High-performance automobile seal ring rubber material and preparation technique thereof

A technology of rubber material and preparation process, which is applied in the field of rubber materials for automobile sealing rings, can solve the problems of not being able to meet the increasingly high requirements of automobile sealing, and achieve improved rubber processing performance, excellent heat resistance, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

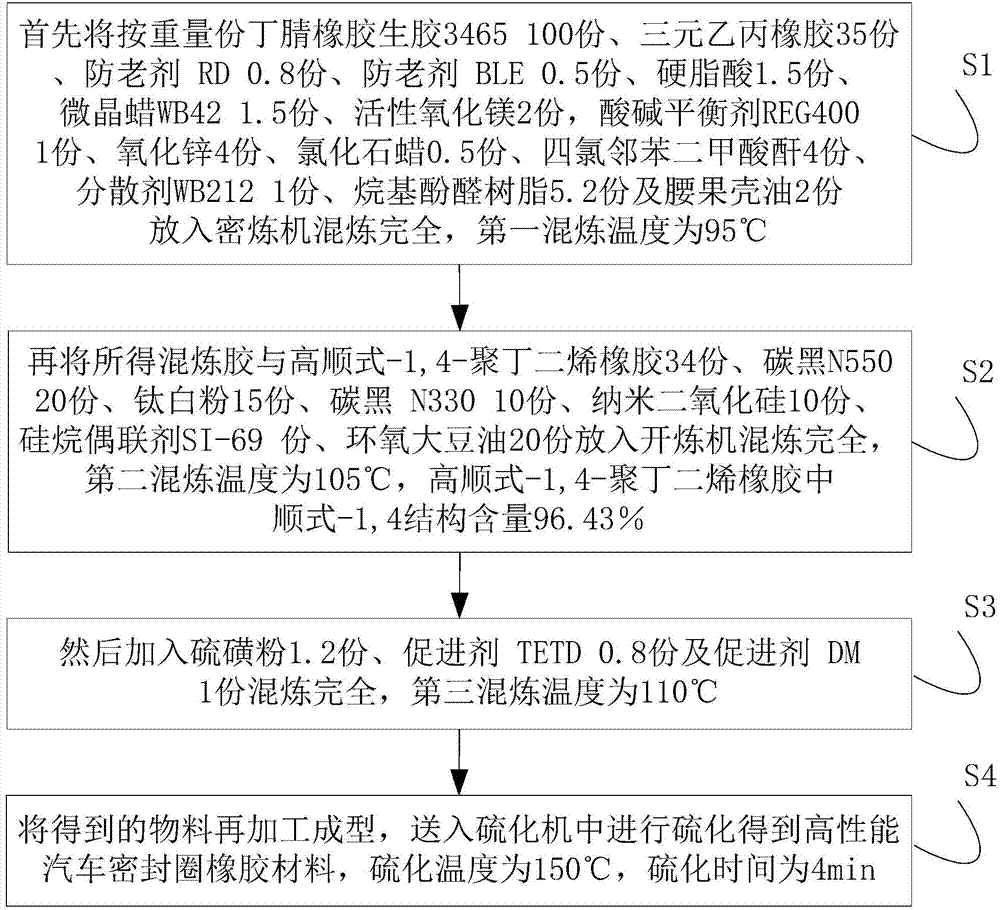

[0020] Such as figure 1 as shown, figure 1 It is a flow chart of the preparation process of a high-performance automobile sealing ring rubber material proposed by the present invention.

[0021] refer to figure 1 , a high-performance automobile sealing ring rubber material, the preparation process of which is:

[0022] S1. First, 3,465,100 parts by weight of nitrile rubber raw rubber, 35 parts of EPDM rubber, 0.8 part of anti-aging agent RD, 0.5 part of anti-aging agent BLE, 1.5 parts of stearic acid, and 1.5 parts of microcrystalline wax WB4 , 2 parts of activated magnesium oxide, 1 part of acid-base balance agent REG4001, 4 parts of zinc oxide, 0.5 parts of chlorinated paraffin, 4 parts of tetrachlorophthalic anhydride, 1 part of dispersant WB2121, 5.2 parts of alkylphenolic resin and cashew nut shell oil Put 2 parts into the internal mixer and mix completely, the first mixing temperature is 95°C;

[0023] S2, then combine the obtained mixed rubber with 34 parts of high ...

Embodiment 2

[0027] A high-performance automotive sealing ring rubber material, the preparation process of which is:

[0028] S1, first by weight 3465100 parts of nitrile rubber raw rubber, 50 parts of EPDM rubber, 0.5 part of anti-aging agent RD, 0.8 part of anti-aging agent BLE, 1 part of stearic acid, 422 parts of microcrystalline wax WB, active 1.5 parts of magnesium oxide, 3 parts of acid-base balance agent REG4003, 2 parts of zinc oxide, 1.8 parts of chlorinated paraffin, 2 parts of tetrachlorophthalic anhydride, 1.2 parts of dispersant WB212, 4.5 parts of alkylphenolic resin and cashew nut shell oil Put 4 parts into the internal mixer and mix completely, the first mixing temperature is 80°C;

[0029] S2, then combine the obtained mixed rubber with 25 parts of high cis-1,4-polybutadiene rubber, 24 parts of carbon black N55024, 13 parts of titanium dioxide, 15 parts of carbon black N33015, 5 parts of nano-silica, silane coupling Put 96 parts of agent SI-6 and 15 parts of epoxidized s...

Embodiment 3

[0033] A high-performance automotive sealing ring rubber material, the preparation process of which is:

[0034] S1. First, 3,465,100 parts of nitrile rubber raw rubber, 45 parts of EPDM rubber, 0.65 parts of anti-aging agent RD, 0.75 parts of anti-aging agent BLE, 1.25 parts of stearic acid, and 1.8 parts of microcrystalline wax WB are prepared by weight. 1.7 parts of activated magnesium oxide, 2.5 parts of acid-base balance agent REG400, 2.5 parts of zinc oxide, 1.3 parts of chlorinated paraffin, 2.5 parts of tetrachlorophthalic anhydride, 1.15 parts of dispersant WB212, 4.8 parts of alkylphenolic resin and 3 parts of cashew nut shell oil are put into the internal mixer and mixed completely, and the first mixing temperature is 92°C;

[0035] S2, then mix the obtained mixed rubber with 31.15 parts of high cis-1,4-polybutadiene rubber, 1.3 parts of carbon black N5502, 13.5 parts of titanium dioxide, 10.5 parts of carbon black N330, and 8.5 parts of nano-silica , 5.5 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com