Preparation process of ultralow-temperature-resistant mixing material

A technology for ultra-low temperature and mixing rubber, which is applied in the field of preparation of ultra-low temperature resistant mixing rubber, can solve the problems of inapplicability in severe cold areas, etc., and achieves the effects of excellent processing technology, reduced production cost, oil resistance, water resistance and metal corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

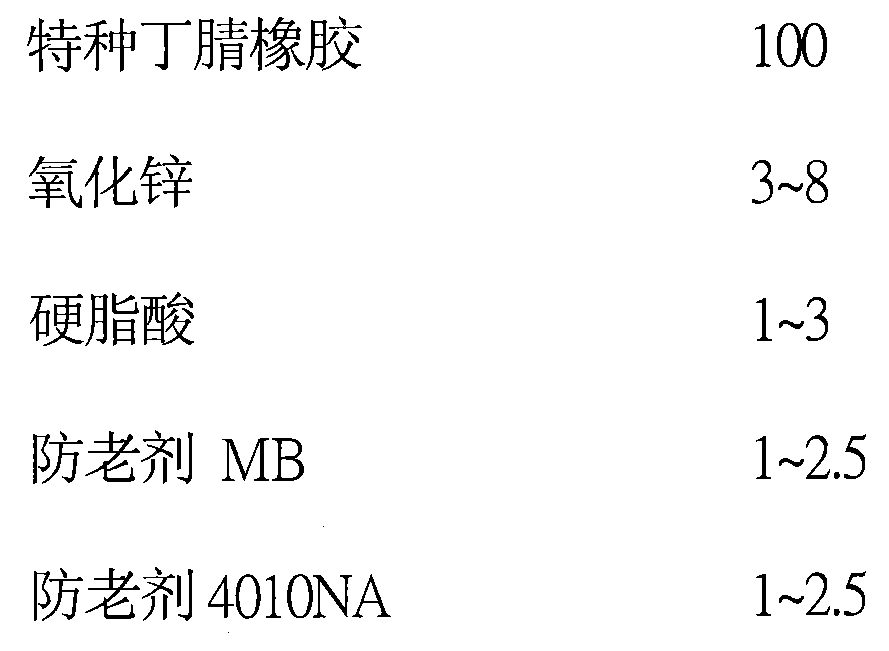

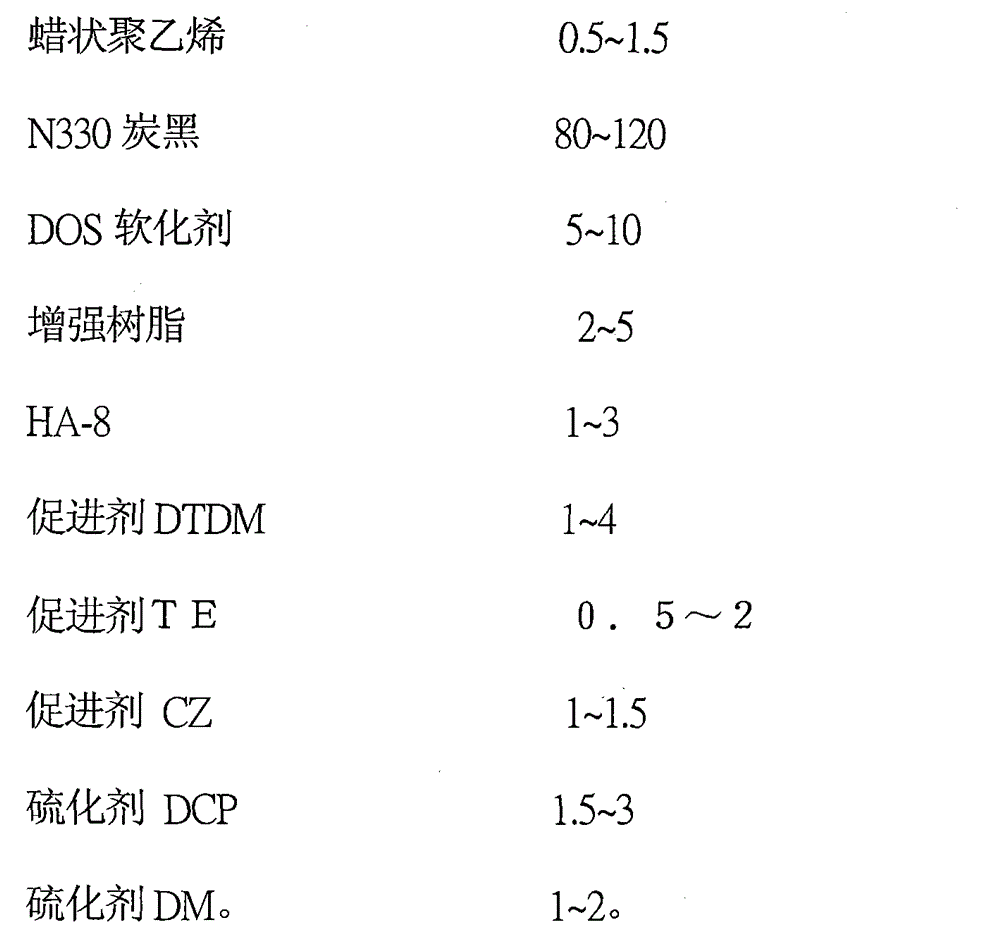

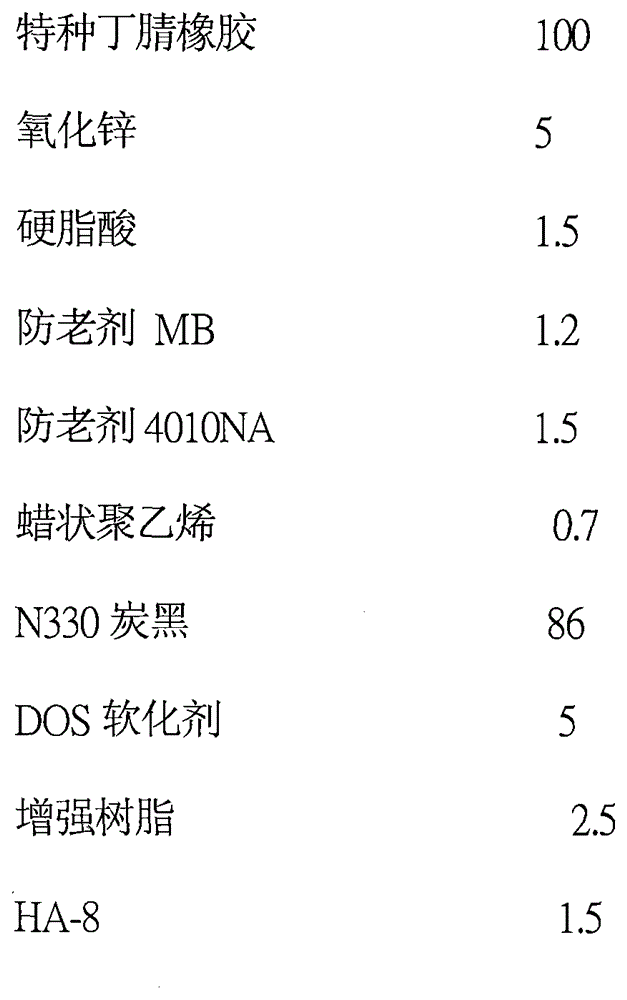

[0042] The best formula of the present invention's ultra-low temperature resistant mixing compound is as follows:

[0043]

[0044] The preparation process of a kind of ultra-low temperature resistant mixing compound of the present invention is as follows:

[0045] (1) Ingredients:

[0046] Aniseed materials: rubber main material, carbon black, low temperature softener,

[0047] Small materials; anti-aging agent, vulcanizing agent, accelerator, active agent, processing aid.

[0048] (2) Mixing process:

[0049] Add the main rubber material, filling reinforcing agent, and low-temperature softener to the mixing chamber of the internal mixer in batches, pressurize the top bolt for 100-200 seconds, lift the top bolt, and add small materials; then pressurize for 200-500 seconds Seconds, lift the top bolt and then pressurize for 30-90 seconds before discharging; the rubber material falls into the open mill and wraps the roll, rams for 3-5 minutes, then unloads, supercools wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com