Starch composite and rubber composite including same

A technology of rubber composition and composite body, which is applied in the field of composite body and rubber composition containing it, can solve the problems of insufficient wear resistance of tires, hinder sulfur vulcanization, etc., and achieve excellent wear resistance, Suppression load, low excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

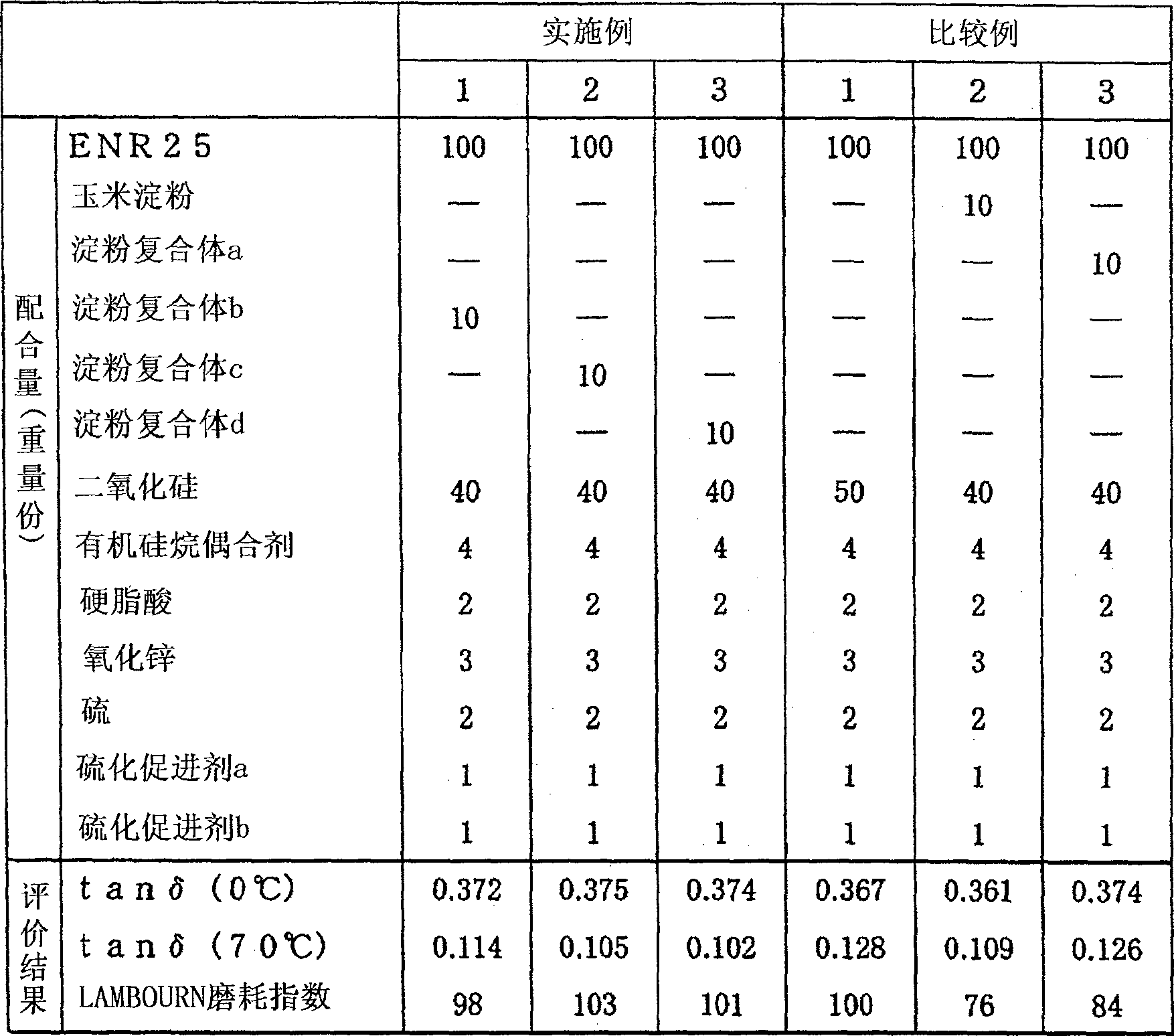

Embodiment 1~3 and comparative example 1~3

[0065] (viscoelasticity test)

[0066] Using a viscoelasticity spectrometer manufactured by Iwamoto Seisakusho Co., Ltd., the loss tangent tanδ of the rubber sheet used for the test at 70°C was measured under the conditions of a frequency of 10 Hz, an initial deformation value of 10%, and a dynamic deformation value of 2%. and the determination of the loss tangent tanδ at 0 °C.

[0067] The smaller the value of tan δ at 70° C., the smaller the rolling resistance of the tire made of the rubber sheet, indicating excellent fuel efficiency. If the value of tan δ at 70° C. is 0.12 or less, it indicates that the low fuel consumption property is good.

[0068] Furthermore, a larger value of tan δ at 0° C. indicates that a tire made of the rubber sheet has excellent wet grip performance. If the value of tan δ at 0°C is 0.37 or more, it indicates good wet grip performance.

[0069] (LAMBOURN abrasion test)

[0070] Using the LAMBOURN abrasion tester manufactured by Iwamoto Seisakus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com