Patents

Literature

174results about How to "Good resistance stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

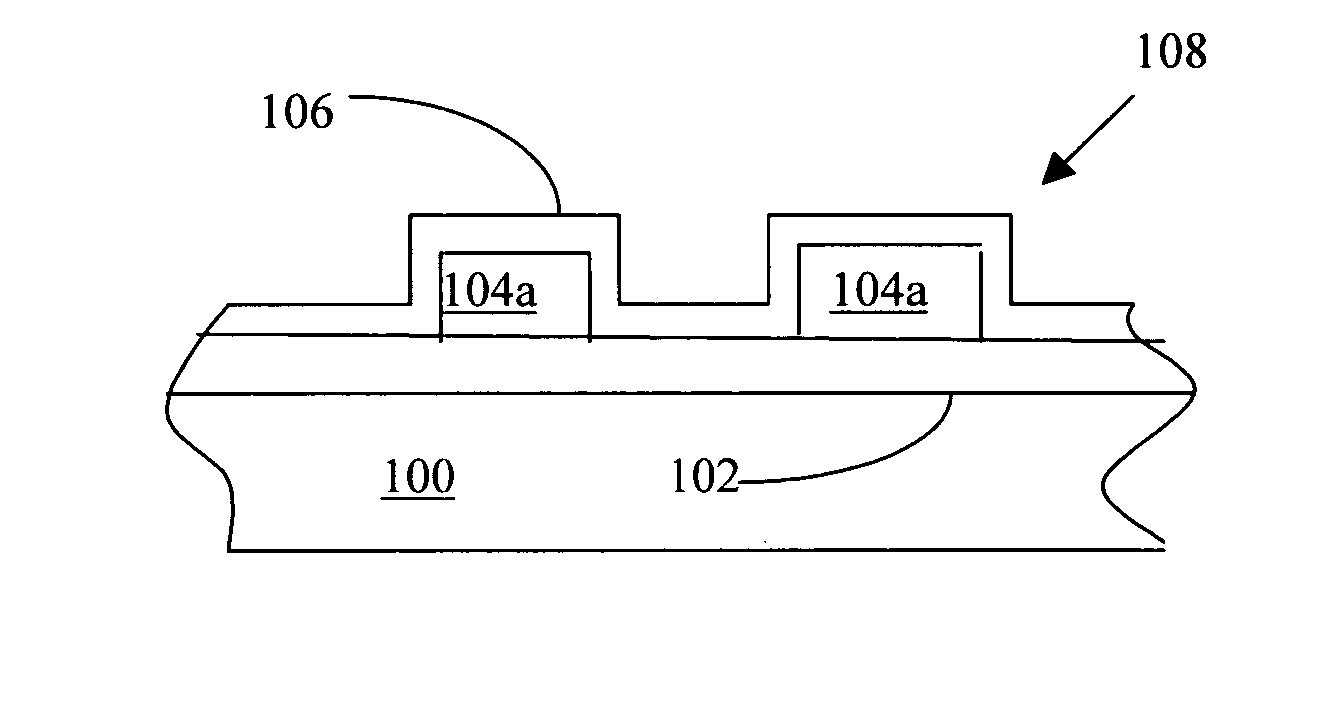

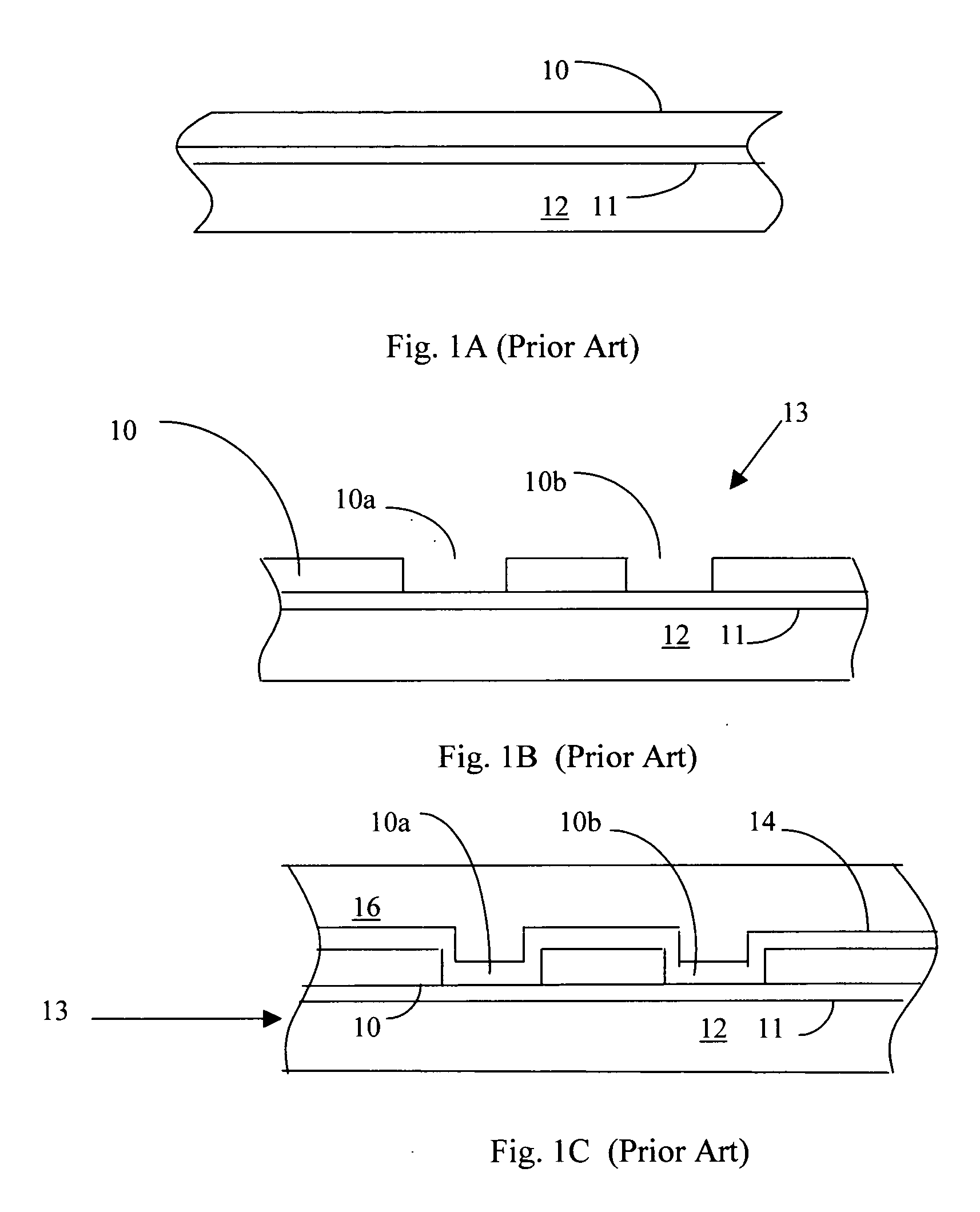

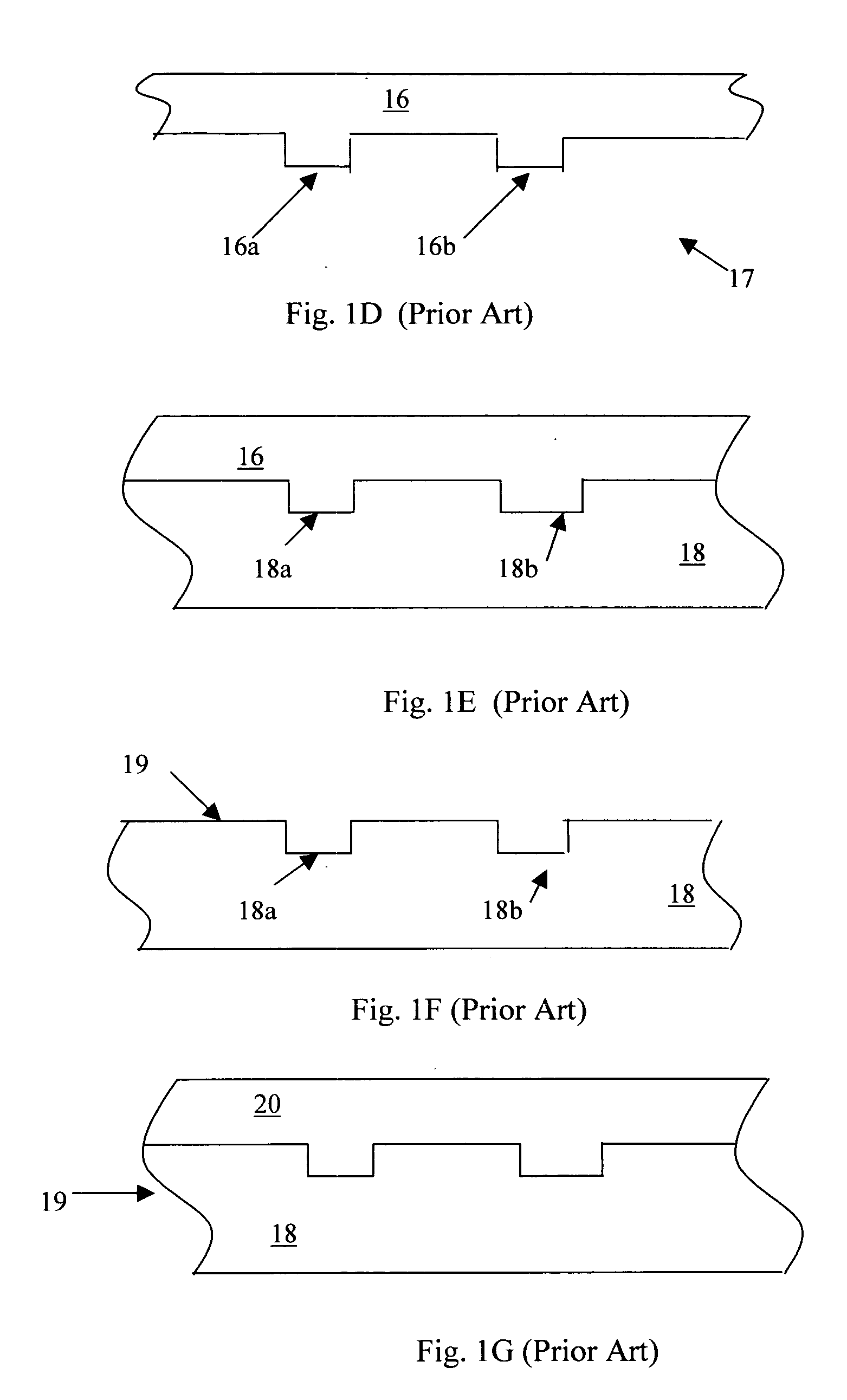

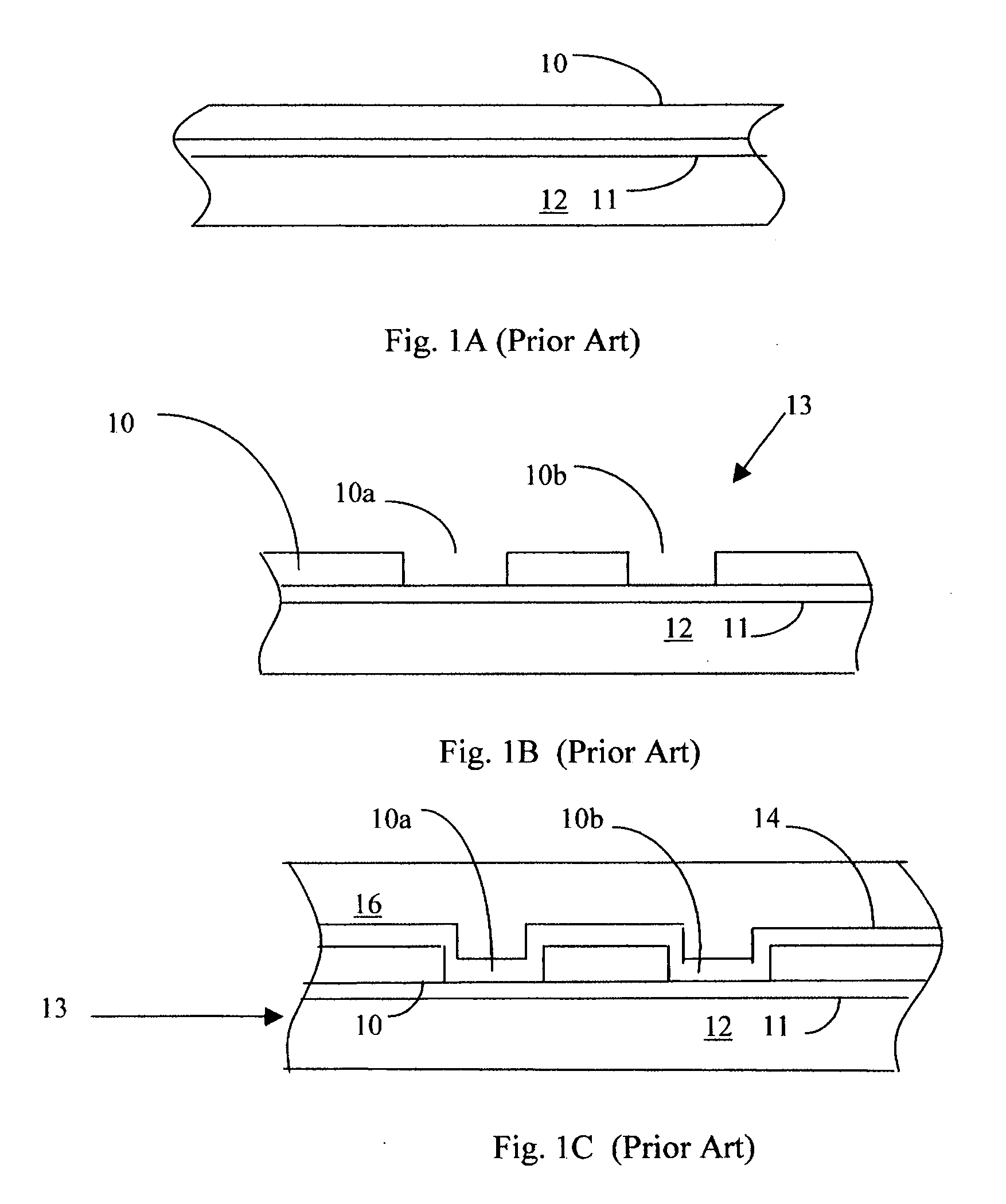

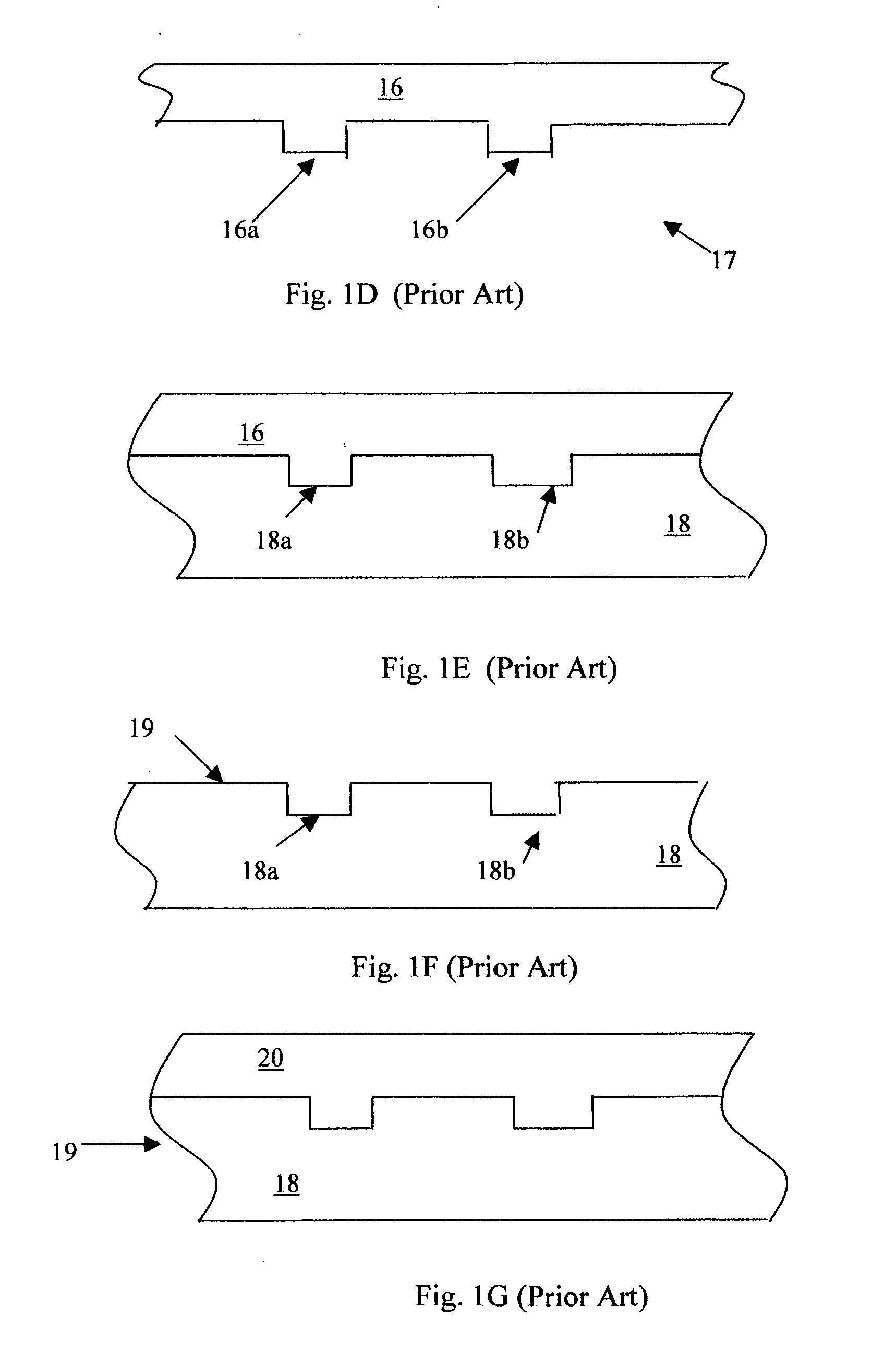

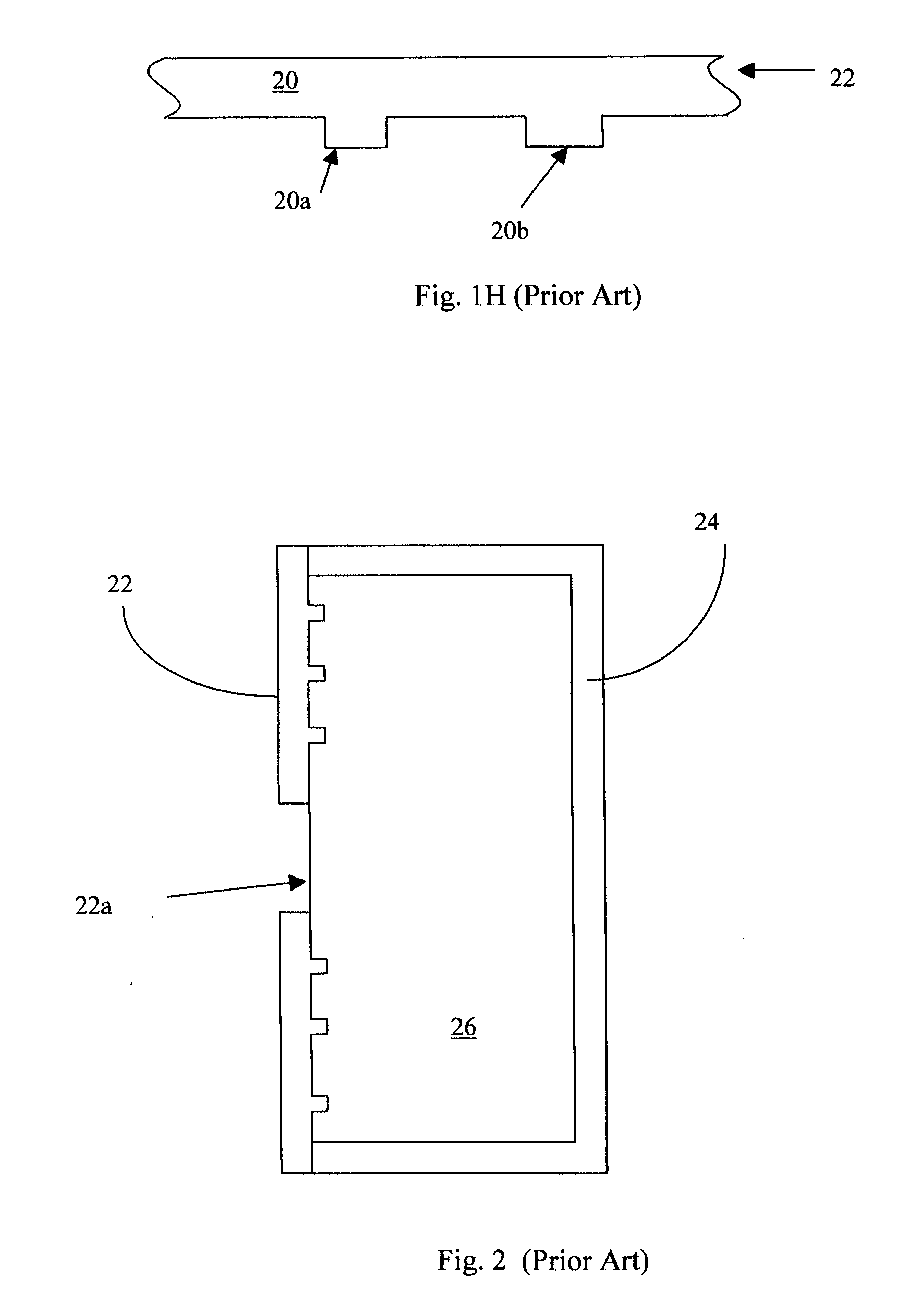

Method and apparatus for making a stamper for patterning CDs and DVDs

InactiveUS20050167867A1Good resistance stabilityUnnecessary to performRecord carriersConfectioneryResistCompact Disc manufacturing

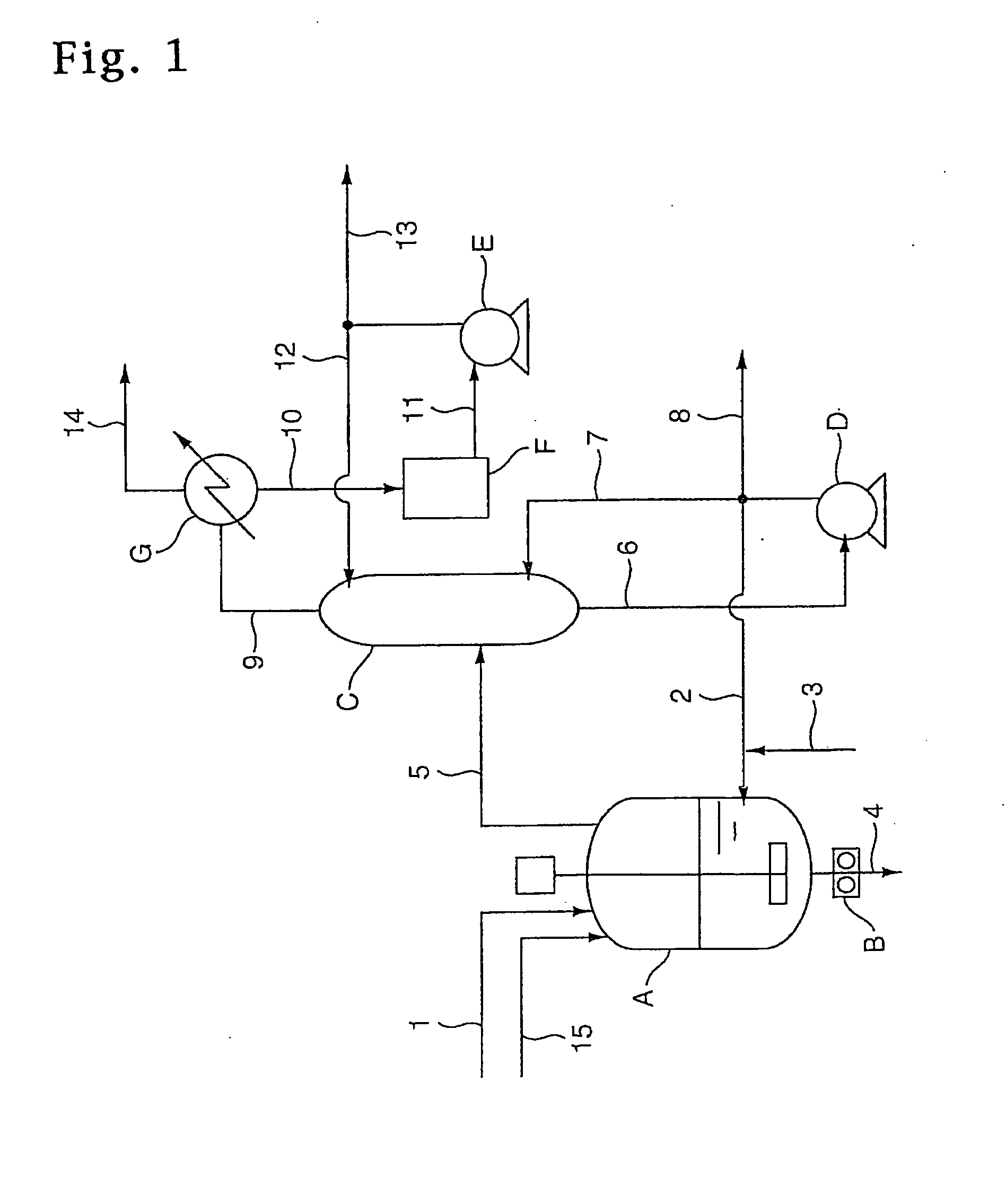

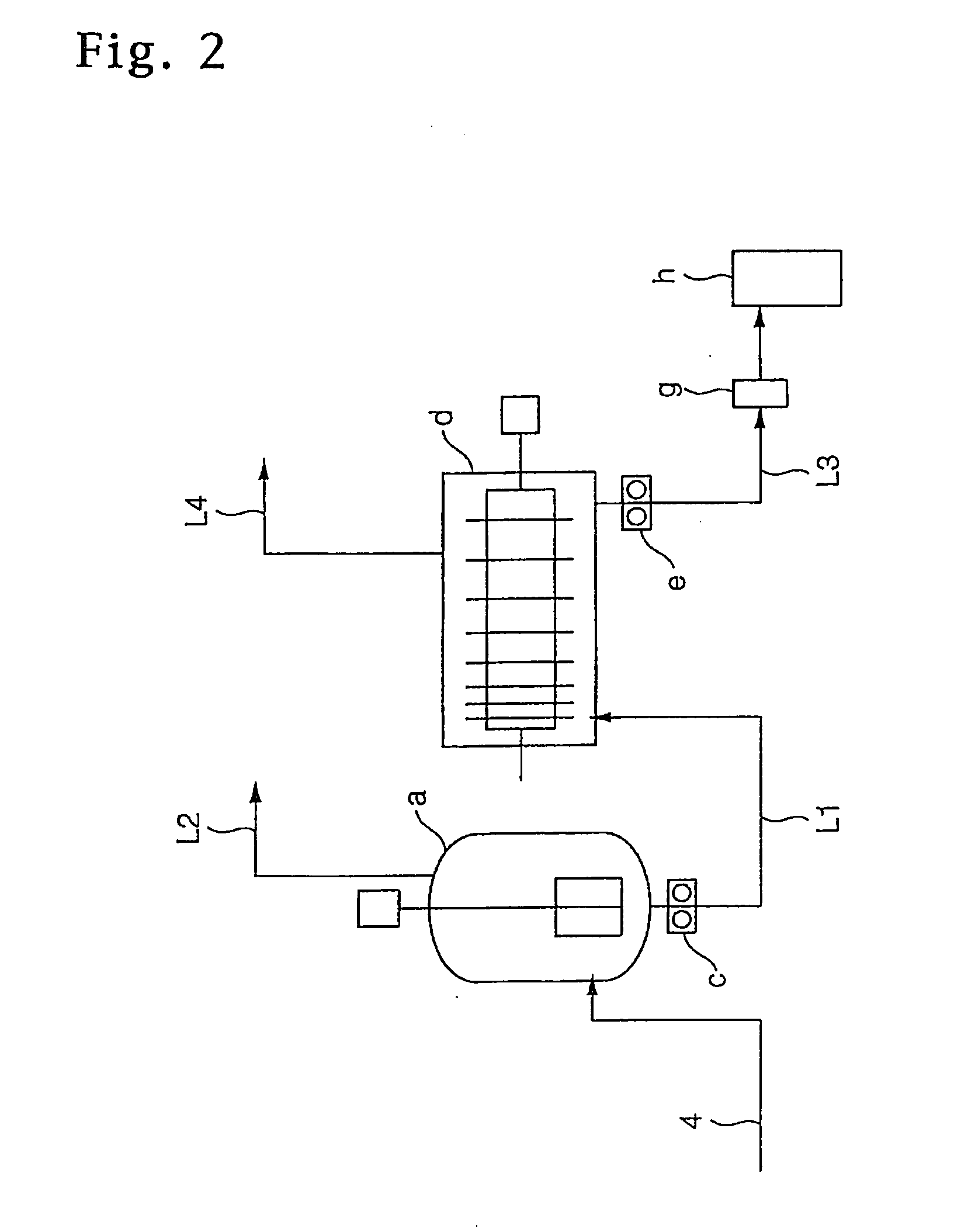

A method for forming a stamper used in the manufacture of CDs, DVDs, and other types of optical disks comprises forming a substrate by rolling. A layer of material is deposited (e.g. by plating) onto the substrate. Thereafter, a resist layer is formed on the layer of material and patterned. Because the substrate is formed by rolling, it is relatively inexpensive to form the substrate to a desired thickness. Because the layer of material is formed by deposition (e.g. plating), it is relatively inexpensive to ensure that the layer has a very smooth surface (i.e. without necessitating a great deal of polishing).

Owner:WD MEDIA

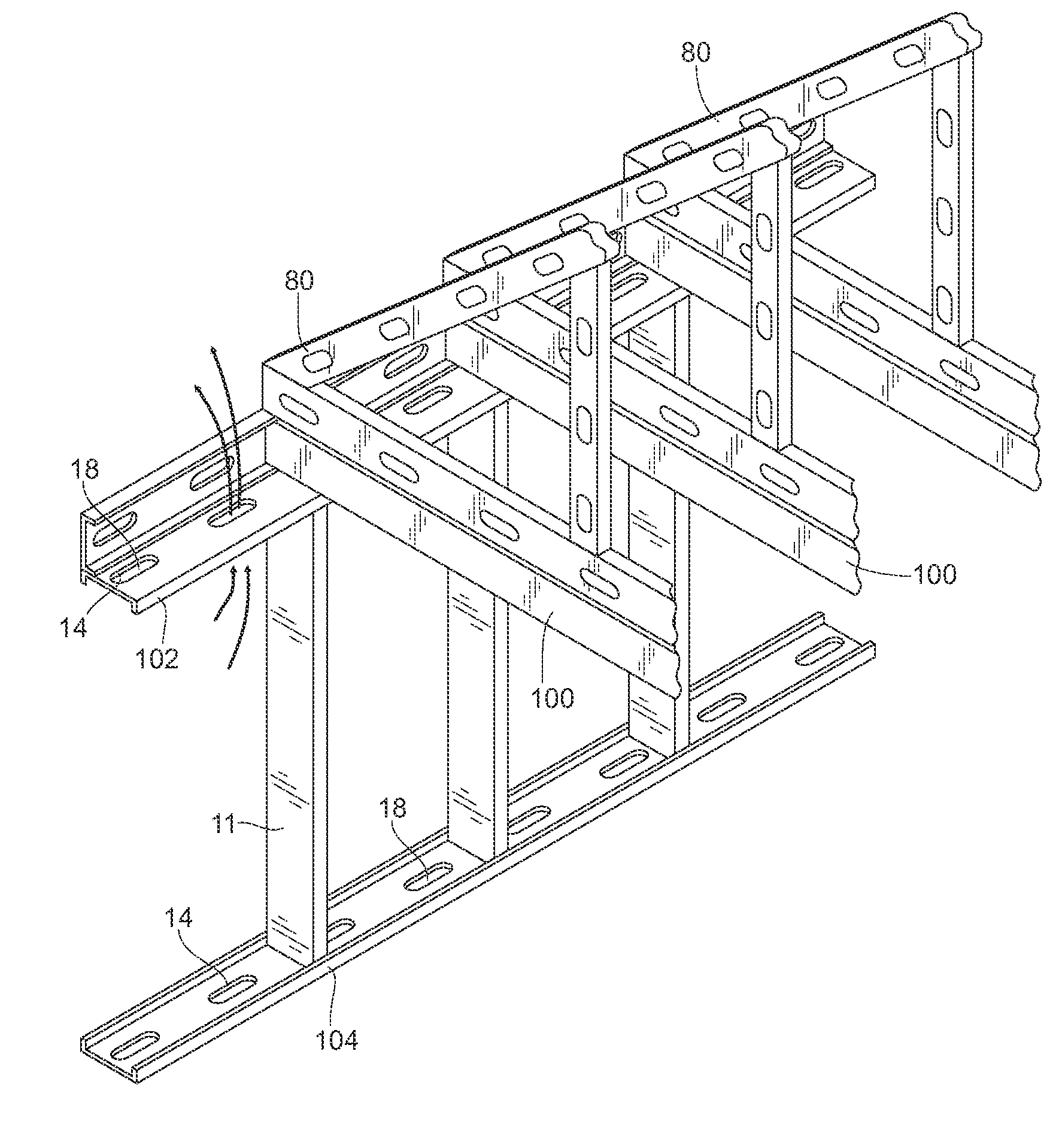

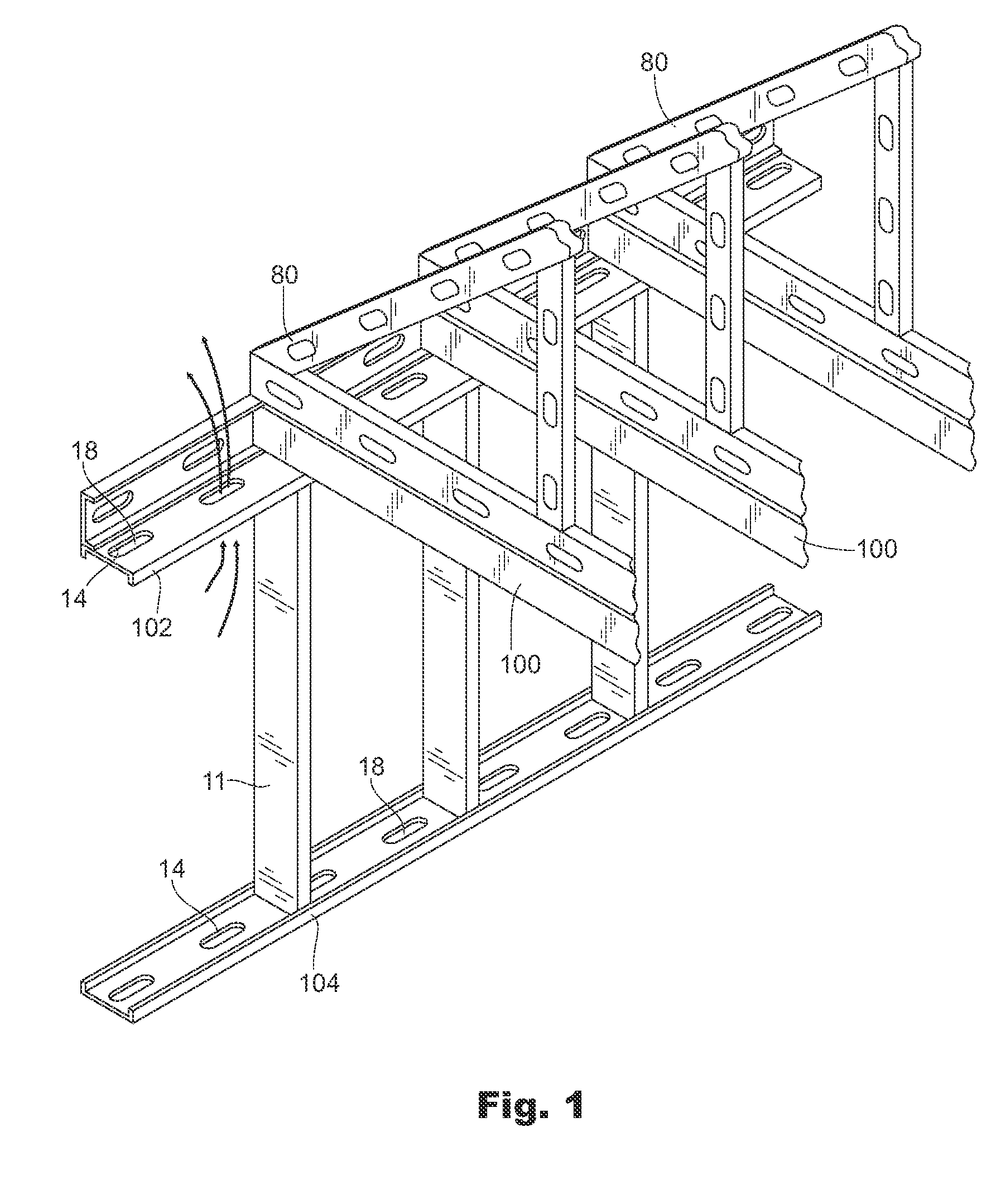

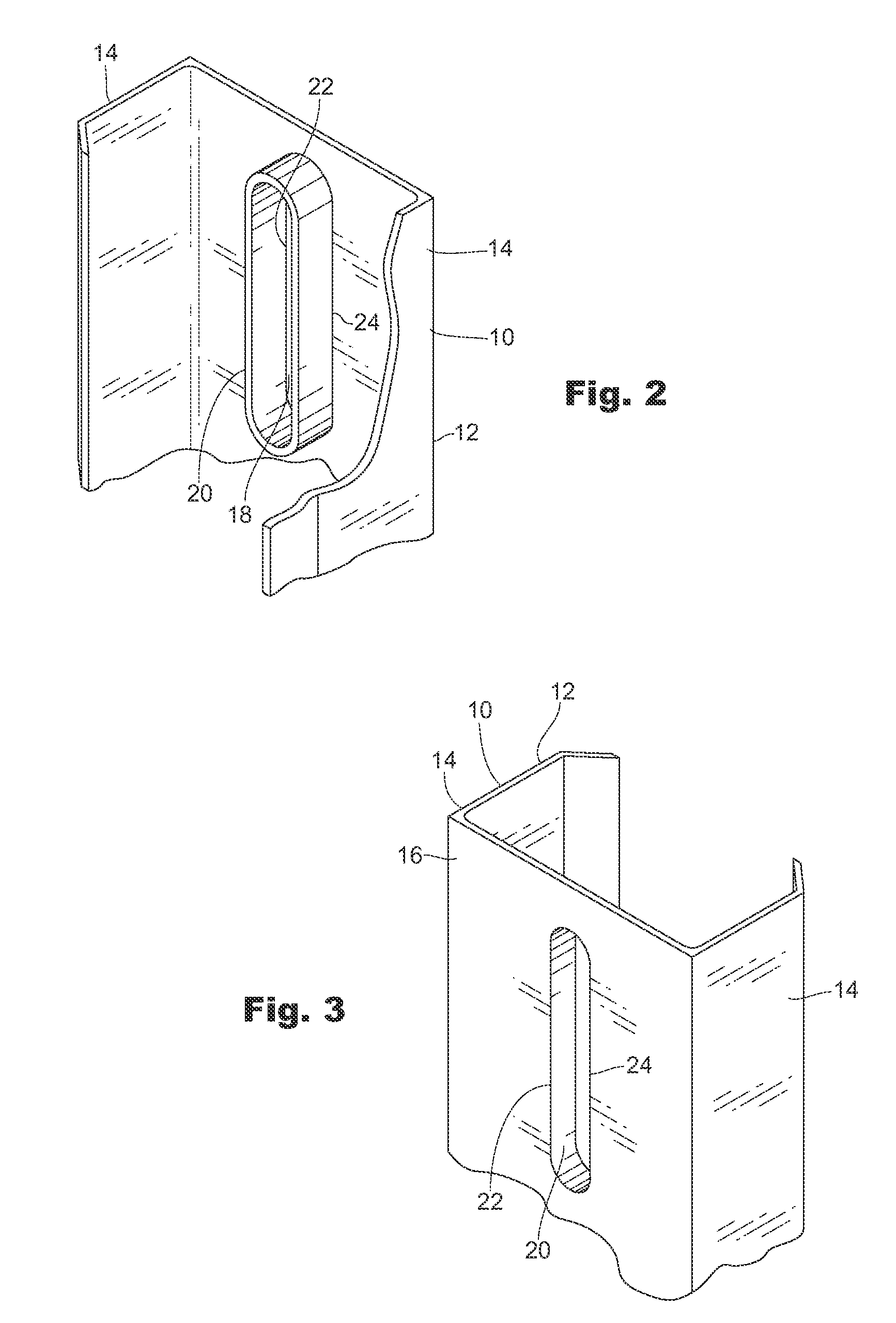

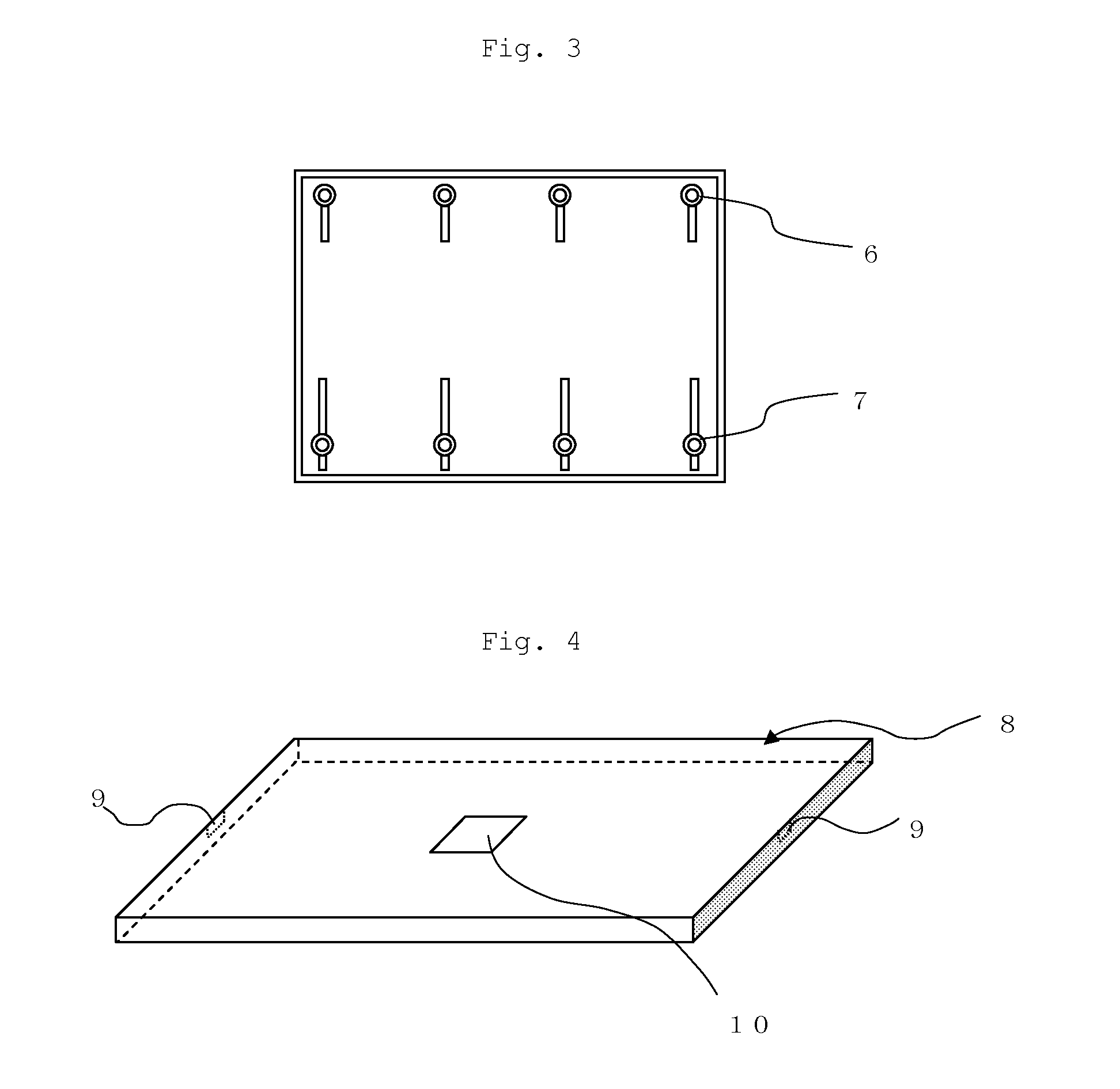

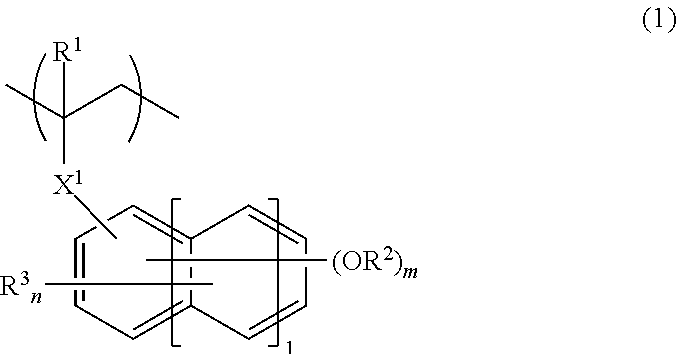

Slotted metal truss and joist with supplemental flanges

A slotted channel with a supplemental flange as a building member has at least one supplemental flange extending from at least one slot in the member web or primary flanges yielding a building member with increased strength, both compressive (longitudinally) and in shear (transverse). The slotted member presents a reduced area through which heat or sound may be conducted and slots in which insulation is received, both increasing resistance to heat and sound transfer.

Owner:LIGHT GAUGE STEEL AMERICA

Method and apparatus for making a stamper for patterning CDs and DVDs

InactiveUS20050151283A1Reduced and no sacrifice in data storage densityHuge savingsRecord carriersOptical articlesResistCompact Disc manufacturing

A method for forming a stamper used in the manufacture of CDs, DVDs, and other types of optical disks comprises forming a substrate by rolling. A layer of material is deposited (e.g. by plating) onto the substrate. Thereafter, a resist layer is formed on the layer of material and patterned. Because the substrate is formed by rolling, it is relatively inexpensive to form the substrate to a desired thickness. Because the layer of material is formed by deposition (e.g. plating), it is relatively inexpensive to ensure that the layer has a very smooth surface (i.e. without necessitating a great deal of polishing).

Owner:WD MEDIA

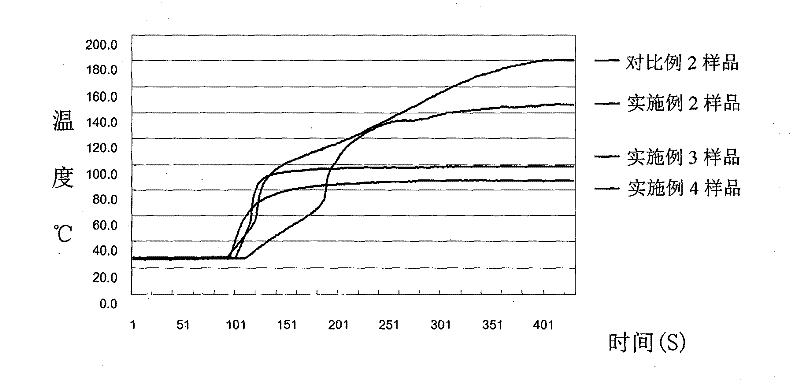

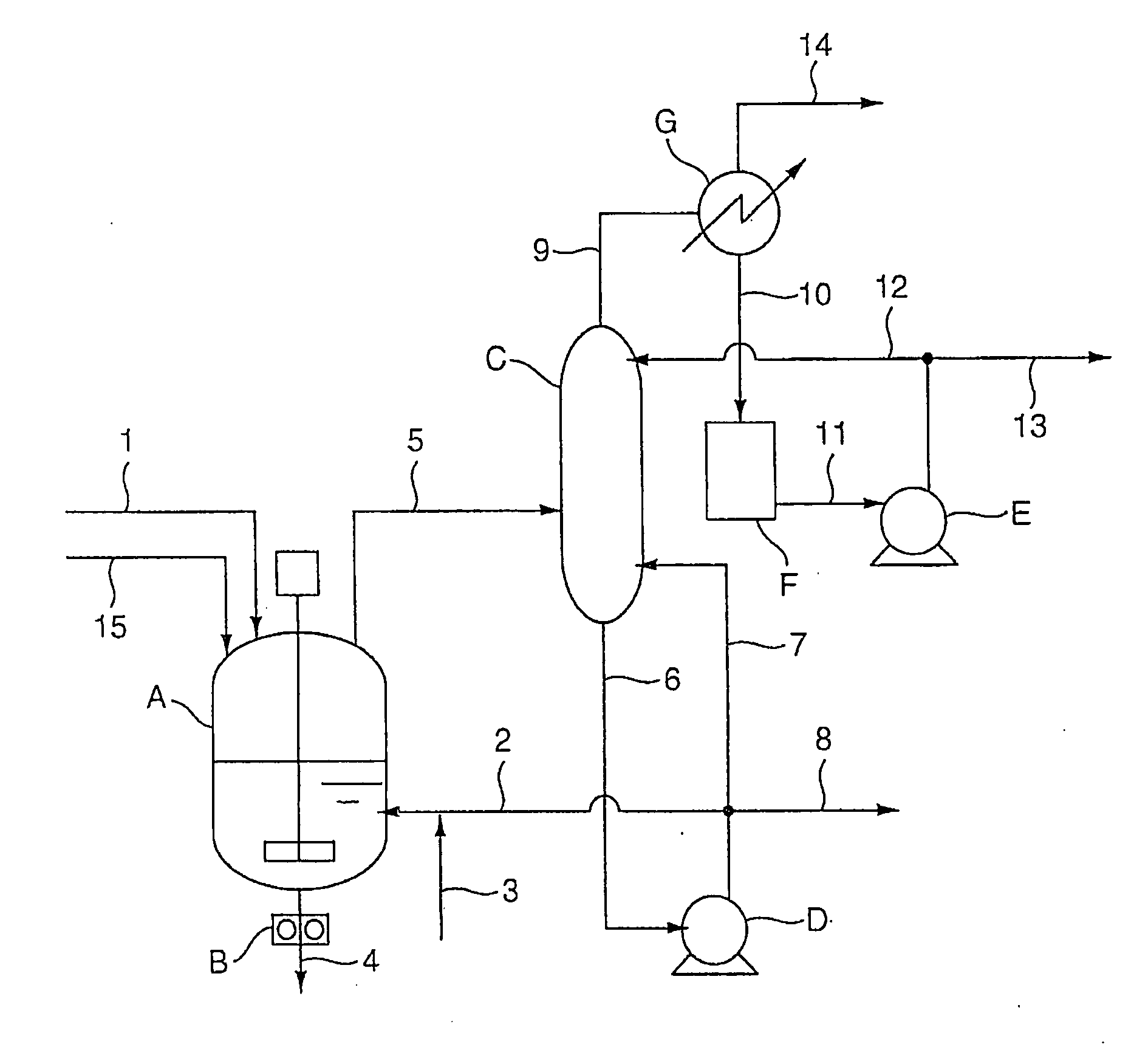

Polymer-carbon nanotube-carbon black composite temperature self-regulating positive temperature coefficient (PTC) electric heating material

InactiveCN102344598ALow resistivityImprove PTC StrengthPositive temperature coefficient thermistorsPigment treatment with macromolecular organic compoundsPolyvinylidene fluorideTemperature coefficient

The invention discloses a polymer-carbon nanotube-carbon black composite temperature self-regulating positive temperature coefficient (PTC) electric heating material. The polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material has positive temperature coefficients and high PTC intensity. The polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material comprises: by weight, 35 to 75% of one or more of high-density polyethylene, low-density polyethylene, ethylene-vinyl acetate copolymer, ethylene-ethyl acrylate copolymer, nitrile rubber buna, epoxy resins and polyvinylidene fluoride, 15 to 55% of carbon black and carbon nanotubes, 3 to 12% of an inorganic filling material, and 0.02 to 0.1% of an antioxidant. The above raw materials are mixed, then are subjected to processing molding by a banbury or a double-screw extruder, and are subjected to radiation crosslinking to form the polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material with high PTC intensity. The polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material has high PTC intensity and thus a leakage current is low and security and heat stability are good. In an electric warming respect, the polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material is widely utilized in the fields of temperature self-regulating heaters, over-current protection and temperature sensors.

Owner:谢志军

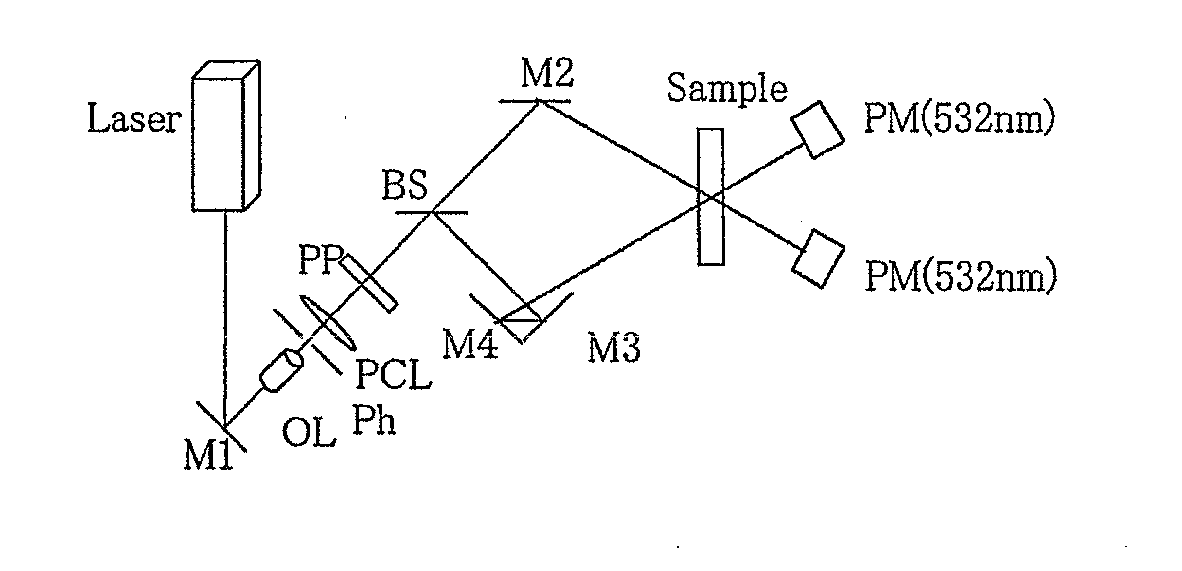

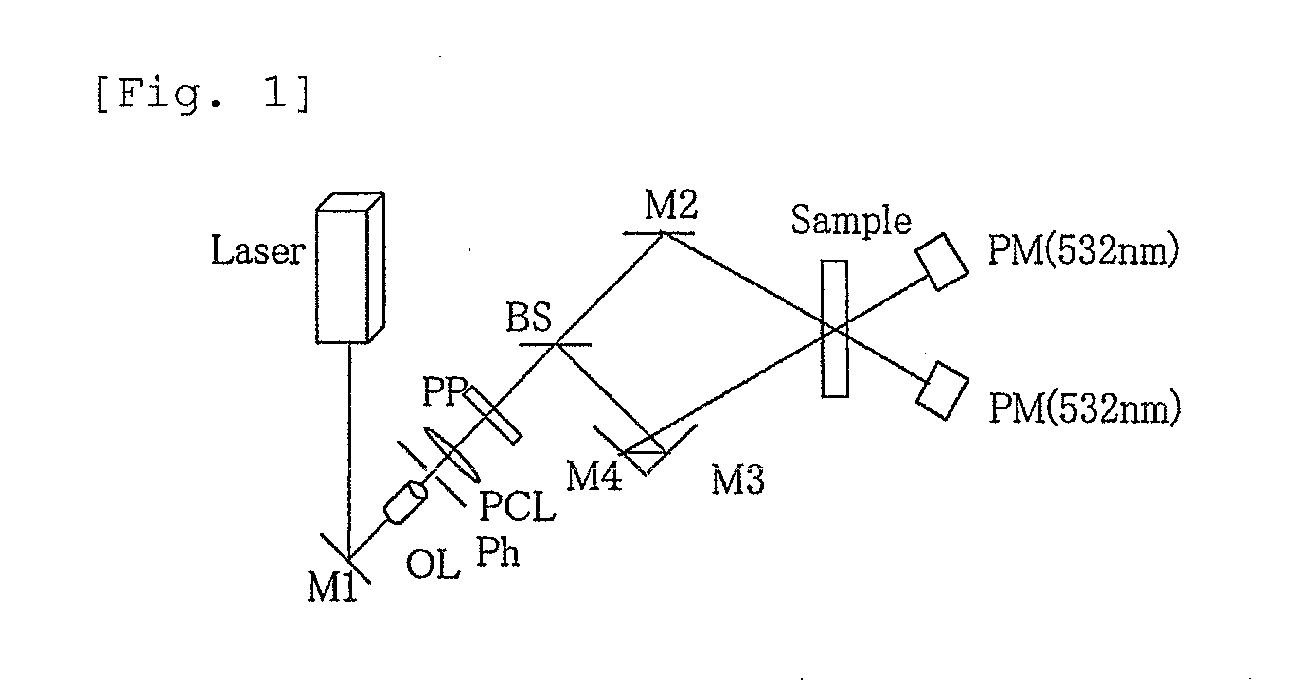

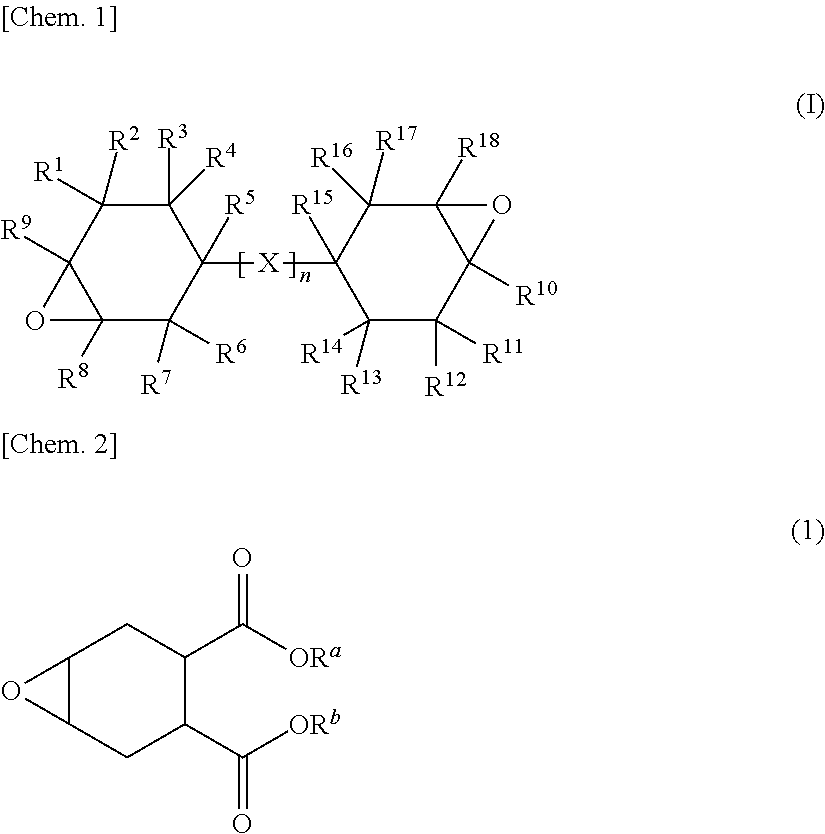

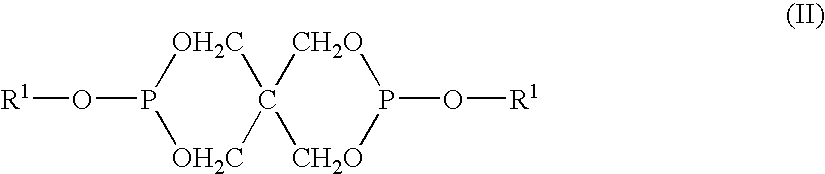

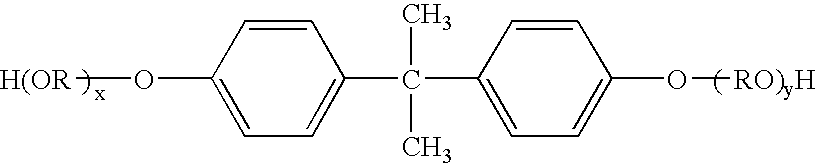

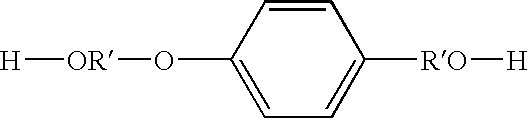

Photosensitive composition for volume hologram recording, volume hologram recording medium using same, method for manufacturing volume hologram recording medium, and hologram recording method

InactiveUS20150086907A1Stay rigidGood resistance stabilityPhotomechanical apparatusRecord information storagePolymerPhotochemistry

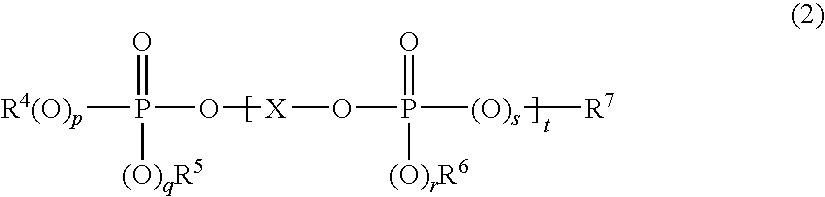

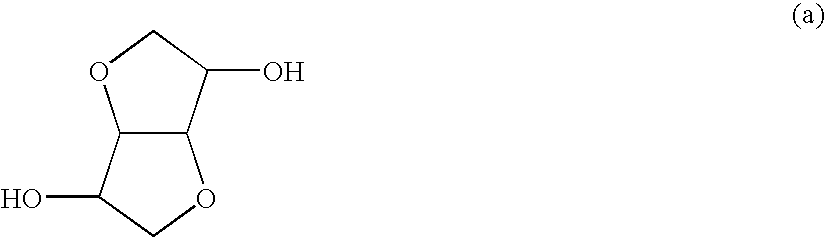

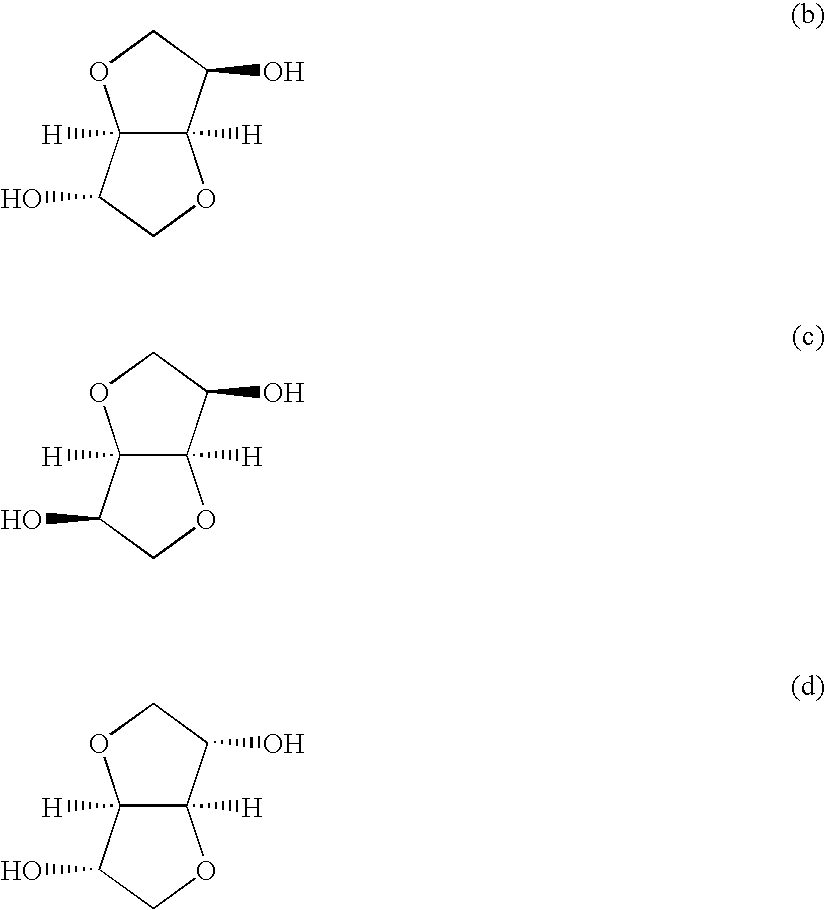

Provided is a photosensitive composition for volume hologram recording capable of forming a volume hologram recording medium that less shrinks upon curing in hologram recording (in hologram formation) and resists cracking. The photosensitive composition for volume hologram recording contains an alicyclic epoxy compound (A) represented by Formula (I); a thermal acid generator (B); a radically polymerizable compound (C); a radical polymerization initiator (D); and at least one epoxy compound (E) selected from the group consisting of compounds represented by Formula (1), epoxidized fatty acid esters, and epoxidized conjugated diene polymers.

Owner:DAICEL CHEM IND LTD

Thermoplastic resin composition

The present invention relates to a thermoplastic resin composition which excels in impact resistance, dimension stability and rigidity, and also excels in appearance, fluidity and paint film adhesion property, and further which is very useful as manufacturing materials for exterior parts of automobile. A thermoplastic resin composition comprising component (A): a polyamide resin; component (B): a hydrogenated product of block copolymer comprising vinyl aromatic polymer block (a) and conjugated diene based polymer block (b), and / or ethylene-α-olefin based block copolymer; component (C): a modified hydrogenated product of block copolymer comprising the vinyl aromatic polymer block (a) and the conjugated diene based polymer block (b), which hydrogenated product is modified by addition of an unsaturated acid and / or derivative thereof; component (D): a plate-like and / or needle-like inorganic filler; and component (F): an ethylene-vinyl alcohol copolymer and / or a partial saponified product of ethylene-vinyl acetate copolymer.

Owner:MITSUBISHI CHEM CORP

Thermoplastic resin composition and resin molded product

InactiveUS20090215934A1Improve flame retardant performanceImprove impact resistanceFibre treatmentPolyolefinThermal stability

The present invention relates to a thermoplastic resin composition comprising an aromatic polycarbonate resin (component A) [which may comprise an aromatic polycarbonate resin (component A1) and a thermoplastic resin other than the aromatic polycarbonate resin (component A2)], a granular talc (component B) having a bulk density of 0.4 to 1.5 g / mL which is obtained by granulating a talc having an average particle size of 0.1 to 10 μm, a rubber polymer (component C; optional component), a flame retardant (component E; optional component) and a fluorinated polyolefin (component F; optional component), wherein the granular talc (component B) has a particle size in which a proportion of a 500 μm-mesh screen residue thereof is not less than 55% by weight; as well as a resin molded product obtained by molding the thermoplastic resin composition. The thermoplastic resin composition and the resin molded product are excellent in extrusion moldability, rigidity, flame retardant, impact resistance and thermal stability, and exhibit an excellent balance between these properties.

Owner:MITSUBISHI ENG PLASTICS CORP

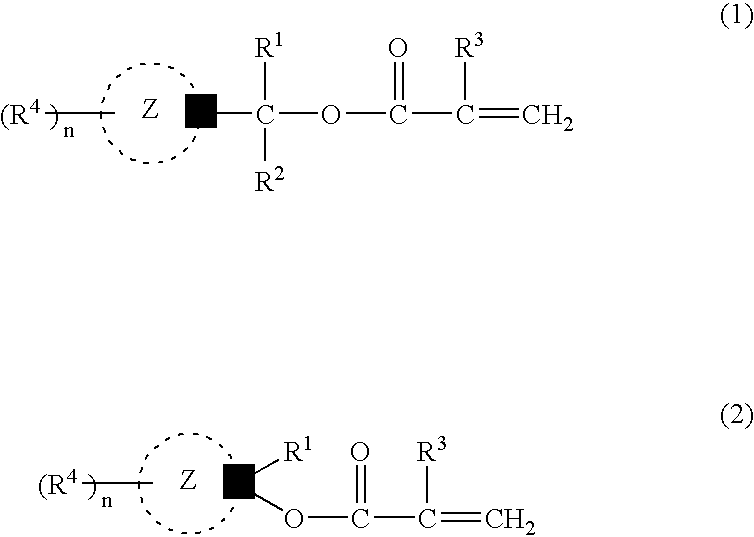

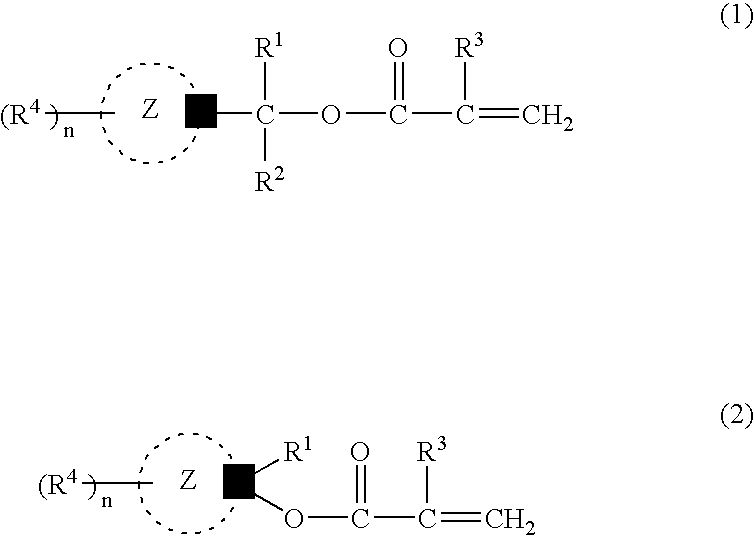

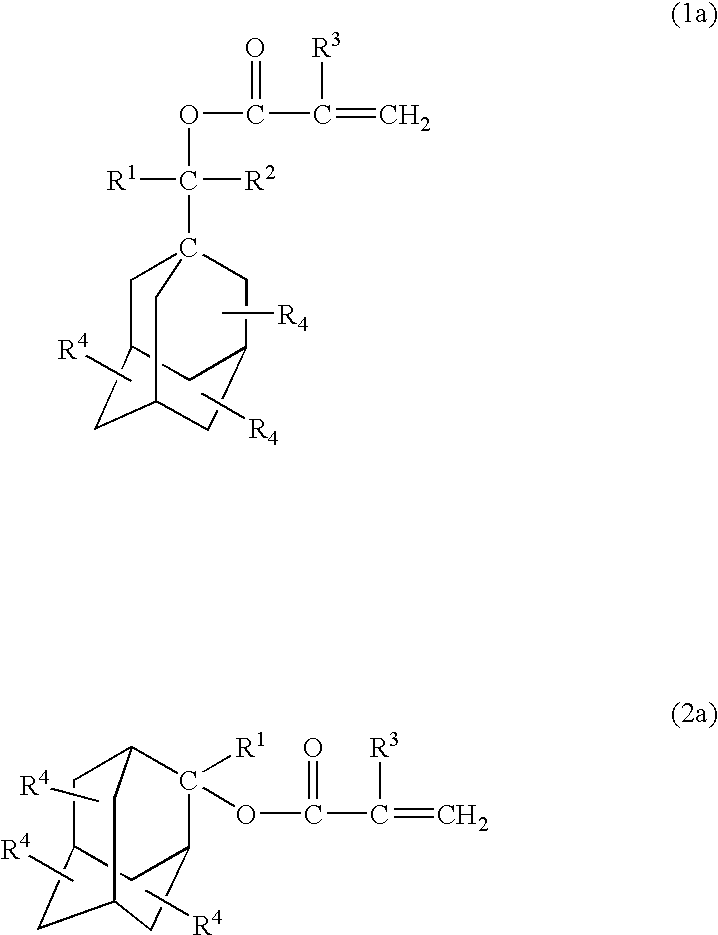

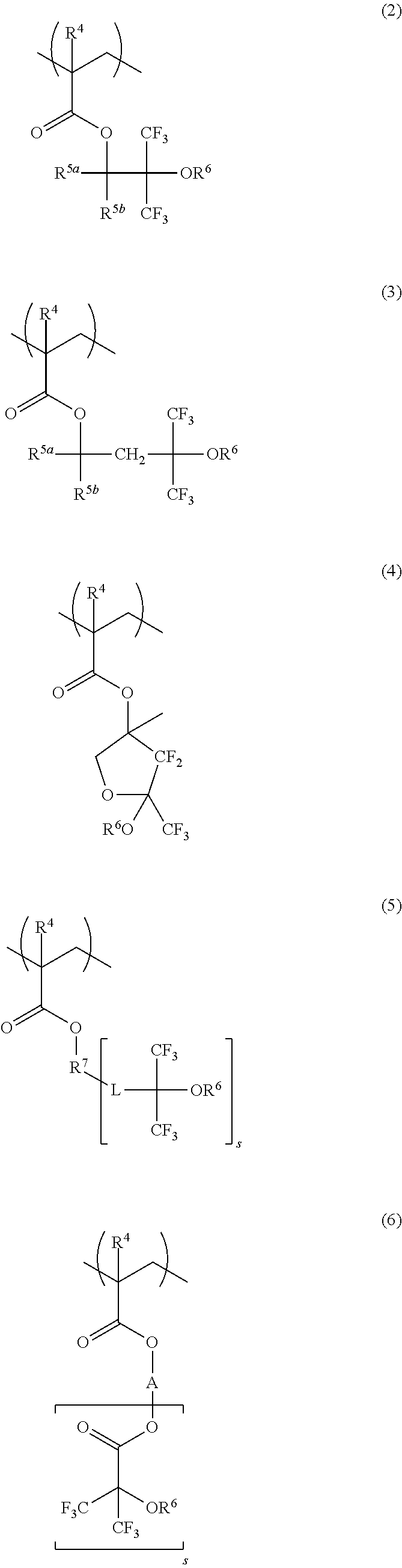

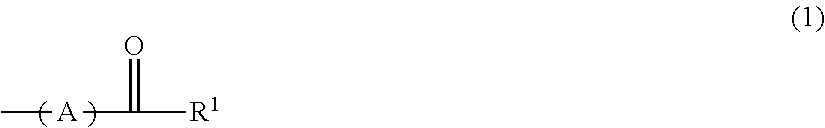

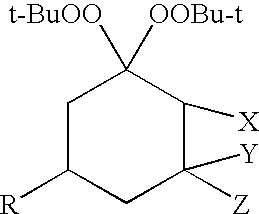

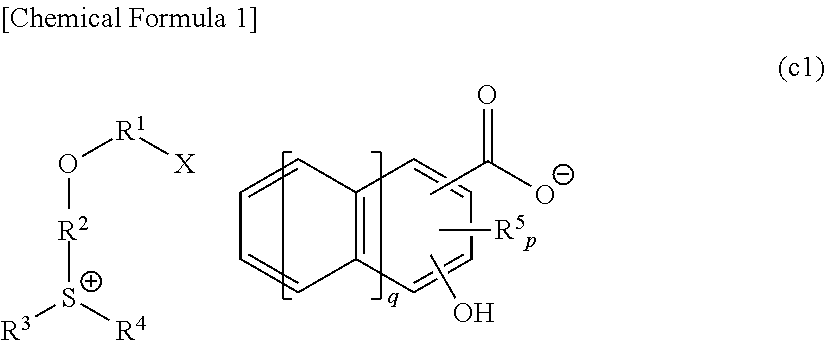

Acid-sensitive compound and resin composition for photoresist

InactiveUS20030180662A1Improve adhesionGood reproducibilityOrganic chemistryPhotosensitive materialsResistAlicyclic Hydrocarbons

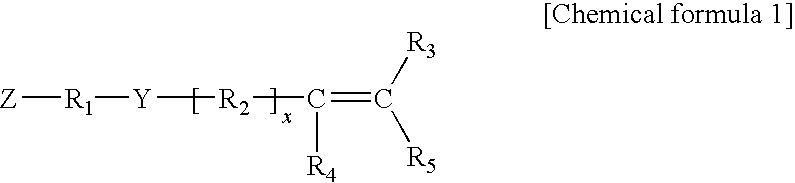

The photoresist resin composition comprises a polymer containing an acid-responsive compound unit of the following formula (e.g. an adamantane skeleton) and a photoactive acid precursor. R<1 >may be an alkyl group having a tertiary carbon atom in the 1-position and the Z ring is a bridged-ring hydrocarbon ring comprising 2 to 4 rings. wherein R<1 >and R<2 >are the same or different from each other and each represents a hydrogen atom, an alkyl group or a cycloalkyl group; R<3 >represents a hydrogen atom or a methyl group; R<4 >represents a hydrogen atom, a halogen atom, an alkyl group, an oxygen-containing group, an amino group or an N-substituted amino group; the Z ring represents a monocyclic or polycyclic alicyclic hydrocarbon ring; n represents an integer of not less than 1; with proviso that R<4 >does not concurrently represent a hydrogen atom, and may be different over n occurrences; in formula (1), R<1 >and R<2 >may, jointly and together with the adjacent carbon atom, form an alicyclic hydrocarbon ring. The above photoresist resin composition is high in etching resistance, can be solubilized by irradiation, and is capable of providing a finer line pattern.

Owner:DAICEL CHEM IND LTD

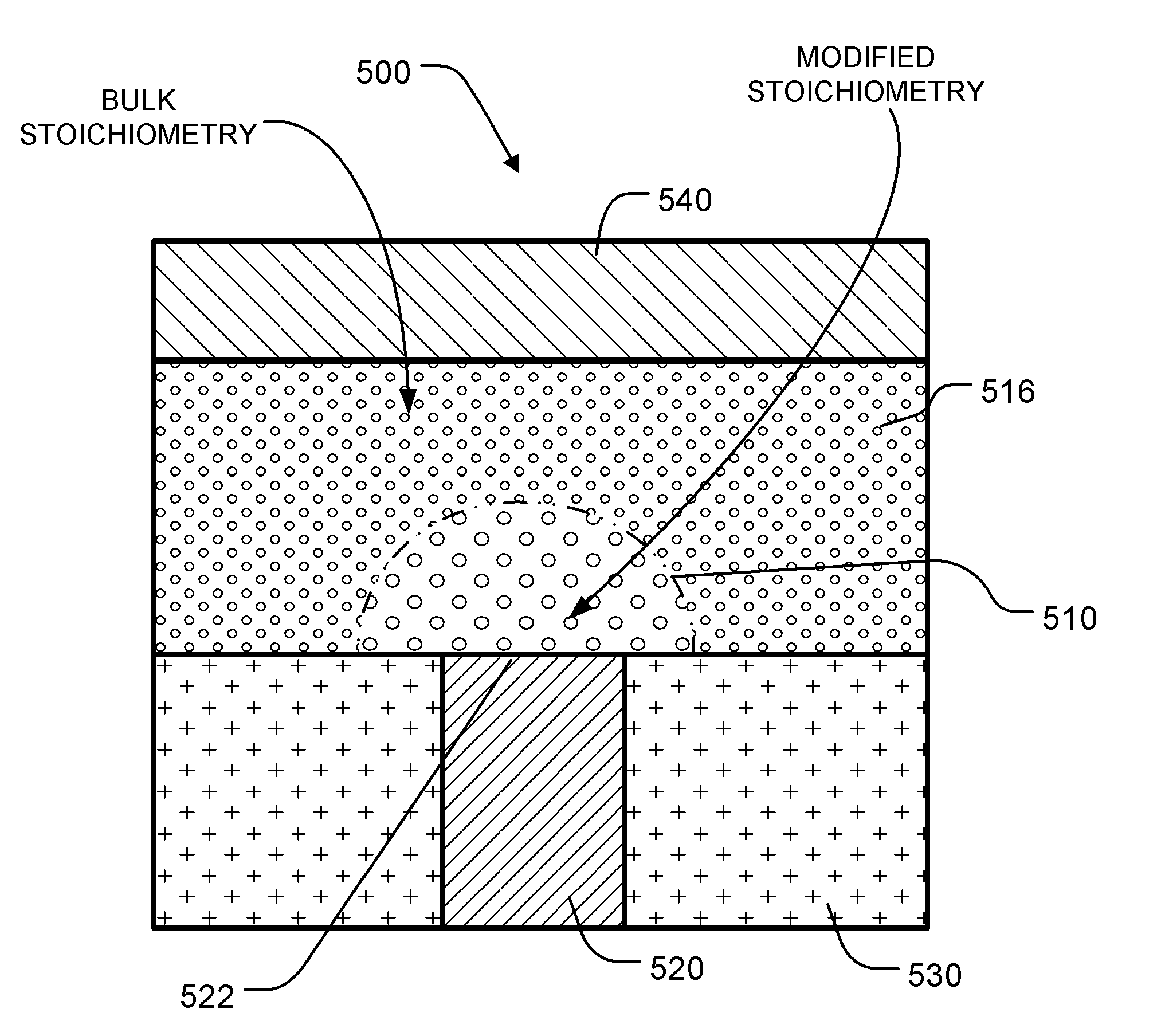

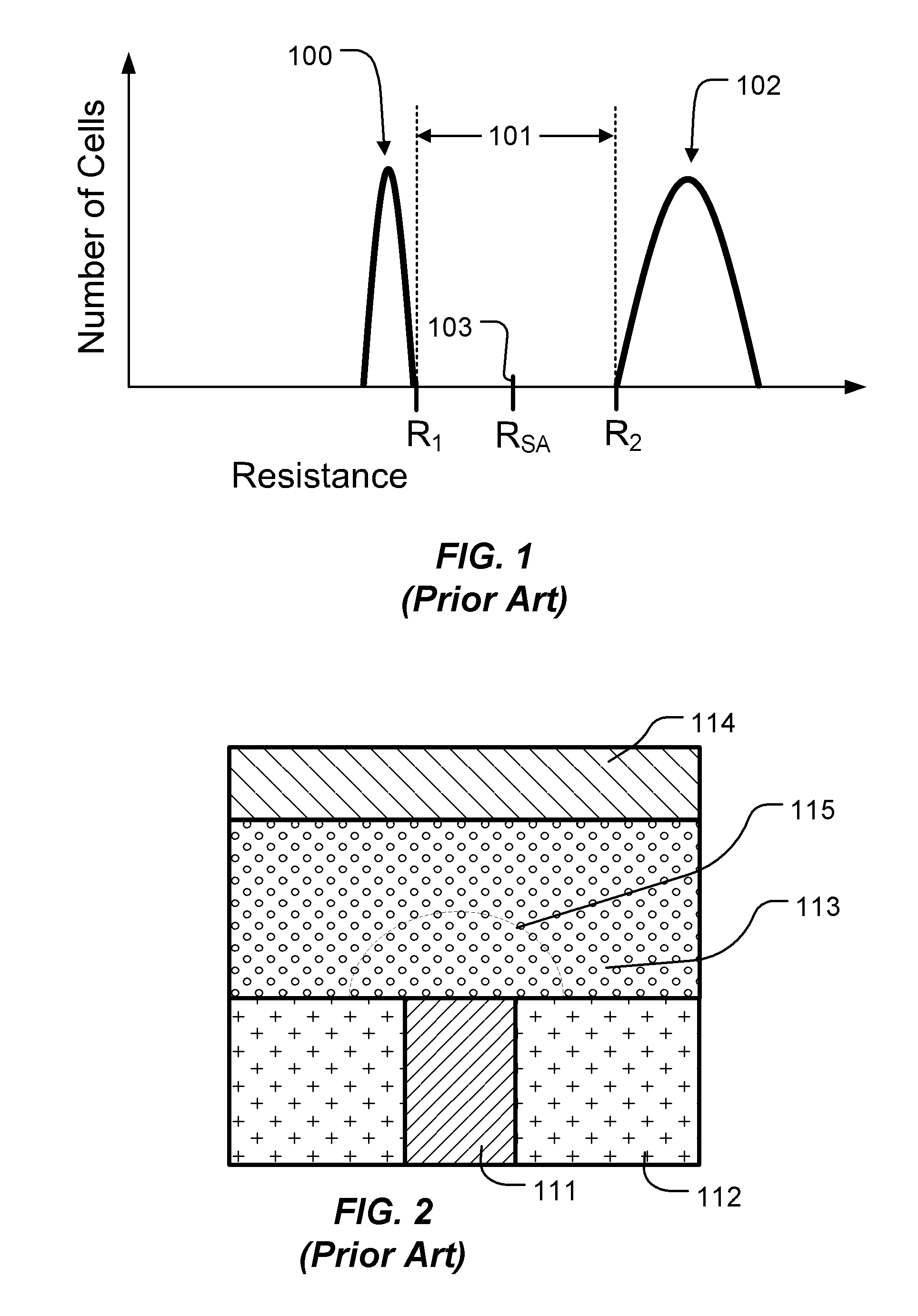

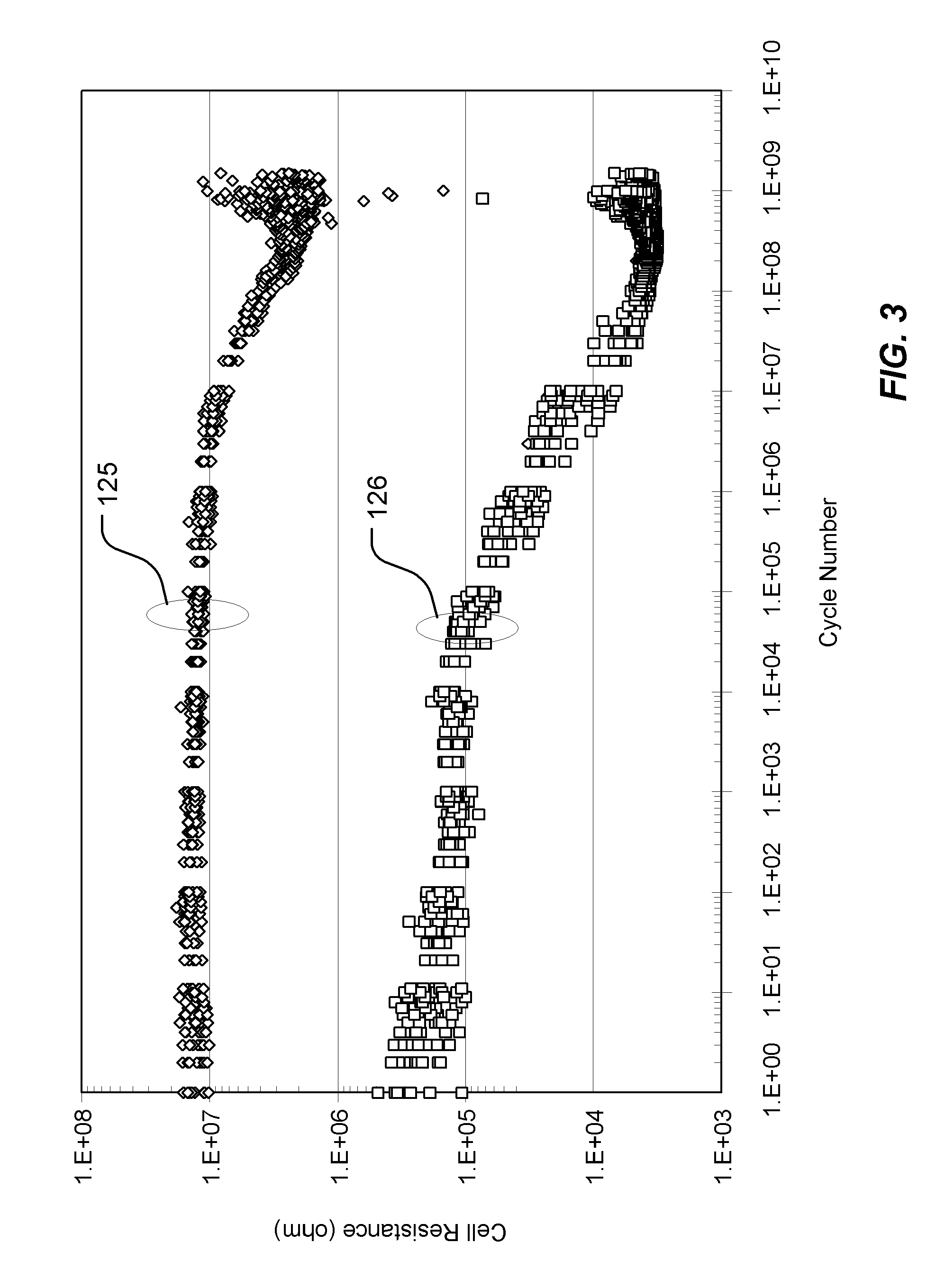

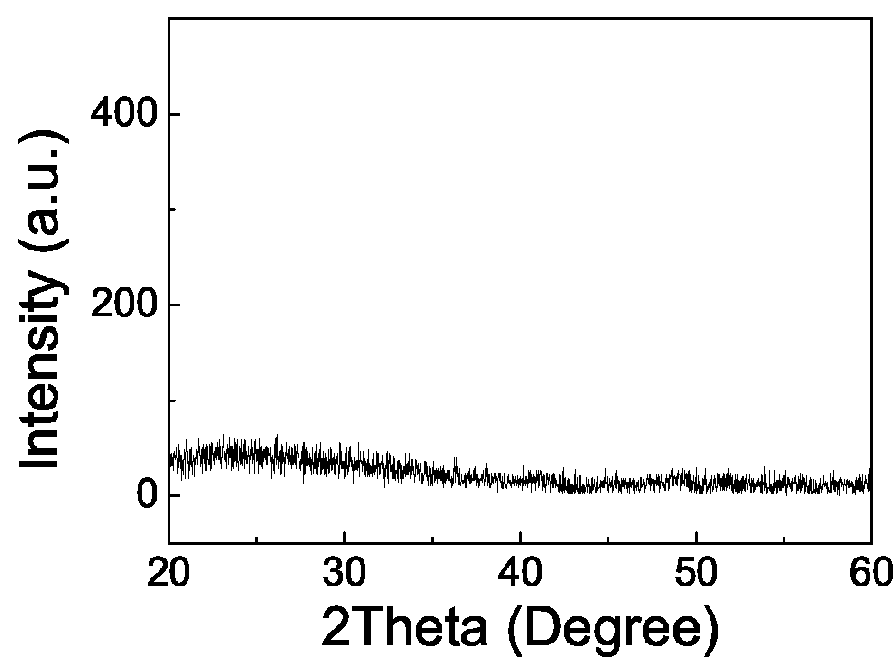

Phase change memory having stabilized microstructure and manufacturing method

ActiveUS20100314601A1Prevent rapid quenching of modification processGood resistance stabilitySemiconductor/solid-state device manufacturingDigital storageStoichiometryIntegrated circuit

A memory device having a phase change material element with a modified stoichiometry in the active region does not exhibit drift in set state resistance. A method for manufacturing the memory device includes first manufacturing an integrated circuit including an array of phase change memory cells with bodies of phase change material having a bulk stoichiometry; and then applying forming current to the phase change memory cells in the array to change the bulk stoichiometry in active regions of the bodies of phase change material to the modified stoichiometry, without disturbing the bulk stoichiometry outside the active regions. The bulk stoichiometry is characterized by stability under the thermodynamic conditions outside the active region, while the modified stoichiometry is characterized by stability under the thermodynamic conditions inside the active region.

Owner:MACRONIX INT CO LTD

Manufacturing method of electrothermal film

ActiveCN104080208AImprove stabilityImprove temperature resistanceHeating element materialsNickel sesquioxideManganese

The invention discloses a manufacturing method of an electrothermal film. The manufacturing method comprises the following steps of A, preparing an electrothermal film treatment solution which comprises tin tetrachloride, titanium trichloride, antimony trichloride, calcium chloride, chromic oxide, manganese dioxide, nickel sesquioxide, isopropanol, alcohol and water, B, masking a substrate, C, heating the substrate to be 400-700 DEG C and then spraying the electrothermal film treatment solution on the substrate by a spray gun to form a semifinished electrothermal film, D, annealing the semifinished electrothermal film, and E, coating silver oxide paste on the surfaces of the two ends of the annealed semifinished electrothermal film, loading the semifinished electrothermal film into an electrode oven, baking and fusing the semifinished electrothermal film to form a whole, and obtaining the finished electrothermal film. The manufacturing method has the advantages that the stability of the electrothermal film is improved by adding antimony; the temperature resistance of the electrothermal film is improved by adding titanium; the infrared emitting ability of the electrothermal film is improved by adding nickel and manganese; and an adhesive force between the electrothermal film treatment solution and the substrate is increased by adding isopropanol.

Owner:成都世纪经尧科技有限公司

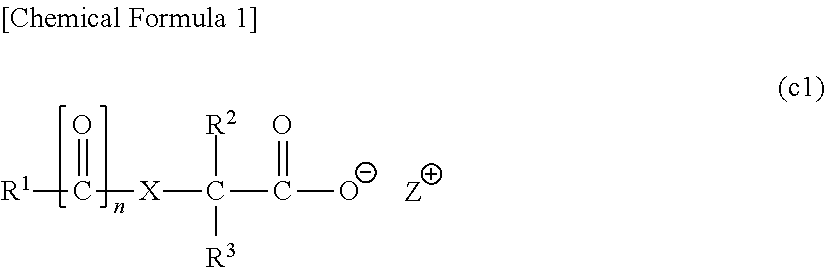

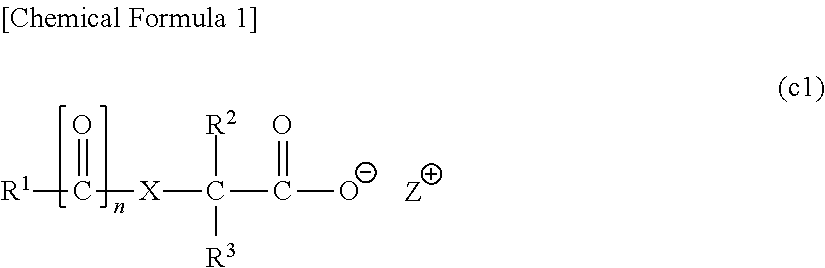

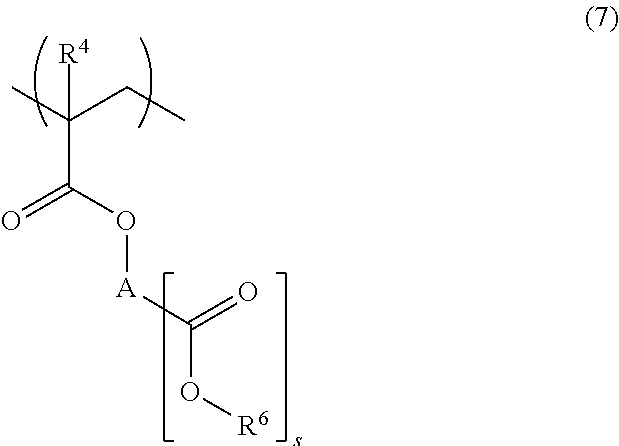

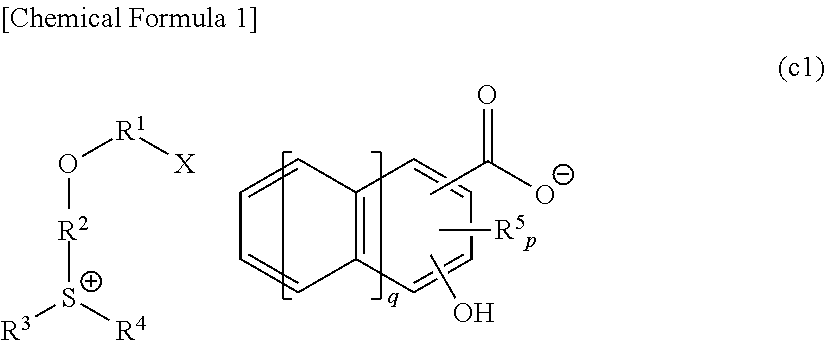

Resist composition, method of forming resist pattern and compound

ActiveUS20130157197A1Maintain good propertiesGood storage stabilityOrganic chemistryOrganic compound preparationResistCompound a

A resist composition comprising: a base component (A) that exhibits changed solubility in a developing solution by the action of acid; a photoreactive quencher (C); and an acid-generator component (B) that generates acid upon exposure, wherein the photoreactive quencher (C) contains a compound represented by general formula (c1) shown below. In the formula, R1 represents a hydrogen atom or a hydrocarbon group of 1 to 20 carbon atoms which may have a substituent; each of R2 and R3 independently represents a hydrogen atom or a hydrocarbon group of 1 to 20 carbon atoms which may have a substituent; at least two of R1 to R3 may be mutually bonded to form a ring; X represents an oxygen atom or a sulfur atom; n represents 0 or 1; and Z+ represents an organic cation.

Owner:TOKYO OHKA KOGYO CO LTD

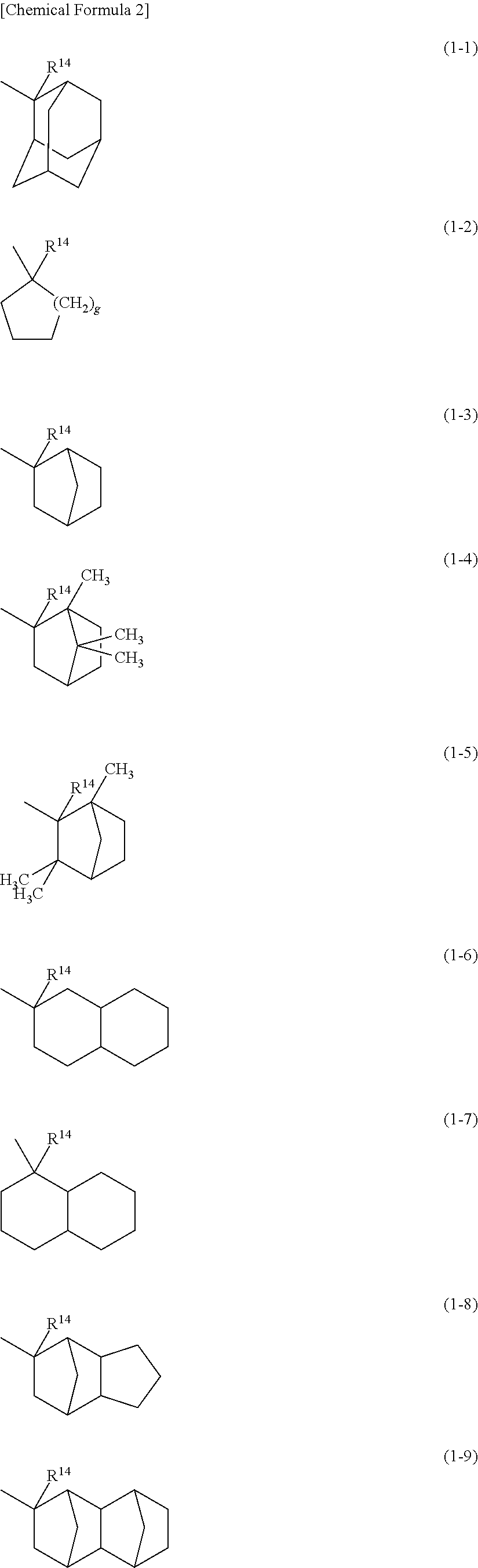

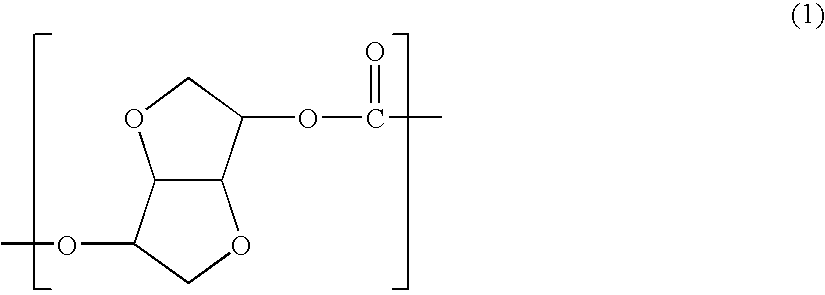

Flame-retardant polycarbonate resin composition

ActiveUS20100184884A1Improve flame retardant performanceImprove heat resistanceGroup 5/15 element organic compoundsPolymer scienceEther

There is provided a resin composition that comprises a polycarbonate resin derived from an ether diol such as isosorbide and that is excellent in flame retardancy, heat resistance, thermal stability, rigidity, transparency and moldability.The resin composition is a flame-retardant resin composition comprising 1 to 60 parts by weight of phosphorus compound (component B) having a thermal decomposition temperature of not higher than 340° C. based on 100 parts by weight of polycarbonate resin (component A) that mainly comprises a recurring unit represented by the following formula (1).

Owner:TEIJIN LTD

Photomask blank, resist pattern forming process, and method for making photomask

ActiveUS20160299431A1Improve efficiencyImprove accuracyPhotomechanical exposure apparatusPhotosensitive material processingResistSolubility

A photomask blank has a chemically amplified negative resist film comprising (A) a polymer comprising recurring units of specific structure and recurring units having fluorine, (B) a base resin adapted to reduce its solubility in alkaline developer under the action of acid, (C) an acid generator, and (D) a basic compound. The resist film is improved in receptivity to antistatic film.

Owner:SHIN ETSU CHEM IND CO LTD

Thermoplastic Resin Composition Having Improved Flowability

ActiveUS20100168292A1Good compatibilityImprove flame resistanceFilm/foil adhesivesPolymer sciencePolyester resin

A thermoplastic resin composition that can have improved flowability of the present invention comprises (A) about 1 to about 98% by weight of a functional group-containing vinyl copolymer resin reactive with polyester; (B) about 1 to about 98% by weight of an aromatic vinyl graft copolymer resin; (C) about 1 to about 98% by weight of a polyester resin; and (D) about 0.5 to about 30 parts by weight of a bromodiphenyl ethane mixture, based on the total weight of a base resin comprising (A), (B) and (C). The resin composition of the present invention can have flame retardancy, excellent impact resistance, and improved flowablity.

Owner:LOTTE ADVANCED MATERIALS CO LTD

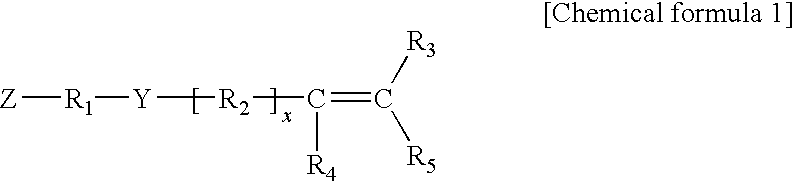

Preparation method of liquid silicone rubber composition

The invention relates to a preparation method of a liquid silicone rubber composition. The preparation method includes mixing polydimethylsiloxane, silica powder, magnesium carbonate, silane modificated conductive carbon black, fumed silica and treating agent to obtain a mixture, subjecting the mixture to heat treatment at 100-150 degrees for 0.5-5h, heating the mixture to 120-160 DEG C, evacuating the mixture under vacuum of -0.04--0.1MPa for 2-6hs, and grinding the mixture 2-4 times to obtain base gum after cooling the same to the indoor temperature; adding and mixing polydimethylsiloxane attenuation and platinum catalyst in the base gum at the normal temperature to obtain material A; adding and mixing polydimethylsiloxane attenuation, cross-linking agent and negative catalyst in the base gum at the normal temperature to obtain material B; mixing the material A and the material B, by weight, in the proportion of 1:1, subjecting the mixture to solidification at 100-200 DEG C for 0.1-50h to obtain the liquid silicone rubber composition. The preparation method is simple, and the liquid silicone rubber contains ultra-low low-molecular-weight content and is high in compression permanent deformation rate.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Electrical devices containing conductive polymers

InactiveUS6987440B2Improved electrodingImprove performanceResistor terminals/electrodesCurrent responsive resistorsConductive polymerMetal foil

An electrical device in which an element composed of a conductive polymer composition is positioned in contact with the first surface of a metal electrode, the first surface having a center line average roughness Ra and a reflection density RD, the product Ra times RD being 0.5 to 1.6 μm. The conductive polymer composition preferably exhibits PTC behavior. In a second embodiment an electrical device has an element composed of a conductive polymer composition in contact with the first surface of a metal electrode produced by providing a base metal foil having an Ra of at most 0.45 μm and depositing material onto the base metal foil to form a first surface having a product of Ra times RD of at least 0.14 μm. Other embodiments include electrical devices with metal electrodes made by pulse plating processes, and metal electrodes made by electrodeposition under diffusion-limited conditions. The electrical devices may be circuit protection devices and have improved electrical and physical properties.

Owner:LITTELFUSE INC

Rubber composition and pneumatic tire

ActiveUS20150126674A1Improve fuel economyImprove wet grip performanceSpecial tyresPolymer scienceWear resistance

The present invention provides a rubber composition capable of improving fuel economy and wet grip performance while maintaining good processability, abrasion resistance and handling stability or improving them, as well as a pneumatic tire including the rubber composition. The rubber composition contains carbon black, silica, and a polymer mixture obtained by modifying a polymer derived from a conjugated diene compound and / or an aromatic vinyl compound with a compound containing an ester group and / or a carboxyl group, the polymer mixture having a weight average molecular weight of from 1.0×103 to 1.0×105, the rubber composition having a tan δ peak temperature of −20° C. or higher, a rubber hardness of from 63 to 75, and a tan δ at 70° C. of from 0.15 to 0.45.

Owner:SUMITOMO RUBBER IND LTD

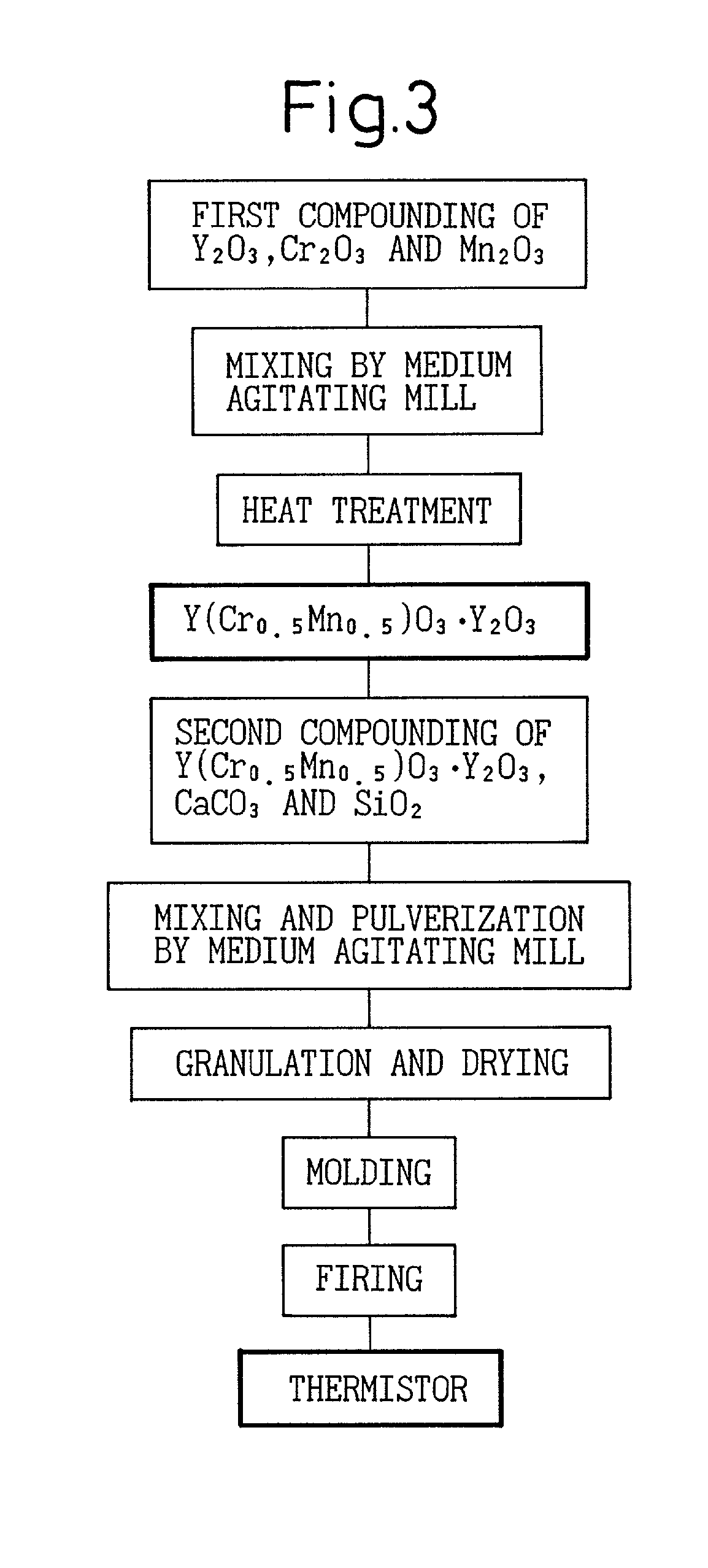

Reduction resistant thermistor, method of production thereof, and temperature sensor

InactiveUS20020036563A1Avoid changeReduce change in resistanceCurrent responsive resistorsConductive materialReducing atmosphereOxygen

A highly accurate reduction resistant thermistor exhibiting stable resistance characteristics even under conditions where the inside of a metal case of a temperature sensor becomes a reducing atmosphere, wherein when producing the thermistor comprised of a mixed sintered body (M1 M2)O3.AOx, the mean particle size of the thermistor material containing the metal oxide, obtained by heat treating, mixing, and pulverizing the starting materials, is made smaller than 1.0 mum and the sintered particle size of the mixed sintered body, obtained by shaping and firing this thermistor material, is made 3 mum to 20 mum so as to reduce the grain boundaries where migration of oxygen occurs, suppress migration of oxygen, and improve the reduction resistance.

Owner:NIPPON SOKEN +1

Toner

ActiveUS20070026336A1Stably provides high image qualityNot cause any image failure with timeDevelopersPolyesterCopolymer

Provided is a toner including at least: a binder resin; and a colorant, in which: the binder resin contains at least a polyester unit and a vinyl copolymer unit; a main peak MpA is present in the molecular weight region of 2,000 to 7,000 in a molecular weight distribution measured by means of gel permeation chromatography (GPC) of a specific tetrahydrofuran (THF) soluble matter A measured by a specific method; a main peak MpB is present in the molecular weight region of 5,000 to 10,000 in a molecular weight distribution measured by means of GPC of a specific THF soluble matter B which contains a component of a molecular weight region of 100,000 or less in range from 70 to 100 mass %, and the peak molecular weight MpA of the THF soluble matter A and the peak molecular weight MpB of the THF soluble matter B satisfy a specific equation.

Owner:CANON KK

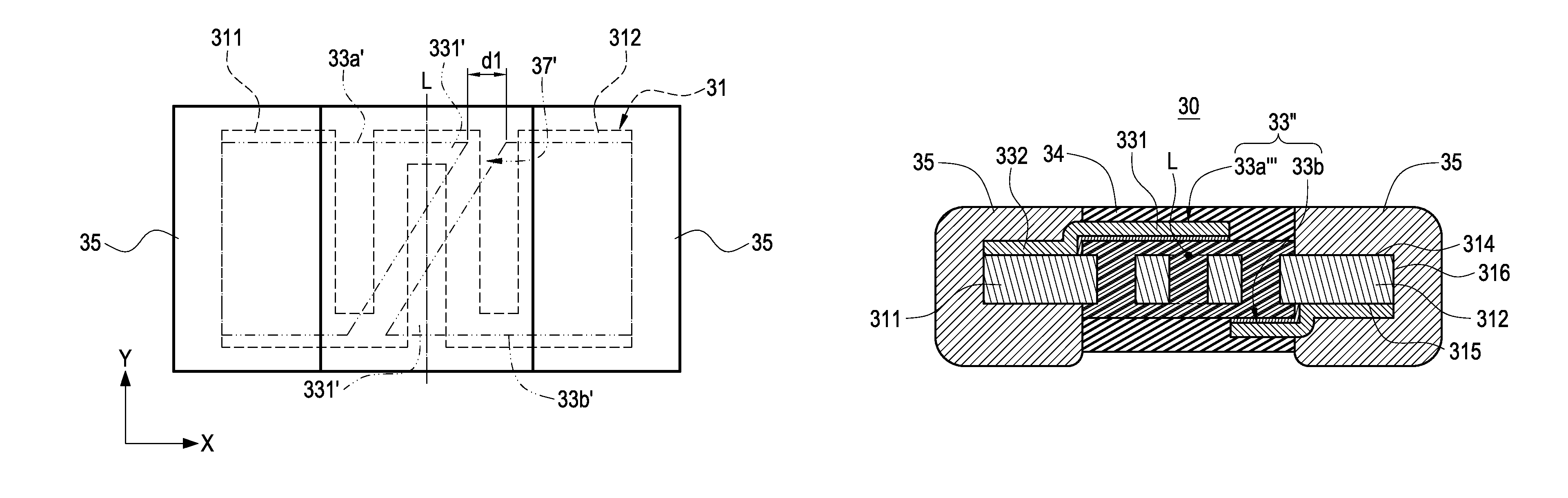

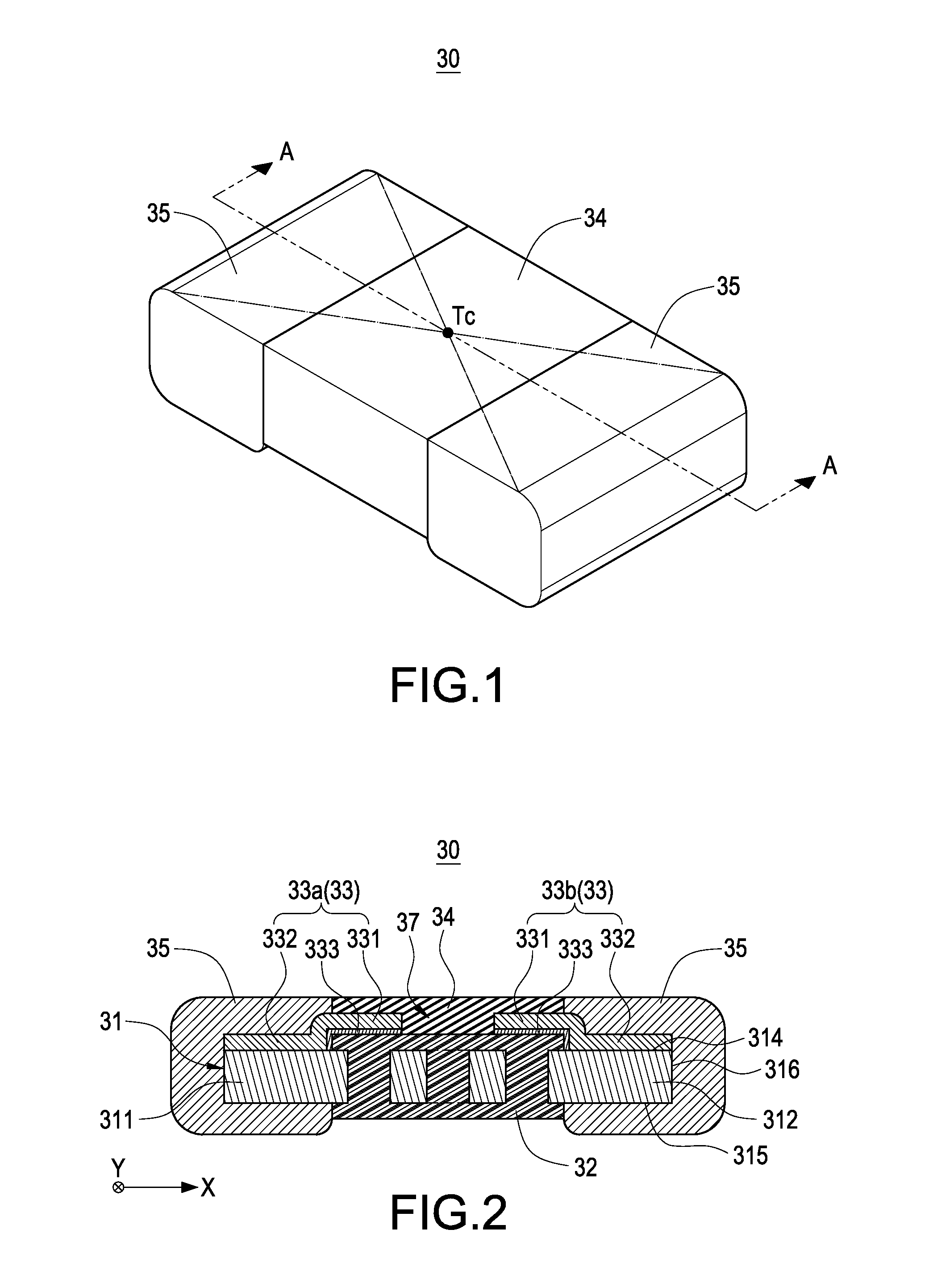

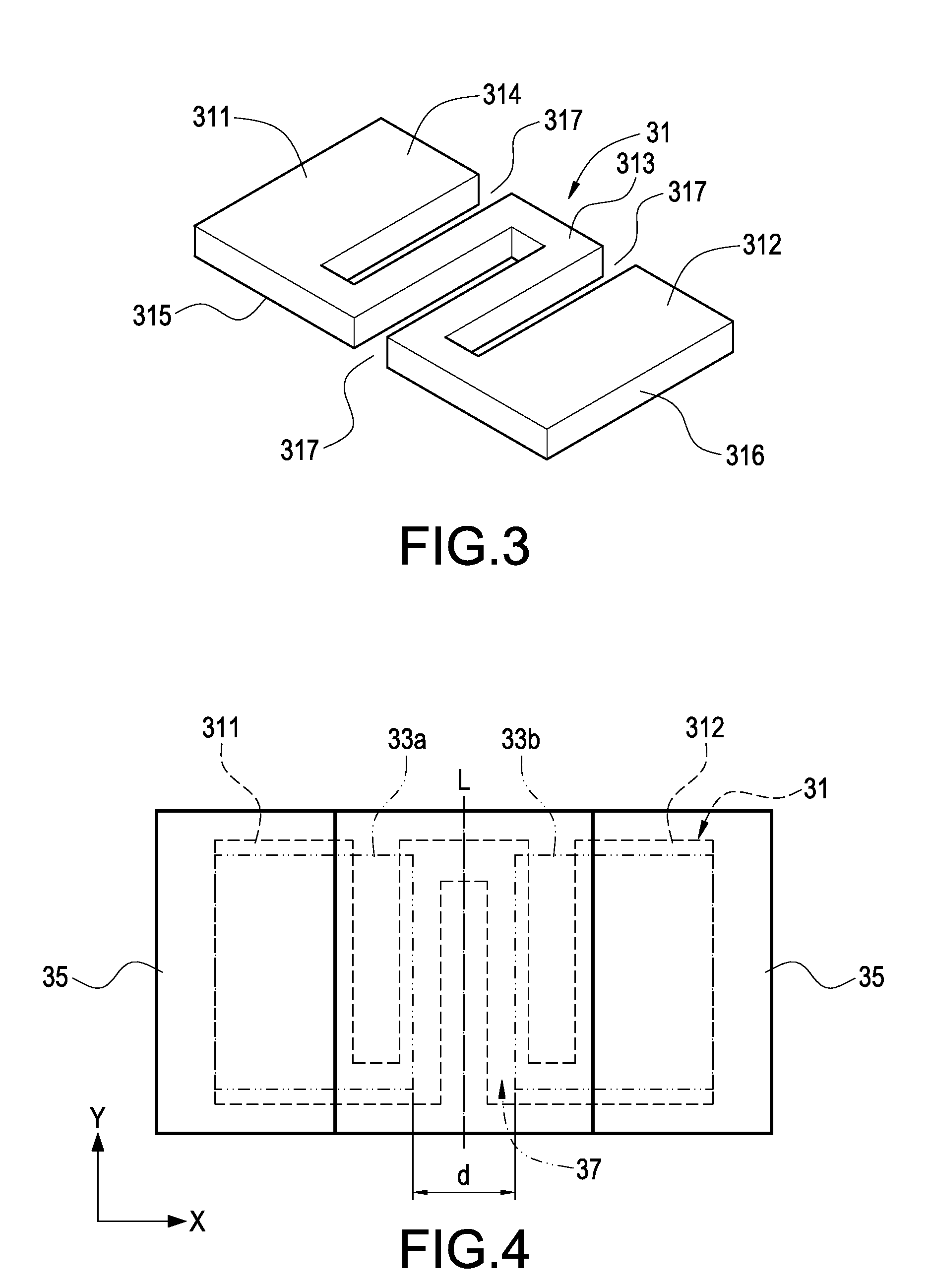

Surface mount resistor

ActiveUS8310334B2Improve cooling effectGood resistance stabilityResistor chip manufactureEnvelope/housing resistor manufactureSurface mountingResistor

Owner:CYNTEC

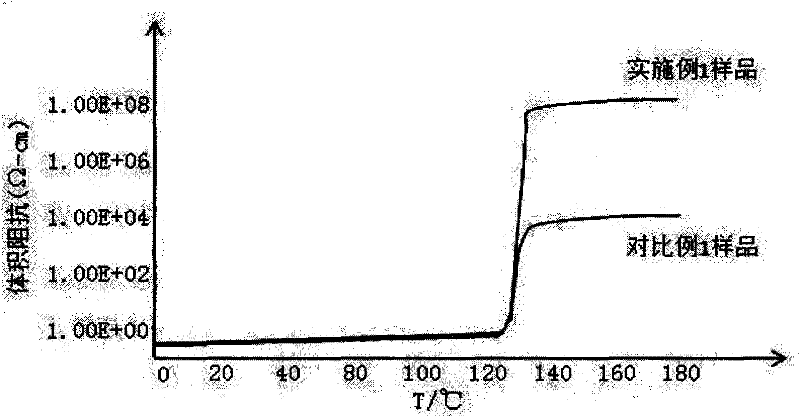

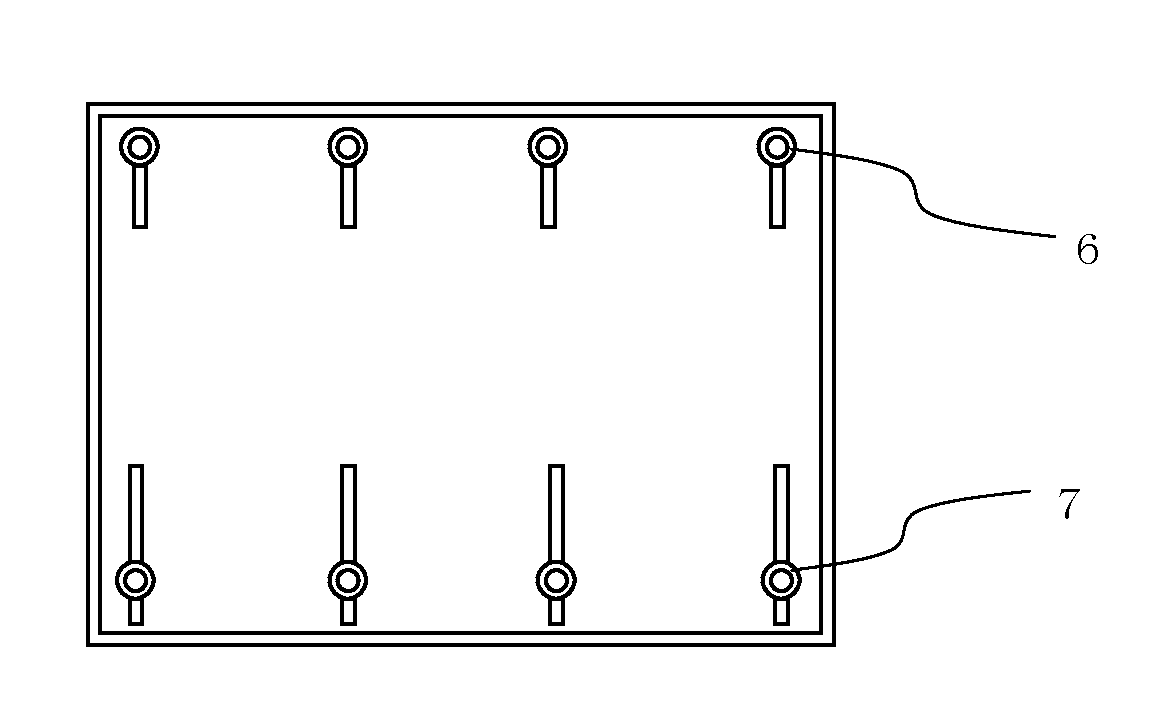

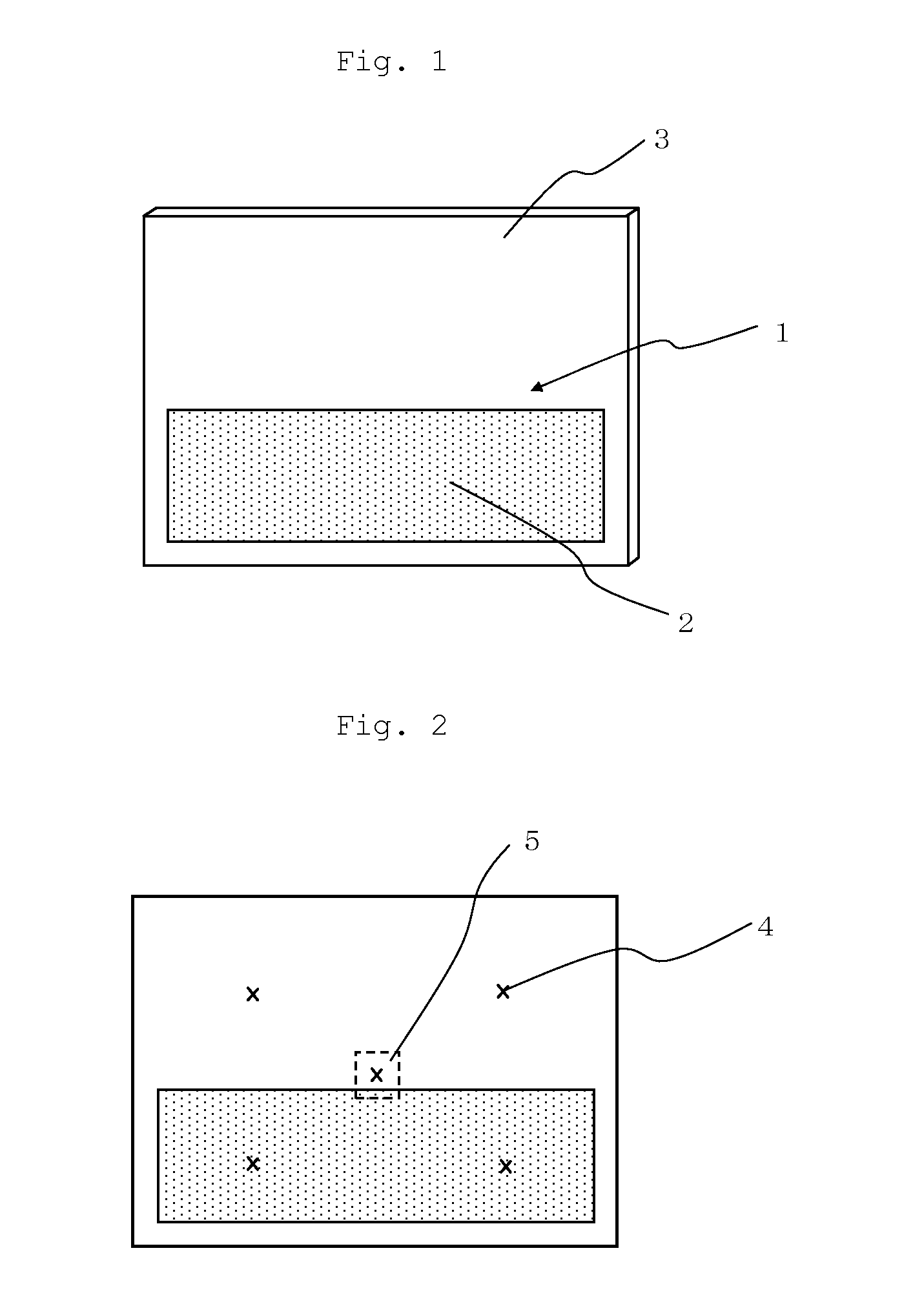

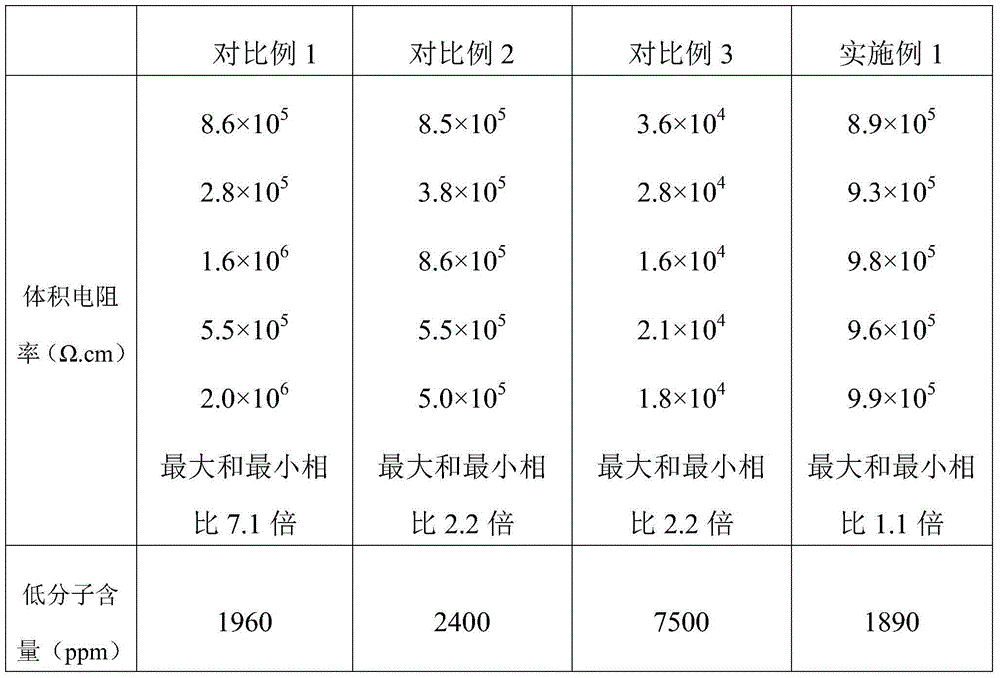

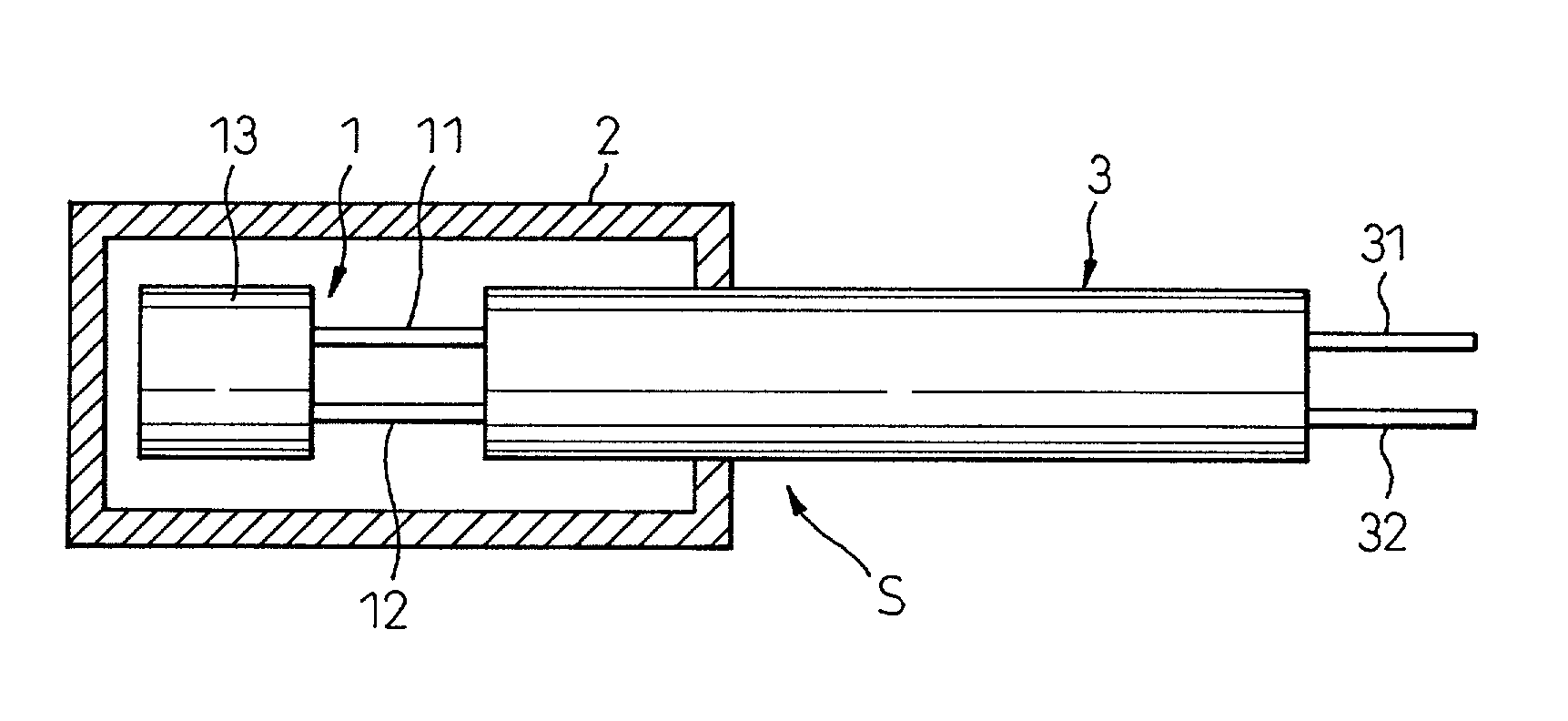

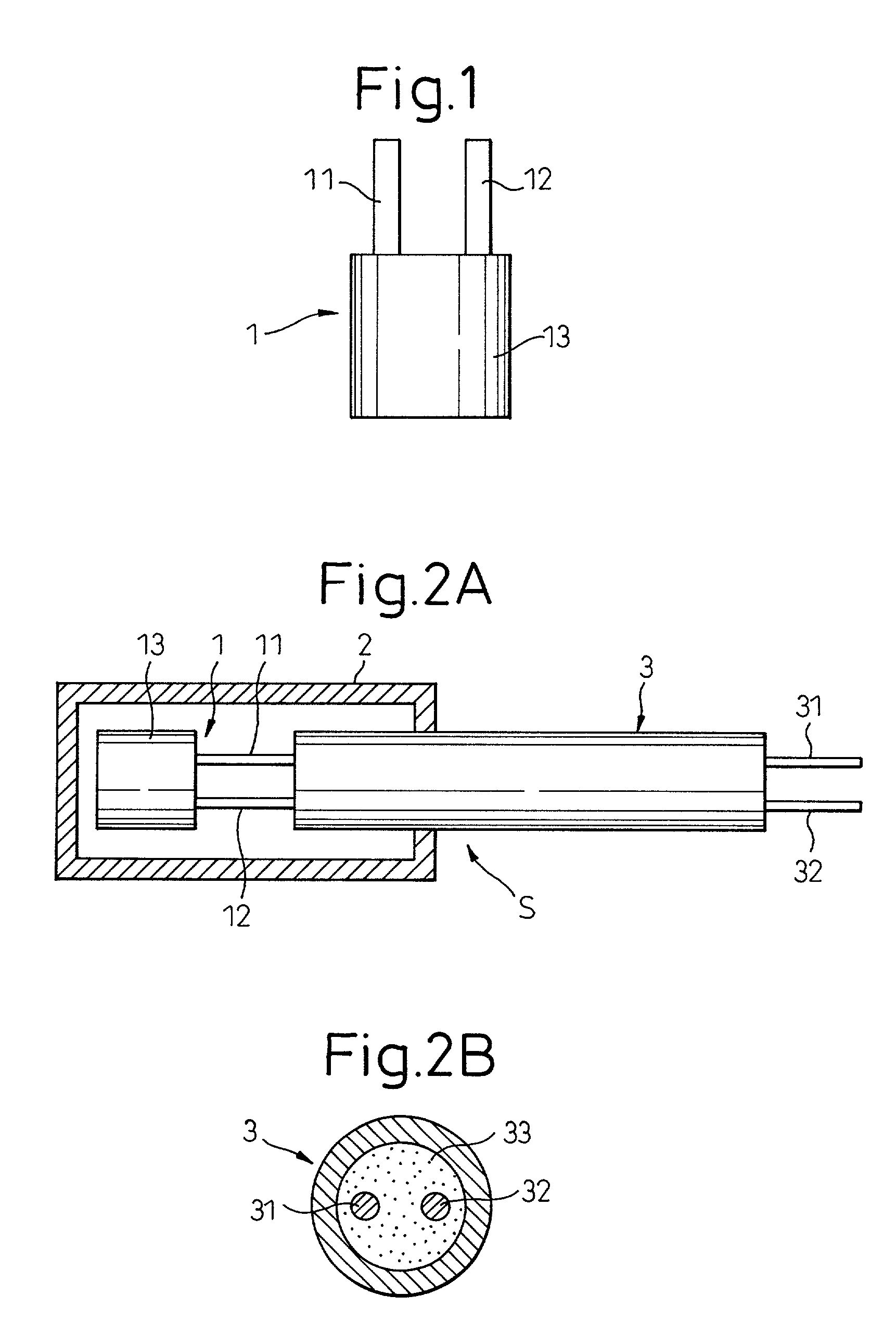

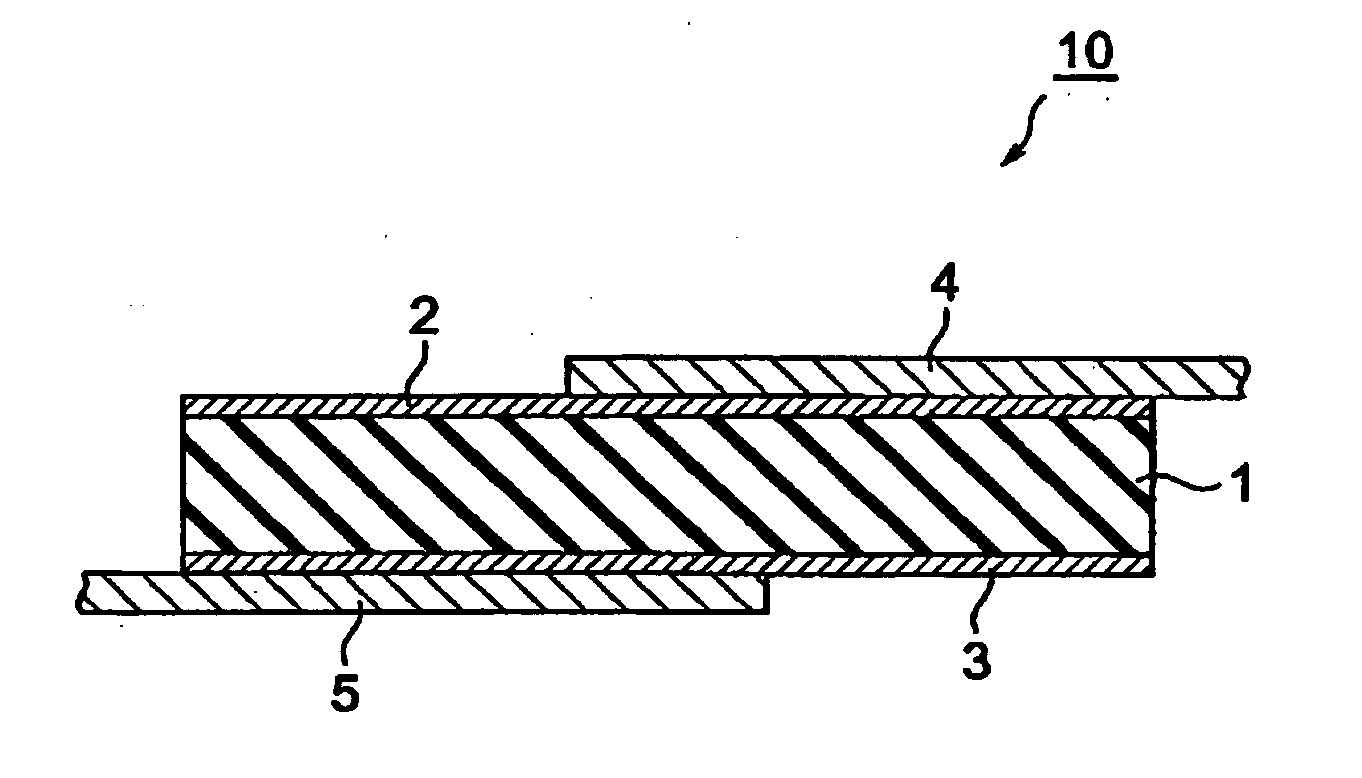

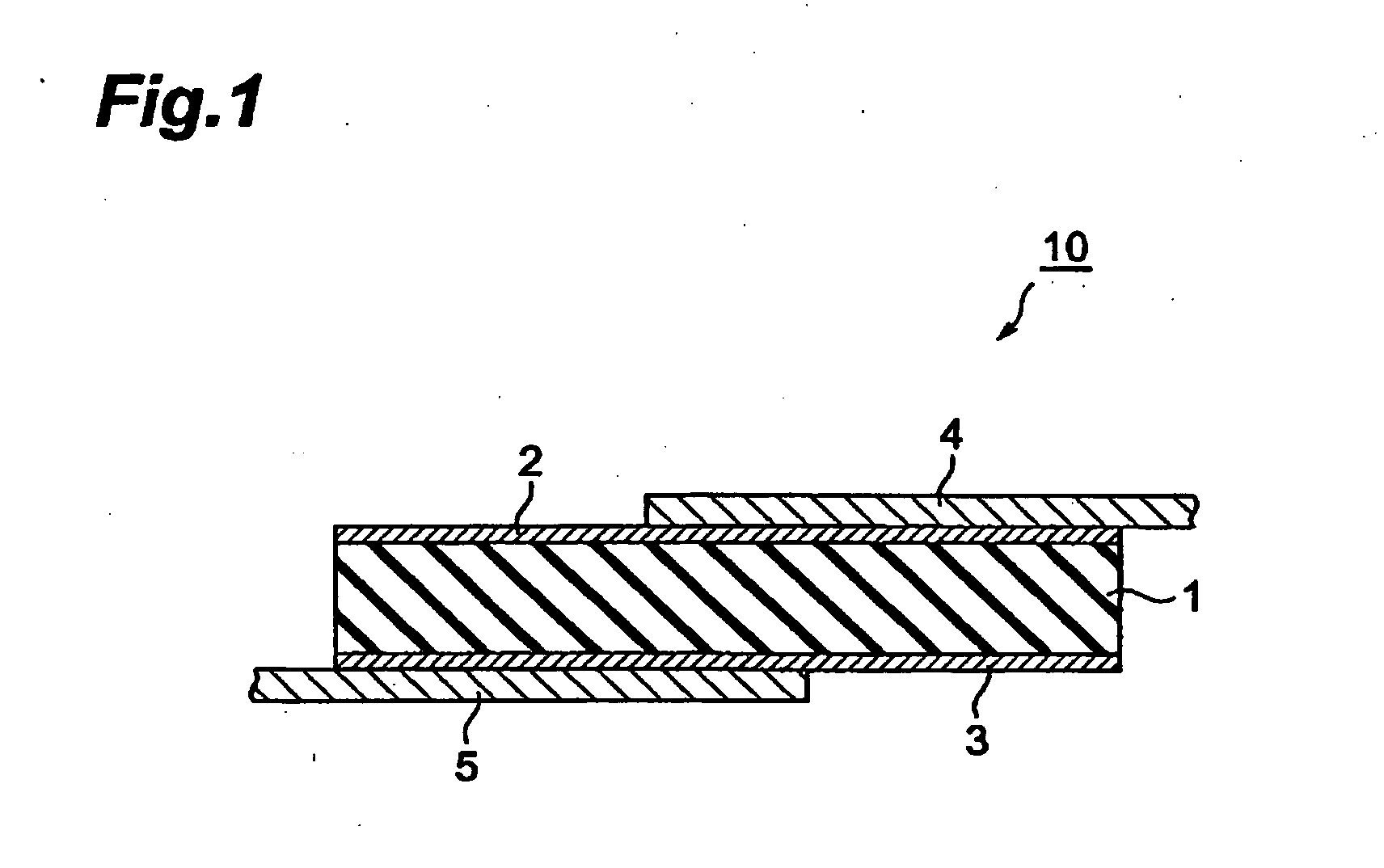

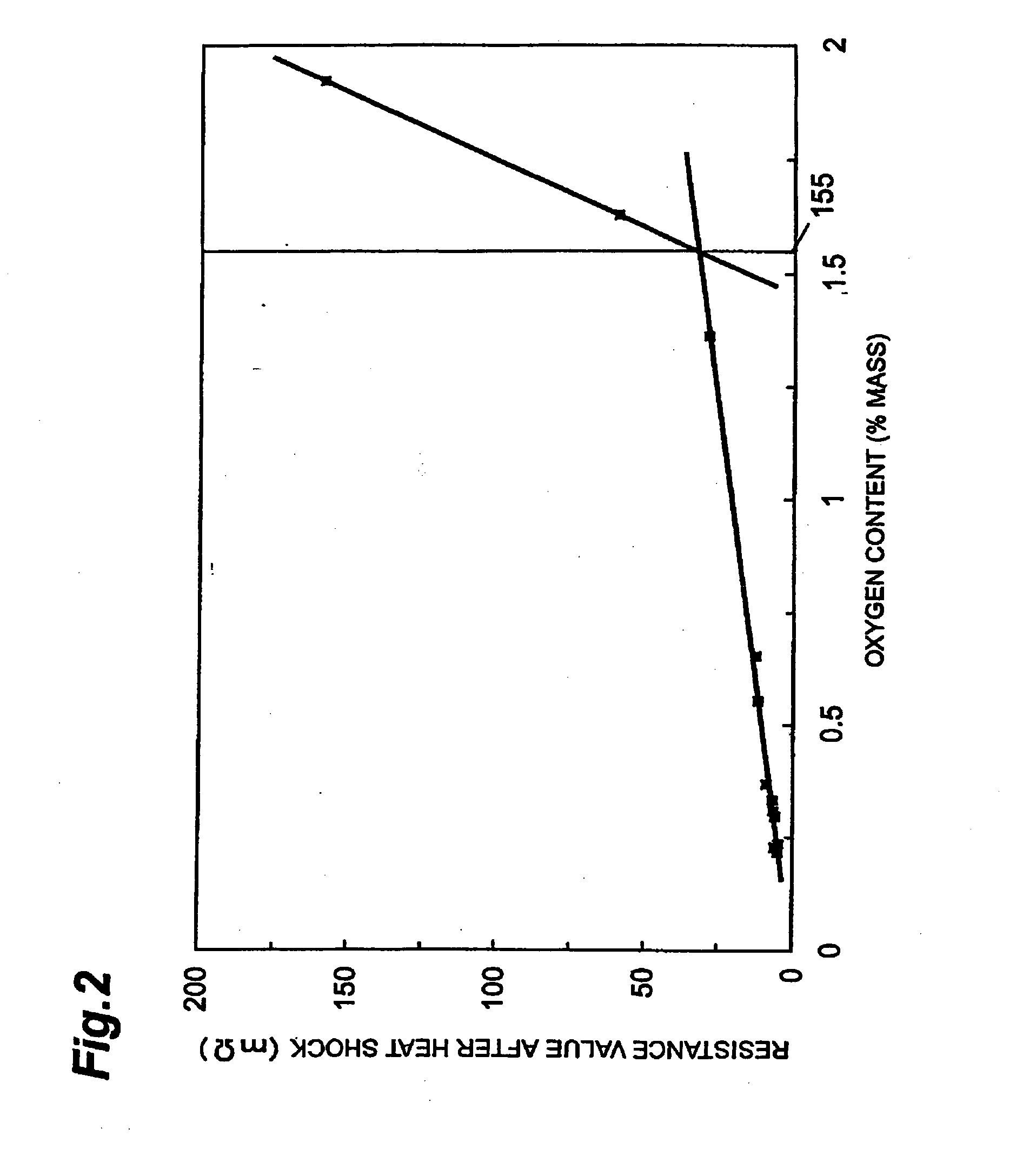

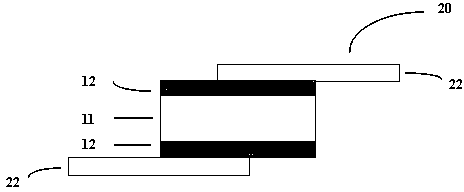

Organic positive temperature coefficient thermistor and manufacturing method therefor

InactiveUS20050024180A1High resistanceLow room-temperature resistanceElectric heatingCurrent responsive resistorsThermistorPositive temperature

An organic positive temperature coefficient thermistor 10 having at least a pair of electrodes 2 and 3 positioned facing each other and a thermistor element 1 having a positive temperature coefficient of resistance which is positioned between the pair of electrodes 2 and 3, wherein the thermistor element 1 is a molded element consisting of a mixture which contains a polymer matrix and conductive particles having electronic conductivity, and wherein the thermistor element 1 has an amount of oxygen calculated by subtracting the amount of oxygen originally present in the various components of the mixture from the amount of oxygen contained in the thermistor element, which is 1.55 weight percent or less of the mass of the thermistor element.

Owner:TDK CORPARATION

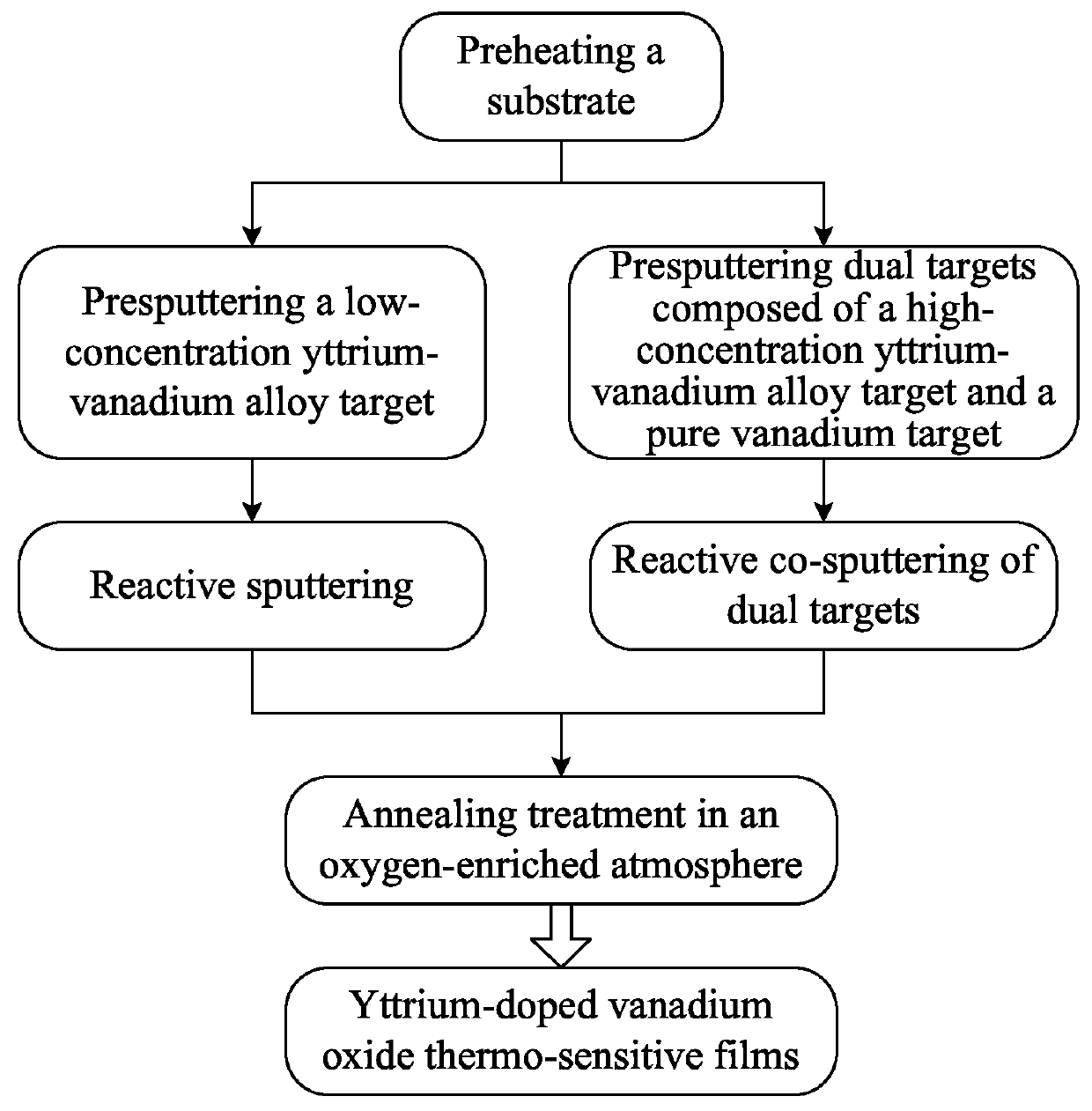

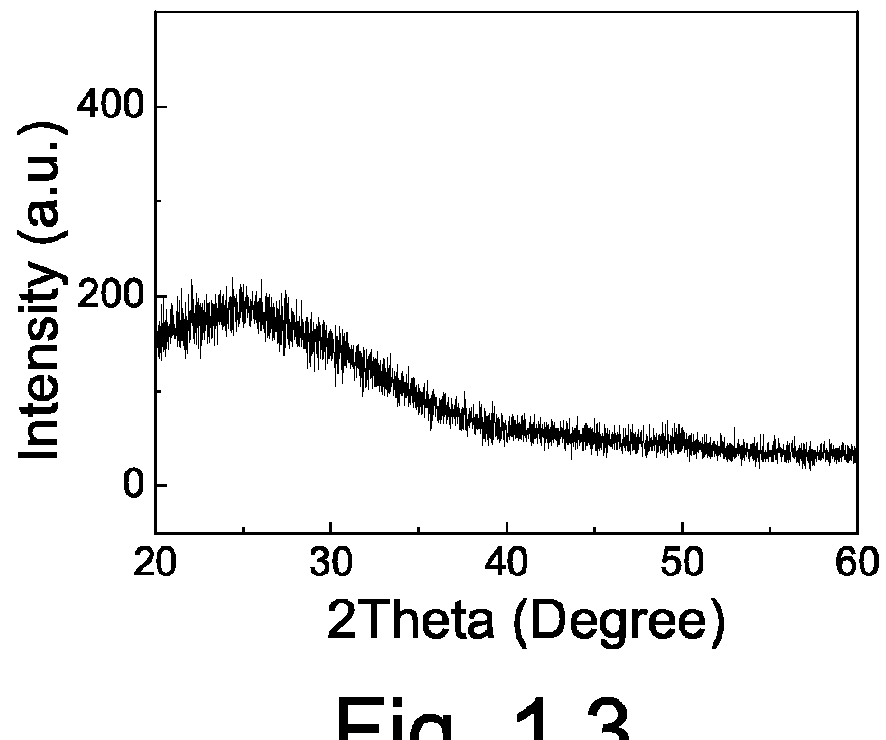

Vanadium oxide thermo-sensitive film material with high temperature coefficient of resistance and a preparing method thereof

ActiveUS20160032443A1Accurate modificationHigh TCRConductive materialVacuum evaporation coatingHigh concentrationRare-earth element

A vanadium oxide thermo-sensitive film material with a high temperature coefficient of resistance (TCR) contains a rare earth element of Yttrium serving as a dopant in a preparation process. The vanadium oxide thermo-sensitive film material includes a substrate and a yttrium-doped vanadium oxide film layer. The yttrium-doped vanadium oxide film layer includes three elements of vanadium, oxygen and yttrium, wherein the atomic concentration of yttrium is at a range of 1%-8%, the atomic concentration of vanadium is at a range of 20-40% and the residue is oxygen. The method for preparing the vanadium oxide thermo-sensitive film material with high TCR includes a reactive magnetron sputtering method using a low-concentration yttrium-vanadium alloy target as a sputtering source or a reactive magnetron co-sputtering method using dual targets including a high-concentration yttrium-vanadium alloy target and a pure vanadium target as a co-sputtering source.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

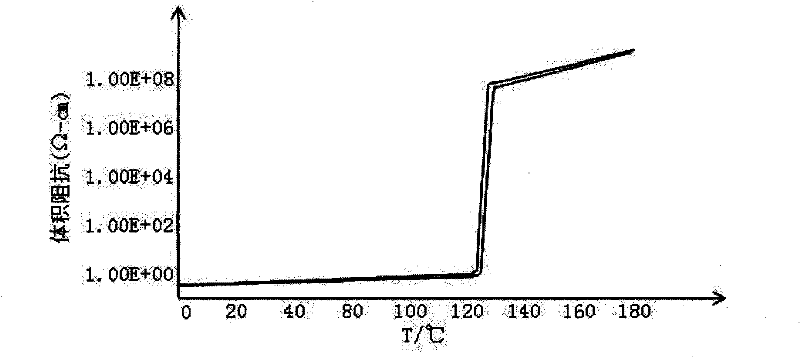

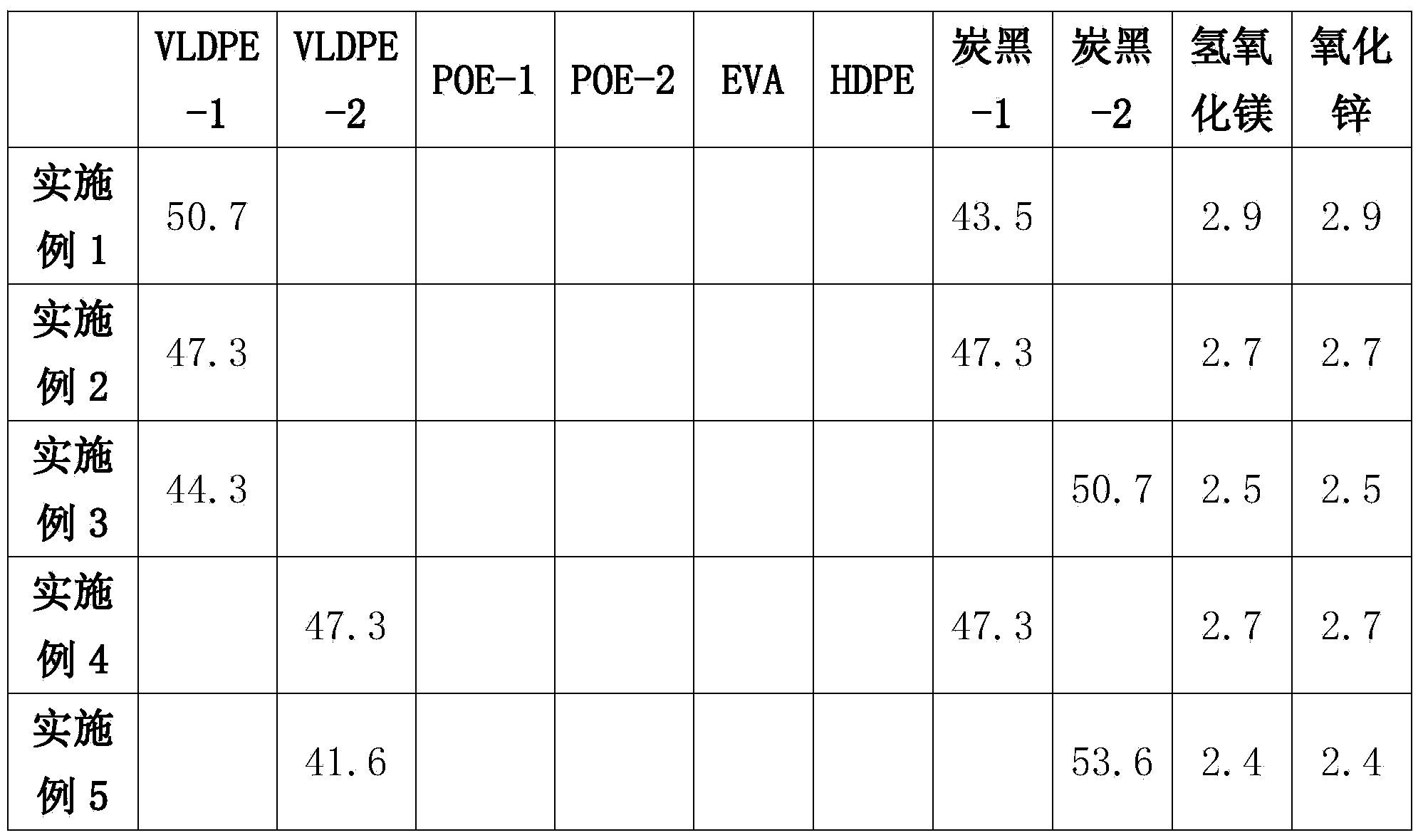

Low-temperature PTC conducting composition, PTC over-current protection device and manufacturing method of PTC over-current protection device

ActiveCN103762012ALower operating temperatureImprove PTC StrengthNon-conductive material with dispersed conductive materialPositive temperature coefficient thermistorsElectrical resistance and conductanceEngineering

The invention relates to a low-temperature PTC conducting composition, a PTC over-current protection device and a manufacturing method of the PTC over-current protection device. The low-temperature PTC conducting composition comprises, by weight, 40%-55% of organic polymer, 40%-55% of conducting carbon black and 1%-10% of voltage-resistant reinforcing filler. The PTC over-current protection device comprises the low-temperature PTC conducting composition. The PTC over-current protection device has an operating temperature lower than 80 DEG C, high PTC strength and good resistance stability, thereby being capable of achieving good over-current and over-temperature protection for circuits in a low-temperature environment.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

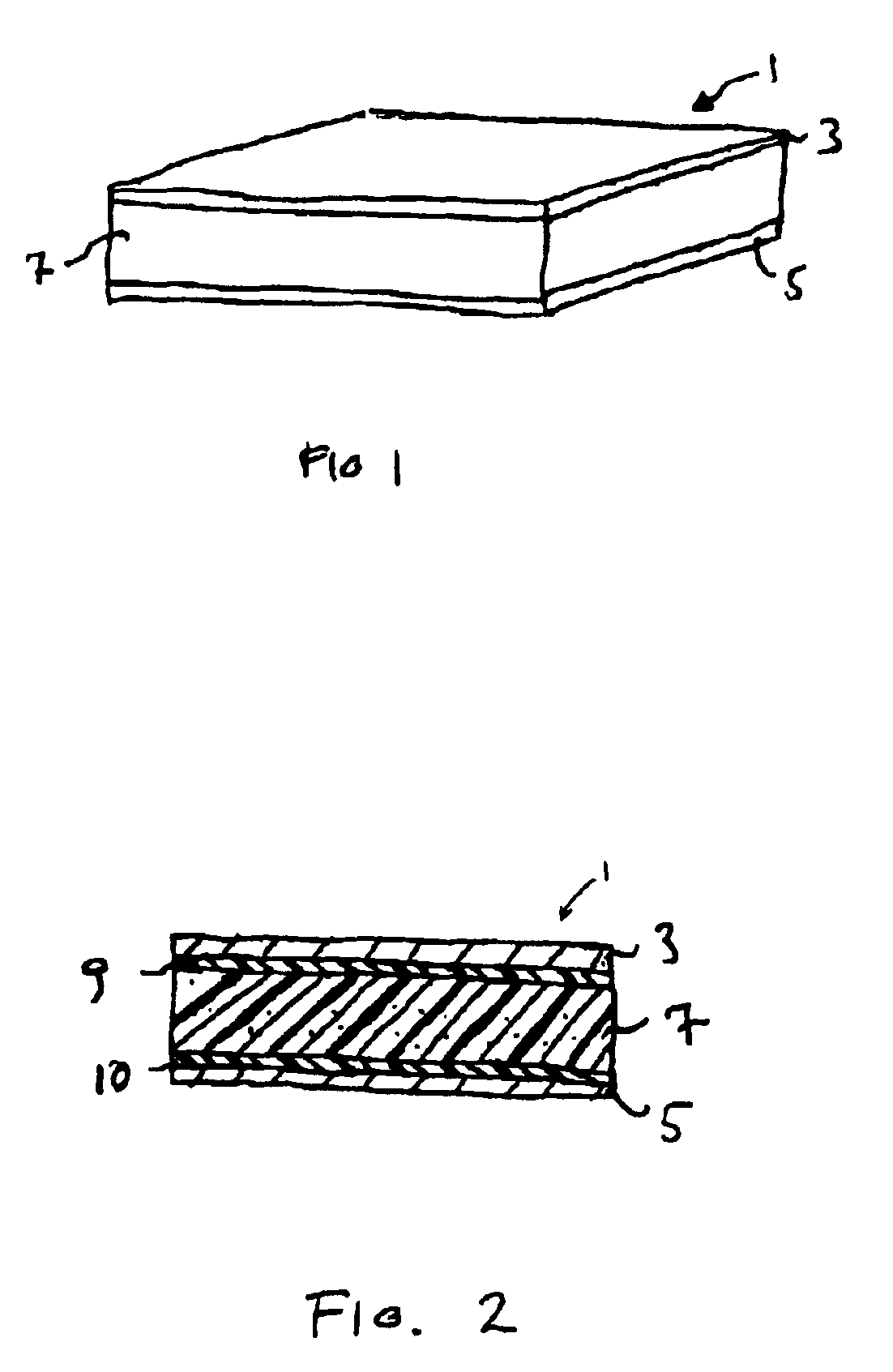

Thin-film sheet including cellulose fine-fiber layer

InactiveUS20170283565A1Improve thermal stabilityImprove stabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersPolymer scienceFiber diameter

The present invention provides a thin-film sheet configured from a single layer or a plurality of layers less than or equal to three layers including at least a cellulose fine-fiber layer that includes regenerated cellulose fine fibers by 50 wt % or more, wherein the thin-film sheet achieves improvements in both thermal stability (thermal coefficient of linear expansion and retention of elasticity at high temperature) and sheet strength, and is characterized in that the requirements: (1) the specific surface area equivalent fiber diameter of fibers constituting the cellulose fine-fiber layer is 0.20-2.0 μm inclusive; (2) the air impermeability is 1-100,000 s / 100 ml inclusive; and (3) the sheet thickness is 2-22 μm inclusive are satisfied. The present invention also provides a composite sheet, a composite prepreg sheet, a separator for power storage devices, etc., that include the thin-film sheet.

Owner:ASAHI KASEI KK

Polybutylene terephthalate

InactiveUS20090264611A1Excellent color toneImprove heat stabilityPolytetramethylene terephthalateFiber

Polybutylene terephthalate has an intrinsic viscosity of 0.7 to 1.0 dL / g and an end carboxyl group concentration of 0.1 to 18 μeq / g, which is produced in a presence of a catalyst comprising a titanium compound and a metal compound containing a metal of Group 2A of the Periodic Table. In the preferable embodiment of the present invention, the polybutylene terephthalate has a crystallization temperature of 170 to 195° C. as measured at a temperature drop rate of 20° C. / min using a differential scanning calorimeter, an end vinyl group concentration of not more than 10 μeq / g, and not more than 10% of a solution haze of a solution prepared by dissolving 2.7 g of said polybutylene terephthalate in 20 mL of a mixed solvent containing phenol and tetrachloroethane at a weight ratio of 3:2.The polybutylene terephthalate of the present invention exhibits excellent color tone, hydrolysis resistance, heat stability, transparency and moldability as well as a less content of impurities, which is suitably applicable to films, monofilaments, fibers, electric and electronic parts, automobile parts, etc.

Owner:MITSUBISHI CHEM CORP

Aromatic polycarbonate resin composition

InactiveUS20050272903A1Improve rigidityImprove hydrolysis resistanceCeramic shaping apparatusCation-exchange capacityIon exchange

An object of the present invention is to provide an aromatic polycarbonate resin composition having good rigidity and good hydrolysis resistance. The present invention is an aromatic polycarbonate resin composition comprising: (A) 100 parts by weight of aromatic polycarbonate (component A) (B) 0.1 to 20 parts by weight of layer silicate (component B) having 50 to 200 milliequivalents / 100 g of cation exchange capacity and ion-exchanged by an organic onium ion represented by the following general formula (I): (wherein M represents a nitrogen atom or a phosphorus atom, R1 and R2 represent an alkyl group having 6 to 16 carbon atoms and may be the same as or different from each other, and R3 and R4 represent an alkyl group having 1 to 4 carbon atoms and may be the same as or different from each other), (C) 0.1 to 50 parts by weight of compound (component C) having an affinity for the component A and having a hydrophilic component, and (D) 0.005 to 1 part by weight of ester (component D) of a higher fatty acid and a polyhydric alcohol.

Owner:TEIJIN KASEK KK

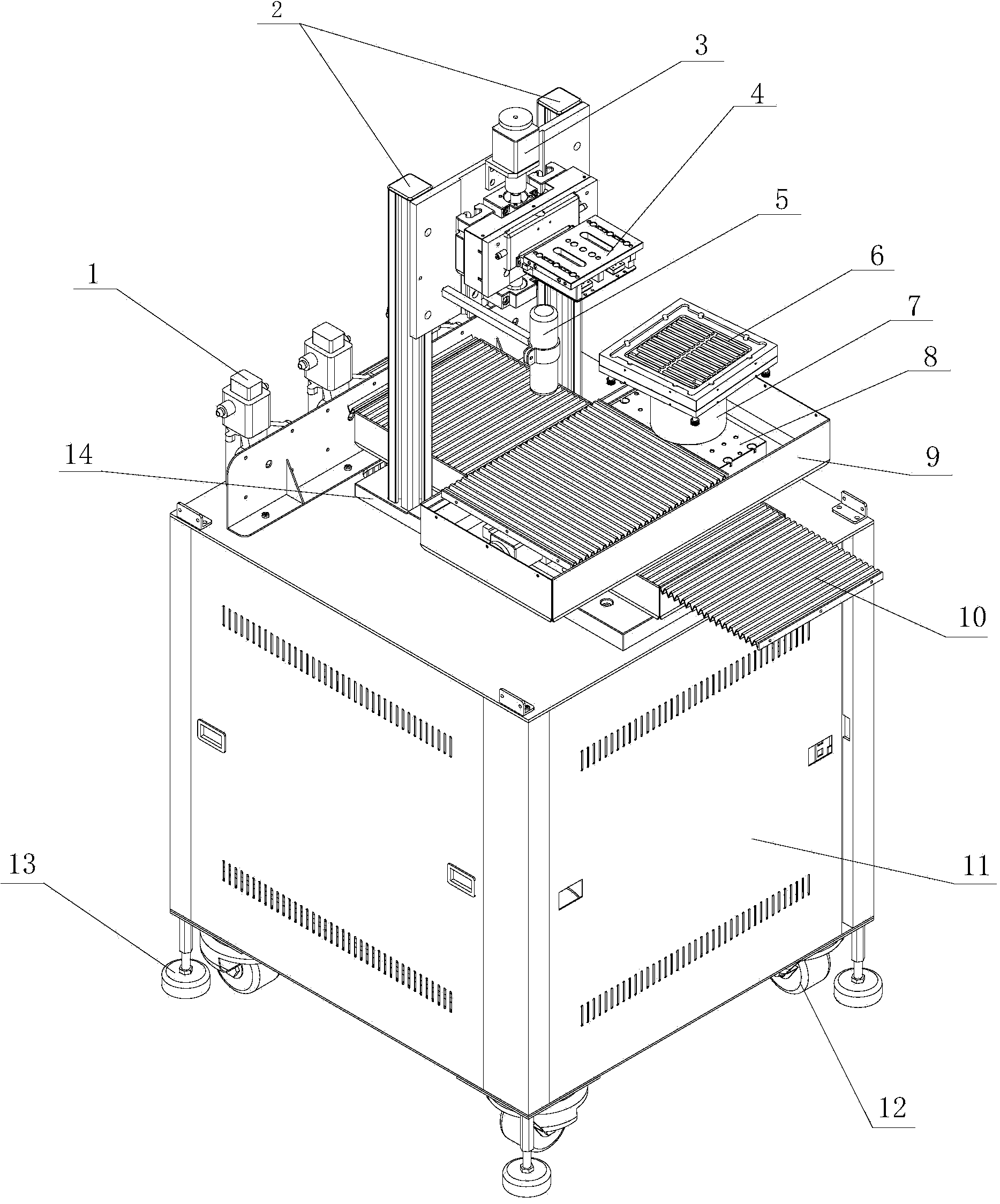

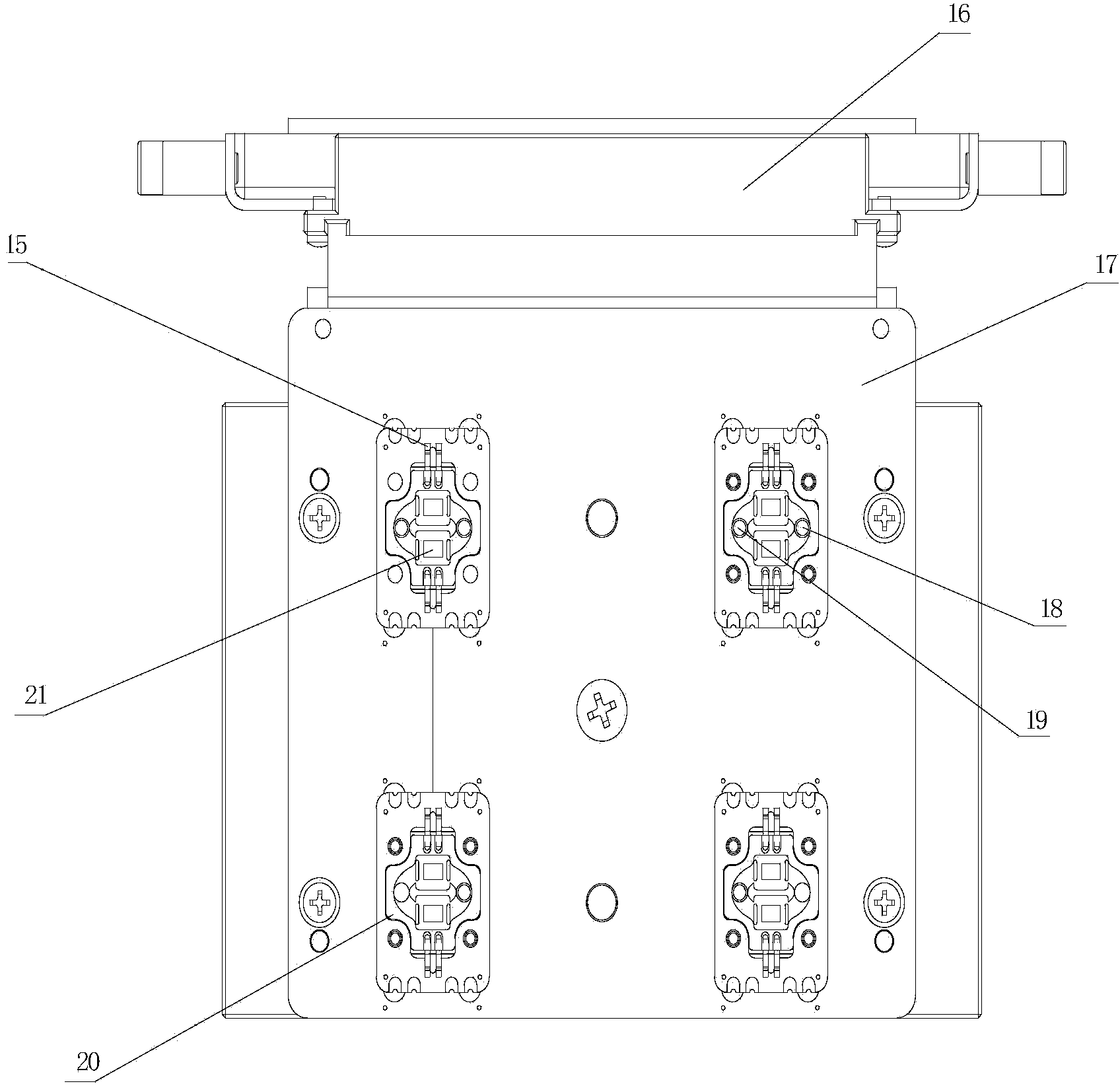

Automatic resistance adjusting device for resistance strain gauge and resistance adjusting method

ActiveCN103668420ARealize automatic resistance adjustment functionHigh control precisionElectrical resistance and conductancePower flow

The invention discloses an automatic resistance adjusting device for a resistance strain gauge and a resistance adjusting method. The device comprises a vertically arranged rack, wherein a Z-axis moving device is mounted on the rack, and a resistance measuring and adjusting device and a CCD (charge coupled device) image acquisition device are fixed on the Z-axis moving device; the automatic resistance adjusting device for the resistance strain gauge further comprises an X-axis moving device, a Y-axis moving device and a gas-liquid combined valve; a product clamping table is mounted on the X-axis moving device; and the resistance measuring and adjusting device is provided with a detecting unit. The adjusting process is controlled by controlling parameters such as current or voltage loaded on the resistance strain gauge, voltage loading time, a resistance adjusting liquid amount and the like, the equipment control accuracy is high, and the operation is easy; the device has a great advantage in the aspects of realizing mass and mechanical operation; and meanwhile, a product whose resistance is adjusted with an electrochemical resistance adjusting method doesn't produce internal stress in a sensitive grid area, so that the stability, the uniformity and the accuracy of the resistance of the product can be improved greatly.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

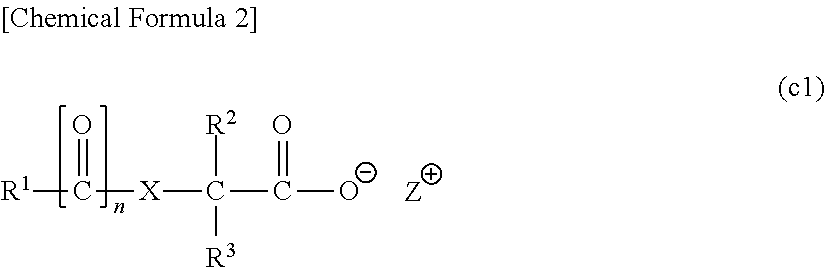

Resist composition and method of forming resist pattern

ActiveUS20130224658A1Maintain good propertiesGood storage stabilityPhotosensitive materialsOriginals for photomechanical treatmentResistHalogen

A resist composition including: a base component (A) that exhibits changed solubility in a developing solution by the action of acid; a photoreactive quencher (C); and an acid generator component (B) that generates acid upon exposure, wherein the photoreactive quencher (C) contains a compound (C) represented by general formula (c1) shown below. In the formula, X represents a cyclic group of 3 to 30 carbon atoms which may have a substituent; R1 represents a divalent linking group; R2 represents an arylene group which may have a substituent, and each of R3 and R4 independently represents an aryl group which may have a substituent; R3 and R4 may be mutually bonded with the sulfur atom to form a ring; R5 represents a hydroxy group, a halogen atom, an alkyl group of 1 to 5 carbon atoms, an alkoxy group or a fluorinated alkyl group; p represents an integer of 0 to 2; and q represents an integer of 0 to 3.

Owner:TOKYO OHKA KOGYO CO LTD

Polycarbonate resin composition

A resin composition comprising a polycarbonate resin derived from an ether diol residue such as isosorbide and has excellent impact resistance, heat resistance, heat stability and moldability.The resin composition comprises a rubber polymer (component B) in an amount of 1 to 30 parts by weight based on 100 parts by weight of a polycarbonate resin (component A) which contains a recurring unit represented by the following formula (1) as the main constituent and has a glass transition temperature (Tg) of 145 to 165° C. and a 5% weight loss temperature (Td) of 320 to 400° C.

Owner:TEIJIN LTD

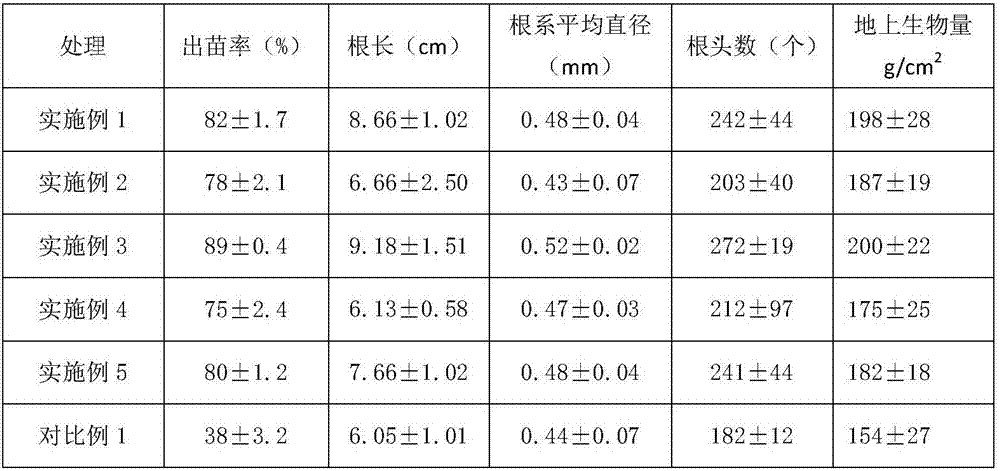

Vegetation particle for high and cold meadows and method for preparing vegetation particle

InactiveCN107417460APrevent mildewPrevent the situationSuperphosphatesMagnesium fertilisersVegetationGrassland

The invention provides a vegetation particle for high and cold meadows, and relates to the field of ecological restoration of grasslands. The vegetation particle is heavier than 0.8 g, and the porosity of the vegetation particle is 45%-50%. The vegetation particle comprises diversified pretreated grass seeds, substrate nutrition layers and water retention layers. The substrate nutrition layers wrap the surfaces of the grass seeds; the water retention layers are positioned between the grass seeds and the substrate nutrition layers. The vegetation particle has the advantages that the technical problems of difficulty in sowing seeds in high and clod grassland regions, high destructiveness, weak material selection pertinence of pelleting processes and the like can be solved by grass seed pelleting processes; the drifting properties of the seeds can be effectively lowered, the seed landing stability can be improved, the seed sowing accuracy can be enhanced, the germination percentage of the seeds can be increased, and the vegetation particle is suitable for near-natural reseeding restoration of high and cold grasslands.

Owner:LANZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com