Patents

Literature

189 results about "Oxide cathode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

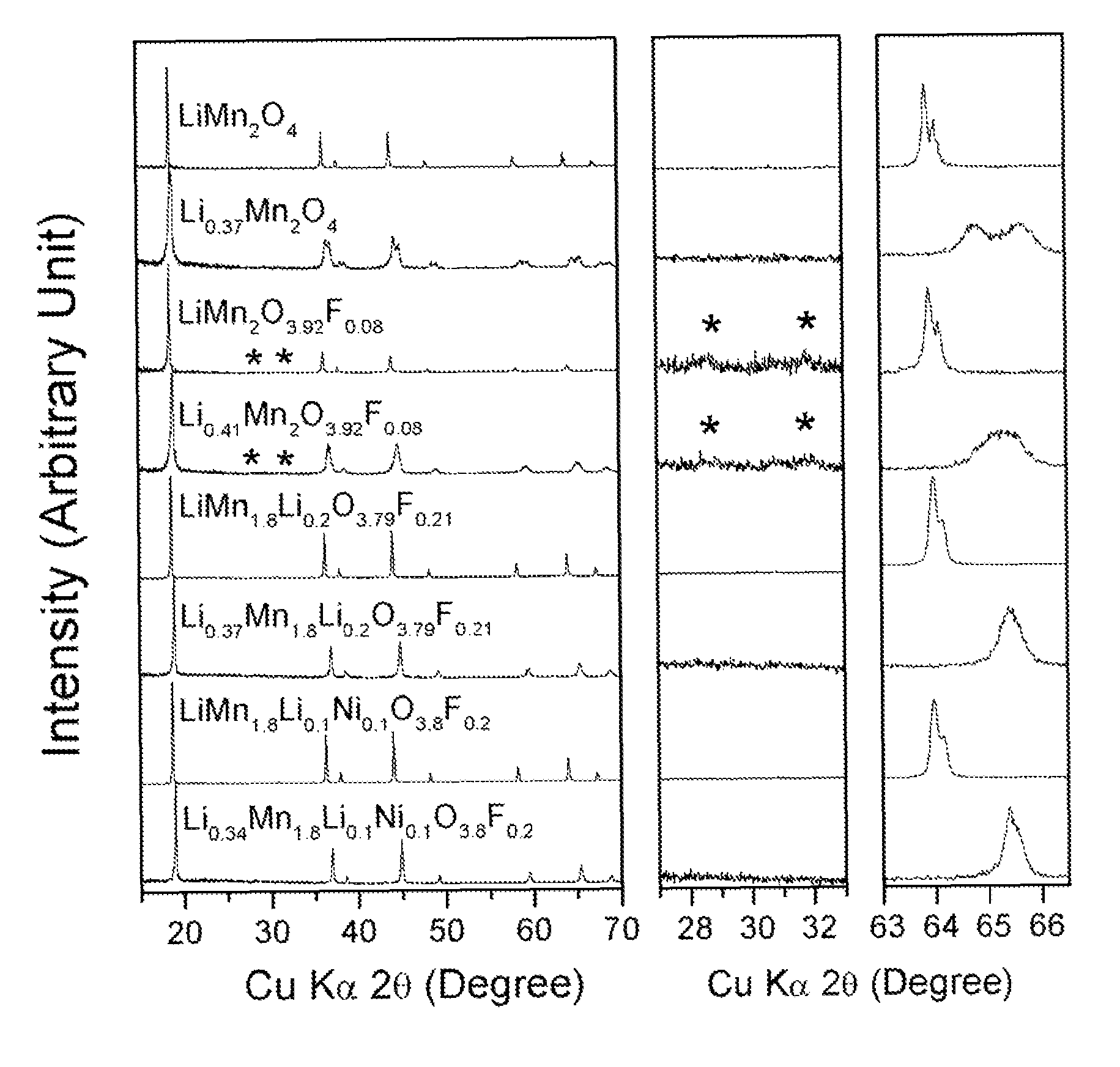

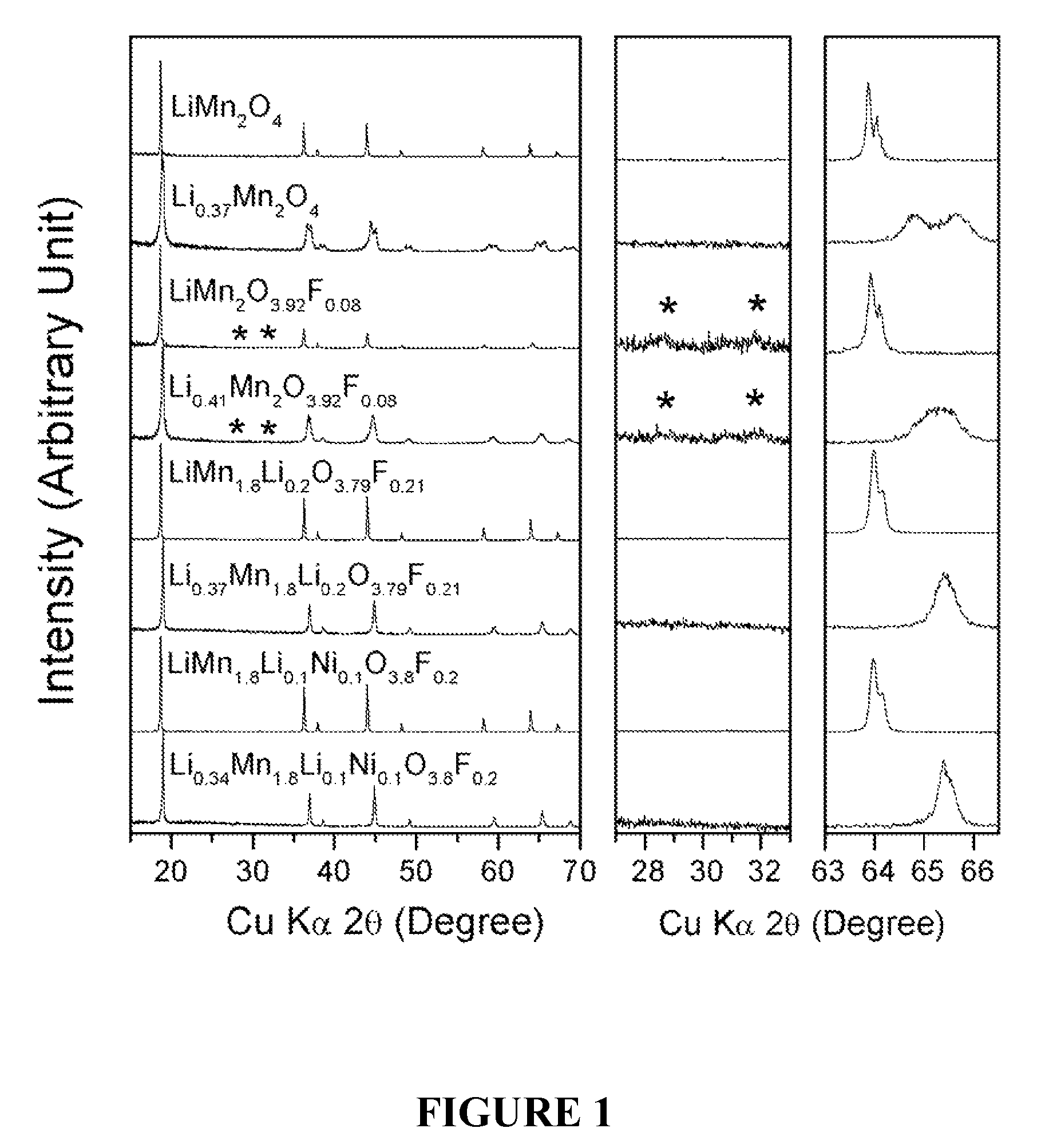

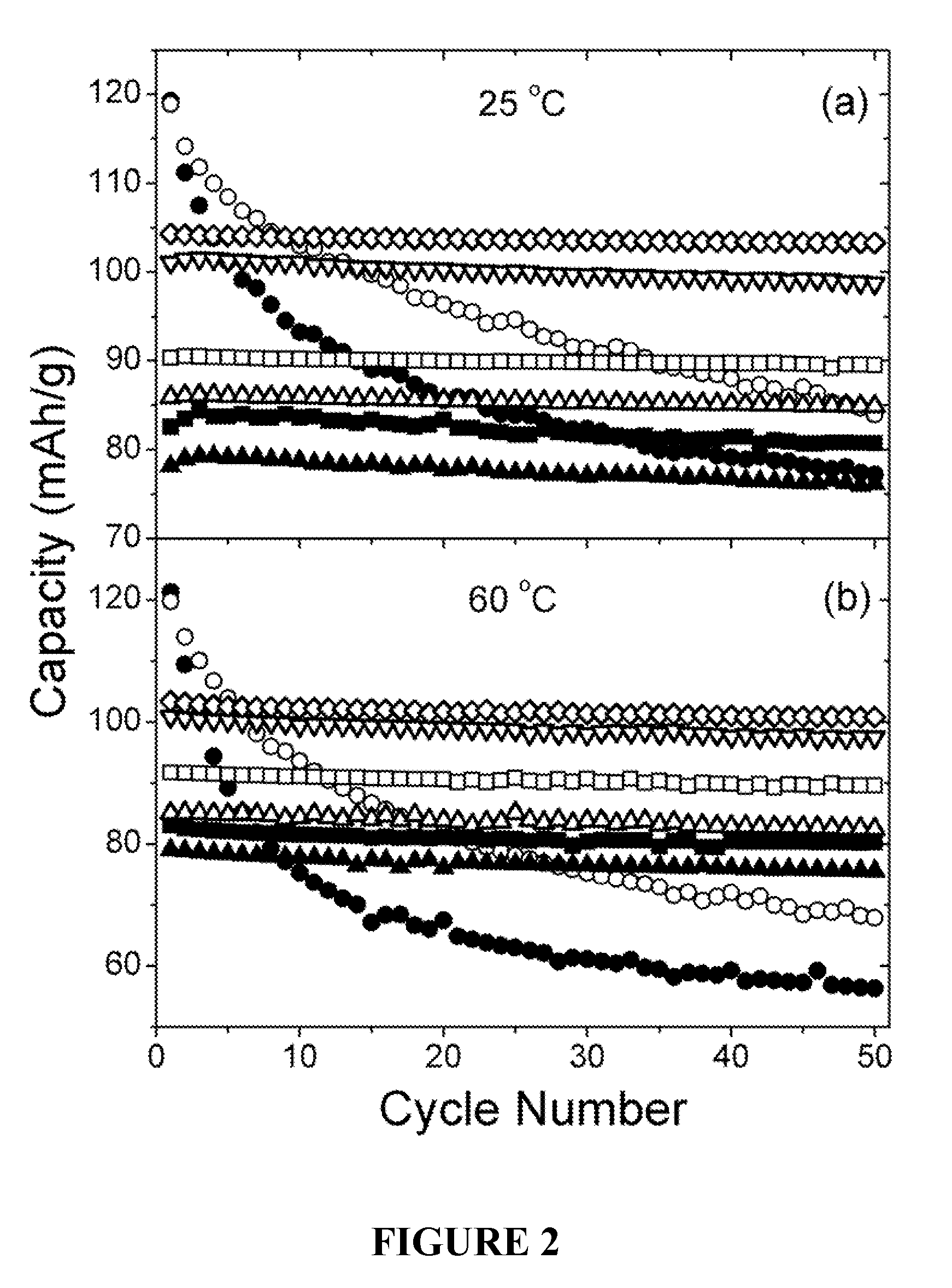

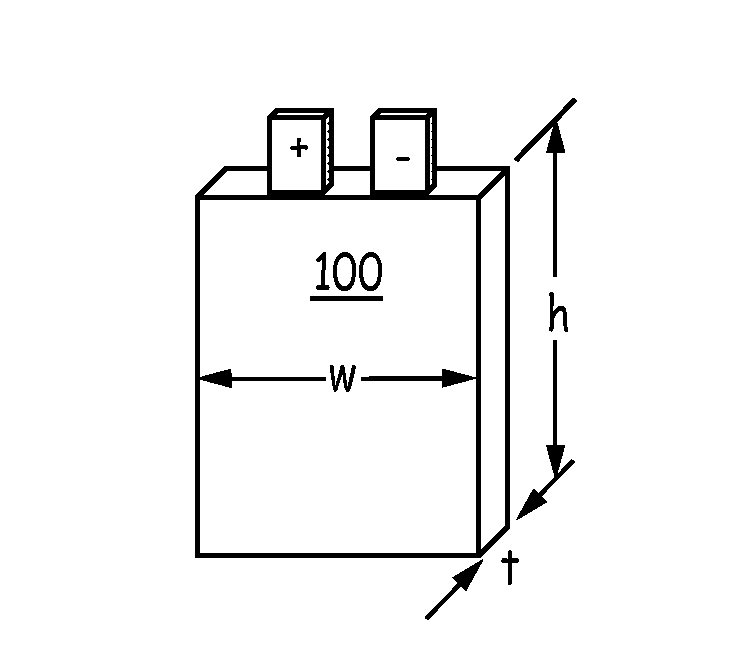

Cation-substituted spinel oxide and oxyfluoride cathodes for lithium ion batteries

InactiveUS7718319B2Cyclability at elevated temperaturesImprove rendering capabilitiesElectrode carriers/collectorsConductive materialSpinelGraphite

The present invention includes compositions and methods of making cation-substituted and fluorine-substituted spinel cathode compositions by firing a LiMn2−y−zLiyMzO4 oxide with NH4HF2 at low temperatures of between about 300 and 700° C. for 2 to 8 hours and a η of more than 0 and less than about 0.50, mixed two-phase compositions consisting of a spinel cathode and a layered oxide cathode, and coupling them with unmodified or surface modified graphite anodes in lithium ion cells.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

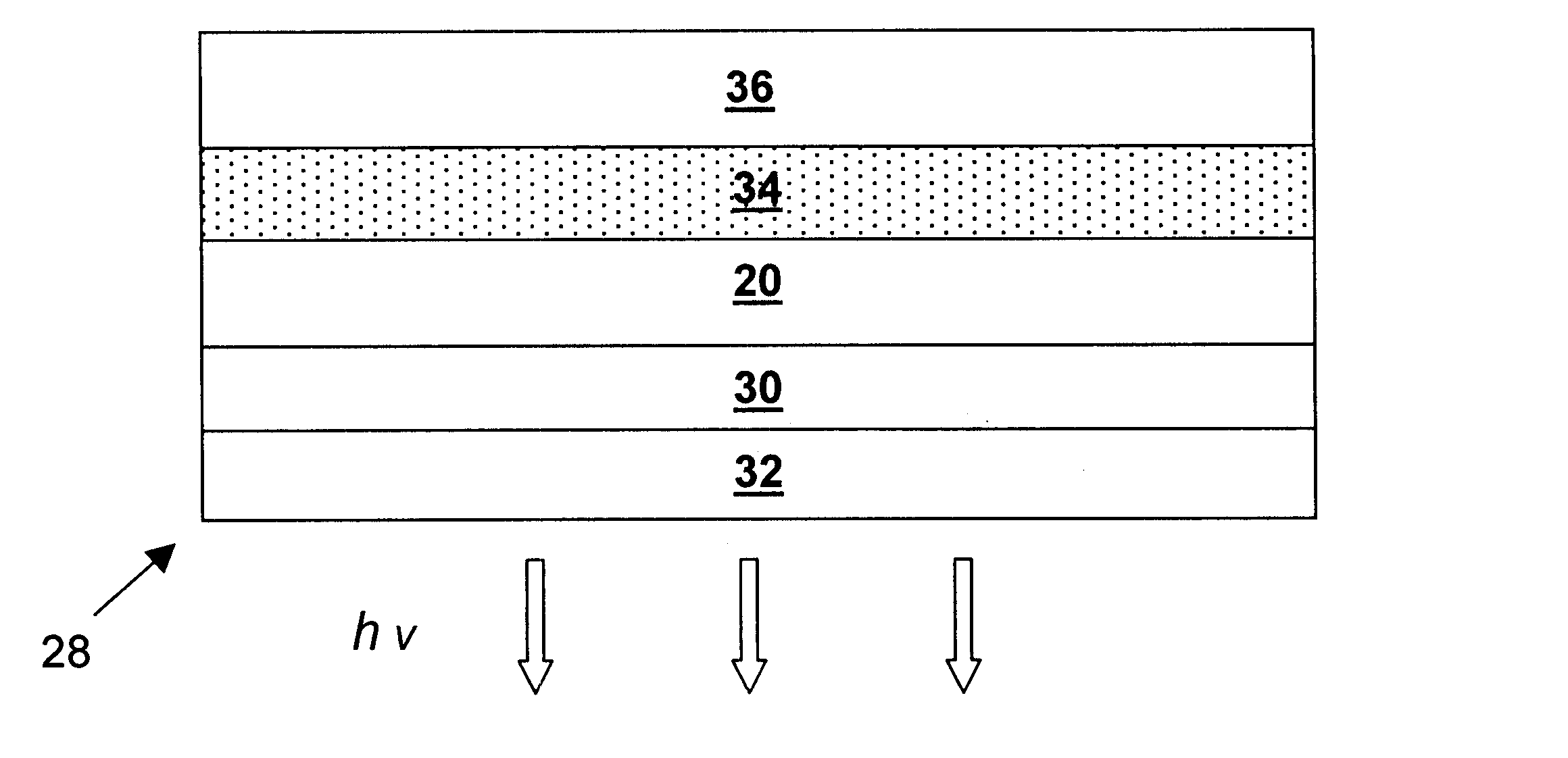

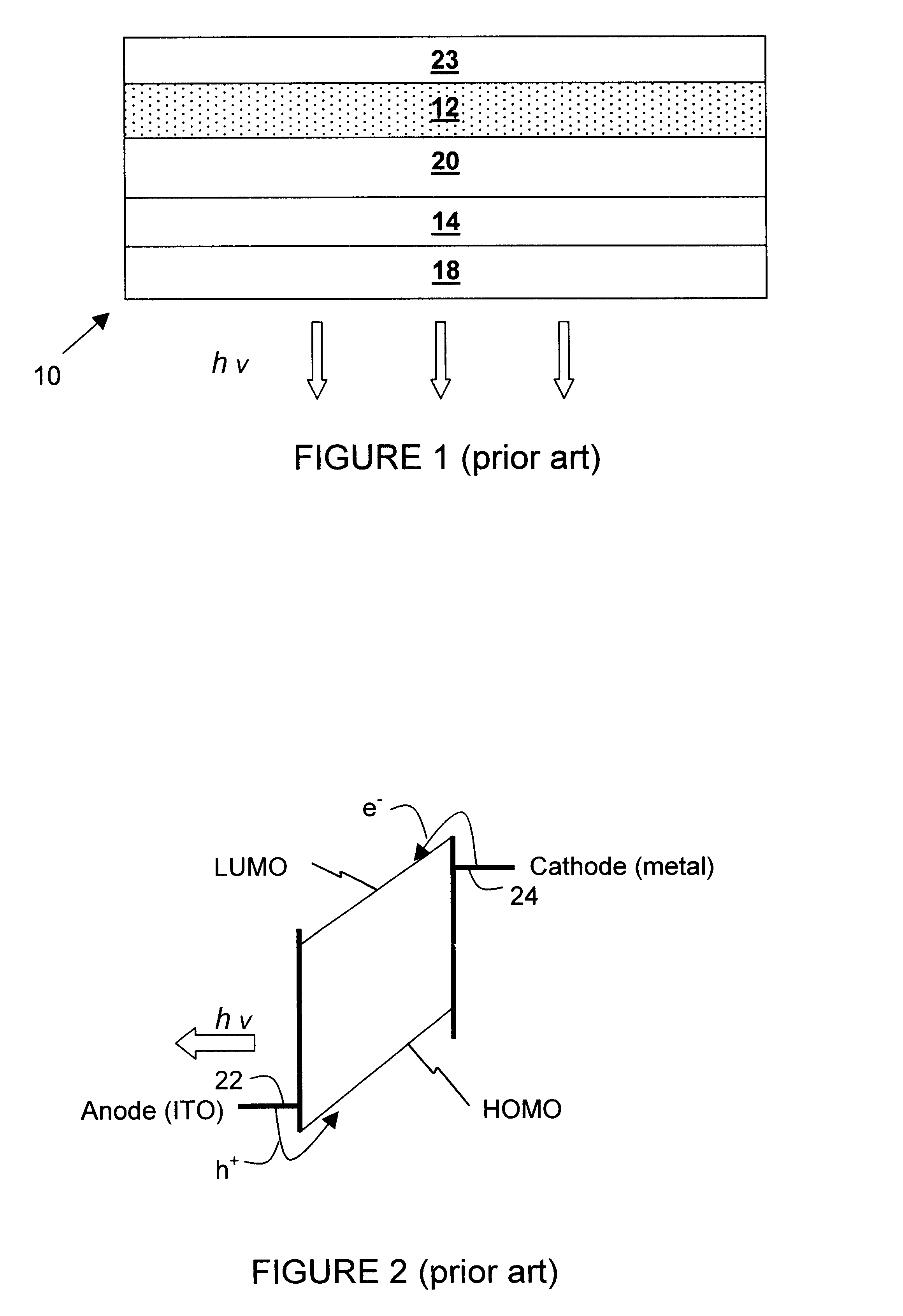

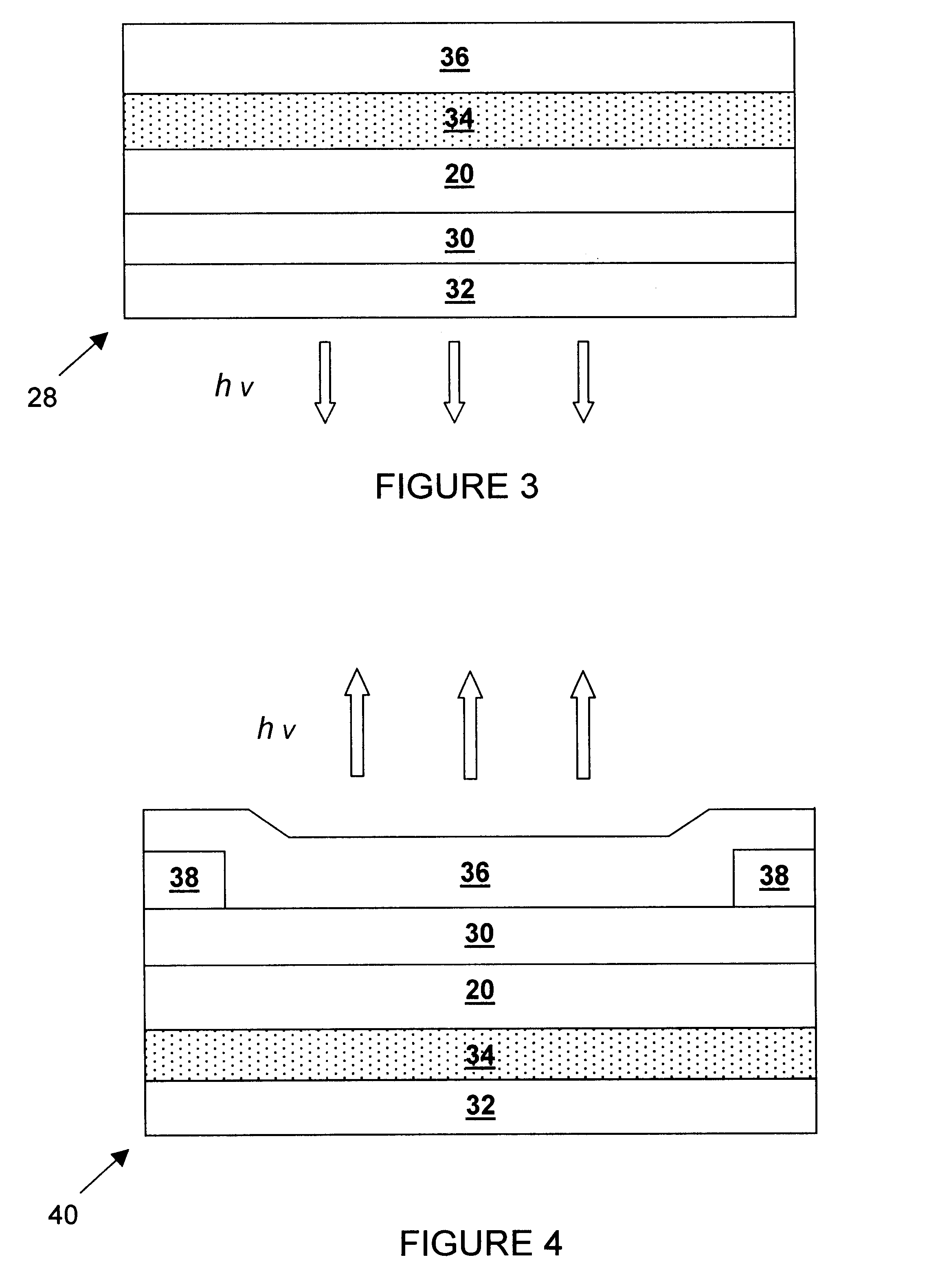

Electronic light emissive displays incorporating transparent and conductive zinc oxide thin film

InactiveUS6541908B1Discharge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOxide cathode

The present invention provides co-doped zinc oxide to flat panel, light emissive display devices and vacuum microelectronic devices to improve their efficiency and lifetime. This material has a low growth temperature and is compatible with metal oxide semiconductor (MOS) processing technology. It is tranparent, chemically stable and has a low work function, which result in many advantages when being used as the cathode for the aforementioned devices. In one embodiment of the emissive display device, an organic light diode (OLED) display has a high work function metal anode, such as platinum (Pt), gold (Au) or nickel (Ni) and a low work function co-doped zinc oxide cathode. Because of the energy level alignment provided by these two materials, the potential energy barriers to injection of electrons from the cathode and holes from the anode into the organic emissive medium are minimized so the display device operates more efficiently.

Owner:TELEDYNE SCI & IMAGING

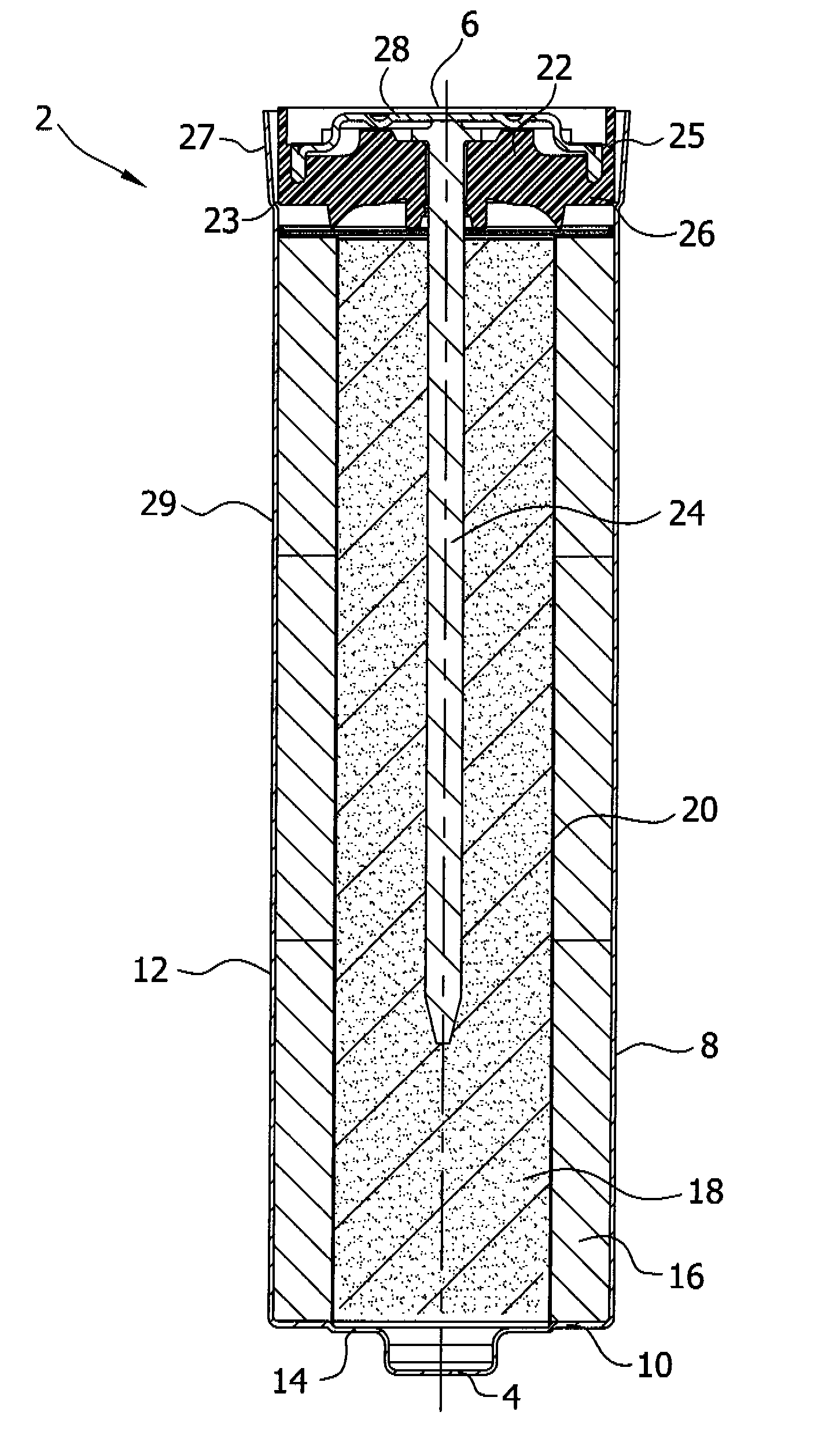

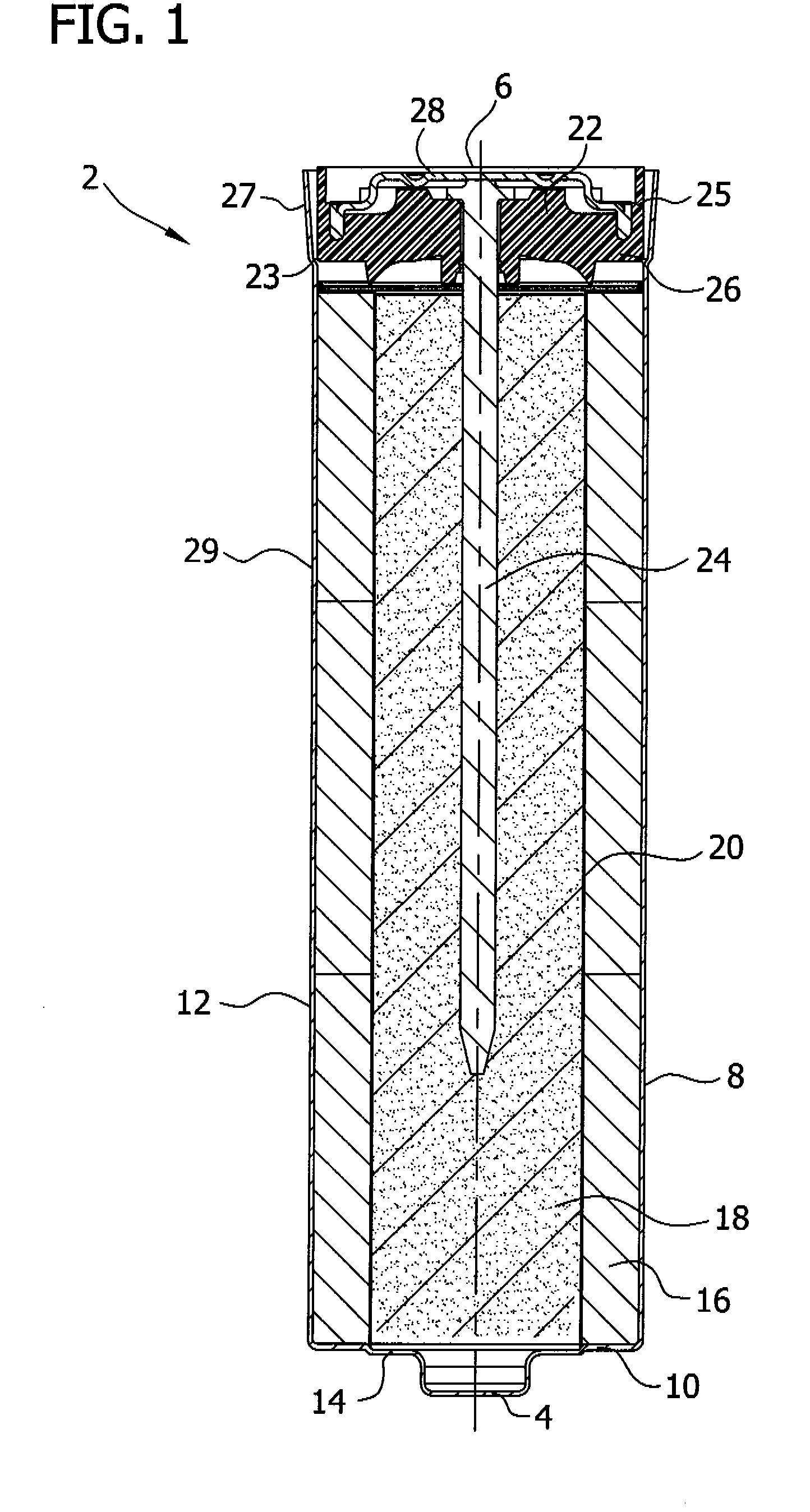

Copper-manganese mixed oxide cathode material for use in alkaline cells having high capacity

ActiveUS20080090138A1Cell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte accumulator electrodesStructural waterMixed oxide

The present invention relates to a copper-manganese mixed oxide cathode material, which is suitable for use in a cathode of an electrochemical cell, and which has the formula MnxCuyOz,.nH2O, wherein the oxidation state of Cu is between about +1 and about +3, the oxidation state of Mn is between about +2 and about +7, x is equal to about 3−y, y is less than about 3, z is calculated or experimentally determined, using means known in the art, based on the values of x and y, as well as the oxidation states of Mn and Cu, and nH2O represents the surface and structural water present in the mixed oxide material. The present invention further relates to an electrochemical cell comprising an anode, a cathode, and a separator disposed between the anode and cathode, and an electrolyte in fluid communication with the anode, the cathode and the separator, wherein the cathode comprises the noted cathode material. The present invention still further relates to such an active cathode material, or an alternative cathode material, wherein the copper-manganese mixed oxide comprises a defect spinel-type structure, which is also suitable for use as a cathode component of an alkaline electrochemical cell.

Owner:ENERGIZER BRANDS

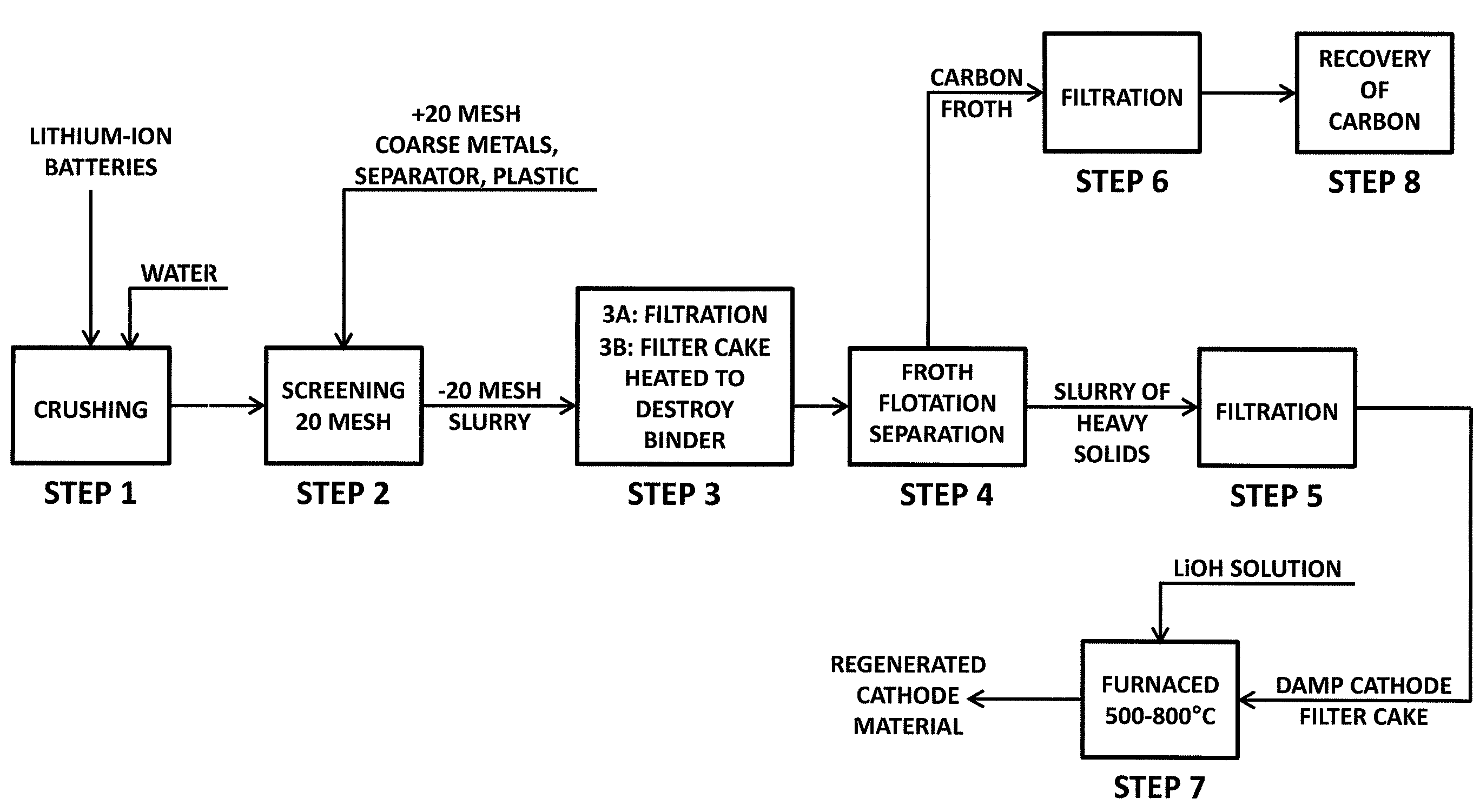

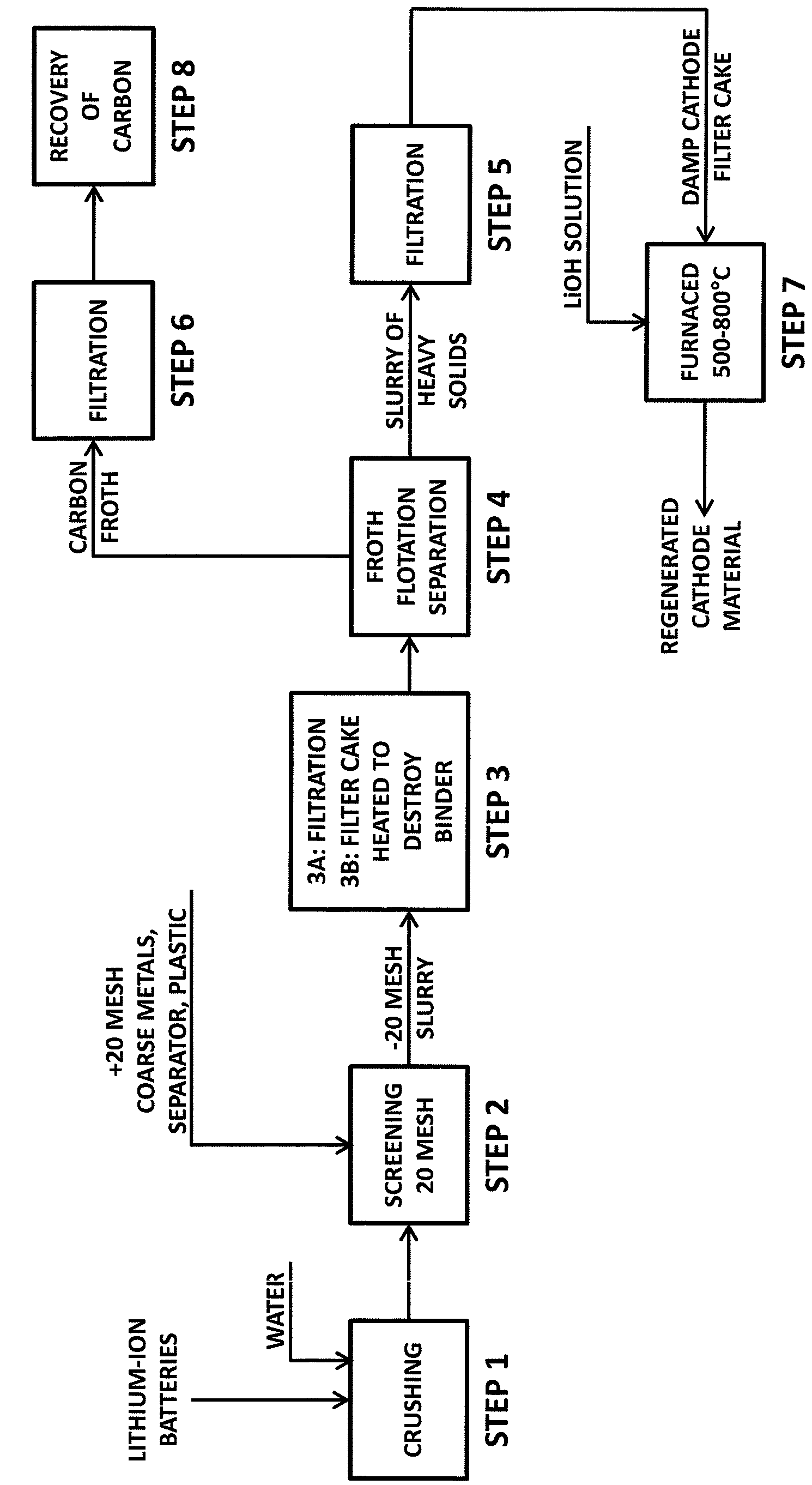

Recovery of lithium ion batteries

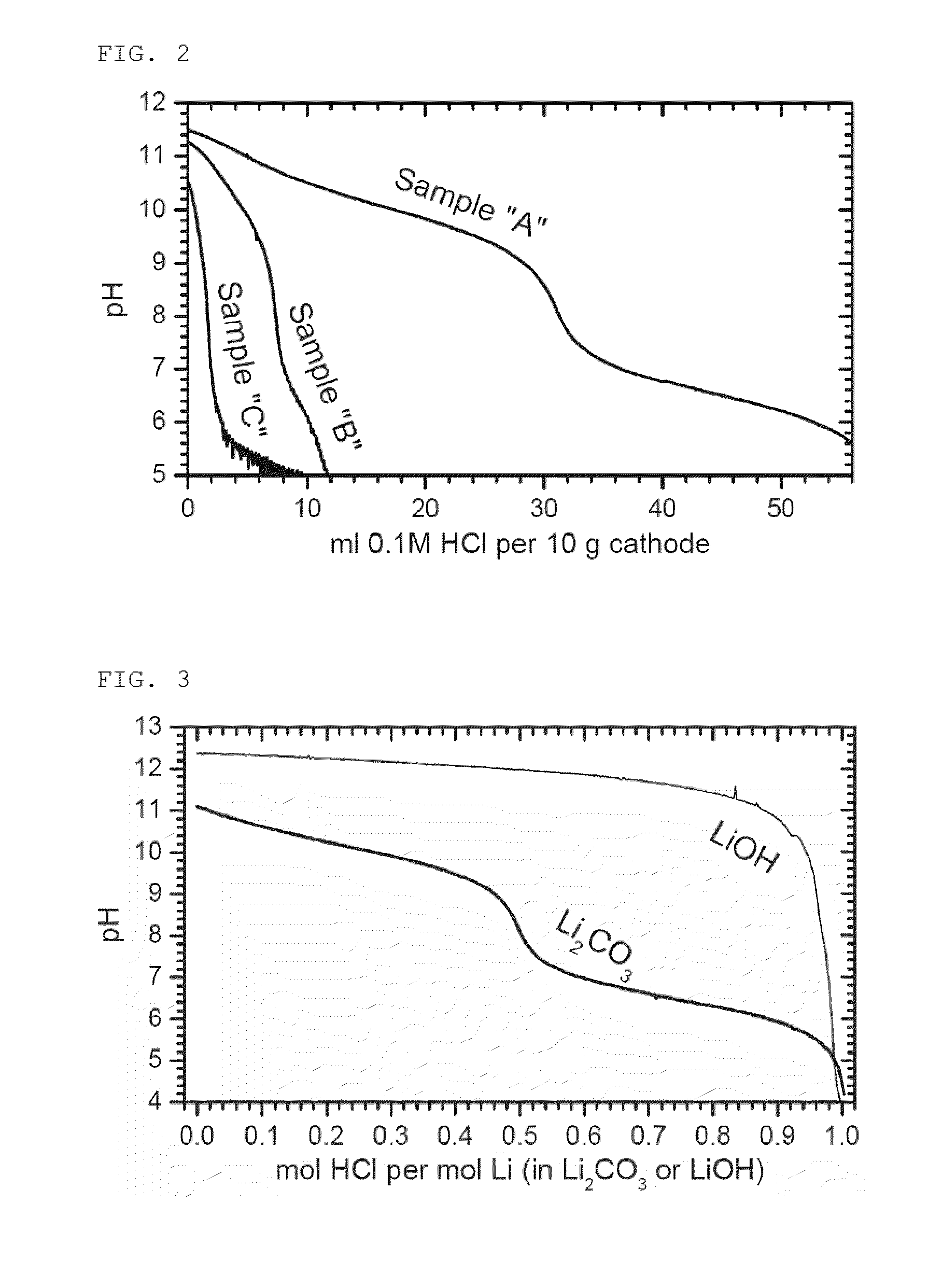

ActiveUS8616475B1Small particle sizeCell electrodesElectrolyte/reactants regenerationLithium hydroxideLithium metal

Owner:RETRIEV TECH

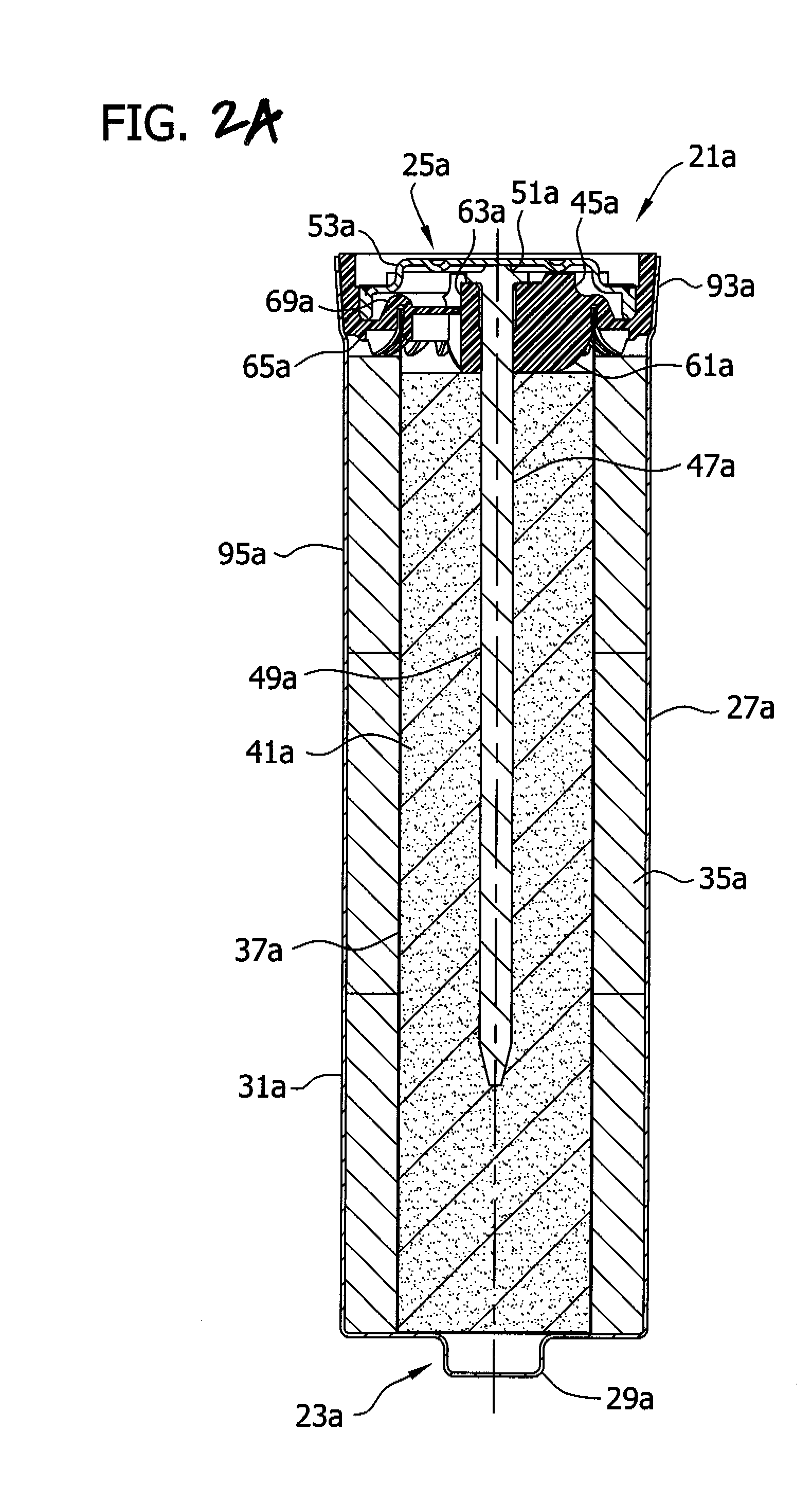

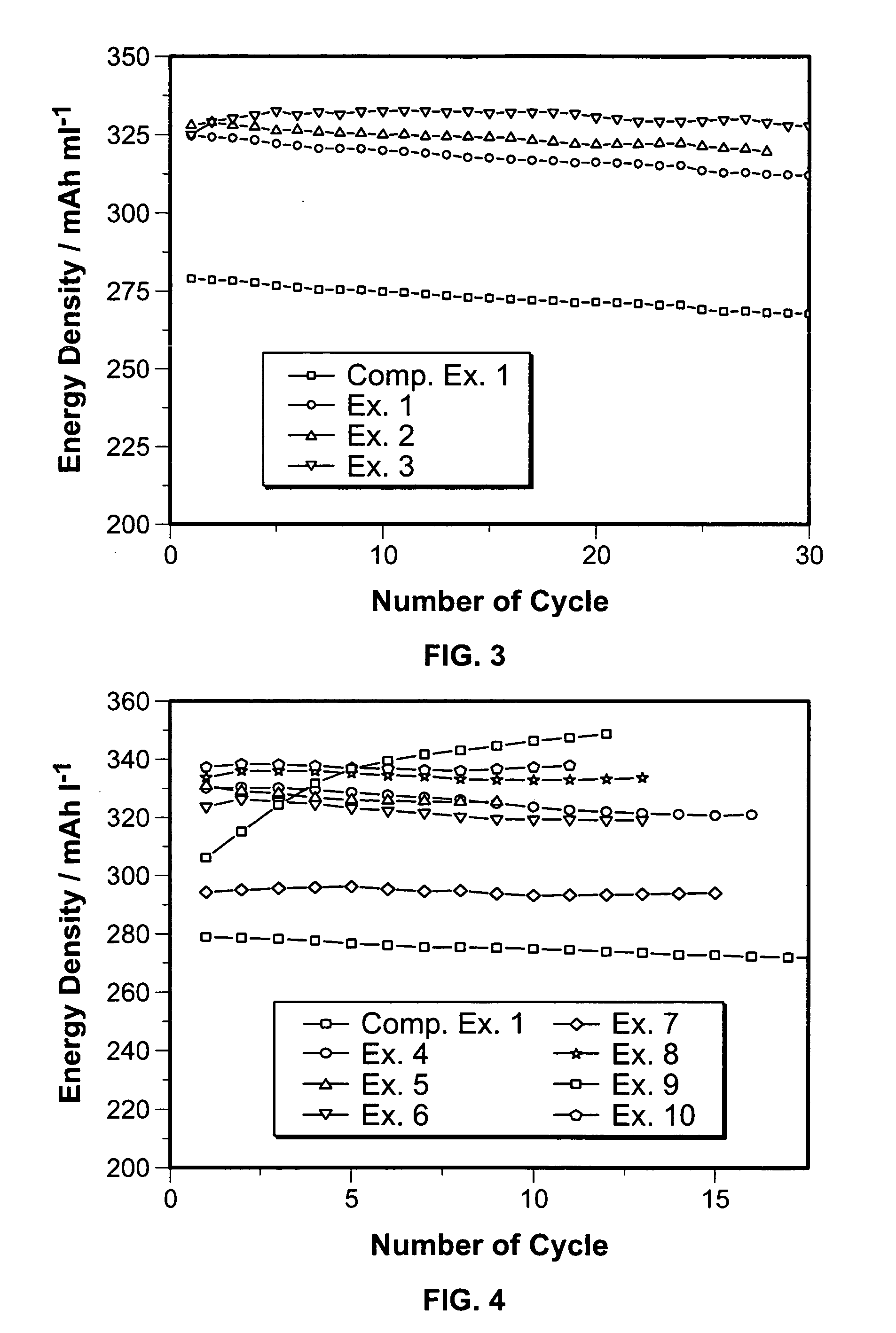

Battery containing ni-based lithium transition metal oxide

ActiveUS20090226810A1Increase hierarchyImprove securityEnergy inputAlkali metal oxidesElectrical batteryOxide cathode

Owner:LG ENERGY SOLUTION LTD

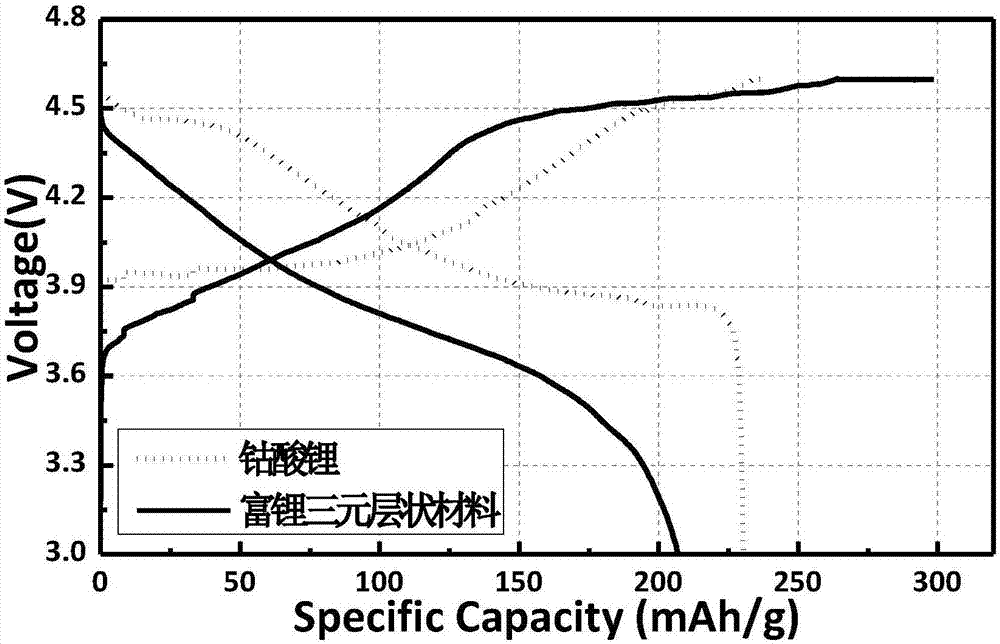

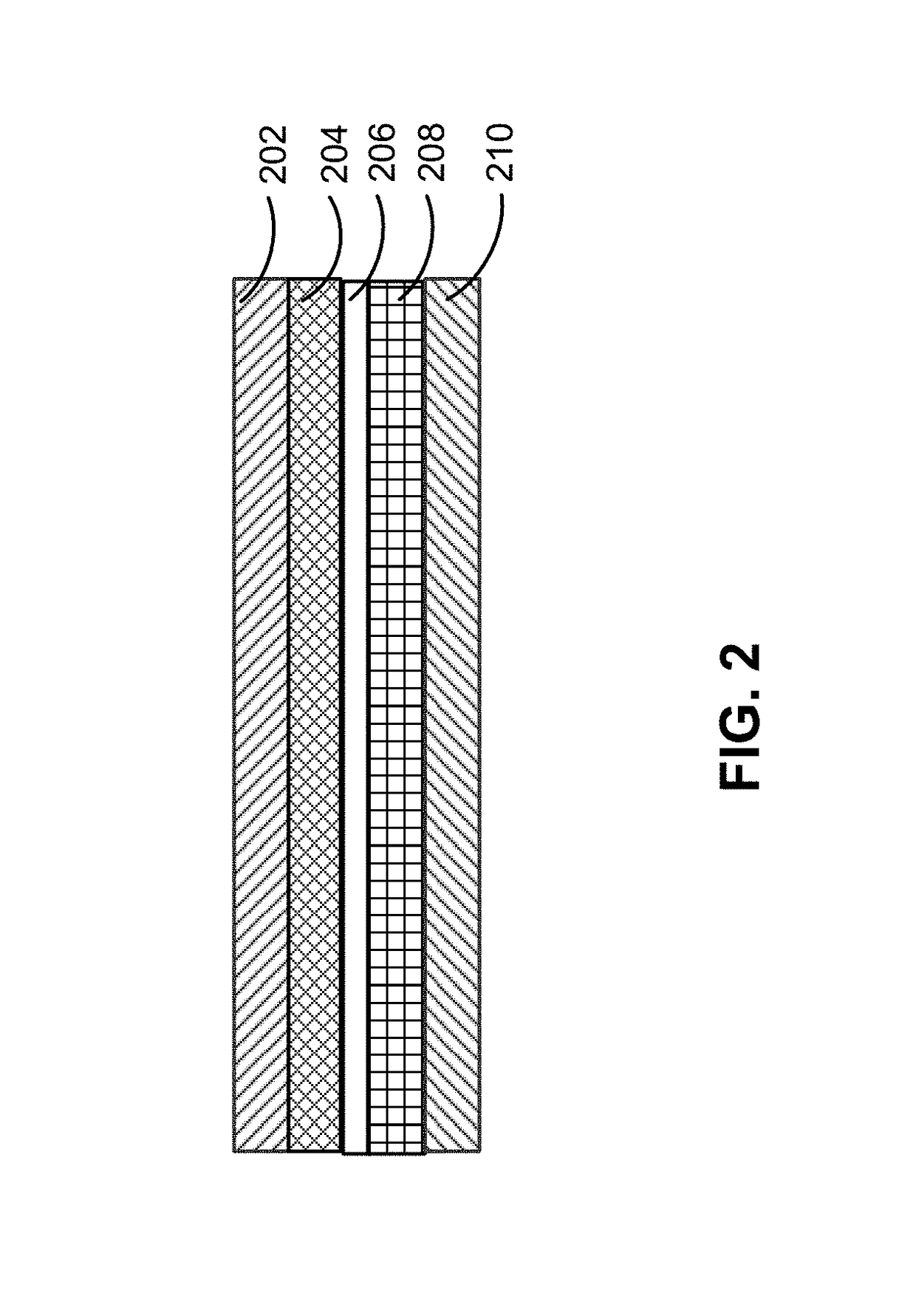

Lithium ion battery

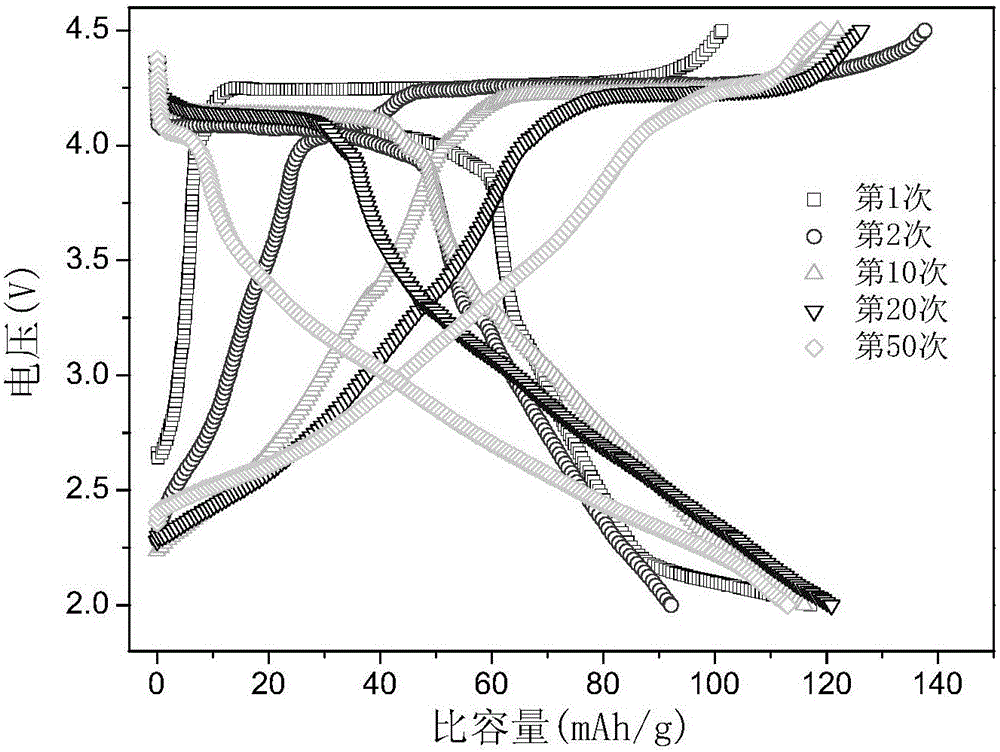

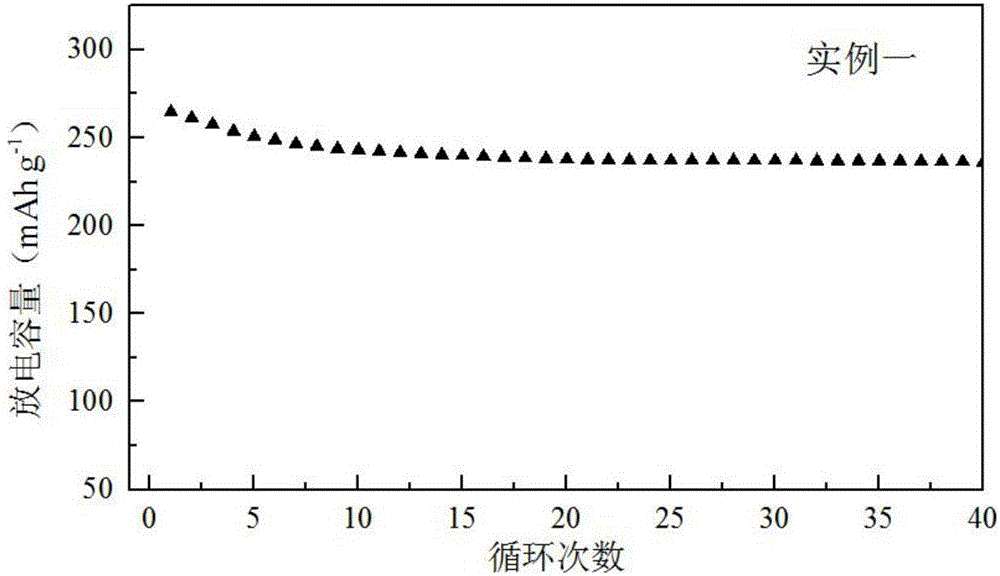

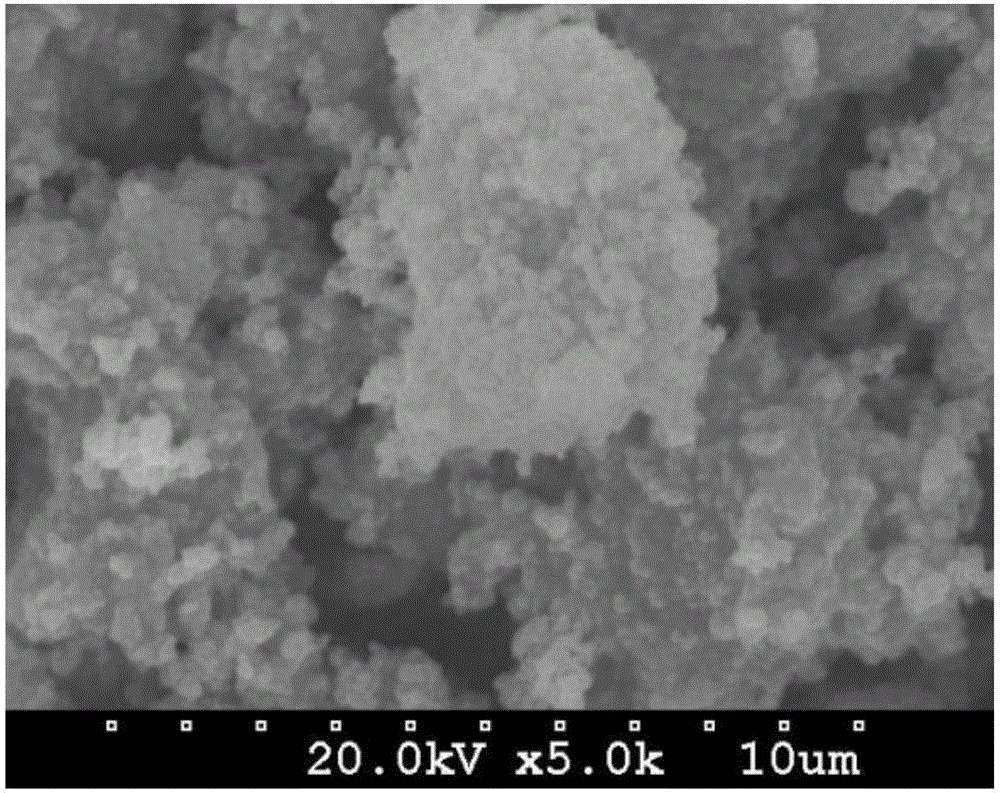

InactiveCN107104245ASimple production processLow costCell electrodesSecondary cells charging/dischargingHigh energyElectrical battery

The invention relates to a lithium ion battery which comprises an anode (1), a cathode (2), a diaphragm (3), an electrolyte (4) and an encapsulating material (5); an active material in the positive pole is that a lithium-rich manganese-based solid solution material and other lithium-containing metal oxide cathode materials are simply and physically mixed; the lithium ion battery with high energy density and good cyclic performance can be obtained through controlling the proportion occupied by the lithium-rich manganese-based solid solution material and the size proportion of the lithium-rich manganese-based solid solution material to the other lithium-containing metal oxide cathode materials and activating by utilizing the first charging process of a battery. The lithium ion battery provided by the invention is simple in preparation method, efficient and good in repeatability, and scale production of the lithium ion battery with high energy density can be really realized.

Owner:AMPRIUS NANJING CO LTD

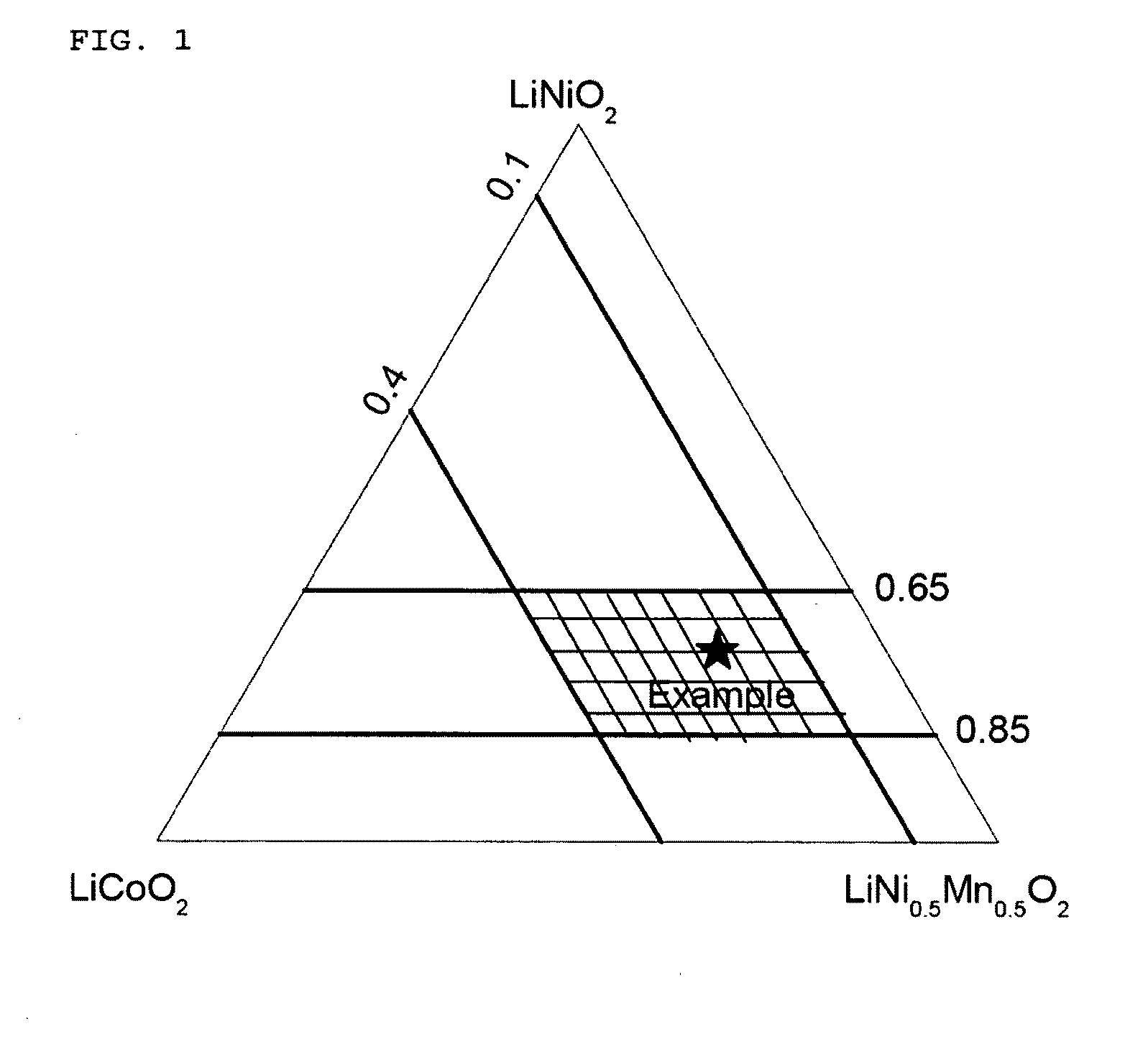

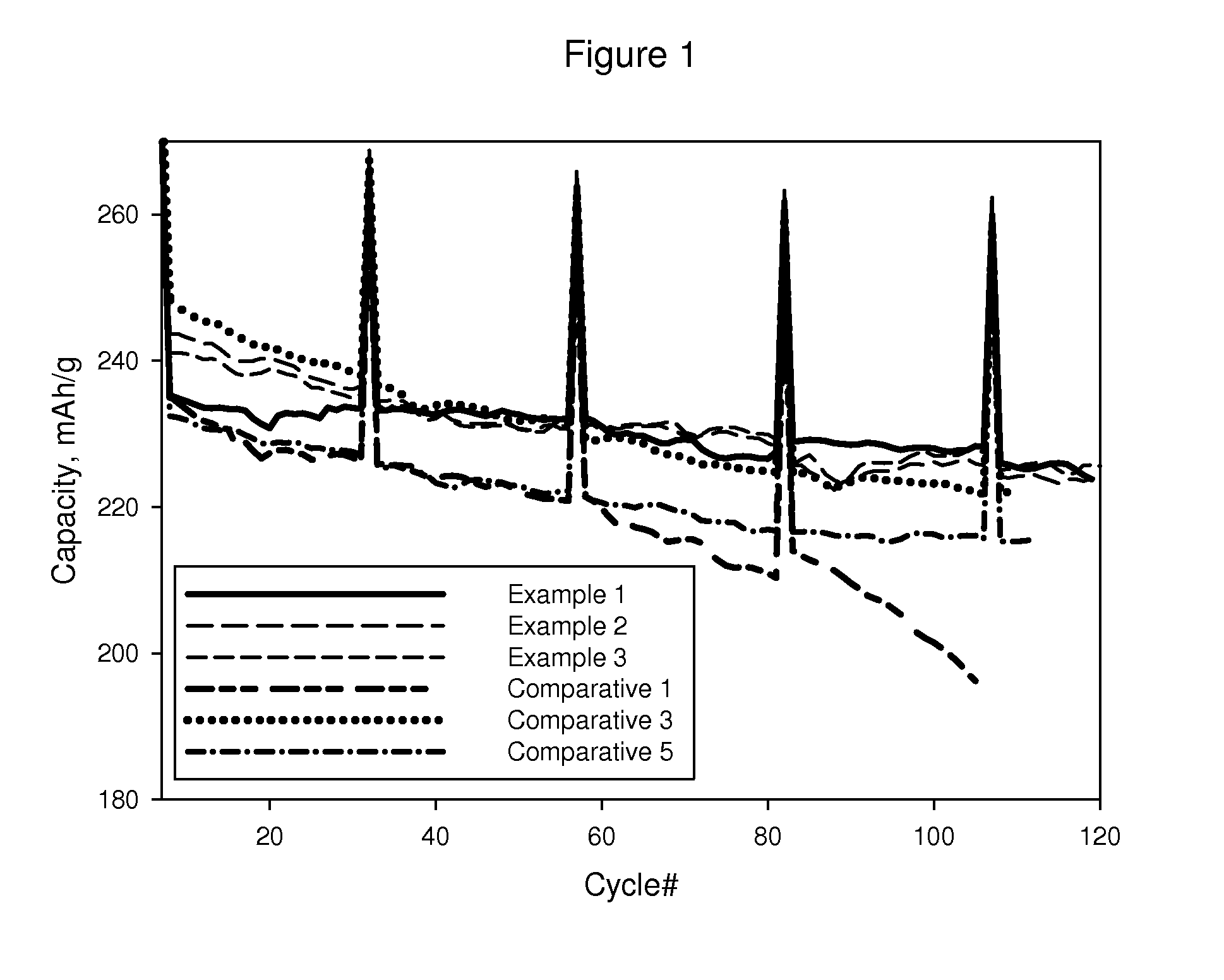

Surface and Bulk Modified High Capacity Layered Oxide Cathodes with Low Irreversible Capacity Loss

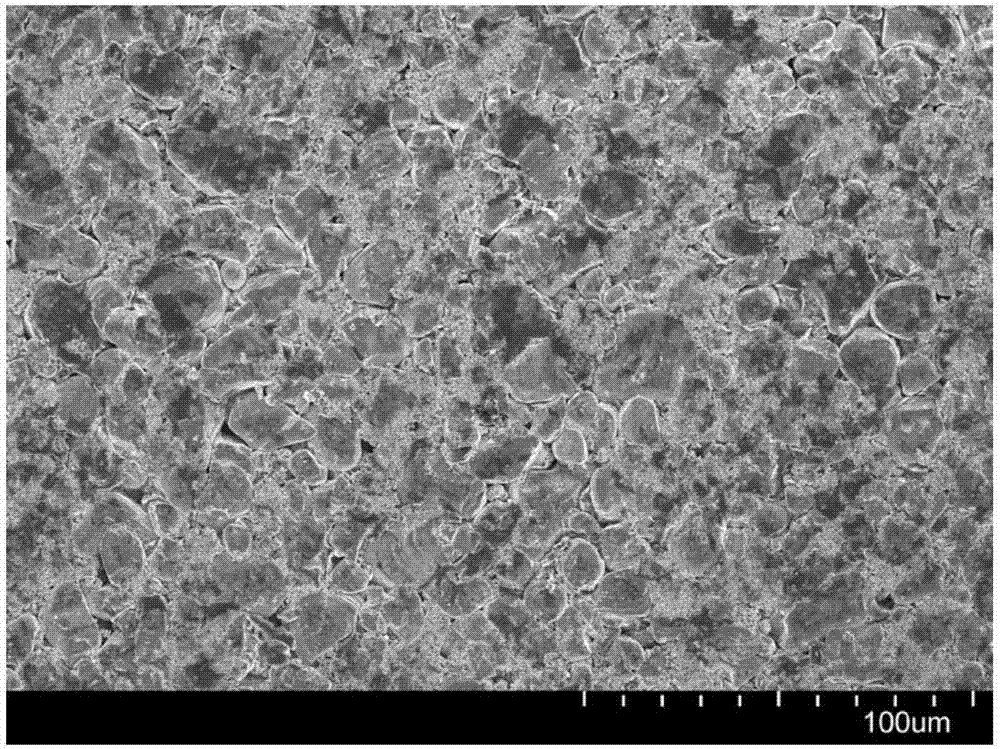

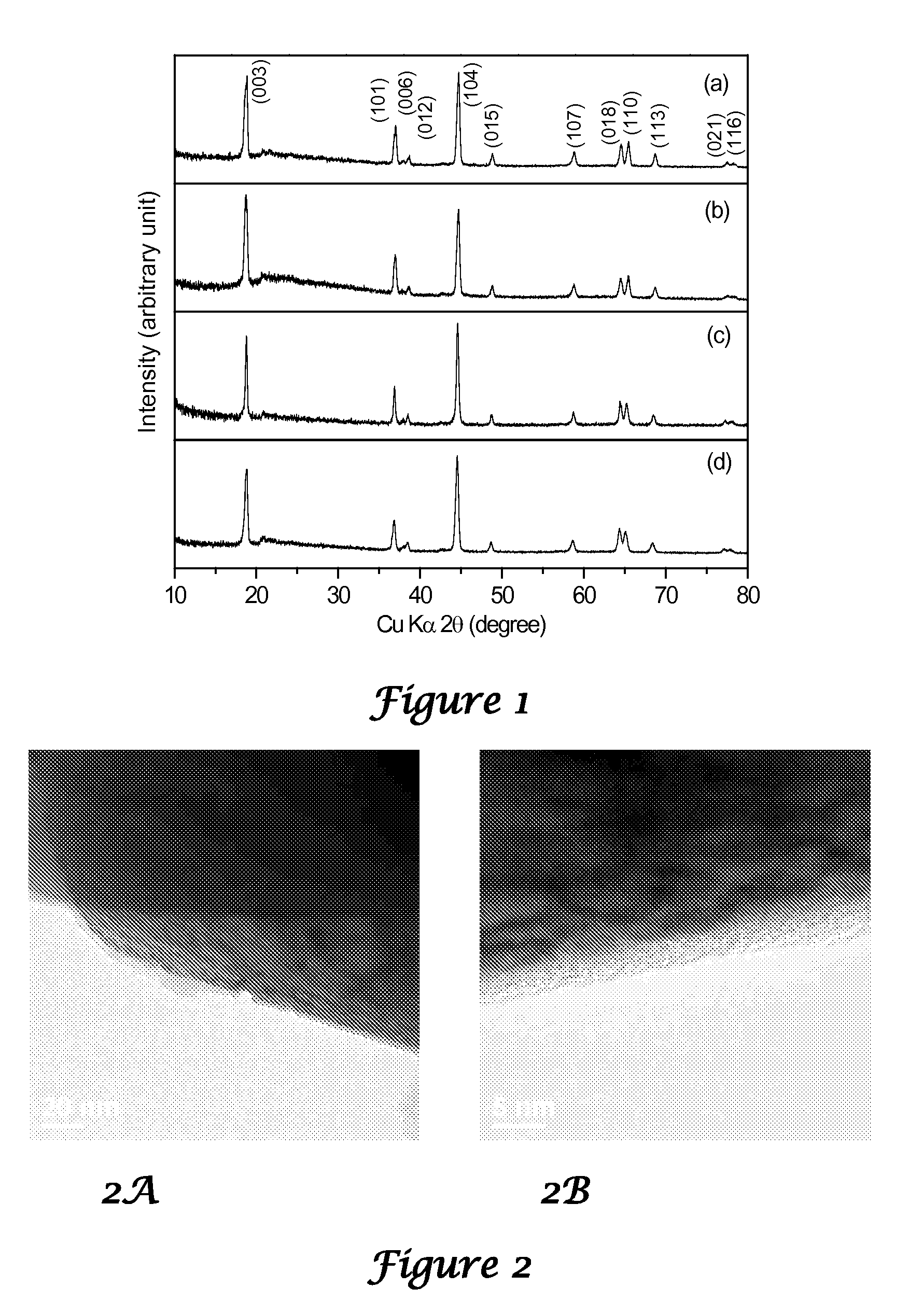

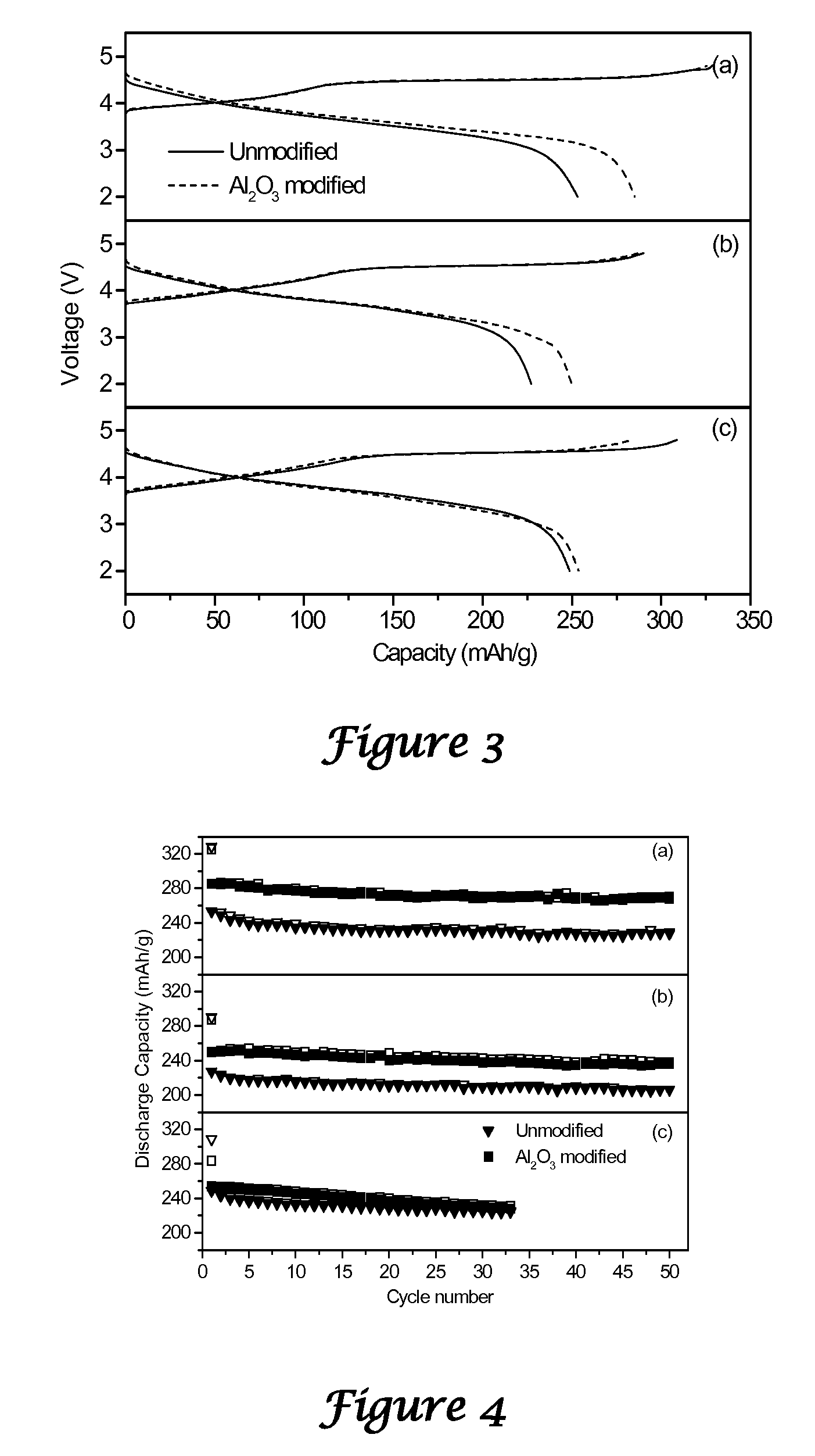

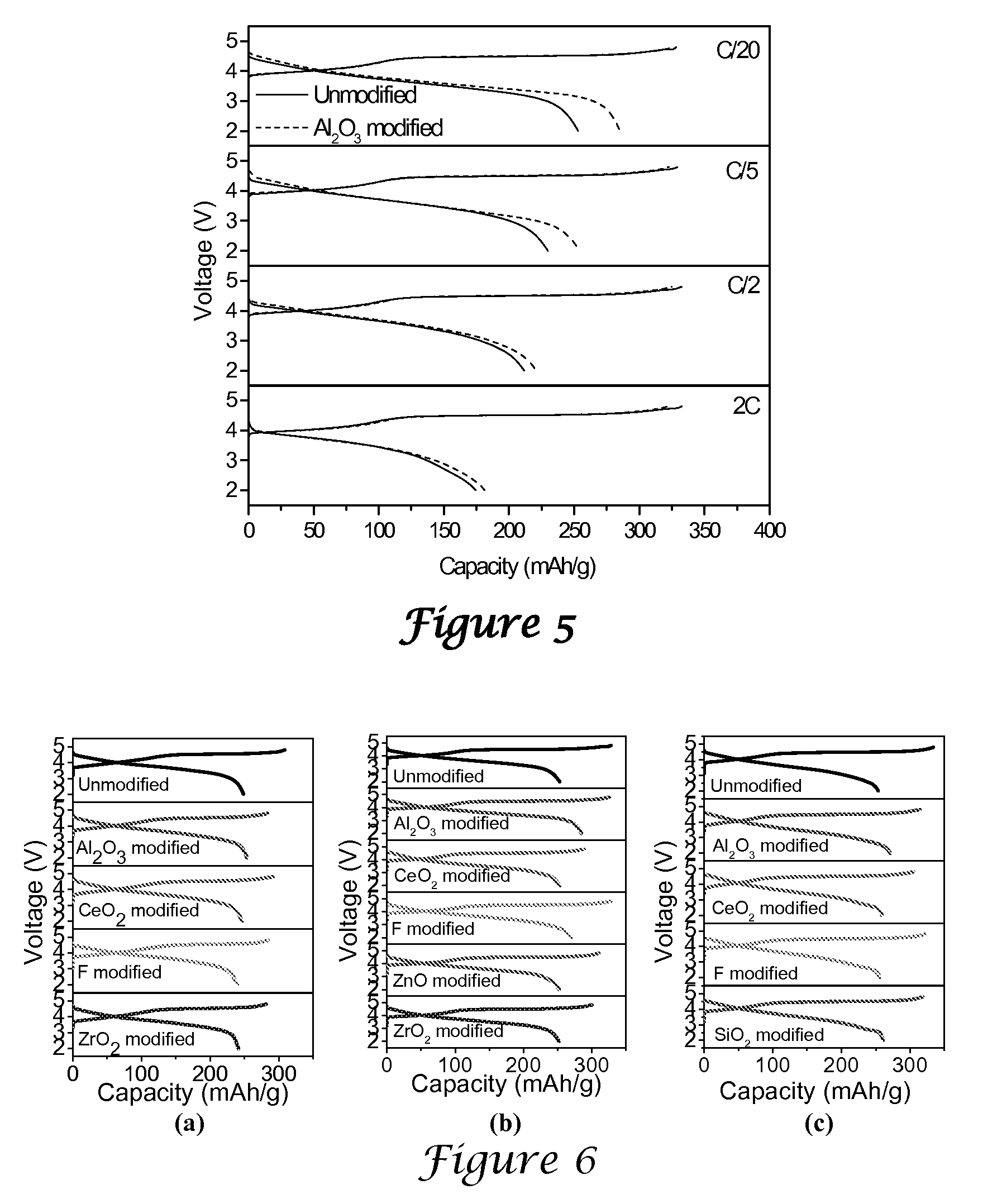

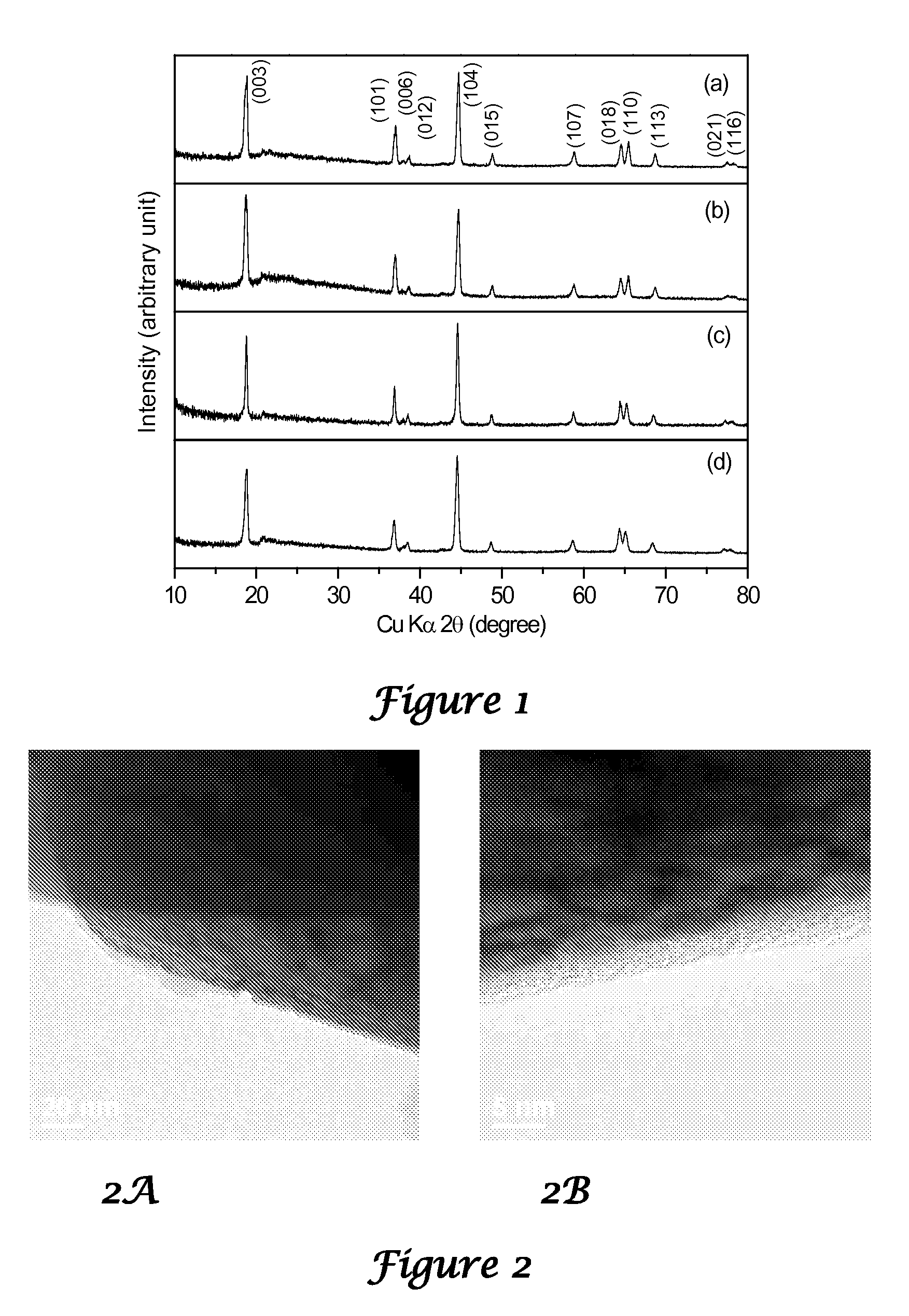

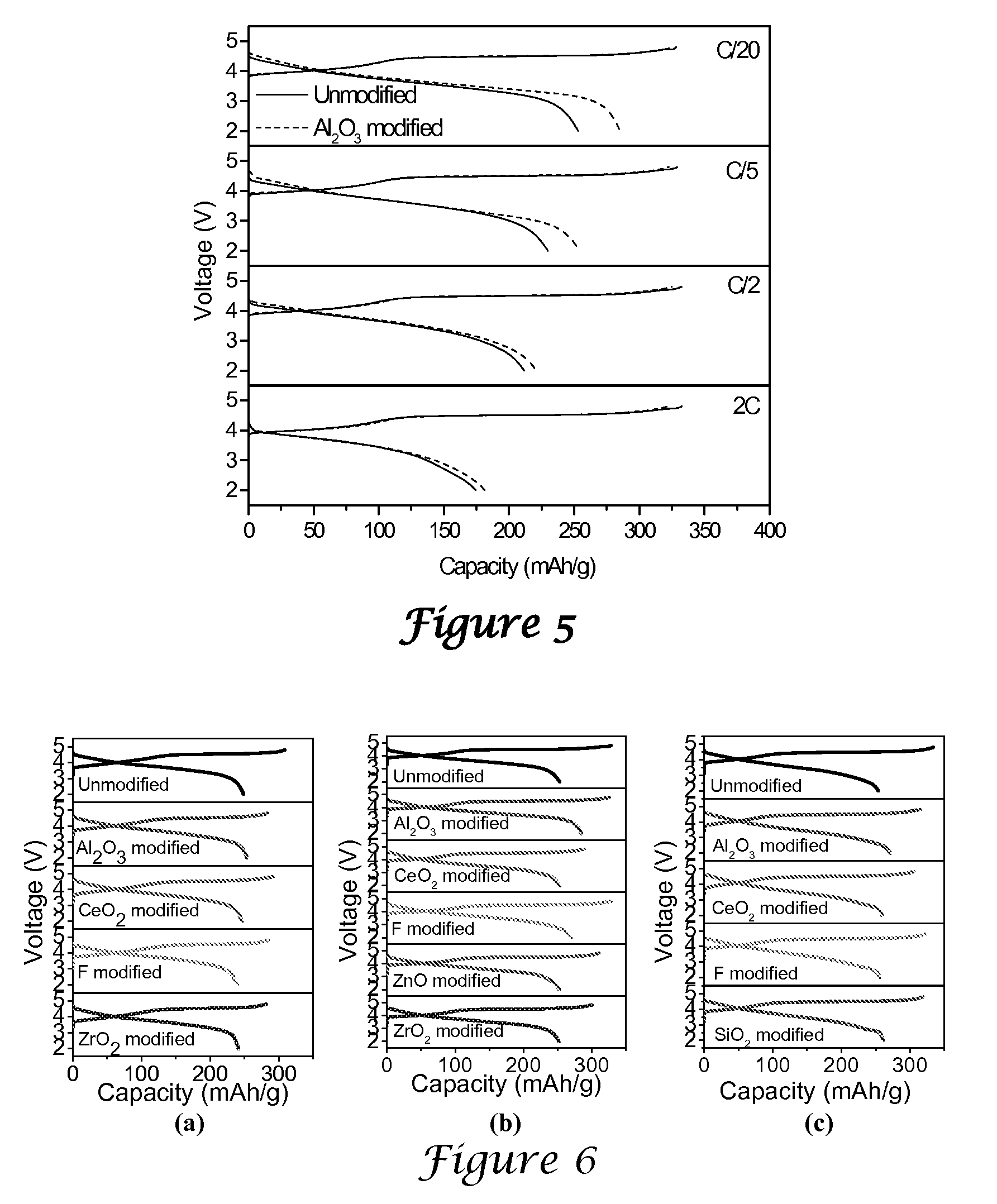

InactiveUS20090224212A1Large capacityLow costNon-metal conductorsConductive materialCapacity lossCrystal structure

The present invention includes compositions, surface and bulk modifications, and methods of making of (1−x)Li[Li1 / 3Mn2 / 3]O2.xLi[Mn0.5-yNi0.5-yCo2y]O2 cathode materials having an O3 crystal structure with a x value between 0 and 1 and y value between 0 and 0.5, reducing the irreversible capacity loss in the first cycle by surface modification with oxides and bulk modification with cationic and anionic substitutions, and increasing the reversible capacity to close to the theoretical value of insertion / extraction of one lithium per transition metal ion (250-300 mAh / g).

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Cathode material for lithium batteries

ActiveUS20070292763A1High tap densityIncrease energy densityAlkali metal oxidesCobalt compoundsOxide cathodeMaterials science

A method of manufacture an article of a cathode (positive electrode) material for lithium batteries. The cathode material is a lithium molybdenum composite transition metal oxide material and is prepared by mixing in a solid state an intermediate molybdenum composite transition metal oxide and a lithium source. The mixture is thermally treated to obtain the lithium molybdenum composite transition metal oxide cathode material.

Owner:UCHICAGO ARGONNE LLC

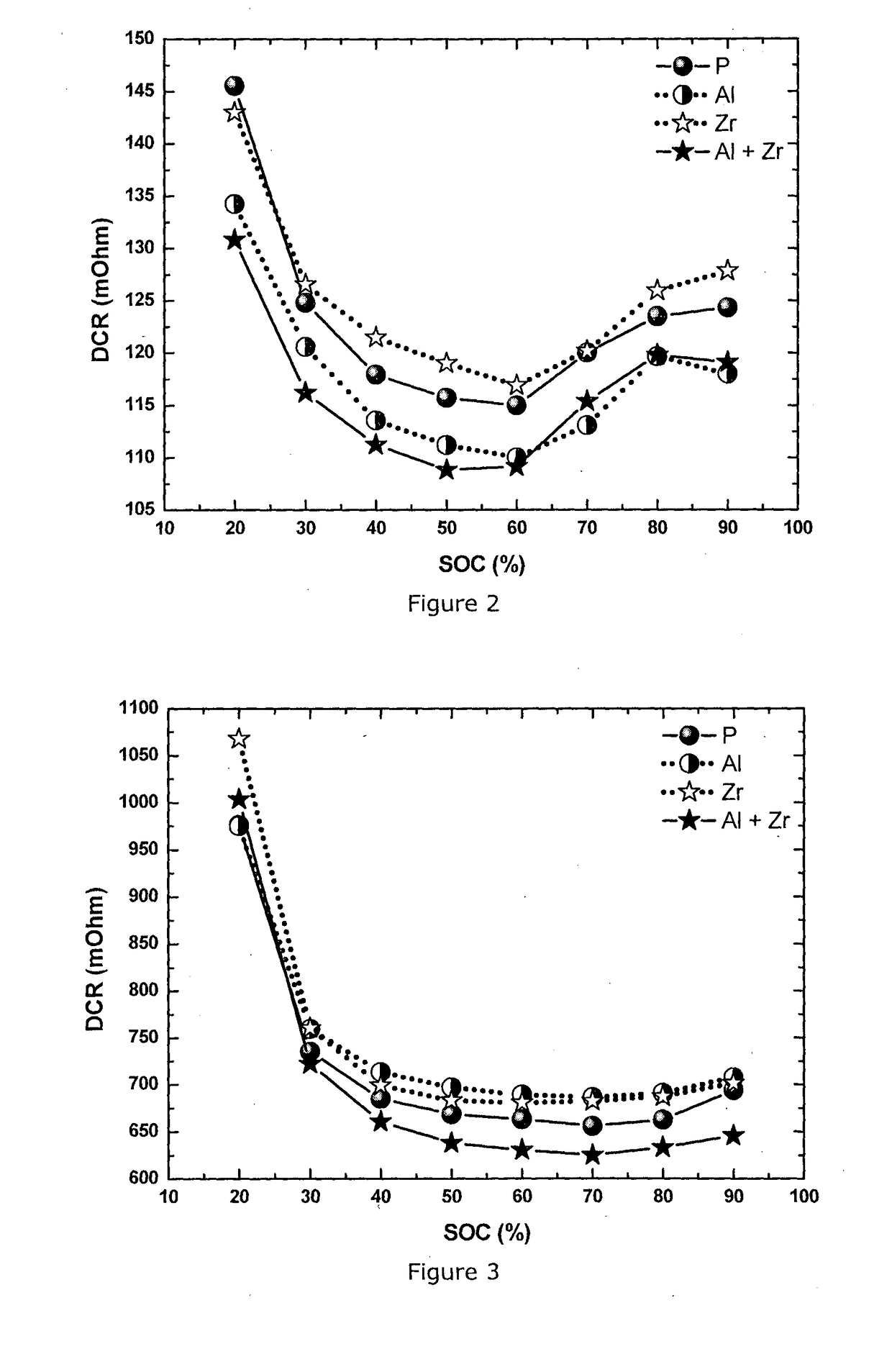

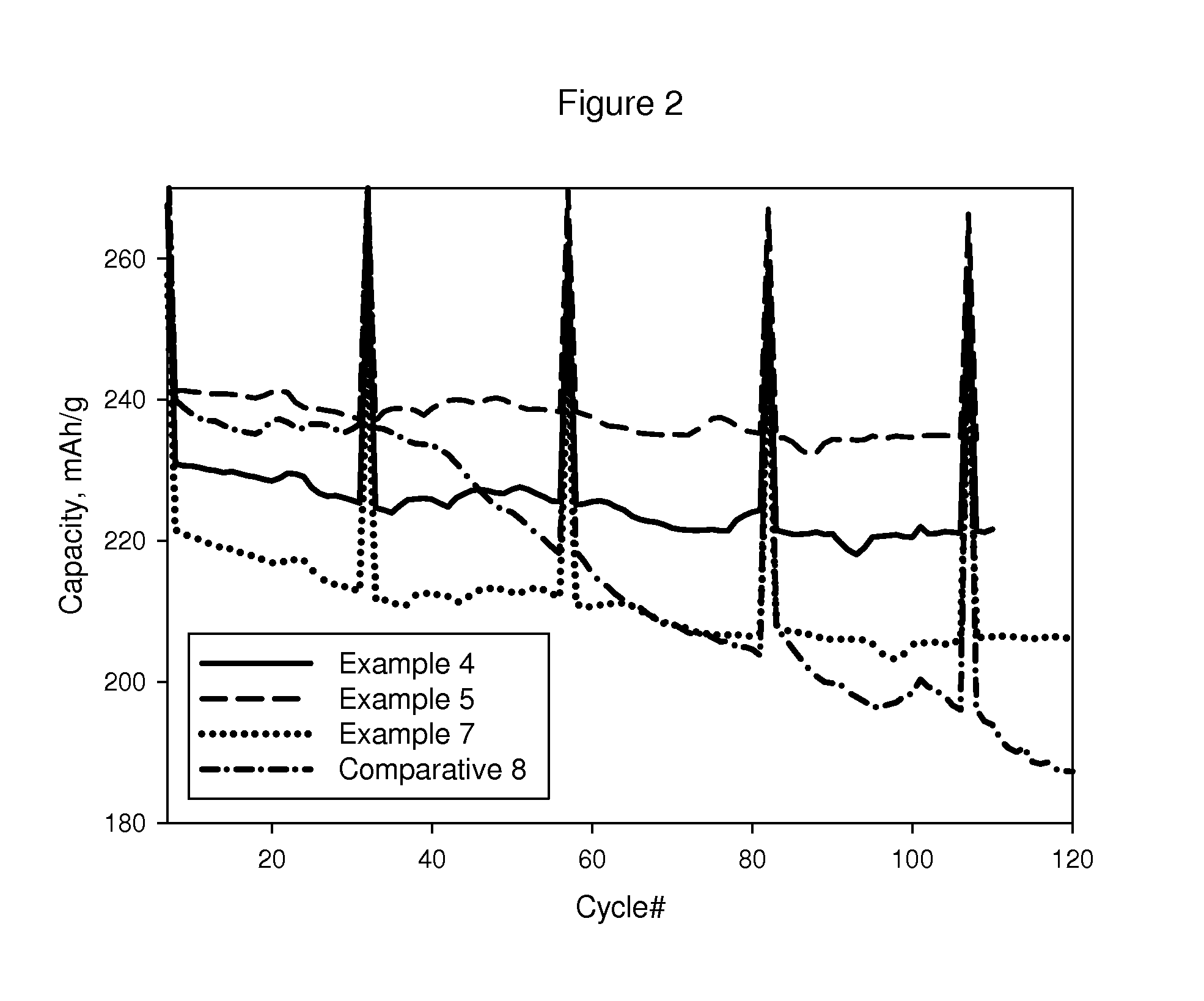

Doped and Coated Lithium Transition Metal Oxide Cathode Materials for Batteries in Automotive Applications

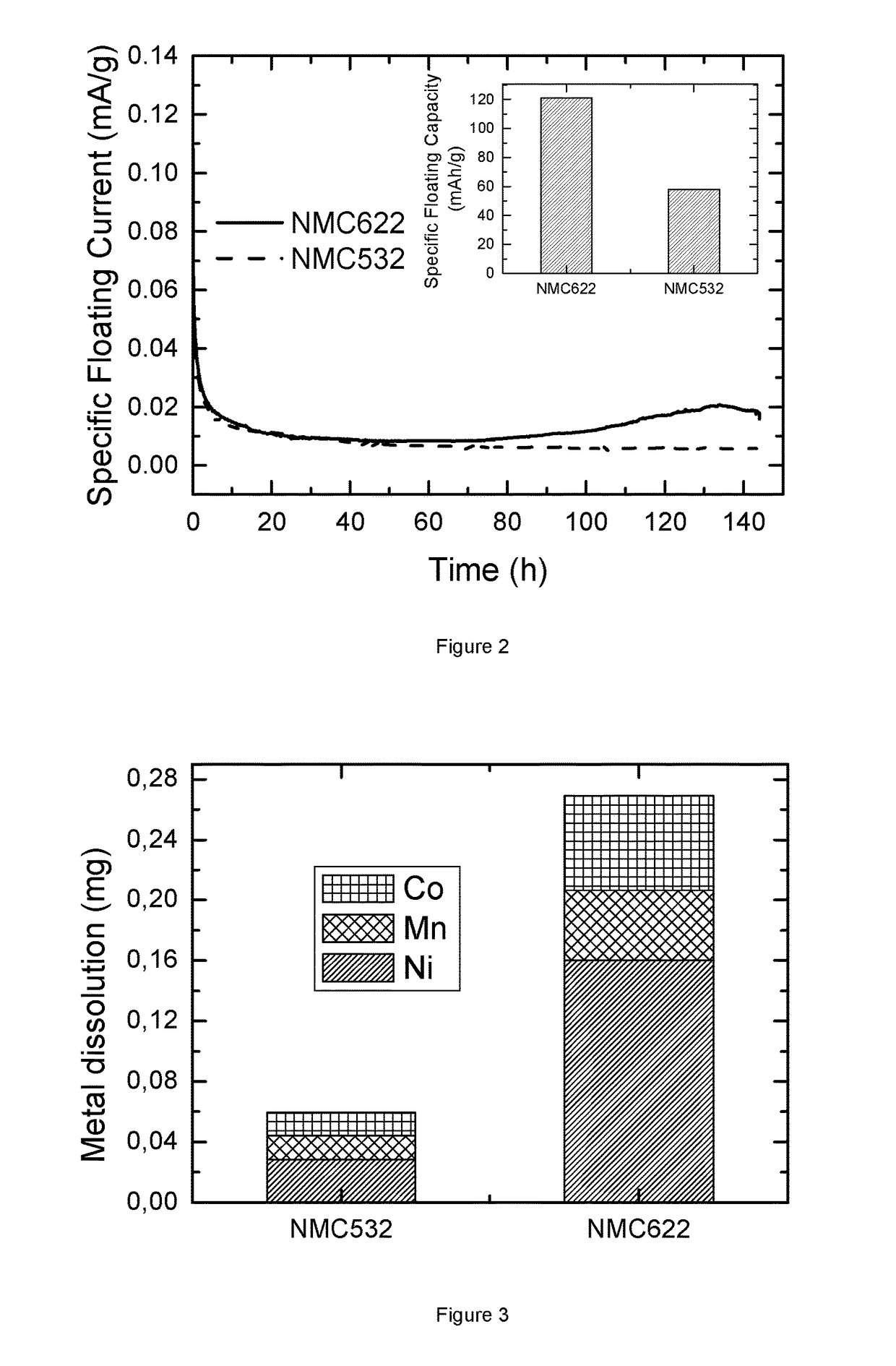

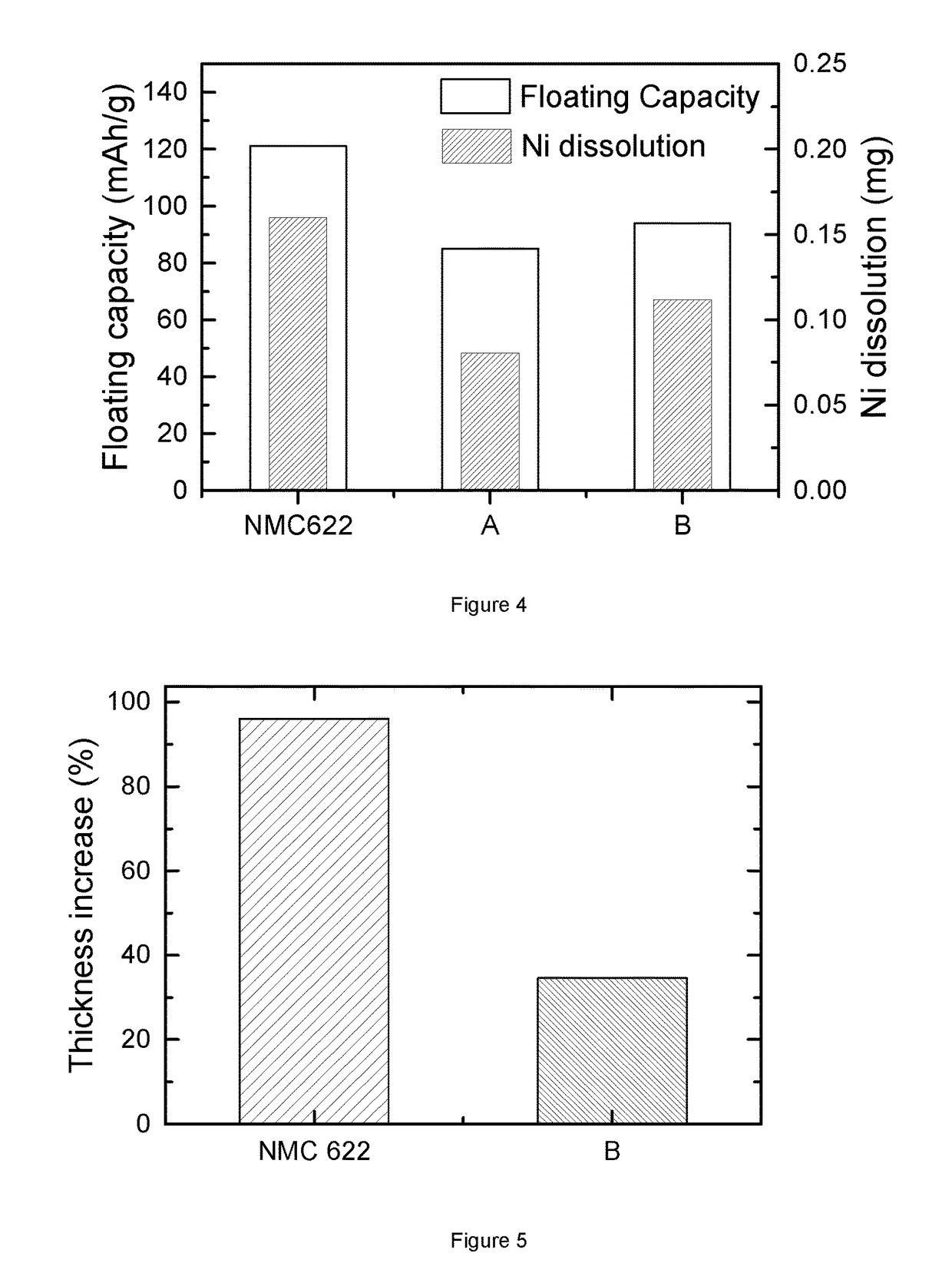

ActiveUS20170069907A1Lower charge transfer resistanceRate performanceElectrode rolling/calenderingFinal product manufactureMetallurgyAutomotive battery

A lithium metal oxide powder for use as a cathode material in a rechargeable battery, consisting of Li metal oxide core particles having a general formula Li1+d (Nix Mny Coz Zrk M′m)i−d 02±e Ar; wherein Al203 is attached to the surface of the core particles; wherein 0≦d≦0.08, 0.2≦x≦0.9, 0<y≦0.7, 0<z≦0.4, 0≦m≦0.02, 0<k≦0.05, e<0.02, 0≦f≦0.02 and x+y+z−k+m=1; M′ consisting of either one or more elements from the group Al, Mg, Ti, Cr, V, Fe and Ga; A consisting of either one or more elements from the group F, P, C, CI, S, Si, Ba, Y, Ca, B, Sn, Sb, Na and Zn; and wherein the Al203 content in the powder is between 0.05 and 1 wt %.

Owner:UMICORE AG & CO KG +1

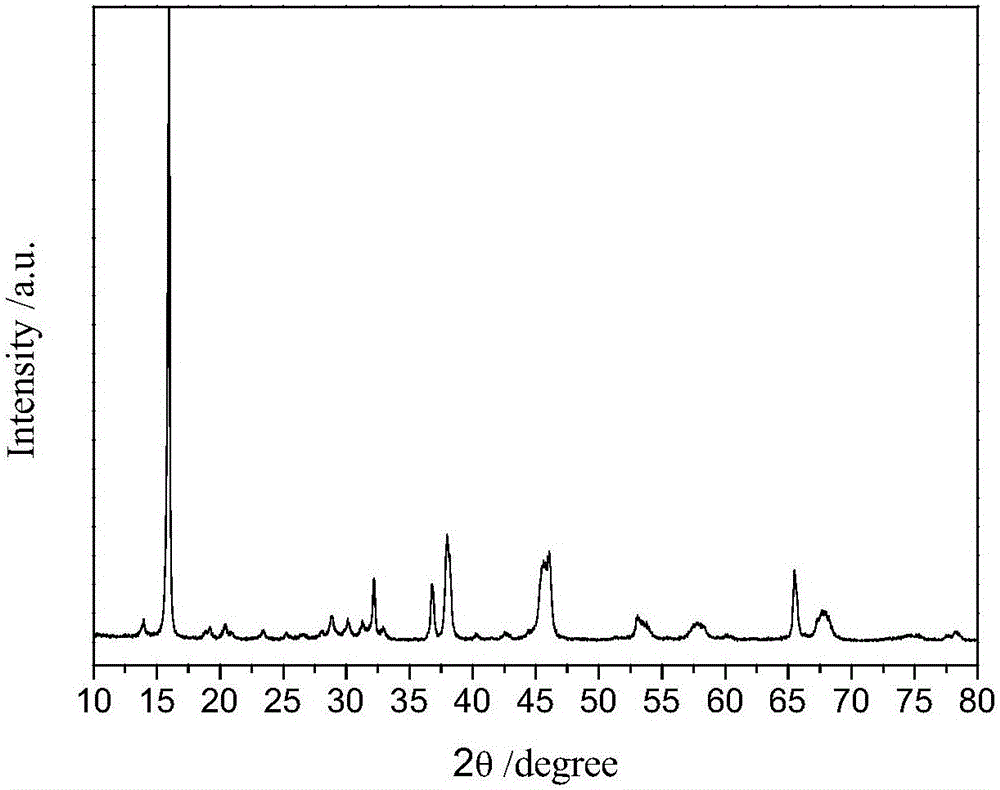

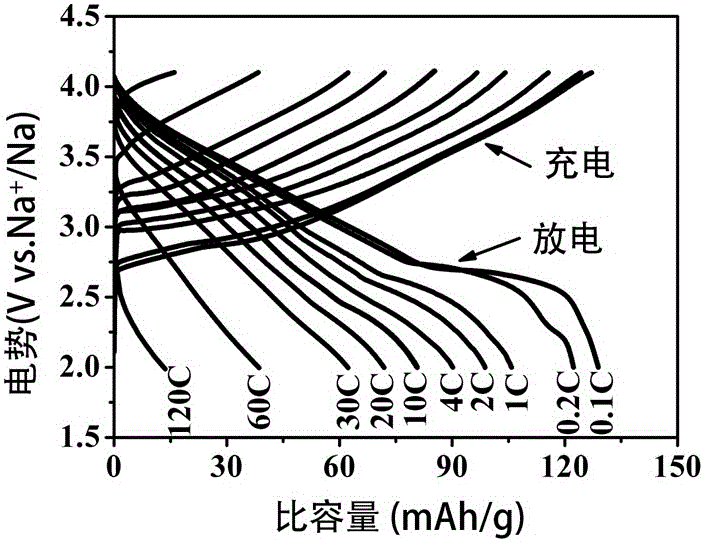

Sodium-ion battery oxide cathode material, and preparation method and application thereof

The invention discloses a sodium-ion battery cathode material, and a preparation method and application thereof. The molecular formula of a lithium-sodium-manganese oxide is Li<x>Na<y>M<z>Mn<1-z>O<2>, wherein x is greater than 0.15 and less than 0.5; y is greater than 0.5 and less than 0.9; z is greater than or equal to 0 and less than 0.5; and M is one or more selected from Fe, Ti, Ni, Mg, Cr, Co, Cu and the like. The preparation method of the material comprises the following steps of after sufficiently mixing and uniformly grinding a manganese source, a sodium source and a lithium source or a manganese source, a sodium source, a lithium source and a M source (M is selected from Fe, Ti, Ni, Mg, Cr, Co and Cu), sintering at 400-1100 DEG C for 4-48 h, and naturally cooling the material to 25-120 DEG C so as to obtain the final product. The cathode material disclosed by the invention can provide reversible charging and discharging voltage above 4V; required raw materials are wide in source; and the preparation method is simple.

Owner:CENT SOUTH UNIV

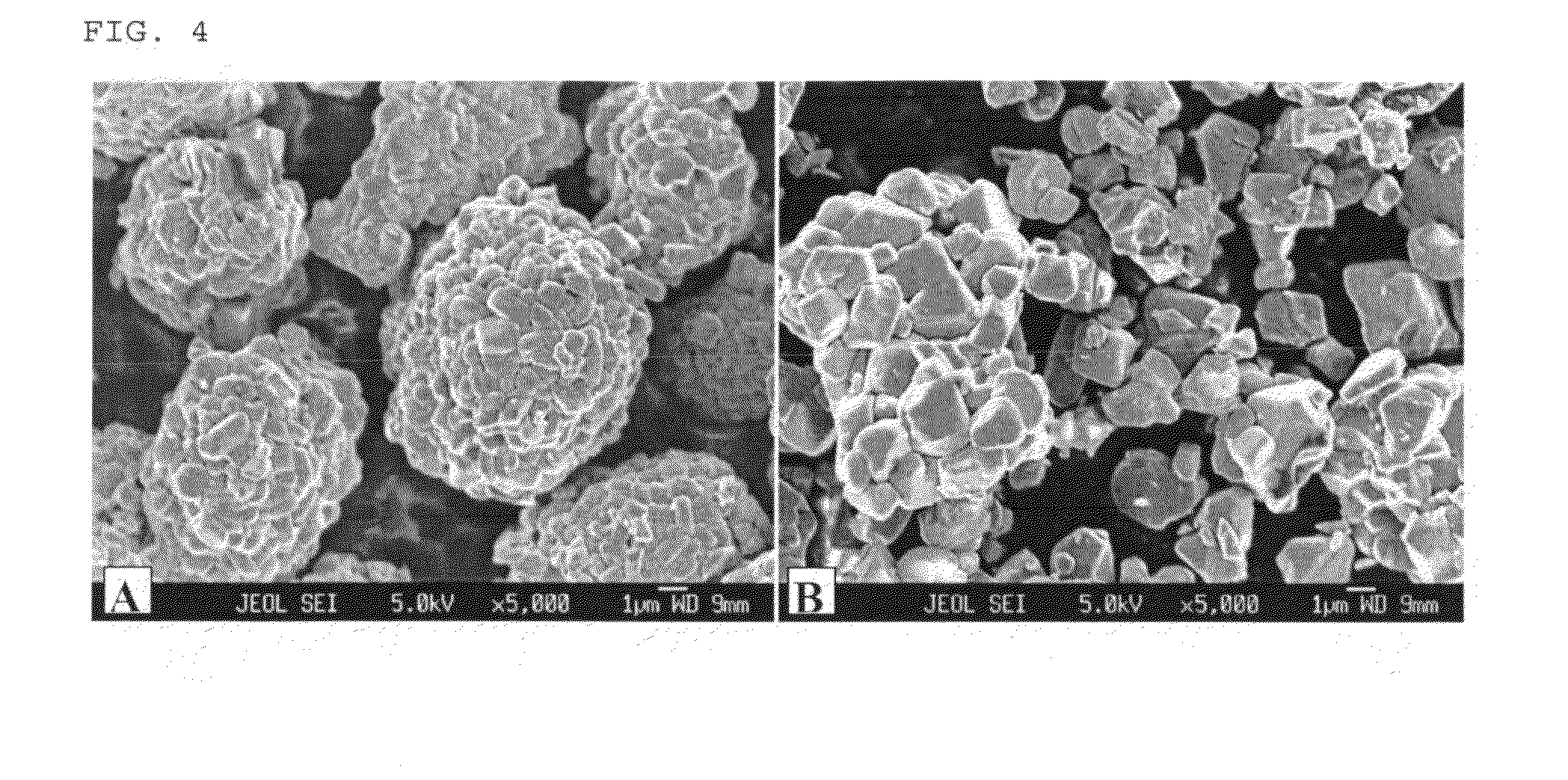

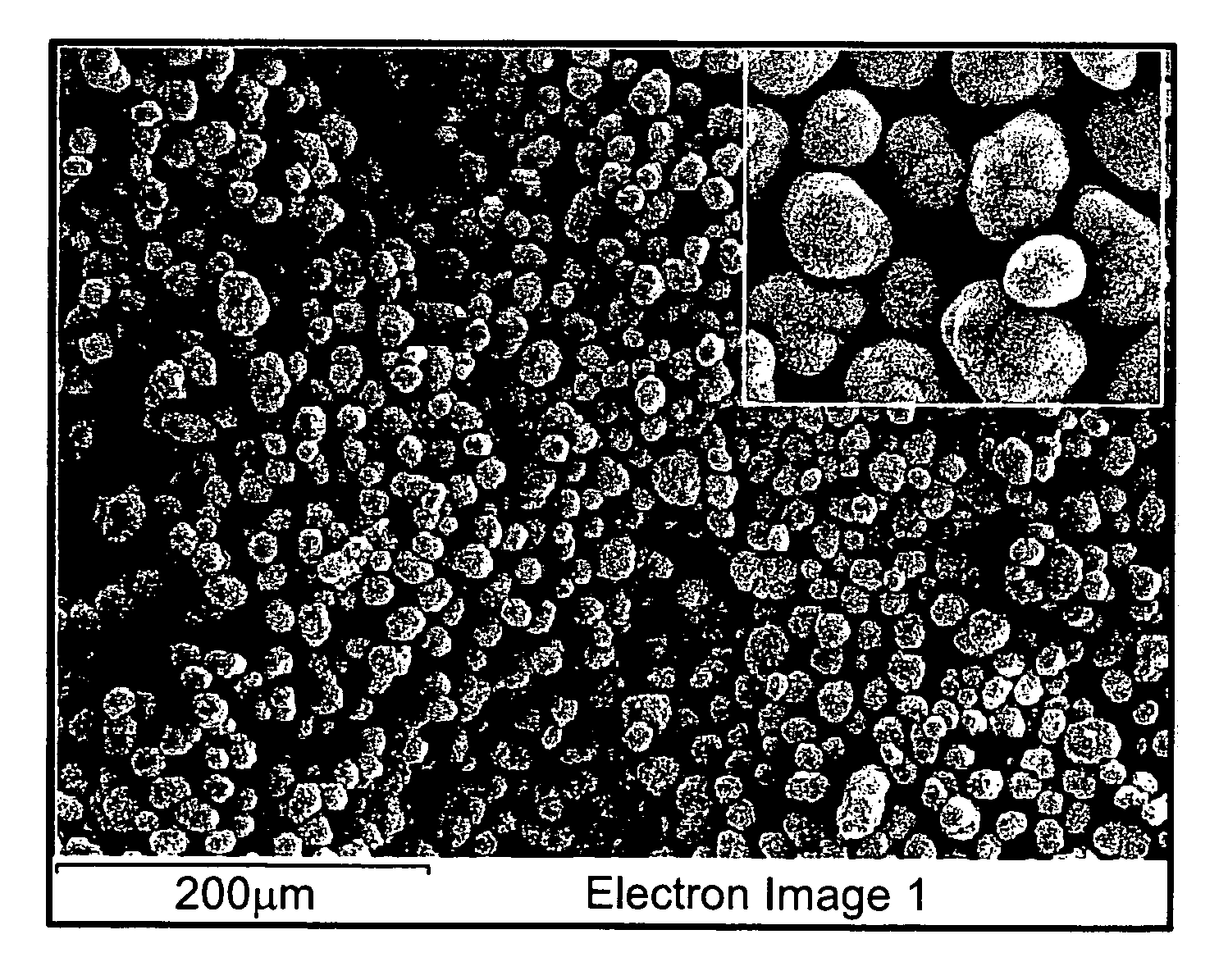

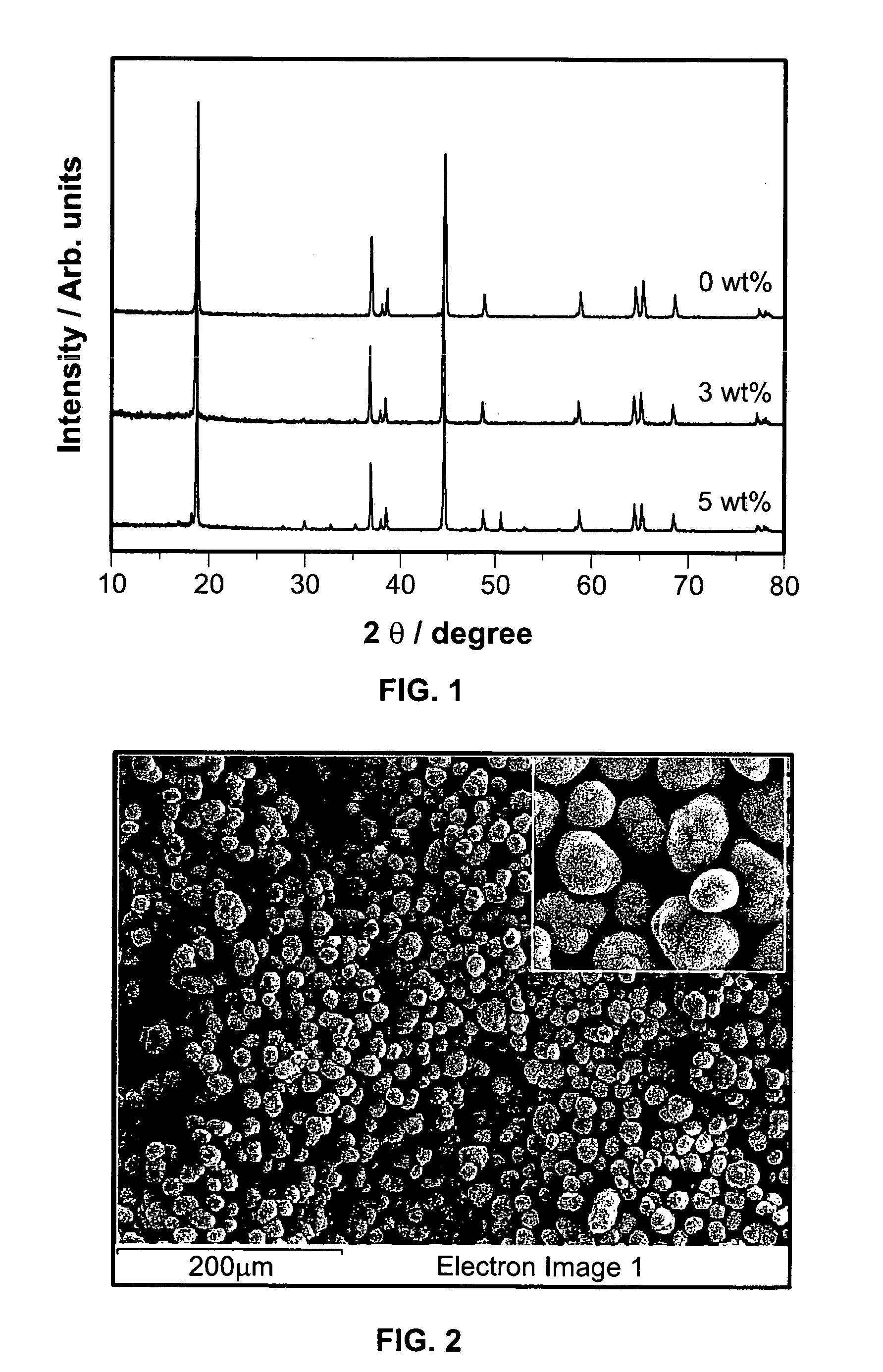

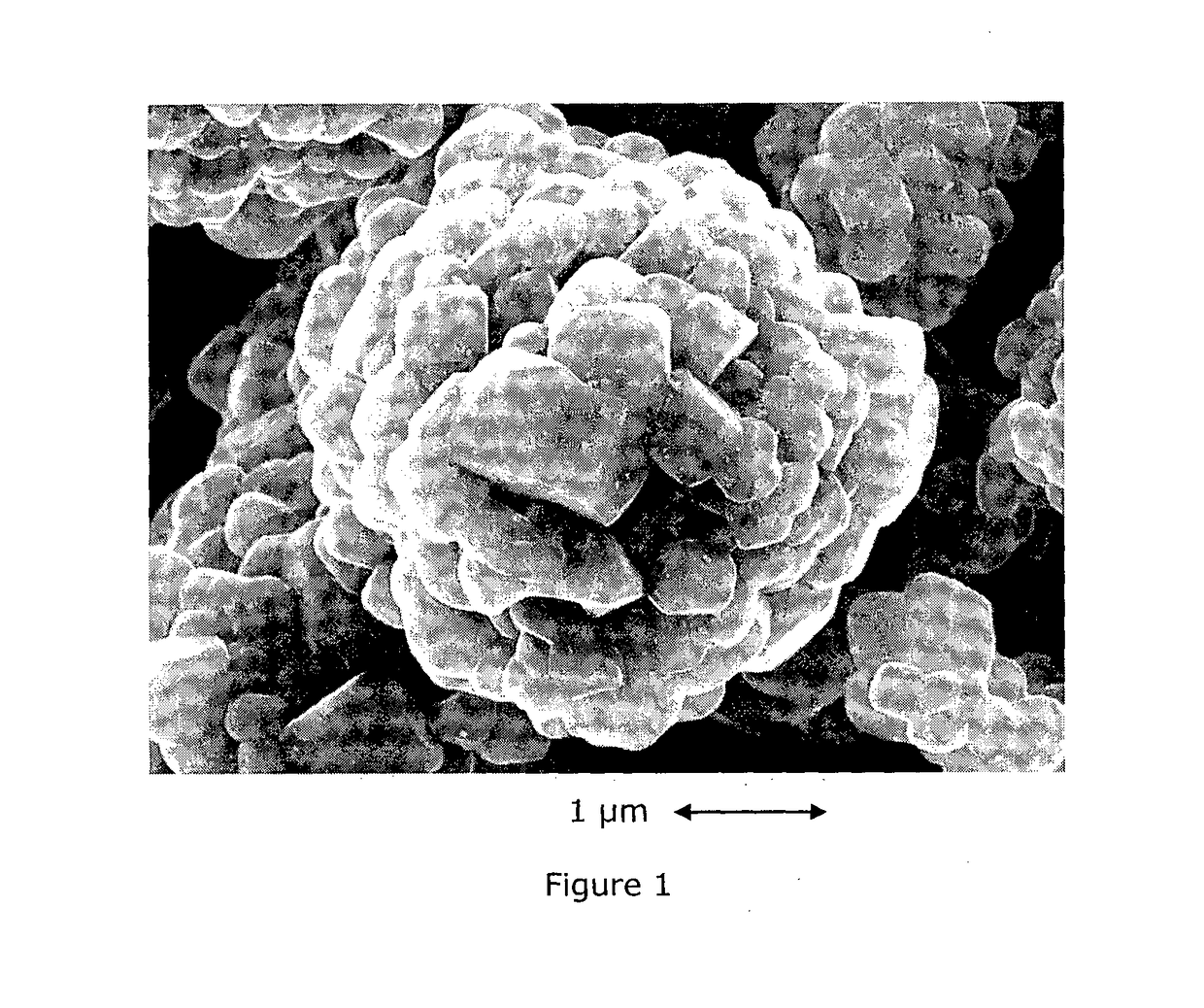

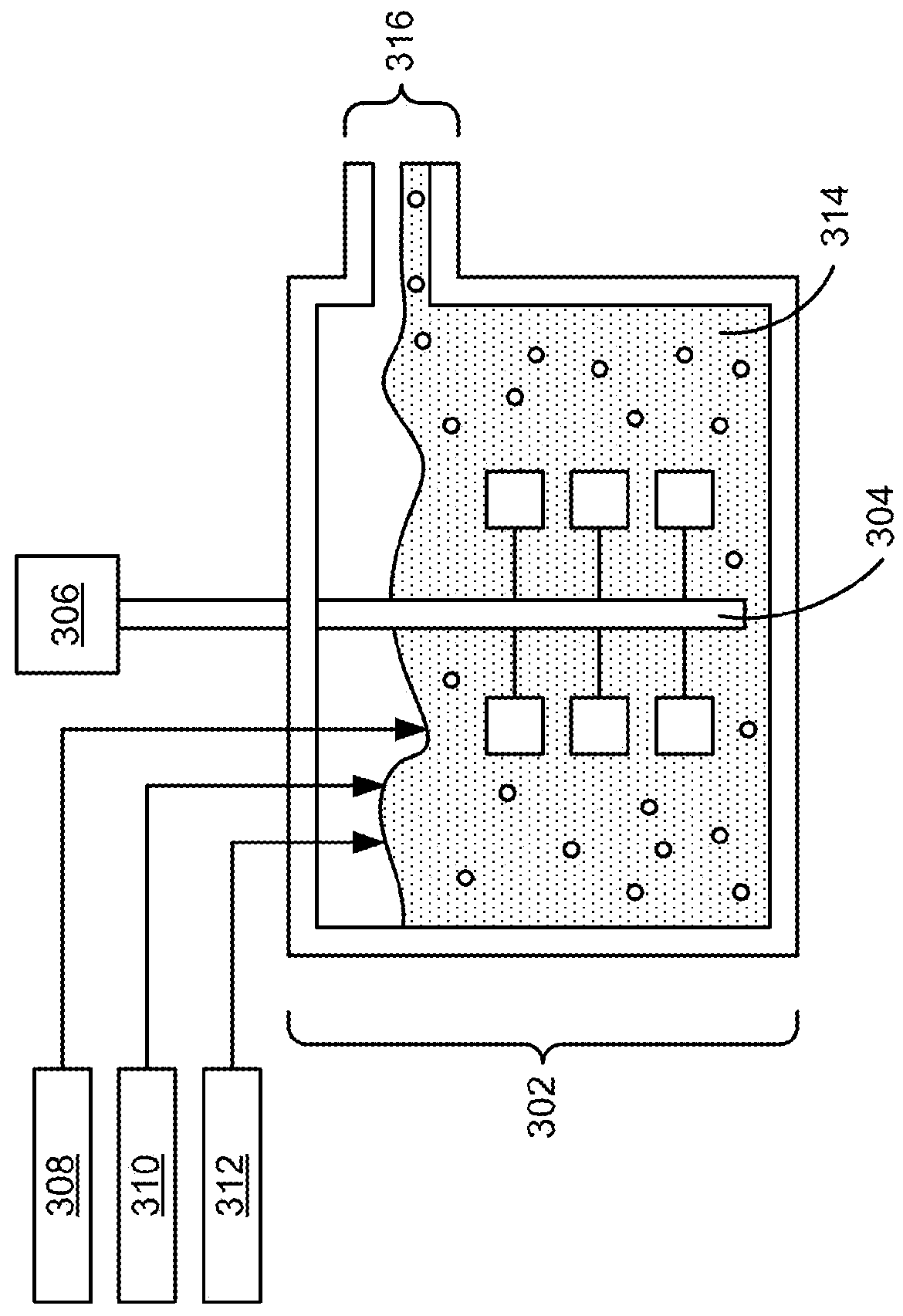

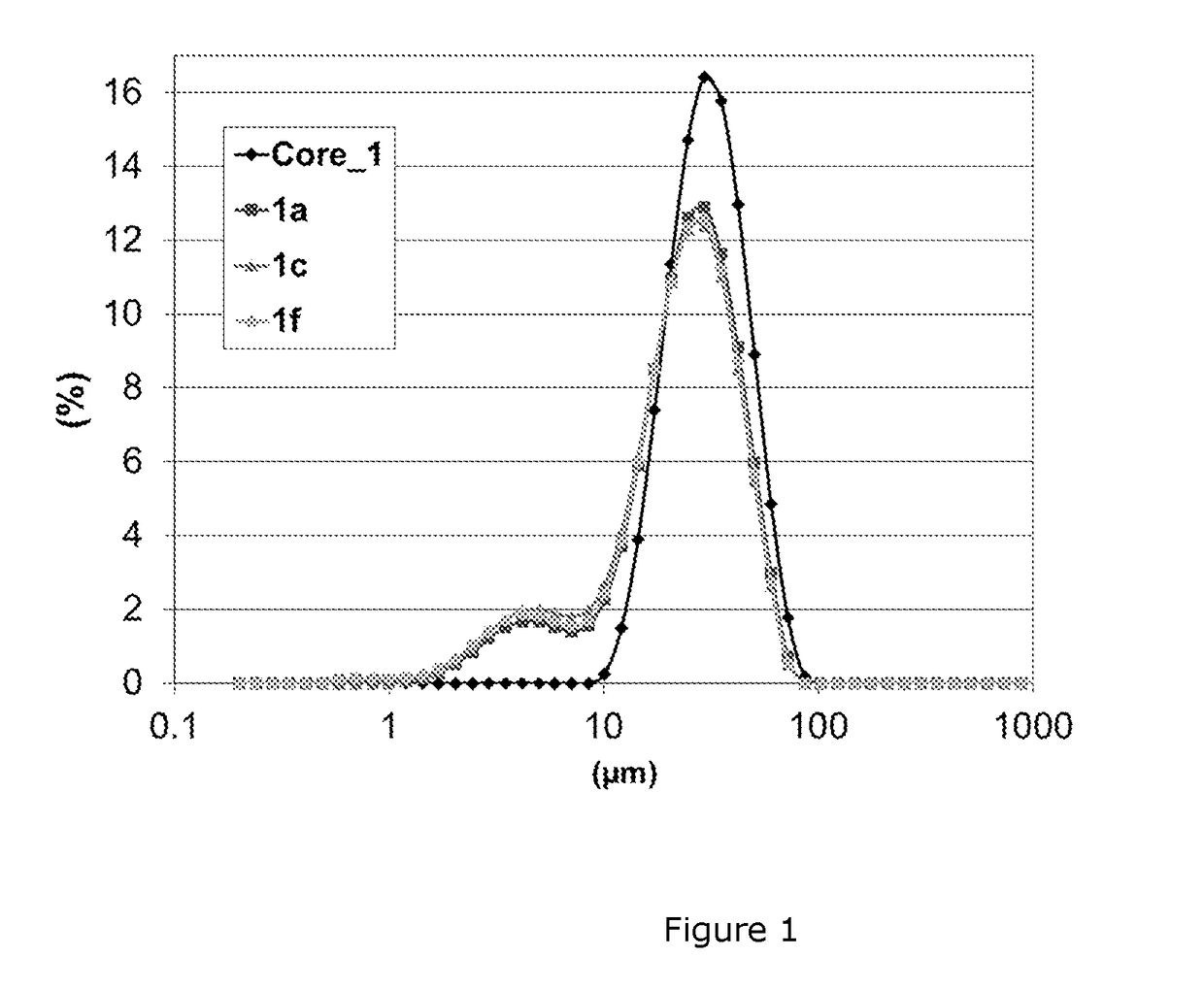

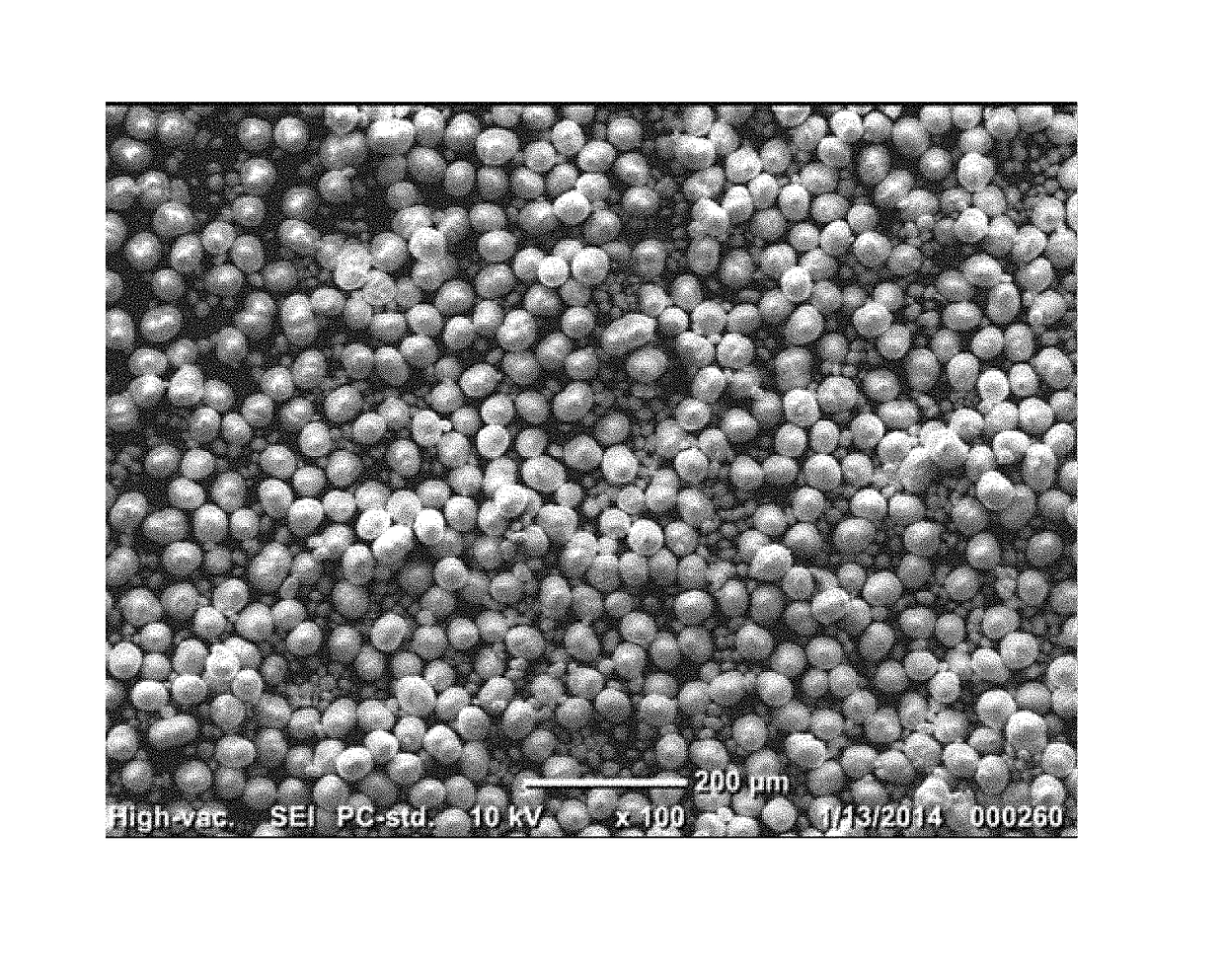

High-density precursor for manufacture of composite metal oxide cathodes for li-ion batteries

The disclosed embodiments relate to the manufacture of a precursor co-precipitate material for a cathode active material composition. During manufacture of the precursor co-precipitate material, an aqueous solution containing at least one of a manganese sulfate and a cobalt sulfate is formed. Next, a NH4OH solution is added to the aqueous solution to form a particulate solution comprising irregular secondary particles of the precursor co-precipitate material. A constant pH in the range of 10-12 is also maintained in the particulate solution by adding a basic solution to the particulate solution.

Owner:APPLE INC

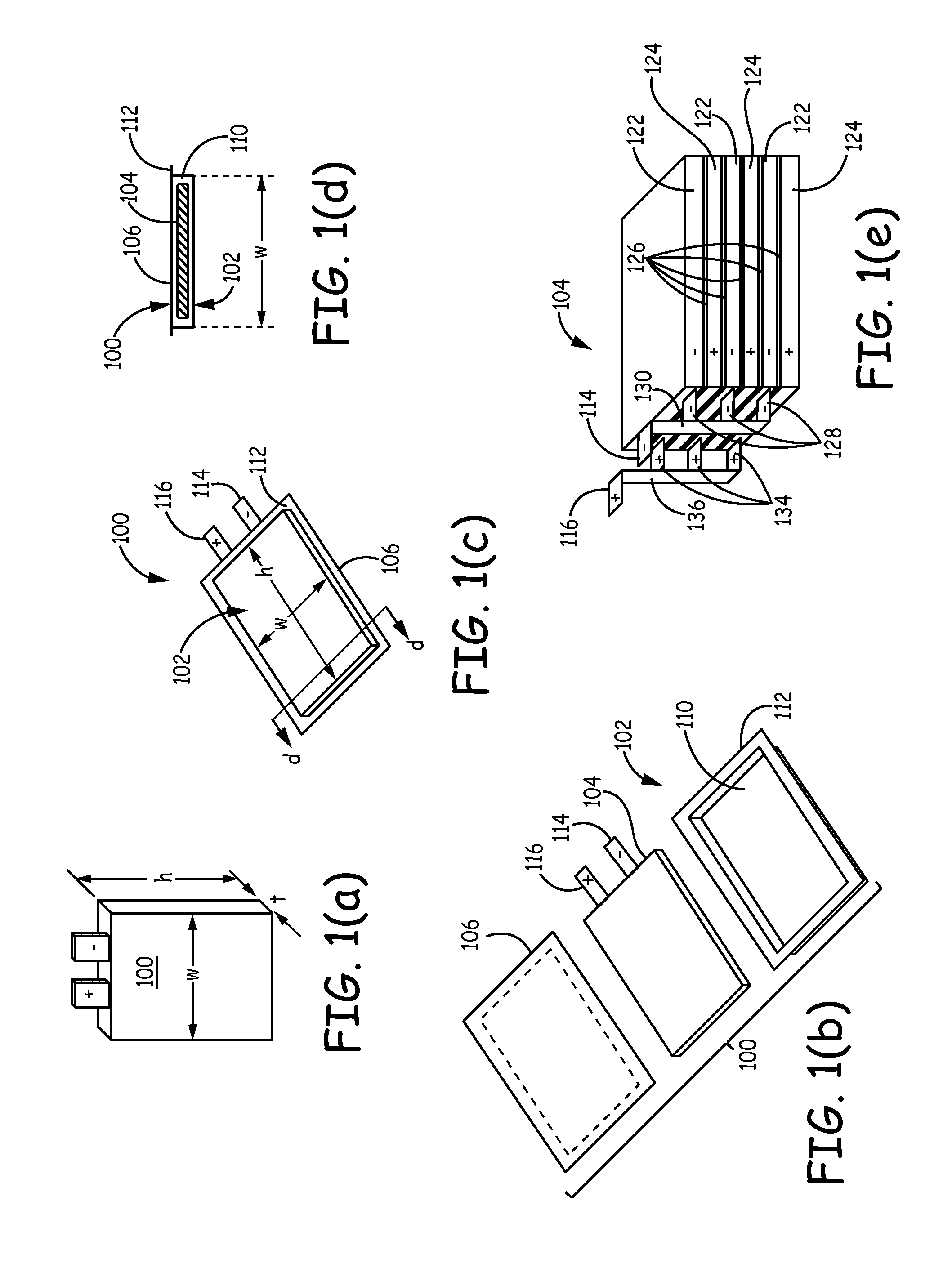

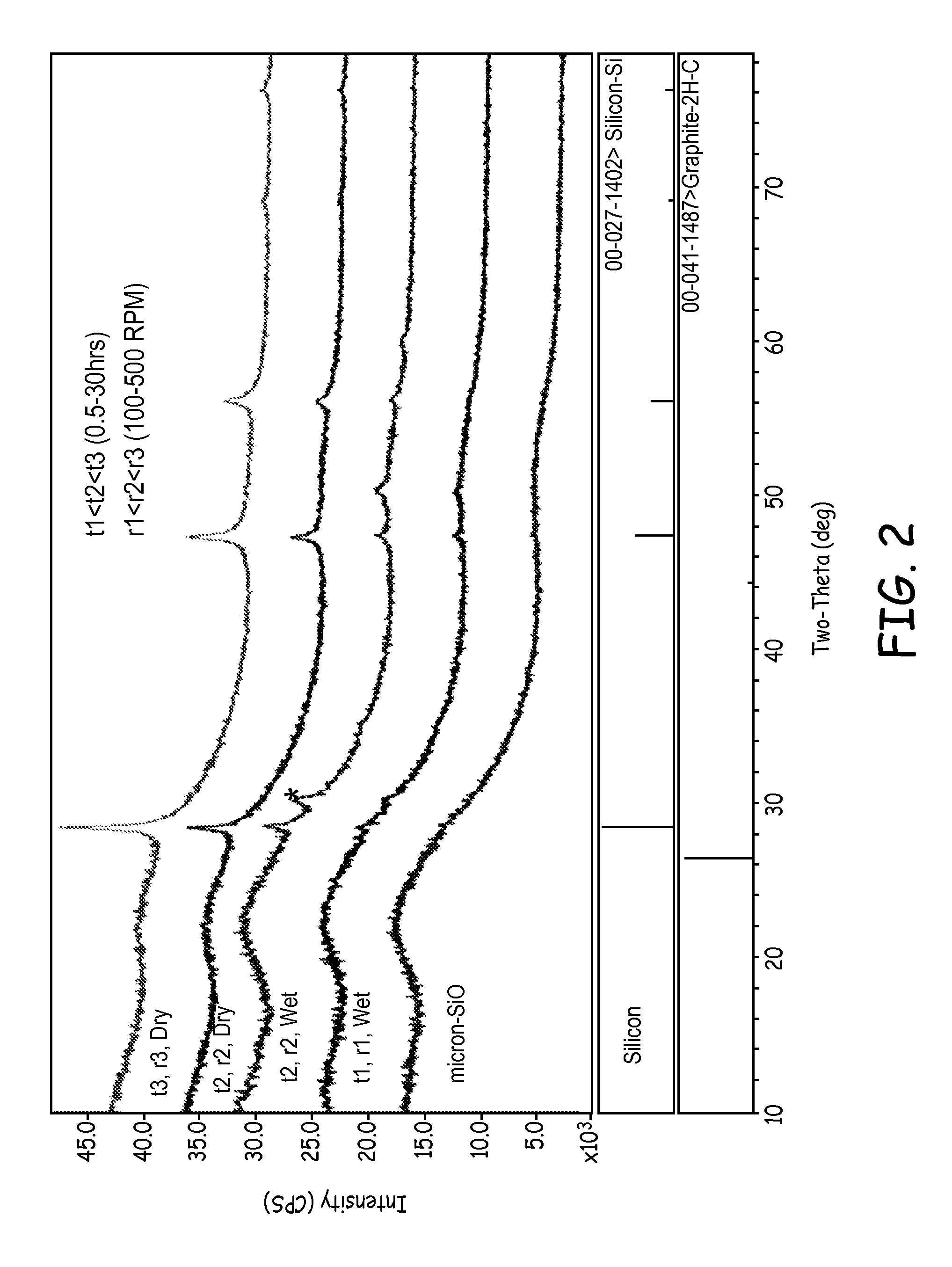

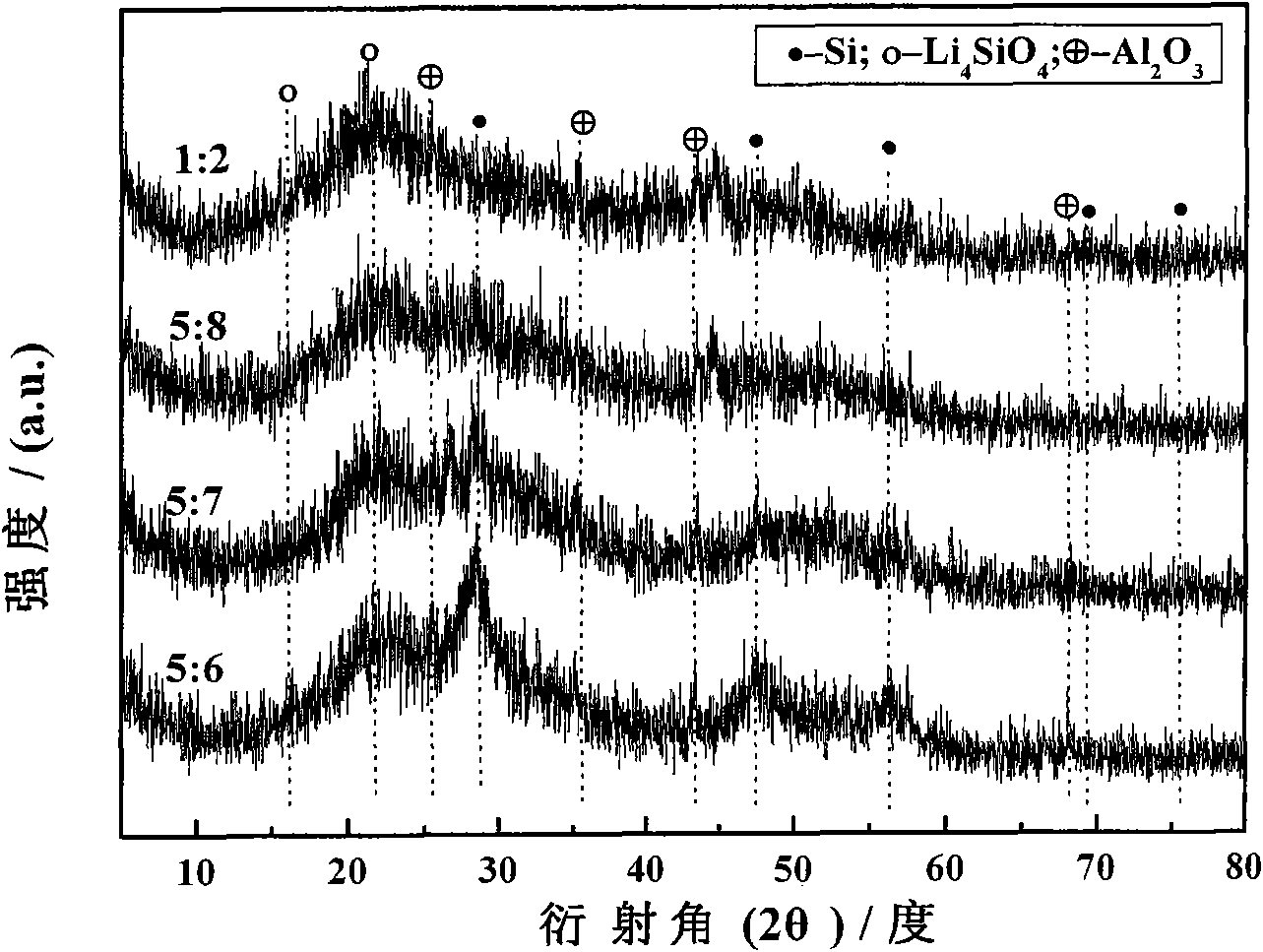

Silicon-silicon oxide-carbon composites for lithium battery electrodes and methods for forming the composites

ActiveUS20140370387A1High energyElectrode manufacturing processesLi-accumulatorsCarbon compositesHigh energy

Composite silicon based materials are described that are effective active materials for lithium ion batteries. The composite materials comprise processed, e.g., high energy mechanically milled, silicon suboxide and graphitic carbon in which at least a portion of the graphitic carbon is exfoliated into graphene sheets. The composite materials have a relatively large surface area, a high specific capacity against lithium, and good cycling with lithium metal oxide cathode materials. The composite materials can be effectively formed with a two step high energy mechanical milling process. In the first milling process, silicon suboxide can be milled to form processed silicon suboxide, which may or may not exhibit crystalline silicon x-ray diffraction. In the second milling step, the processed silicon suboxide is milled with graphitic carbon. Composite materials with a high specific capacity and good cycling can be obtained in particular with balancing of the processing conditions.

Owner:IONBLOX INC

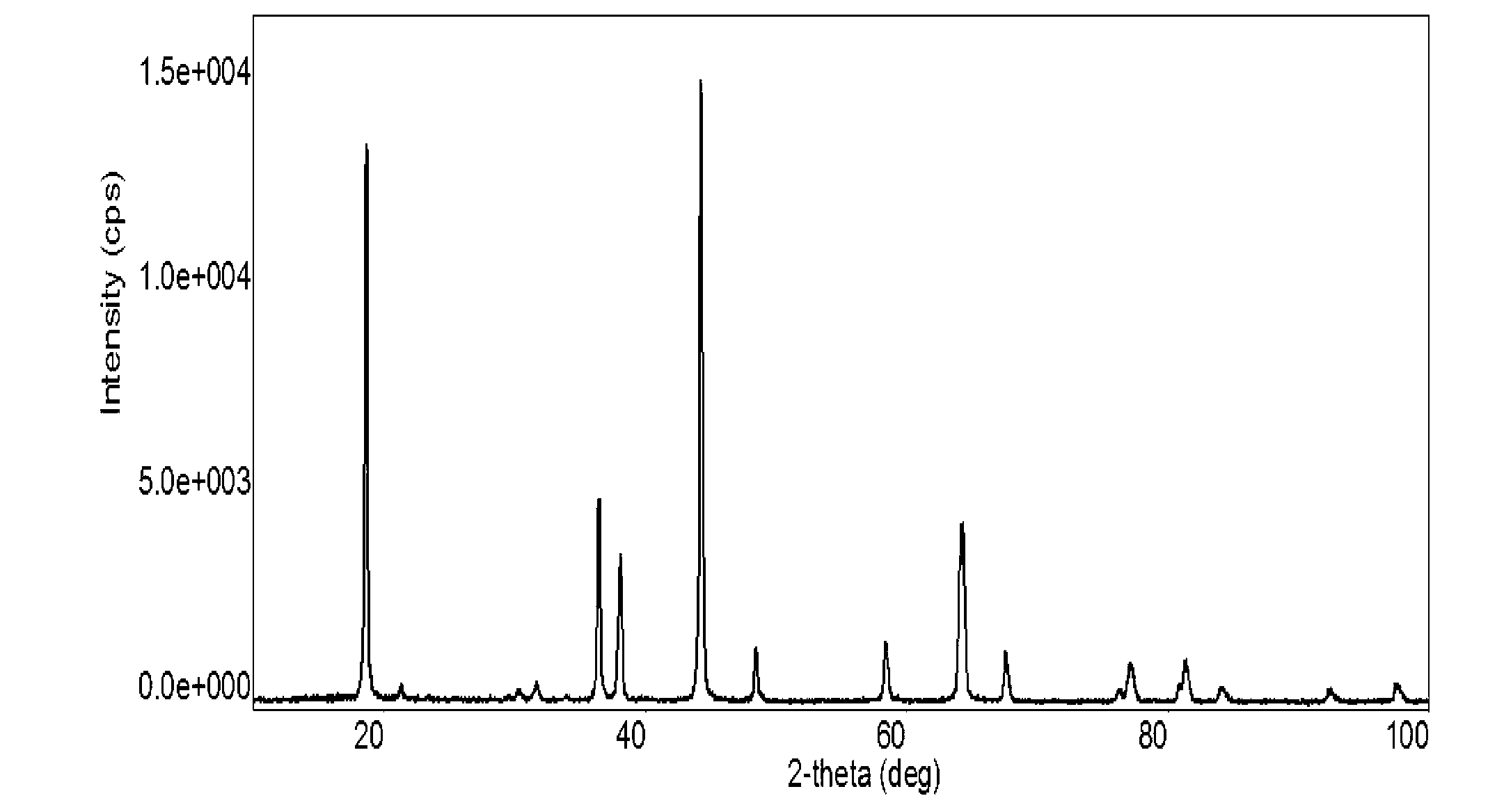

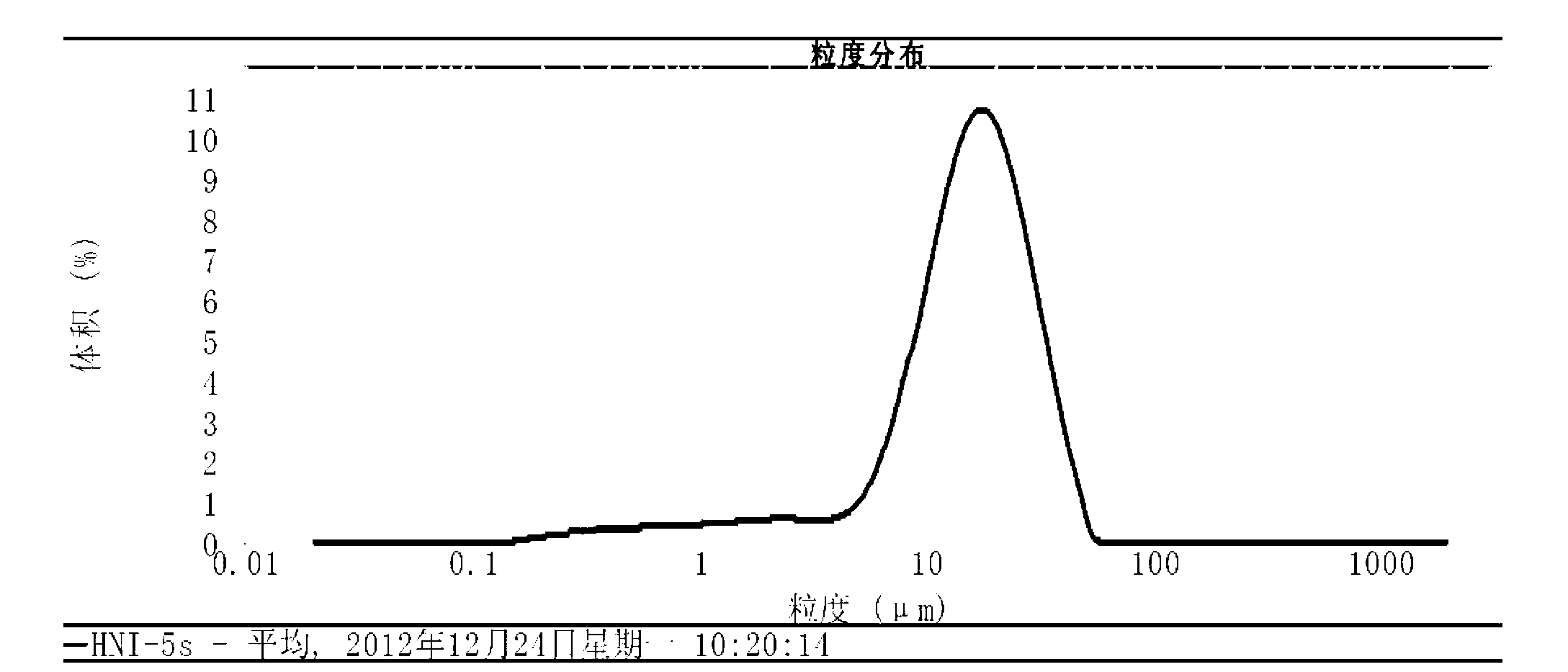

Lithium manganese phosphate clad lithium-rich layered oxide cathode material as well as preparation and application thereof

ActiveCN103035906AInhibition of dissolutionAvoid corrosionCell electrodesSecondary cellsManganesePhosphoric acid

The invention relates to a LiMnPO4 clad lithium-rich layered oxide Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 (M is at least one of Ni or Co, wherein x is more than 0 and not less than 0.33) and a preparation method thereof. The Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 is dipped in water solution containing Li, Mn and PO43- (the mol ratio is 1: 1: 1), is continuously stirred for 3-8 hours in an opening container at the temperature of 60-90 DEG C to prepare solid powder, then is dried for 2-24 hours at the temperature of 100 DEG C, and is roasted for 5-10 hours at the temperature of 300-600 DEG C to prepare the LiMnPO4 clad lithium-rich layered oxide Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 cathode material, wherein the mass ratio of the LiMnPO4 to the Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 is 3-10 wt%. The electrode material prepared by the method has the characteristics of high electrochemical capacity, good circulating stability, excellent rate capacity and the like, and has the advantages of simple preparation process, low cost and good reproducibility.

Owner:NANKAI UNIV

Anion-doped sodium ion battery oxide cathode material

InactiveCN107093713AImprove electrochemical performanceImprove cycle lifeCell electrodesSecondary cellsSodium-ion batteryOxide cathode

The invention relates to an anion-doped sodium ion battery oxide cathode material. The general formula of the material is NaaMbNcOdYy, wherein a is greater than 0.4 and smaller than 1, b is greater than 0 and equal to or smaller than 1, c is equal to or greater than 0 and equal to or smaller than 1, b plus c is 1, y is greater than 0 and equal to or smaller than 0.1, double d plus a value obtained by multiplying n and y is 4, and the n is the valence state of an anion represented by Y; M is one or more of variable-valence metal elements of Fe, Ni, Mn, Co, V, Cr and Ti; N is one or more of immutable-valence metal elements of Zn, Mg, K, Ca and Al; Y is one or more of F<->, Cl<->, SO4<2->, BO3<3->, PO4<3-> and SiO4<4->. According to the anion-doped sodium ion battery oxide cathode material, anion doping is introduced in a sodium ion battery oxide cathode material, the stability of the structure of the material can be maintained, the electrochemical performance of the material is improved, and the material has very good application prospects.

Owner:WUHAN UNIV

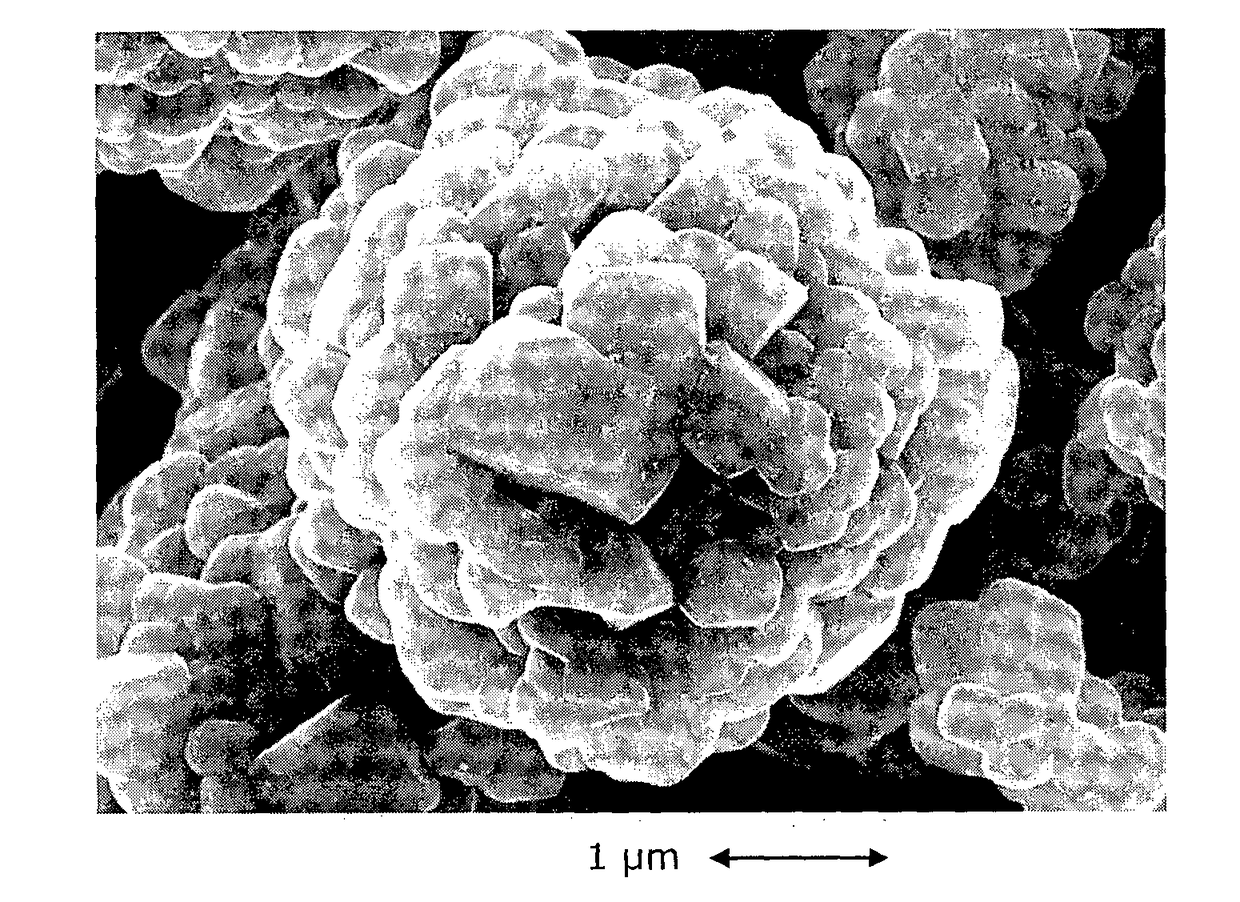

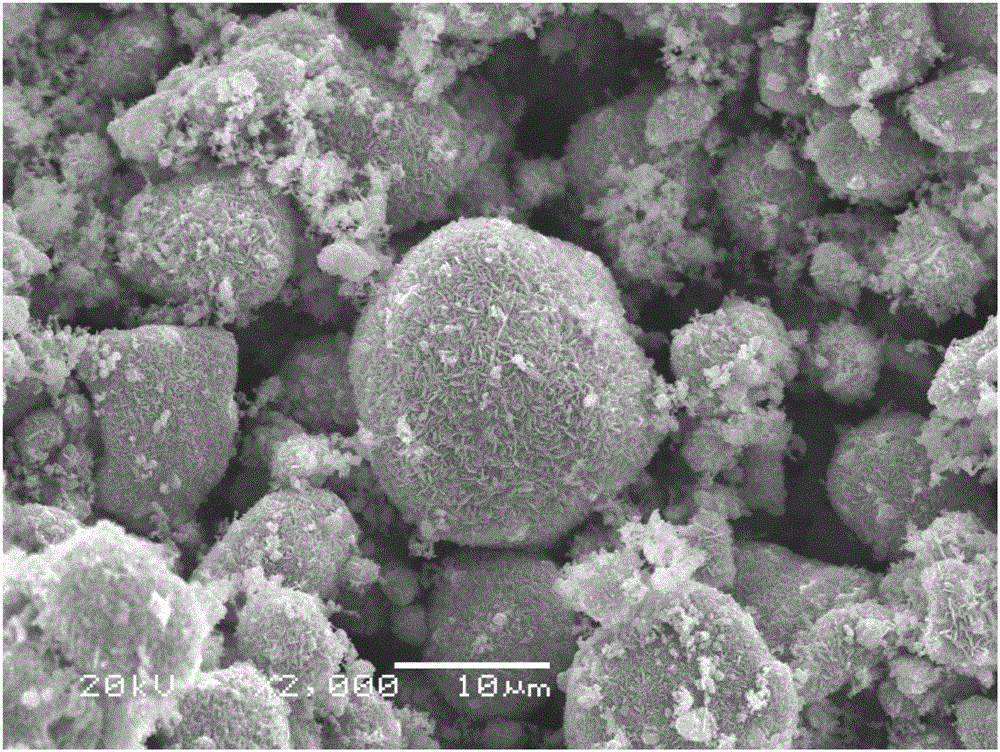

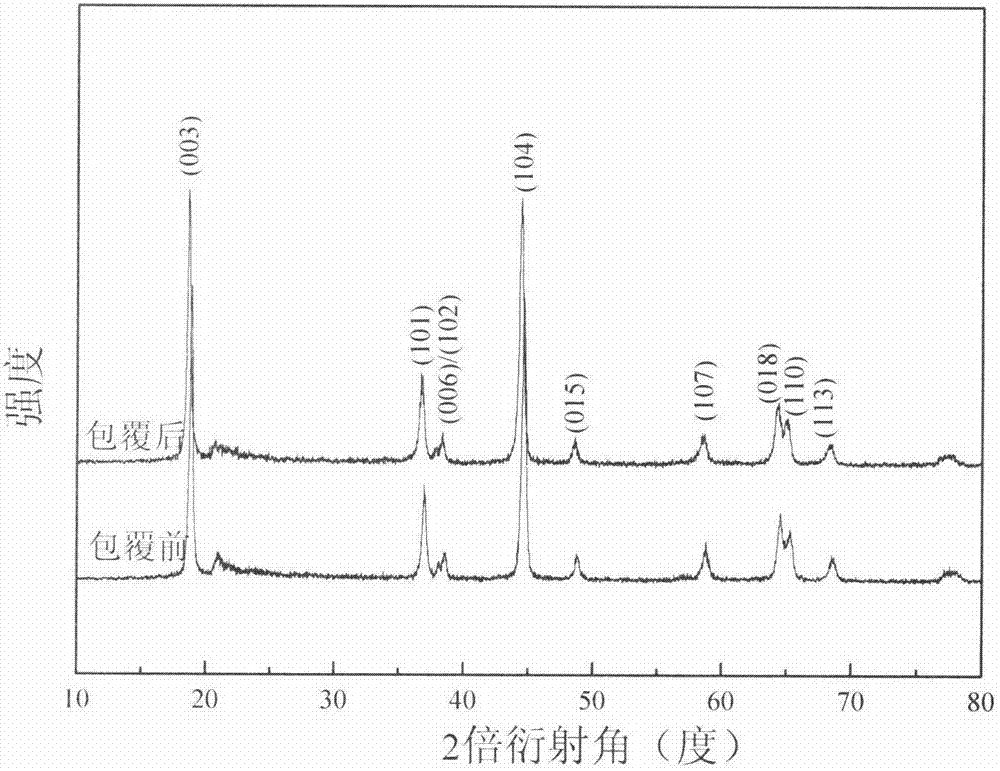

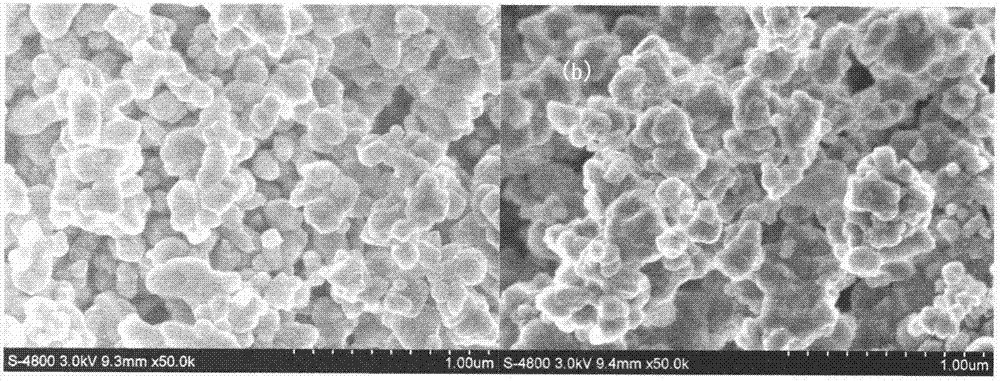

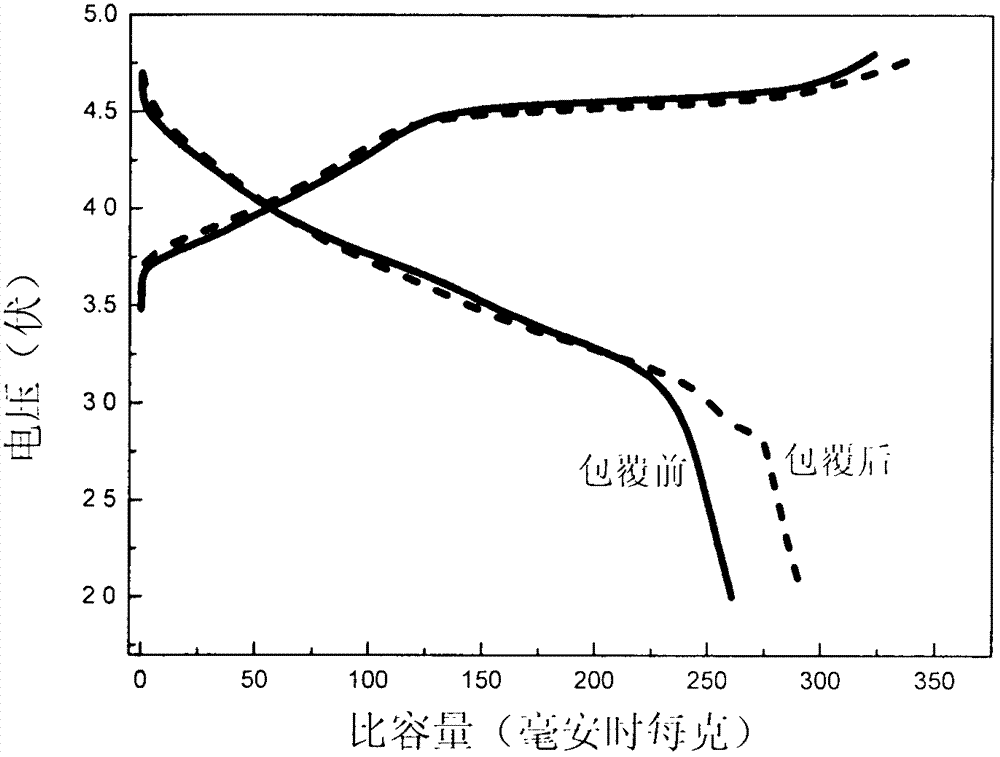

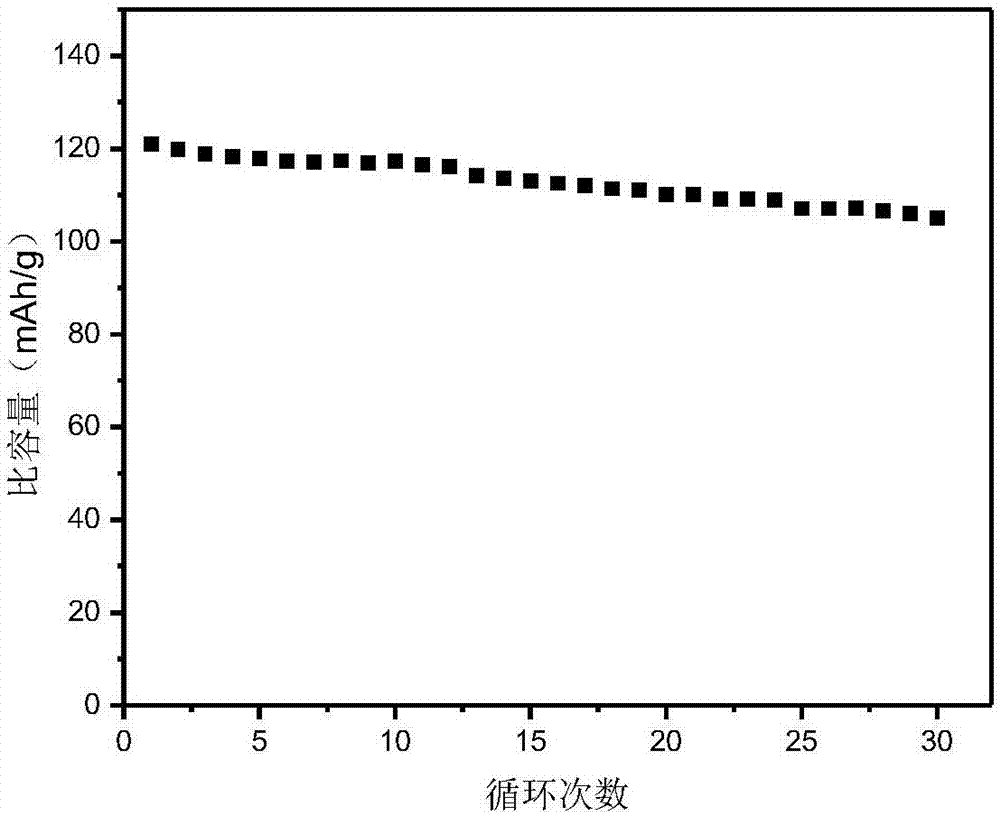

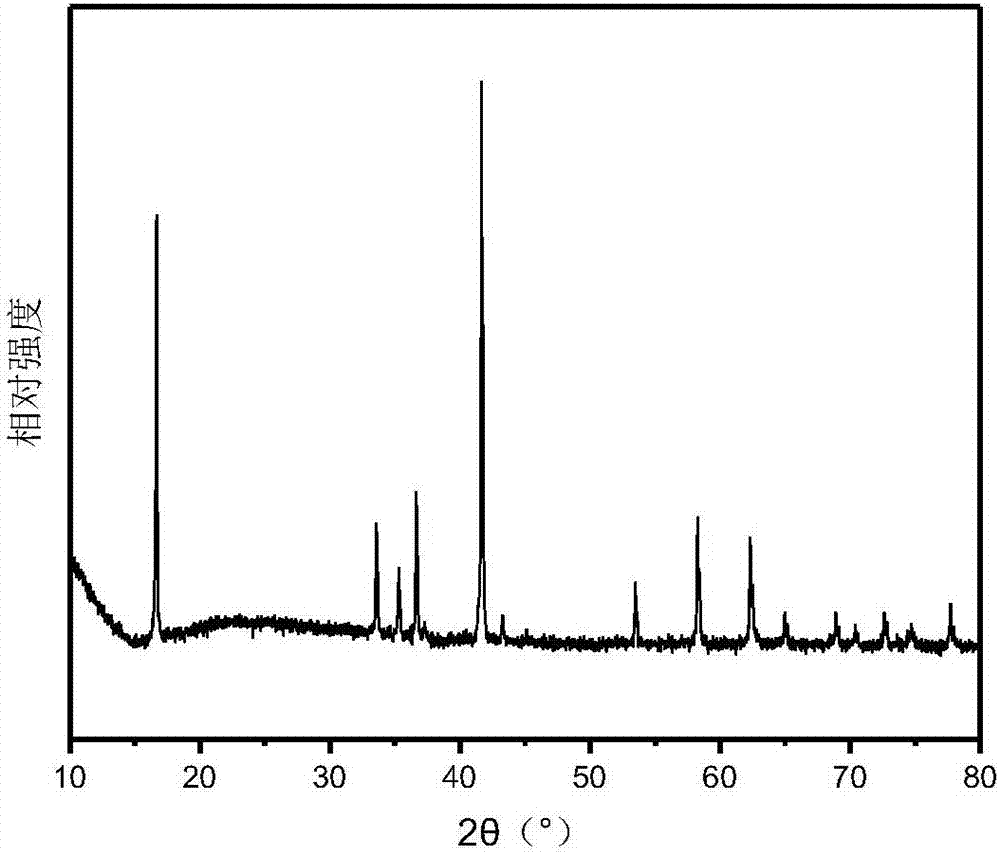

A synthesis method for a high-capacity and high-nickel multi-metal oxide cathode material

ActiveCN103066261ACost effective high capacity highIncrease capacityCell electrodesSecondary cellsSynthesis methodsOxide cathode

The present invention discloses a synthesis method for a high-capacity and high-nickel multi-metal oxide cathode material, and the method comprises the steps of: (1) in the presence of water, an aqueous solution or a solvent, grinding lithium, cobalt, nickel, and a metal M compound; (2) spray-drying the above mixture; (3) high-temperature sintering the mixture to obtain LiNi[x]Co[y]M[z]O[2]; and (4) introducing a coating on the LiNi[x]Co[y]M[z]O[2] surface to obtain the cathode material. The coated LiNi[x]Co[y]M[z]O[2] material shows excellent electrochemical performance, for instance, under 0.1C and 3C, the discharge capacity of the LiNi[0.928]Co[0.069]Mg[0.003]O[2] material coated by LiCoO[2] can respectively be more than 200 and 165mAh / g (2.75-4.3V vs Li / Li <+>). The synthesis method of the present invention has the characteristics of being simple in the implementation of method, low in costs of processes and raw materials, and easy to realize industrialization.

Owner:LONG POWER SYST NANTONG CO LTD

Surface and bulk modified high capacity layered oxide cathodes with low irreversible capacity loss

InactiveUS7678503B2Large capacityLow costElectrode carriers/collectorsAlkali metal oxidesOxide cathodeSurface modification

The present invention includes compositions, surface and bulk modifications, and methods of making of (1−x)Li[Li1 / 3Mn2 / 3]O2.xLi[Mn0.5-yNi0.5-yCo2y]O2 cathode materials having an O3 crystal structure with a x value between 0 and 1 and y value between 0 and 0.5, reducing the irreversible capacity loss in the first cycle by surface modification with oxides and bulk modification with cationic and anionic substitutions, and increasing the reversible capacity to close to the theoretical value of insertion / extraction of one lithium per transition metal ion (250-300 mAh / g).

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

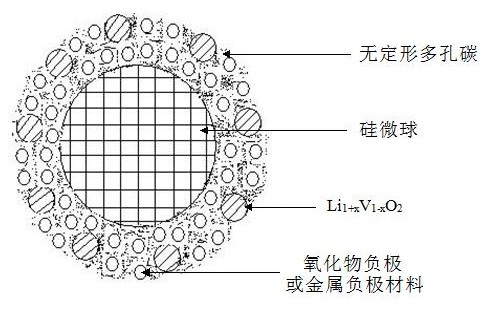

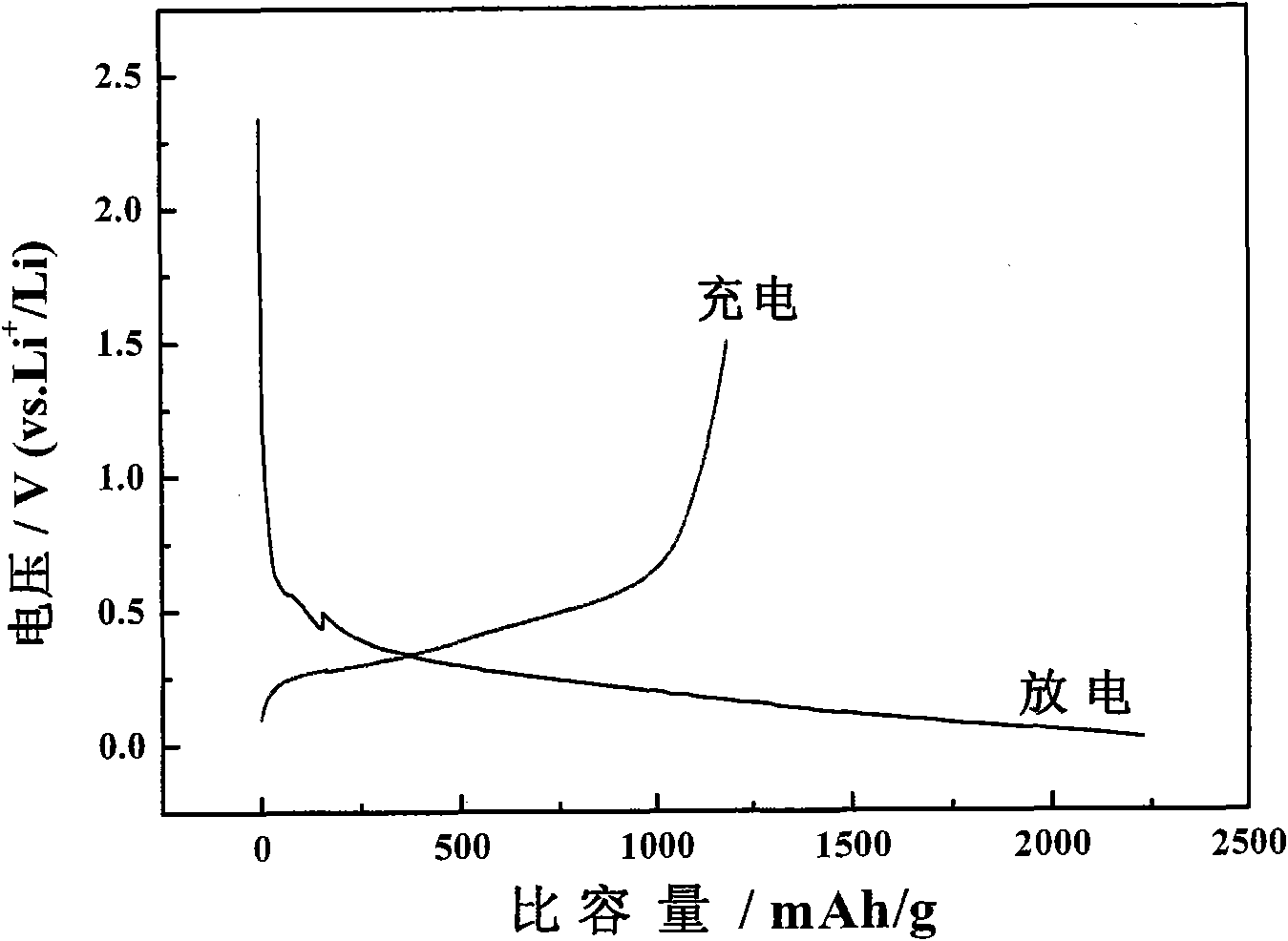

Micro-sphere compound anode material with core-shell structure and preparation method thereof

InactiveCN102169996AConstant volumeShorten the diffusion distanceElectrode carriers/collectorsPorous carbonOxide cathode

The invention discloses a micro-sphere compound anode material with a core-shell structure and a preparation method thereof. The compound anode material is a compound micro-sphere with the core-shell structure; the material of the core is a silicon micro-sphere; and the material of the shell layer is formed by uniformly embedding Li1+xV1-xO2 and oxide cathode or metal anode materials in amorphousporous carbon. The preparation method of the compound anode material comprises the following steps of dissolving a lithium source and a vanadium source in deionized water at a constant temperature; adding macromolecule glue and uniformly dispersing by adopting ultrasonic wave; slowly adding in the glue state phase when dispersing the silicon micro-sphere and the oxide cathode or the metal anode material by adopting the ultrasonic wave; and then sequentially carbonizing and combining in the inertia or reducing atmosphere to obtain the core-shell structured compound micro-sphere taking the silicon micro-sphere as the core and the porous amorphous carbon as the shell. The discharging ratio capacity is more than 980mA h / g when the compound micro-sphere material is used at the cathode of the lithium ion battery. And the charging and discharging efficiency at the first time is more than 85%; the capacity conservation rate is more than 92% after the micro-sphere compound anode material is recycled for 500 times.

Owner:HUNAN UNIV OF TECH

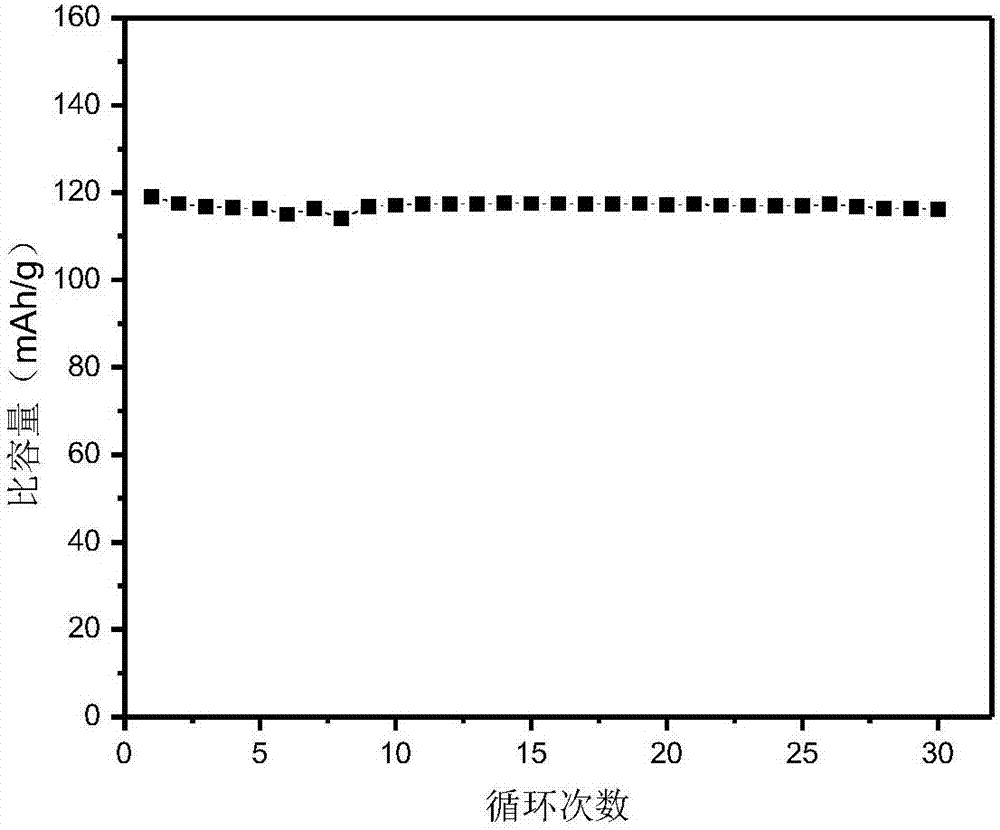

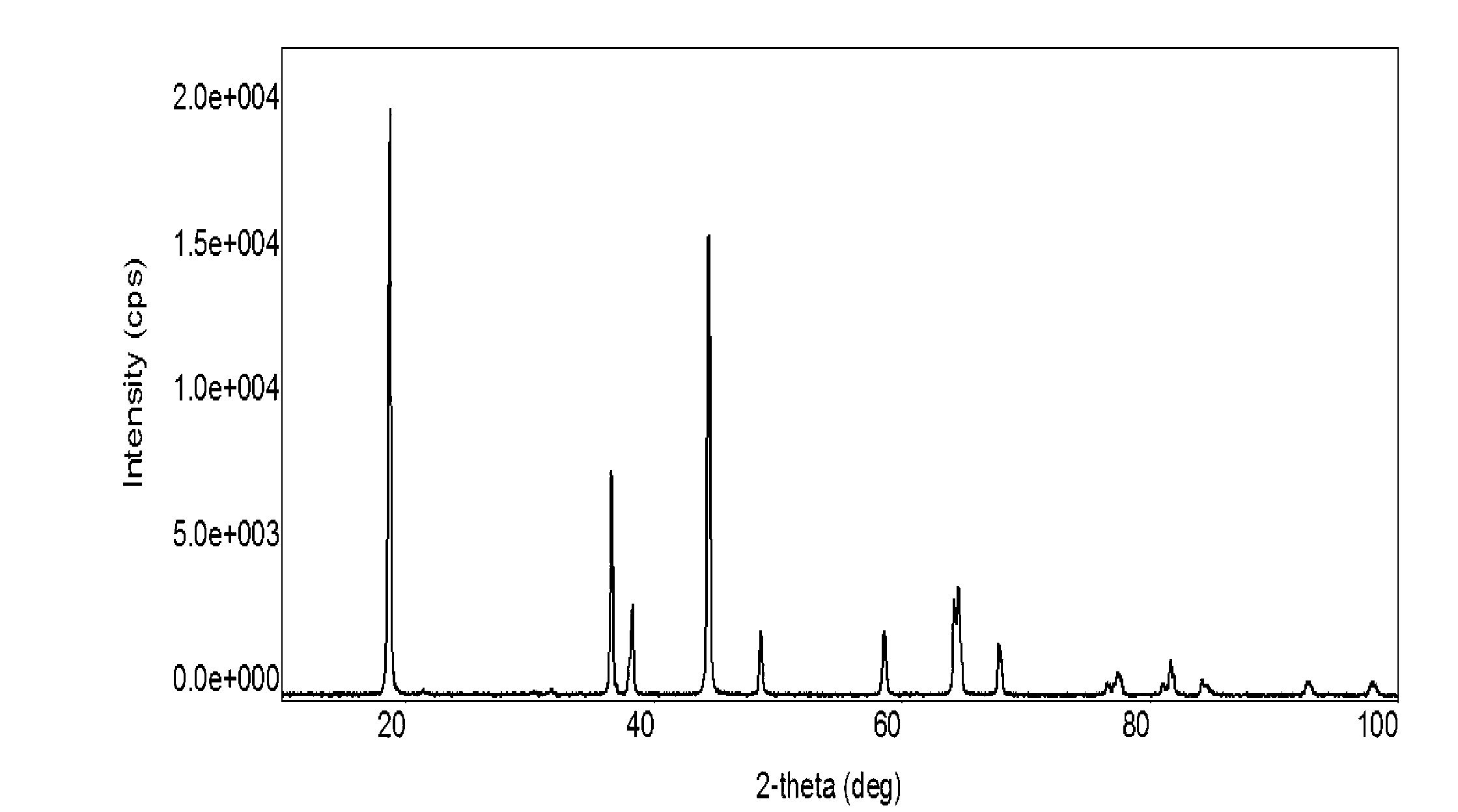

Quintuple layered oxide cathode material for sodium ion battery and preparation method of quintuple layered oxide cathode material

InactiveCN105161703AImprove electrochemical stabilityHigh specific capacityCell electrodesSecondary cellsDecompositionSodium-ion battery

The invention belongs to the technical field of a sodium ion battery, in particular relates to a quintuple layered oxide cathode material for a sodium ion battery and a preparation method of the quintuple layered oxide cathode material. A single-phase quintuple layered oxide NaNi<m>Fe<n>Co<x>Mn<y>Ti<z>O2 is obtained by uniformly mixing materials of sodium carbonate, nickel oxide, cobalt oxide, ferric oxide, titanium oxide and manganese oxide (or other precursors of manganese oxides only can be generated through high-temperature decomposition) according to stoichiometric ratios, pressing the mixture into a small wafer and placing the small wafer in an electric furnace having oxygen flow and air for high-temperature reaction, wherein m, n, x, y and z are more than 0 and less than 1. When the electrode material is applied to the sodium ion battery, the initial specific capacity reaches 128mAh / g, the average voltage is 3.1V, for Na<+> / Na, the specific energy can reaches 396Wh / kg, and the capacity retention ratio of the electrode after 300 cycles in a 4C rate is 90%. The NaNi<m>Fe<n>Co<x>Mn<y>Ti<z>O2 is high in electrochemical stability, specific capacity, rate performance and cycle performance, and the preparation method is simple and is applicable for the sodium ion battery.

Owner:FUDAN UNIV

Improved lithium metal oxide cathode materials and method to make them

InactiveUS20160315315A1Improve performanceImprove cycle lifeElectrode rolling/calenderingElectrode thermal treatmentParticulatesLithium metal

A coated cathode material comprises a lithium metal oxide particulate having a surface at least partially coated with a coating comprised of a complex metal oxide of aluminum and a second metal that is lanthanum, yttria or combination thereof. The coated cathode material may be made by providing a lithium metal oxide particulate which is then contacted with a precursor compound that forms a complex metal oxide upon heating. The coated lithium metal oxide is then heated to a temperature sufficient to form the complex metal oxide, wherein the complex metal oxide is amorphous and contains aluminum and a second metal that is lanthanum, yttria or combination thereof and the complex metal oxide is bonded to the lithium metal oxide.

Owner:DOW GLOBAL TECH LLC

Cobalt-Based Lithium Metal Oxide Cathode Material

A layered lithium metal oxide powder for a cathode material used in a rechargeable battery, with the general formula (1−x)[Lia-bAb]3a[CO1-cMc]3b[O2-d-eN′e]6c.xLi3PO4, with 0.0001≤x≤0.05, 0.90≤a≤1.10, 0<b+c≤0.1, −0.1≤d≤0.1 and e≤0.05, wherein A and M are one or more elements including at least one of the group consisting of Mg, Ti and Al; wherein N′ is either one or more dopants of the group consisting of F, S, N and P; the powder consisting of a core and an ion-conductive electron-insulating surface layer, the core having a layered crystal structure and the surface layer comprising a mixture of elements of the core material, oxides comprising either one or more elements of the group consisting of Mg, Ti and Al; and Li3PO4.

Owner:UMICORE AG & CO KG +1

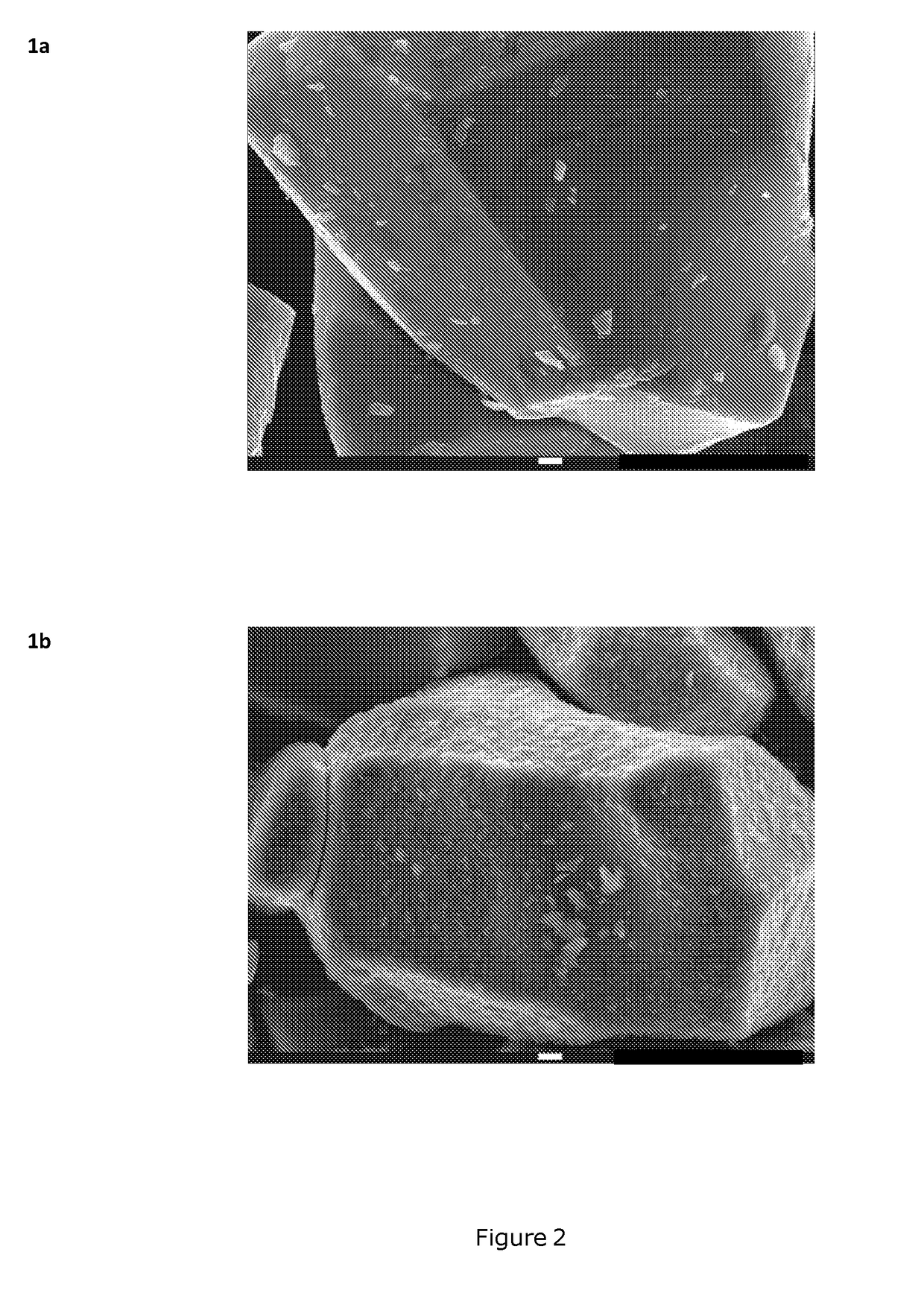

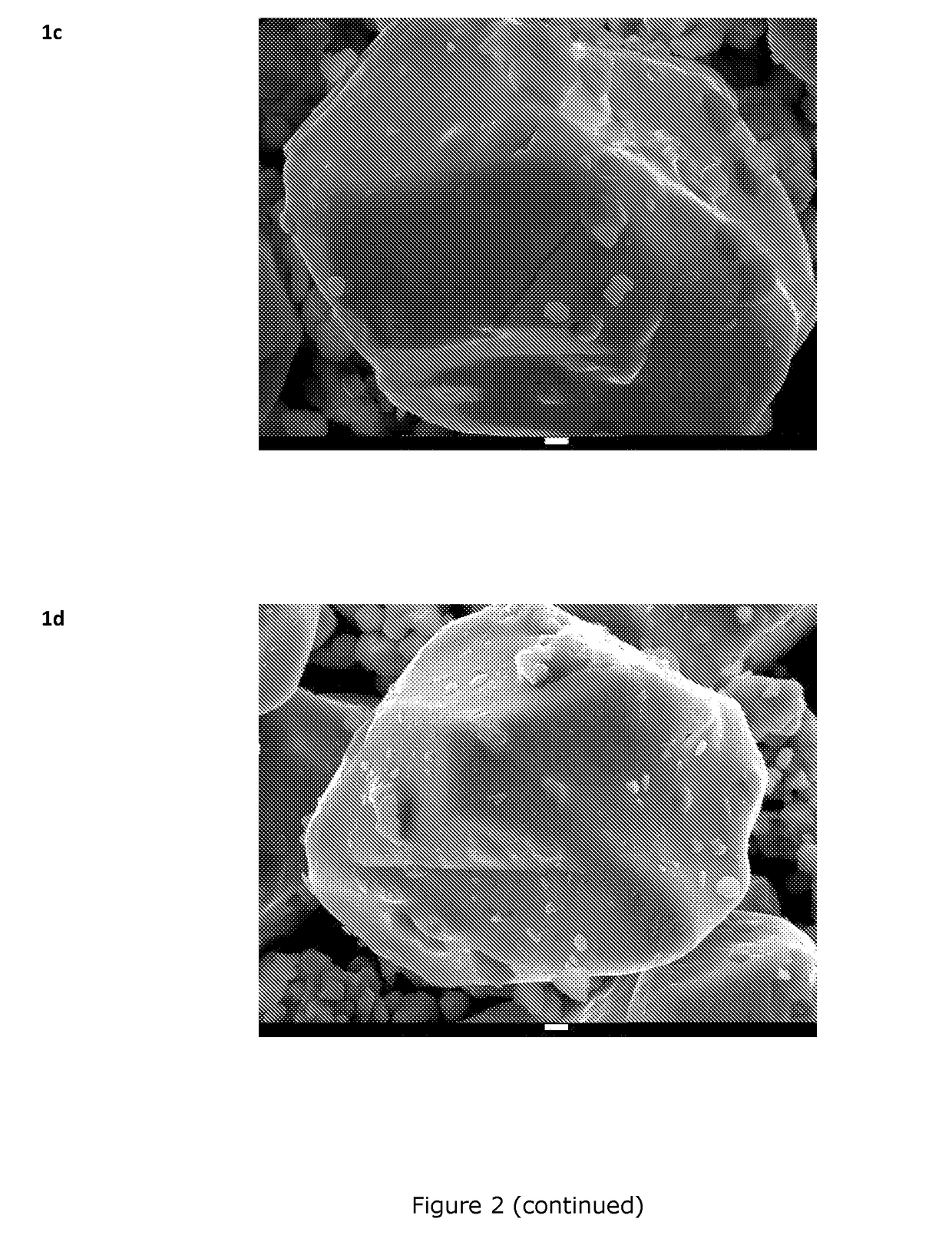

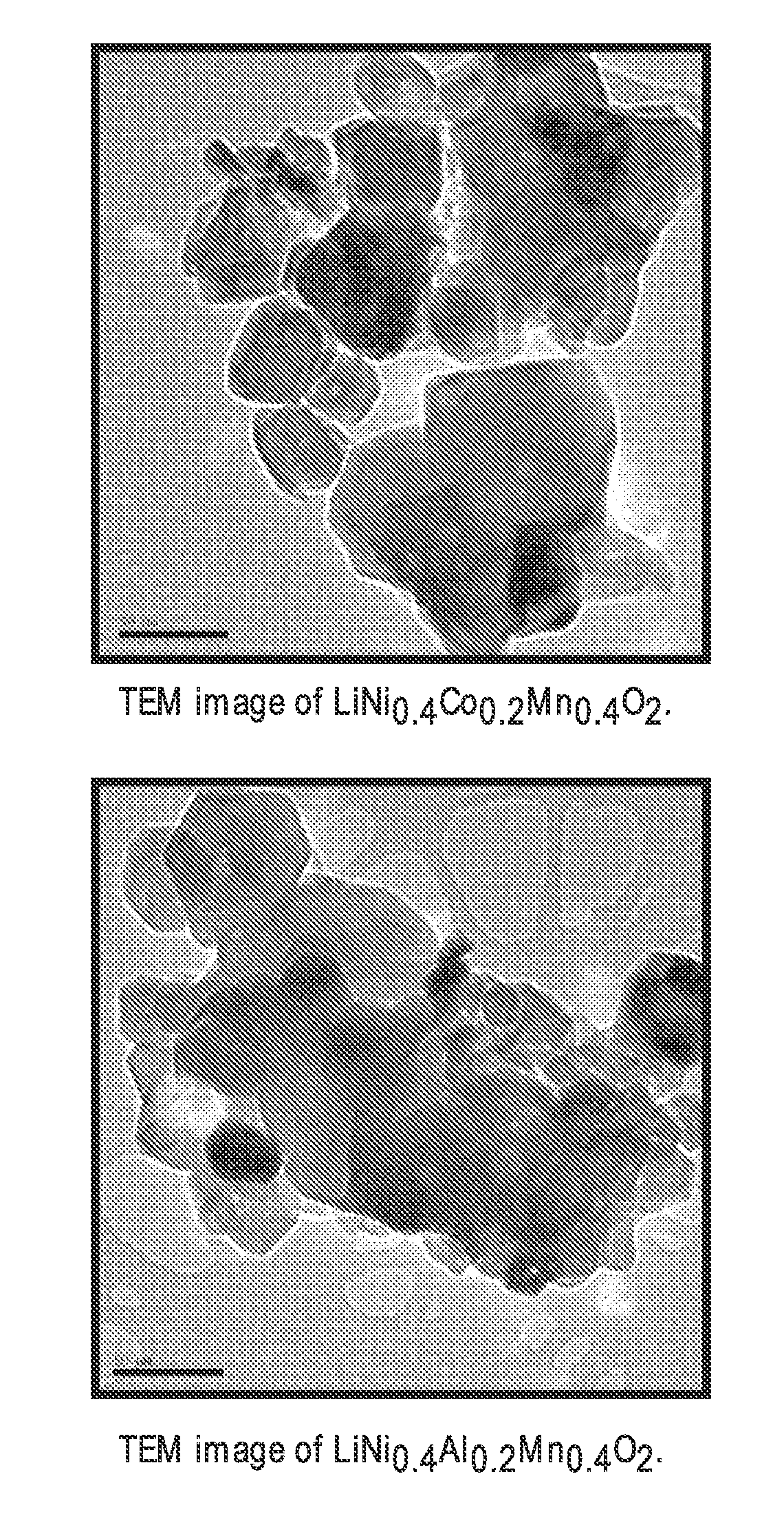

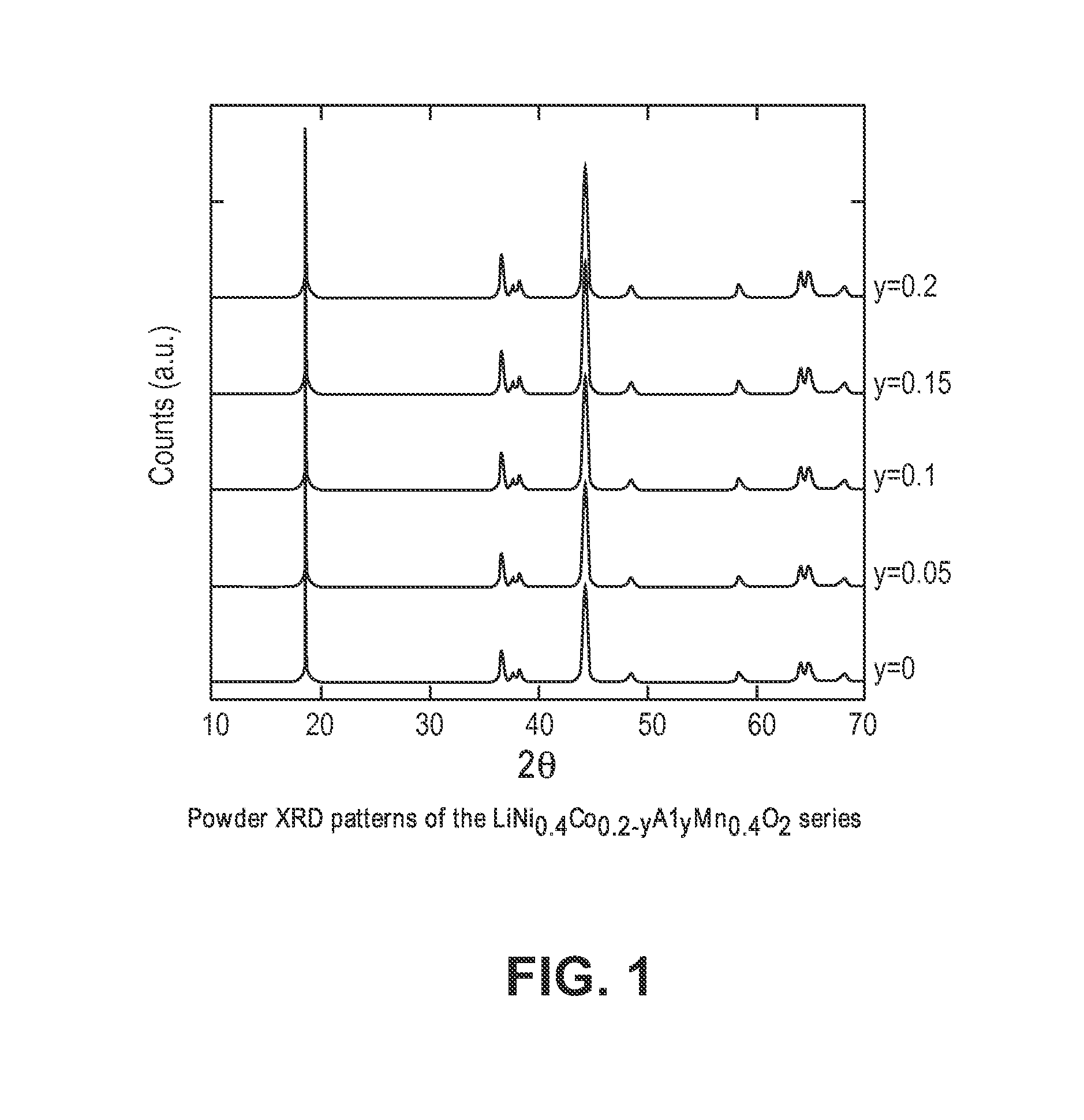

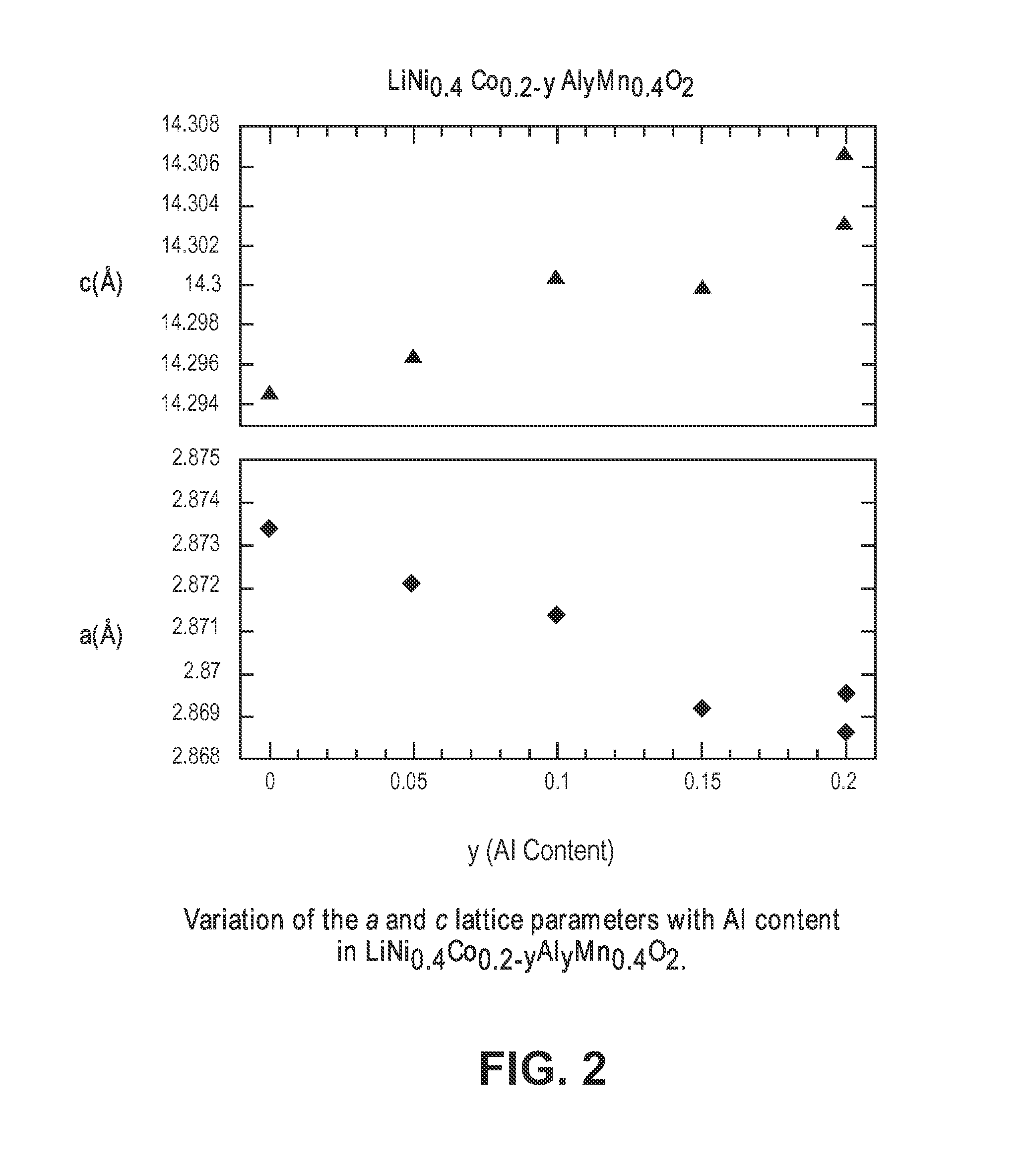

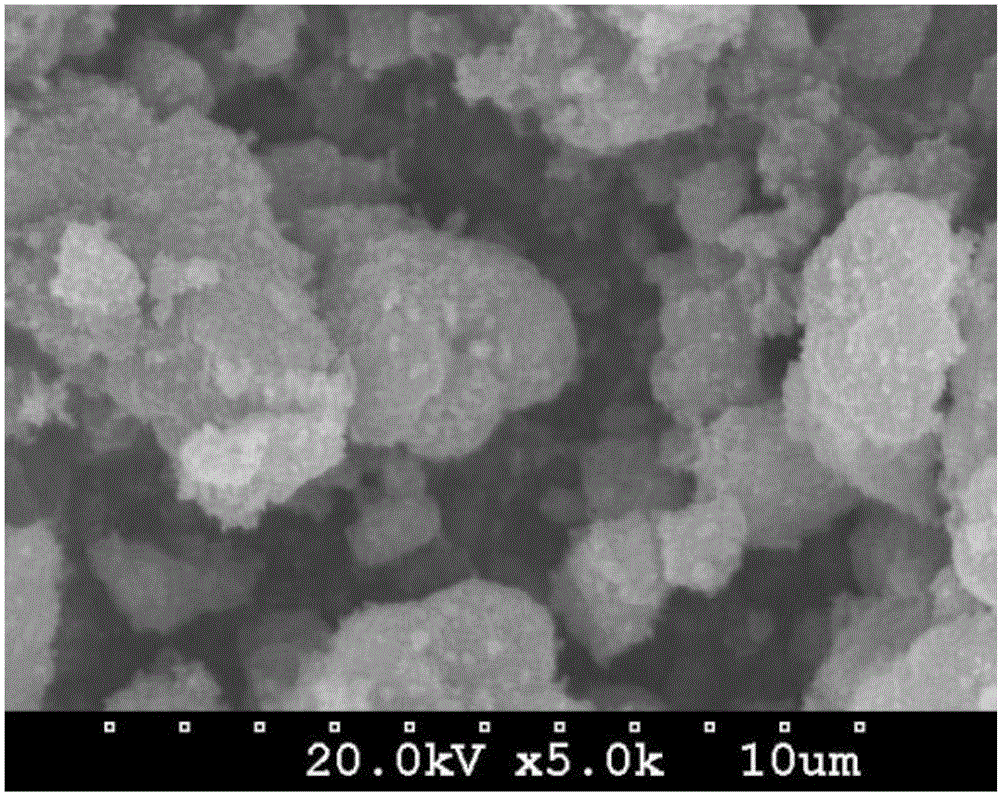

Aluminum Substituted Mixed Transition Metal Oxide Cathode Materials for Lithium Ion Batteries

InactiveUS20110291043A1Low power capabilityReduces mobility of lithium ionCell electrodesSecondary cellsOxide cathodeCobalt

A mixed transition metal oxide is provided described wherein Aluminum is partially substituted for Cobalt in a Li[NixCoyMnz]O2 composition wherein the resulting aluminum substituted product Li[Ni0.4Co0.2-yAlyMn0.4]O2 is less costly than the parent product, is safer to use, and provides enhanced electrochemical performance as a cathode material for use in Lithium-ion based batteries.

Owner:RGT UNIV OF CALIFORNIA

Preparation method and application of lithium-rich layered oxide cathode material

ActiveCN106410186AStable structureInhibition of structural transformationCell electrodesSecondary cellsUltrasound attenuationButton battery

The invention discloses a preparation method of a lithium-rich layered oxide cathodee material. The chemical formula of the lithium-rich layered oxide cathode material is Li[Li<(1-2x) / 3>Ni<x-y>M<2y>Mn<2 / 3-x / 3-y>]O<2>, wherein x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than x, and M is one or a mixture of two or more than two of Fe, Co, Al and Cr in any proportion. The preparation method of the lithium-rich layered oxide cathode material comprises the following steps: firstly using a high-temperature solid-phase method to prepare an M-doped Li2MnO3 material, then mixing the M-doped Li2MnO3 material with an Li source material, an Ni source material and an Mn source material, and mixing at the temperature of 700 to 950 DEG C and roasting for 5 to 15 h so as to obtain the target object. The material prepared by the invention has the advantages of stable structure, easily controlled conditions, high batch stability and the like, and is suitable for scale production; and a button cell assembled by using the prepared lithium-rich layered oxide cathode material has the advantages of high first-time charging and discharging efficiency, small voltage attenuation, good cycle performance and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

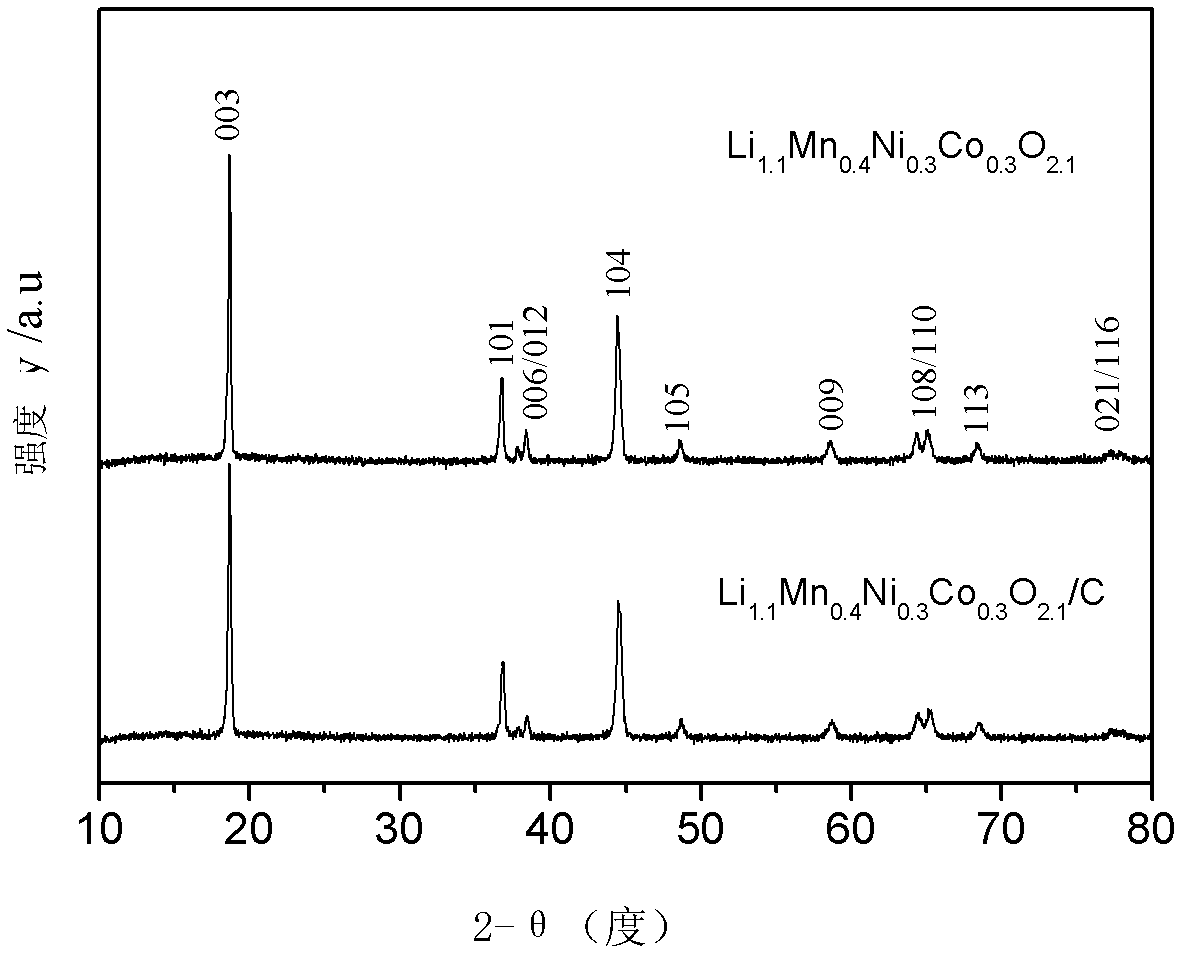

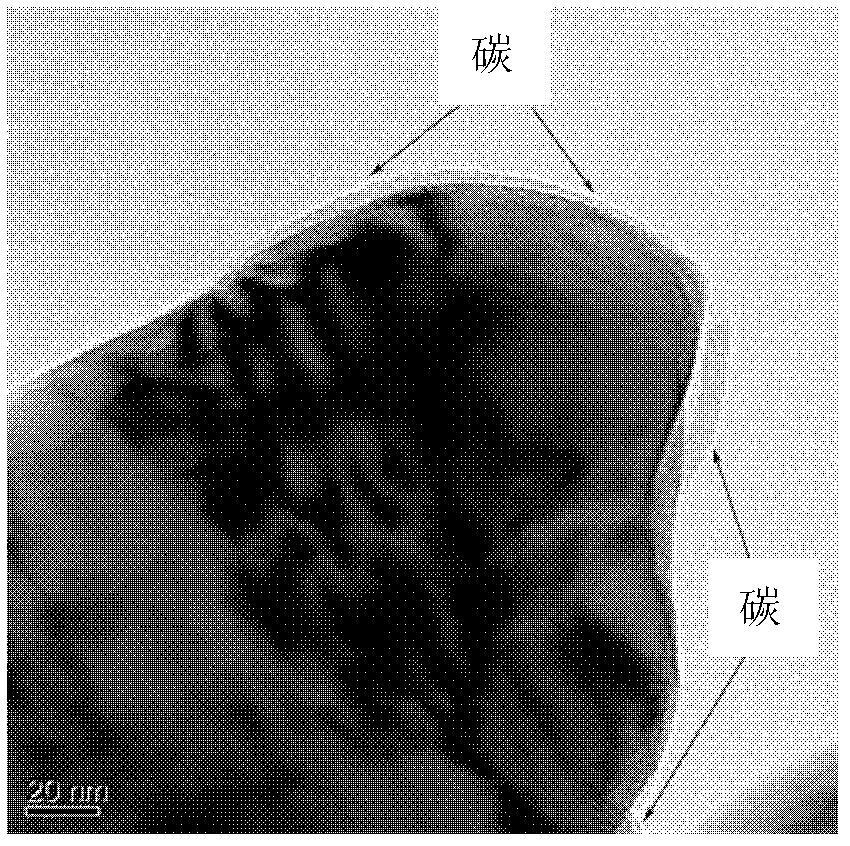

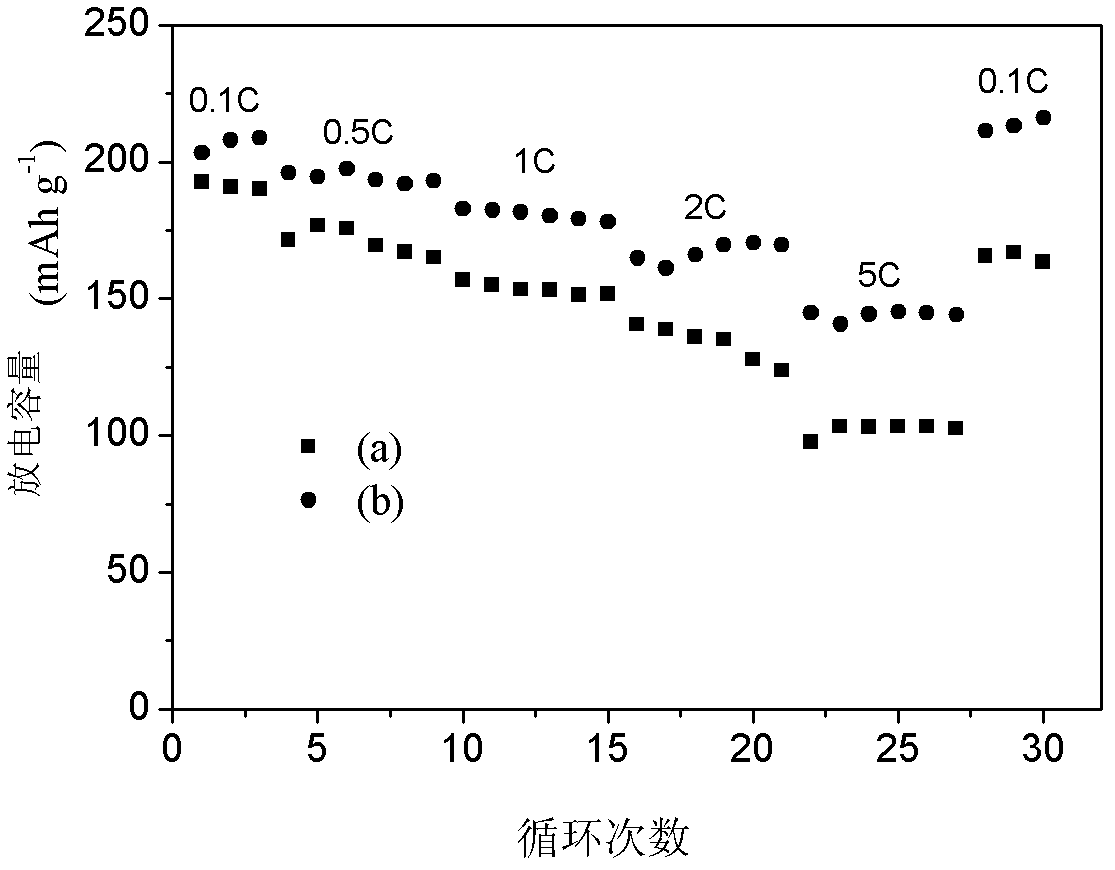

A layered oxide lithium ion battery positive electrode and preparation method thereof

InactiveCN102299316AImprove cycle stabilityImproved magnification performanceCell electrodesLithium oxideCarbon layer

The invention relates to a positive electrode of a layered oxide lithium ion battery and a preparation method thereof. The positive electrode includes a pole piece and a carbon layer on the pole piece. The carbon layer is formed by magnetron sputtering under an inert atmosphere using a graphite target The carbon source is formed by sputtering on the surface of the pole piece. The present invention uses the magnetron sputtering method to coat the positive electrode with carbon, which breaks through the limitation of the traditional thermal decomposition method to coat the positive electrode material, and prepares the positive electrode of the carbon-coated lithium-rich layered structure oxide lithium ion battery. By using the carbon layer The effect of effectively preventing the side reaction between the active material and the electrolyte during the charging and discharging process improves the cycle stability and rate performance of the positive electrode of the layered lithium-rich lithium-ion battery. Experiments have found that it can meet the requirements of power lithium-ion batteries.

Owner:浙江吉能电池科技有限公司

Lithium Metal Oxide Cathode Powders for High Voltage Lithium-Ion Batteries

ActiveUS20180034045A1Raise the ratioAlter electrical propertyElectrode thermal treatmentSecondary cellsLithium metalOxide cathode

This invention discloses a lithium metal oxide powder for a cathode material in a rechargeable battery, consisting of a core and a surface layer, the core having a layered crystal structure comprising the elements Li, M and oxygen, wherein M has the formula M=(Niz(Ni1 / 2Mn1 / 2)yCox)1-kAk, with 0.15≦x≦0.30, 0.20≦z≦0.55, x+y+z=1 and 0≦k≦0.1, wherein A is a dopant, wherein the Li content is stoichiometrically controlled with a molar ratio 0.95≦Li:M≦1.10; and wherein the surface layer comprises the elements Li, M′ and oxygen, wherein M′ has the formula M′=(Niz′(Ni1 / 2Mn1 / 2)y′Cox′)1-k′Ak′, with x′+y′+z′=1 and 0≦k′≦0.1, and wherein y′ / (y′+2z′)≧1.1*[y / (y+2z)]. The surface layer may also comprise at least 3 mol % Al, the Al content in the surface layer 10 being determined by XPS.

Owner:UMICORE AG & CO KG +1

High-density precursor for manufacture of composite metal oxide cathodes for Li-ion batteries

The disclosed embodiments relate to the manufacture of a precursor co-precipitate material for a cathode active material composition. During manufacture of the precursor co-precipitate material, an aqueous solution containing at least one of a manganese sulfate and a cobalt sulfate is formed. Next, a NH4OH solution is added to the aqueous solution to form a particulate solution comprising irregular secondary particles of the precursor co-precipitate material. A constant pH in the range of 10-12 is also maintained in the particulate solution by adding a basic solution to the particulate solution.

Owner:APPLE INC

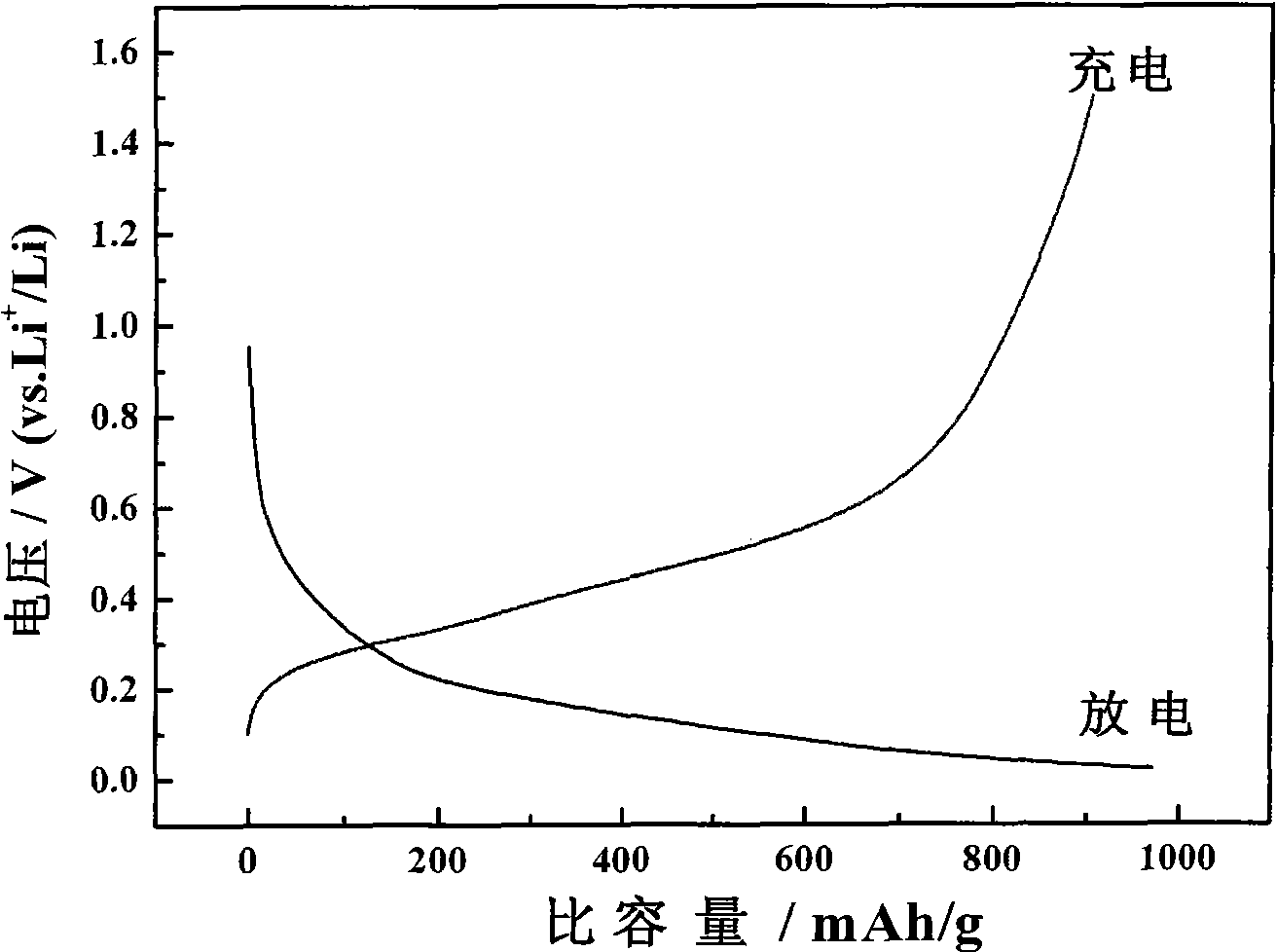

Composite cathode material for lithium ion battery and preparation method thereof

ActiveCN101789506ASimple preparation processEasy to operateElectrode manufacturing processesSource fieldSodium-ion battery

The invention relates to composite cathode material for a lithium ion battery and a preparation method thereof, belonging to the chemical power source field. The invention aims to solve the problems that the first lithium ion insertion process of oxide cathode material performs an irreversible reaction, the first coulombic efficiency is low, etc. The preparation method comprises the following steps: using precursor MO, reducing agent metal lithium and a defined amount of organic solvent to perform wet mechanochemical in situ reduction and obtain power, heating the obtained power under vacuum atmosphere to remove organic solvent, and obtaining the composite material. The method of the invention has simple process, low cost and wide application range; and the first efficiency of the prepared composite cathode material is more than 80%, the maximum is more than 95%, and the composite cathode material also has good electrochemical cycle stability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

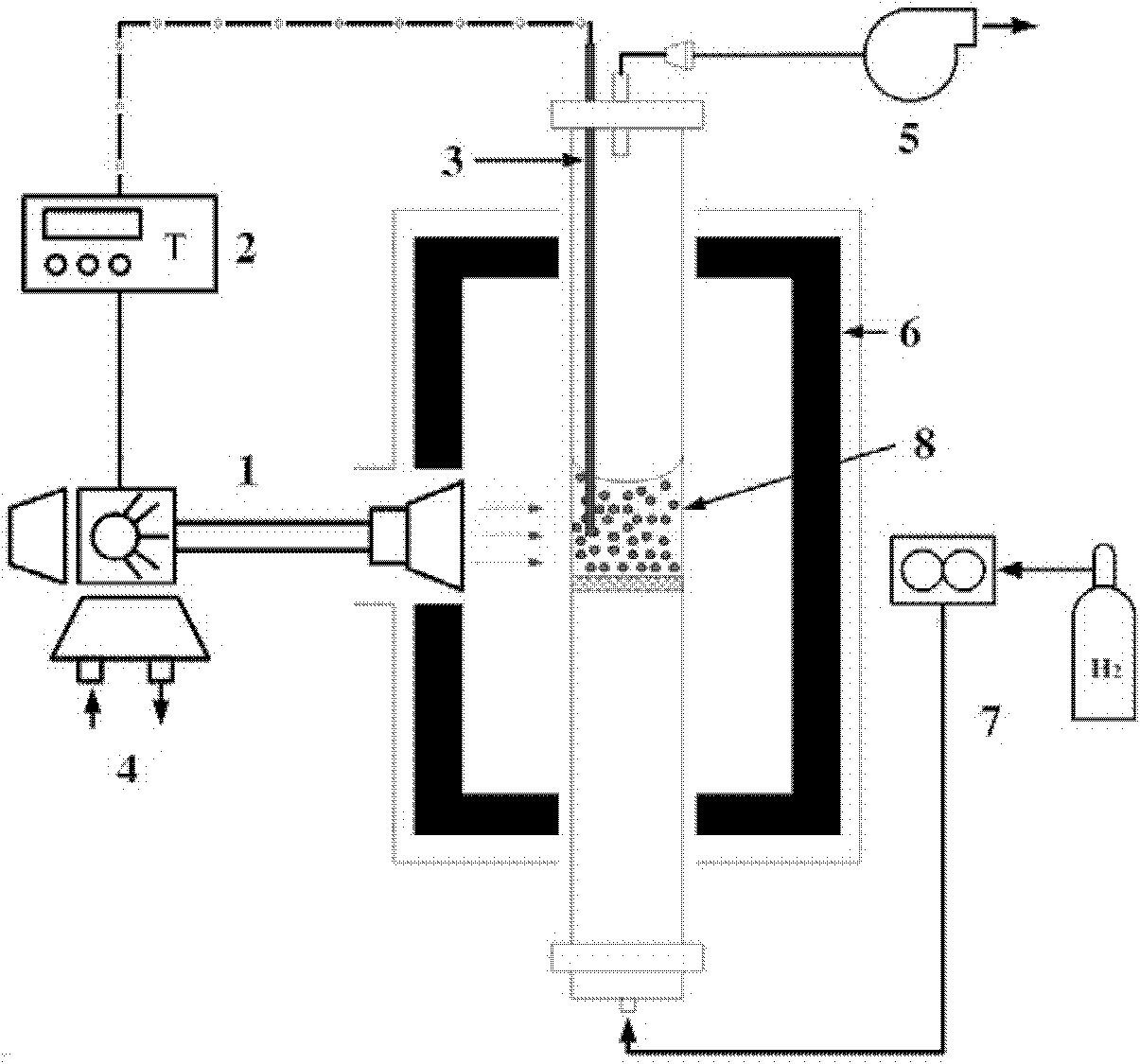

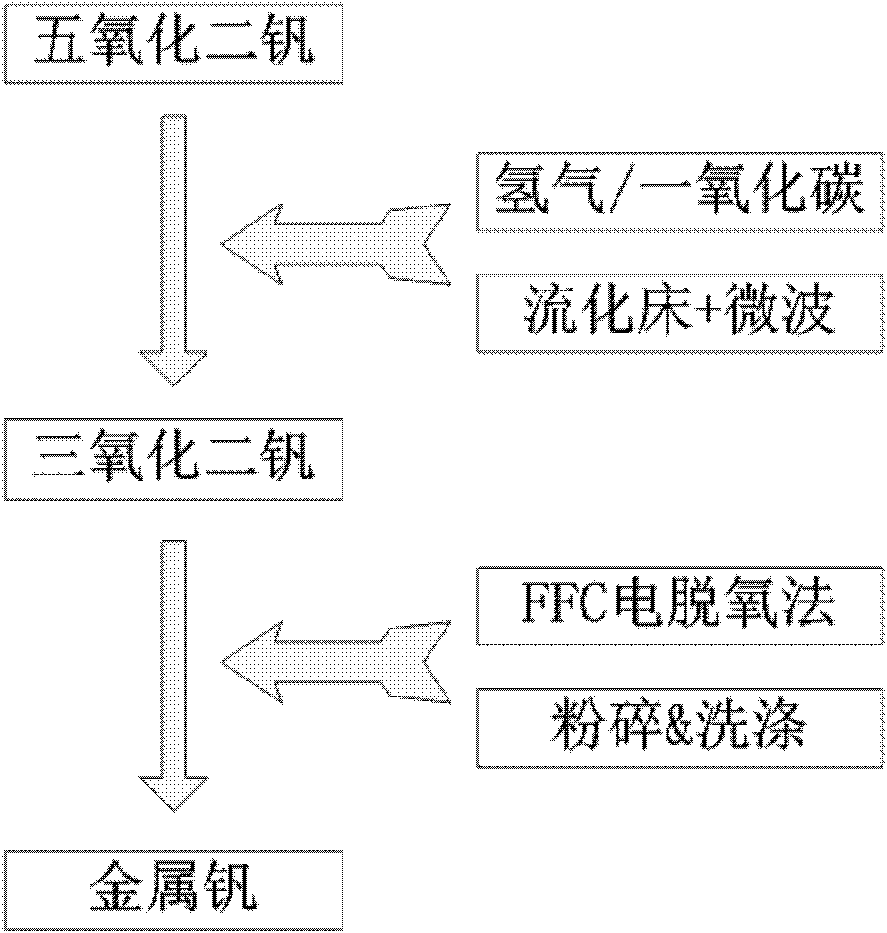

Vanadium metal smelting process

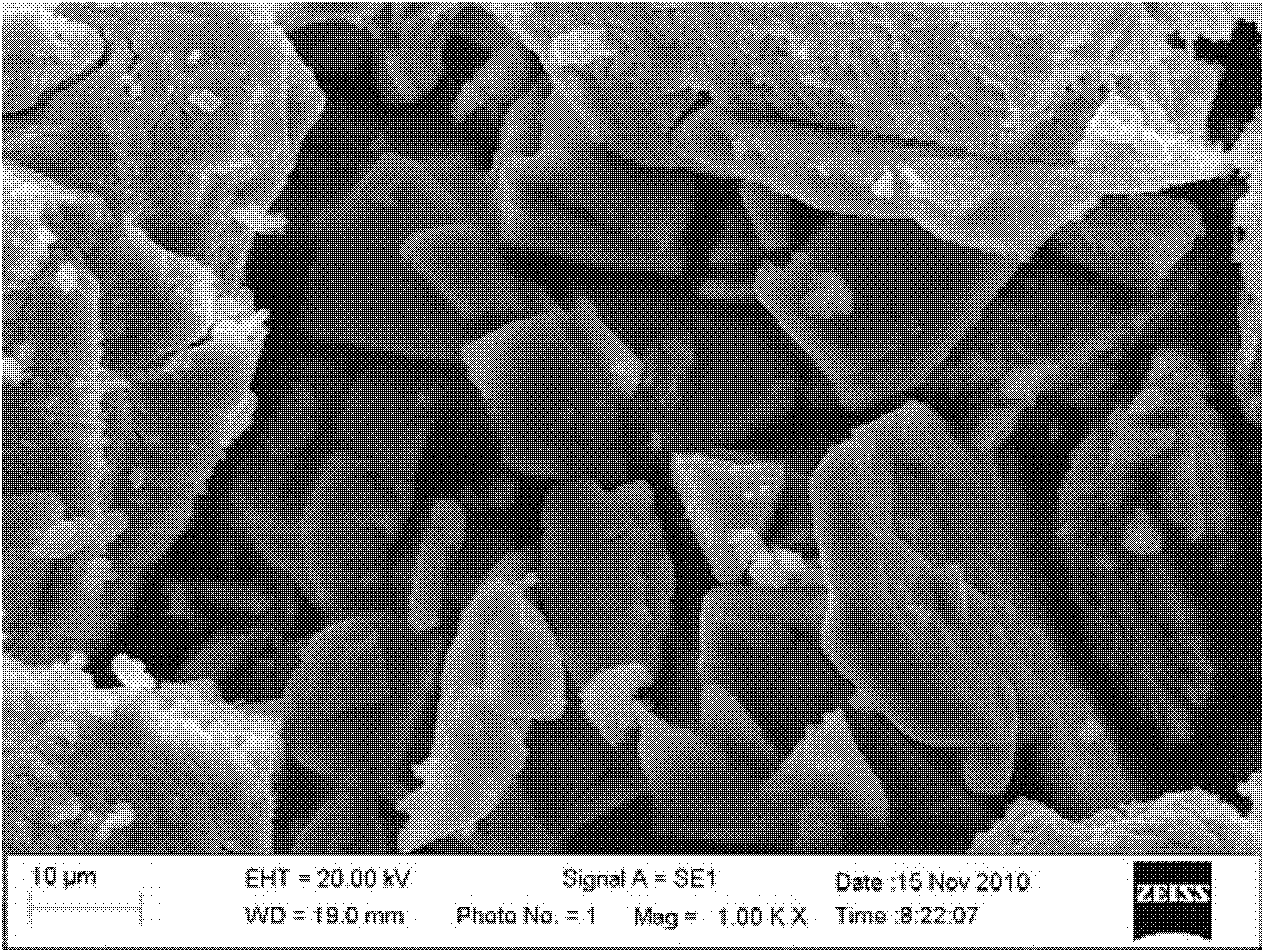

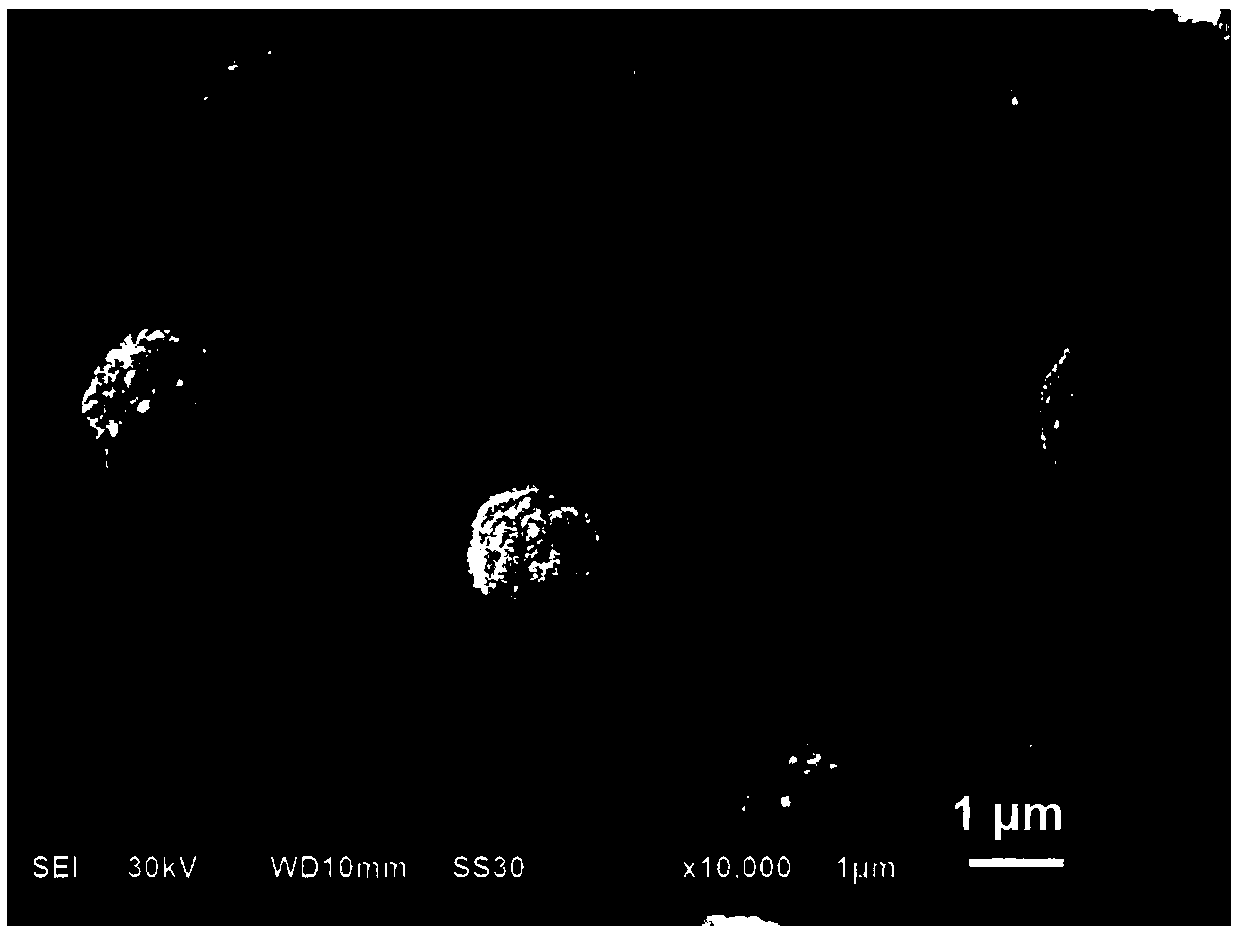

The invention discloses a vanadium metal smelting process. The process prepares vanadium metal by combining a microwave fluidized bed technology and a flexible flat cable (FFC) electric deoxidation technology and using vanadium pentoxide as a raw material. The method comprises the following steps of: directly reducing the vanadium pentoxide with low melting point (the melting point is 690 DEG C) into vanadium trioxide in short time at the temperature of between 600 and 650 DEG C by using the characteristics of high heating efficiency, quick temperature rise and gas-solid contact of a microwave fluidized bed and adopting hydrogen and / or carbon monoxide as reducing gas; directly preparing the vanadium trioxide which has high melting point into an oxide cathode by molding and sintering processes; and performing FFC electric deoxidation on the oxide cathode in molten salt of calcium chloride or mixed molten salt of calcium chloride and sodium chloride, crushing the electrolyzed cathode by using ultrasonic wave, then performing water washing, acid washing and alcohol washing to remove impurities, and finally obtaining the vanadium metal with purity of over 99 percent, wherein the current efficiency is kept over 70 percent, the energy utilization rate of microwave heating equipment is over 80 percent, and the electrolysis energy consumption is 10kwh to 13kwh / kg.

Owner:UNIV OF SCI & TECH BEIJING

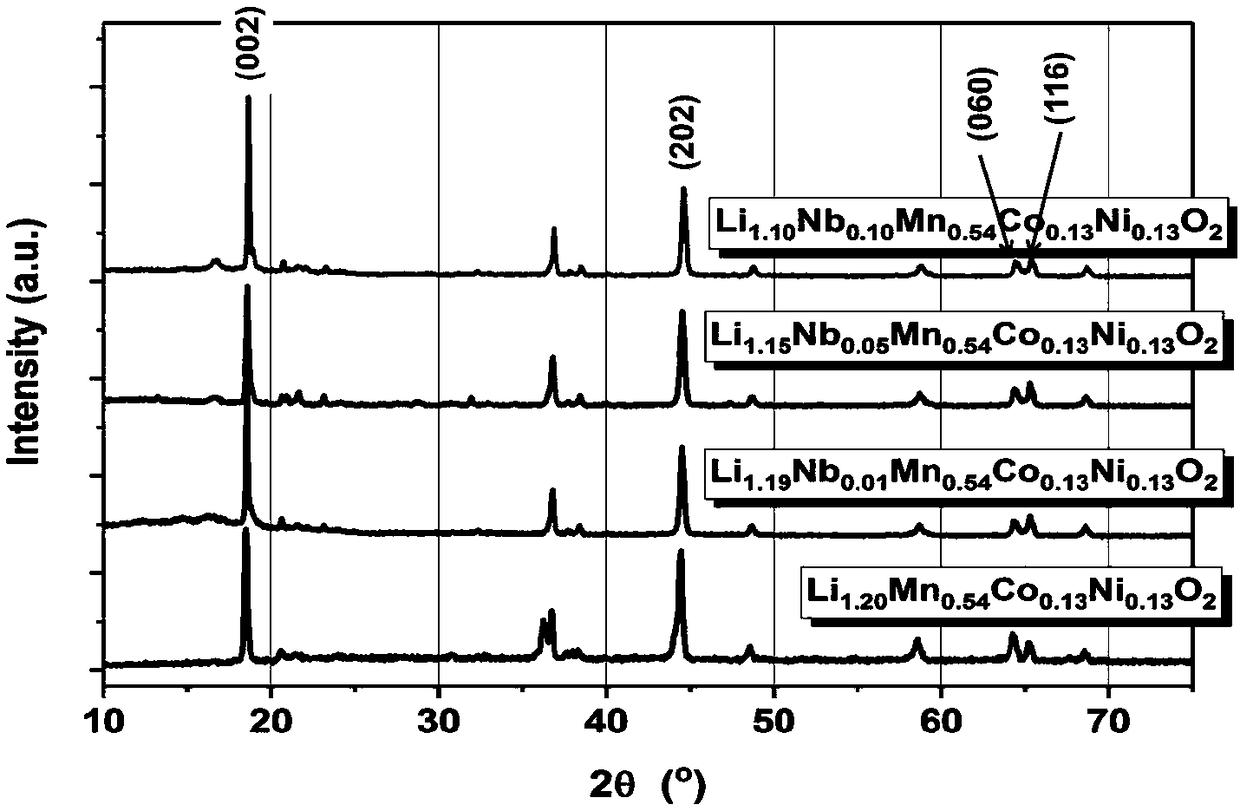

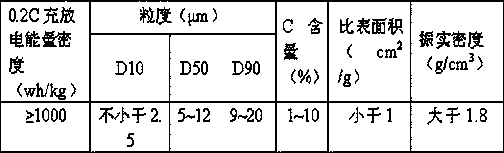

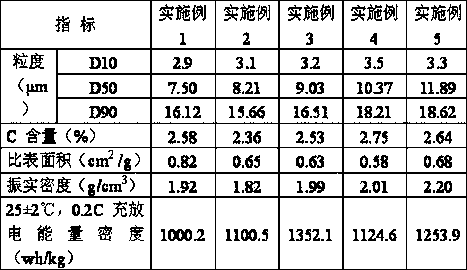

A niobium-doped lithium-rich manganese-based layered oxide cathode material and a preparation method thereof

ActiveCN109244444AExcellent rate performanceImprove electronic conductivityCell electrodesSecondary cellsCross-linkNiobium

The invention discloses a niobium-doped lithium-rich manganese-based layered oxide cathode material, which has the chemical formula of Li1.20-XNbxMn0. 54Co0. 13Ni0. 13O2 (0 <= x <= 0. 10). The invention adopts a polymer template method to prepare, the main steps are as follows: the dried cross-linked poly (acrylamide-methacrylic acid) microspheres are immersed in an aqueous solution containing Mn2+, Co2 + and Ni2 + ions of urea, the solution is adsorbed completely, and then heating and drying are performed; the dried microspheres are added into a solution containing lithium salt and niobium salt, heating is performed to remove moisture, and obtaining a lithium-rich cathode material precursor is obtained; the obtained precursor is calcined in air at high temperature to obtain a product-Niobium-doped lithium-rich manganese oxide base cathode material. As that crosslink polymer microsphere is used as a template, the transition metal hydroxide nanoparticle are synthesized in situ, the morphology of the lithium-rich manganese base oxide positive electrode material can be effectively regulated and the electrochemical performance can be greatly improved, and the preparation process of the niobium-doped lithium-rich manganese-based layered oxide cathode material is simple, the particle morphology is good in reproducibility, and the niobium-doped lithium-rich manganese-based layered oxide cathode material is suitable for industrial production.

Owner:XIANGTAN UNIV

Preparation method of lithium-nickel-cobalt-aluminum composite oxide cathode material for lithium ion battery

Owner:济宁市无界科技有限公司

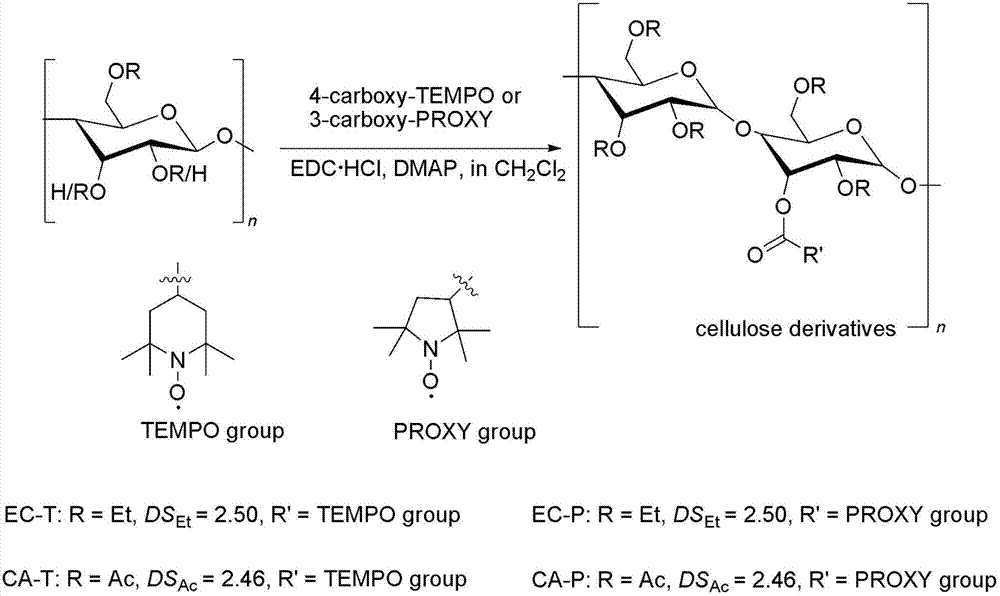

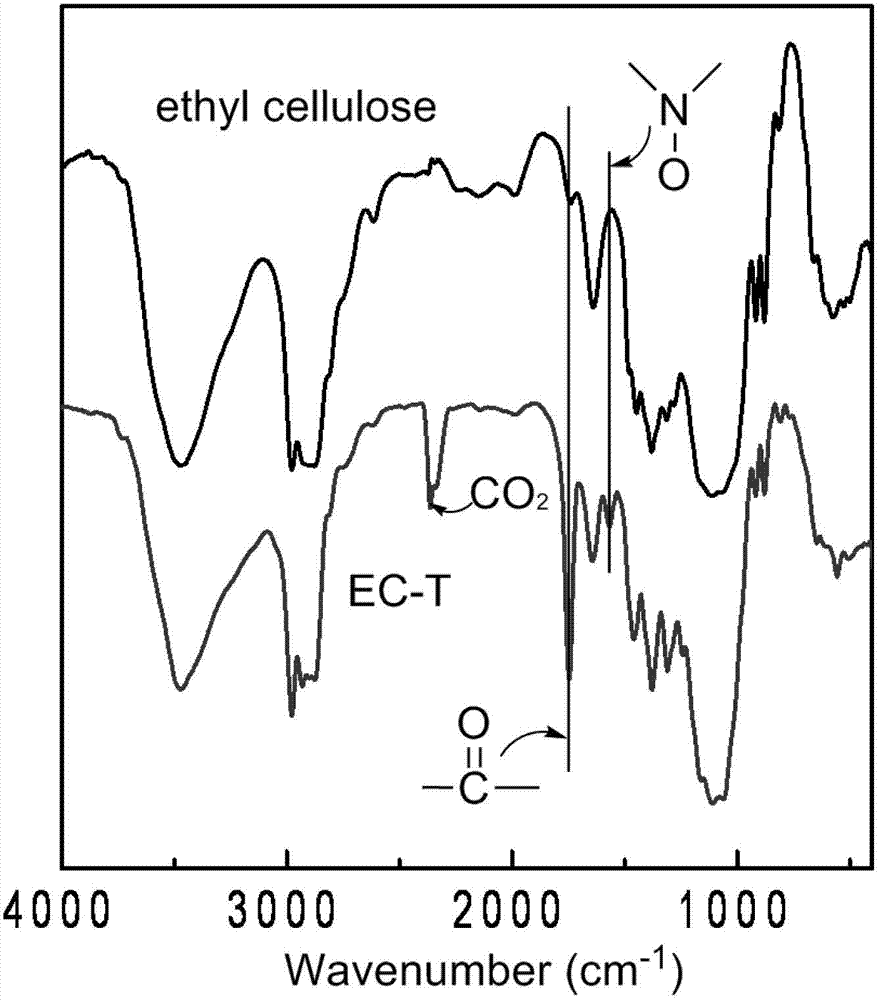

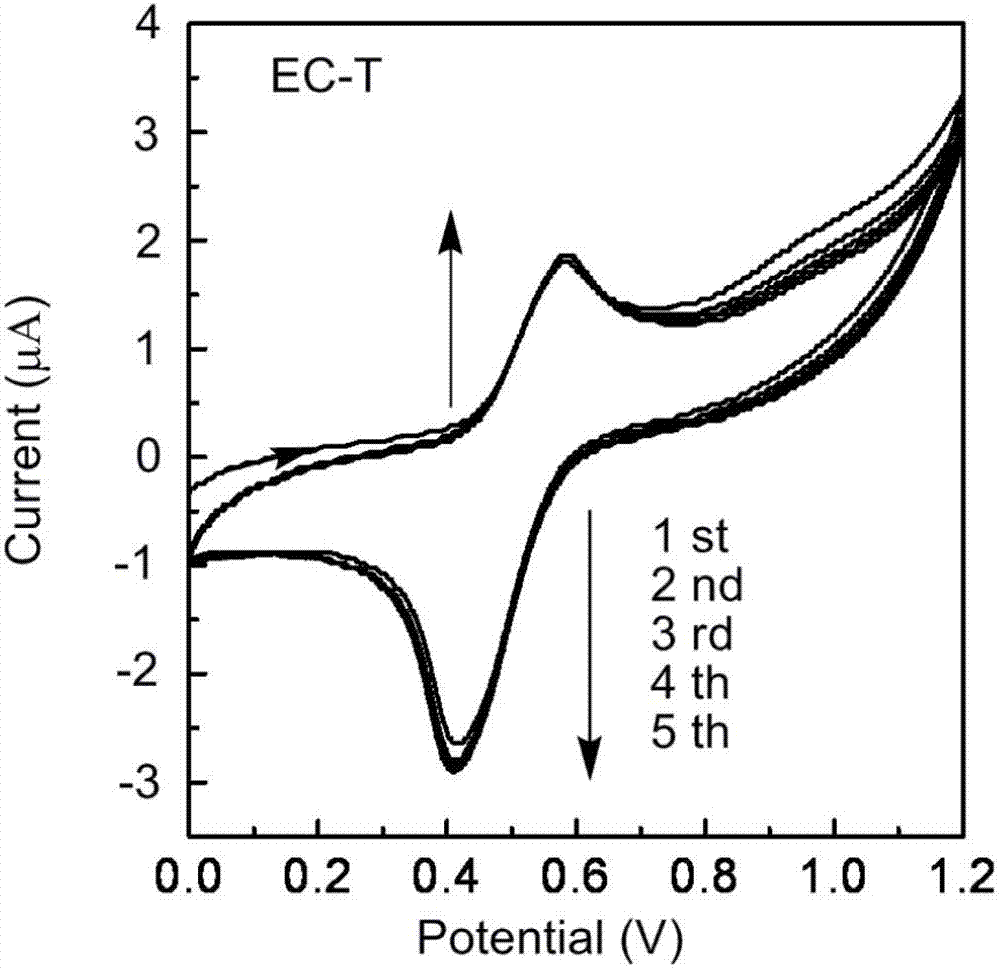

Organic radical-modified cellulose derivative, as well as preparation method and application thereof

InactiveCN102903922AShort charging timeImprove cycle stabilityCell electrodesLithium metalCarbon nanotube

The invention discloses an organic radical-modified cellulose derivative, as well as a preparation method and an application thereof. The method comprises: dissolving a hydroxyl-containing cellulose derivative in an organic solvent, mixing with a stable nitroxide radical containing carboxyl or acyl chloride, and reacting in the presence of a catalyst to obtain a stable organic radical-modified cellulose derivative; and preparing a cathode material of a lithium ion battery from the organic radical-modified cellulose derivative alone or after blending and doping with the organic radical-modified cellulose derivative with graphene / carbon nanotubes. The cathode material prepared by the method can overcome the disadvantages of a lithium metal oxide cathode material, has second-order charging / discharging performance, and has the advantages of high discharging capacity up to 121% to 167% of the theoretical value, high charging speed, and short charging time (60 seconds). The organic radical-modified cellulose derivative cathode material provided by the invention is free of heavy metals, and has the advantages of no toxicity, environmental protection and biodegradability; and the organic radical-modified cellulose derivative lithium ion battery prepared by the invention has excellent charging / discharging cycle stability.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com