Rubber composition and pneumatic tire

A rubber composition and rubber technology, applied in special tires, tire parts, rolling resistance optimization and other directions, can solve the problems of self-aggregation and dispersion difficulties of silica, and achieve the effect of improving low fuel consumption and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

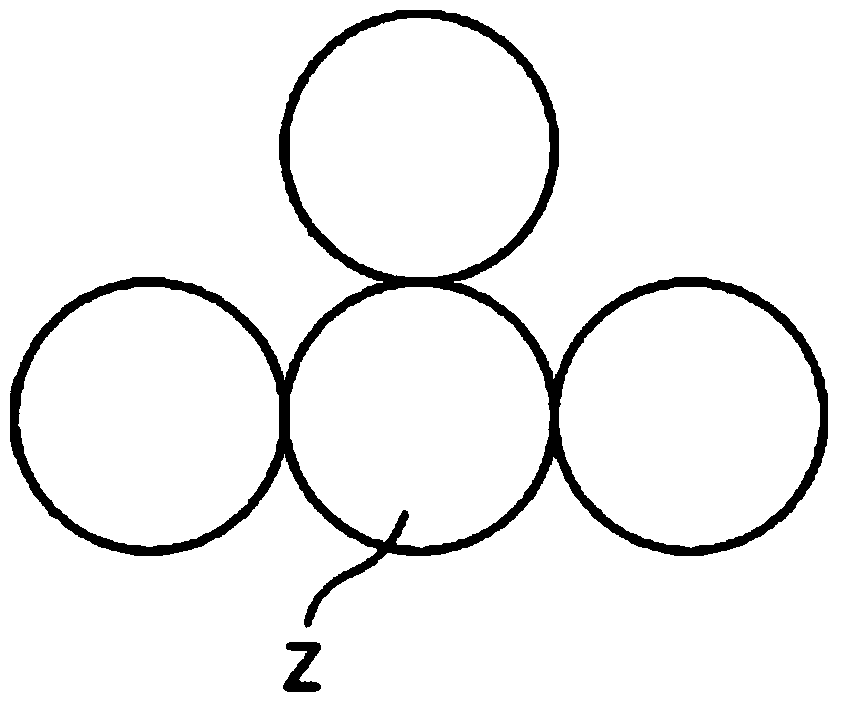

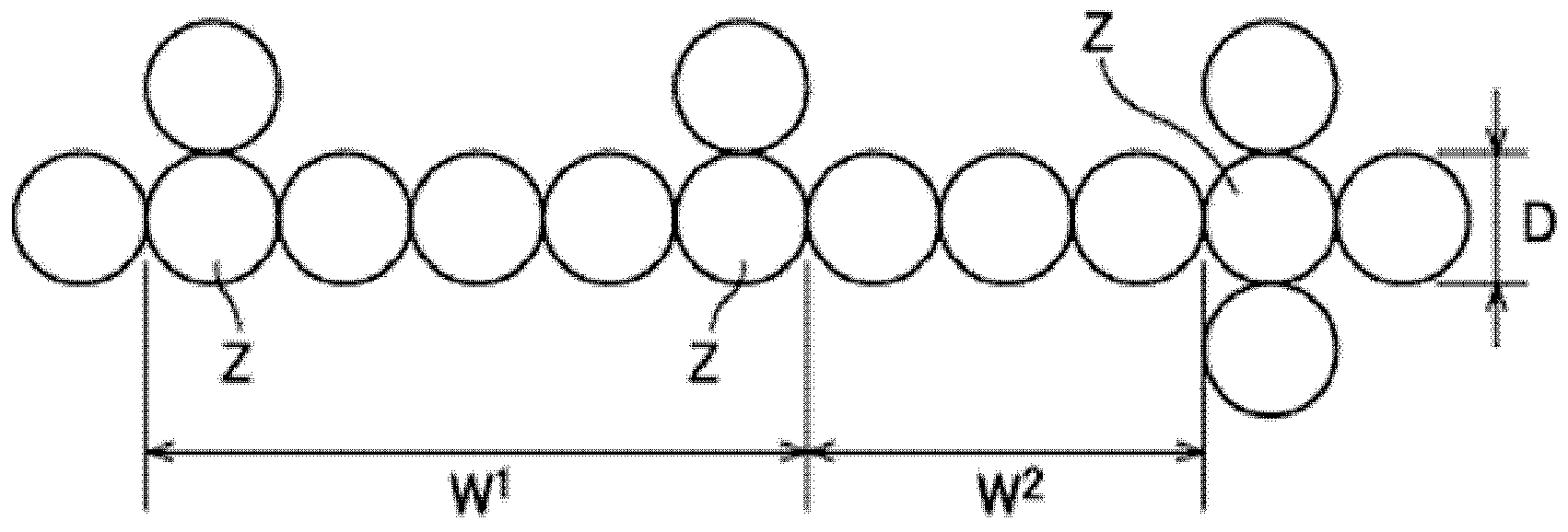

Image

Examples

Embodiment

[0223] The present invention will be specifically described based on examples, but the present invention is not limited to the following examples.

[0224] The various chemicals used for synthesis and polymerization are summarized below. In addition, chemicals can be purified according to conventional methods if necessary.

[0225] n-Hexane: manufactured by Kanto Chemical Co., Ltd.

[0226] Styrene: manufactured by Kanto Chemical Co., Ltd.

[0227] 1,3-Butadiene: manufactured by Tokyo Chemical Industry Co., Ltd.

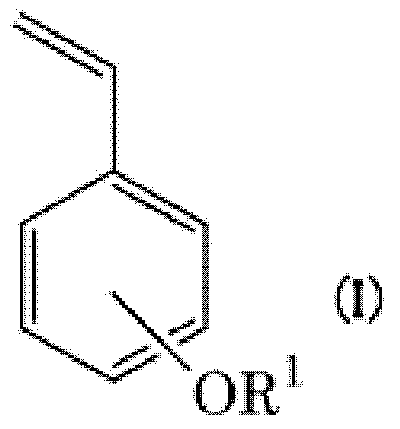

[0228] p-Methoxystyrene: manufactured by Kanto Chemical Co., Ltd. (compound represented by formula (I))

[0229] p-tert-butoxystyrene: manufactured by Wako Pure Chemical Industries, Ltd. (compound represented by formula (I))

[0230] Tetramethylethylenediamine: manufactured by Kanto Chemical Co., Ltd.

[0231] Modifier A-1: Dimethylamine manufactured by Kanto Chemical Co., Ltd.

[0232] Modifier A-2: Pyrrolidine manufactured by Kanto Chemical Co., Ltd.

[02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com