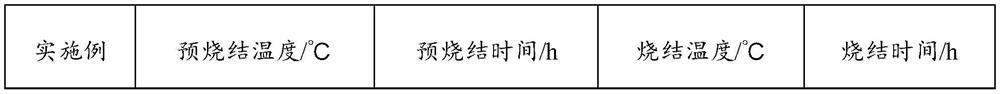

Patents

Literature

33results about How to "Improve sintering stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

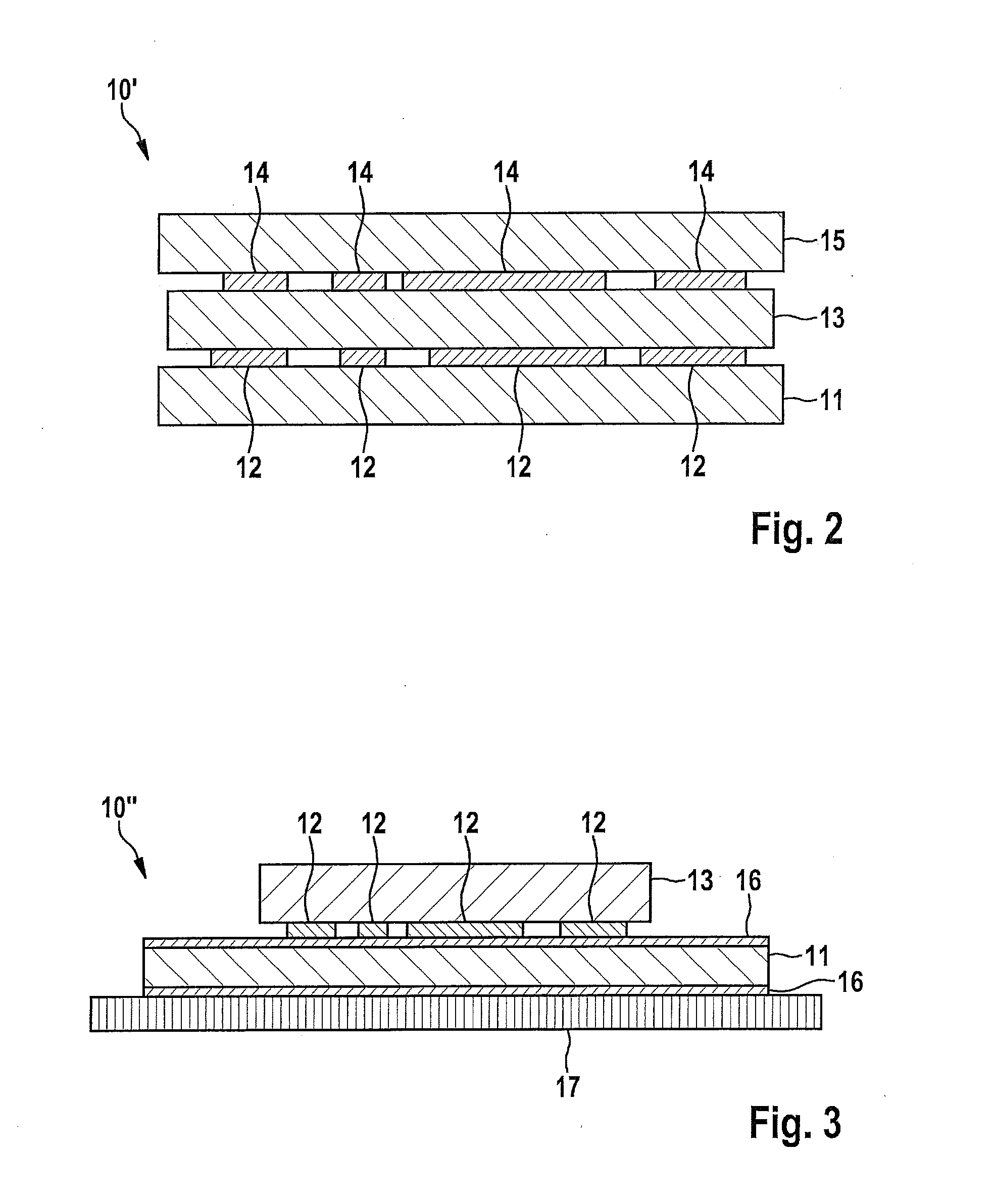

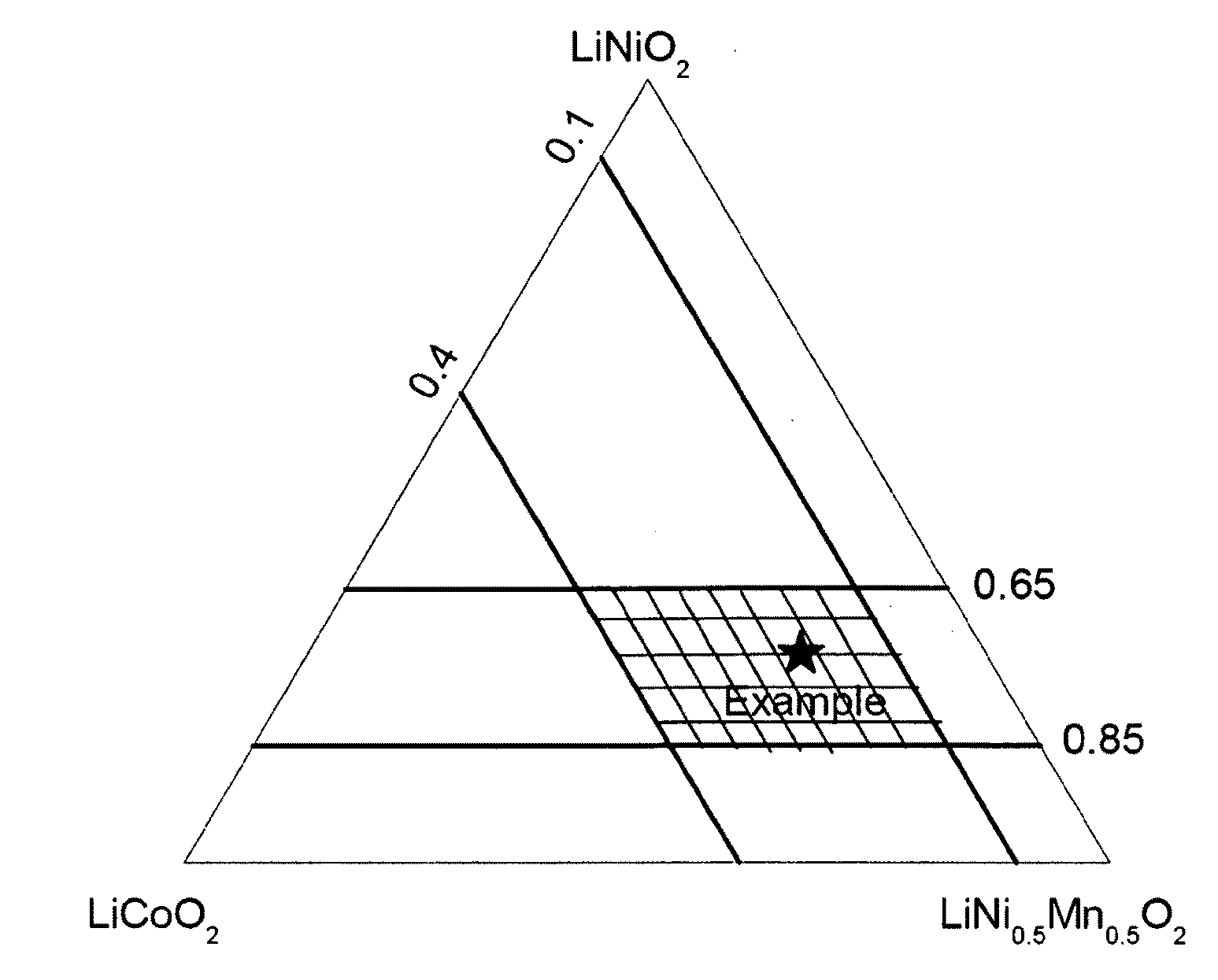

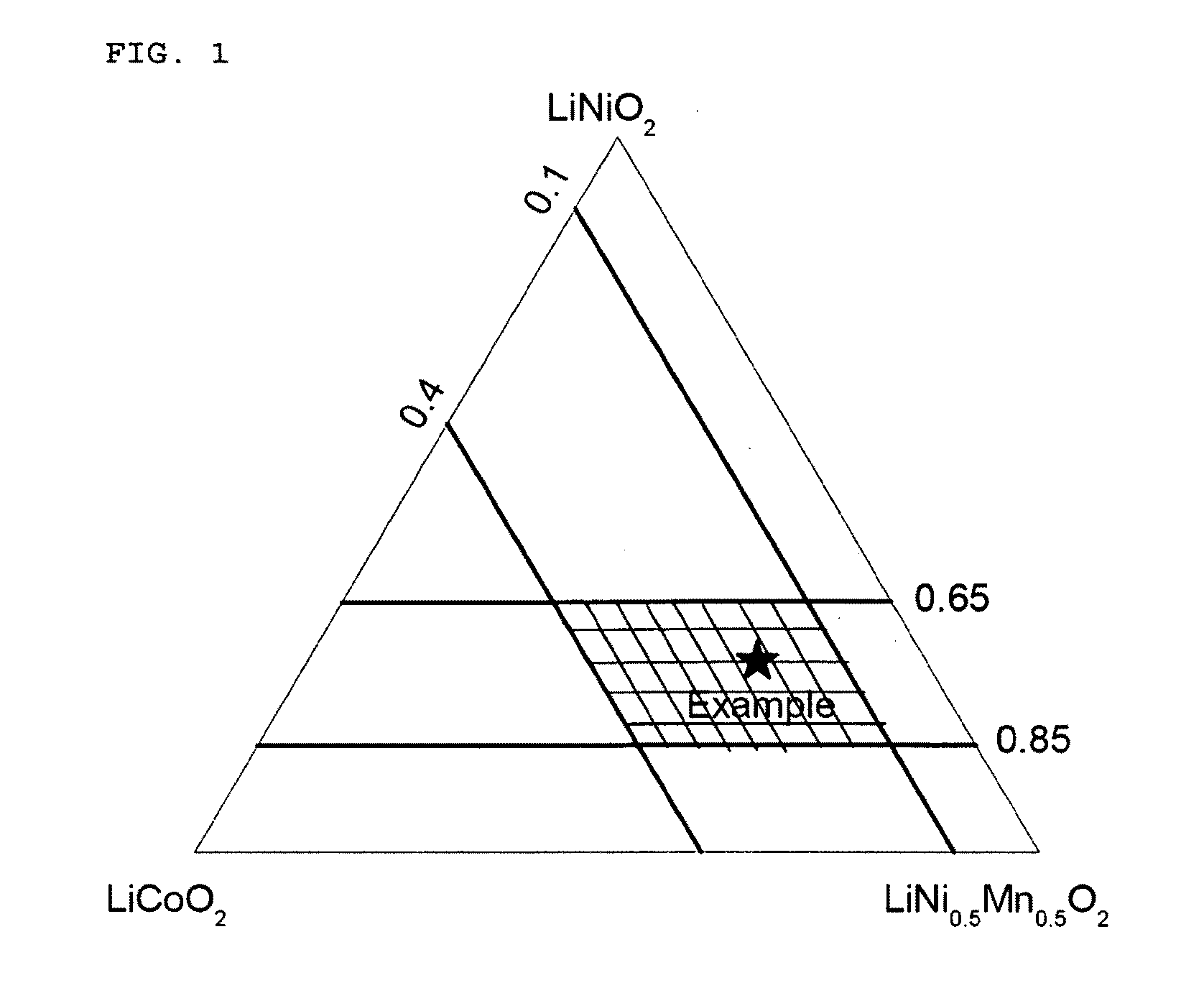

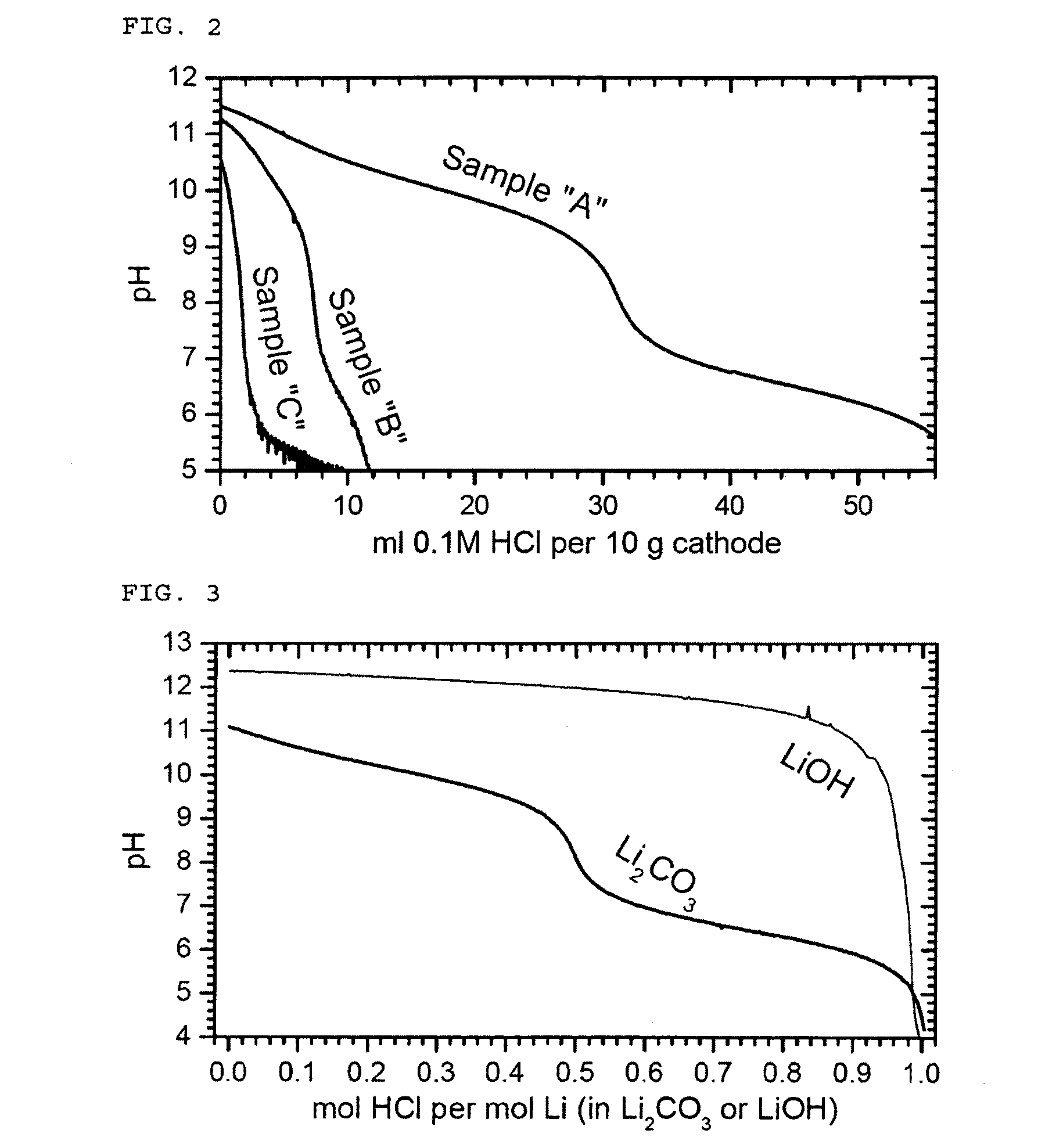

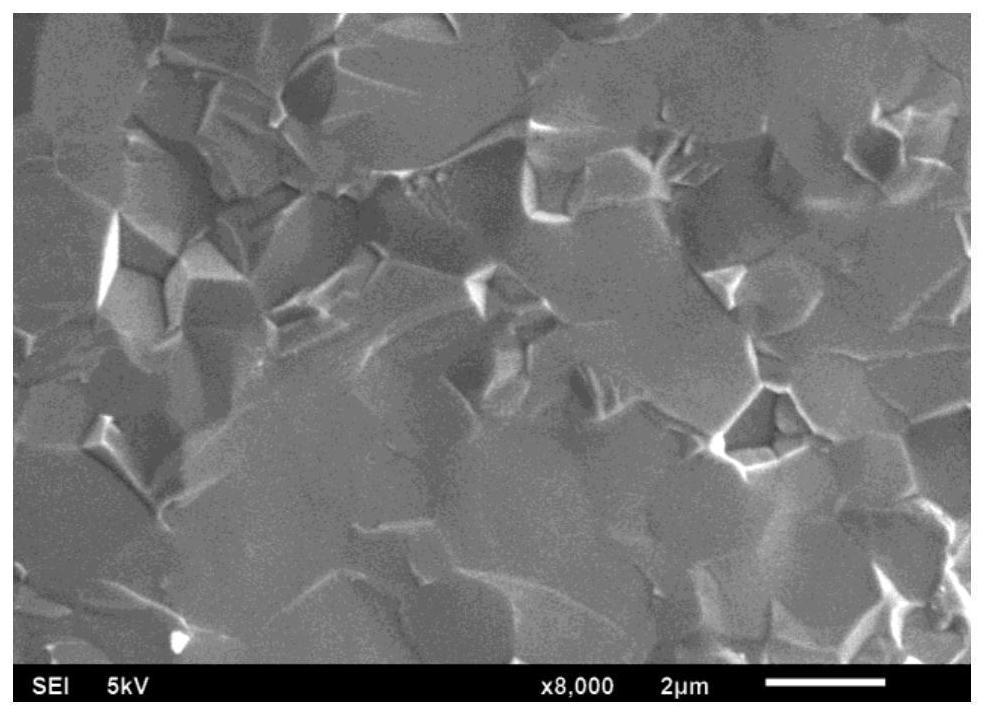

Ni-based lithium transition metal oxide

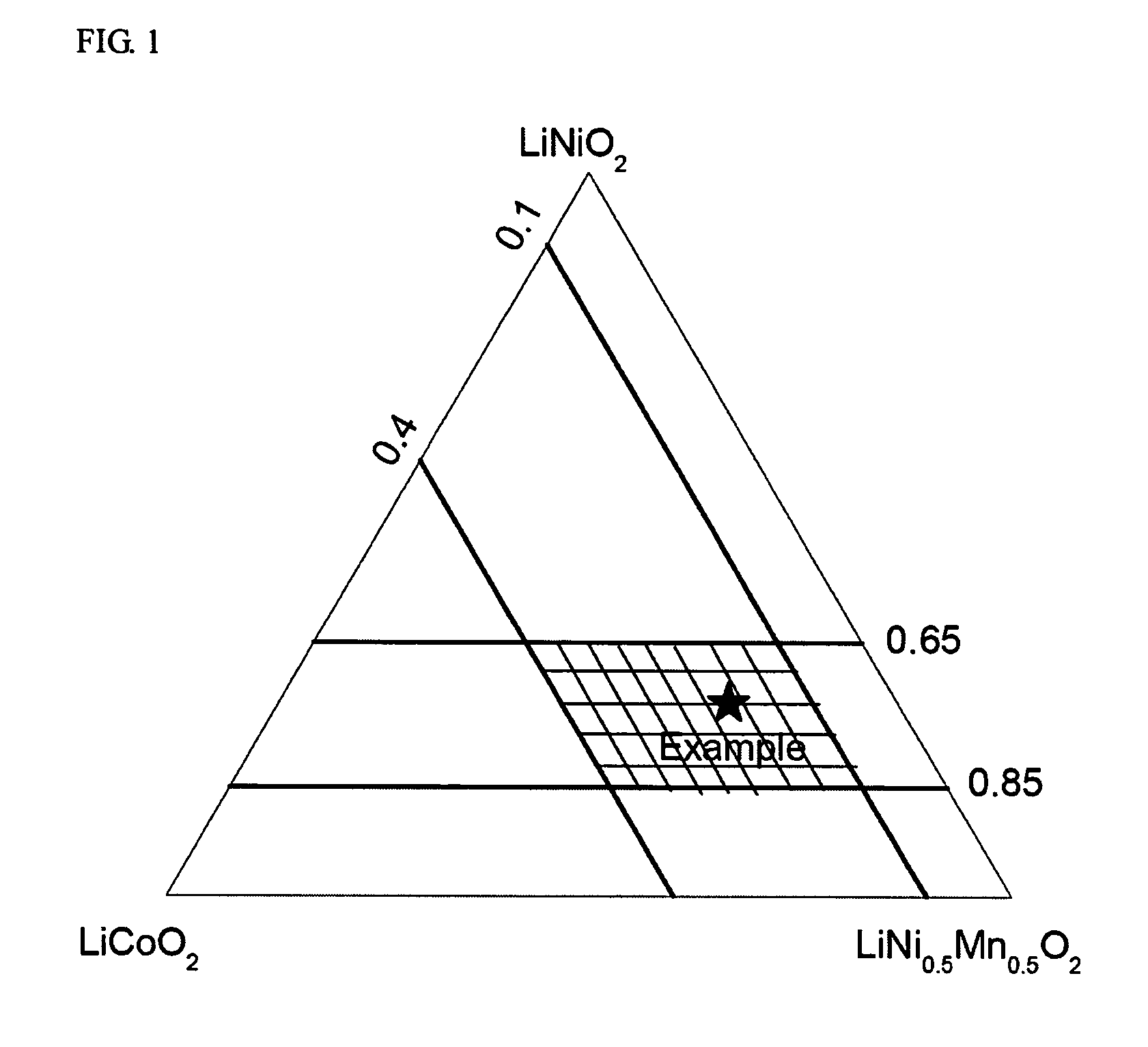

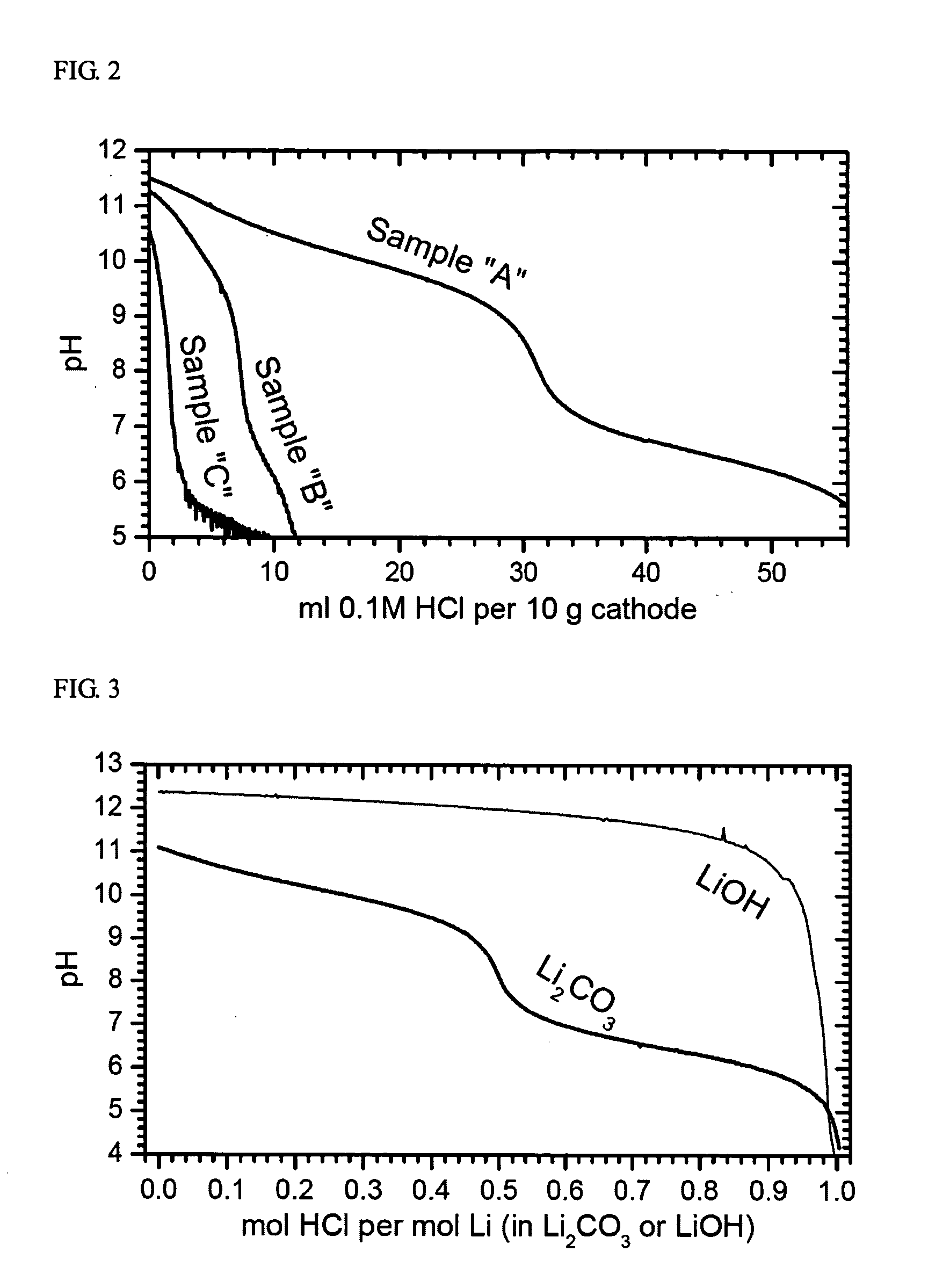

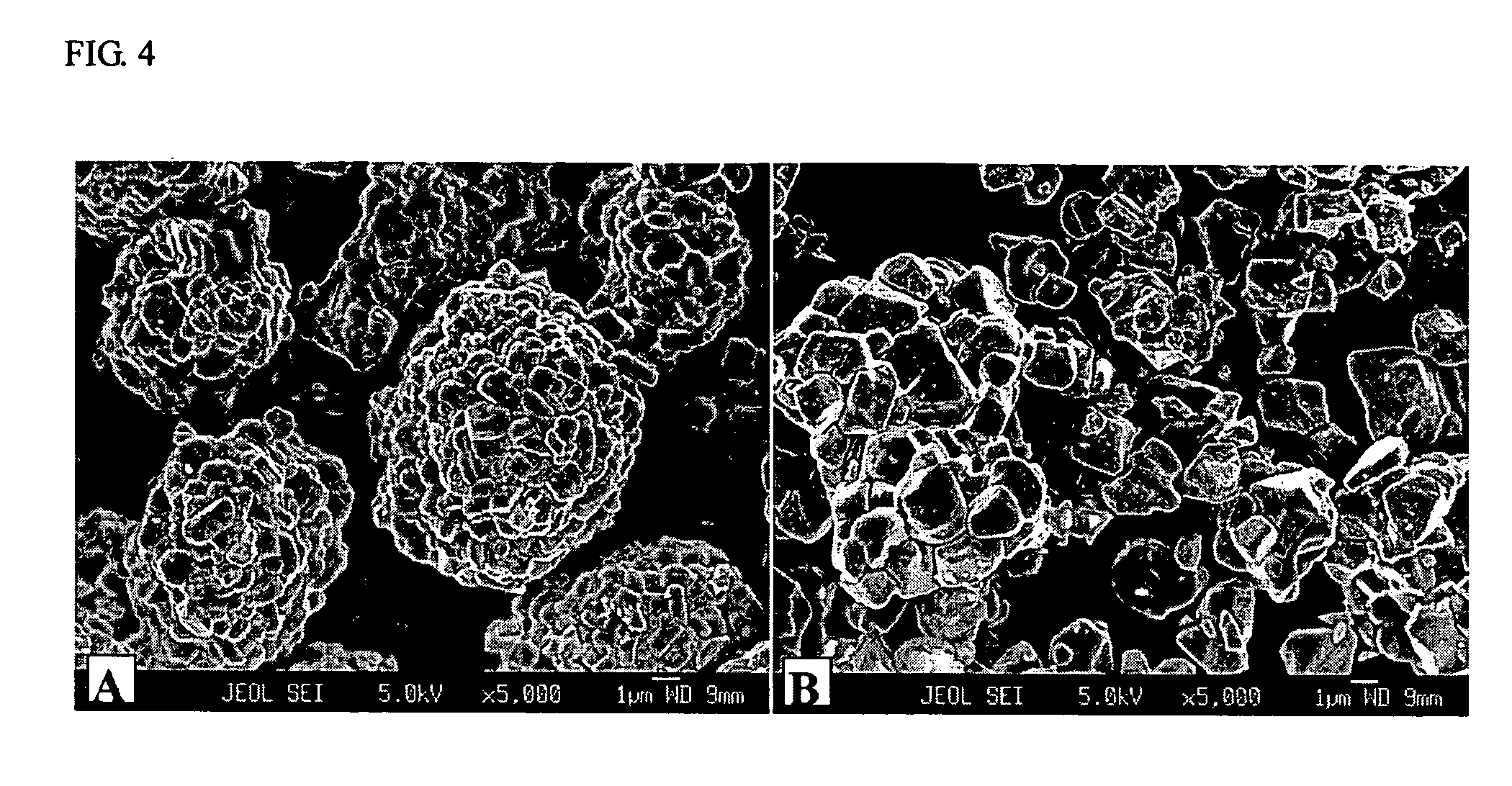

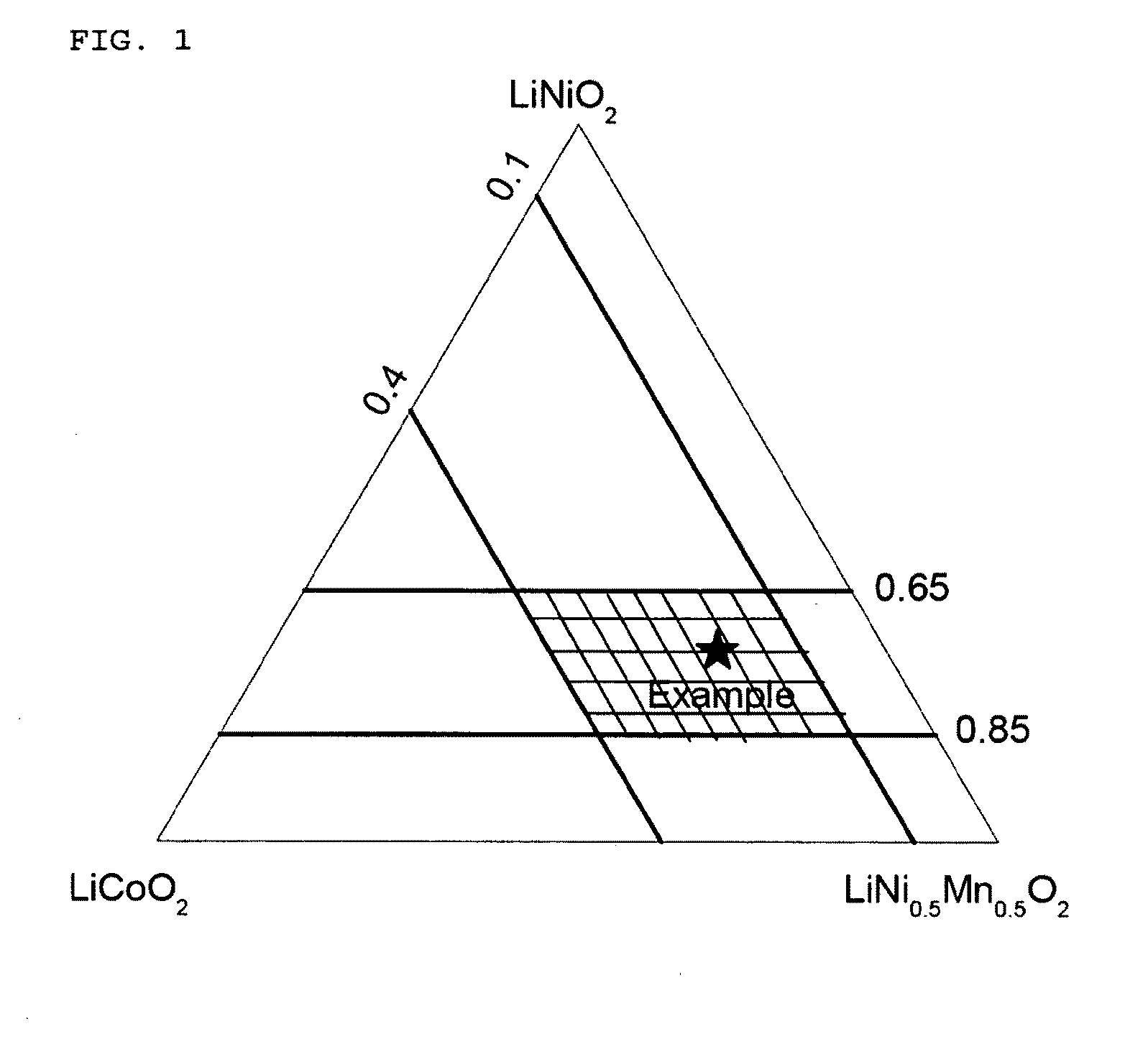

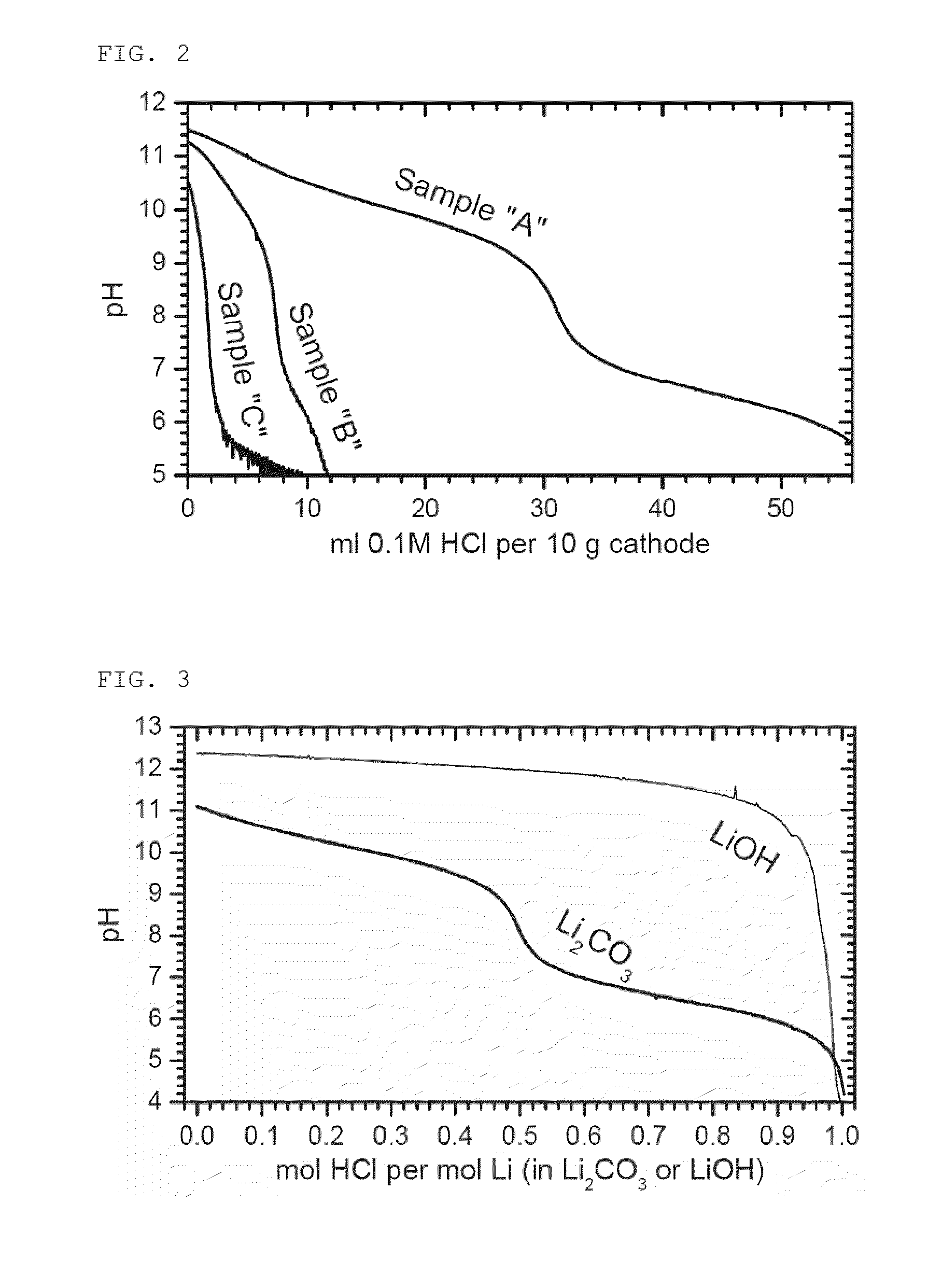

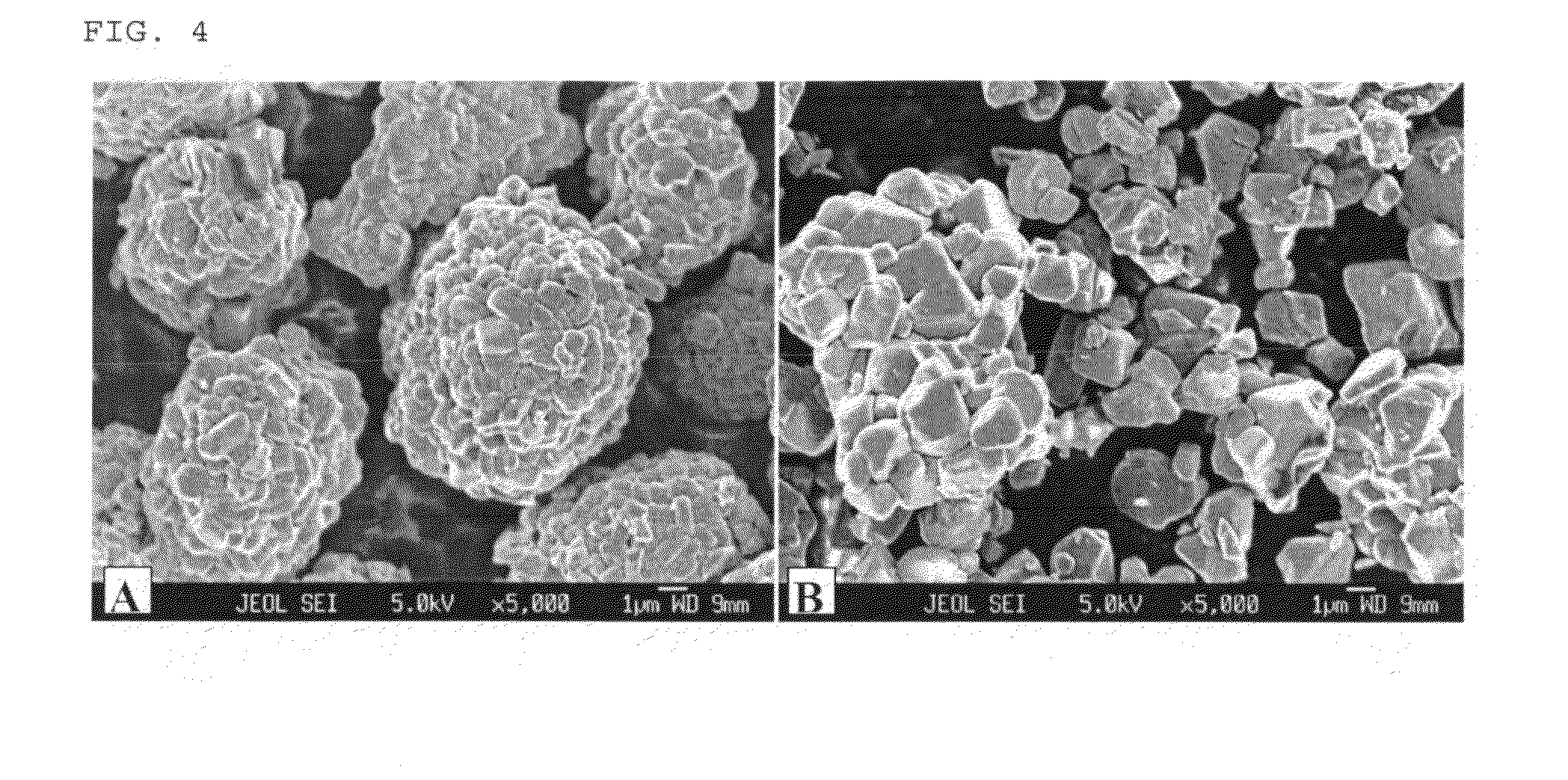

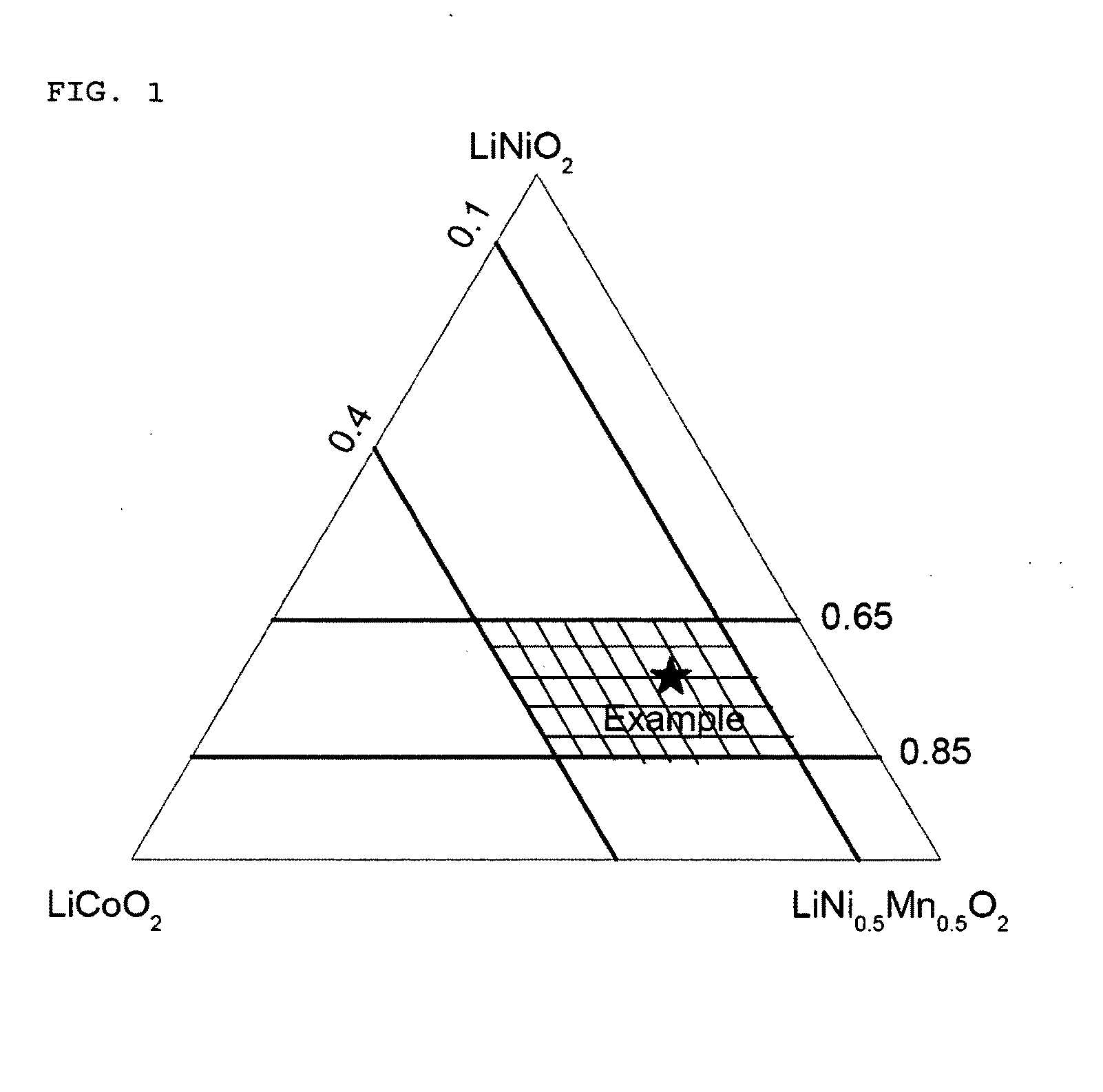

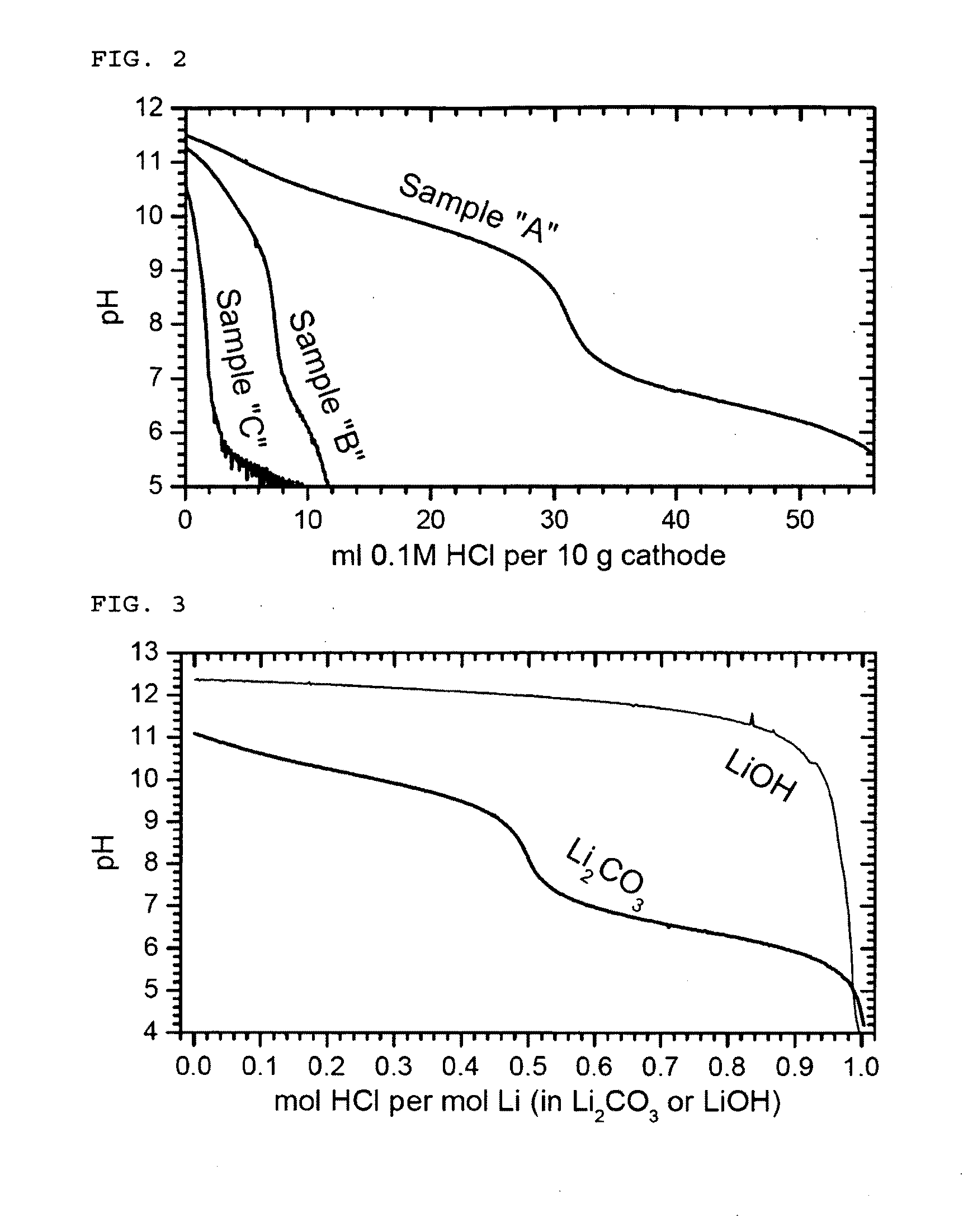

The present invention provides a powderous lithium transition metal oxide with the composition as represented by the below Formula and prepared by solid state reaction in air from a mixed transition metal precursor and Li2CO3, with being practically free of Li2CO3 impurity: LixMyO2 wherein M=M′l-kAk, where M′=Nil-a-b(Ni1 / 2Mn1 / 2)aCob on condition of 0.65≦a+b≦0.85 and 0.1≦b≦0.4; A is a dopant; and 0≦k≦0.05; and x+y=2 on condition of 0.95≦x≦1.05. The Ni-based lithium transition metal oxide according to the present invention has a well-layered structure, and also improved safety, cycling stability and stability against aging and low gas evolution during storage, when used as an active material for cathode of lithium secondary batteries, because it has a high sintering stability and is substantially free of soluble bases. Moreover, the lithium transition metal oxide of the present invention can be prepared by a low-cost process using a mixed transition metal precursor and Li2CO3 as raw stocks and under relatively unrestricted conditions.

Owner:LG ENERGY SOLUTION LTD

Battery containing ni-based lithium transition metal oxide

ActiveUS20090226810A1Increase hierarchyImprove securityEnergy inputAlkali metal oxidesElectrical batteryOxide cathode

Owner:LG ENERGY SOLUTION LTD

Supported catalysts having a high sintering stability and a process for producing them

InactiveUS6372687B1High activity and selectivityHigh operational lifeOrganic chemistry methodsOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl groupOrganic compound

Supported catalysts having a high sintering stability and comprising one or more noble metal cluster carbonyl compounds of the formula (1)and their use for the dehydrogenation, hydrogenation and oxidation of organic compounds wherewherein the compounds of the formula (1) are located in the pores of a mesoporous support material.

Owner:AVENTIS RES & TECH GMBH & CO KG

Method for preparing copper-based powder with low oxygen content and low apparent density through atomization

The invention discloses a method for preparing copper-based powder with low oxygen content and low apparent density through atomization, which comprises the following steps: melting metallic coppers into liquid copper; atomizing the liquid copper; carrying out absorption and filtration on the atomized liquid copper so as to obtain the copper-based powder. The invention is characterized in that in the process of atomization, two nozzles are arranged below the liquid copper, and arranged in a same vertical line so as to form two focuses; the diameter of an orifice is 1.2 to 1.5mm; and atomized vertical angles are respectively 28 to 32 degrees and 18 to 22 degrees. The copper-based powder prepared by using the method of the invention has the advantages of low oxygen content, low apparent density and good metallurgical properties.

Owner:铜陵铜基粉体科技有限公司

Process of making cathode material containing Ni-based lithium transition metal oxide

ActiveUS20090224201A1Increase hierarchyImprove securityEnergy inputAlkali metal oxidesOxide cathodeImpurity

Owner:LG ENERGY SOLUTION LTD

Fuel pellet with continuous phase structure and preparation method of fuel pellet

InactiveCN108831575AHigh thermal conductivityImprove performanceNuclear energy generationReactors manufactureMetallurgyThermal conductivity

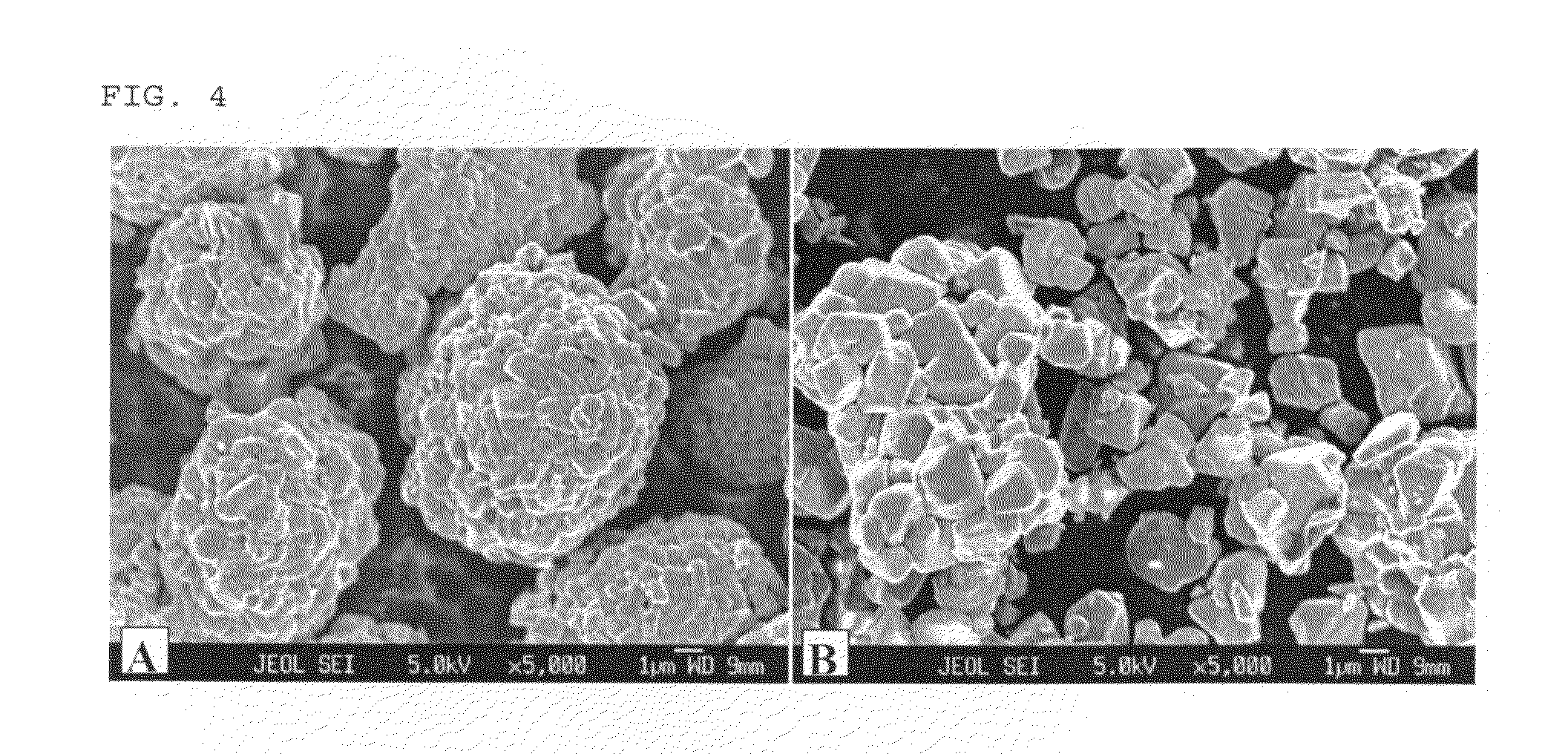

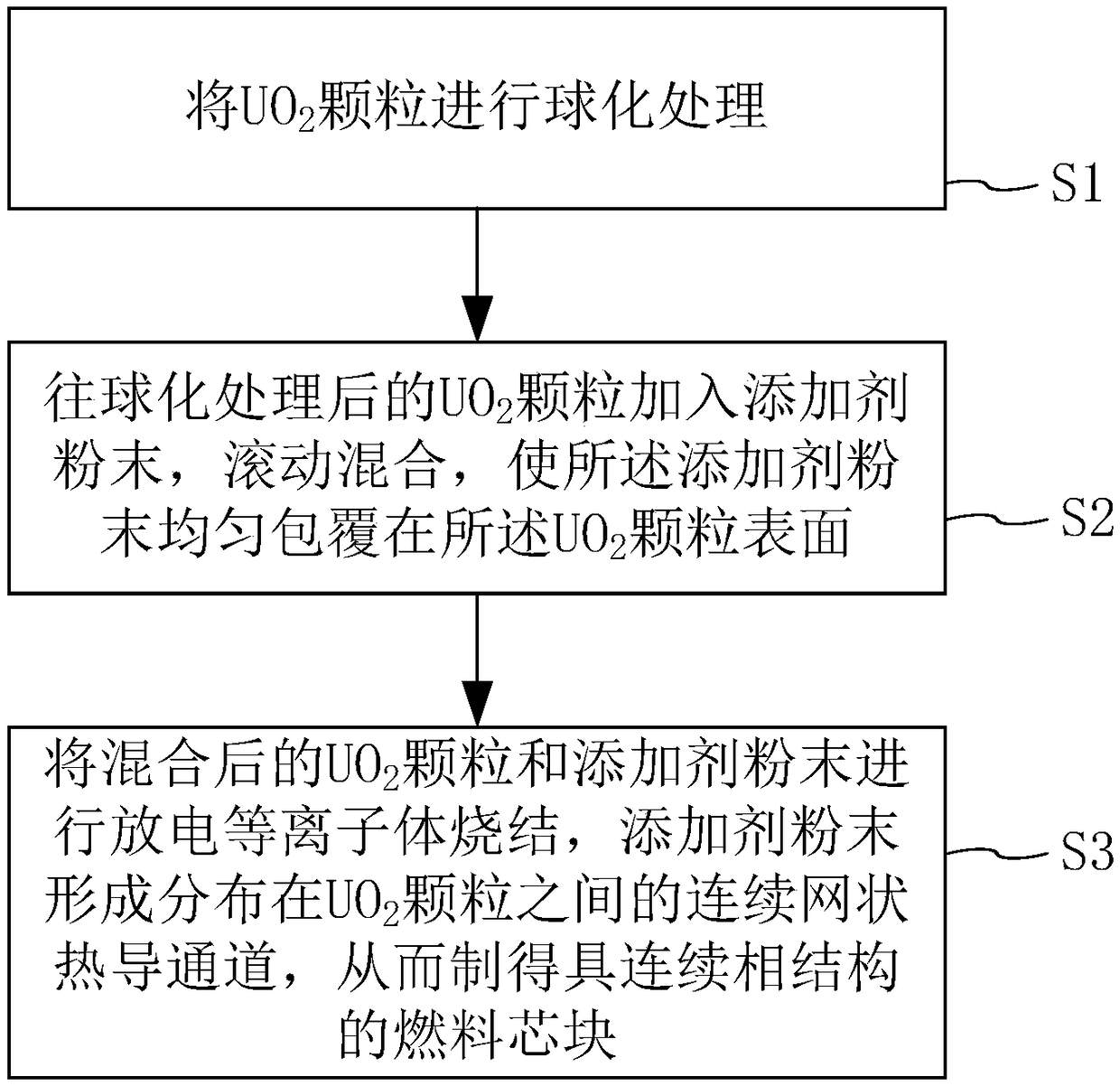

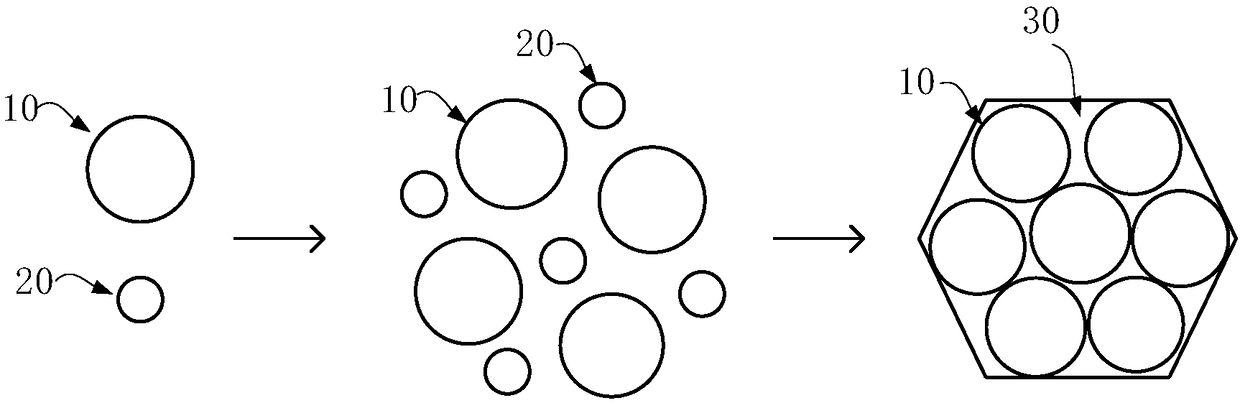

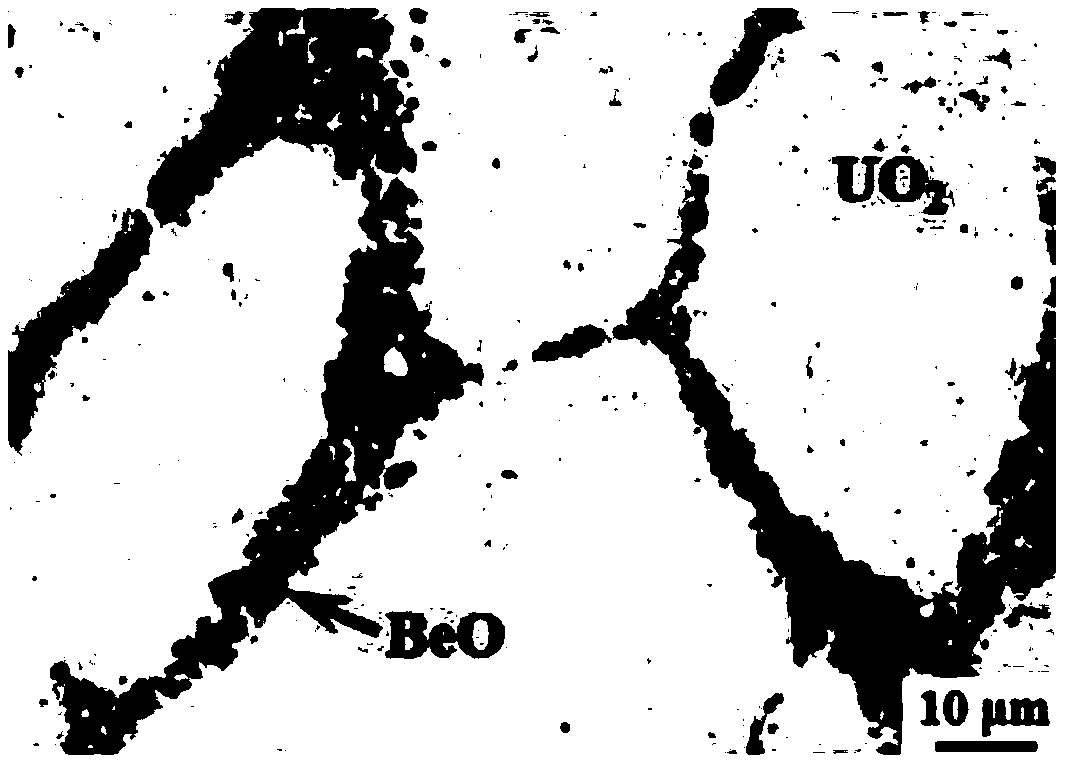

The invention discloses a fuel pellet with a continuous phase structure and a preparation method of the fuel pellet. The preparation method comprises the following steps: S1, spheroidizing UO2 particles; S2, adding additive powder into the spheroidized UO2 particles, and mixing the additive powder and the spheroidized UO2 particles in a rolling manner to uniformly cover the surfaces of the UO2 particles with the additive powder; and S3, performing discharge plasma sintering on the mixed UO2 particles and additive powder to allow the additive powder to form continuous meshed thermal conductancechannels distributed between the UO2 particles, thereby preparing the fuel pellet with the continuous phase structure. In the preparation method disclosed by the invention, the surfaces of the spheroidized UO2 particles are coated with the additive powder at first, and then the discharge plasma sintering is performed, so that the continuous meshed phase structure can be formed in the fuel pelletto reduce the preparation difficulty, and then the thermal conductivity and the comprehensive performance of the fuel pellet are improved, the sintering time is shortened, and the sintering efficiencyis improved.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

Microwave dielectric ceramic material and preparation method thereof

The invention provides a microwave dielectric ceramic material prepared by a composite oxide and an additive. The composite oxide is represented by the following general formula: MLa4Ti3M'O15, whereinM is Ca, Ba or Mg, and M' is Al, Sb or Bi. Compared with the prior art, the microwave dielectric ceramic material provided by the invention is prepared by the compound oxide represented by a specificgeneral formula and the additive and is a medium-dielectric-constant microwave dielectric ceramic; the microwave dielectric ceramic material satisfies the dielectric constant near 45 and is continuously adjustable, has an extremely high Q*f value and good sintering stability, and also can achieve continuous adjustment of temperature drift to meet various needs. Experimental results show that therelative dielectric constant [epsilon]r of the microwave dielectric ceramic material provided by the invention is 43.2-46.8, the quality factor Q*f value is more than or equal to 46200 GHz, and the sintering is stable; at the same time, the temperature drift adjusting range is from -8 to +13 ppm / DEG C and can be continuously adjustable to meet various needs, and the microwave dielectric ceramic material has excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Nano molybdenum disilicide-enhanced high-thermal-conductivity silicon carbide-based ceramic circuit board substrate material and preparation method thereof

The invention discloses a nano molybdenum disilicide-enhanced high-thermal-conductivity silicon carbide-based ceramic circuit board substrate material. According to a silicon carbide-based ceramic circuit board substrate, micron-sized silicon carbide powder and nano-sized aluminum oxide powder are compounded for use, so that a blank body is higher in density and better in sintering stability. The sintering temperature can be effectively decreased through added pyrophyllite. Nano molybdenum disilicide has the good reinforcement and toughening effect, can promote the thermal conductivity and does not damage the insulativity of the substrate. A polyethylene glycol complex solvent containing nano-ceramic powder transparent liquid has the high wettability and bonding capability for powder, the various materials can be evenly scattered and coated to form the blank body of a uniform structure, and the composite ceramic substrate with the high density, strength and thermal conductivity can be obtained at the relatively low temperature. The production process is safe and environmentally friendly, and the application potential is great.

Owner:HEFEI LONG DUO ELECTRONICS SCI & TECH

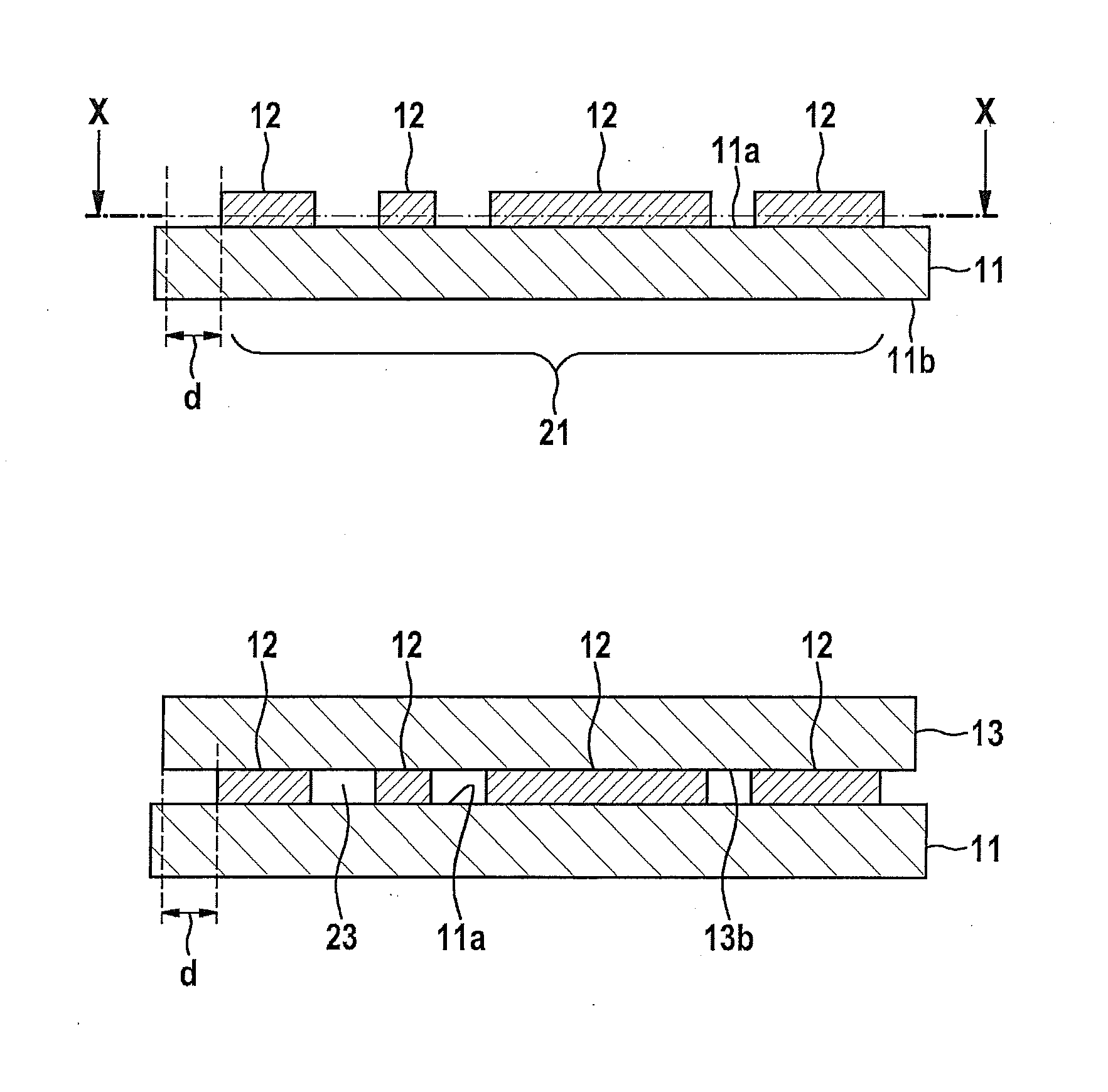

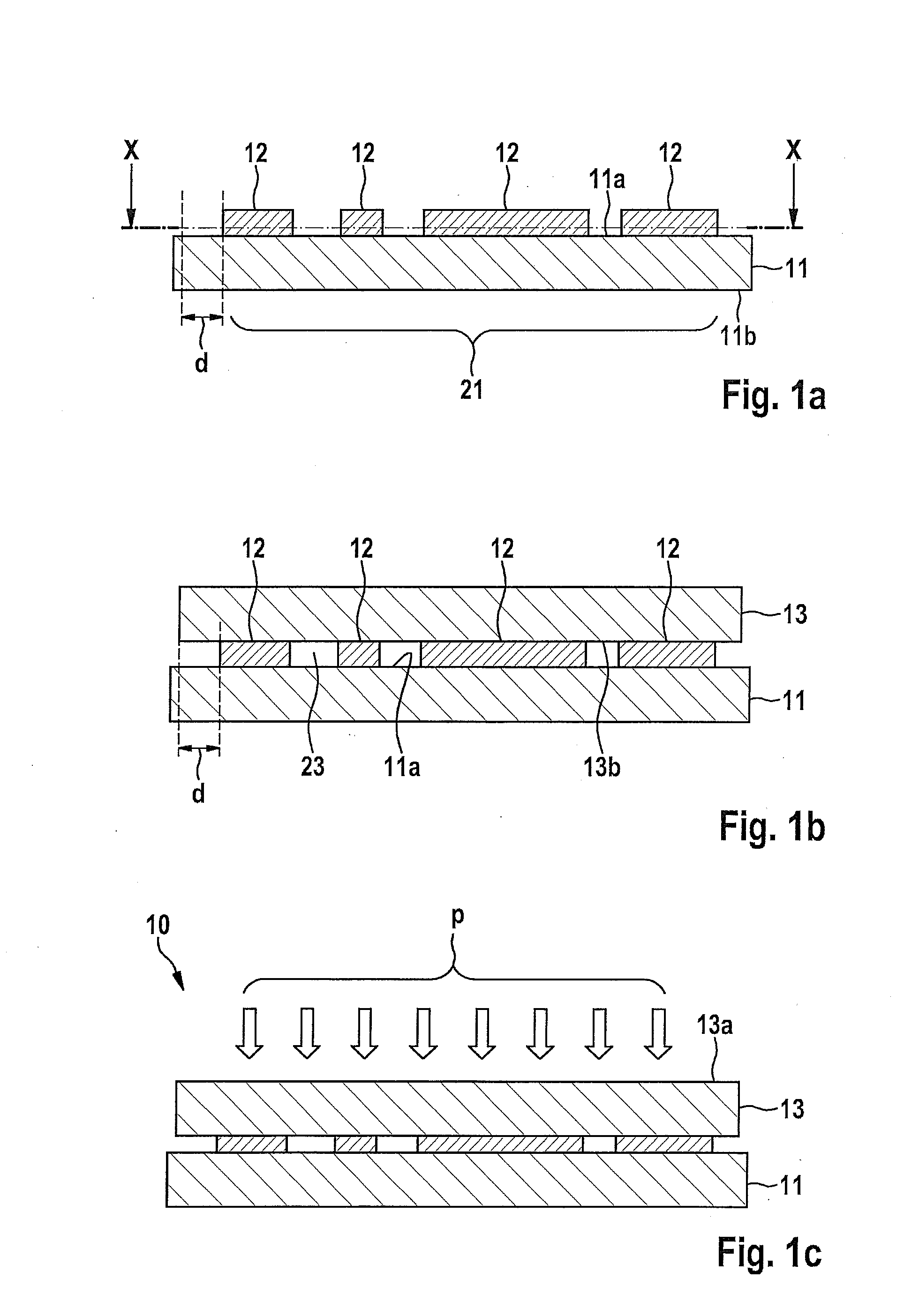

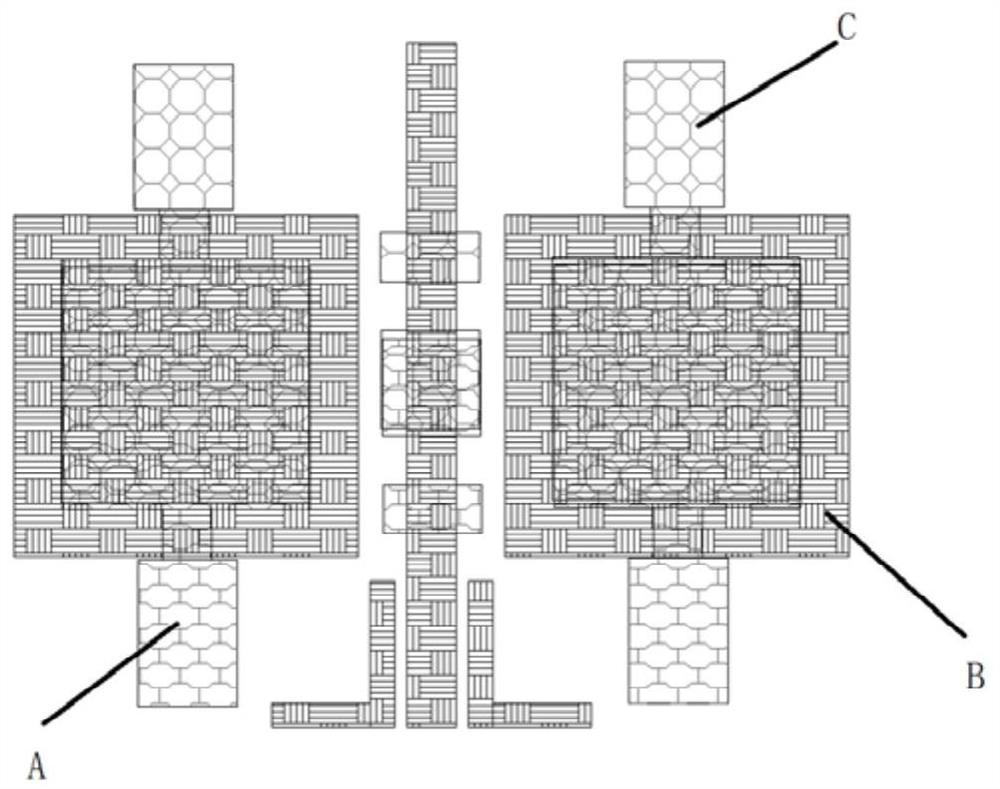

Method for Producing Structured Sintered Connection Layers, and Semiconductor Element Having a Structured Sintered Connection Layer

ActiveUS20140225274A1Satisfactory electric connectionSatisfactory thermal connectionSemiconductor/solid-state device detailsSolid-state devicesSurface coverMechanical tension

A method for producing a sinter layer connection between a substrate and a chip resulting in an electric and thermal connection therebetween and in reduced mechanical tensions within the chip. The method produces a sinter layer by applying a multitude of sinter elements of a base material forming the sinter layer in structured manner on a contact area of a main surface of a substrate; placing a chip to be joined to the substrate on the sinter elements; and heating and compressing the sinter elements to produce a structured sinter layer connecting the substrate and chip and extending within the contact area, the surface coverage density of the sinter elements on the substrate in a center region of the contact area being greater than the surface coverage density of the sinter elements in an edge region of the contact area, and at least one through channel, extending laterally as to the substrate's main surface being provided towards the contact area's edge. A large-area sinter element is situated in the contact area's center region, and circular sinter elements is situated in a contact area edge region. The sinter elements may also have notches. Also described is a related device.

Owner:ROBERT BOSCH GMBH

Cathode material containing Ni-based lithium transition metal oxide

ActiveUS20090224215A1Increase hierarchyImprove securityConductive materialEnergy inputOxide cathodeImpurity

Owner:LG ENERGY SOLUTION LTD

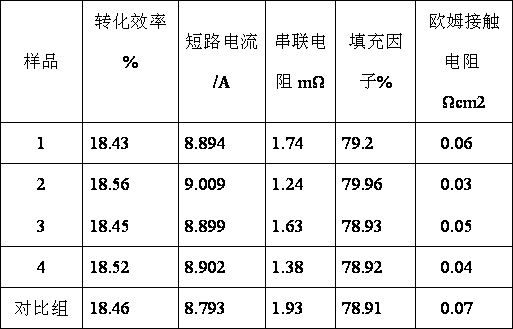

Conductive slurry used for solar energy battery

InactiveCN108666008AImprove conversion efficiencySpeed up the flowNon-conductive material with dispersed conductive materialPhotovoltaic energy generationFine lineSlurry

The invention discloses a conductive slurry used for a solar energy battery. The conductive slurry is prepared from the following components, by weight: 75-92 parts of silver powder, 5-12 parts of anorganic solvent, 2-3 parts of an organic carrier, 0.5-1 part of alkyl phenol polyoxyethylene ether, and 0.8-5.3 parts of metal microcrystalline glass powder. The particle size D50 of the metal microcrystalline glass powder is 0.3-2 [mu]m. The metal microcrystalline glass powder is prepared from the following components: 10-50 parts of tellurium dioxide, 15-70 parts of bismuth oxide, 2-10 parts ofzinc oxide, 1-15 parts of tungsten oxide, 5-20 parts of lithium oxide, 0.4-2 parts of boric acid, 1-6 parts of molybdenum chloride, 1-4 parts of silicon oxide, and 1-2 parts of barium carbonate. The battery conversion efficiency is effectively improved, the conductive slurry has characteristics of large viscosity and large surface tension at high temperature, the molten glass does not flow easilyduring a slurry sintering process, and the fine line is maintained.

Owner:SUZHOU ISILVER MATERIALS

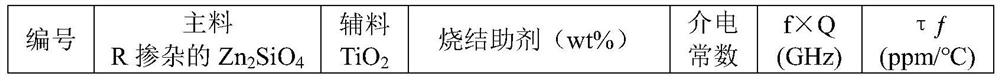

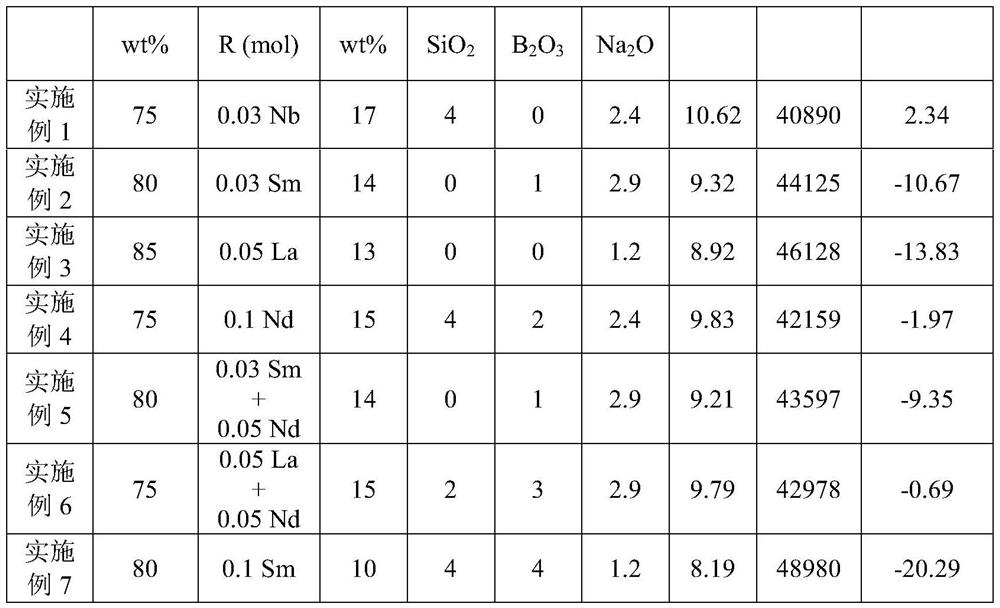

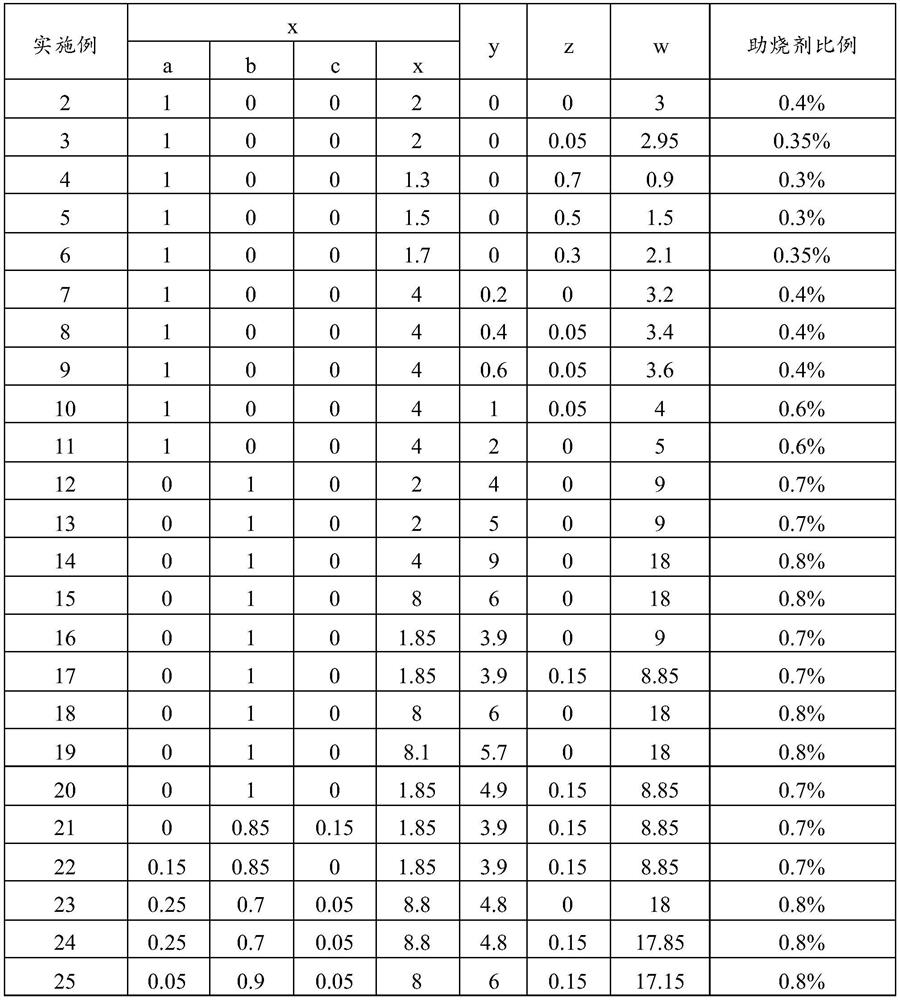

Low-dielectric-constant microwave dielectric ceramic material and ceramic component

ActiveCN112979297AImprove sintering stabilityFacilitate crystal phase synthesisMicrowaveDielectric permittivity

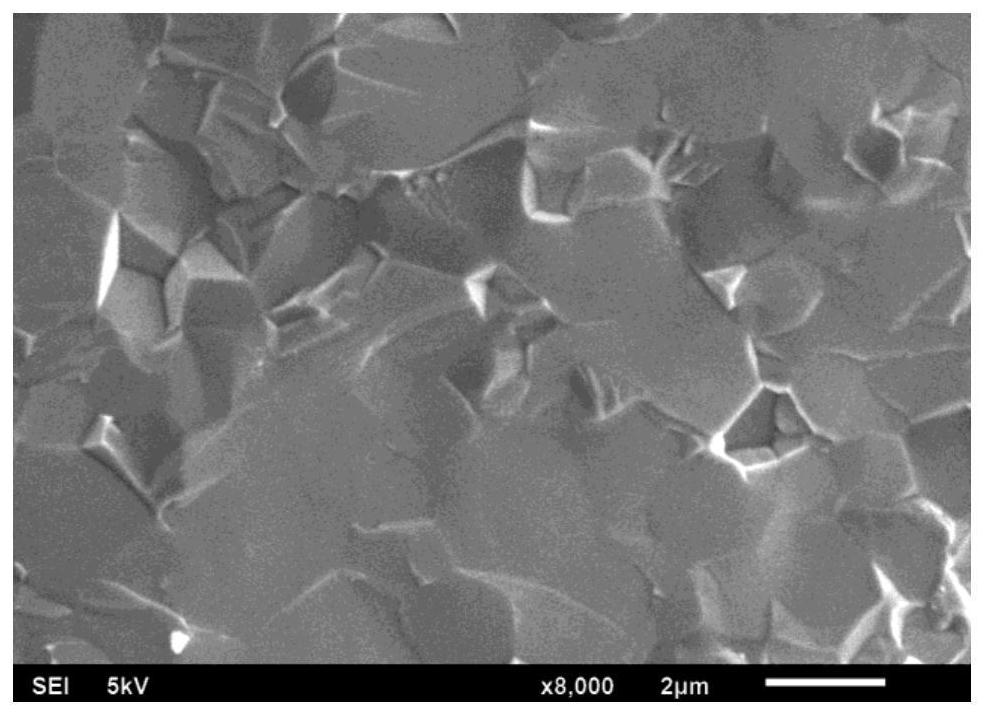

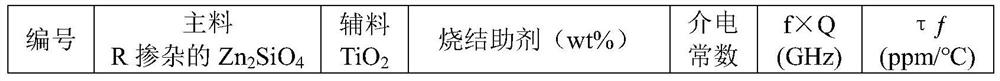

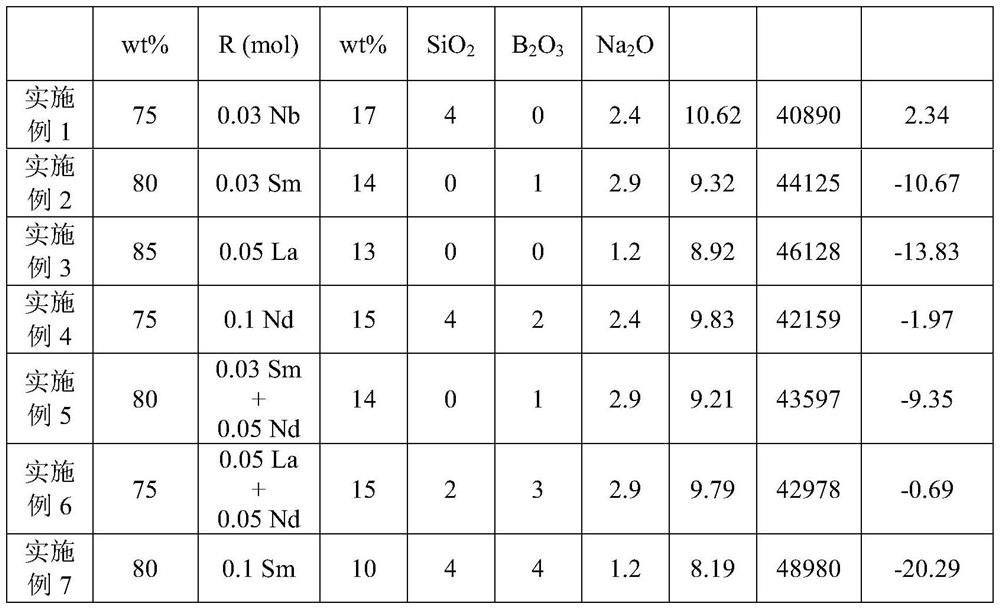

The invention relates to a low-dielectric-constant microwave dielectric ceramic material, which is characterized by comprising the following components by mass: 75-85 wt% of a main material, wherein the main material is R-doped Zn2SiO4, R comprises one or more of Nb, Sm, La and Nd, and the content of R is 0.01-0.1 time the molar content of Si; 10-17 wt% of an auxiliary material TiO2; and 1-10 wt% of a sintering aid comprising one or more of SiO2, Na2O and B2O3. According to the invention, the dielectric constant of the low-dielectric-constant microwave dielectric ceramic material is 8-11, the quality factor is greater than 40000, the temperature coefficient of resonance frequency tau f is-35-0 ppm / DEG C, and the low-dielectric-constant microwave dielectric ceramic material can be widely applied to dielectric resonant antennas, filters, duplexers and other ceramic components.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

A kind of microwave dielectric ceramic material and preparation method thereof

ActiveCN108821768BContinuously adjustable dielectric constantHigh Q*f valueDielectricDielectric permittivity

The invention provides a microwave dielectric ceramic material, which is prepared from composite oxides and additives; the composite oxide has the general formula shown in the following formula: MLa 4 Ti 3 M'O 15 ; Wherein, M is Ca, Ba or Mg; M' is Al, Sb or Bi. Compared with the prior art, the microwave dielectric ceramic material provided by the present invention is prepared from a composite oxide of a specific general formula and additives, and is a microwave dielectric ceramic with a medium dielectric constant; the microwave dielectric ceramic material satisfies a dielectric constant near 45 and It is continuously adjustable, and has a very high Q*f value and good sintering stability. At the same time, it can realize continuous adjustment of temperature drift to meet various needs. The experimental results show that the relative permittivity ε of the microwave dielectric ceramic material provided by the invention r 43.2~46.8, quality factor Q*f value ≥46200GHz, and sintering is stable; at the same time, the temperature drift adjustment range is ‑8~+13ppm / ℃, and can be continuously adjusted to meet various needs. It has very excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

A kind of nanometer microwave dielectric ceramic material and preparation method thereof

The invention provides a nano-microwave dielectric ceramic material prepared from a mixture comprising a composite oxide and a sintering aid; the composite oxide has a general formula shown in formula (I): xLn 2 o 3 ‑yBaO‑zAl 2 o 3 ‑wTiO 2 ; In formula (I), 0<x≤10, 0≤y≤10, 0≤z≤1, 0<w≤20. Compared with the prior art, the nano-microwave dielectric ceramic material provided by the present invention takes the composite oxide of the above-mentioned specific general formula as the main component, and its crystal structure changes from the perovskite structure as the ratio of x, y, z, and w changes. Transforming to the composite perovskite structure and then to the black bronze structure, the BaO‑Ln 2 o 3 -TiO 2 (Ln: La\Sm\Nd) system microwave dielectric ceramic material is effectively improved; the nano-microwave dielectric ceramic material also has a high dielectric constant, extremely low dielectric loss and good sintering stability, and at the same time resonant The frequency temperature coefficient is adjustable, and it has very broad application prospects in the field of microwave communication.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Sol powder metallurgy material and preparation method thereof

InactiveCN108405850AHigh bond strengthImprove sintering stabilityTransportation and packagingMetal-working apparatusAmmonium sulfatePowder metallurgy

The invention discloses a sol powder metallurgy material. The material is composed of the following raw materials of, by weight, 17-20% of ethyl orthosilicate, 3-4% of aluminum oxide, 0.1-0.2% of leadpowder, 0.5-0.7% of ricinoleic acid, 0.1-0.2% of 8-hydroxyquinoline copper, 0.1-0.3% of zinc cyanurate, 0.1-0.4% of ethoxylated alkyl ammonium sulfate, 4-7% of nickel powder, 2-5% of manganese powder, and the balance iron. According to the material, the ethyl orthosilicate is taken as a precursor to hydrolyze in an alcohol aqueous solution containing the 8-hydroxyquinoline copper to obtain antibacterial sol, then the antibacterial sol is blended with the ricinoleic acid, high-temperature esterification is carried out, so that bonding strength of the sol is improved, and sintering stability ofa finished product metallurgy material is enhanced.

Owner:胡佳佳

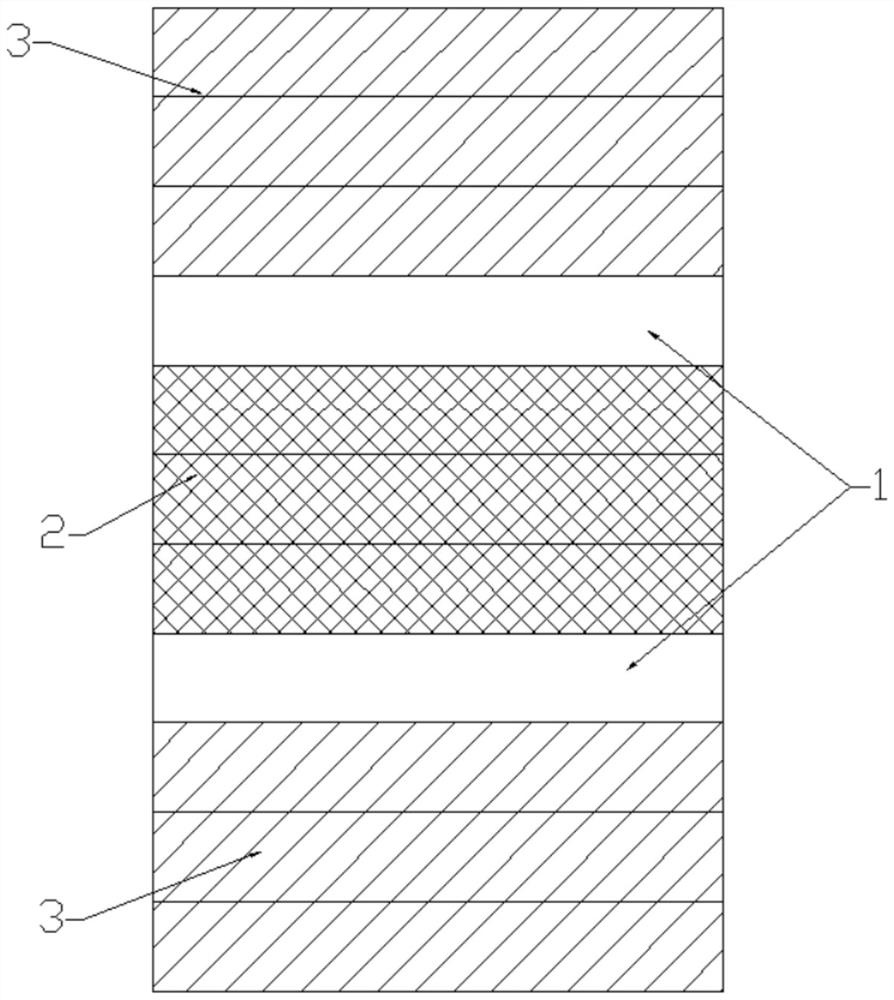

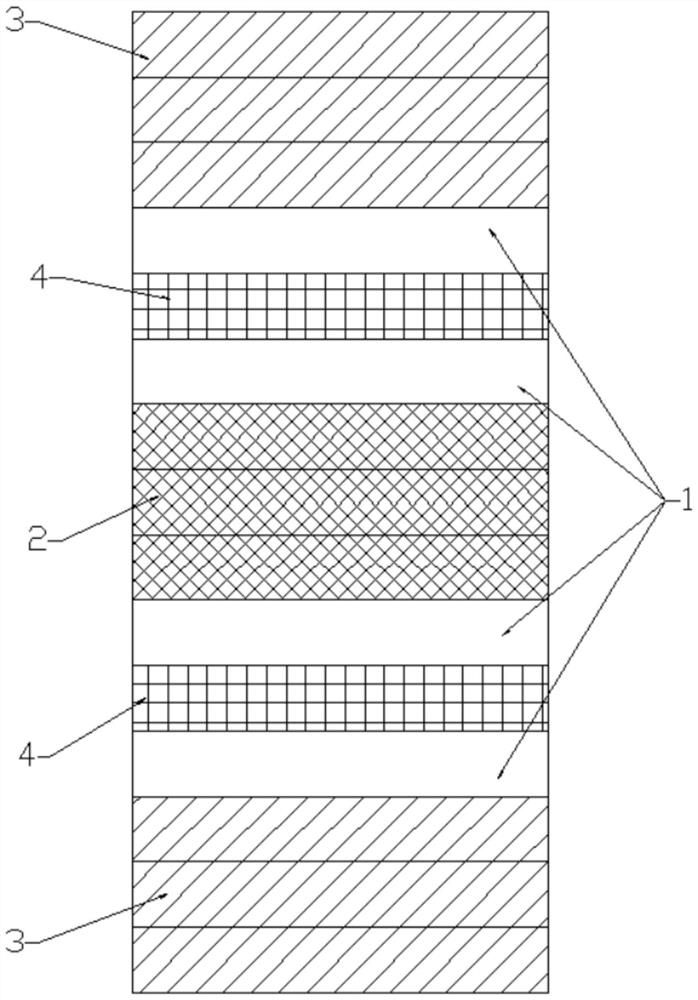

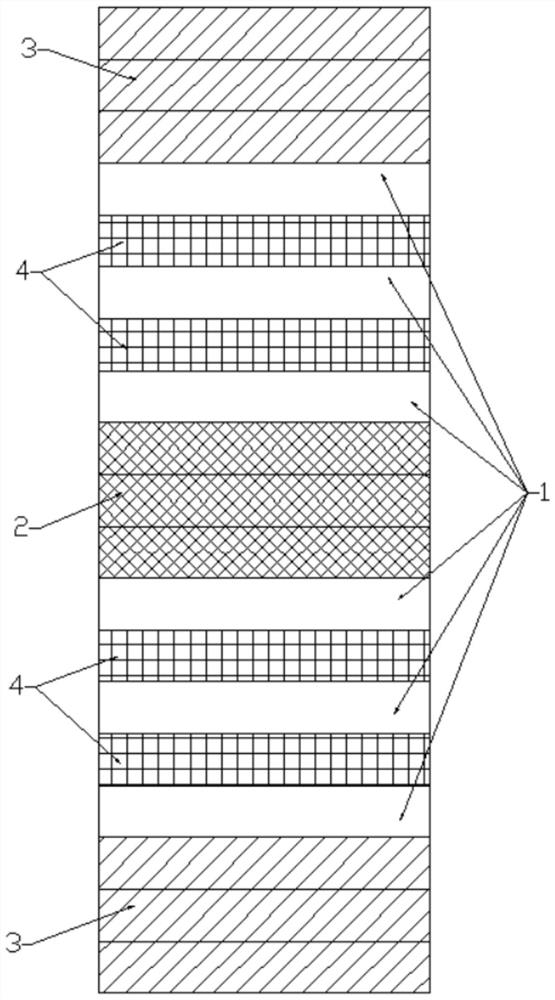

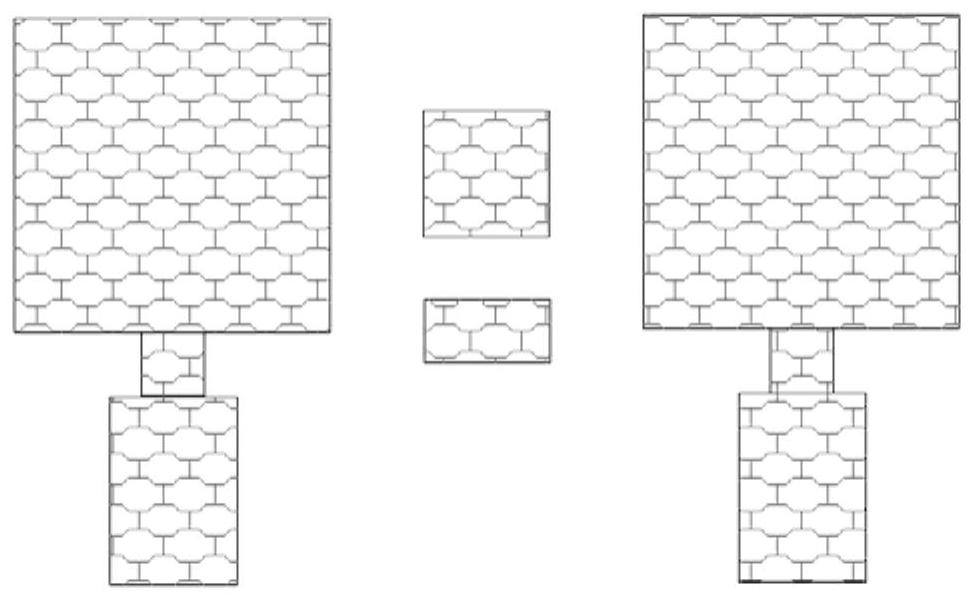

Ultrathin hard alloy tool bit structure with center partition

PendingCN113814403AAvoid erosionImprove sintering stabilityTurbinesOther manufacturing equipments/toolsCemented carbideTool bit

The invention discloses an ultrathin hard alloy tool bit structure with a center partition. The ultrathin hard alloy tool bit structure comprises an even number of hard alloy tool bit layers, a graphite mold center partition layer is arranged between the two middlemost adjacent hard alloy tool bit layers, and graphite mold pressing heads are arranged on the outer sides of the two outermost hard alloy tool bit layers. Compared with the prior art, the ultrathin hard alloy tool bit structure has the advantages that the structure is simple, implementation is convenient, the center partition layer is used for avoiding a center point high-temperature area of a graphite mold, the center partition layer adopts a graphite material with higher density, erosion of center high temperature to a center layer tool bit is effectively avoided, the center layer is removed, the center point of the sintered and fired hard alloy tool bit is burnt blue, the sintering stability of the hard alloy tool bit is greatly improved, the alloying degree is more uniform and higher, and the optimal and most reasonable hardness of the hard alloy tool bit is guaranteed. Good market popularization value is realized.

Owner:林友平

3D printed product and preparation method thereof

ActiveCN113699454AIncrease stiffnessHigh strengthAdditive manufacturing apparatus3d printParaffin wax

The invention discloses a 3D printed product and a preparation method thereof. The invention discloses a 3D printed product which is made of a 3D printing composite wire material. The 3D printing composite wire material is prepared from the following elements in percentage by mass: 0.01 to 0.03 percent of C, 0.1 to 1 percent of Si, 0.1 to 2 percent of Mn, 0.01 to 0.04 percent of P, 0.01 to 0.03 percent of S, 16 to 18 percent of Cr, 0.1 to 1.0 percent of Cu, 10 to 12 percent of Ni, 2 to 3 percent of Mo and the balance of Fe and impurities. The invention further discloses a preparation method of the 3D printed product. The 3D printing stability is improved, the composite wire material for 3D printing is high in rigidity and strength and good in sintering stability, and the surface of the 3D printed product is smooth and glossy; the prepared 3D printing composite wire material is suitable for various printers sold in the market, high in adaptability, convenient to use and high in economic value; and SEBS, SBS, paraffin and palm wax have good intermiscibility, and powder distribution uniformity is promoted.

Owner:JIANGSU UNIV OF SCI & TECH +1

A low dielectric constant microwave dielectric ceramic material and ceramic components

ActiveCN112979297BImprove sintering stabilityFacilitate crystal phase synthesisMicrowaveDielectric permittivity

A low dielectric constant microwave dielectric ceramic material, characterized in that it includes the following components by mass: main material, the content of the main material is 75-85wt%, and the main material is R-doped Zn 2 SiO 4 , wherein R includes one or more of Nb, Sm, La, and Nd, and the content of R is 0.01-0.1 times the molar content of Si; the auxiliary material is TiO 2 , the content of the auxiliary materials is 10-17wt%; the sintering aids, the sintering aids include SiO 2 , Na 2 O and B 2 O 3 One or more of the above, the content of the sintering aid is 1-10wt%. The low dielectric constant microwave dielectric ceramic material has a dielectric constant of 8‑11, a quality factor greater than 40000, and a resonant frequency temperature coefficient τf of ‑35 to 0ppm / ℃, which can be widely used in dielectric resonant antennas, filters, duplexers, etc. in ceramic components.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

A kind of microwave dielectric ceramic material and preparation method thereof

ActiveCN108383519BLow dielectric constantHigh Q*f valueCeramicsDielectric ceramicsDielectric permittivity

The invention provides a microwave dielectric ceramic material, which is prepared from composite oxides and additives; the general formula of the composite oxides is xMg 1.2 Zn 0.8 SiO 4 -yMg 0.65 Zn 0.35 al 2 o 4 ; Wherein, x+y=1, 0.4≤x≤0.9, 0.1≤y≤0.6. Compared with the prior art, the microwave dielectric ceramic material provided by the present invention is prepared from a composite oxide of a specific general formula and additives, and realizes the microwave dielectric ceramic material Mg 2 SiO 4 Effective improvement; the microwave dielectric ceramic material also has a low dielectric constant, a very high Q*f value and good sintering stability, and can realize continuous adjustment of temperature drift to meet various needs. The experimental results show that the relative permittivity ε of the microwave dielectric ceramic material provided by the invention r It is 7~8, the quality factor Q*f value is ≥180000GHz, the temperature drift adjustment range is -10~+6ppm / ℃, and the sintering is stable, which has very excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Anti-battery effect isolation dielectric paste for thick film circuit

ActiveCN112201387BPromote crystallizationImprove stabilitySolid-state devicesGlass shaping apparatusDielectricMicron scale

The invention discloses an anti-battery effect isolation medium slurry for a thick film circuit. The medium slurry comprises the following components in mass percentages: 60%-75% of glass powder, 3%-12% of additives, and 1% of inorganic pigments ~5%, organic vehicle 20%~35%, among which the glass powder is composed of ZnO, CaO, Al 2 o 3 , SiO 2 , B 2 o 3 , TeO 2 Composition, the additives are composed of micron-sized anorthite, α-type nano-alumina, nano-ZrO 2 Composition, the micron grade anorthite ore is made by crushing anorthite ore, sieving through an 80-mesh sieve, and then roasting at 750-800°C for 1-3 hours, and then ball milling to a particle size of 1-2 μm after natural cooling. to make. The anti-battery effect isolation medium paste for thick film circuits of the present invention has the characteristics of excellent anti-battery effect, good printability, dense firing film layer, high breakdown voltage resistance, high insulation resistance and small dielectric constant.

Owner:西安宏星电子浆料科技股份有限公司

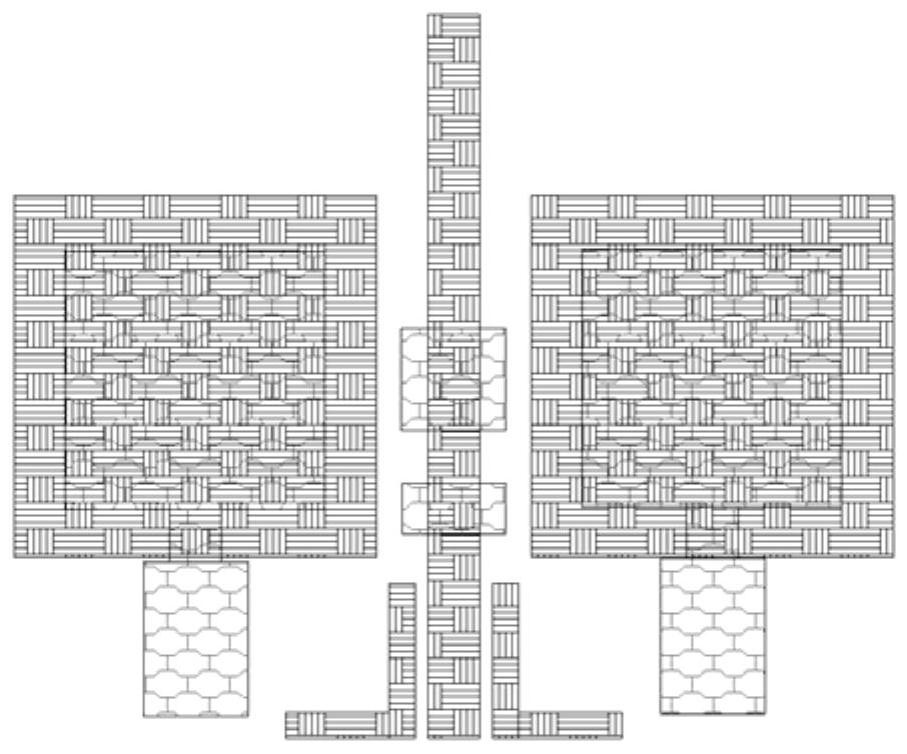

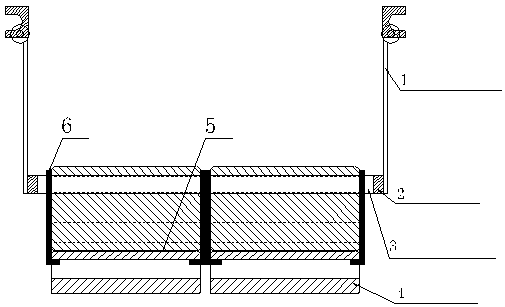

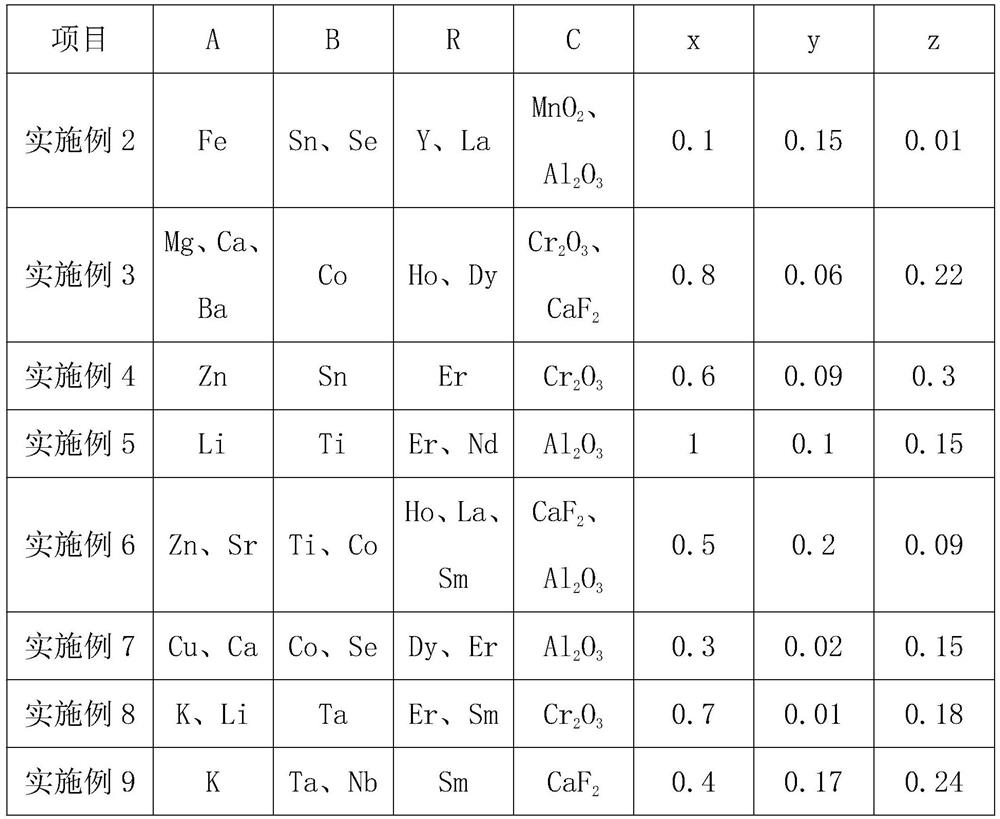

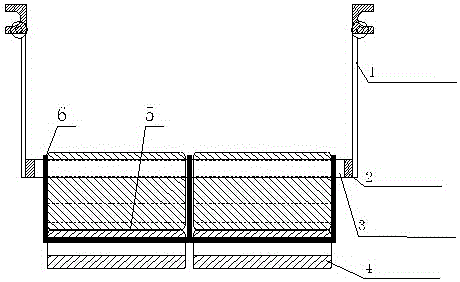

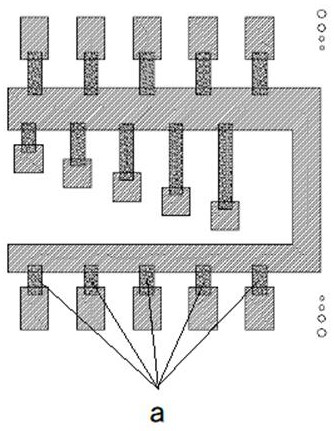

A kind of carbon block fixing method and device for continuous prebaked anode

ActiveCN105821447BImprove sintering stabilityAvoid falling blocksPhysical chemistryMaterials science

The invention discloses a carbon block fixing method used for a continuous prebaked anode. The carbon block fixing method is characterized in that a new anode carbon block (4) is arranged on an anode carbon block (4) which is in electrolysis, and the part between the upper anode carbon block (4) and the lower anode carbon block (4) is coated with a bonding layer (5); and through heat conduction of the lower anode carbon block (4) in the electrolytic process, the anode carbon blocks (4) are sintered together. By means of the carbon block fixing method used for the continuous prebaked anode, the new anode carbon block is arranged on the anode carbon block which is in electrolysis, coating of the bonding layer is conducted, and the upper anode carbon block and the lower anode carbon block are sintered together through electrolysis heat transfer.

Owner:周俊和 +1

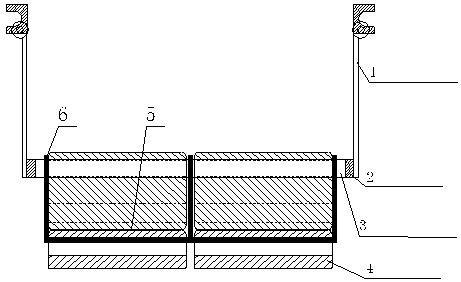

A kind of red pigment for zirconia ceramics, its preparation method and its application

The present application relates to a red colorant for zirconia ceramics, a preparation method and application thereof. The red pigment for zirconia ceramics of the present application has the formula of xABO 3 +yR 2 O 3 +zC, this pigment does not contain toxic heavy metals and has bright color. The present application provides a method for producing a red colorant for zirconia ceramics, including the steps of pretreatment, batching, ball milling and mixing, drying, powder pretreatment, heterogeneous coating, and powder posttreatment. One of the cores of the method is to use Heterogeneous encapsulation technology to improve the stability of red pigments under high temperature sintering conditions. The present application provides a red yttrium-stabilized zirconia granulated powder, which is prepared by mixing the aforementioned red pigment and yttrium-stabilized zirconia. The present application also provides red zirconia ceramics obtained by sintering the aforementioned granulated powder and ceramic products obtained by processing.

Owner:深圳市丁鼎陶瓷科技有限公司

Iron-based powder metallurgical material and preparation method thereof

The invention discloses an iron-based powder metallurgical material. The iron-based powder metallurgical material is prepared from the following raw materials in percentage by weight: 10-14% of aluminum isopropoxide, 1-2% of dithio-salicylic acid, 2-4% of bidecyl dimethyl ammonium bromide, 1-4% of hydroxyethyl cellulose, 0.1-0.4% of fatty acid polyethylene glycol ester, 2-4% of lead powder, 10-11%of Cr, 1-2% of nickel powder, 0.4-1% of triethanolamine, 2-3% of zinc powder, 1-2% of calcium phosphate and the balance of iron. According to the iron-based powder metallurgical material disclosed bythe invention, hydroxyethyl cellulose is taken as the raw material and is dispersed into dimethyl formamide, and aluminum isopropoxide is taken as a precursor and is hydrolyzed to obtain fiber sol which can effectively improve bonding strength of the raw materials, strengthens sintering stability, and can improve toughness.

Owner:张庆

Carbon block fixing method and device used for continuous prebaked anode

The invention discloses a carbon block fixing method used for a continuous prebaked anode. The carbon block fixing method is characterized in that a new anode carbon block (4) is arranged on an anode carbon block (4) which is in electrolysis, and the part between the upper anode carbon block (4) and the lower anode carbon block (4) is coated with a bonding layer (5); and through heat conduction of the lower anode carbon block (4) in the electrolytic process, the anode carbon blocks (4) are sintered together. By means of the carbon block fixing method used for the continuous prebaked anode, the new anode carbon block is arranged on the anode carbon block which is in electrolysis, coating of the bonding layer is conducted, and the upper anode carbon block and the lower anode carbon block are sintered together through electrolysis heat transfer.

Owner:周俊和 +1

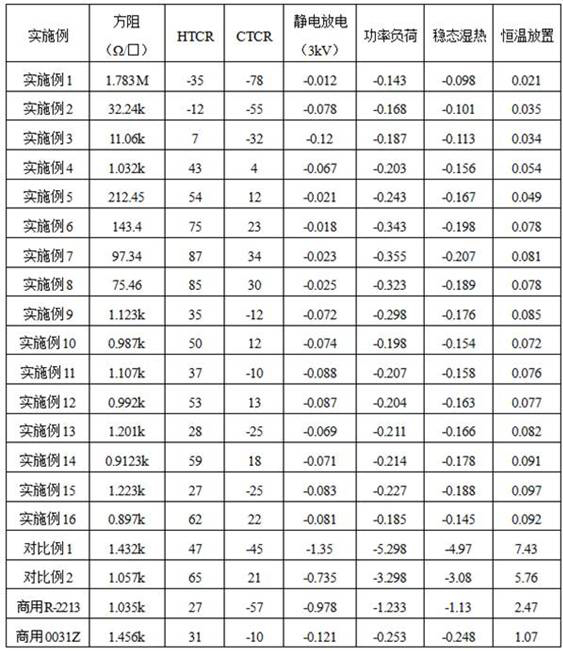

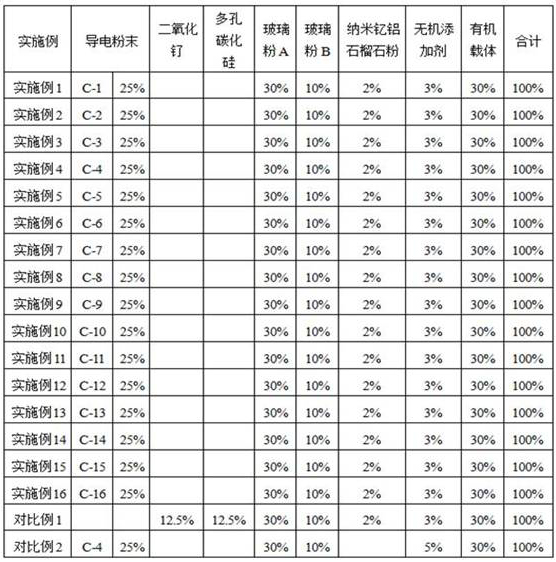

A kind of resistance paste for high performance thick film resistor

ActiveCN113053560BHigh precisionImprove reliabilityNon-conductive material with dispersed conductive materialThick film resistorsSlurryBall mill

The invention discloses a resistance paste for a high-performance thick-film resistor. The resistance paste comprises the following components in mass percentage: 20%-45% of conductive powder, 25%-40% of calcium borosilicate glass powder, nanometer yttrium Aluminum garnet powder 1%~3%, inorganic additive 0.5%~10%, organic carrier 25%~35%, among them, the conductive powder is a composite material produced by ruthenium dioxide and porous silicon carbide, and the specific surface area is 75~95m 2 After mixing and granulating ruthenium dioxide per g and porous silicon carbide with a particle size of 1-2 μm, it is isostatically pressed at 100-150 MPa for 4-6 hours, vacuum heat-treated at 400-500 °C for 1-2 hours, crushed and ball-milled to 1~2μm powder. The resistance slurry of the present invention has the characteristics of lead-free environmental protection, high resistance precision, strong power resistance, good electrostatic discharge, and good stability when placed at a constant temperature.

Owner:西安宏星电子浆料科技股份有限公司

A kind of high temperature resistant grinding wear-resistant diamond grinding block and preparation method thereof

ActiveCN110253460BImprove adhesionInhibit sheddingAbrasion apparatusGrinding devicesToluene diisocyanatePyrrolidinones

The invention discloses a high-temperature-resistant grinding-resistant diamond grinding block. The high-temperature-resistant grinding-resistant diamond grinding block is prepared from, by weight, 90-100 parts of diamond, 40-50 parts of aluminum isopropoxide, 2-3 parts of tin powder, 1-2 parts of polyvinylpyrrolidone, 20-30 parts of ferric chloride hexahydrate, 17-21 parts of ferric chloride tetrachloride, 10-15 parts of toluene diisocynate, 14-20 parts of polyadipic acid-1,4-butanediol ester diol, 3-4 parts of acetone and 0.4-1 part of 2,6-butylated hydroxytoluene. According to the high-temperature-resistant grinding-resistant diamond grinding block, the colloidal sol-coated ferric oxides, diamond and tin powder are added, and therefore the sintering stability of a finished product can be effectively improved; and the added prepolymers have the very good bonding effect, therefore, the coating stability can be improved, and the high temperature resistance and the grinding resistance of a finished product module can be enhanced.

Owner:湖南奇亮磨具有限公司

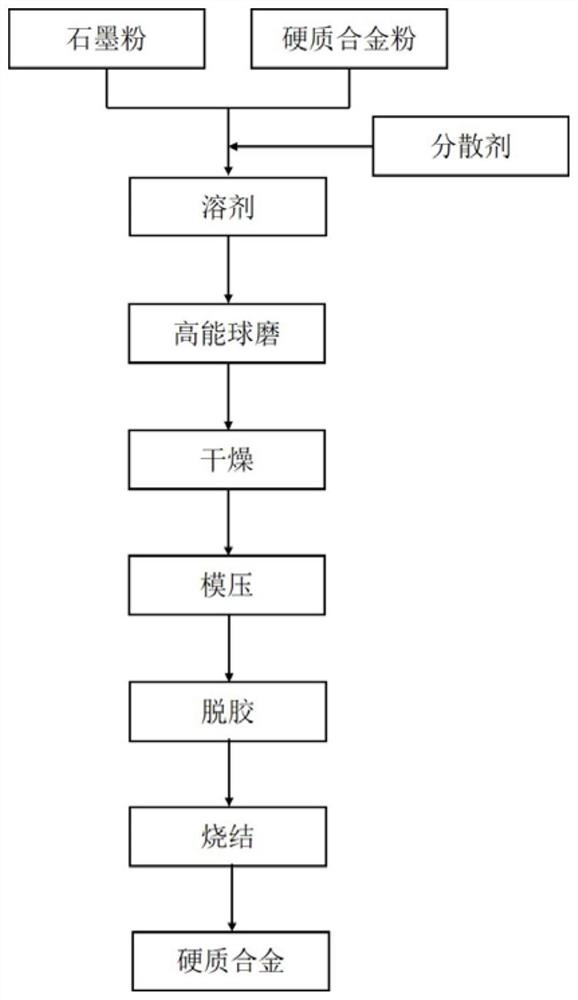

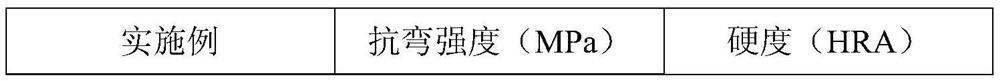

A kind of graphene modified cemented carbide and preparation method thereof

The invention discloses a graphene modified hard alloy and a preparation method thereof. The preparation method includes: uniformly mixing graphite, dispersant, hard alloy and solvent, and performing high-energy ball milling treatment to exfoliate the graphite into graphene to obtain a cemented carbide composite powder comprising graphene and hard alloy, and then carry out Drying, granulation, press molding, degumming, sintering and other treatments to obtain graphene modified hard alloy. The invention utilizes the cemented carbide powder ball milling process, which can realize the exfoliation and dispersion of graphene and the ball milling refinement of cemented carbide powder at the same time, avoid the cumbersome process of exfoliating graphene alone, and precisely combine the powder metallurgy process without changing the existing process conditions. At the same time, the graphene exfoliated in situ by mechanical ball milling has the advantages of complete structure and low defect level, which can significantly improve its sintering stability, and has a significant effect on the performance of cemented carbide and grain refinement. effect and has important industrial application prospects.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

High-temperature-resistant grinding-resistant diamond grinding block and preparation method thereof

ActiveCN110253460AImprove adhesionInhibit sheddingAbrasion apparatusGrinding devicesButylated hydroxytolueneTemperature resistance

The invention discloses a high-temperature-resistant grinding-resistant diamond grinding block. The high-temperature-resistant grinding-resistant diamond grinding block is prepared from, by weight, 90-100 parts of diamond, 40-50 parts of aluminum isopropoxide, 2-3 parts of tin powder, 1-2 parts of polyvinylpyrrolidone, 20-30 parts of ferric chloride hexahydrate, 17-21 parts of ferric chloride tetrachloride, 10-15 parts of toluene diisocynate, 14-20 parts of polyadipic acid-1,4-butanediol ester diol, 3-4 parts of acetone and 0.4-1 part of 2,6-butylated hydroxytoluene. According to the high-temperature-resistant grinding-resistant diamond grinding block, the colloidal sol-coated ferric oxides, diamond and tin powder are added, and therefore the sintering stability of a finished product can be effectively improved; and the added prepolymers have the very good bonding effect, therefore, the coating stability can be improved, and the high temperature resistance and the grinding resistance of a finished product module can be enhanced.

Owner:湖南奇亮磨具有限公司

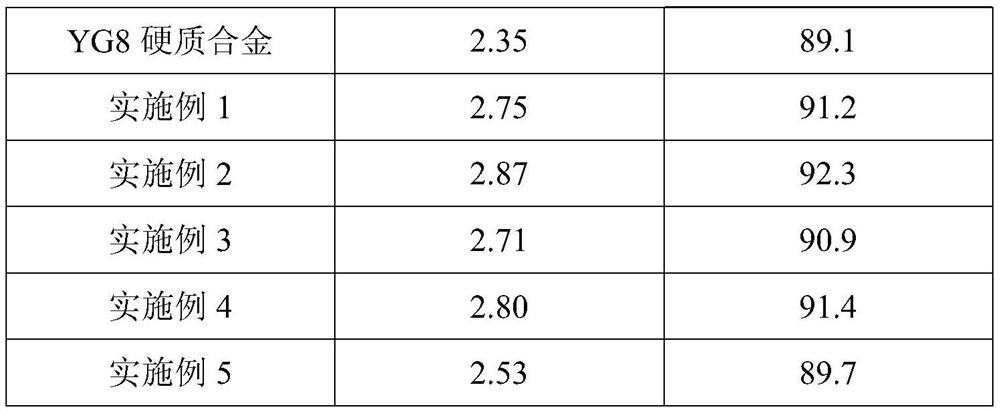

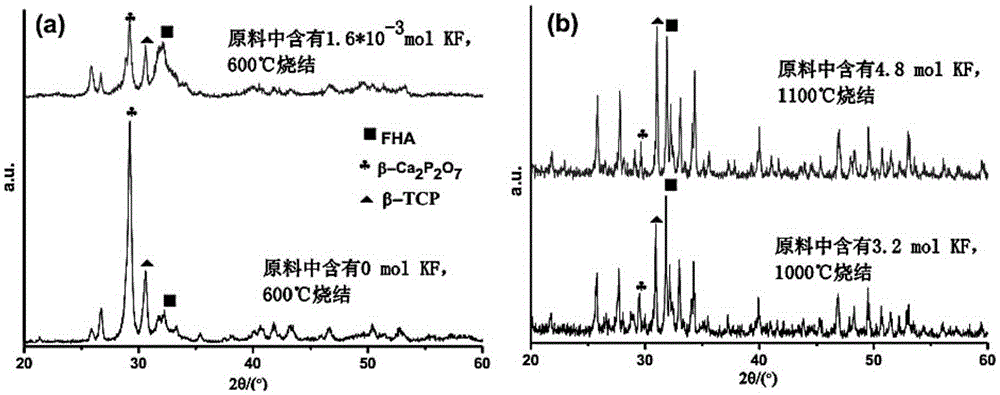

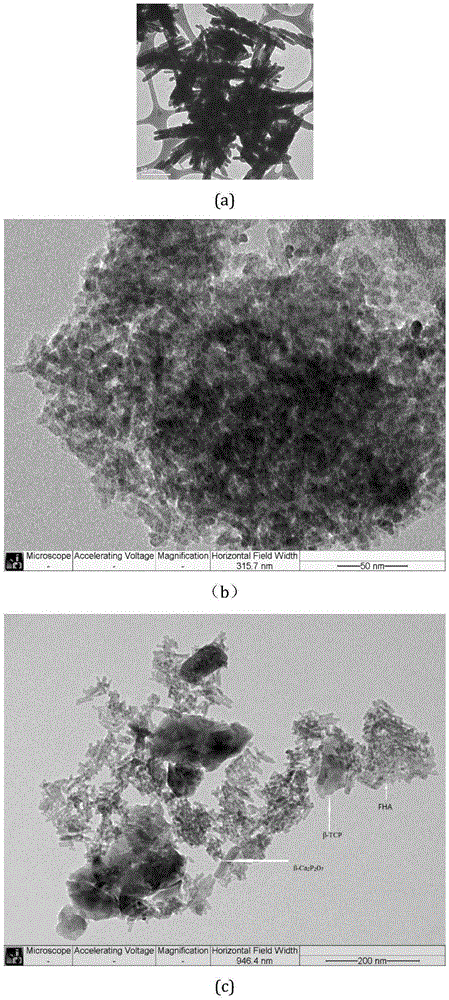

FHA/beta-TCP/beta-Ca2P2O7 three-phase ceramic preparation method

InactiveCN105272200APromote degradationImprove sintering stabilityCalcium Acetate MonohydrateMaterials preparation

The invention provides an FHA / beta-TCP / beta-Ca2P2O7 three-phase ceramic preparation method in the field of biomedical material preparation. FHA / beta-TCP / beta-Ca2P2O7 three-phase ceramic is obtained by preparing precursor powder through a chemical precipitation method with calcium acetate monohydrate, monopotassium phosphate and potassium fluoride dehydrate as raw materials and sintering the precursor powder at a high temperature for 2 h. The process is simple, and the obtained three-phase ceramic is uniform in component and has high osteoconduction, biodegradability and mechanical strength, and is an ideal biochemical medical material.

Owner:SHANGHAI JIAO TONG UNIV

A lithium ion battery material and a preparation method thereof

InactiveCN109088063AImprove surface activityImprove stabilityCell electrodesSecondary cellsFerrous ammonium phosphateLithium hydroxide

The invention discloses a lithium ion battery material, which is composed of the following raw materials in parts by weight: lithium hydroxide 50-80, ferrous ammonium phosphate 80-100, 2-thiol benzimidazole 1-2, nano-dispersion 30- 40, thiophene 15-20, and dibenzoyl peroxide 0.3-0.4., The nano-silicon dioxide is first doped with phosphorus trichloride and then reacts with triethanolamine to effectively improve the surface activity of the silicon dioxide. The invention uses thiophene as a monomer and the nano-dispersion as a reaction solvent and realizes the effective combination of the nano-silicon dioxide and the polythiophene through polymerization, thereby improving the sintering stability and the electric conductivity of the finished product material.

Owner:崔晓迪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com