Rubber composition for studless tire and studless tire

一种无钉防滑轮胎、橡胶组合物的技术,应用在无钉防滑轮胎用橡胶组合物和无钉防滑轮胎领域,能够解决不能达到、降低耐磨性、降低低温性能等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

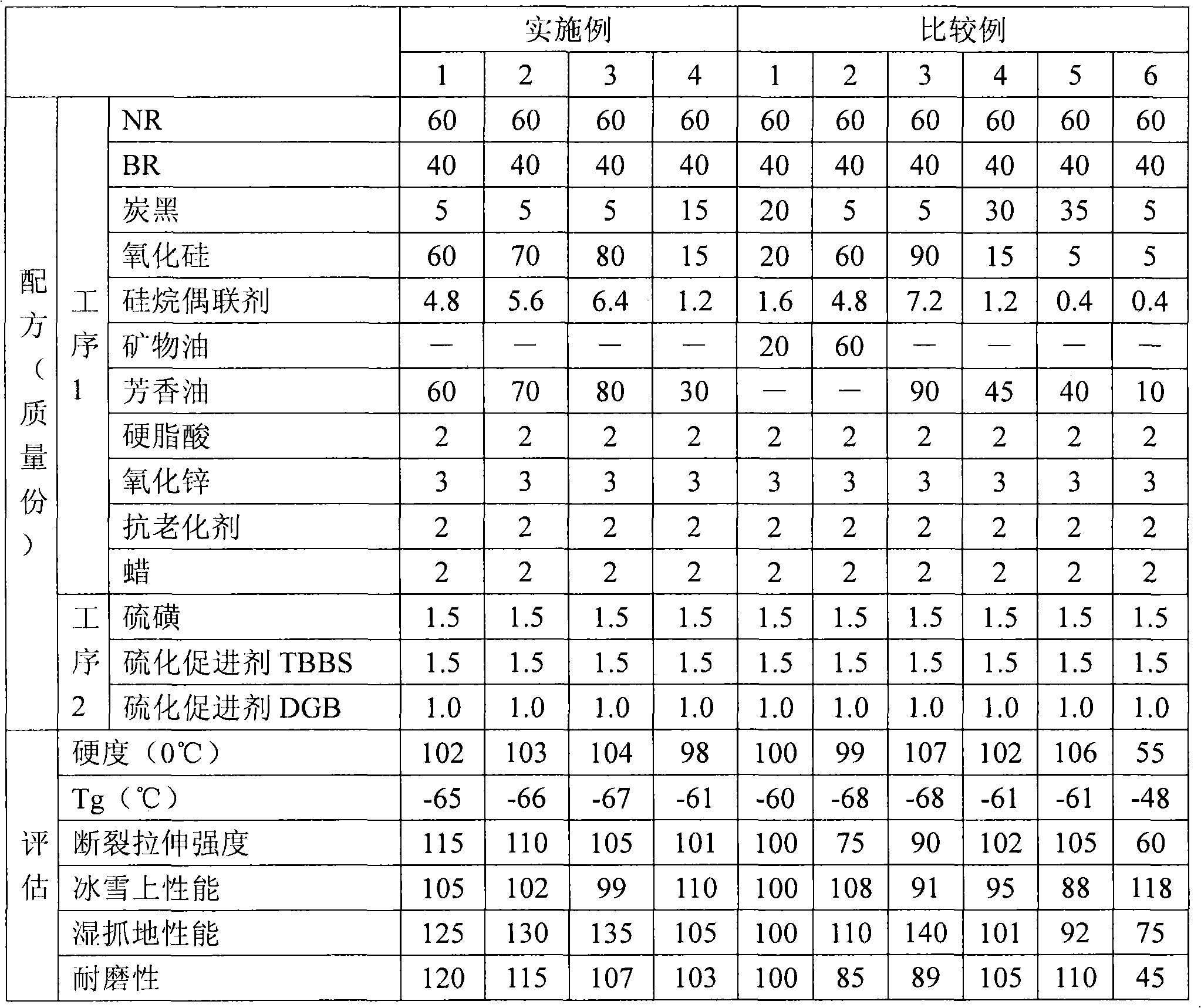

Embodiment 1 to 4 and comparative example 1 to 6

[0063] The chemical reagents were mixed according to the recipe amounts shown in Procedure 1 in Table 1, and kneaded in a Banbury mixer for 5 minutes, thereby raising the outlet temperature to about 150°C. Subsequently, sulfur and a vulcanization accelerator were added to the mixture produced by the process 1 in the amounts shown in the process 2, and mixed and kneaded by an open mill at about 80° C. for 3 minutes, thus producing an unvulcanized rubber composition. The produced unvulcanized rubber composition was pressure vulcanized at 170° C. for 10 minutes to produce a vulcanized rubber composition (vulcanized rubber sheet).

[0064] Also, the produced unvulcanized rubber composition is molded into a tread shape and assembled with other tire components. Then, the assembled assembly was vulcanized at 170° C. for 15 minutes, and thus a studless tire for testing was produced.

[0065] The vulcanized rubber sheets and test studless tires were evaluated in the following manner.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com