Patents

Literature

149results about How to "Improve wet grip performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber composition for use in tires

ActiveUS20110226395A1Low in roll resistanceHigh wet grip performanceSpecial tyresTyre tread bands/patternsFuel efficiencyViscosity

A rubber composition for use in tires is described which provides increased fuel efficiency and improved wet grip performance. The rubber composition includes from 5 to 70 parts by mass of silica having a BET specific surface area from 50 to 200 m2 / g per 100 parts by mass of a diene rubber. The rubber composition includes from 1 to 25 parts by mass of an aromatic modified terpene resin and at least one terpene per 100 parts by mass of a diene rubber. The rubber composition further includes from 1 to 70 parts by mass of a naphthenic oil per 100 parts by mass of a diene rubber, where a CN % proportion of a CA %·CP %·CN % ratio calculated according to ASTM D2140 / ASTM D3238 is the greatest and the CA % proportion is less than 15%, and a dynamic viscosity at 40° C. is from 17 to 30 mm2 / sec.

Owner:YOKOHAMA RUBBER CO LTD

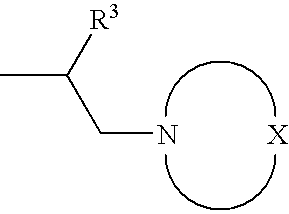

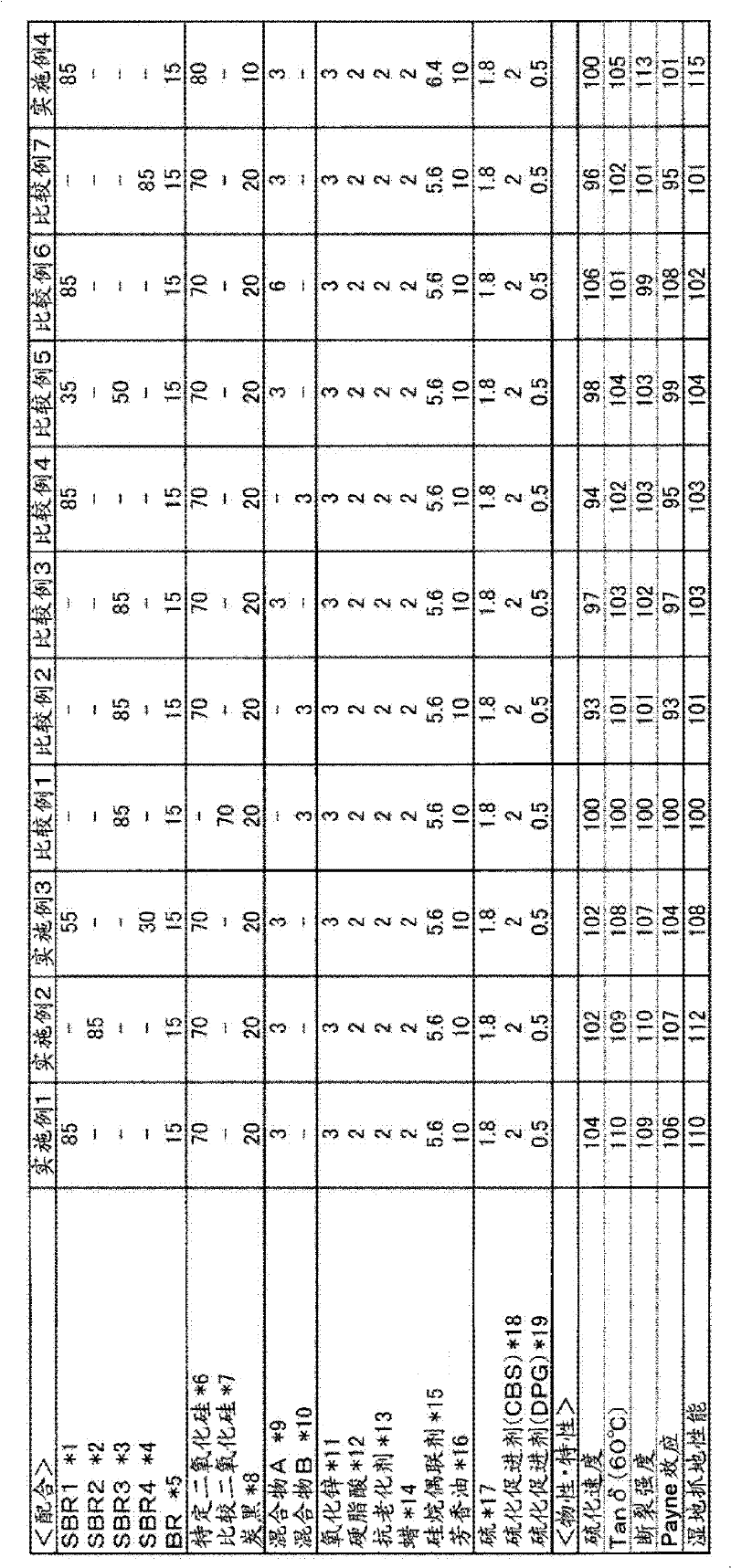

Rubber composition and tire

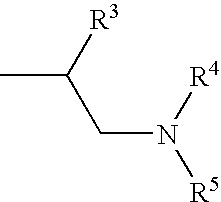

InactiveUS20100099795A1Excellent in low heat build-up propertyImprove wet grip performanceSpecial tyresPolymer scienceNitrogen

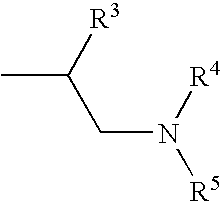

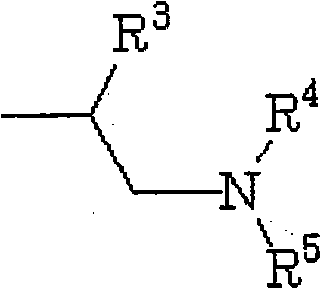

The present invention has its object to provide a rubber composition that can be used for a tread to supply a tire excellent in low heat build-up property and wet grip performance.The present invention relates to a rubber composition including a rubber component that containsa modified styrene-butadiene rubber in an amount of 5% by weight or more per 100% by weight of the rubber component,the modified styrene-butadiene rubber having, in a main chain thereof, a constitutional unit derived from a specific nitrogen-containing compound; andthe rubber composition further including silica in an amount of 10 to 150 parts by weight per 100 parts by weight of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and tire

ActiveCN101724185AExcellent low heat generationImprove wet grip performanceSpecial tyresPolymer scienceSilicon dioxide

The present invention has its object to provide a rubber composition that can be used for a tread to supply a tire excellent in low heat build-up property and wet grip performance. The present invention relates to a rubber composition including a rubber component that contains a modified styrene-butadiene rubber in an amount of 5% by weight or more per 100% by weight of the rubber component, the modified styrene-butadiene rubber having, in a main chain thereof, a constitutional unit derived from a specific nitrogen-containing compound; and the rubber composition further including silica in anamount of 10 to 150 parts by weight per 100 parts by weight of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tire and pneumatic tire

ActiveCN104130461AImprove wear resistanceImproved elongation at breakSpecial tyresIsopreneButadiene-styrene rubber

A rubber composition, for tires, which allows improvement of both wet grip performance and performance on ice and snow, and further allows abrasion resistance and elongation at break to be advantageously obtained, and a pneumatic tire using the rubber composition, are provided. A rubber composition for tires is provided in which a content of an isoprene-based rubber in 100% by mass of a rubber component ranges from 10% by mass to 100% by mass, a content of a butadiene rubber in 100% by mass of the rubber component ranges from 0% by mass to 80% by mass, a content of a styrene butadiene rubber in 100% by mass of the rubber component ranges from 0% by mass to 70% by mass, and a content of a terpene-based resin having a hydroxyl value that is less than or equal to 20 and a softening point ranging from 106°C to 124°C ranges from 1 part by mass to 50 parts by mass, per 100 parts by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

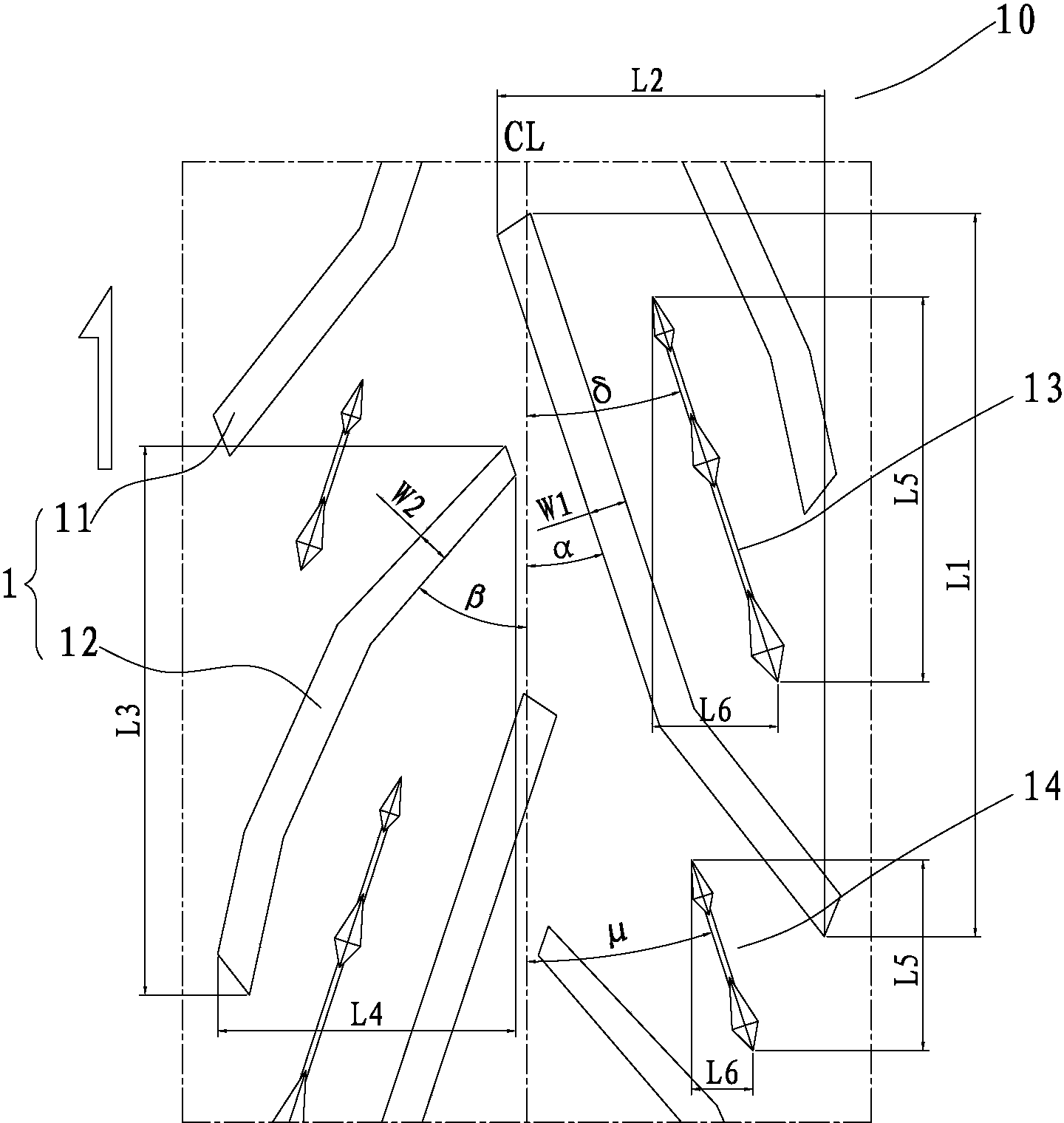

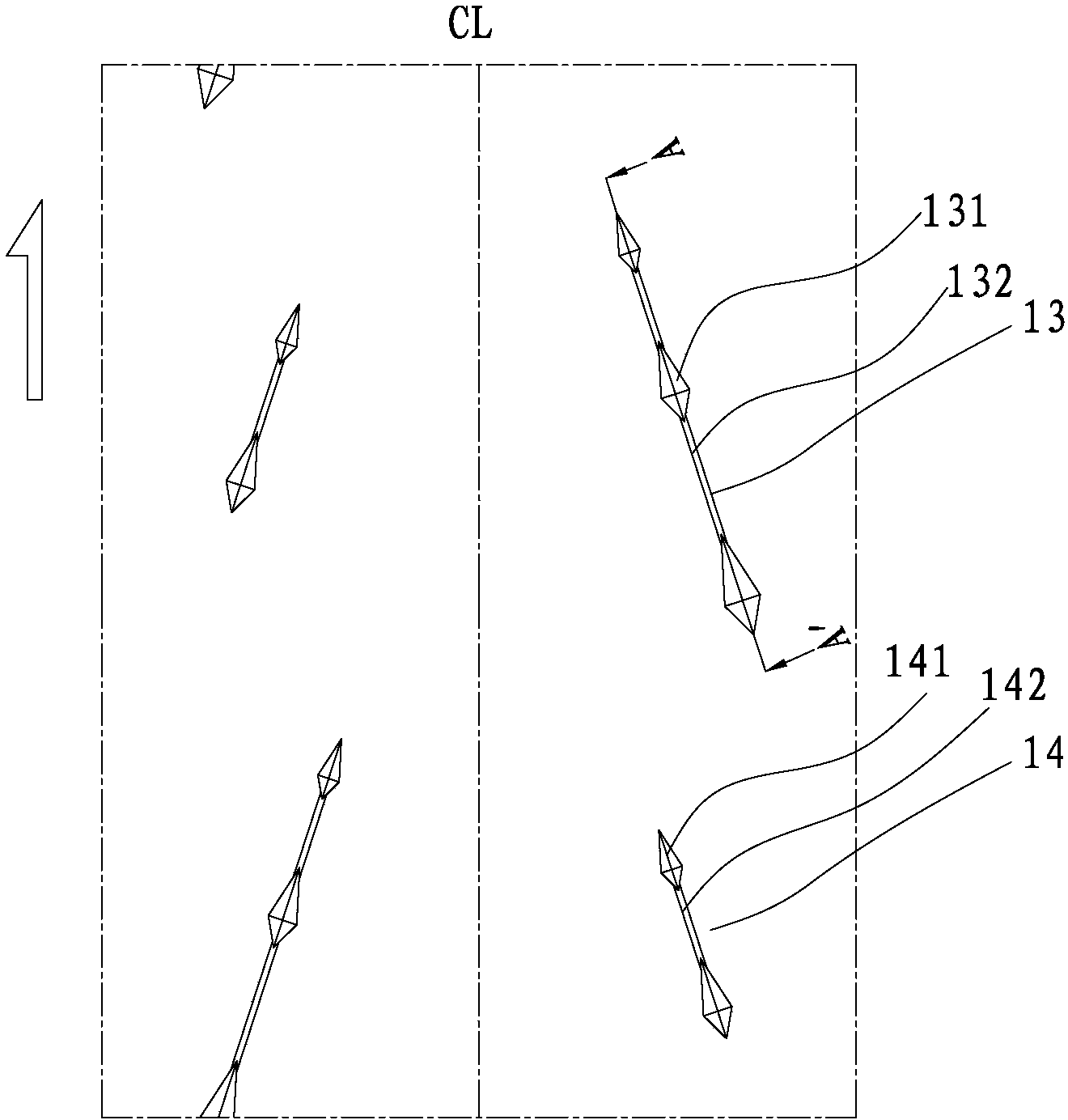

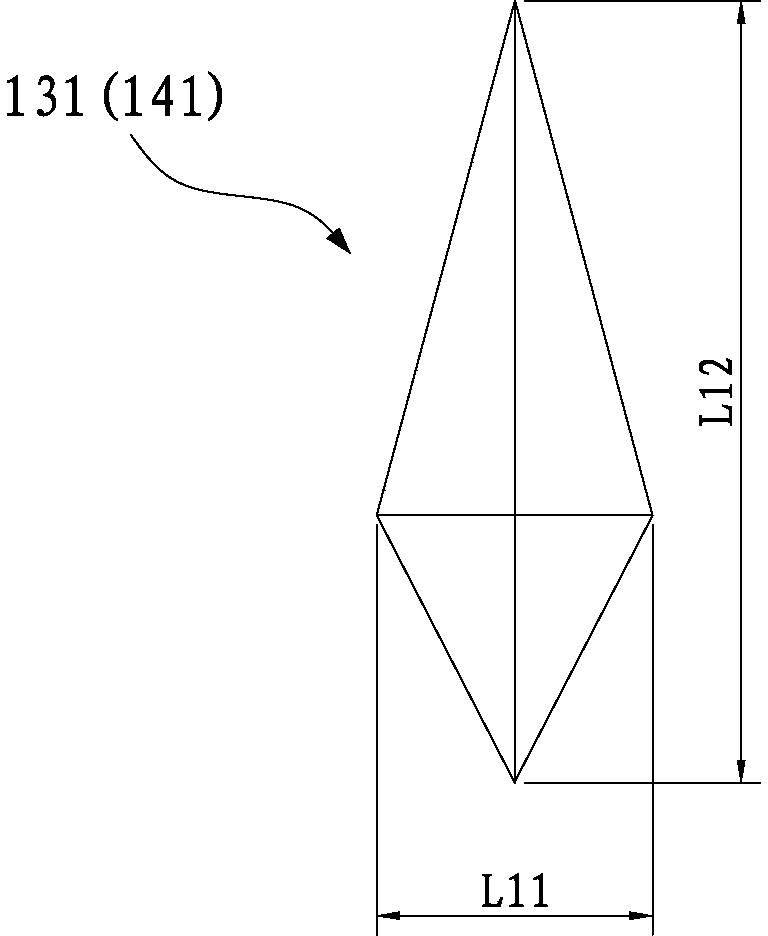

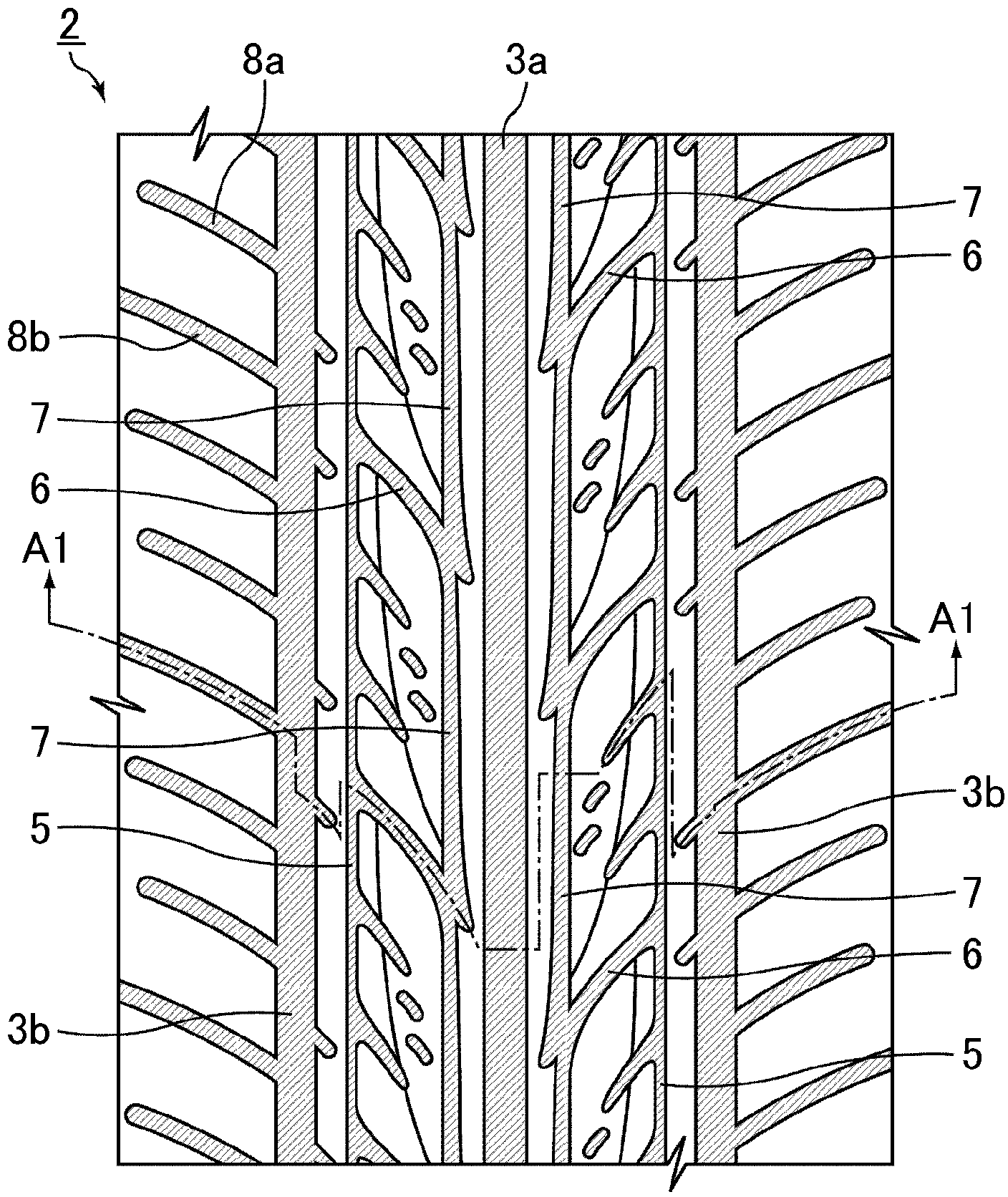

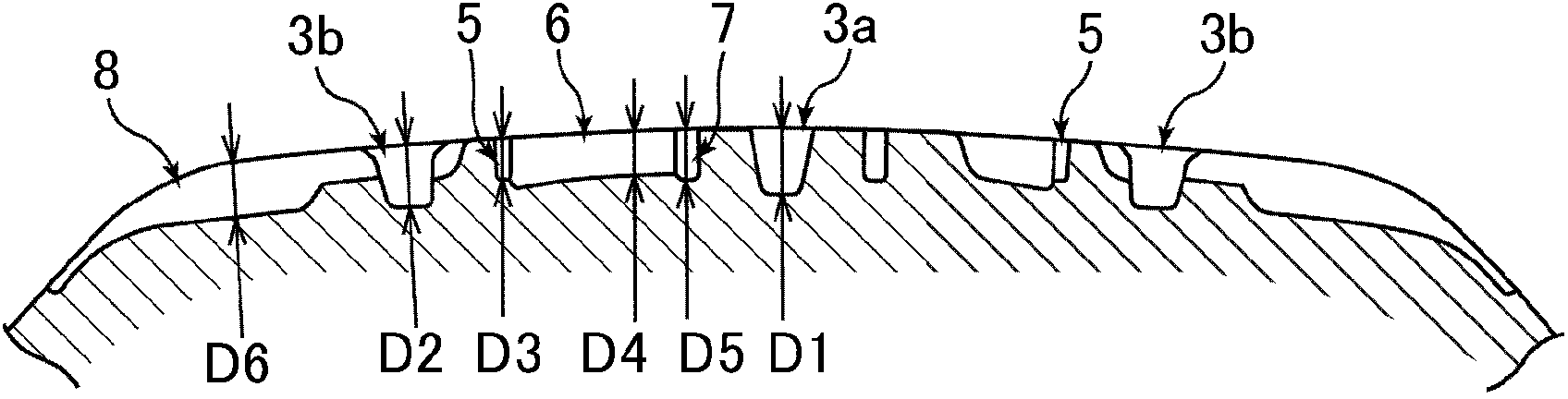

Tread structure of pneumatic tire for motorcycle

ActiveCN104029567AImprove tire drainage performanceImproves tire grip in wet conditionsTyre tread bands/patternsEngineeringTread

The invention discloses a tread structure of a pneumatic tire for a motorcycle. A tread comprises a plurality of main pattern groove groups which are formed in a staggered manner by using the center of the tread as a symmetry center, wherein first auxiliary fine diamond pattern grooves are formed among the main pattern groove groups, and each first auxiliary fine diamond pattern groove comprises a fine diamond part which is provided with a plurality of tangent planes and a fine groove which is connected with the fine diamond part. The fine diamond parts and the fine grooves of the auxiliary fine diamond pattern grooves are designed to be in mutual connection, so that water films can be effectively broken, the water drainage performance of the tire is effectively improved, and the wet land gripping performance of the tire is improved.

Owner:CHENG SHIN RUBBER XIAMEN IND

Rubber composition for use in tires

ActiveUS8362118B2Improve wet grip performanceGood dispersionSpecial tyresPolishing compositionsPolymer sciencePlasticizer

A rubber composition for use in tires including from 60 to 120 parts by weight of a silica having a CTAB specific surface area of from 70 to 175 m2 / g and from 3 to 25 parts by weight of an aromatic modified terpene resin excluding terpene phenol resins per 100 parts by weight of a diene rubber including from 30 to 80 weight % of a terminal-modified styrene-butadiene rubber and from 10 to 50 weight % of a butadiene rubber. An average glass transition temperature of the diene rubber is −55° C. or lower and an average glass transition temperature of a component formed from the diene rubber, the aromatic modified terpene resin, and an optional plasticizer is −45° C. or lower.

Owner:THE YOKOHAMA RUBBER CO LTD

Process for producing resin-extended isoprene rubber, rubber composition obtained by the process and pneumatic tire

ActiveUS20120031537A1Excellent abrasion resistanceExcellent characteristicsSpecial tyresPneumatic tyre reinforcementsPolymer scienceSlurry

The present invention relates to a process for producing a resin-extended isoprene rubber comprising (A) a rubber component containing a natural rubber and / or a synthetic isoprene rubber and (B) a thermoplastic resin, wherein a resin slurry liquid prepared by dispersing the component (B) described above in water is mixed with a latex of the rubber component (A) described above, and then the mixture is coagulated and subjected to drying treatment, a rubber composition containing the resin-extended isoprene rubber obtained by the above process and a pneumatic tire prepared by using the above rubber composition for a member for a tread, and provided are a process for producing a resin-extended isoprene rubber in which a natural rubber and / or a synthetic isoprene rubber and a resin are used and in which the above resin is highly dispersed, a rubber composition which contains the resin-extended isoprene rubber obtained by the above process and which can secure a fracture characteristic and the like and a pneumatic tire prepared by using the above rubber composition.

Owner:BRIDGESTONE CORP

Rubber composition and pneumatic tire

InactiveCN103003346AExcellent low fuel consumption performanceImprove wet grip performanceSpecial tyresRolling resistance optimizationPolymer scienceFuel efficiency

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and pneumatic tire

ActiveUS20150126674A1Improve fuel economyImprove wet grip performanceSpecial tyresPolymer scienceWear resistance

The present invention provides a rubber composition capable of improving fuel economy and wet grip performance while maintaining good processability, abrasion resistance and handling stability or improving them, as well as a pneumatic tire including the rubber composition. The rubber composition contains carbon black, silica, and a polymer mixture obtained by modifying a polymer derived from a conjugated diene compound and / or an aromatic vinyl compound with a compound containing an ester group and / or a carboxyl group, the polymer mixture having a weight average molecular weight of from 1.0×103 to 1.0×105, the rubber composition having a tan δ peak temperature of −20° C. or higher, a rubber hardness of from 63 to 75, and a tan δ at 70° C. of from 0.15 to 0.45.

Owner:SUMITOMO RUBBER IND LTD

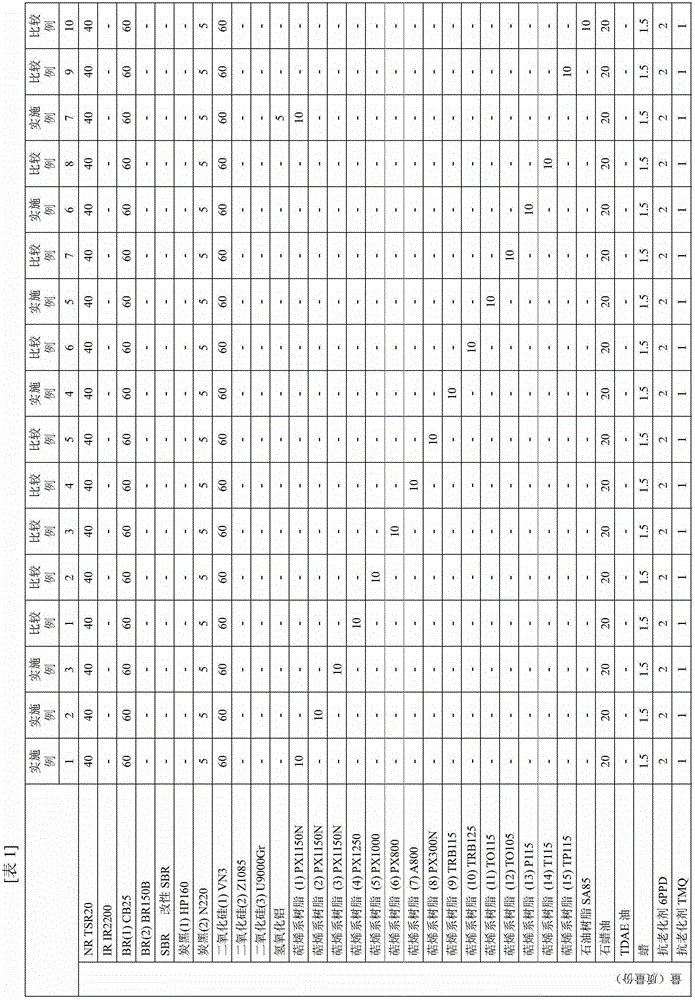

Tread compound for passenger tyre with high wet skid resistance and preparation method thereof

InactiveCN105001475AImproved wet grip performanceImproves wet grip performanceSpecial tyresButadiene-styrene rubberAntioxidant

The invention relates to a tread compound for a passenger tyre with high wet skid resistance and a preparation method thereof. The tread compound comprises, by weight, 13 to 16 parts of natural rubber, 61 to 83 parts of first solution-polymerized styrene butadiene rubber, 25 to 40 parts of second solution-polymerized styrene butadiene rubber, 10 to 20 parts of carbon black, 45 to 55 parts of white carbon black, 2 to 7 parts of a softener, 5 to 6 parts of an activator, 3 to 4 parts of an antioxidant, 1.8 to 2.2 parts of a wet skid resistance reinforcing agent, 4.5 to 5.5 parts of resin with high wet skid resistance, 7 to 9 parts of a coupling agent and 3 to 3.5 parts of a vulcanizing agent. The tyre prepared from the raw materials provided by the invention has wet skid resistance reaching grade A or above and is a high quality tyre with superhigh wet skid resistance.

Owner:山东盛世泰来橡胶科技有限公司

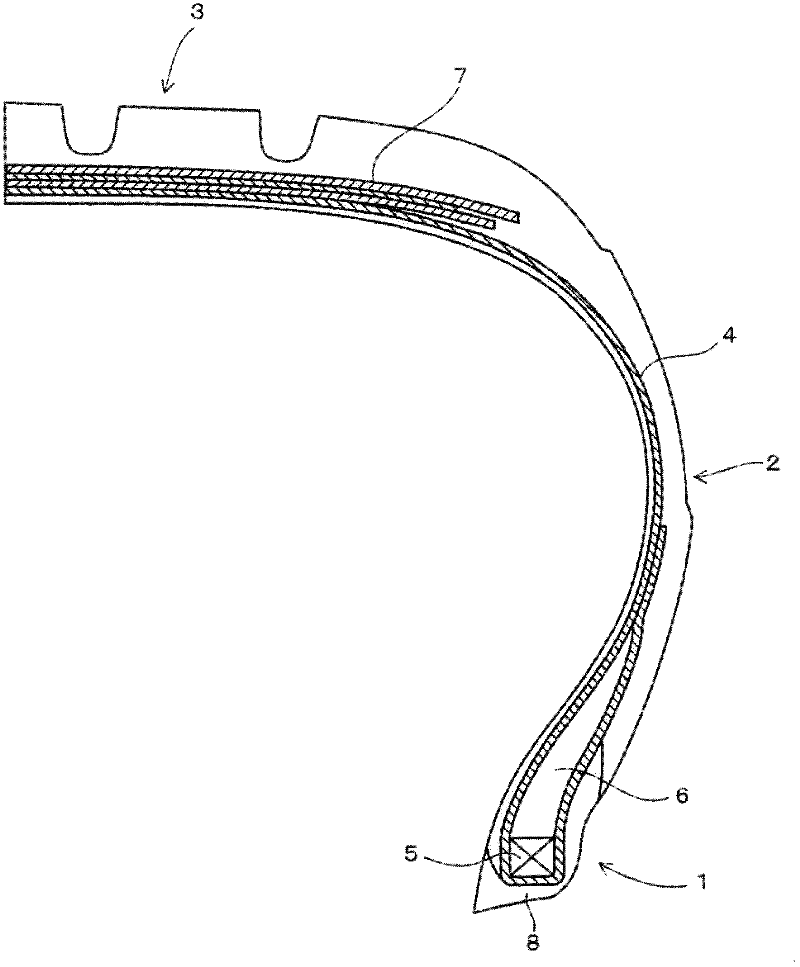

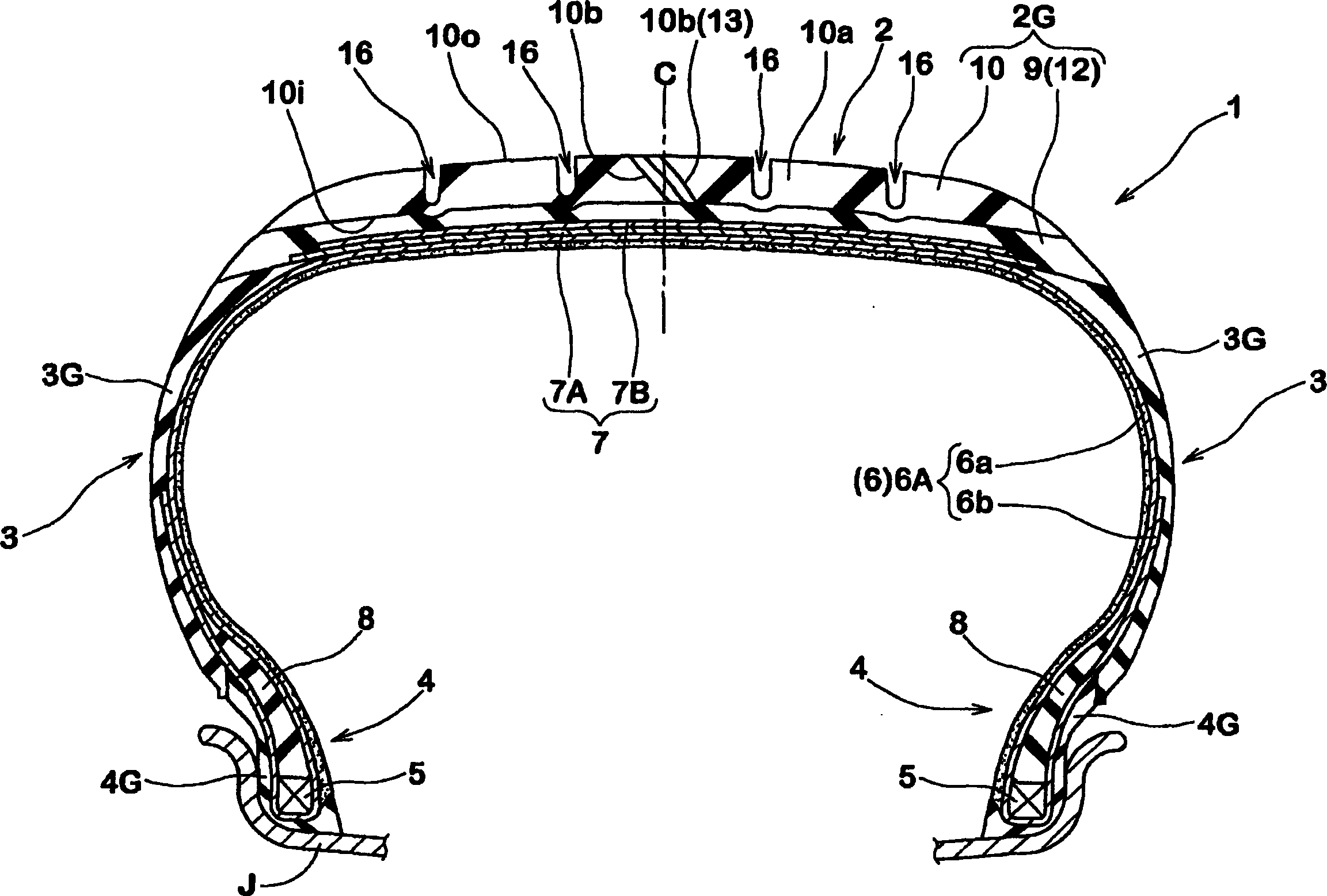

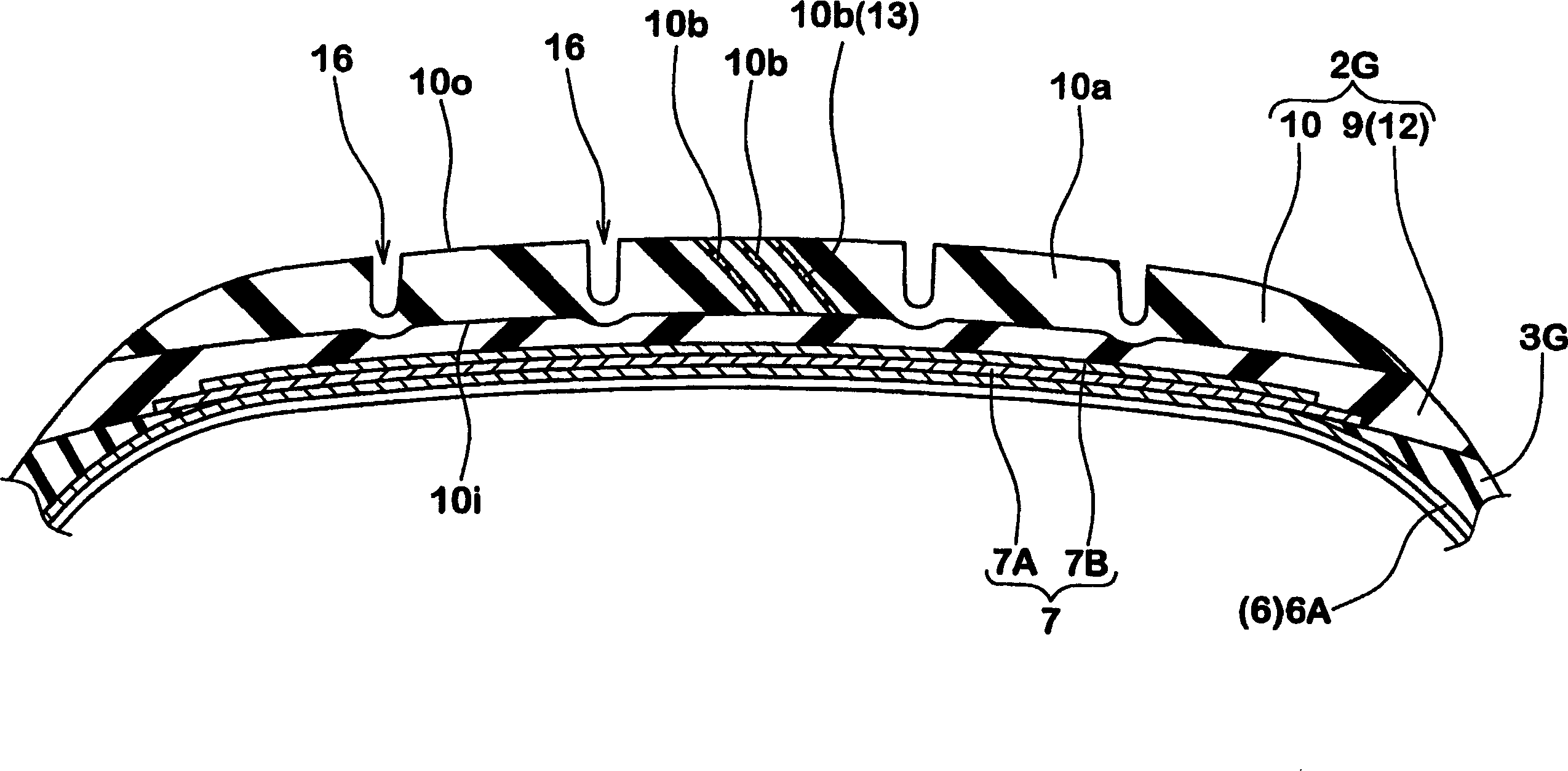

Pneumatic tire

InactiveUS20050045258A1Improve antistatic performanceReduce rolling resistanceSpecial tyresTyre tread bands/patternsSilicon dioxideMechanical engineering

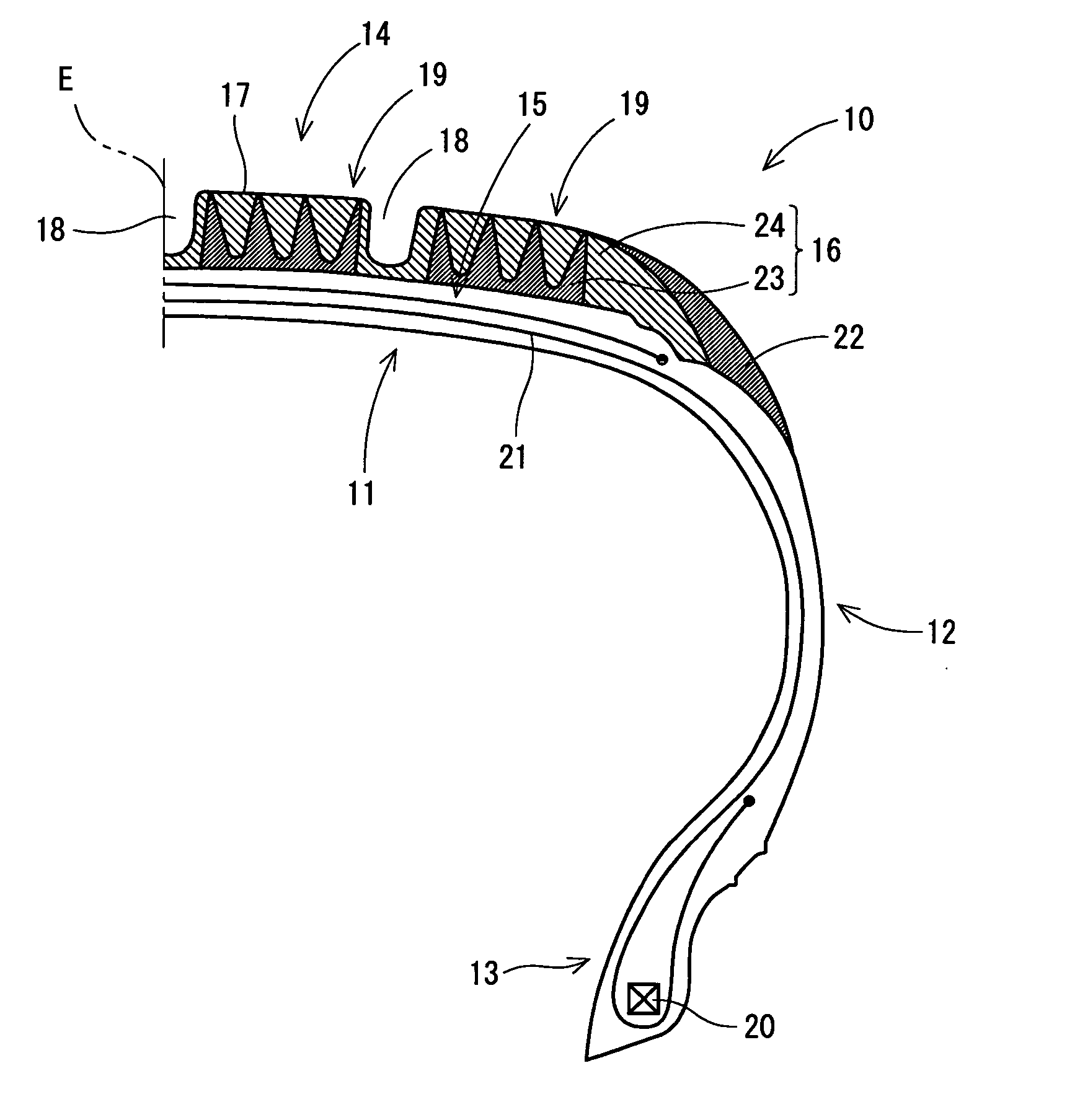

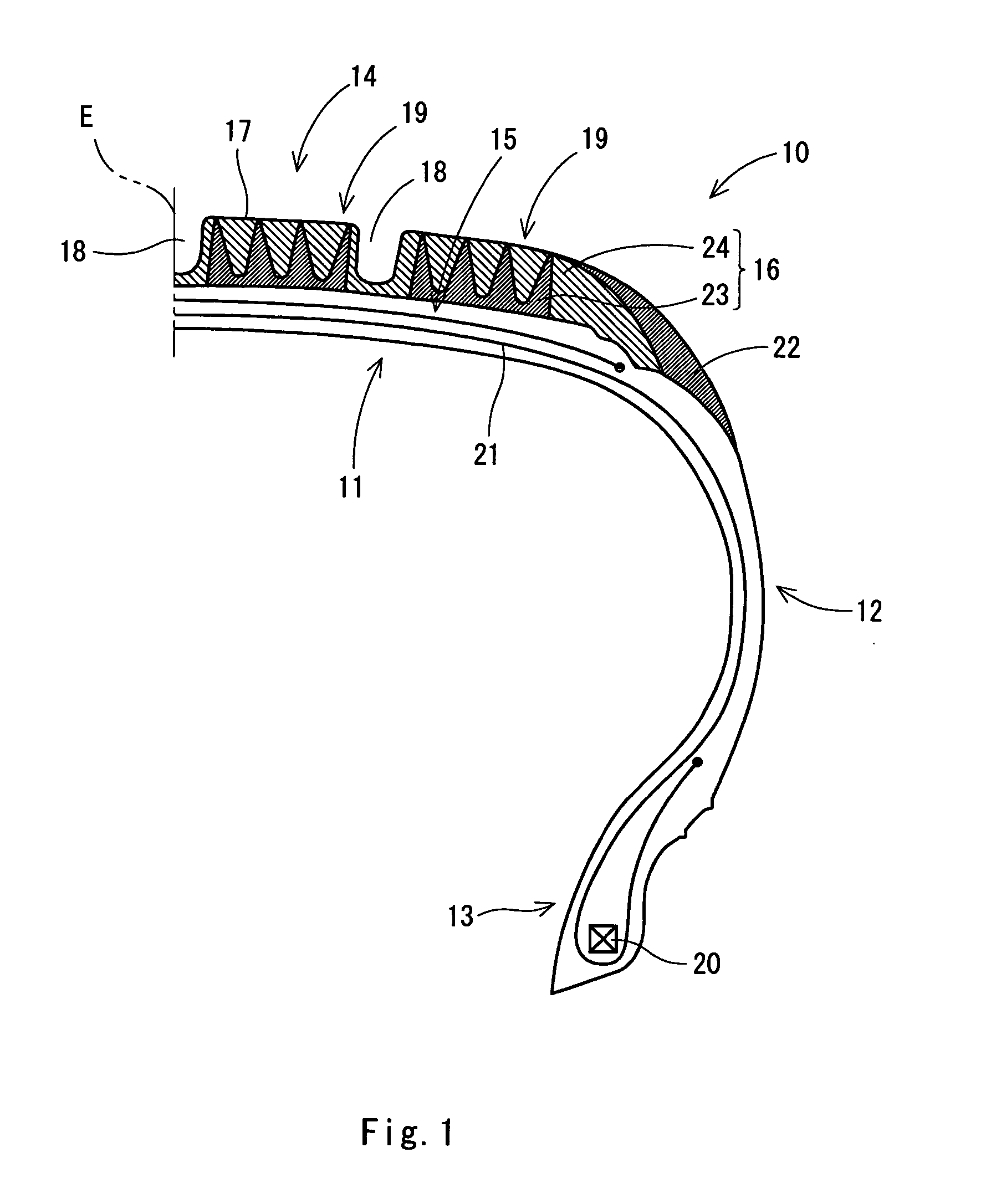

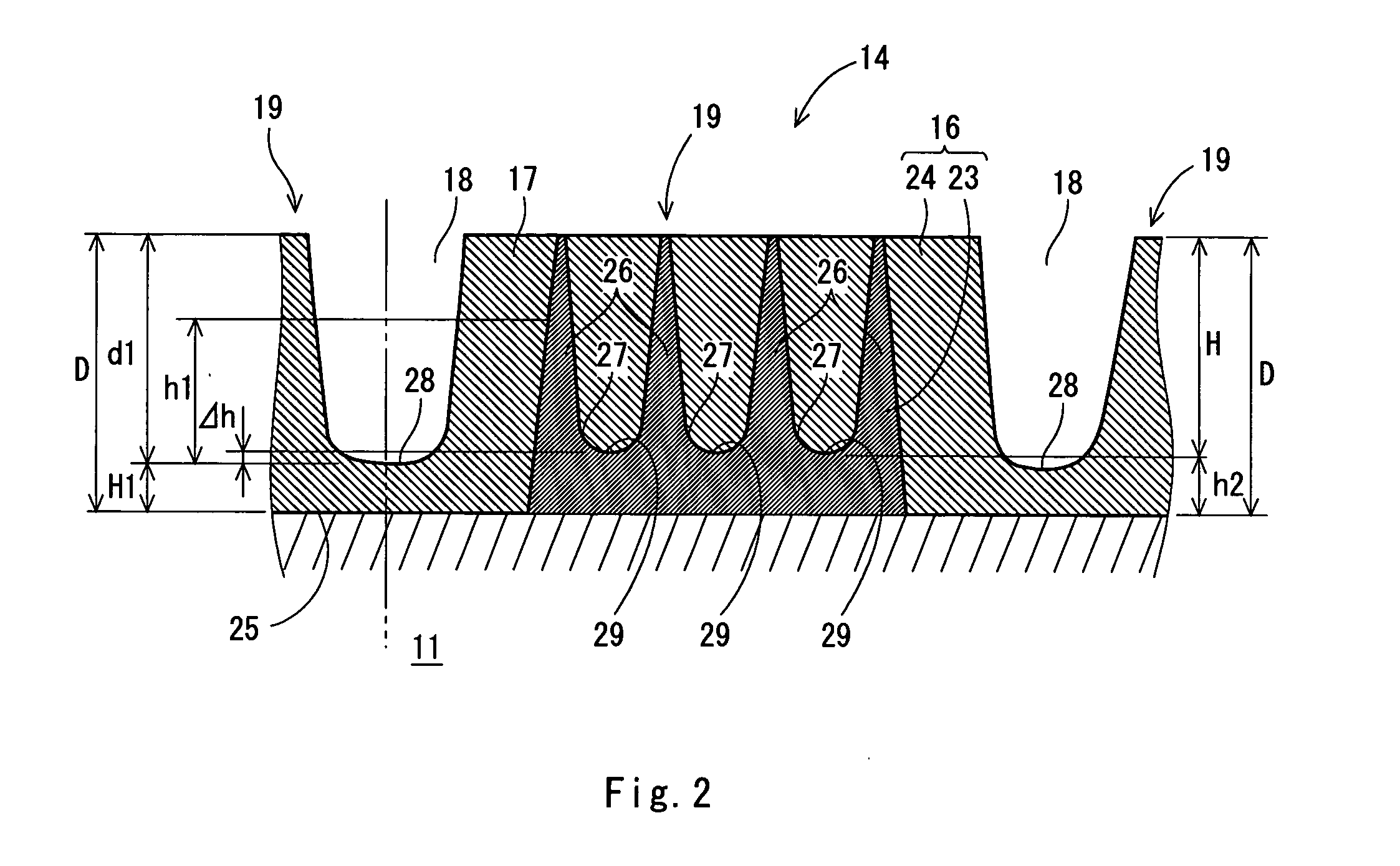

A tread (14) of a tire (10) includes a tread rubber layer (16). The tread rubber layer (16) has a two-layer structure including a base layer (23) and a cap layer (24). The base layer (23) is provided with a comb-shaped convex portion (26). The convex portion (26) is formed like a circle extended in the circumferential direction of the tire (10). A plurality of convex portions (26) is arranged in the axial direction of the tire (10) and is protruded in a radial direction. At least a part of the convex portions (26) is exposed to a tread surface (17) when the tire (10) is unused (brand-new). The cap layer (24) contains silica and the base layer (23) does not contain the silica.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for treads and pneumatic tire

ActiveCN106574078AImprove puncture resistanceImprove wet grip performanceSpecial tyresPolymer scienceButadiene-styrene rubber

The present invention provides: a rubber composition for treads, which contains a diene rubber as a rubber component and is capable of achieving a good balance among wet grip performance, wear resistance and blowout resistance on dry roads; and a pneumatic tire having a tread which is produced using this rubber composition for treads. The present invention is a rubber composition for treads, which contains: a diene rubber containing a styrene butadiene rubber; zinc dithiophosphate; an inorganic filler which is composed of at least one substance selected from the group consisting of compounds represented by the formula described below, magnesium sulfate and silicon carbide, and which has a BET value of 5-120 m<2> / g and a linseed oil absorption of 30-80 ml / 100 g; and sulfur. Relative to 100 parts by mass of the diene rubber, the content of the zinc dithiophosphate is 0.2-15 parts by mass, the content of the inorganic filler is 1-70 parts by mass, and the content of zinc oxide is less than 2.5 parts by mass. In the formula of mM.xSiOy.zH2O, M represents at least one metal selected from the group consisting of Al, Mg, Ti, Ca and Zr, or an oxide or hydroxide of the metal; m represents an integer of 1-5; x represents an integer of 0-10; y represents an integer of 2-5; and z represents an integer of 0-10.

Owner:SUMITOMO RUBBER IND LTD

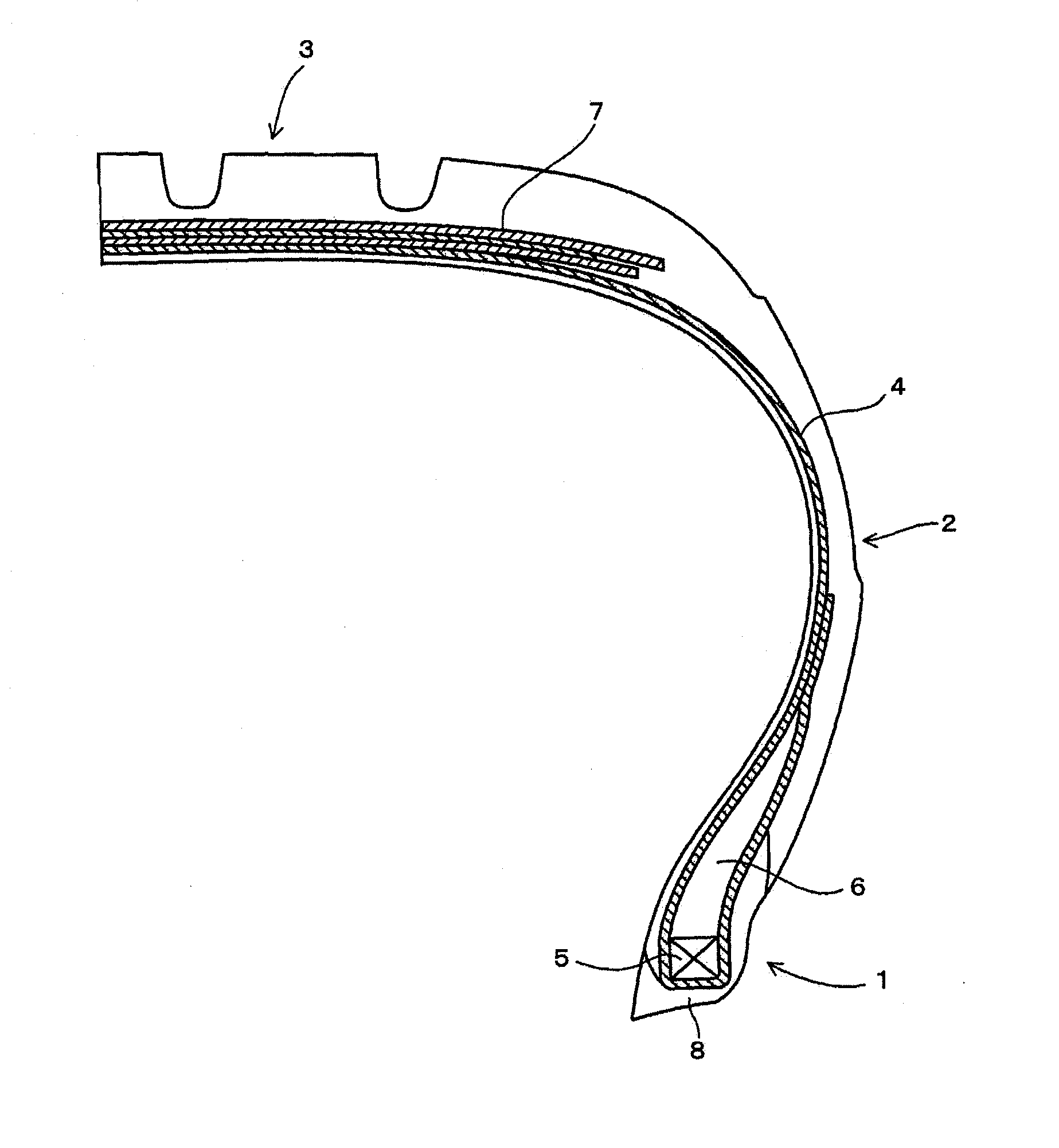

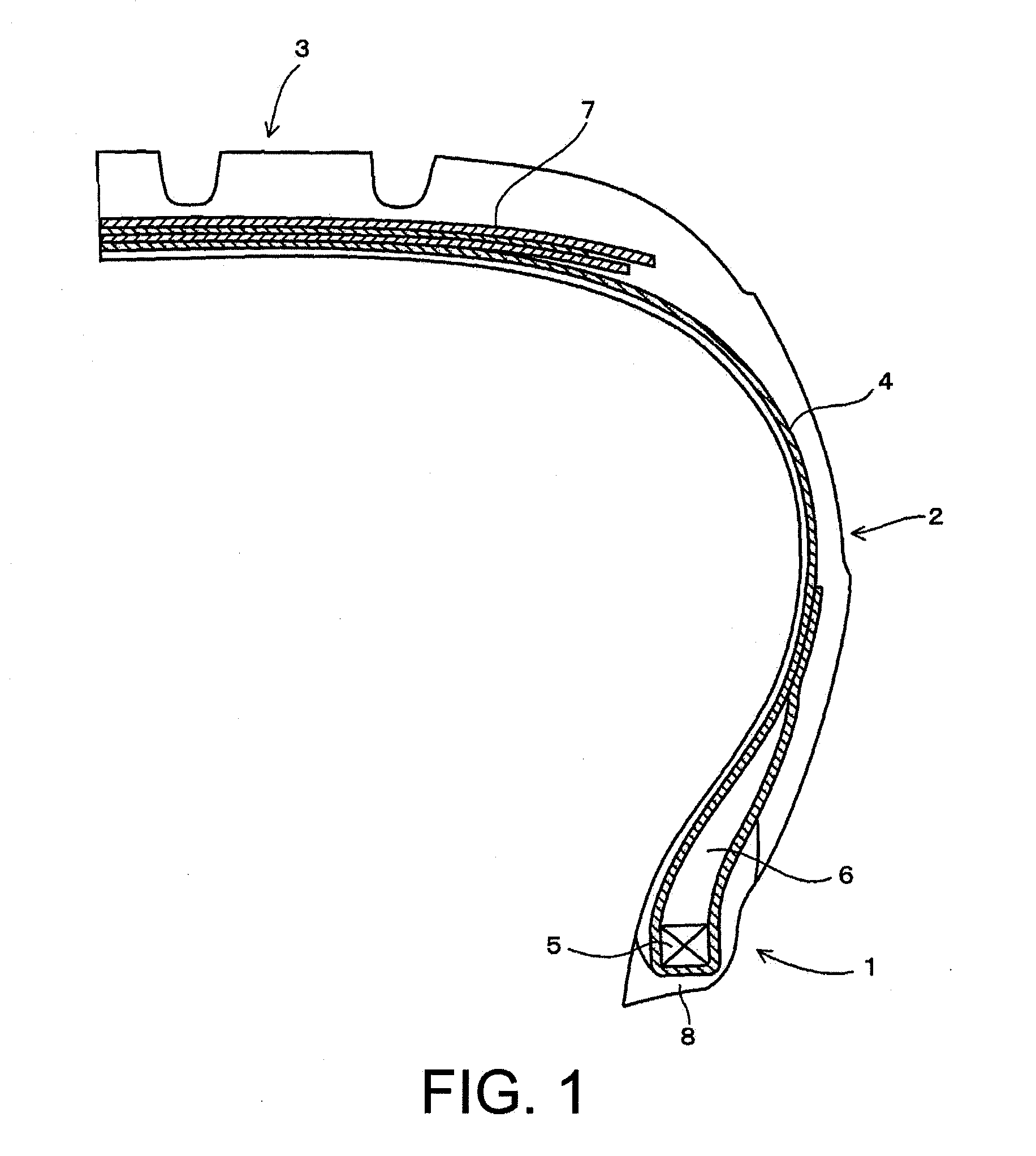

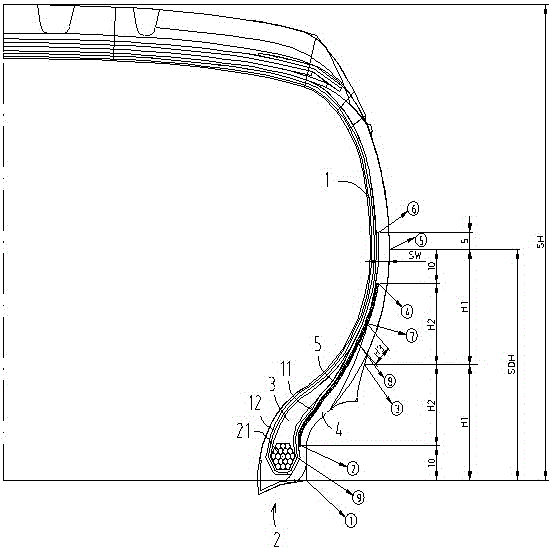

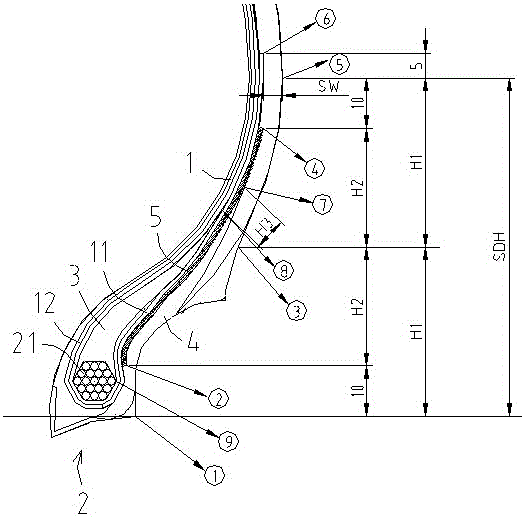

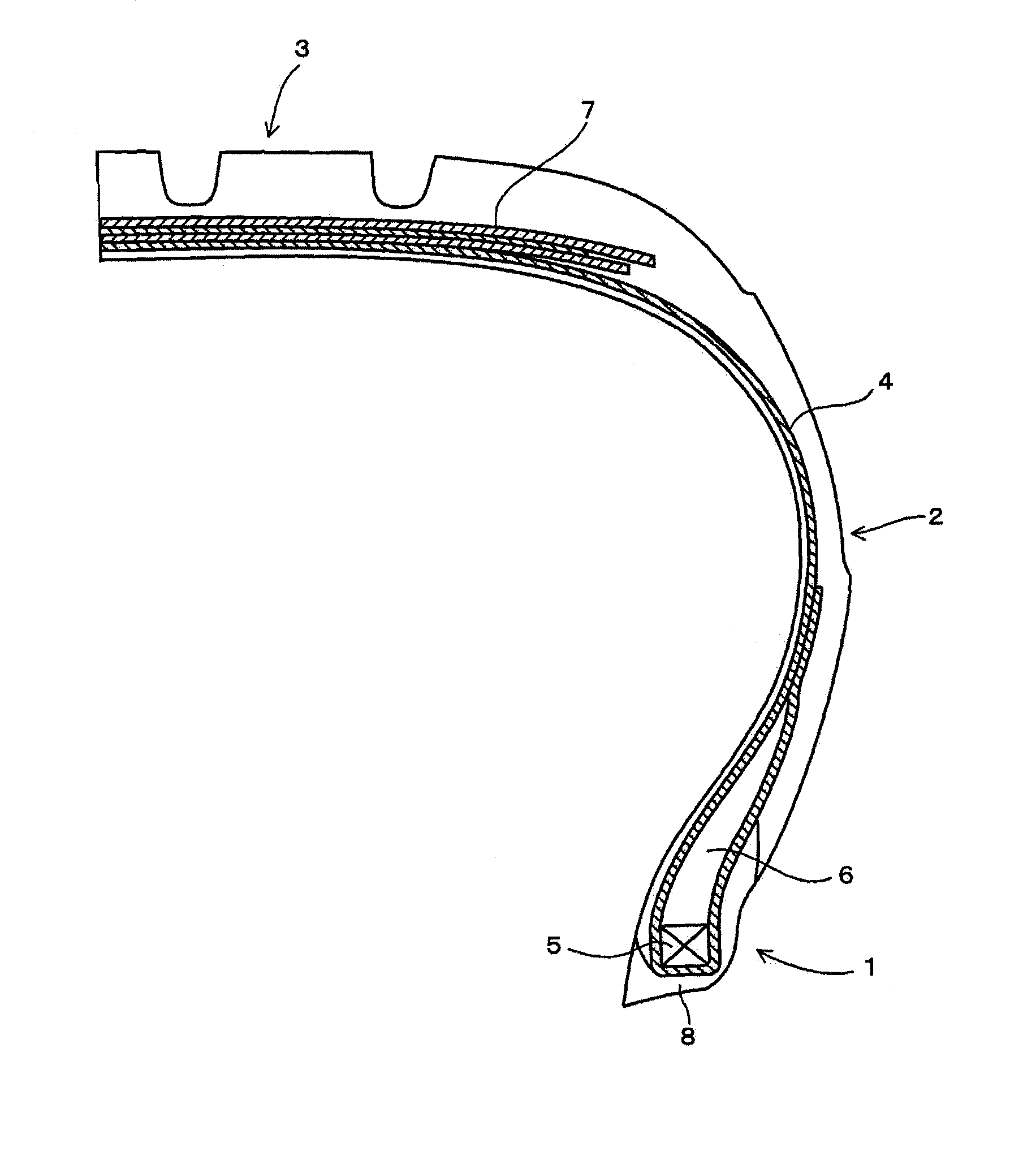

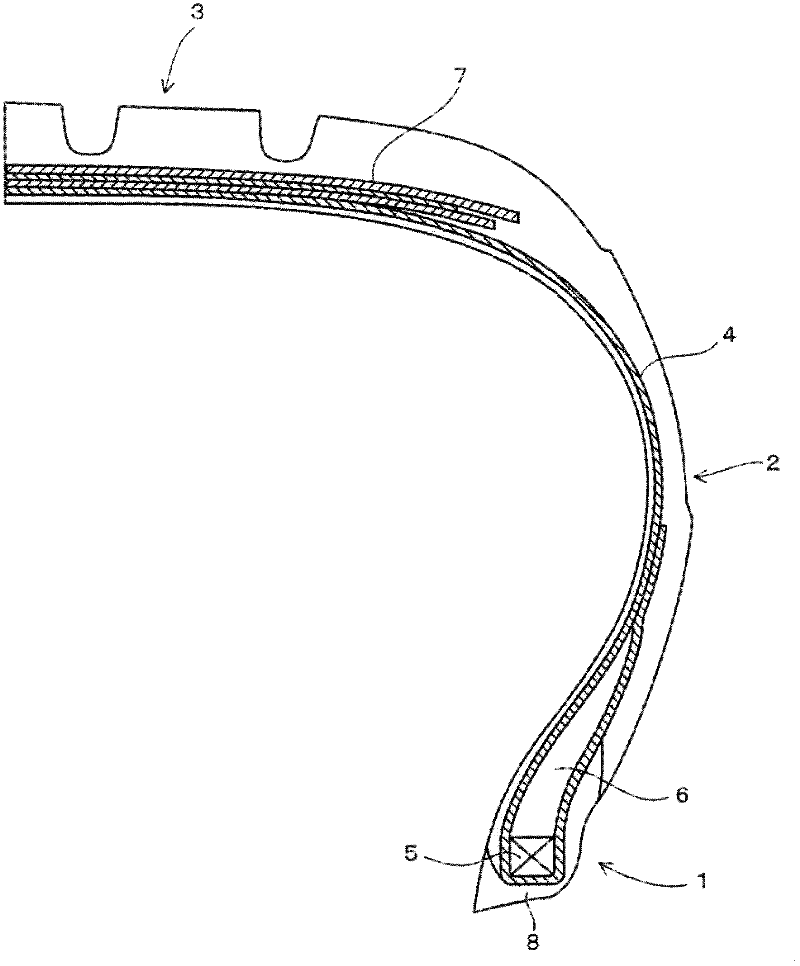

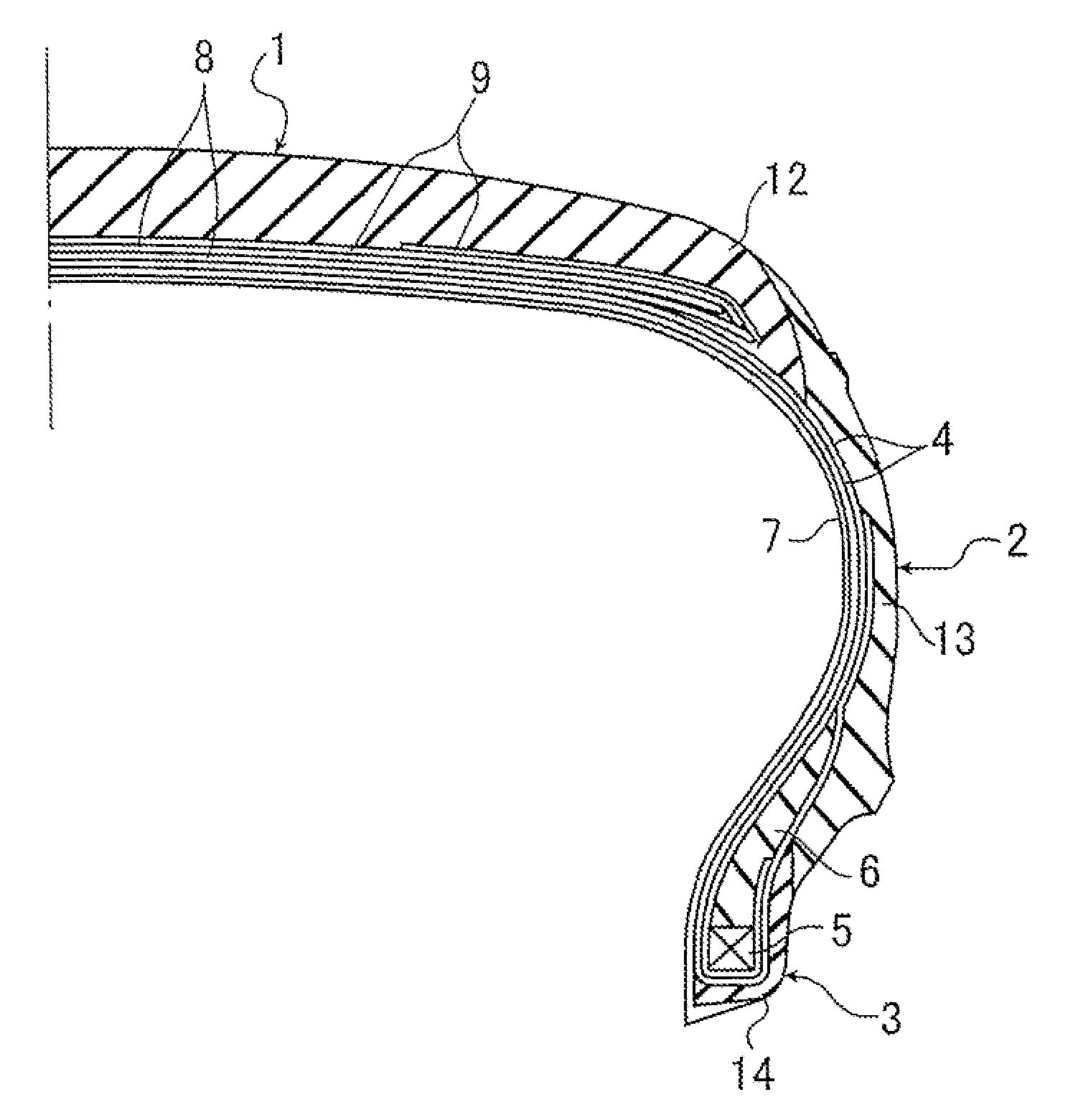

Pneumatic radial tire capable of promoting wetland grip performance

ActiveCN104985987AAvoid stress concentrationReasonable designPneumatic tyre reinforcementsTyre beadsTire beadTweel

The invention provides a pneumatic radial tire capable of promoting a wetland grip performance. The pneumatic radial tire capable of promoting the wetland grip performance comprises a tire body layer and a tire bead portion, the tire body layer winds a tire bead core in the tire bead portion and wraps the tire bead core from inside to outside in an inverse mode, the tire body layer is composed of one or more main body portions and one or more inverse wrapping portions, bead filler is arranged between the main body portions and the inverse wrapping portions, a rim cushion is arranged on the tire axial outer side of each inverse wrapping portion, and one or more tire sidewall strengthening layers are arranged on the positions from 40%-44% of the tire section height to 4.5-8% of the tire section height along each inverse wrapping portion between the tire axial outer side of the inverse wrapping portion of the tire body layer and the tire axial inner side of the corresponding rim cushion. According to the pneumatic radial tire capable of promoting the wetland grip performance, formulas and patterns are not changed, on the basis that excellent handling performance is guaranteed, a change of tire torsional rigidity is achieved through the additional arrangement of the tire sidewall strengthening layers on the tire sidewall positions and limit of the distribution ranges of the sidewall strengthening layers, and therefore the wetland grip performance of the tire is promoted.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

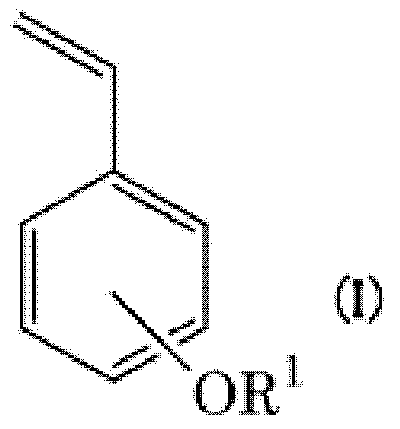

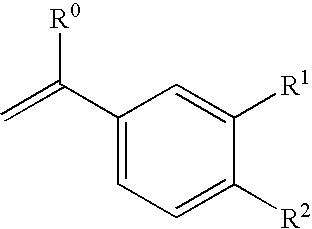

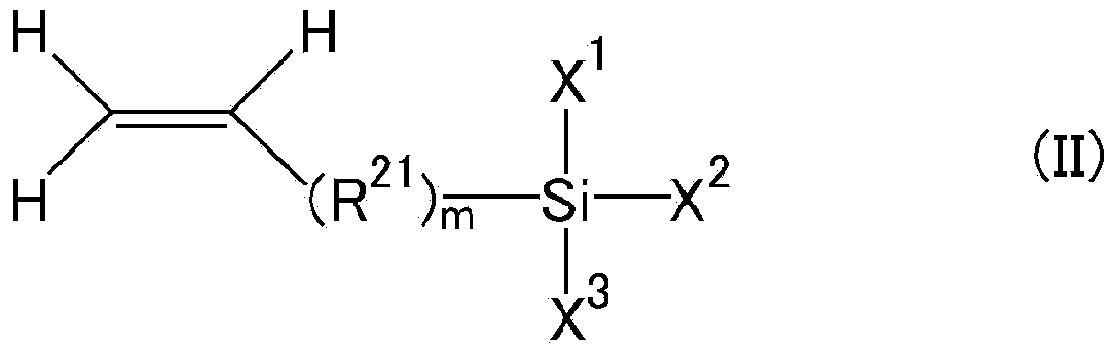

Rubber composition and pneumatic tire

InactiveCN103764746AImprove low fuel consumptionImprove wet grip performanceSpecial tyresRolling resistance optimizationPolymer scienceChemical compound

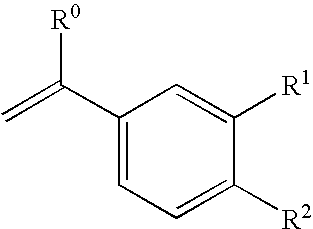

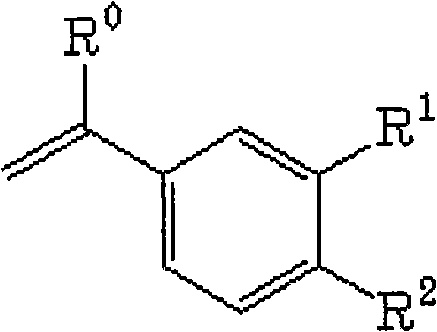

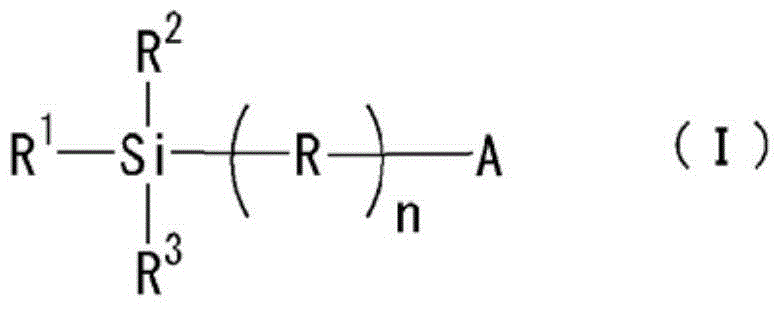

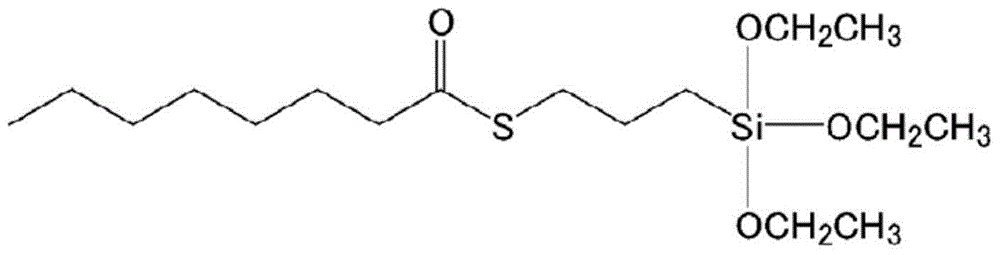

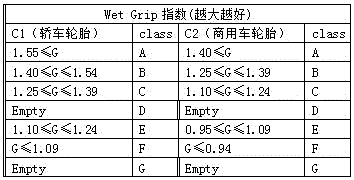

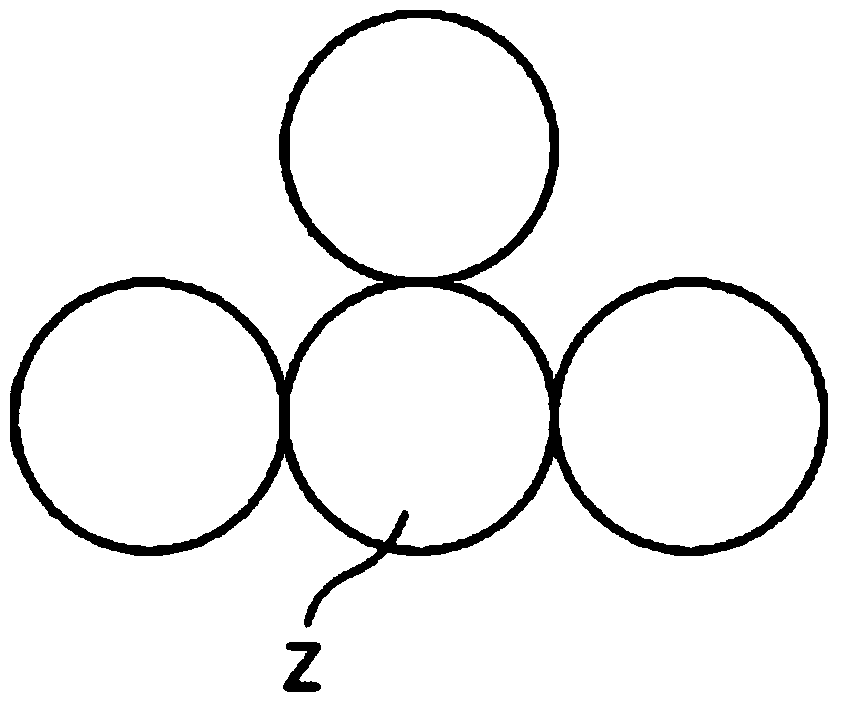

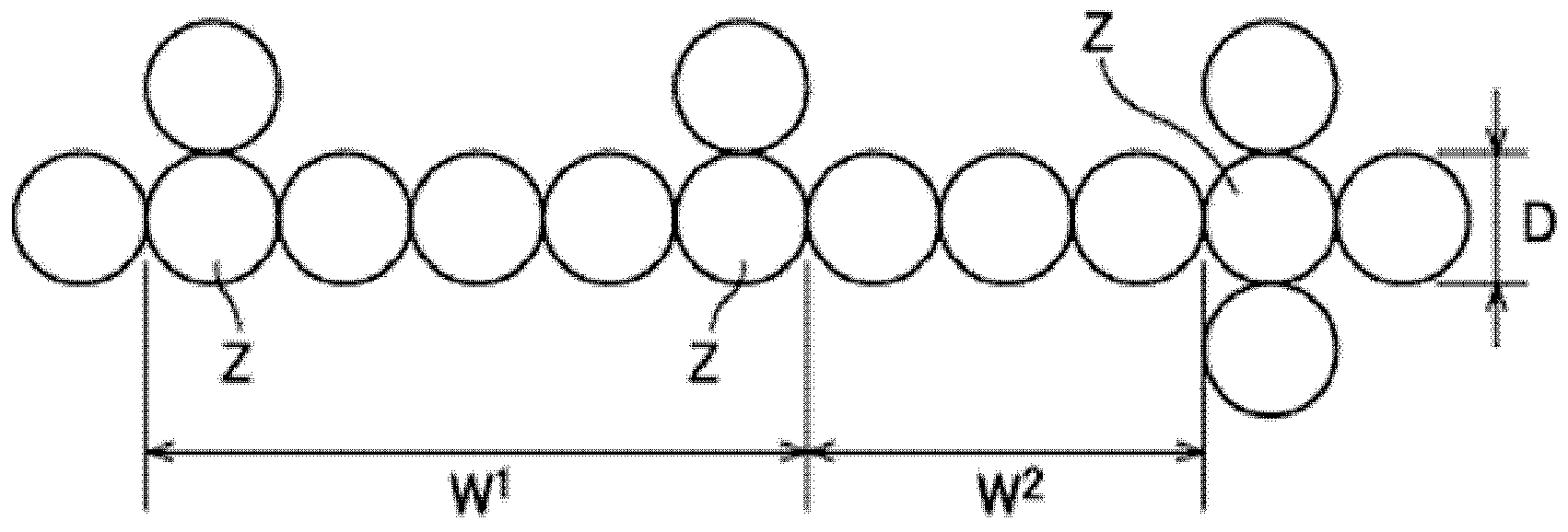

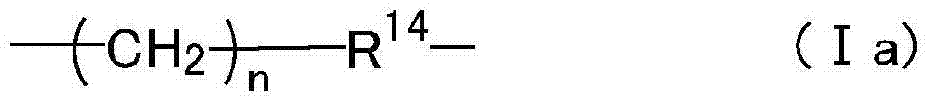

Provided are: a rubber composition which is capable of improving low fuel consumption, wet grip performance and dry grip performance in a balanced manner; and a pneumatic tire which uses the rubber composition in tire constituent members (especially in a tread). The present invention relates to a rubber composition which contains: a rubber component that contains a copolymer which is obtained by copolymerizing 1,3-butadiene, styrene and a compound represented by formula (I), said copolymer having an amino group at one end, having a functional group containing at least one atom selected from the group consisting of nitrogen, oxygen and silicon at the other end, and having a weight average molecular weight of from 1.0 105 to 2.5 106; and silica wherein when a particle having three or more adjacent particles is considered as a branch particle Z, the average length (W1) between branch particles Z-Z including the branch particles Z is 30-400 nm. (In the formula, R1 represents a hydrocarbon group having 1-10 carbon atoms.)

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for use in tires

ActiveUS8697793B2Reduce rolling resistanceImprove wet grip performancePlastic/resin/waxes insulatorsSpecial tyresPolymer scienceFuel efficiency

A rubber composition for use in tires is described which provides increased fuel efficiency and improved wet grip performance. The rubber composition includes from 5 to 70 parts by mass of silica having a BET specific surface area from 50 to 200 m2 / g per 100 parts by mass of a diene rubber. The rubber composition includes from 1 to 25 parts by mass of an aromatic modified terpene resin and at least one terpene per 100 parts by mass of a diene rubber. The rubber composition further includes from 1 to 70 parts by mass of a naphthenic oil per 100 parts by mass of a diene rubber, where a CN % proportion of a CA %·CP %·CN % ratio calculated according to ASTM D2140 / ASTM D3238 is the greatest and the CA % proportion is less than 15%, and a dynamic viscosity at 40° C. is from 17 to 30 mm2 / sec.

Owner:THE YOKOHAMA RUBBER CO LTD

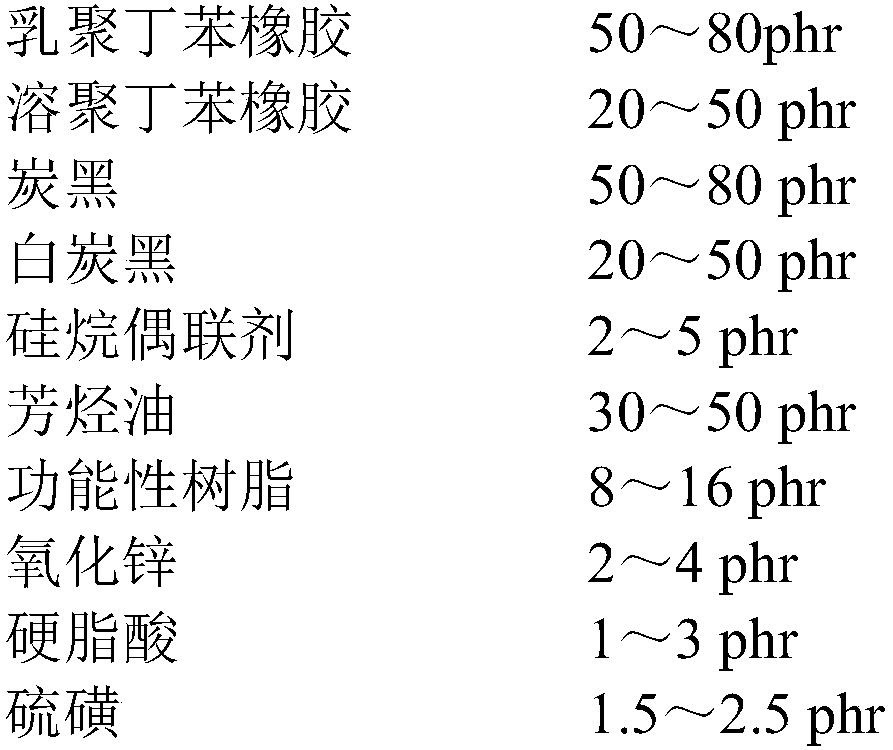

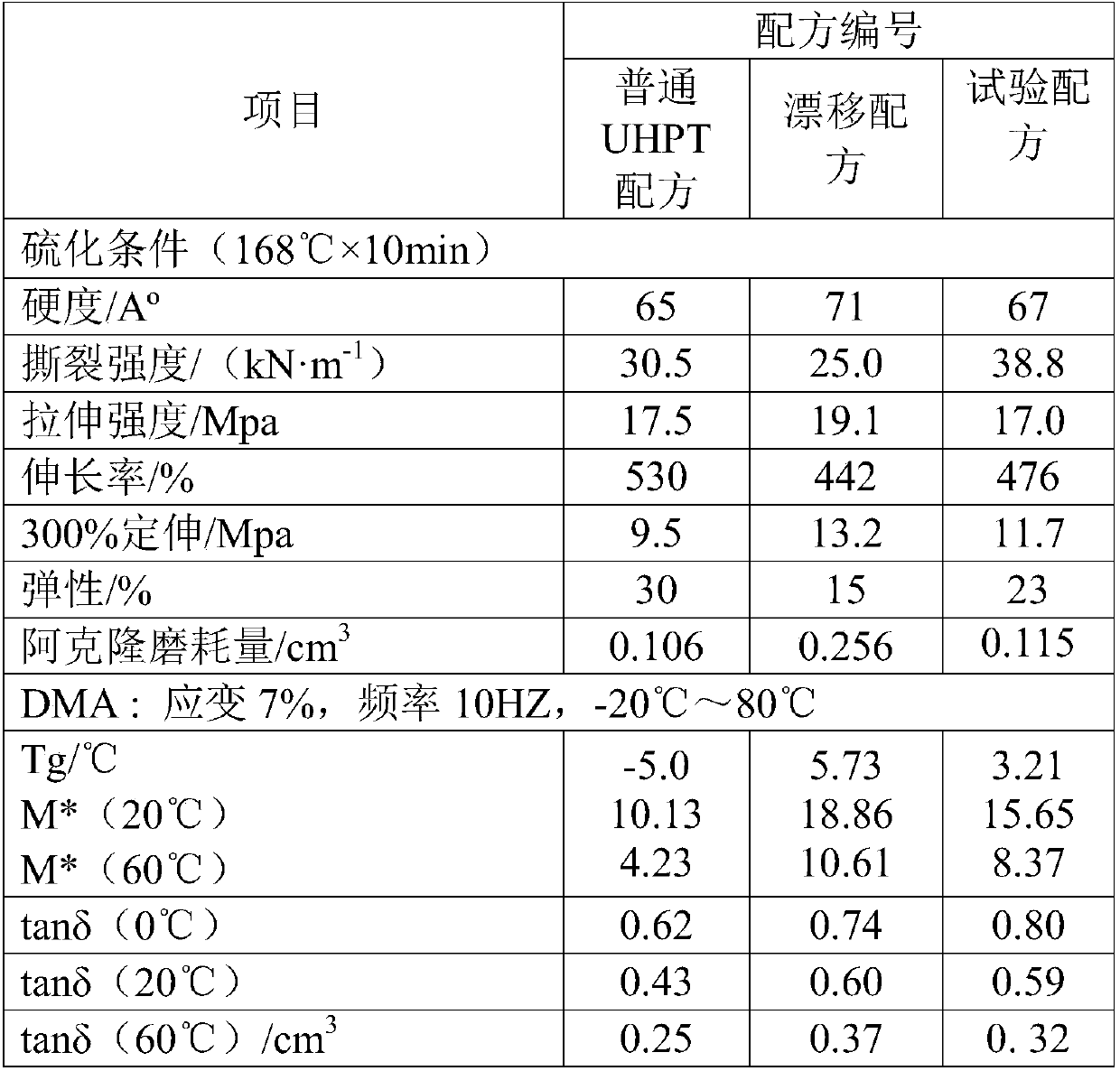

UHPT tread rubber which can be used in drifting competition

The invention discloses UHPT tread rubber which can be used in a drifting competition. The tread rubber comprises the following components: emulsion polymerized styrene-butadiene rubber 50-70 phr, solution polymerized styrene-butadiene rubber 30-50 phr, carbon black 50-80 phr, white carbon black 20-50 phr, a silane coupling agent 2-5 phr, oil 30-50 phr, functional resin 8-16 phr, zinc oxide 2-4 phr, stearic acid 1-3 phr, sulfur 1.5-2.5 phr, an accelerator 2.0-3.0 phr, and other components 4-7 phr. The formula of the tread rubber provided by the invention innovatively uses the modified solutionpolymerized styrene-butadiene rubber, the highly-dispersed white carbon black with a high specific surface area and the functional resin, also the ratio of fillers and the mixing process of the treadrubber are reasonably adjusted, and the requirements of the usage performance of daily driving and the drifting competition are taken into account: compared with ordinary UHPT tread rubber, the treadrubber provided by the invention has excellent dry ground gripping and manipulating performance; and compared with professional drifting tread rubber, the tread rubber provided by the invention has significantly-improved service life and better-improved wet ground gripping performance, and can meet multi-purpose requirements of usual driving and the drifting competition.

Owner:SAILUN GRP CO LTD

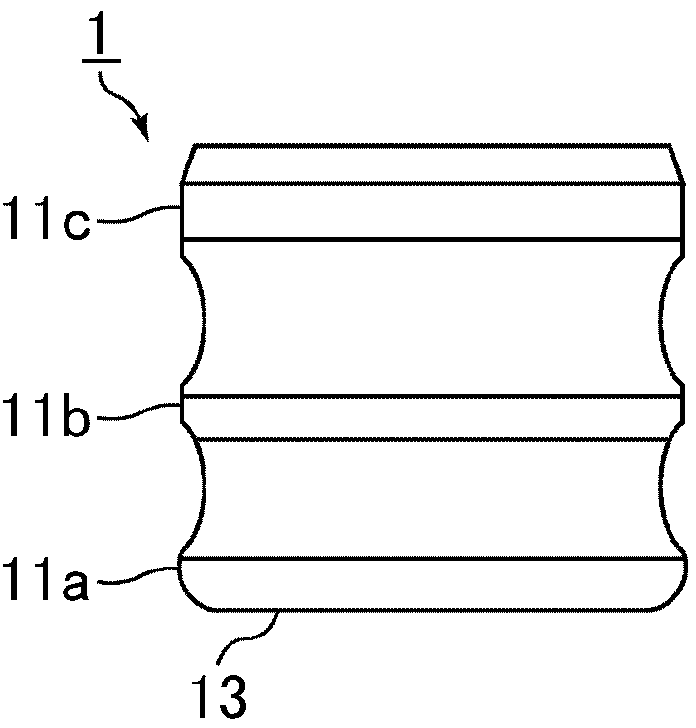

Tread rubber composition for two-wheeled vehicle tire and two-wheeled vehicle tire

It is an object of the present invention to provide a tread rubber composition for a two-wheeled vehicle tire which can exhibit both good wet grip performance and good chunk resistance, and a two-wheeled vehicle tire including a tread produced using the rubber composition. The present invention relates to a tread rubber composition for a two-wheeled vehicle tire, including: a rubber component, silica, and carbon black, wherein the rubber component contains natural rubber, and styrene butadiene rubber and / or butadiene rubber, the silica has a CTAB specific surface area of 180 m2 / g or more and a BET specific surface area of 185 m2 / g or more, and the amount of the carbon black is 15 parts by mass or more per 100 parts by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

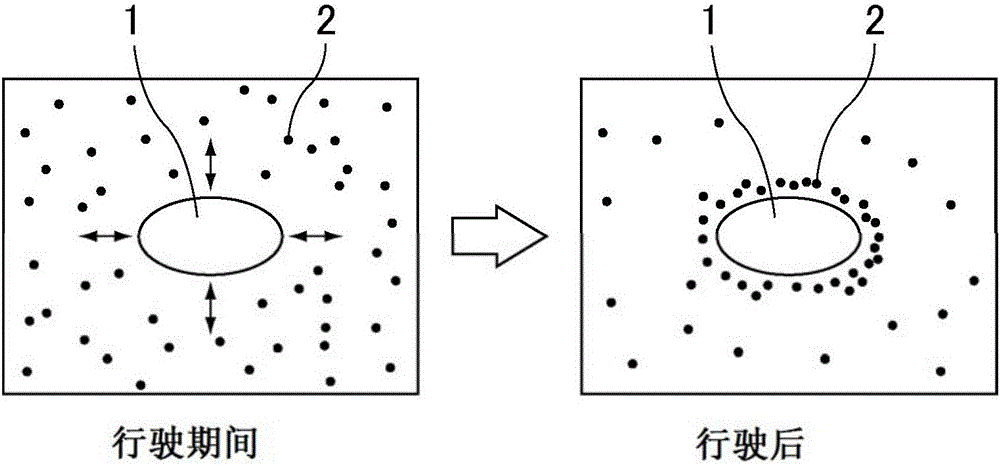

Surface modification method and surface modification elastormer

Owner:SUMITOMO RUBBER IND LTD

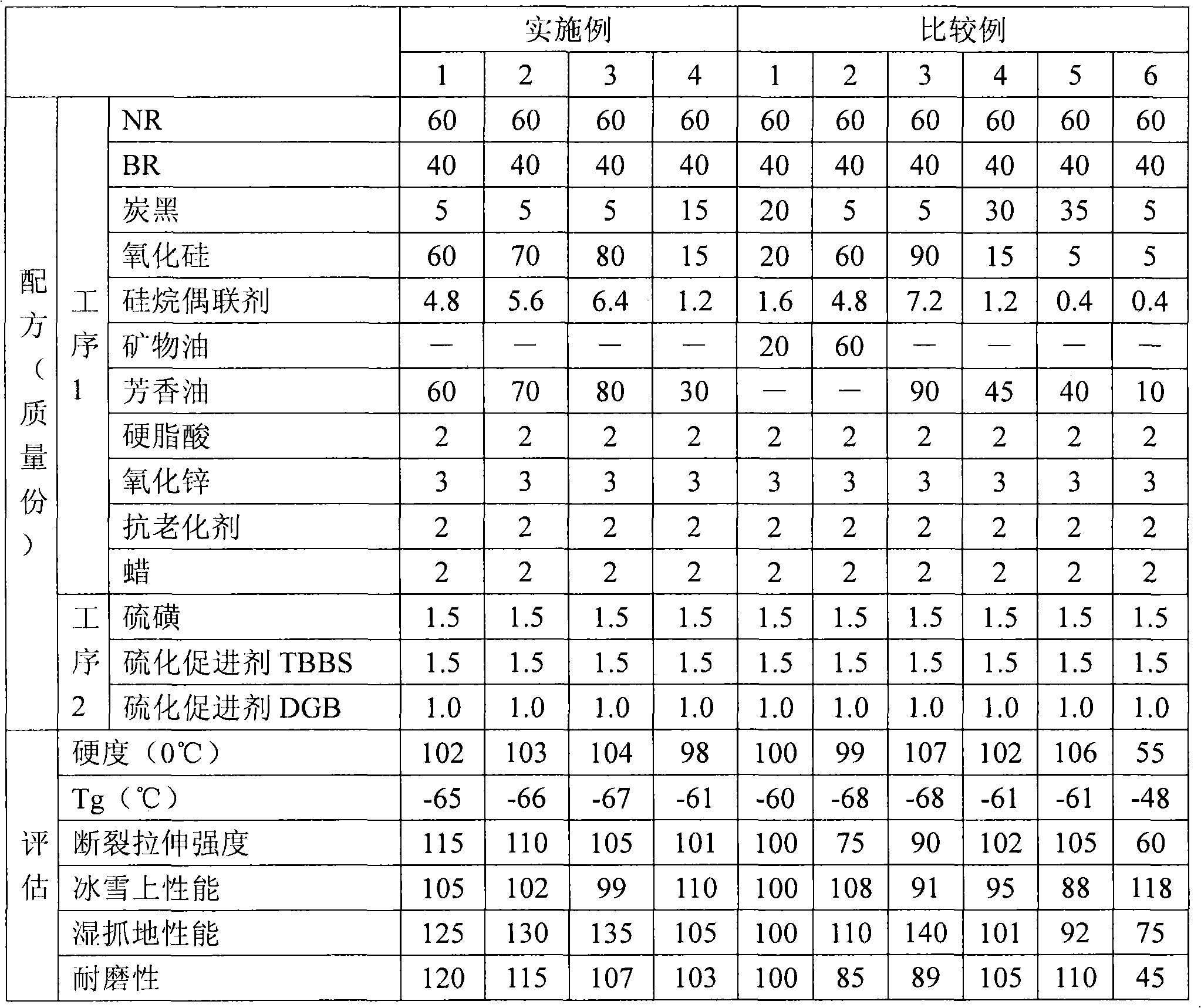

Rubber composition for studless tire and studless tire

ActiveCN101993552AImprove wear resistanceExcellent performance on snow and iceSpecial tyresPolymer scienceSilicon dioxide

The present invention provides a rubber composition for a studless tire, which can achieve sufficient abrasion resistance, performance on ice and snow, and wet grip performance in a balanced manner, and a studless tire having a tread produced from the above composition. The rubber composition for a studless tire contains a rubber component including natural rubber and butadiene rubber; aromatic oil; silica; and carbon black, wherein the total amount of the natural rubber and the butadiene rubber is 30% by mass or more based on 100% by mass of the rubber component, the amount of the aromatic oil is 12-85 parts by mass and the amount of the silica is 12-85 parts by mass, per 100 parts by mass of the rubber component, and the proportion of the silica is 45% by mass or more based on 100% by mass of the total of the silica and the carbon black.

Owner:SUMITOMO RUBBER IND LTD

Rubber material for agriculture vehicle tire

InactiveCN104403140AHigh tensile strengthHigh tear strengthSpecial tyresRubber materialAluminium hydroxide

The invention discloses a rubber material for agriculture vehicle tires. The rubber material is prepared from the following raw materials in parts by weight: 40-50 parts of natural rubber, 10-14 parts of epoxy natural rubber, 15-20 parts of silicon dioxide, 2-4 parts of a silane coupling agent, 20-30 parts of brominated butyl rubber, 20-30 parts of superfine glass bead, 30-40 parts of carbon black N660, 20-30 parts of light calcium carbonate, 1-2 parts of tetramethyl thiuram disulfide, 1-2 parts of diisopropylbenzene peroxide, 2-3 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 2-4 parts of zinc oxide, 1-2 parts of an accelerant DM, 0.5-1.0 part of an accelerant CZ, 1-2 parts of N-phenyl-N'-(1,3-dimethyl)-p-phenylenediamine, 1-2 parts of 2,2'-methylene-bi(4-methyl-6-tertiary butyl phenol), 1-2 parts of petroleum oil, 2-5 parts of stearic acid, 1-2 parts of protecting wax OK5194, 5-6 parts of rubber tackifying resin A-90, 5-8 parts of antimonous oxide, 5-10 parts of molybdenum trioxide and 20-30 parts of aluminium hydroxide.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

Pneumatic tire

InactiveUS20170226331A1Improve wet grip performanceHigh tensile strengthSpecial tyresPolymer scienceWear resistance

The present invention provides a pneumatic tire having improved rubber tensile strength, abrasion resistance, and wet-grip performance while maintaining good fuel economy. The present invention relates to a pneumatic tire containing: a hydrogenated copolymer obtained by copolymerization of an aromatic vinyl compound and a conjugated diene compound, the hydrogenated copolymer having a degree of hydrogenation of the conjugated diene units of 75 mol % or more; and a resin having a softening point of 60° C. to 120° C., the rubber composition containing, per 100% by mass of a rubber component, 75% by mass or more of the hydrogenated copolymer, the rubber composition containing, relative to 100 parts by mass of the rubber component, 1 to 30 parts by mass of the resin.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and tire

InactiveUS8431644B2Reduce the heating effectImprove wet grip performanceSpecial tyresPolymer scienceNitrogen

The present invention has its object to provide a rubber composition that can be used for a tread to supply a tire having both low heat build-up property and good wet grip performance. The present invention relates to a rubber composition including: silica and a rubber component that contains a modified butadiene rubber having a vinyl content of 35% by weight or less and having, in a main chain thereof, a constitutional unit derived from a specific nitrogen-containing compound, wherein an amount of the modified butadiene rubber is 5 to 45% by weight per 100% by weight of the rubber component, and wherein an amount of the silica is 10 to 150 parts by weight per 100 parts by weight of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tire tread and pneumatic tire using the rubber composition

InactiveCN102268149AGood dispersionImprove vulcanization speedSpecial tyresRolling resistance optimizationTire beadPolymer science

The object of the present invention is to provide a rubber composition for tire treads which has a good vulcanization rate and excellent wet grip and fuel efficiency. As a means of solving the problems of the present invention, there is provided a rubber composition for tire treads containing 40 parts by mass or more of a solution-polymerized SBR diene having a Mw of 900,000 to 1.5 million and a styrene content of 35 to 45%. 100 parts by mass of rubber, compounded with 60 to 110 parts by mass of silicon dioxide satisfying all the conditions of (1) to (4) below, and relative to the silicon dioxide, compounded with fatty acid metal salts (except zinc salts) 2-8 mass % of the mixture formed with fatty acid ester. The conditions for the above silica are: (1) N2SA is 194-225m2 / g. (2) The specific surface area of CTAB is 170-210m2 / g. (3) The relationship between the above-mentioned N2SA and the above-mentioned CTAB specific surface area is that the N2SA / CTAB specific surface area is 0.9 to 1.4. (4) DBP absorption is 190ml / 100g or more.

Owner:THE YOKOHAMA RUBBER CO LTD

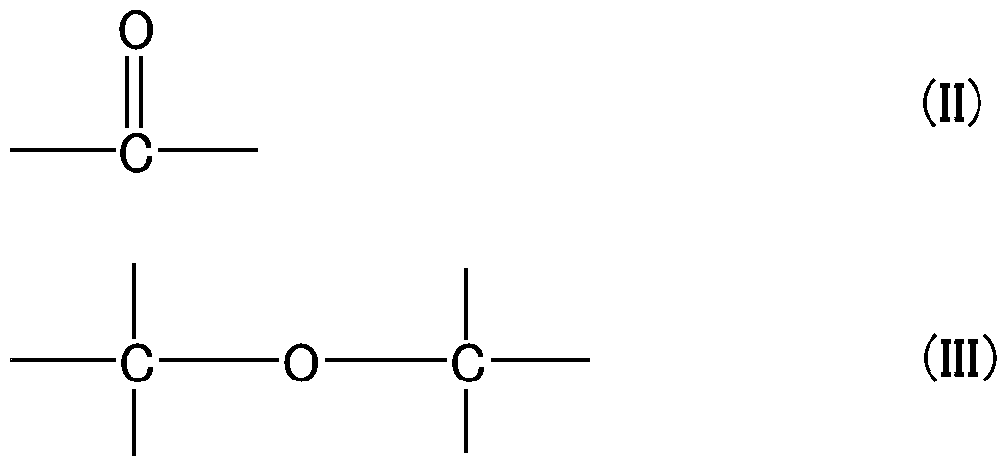

Rubber composition, and pneumatic tire

InactiveCN103946299AHigh strengthImprove wear resistanceSpecial tyresRolling resistance optimizationPolymer scienceSilicon dioxide

Owner:SUMITOMO RUBBER IND LTD

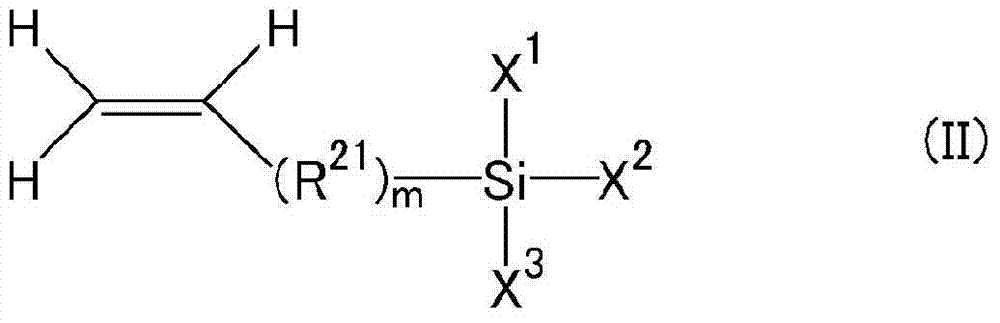

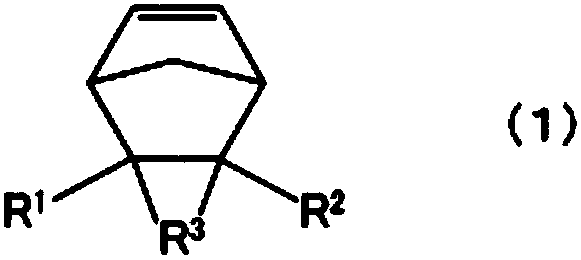

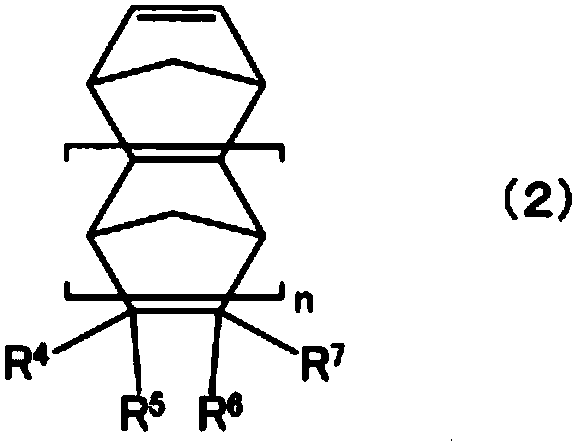

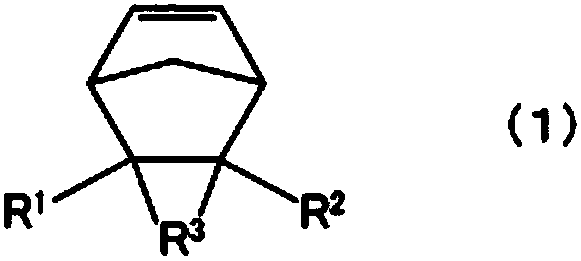

Cyclopentene ring-opened copolymer

InactiveCN107922594AHigh breaking strengthImprove wear resistanceSpecial tyresCyclopenteneNorbornene

Provided is a cyclopentene ring-opened copolymer comprising structural units derived from cyclopentene, and structural units derived from a norbornene compound having at least 3 rings, wherein the content ratio of structural units derived from the norbornene compound having at least 3 rings is 40-80wt.% with respect to all of the repeating structural units in the cyclopentene ring-opened copolymer.

Owner:ZEON CORP

Rubber composition for tire tread and pneumatic tire using the same

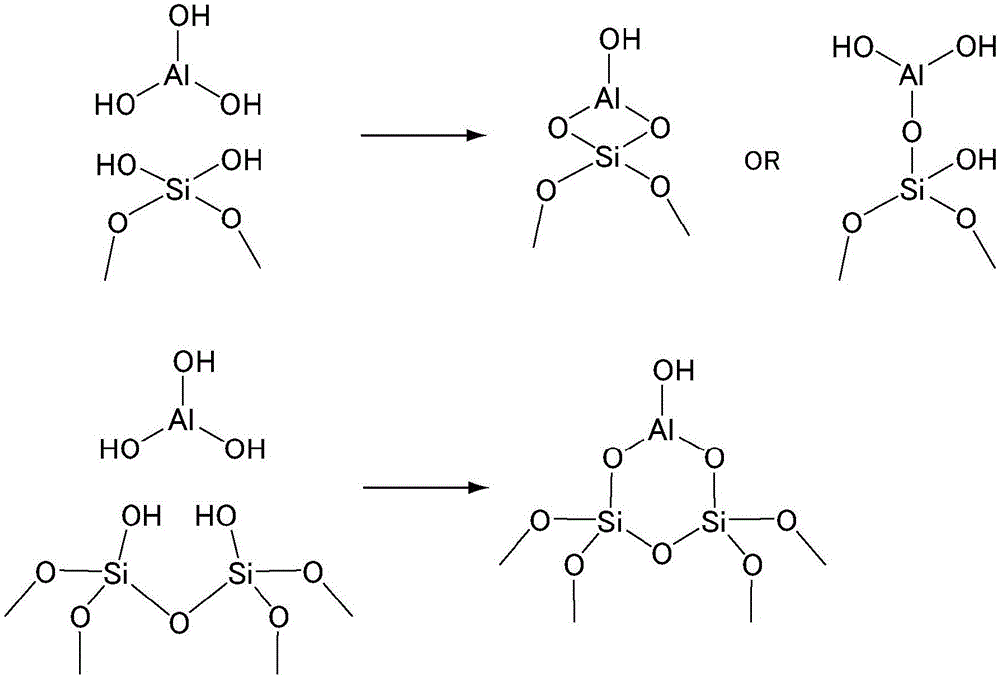

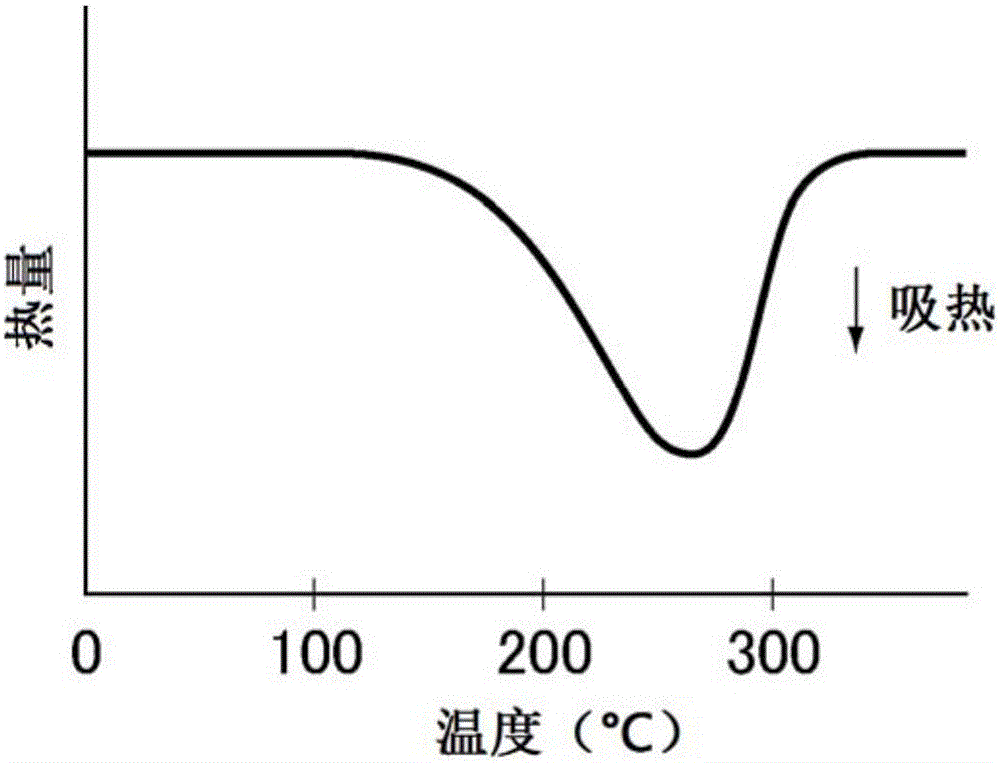

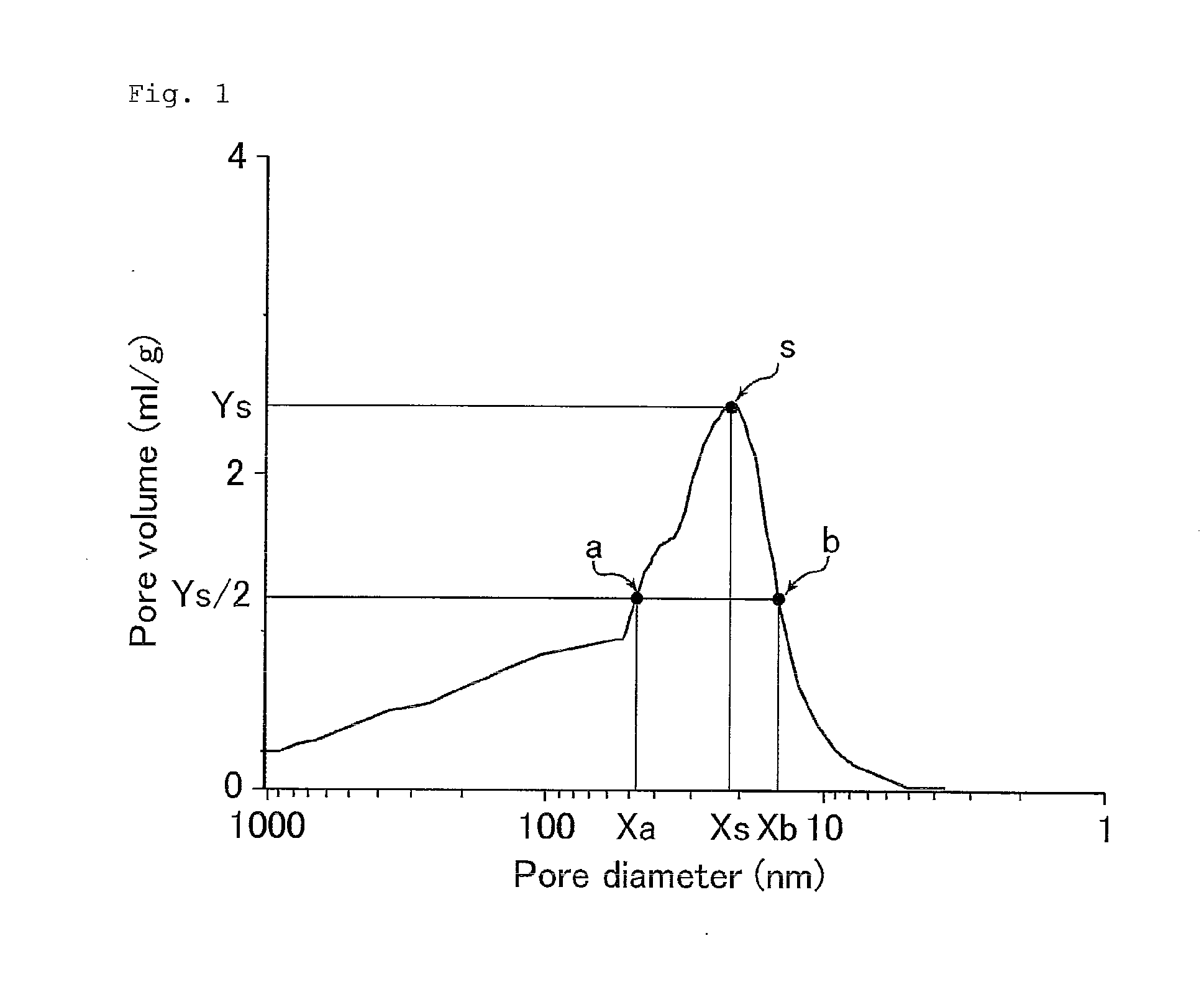

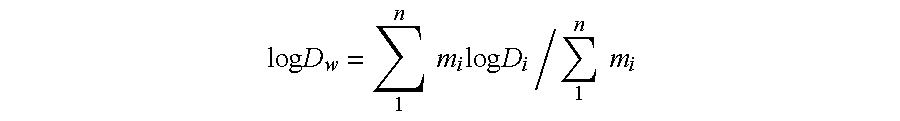

InactiveUS7338999B2Improve wet grip performanceGood dispersionPigmenting treatmentSpecial tyresRolling resistancePolymer science

To provide a rubber composition having excellent wet grip performance while maintaining low heat build-up characteristics without lowering processability, abrasion resistance and rolling resistance. The rubber composition of the present invention comprises, based on 100 parts by weight of a diene rubber (A), 5 to 150 parts by weight of particular inorganic filler (B), 5 to 150 parts by weight of carbon black (C) having a nitrogen adsorption specific surface area of 70 to 300 m2 / g, and 1 to 20 % by weight of a silane coupling agent (D). The pneumatic tire of the present invention is obtained by using the rubber composition for the tread rubber.

Owner:SUMITOMO RUBBER IND LTD

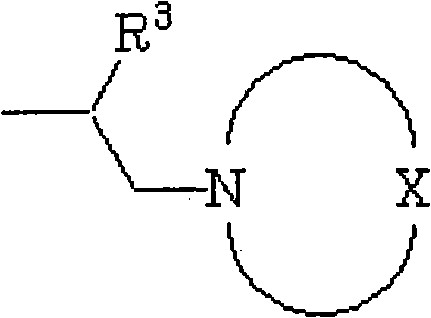

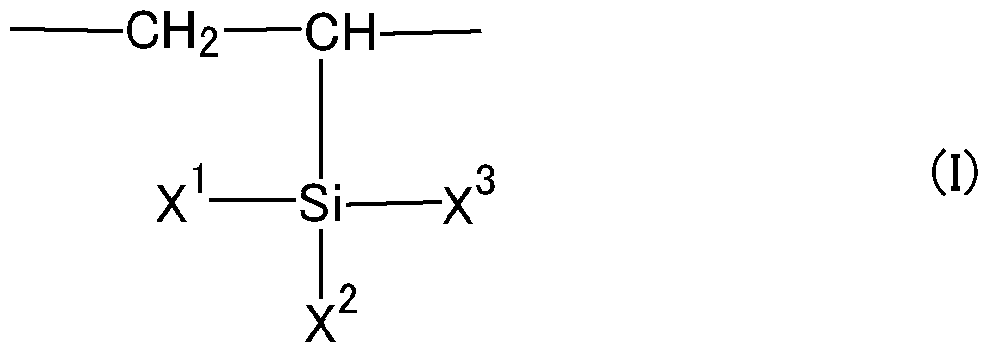

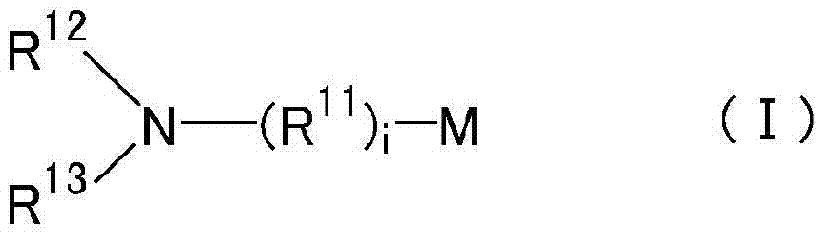

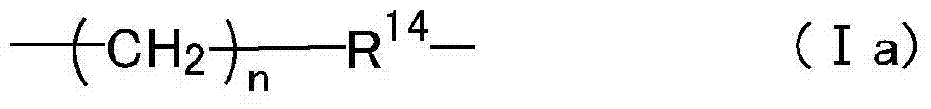

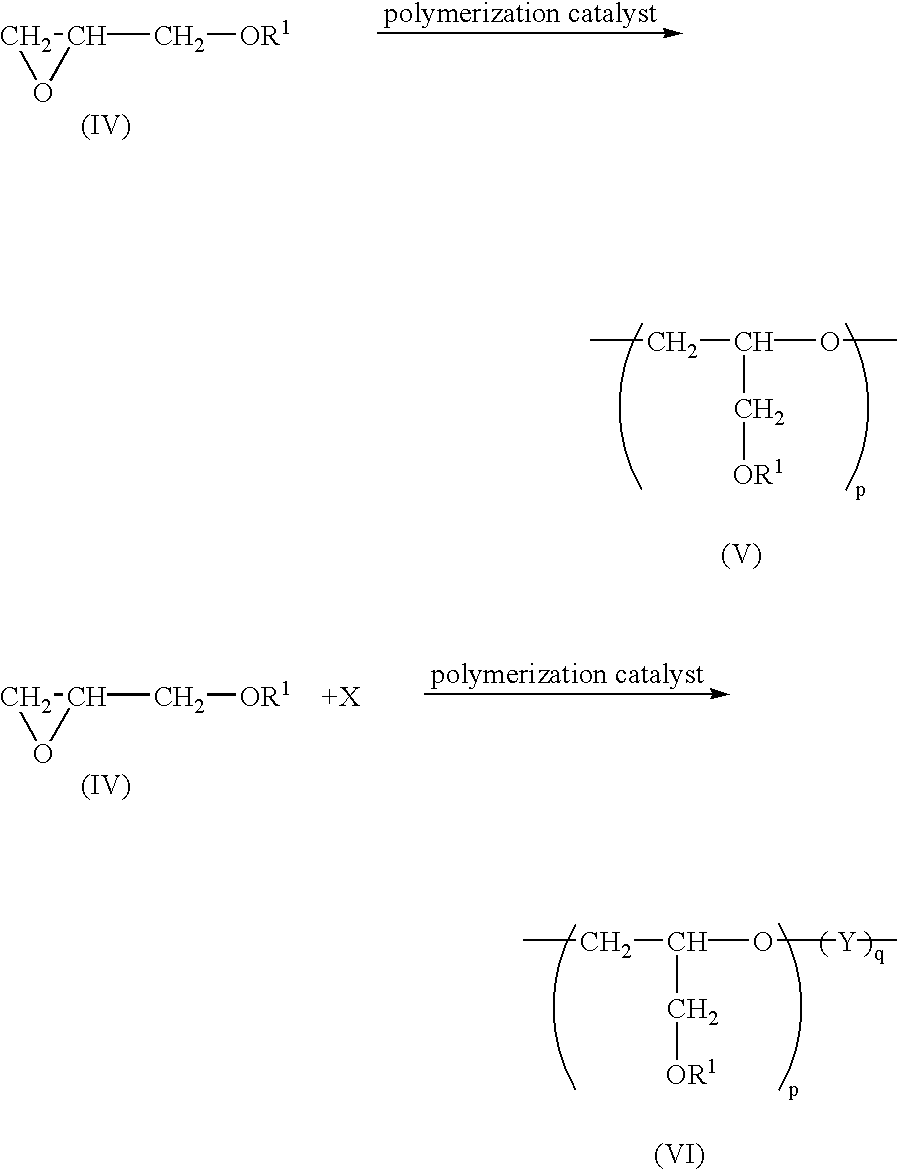

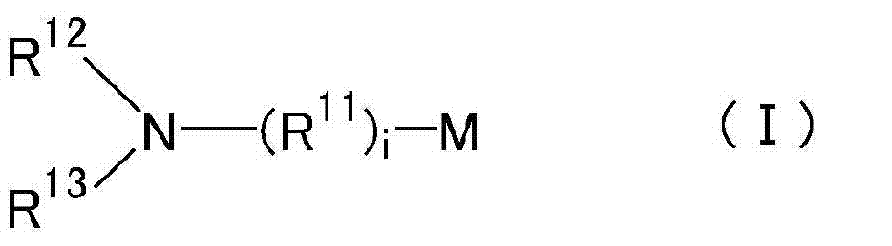

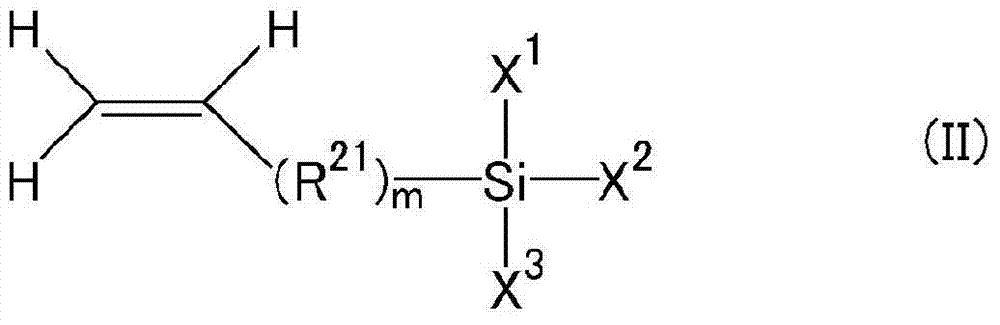

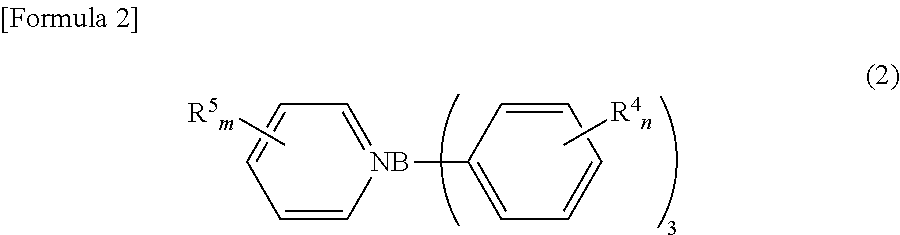

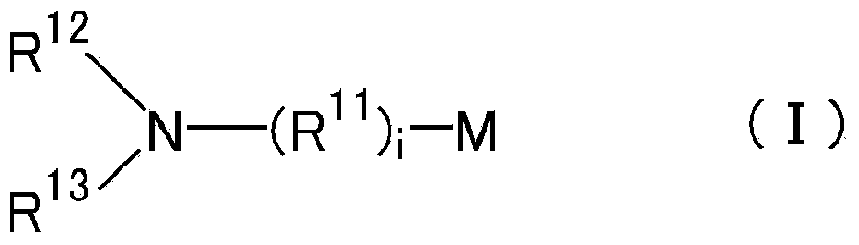

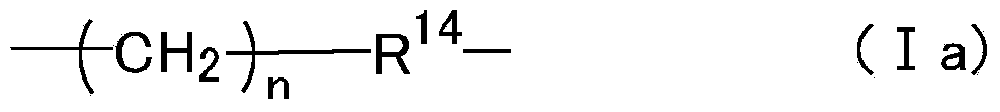

Rubber composition and pneumatic tire

InactiveCN103946302AHigh strengthImprove wear resistanceSpecial tyresRolling resistance optimizationPolymer scienceNitrogen

The present invention provides a rubber composition whereby it is possible to improve processability, low fuel consumption, rubber strength, resistance to corrosion, wet grip performance, and steering stability in a balanced manner. The present invention also provides a pneumatic tire using said rubber composition. The present invention pertains to a rubber composition comprising: a conjugated diene-based polymer obtained by reacting a compound containing nitrogen atoms and / or silicon atoms with the active terminal of a co-polymer obtained by polymerizing a monomer component containing a conjugated diene compound and a silicon-containing vinyl compound using a polymerization initiator represented by formula (I); and a silica having a nitrogen adsorption specific surface area between 40 and 400 m2 / g. The rubber composition is characterized in that the content of the conjugated diene-based polymer is 1 to 90 mass% and the content of a polyisoprene-based rubber is 0 to 70 mass% in 100 mass% of a rubber component, and the content of silica is 10 to 150 parts by mass relative to 100 parts by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

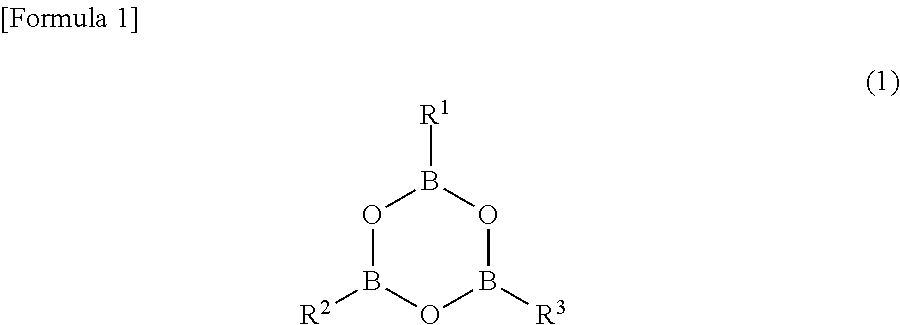

Rubber composition and pneumatic tire using same

The present invention provides a rubber composition formed by blending from 1 to 100 parts by mass of carbon black and / or from 5 to 150 parts by mass of an inorganic filler, from 0.5 to 30 parts by mass of a sulfur-containing compounding agent, and from 0.01 to 20 parts by mass of a boron-containing compounding agent into 100 parts by mass of a sulfur-crosslinkable diene rubber, and a pneumatic tire in which the rubber composition is used in at least one type selected from the group consisting of a capped tread, a side wall, a belt, an inner liner, a carcass, and a bead.

Owner:THE YOKOHAMA RUBBER CO LTD

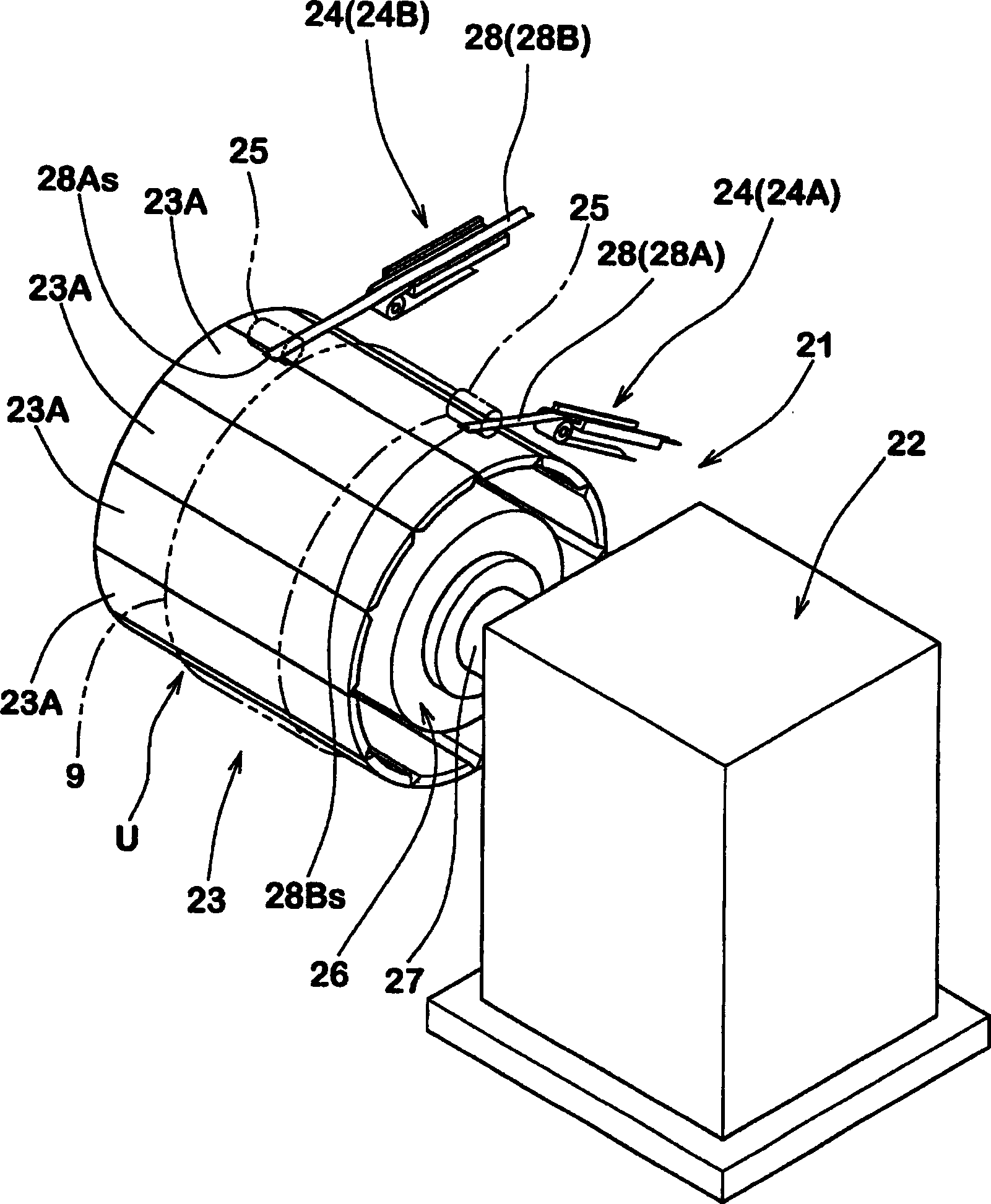

Producing method of pneumatic tire

InactiveCN1772465AReduce usage ratioUse the ratio to ensureTyresTyre tread bands/patternsRoad surfaceEngineering

It is an object of the present invention to provide a method of manufacturing a pneumatic tire capable of releasing the static charge of a vehicle to a road surface. A pneumatic tire manufacturing method for manufacturing a pneumatic tire in which a tread portion includes: an electrically conductive inner conductive portion which conducts with a rim when the rim is assembled; and an annular cap rubber portion thereof, in which The peripheral surface is in contact with the inner conductive part and its outer peripheral surface is in contact with the road surface. The manufacturing method includes a cap rubber forming step for forming a cylindrical unvulcanized cap rubber by helically winding a band-shaped unvulcanized rubber strip 28 around the central axis of a substantially cylindrical wound body 23 part, wherein the cover rubber forming step includes a simultaneous winding step for simultaneously winding the non-conductive rubber strip 28A and the conductive rubber strip around the body to be wound by using the applicators 24A and 24B which guide the rubber strips 28A and 28B with 28B.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and pneumatic tire

InactiveCN103917588AHigh strengthImprove wear resistanceSpecial tyresRolling resistance optimizationPolymer scienceNitrogen

This invention provides a rubber composition capable of improving workability, low fuel consumption, rubber strength, abrasion resistance, and wet grip performance in a balanced manner; and a pneumatic tire in which same is used. This invention relates to a rubber composition comprising, at the active end of a copolymer, a conjugated diene polymer obtained by reacting a compound containing a nitrogen atom and / or a silicon atom, and silica having a nitrogen-adsorption specific surface area of 40-400 m2 / g. The copolymer is obtained by polymerizing a monomer component comprising a conjugated diene compound and a silicon-containing vinyl compound using a polymerization initiator as represented by formula (I). The amount of the conjugated diene polymer and the amount of the polyisoprene rubber content are 1 to 60wt% and 0-99wt%, respectively, relative to 100wt% of the rubber component. The silica content is 10-80 parts by weight to 100 parts by weight of rubber component, and the carbon ratio is at least 50.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com