Flue-curing process method capable of reducing protein content in flue-cured tobacco

A technology of protein content and baking process, applied in tobacco, tobacco preparation, application, etc., can solve the problems of protein reduction, coordination, and cigarette cost increase, and achieve the effects of promoting degradation and transformation, improving sensory quality, and improving sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

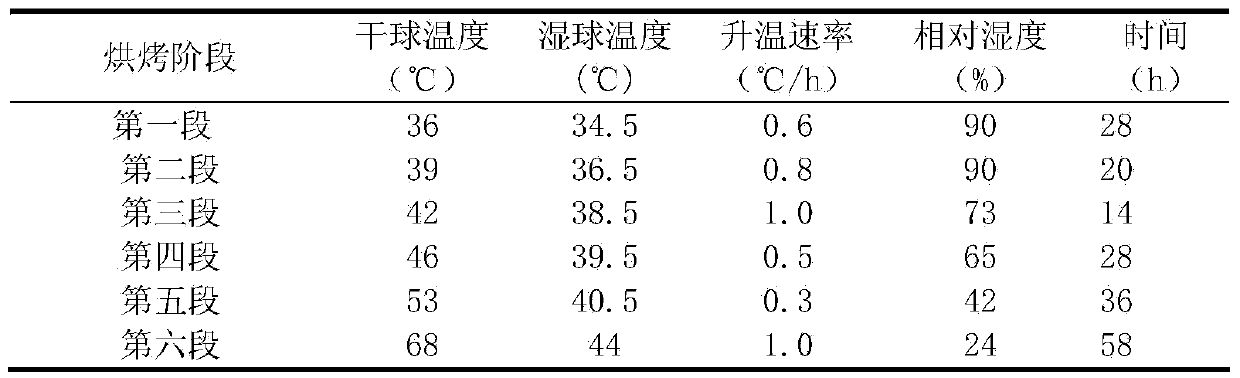

[0048] The baking process conditions of four short-time baking stages and two long-time baking stages of the present embodiment are as follows:

[0049] The process conditions of the first short-time baking stage are: the dry bulb temperature of baking is 36°C, the wet bulb temperature is 34.5°C, the relative humidity is 90%, the baking time is 28h, the temperature rise of the dry bulb temperature and the wet bulb temperature The rate is 0.6°C / h;

[0050] The process conditions of the second short-time baking stage are: the dry bulb temperature of baking is 39°C, the wet bulb temperature is 36.5°C, the relative humidity is 90%, the baking time is 20h, the temperature rise of the dry bulb temperature and the wet bulb temperature The rate is 0.8°C / h;

[0051] The process conditions of the third short-time baking stage are: the dry bulb temperature of baking is 42°C, the wet bulb temperature is 38.5°C, the relative humidity is 73%, the baking time is 14h, the temperature rise of...

Embodiment 2

[0072] The baking process conditions of four short-time baking stages and two long-time baking stages of the present embodiment are as follows:

[0073] The process conditions of the first short-time baking stage are: the dry bulb temperature of baking is 32°C, the wet bulb temperature is 31°C, the relative humidity is 85%, the baking time is 16h, the temperature rise of the dry bulb temperature and the wet bulb temperature The rate is 1.0°C / h;

[0074] The process conditions of the second short-time baking stage are: the dry bulb temperature of baking is 35°C, the wet bulb temperature is 33°C, the relative humidity is 90%, the baking time is 26h, the temperature rise of the dry bulb temperature and the wet bulb temperature The rate is 0.5°C / h;

[0075] The process conditions of the third short-time baking stage are: the dry bulb temperature of baking is 38°C, the wet bulb temperature is 34°C, the relative humidity is 72%, the baking time is 30h, the temperature rise of the d...

Embodiment 3

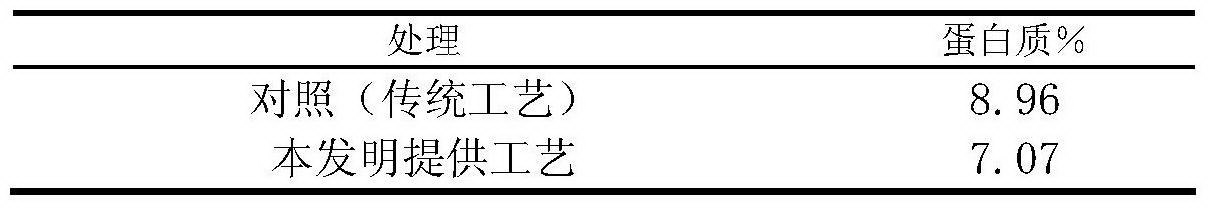

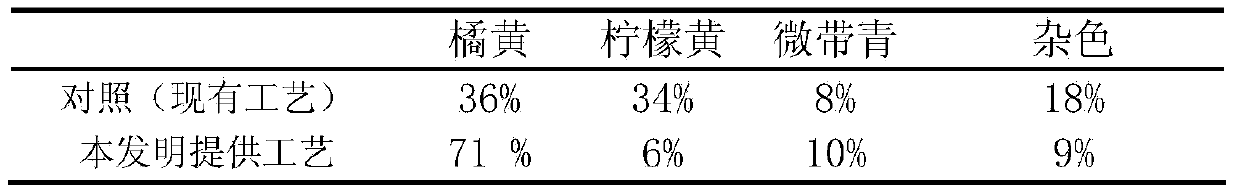

[0098] In this example, Yunyan 87 is used as the material, and the tobacco leaf samples come from concentrated and contiguous tobacco fields with an area of about 200 mu and a relatively flat terrain. The tobacco leaf transplanting period, fertilization and management measures are basically the same. The growth, development and maturity of the tobacco leaves are normal, and the size, position, nutritional level and maturity of the tobacco leaves are basically the same, and the leaves are in the 9th to 11th positions in the middle. Tobacco leaves with consistent maturity were harvested, and the test tobacco leaves were listed according to the leaf position requirements before harvesting. Based on the classification of fresh tobacco leaves, the same stalk is of the same quality. When loading cigarettes, the pole distance between the upper and lower layers is balanced and consistent to ensure that the fresh weight of a single pole is basically the same.

[0099] Tobacco leaves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com