Patents

Literature

1214results about How to "Improve electrochemical activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy for preparing hydrogen by hydrolytic decomposition and preparation thereof

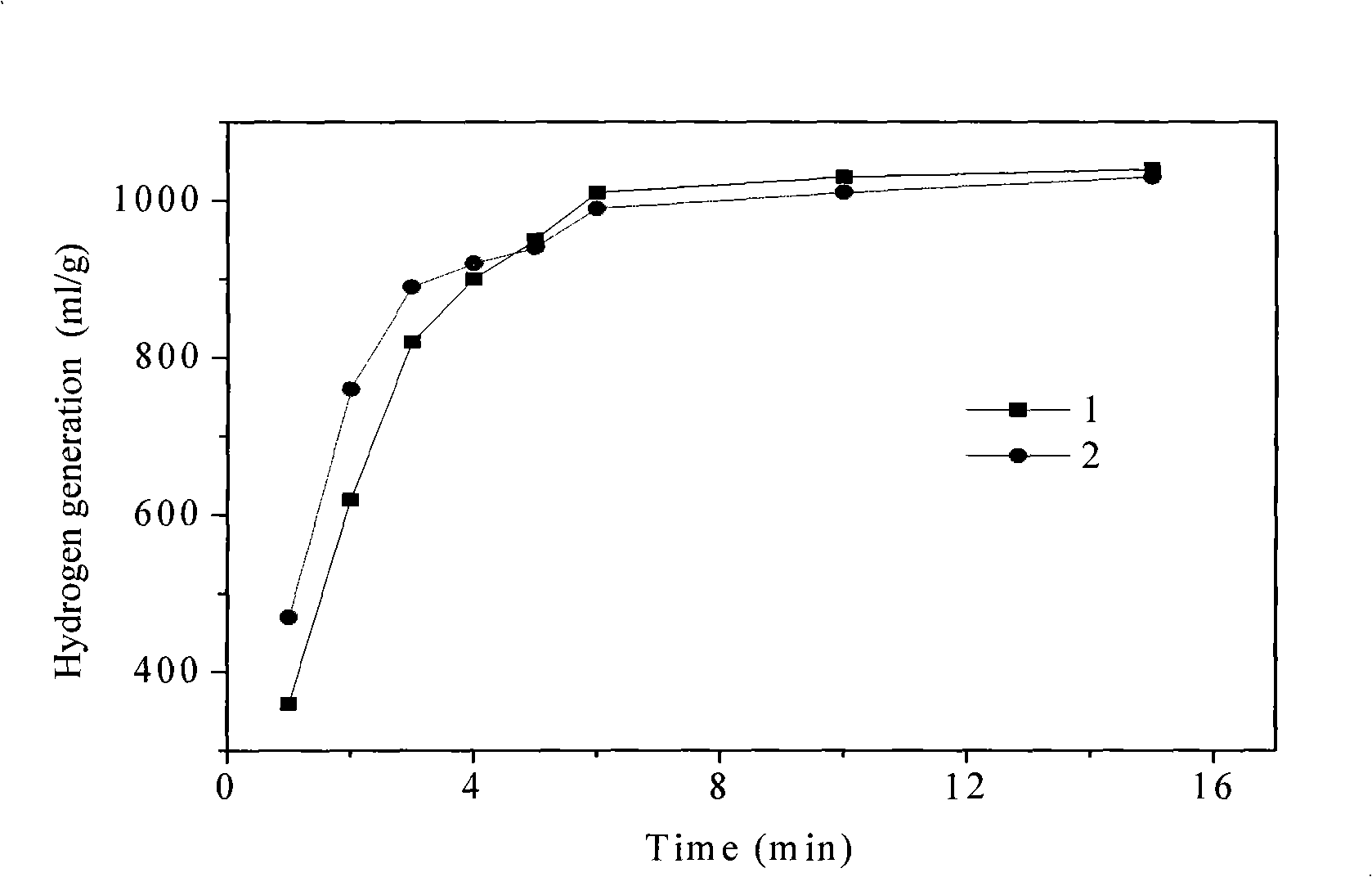

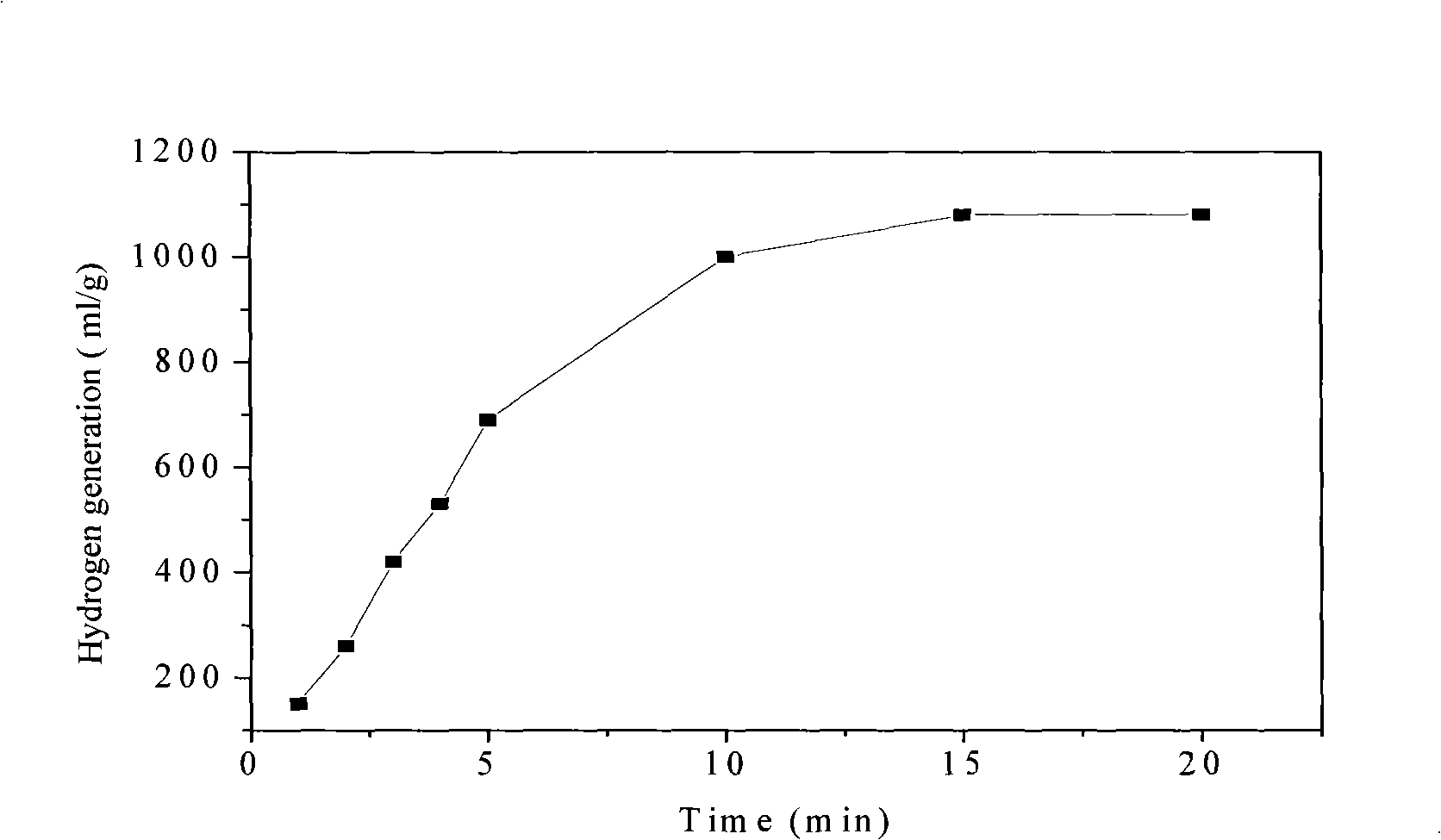

InactiveCN101289163ALower the hydrolysis reaction temperatureImprove electrochemical activityHydrogen productionDecompositionReaction rate

The invention relates to a hydrogen preparation method by hydrolyzing aluminum alloy, in particular to an aluminum alloy which can be hydrolyzed to make hydrogen and a preparation method thereof. The alloy consists of simple-substance metal aluminum, metal bismuth, metals with low melting point and water-soluble compound; according to weight percentage, the content of the metal bismuth is 8 to 50 percent, low melting point metal is 0 to 15 percent, water soluble compound is 1 to 40 percent and metal aluminum is 40 to 90 percent. The method of the invention reduces reaction temperature of aluminum hydrolysis, speeds up reaction rate of aluminum hydrolysis, enhances hydrogen yield rate, simplifies reaction devices as well as reduces hydrogen storage cost. The aluminum alloy prepared by the method of the invention is portable easily, is capable of preparing and providing hydrogen at any time and is applicable to providing humid hydrogen for fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

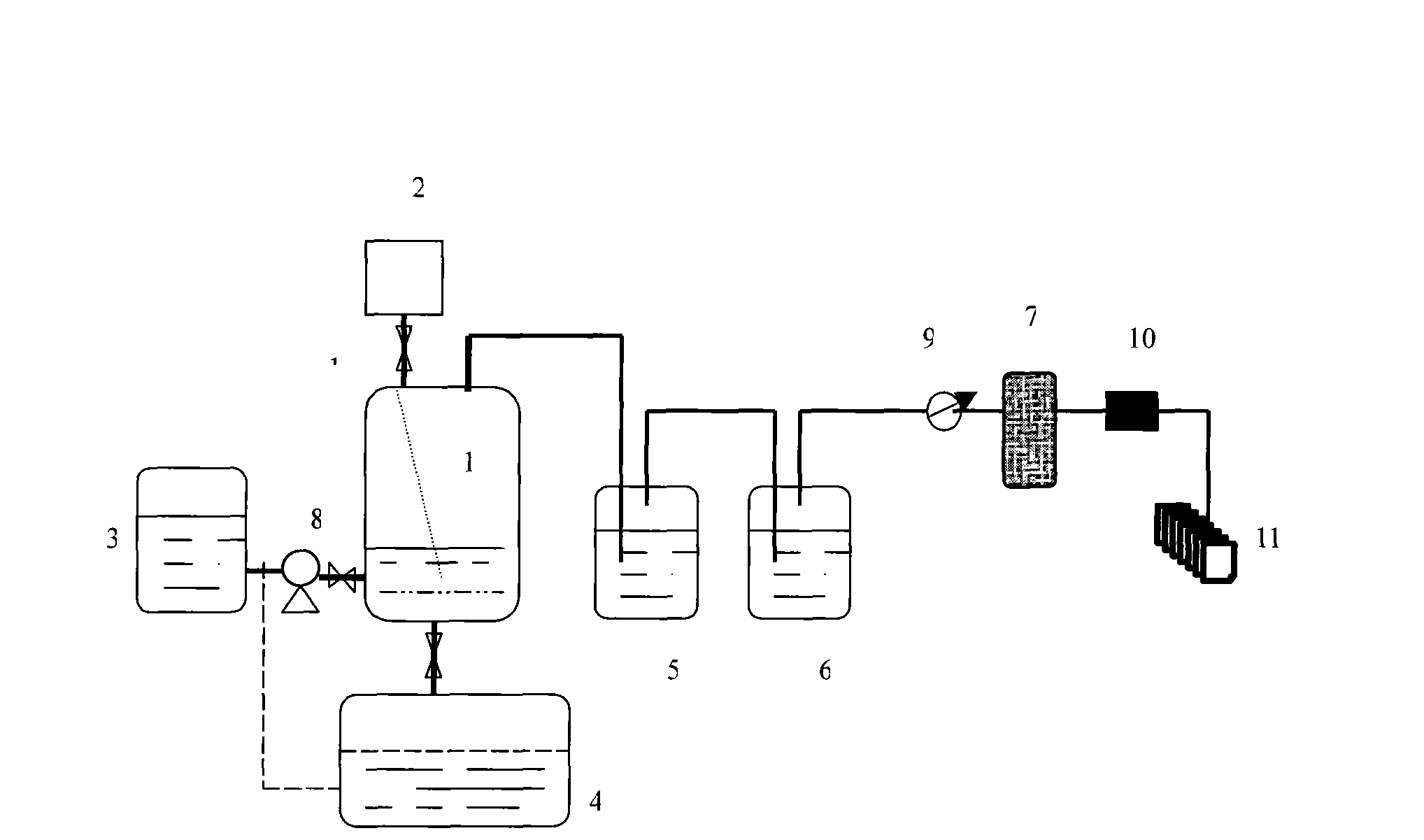

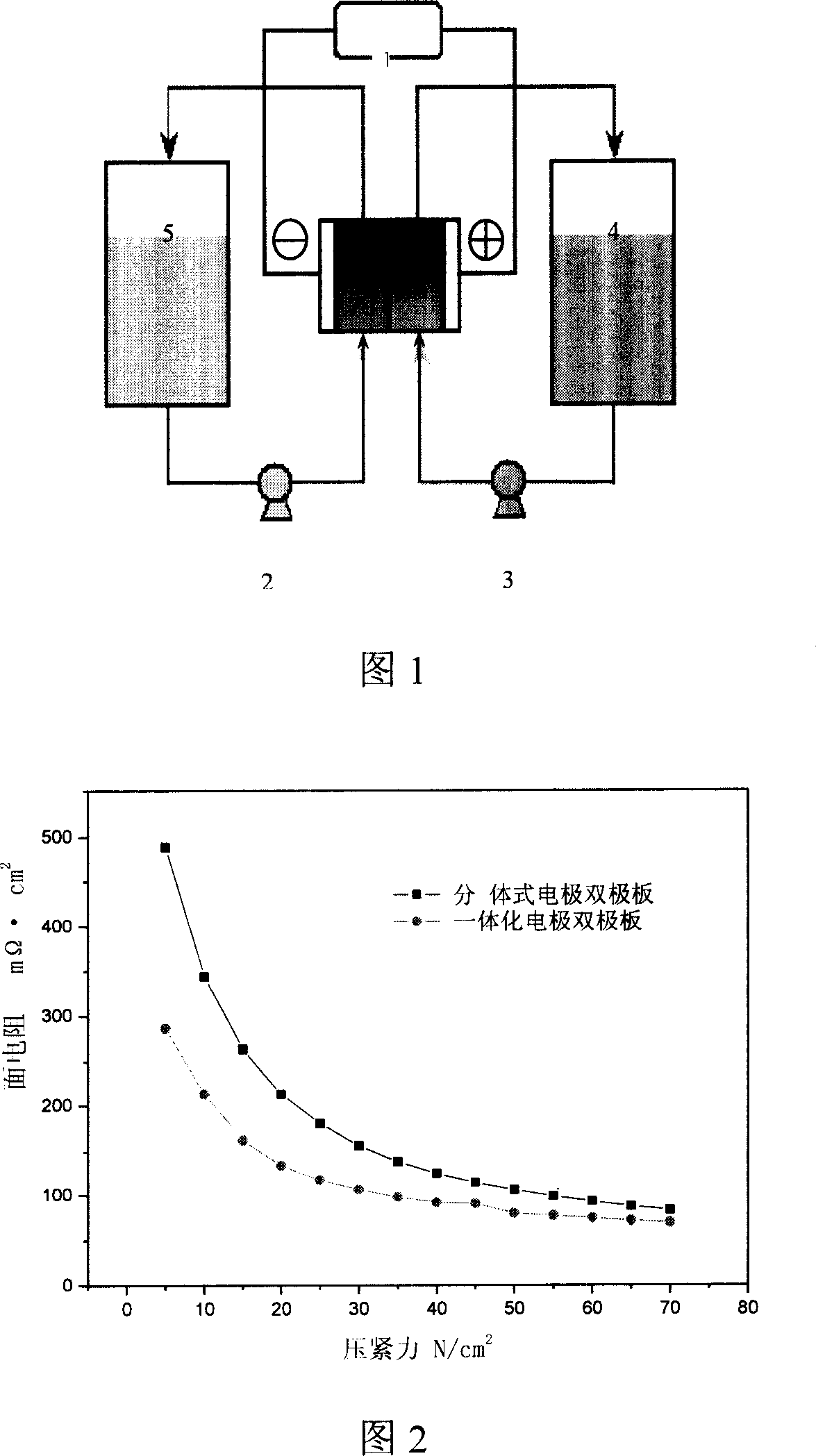

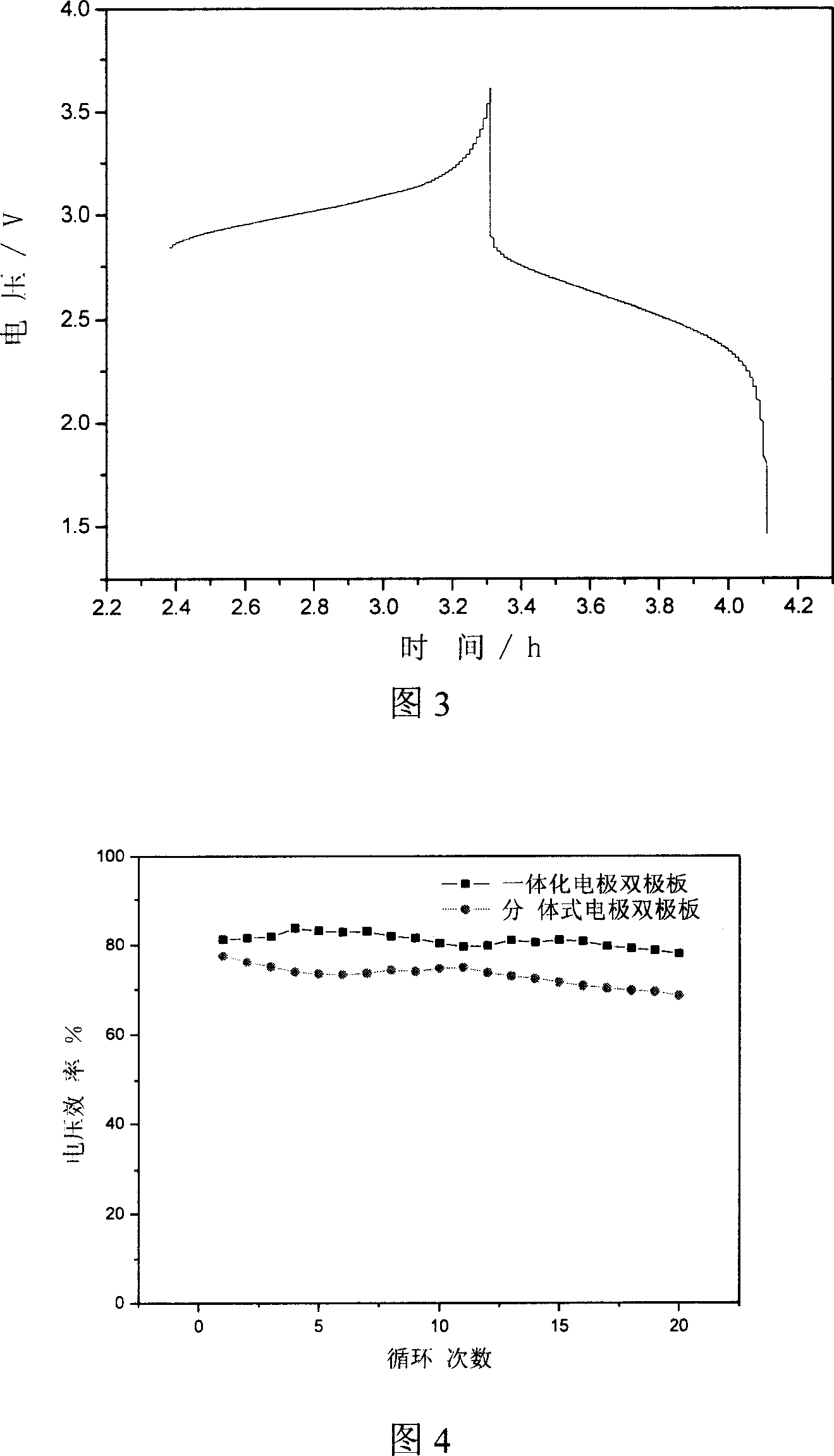

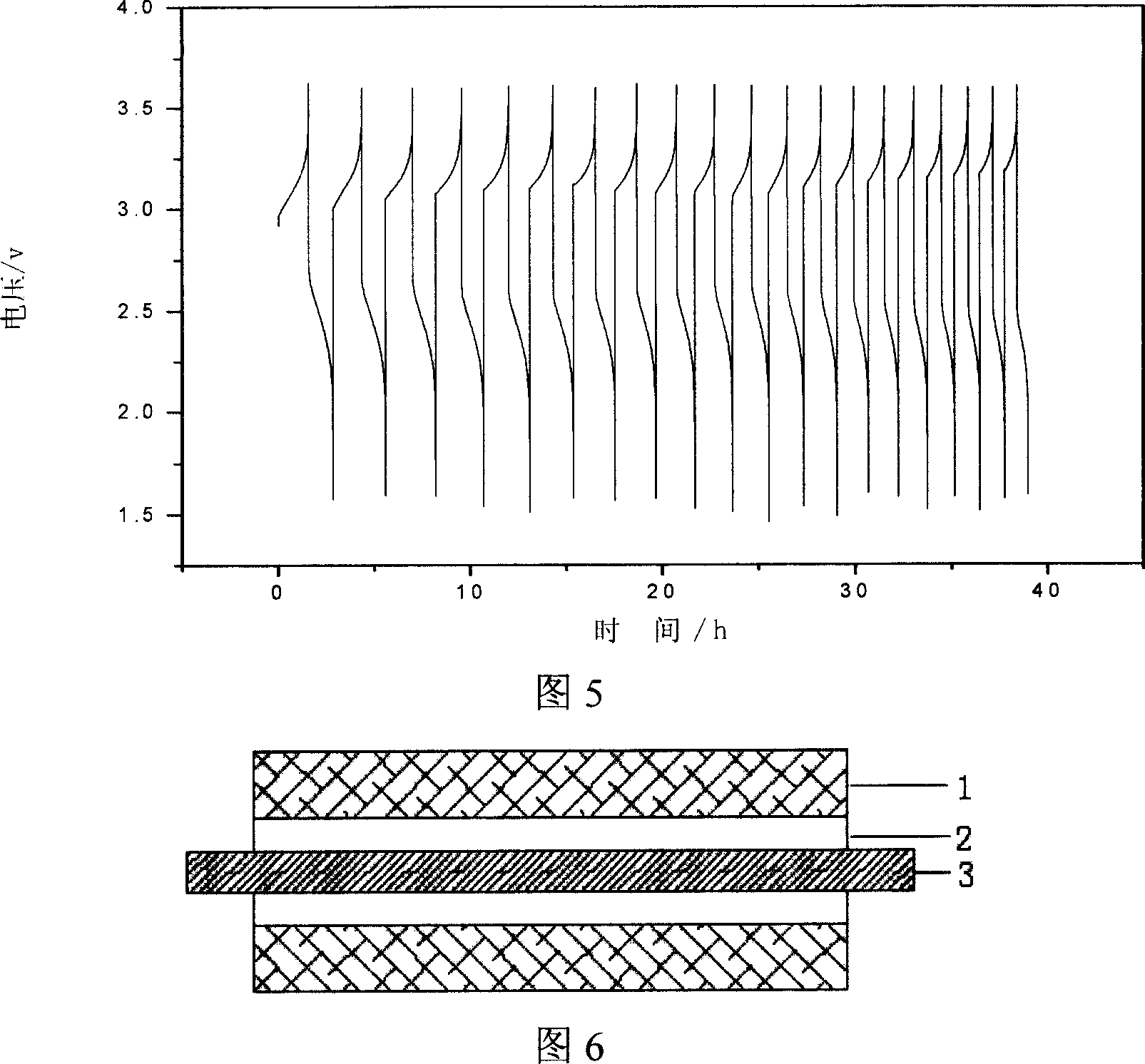

Integrated pole dual-pole board for oxidation deoxidization liquid energy-storing battery and its preparation

InactiveCN101009376AReduce contact resistanceImprove efficiencyElectrode manufacturing processesElectrode carriers/collectorsElectrical resistance and conductanceStored energy

The invention relates to the oxidation-reduction liquid stored-energy cell, especially integral electrode dipole plate and preparation, the integral electrode dipole plate includes: multiple-arch electrode and dipole plate, viscous conducting layer which is between the dipole plate and multiple-arch electrode, that is the multiple-arch electrode and dipole plate are felt to the dipole plate via the viscous conducting material. The advantages of the invention are: the integral electrode dipole plate can decrease the contact resistance between the multiple-arch electrode and dipole plate evidently, increase the voltage efficiency and energy efficiency of the oxidation-reduction liquid stored-energy cell, at the same time the distribution of the electrolyte in electrode is more even; the conductivity of the integral electrode dipole plate is perfect, the electrochemistry property is high, the chemical property is stable, it possesses high practicality value and wide application foreground.

Owner:DALIAN RONGKE POWER

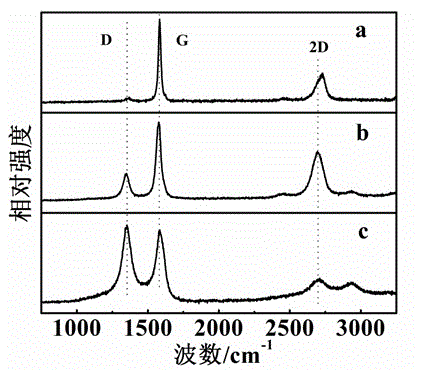

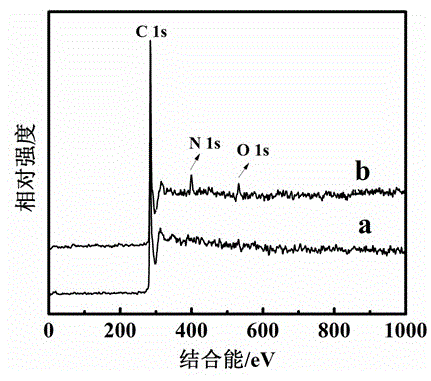

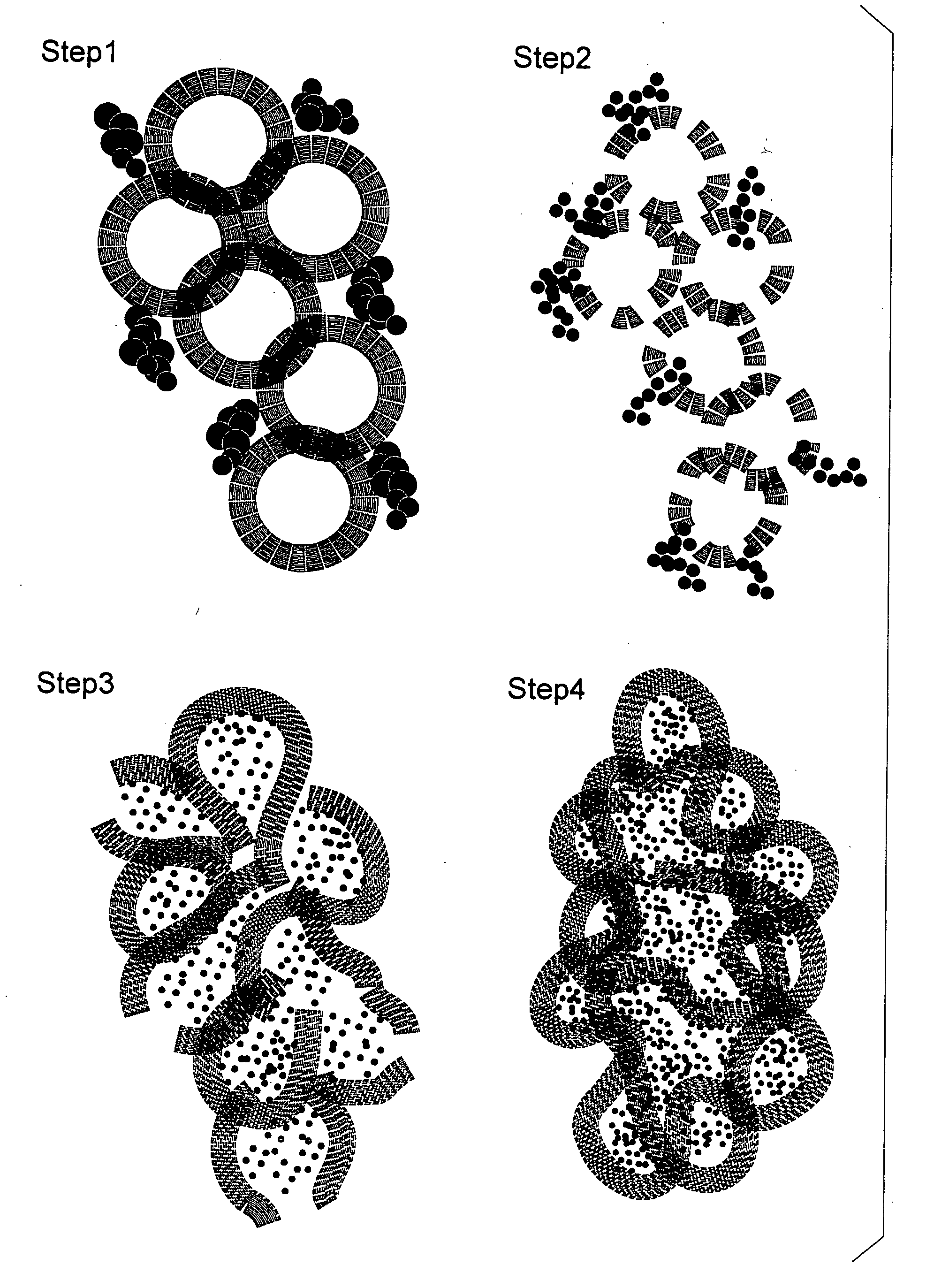

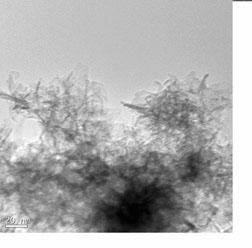

Method for preparing three-dimensional graphene-carbon nitrogen nanotube composite

InactiveCN102745679ASimple preparation processLow costMaterial nanotechnologyNitrogen preparationGrapheneChemical vapor deposition

The invention discloses a simple method of using foam nickel as a substrate to prepare a three-dimensional graphene-carbon nitrogen nanotube composite. Effective composite of three-dimensional graphene and carbon nanotubes is realized by directly growing the carbon nanotubes on the surface of the three-dimensional graphene by means of the two-step chemical vapor deposition technique, and functionalization of a carbon-based three-dimensional structure is realized by introducing nitrogen-doped atoms into the carbon nanotubes. Compared with other methods for preparing the three-dimensional graphene-carbon nitrogen nanotube composite, the method has the advantages of simplicity in preparation process, low cost, high product conductivity, large specific surface area and the like. The three-dimensional graphene-carbon nitrogen nanotube composite obtained by the method has excellent performances in terms of catalysis oxygen reduction reaction, electrochemical capacitors, electrochemical biological sensing, super-hydrophobic oleophylic foams and the like, and has high potential application values in terms of ionic cells, drug transmission, microreactors and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

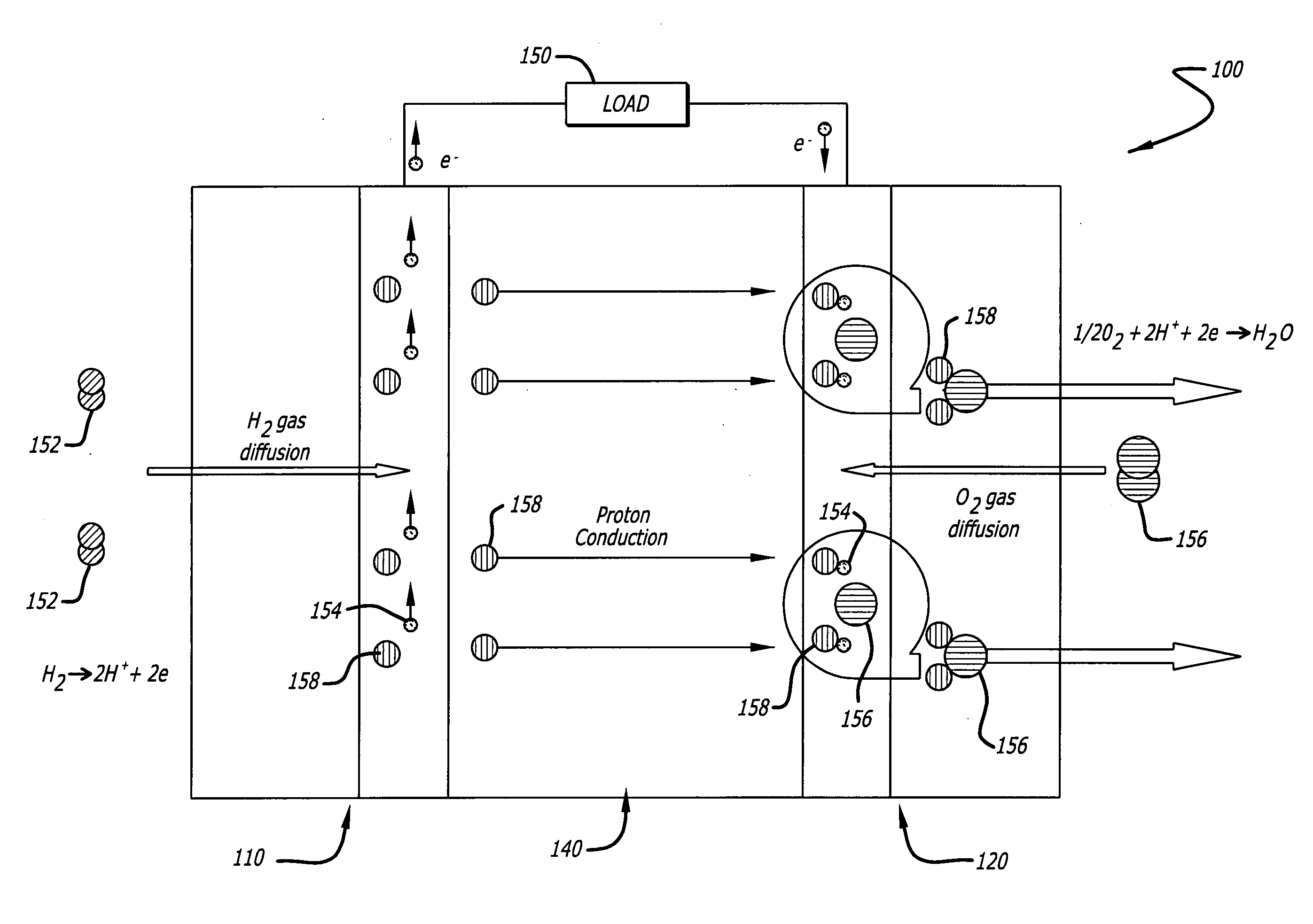

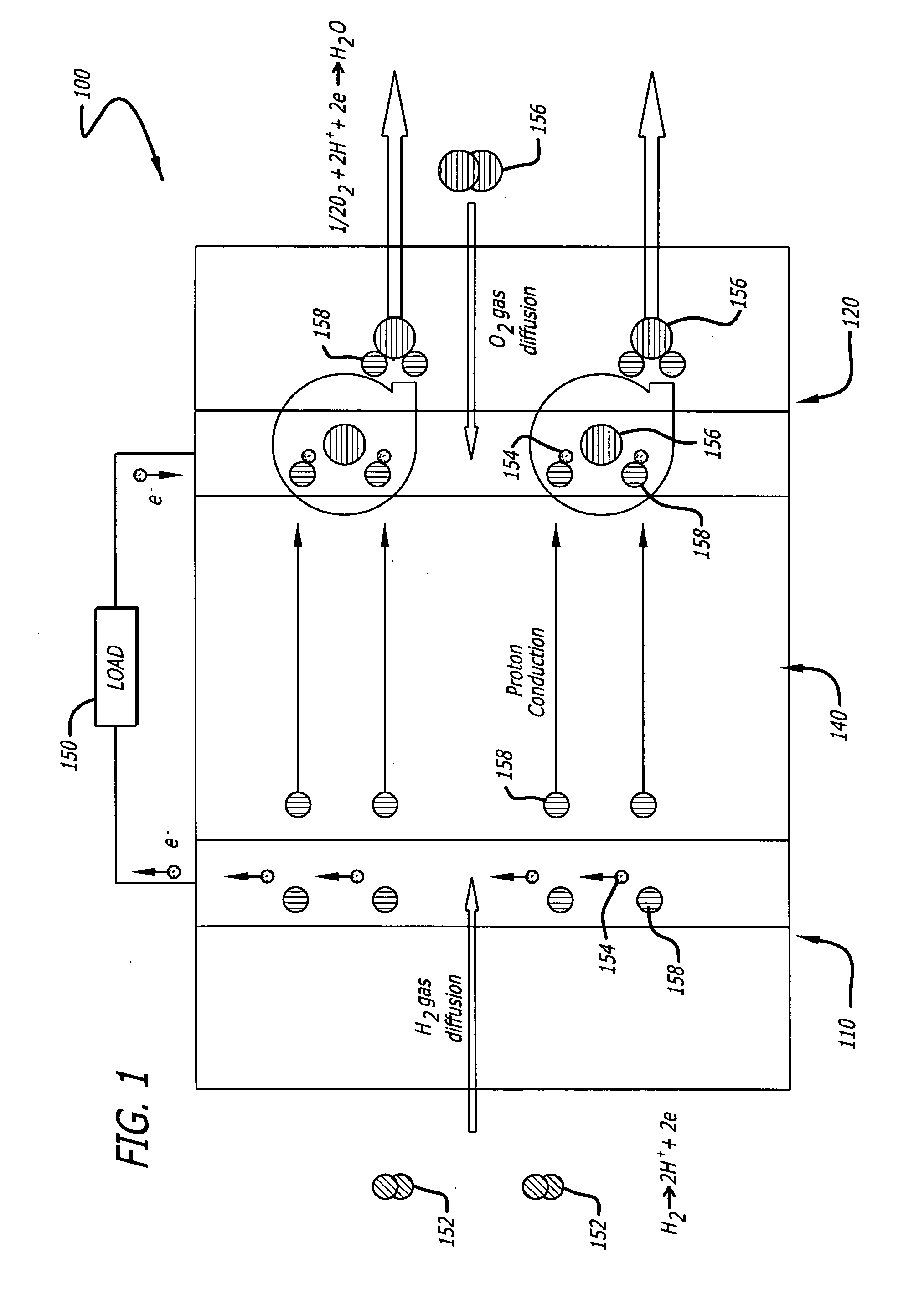

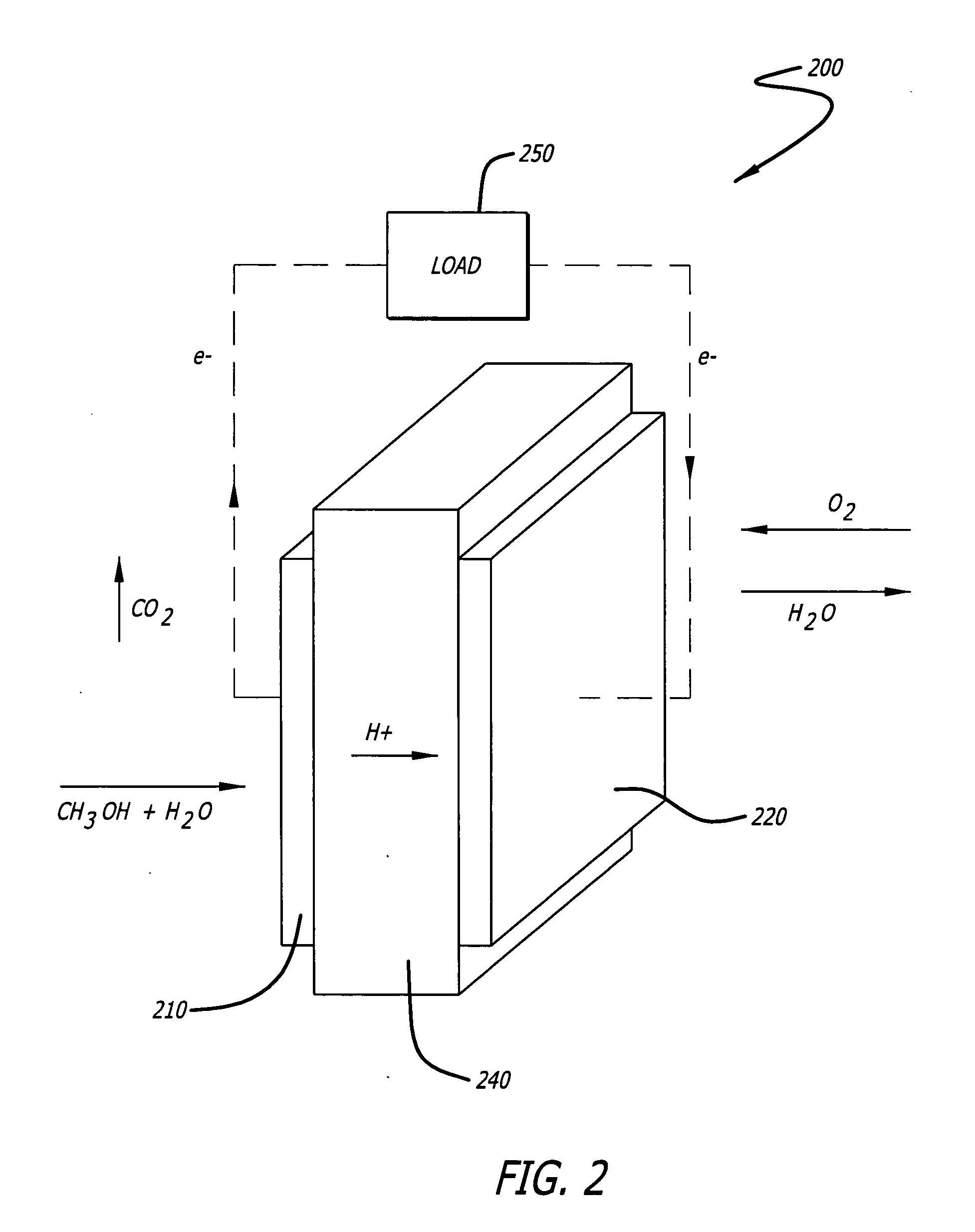

Carbon based electrocatalysts for fuel cells

InactiveUS20100159305A1High utilization rateHigh power densityActive material electrodesCoatingsHot pressPrecious metal

Novel proton exchange membrane fuel cells and direct methanol fuel cells with nanostructured components are configured with higher precious metal utilization rate at the electrodes, higher power density, and lower cost. To form a catalyst, platinum or platinum-ruthenium nanoparticles are deposited onto carbon-based materials, for example, single-walled, dual-walled, multi-walled and cup-stacked carbon nanotubes. The deposition process includes an ethylene glycol reduction method. Aligned arrays of these carbon nanomaterials are prepared by filtering the nanomaterials with ethanol. A membrane electrode assembly is formed by sandwiching the catalyst between a proton exchange membrane and a diffusion layer that form a first electrode. The second electrode may be formed using a conventional catalyst. The several layers of the MEA are hot pressed to form an integrated unit. Proton exchange membrane fuel cells and direct methanol fuel cells are developed by stacking the membrane electrode assemblies in a conventional manner.

Owner:RGT UNIV OF CALIFORNIA

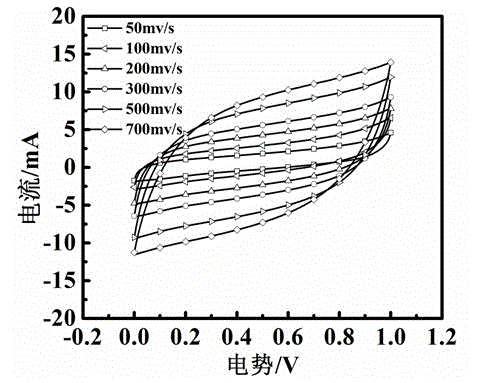

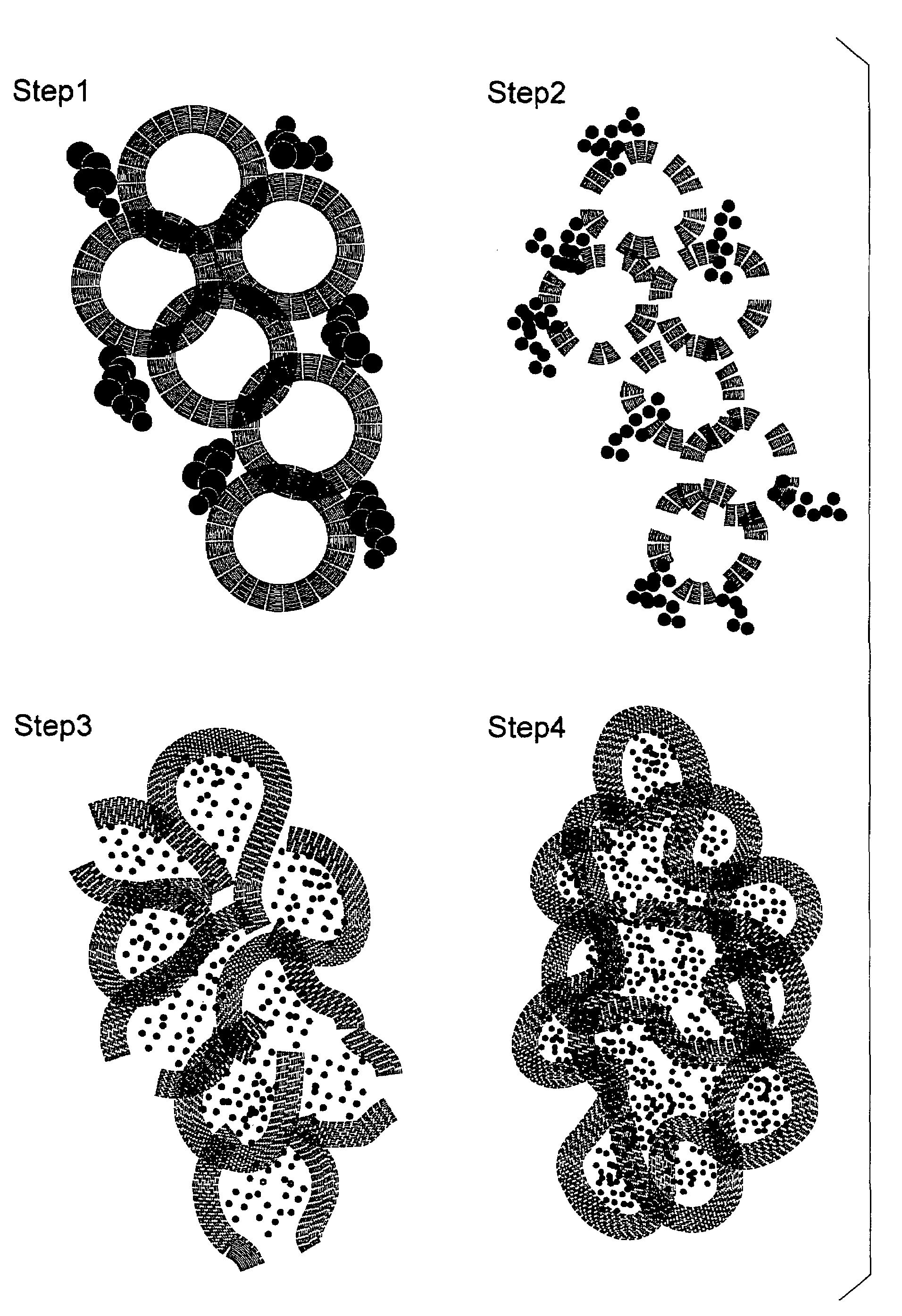

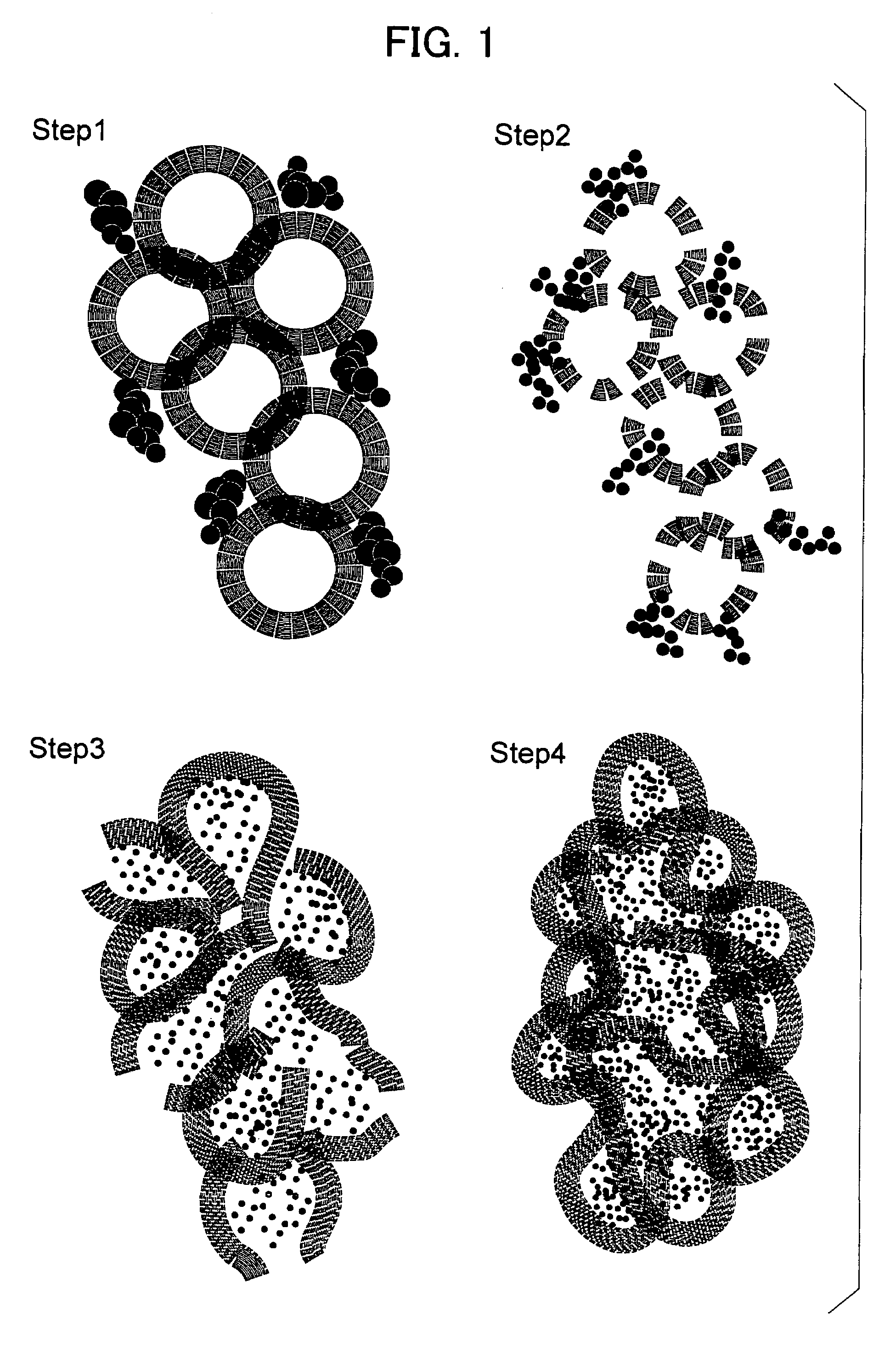

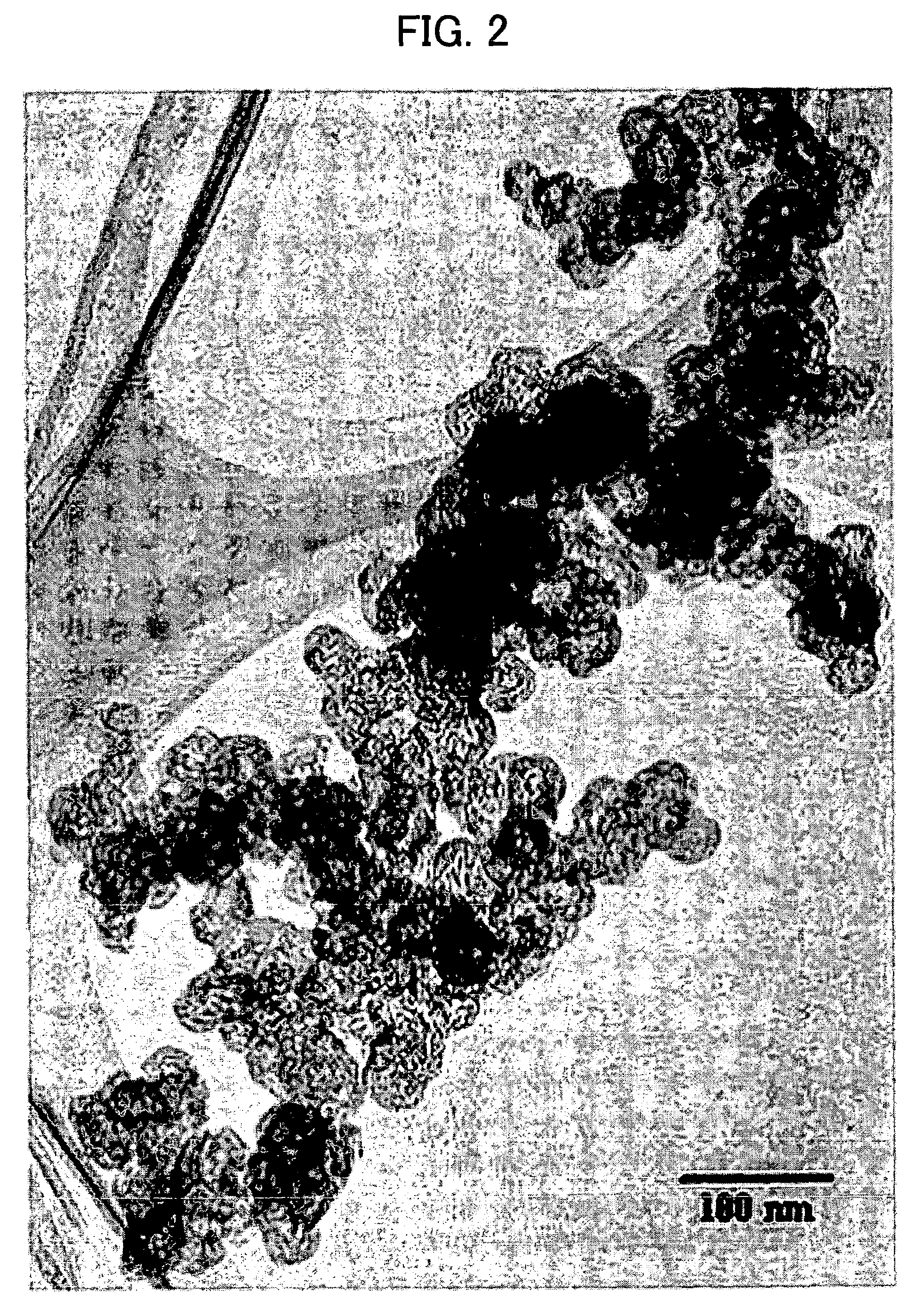

Nanocarbon Composite Structure Having Ruthenium Oxide Trapped Therein

InactiveUS20080048153A1Increase capacitanceImprove electrochemical activityMaterial nanotechnologyCarbon compoundsReaction fieldNanoparticle

A novel nanocarbon composite structure is provided having trapped ruthenium oxide. By using Ketjen black, and through chemical-mechanical effect utilizing an ultracentrifugal reaction field, both the specific surface area of ruthenium oxide and space of electrode material are expanded to have nanoparticles of ruthenium oxide highly dispersed in a graphene layer. This nanocarbon composite structure having trapped ruthenium oxide exhibits high electrochemical activity and is suitable for use as an electrical energy storing device, such as a large-capacity capacitor.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH

Multi-layer non-carbon metal-based anodes for aluminum production cells and method

InactiveUS6077415AImprove electrochemical activitySolution to short lifeMachining electrodesIsotope separationElectrical batteryOxygen ions

A composite, high-temperature resistant, non-carbon metal-based anode of a cell for the electrowinning of aluminium comprises a metal-based core structure of low electrical resistance, for connecting the anode to a positive current supply, coated with a series of superimposed, adherent, electrically conductive layers. These layers consist of at least one layer on the core structure constituting a barrier substantially impervious to monoatomic oxygen and molecular oxygen; one or more intermediate, protective layers on the oxygen barrier layer which remain inactive in the reactions for the evolution of oxygen gas; and an electrochemically active layer for the oxidation reaction of oxygen ions present at the anode / electrolyte interface into nascent monoatomic oxygen, as well as for subsequent reaction for the formation of gaseous biatomic oxygen. The active layer on the outermost intermediate layer is slowly consumable during electrolysis and protects the intermediate protective layer by inhibiting its dissolution into the electrolyte.

Owner:MOLTECH INVENT

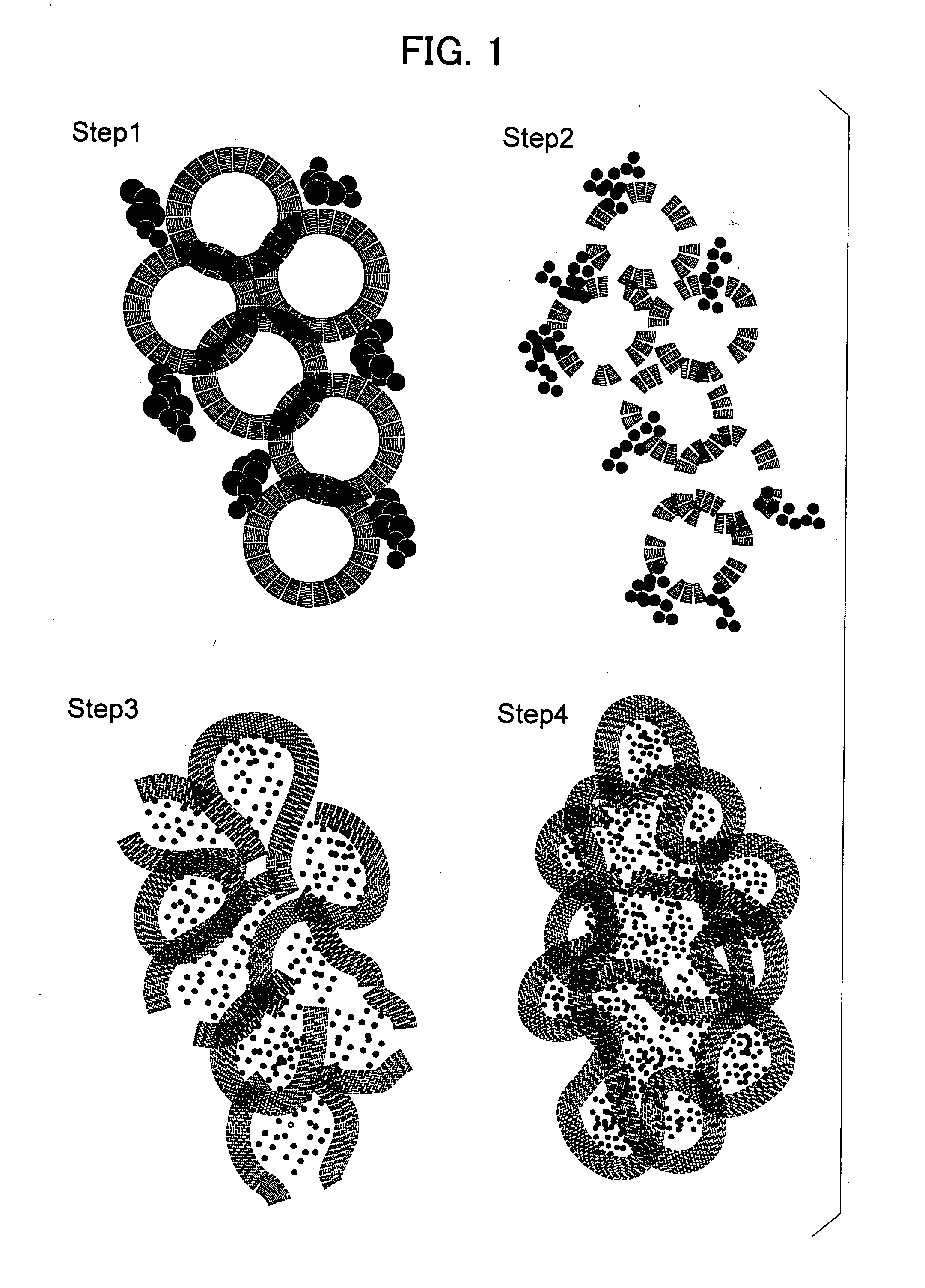

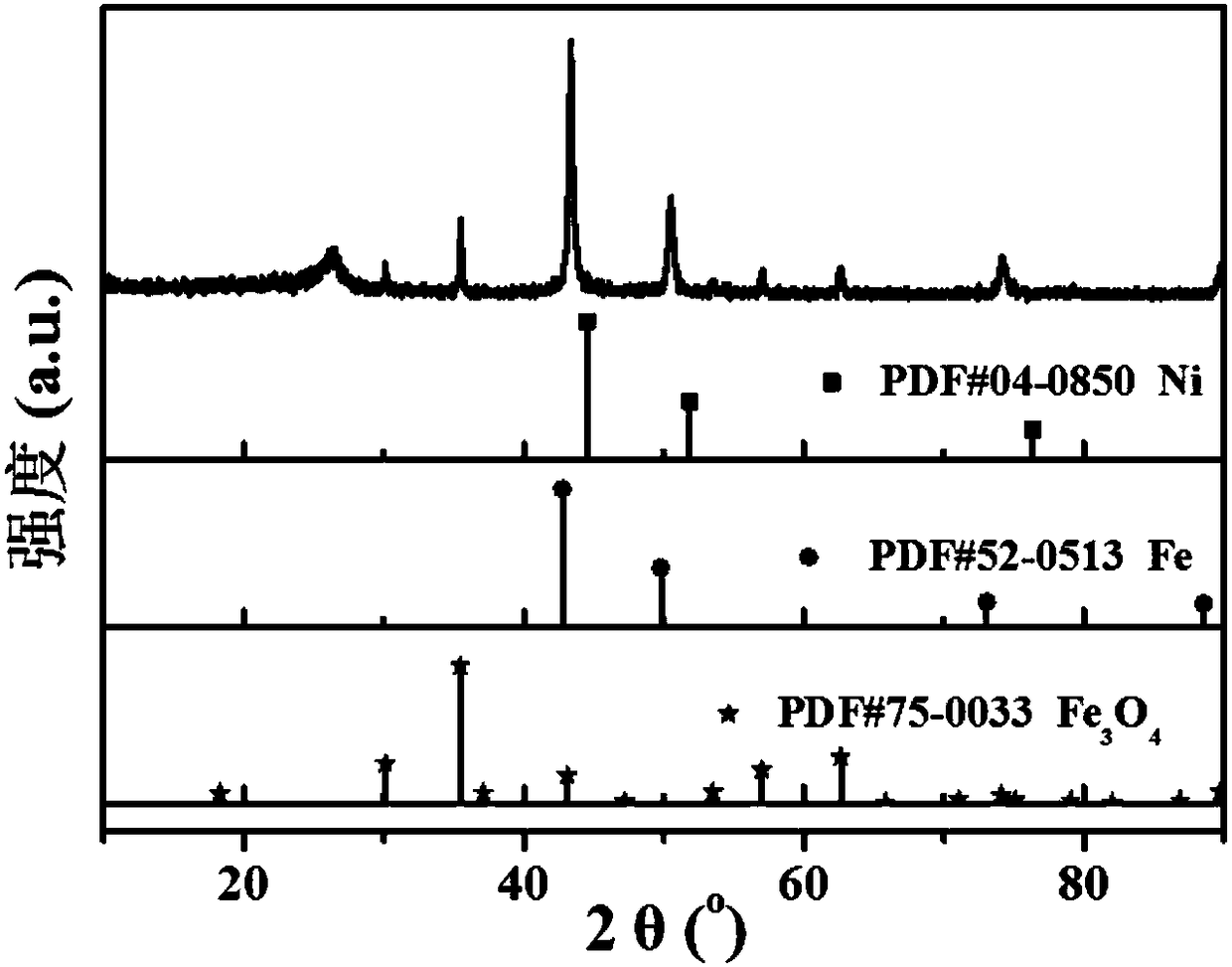

Fe, Ni and N three-doped carbon nanotube coated type FeNi@NCNT catalyst as well as preparation method and application thereof

InactiveCN108543545AIncrease the areaImprove conductivityPhysical/chemical process catalystsCell electrodesMetal particleOxygen

The invention discloses a Fe, Ni and N three-doped carbon nanotube coated type FeNi@NCNT catalyst as well as a preparation method and application thereof, and belongs to the fields of energy materialsand electrochemistry. The catalyst is prepared by using dicyandiamide as a C source and N source and ammonium ferric citrate and NiCl2.6H2O as metal sources, adopting one pot method and performing pyrolysis in two steps; and a plurality of Fe and Ni metal particles in the catalyst are uniformly wrapped in walls of ''bamboo-like'' N-doped carbon nanotubes, and a small number of the particles are distributed at the tip ends of the carbon nanotubes. Compared with a common metal alloy oxygen reduction reaction and oxygen evolution reaction bifunctional catalyst, the catalyst disclosed by the invention exhibits good oxygen evolution reaction activity and stability under alkaline conditions; the preparation method is simple, and raw materials used in the method have low costs and wide sources;and the catalyst can be widely used in the fields of proton exchange membrane fuel cells, electrolyzed water, metal-air batteries and the like, and has higher practical value.

Owner:DALIAN UNIV OF TECH

Electrolyte for all-vanadium redox flow battery and preparation method thereof, and all-vanadium redox flow battery including the electrolyte

ActiveCN101572319AHigh total vanadium concentrationImprove stabilityHybrid cell detailsFinal product manufactureRedoxSULFATE ION

The invention provides an electrolyte for an all-vanadium redox flow battery and a preparation method thereof, and an all-vanadium redox flow battery including the electrolyte. The electrolyte for an all-vanadium redox flow battery comprises anode electrolyte and cathode electrolyte which contain vanadiferous ions and sulfate ions, concentration of the sulfate ions in the anode electrolyte is more than that of the sulfate ions in the cathode electrolyte, the total vanadium concentration of the anode electrolyte and the cathode electrolyte is 2.0-8.0mol / L respectively. The preparation method of the electrolyte for an all-vanadium redox flow battery comprises the following steps: dissolving one or more vanadium oxides and optional reducers in sulfuric acid solution with a first concentration and a second concentration respectively to obtain an anode electrolyte precursor and a cathode electrolyte precursor with the total vanadium concentration of 2.0-8.0mol / L respectively, wherein, the first concentration is larger than the second concentration; and electrolyzing the anode electrolyte precursor and the cathode electrolyte precursor respectively to obtain the anode electrolyte and the cathode electrolyte of the all-vanadium redox flow battery.

Owner:大力储能技术湖北有限责任公司

Nanocarbon composite structure having ruthenium oxide trapped therein

InactiveUS7572542B2Increase capacitanceImprove electrochemical activityMaterial nanotechnologyCarbon compoundsReaction fieldNanoparticle

A novel nanocarbon composite structure is provided having trapped ruthenium oxide. By using Ketjen black, and through chemical-mechanical effect utilizing an ultracentrifugal reaction field, both the specific surface area of ruthenium oxide and space of electrode material are expanded to have nanoparticles of ruthenium oxide highly dispersed in a graphene layer. This nanocarbon composite structure having trapped ruthenium oxide exhibits high electrochemical activity and is suitable for use as an electrical energy storing device, such as a large-capacity capacitor.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH

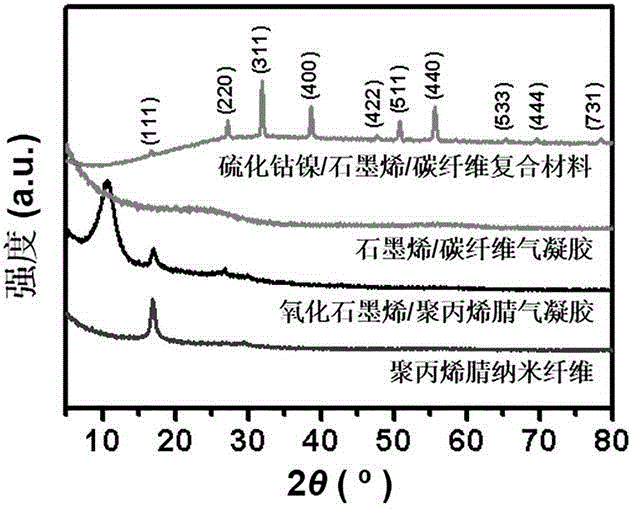

Vulcanized cobalt-nickel/graphene/carbon nano fiber composite material and preparation method thereof

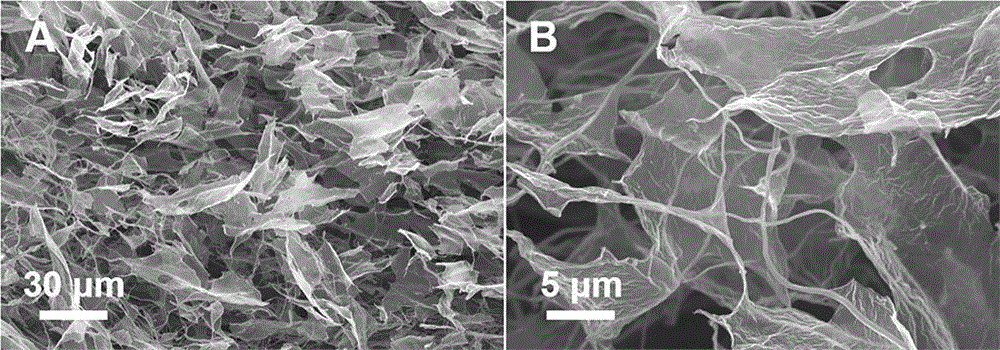

InactiveCN105293590AEasy to prepareEasy to operateHybrid capacitor electrodesCell electrodesLithium electrodeCarbon nanofiber

The invention belongs to the technical field of transition metal sulfide-carbon materials, and particularly relates to a vulcanized cobalt-nickel / graphene / carbon nano fiber composite material and a preparation method thereof. The preparation method includes the steps that polyacrylonitrile nano fibers are prepared through electrostatic spinning, oxidized graphene / polyacrylonitrile nano fiber aerogel is prepared through mechanical stirring and freezing drying, then graphene / carbon nano fiber aerogel is prepared through high-temperature carbonization, and finally, vulcanized cobalt-nickel nanosheets grow in situ on the graphene / carbon nano fiber aerogel through the one-step hydrothermal method. The vulcanized cobalt-nickel / graphene / carbon nano fiber composite material prepared through the method has the advantages that the material has a three-dimensional porous space structure, conductivity is good and chemical properties are stable, and can serve as an ideal high-performance electro-catalysis material and electrode materials of new energy devices such as lithium ion batteries and solar batteries.

Owner:FUDAN UNIV

Preparation method of oxidized Mxene/S compound applied to lithium-sulphur battery cathode

ActiveCN107579235ALow costImprove adsorption capacityCell electrodesSecondary cellsWater bathsHigh conductivity

The invention discloses a preparation method of an oxidized Mxene / S compound applied to a lithium-sulphur battery cathode, relates to a preparation method of an S compound applied to the lithium-sulphur battery cathode, and aims to solve the technical problem of complex process of an existing Mxene / S compound preparation method. The preparation method disclosed by the invention comprises the following steps: 1, preparing Mxene powder; 2, oxidizing; 3, performing a water bath method. According to the preparation method, oxidized Mxene with high conductivity is taken as an S carrier, the preparation process is simple and safe, the production cost is low, large scale production is hopefully realized, and the oxidized Mxene / S compound as a lithium-sulphur battery cathode material has very highspecific capacity and cycling stability. The preparation method is applied to preparation of the lithium-sulphur battery cathode material.

Owner:HARBIN INST OF TECH

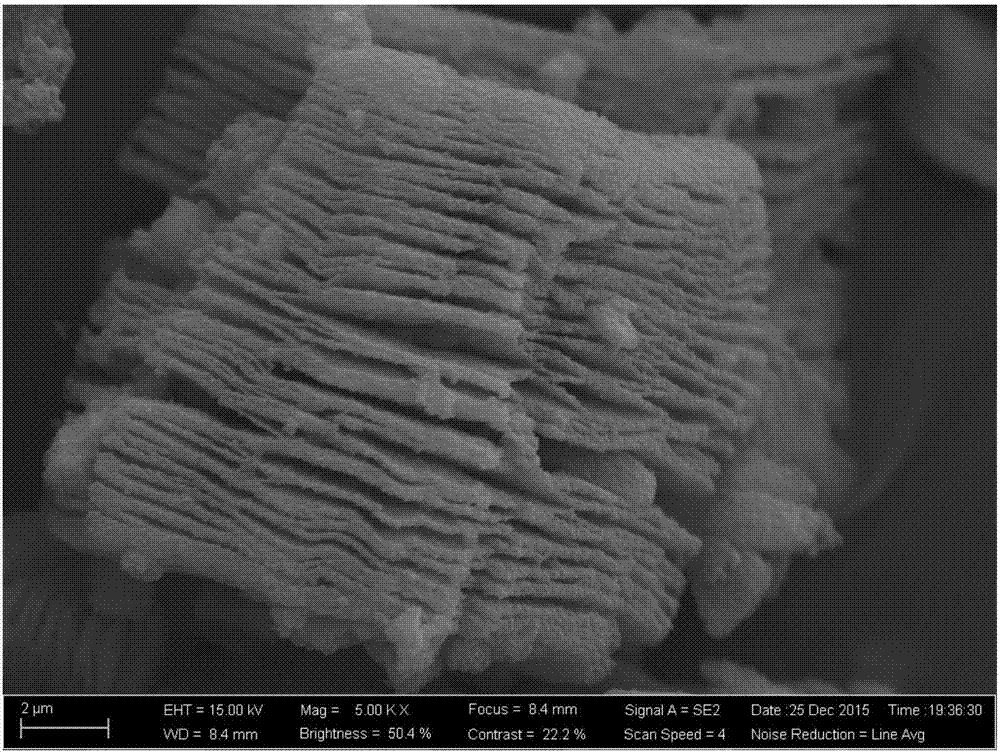

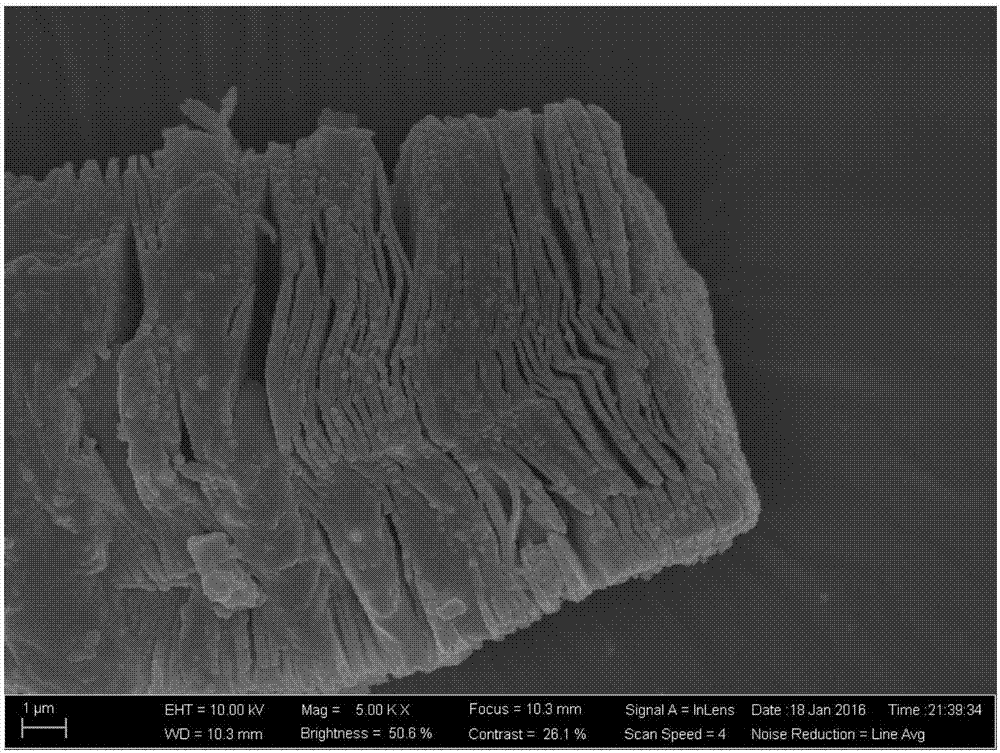

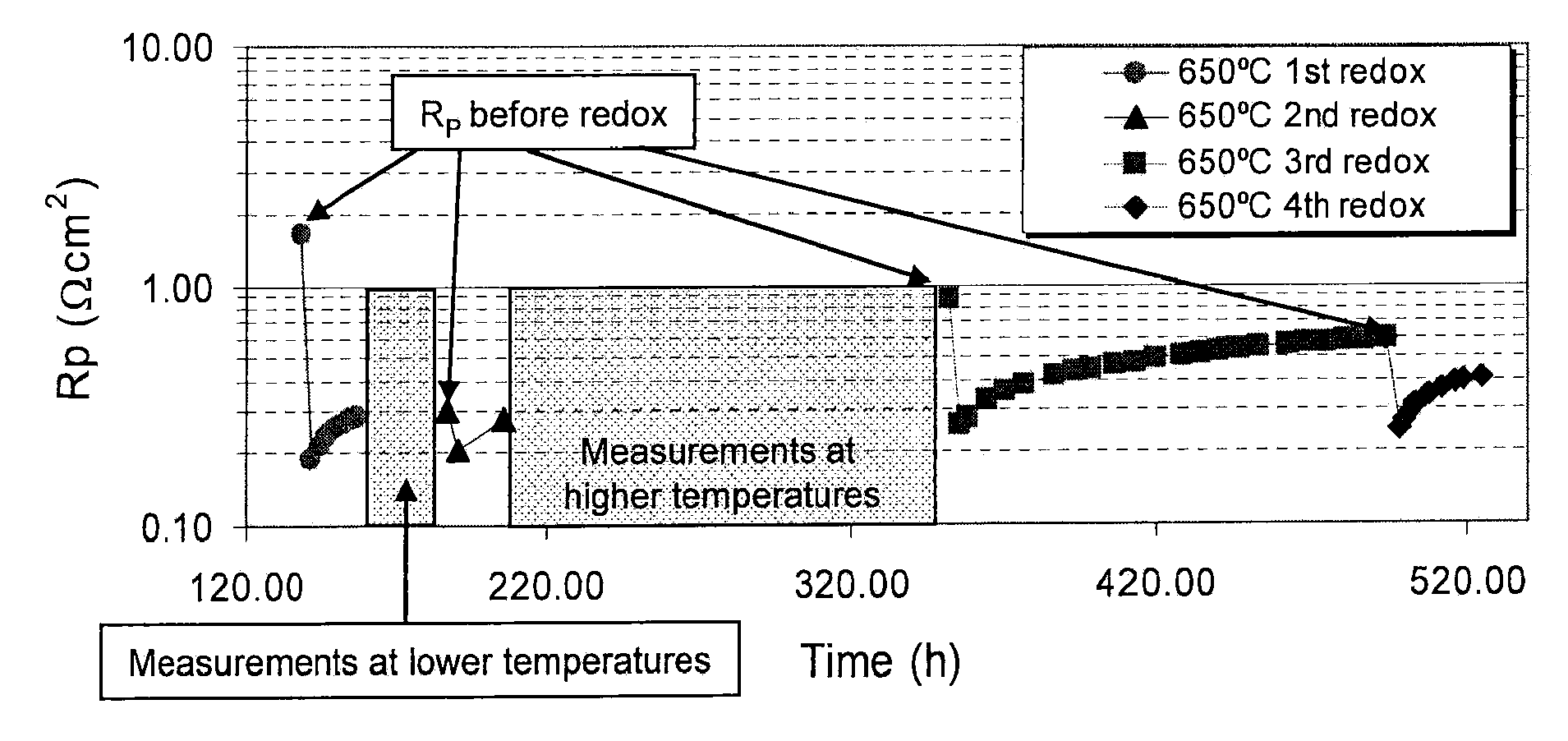

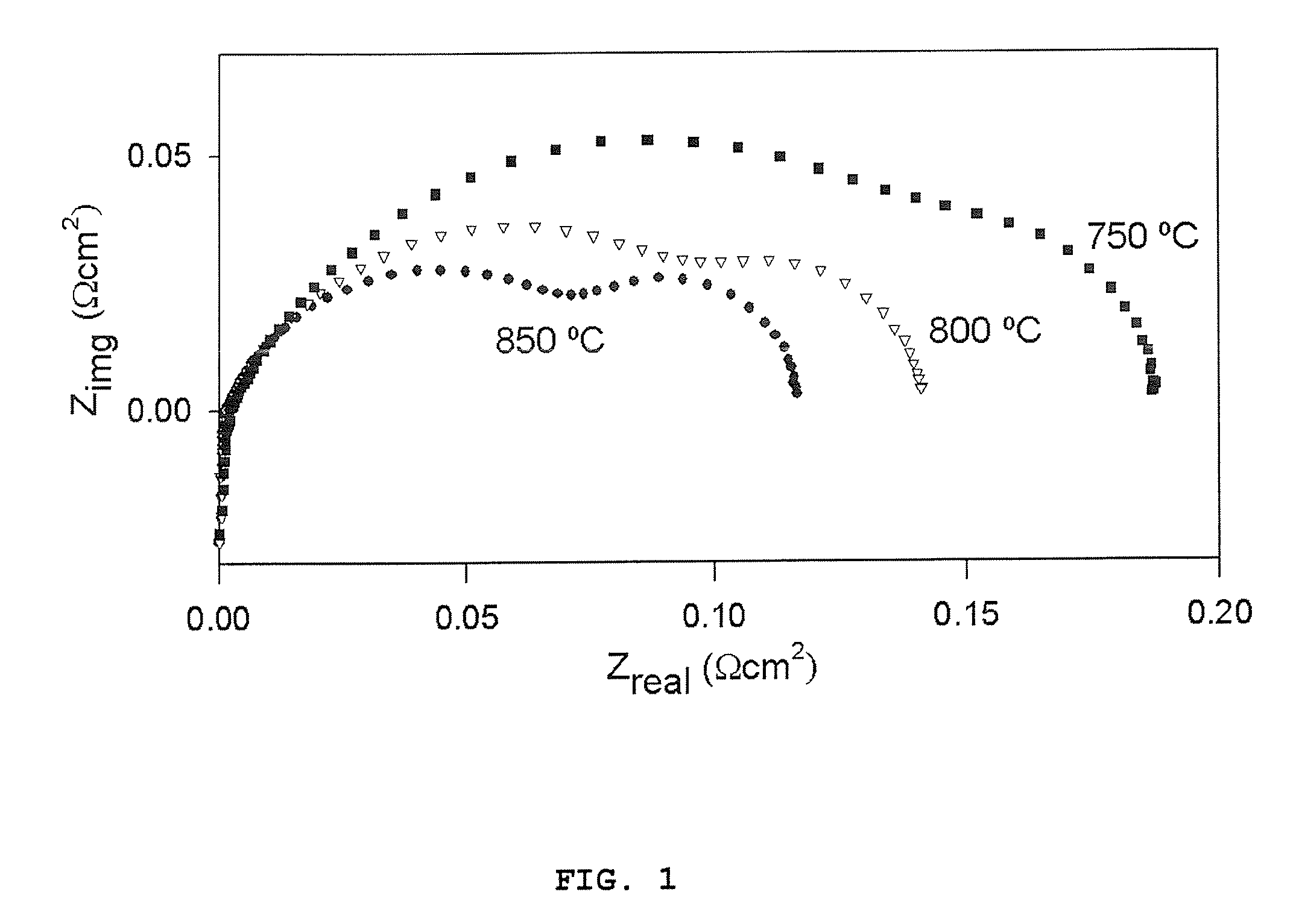

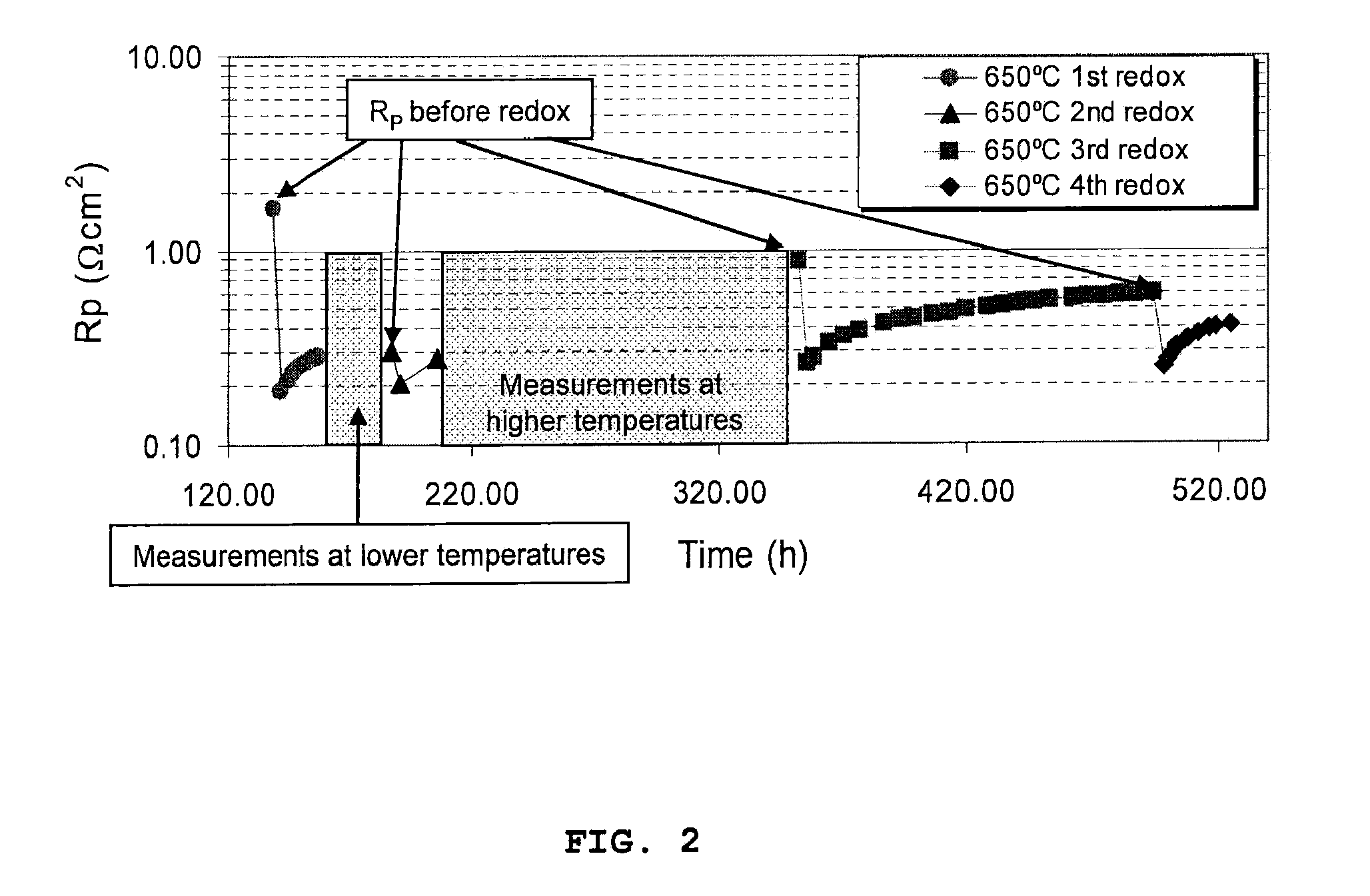

Ceria and strontium titanate based electrodes

InactiveUS20090061284A1High BET surface areaSpeed up calcination procedureFuel cells groupingCell electrodesStrontium titanateVanadium doping

A ceramic anode structure obtainable by a process comprising the steps of: (a) providing a slurry by dispersing a powder of an electronically conductive phase and by adding a binder to the dispersion, in which said powder is selected from the group consisting of niobium-doped strontium titanate, vanadium-doped strontium titanate, tantalum-doped strontium titanate, and mixtures thereof, (b) sintering the slurry of step (a), (c) providing a precursor solution of ceria, said solution containing a solvent and a surfactant, (d) impregnating the resulting sintered structure of step (b) with the precursor solution of step (c), (e) subjecting the resulting structure of step (d) to calcination, and (f) conducting steps (d)-(e) at least once.

Owner:DANMARKS TEKNISKE UNIV

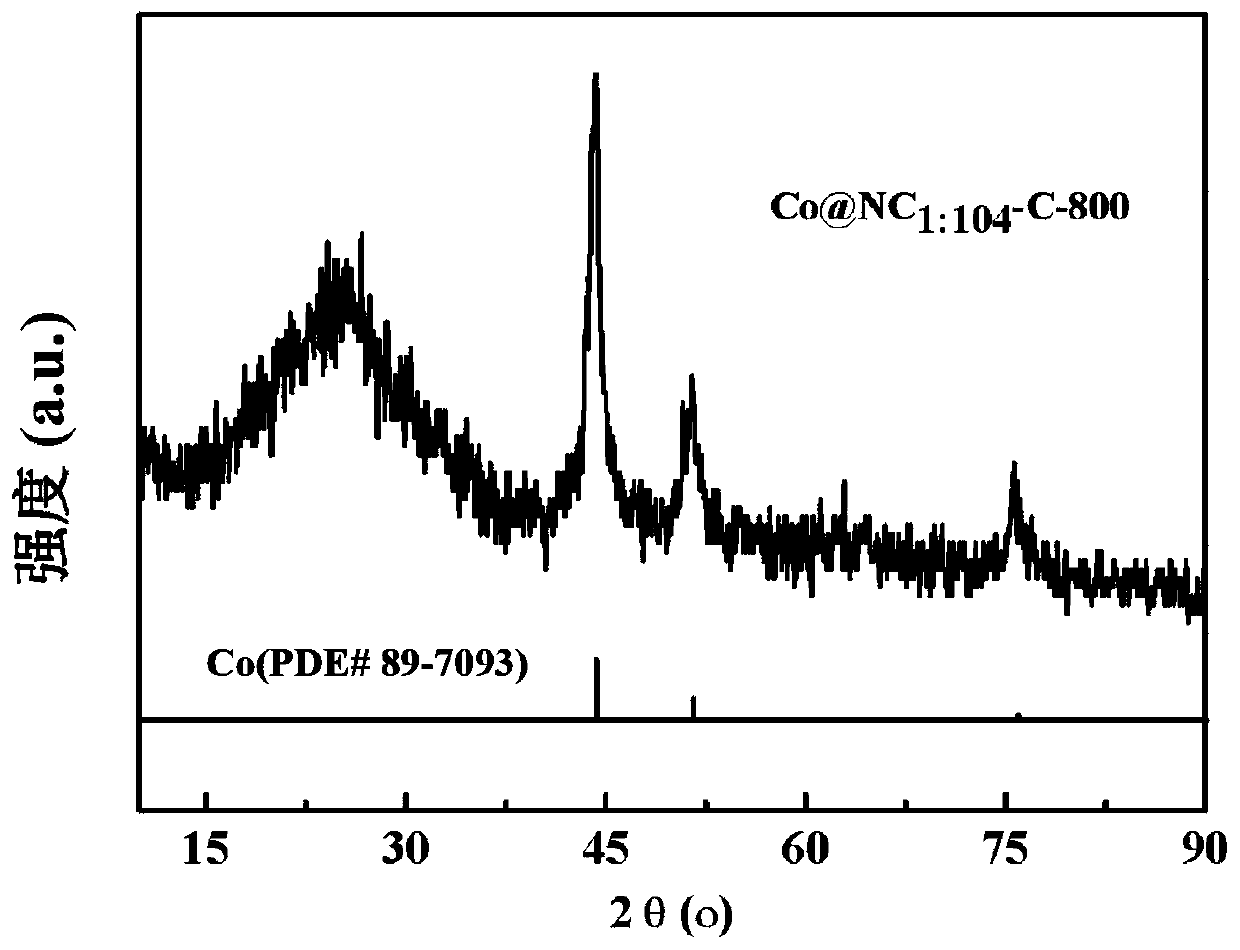

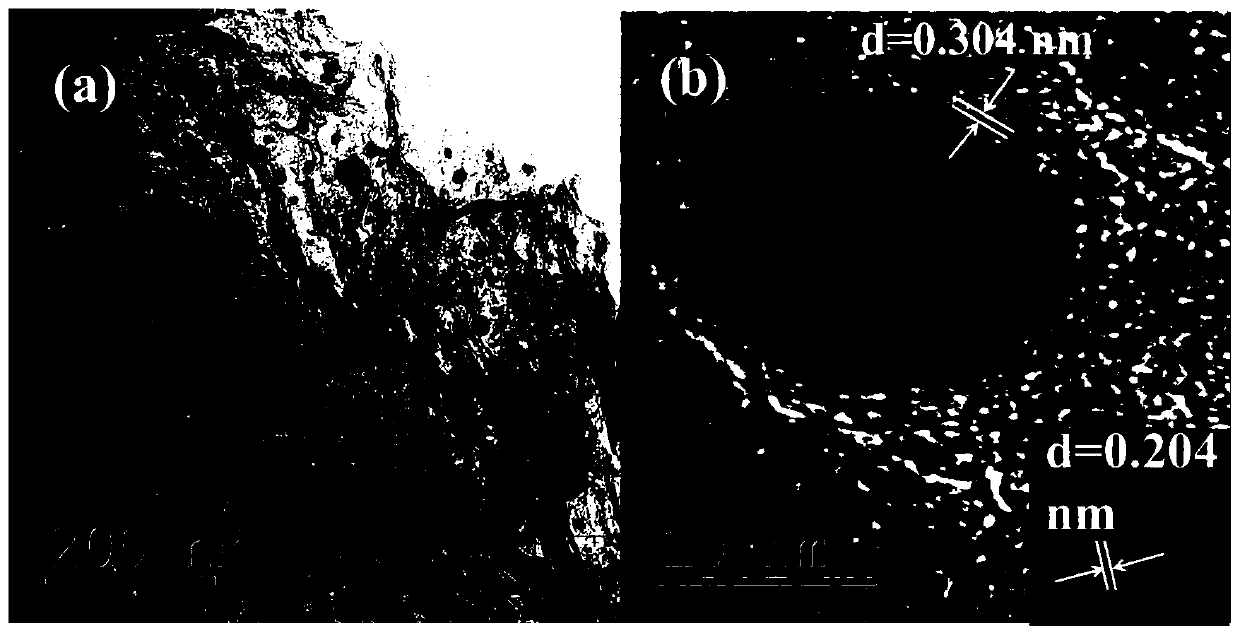

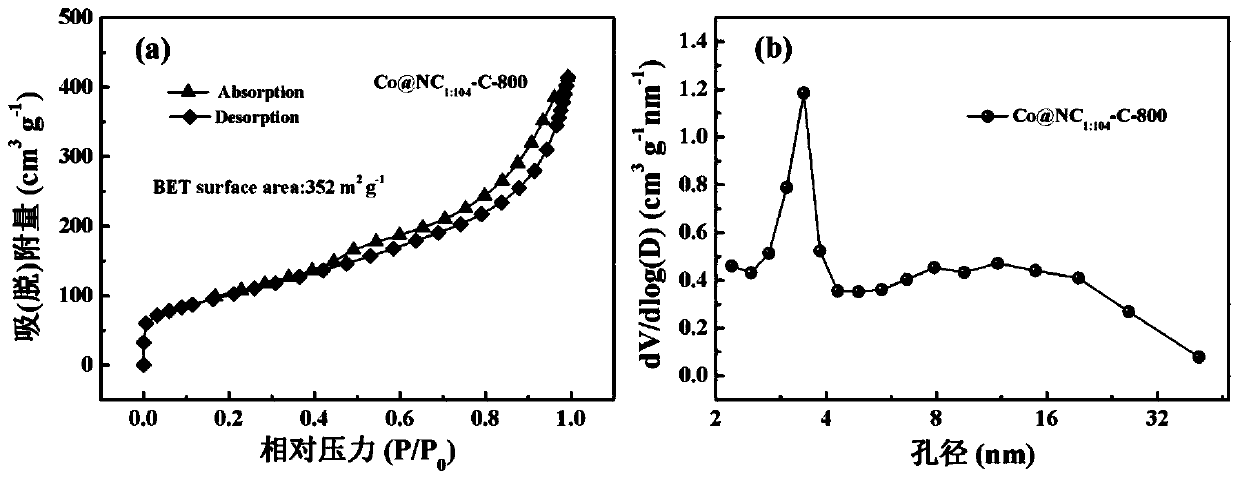

Co@NC high-dispersion core-shell structure catalyst, and preparation method and application of catalyst

InactiveCN110176606AImprove stabilityHigh resistance to methanolMaterial nanotechnologyPhysical/chemical process catalystsCvd grapheneDecomposition

The invention discloses a Co@NC high-dispersion core-shell structure catalyst, and a preparation method and an application of the catalyst, and belongs to the technical field of energy source materials and electrochemistry. The preparation method of the catalyst comprises the steps of taking glucose as a C source, taking cyanoguanidine as a C-N source, taking Co(No3).6H2O as a Co source, and performing high temperature calcination. The cyanoguanidine performs high temperature decomposition to generate two-dimensional flaky g-C3N4; the glucose performs high temperature decomposition to generatea carbon intermediate and a metal species which are inserted into flakes of g-C3N4; and Co nanoparticles coated by an N-C layer in the catalyst are uniformly dispersed on a graphene carbon layer. Thecatalyst can serve as a cathode oxygen reduction electrocatalyst of a metal-air battery and a fuel battery. The catalyst is cheap and easy obtaining in raw material, and simple in preparation technology; amplification production is facilitated; in-situ decomposition of the cyanoguanidine provides rich N doped active sites for the catalyst; rich mesoporous structures are formed; the activity of the catalyst is improved; a channel is provided for transfer and transport of reaction participation substances in an ORR process; a mass transfer demand of a reaction process is met; and the catalyst is good in stability and high in methanol resistance.

Owner:DALIAN UNIV OF TECH

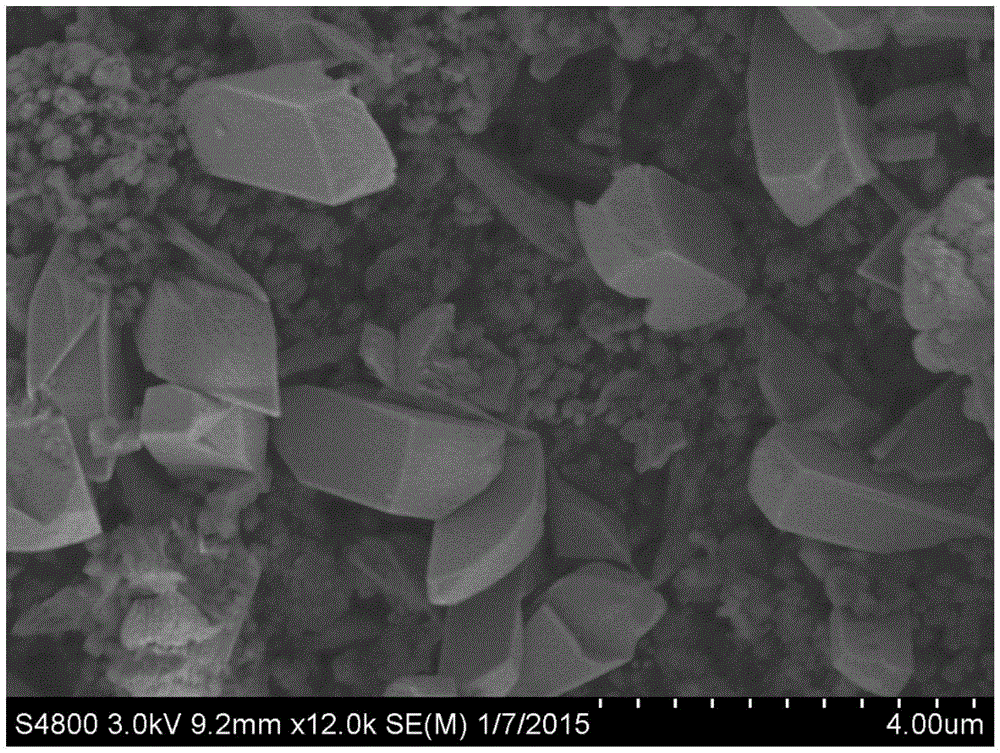

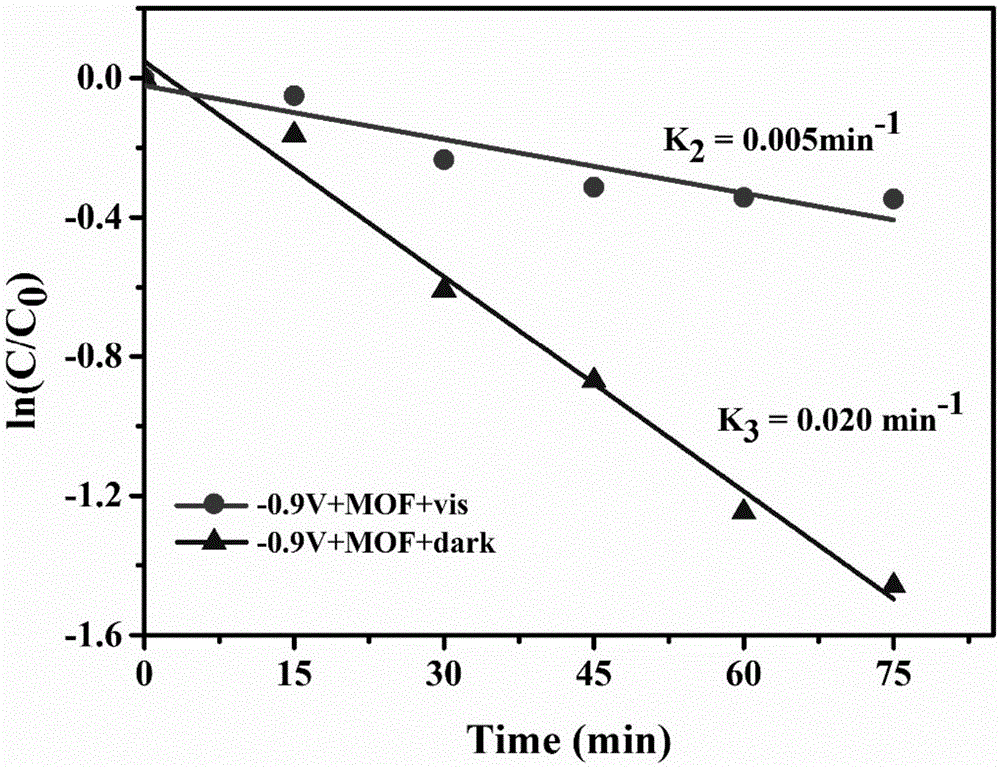

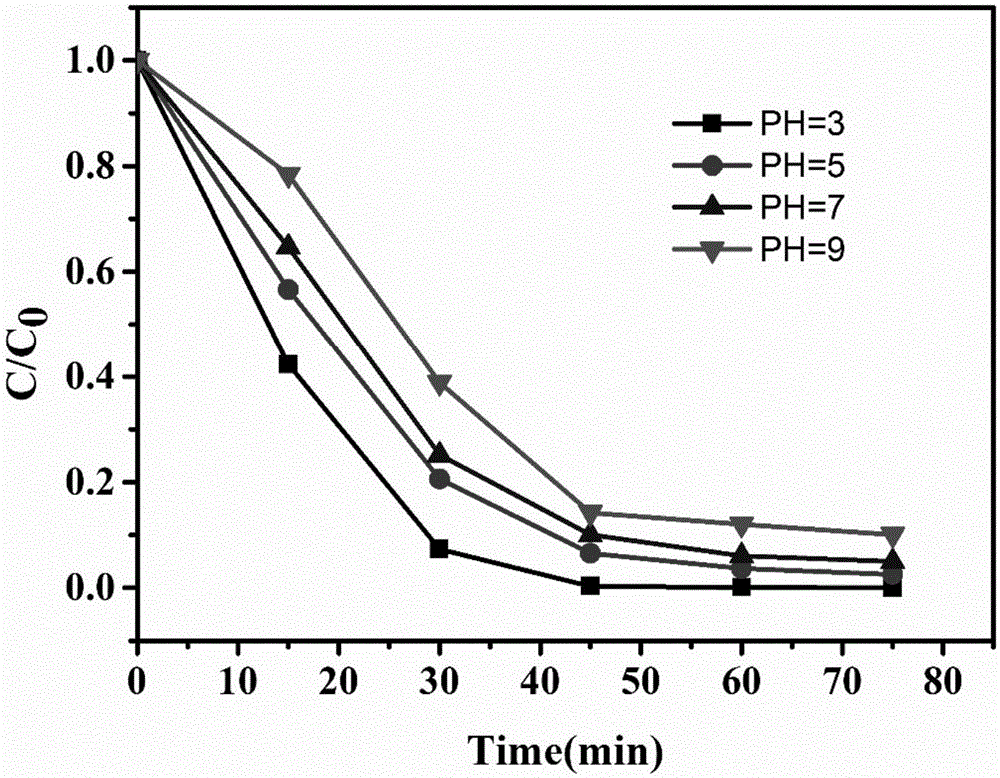

Carbon-aerogel-carried bimetal organic framework electro-Fenton cathode and preparation method thereof

ActiveCN105110423AEfficient degradationReduce energy consumptionWater/sewage treatment by irradiationWater contaminantsMetal-organic frameworkCombined technique

The invention relates to a carbon-aerogel-carried bimetal organic framework electro-Fenton cathode and a preparation method thereof. The preparation method comprises the following steps: by using a block carbon aerogel as a substrate electrode, carrying out hydrothermal reaction to load a bimetal organic framework onto the substrate electrode, filtering, washing, and carrying out vacuum drying to obtain the carbon-aerogel-carried bimetal organic framework electro-Fenton cathode, wherein the bimetal organic framework is a Fe / Co bimetal organic framework. Compared with the prior art, by combining the photocatalytic technique and electro-Fenton, the carbon-aerogel-carried bimetal organic framework electro-Fenton cathode can degrade organic pollutants by using the higher-efficiency low-energy-consumption advanced oxidation technique, thereby providing a new way for using the electro-Fenton cathode in the photocatalytic / electro-Fenton combined technique for treating nondegradable organic pollutants. The carbon-aerogel-carried bimetal organic framework electro-Fenton cathode has the advantages of simple technical operation, energy saving and high efficiency, and has very wide application range in the field of actual water treatment.

Owner:TONGJI UNIV

Molybdate doped polypyrrole/epoxy resin self-healing coating, preparation method thereof and application thereof

InactiveCN105001759AExcellent self-healing performanceAvoid corrosionEpoxy resin coatingsEpoxyPolypyrrole

The invention relates to a molybdate doped polypyrrole / epoxy resin self-healing coating, a preparation method thereof and an application thereof, and belongs to the field of metal anti-corrosion coatings. The coating is composed of two parts, namely a polypyrrole / epoxy resin system mother liquor, and a polyamide curing agent. The polypyrrole / epoxy resin system mother liquor comprises molybdate doped polypyrrole, epoxy resin, an anti-settling agent, an anti-foaming agent, a levelling agent and an organic solvent. The molybdate doped polypyrrole is added in the organic solvent and then the mixture is uniformly dispersed in an ultrasonic dispersion instrument. After that, the anti-settling agent, the antifoaming agent and the levelling agent are added respectively, and are stirred on a magnetic stirring apparatus. Then the epoxy resin is added to form the uniformly dispersed polypyrrole / epoxy resin system mother liquor. The polyamide curing agent is added in the prepared mother liquor, and is stirred to be uniformly dispersed. In this way, a molybdate doped polypyrrole / epoxy resin self-healing coating can be obtained. The coating is sprayed or brushed onto the 2024 type aluminum alloy after being subjected to oil-removing treatment. After the drying and curing process of the coating at the room temperature, a molybdate doped polypyrrole / epoxy resin self-healing coating can be formed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Combined electrode for super capacitor and preparation method thereof

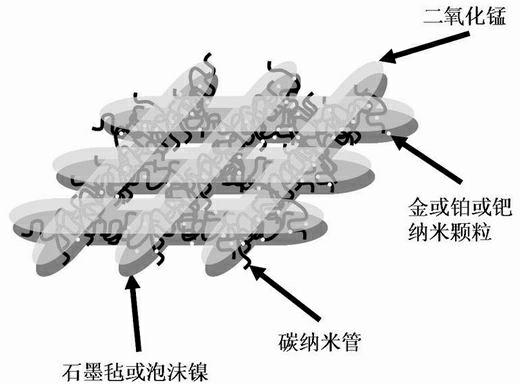

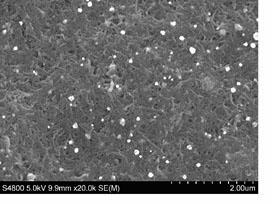

InactiveCN102683044AHigh mechanical strengthLarge specific surface areaElectrolytic capacitorsHybrid capacitor electrodesPlatinumNickel substrate

The invention relates to a nanometer combined electrode material for a super capacitor and a preparation method thereof. The combined electrode material for the super capacitor is as follows: the surface of a graphite felt or a foam nickel substrate material is provided with a carbon nanometer tube layer; the surface of the carbon nanometer tube layer is provided with a layer of trace discontinuous palladium or platinum or gold nanometer particles; and the carbon nanometer tube layer with a layer of trace discontinuous palladium or platinum or gold nanometer particles on the surface is provided with a manganese dioxide layer.

Owner:昆山昆鹏利杰高分子材料技术有限公司

Preparation method of high compaction density lithium ion cathode material

The invention relates to a preparation method of a high compaction density lithium ion cathode material. The preparation method comprises the following steps: (1) uniformly mixing a boron compound with a precursor material to obtain a pretreated precursor material; (2) sufficiently mixing the pretreated precursor material with a lithium salt to obtain a mixture; and (3) carrying out solid phase sintering on the mixture in an oxidizing atmosphere, cooling and crushing to obtain the high compaction density lithium ion cathode material. According to the preparation method, the precursor material is pretreated, the boron compound is firstly uniformly attached to the precursor, and then the pretreated precursor material is mixed with the lithium salt for sintering, so that doped element boron is uniformly distributed in a product phase so as to achieve the purpose of uniform doping. According to the high compaction density lithium ion cathode material prepared by the invention, the tap density is greater than or equal to 2.3 g / cm<3>, the manufacturing compaction density is greater than or equal to 3.70 g / cm<3>, the primary discharge gram capacity can reach more than 153 mAh / g, and the circulating capacity retention rate in 300 circles reaches more than 85%.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

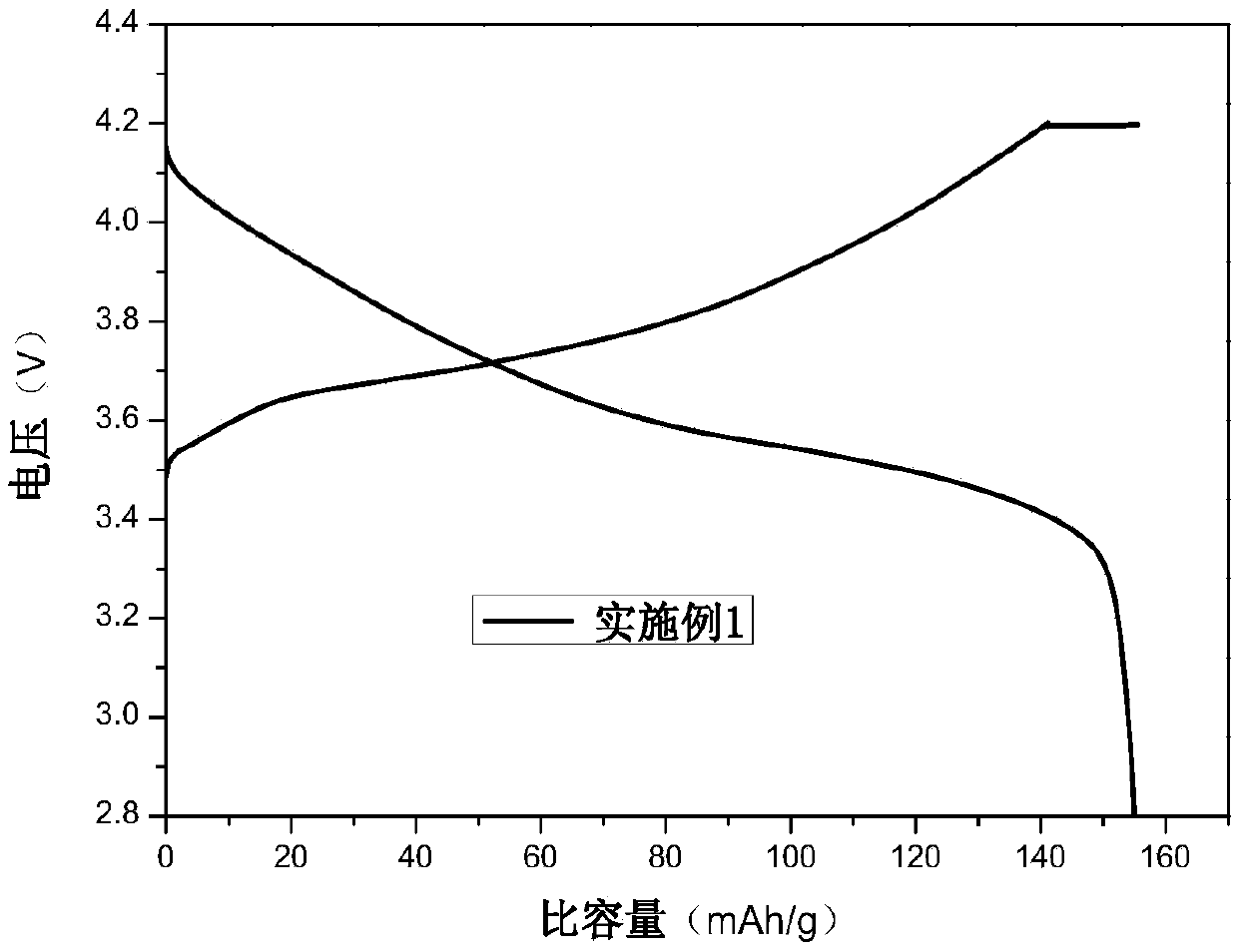

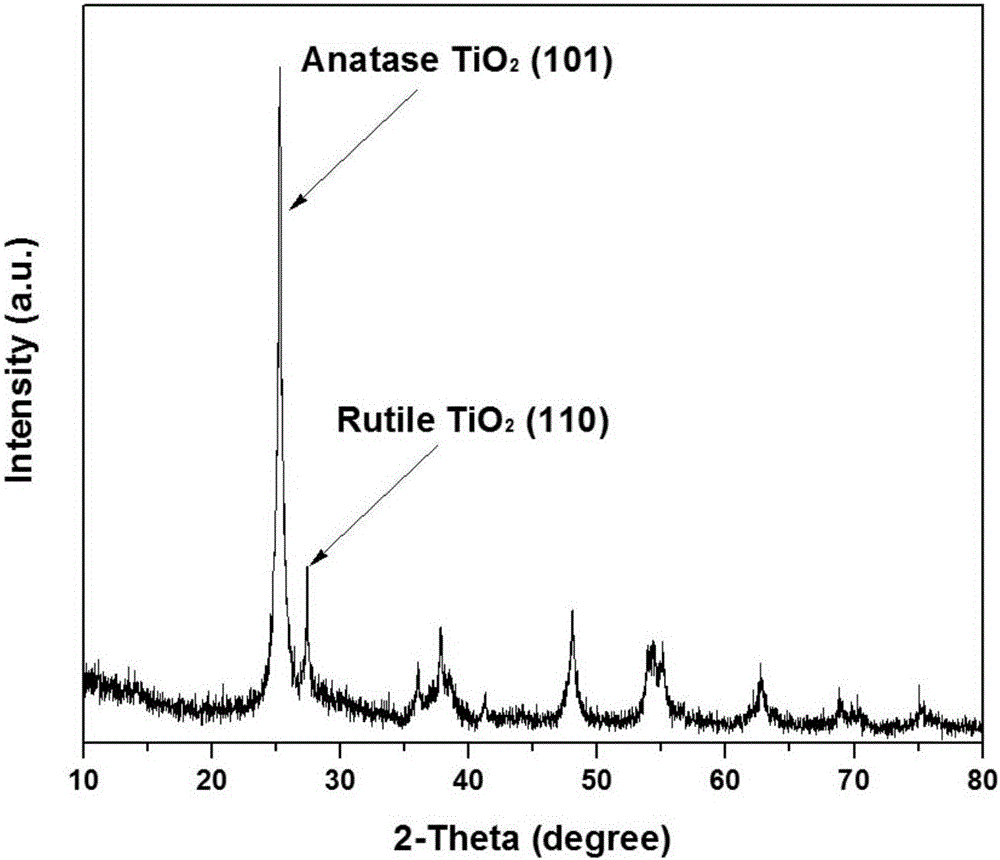

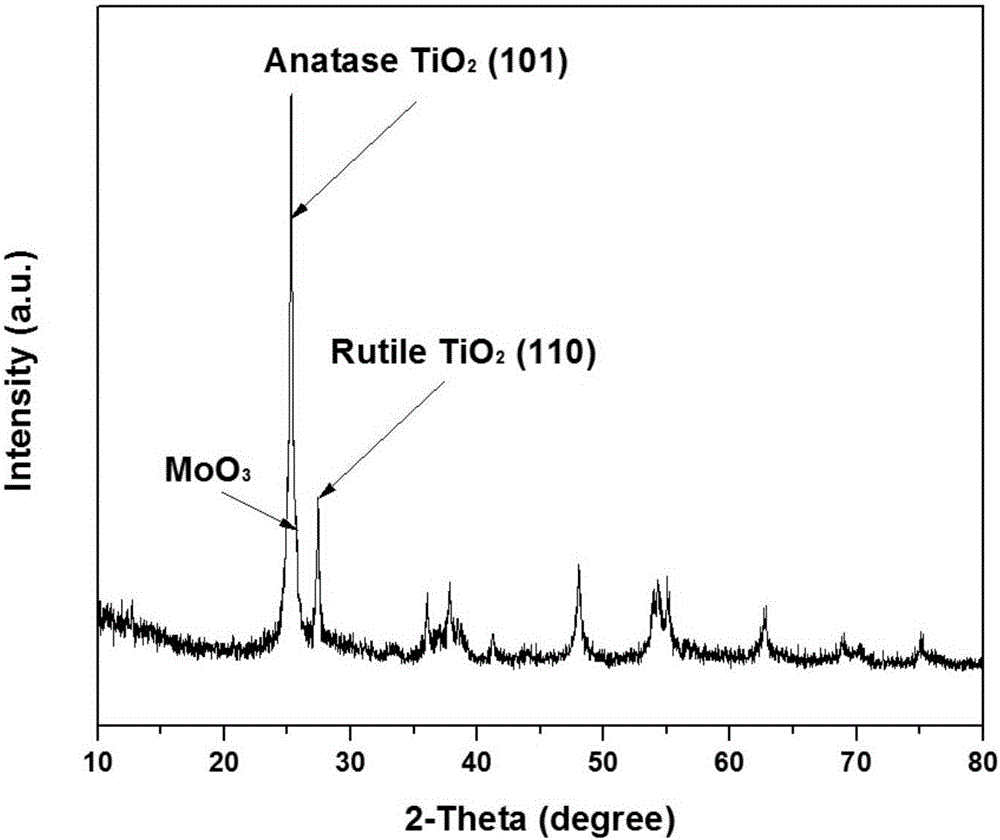

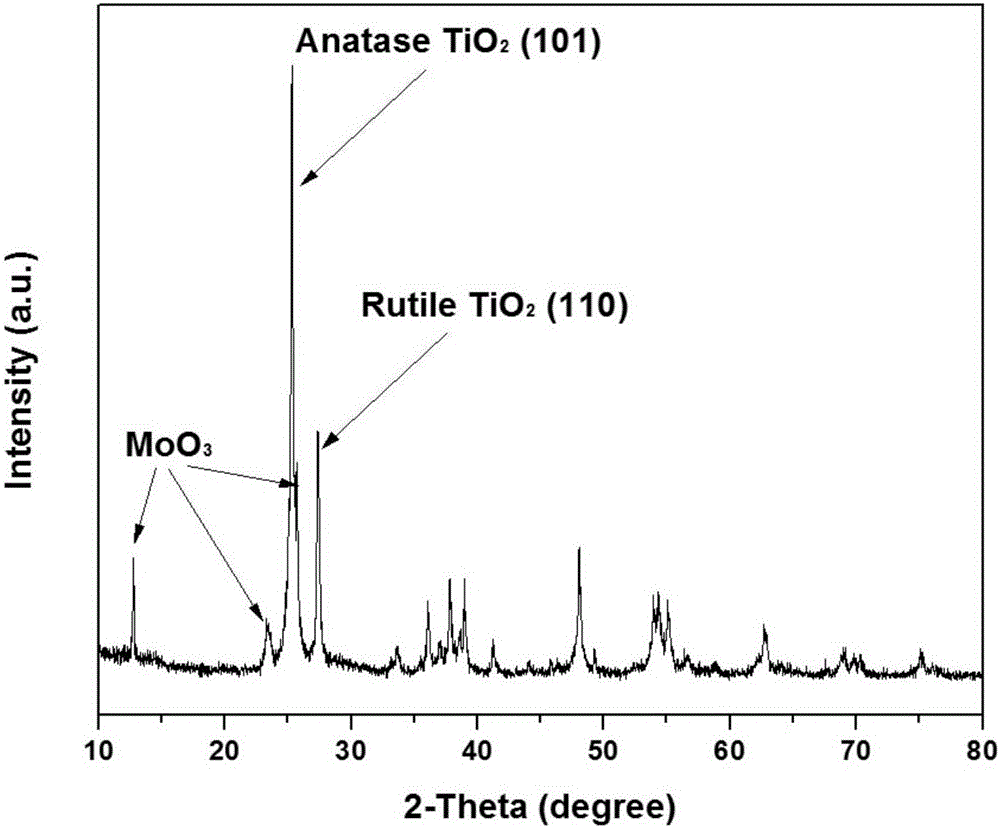

Molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle and preparation method and application thereof

InactiveCN105161700AGood transmission and diffusion effectImprove conductivityMaterial nanotechnologyCell electrodesHigh rateElectrochemistry

The invention relates to a molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle. The surface of a trivalent molybdenum ion doped titanium dioxide nano particle is coated with molybdenum trioxide, titanium dioxide is a mixed phase composed of an anatase phase and a rutile phase, and a sintered interface is arranged among titanium dioxide particles and is of a chain structure. A flame spraying combustion technology is adopted, and the molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle can be rapidly and continuously prepared; a synergistic effect is played to the greatest extent; and the conductivity of TiO2 is improved, an extra lithium insertion space is provided by the TiO2 and MoO3 grown on the surface, the specific capacity is improved, high electrochemical activity and high rate performance of a material are ensured, and the molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle has excellent rate performance and cyclic stability when applied to the field of an anode material of a lithium ion battery.

Owner:EAST CHINA UNIV OF SCI & TECH +1

A ball hydroxide oxidated Ni-Co-Mn and its making method

InactiveCN101127398AHigh tap densityImprove electrochemical activityElectrode manufacturing processesCobalt compoundsReaction timingOxidizing agent

The utility model discloses a spherical hydroxyl nickel oxide cobalt manganese and the fabrication method, relating to the anode material of a lithium battery, and aiming to provide a spherical hydroxyl nickel oxide cobalt manganese and the fabrication method. The fabricated anode material of the lithium battery has the advantages of big tap density, good electrochemical activity, big specific volumetric capacity, low synthesis temperature and short reaction time. The key points of the technical proposal of the utility model are that: the general formula of the spherical hydroxyl nickel oxide cobalt manganese is Ni1-x-yCoxMnyOOH; the spherical hydroxyl nickel oxide cobalt manganese and the fabrication method comprise the following steps: (1)a mixed salt solution of nickel, cobalt and manganese is confected according to the ratio that Ni:Co:Mn=1:(1 / 5-2 / 5):(1 / 5-2 / 5); (2) an alkaline solution of two to ten mol / L is confected; (3) the mixed salt solution of nickel, cobalt and manganese, the alkaline solution and the ammonia are conducted to an reaction kettle; (4) the intermediate products are added to the reaction kettle according to the solid-liquid ratio of 1:2 to 10, and reacted with the oxidant to produce the utility model. The utility model is used as the anode material of lithium batteries.

Owner:HENAN NORMAL UNIV +1

Method for preparing carbon nanotube composite conductive hydrogel coating modified electrode

InactiveCN103196965AImprove electrochemical activityGood biocompatibilityMaterial electrochemical variablesMetal electrodesPolymer chemistry

The invention relates to the field related to biomedical materials and medical apparatuses and in particular relates to a method for preparing a carbon nanotube composite conductive hydrogel coating modified electrode by adopting an electrophoretic deposition method. The method comprises the following steps of: 1. preparing carbon nanotube dispersion liquid; 2. preparing a carbon nanotube composite polymer sol body; 3. pretreating a metal electrode; 4. preparing a composite conductive hydrogel coating through electrophoretic deposition; and 5. crosslinking the composite coating and finally forming the carbon nanotube composite conductive hydrogel coating modified electrode, wherein the prepared electrode is put in phosphate buffered solution for standby use. The method has the advantages that various carbon nanotube surface treatment methods and various sol-gel phase transformation or crosslinking methods are adopted, thus solving the problems that the carbon nanotube and the composite material thereof are difficult to disperse in the water solution systems, are easy to agglomerate and have potential biosafety risks and the like.

Owner:UNIV OF SCI & TECH BEIJING

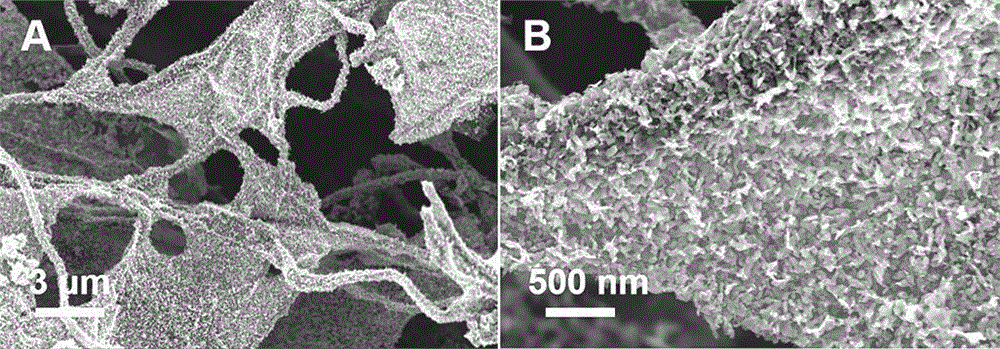

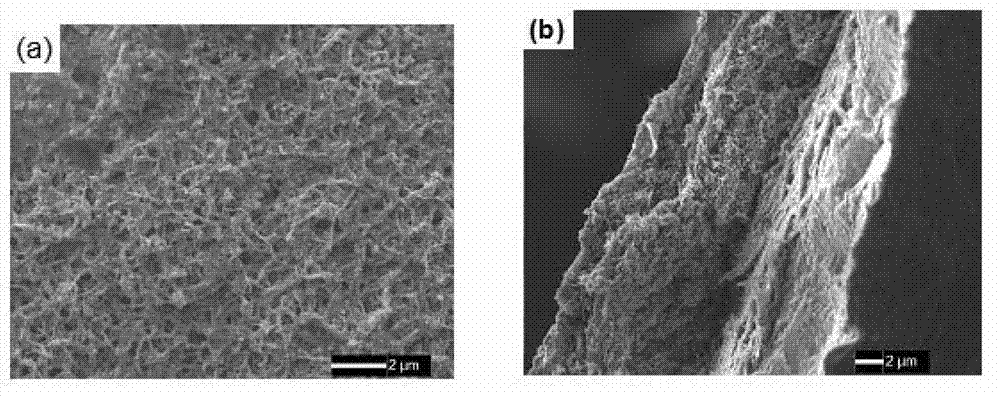

Preparation method of thermally-reduced graphene oxide/nano carbon fiber composite electrode for full-vanadium flow battery

InactiveCN104332640ALarge specific surface areaIncrease the reaction areaCell electrodesFiberCarbon fibers

The invention relates to the field of battery manufacturing and energy source storage and particularly provides a preparation method of a thermally-reduced graphene oxide / nano carbon fiber composite electrode for a full-vanadium flow battery. The preparation method comprises the following steps: firstly, preparing a spinning solution for an experiment; secondly, uniformly mixing graphite oxide powder and the spinning solution; stripping the graphite oxide powder into graphene oxide by using an ultrasonic manner; preparing a nano fiber membrane by adopting an electrostatic spinning method; and then pre-oxidizing the nano fiber membrane in the air and carbonizing in an inert atmosphere pipe type furnace to obtain the needed thermally-reduced graphene oxide / nano carbon fiber composite electrode. According to the full-vanadium flow battery composite electrode prepared by the method, the diameter of carbon fibers is a nano scale; and the carbon fibers are compounded with thermally-reduced graphene oxide and the roughness of the fibers is greatly increased, so that the specific surface area of the electrode is two orders of magnitudes higher than that of a traditionally-used electrode material. Meanwhile, the high-activity thermally-reduced graphene oxide is adopted so that the electrochemical activity of the electrode is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Recycling method for graphite anode material from waste lithium-ion battery

InactiveCN105552468AReduce recycling costsHigh recovery rateWaste accumulators reclaimingBattery recyclingOxalateElectricity

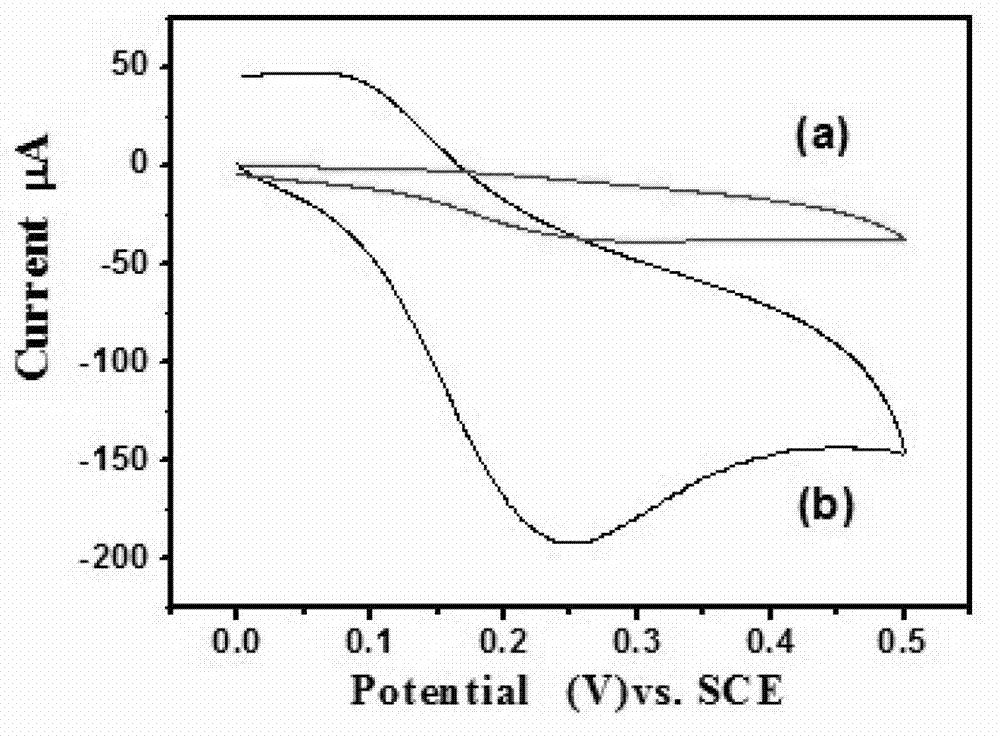

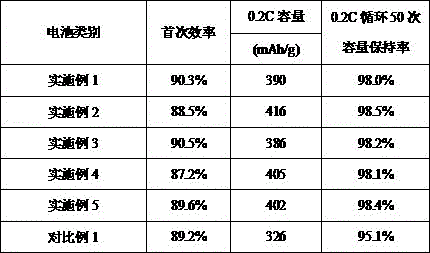

The invention discloses a recycling method for a graphite anode material from a waste lithium-ion battery, and belongs to the technical field of recovering of materials from the waste lithium-ion battery. According to the main points of the technical scheme, the method comprises the following steps: carrying out soaking pretreatment on the graphite material recovered from the waste lithium-ion battery; carrying out ball-mill mixing on pre-calcined and separated graphite powder and a ferrous oxalate or zinc oxalate or ferrous oxalate and zinc oxalate mixture evenly; and finally preparing the battery-grade graphite anode material through high-temperature treatment. The graphite anode material prepared by the method has excellent electrochemical activity and cyclic reversibility; the discharge capacity at 0.2C reaches over 400mAh / g; and the capacity retention rate after 50 cycles is greater than 98.0%. The recycling method can efficiently recover the graphite anode material from the waste lithium-ion battery, further improves the electrical property and achieves recycling of the graphite anode material.

Owner:河南环宇赛尔新能源科技有限公司

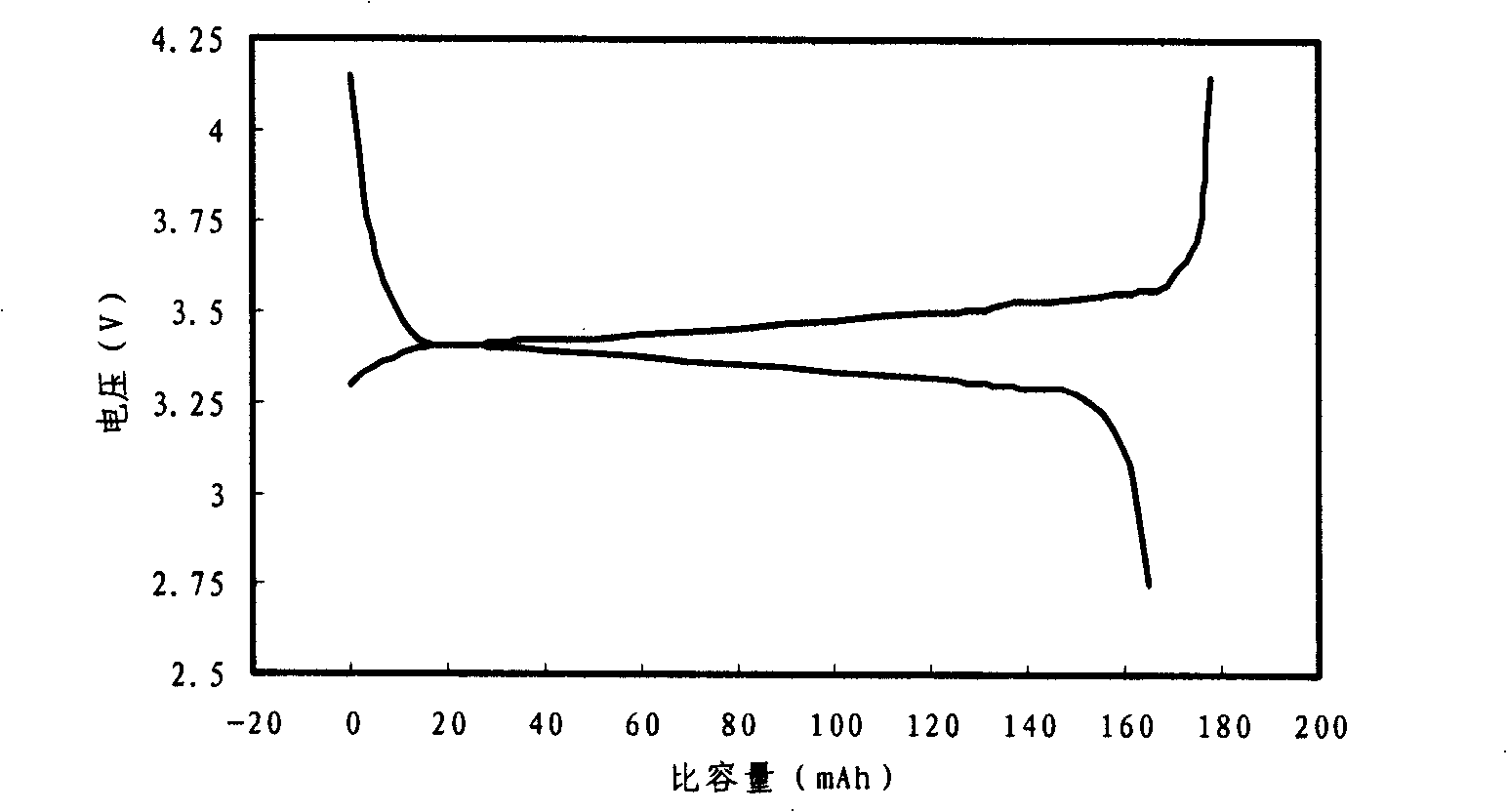

Positive electrode material of lithium ion cell and its preparation method

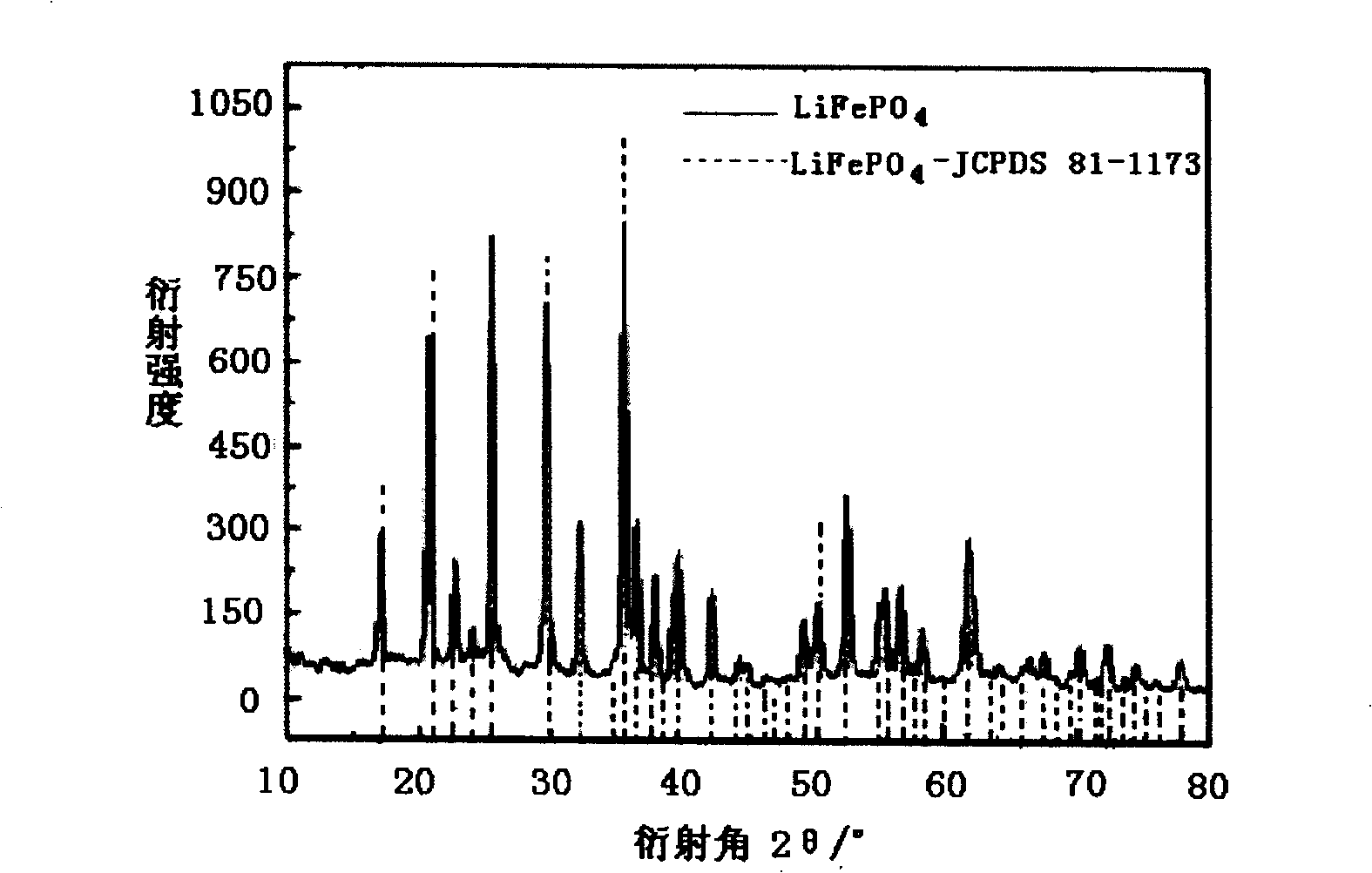

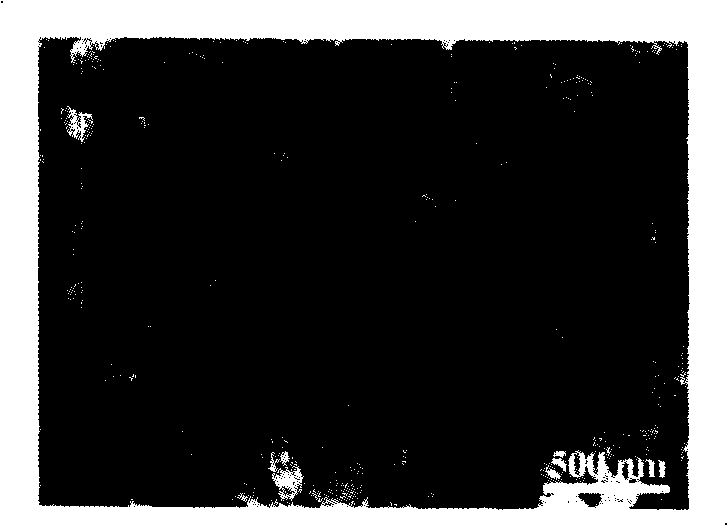

InactiveCN101339988ASolve the control puzzleWell mixedElectrode manufacturing processesPhosphorus compoundsPhosphateCopper nitrate

The invention discloses an electrode material of a lithium-ion battery and a preparation method thereof. The electrode material is lithium iron phosphate (LiFePO4) with the surface coated with nano-copper and is prepared by using the following method: water solution of ferrous phosphate and lithium phosphate is evenly mixed according to a chemical formula, and is added with a stabilizer OP-10 water solution for mixing and stirring, the mixed solution is controlled at a certain temperature for precipitation, and then the precipitate is filtered, rinsed and aired. Heat treatment is carried out for an aired precursor obtained from the previous step at high temperature, therefore a lithium iron phosphate semi-finished product is obtained. The problem of the imperfect particle size of the lithium iron phosphate is solved by controlling the process conditions. Copper nitrate solution is mixed with the lithium iron phosphate semi-finished product and is added with vitamin C for reducing to obtain the copper; metal copper is evenly clad on the surface of the lithium iron phosphate particles. The preparation method has simple operational procedure; the lithium-ion battery anode material of the prepared lithium-ion battery electrode material has high ionic conductivity and electron conductivity, the 1C initial specific capacity is not less than 162mAh / g and the lC tap density is not less than 1.5g / cm<3>.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

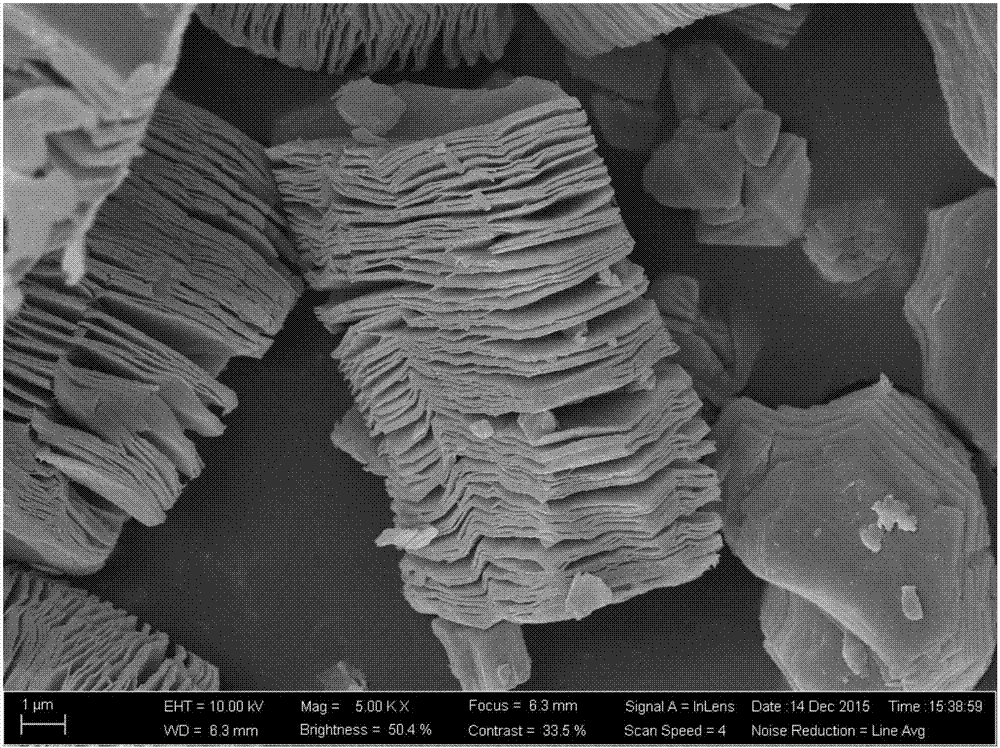

Preparation method for combination electrode for all-vanadium redox flow battery

InactiveCN104241661AImprove electrochemical activityImprove energy efficiencySucessive textile treatmentsCell electrodesCarbon fibersCharge discharge

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method of a bismuth-base catalyst / carbon nanofiber combination electrode for an all-vanadium redox flow battery. Firstly, spinning solution required for an experiment is prepared and then bismuth salt and the spinning solution are uniformly mixed. According to an electrostatic spinning method, a required nanofiber film is prepared and then the nanofiber film is pre-oxidized in the air and is carbonized in an inert atmosphere tube furnace so as to obtain the required bismuth-base electrocatalyst / carbon nanofiber combination electrode. After the obtained electrode material is cleaned and dried, testing of related electrochemical performance representation and charge-discharge properties can be carried out on the electrode material. The carbon fiber diameter, which is prepared according to the preparation method, is in the nano class; compared with a specific surface area of a conventionally used electrode material, the specific surface area of the bismuth-base catalyst / carbon nanofiber combination electrode is greatly increased. Moreover, the carbon nanofibers are compounded with a high-activity bismuth-base electrocatalyst, and thus, electrochemical activity of the electrode can be greatly improved, so that energy efficiency of the all-vanadium redox flow battery is greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method and application of immunosensor based on dopamine biomemetic modification

ActiveCN103575874ASolving Synthetic DifficultiesSolving the lack of simplicityMaterial analysis by electric/magnetic meansDisease diagnosisNanomaterialsMultiple tumors

The invention discloses a preparation method and application of a non-enzymatic electrochemical immunosensor based on dopamine biomemetic modification and relates to the fields of nano-science, biological immune technology, electrochemical sensing and the like. An electrode is functionalized by utilizing dopamine biomemetic modification, and platinum, silver, palladium and other metal nanoparticles with enzymatic activity are synthesized in situ by utilizing the reduction characteristic of a poly-dopamine modification layer; an antibody is immobilized on the surface of the electrode by means of the interaction of the metal nanoparticles and poly-dopamine modification layer; electrochemical immunoassay on a tumor marker can be realized based on the electrocatalytic effect of the metal nanoparticles to an H2O2 reduction reaction and the identification effect of the antibody molecule to an antigen. The method is simple in steps, easy to operate and low in cost, has a high electrochemical activity and excellent response performance, can solve the problem of difficult nano-material synthesis in a conventional method and lack of simple and effective method, is applicable to preparation of multiple tumor marker immunosensor electrodes, and has a wide application prospect in scientific research and clinical application.

Owner:UNIV OF JINAN

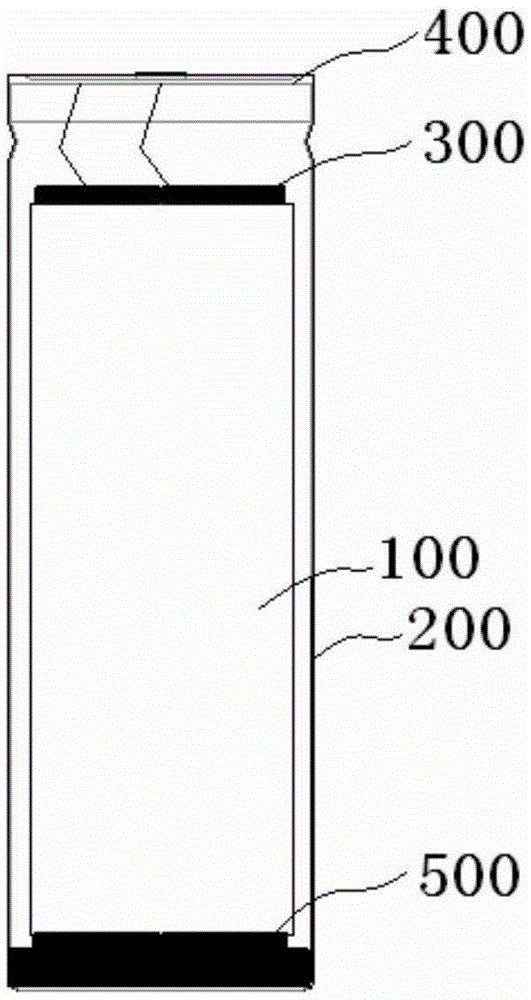

Super-wide-temperature-range nickel-hydrogen battery and manufacturing method therefor

ActiveCN105390755AImprove conductivityLower ohmic resistanceCell seperators/membranes/diaphragms/spacersFinal product manufacturePotassiumNickel electrode

The invention discloses a super-wide-temperature-range nickel-hydrogen battery. The battery comprises an iron shell as well as a nickel electrode, a hydrogen electrode, a diaphragm and an electrolyte solution mounted in the iron shell, wherein the nickel electrode takes foam nickel as a substrate material; the space in foam nickel is filled with a positive electrode active substance Ni(OH)2, a conductive agent, an additive and a binder; the hydrogen electrode takes a porous nickel-plated steel belt, a copper net or foam nickel as a substrate material; the porous nickel-plated steel belt, the copper net or foam nickel is coated with a negative electrode active substance, namely, hydrogen storage alloy powder, the conductive agent, the additive or the binder; and the electrolyte solution is a mixture of a potassium-rich alkaline aqueous solution and sodium tungstate or tungstic acid crystals. The invention furthermore discloses a manufacturing method for the super-wide-temperature-range nickel-hydrogen battery. According to the super-wide-temperature-range nickel-hydrogen battery disclosed by the invention, the ratio of 0.2C discharge capacity to normal-temperature capacity maximally can reach 70-80% in an environment with the temperature of -45 DEG C; and the ratio of 0.2C discharge capacity to normal-temperature capacity of the nickel hydrogen battery maximally can reach 85-95% in an environment with the temperature of 70 DEG C. Moreover, the manufacturing method is simple and suitable for large-scale production.

Owner:HENGYANG BST POWER

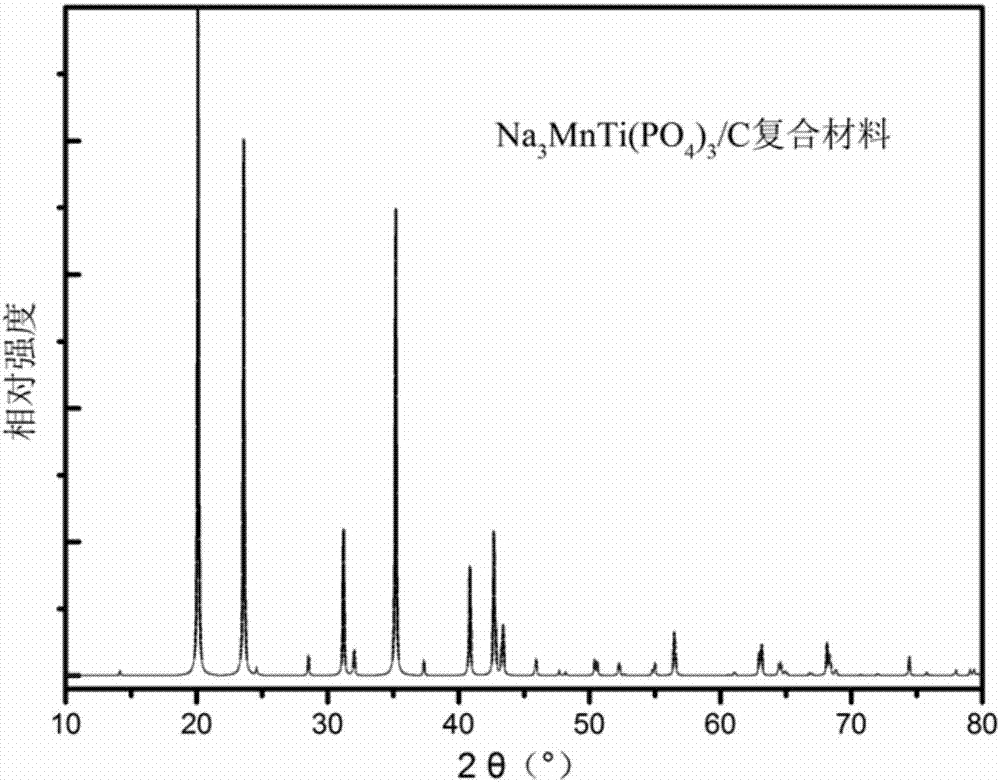

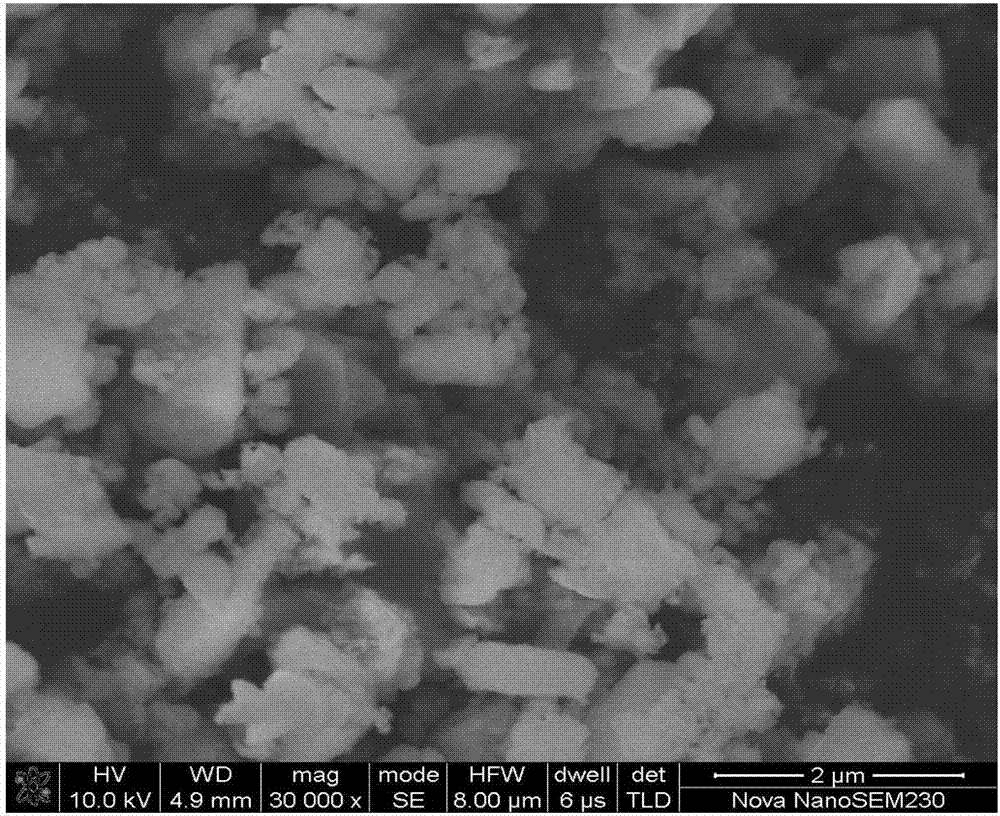

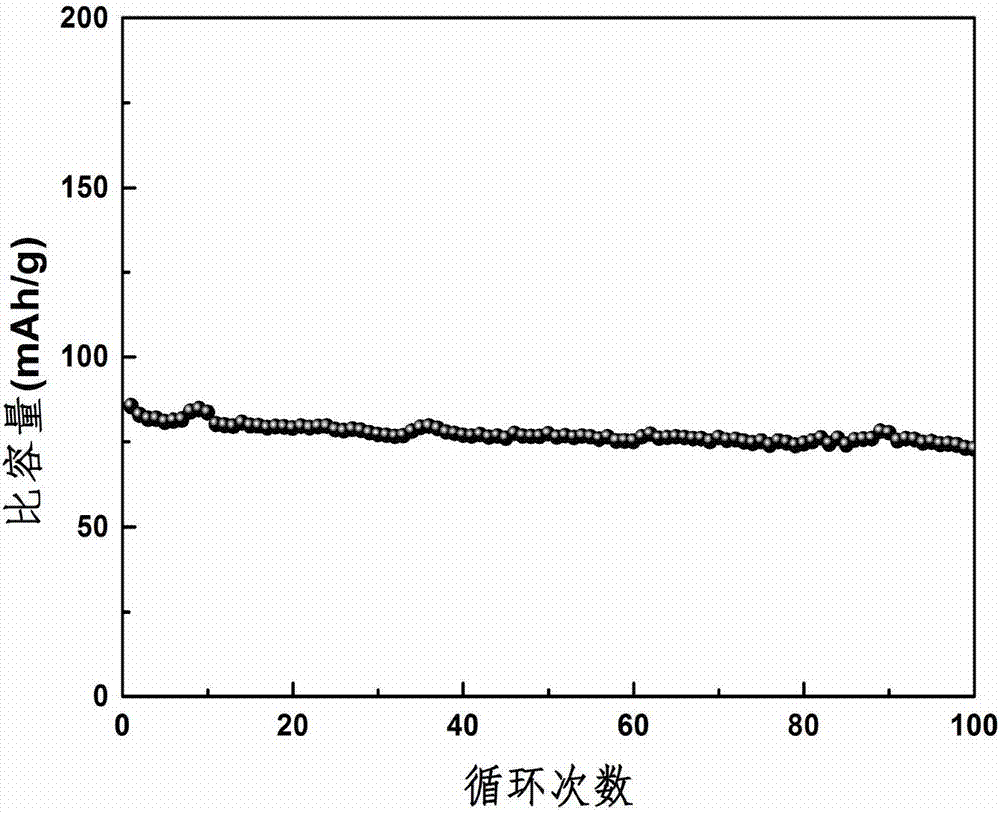

Carbon coated titanium manganese sodium phosphate composite material, preparation method and application thereof in sodium-ion battery

ActiveCN106981641AImprove stabilityImprove conductivityCell electrodesSecondary cellsSodium phosphatesHigh energy

The invention discloses a Na3MnTi(PO4)3 / C composite material, a preparation method and an application thereof in a sodium-ion battery. The composite material is composed of carbon coated Na3MnTi(PO4)3 particles. The preparation method comprises the following steps: utilizing an organic matter as a reducing agent and a carbon source, taking low-cost manganese source and titanium source as raw materials and adopting a solid phase method for synthesizing a carbon coated Na3MnTi(PO4)3 composite anode material with an excellent performance. The preparation method is simple and practicable, the condition is mild and the yield is high. When the prepared composite material is used as an anode material of the sodium-ion battery, the anode material shows high energy density, high working voltage, excellent circulatory stability and excellent rate capability.

Owner:湖南钠邦新能源有限公司

Preparing method for nano micron lead sulfate with electrochemical activity and method adopting lead sulfate to prepare lead-acid cell

ActiveCN103723761AShorten the production cycleShorten board making timeMaterial nanotechnologyLead-acid accumulator electrodesFiberSulfate

The invention discloses a preparing method for nano micron lead sulfate with electrochemical activity and a method adopting the lead sulfate to prepare a lead-acid cell. The preparing method for nano micron lead sulfate includes the following steps: using a morphological control agent for controlling the crystal growth of lead sulfate; enabling a water solution of soluble lead salt to react with a water solution of soluble sulfate / sulfuric acid, or enabling an aqueous dispersion of lead elementary substance / insoluble lead compound to react with a water solution of sulfuric acid in a clash flow reactor; finally obtaining the nano micron lead sulfate. The preparing method for the lead-acid cell includes the following steps: adopting the lead sulfate as active substances for an anode and a cathode; preparing a positive plate and a negative plate through adding fibers, a conductive agent, an expanding agent and the like; adding membranes between the two poles; then placing the two plates in a cell box for battery charging and formation. The invention has the advantages that the nano micron lead sulfate is high in electrochemical activity; the performance of the lead-acid cell is high and the service life of the lead-acid cell is long after the nano micron lead sulfate is adopted as the active substances of the lead-acid cell; besides, the preparing methods for the lead sulfate and the lead-acid cell are simple and feasible and have the characteristics of energy conservation and environmental protection.

Owner:SOUTHEAST UNIV

Iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and preparation method and application therefor

InactiveCN105609793ALarge specific surface areaMany active sitesCell electrodesPyrroleNitrogen doped

The invention belongs to the technical field of a nanomaterial, and specifically relates to an iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and a preparation method and an application therefor. The porous material is formed by embedding graphite-carbon-coated iron carbide into a nitrogen-doped porous graphene band network structure; the preparation method for the iron-nitrogen-doped graphene porous material comprises the steps of preparing a graphene oxide solution; adding a proper amount of conductive macromolecular pyrrole to the graphene oxide solution; obtaining uniform hydrogel through a hydrothermal process; performing oxidative polymerization on the hydrogel by ferric iron; then dispersing the hydrogel into a fresh ferric iron solution to complete adsorption; then performing drying and high-temperature carbonization thermal processing; and finally removing non-active and free iron phase from the reaction system by dilute acid so as to obtain the iron-nitrogen-doped graphene porous material. The porous material can be used as the negative electrode catalyst for a fuel cell, and shows quite high catalytic oxygen reduction activity, so that the porous material has quite important research meaning and bright application prospects.

Owner:FUDAN UNIV

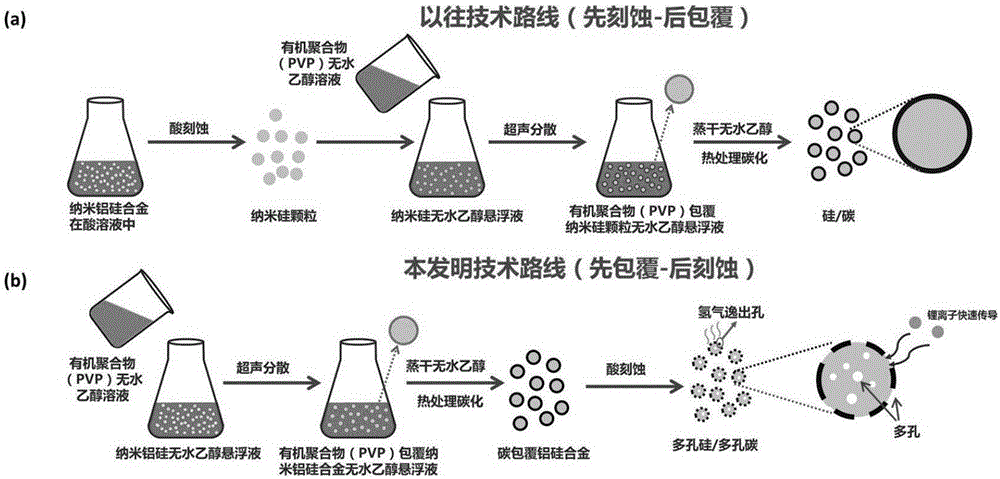

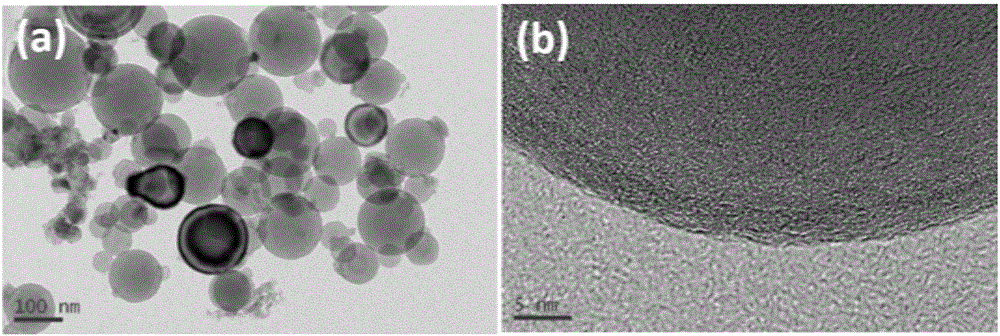

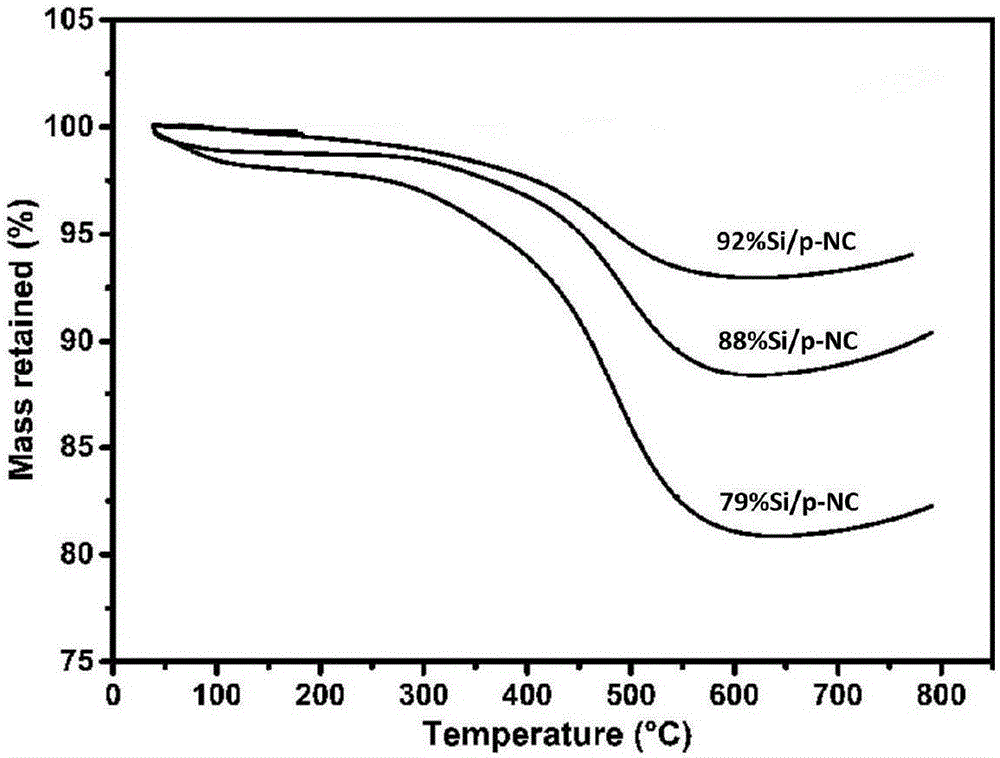

Nano silicon/porous carbon composite anode material of lithium ion batteries as well as preparation method and application of composite anode material

The invention discloses a nano silicon / porous carbon composite anode material of lithium ion batteries as well as a preparation method and an application of the composite anode material. The composite anode material is a core-shell structure material consisting of a porous nano silicon particle core and a porous carbon layer shell. The preparation method of the composite anode material comprises the steps as follows: carbonization treatment is performed after an organic polymer layer is coated on the surface of aluminum-silicon alloy powder, aluminum is removed by performing acid etching on a carbonization product, pore forming is performed on a carbon layer, and thus the nano silicon / porous carbon composite anode material is obtained. The preparation method is simple and low in cost, the mass production requirement is met, and the prepared composite anode material can be used for preparing the lithium ion battery and shows high capacity and excellent cycle and rate performance.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com