Patents

Literature

73results about How to "Good processing technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carburizing alloy steel, and preparation method and application thereof

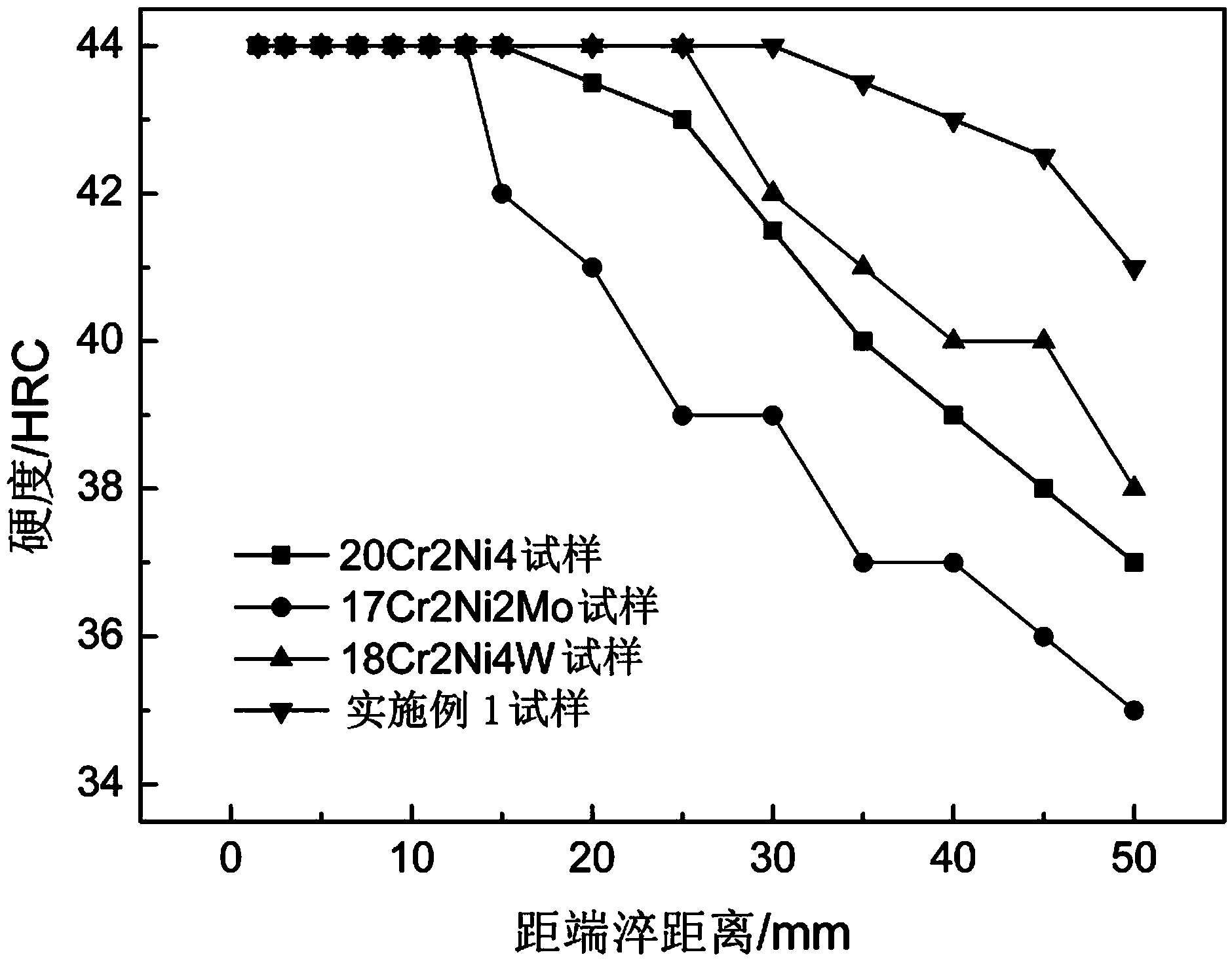

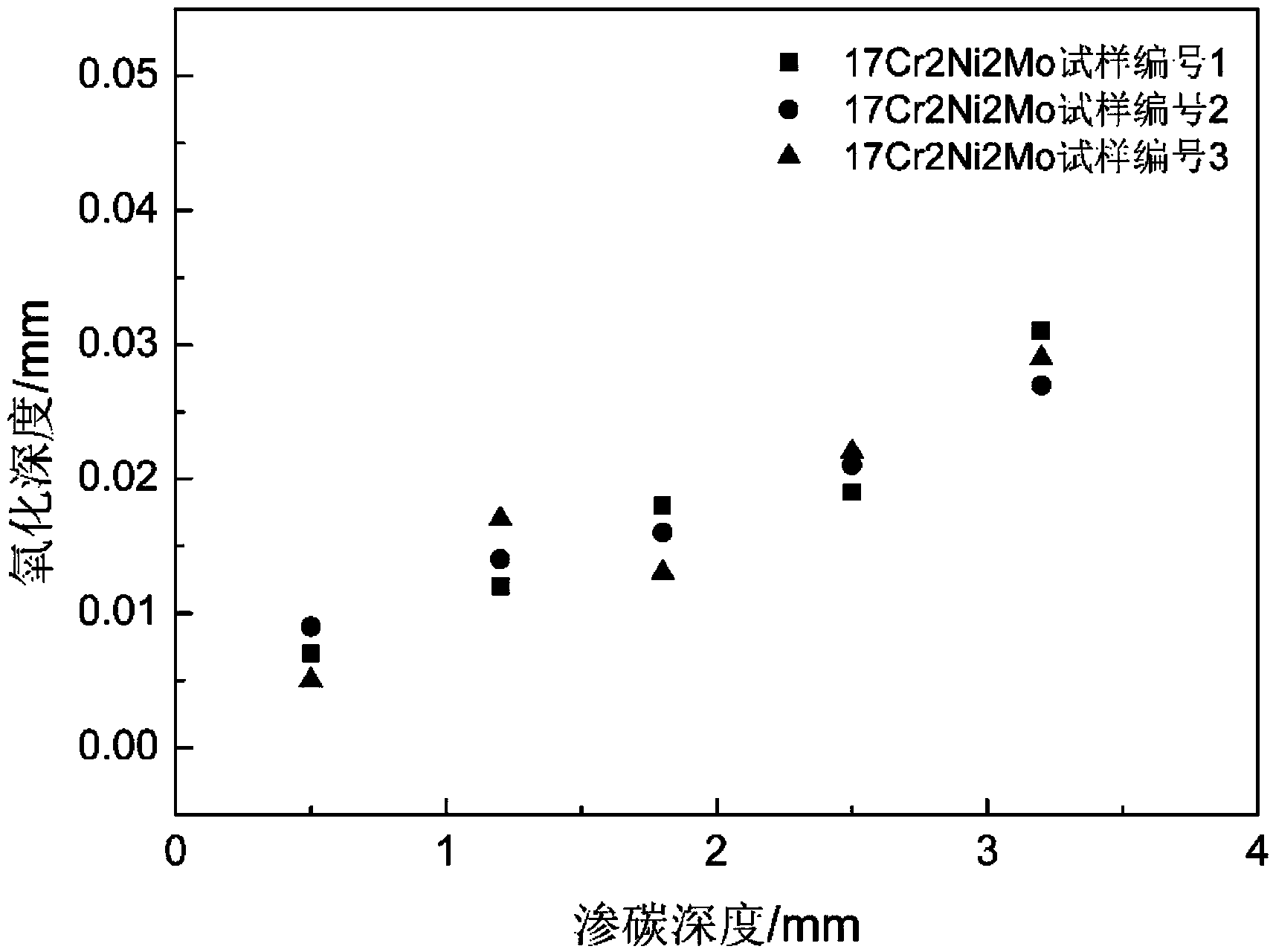

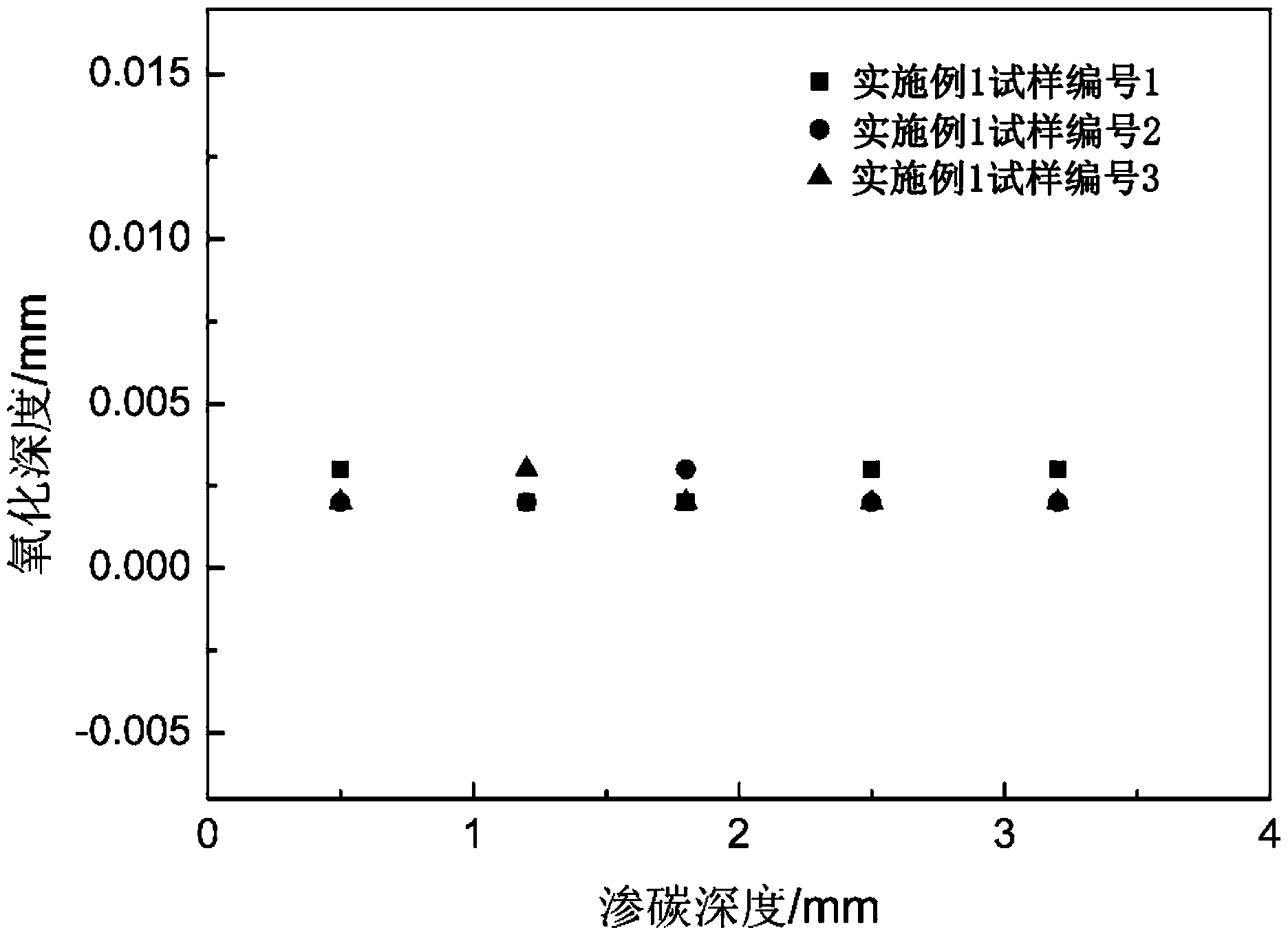

The invention relates to carburizing alloy steel, and a preparation method thereof. The alloy of the carburizing alloy steel comprises, by mass, 0.15%-0.25% of C, less than or equal to 0.30% of Si, 0.30%-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-1.50% of Cr, 2.80%-3.80% of Ni, 0.30%-1.00% of Mo, 0.01%-0.08% of Al, at least one selected from 0.05%-0.15% of V and 0.025-0.10% of Nb, and the balance being Fe and inevitable impurities. A mass percentage of V, Nb and Al meets an equation of V+Nb+Al <= 0.30%. The carburizing alloy steel provided by the invention has good anti-fatigue performance, excellent comprehensive properties, good hardenability, high yield ratio, extremely small internal oxidation and the characteristic of resisting grain growth at a high temperature, and is suitable for manufacturing heavy-duty gears.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Method of manufacturing thin titanium/steel composite board

InactiveCN101428389AHigh bonding strengthGuaranteed Thickness RequirementsMetal rolling arrangementsNon-electric welding apparatusSheet steelTitanium

The invention discloses a method for preparing a thin-type titanium or steel composite plate, and particularly relates to a method for preparing a composite plate manufactured by the titanium steel-based composite plate through explosion and pack rolling. The method is characterized in that in the preparation process of the thin-type titanium or steel composite plate, the titanium or steel composite plate is compounded and formed by the titanium plate and the steel plate through explosion, then two composite plates are folded and welded into a billet body, and then the thin-type titanium or steel composite plate is formed through rolling. The preparation method adopts the explosive composite process, the rolling billet body has high bonding strength after explosive compounding, the titanium or steel composite plate billet is folded and welded for rolling, and the deformation amount is in 4 to 7 times; therefore, the preparation method not only ensures higher bonding strength of the titanium or steel composite plate after rolling, but also ensures the respective thickness requirements, the prepared titanium or steel composite plate has good processing technological property, the explosive composite billets of the titanium plate and the steel plate after pack rolling have good bonding property, the bending test is performed without layering, the titanium plate surface is free from cracks and impurities, and the method has the advantages of higher bonding strength, corrosion resistance and fatigue resistance.

Owner:XIAN TIANLI CLAD METAL MATERIALS

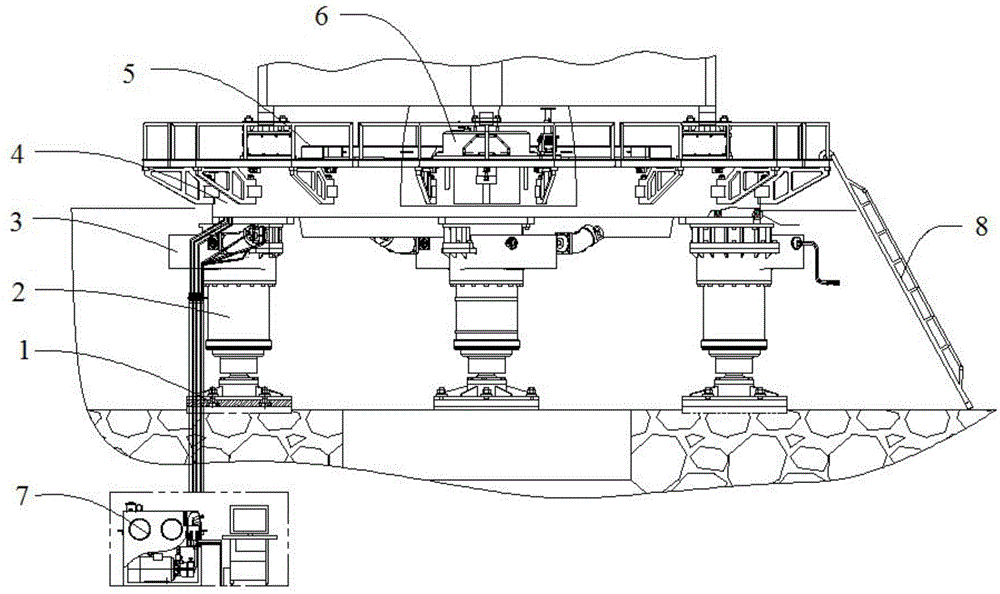

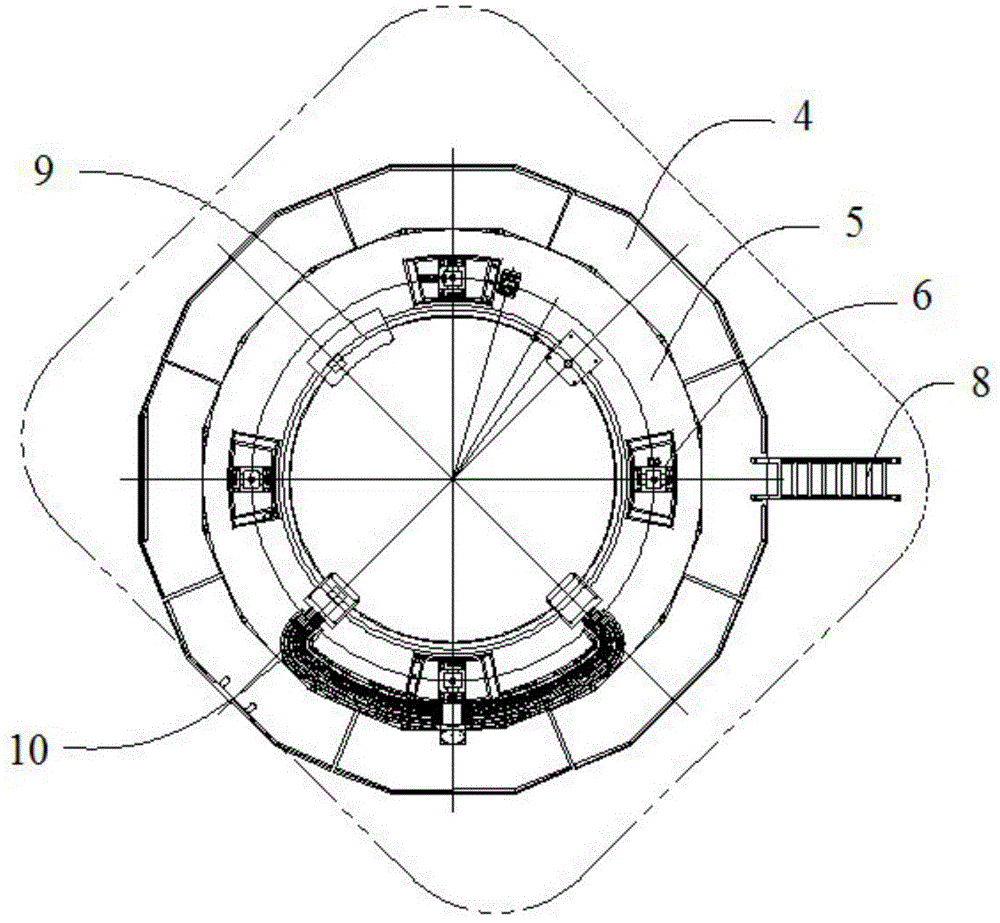

Simple carrier rocket launching system

ActiveCN103954172ASimple structureGood processing technologyRocket launchersRocket launchLaunch vehicle

The invention discloses a simple launching system for measuring and launching a carrier rocket. The simple carrier rocket launching system comprises multiple adapter plates fixedly connected with the ground; levelling support legs and a speed reducer are sequentially arranged on the multiple adapter plates from bottom to top; the speed reducer is fixedly connected with the lower surface of a table body; an operation platform is arranged on the upper surface of the table body; multiple support devices are uniformly distributed on the circumferential direction of the operation platform; the support devices are used for supporting the carrier rocket; the simple launching system also comprises an electrohydraulic control system for controlling the speed reducer to act so as to drive the levelling legs for levelling. The simple carrier rocket launching system is simple in structure and good in machining manufacturability; when being overturned, erected and vertically positioned on a launcher, the rocket can be secondly finely tuned by the levelling support legs; the use is convenient, the measuring and launching process of the carrier rocket is simplified, and the response and adaptivity capacities of the launching task are improved; the simple carrier rocket launching system can be used in a site with easy facilities for performing a simple, fast and automatic measuring and launching task; the simple carrier rocket launching system has a function of being used repeatedly for multiple times, and has the advantages of high safety and reliability and the like.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

Modified fiber reinforced PVC plastic pipe and preparation method thereof

The invention discloses a modified fiber reinforced PVC plastic pipe and a preparation method thereof. The prepared modified fiber reinforced PVC plastic pipe is prepared from, by weight, 100 parts of PVC, 1-15 parts of modified fiber material, 0.001-0.005 part of adhesive, 0.05-0.25 part of filler, 0.01-0.05 part of auxiliary and 0.02-0.15 part of coupling agent. The preparation method includes the steps of preparation of the modified fiber material, mixing and extrusion forming. The tensile properties, mechanical strength, toughness and bending resistance of the prepared modified fiber reinforced PVC plastic pipe are remarkably improved.

Owner:广东胜达塑胶科技有限公司

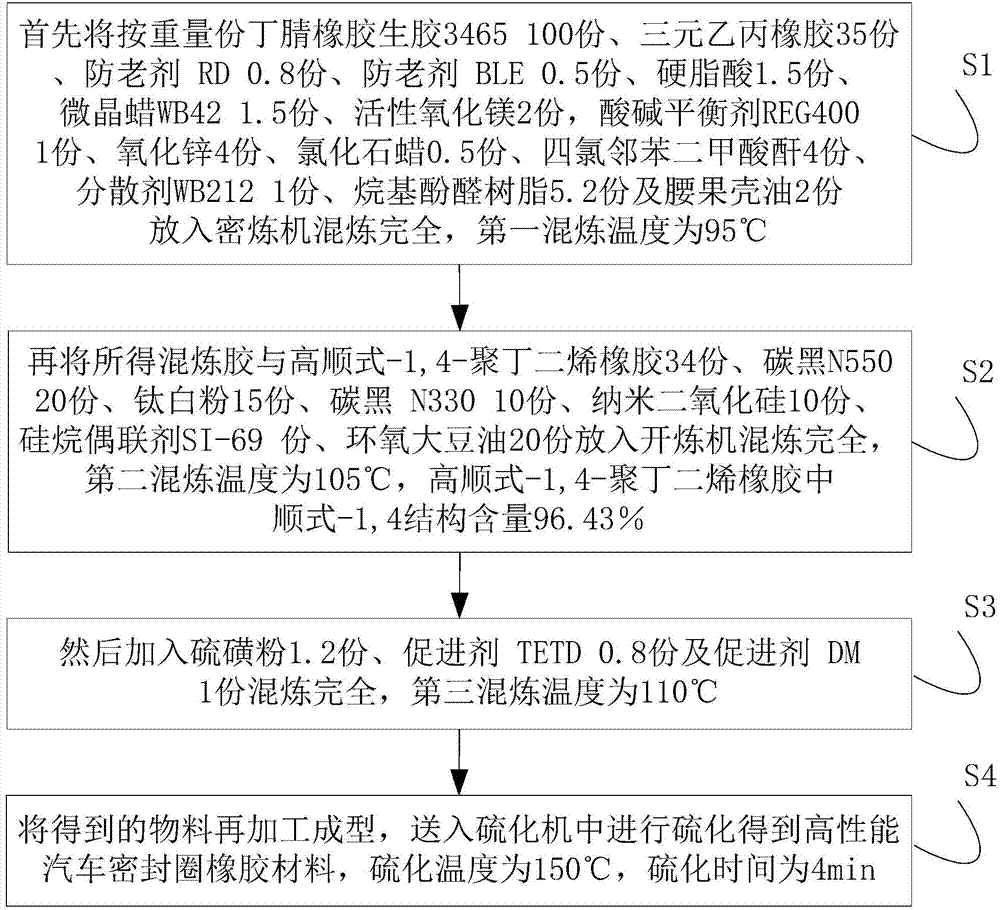

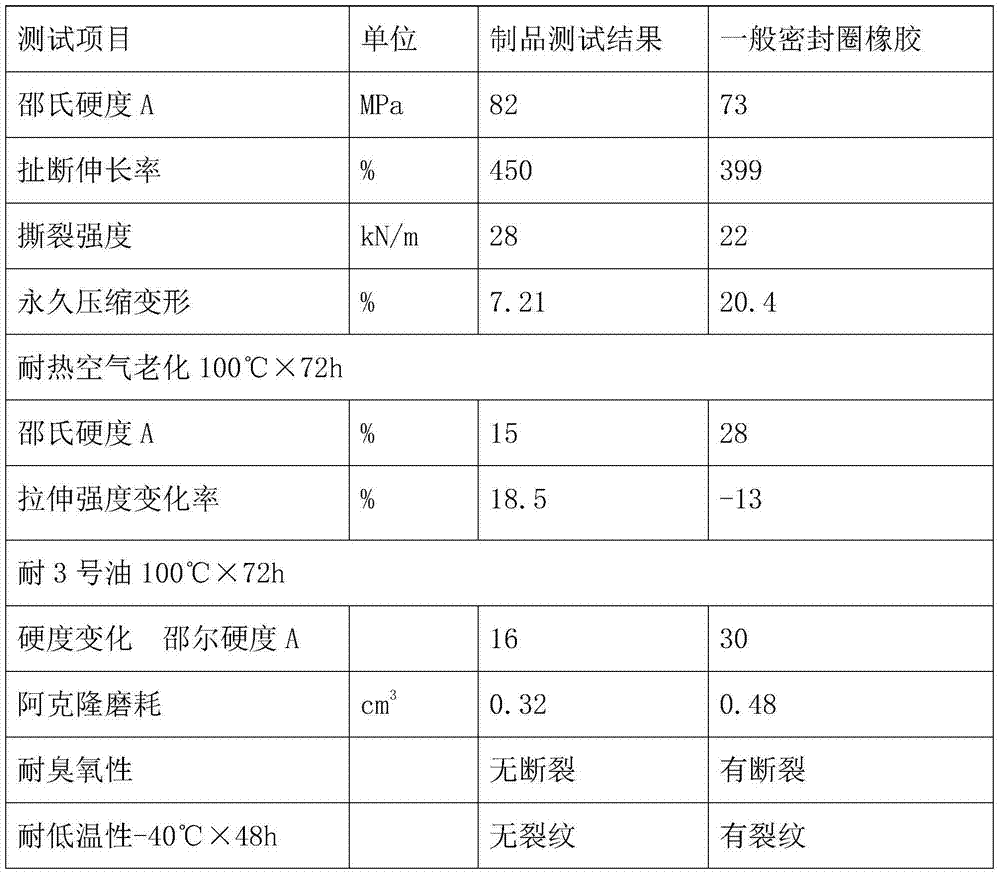

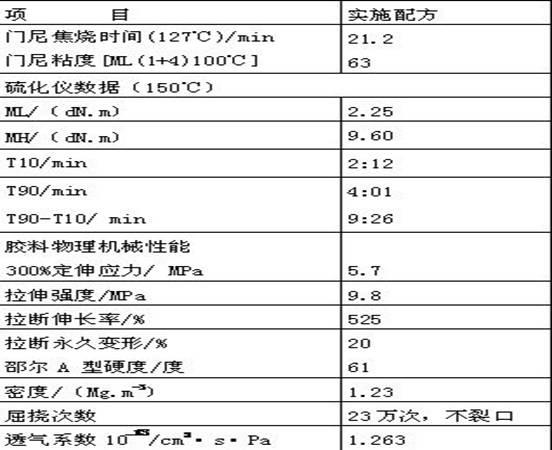

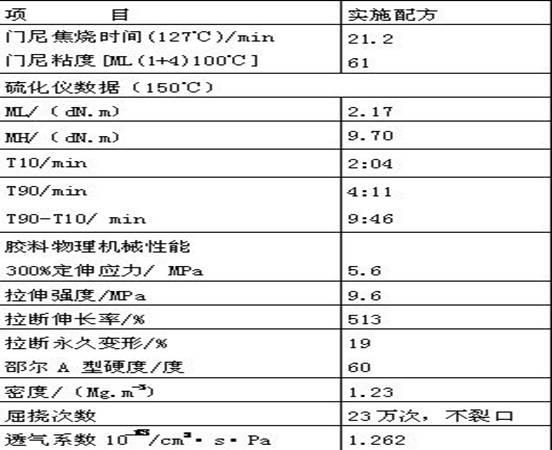

High-performance automobile seal ring rubber material and preparation technique thereof

The invention discloses a high-performance automobile seal ring rubber material which is prepared from the following raw materials in parts by weight: unvulcanized nitrile-butadiene rubber 3465, high cis-1,4-polybutadiene rubber, ethylene propylene diene monomer rubber, anti-aging agent RD, anti-aging agent BLE, stearic acid, sulfur powder, microcrystalline wax WB42, activator magnesium oxide, acid-base balancing agent PEG 400, zinc oxide, chlorinated paraffin, tetrachlorophthalic acid anhydride, dispersing agent WB212, alkyl phenol aldehyde resin, rubber plastizing agent cashew nut shell oil, carbon black N550, titanium white, carbon black N330, nano silicon dioxide, silane coupling agent Si-96, epoxy soybean oil, accelerator TETD (tetraethyl thiuram disulfide) and accelerator DM. The invention also discloses a preparation technique of the high-performance automobile seal ring rubber material. The high-performance automobile seal ring rubber material has the advantages of excellent abrasion resistance, excellent aging resistance, excellent high / low temperature resistance, high hardness, favorable tear resistance, favorable processability and low cost.

Owner:安徽宁国尚鼎橡塑制品有限公司

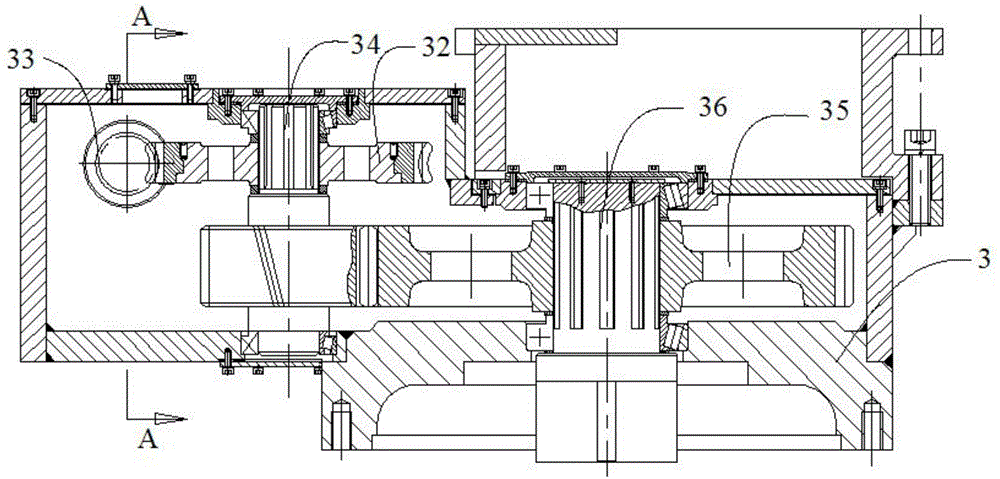

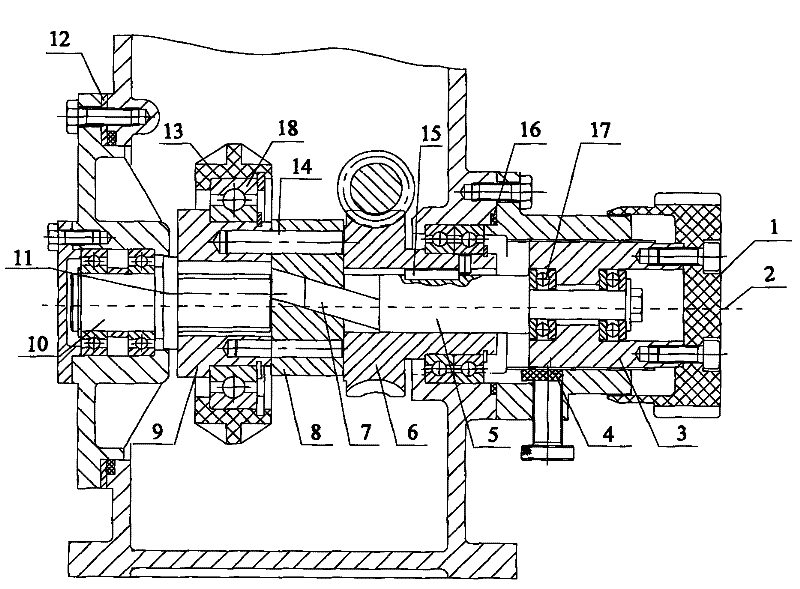

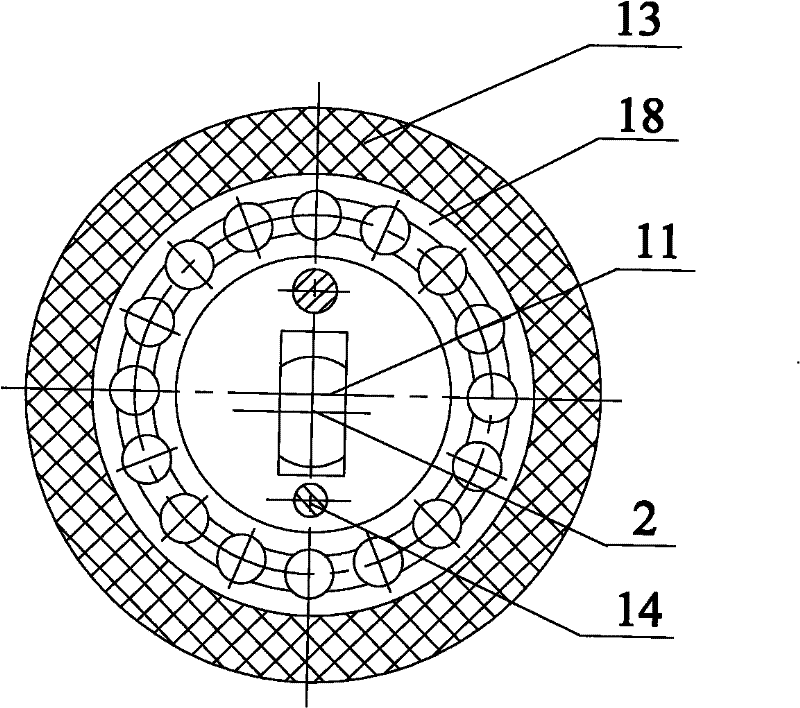

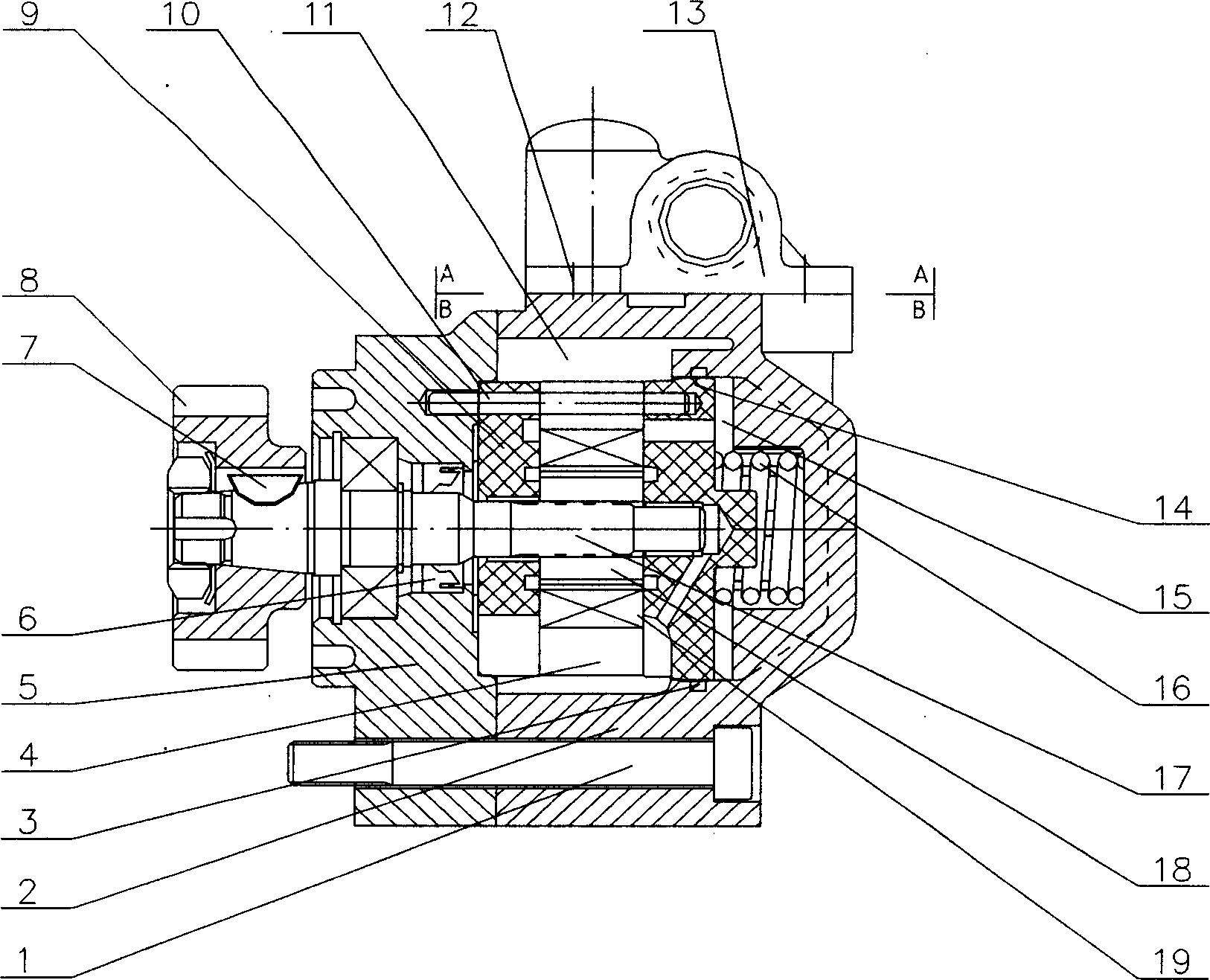

A Metering Pump Stroke Adjusting Mechanism

InactiveCN102261329AHigh overload enduranceHigh precisionPump controlPositive-displacement liquid enginesEngineeringMachining process

The invention relates to a stroke regulation mechanism for a metering pump. The regulation mechanism comprises a regulation handwheel, a hollow swivel nut, a push rod shaft, a worm wheel, an inclined block, a sliding block, a crank pin, a rotary sleeve, a connecting rod and a guide shaft, wherein the regulation handwheel is connected with the front part of the hollow swivel nut through a bolt; the front part of the push rod shaft is arranged in the hollow swivel nut and the rear part of the push rod shaft is arranged in the worm wheel; the inclined block is arranged on the tail part of the push rod shaft; the sliding block is arranged in a guide slot of the worm wheel; the sliding block is matched and connected with the inclined block; the crank pin is arranged on the sliding block; the crank pin is connected with the rotary sleeve; the connecting rod is sleeved on the outer side of the rotary sleeve; and the guide shaft is matched and connected with the rotary sleeve. Compared with the prior art, the stroke regulation mechanism has high overload resistance, high linearity performance and reproduction performance, high precision, a simple structure, and is good in a machining process and low in manufacturing cost and can statically transmit load and manually perform stepless adjustment on stroke.

Owner:SHANGHAI UNIV OF ENG SCI

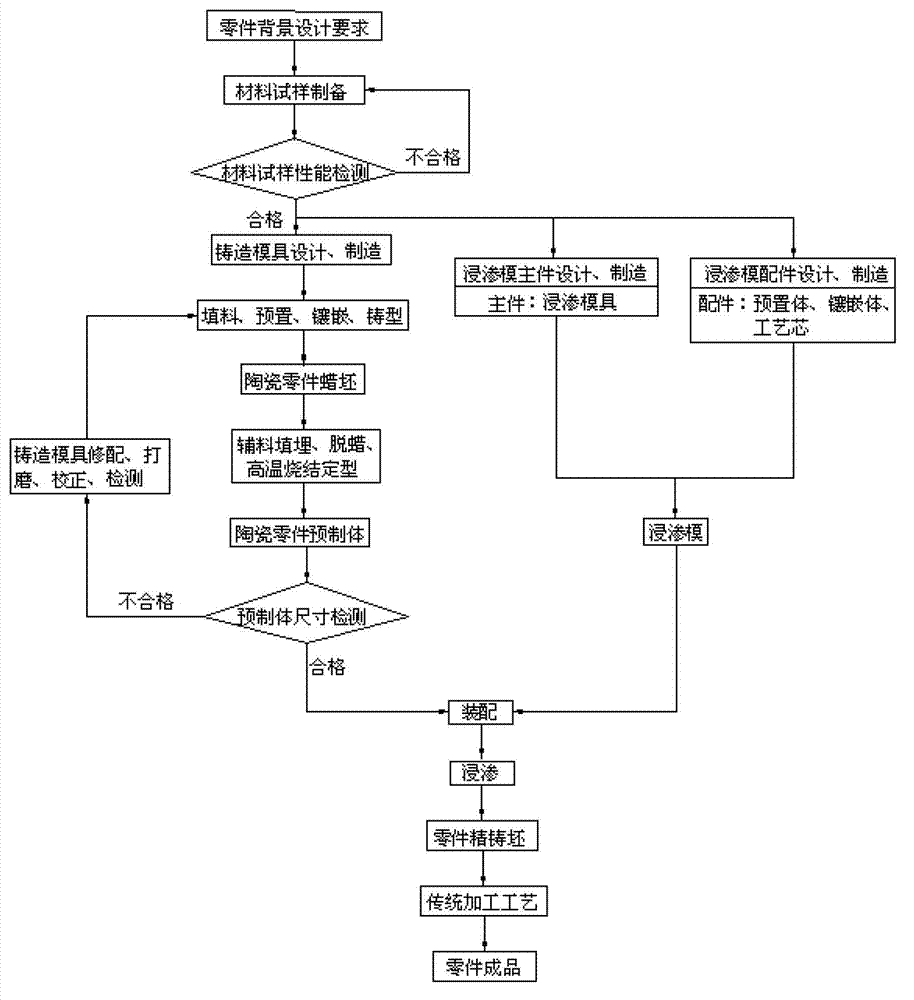

Method for manufacturing metal matrix ceramic composite part

The invention discloses a method for manufacturing a metal matrix ceramic composite part. The method includes the steps: 1) preparing a material sample; 2) detecting the performance of the material sample; 3) designing and manufacturing a casting mould; 4) placing fillers in the casting mould and performing presetting, inlaying and casting to manufacture a ceramic part wax blank; 5) embedding auxiliary materials into the ceramic part wax blank, de-waxing the ceramic part wax blank and sintering the ceramic part wax blank at a high temperature to obtain a ceramic part preform; 6) detecting the size of the ceramic part preform; 7) designing and manufacturing an infiltration mould; 8) assembling the ceramic part preform and the infiltration mould to obtain an assembly; 9) infiltrating metal into the assembly to obtain a metal matrix ceramic part precision casting blank; and 10) performing rough machining, heat treatment, semi-finishing, surface treatment, finishing and super-finishing for the precision casting blank to obtain the finished metal matrix ceramic composite part. By the method, post machining difficulty and machining amount of the part are decreased, high-precision and ultrahigh-precision machining of complicated parts are realized, the cost is low, and mass production is easily realized.

Owner:珠海凯利得新材料有限公司

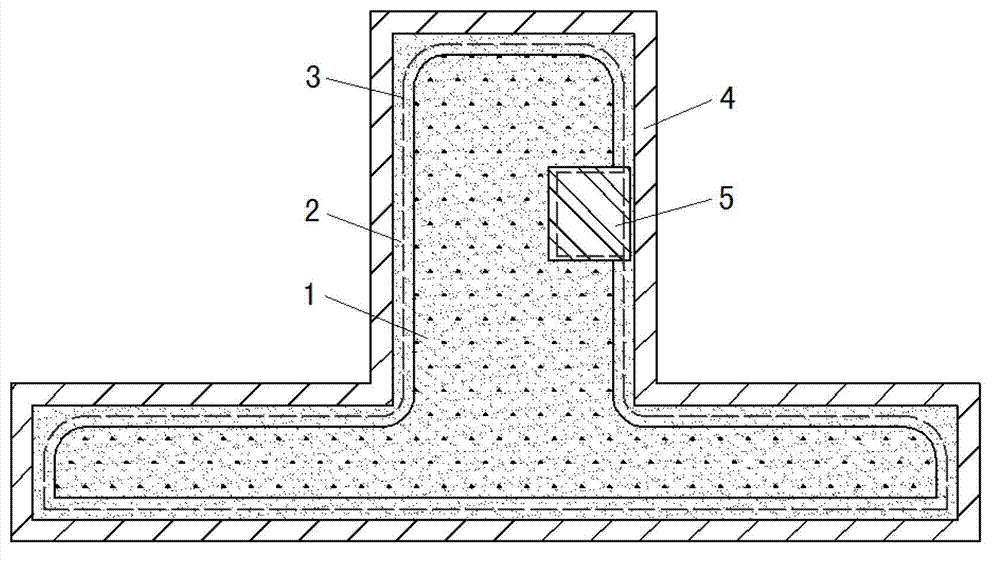

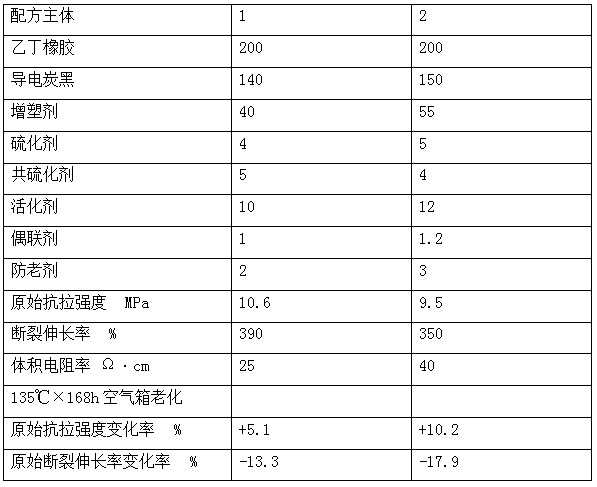

Semiconductor shielding cable material

ActiveCN102838801AGood filling effectImprove heat resistancePlastic/resin/waxes insulatorsShielded cableVulcanization

The invention relates to a semiconductor shielding cable material, and belongs to the technical field of cable materials. The semiconductor shielding cable material comprises the following components in parts by weight: 100 parts of butyl rubber, 50-120 parts of conducting carbon black, 20-45 parts of plasticizing agent, 1.0-6.0 parts of vulcanizing agent, 1.0-6.0 parts of co-vulcanizing agent, 1.0-10 parts of activating agent, 0.2-0.5 part of coupling agent, and 0.5-5.0 parts of anti-aging agent. The semiconductor shielding cable material has the advantages that the formula not only is low in cost, but also is simple in component; the butyl rubber with low cost, low viscosity and high fallibility is adopted as a base material, the vulcanization system matched with the butyl rubber is selected, and the conducting carbon black with good conductivity and processing performance is added, so that the defects of bad processing performance and high price in the prior art are overcome.

Owner:SICHUAN MINGXING CABLE

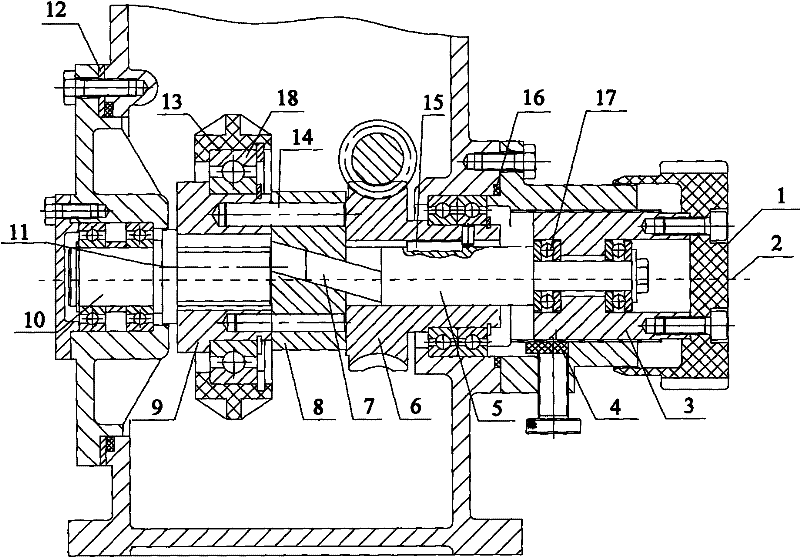

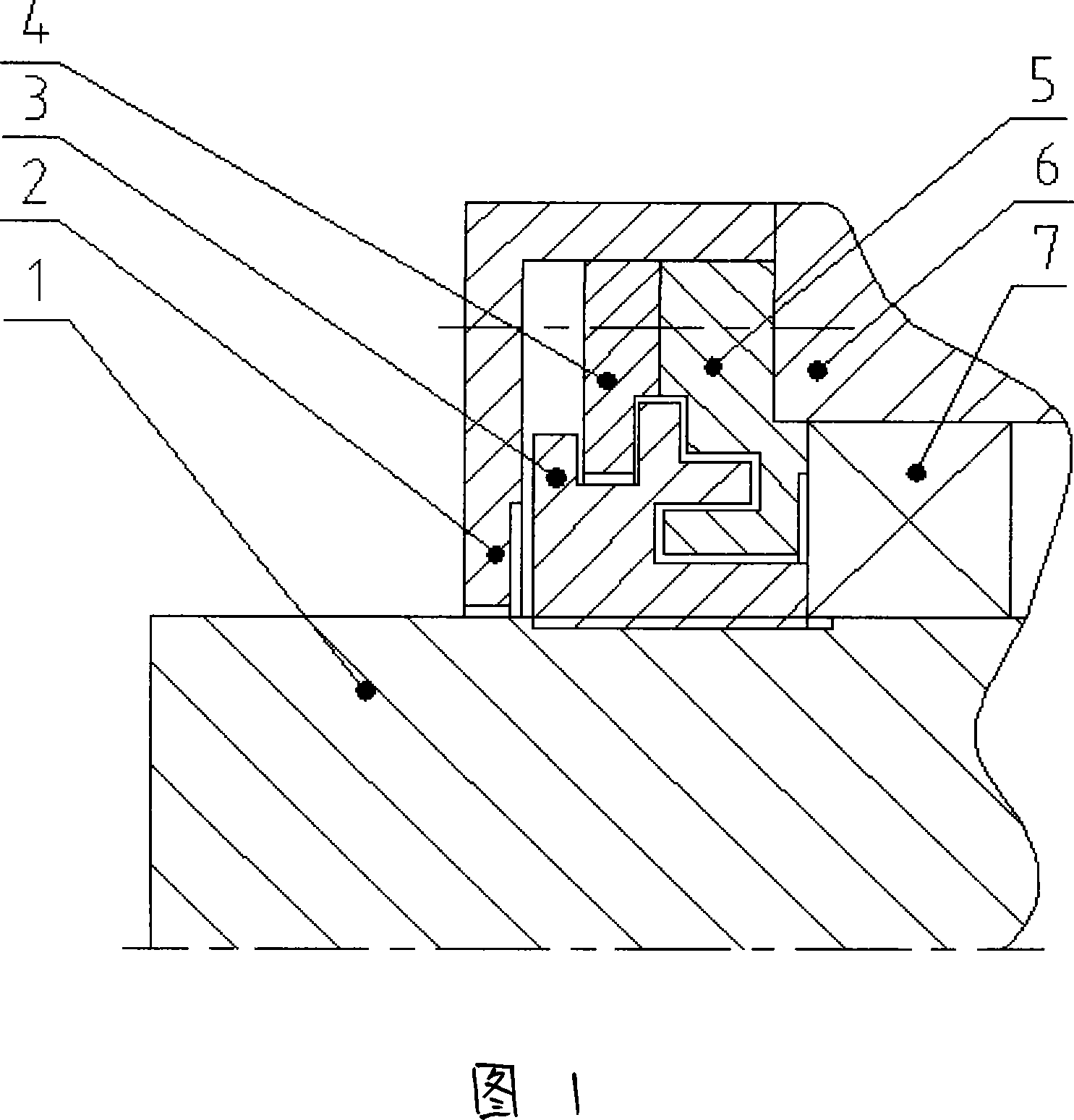

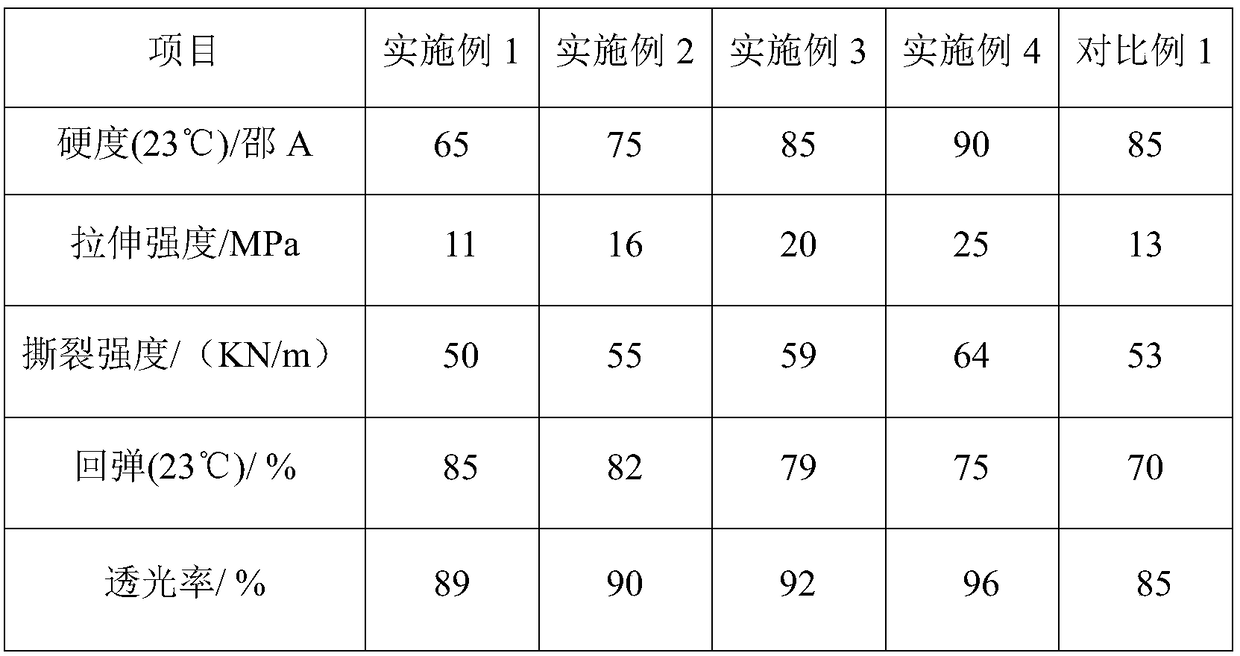

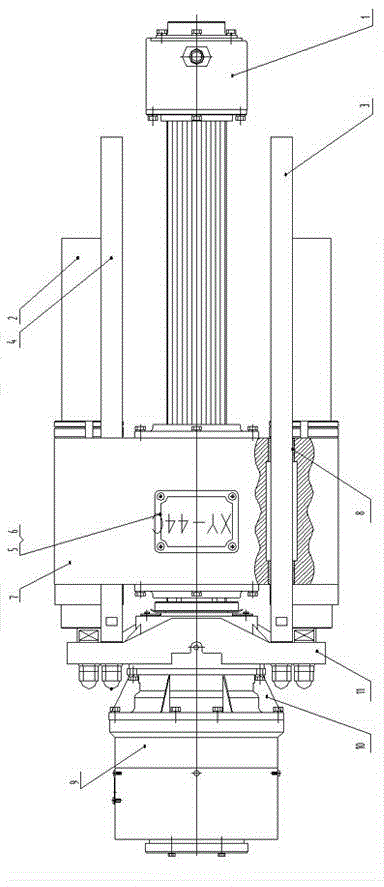

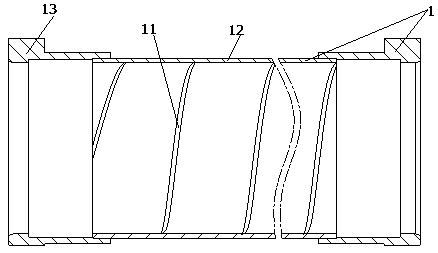

Sealing method for oil fog lubrication electric mainshaft bearing

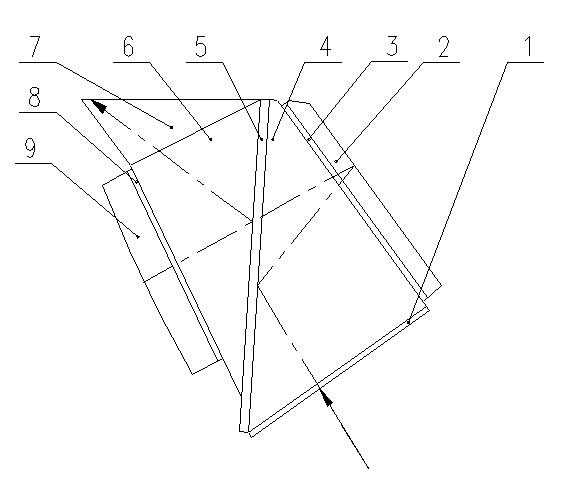

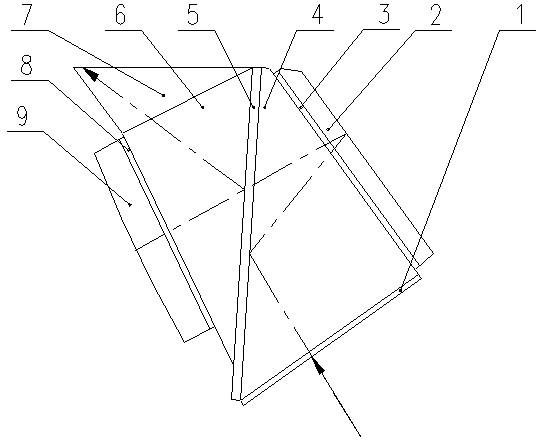

InactiveCN101216109ASimple structural designGood processing technologyEngine sealsBoring/drilling componentsEngineeringCentrifugal force

A sealing method used with an oil-mist lubricated electric main shaft bearing is provided. A front bearing 7 of the electric main shaft is sealed by the combination of larmier seal, small-clearance seal and labyrinth seal. A front screw cap 3 is designed with two water-throwing edges to form the larmier seal with strong blocking effect under the centrifugal action. The small-clearance seal is arranged between the front screw cap and a baffle 4, with a clearance diameter of 0.4-0.6 mm and an axial clearance of 0.5-1 mm, and the clearance size is defined by the basic size. The labyrinth seals formed by flexible joint planes are arranged between the front screw cap, the baffle and a front small cover 5, with a radial clearance less than 0.25 mm and an axial clearance less then 0.5 mm. Discharge holes are arranged below a dust-proof cover 2. The front bearing and a rotating shaft 1 are fixed on a front bearing seat 6. The rotating shaft 1 is locked by the front thread thereof. The baffle is fixed by bolt on the front small cover. The dust-proof cover is fixed by bolt on the front end of the baffle.

Owner:LUOYANG BEARING SCI & TECH CO LTD

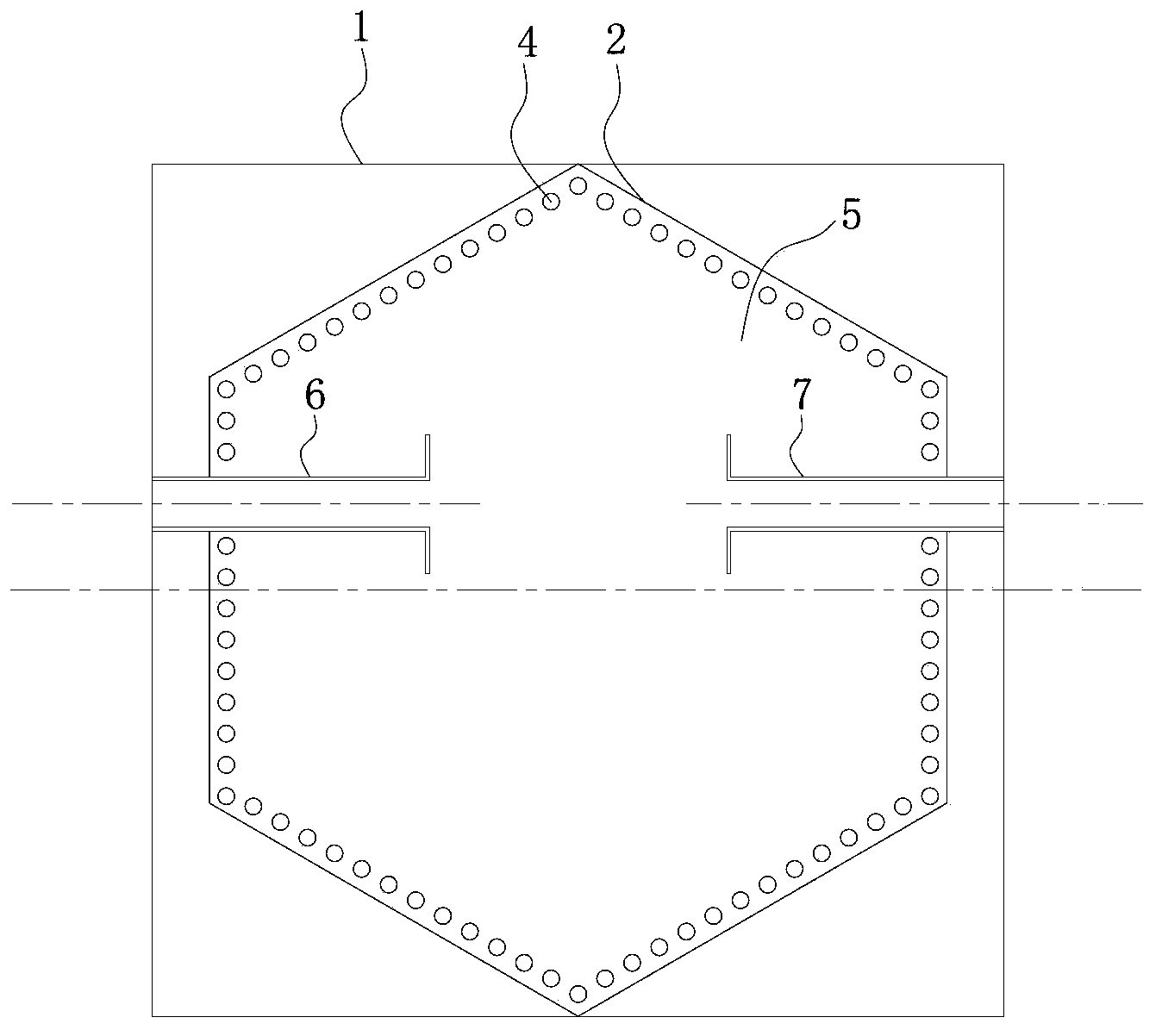

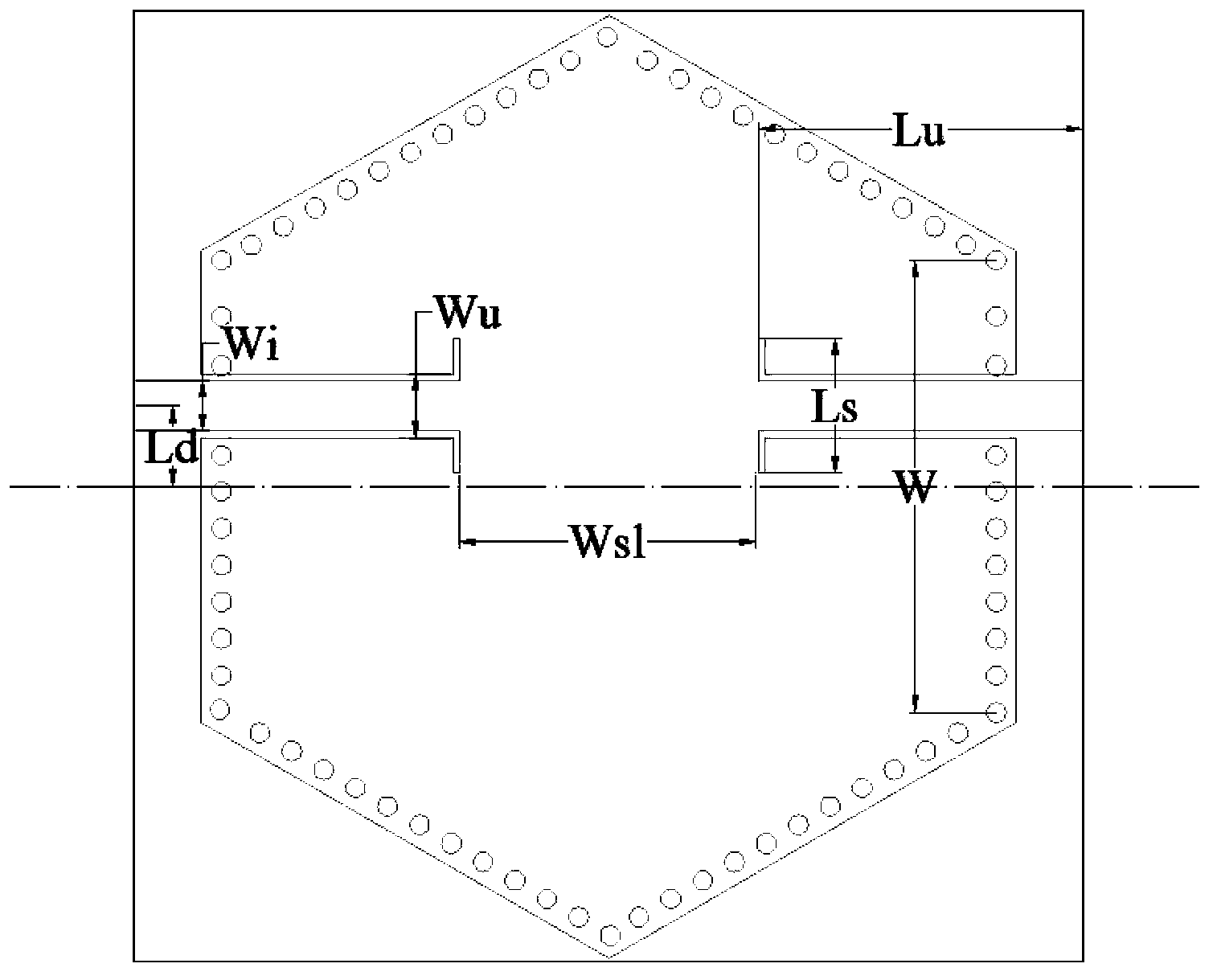

Single-cavity double-die hexagonal substrate integrated waveguide filter

The invention discloses a single-cavity double-die hexagonal substrate integrated waveguide filter which is high in selectivity, low in loss and small in size. The filter comprises a medium substrate, an upper surface metal layer and a lower surface metal layer, a metallized through hole array penetrating through the medium substrate is arranged on the medium substrate, the metallized through hole array, the upper surface metal layer and the lower surface metal layer define a double-die hexagonal resonant cavity together, an input end and an output end are arranged on the upper surface metal layer, the axis of the input end and the axis of the output end are parallel to the central axis of the double-die hexagonal resonant cavity and do not coincide with the central axis of the double-die hexagonal resonant cavity, two resonant modes of TM11 left leaning and TM11 right leaning of the resonant cavity can be triggered, and a transmission zero point and two poles can be led in. Therefore, the out-of-band selectivity of the filter can be improved without increasing the number of the levels of the filter, meanwhile, the size of the filter is reduced, losses are lowered, and the filter is suitable for being popularized and applied in the technical field of microwaves and millimeter waves.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Heatproof corrosion-resistant waterborne polyurethane paint

InactiveCN105385323AImprove curing effectGood mechanical propertiesAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPhosphoric acid

The invention discloses a heatproof corrosion-resistant waterborne polyurethane paint. The paint comprises the following raw materials by weight: 100 to 120 parts of waterborne polyurethane resin, 22 to 25 parts of bisphenol F type epoxy resin, 20 to 40 parts of novolac epoxy resin, 2 to 4 parts of bentonite, 1 to 3 parts of fumed silica, 12 to 15 parts of mica powder, 17 to 20 parts of calcined kaolin, 8 to 12 parts of heavy calcium carbonate, 22 to 25 parts of expanded perlite, 1 to 2 parts of magnesium oxide, 1 to 3 parts of aluminum triphosphate, 5 to 10 parts of zinc borate, 15 to 20 parts of magnesium hydroxide, 3 to 5 parts of a leveling agent, 5 to 8 parts of a dispersant, 2.5 to 4 parts of an antiseptic, 1 to 2 parts of an antifoaming agent, 1 to 2 parts of a wetting agent and 30 to 50 parts of water. The waterborne polyurethane paint has excellent heat resistance and corrosion resistance, good resistance to wear and water, superior flame resistance, strong adhesion and good curing performance.

Owner:NINGGUO LONGSHI METAL PROD CO LTD

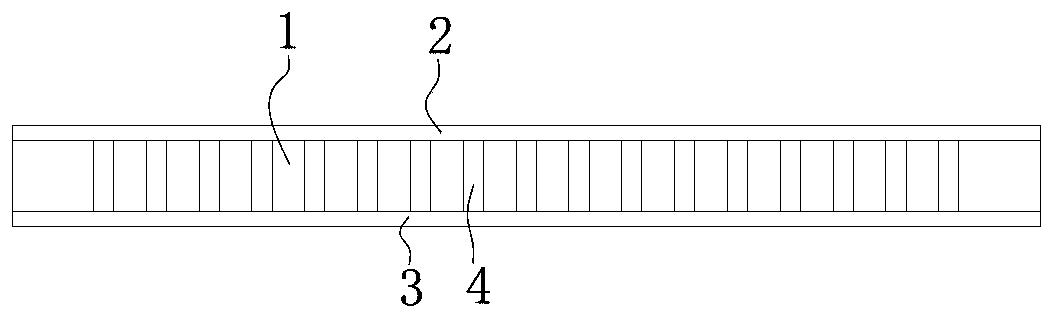

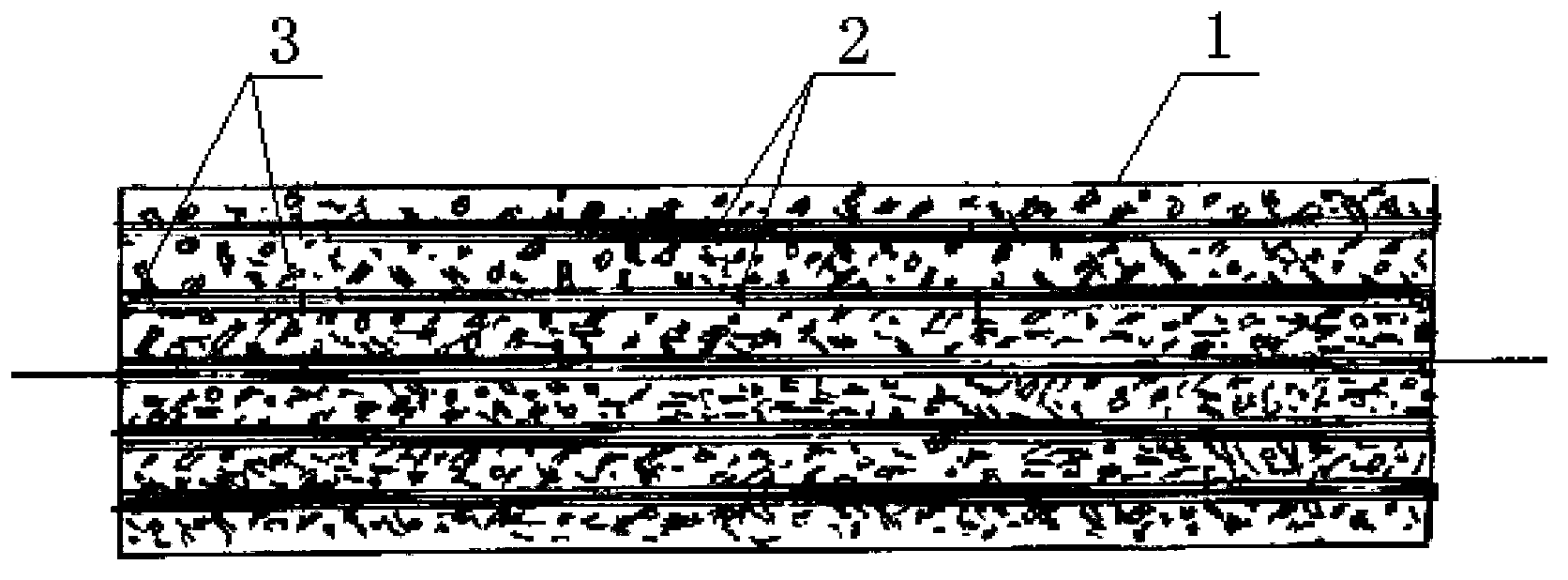

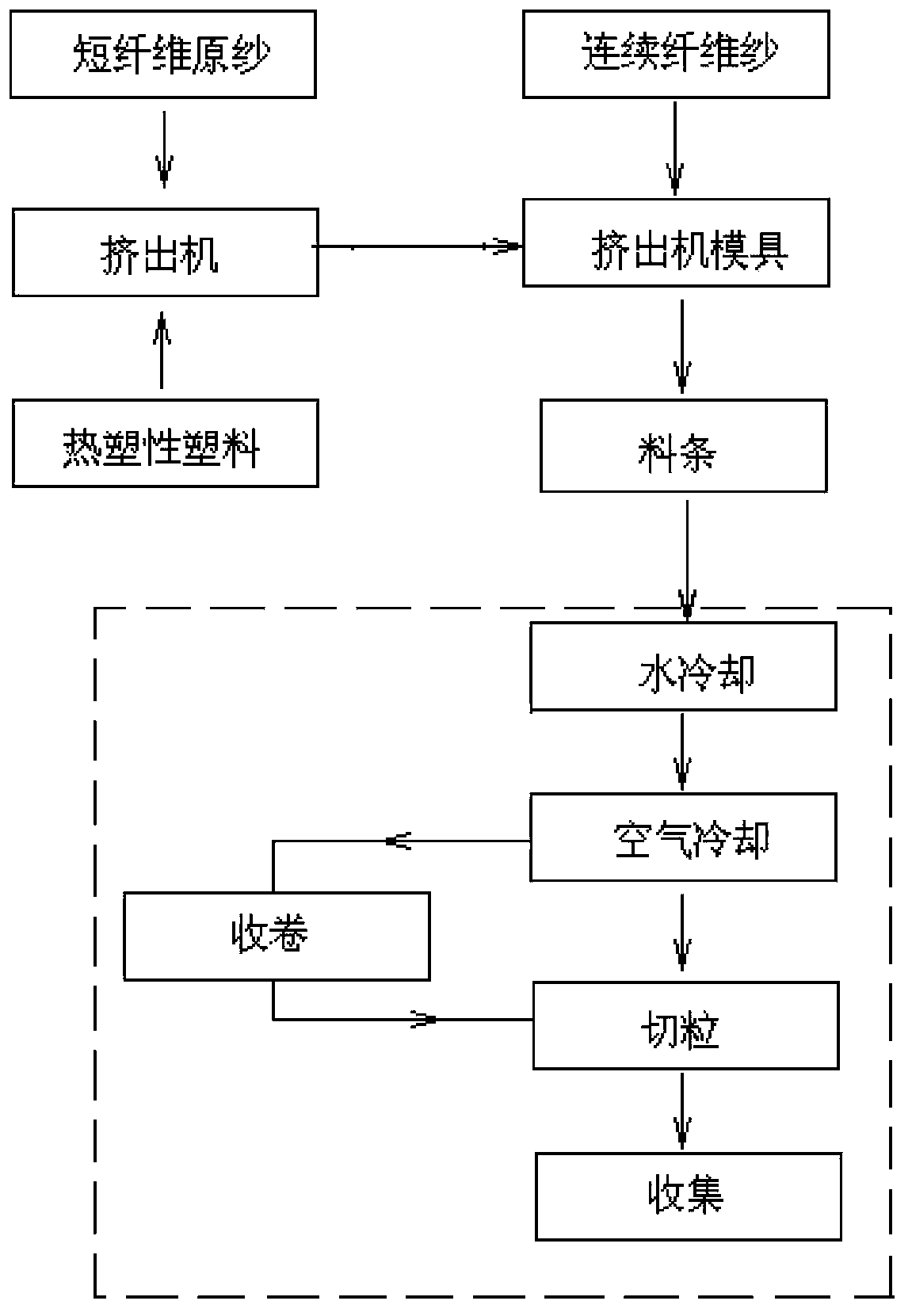

Long and short fiber composite strengthening thermoplastic plastic particle material and production method thereof

The invention discloses a long and short fiber composite strengthening thermoplastic plastic particle material and a production method thereof. The particle materials are composed of thermoplastic plastic substrate, strengthening long fibers and strengthening short fibers, wherein the strengthening long fibers have the same lengths as those of the particle materials, are parallelly distributed in the direction of particle material axis, and the short strengthening fibers are randomly and astatically distributed in the particle materials. Two strengthening fibers exist in the particle materials at the same time, namely the strengthening long fibers with the same lengths as those of the particle materials and the strengthening short fibers, which are randomly distributed in the particle materials, with different lengths. Therefore the particle materials integrate the strong mechanical property of the long fiber particle material LFT and the good processing technology property of the short fiber particle material SFT together. Furthermore, the ratio of the long fiber to short fiber in the particle materials can be adjusted through the technology to produce products with different mechanical properties and processing technology properties.

Owner:JURONG BASTEP COMPOSITE MATERIALS

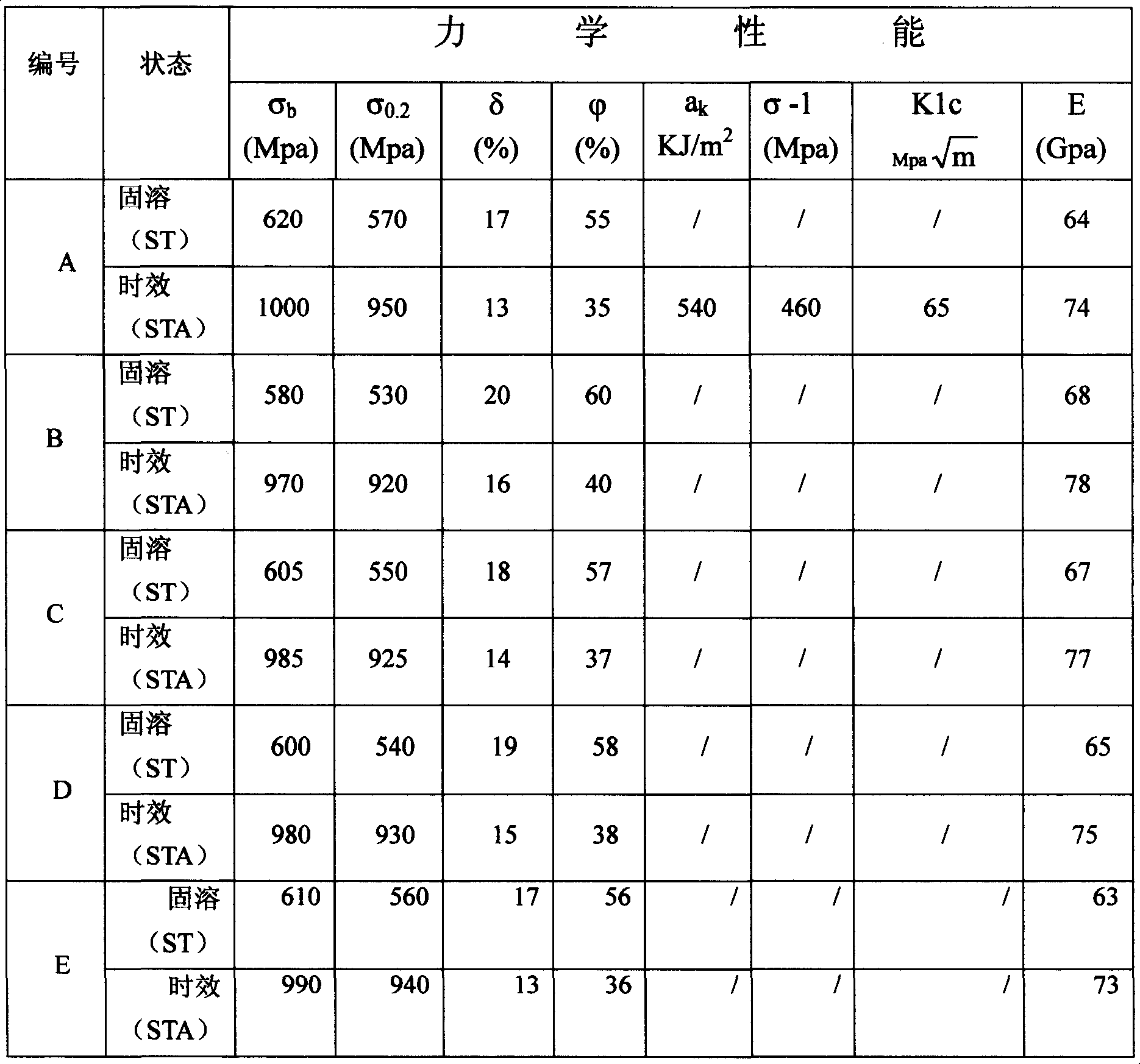

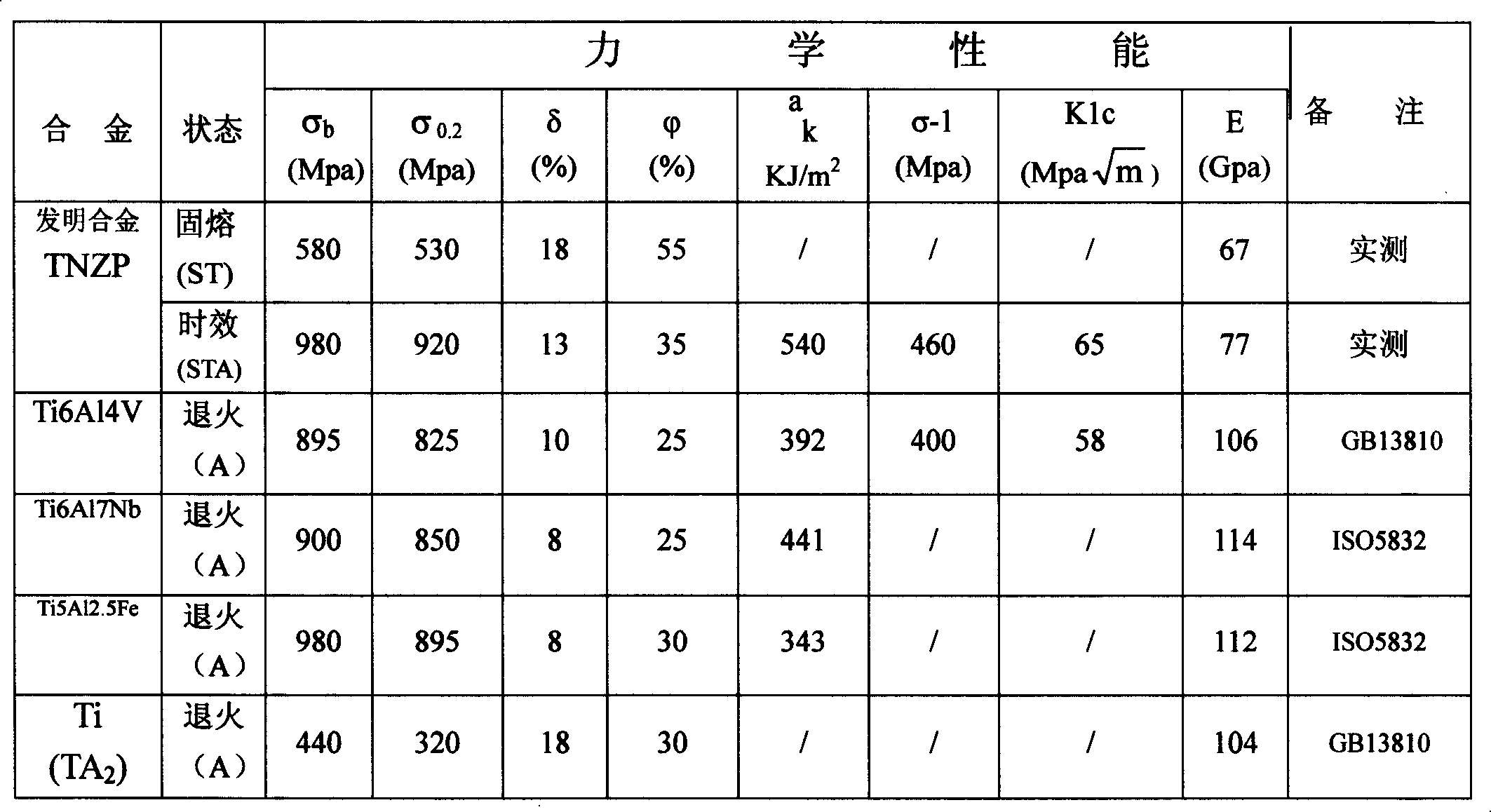

Medical used titanium alloy for surgery implantation material

InactiveCN1569250AGood biocompatibilityImprove biomechanical compatibilityProsthesisBiomechanicsNiobium

The invention discloses an alloy material characterizing in that it is composed of titanium(Ti), niobium(Nb), zirconium(Zr) and palladium(Pd). The weight percentages of the components are as follows: Nb 22-32%, Zr 4-12%, Pd 0.1-0.2%, Ti(the rest). The advantages of the product provided by the invention over the prior part are as follows: 1. favorable biocompatibility 2.low elastic modulus(30%-35%), better biomechanics compatibility 3. favorable comprehensive mechanical properties, wherein, the impact toughness(a#-[k]) is as high as 40%, the endurance limit(ªÊ#-[-1]) is as high as 12%, the fracture toughness(K#-[1]c) is high as 10% 4. better processing properties, the heat processing temperature is as low as 150íµí½200íµ, the expansion rate (ª€)is as high as 30%, the shrinkage rate after cut(ªŽ) is as high as 40%. 5.excellent corrosion proof property: the corrosion velocity is less than 0.0001mm / a in normal saline

Owner:DALIAN SUNNY TITANIUM IND

Inner liner sizing material for semi-steel-wire radial ply tire

InactiveCN102492230AGood processing technologyNo air tightnessSpecial tyresPolymer sciencePrecipitated calcium carbonate

The invention relates to an inner liner extrusion sizing material produced by applying novel modified synthetic rubber instead of airtight rubber to a semi-steel-wire radial ply tire. Key points are that: the inner liner extrusion sizing material is prepared from a plurality of raw materials in a formula including natural rubber (No.SMR20#), chlorinated butyl rubber (CIIR1066), styrene-butadiene rubber (SBR1712), modified chlorosulfonated rubber (CSM), zinc oxide, magnesium oxide, stearic acid, precipitated calcium carbonate, resin (RT-40FE) serving as a homogenizing agent, an anti-ageing agent (RD), carbon black (N660), an accelerant NS, an accelerant TBzTD, insoluble sulfur IS-6005 and a vulcanizing agent WP5.

Owner:SICHUAN TYRE & RUBBER CO LTD

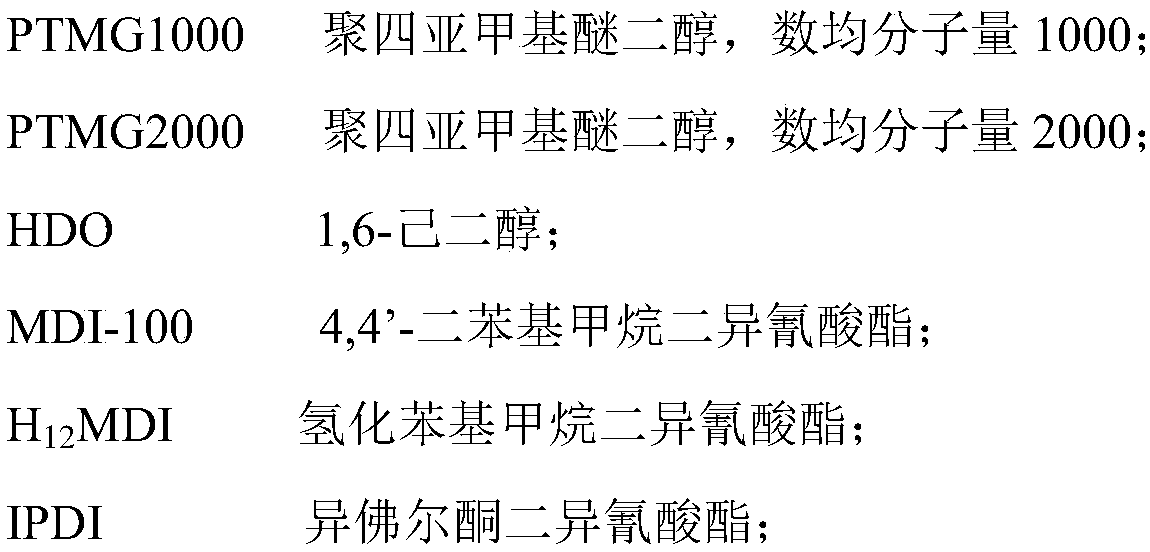

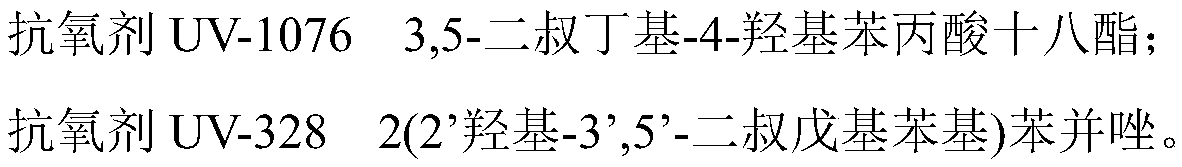

Preparation method of high-permeability and high-elastic polyurethane elastomer

The invention relates to a preparation method of a high-permeability and high-elastic polyurethane elastomer and belongs to the technical field of polyurethane application. The preparation method of the high-permeability and high-elastic polyurethane elastomer comprises the steps of preserving PTMG, HDO, a catalyst and an antioxidant in a sealed manner after uniformly mixing the PTMG, the HDO, thecatalyst and the antioxidant under a room temperature condition according to a certain mass ratio; enabling the PTMG to react with isocyanate for 2-3 hours at 80-85 degrees centigrade, wherein the vacuum degree is larger than or equal to -0.095 MPa; obtaining a polyurethane prepolymer component with isocyanate content of 8.5-13.2%; controlling a polymer component and the polyurethane prepolymer component at a temperature of 60-80 degrees centigrade to be mixed; after uniformly mixing the polymer component and the polyurethane prepolymer component according to a ratio of (40-100):100, pouringan obtained mixture into a mold at the temperature of 70-90 degrees centigrade; and opening the mold after 30-45 minutes to obtain the high-permeability and high-elastic polyurethane elastomer. The high-permeability and high-elastic polyurethane elastomer prepared with the preparation method of the high-permeability and high-elastic polyurethane elastomer, provided by the invention, has the advantages that the transparency is relatively high, the rebound resilience is relatively high, the yellowing resistance is relatively high, and demands of the market on the high-permeability and high-elastic polyurethane elastomer are met.

Owner:SHANDONG INOV POLYURETHANE

Transmission with two clutches and two intermediate shafts

InactiveCN103867656AReduce axial sizeGood processing technologyToothed gearingsGearing detailsEngineeringClutch

The invention relates to a transmission with two clutches and two intermediate shafts. The transmission comprises the two clutches, a solid input shaft, a hollow input shaft, the two intermediate shafts and an output shaft, wherein the left ends of the coaxially designed solid input shaft and hollow input shaft are respectively connected with the two clutches, the right ends of the solid input shaft and the hollow input shaft are respectively connected with normally engaged gears in the transmission, the transmission has twelve speed states comprising five low-speed forward gears, five high-speed forward gears and two reverse gears, driving gears connected with the solid input shaft are simultaneously engaged with corresponding driven gears on the two intermediate shafts with relatively small transmission degree for forming the five high-speed forward gears and a high-speed reverse gear of the transmission, and driving gears connected with the hollow input shaft are simultaneously engaged with corresponding driven gears on the two intermediate shafts with relatively large transmission degree for forming the five speed-speed forward gears and a low-speed reverse gear of the transmission. An auxiliary box of the existing transmission with two intermediate shafts is omitted, the structure of the transmission is more compact, the axial size of the whole transmission is reduced, and the weight of the main body of the transmission is reduced by 5%-20%.

Owner:HEFEI UNIV OF TECH +1

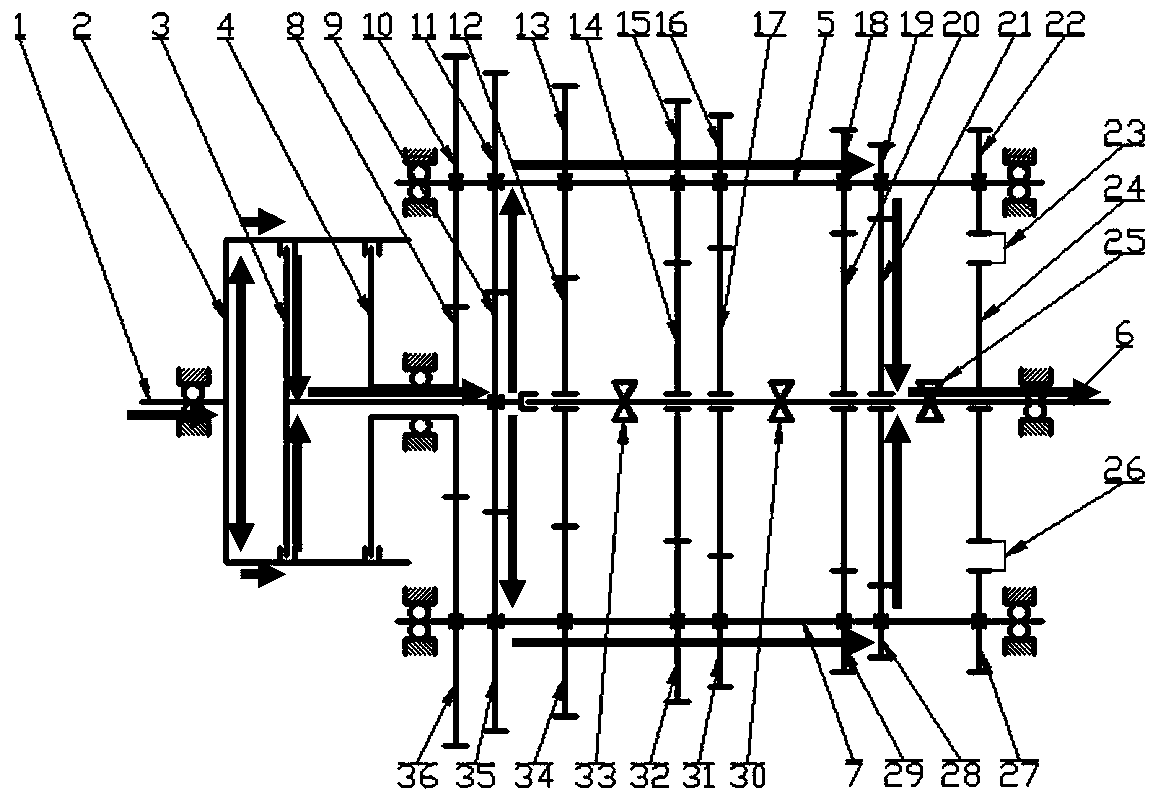

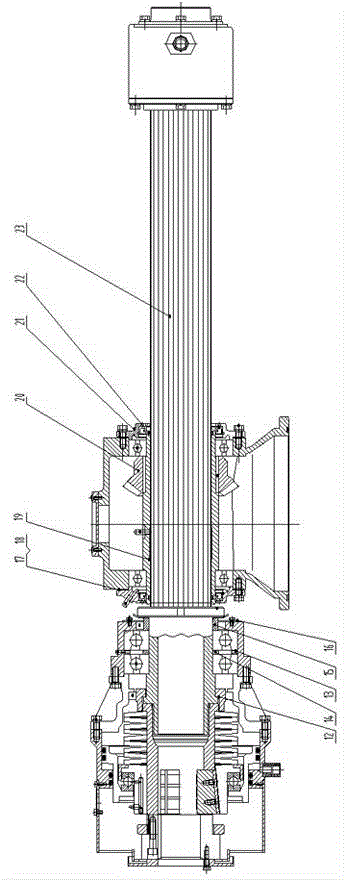

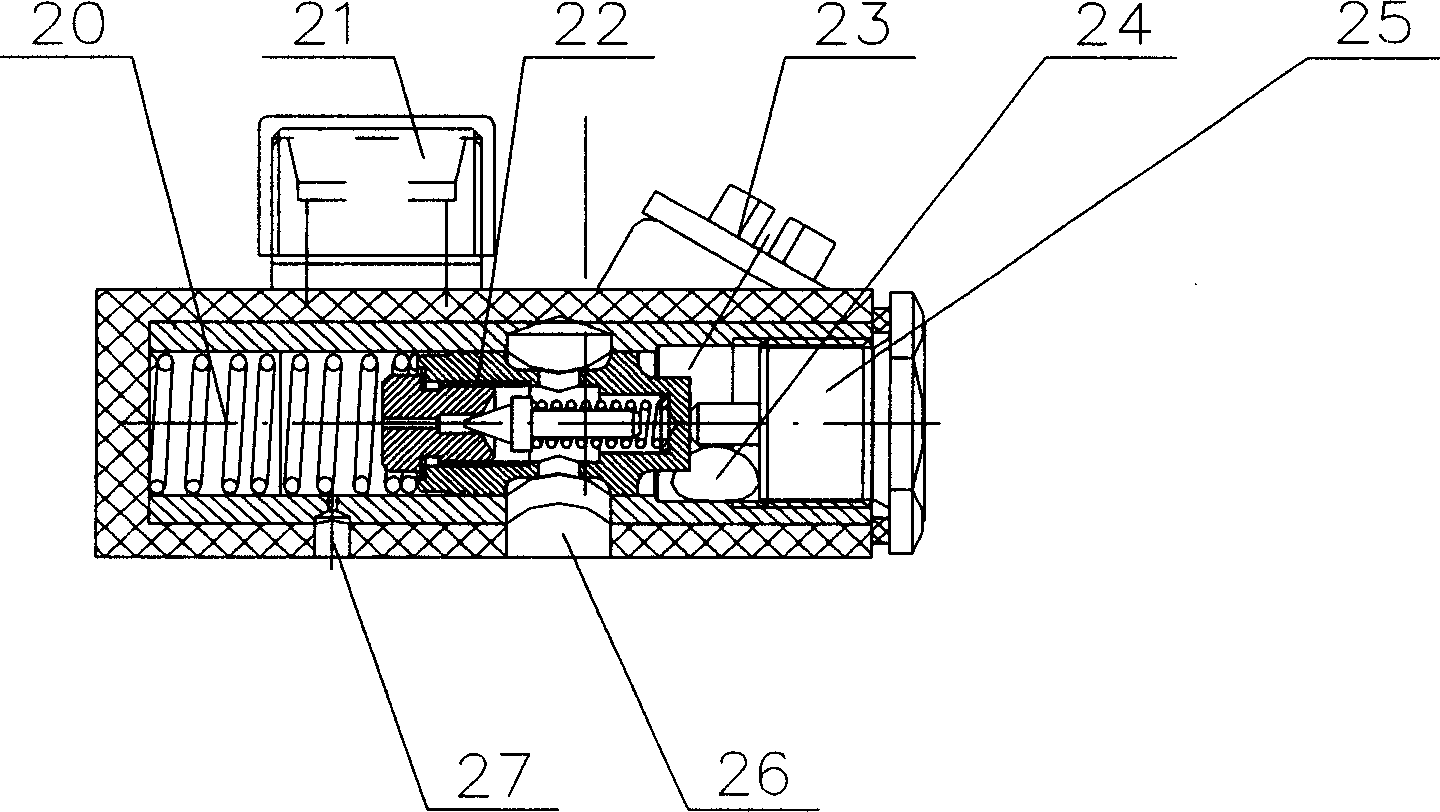

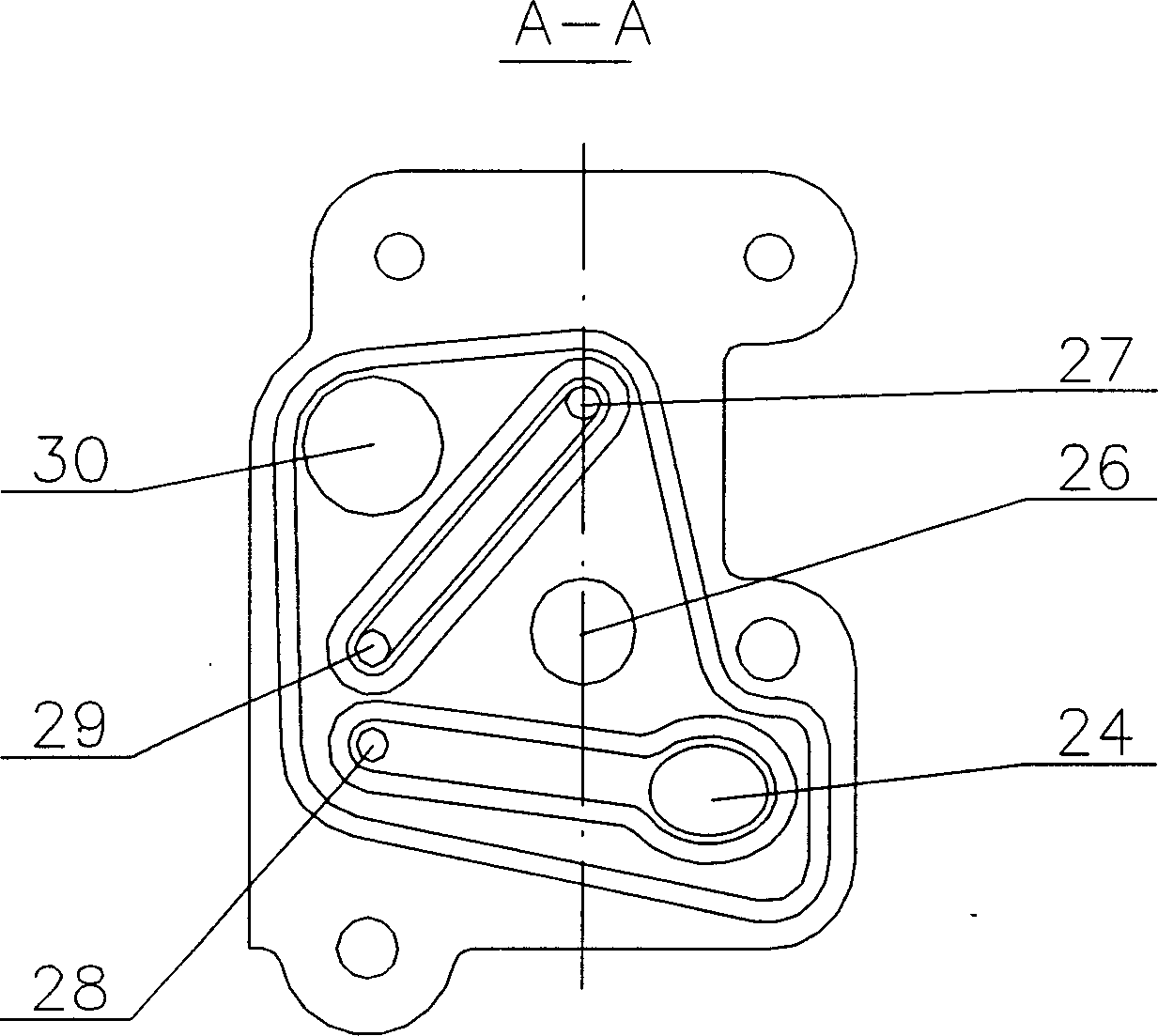

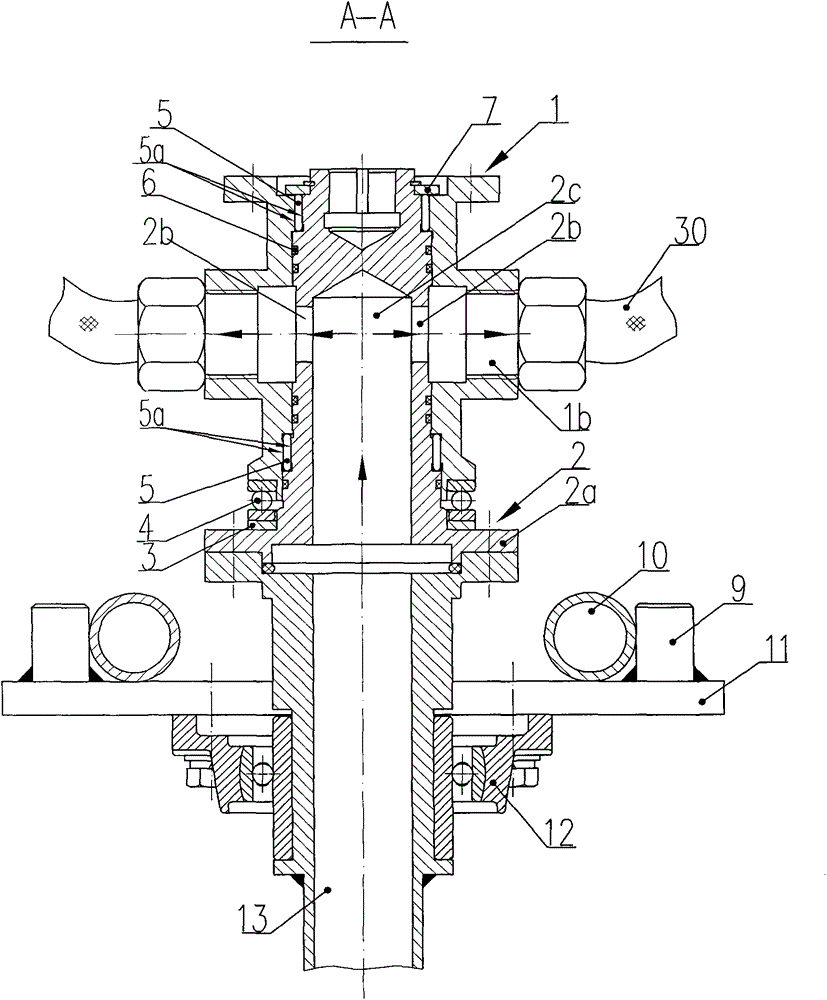

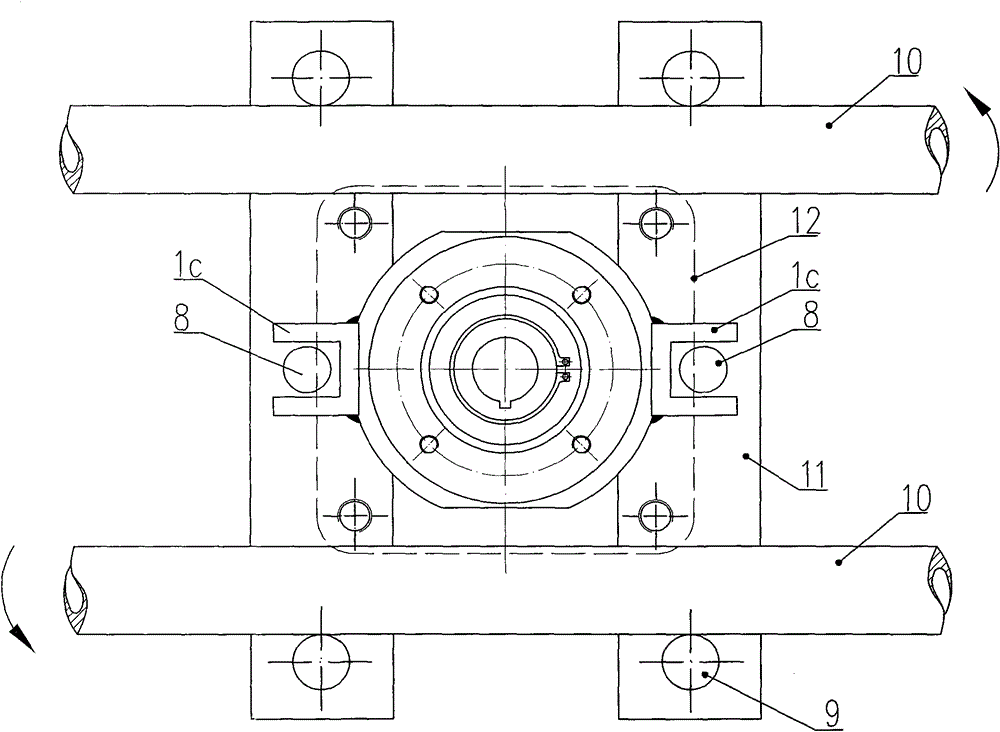

Power head of vertical shaft type rock core drilling machine

InactiveCN102943616AGood processing technologyAvoid poor processing technologyConstructionsReciprocating drilling machinesTransfer caseBatch production

The invention provides a power head of a vertical shaft type rock core drilling machine. The power head comprises a power head shell which is connected with a transfer case, wherein compression and decompression oil cylinders are arranged at left and right sides of the power head shell; a vertical shaft guide pipe is arranged in the power head shell in the vertical direction; the vertical shaft guide pipe is internally provided with a vertical shaft; the upper end of the vertical shaft is connected with a hydraulic clamping disc; a pressing beam is arranged between the upper side of the vertical shaft and the hydraulic clamping disc; the left and right ends of the pressing beam are downward and are connected with the compression and decompression oil cylinders; left and right guide rods are downward arranged at the front part of the pressing beam; the power head shell has a guide hole which is matched with the left and right guide rods to play the guiding role; a middle transmission section of the vertical shaft is cylindrical and a columnar surface of the middle transmission section of the vertical shaft is provided with an outer involute spline; an inner involute spline which is matched with the vertical shaft for transmission is arranged on the inner wall of the vertical shaft guide pipe; and the machining process performance of an involute spline vertical shaft is good, the guide precision is high, the drilling precision is correspondingly improved and a clamped grinding phenomenon is not generated. The power head has the advantages that the service life is greatly prolonged, the power head is suitable for large-batch production, the forming of a complete set is rapid, and the like.

Owner:LIANYUNGANG TIANMING EQUIP

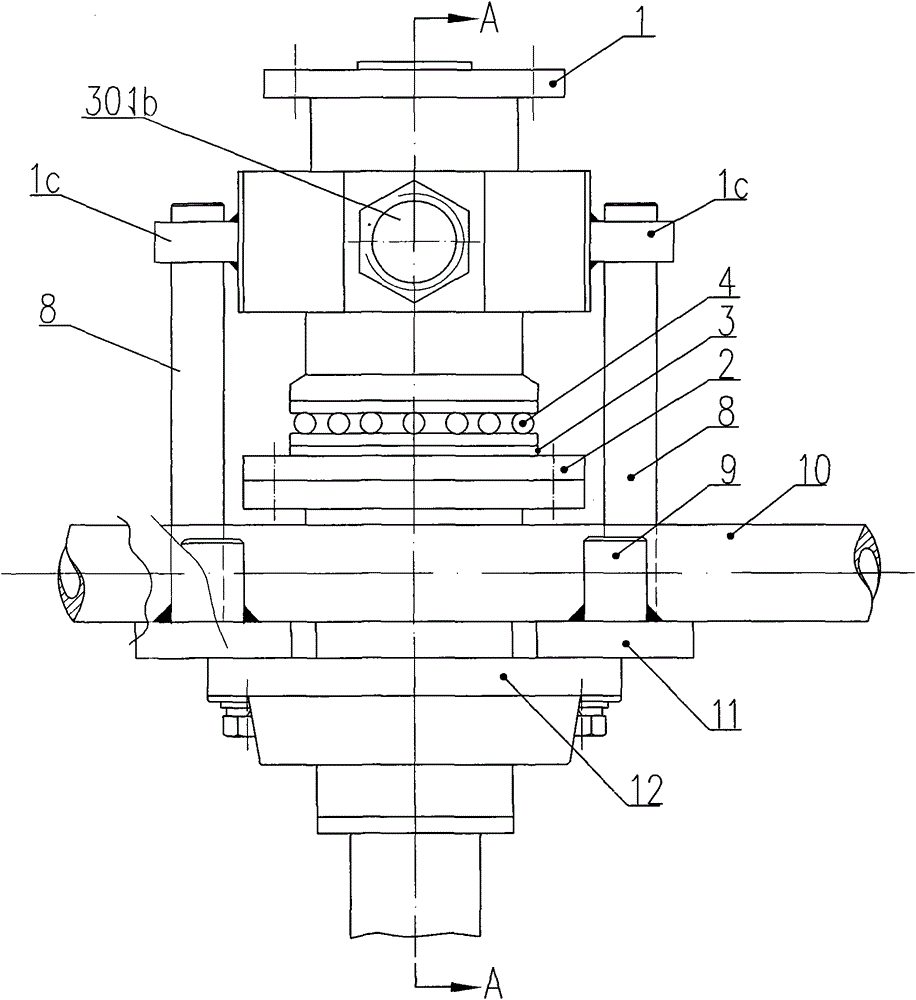

Power steering oil pump for automobile

InactiveCN1500992AImprove shock absorptionGood processing technologyRotary piston pumpsRotary piston liquid enginesPower steeringStator

The power steering oil pump for automobile includes pump body, valve body, pump cover, transmission member and inner pump cavity. The inner pump cavity includes oil inlet pressure board, oil outlet pressure board, stator, rotor, vane and spring; the valve body has slide valve, screw plug and spring as well as oil inlet and oil outlet on the upper end; the transmission member is connected via the valve shaft and the rotor inside the inner pump cavity; and there are skeleton oil sealing between the pump body and the pump shaft and O-ring on the oil outlet pressure board inside the inner pump cavity. The present invention features the separate plastic molding of and screw connection among the pump body, pump cover and valve body; planar connection between the pump cover and the valve body; pump body oil path set interface plane between the pump cover and the valve body; parting of the pump cover and the valve body at the low pressure oil cavity and high pressure cavity formed by the pump cover and the inner cavity parts.

Owner:一汽光洋转向装置有限公司

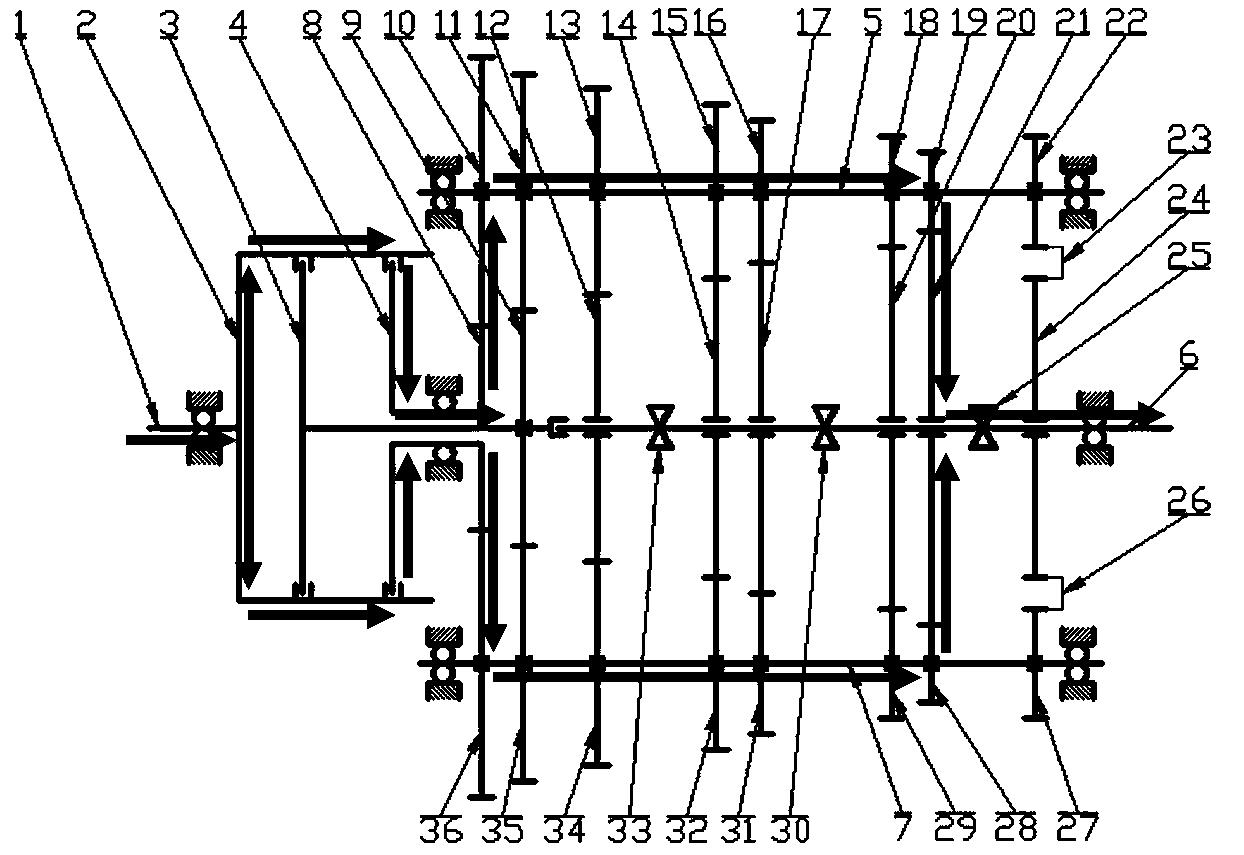

Rotary joint for connecting pipeline system

ActiveCN103982724AGood processing technologyGood strengthAdjustable jointsPipe elementsEngineeringStressed state

The invention discloses a rotary joint for connecting a pipeline system. The rotary joint comprises an outer sleeve, wherein the outer sleeve is axially and vertically arranged, the outer sleeve is provided with an outer sleeve through hole, and the outer sleeve is connected with a rotary driving mechanism; the upper end of a center shaft is inserted in an outer sleeve inner hole in a sealing and hinging way, the lower end of the center shaft is provided with a blind hole, the side wall of the blind hole is provided with a center shaft through hole, and the center shaft through hole is communicated with the outer sleeve through hole and the blind hole; pressure bearings are arranged between an end surface flange at the lower end of the center shaft and the end surface of the outer sleeve. The rotary joint disclosed by the invention has the beneficial effects that the defect of the prior art is overcome, the axis of the rotary joint is vertically arranged, the weight of the outer sleeve and a connecting piece is borne by the pressure bearings, a raceway does not deform, the abrasion during a working process is reduced, the outer sleeve and the center shaft are enabled to be in a good stress state and a long-term hinging state, the service life of the rotary joint is prolonged, the normal work of the rotary joint is ensured, the running efficiency is increased, the raceway is annular, the processing technology is good, and the cost is low.

Owner:天津市长龙宏业燃气设备有限公司

Method for producing and processing aged Tie Guanyin tea

InactiveCN105851277AUnique qualityEasy to storePre-extraction tea treatmentClimate change adaptationSunstrokesNatural state

The invention discloses a method for producing and processing aged Tie Guanyin tea. The method includes the steps of selecting raw materials, conducting the primary processing process, achieving balance of moisture of raw tea through re-firing, keeping activity of tea leaves and storing the tea leaves by entering a cellar. The tea can be kept for 10 years or above in the natural state, the tea leaves are naturally oxidized during storage, and the formed aged tea has good quality and special health-care effects. According to tea production and processing, strict requirements need to be met from the raw materials in the method, and the whole process is the optimal production and processing process through proof of long-term practices. The produced aged Tie Guanyin tea is unique in quality, smooth, mellow and sweet in taste, light in color, yellow-red in color, lasting in aroma and obvious in stale flavor, and has the effects of preventing sunstrokes, decreasing internal heat and the like.

Owner:连建设

Green energy-saving wearproof cold-resistant and flame retardant thermoplastic rubber and preparation method thereof

The invention discloses a green energy-saving wearproof cold-resistant and flame retardant thermoplastic rubber and a preparation method thereof. An SIBR / PP / SBS / TPU polymer composite system, wearproof, loss reduction factor and good cold-resistant assistant materials and a halogen-free and antimony-free compound flame-retardant system are adopted as the main components, and preparation of SIBR masterbatch, silane modification treatment of a flame retardant, high-speed mixing pre-plasticization, internal mixer and extruder combined dynamic vulcanization and other processes are carried out. Under the conditions of an internal mixer rotation speed of 40rpm and a temperature of 160DEG C-165DEG C, dynamic vulcanization is carried out for 2-3min, then dynamic vulcanization by an extruder is conducted, and under the conditions of a screw rotation speed of 50-70rpm and a temperature of 165DEG C-180DEG C, dynamic vulcanization is conducted for 5-7min so as to obtain the thermoplastic rubber. Inaddition to the basic performance of thermoplastic rubber, the thermoplastic rubber provided by the invention also has excellent energy-saving, environmental protection, flame retardant, cold-resistant and other properties, and at the same time has the advantages of simple process, easy manufacturing, and low production cost.

Owner:ANHUI ZHONGYI RUBBER BELTS

Waxy corn chicken fermented sausage

The invention discloses a waxy corn chicken fermented sausage which comprises main materials and auxiliary materials by mass percent, wherein the main materials comprise waxy corn, pig backfat and chicken according to a ratio of (5-15): (15-25): (70-80); the auxiliary materials comprise 1% of glucose, 1.5% of sucrose, 4% of a fermenting agent and 0.06% of a tenderizing agent based on the total amount of the main materials. The chicken is rich in various amino acids necessary for a human body, the fat substances of the chicken contain a large amount of monounsaturated fatty acids and polyunsaturated fatty acids, the cholesterol intake of consumers is reduced, the sausage is relatively rich and relatively balanced in nutrition due to calcium, magnesium, selenium, vitamins A and E, glutathione and unsaturated fatty acids in the waxy corn, carbon sources are provided for fermentation to facilitate bacterial growth, and the tenderizing agent can be used for improving the mouth feel of the sausage.

Owner:ANHUI SCI & TECH UNIV

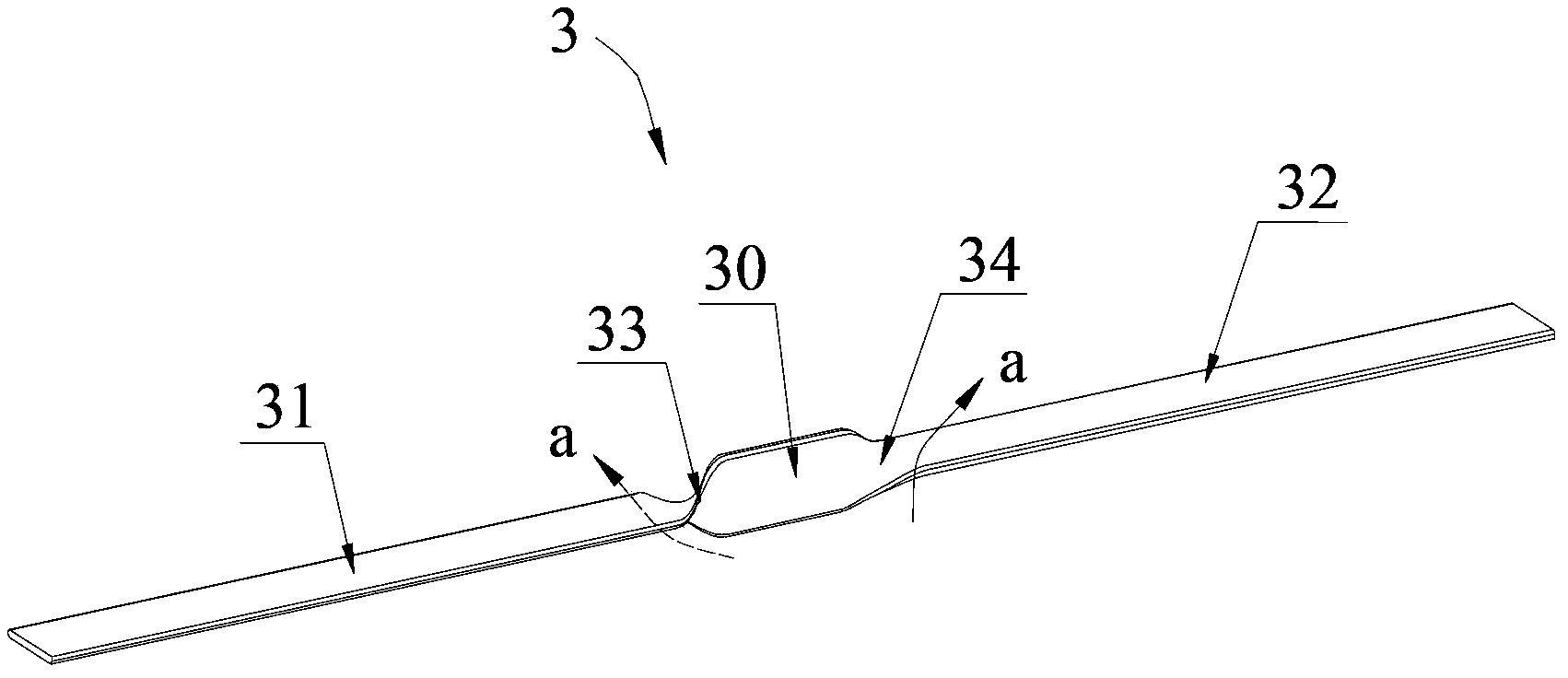

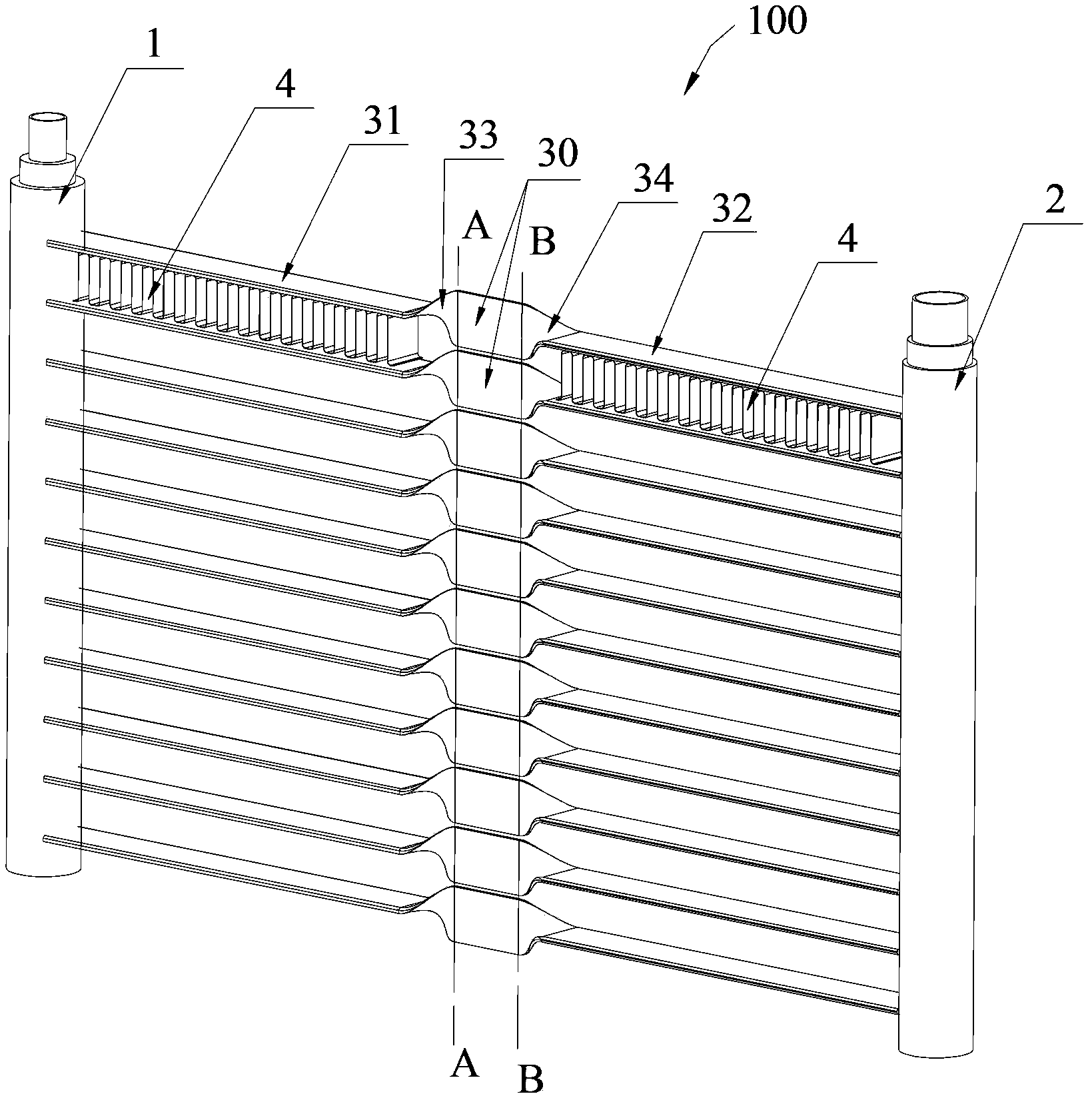

Heat exchanger and manufacturing method thereof

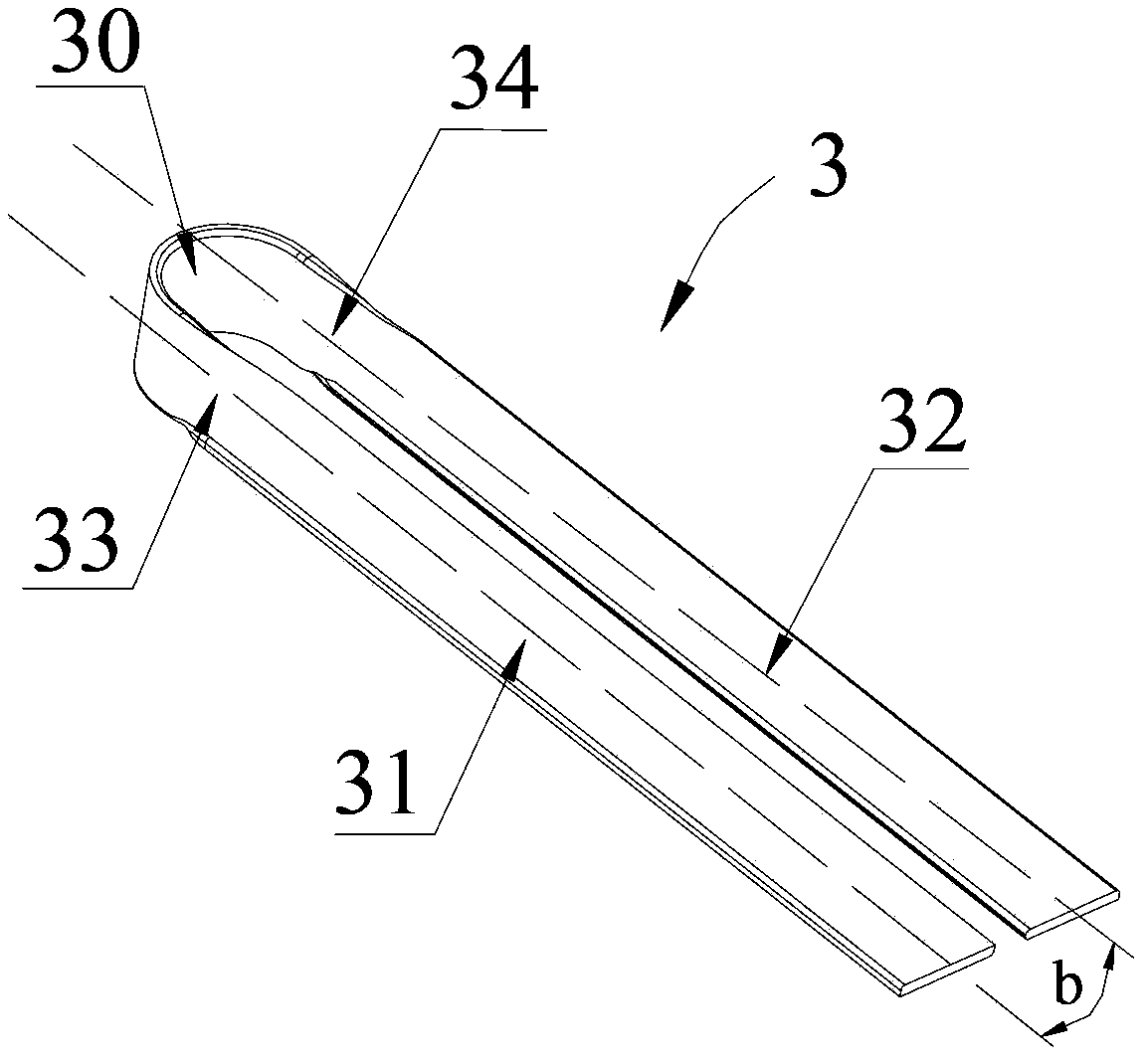

InactiveCN104344745AGood processing technologySimple processing technologyStationary conduit assembliesTubular elementsEngineeringHeat exchanger

Provided are a heat exchanger (100) and a machining method for the heat exchanger. The heat exchanger (100) comprises a first header pipe (1), a second header pipe (2), several flat pipes (3) and several fins (4). The flat pipe (3) comprises an intermediate part (30), a first straight part (31) twisted relative to the intermediate part (30), a second straight part (32) twisted relative to the intermediate part (30), a first twist part (33) connecting the intermediate part (30) and the first straight part (31), and a second twist part (34) connecting the intermediate part (30) and the second straight part (32). The first straight part (31) and the second straight part (32) are respectively positioned at the two sides of the intermediate part (30) and roughly positioned in the same plane. Fins (4) are welded between adjacent first straight parts (31), and fins (4) are welded between adjacent second flat and straight parts (32).

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

Optical path folding system based on polarization beam splitter plate and wave zone plates

InactiveCN102590997ACompact and reasonable structureGood processing technologyOptical elementsPolarizerOptical path

The invention discloses an optical path folding system based on a polarization beam splitter plate and wave zone plates, which is composed of a polarizer, a first prism, a first wave zone plate, a reflector, the polarization beam splitter plate, a second prism, a second wave zone plate, a collimator objective and a third prism. The collimator objective is adhered with the second wave zone plate and then adhered with the second prism, the polarization beam splitter plate is adhered with the first prism and then adhered with the polarizer, the reflector is adhered with the first wave zone plate, and the collimator objective, the polarization beam splitter plate and the reflector are respectively adhered with the third prism. All the components of the optical path folding system are made of cheap and common glass K9 materials which can be purchased easily, the optical path folding system is compact and reasonable in structure, good in processing technology and simple in assembling process and achieves the aim of being light in integral design.

Owner:河南平原光电有限公司

High-voltage direct-current glass insulator

The invention discloses a high-voltage direct-current glass insulator which comprises a glass part, wherein the glass part comprises the following chemical components in percentage by weight: 65-72% of silicon oxide, 2-4% of aluminum oxide, 6-9% of calcium oxide, 2-5% of magnesium oxide, 1-3% of barium oxide, 7-12% of sodium oxide, 3-9% of potassium oxide and no more than 1% of lithium oxide; and the insulating property of the glass part is as follows: the volume resistivity is not lower than 10<13> ohm.cm at 50 DEG C, is not lower than 10<10> ohm.cm at 90 DEG C, is not lower than 10<9> ohm.cm at 120 DEG C and is not lower than 10<8> ohm.cm at 150 DEG C. According to the invention, the volume resistivity of the glass part can meet the requirements of the high-voltage direct-current power transmission glass part for insulating property: the volume resistivity is not lower than 10<13> ohm.cm at 50 DEG C, is not lower than 10<10> ohm.cm at 90 DEG C, is not lower than 10<9> ohm.cm at 120 DEG C and is not lower than 10<8> ohm.cm at 150 DEG C; and the glass part has favorable processing property and is suitable for industrial production.

Owner:三瑞科技(江西)有限公司

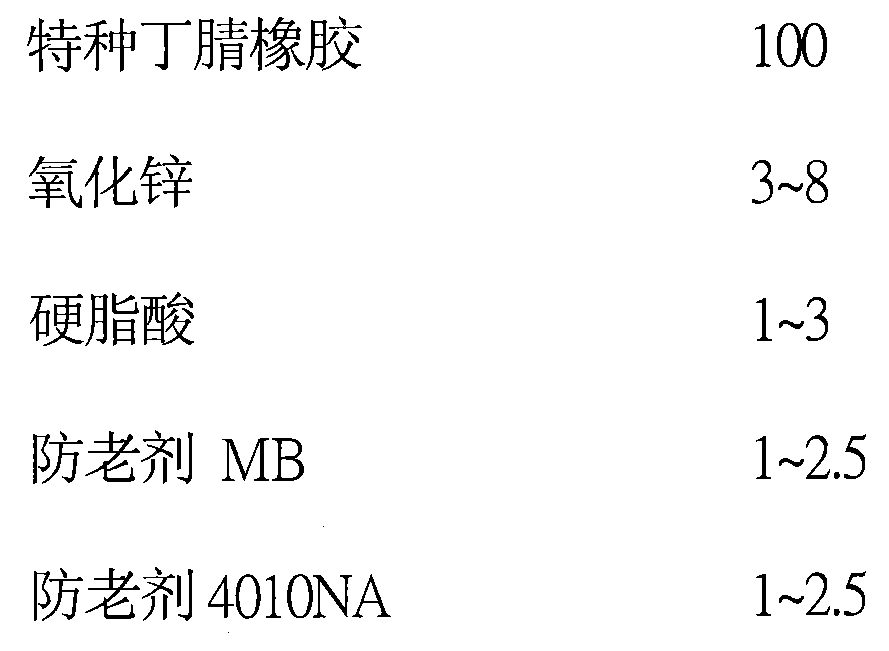

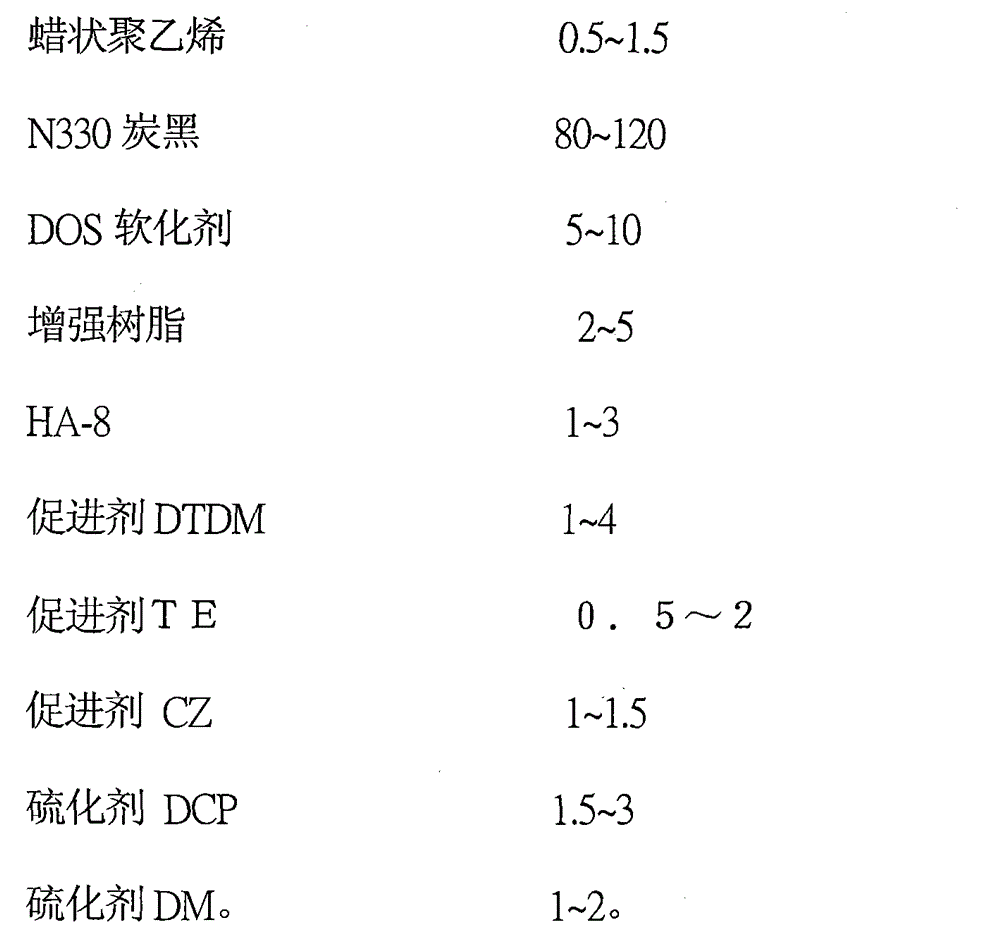

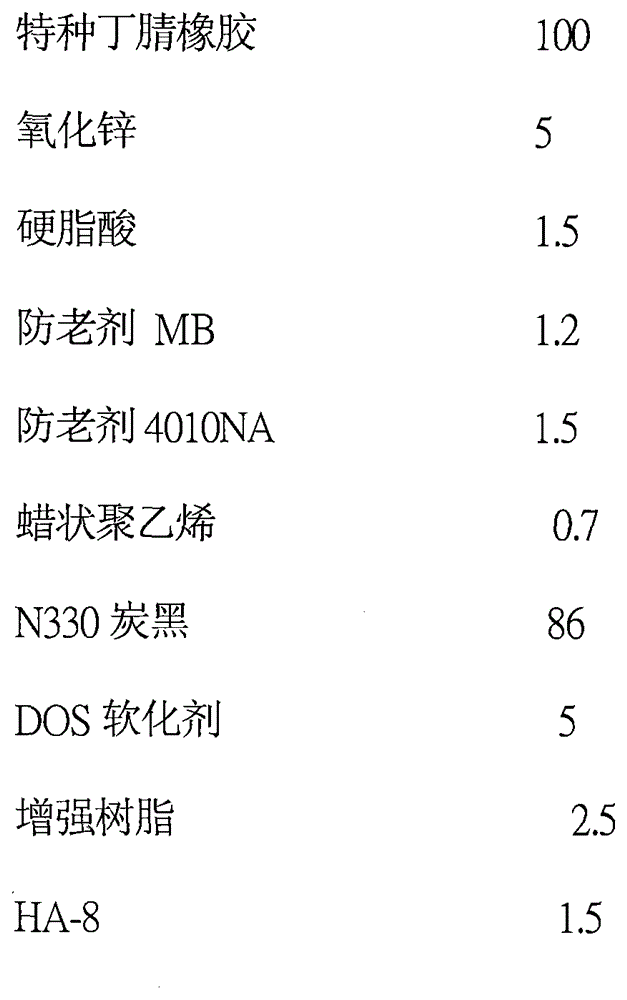

Preparation process of ultralow-temperature-resistant mixing material

The invention relates to a preparation process of an ultralow-temperature-resistant mixing material. A rubber compound, which is resistant to minus 50 DEG C and has an excellent processing property, is suitable for mold pressing vulcanization molding. Special buna-N rubber is adopted as a base material, carbon black N330 is taken as a filler, reinforced resin, wax-shaped polyethylene and HA-8 are taken as modifying agents, DOS is taken as a softening agent, and meanwhile an appropriate amount of anti-aging agents 4010NA and MB, active agent zinc oxide and stearic acid as well as vulcanizating agents DCP, DTDM, CZ, DM and TE are taken as ingredients, so that the ultralow-temperature-resistant mixing material is formed through compounding, smelting and cooking. The ultralow-temperature-resistant mixing material has the performance advantages and practicability that firstly, a sealing element produced by using the ultralow-temperature-resistant mixing material can meet the sealing performance requirements of coal mine hydraulic support upright columns and jacks and is normally used under the condition of minus 50 DEG C; secondly, the ultralow-temperature-resistant mixing material is good in processability in production and higher in product percent of pass, and the production cost is relatively reduced; thirdly, the performance of the ultralow-temperature-resistant mixing material accord with the HG / T 3326-2007 standard.

Owner:XIANYANG KELONG SPECIAL RUBBER PROD

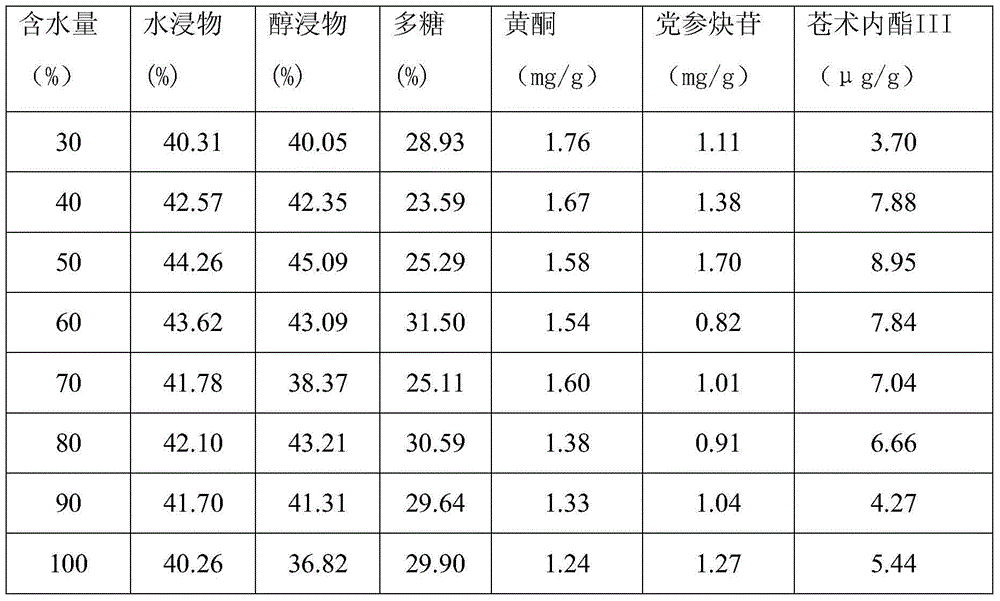

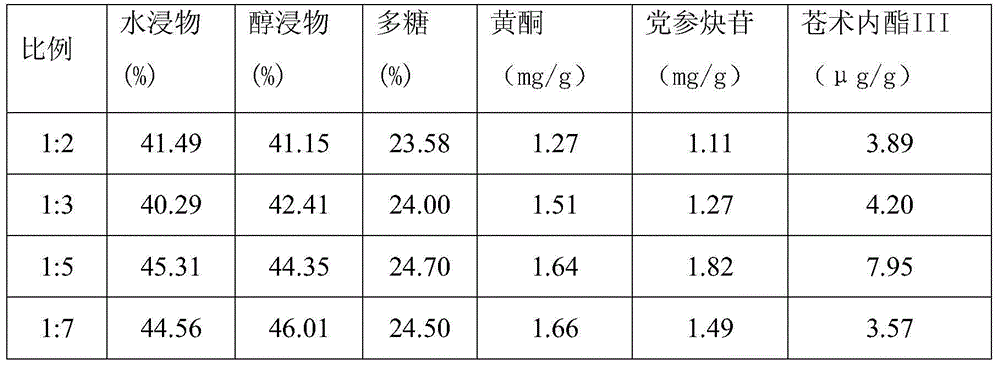

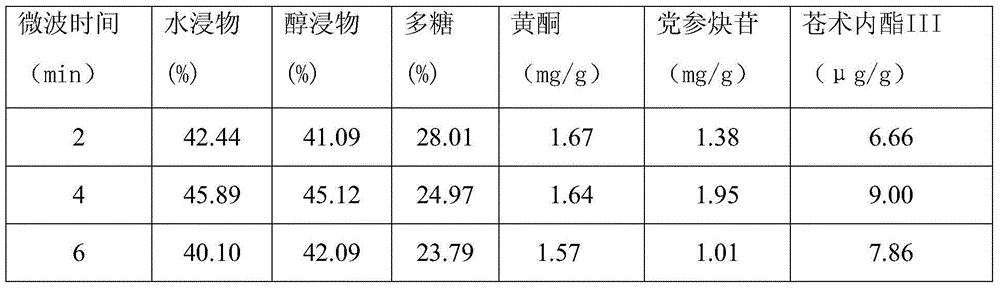

Preparation method for stir-fried codonopsis pilosula decoction pieces with rice

ActiveCN104906166ASimple processing methodQuality improvementPlant ingredientsHeating timeMicrowave oven

The invention discloses a preparation method for stir-fried codonopsis pilosula decoction pieces with rice. The preparation method for the stir-fried codonopsis pilosula decoction pieces with rice includes the steps that fresh codonopsis pilosula is cleaned and then aired to be of a certain water content, the codonopsis pilosula is cut into slices and mixed with rice, the codonopsis pilosula is moistened through the rice and absorbs water, the mixture is heated in a microwave oven, dried and sieved, and then the stir-fried codonopsis pilosula decoction pieces with rice can be obtained. The preparation method for the stir-fried codonopsis pilosula decoction pieces with rice has the advantages that compared with an existing rice stir-frying process, the codonopsis pilosula medicinal materials do not need to be dried in advance or moistened with water when cut, so that the labor loss and the loss of effective constituents are greatly reduced; the fresh medical materials are cut when reaching the water content of 50%, thus, only a little fluid can flow out, and the medical materials can be easily cut. Meanwhile, the medical material slices make full contact with the rice before being stir-fried with the rice, on one hand, the rice will absorb water in the medical materials, and on the other hand, no water needs to be added in the stir-frying process. By means of the microwave drying method, the heating time is greatly shortened. The heating temperature and time are controllable in the drying process. The preparation method for the stir-fried codonopsis pilosula decoction pieces with rice largely reduces the operation steps, shortens the operation time, is more efficient and realizes quantitative control over the process.

Owner:LANZHOU FOCI PHARM CO LTD

High-temperature-resistant ablation-resistant ceramic mineral filled oxygen-isolating material for cables, and preparation method thereof

The invention relates to a preparation method of a high-temperature-resistant ablation-resistant ceramic mineral filled oxygen-isolating material for a cable, wherein the high-temperature-resistant ablation-resistant ceramic mineral filled oxygen-isolating material for the cable comprises a flame retardant, a smoke suppressant, ceramic powder A, ceramic powder B, a binder, a coupling agent, a lubricant, an antistatic agent, a demolding agent and a thickener. According to the invention, the preparation process is simple and easy to operate, wherein the raw materials are highly and uniformly mixed, the binder is added according to a certain proportion, mixing is performed, and surface extrusion is performed by using a single-screw extrusion process; and the high-temperature-resistant ablation-resistant ceramic mineral filled oxygen-isolating material is mainly used for a medium-low voltage cable filling layer, is excellent in flame-retardant effect, low in smoke density and high in curing strength, can form a compact ceramic product in a high-temperature environment, and can effectively protect the internal structure of a cable.

Owner:BAOSHENG SCI & TECH INNOVATION

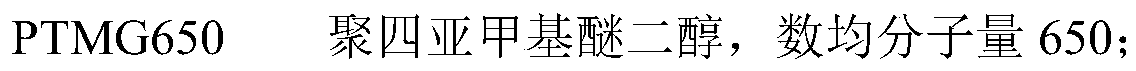

Preparation method of polyurethane elastomer with adjustable hardness

The invention belongs to the technical field of polyurethane application, and particularly relates to a preparation method of a polyurethane elastomer with adjustable hardness. The polyurethane elastomer with adjustable hardness is prepared from the following three components: a component A which is formed by mixing polytetrahydrofuran ether polyol with a catalyst; a component B which is a prepolymer obtained by reacting polytetrahydrofuran ether polyol with diisocyanate; and a component C obtained after a chain extender is dehydrated until the moisture content is less than or equal to 0.03%.The component A and the component C are premixed to serve as a curing agent component, then the component B and the curing agent component are mixed and poured into a mold, the mold is opened, and vulcanization is conducted to obtain the polyurethane elastomer. The hardness-adjustable polyurethane elastomer prepared by the method overcomes the defects that the existing polyurethane elastomer is high in viscosity, a catalyst is easy to layer with an alcohol curing agent and the like, has obvious advantages in the aspects of resilience, wear resistance and mechanical properties, and further widens the hardness range of the polyurethane elastomer.

Owner:SHANDONG INOV POLYURETHANE

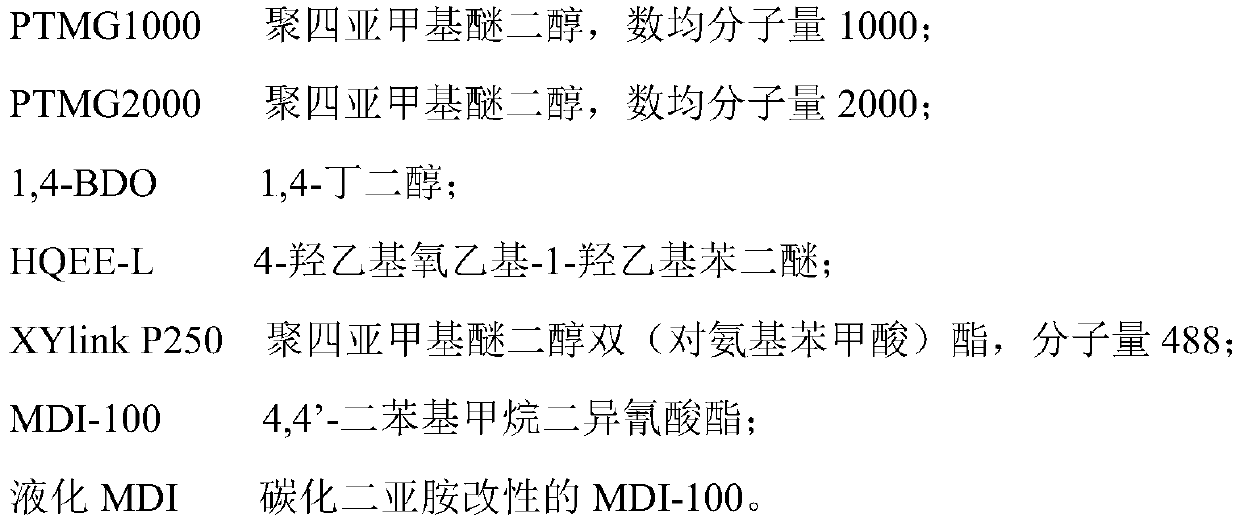

Buoyancy adjusting device

ActiveCN109501987AConvenient and efficient buoyancy adjustmentGood buoyancy adjustmentUnderwater vesselsUnderwater equipmentEngineeringFlange

The invention discloses a buoyancy adjusting device and aims to provide the buoyancy adjusting device capable of quickly draining water. The buoyancy adjusting device comprises a cabin body, an air bag positioned in the cabin body, a front cover arranged at one end of the cabin body, and a rear cover; the cabin body comprises a shell and flanges, wherein the inner wall of the shell is provided with a spiral drainage groove, and the flanges are arranged at two ends of the shell; the air bag comprises a pipe body made of rubber, an air inlet end which is in liquid-tight connection with a pipe body and is close to the front cover, and a water inlet end which is in liquid-tight connection with the pipe body and is close to the rear cover; an air inlet groove is arranged at one end of the air inlet end facing the outside of the pipe body, and a vent hole communicated with the pipe body is arranged at the bottom of the air inlet groove; the inner end of the front cover is provided with an air inlet inner ring which is hermetically connected with the air inlet groove, and the outer end of the front cover is provided with an air inlet and outlet joint which is communicated with the vent hole and is used for air inlet and outlet; the inner end of the front cover is arranged on an air inlet outer ring which is in fluid-tight fit with the inner wall of the shell, and a front gap is formedbetween the air inlet outer ring and the adjacent end surface of the air inlet joint.

Owner:云南昆船机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com