Patents

Literature

373 results about "Thiuram disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

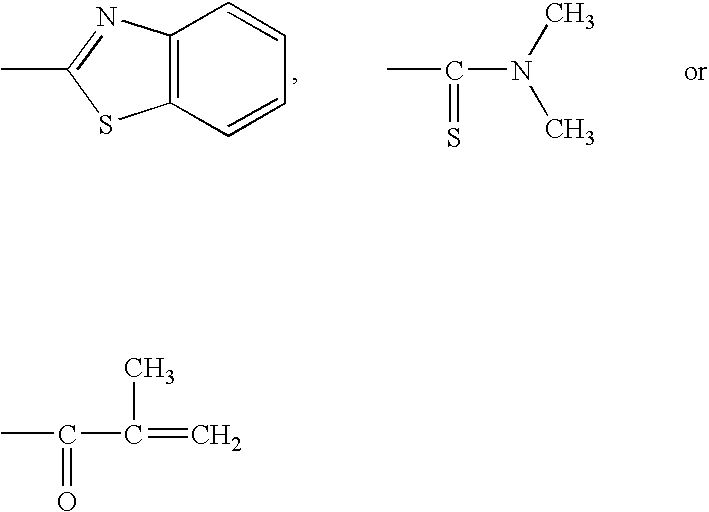

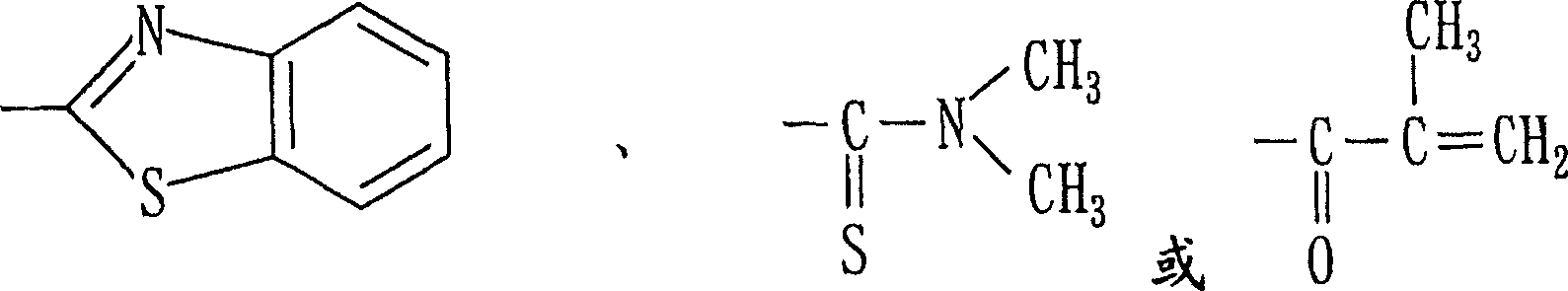

Thiuram disulfides are a class of organosulfur compounds with the formula (R₂NCSS)₂. Many examples are known, but popular ones include R = Me and Et. They are disulfides obtained by oxidation of the dithiocarbamates. These compounds are used in sulfur vulcanization of rubber as well as pesticides and drugs. They are typically white or pale yellow solids that are soluble in organic solvents.

Formula of environment protection type flame-retardant rubber pipe

InactiveCN101463166ALow costGood physical and mechanical propertiesFlexible pipesMorpholineAluminium hydroxide

The invention relates to a formula of an environment-friendly flame retardant hose, which comprises the following compositions and weight portions: 100 portions of ethylene propylene diene rubber, 20 portions to 40 portions of fast extruded carbon black, 40 portions to 60 portions of calcined clay, 120 portions to 160 portions of aluminium hydroxide, 5 portions to 10 portions of zinc borate, 10 portions to 20 portions of antimony trioxide, 0.5 portion to 0.8 portion of thiuram tetrasulfide, 1.5 portions to 2.0 portions of zinc dibutyl dithiocarbamate, 0.5 portion to 0.8 portion of tetramethyl thiuram disulfide, 3 portions to 5 portions of zinc oxide, 1 portion to 3 portions of stearic acid, 1 portion to 3 portions of polyethylene glycol, 1.5 portions to 2.0 portions of morpholine disulfide, 0.3 portion to 0.6 portion of sulfur and 20 portions to 40 portions of paraffin oil. Compared with the traditional product, the invention has the tensile strength of physical and mechanical property of 14MPa, which is higher than the traditional formula by 1.5 times. The invention can obtain FV-0 grade of vertical burn of national standard of flame resistance, namely the requirements of nonflammable material, can achieve the same flame resistant effect with the traditional method and meet the requirements of environment protection and safety of the hose of the modern automobile.

Owner:TIANJIN PENGYI GRP CO LTD

Waterproof rubber material

InactiveCN105384989AImprove thermal conductivityImprove conductivityPolyethylene glycolMaterials science

The invention discloses a waterproof rubber material. The waterproof rubber material is prepared from the following raw materials by weight: 7 to 8 parts of polyethylene glycol terephthalate, 3 to 4 parts of trioctyl citrate, 1 to 2 parts of rosin, 24 to 27 parts of polyacrylonitrile, 1 to 2 parts of sodium diacetate, 12 to 13 parts of graphite, 3 to 4 parts of fly ash bead, 0.7 to 1 part of sodium dodecyl sulfate, 42 to 55 parts of liquid acrylonitrile-butadiene rubber, 0.6 to 1 part of methacrylic acid, 52 to 60 parts of acrylonitrile-butadiene rubber, 20 to 255 parts of butadiene styrene rubber, 5 to 6 parts of nanometer silica sol, 3 to 4 parts of tetramethyl-thiuram disulfide, 2 to 3 parts of diglycol, 6 to 8 parts of VAE emulsion, 14 to 16 parts of activated clay, 5 to 7 parts of barium titanate, 7 to 9 parts of magnesium hydroxide and 0.2 to 0.3 part of calcium propionate. The waterproof rubber material prepared in the invention has good waterproof performance and acid resistance, oil resistance and flame retardation performance, can perfectly meet requirements of production and is worth popularization.

Owner:安徽创奇乐智能游乐设备有限公司

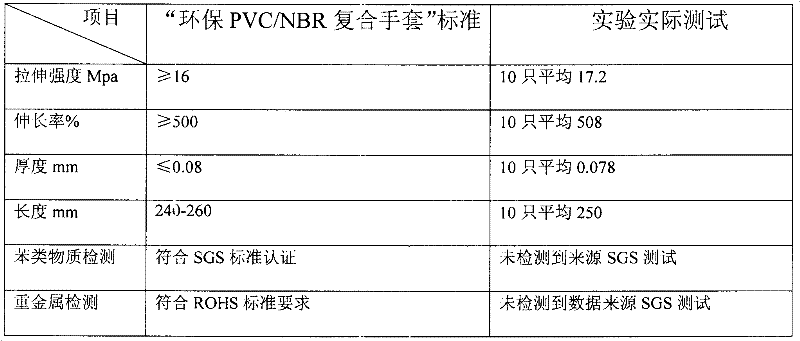

Environmentally-friendly polyvinyl chloride/nitrile butadiene rubber (PVC/NBR) composite gloves

InactiveCN102336988AReduced ability to migrateReduce volatilityCoatingsProtective garmentPolyesterPolymer science

The invention discloses environmentally-friendly polyvinyl chloride / nitrile butadiene rubber (PVC / NBR) composite gloves. The composite gloves are prepared from the following raw materials: PVC paste resin powder, plasticizer, heat stabilizer, NBR, accelerant, vulcanizing agent and color paste in a ratio of 100:(40-60):(0.9-1.8):(25-40):(0.5-1):(0.5-1):(2-5), wherein the plasticizer is ATBC (acetyl tributyl citrate) / polyester plasticizer; the heat stabilizer is phenol-free environmentally-friendly calcium-zinc heat stabilizer; the accelerant is tetramethyl thiuram disulfide / N-cyclohexyl-2-benzothiazole sulfonamide (TMTD / CZ); and the vulcanizing agent is sulfur. The composite gloves have the advantages that the mobility and volatility of the materials in the raw materials are reduced, the energy consumption is lowered, the wearing comfort is improved at the same time, and harm to human bodies is completely avoided.

Owner:江苏尤佳手套有限公司

Acrylic ester rubber and preparation method thereof

InactiveCN101633768AImprove the defect of sticky rollerReasonable ratioSodium stearatePolymer science

The invention provides acrylic ester rubber and a preparation method thereof. The acrylic ester rubber is characterized by comprising the following components by weight: 70-90 portions of tri-acrylate rubber AR840, 10-30 portions of butyronitrile rubber NBR, 55-75 portions of fast extruding carbon black N550, 1-2 portions of anti-aging agent RD, 1-2 portions of anti-aging agent MB, 0.5-1 portion of anti-scorching agent CTP, 3-5 portions of dioctyl phthalate DOP, 1-2 portions of dispersant rhine powder-42, 0.3-0.5 portion of common sulphur, 0.2-0.4 portion of tetramethyl thiuram disulfide TMTD, 3.5-4.0 portions of sodium stearate and 0.3-0.5 portion of potassium stearate. The sticking phenomenon is reduced and the elasticity, extensile intensity and low temperature resistance of the acrylic ester rubber are improved.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

Wear-resistant diamond polishing grinder and production method thereof

InactiveCN102501186AImprove mechanical propertiesImprove heat resistanceAbrasion apparatusGrinding devicesWear resistantStearic acid

The invention relates to a wear-resistant diamond polishing grinder and a production method thereof. The diamond polishing grinder comprises an abrasive layer arranged on a clamping seat, and the abrasive layer is prepared with raw materials by the following volume percentage: 6.25-15 percent of diamond, 0-15 percent of silicon carbide, 35-60 percent of 200-mesh fine heat-resistant phenolic resin, 10-50 percent of 40-mesh fine carboxylated nitrile rubber, 0.5-1 percent of zinc stearate, 0.5-5 percent of zinc oxide, 0-5 percent of sulfur, 0-5 percent of promoting agent TMTD (tetramethyl thiuram disulfide) and 0-5 percent of stearic acid. A binder in the abrasive layer is prepared by adding carboxylated nitrile rubber into the heat-resistant phenolic resin, and the volume ratio of the heat-resistant phenolic resin and the carboxylated nitrile rubber is 100: (10-100). The particle size of the diamond is of 200-8000 meshes, and the particle size of the silicon carbide is of 200-3000 meshes. The invention has the advantages of good grinding effects, long service life, high polishing speed and low overall cost.

Owner:广东奔朗新材料股份有限公司

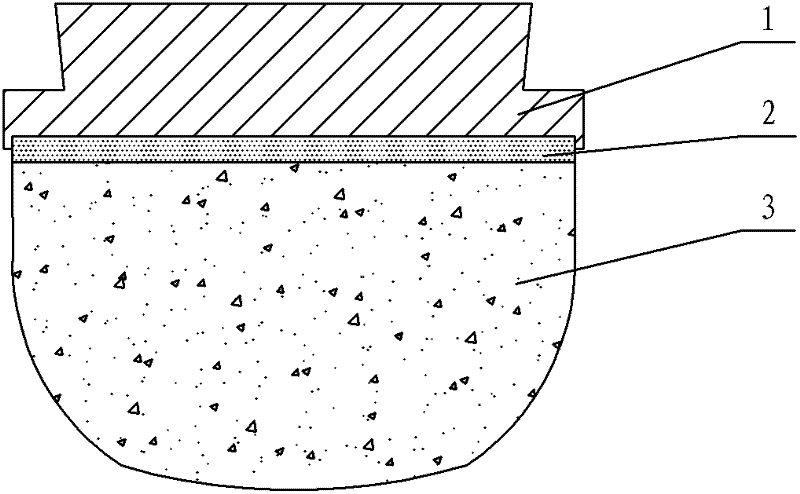

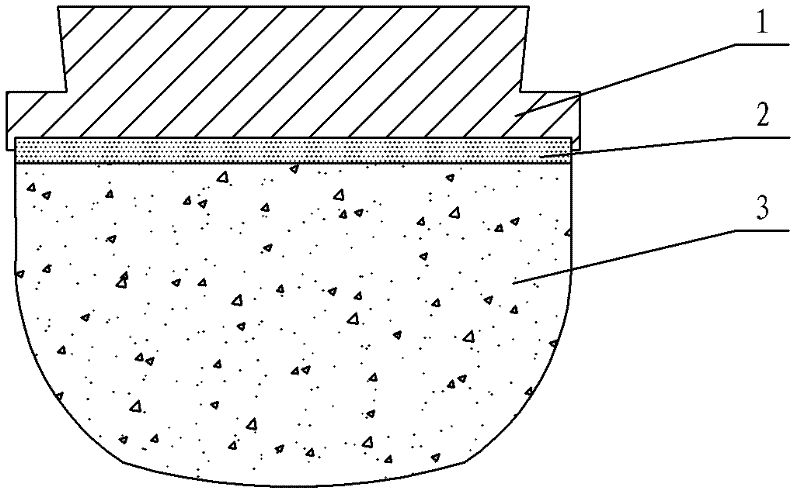

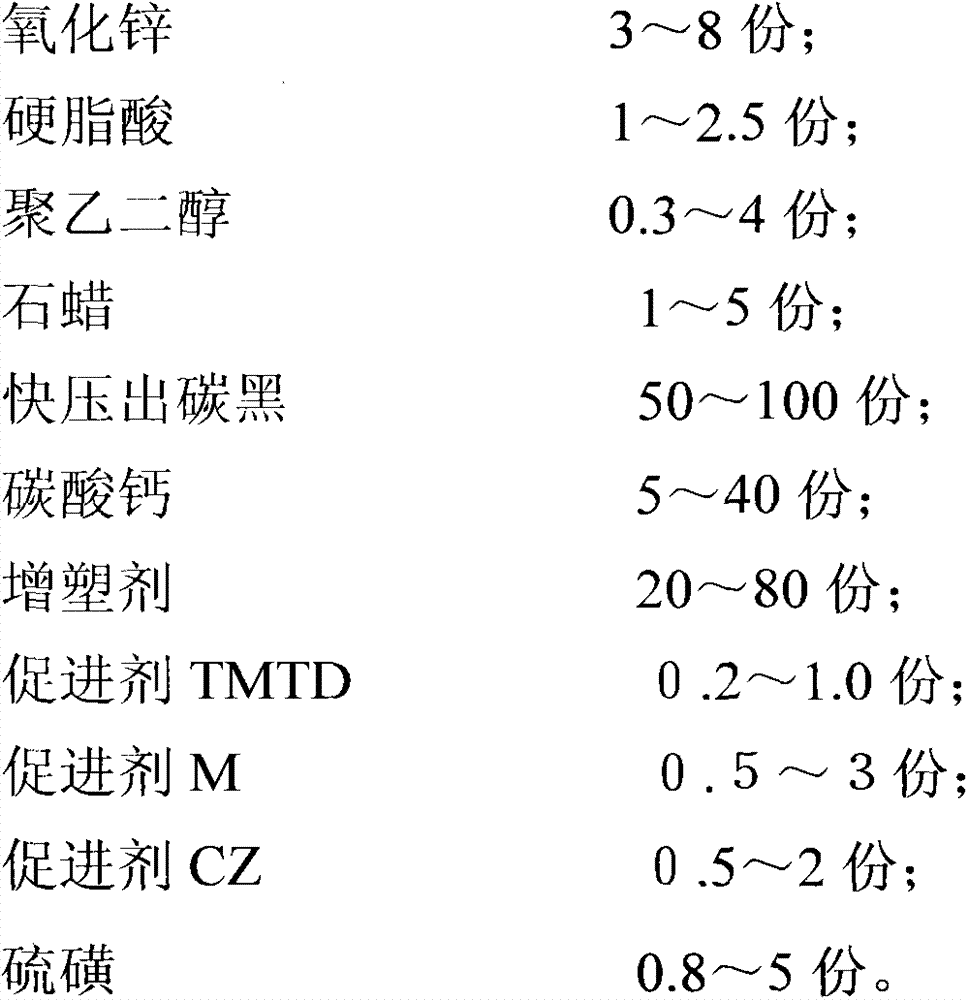

Reactive rubber composite water-proof roll and production method thereof

ActiveCN103031858AThere will be no "water channeling" phenomenonLaminationProtective foundationPolymer scienceLithium chloride

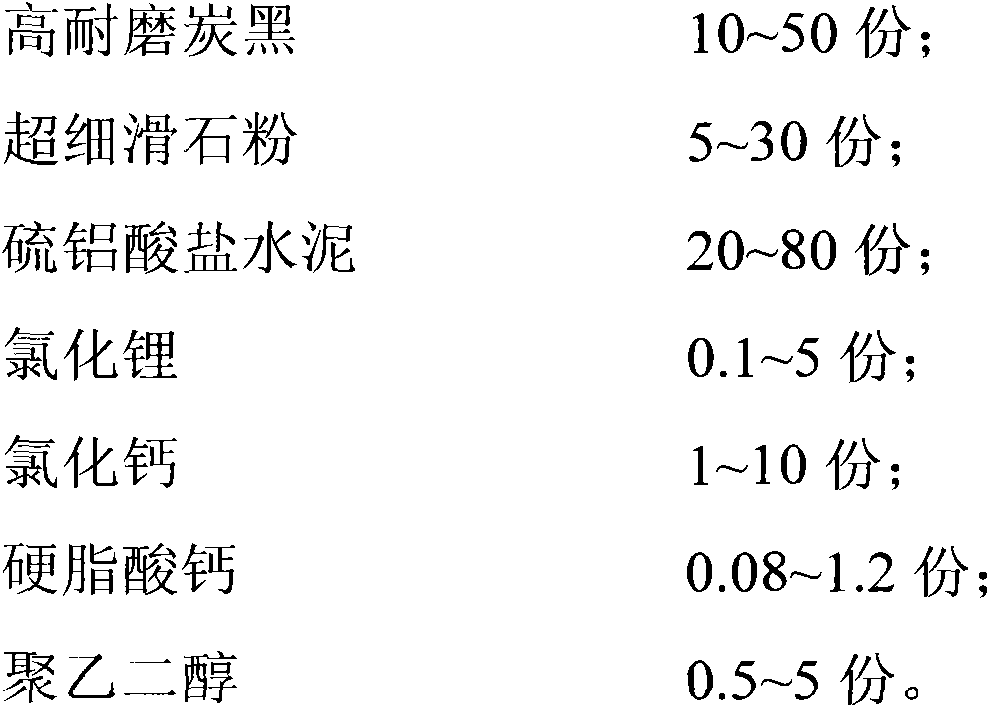

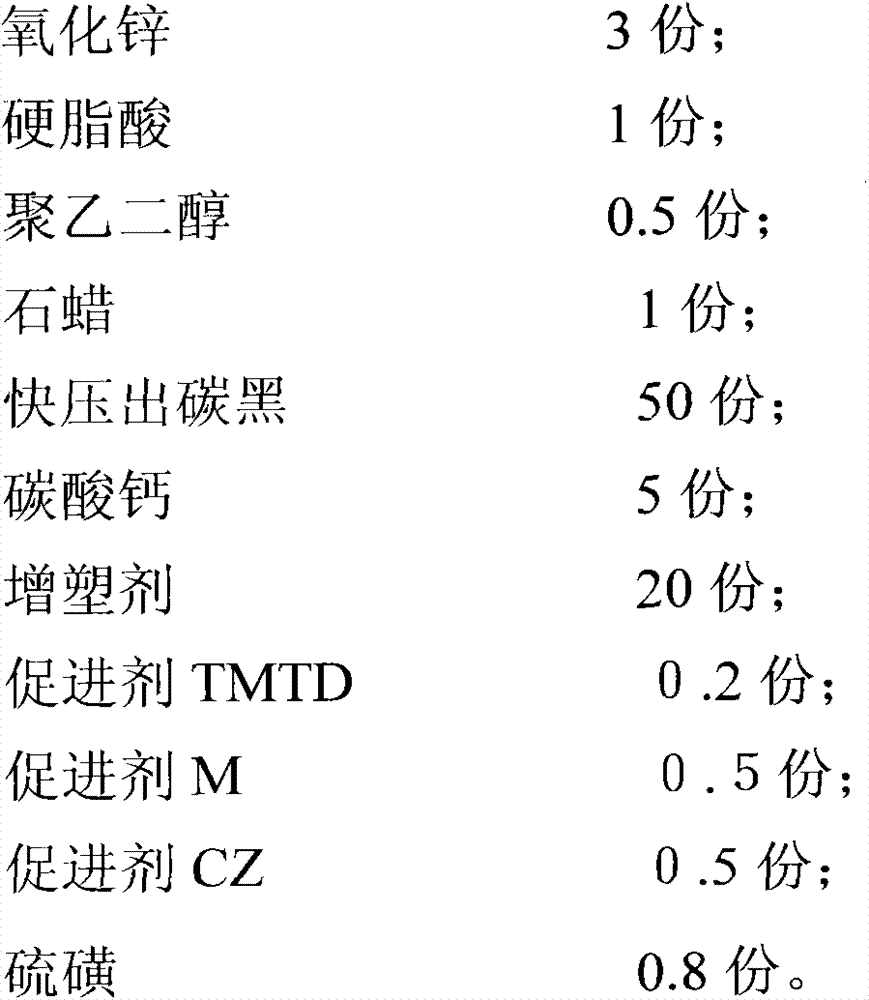

The invention relates to a reactive rubber composite water-proof roll and a production method thereof, wherein the reactive rubber composite water-proof roll is formed by compounding a base layer and a surface layer; the base layer is an ethylene propylene terpolymer water-proof layer; the surface layer is a reactive butyl rubber reaction layer; the base layer rubber comprises other components in parts by weight based on 100 parts of ethylene propylene terpolymer: 3-8 parts of zinc oxide, 1-2.5 parts of stearic acid, 0.3-4 parts of polyethylene glycol, 1-5 parts of wax, 50-100 parts of fast extruding furnace black, 5-40 parts of calcium carbonate, 20-80 parts of plasticizer, 0.2-1.0 part of accelerator TMTD (Tetramethyl Thiuram Disulfide), 0.5-3 parts of accelerator M, 0.5-2 parts of accelerator CZ and 0.8-5 parts of sulfur; surface layer rubber comprises other components in parts by weight based on 100 parts of butyl rubber: 10-50 parts of highly abrasion resistant carbon black, 5-30 parts of superfine talcum powder, 20-80 parts of sulfate aluminum cement, 0.1-5 parts of lithium chloride, 1-10 parts of calcium chloride, 0.08-1.2 parts of calcium stearate and 0.5-5 parts of polyethylene glycol. The reactive rubber composite water-proof roll and concrete can form a whole body just like that a rubber skin is implanted into a concrete surface layer without causing phenomenon of water channeling.

Owner:解忠深

High-strength tear-resistant modified cable material and preparation method thereof

The invention discloses a high-strength tear-resistant modified cable material. The high-strength tear-resistant modified cable material comprises the following raw materials in part by weight: 36-42 parts of polyurethane rubber, 52-56 parts of butadiene-vinylpyridine rubber, 6-9 parts of hydrogenated nitrile rubber, 10-13 parts of nano-cellulose whisker, 1.8-2.2 parts of silane coupling agent A-151, 2-2.5 parts of sulphur, 1.1-1.4 parts of accelerant TMTD (tetramethyl thiuram disulfide), 1.5-1.8 parts of accelerant AC, 7-8 parts of light calcium carbonate, 5-6 parts of modified graphene, 24-28 parts of hard clay, 20-23 parts of mica powder, 2-3 parts of diethyl phthalate DEP, 3-5 parts of epoxy butyl oleate, 2-3 parts of pentaerythritol fatty acid ester, 2.3-2.6 parts of melamine phosphate, 8-11 parts of microencapsulated red phosphorus, 11-14 parts of zinc borate, 1.5-1.8 parts of anti-aging agent ODA and 0.9-1.2 parts of anti-aging agent DFC-34. The invention discloses a preparation method of the high-strength tear-resistant modified cable material.

Owner:ANHUI ELECTRIC GRP SHARES

Rubber Composition for Tires

InactiveUS20080033103A1Appropriate hardnessWet strengthSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

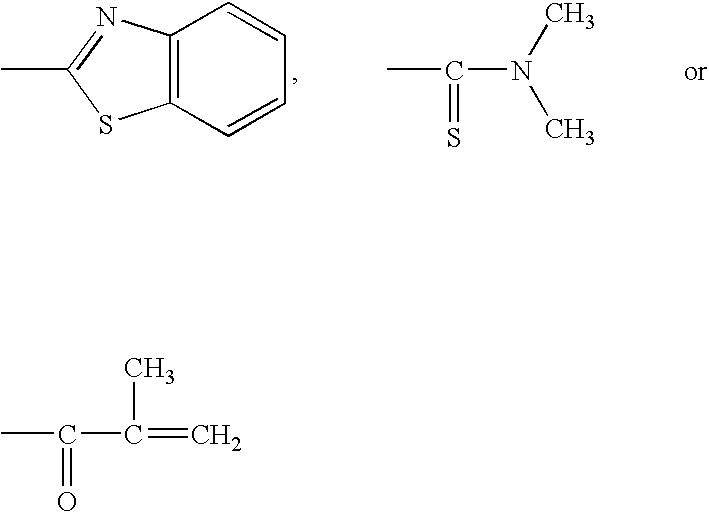

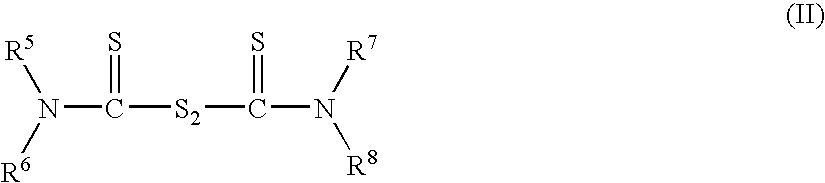

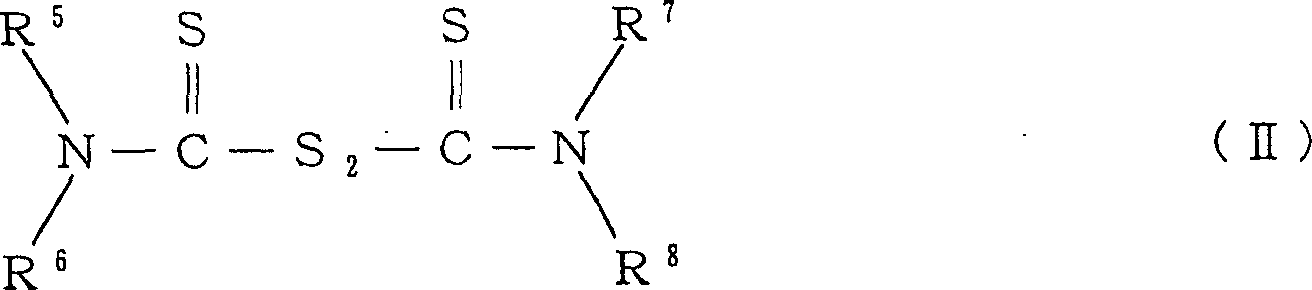

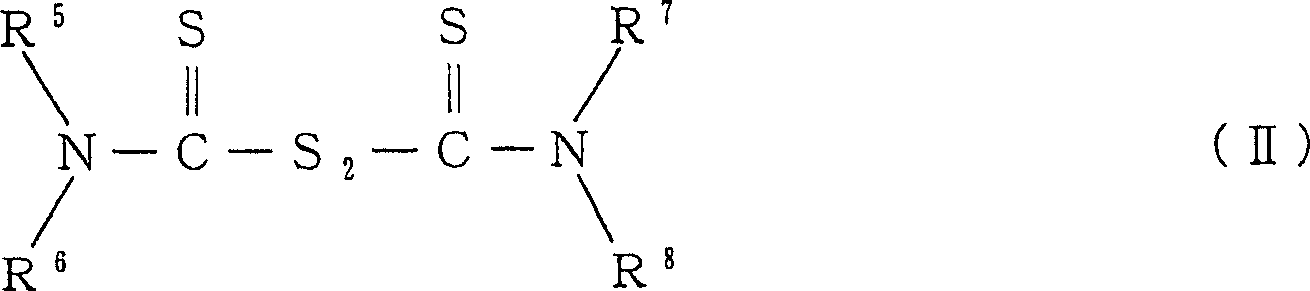

A rubber composition for a tire having greatly shortened vulcanization time, good silica dispersibility and, after vulcanization, superior braking capability, abrasion resistance and low rolling resistance, comprising (A) 100 parts by weight of a conjugated diene-based rubber, (B) 90 to 150 parts by weight of a reinforcing filler containing silica, (C) 0 to 40 parts by weight of an oil, (D) 4 to 20% by weight, based upon the weight of the silica, a silane coupling agent having the formula (I):Y3Si—CnH2nA (I)wherein Y indicates a C1 to C25 alkyl or alkoxyl group or a chloro group, the three Y's may be the same or different, n is an integer of 1 to 6, A is a mercapto group or SmZ group, where Z is the group:and m is an integer of 1 to 6)(E) sulfur, and (F) 0.05 to 5 parts by weight of a thiuram disulfide-based vulcanization accelerator having the formula (II):wherein R5, R6, R7 and R8 are independently hydrocarbon groups having 2 to 18 carbon atoms, is provided.

Owner:THE YOKOHAMA RUBBER CO LTD

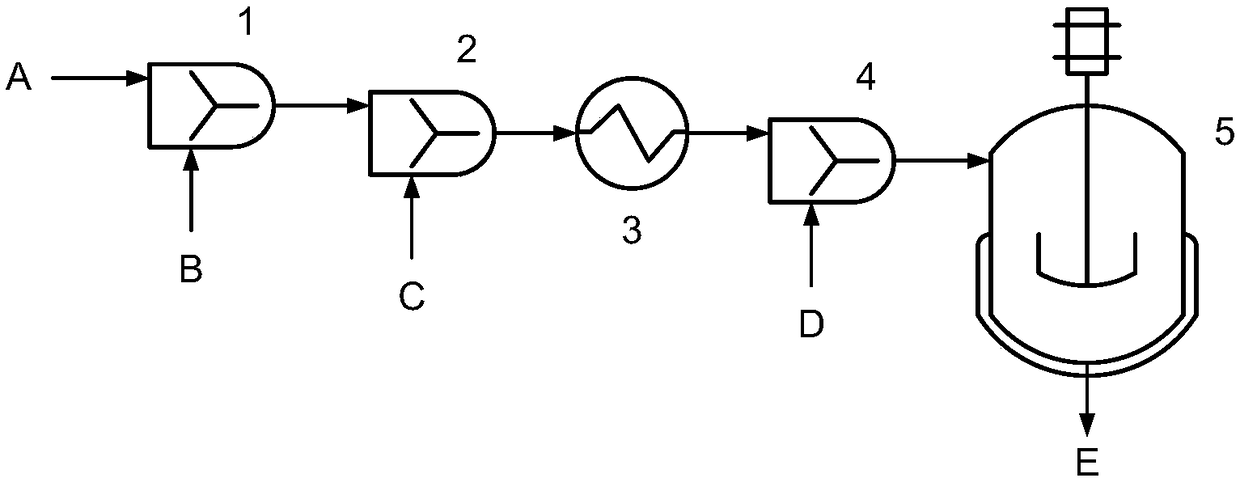

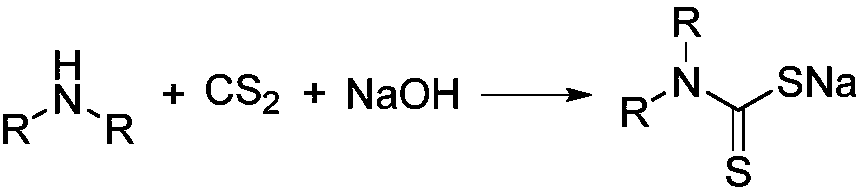

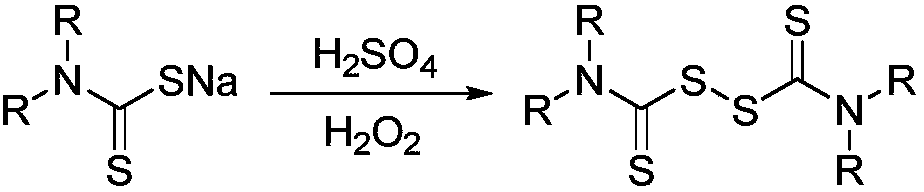

Micro-reaction method for continuous synthesis of thiuram disulfide

The invention discloses a method for producing thiuram disulfide as thiofide by a continuous micro-reaction system. According to the method, three processes including secondary amine-NaOH solution mixing, CS2-secondary amine condensation reaction and sodium dithiocarbamate oxidation reaction are sequentially completed by a micro-mixer and a micro-reactor which are connected in series; reaction materials are efficiently mixed by the micro-reaction device, and side reactions such as overoxidation and the like are avoided; by means of a series-integrated operation mode, production efficiency is improved, and product stability is improved. The method can be applied to production of multiple thiuram vulcanizing agents such as tetramethyl thiuram disulfide, tetraethylthiuram disulfide, tetrabutylthiuram disulfide and the like, the yield can reach 98% or higher, and product purity is high.

Owner:WILLING NEW MATERIALS TECH CO LTD +1

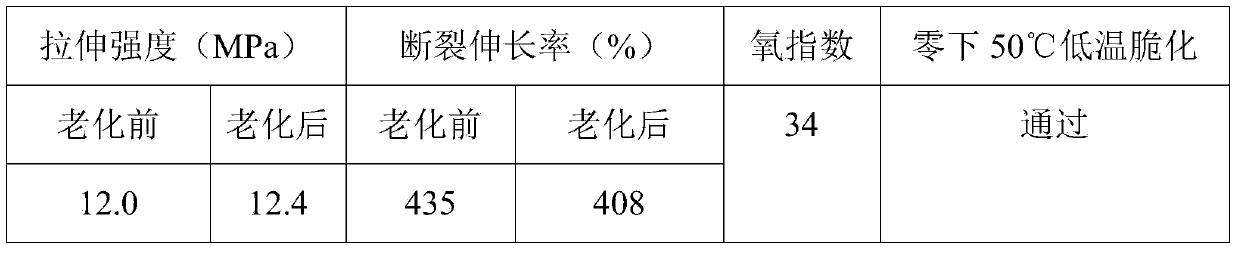

Electrochemical corrosion resistant inner ply compound formula

InactiveCN101423638AGood physical and mechanical propertiesExtended service lifeFlexible pipesPolyethylene glycolStearic acid

The invention relates to an inner hose formula for an electrochemical corrosion resistant hose, which comprises the following compositions in portion by weight: 30 to 70 portions of low-mooney ethylene propylene diene rubber, 70 to 30 portions of high-mooney ethylene propylene diene rubber, 60 to 80 portions of semi-reinforcing carbon black, 60 to 90 portions of silica fume, 1.2 to 1.8 portions of bi-thiuram tetrasulfide, 1.7 to 2.3 portions of zinc dibutyl dithiocarbamate, 0.5 to 0.8 portion of tetramethyl thiuram disulfide, 3 to 5 portions of zinc oxide, 1 to 3 portions of polyethylene glycol, 1.5 to 2.0 portions of morphine disulfide, 0.3 to 0.6 portion of sulfur, 50 to 60 portions of paraffin oil, 1 to 3 portions of stearic acid and 2 to 4 portions of 2, 2, 4-trimethyl-1, 2-biquionlyl dihydride polymers. Compared with the prior product, the inner hose formula for the electrochemical corrosion resistant hose has obvious differences; the tensile strength is 12.0 MPa; the volume resistivity is 1X10<12> omega.cm and 1X10<5> omega.cm higher than that of the prior product; the service life of the electrochemical corrosion resistant hose is greatly improved; and the inner hose formula for the electrochemical corrosion resistant hose can well meet the demands of heat resistance and electrochemical corrosion resistance of a radiator hose of a motor vehicle.

Owner:TIANJIN PENGYI GRP CO LTD

Rubber composition for tires

InactiveCN101014660ALow heat generationImprove wear resistanceSpecial tyresRolling resistance optimizationTO-18Rolling resistance

The invention relates to a rubber composition for tire, which comprises: (A) conjugated diene rubber of 100 weight, (B) 90 to 150 parts by weight of a reinforcing filler containing silica, (C) 0 to 40 parts by weight of an oil, (D) 4 to 20% by weight, based upon the weight of the silica, a silane coupling agent having the formula (I): Y<3>Si-CH<2n> A (I). Wherein, Y represents the alkyl or alkoxy or chlorine with 1 to 25 carbon atoms, and the three Y's may be the same or different, n is an integer of 1 to 6; A is a hydrosulphonyl or SZ radical, wherein Z is the following radical: formula (1-1), (1-2) or (1-3) and m is the integer of 1 to 6, (E) sulfur, and (F) 0.05 to 5 parts by weight of a thiuram disulfide-based vulcanization accelerator having the formula (II). Wherein, R<5>, R<6>, R<7> and R<8> independently have an alkyl with 2 to 18 carbon atoms, with the greatly shortened vulcanization time, preferable dispersibility of silicon dioxide, with preferable braking performance, abrasion bearing performance and low rolling resistance of the vulcanized rubber.

Owner:YOKOHAMA RUBBER CO LTD

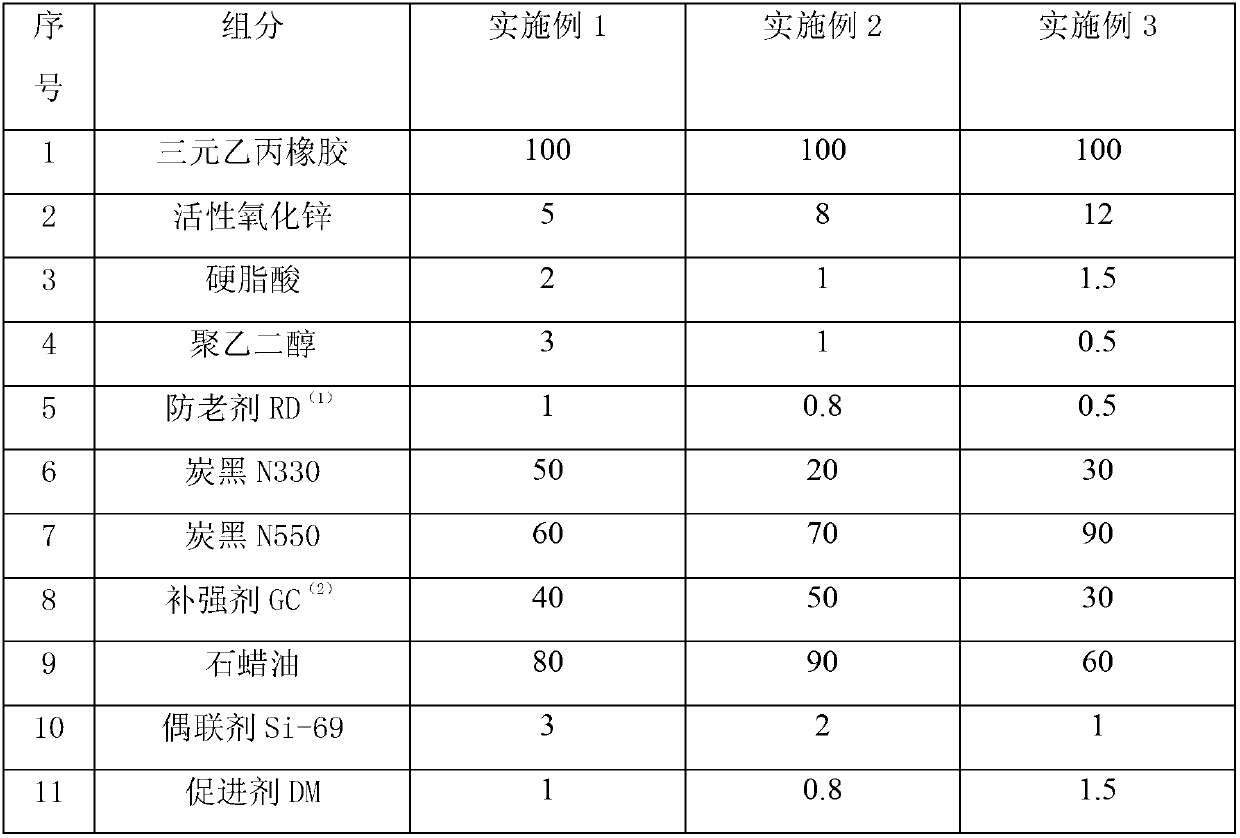

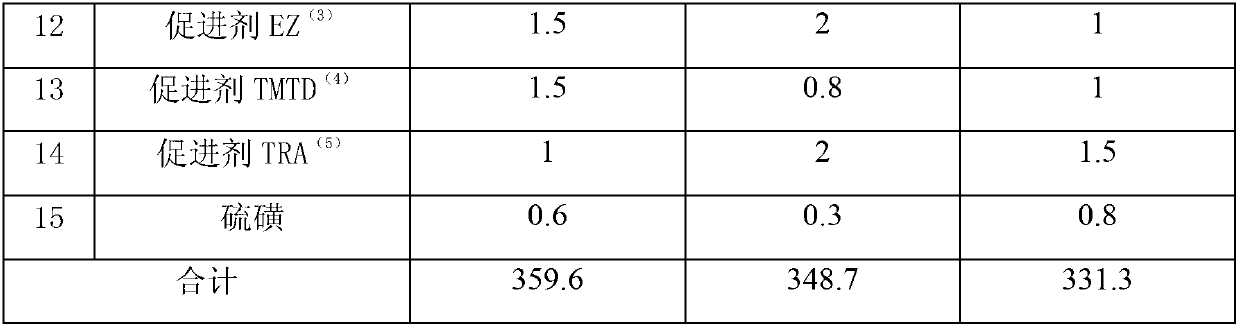

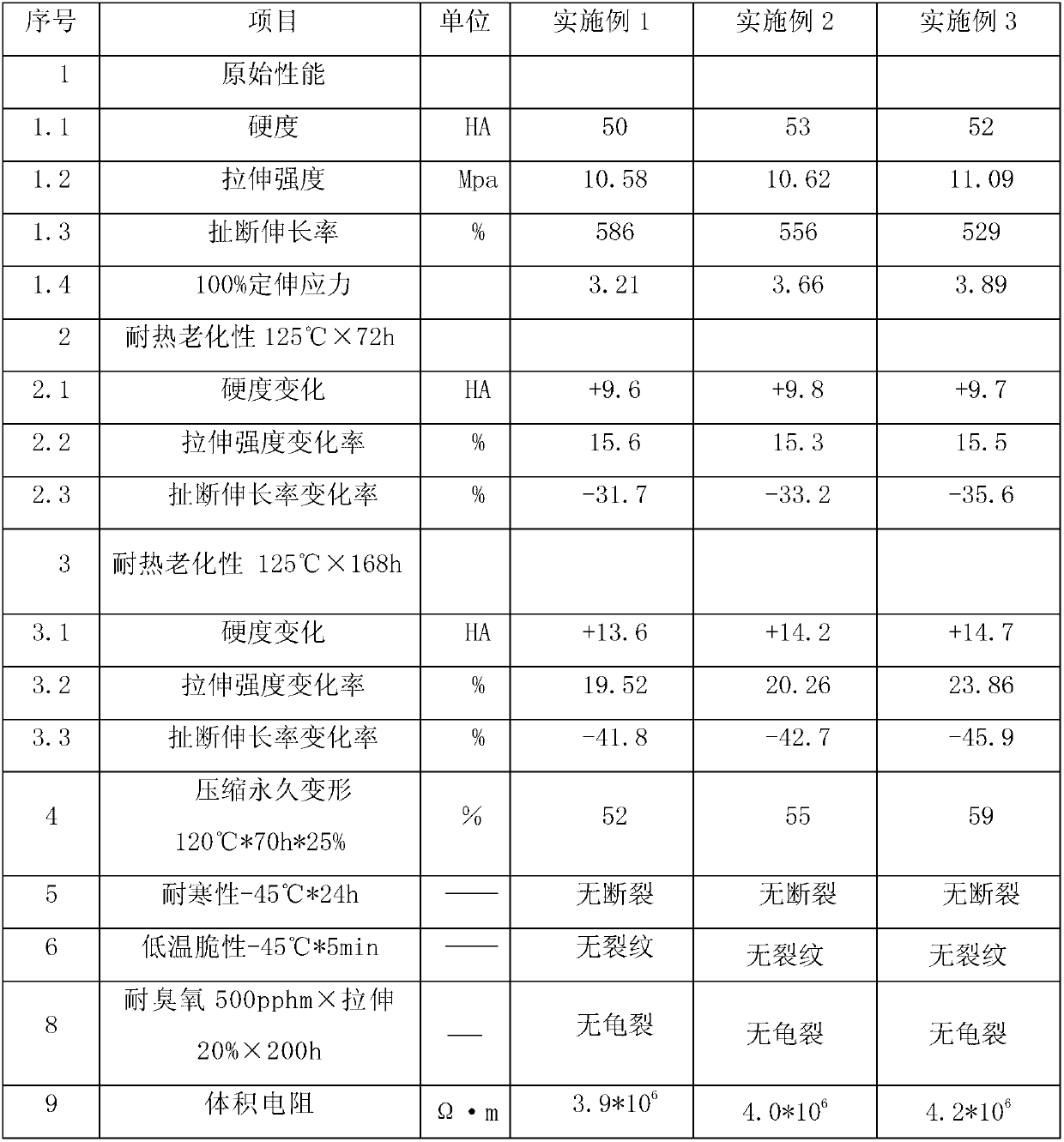

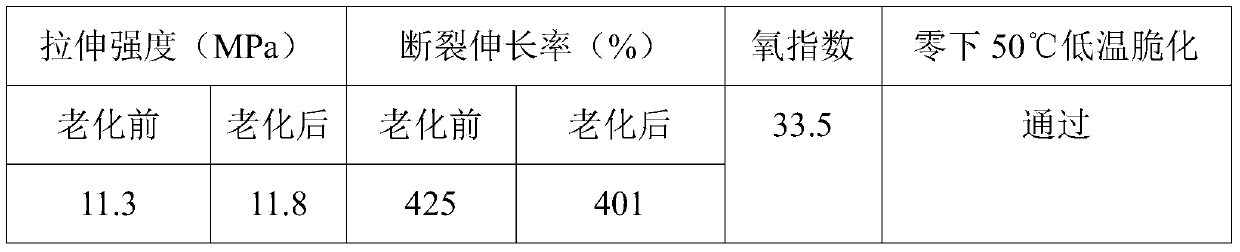

Ethylene propylene diene monomer (EPDM) composition for low-hardness glue injection

The invention relates to an ethylene propylene diene monomer (EPDM) composition for low-hardness glue injection. The composition comprises the following ingredients: EPDM rubber, activated zinc oxide, stearic acid, polyethylene glycol, 2,2,4-trimethyl-1,2-dihydroisoquinoline polymer, carbon black N330, carbon black N550, silicon dioxide hydrate, paraffin oil, coupling agent Si-69, accelerator DM, zinc diethyl dithiocarbamate, tetramethyl thiuram disulfide, bis(pentamethylene)thiuram tetrasulfide, and sulphur. According to the formula of the composition, the original hardness is low and is only about 50 degrees, the tensile strength and 100% stress at definite elongation are high, thermal air aging resistance property, the coldness resistance and low-temperature crispness are all excellent to meet the use requirement under low-temperature environment of different regions in winter, the lowest temperature can reach minus 45 degrees, glue injection technique is adopted to be capable of saving labor time and manual work. The composition formula can meet the requirements of RCF-510 grade material in MES MN300 standard.

Owner:TIANJIN PENGYI GRP CO LTD

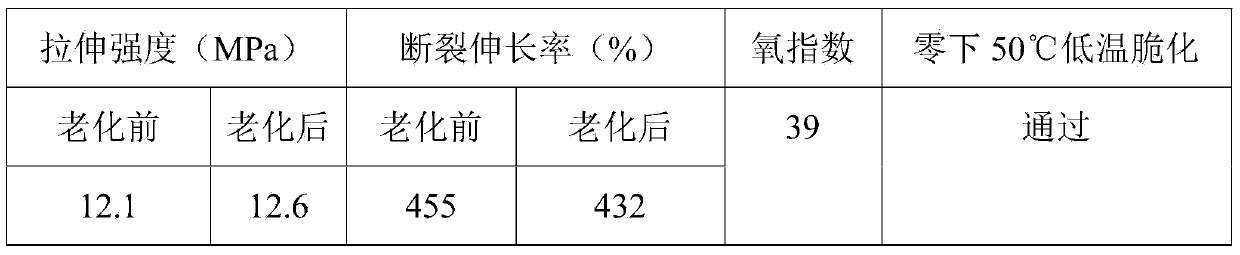

Method for preparing cooling water pipe rubber material for automobile

The invention discloses a method for preparing a cooling water pipe rubber material for an automobile. A formula and a preparation process are involved. Ethylene-propylene-diene monomer is adopted; a vulcanization system of sulfur, tetramethyl thiuram disulfide, and dipentamethylenethiuram tetrasulfide is adopted in the formula so as to improve the pressing deformation resistance and heat resistance of the material; poly(1,2-dihydro-2,2,4-trimethyl-quinoline) antiager is added in the formula so as to improve the heat resistance and ageing resistance of the material; filling reinforcing agents, namely sillitin powder and active calcium carbonate are added in the formula so as to improve the electrical resistance of the material; and the corresponding technical scheme of the preparation process is matched with the formula so as to overcome the defects of low heat resistance, pressing deformation resistance, and electrical resistance in the prior art, and by preparing the rubber materialwith high heat resistance, high pressing deformation resistance and high electrical resistance, the heat resistance, the pressing deformation resistance and the electrical resistance of the manufactured cooling water pipe product for the automobile are improved, and the aims of meeting increasingly high requirements of automobile industry on rubber products, and meeting the Mazda MES PA15 185A standard can be fulfilled.

Owner:宁波市天基汽车部件有限公司

Thermoplastic powder coating

InactiveCN103740181AReduce surface temperatureEasy to usePolyurea/polyurethane coatingsPowdery paintsAluminateCooling effect

The invention discloses a thermoplastic powder coating. The thermoplastic powder coating is composed of following raw materials in parts by weight: 90-94 parts of polyethylene E309, 6-10 parts of thermoplastic polyurethane elastomer, 1-2 parts of perfluor-butyl potassium sulphonate, 0.2-0.4 part of tetramethyl thiuram disulfide, 0.4-1 part of N,N-diethyl aniline, 1-2 parts of ricinoleic acid, 1-2 parts of 1-ethoxyl-2-oleic imidazoline, 0.5-1 part of distearoyl isopropoxy aluminate, 2-4 parts of guar gum, 10-14 parts of epoxy soybean oil and 15-20 parts of modified fillers. The powder coating provided by the invention is particularly suitable for heat radiation coating of an LED (Light Emitting Diode) lamp and is convenient to use; the surface temperatures of a heat radiation cup, an aluminum substrate, a lamp cover and the like of the LED lamp so that the cooling effect is realized.

Owner:WUHU BAOYI AMUSEMENT EQUIP

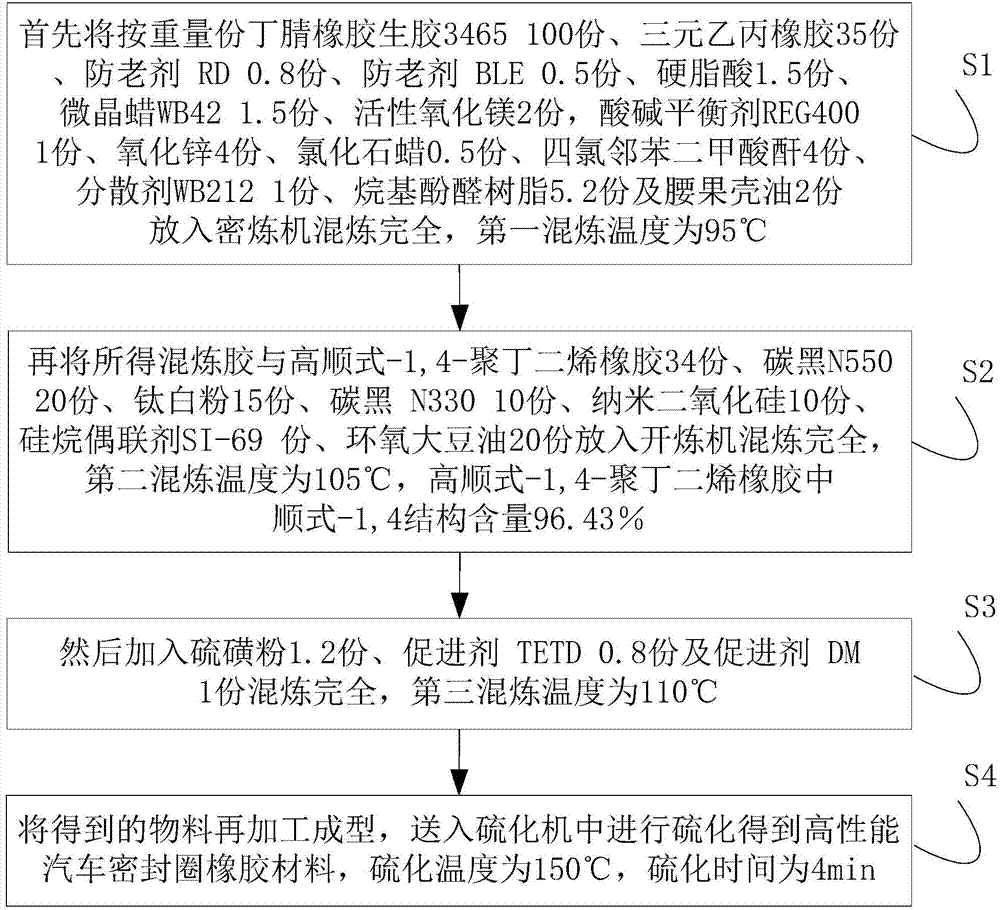

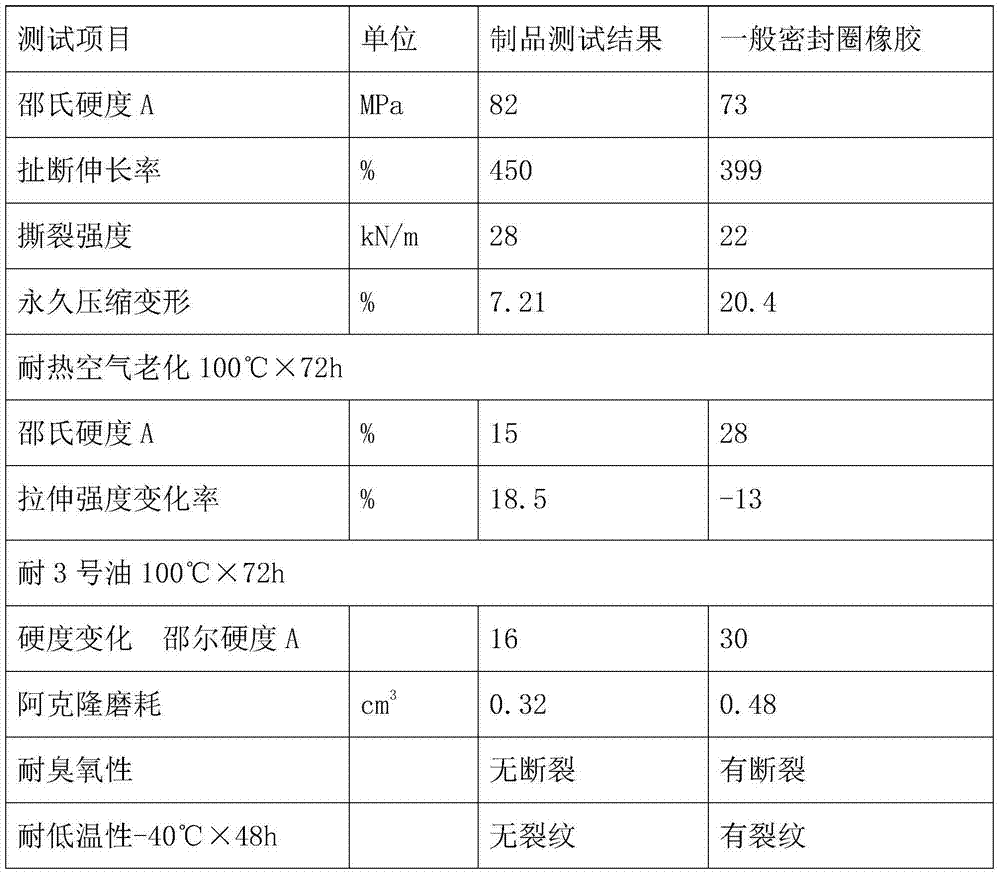

High-performance automobile seal ring rubber material and preparation technique thereof

The invention discloses a high-performance automobile seal ring rubber material which is prepared from the following raw materials in parts by weight: unvulcanized nitrile-butadiene rubber 3465, high cis-1,4-polybutadiene rubber, ethylene propylene diene monomer rubber, anti-aging agent RD, anti-aging agent BLE, stearic acid, sulfur powder, microcrystalline wax WB42, activator magnesium oxide, acid-base balancing agent PEG 400, zinc oxide, chlorinated paraffin, tetrachlorophthalic acid anhydride, dispersing agent WB212, alkyl phenol aldehyde resin, rubber plastizing agent cashew nut shell oil, carbon black N550, titanium white, carbon black N330, nano silicon dioxide, silane coupling agent Si-96, epoxy soybean oil, accelerator TETD (tetraethyl thiuram disulfide) and accelerator DM. The invention also discloses a preparation technique of the high-performance automobile seal ring rubber material. The high-performance automobile seal ring rubber material has the advantages of excellent abrasion resistance, excellent aging resistance, excellent high / low temperature resistance, high hardness, favorable tear resistance, favorable processability and low cost.

Owner:安徽宁国尚鼎橡塑制品有限公司

Microwave vulcanized ethylene propylene diene monomer (EPDM) sponge sheath and processing method thereof

InactiveCN102336971AEasy to porosityEnsure completenessFlexible pipesPipe protection against damage/wearPolymer sciencePolyethylene glycol

The invention relates to a microwave vulcanized EPDM sponge sheath and a processing method thereof. Rubber components for the sponge sheath comprise EPDM rubber, fast extruding carbon black, light calcium carbonate, paraffin oil, white factice, a dehumidifying and antifoaming agent, zinc oxide, stearic acid, polyethylene glycol, azodicarbonamide, N-cyclohexyl-2-benzothiazolesulfenamide, dibenzothiazyl disulfide, tetramethyl-thiuram disulfide and sulphur. According to the invention, mixed stock is extruded by an extruder which works under the condition that temperatures of a head, a screw section, a plasticizing section and a feeding section are set; microwave vulcanization is carried out by allowing a semi-finished product extruded by the extruder to directly enter into microwave vulcanizing equipment for vulcanization, with microwave total power maintained to be in range of 6000 to 8000 W, temperature of a microwave section set to be 200 DEG C, and temperature of a heating section set to be 200 to 220 DEG C from beginning to end. The invention enables a uniformly distributed closed pore bubble structure to be formed easily and dimension of a product to be controlled easily. Rapid heat generation of microwave enables vulcanization time to be reduced to some extend, thereby improving production efficiency.

Owner:TIANJIN PENGYI GRP CO LTD

Environment-friendly high-elasticity rubber material

The invention discloses an environment-friendly high-elasticity rubber material which is prepared from the following raw materials in parts by weight: 30-40 parts of powder nitrile-butadiene rubber, 10-18 parts of polyvinyl chloride thermoplastic elastomer, 10-20 parts of ABS (acrylonitrile-butadiene-styrene) resin, 3-5 parts of p-tert-butyl phenol-formaldehyde resin, 1.5-2 parts of sulfur, 1.2-1.8 parts of accelerator TMTD (tetramethyl thiuram disulfide), 2-4 parts of magnesium oxide, 1-3 parts of zinc oxide, 5-8 parts of epoxy soybean oil, 0.5-1 part of paraffin, 1-3 parts of zinc-barium stabilizer, 2-3 parts of organophosphate, 20-30 parts of modified kaolin, 15-20 parts of silica white, 1.5-3 parts of carbon master batch and 0.5-1.5 parts of novel rubber reinforcing agent XRE. The rubber material has the advantages of excellent elasticity, wear resistance, favorable tear resistance and low cost, and reduces the hazard to the environment.

Owner:宁国日格美橡塑股份有限公司

Ethylene-propylene-diene monomer rubber waterproof roll and production method thereof

The invention discloses an ethylene-propylene-diene monomer rubber waterproof roll. The ethylene-propylene-diene monomer rubber waterproof roll is prepared from the following raw materials in parts by weight: ethylene-propylene-diene monomer rubber, DOP (Dioctyl-Phthalate) thermal welding agent, carbon black, light calcium carbonate, stearic acid, zinc oxide, rubber accelerator, sulfur, processing oil, fire-retardant plasticizer, chlorinated polyethylene (CPE), white carbon black and rubber accelerator tetramethyl thiuram disulfide (TMTD). A production method of the ethylene-propylene-diene monomer rubber waterproof roll comprises the steps of banburying, filtering, compounding, thermal cracking, calendering, rolling, vulcanization and packaging. The ethylene-propylene-diene monomer rubber waterproof roll produced by the method has good ageing resistance, small possibility of cracking and good waterproof effect and has an inflaming retarding function, the initiation temperature exceeds 300 DEG C, and the ethylene-propylene-diene monomer rubber waterproof roll has no water-permeating phenomenon through permeable experiments.

Owner:WEIFANG ZHENGTAI WATERPROOF MATERIAL

Wear-resistant tear-resistant ethylene propylene diene monomer rubber material

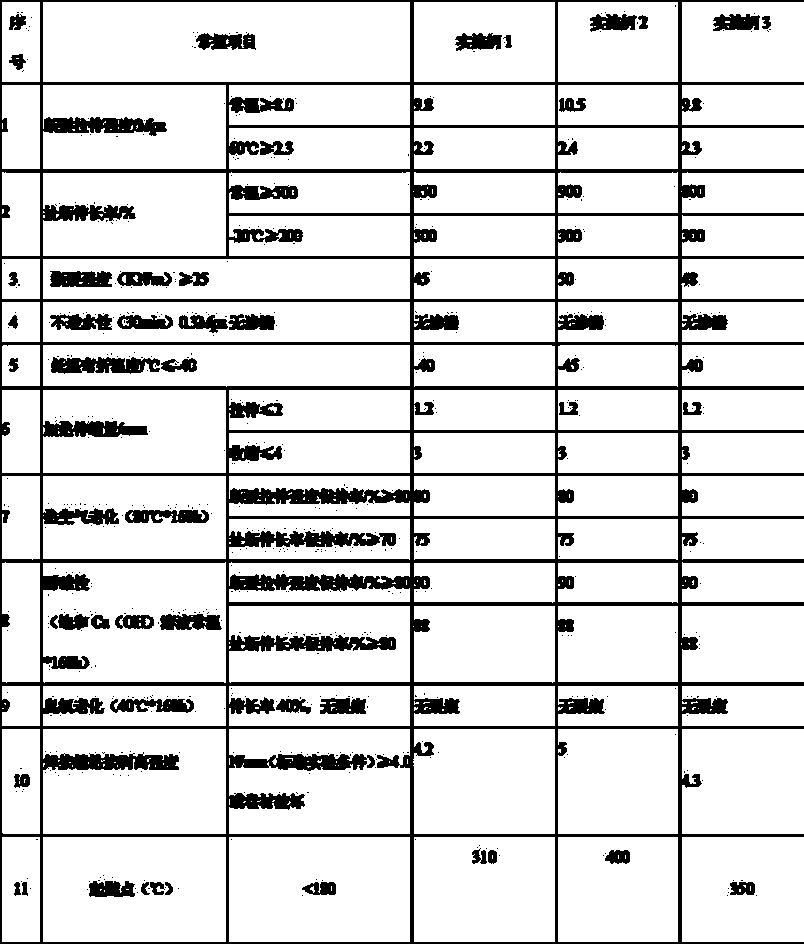

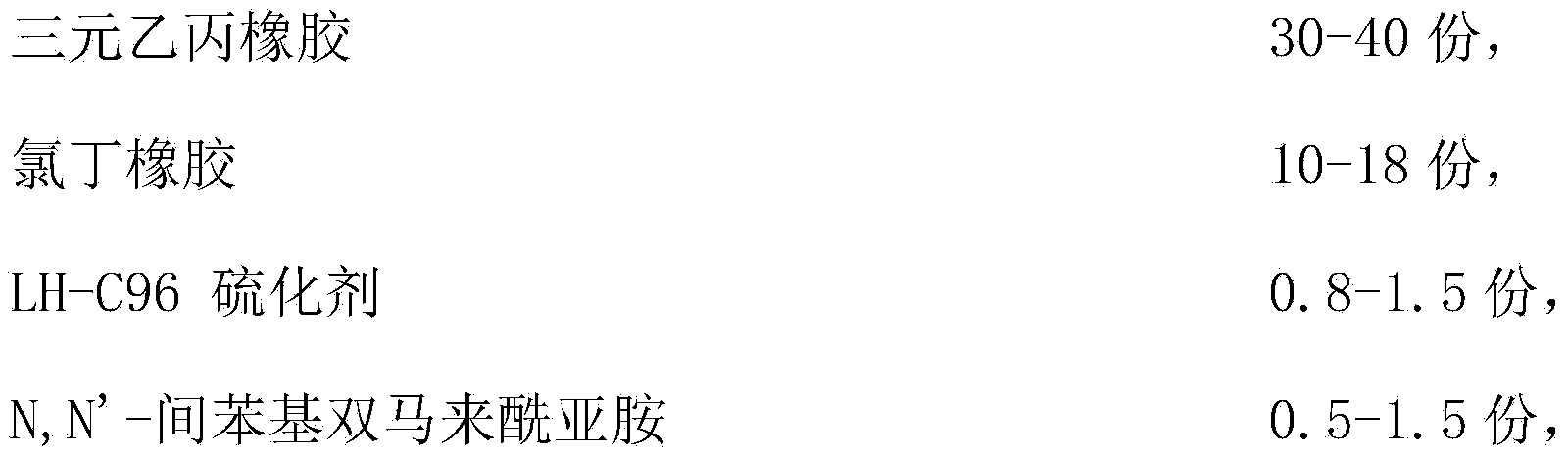

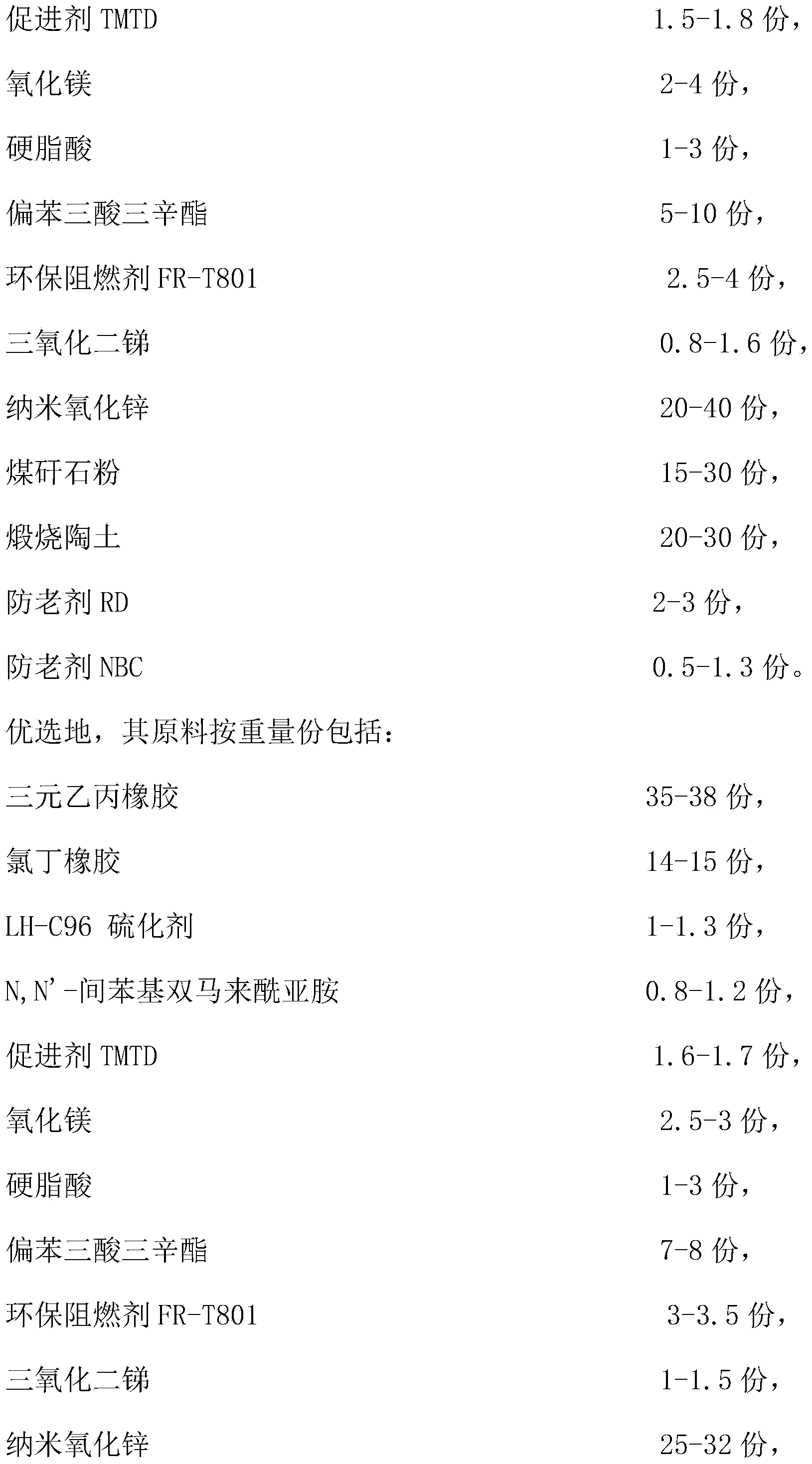

The invention discloses a wear-resistant tear-resistant ethylene propylene diene monomer rubber material which is prepared from the following raw materials in parts by weight: 30-40 parts of ethylene propylene diene monomer rubber, 10-18 parts of chloroprene rubber, 0.8-1.5 parts of LH-C96 vulcanizing agent, 0.5-1.5 parts of N,N'-m-phenyl bismaleimide, 1.5-1.8 parts of accelerator TMTD (tetramethyl thiuram disulfide), 2-4 parts of magnesium oxide, 1-3 parts of stearic acid, 5-10 parts of trioctyl trimellitate, 2.5-4 parts of environment-friendly flame retardant FR-T801, 0.8-1.6 parts of antimony trioxide, 20-40 parts of nano zinc oxide, 15-30 parts of coal gangue powder, 20-30 parts of calcined argil, 2-3 parts of anti-aging agent RD and 0.5-1.3 parts of anti-aging agent NBC. The material has the advantages of excellent wear resistance, excellent wear resistance and favorable aging resistance.

Owner:安徽宁国尚鼎橡塑制品有限公司

Hollow polymer particles, aqueous dispersion thereof and production process thereof

ActiveUS20050113505A1Improve uniformitySmall particle sizeFoundry mouldsInksMonomer compositionHydrophilic monomer

Disclosed are hollow polymer particles composed of a crosslinked polymer having a comparatively small particle diameter and a narrow particle diameter distribution, an aqueous dispersion of the particles, and an ink having good flying property. The hollow polymer particles are obtained by emulsion-polymerizing a crosslinkable polymerizable monomer composition absorbed in seed particles and containing a crosslinkable monomer component and a hydrophilic monomer component, wherein the seed particles are particles of a polymer having a weight average molecular weight of 500 to 15,000, and obtained by emulsion-polymerizing 100 parts by mass of a non-crosslinkable polymerizable monomer in the presence of 0.01 to 5 parts by mass of a chain transfer agent composed of at least one compound selected from the group consisting of α-methylstyrene dimer, thiuram disulfides and terpene hydrocarbons. The ink contains the hollow polymer particles.

Owner:JSR CORPORATIOON

Rubber compositions and method for increasing the mooney scorch value

A rubber composition is disclosed wherein the rubber composition contains at least (a) a rubber component; (b) a silica filler; and, (c) at least one thiuram disulfide accelerator, it being provided that diphenyl guanidine is substantially absent in the rubber composition. The compositions may also include suitable amounts of other ingredients such as carbon black, coupling agents, antiozonants, antioxidants, etc.

Owner:UNIROYAL CHEM CO INC

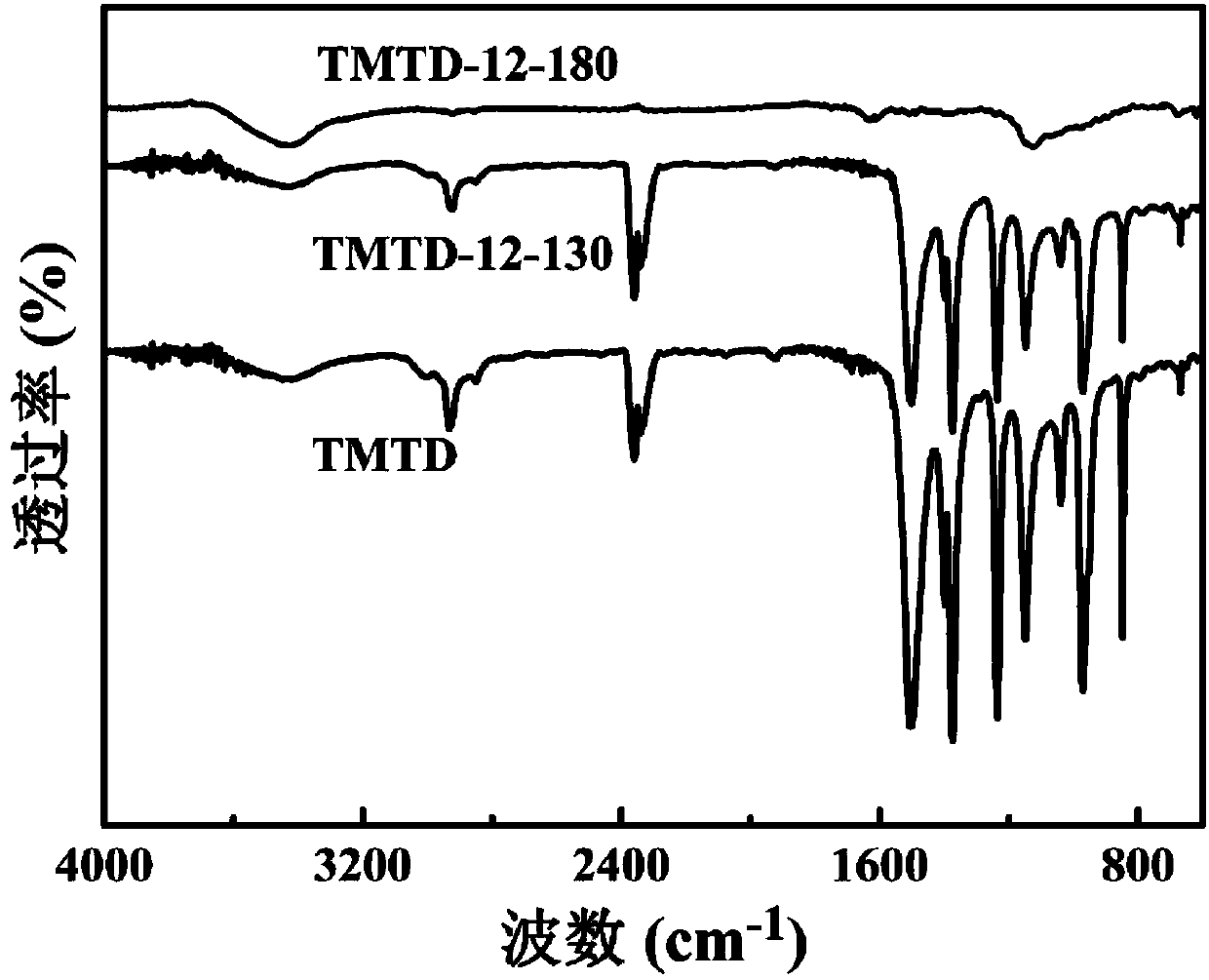

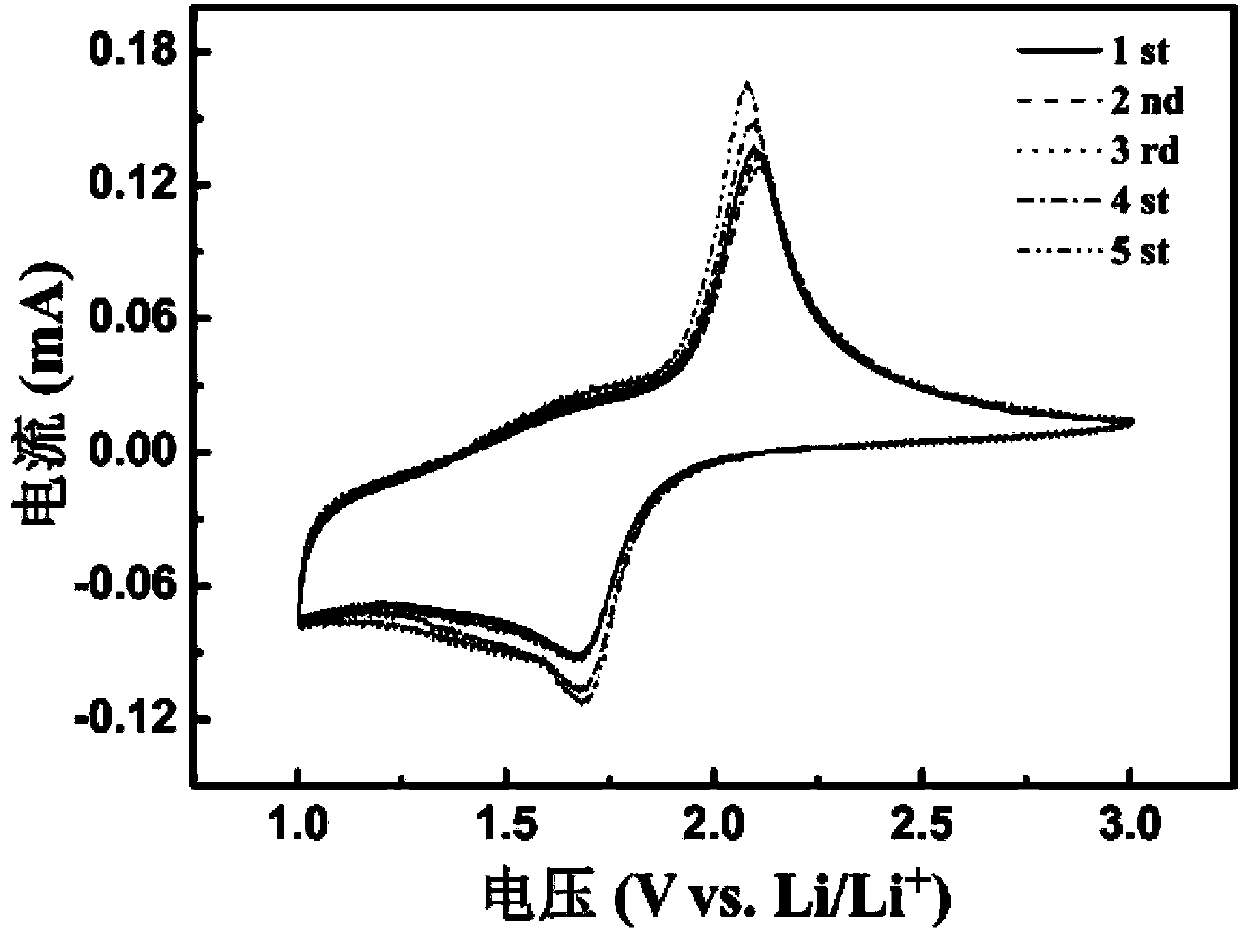

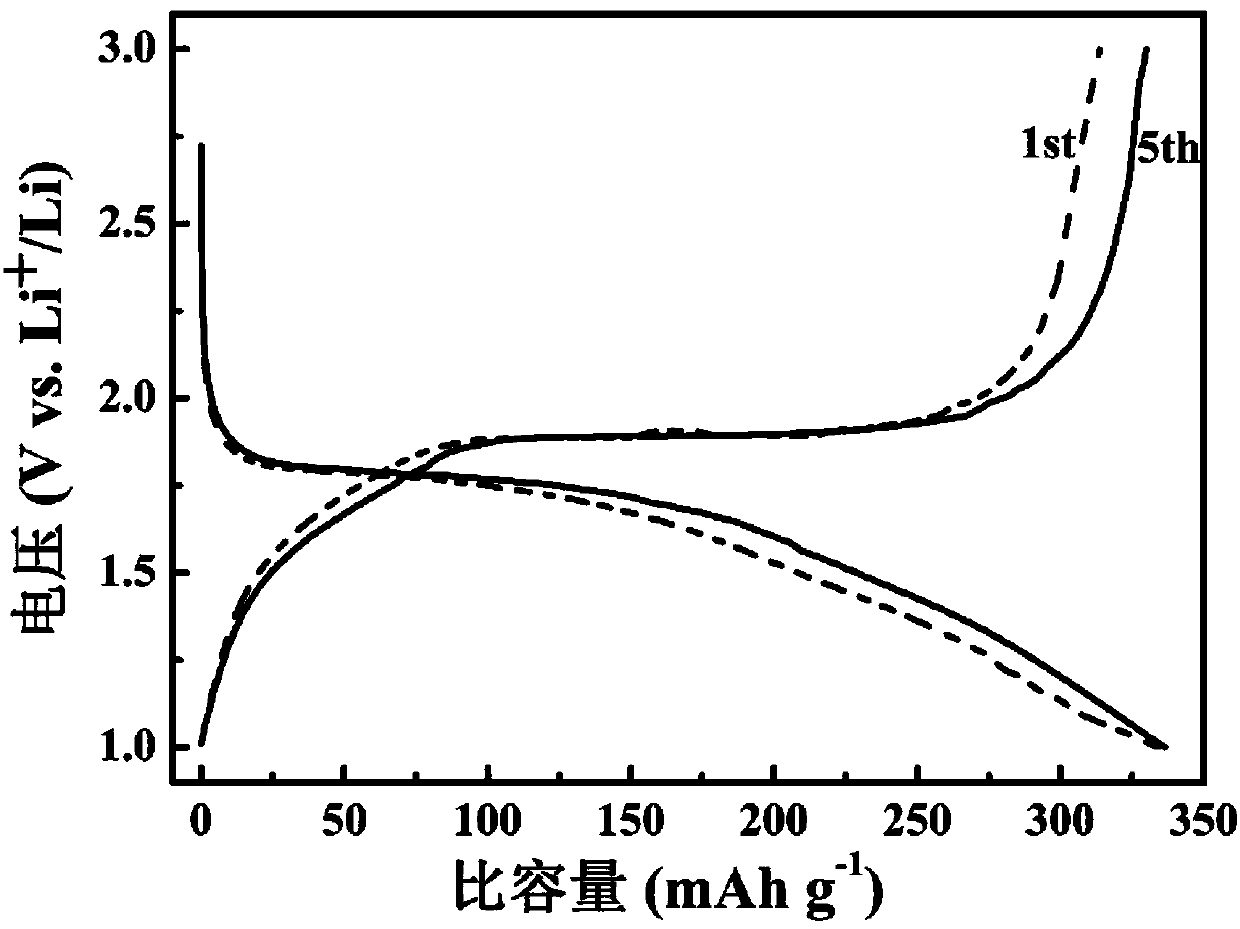

Anode material for lithium-sulfur batteries and preparation method of anode material

ActiveCN103427068ASolve poor reversibilitySolve UtilizationNon-aqueous electrolyte accumulator electrodesLithium sulfurThiuram disulfide

The invention relates to an anode material for lithium-sulfur batteries and a preparation method of the anode material. The anode material comprises a current collector, an anode active substance spread on the current collector, a conductive agent and a binding agent, wherein the current collector is aluminium foil, the conductive agent is acetylene black, and the binding agent is polyvinylidene fluoride; the anode material is characterized in that the anode active substance is sulfur source TMTD-t-T decomposed from TMTD (tetramethyl thiuram disulfide) at different times t and different temperatures T, wherein t is equal to 12 or 24 h, T is equal to 120, 140, 160 or 180 DEG C; the anode material is prepared in such a way that the TMTD-t-T, the conductive agent and the binding agent are homogeneously mixed and dissolved in N-methyl-2-pyrrolidone to form paste, the paste is spread on the surface of the current collector, and vacuum drying is performed; through introduction of the organic sulfur source TMTD, the electrochemical reversibility and circulating stability of the lithium-sulfur batteries are remarkably improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

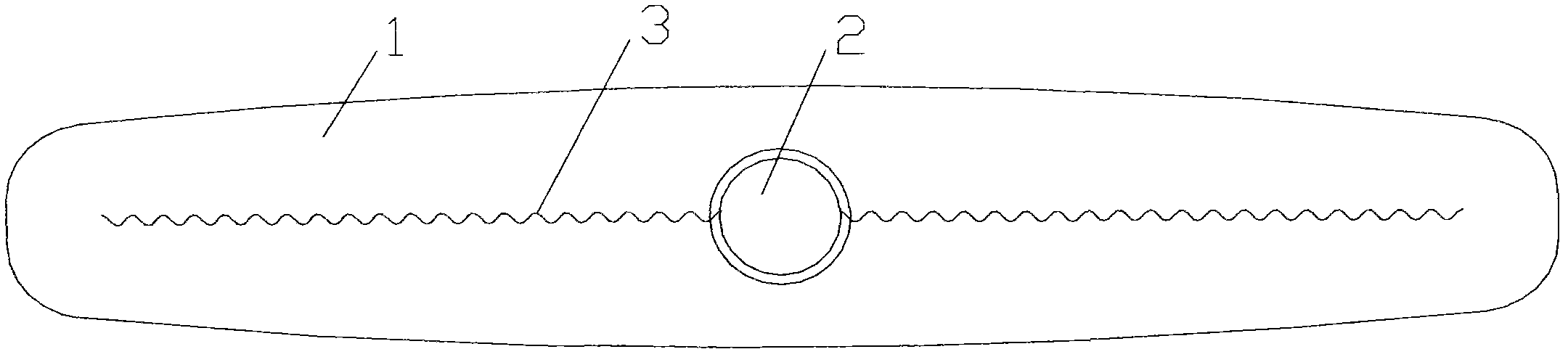

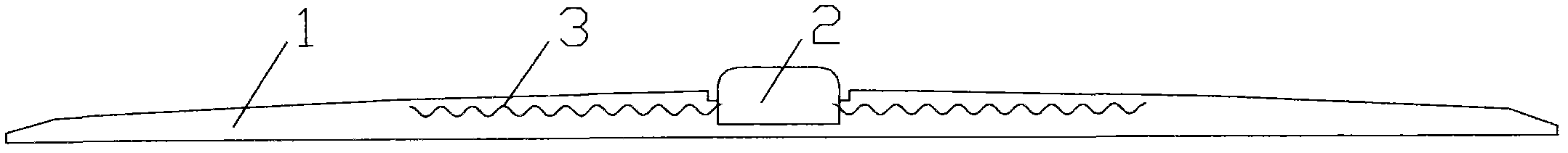

Dielectric rubber body for packaging sensor and radio-communication system taking dielectric rubber body as carrier

ActiveCN103183876AIncrease elasticityImprove mechanical propertiesOther chemical processesTyre measurementsDielectricPolymer science

The invention relates to a dielectric rubber body for packaging a sensor. The dielectric rubber body is characterized in that the formula thereof comprises 60-70 parts of chlorinated butyl rubber, 10-20 parts of butadiene styrene rubber, 20-30 parts of natural rubber, 20-30 parts of light calcium carbonate, 30-40 parts of carbon black, 5-10 parts of conductive carbon black, 1-3 parts of stearic acid, 2-5 parts of magnesium oxide, 1-5 parts of octyl phenol-phenolic resin, 3-6 parts of zinc oxide, 1-3 parts of N-tertiary butyl-2-benzothiazole sulfenamide, 0.5-2 parts of tetramethyl thiuram disulfide, and 0.5-2 parts of insoluble sulphur. The dielectric rubber body disclosed by the invention is used for a conductive radiofrequency device in tire; the device comprises a radio assembly and an antenna, and can be used for tracking and recording data during manufacturing, sales and use; and the measurement range covers temperature, pressure or other physical parameters in tire. During the loading process of a sensor, the conductive material with a certain dielectric constant and a certain adhesive force disclosed by the invention is chosen, so that the device can be firmly connected with a tire and can be used for transmitting data more stably; simultaneously, via high elasticity and good mechanical property of rubber, the device can withstand the stress brought by cyclic deformation of the tire excellently.

Owner:QINGDAO TONGSHENGTONG RUBBER & PLASTIC

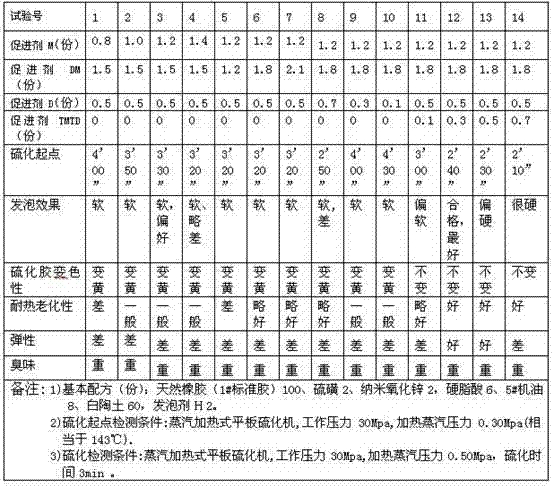

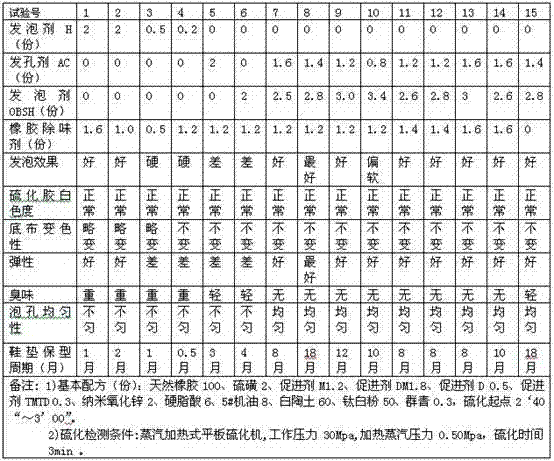

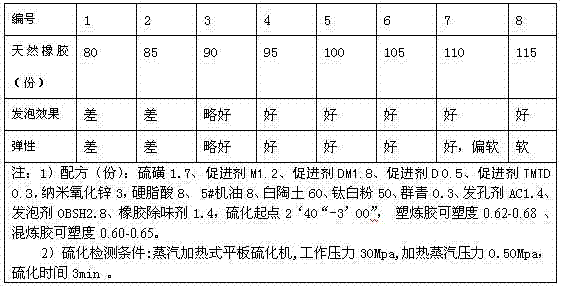

Natural rubber white odorless spongy cushion for in situ color-protecting shoes and preparation method thereof

ActiveCN102391550APrevent high temperature agingShort vulcanization timeInsolesLaminationActivated carbonPolymer science

The invention discloses a natural rubber white odorless spongy cushion for in situ color-protecting shoes and a preparation method thereof. The raw materials of the spongy cushion comprises natural rubber, sulfur, an accelerating agent, a vulcanizing active agent, a hole-forming agent AC (activated carbon), titanium white, 5# engine oil, kaolin, a rubber odor-removing agent and a foaming agent OBSH (oxybis(benzenesulfonyl hydrazide)). In the invention, the odorless spongy for shoes is prepared by utilizing the natural rubber as a main body; vulcanization is promoted by using a thiuram accelerating agent TMTD (tetramethyl thiuram disulfide) to inhibit the high-temperature ageing of the natural rubber, thereby ensuring that titanium white and kaolin filled white spongy rubber do not generate high yellowing to discolor the bottom surfaces in the shoes; the foaming agent AC and OBSH are jointly used, so as to achieve the shape keeping property and even bubbles and low odor of the inner bottoms of the spongy shoes; because no water gas is generated in the foaming process of spongy, heterochromatic substances are not dissolved and transported to cause the yellowing and discoloring of white soft goods of the inner bottoms of the shoes, thus the spongy cushion has abundant white keeping capacity; and the odor generated in the process of vulcanizing the spongy rubber can be effectively removed through the rubber odor-removing agent.

Owner:际华制鞋工业有限公司

Rubber material for wind power generation cable sheath

InactiveCN104194106AIncrease the degree of cross-linkingImprove mechanical propertiesRubber insulatorsInsulated cablesRubber materialPolyisocyanurate

The invention discloses a rubber material for a wind power generation cable sheath. The rubber material is prepared from the following raw materials in parts by weight: 50-70 parts of chloroprene rubber, 10-18 parts of butadiene rubber, 20-32 parts of natural rubber, 15-20 parts of organic modified montmorillonite, 1-1.5 parts of magnesium oxide, 0.8-1.3 parts of zinc oxide, 1.5-2.8 parts of dicumyl peroxide, 0.3-0.8 part of triallyl polyisocyanurate, 1-3 parts of diisobutyl adipate, 0.8-2.2 parts of ethyl oleate, 5-8 parts of hazelnut oil, 1.2-1.6 parts of stearic acid, 20-35 parts of carbon black, 10-15 parts of carbon black purple, 1.0-1.5 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 0.5-1.6 parts of tetramethyl thiuram disulfide, 1.8-2.2 parts of N-isopropyl-N'-phenyl p-phenylenediamine and 0.4-0.8 part of N-phenyl-2-naphthylamine. The organic modified montmorillonite is prepared by the following steps: adding sodium-based montmorillonite into water, stirring and standing and taking supernate; and after heating the supernate, adding octadecyl trimethyl ammonium chloride, carrying out ultrasonic treatment for 60-80 minutes, and after stirring, filtering and washing. The rubber material for the wind power generation cable sheath, which is disclosed by the invention, has low-temperature resistance and high elasticity and the flame retardance is further improved.

Owner:ANHUI LAND GRP

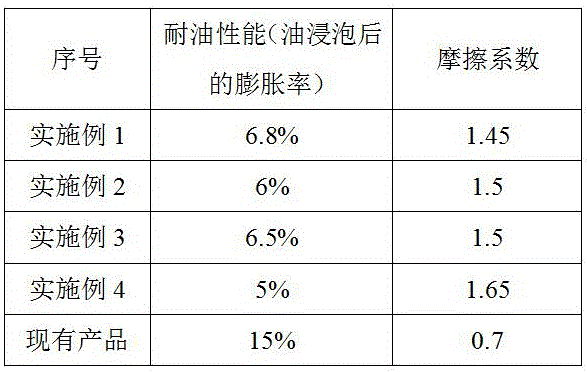

Oil-resistant and low-temperature-resistant material for shoe sole and method for preparing oil-resistant and low-temperature-resistant material

The invention discloses an oil-resistant and low-temperature-resistant material for shoe soles and a method for preparing the oil-resistant and low-temperature-resistant material. The oil-resistant and low-temperature-resistant material comprises, by weight, 60-80 parts of nitrile rubber, 40-50 parts of brominated butyl rubber, 5-8 parts of fluorine-based alkyl polyether-modified polysiloxane, 8-12 parts of zinc oxide, 20-25 parts of white carbon black, 3-5 parts of N, N'-bicyclo-caproyl-2-benzothiazole sulfonamide, 3-5 parts of tetramethyl thiuram disulfide, 2-4 parts of dioctyl phthalate, 6-12 parts of wood powder, 4-6 parts of 2-mercapto benzimidazole, 1-3 parts of sulfur, 1-3 parts of stearic acid and 1-2 parts of percarbamide. The oil-resistant and low-temperature-resistant material for the shoe soles and the method have the advantages that the oil-resistant and low-temperature-resistant material for the shoe soles is excellent in oil resistance, the oil resistance (the expansion rate of the oil-resistant and low-temperature-resistant material after the oil-resistant and low-temperature-resistant material is soaked in oil) can reach 5%-6.8%, the tensile strength of the oil-resistant and low-temperature-resistant material at the temperatures of minus 50 DEG C is 18-22 Mpa, the rebound rate of the oil-resistant and low-temperature-resistant material is 48-51%, the oil-resistant and low-temperature-resistant material is excellent in abrasion resistance, and a friction coefficient of the oil-resistant and low-temperature-resistant material is 1.45-1.65.

Owner:PUTIAN XIESHUN SHOES IND CO LTD

Inflaming retarding ethylene-propylene-diene-monomer rubber foam material and preparing method thereof

ActiveCN105330986AImprove performanceIt has dual functions of flame retardant and plasticizingHalogenEthylene-propylene-diene-monomer

The invention relates to an inflaming retarding ethylene-propylene-diene-monomer rubber foam material and a preparing method thereof. The inflaming retarding ethylene-propylene-diene-monomer rubber foam material is mainly prepared from, by weight, 100 parts of ethylene-propylene-diene-monomer rubber, 10 parts to 35 parts of naphthenic oil, 10 parts to 30 parts of carbon black, 5 parts to 20 parts of organo-phosphorus flame retardant, 10 parts to 25 parts of chitosan, 10 parts to 45 parts of hydrotalcite, 0.5 part to 1.5 parts of stearic acid, 1.0 part to 3.5 parts of zinc oxide, 4.0 parts to 8.5 parts of sulphur, 2.0 parts to 4.5 parts of tetramethyl thiuram disulfide (TMTD), 1.0 part to 3.5 parts of 2, 2'- disulfbenzothiazole (DM) and 1.5 parts to 4.5 parts of azodicarbonamide (AC). The inflaming retarding ethylene-propylene-diene-monomer rubber foam material has the advantages of being free of halogen, good in flame retardant performance, excellent in combination performance and the like, and is suitable for industries such as building heat preservation, auto spare parts, waterproof materials, electric wires, air conditioner cooling and war industry apparatuses.

Owner:浙江百纳橡塑设备有限公司 +1

Aircraft tire flap rubber

InactiveCN102977438AHigh hardnessHigh strengthBuilding insulationsCyclohexylthiophthalimideEngineering

The invention discloses an aircraft tire flap rubber which is prepared by using a banbury mixer according to a conventional technology from the following raw materials in parts by weight: 30-50 parts of 20# standard glue, 30-50 parts of butadiene-styrene rubber, 50-70 parts of reclaimed rubber, 1-6 parts of zinc oxide, 1-6 parts of stearic acid, 0-2 parts of anti-aging agent A, 0-2 parts of anti-aging agent D, 0-2 parts of paraffin, 2-6 parts of asphalt, 40-60 parts of N660 carbon black, 5-10 parts of aromatic oil, 1-3 parts of sulfur, 0-2 parts of accelerant TMTD (teramethyl-thiuram disulfide), 0-2 parts of accelerant MBTS (mercaptobenzthiazole disulfide) and 0.1-2 parts of scorch retarder CTP (cyclohexylthiophthalimide). The aircraft tire flap rubber has the advantages of improving hardness and strength of a sizing material by adopting the carbon black N660 as a reinforcing agent; prolonging scorch time without reducing the curing speed in a curing stage and improving processing and storing stabilities of the sizing material by adding the scorch retarder CTP in the formula; and improving plasticity and uniformity of the sizing material, improving technological operation properties of the sizing material and effectively solving various problems in a production process by adopting the aromatic oil as a softening agent.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

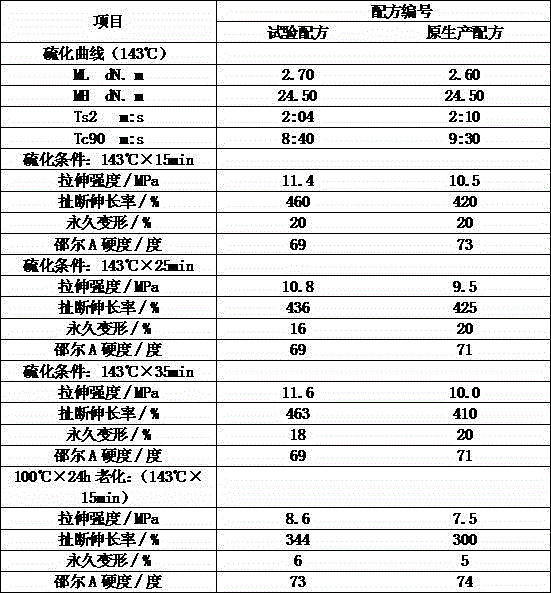

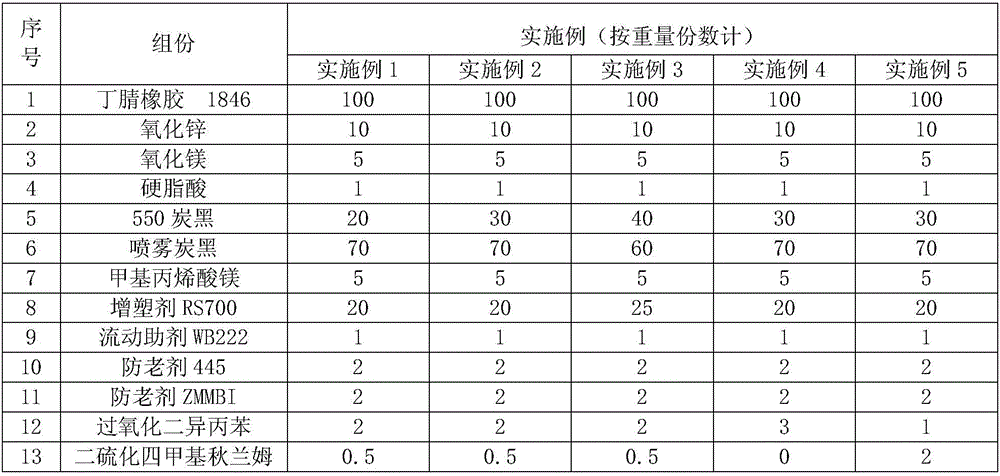

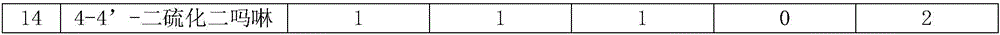

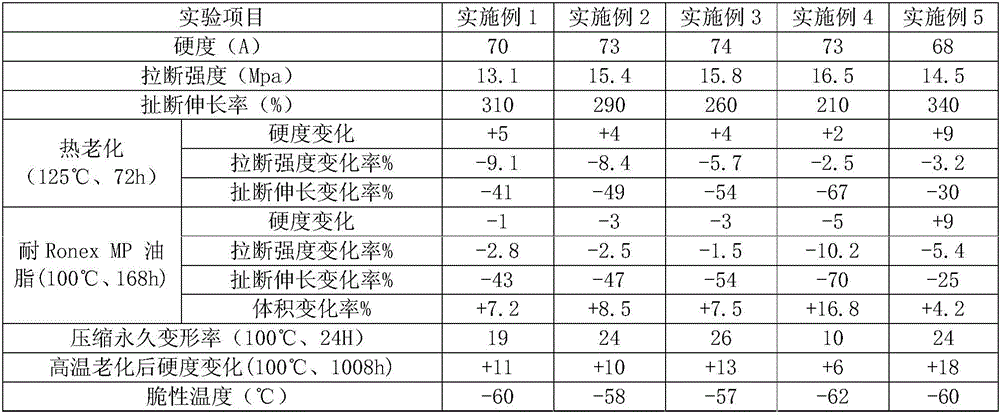

Rubber composition with low temperature resistance, grease resistance and high temperature resistance, preparation method, use and application product thereof

The invention discloses a rubber composition with low temperature resistance, grease resistance and high temperature resistance, a preparation method, a use and an application product thereof. The composition is prepared by the following raw materials: 100 parts of nitrile rubber, 1-35 parts of an active agent, 1-150 parts of carbon black, 1-5 parts of a reinforcing agent, 20-50 parts of plasticizer, 1-5 parts of a flow promotor, 1-10 parts of anti-aging agent, 1-5 parts of dicumyl peroxide, 1-3 parts of tetramethyl thiuram disulfide, and 1-5 parts of 4-4'-dithiodimorpholine. The rubber composition has three characters of the low temperature resistance, grease resistance and high temperature resistance on the basis of the good characters of the pure nitrile rubber, the production process is simple, and the cost is low.

Owner:NANJING ORIENTLEADER TECH CO LTD

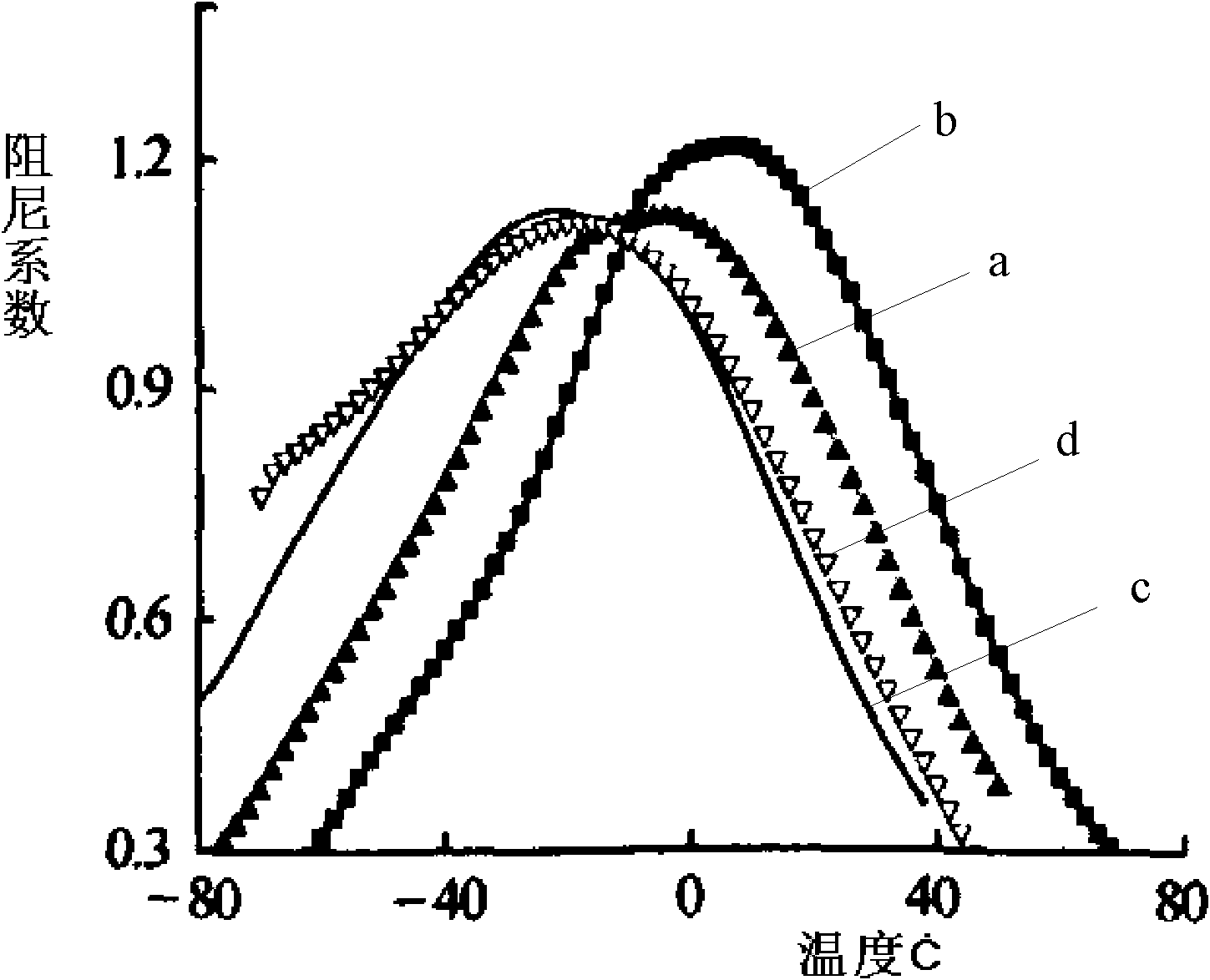

Method for preparing chlorinated butyl rubber damping material

InactiveCN102030951ALower glass transition temperatureWide temperature rangePetroleum resinWorking temperature

The invention provides a method for preparing a chlorinated butyl rubber damping material, comprising the following steps of: mixing chlorinated butyl rubber, C5 / C9 copolymerized petroleum resin, padding, zinc oxide, 2,2-dithio benzothiazole and tetramethyl thiuram disulfide to obtain a sizing material, wherein the mass ratio of the chlorinated butyl rubber to the C5 / C9 copolymerized petroleum resin is (75-85):(15-25); and carrying out vulcanization on the sizing material to obtain the chlorinated butyl rubber damping material. In the invention, when the mass ratio of the chlorinated butyl rubber to the C5 / C9 copolymerized petroleum resin is (75-85):(15-25), the temperature of the effective damping functional area of the obtained damping material is -40 DEG C to 40 DEG C; the temperature area is wider and covers higher temperature and lower temperature; therefore, the obtained damping material can be applied to the device or the equipment with a working temperature of -40 DEG C to 40 DEG C and has wider application range. Furthermore, the preparation method provided by the invention is simple in processing and easy for realizing the industrial production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com