A kind of resistance paste for high performance thick film resistor

A thick film resistor and resistance paste technology, applied in thick film resistors, resistors, non-adjustable metal resistors, etc., can solve the problems of large changes in electrostatic discharge, wide TCR range, and poor resistance accuracy. Good electrostatic discharge, good sintering stability, excellent electrostatic discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

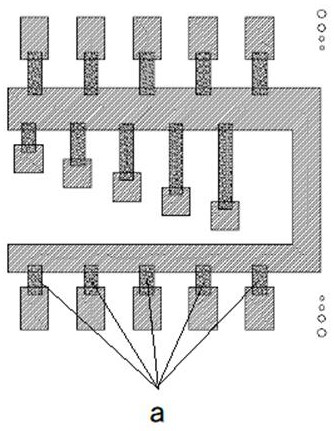

Image

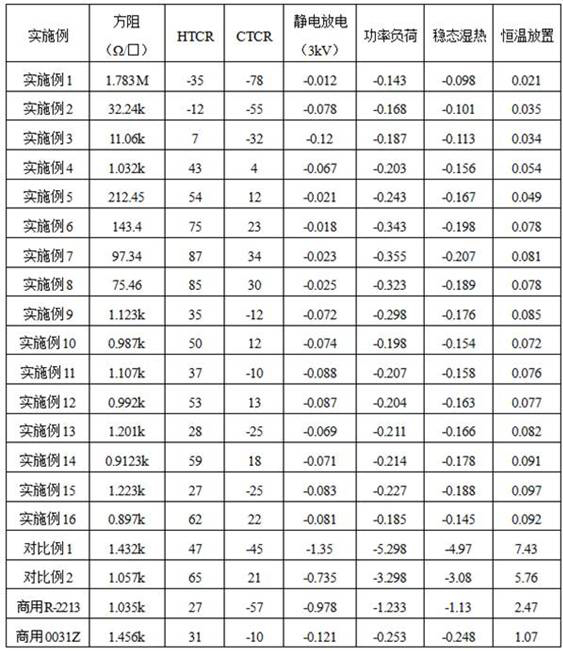

Examples

Embodiment 1~16

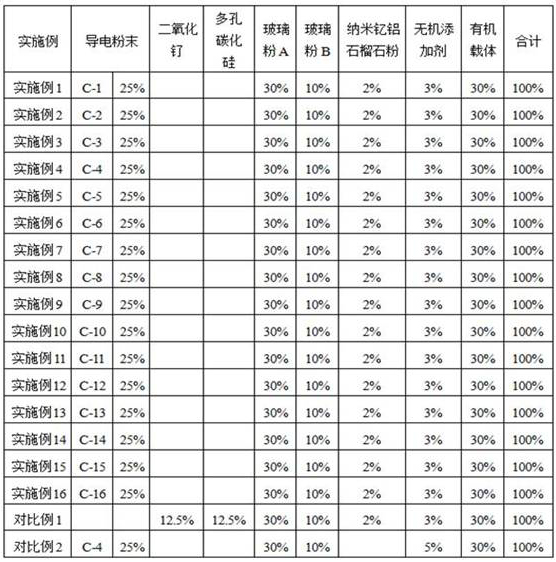

[0021] Preparation of conductive powder: According to the mass percentage listed in Table 1 and the conditions of isostatic pressing and heat treatment, the specific surface area is 75 ~ 95m 2 / g of ruthenium dioxide and porous silicon carbide with a particle size of 1-2 μm are mixed and granulated, subjected to isostatic pressing and vacuum heat treatment, crushed and ball-milled to 1-2 μm, and the obtained powder is a conductive powder.

[0022] Table 1 Proportion and preparation process of conductive powder

[0023]

[0024] Preparation of glass powder: according to CaO 44%, Al 2 o 3 9%, B 2 o 3 25%, SiO 2 22%, and according to CaO 44%, B 2 o 3 25%, SiO 2 22%, ZnO 5%, K 2 O 4% mass percentage for batching, after mixing various oxides evenly, put the obtained mixture in a melting furnace at 1400°C for melting, holding time for 1.5h, the obtained glass solution is water-quenched to obtain glass, and the glass is broken Form glass slag, and use a ball mill to gri...

Embodiment 17

[0048] Preparation of conductive powder: the specific surface area is 75 ~ 95m 2 / g of ruthenium dioxide and porous silicon carbide with a particle size of 1-2 μm are mixed according to the mass percentage of 50%:50%, then granulated, isostatically pressed at 125MPa for 5h, vacuum heat-treated at 450°C for 1.5h, and then crushed and ball-milled to 1 ~2μm powder, the resulting powder is the conductive powder.

[0049] Preparation of glass powder: according to CaO 44%, Al 2 o 3 9%, B 2 o 3 25%, SiO 2 22%, and according to CaO 44%, B 2 o 3 25%, SiO 2 22%, ZnO 5%, K 2 O 4% mass percentage for batching, after mixing various oxides evenly, put the obtained mixture in a melting furnace at 1400°C for melting, holding time for 1.5h, the obtained glass solution is water-quenched to obtain glass, and the glass is broken Form glass slag, and use a ball mill to grind the glass slag to a particle size of 1.0-1.3 μm, and dry it to obtain the corresponding Ca-Al-B-Si system (referr...

Embodiment 18

[0054] Preparation of conductive powder: the specific surface area is 75 ~ 95m 2 / g of ruthenium dioxide and porous silicon carbide with a particle size of 1-2 μm are mixed according to the mass percentage of 50%:50%, then granulated, isostatically pressed at 125MPa for 5h, vacuum heat-treated at 450°C for 1.5h, and then crushed and ball-milled to 1 ~2μm powder, the resulting powder is the conductive powder.

[0055] Preparation of glass powder: according to CaO 44%, Al 2 o 3 9%, B 2 o 3 25%, SiO 2 22%, and according to CaO 44%, B 2 o 3 25%, SiO 2 22%, ZnO 5%, K 2 O 4% mass percentage for batching, after mixing various oxides evenly, put the obtained mixture in a melting furnace at 1400°C for melting, holding time for 1.5h, the obtained glass solution is water-quenched to obtain glass, and the glass is broken Form glass slag, and use a ball mill to grind the glass slag to a particle size of 1.0-1.3 μm, and dry it to obtain the corresponding Ca-Al-B-Si system (referr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com