Manufacturing method of membrane electrode of fuel cell

A fuel cell membrane and manufacturing method technology, applied in fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems of rare commercial CCM, unfavorable mass production, troublesome operation process, etc., and avoid technical difficulties. , maintain simplicity, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

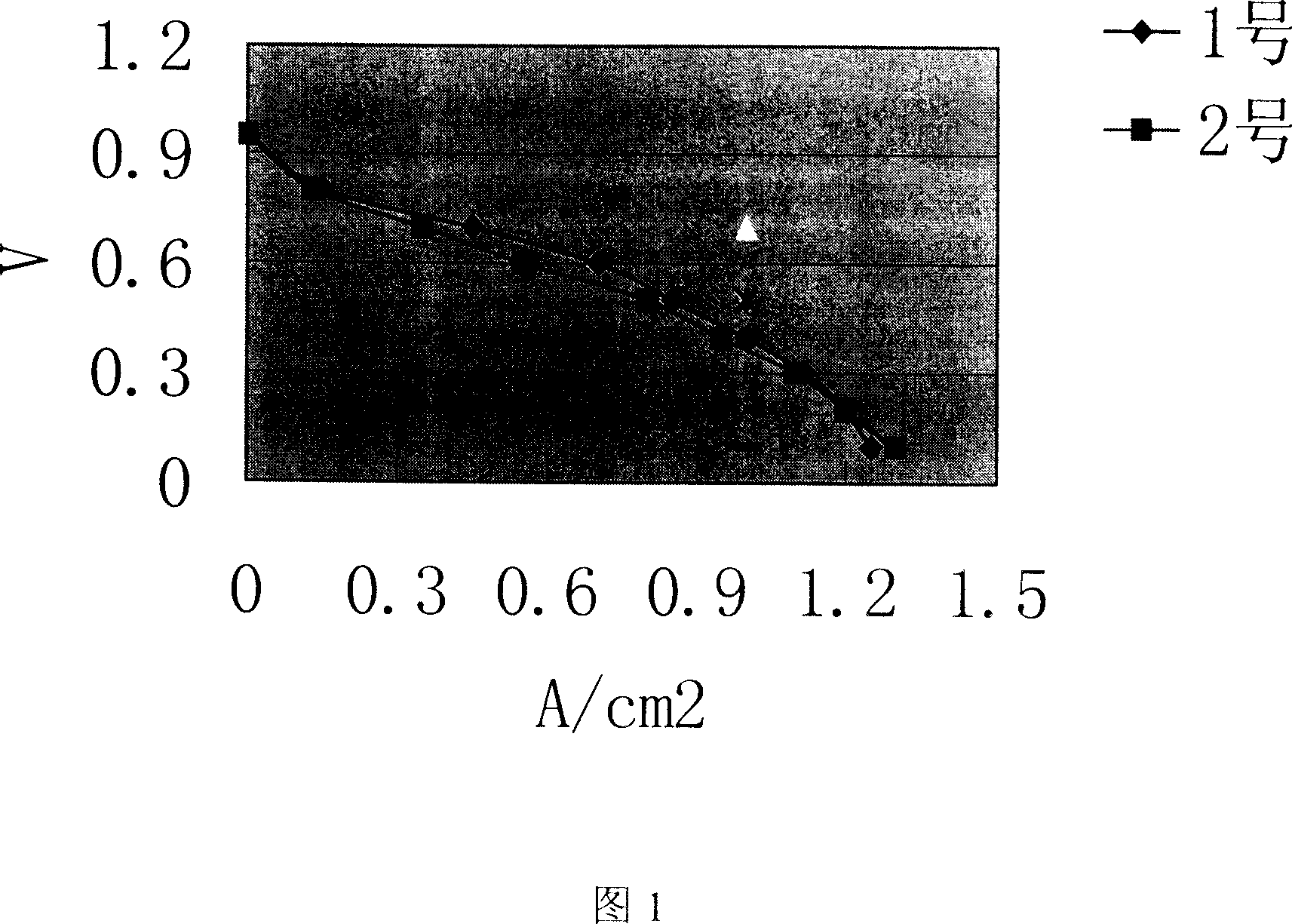

Embodiment 1

[0031] After cleaning the commercially available expanded PTFE microporous membrane (thickness is 4-5 μm, porosity greater than 85%, pore diameter is 0.5-1 μm) with ethanol and put it flat on the 30BC carbon paper produced by SGL company; Nafion (5%wt) solution and 40%wt Pt / C particles are mixed into (Nafion solid: 40%Pt / C catalyst = 1: 3) catalyst dispersion and coated on the PTFE microporous membrane, after drying at 120°C A single electrode with a catalytic layer film attached to the carbon paper was prepared, wherein the loading amount of the catalyst and NAFION mixture was 1.4mg / cm 2 . Then two single electrodes with one NAFION111 membrane were heated at 180°C and 40kg / cm 2 The No. 1 membrane electrode was prepared by hot pressing under pressure for 1 min.

[0032] Contrast test: the commercially available Nafion (5%wt) solution and the particle of 40%wt Pt / C are mixed into (Nafion solid: 40%Pt / C catalyst=1: 3) catalyst dispersion liquid is coated on SGL company's produ...

Embodiment 2

[0034]Commercially available Nafion (5%wt) solution and 40%wt Pt / C particles were mixed into (Nafion solid: 40%Pt / C catalyst=1: 3) catalyst dispersion was applied to expanded PTFE microporous membrane ( The thickness is 4-5μm, the porosity is greater than 85%, and the pore size is 0.5-1μm) to make a catalytic layer membrane, in which part of the catalyst has entered the inside of the membrane pores, and part of the catalyst is located on one surface of the membrane, and a small amount of catalyst passes through the membrane to reach the membrane another surface of the The prepared catalytic layer film was dried at 120°C. Brush NAFION several times on an expanded PTFE film (thickness 10 μm, pore size 0.1 μm, porosity greater than 80%) to prepare a transparent e-PTFE reinforced proton exchange membrane, the thickness measured after preparation is 12 μm. Put the catalyst side of the two catalytic layer membranes against an e-PTFE reinforced proton exchange membrane, at 180°C, 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com