Pneumatic tire

A technology of pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, heavy tires, tire parts, etc., and can solve the problems of easy damage and fast wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

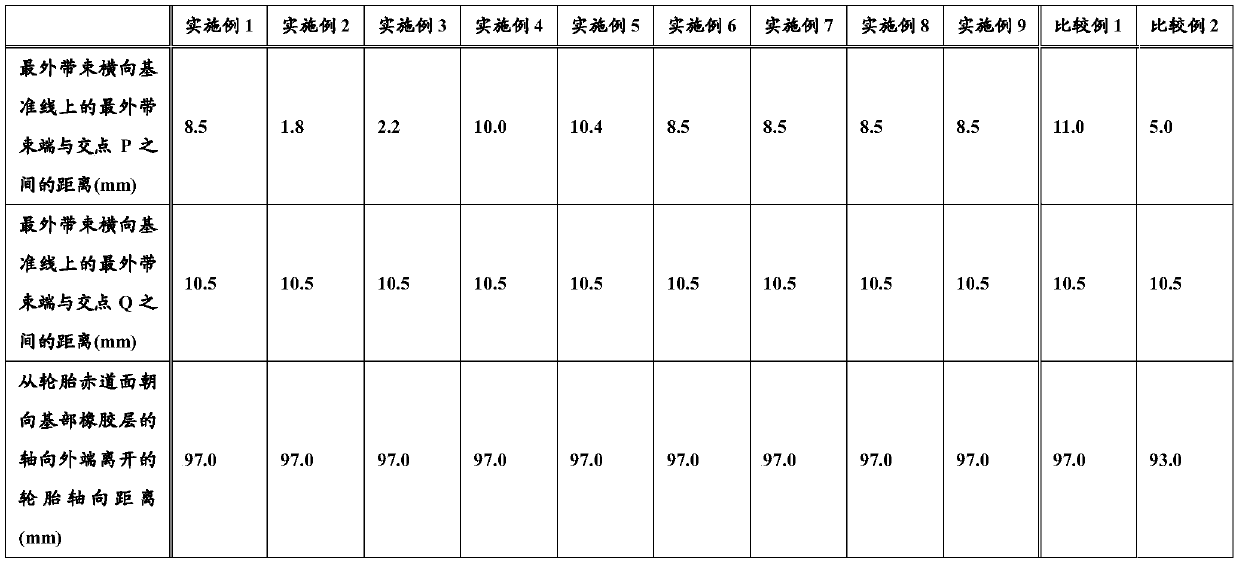

Examples

Embodiment Construction

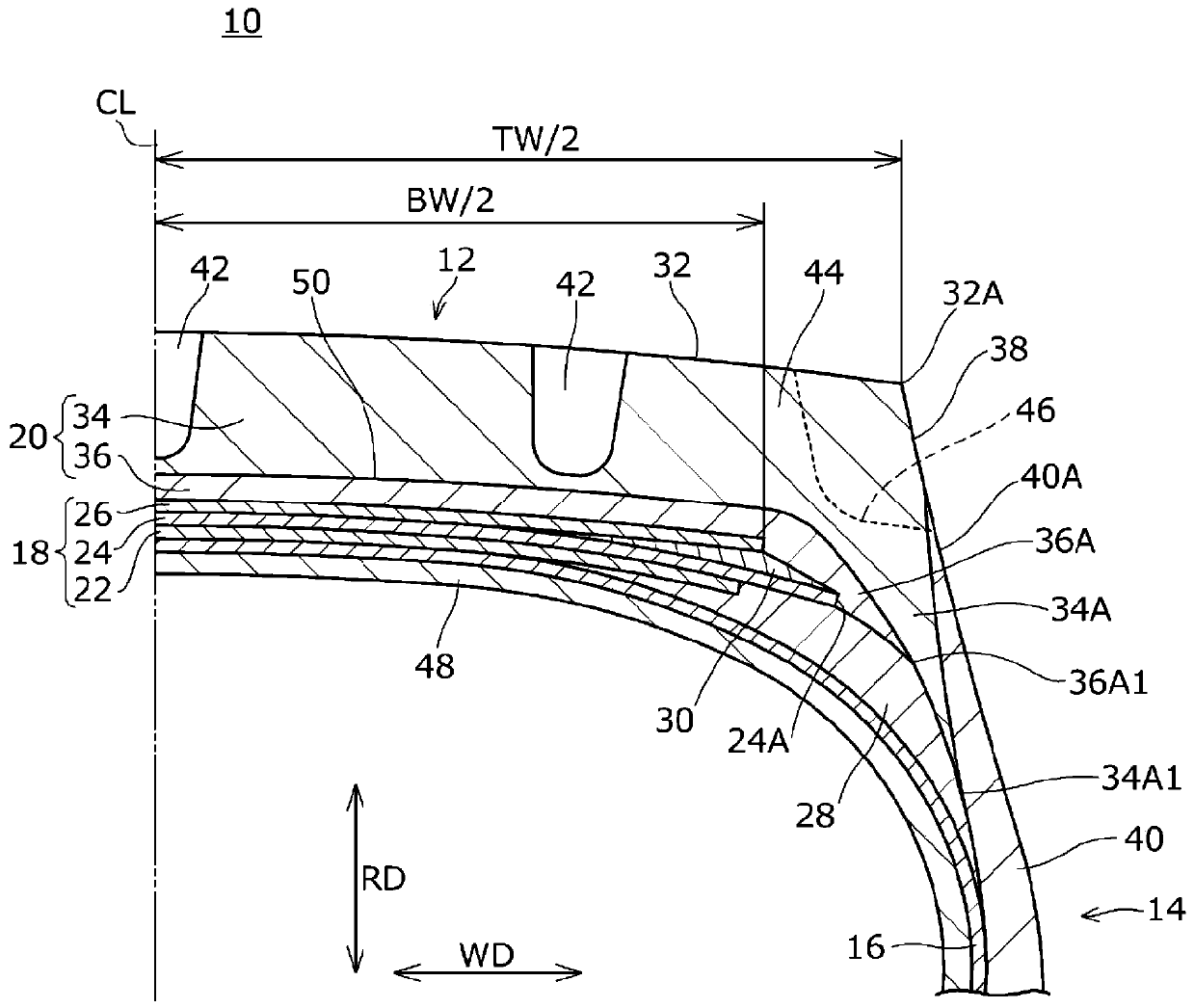

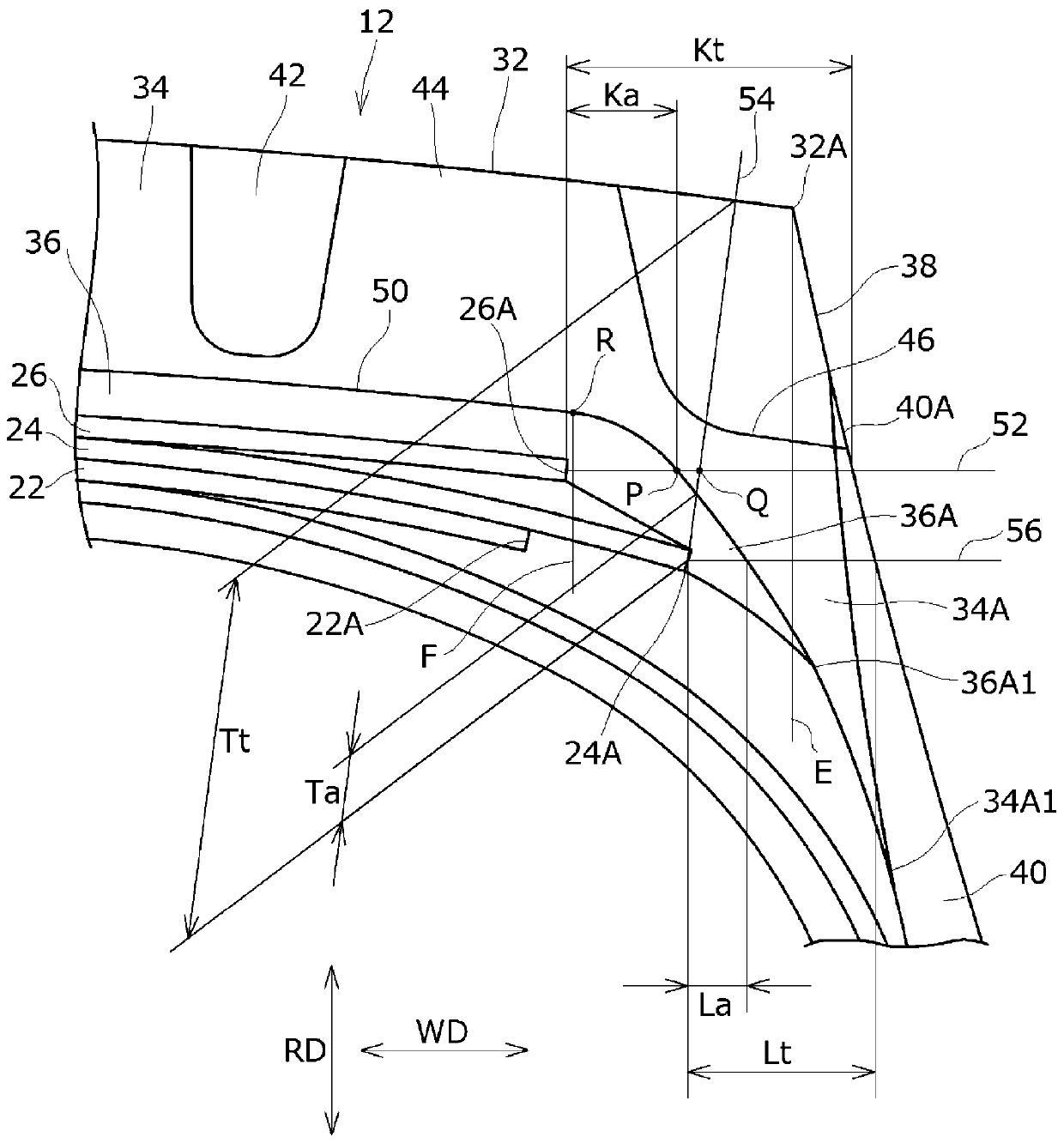

[0022] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0023] figure 1 A pneumatic tire 10 according to the illustrated embodiment includes a tread portion 12 constituting a contact surface, a pair of left and right bead portions, and a pair of left and right sidewall portions 14 interposed between the tread portion 12 and the bead portions. The pneumatic tire 10 according to the present embodiment is a heavy-duty pneumatic tire mounted on a truck, a bus, or the like.

[0024] In the drawings, symbol CL denotes a tire equatorial plane corresponding to the tire axial center. In this example, the pneumatic tire 10 is bilaterally symmetrical with respect to the tire equatorial plane CL.

[0025] Here, the tire axial direction refers to a direction parallel to the tire rotation axis, and is indicated by a symbol WD in the drawings. The inner side in the tire axial direction WD refers to a direction approaching the tire equat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com