Optical fiber element packaging box

A technology for optical fiber components and packaging boxes, applied in the field of optical fiber component packaging boxes, can solve the problems of being susceptible to changes in ambient temperature, surface damage of optical components, and changes in characteristics of optical components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

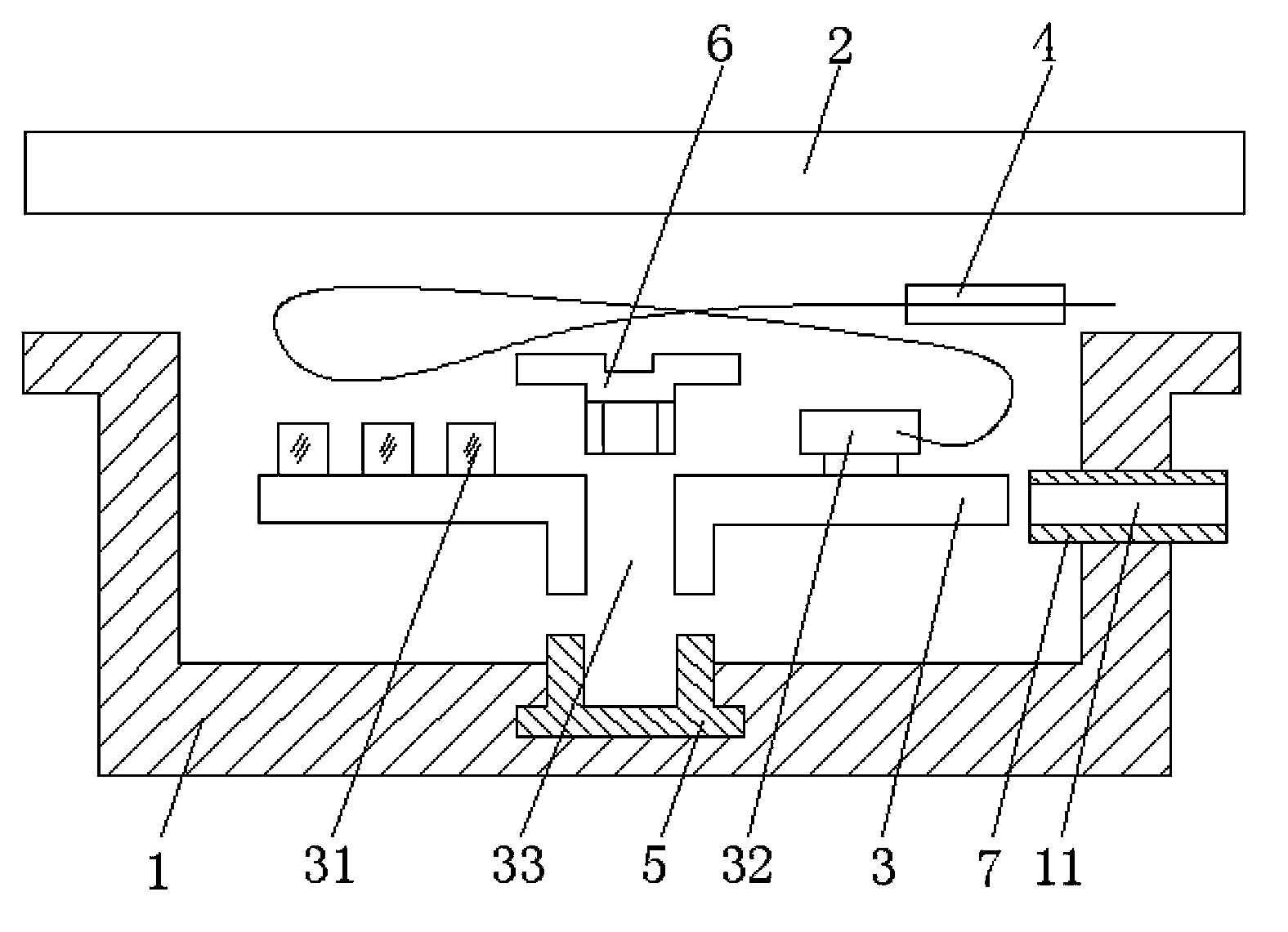

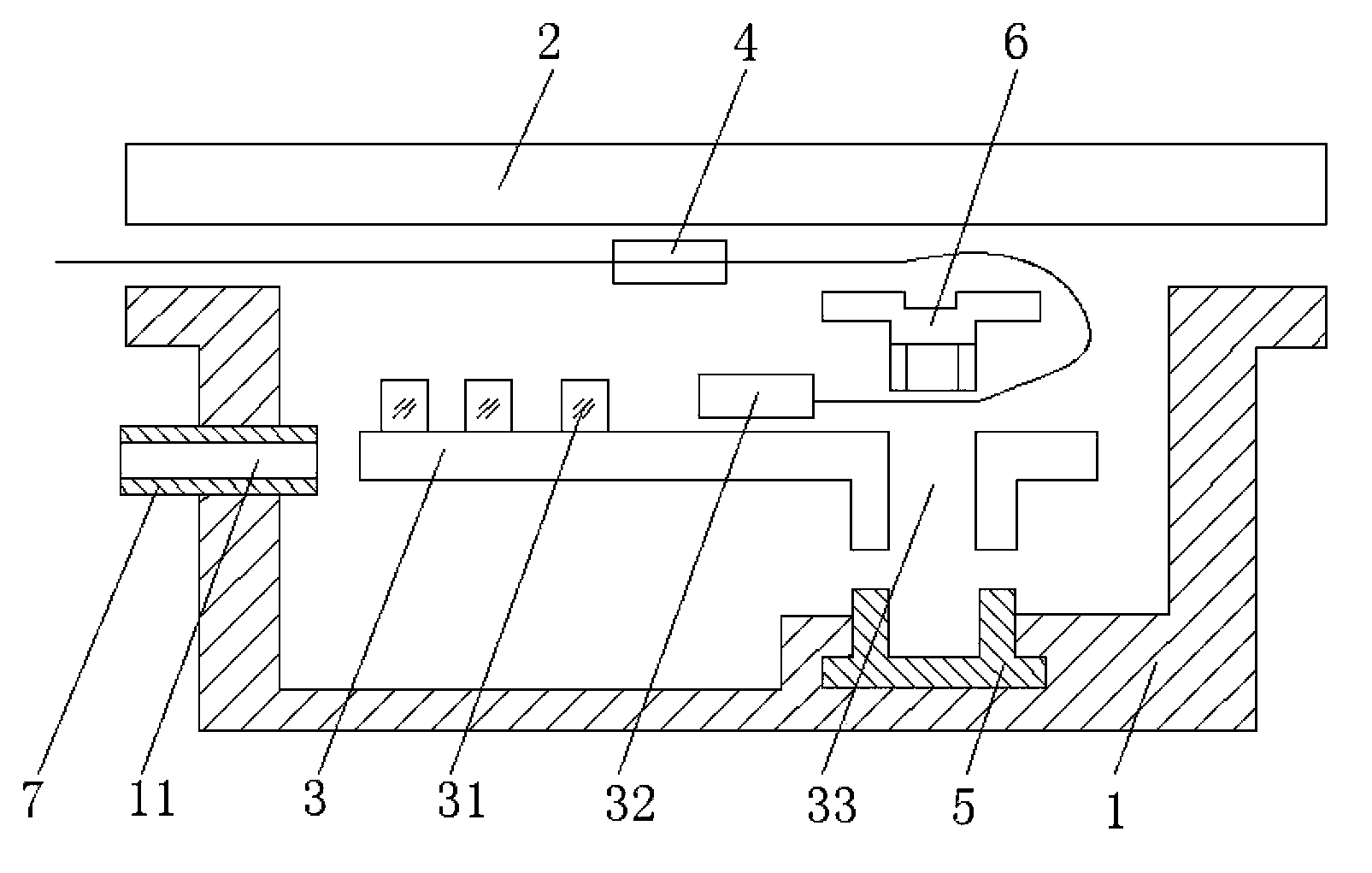

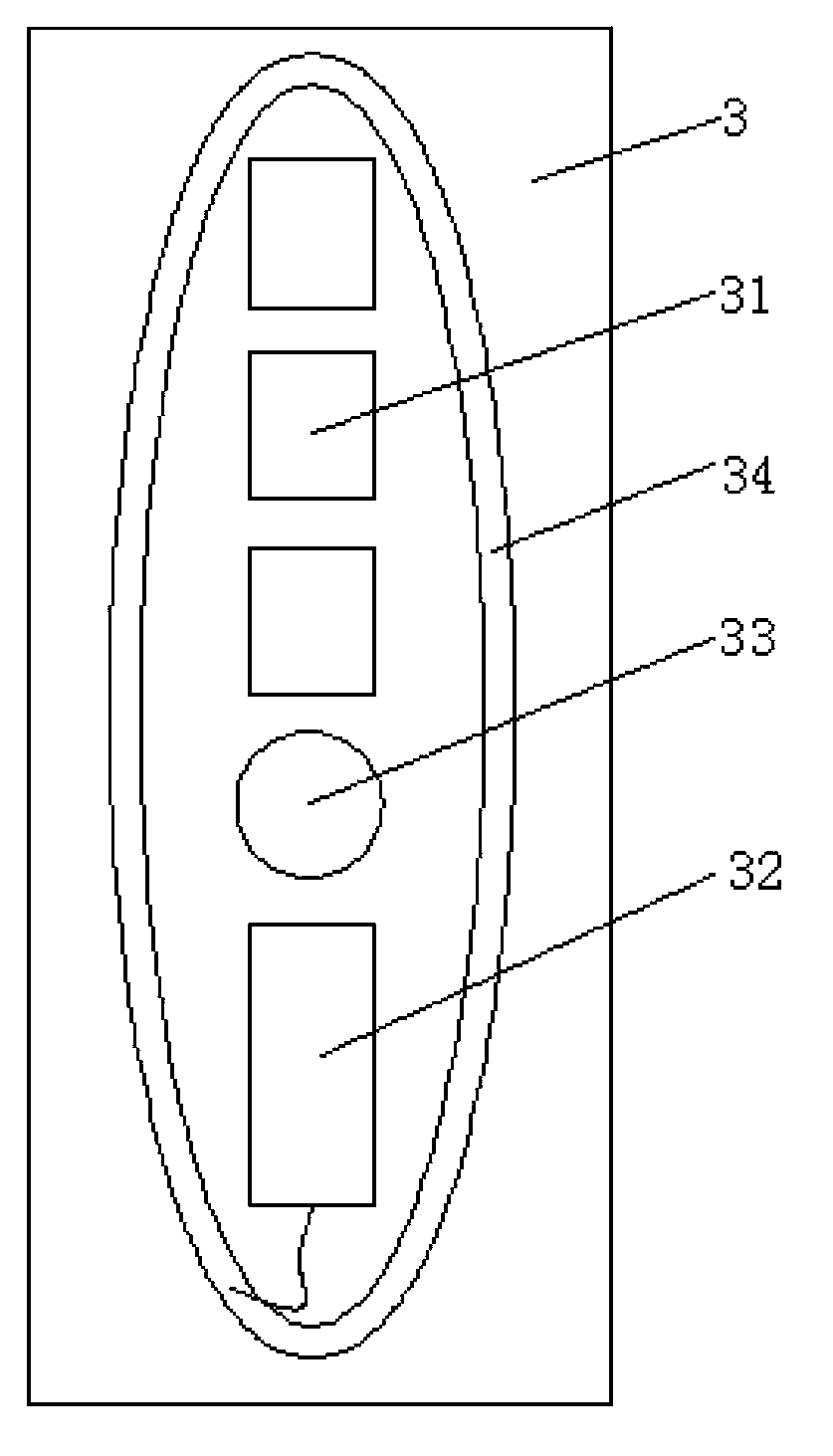

[0017] Such as figure 1 or figure 2 As shown, it includes a plastic housing 1 and a plastic cover 2 that are sealed and connected; one side of the plastic housing is provided with a through hole 11, which is used to realize the connection between the internal optical component group and the external optical signal; the plastic The housing 1 is provided with an optical platform 3 and an optical fiber metal tube 4. The optical platform 3 is fixed with an optical element group 31 and a collimator 32. The optical element group 31 and the collimator 32 are glued or welded. fixed on the optical platform 3; the function of the collimator 32 is to collimate the optical signal transmitted in the optical fiber and then pass through the optical element group 31 and collect the collimated light beam passing through the optical element group 31 to the optical fiber of the collimator 32 transfer within. The output end of the collimator 32 is connected to one end of the optical fiber, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com