Patents

Literature

45results about How to "Increase hierarchy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

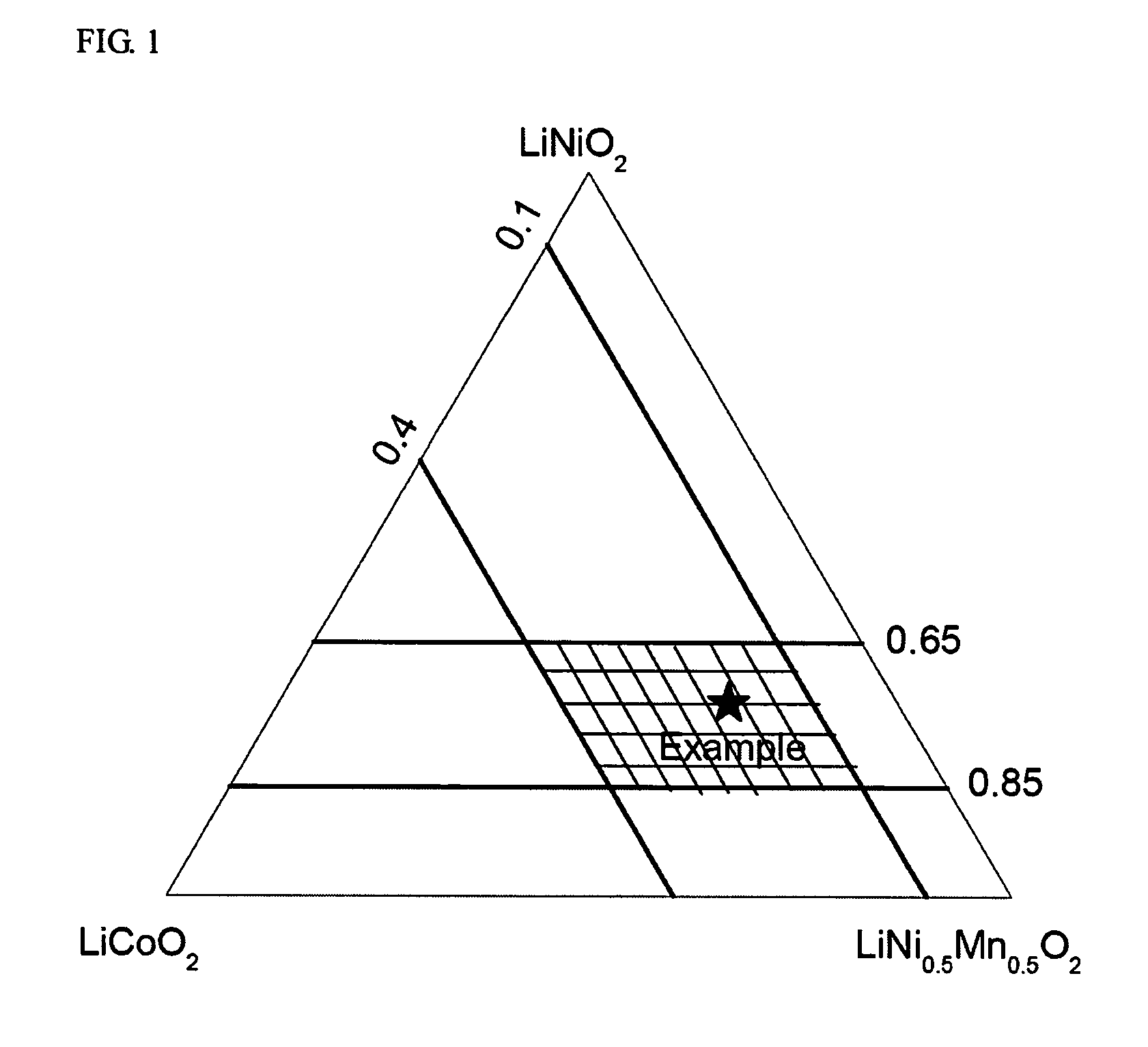

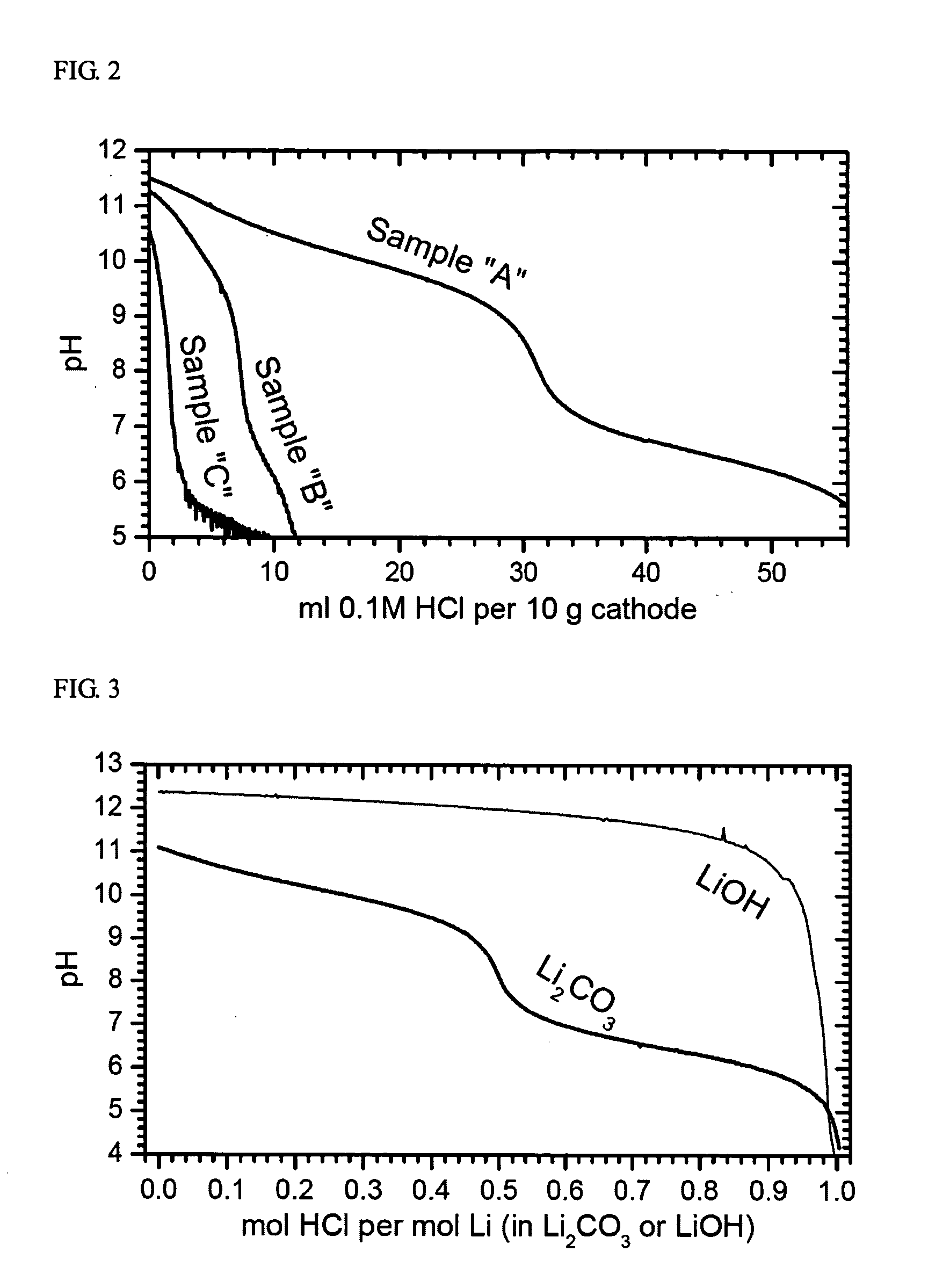

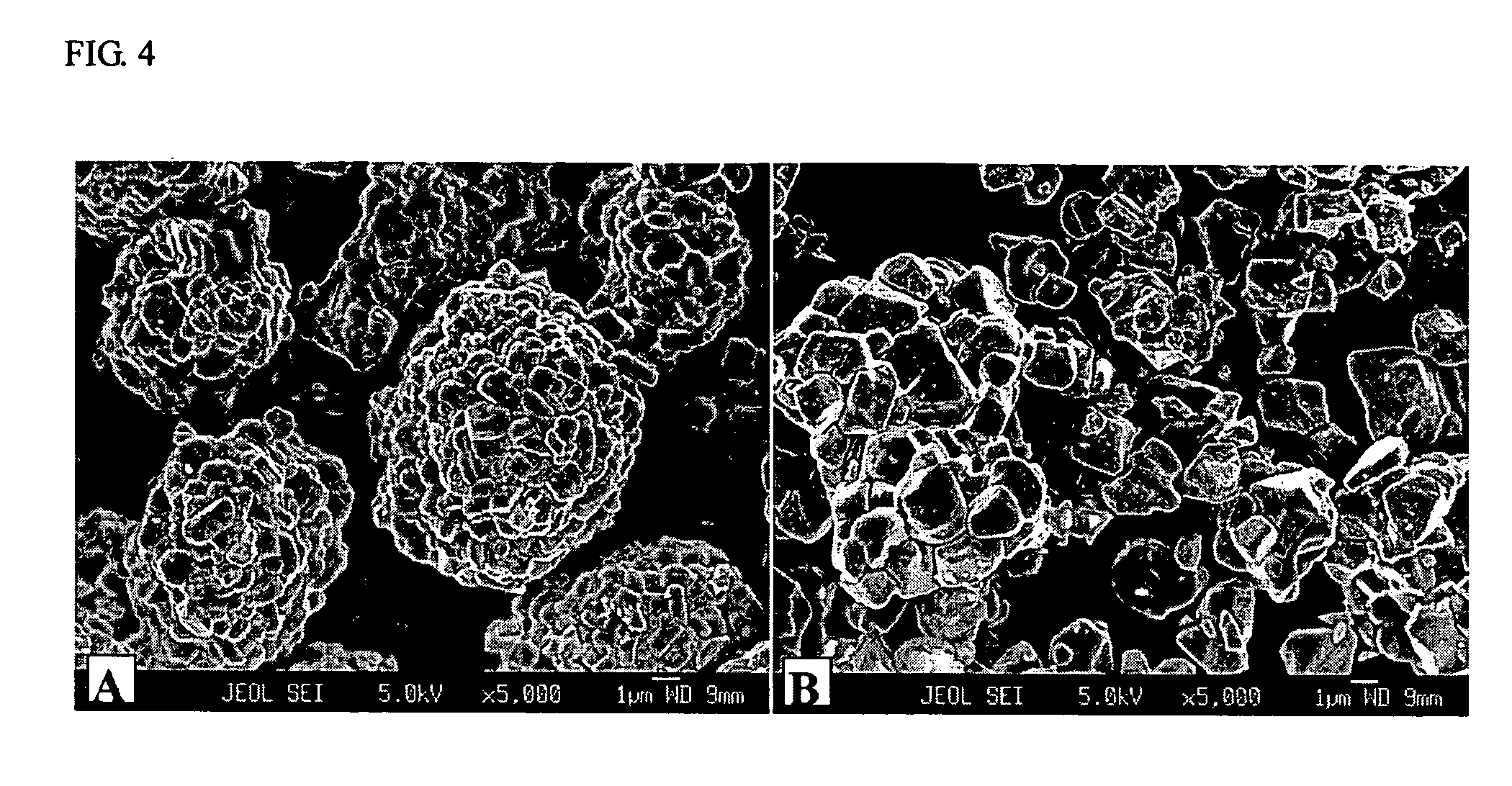

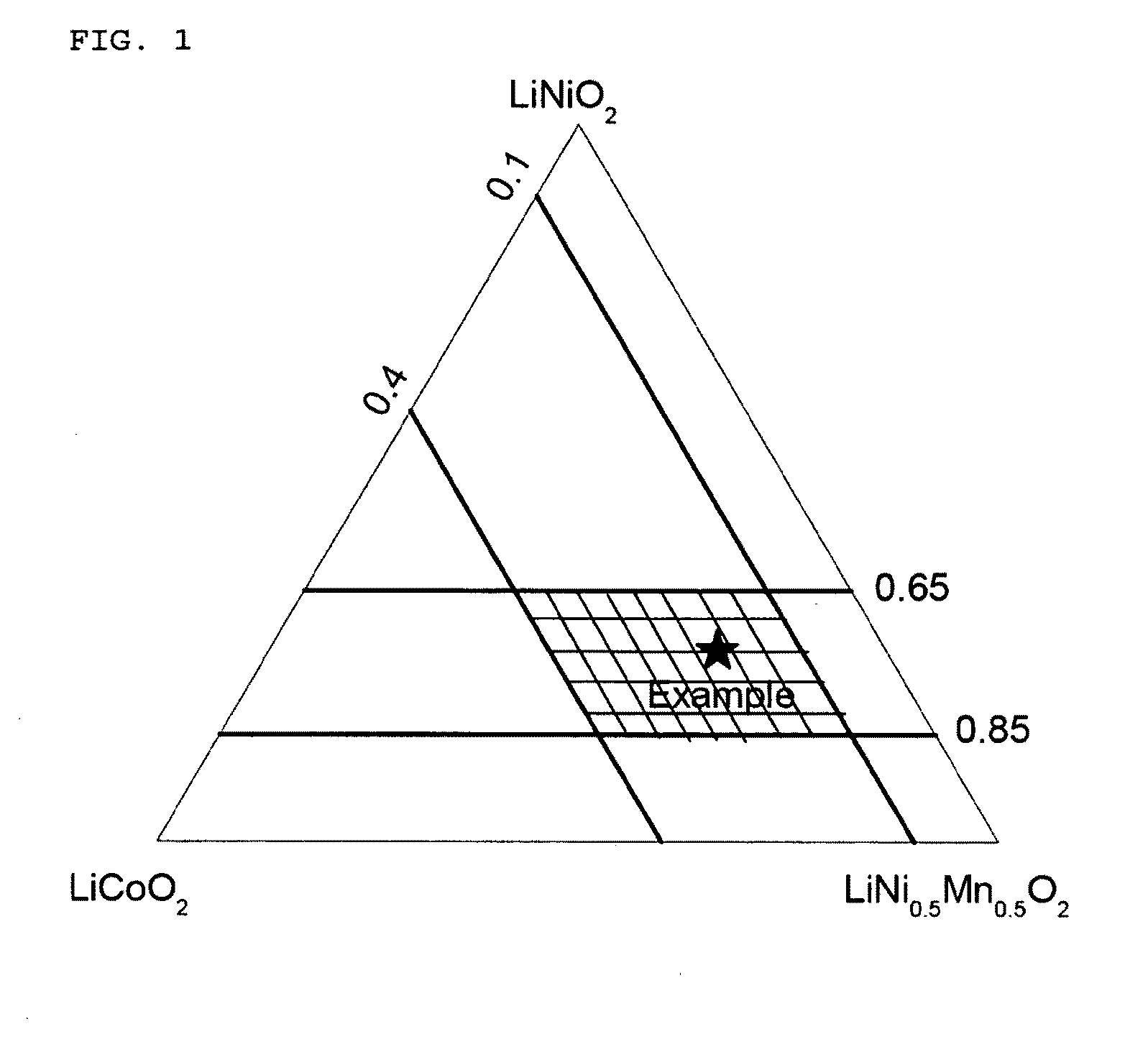

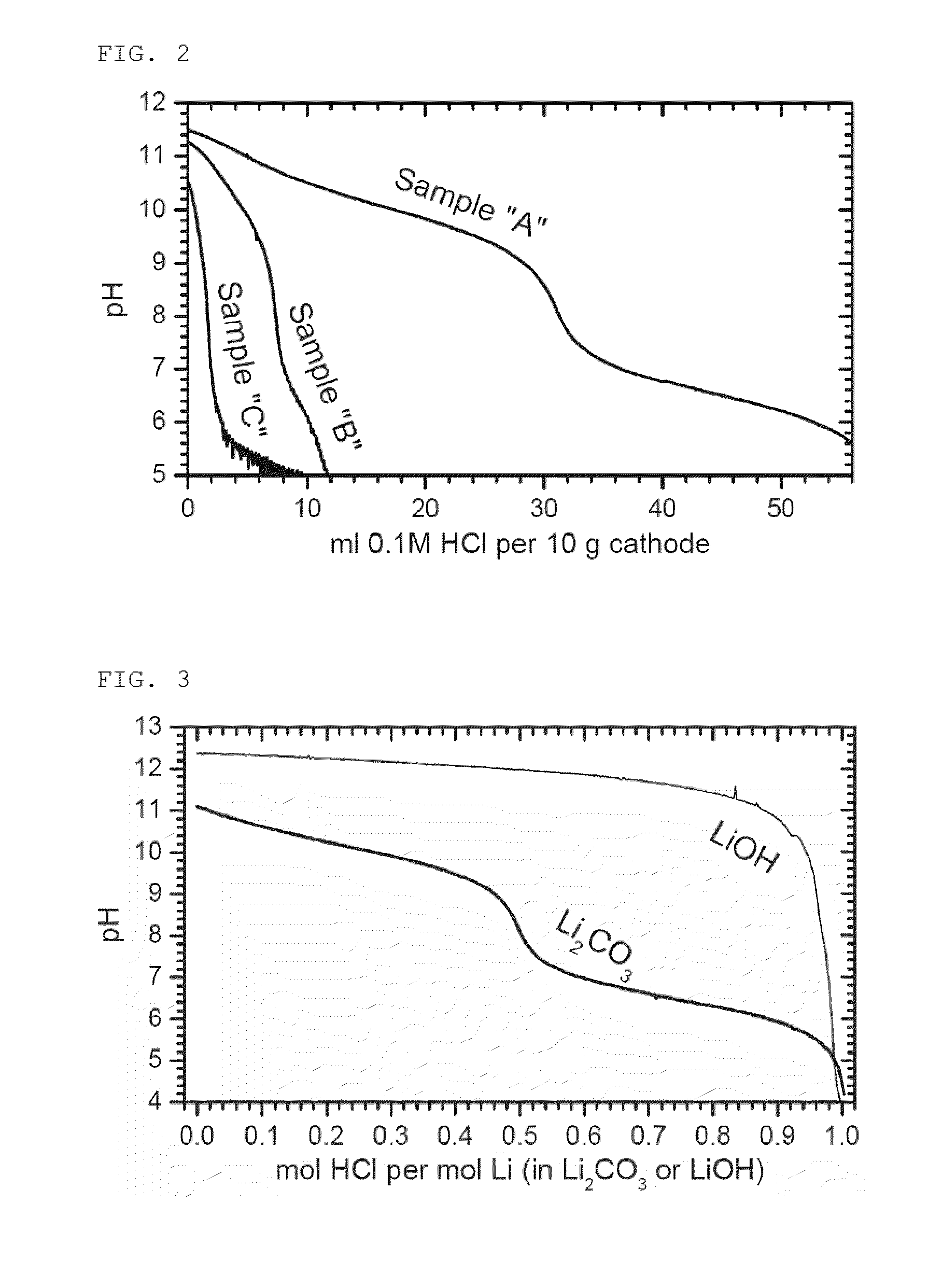

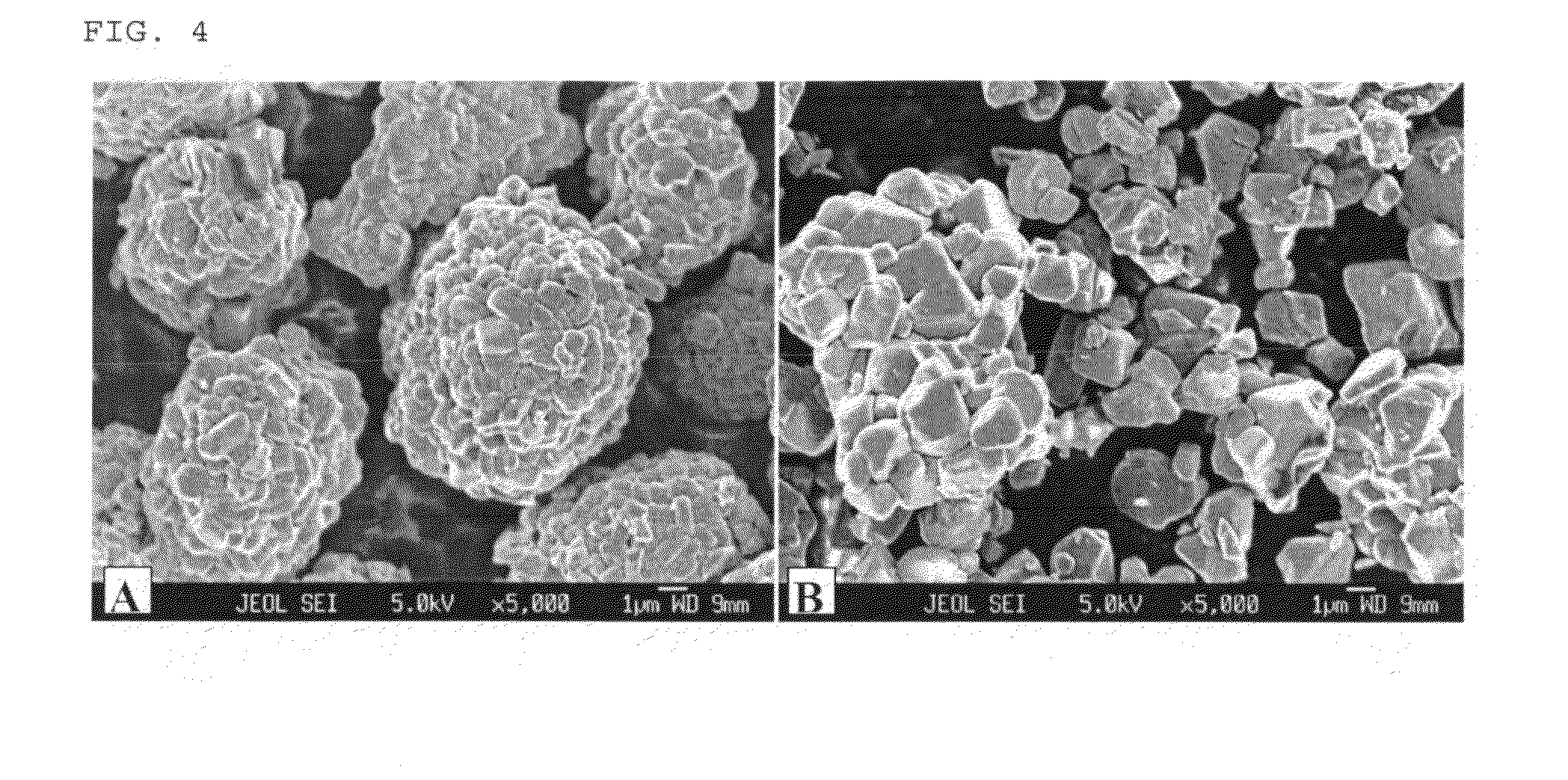

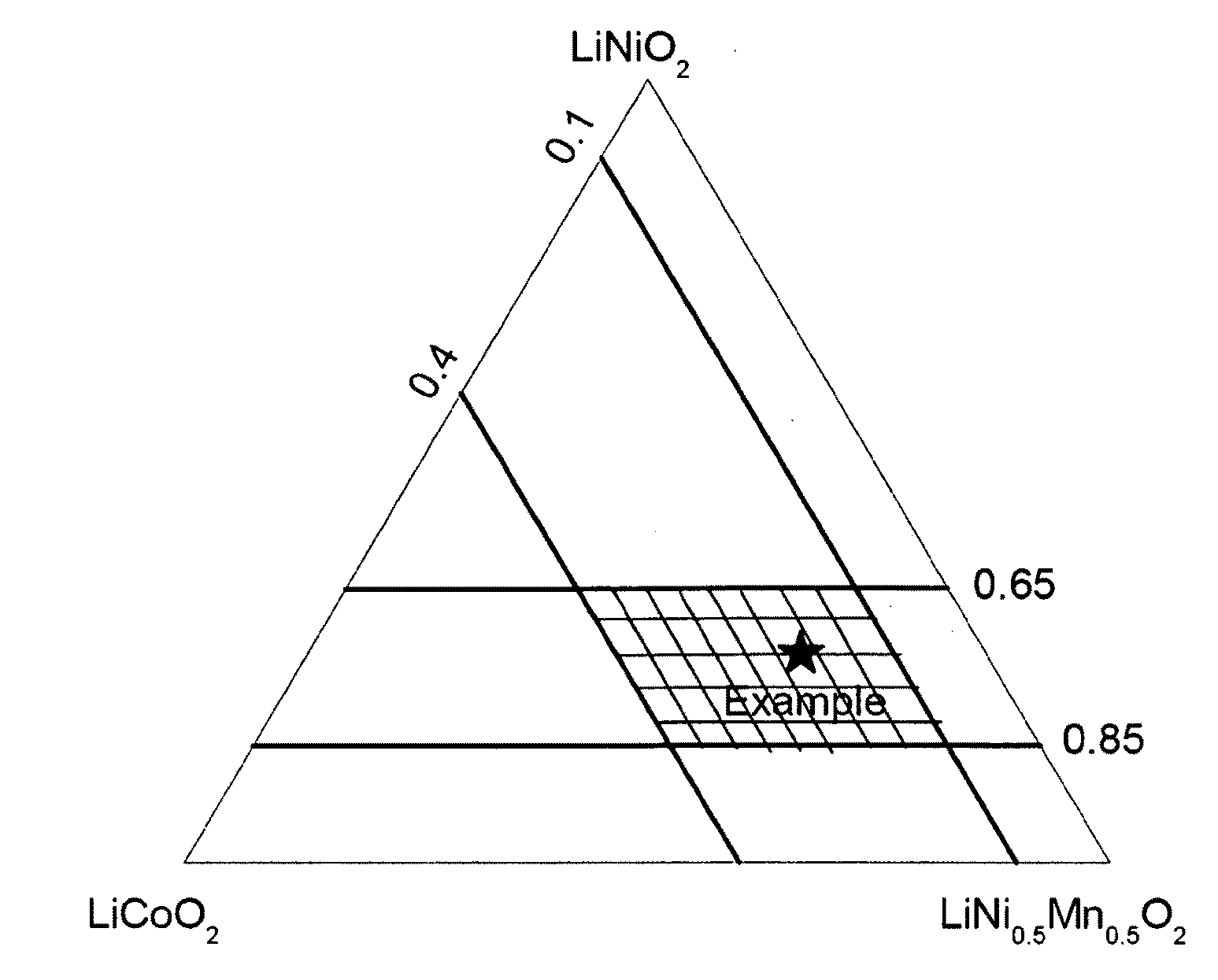

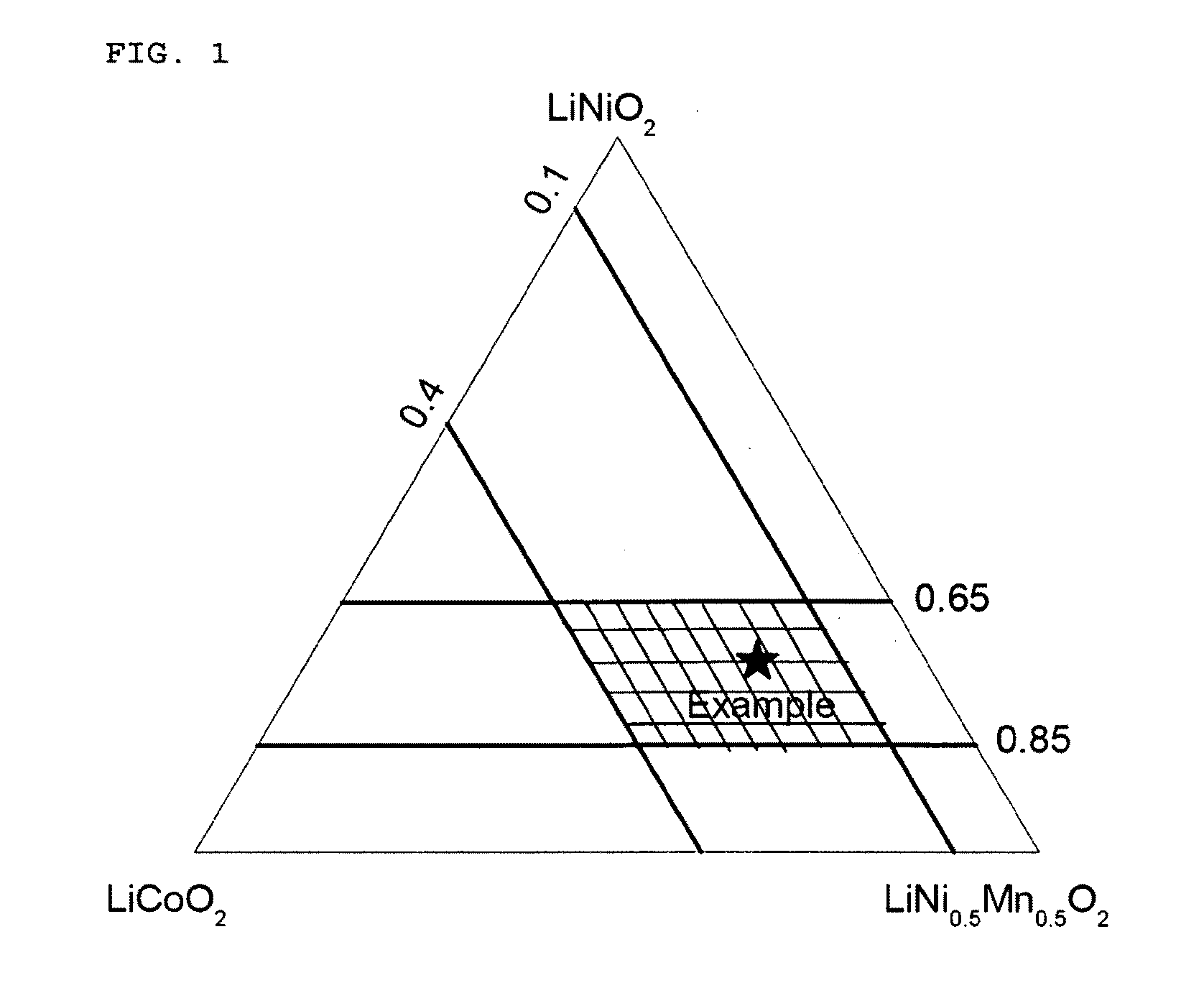

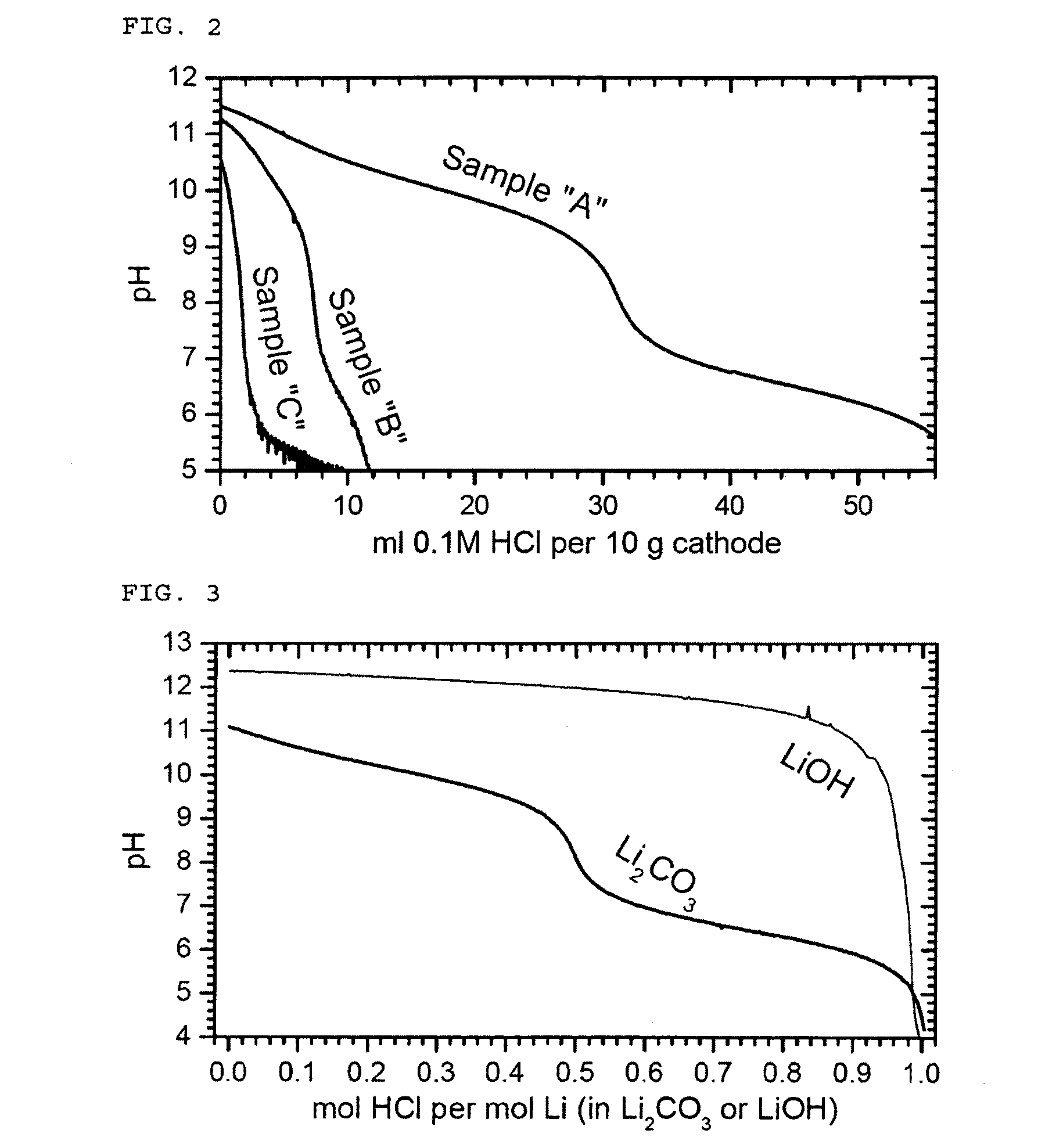

Ni-based lithium transition metal oxide

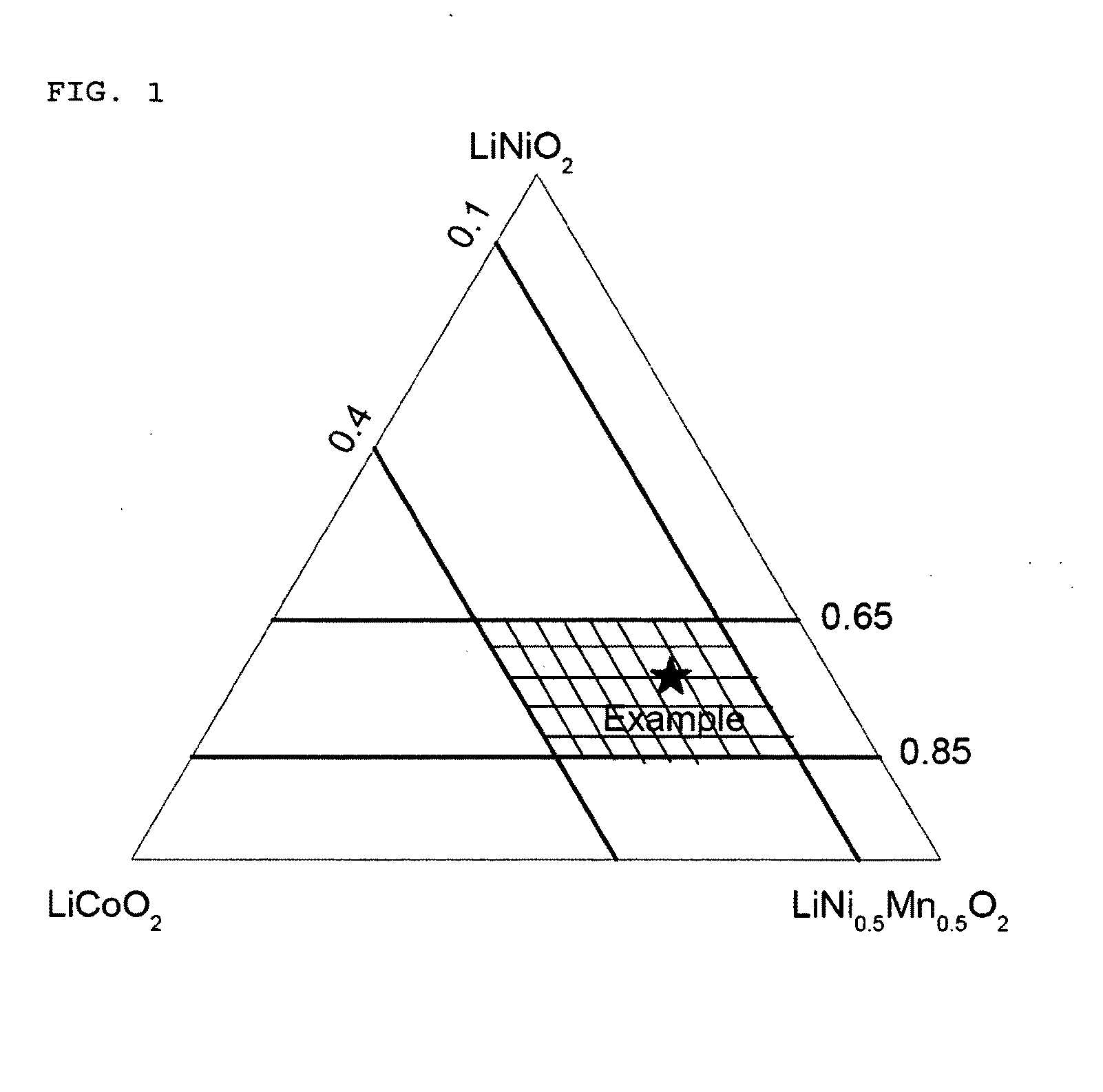

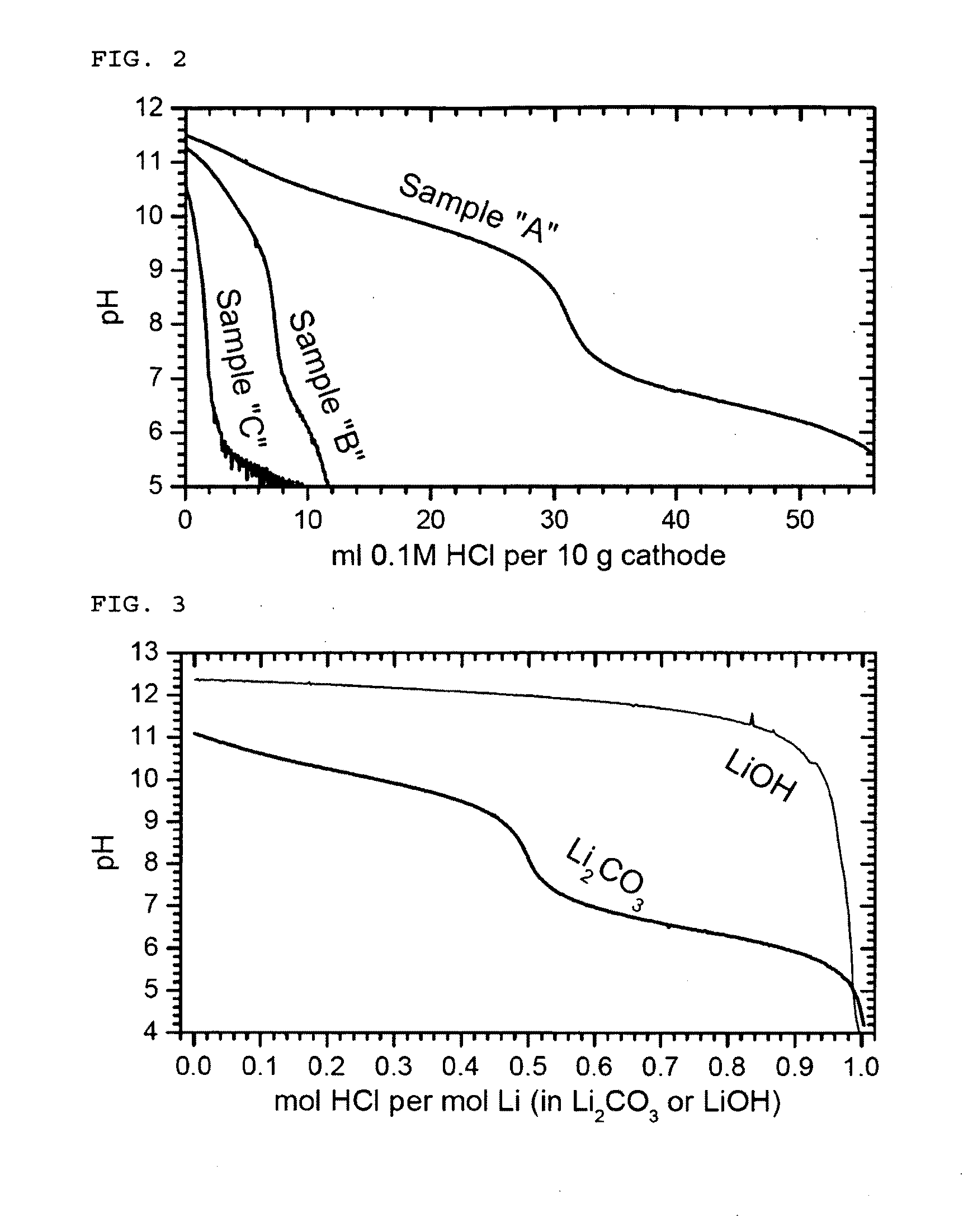

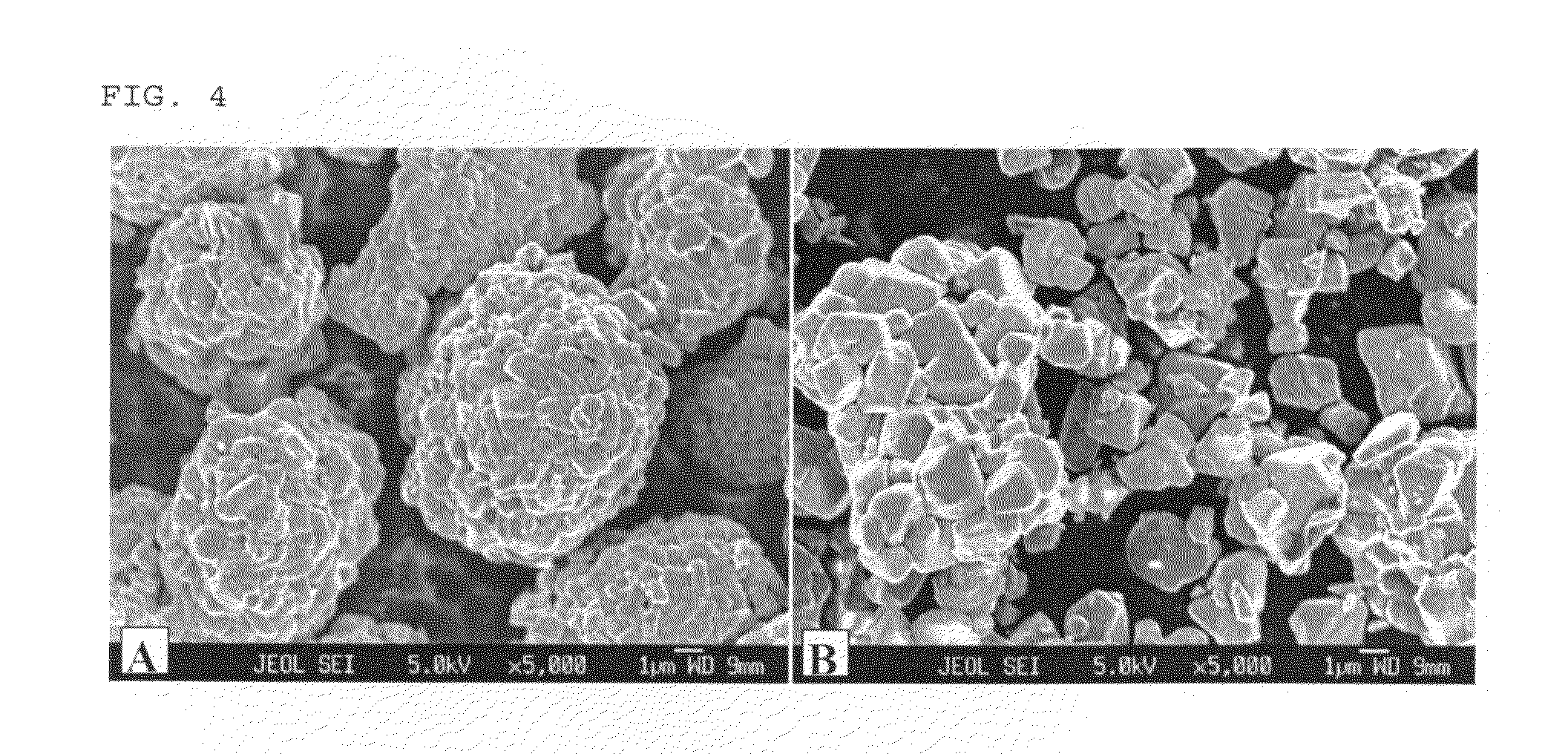

The present invention provides a powderous lithium transition metal oxide with the composition as represented by the below Formula and prepared by solid state reaction in air from a mixed transition metal precursor and Li2CO3, with being practically free of Li2CO3 impurity: LixMyO2 wherein M=M′l-kAk, where M′=Nil-a-b(Ni1 / 2Mn1 / 2)aCob on condition of 0.65≦a+b≦0.85 and 0.1≦b≦0.4; A is a dopant; and 0≦k≦0.05; and x+y=2 on condition of 0.95≦x≦1.05. The Ni-based lithium transition metal oxide according to the present invention has a well-layered structure, and also improved safety, cycling stability and stability against aging and low gas evolution during storage, when used as an active material for cathode of lithium secondary batteries, because it has a high sintering stability and is substantially free of soluble bases. Moreover, the lithium transition metal oxide of the present invention can be prepared by a low-cost process using a mixed transition metal precursor and Li2CO3 as raw stocks and under relatively unrestricted conditions.

Owner:LG ENERGY SOLUTION LTD

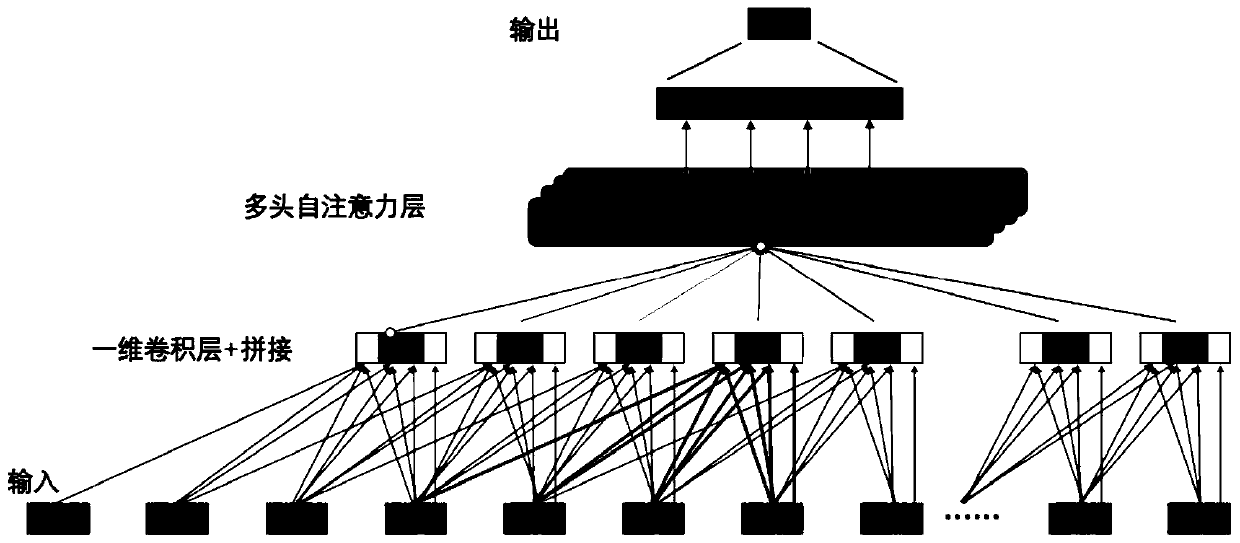

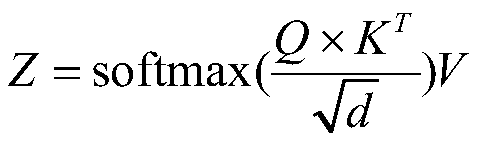

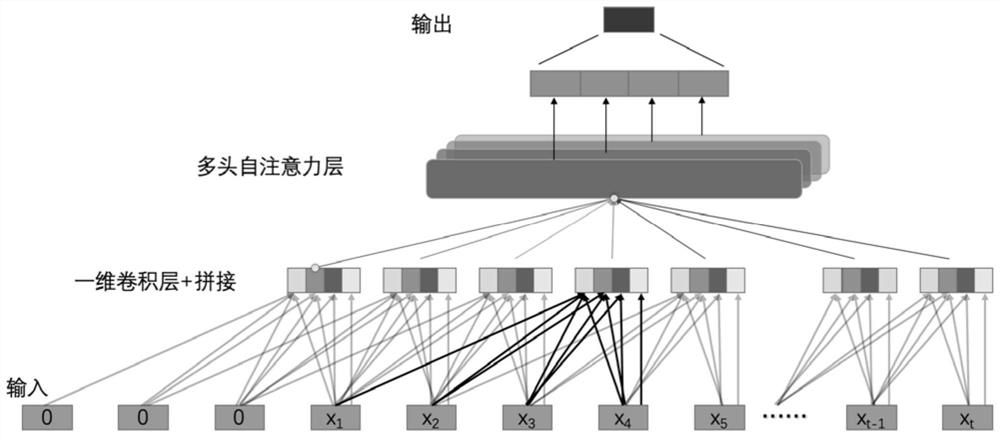

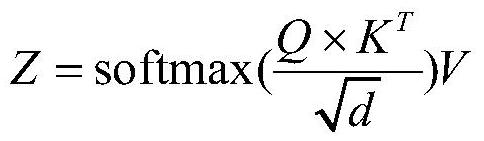

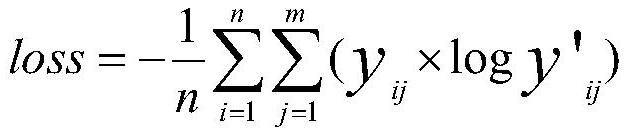

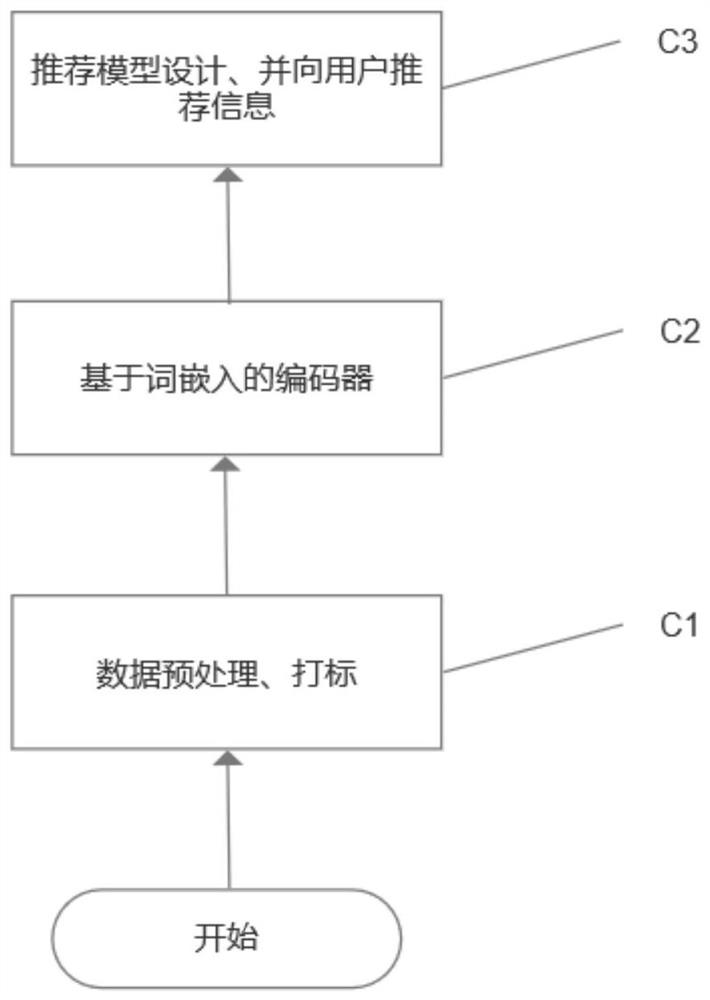

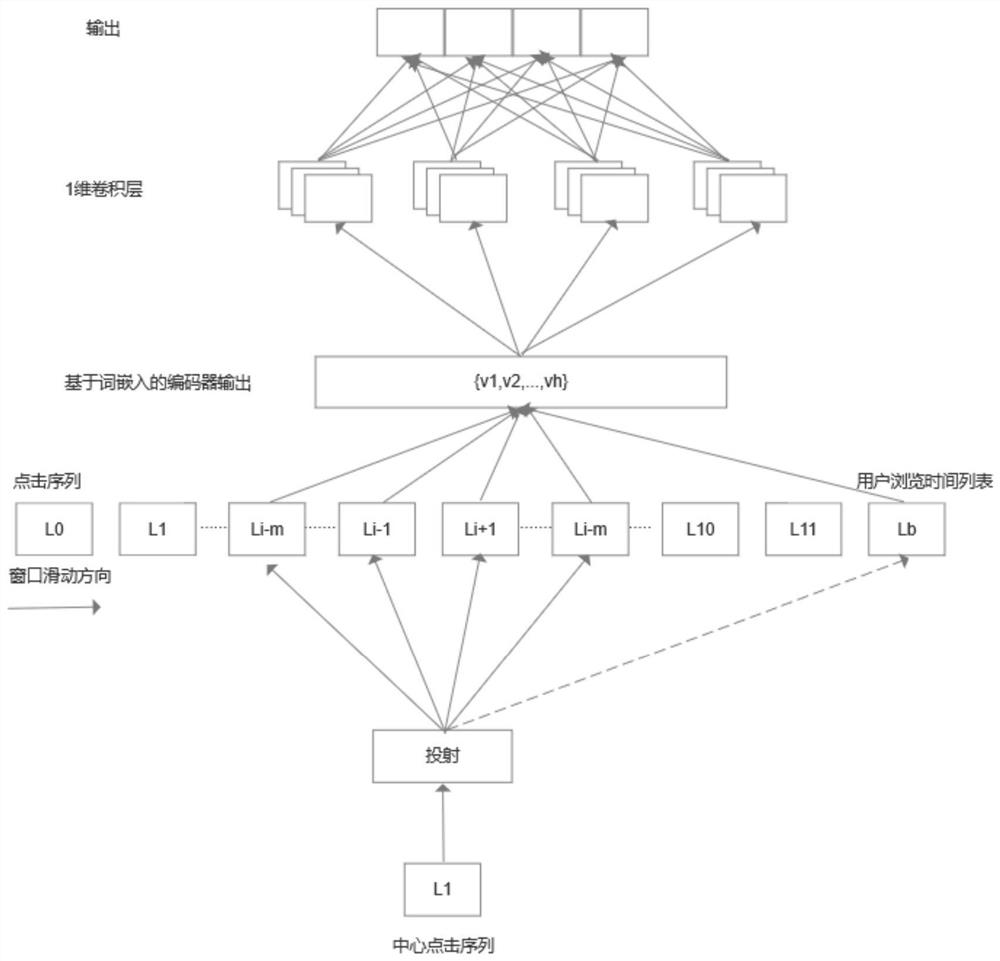

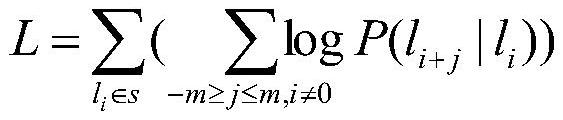

Personalized recommendation method based on deep learning

InactiveCN110196946AReduce serial operationsImprove training efficiencyDigital data information retrievalAdvertisementsPersonalizationRecommendation model

The invention discloses a personalized recommendation method based on deep learning. The method comprises the steps of according to the viewing time sequence behavior sequence of the user, predictingthe next movie that the user will watch, including three stages of preprocessing the historical behavior characteristic data of the user watching the movie, modeling a personalized recommendation model, and performing model training and testing by using the user time sequence behavior characteristic sequence; at the historical behavior characteristic data preprocessing stage when the user watchesthe movie, using the implicit feedback of interaction between the user and the movie to sort the interaction data of each user and the movie according to the timestamp, and obtaining a corresponding movie watching time sequence; and then encoding and representing the movie data,wherein the personalized recommendation model modeling comprises the embedded layer design, the one-dimensional convolutional network layer design, a self-attention mechanism, a classification output layer and the loss function design. According to the method, the one-dimensional convolutional neural network technologyand the self-attention mechanism are combined, so that the training efficiency is higher, and the number of parameters is relatively small.

Owner:SOUTH CHINA UNIV OF TECH

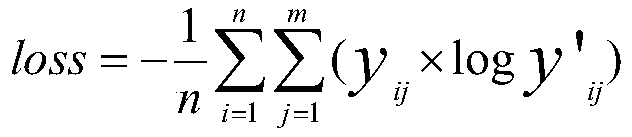

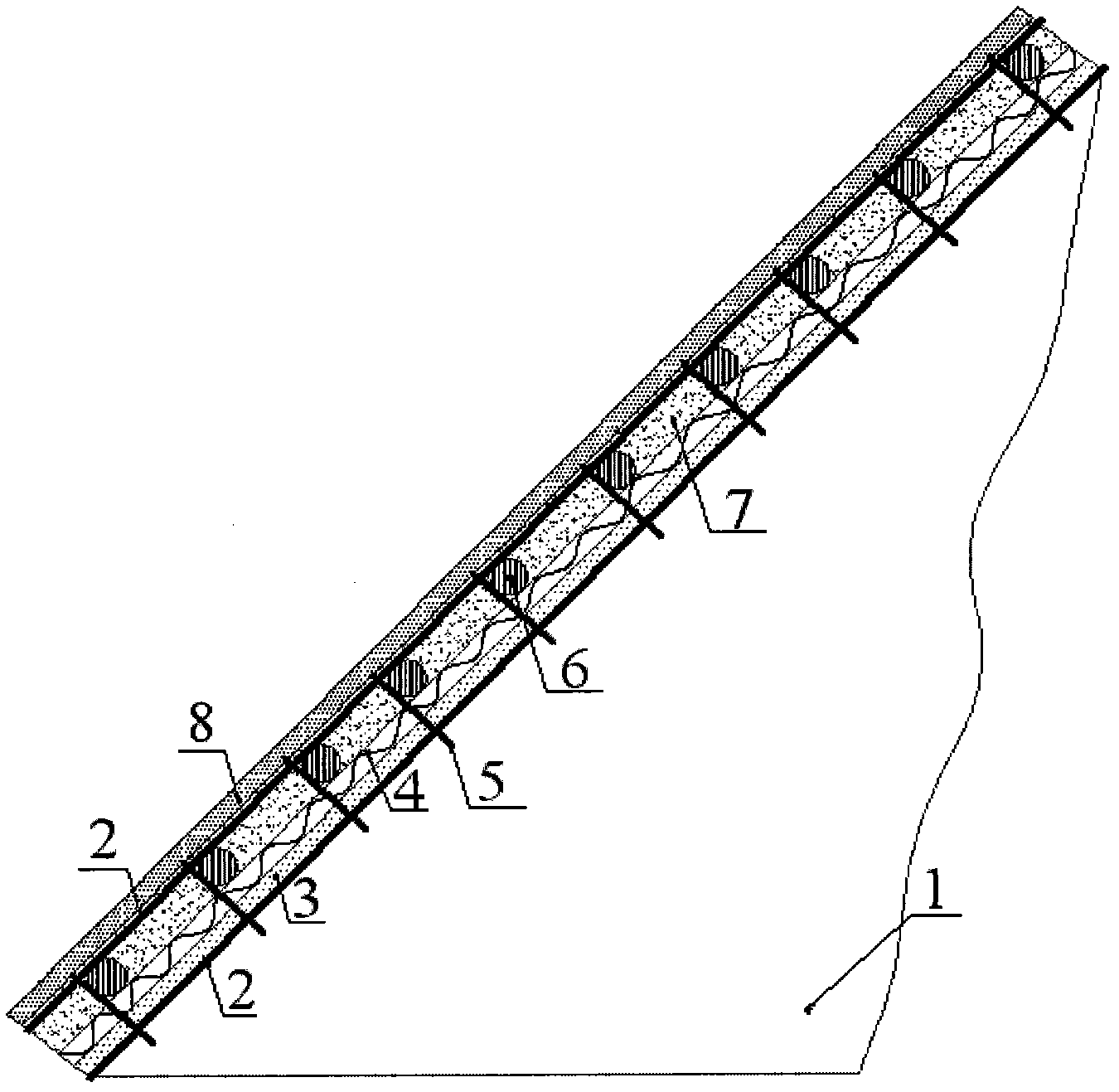

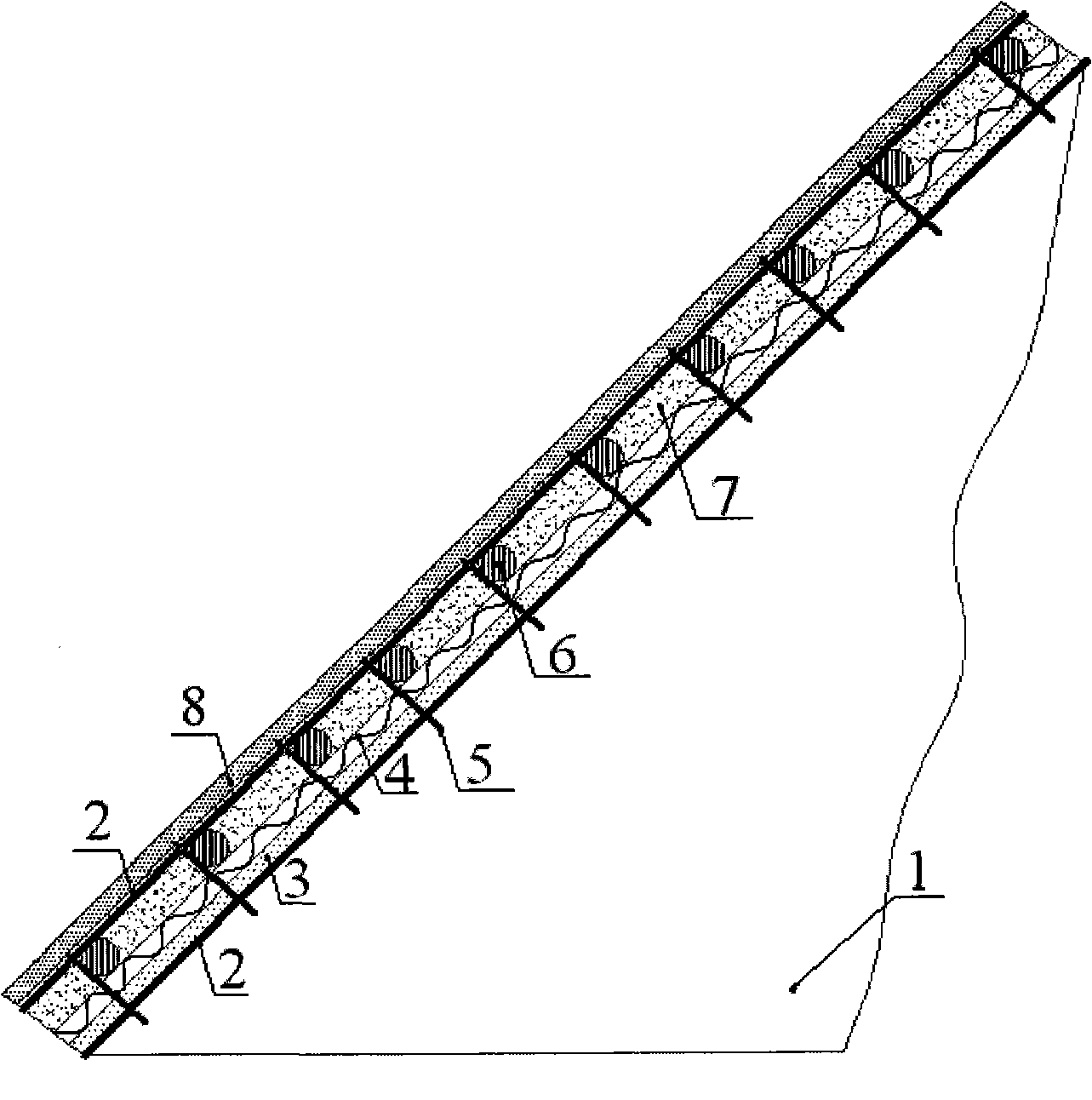

Method for ecological restoration of side slopes of acid waste-rock yard

The invention discloses a special composite isolation layer for ecological restoration of side slopes of an acid waste-rock yard, comprising a plastic biaxial geogrid, a soil improvement layer and a water discharging plate. The invention further discloses a method for ecological restoration of the side slopes of the acid waste-rock yard, comprising the following steps: arranging the composite isolation layer, an ecological rod, a geogrid mesh, a base material layer and a seed layer on side slopes, leading the plastic biaxial geogrid, the ecological rod, the composite isolation layer, the base material layer and the seed layer to act mutually, effectively improving the growth conditions of plants and leading the growth of the plants to have sufficient water and nutrients. The invention better realizes the ecological restoration and creation of ecological landscapes on the side slopes of the acid waste-rock yard without conditions for plant growth, and simultaneously guarantees the structure and stability of the side slopes, thus achieving the purposes of greening and beautifying the environment, conserving water and soil and inhibiting runoff, also having simple construction technique, easy implementation and high efficiency and being suitable for large-area application.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Battery containing ni-based lithium transition metal oxide

ActiveUS20090226810A1Increase hierarchyImprove securityEnergy inputAlkali metal oxidesElectrical batteryOxide cathode

Owner:LG ENERGY SOLUTION LTD

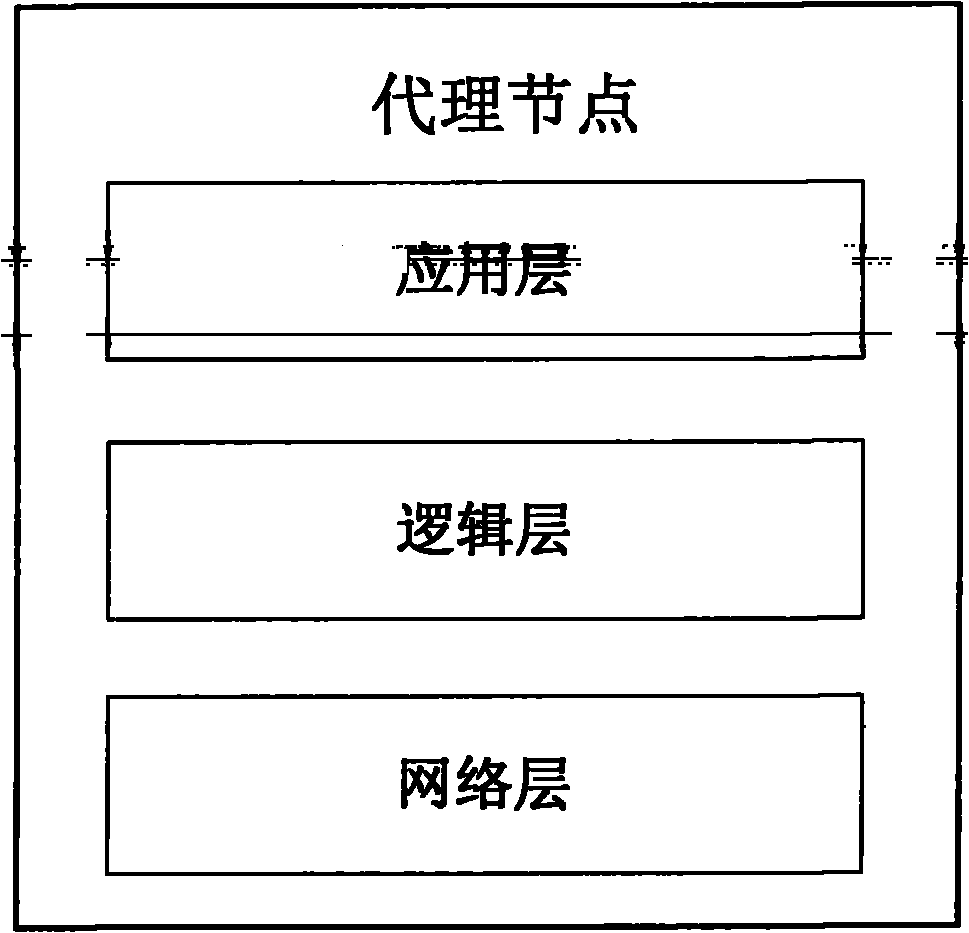

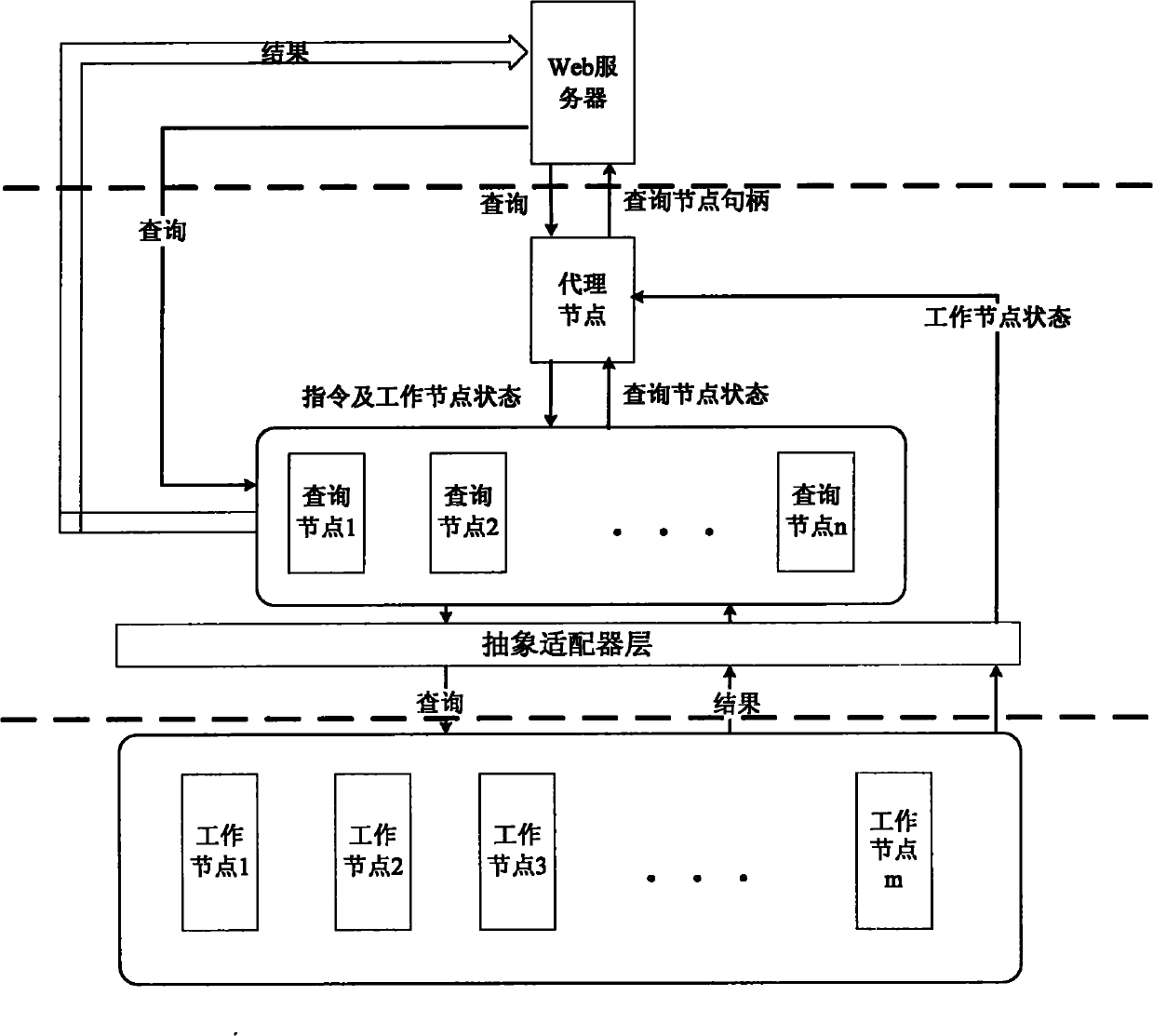

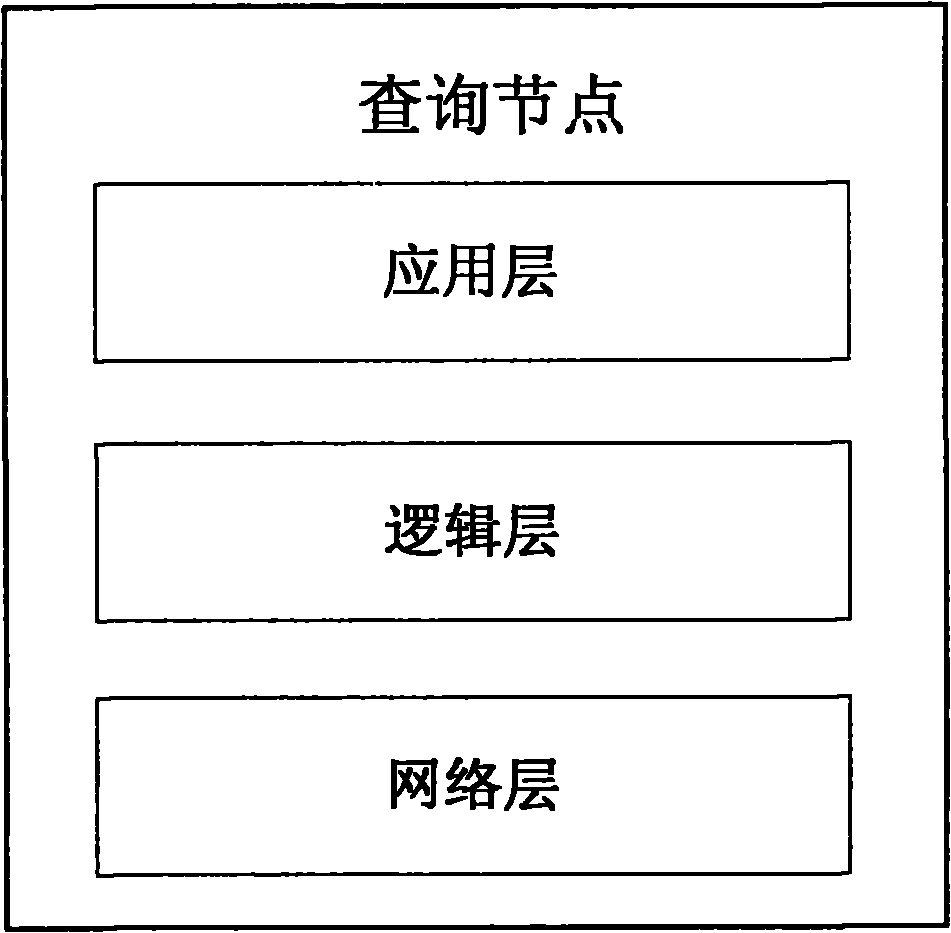

Hierarchical structure, distributed search engine system and implementation method thereof

InactiveCN101950300ASolve large-scaleImprove performanceSpecial data processing applicationsWeb serviceInformation retrieval

The invention discloses a hierarchical structure applied to a distributed search engine. The hierarchical structure comprises a physical layer, an abstract layer, an application layer and a presentation layer. The invention also discloses a distributed search engine system, which comprises a Web server, an agent node, a query agent pool, an abstract adapter and a plurality of working nodes, wherein the query agent pool consists of a plurality of query nodes. The invention also discloses an implement method for the distributed search engine system, which comprises the following steps of: S1, registration of a query node; S2, registration of working nodes; S3, state update of the nodes; and S4, distribution and retrieval of a query request. The hierarchical structure has the advantages of good performance, high reliability, diversification, specialization, strong applicability and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

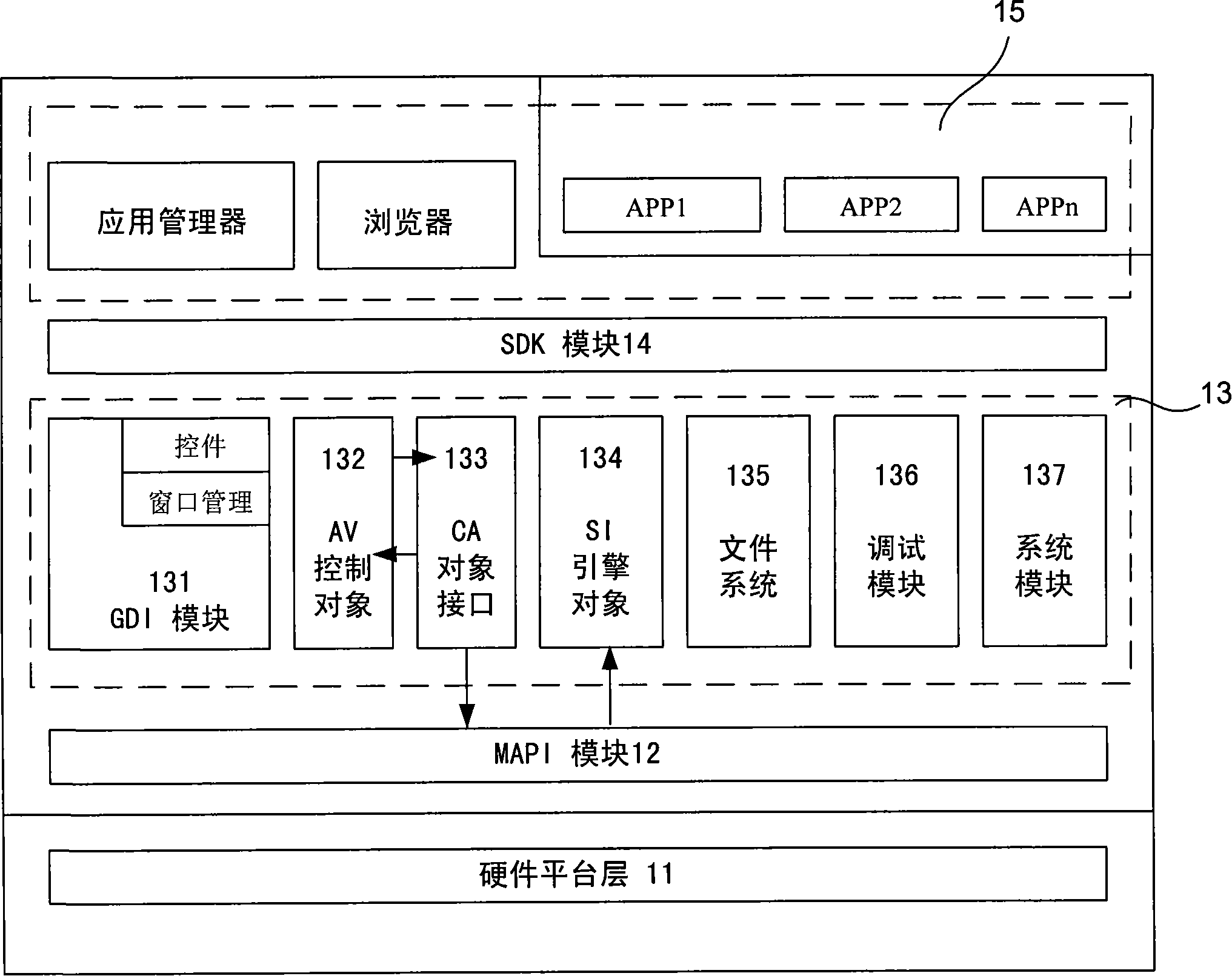

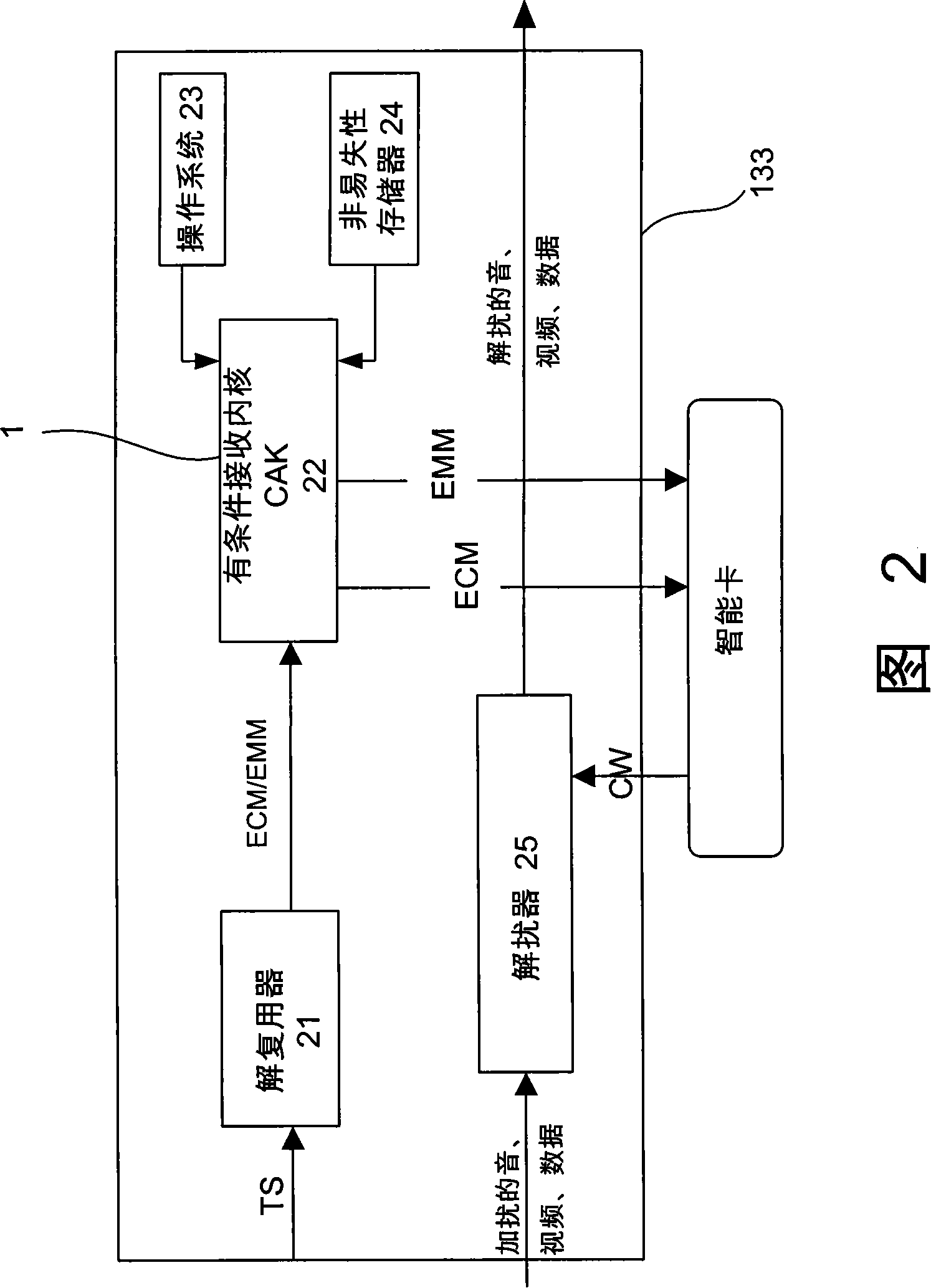

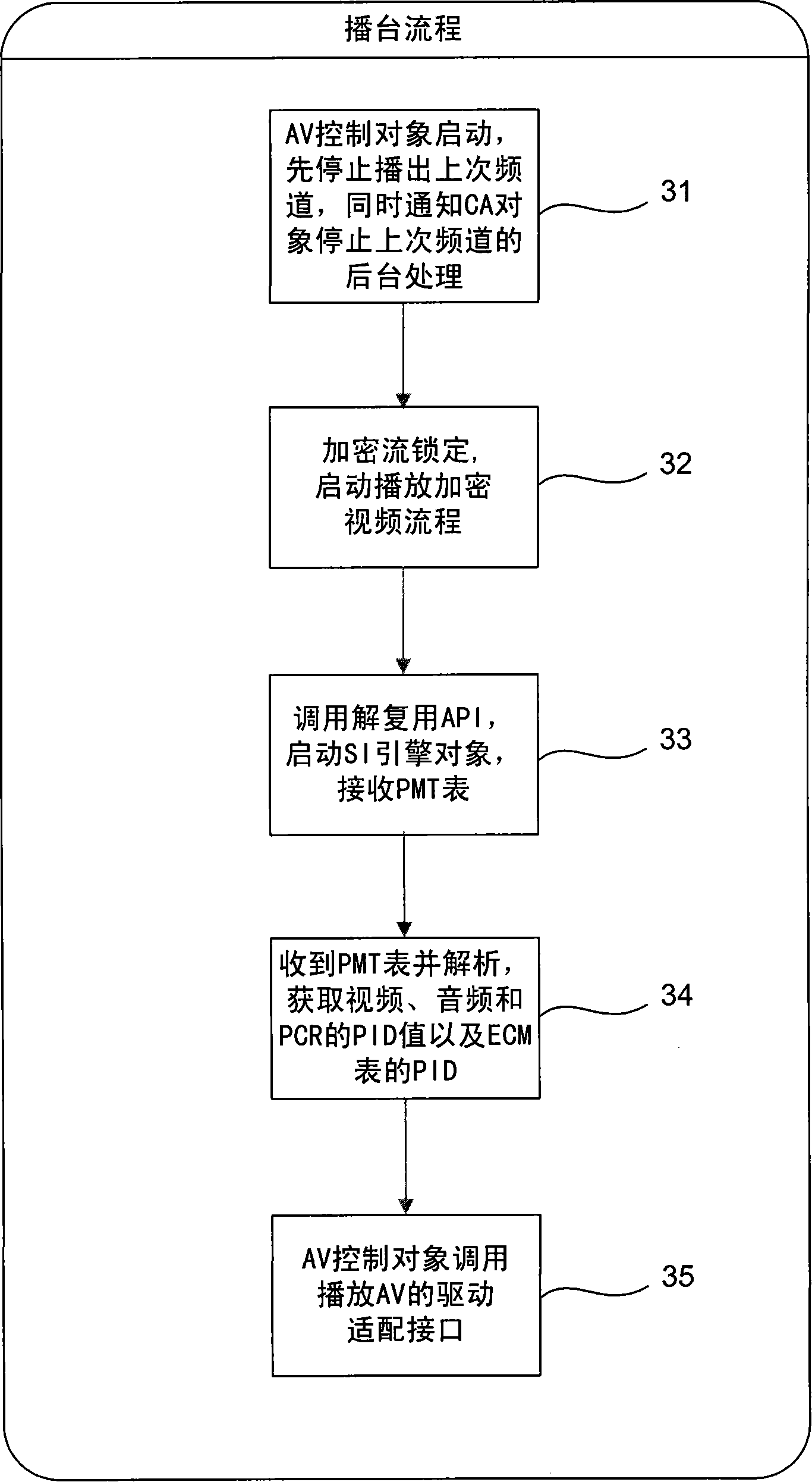

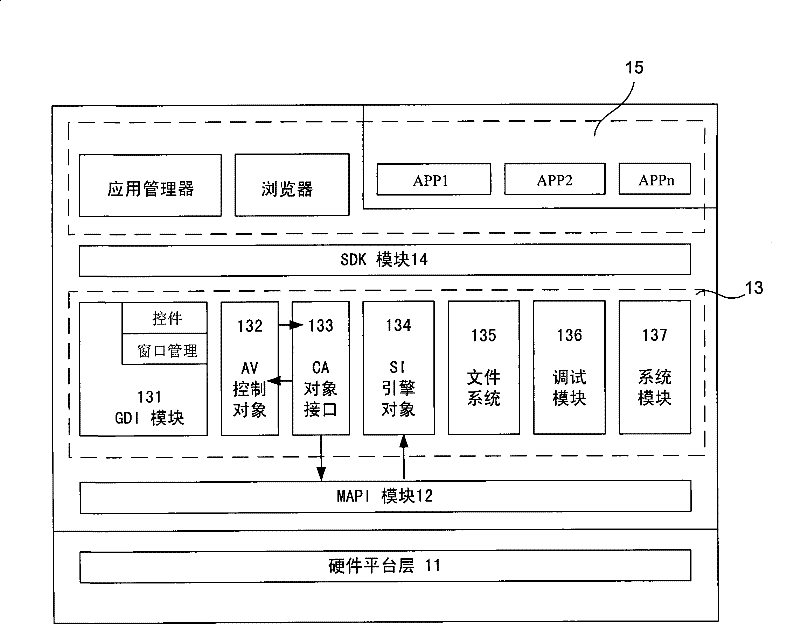

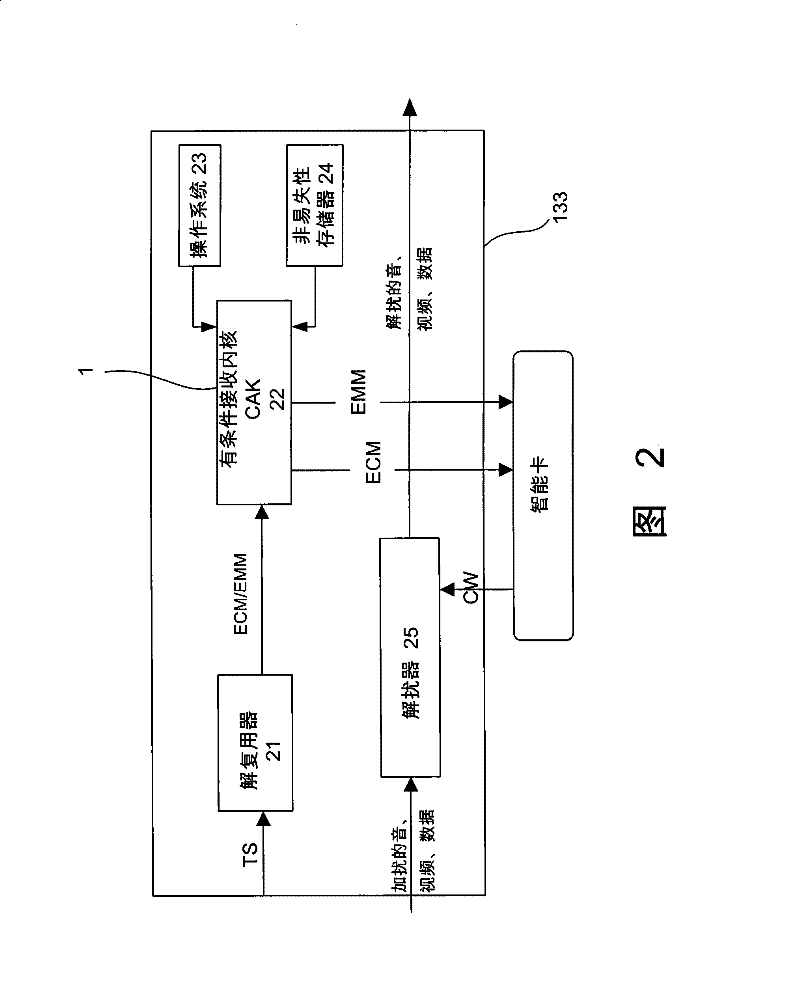

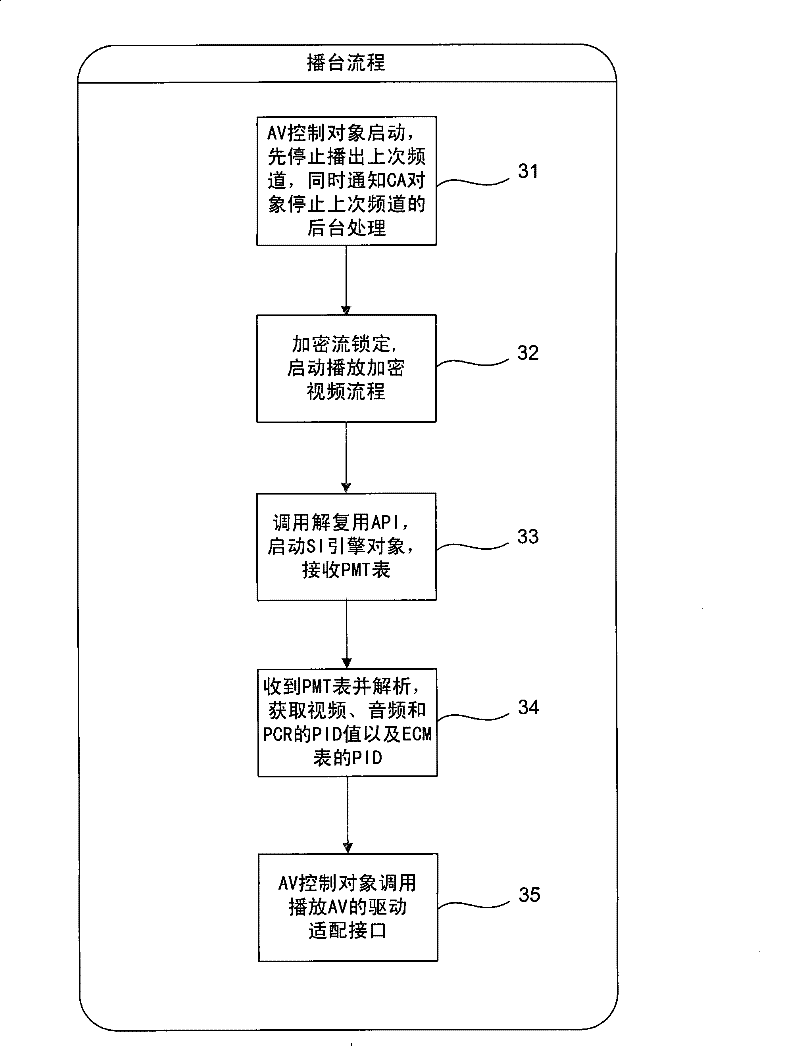

Multi-condition reception supporting system and method used for set up box

ActiveCN101184196AIncrease hierarchyImprove reusabilityTelevision system detailsAnalogue secracy/subscription systemsSupporting systemOperational system

The invention discloses a system and a method for multi-condition receiving and support on the set-top box; the method is used in the set-top box system formed by an interlayer, a software development kit module and a portable application programming interface module. The interlayer comprises a video and audio control object, a service information engine object and a condition receiving object interface. The method comprises two concurrent processes of a background processing of the authorization management information and a radio station processing. The multi-condition receiving and support system used in the set-top box of the invention comprises an interlayer and a portable application programming interface module, and the interlayer further comprises: a video and audio control object and a condition receiving object interface, and a service information engine object used to acquire the related control information of the condition receiving according to analyzing the service information form; the portable application programming interface module can be used to support the broadcasting of the video and audio, the receiving of the service information and the condition receiving data, the transmission of the smart card data, the usage of the descrambling device and the invoke of the operating system.

Owner:上海云视科技股份有限公司

Method for preparing carbon nanotube-reinforced iron-rich porous composite material through laser-induction composite cladding

The invention provides a method for preparing a carbon nanotube-reinforced iron-rich porous composite material through laser-induction composite cladding. The method is characterized by comprising the following steps: (1) mixing copper alloy powder, ferroalloy powder and a carbon nanotube and adding the obtained mixture into an acrylic resin to prepare slurry; (2) uniformly mixing the slurry by using a planetary ball mill, carrying out drying and then carrying out grinding to obtain carbon nanotube uniformly-distributed Cu-Fe-based composite powder; and (3) preparing a carbon nanotube-reinforced Cu-Fe-based composite material on the surface of a substrate through laser-induction composite cladding and carrying out selective electrochemical corrosion in a nitric acid solution so as to obtain the high-strength porous iron-rich composite material with a three-dimensional structure. According to the invention, the carbon nanotube with a high-melting point is used to inhibit convection of molten Cu-Fe-based composite powder, reduce the movement speed and particle size of spherical Fe-rich particles and improve structural segregation and layering of the Cu-Fe-based composite material. Thus, the crack-free high-strength porous iron-rich composite material with uniformly distributed carbon nanotubes can be prepared under the conditions of high efficiency and low cost.

Owner:NANCHANG HANGKONG UNIVERSITY

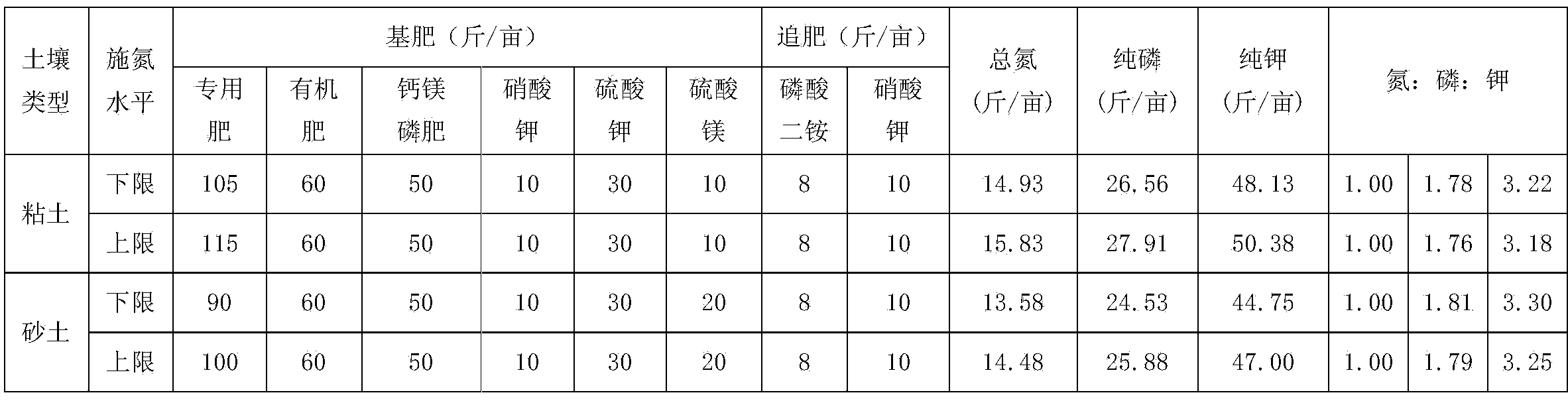

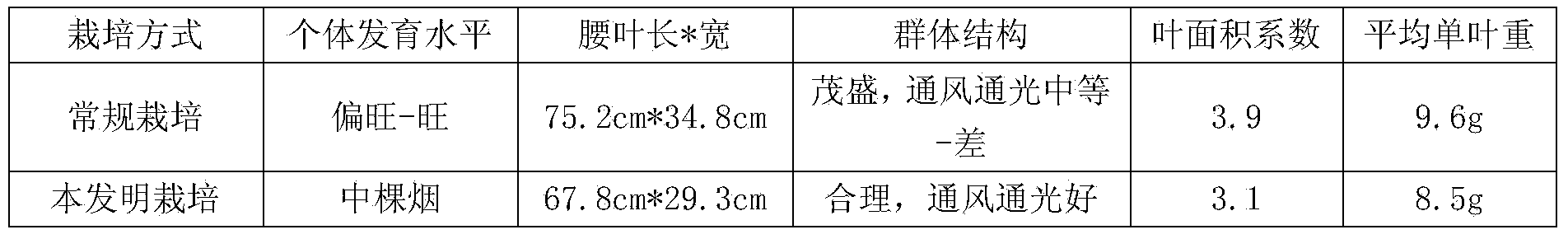

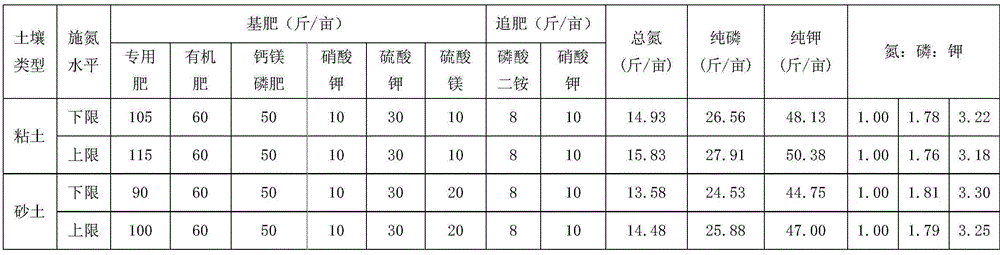

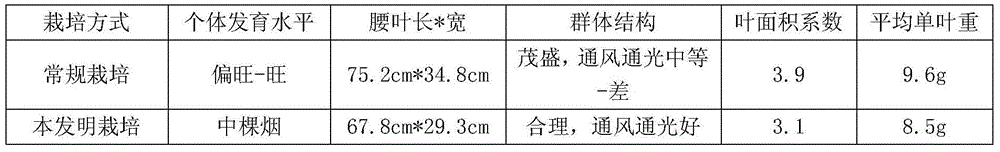

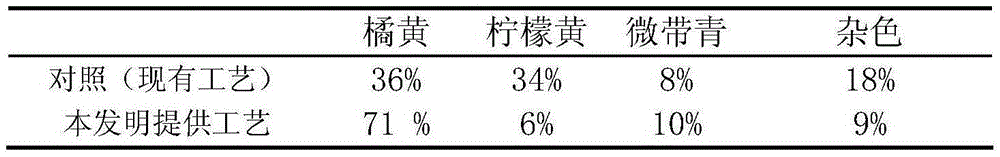

Cultivation method for Yunnan flue-cured tobacco 97

InactiveCN103858651AAchieve real maturityIncrease hierarchyFertilising methodsHorticultureNicotiana tabacumQuality level

The invention discloses a cultivation method for Yunnan flue-cured tobacco 97. The problems that on conventional cultivation conditions, individual development goes beyond the limit, the group structure excessively grows, the ventilation and light transmission performance is poor, tobacco leaves cannot be really matured, and the quality level, industrial availability and benefit level of the tobacco leaves are low are solved by changing fertilizer and controlling row spacing and planting distance. The individual development level and group development level of the tobacco plants are improved and coordinated, the medium tobacco is cultivated, the tobacco leaves are matured really, the tobacco quality, tobacco planting benefit and industrial availability are improved, the fertilizer cost is reduced, and the cost-saving and income-increasing purposes are achieved.

Owner:ANHUI WANNAN TOBACCO LEAF

Process of making cathode material containing Ni-based lithium transition metal oxide

ActiveUS20090224201A1Increase hierarchyImprove securityEnergy inputAlkali metal oxidesOxide cathodeImpurity

Owner:LG ENERGY SOLUTION LTD

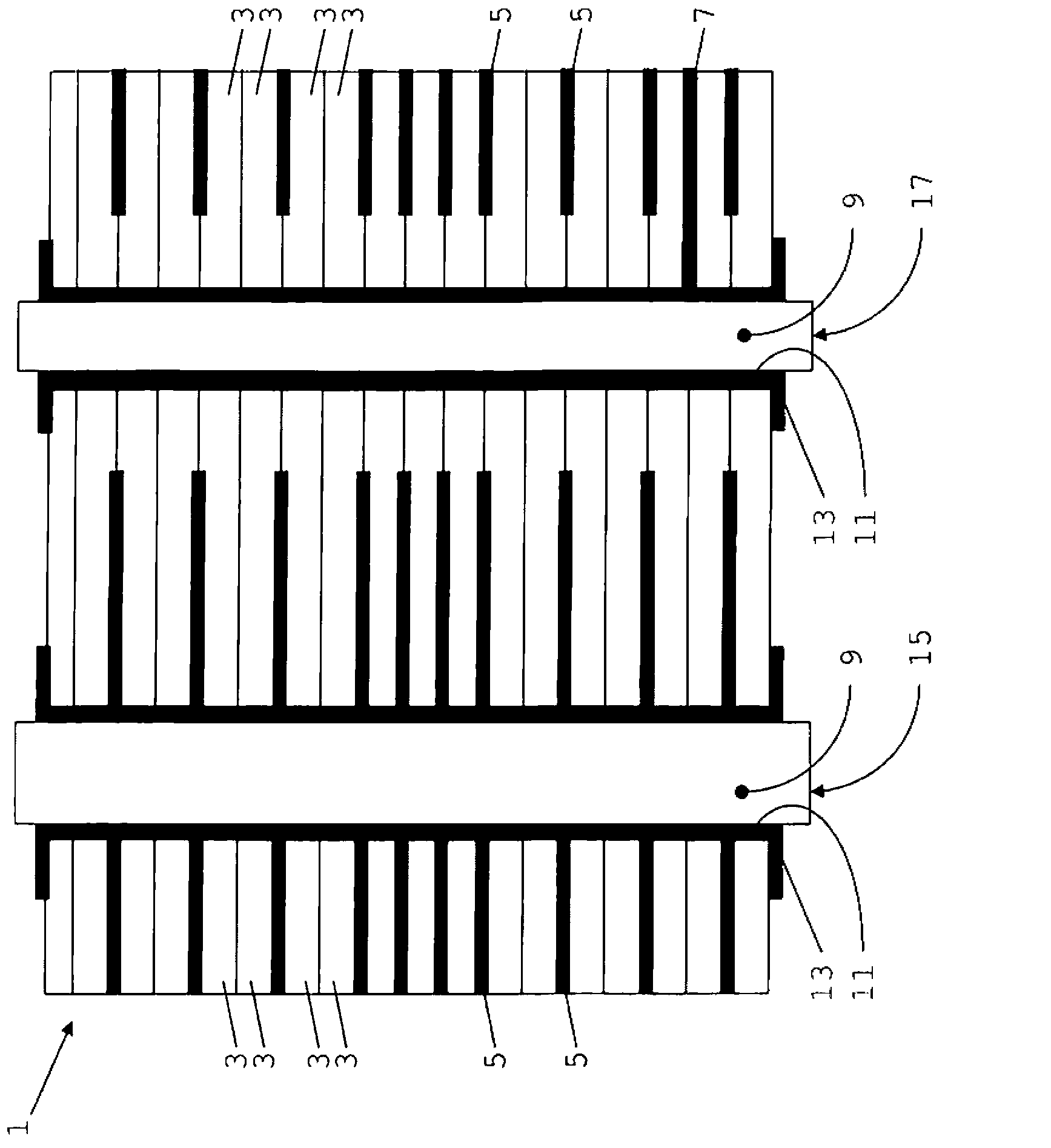

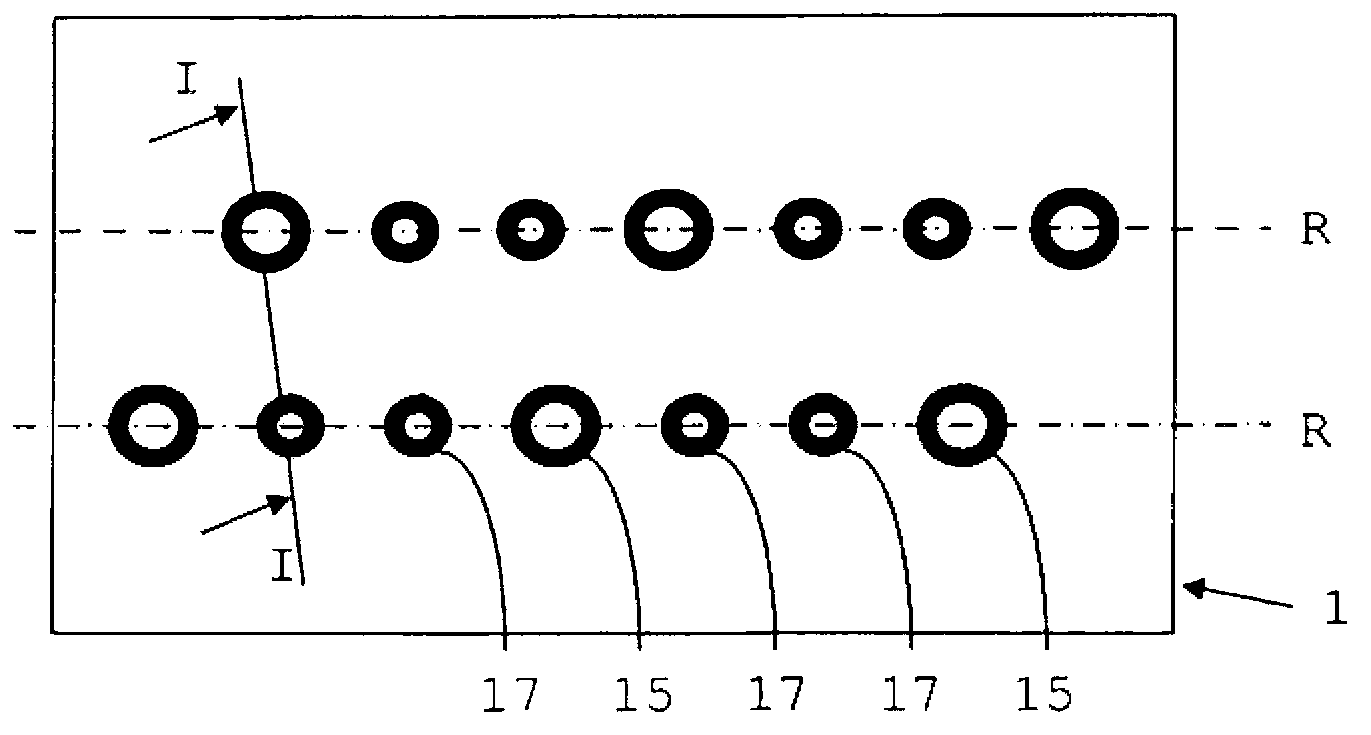

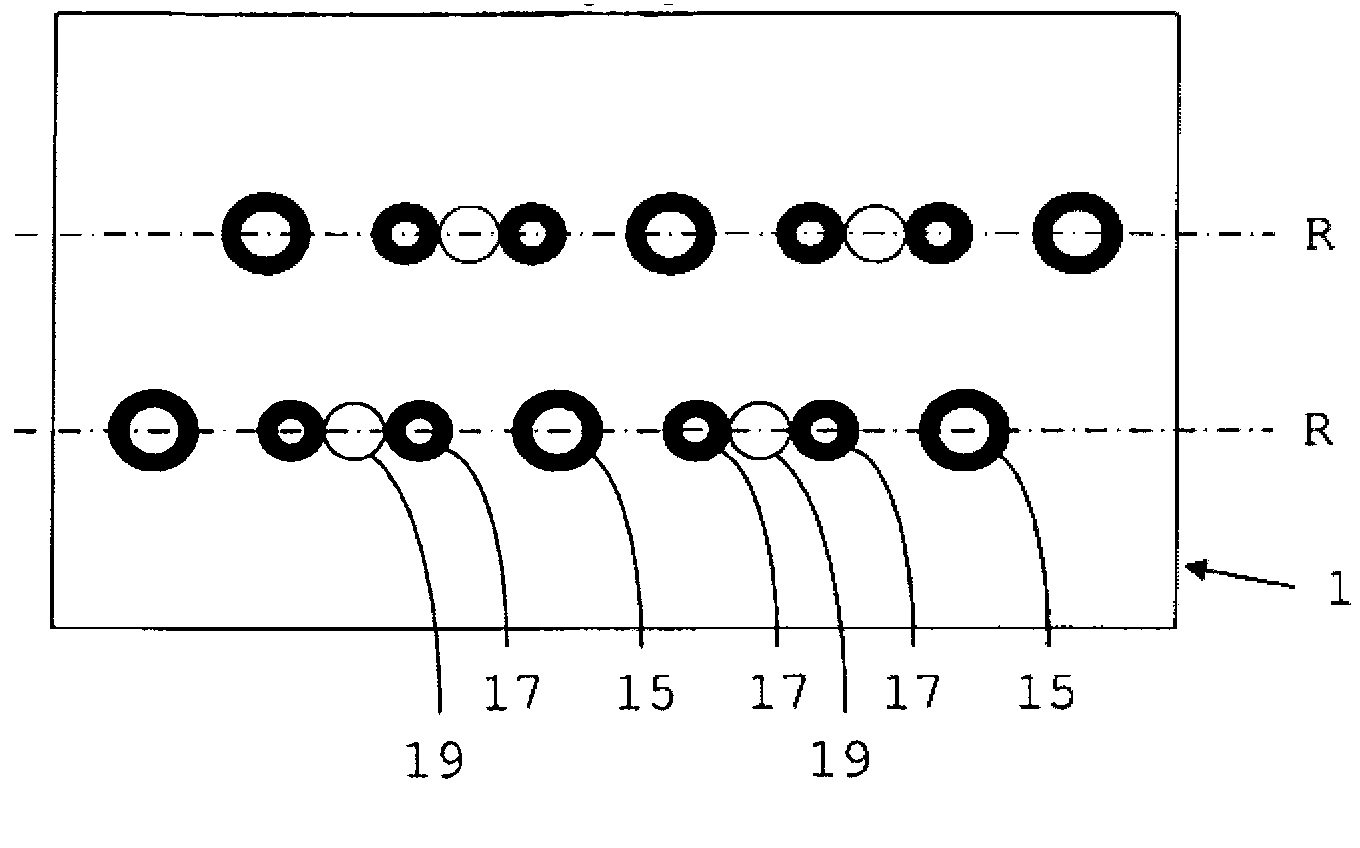

Structured circuit board and method

ActiveCN102986307AReduce and/or prevent impedance mismatchImprove signal qualityCoupling device detailsHigh frequency circuit adaptationsGround planeMaterials science

A circuit board (1) is provided comprising a plurality of insulating layers, at least one ground layer and at least one layer comprising signal traces. The circuit board comprises at least a first conductive via (17) and a second conductive via (17). The first conductive via and the second conductive via penetrate through at least a first insulating layer of the plurality of insulating layers and are connected to a signal trace. The first conductive via and the second conductive via are arranged adjacent each other. At least in the first insulating layer the first conductive via and the second conductive via are separated in a first direction of separation (R) by a first adjustment portion comprising a dielectric material property different from the first insulating layer.

Owner:FRAMATOME CONNECTORS INT SA

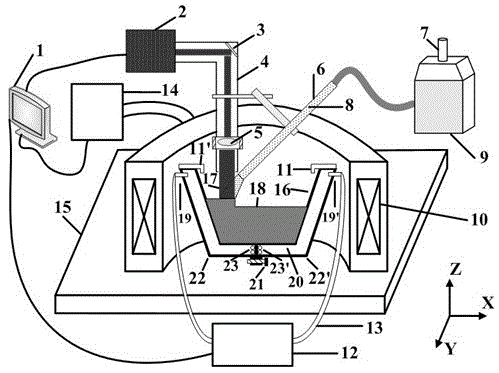

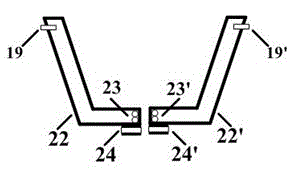

Method for preparing monotectic alloy through casting by combining laser with high-intensity magnetic field

InactiveCN102978427AImprove tissue segregationIncrease hierarchyIncreasing energy efficiencyAlloyCasting mold

The invention relates to a method for preparing a monotectic alloy through casting by combining laser with high-intensity magnetic field, which is characterized by comprising the following steps: mixing the metal powder of all components of the monotectic alloy by mass percent according to the chemical components of the monotectic alloy to prepare the monotectic alloy powder with uniform particle size and good flowability; putting a copper casting mould with a circulating cooling water system in the center position of a high-intensity magnetic field device; and injecting the monotectic alloy powder into a CO2 laser beam heat source by a powder nozzle to melt the monotectic alloy powder quickly, wherein when the laser beam moves away, the molten monotectic alloy powder solidifies in the copper casting mould quickly, and the monotectic alloy is formed. According to the method, when the CO2 laser beam is used to heat and melt the monotectic alloy powder quickly, the high-intensity magnetic field is introduced, thus the convection of the melt is inhibited, the movement speed of the second-phase particles is reduced, and the tissue segregation and the hierarchical structure of the monotectic alloy are improved. Therefore, the method can be used for preparing the monotectic alloy with large size, uniform distribution of second-phase particles and high performance under the condition of high efficiency and low cost, and the problems that the monotectic alloy is hard to cast under the gravitational field condition, has nonuniform tissue distribution and is layered are solved.

Owner:NANCHANG HANGKONG UNIVERSITY

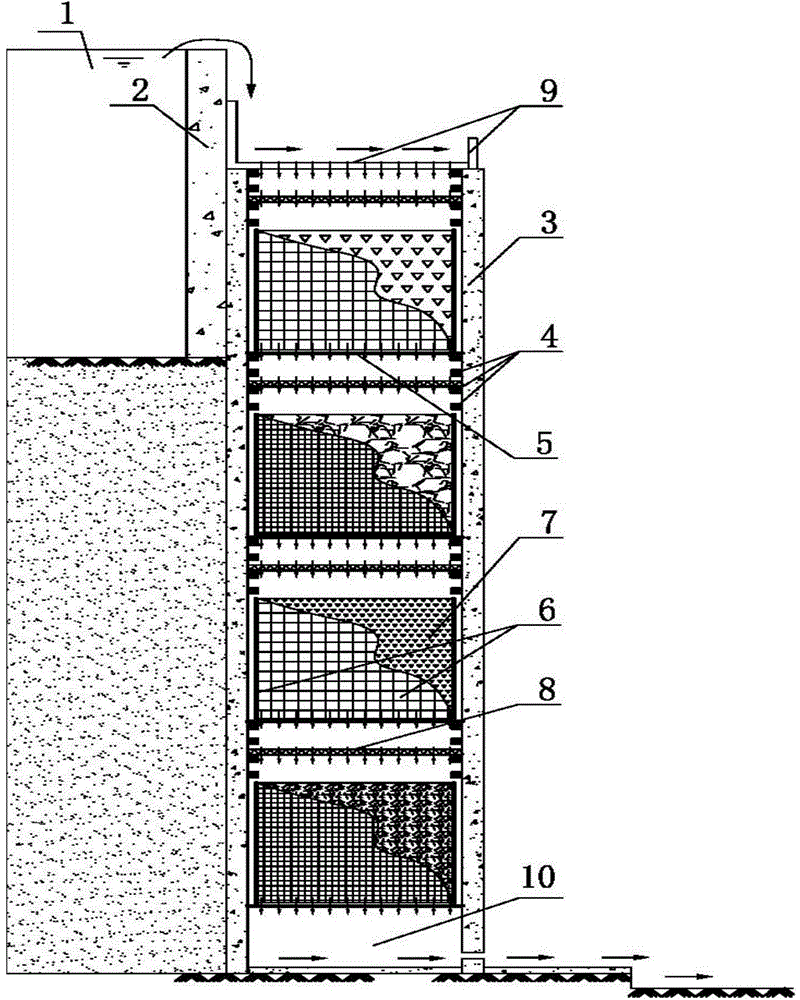

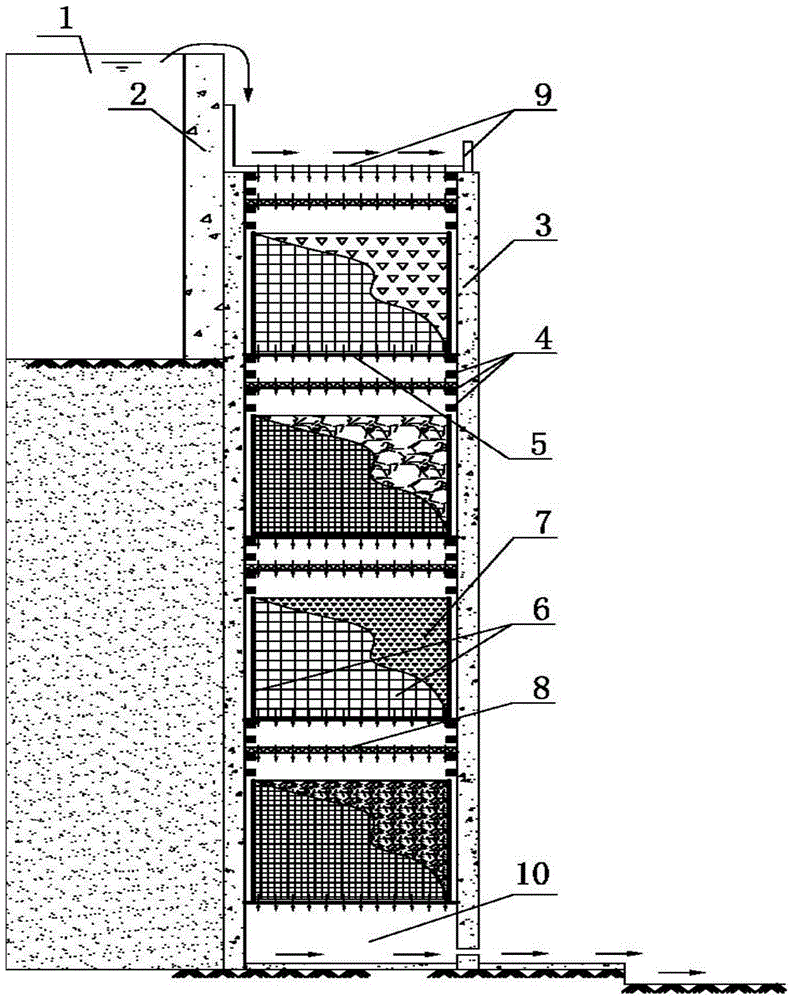

Device and method for restoring polluted water source through multi-media bio-filter

ActiveCN104528939AIncrease hierarchySimple hierarchyWater treatment compoundsTreatment with aerobic and anaerobic processesWater sourceWater quality

The invention discloses a device and method for restoring a polluted water source through a multi-media bio-filter. The device is used for restoring polluted water of an upstream river way of a river type water source. A dam is arranged in the upstream river way. The device is arranged on the outer side of the dam. The device comprises a tower layer frame, carrier packing layers and a water collector. Water distributors are arranged at the upper end of the tower layer frame and used for introducing the polluted water source in the dam into the tower layer frame. The multiple carrier packing layers are arranged in the tower layer frame from top to bottom. The water collector is arranged at the lower end of the tower layer frame, collects the water source filtered through the carrier packing layers and drains the water source to a downstream river way. By the adoption of the device and method for restoring the polluted water source through the multi-media bio-filter, the water quality of the water source can be improved, the water body of the water source can be restored, the functions of the water source can be restored, and the safety of drinking water can be guaranteed.

Owner:PEKING UNIV

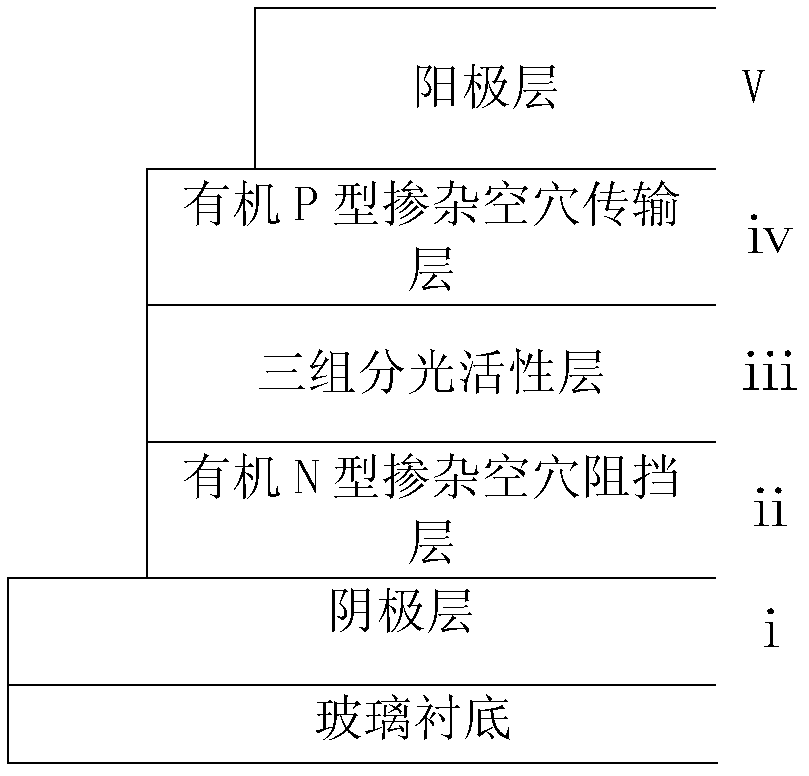

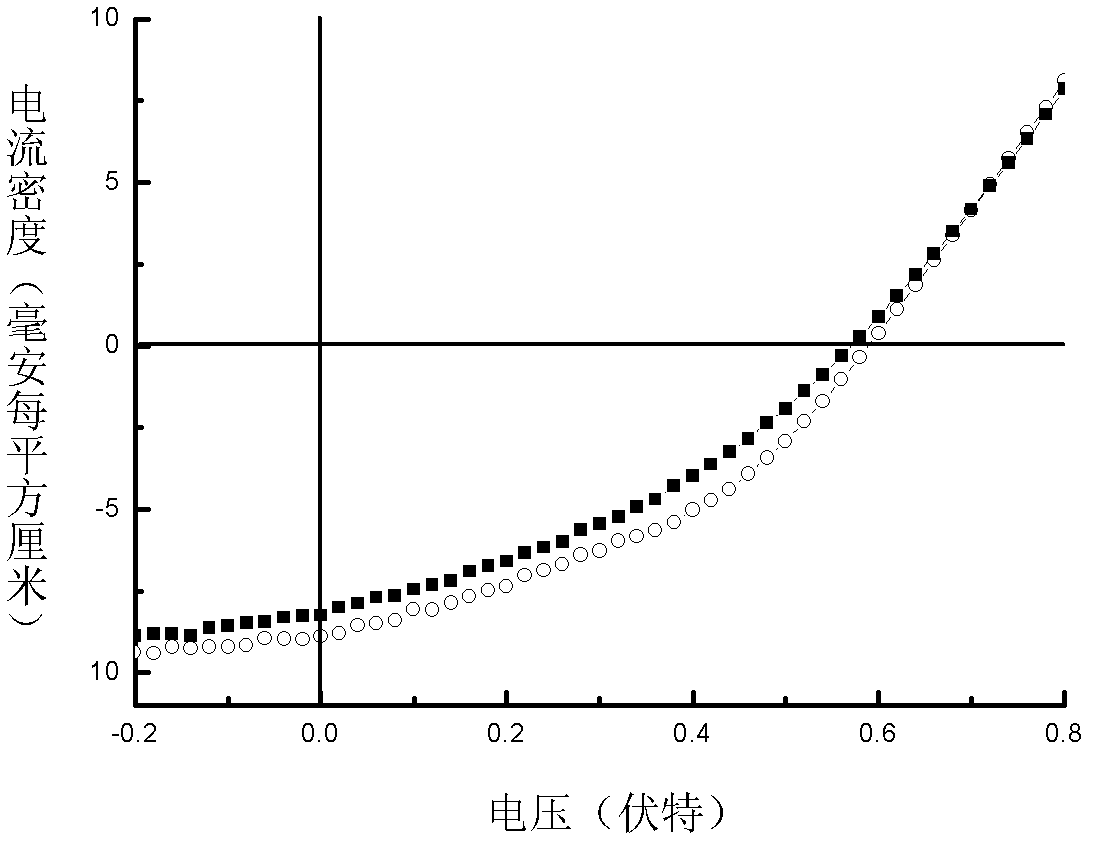

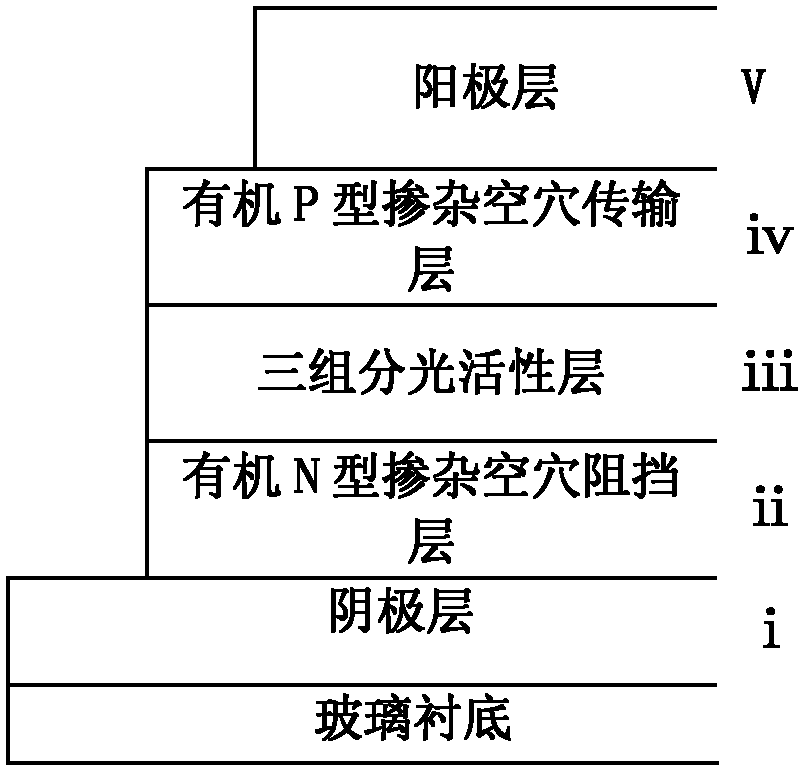

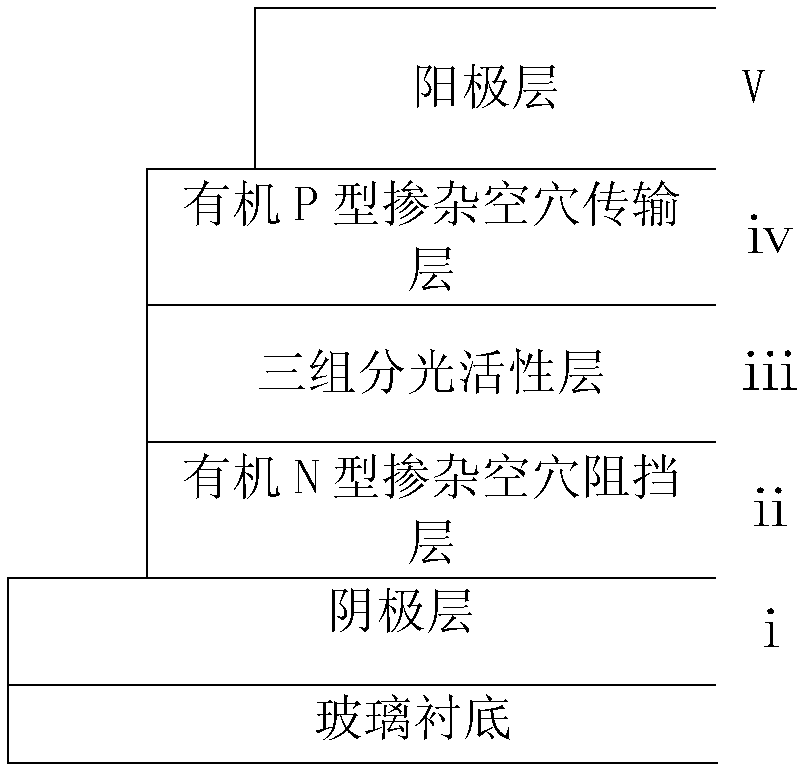

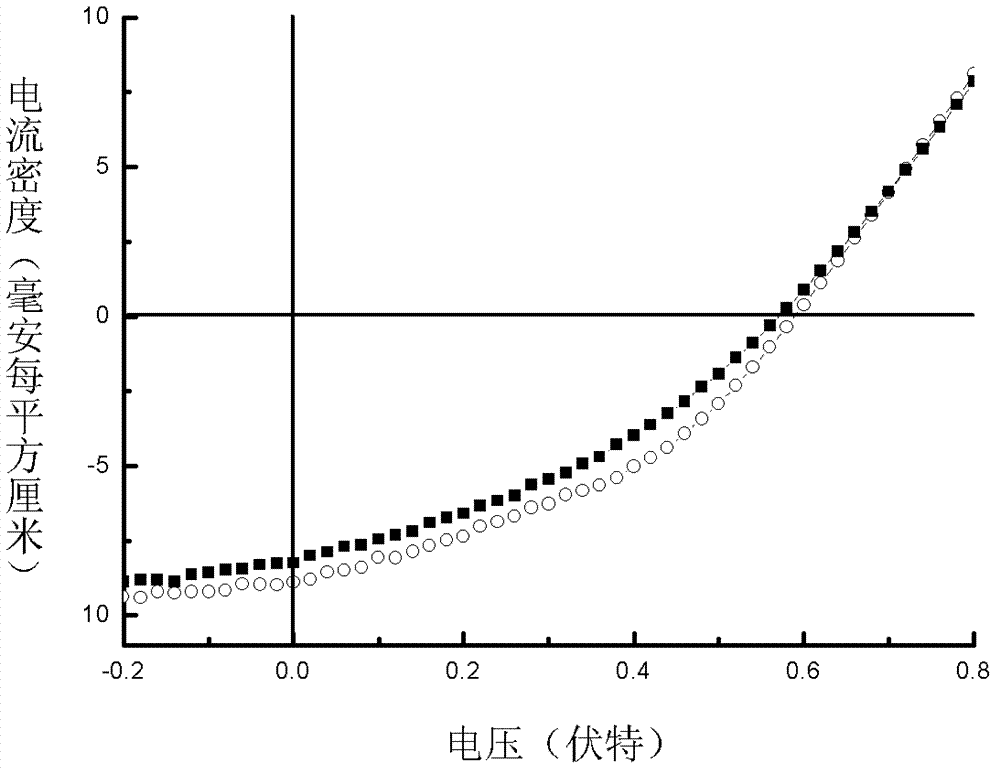

Polymer solar cell with reverse structure and preparation method thereof

ActiveCN102280586AHighlight substantive featuresOriginal and innovativeSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeOptical energy

The invention discloses a polymer solar cell with a reverse structure and a preparation method thereof and relates to a solid apparatus especially suitable for converting optical energy into electric energy. The cell is a polymer solar cell which is of a reverse structure and has a three-component photoactivity film in a layered structure; the polymer solar cell is composed of a cathode layer, anorganic N-type doped electron hole barrier layer, a three-component photoactivity layer, an organic P-type doped electron hole transmission layer and an anode layer which are orderly deposited on a glass substrate, wherein the mass proportion of the three-component film is as follows: P3HT:PC61BM:BCP=12:10:(0.01-12):10:0.1 or PCPDTBT:PC71BM:Bphen=12:15:(0.01-12):15:0.1. The energy conversion efficiency of the three-component photoactivity layer is 20% higher than the existing two-component photoactivity layer, and a filling factor is further 10% higher than that in the prior art; and meanwhile, the defects of the existing polymer solar cell with a reverse structure are overcome.

Owner:HEBEI UNIV OF TECH

Kiwi fruit planting method

InactiveCN106508587AImprove growth and survival rateImprove fruit-setting abilityCultivating equipmentsDiseaseActinidia

The invention provides a kiwi fruit planting method. The planting method comprises the first step of choosing a mountain area in which mean area annual temperature is 16 DEG C or above, altitude is 400-1200 meters, water drainage and ventilation are good, soil texture is fine, and sandiness soil is loose and fertile; the second step of setting up a plane shed frame on a gentle slope with gradient being 0-20 degrees, arranging a flood draining top furrow, a vertical flood diversion drainage ditch and an enclosure ditch, and afterwards building a terrace wall along the shed frame; the third step of firstly planting a male tree, and then planting a female tree; the fourth step of conducting field planting for three years; the fifth step of applying nitrogenous fertilizer and phosphate fertilizer and conducting watering and irrigation before the trees bloom, and conducting artificial pollination after the trees blossom; the sixth step of conducting disease and pest prevention and control on the kiwi fruit trees in the planting process. By using the kiwi fruit planting method, the survival rate of kiwi fruit saplings is increased, the quality index of kiwi fruit is improved, the risk of pest and disease damage is effectively lowered, economic benefits are greatly improved, and thus a new method for planting the kiwi fruit is provided.

Owner:巫溪县茶园子种植专业合作社

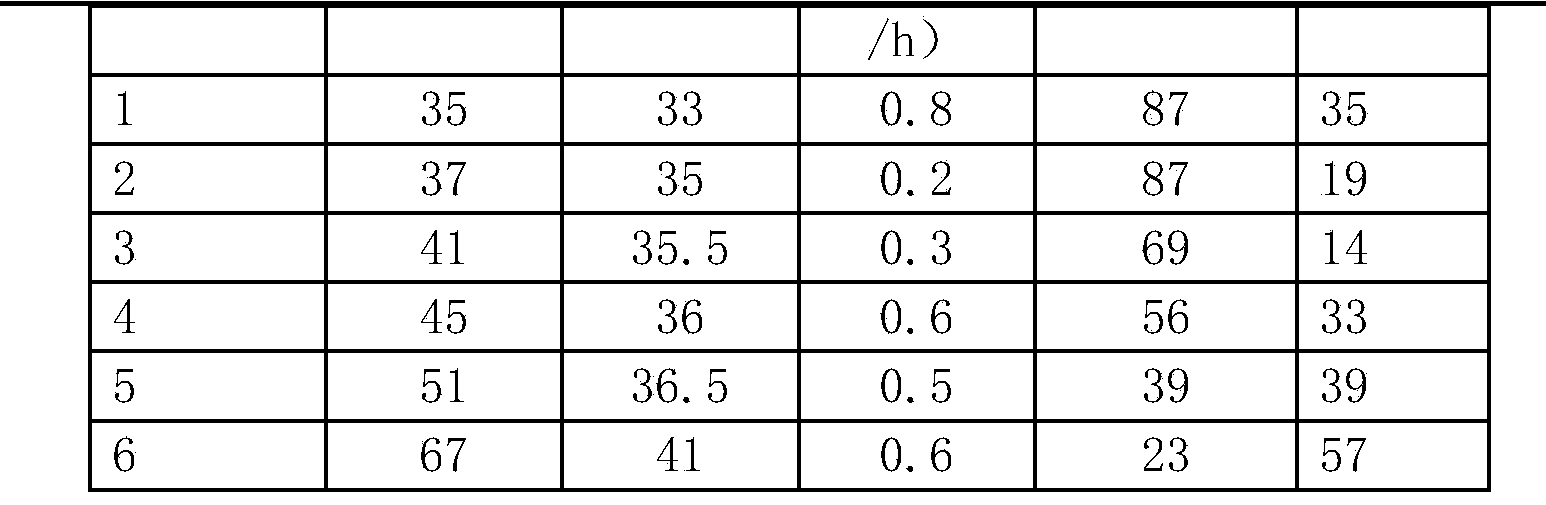

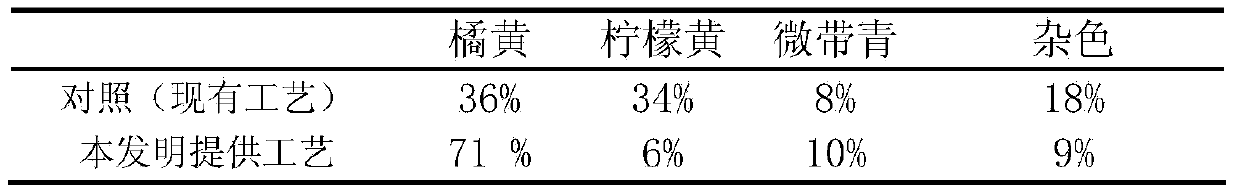

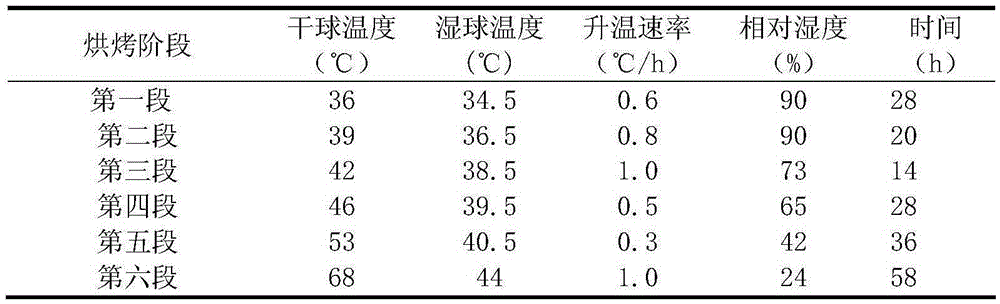

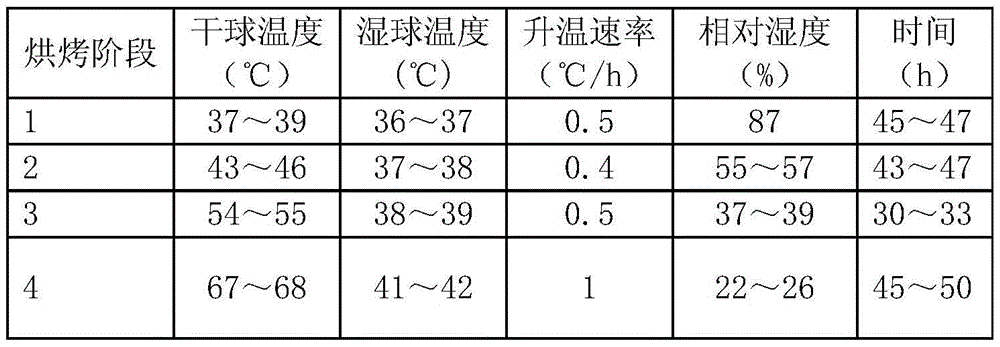

Baking process method for reducing release amount of benzopyrene in flue-cured tobacco

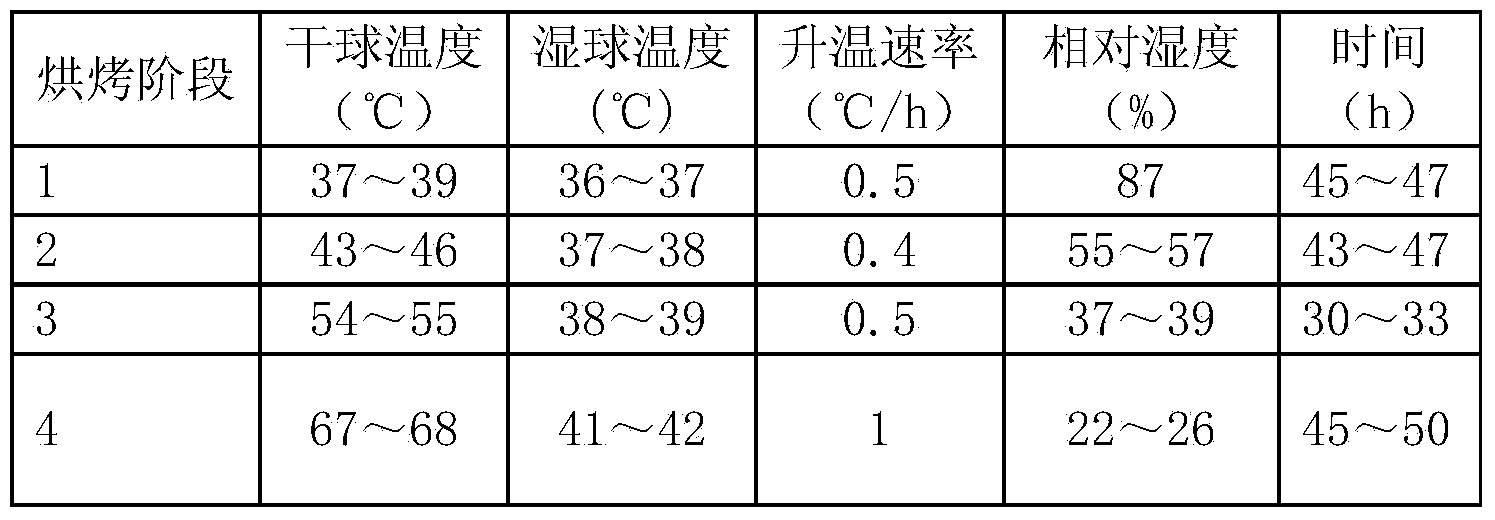

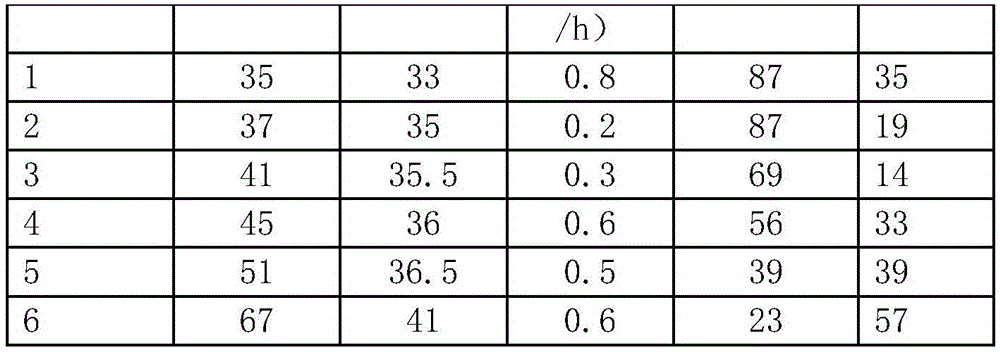

InactiveCN103815533AReduced release of benzopyreneIncrease hierarchyTobacco preparationCooking & bakingWet-bulb temperature

The invention discloses a baking process method for reducing the release amount of benzopyrene in flue-cured tobacco. A tobacco curing process is partitioned into six stages, the dry-bulb temperature is set to gradually raise between 35 DEG C and 68 DEG C, the wet-bulb temperature is 33-42 DEG C, the temperature raising rate is 0.2-0.8 DEG C / h, the relative humidity is 22-87 percent and falls in sequence, the baking time is 13-57 hours, and the first four stages are shorter in baking time while the last two stages are longer in baking time. The six stages are carried out continuously. After baking, the release amount of the benzopyrene in tobacco leaves is lowered by over 20 percent than that of benzopyrene in a blank control, the grade structure of the tobacco leaves is improved, the sensory quality of the tobacco leaves is improved, and the quality and amount of aroma are improved greatly. Moreover, irritation and offensive odor are reduced, the price of the baked tobacco leaves is higher, and the economic value of the tobacco leaves is raised.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

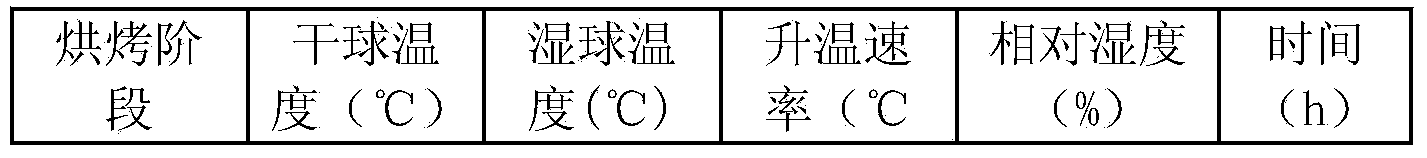

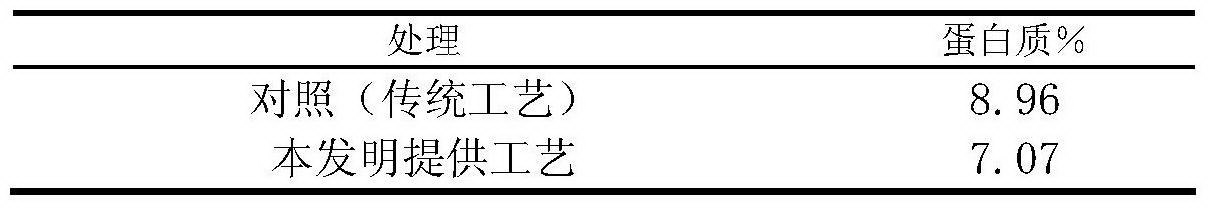

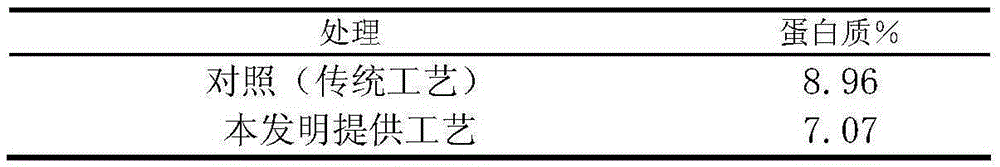

Flue-curing process method capable of reducing protein content in flue-cured tobacco

InactiveCN103798945AIncrease hierarchyImprove sensory qualityTobacco preparationChemical qualityNitrogen

The invention discloses a flue-curing process method capable of reducing protein content in the flue-cured tobacco. The process method disclosed by the invention is implemented according to the following steps of: A, preparing the flue-cured tobacco and placing the flue-cured tobacco into flue-curing equipment; B, sequentially carrying out six continuous flue-curing stages comprising four short-time flue-curing stages and two long-time flue-curing stages in the flue-curing process of the flue-cured tobacco; C, after flue-curing, obtaining the flue-cured tobacco with low protein content. According to the invention, on the premise of ensuring quality of the flue-cured tobacco, the step of controlling the content of a protein which is an important nitrogen-containing compound is migrated to the tobacco leave modulating stage, so that the flue-curing process method is helpful for improving chemical quality of tobacco leaves, and thus, damage of smoking to health of human bodies is further reduced. By the process conditions of the flue-curing process method, compared with a flue-cured sample in a conventional method, the flue-cured tobacco leaves has the advantages that the appearance quality, the proportion of medium-class and first-class tobacco and the smoking quality are all improved and the release amount of the protein is reduced by 15 percent to 25 percent.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

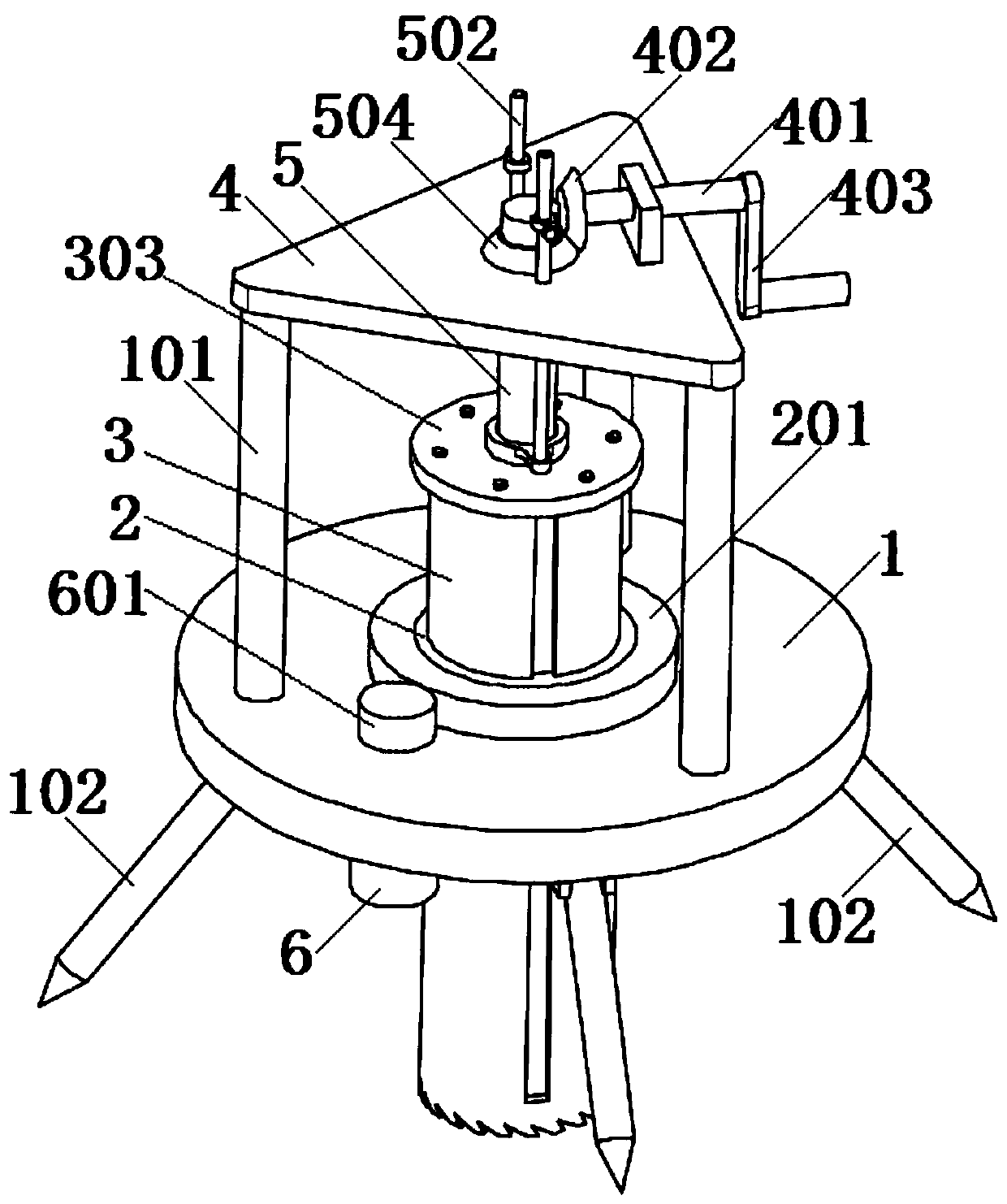

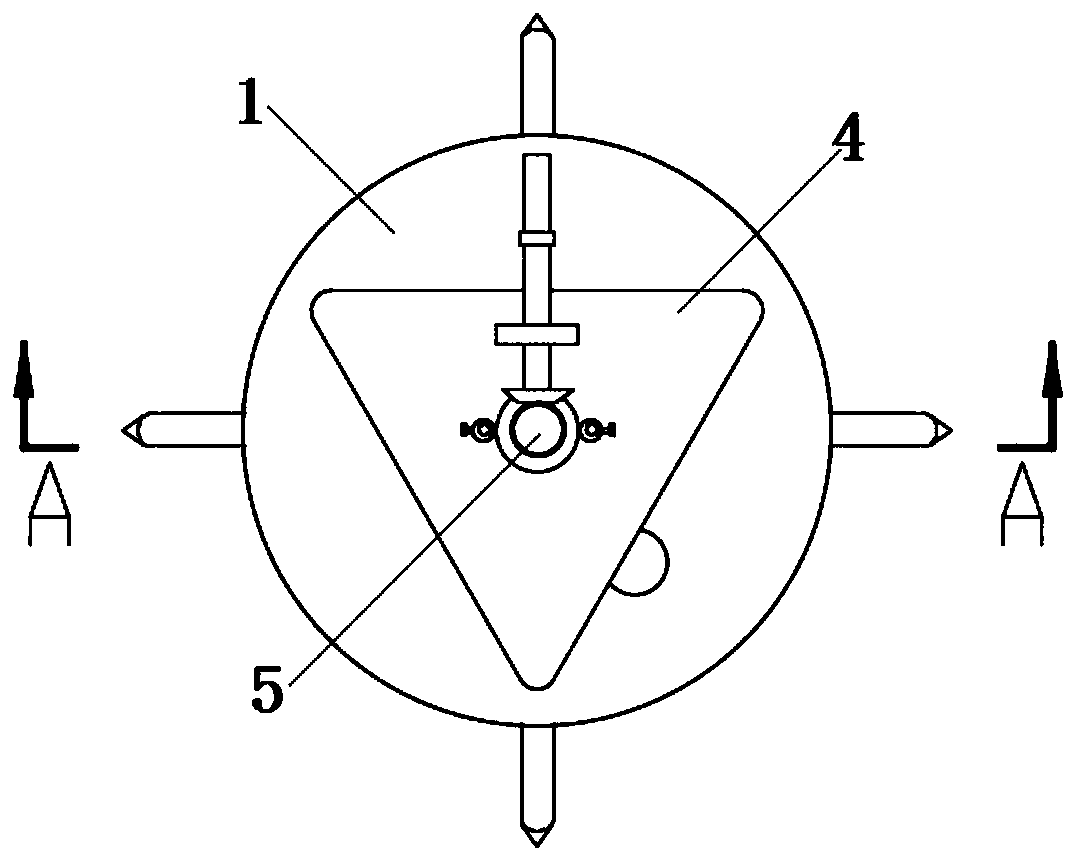

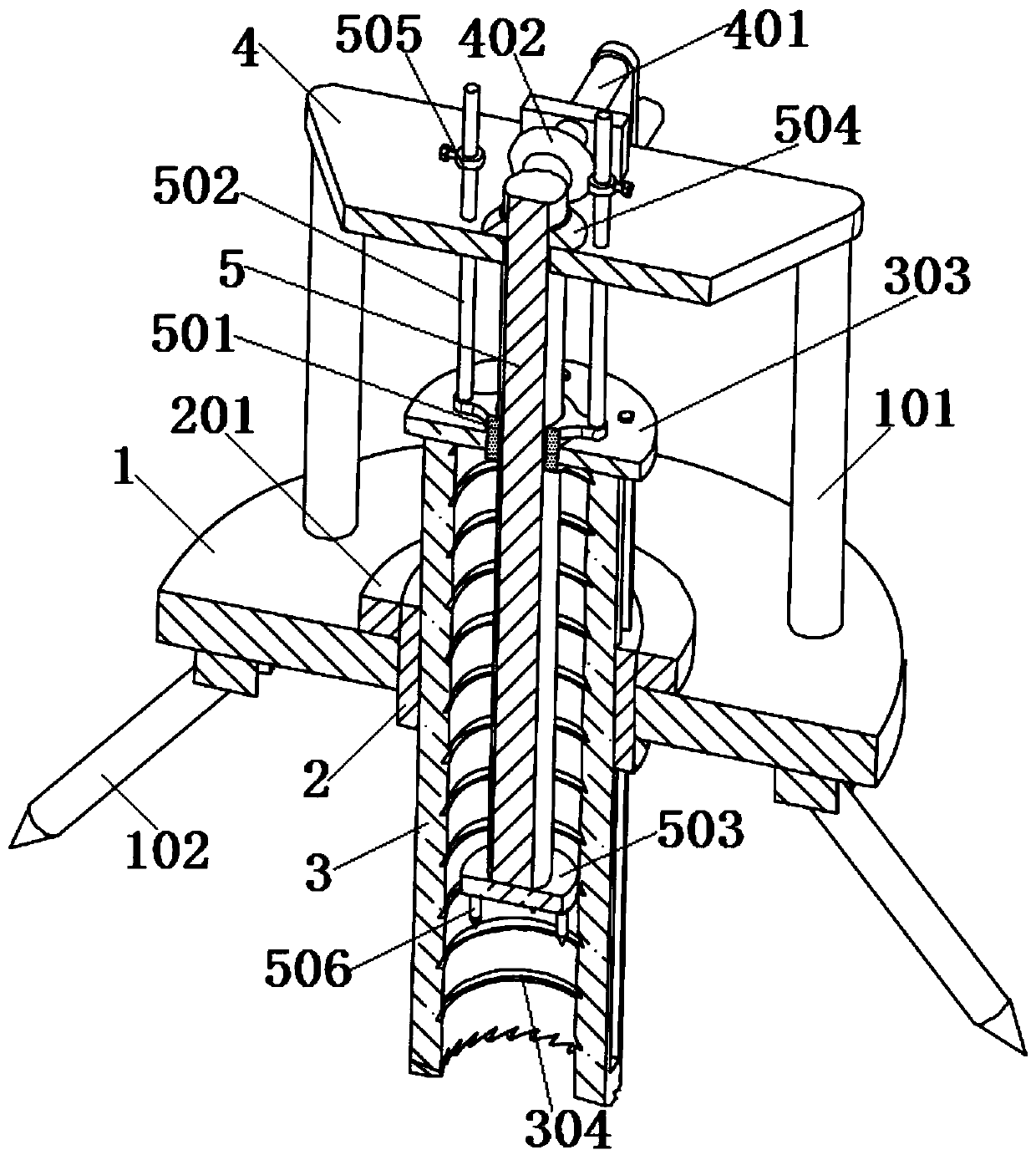

Accurate soil sampling device and method

InactiveCN110411783AAchieving borehole samplingReduce labor intensityWithdrawing sample devicesGeotechnical engineering

Owner:安徽金联地矿科技有限公司

Cathode material containing Ni-based lithium transition metal oxide

ActiveUS20090224215A1Increase hierarchyImprove securityConductive materialEnergy inputOxide cathodeImpurity

Owner:LG ENERGY SOLUTION LTD

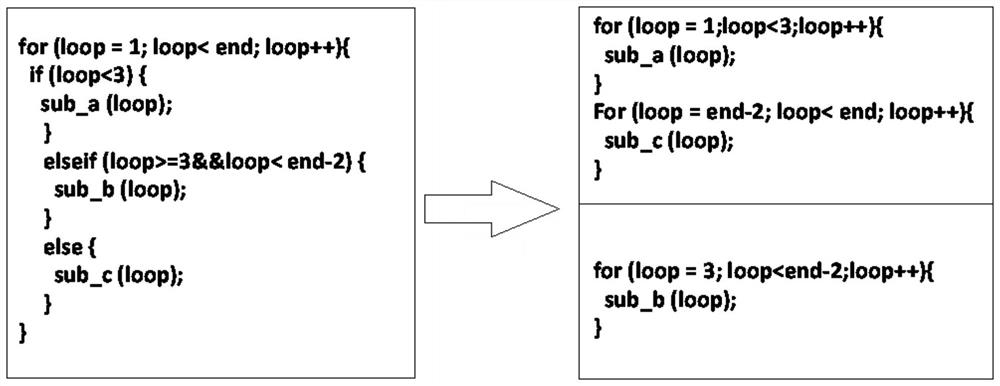

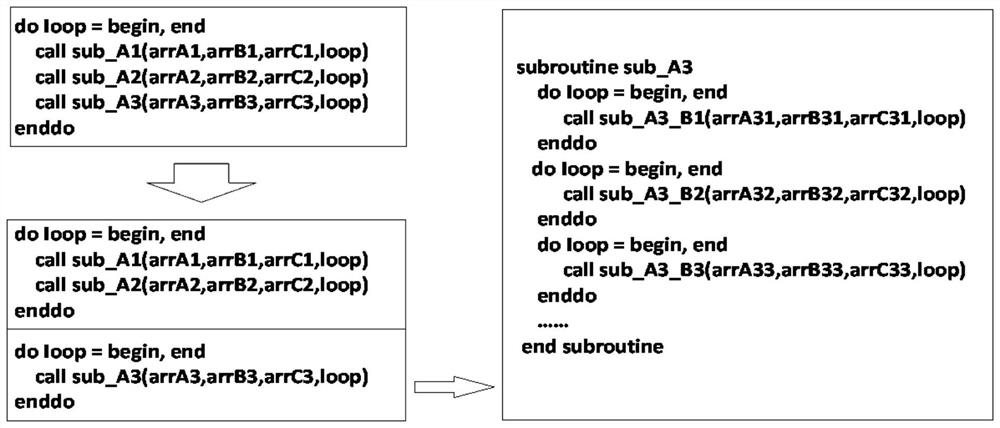

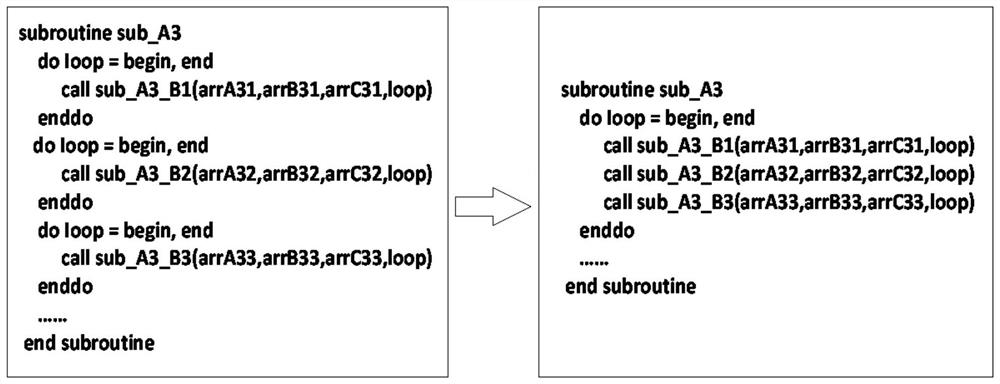

Many-core program reconstruction method based on cycle segment

ActiveCN112559032AImprove performanceImprove computing powerCode refactoringProgram code adaptionAlgorithmTheoretical computer science

The invention discloses a many-core program reconstruction method based on a cyclic segment. The method comprises a reconstruction algorithm based on cyclic segment splitting and a reconstruction algorithm based on cyclic segment merging, wherein the reconstruction algorithm based on cyclic segment splitting comprises cyclic segment splitting based on a master-slave cooperative task and cyclic segment splitting based on space compression; and the reconstruction algorithm based on cyclic segment merging comprises cyclic segment merging based on a similar structure and cyclic segment merging based on cyclic amount increase. According to the structural characteristics and performance indexes of the heterogeneous system, the hierarchical structure and sequence of the circulation section are optimized, the performance advantages of the system are fully played, and therefore the computing performance of application software is improved to the maximum extent.

Owner:JIANGNAN INST OF COMPUTING TECH

A Personalized Recommendation Method Based on Deep Learning

InactiveCN110196946BReduce serial operationsImprove training efficiencyDigital data information retrievalAdvertisementsPersonalizationRecommendation model

The invention discloses a personalized recommendation method based on deep learning. The method comprises the steps of according to the viewing time sequence behavior sequence of the user, predictingthe next movie that the user will watch, including three stages of preprocessing the historical behavior characteristic data of the user watching the movie, modeling a personalized recommendation model, and performing model training and testing by using the user time sequence behavior characteristic sequence; at the historical behavior characteristic data preprocessing stage when the user watchesthe movie, using the implicit feedback of interaction between the user and the movie to sort the interaction data of each user and the movie according to the timestamp, and obtaining a corresponding movie watching time sequence; and then encoding and representing the movie data,wherein the personalized recommendation model modeling comprises the embedded layer design, the one-dimensional convolutional network layer design, a self-attention mechanism, a classification output layer and the loss function design. According to the method, the one-dimensional convolutional neural network technologyand the self-attention mechanism are combined, so that the training efficiency is higher, and the number of parameters is relatively small.

Owner:SOUTH CHINA UNIV OF TECH

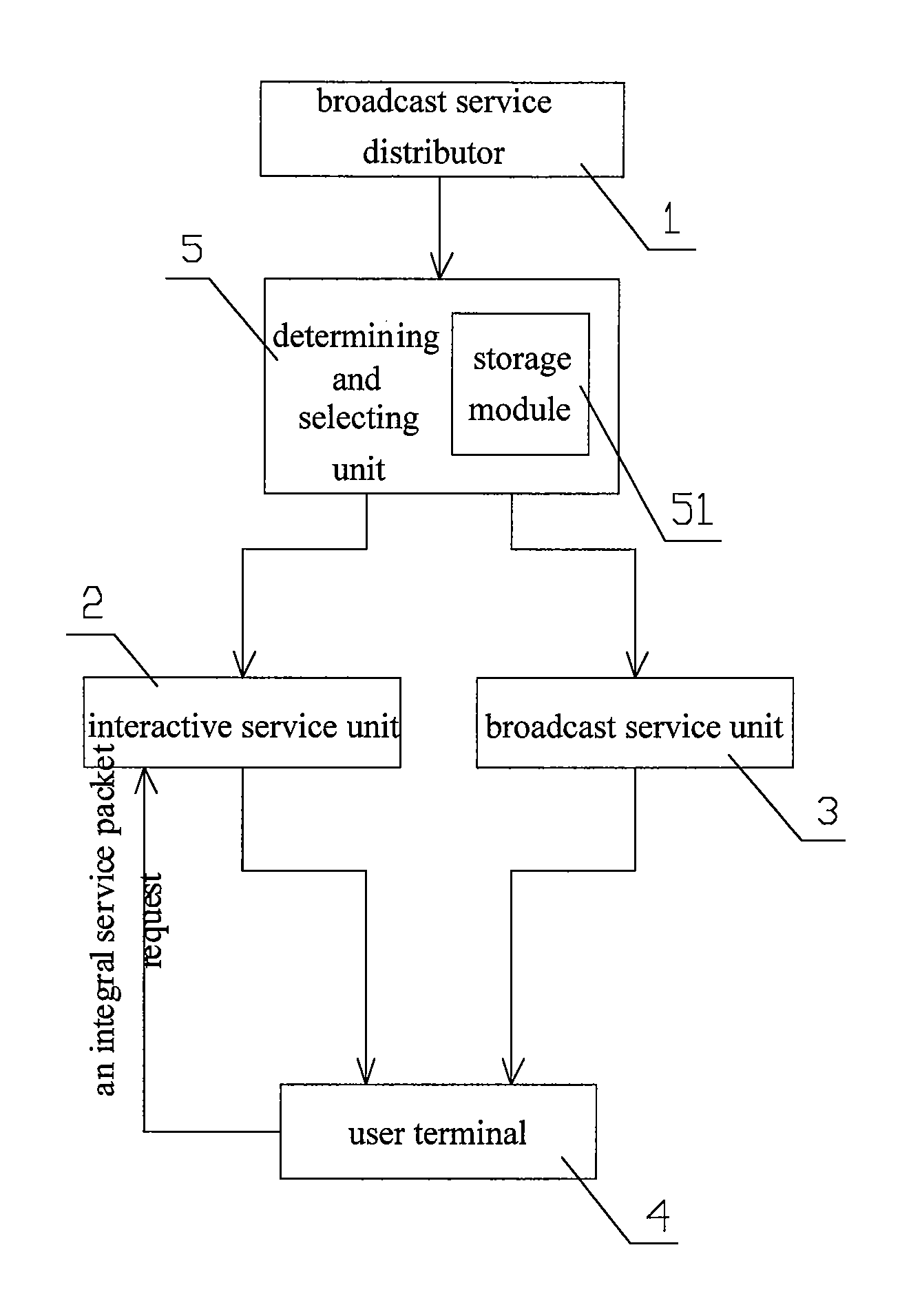

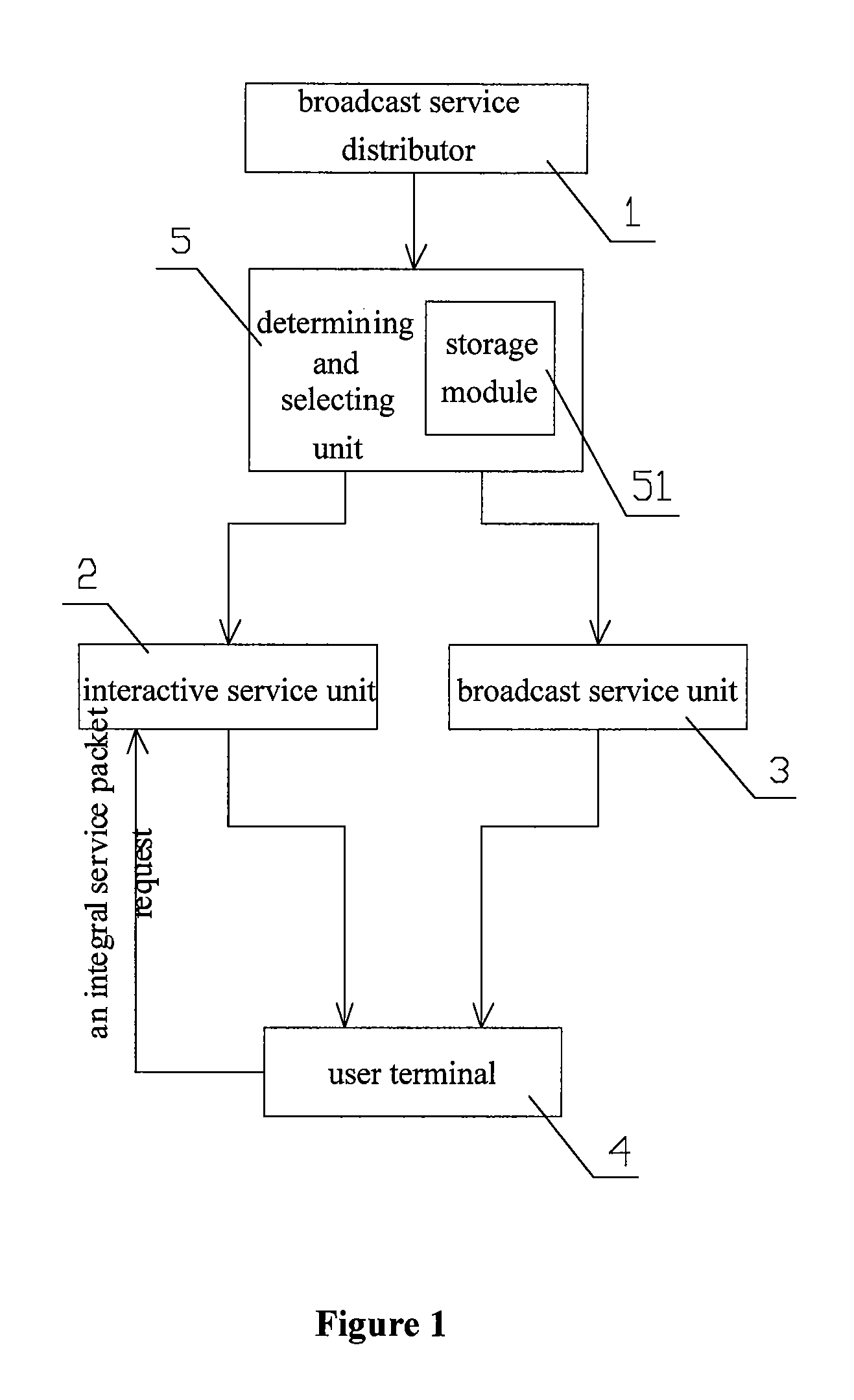

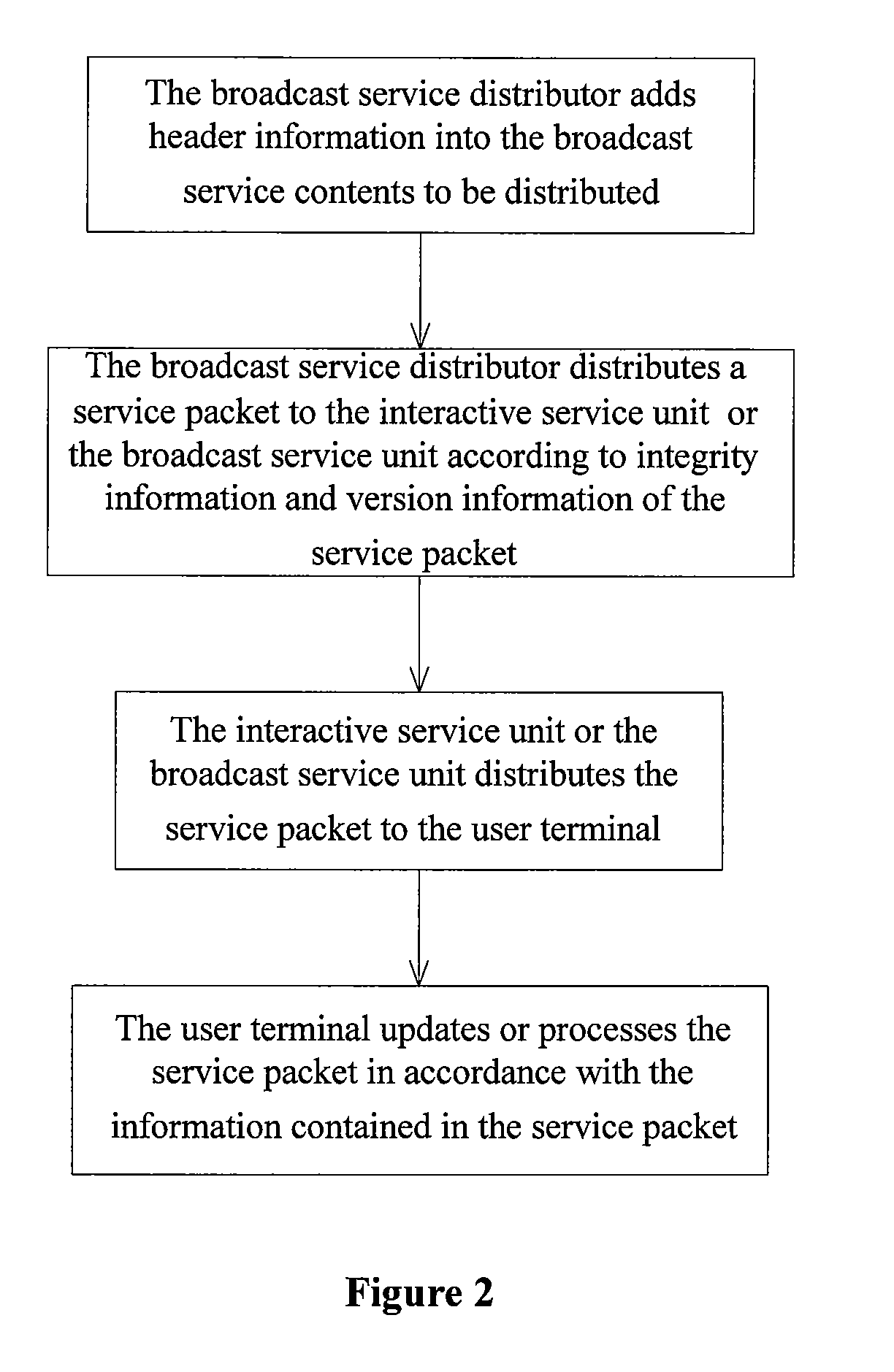

Method and system for distributing mobile broadcast service and mobile terminal

ActiveUS7944921B2Addressing Insufficient ControlImprove transmission efficiencyData switching by path configurationBroadcast service distributionComputer terminalBroadcast service

A method and a system for distributing a mobile broadcast service are provided. The method includes: adding header information into broadcast service contents, the header information comprising integrality information and version information of a service packet containing the broadcast service contents; distributing the service packet to a user terminal; updating or accepting, by the user terminal, its own service data by use of the service packet in accordance with the integrality information and version information of the service packet. The method and the system according to the embodiments in the present invention may bring about higher transmission efficiency of data packet.

Owner:HUAWEI TECH CO LTD

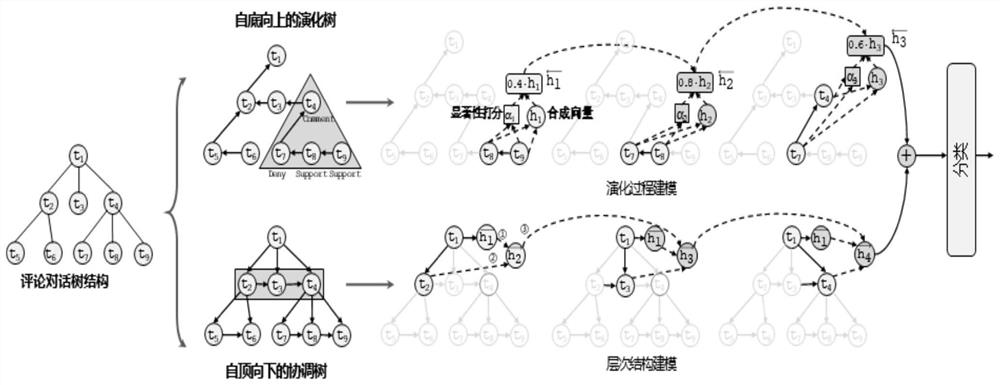

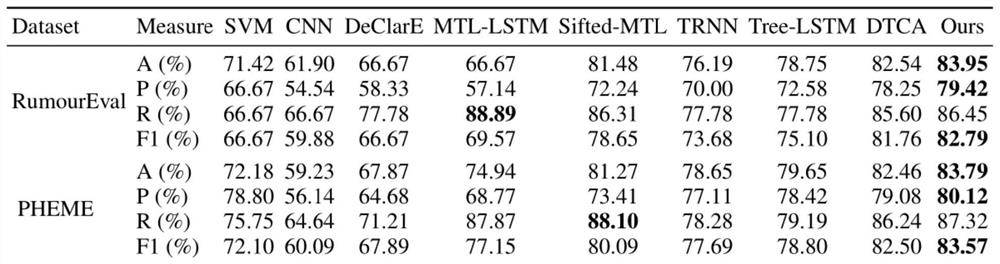

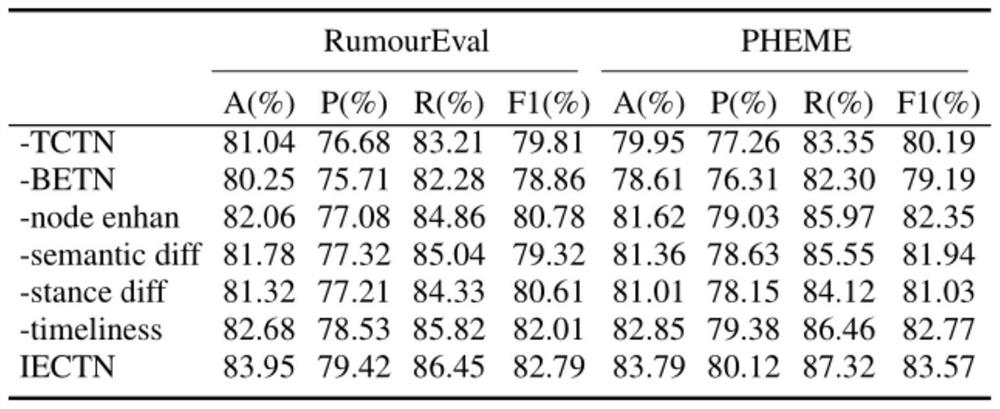

False news interpretability detection system and method based on induction consciousness

PendingCN112711951AEnhanced HierarchyImprove interpretabilityData processing applicationsDigital data information retrievalNetwork modelTree network

The invention discloses a false news interpretability detection system and a false news interpretability detection method based on induction consciousness, valuable comment sub-chains of questionable news are discovered by exploring evolution rules and hierarchical structure characteristics of a site in a comment thread, and the defects of deficiency of relevance mining and mutual influence among comments in the prior art are overcome. According to the method, interdisciplinary knowledge and a neural network model are combined, and semantic association mining and mutual influence mining between comment nodes in a false news comment tree are explored; an evolution tree network from bottom to top considers two social psychology theories to research the evolution law of the site in the comment clue so as to strengthen the valuable comments of the questioned news; according to the top-down coordination tree network provided by the invention, information absorption between the father node and the brother node is coordinated, the hierarchical structure of comments is enhanced, valuable comments are obtained by fusing the hierarchical structure of comments with evolutionary tree network features, a comment subchain is highlighted, and the interpretability of a verification result is enhanced.

Owner:XI AN JIAOTONG UNIV

A kind of cultivation method of Yunyan 97 flue-cured tobacco variety

InactiveCN103858651BAchieve real maturityIncrease hierarchyFertilising methodsHorticultureNicotiana tabacumQuality level

The invention discloses a cultivation method for Yunnan flue-cured tobacco 97. The problems that on conventional cultivation conditions, individual development goes beyond the limit, the group structure excessively grows, the ventilation and light transmission performance is poor, tobacco leaves cannot be really matured, and the quality level, industrial availability and benefit level of the tobacco leaves are low are solved by changing fertilizer and controlling row spacing and planting distance. The individual development level and group development level of the tobacco plants are improved and coordinated, the medium tobacco is cultivated, the tobacco leaves are matured really, the tobacco quality, tobacco planting benefit and industrial availability are improved, the fertilizer cost is reduced, and the cost-saving and income-increasing purposes are achieved.

Owner:ANHUI WANNAN TOBACCO LEAF

A Personalized Text Recommendation Method Based on Deep Learning

ActiveCN111209386BSolve the sparsity problemImprove training efficiencyDigital data information retrievalNeural learning methodsPersonalizationHidden layer

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Toasting process that can reduce protein content in flue-cured tobacco

InactiveCN103798945BIncrease hierarchyImprove sensory qualityTobacco preparationChemical qualityNitrogen

The invention discloses a flue-curing process method capable of reducing protein content in the flue-cured tobacco. The process method disclosed by the invention is implemented according to the following steps of: A, preparing the flue-cured tobacco and placing the flue-cured tobacco into flue-curing equipment; B, sequentially carrying out six continuous flue-curing stages comprising four short-time flue-curing stages and two long-time flue-curing stages in the flue-curing process of the flue-cured tobacco; C, after flue-curing, obtaining the flue-cured tobacco with low protein content. According to the invention, on the premise of ensuring quality of the flue-cured tobacco, the step of controlling the content of a protein which is an important nitrogen-containing compound is migrated to the tobacco leave modulating stage, so that the flue-curing process method is helpful for improving chemical quality of tobacco leaves, and thus, damage of smoking to health of human bodies is further reduced. By the process conditions of the flue-curing process method, compared with a flue-cured sample in a conventional method, the flue-cured tobacco leaves has the advantages that the appearance quality, the proportion of medium-class and first-class tobacco and the smoking quality are all improved and the release amount of the protein is reduced by 15 percent to 25 percent.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

Multi-condition reception supporting system and method used for set up box

ActiveCN101184196BIncrease hierarchyImprove reusabilitySelective content distributionSupporting systemSoftware engineering

The invention discloses a system and a method for multi-condition receiving and support on the set-top box; the method is used in the set-top box system formed by an interlayer, a software development kit module and a portable application programming interface module. The interlayer comprises a video and audio control object, a service information engine object and a condition receiving object interface. The method comprises two concurrent processes of a background processing of the authorization management information and a radio station processing. The multi-condition receiving and support system used in the set-top box of the invention comprises an interlayer and a portable application programming interface module, and the interlayer further comprises: a video and audio control object and a condition receiving object interface, and a service information engine object used to acquire the related control information of the condition receiving according to analyzing the service information form; the portable application programming interface module can be used to support the broadcasting of the video and audio, the receiving of the service information and the condition receiving data, the transmission of the smart card data, the usage of the descrambling device and the invoke of the operating system.

Owner:上海云视科技股份有限公司

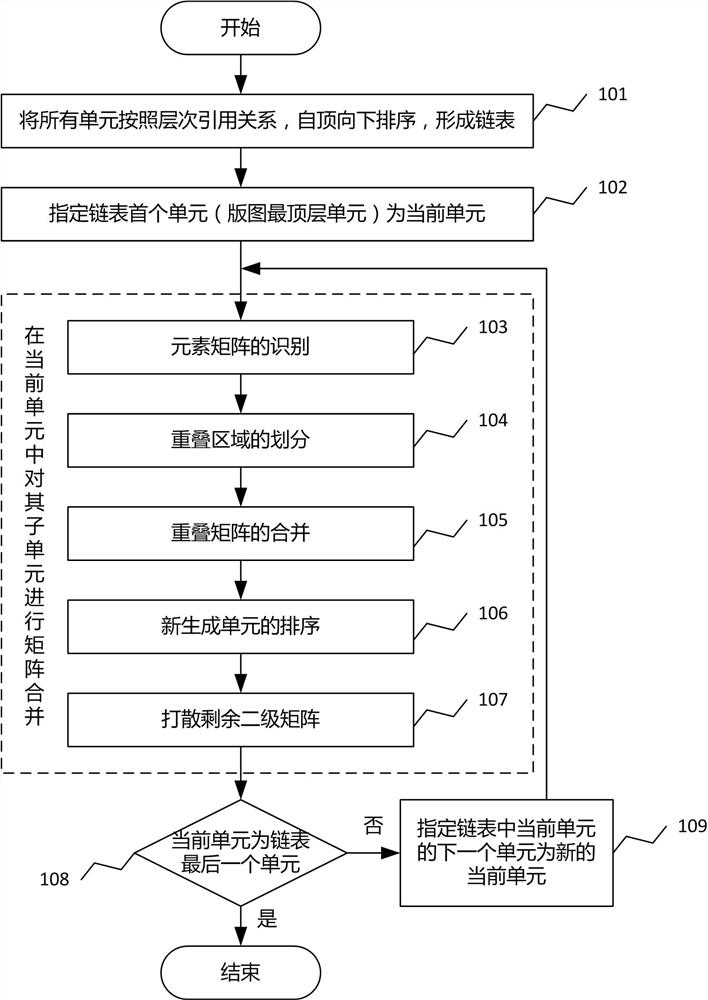

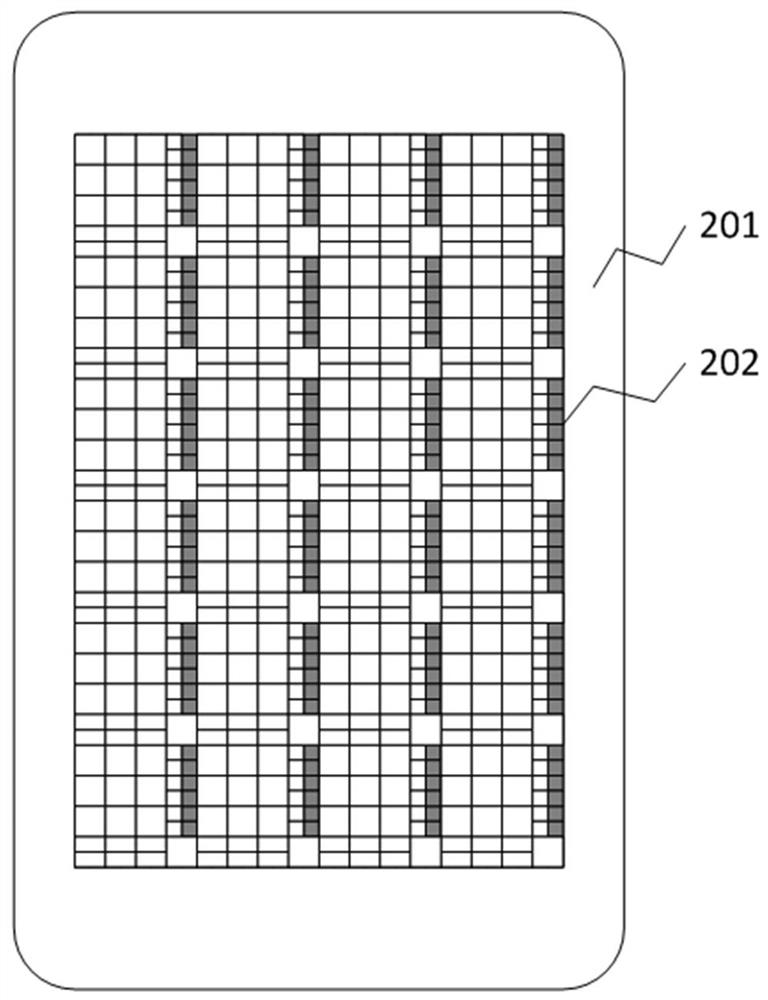

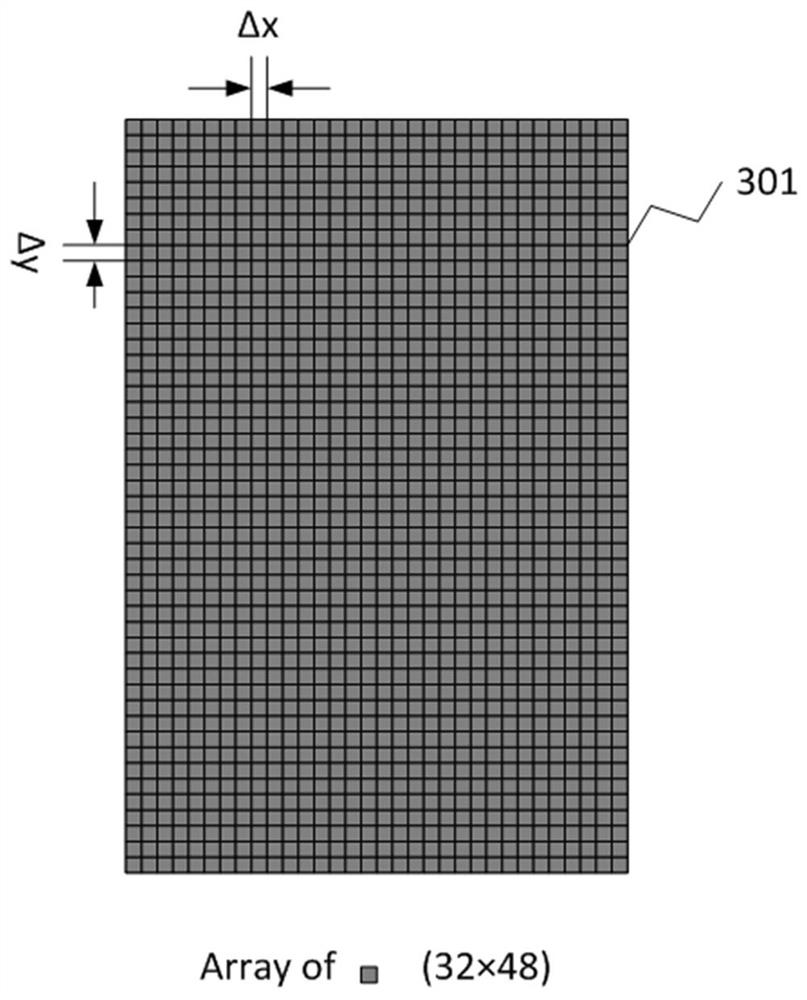

A Cell Matrix Merging Method in Physical Verification of Flat Panel Display Layout

ActiveCN111008513BReduce overlapping areasAvoid Worst-Case LayoutsComputer aided designSpecial data processing applicationsCurrent cellTopological order

A cell matrix merging method in physical verification of flat panel display layout, comprising the following steps: 1) performing topological sorting of cells, sorting all cells from top to bottom according to a hierarchical reference relationship, and forming a linked list; 2) specifying a current cell, and performing element sorting Recognition of the matrix; 3) The calculation unit refers to the overlapping area, and divides the current unit into multiple blocks according to the overlapping area; 4) In each overlapping area block, merge the overlapping matrices in sequence to form a new unit , form a matrix of new units; 5) Insert a new unit linked list after the current unit, maintaining the topological order of the entire linked list. The unit matrix merging method in the physical verification of the layout of the flat panel display of the present invention reduces the overlapping area between the unit references to the greatest extent, avoids the occurrence of the worst situation of the layout layout, significantly improves the execution efficiency, and significantly optimizes the result level. And the follow-up operations are very positive.

Owner:北京华大九天科技股份有限公司

Toasting process for reducing the release of benzopyrene in flue-cured tobacco

InactiveCN103815533BReduced release of benzopyreneIncrease hierarchyTobacco preparationWet-bulb temperatureDry-bulb temperature

The invention discloses a baking process method for reducing the release amount of benzopyrene in flue-cured tobacco. A tobacco curing process is partitioned into six stages, the dry-bulb temperature is set to gradually raise between 35 DEG C and 68 DEG C, the wet-bulb temperature is 33-42 DEG C, the temperature raising rate is 0.2-0.8 DEG C / h, the relative humidity is 22-87 percent and falls in sequence, the baking time is 13-57 hours, and the first four stages are shorter in baking time while the last two stages are longer in baking time. The six stages are carried out continuously. After baking, the release amount of the benzopyrene in tobacco leaves is lowered by over 20 percent than that of benzopyrene in a blank control, the grade structure of the tobacco leaves is improved, the sensory quality of the tobacco leaves is improved, and the quality and amount of aroma are improved greatly. Moreover, irritation and offensive odor are reduced, the price of the baked tobacco leaves is higher, and the economic value of the tobacco leaves is raised.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

Polymer solar cell with reverse structure and preparation method thereof

ActiveCN102280586BHighlight substantive featuresOriginal and innovativeSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeOptical energy

The invention discloses a polymer solar cell with a reverse structure and a preparation method thereof and relates to a solid apparatus especially suitable for converting optical energy into electric energy. The cell is a polymer solar cell which is of a reverse structure and has a three-component photoactivity film in a layered structure; the polymer solar cell is composed of a cathode layer, anorganic N-type doped electron hole barrier layer, a three-component photoactivity layer, an organic P-type doped electron hole transmission layer and an anode layer which are orderly deposited on a glass substrate, wherein the mass proportion of the three-component film is as follows: P3HT:PC61BM:BCP=12:10:(0.01-12):10:0.1 or PCPDTBT:PC71BM:Bphen=12:15:(0.01-12):15:0.1. The energy conversion efficiency of the three-component photoactivity layer is 20% higher than the existing two-component photoactivity layer, and a filling factor is further 10% higher than that in the prior art; and meanwhile, the defects of the existing polymer solar cell with a reverse structure are overcome.

Owner:HEBEI UNIV OF TECH

Device and method for repairing polluted water source with multi-media biological filter bed

ActiveCN104528939BIncrease hierarchySimple hierarchyTreatment with aerobic and anaerobic processesEnergy based wastewater treatmentWater sourceBiological filter

The invention discloses a device and method for restoring a polluted water source through a multi-media bio-filter. The device is used for restoring polluted water of an upstream river way of a river type water source. A dam is arranged in the upstream river way. The device is arranged on the outer side of the dam. The device comprises a tower layer frame, carrier packing layers and a water collector. Water distributors are arranged at the upper end of the tower layer frame and used for introducing the polluted water source in the dam into the tower layer frame. The multiple carrier packing layers are arranged in the tower layer frame from top to bottom. The water collector is arranged at the lower end of the tower layer frame, collects the water source filtered through the carrier packing layers and drains the water source to a downstream river way. By the adoption of the device and method for restoring the polluted water source through the multi-media bio-filter, the water quality of the water source can be improved, the water body of the water source can be restored, the functions of the water source can be restored, and the safety of drinking water can be guaranteed.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com