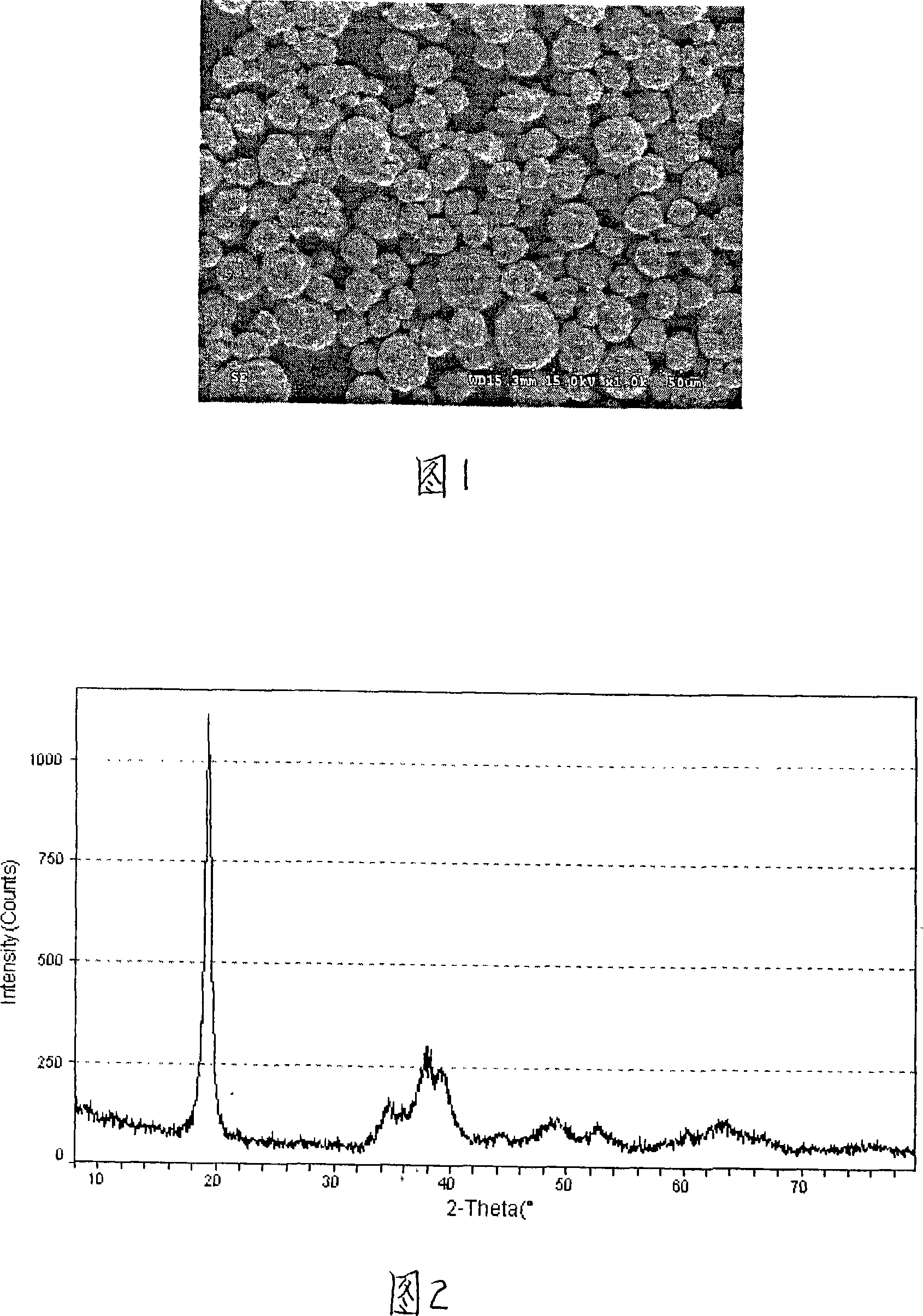

A ball hydroxide oxidated Ni-Co-Mn and its making method

A nickel oxyhydroxide, spherical technology, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems of affecting volume specific capacity, long time, low reactivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] Prepare the mixed solution of nickel sulfate, cobalt sulfate and manganese sulfate of 1.5mol / L, wherein the ratio of the substance amount (moles) of nickel, cobalt and manganese element is 1: 1: 1, under vigorous stirring, mix solution and 25% ammonia solution was fed into the 100L reactor at the flow rate of 10L / h and 1L / h respectively, and 8mol / L sodium hydroxide solution was added in parallel to control the pH value to 11.5, the reaction temperature was 60°C, and the upper continuous Spherical Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 . The prepared spherical Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 According to the ratio of solid to liquid 1:4 and deionized water into another reactor, then add 600ml of 30% H2O per kg of solids 2 o 2 The solution was stirred and reacted for 4 hours at a certain speed, and the product of the present invention was obtained by filtering, washing and drying.

Embodiment 2

[0009] Spherical Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 The preparation is the same as example 1, the spherical Ni of preparation 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 Add 1:2 solid-liquid ratio and deionized water into another reaction kettle, then add 4.5L of 10% NaClO solution per kg of solid matter, stir and react at a certain speed for 6h, and obtain this product through filtration, washing and drying. Invent products.

Embodiment 3

[0011] Spherical Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 The preparation is the same as example 1, the spherical Ni of preparation 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 Add 1:6 solid-to-liquid ratio and deionized water into another reactor, and then add 1.5kg K per kg of solids 2 S 2 o 4 , stirred and reacted at a certain speed for 8 hours, and the product of the present invention was obtained by filtering, washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com