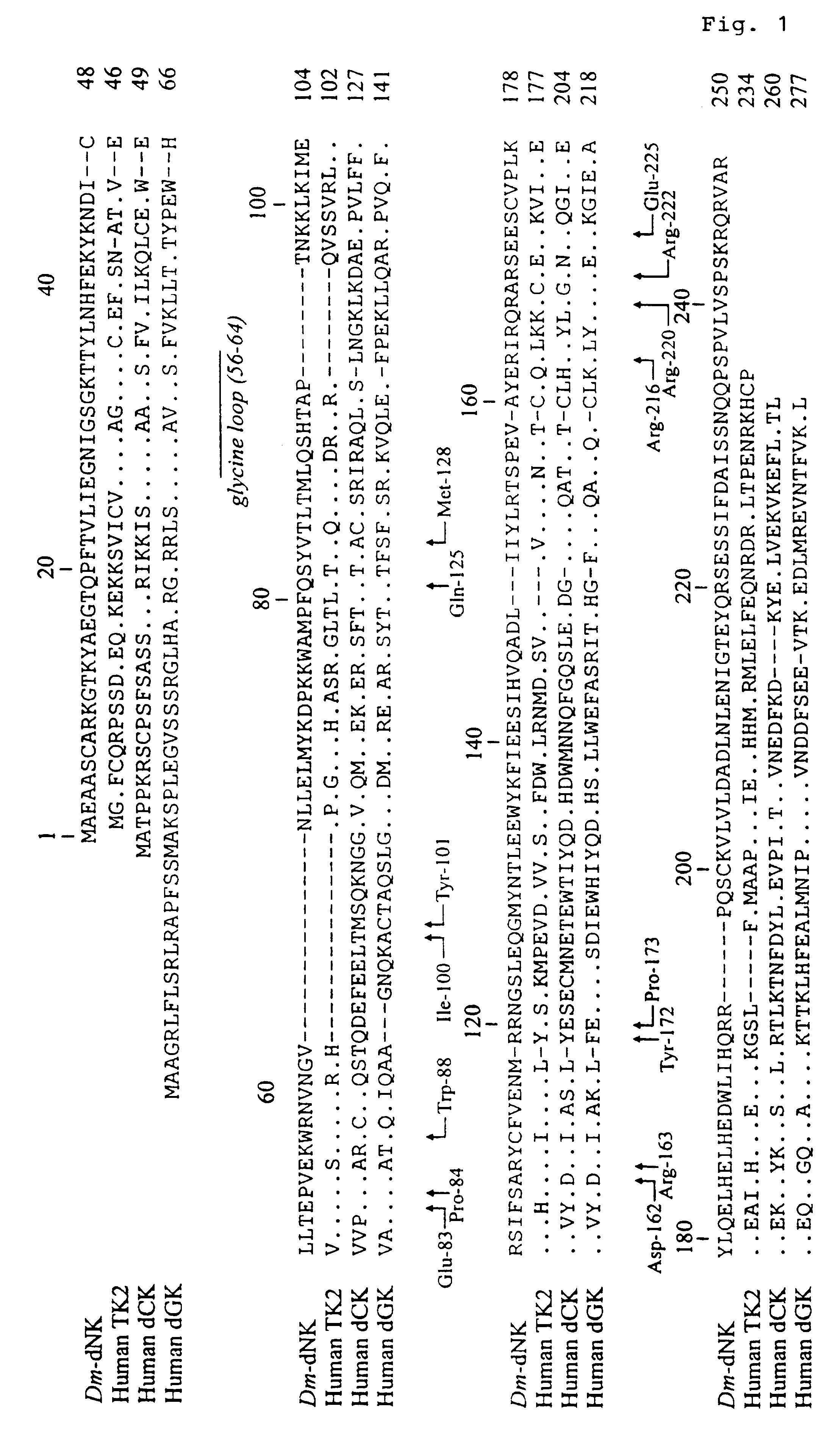

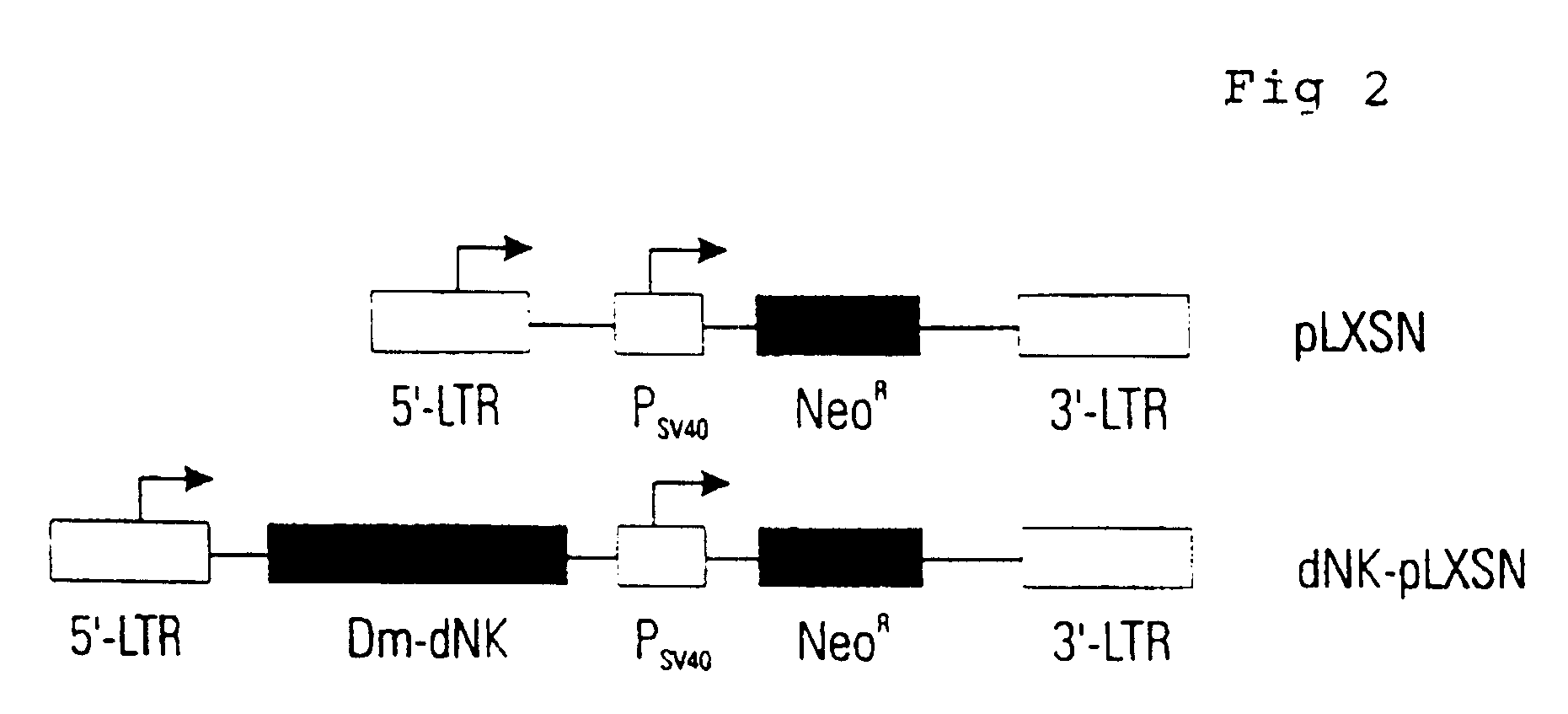

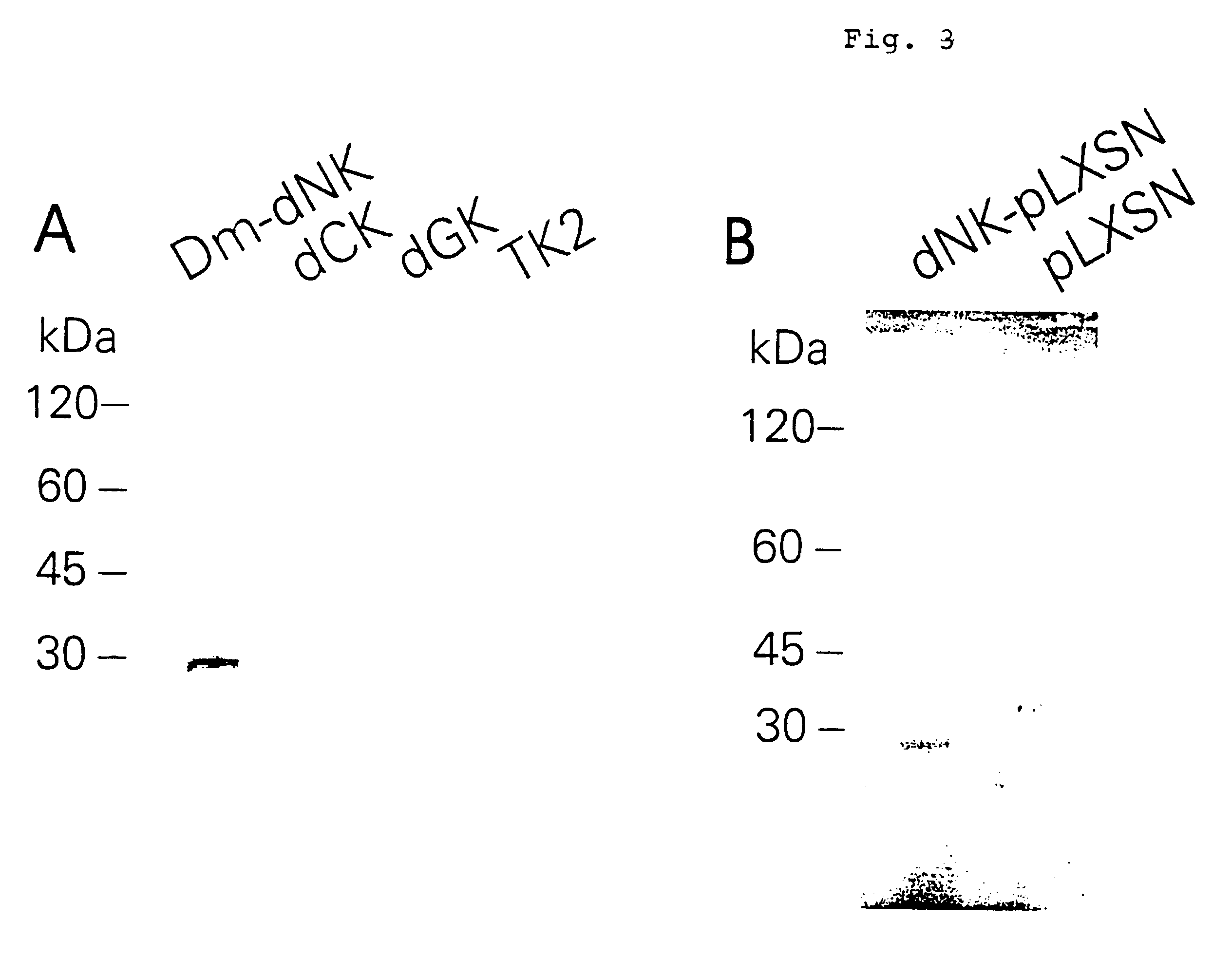

Medical use of gene and vector encoding a multisubstrate deoxyribonucleoside kinase

By inserting a DNA or RNA sequence comprising a subsequence showing a homology of at least 60%, preferably at least 80%, and most preferably at least 90% of the DNA sequence of SEQ. ID. NO. 1 into a cell, that cell will obtain a broad specificity for changing nucleoside analog prodrugs to active drugs by phosphorylation. Likewise this changement will occur at a high catalytic rate. Preferably the DNA sequence is inserted into the cell by transformation with a suitable virus or another suitable vector. Such viruses and vectors also constitute a part of the present invention.

Owner:ZGENE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com