Patents

Literature

96results about How to "Meet the tightness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

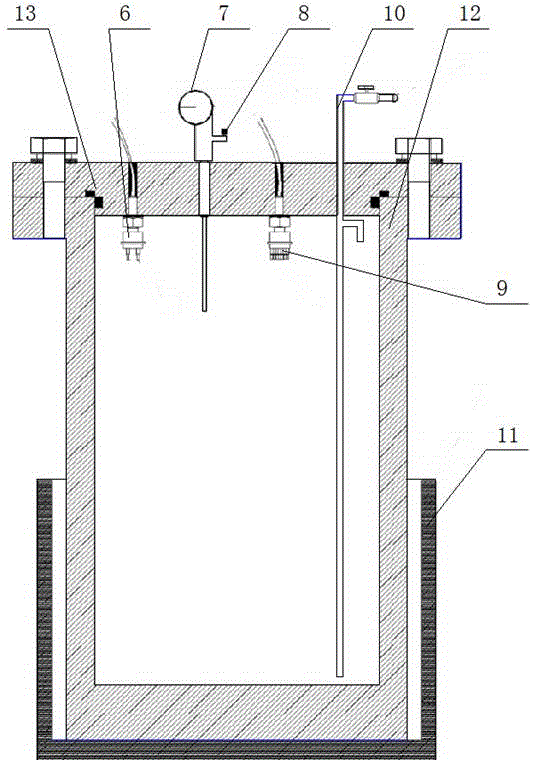

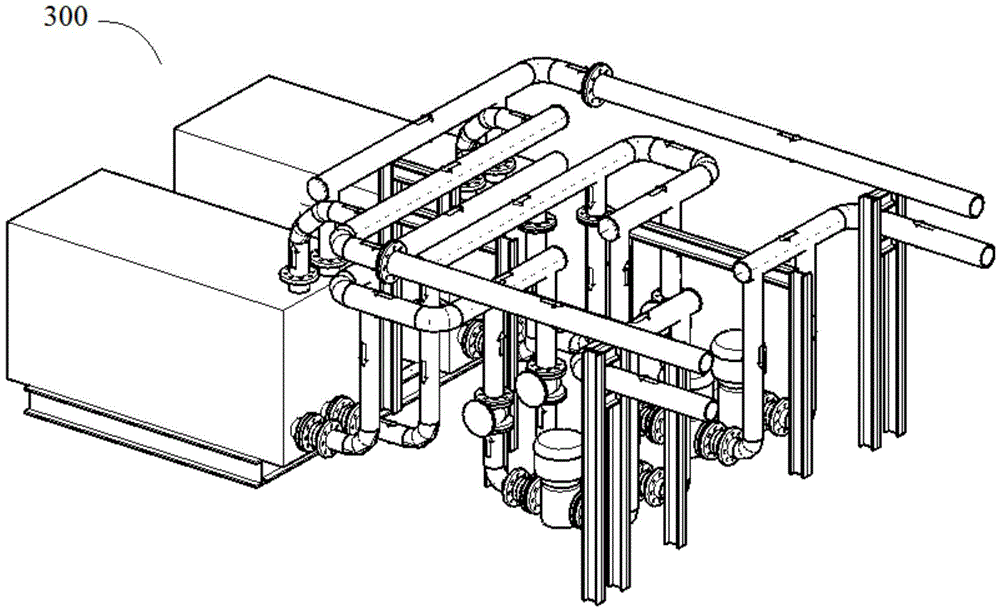

Adjustable charge-discharge type high temperature and high pressure helium gas experimental system and method

InactiveCN105118536AMeet the tightness requirementsMeet the needs of different experimental conditionsNuclear energy generationNuclear monitoringClosed loopCharge discharge

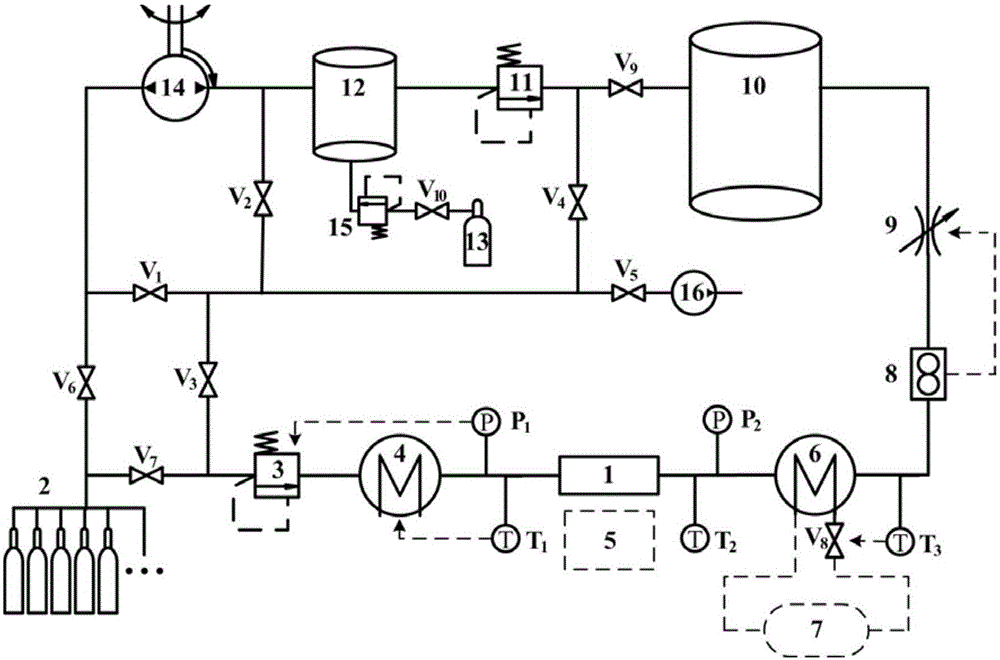

The invention discloses an adjustable charge-discharge type high temperature and high pressure helium gas experimental system and an adjustable charge-discharge type high temperature and high pressure helium gas experimental method. The method comprises: supplying gas by a high pressure helium gas tank set, reducing the pressure of the helium gas to desired pressure through a pressure reducing valve, performing the closed-loop control on the pressure reducing valve by using a pressure transmitter, heating the helium gas by an electric heater, performing the closed-loop control on heating power of the electric heater by using a temperature transmitter, adjusting opening degree of a control valve according to a set flow value and a difference value measured by a flow gauge so as to obtain the helium gas with a rated pressure, temperature and flow quantity, and introducing the helium gas to a thermal hydraulic power experiment section to perform experiment. The high-temperature helium gas enters a gas storage tank for collection after a cooler exchanges heat, the helium gas recycled in the gas storage tank is pressed into the high pressure helium tank set through a helium gas compressor to carry out experiment repeatedly. According to the system provided by the present invention, a high temperature and high pressure section is only in an experimental section, so that high temperature and high pressure sealing performance requirements of other experimental devices in a loop are reduced, pressure, temperature and flow quantity of the experiment helium gas are adjusted, and requirements on a working condition for high temperature and high pressure helium gas thermal hydraulic power experiment can be met.

Owner:中国人民解放军陆军军官学院

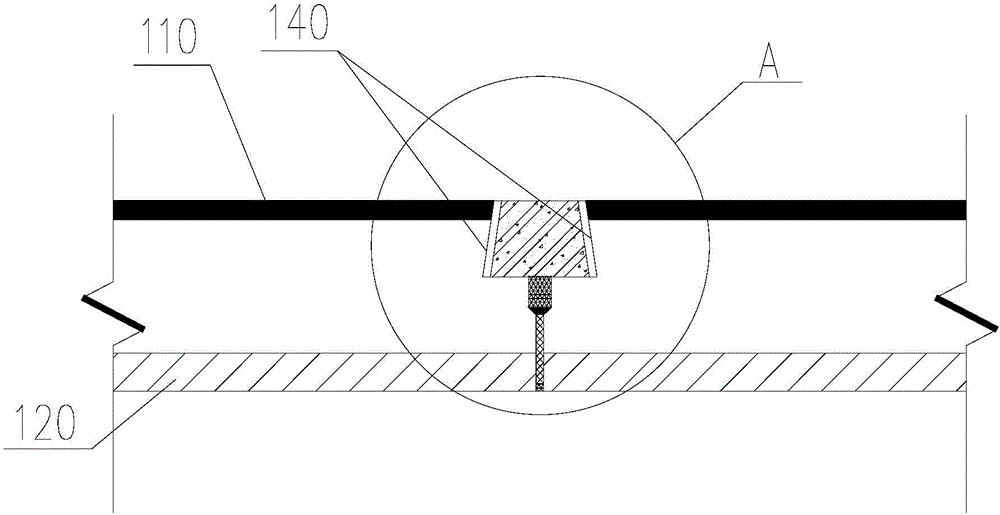

Cylinder battery capacitor

ActiveCN103137343AAvoid WeldingAvoid oversolderingCell component detailsHybrid cases/housings/encapsulationsEngineeringCapacitor

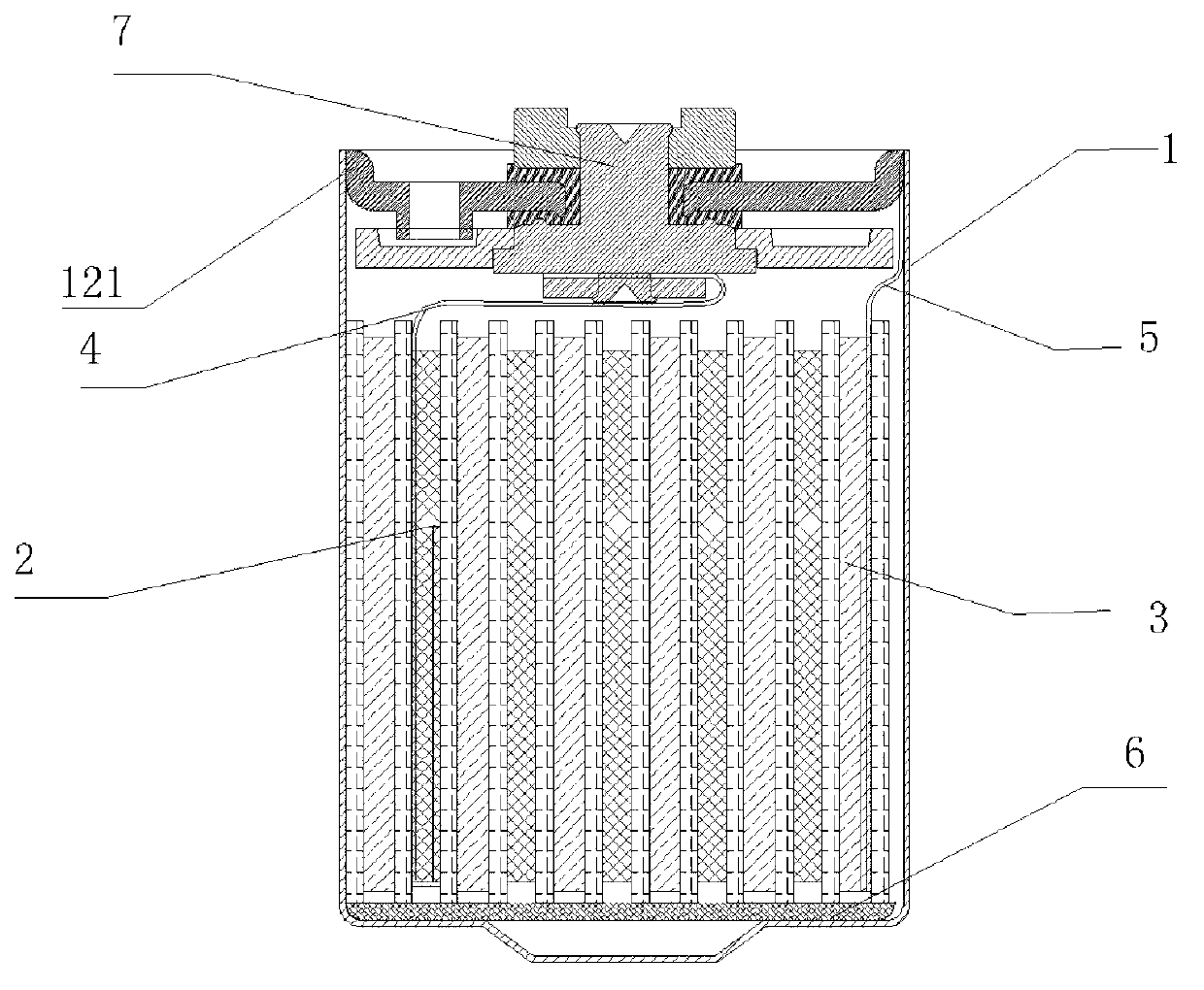

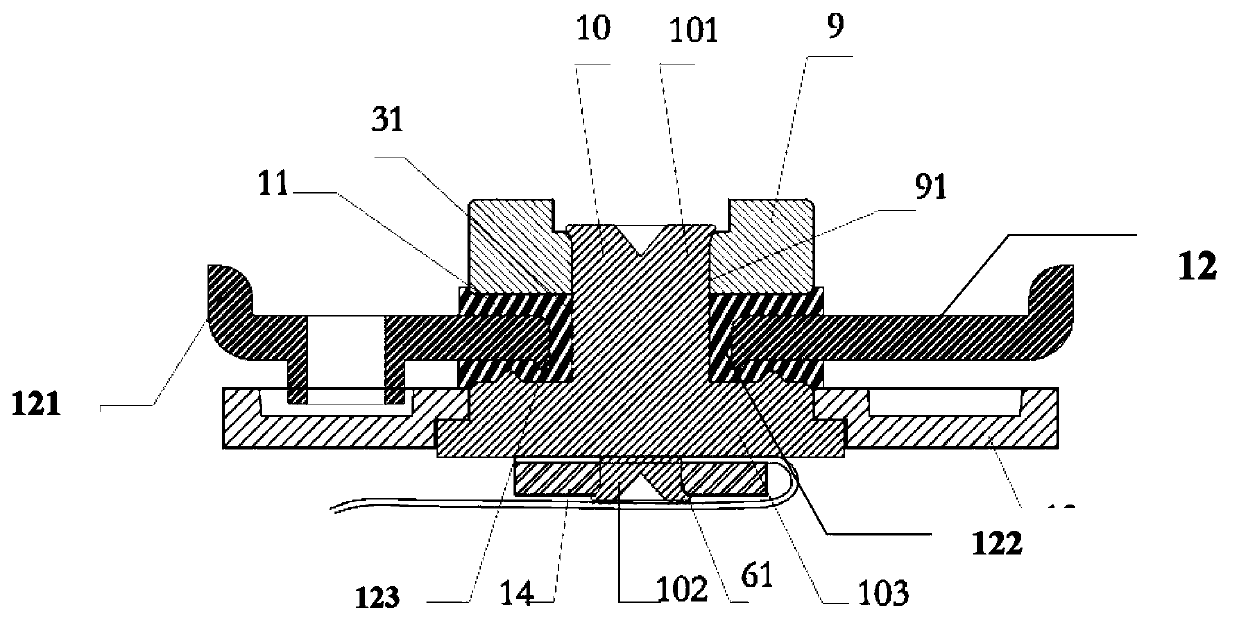

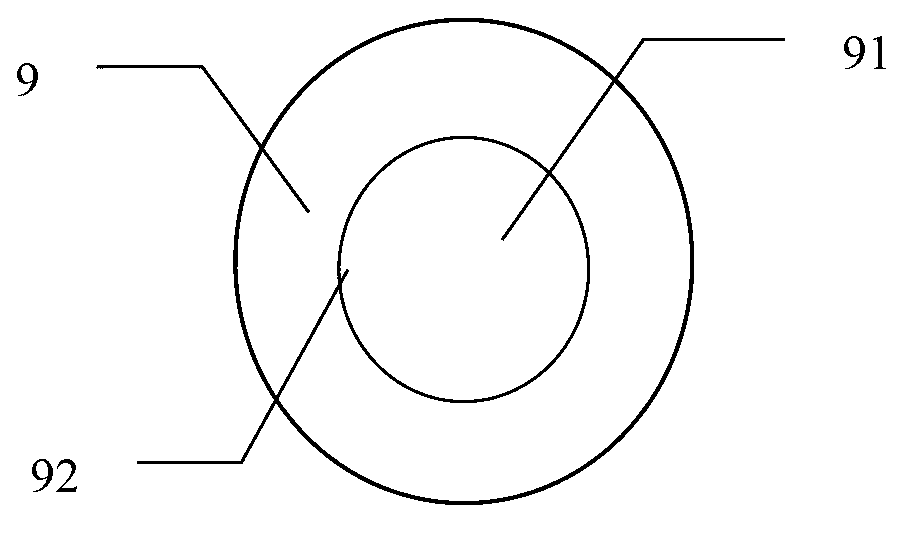

The invention relates to a cylinder battery capacitor. The cylinder battery capacitor comprises a cylinder shaped shell with an opening formed in the top end and the sealed bottom, electrode sets arranged inside the shell, wherein the electrode sets comprise positive electrode plates, negative electrode plates, positive electrode ears connected with the positive electrode plates and negative electrode ears connected with the negative electrode plates. The cylinder battery capacitor further comprises a seal assembly arranged on the top of the cylinder shaped shell and an insulation basement membrane arranged on the bottom of the cylinder shaped shell. The periphery of the battery capacitor is welded with the cylinder shaped shell and the negative electrode ears, and the bottom of the sealing assembly and the positive electrode ears are connected in a rivet joint mode. By arranging the seal assembly inside the battery capacitor and achieving a complete sealing of the battery capacitor in a rivet joint mode, seal performance of the battery capacitor is improved.

Owner:EVE ENERGY CO LTD

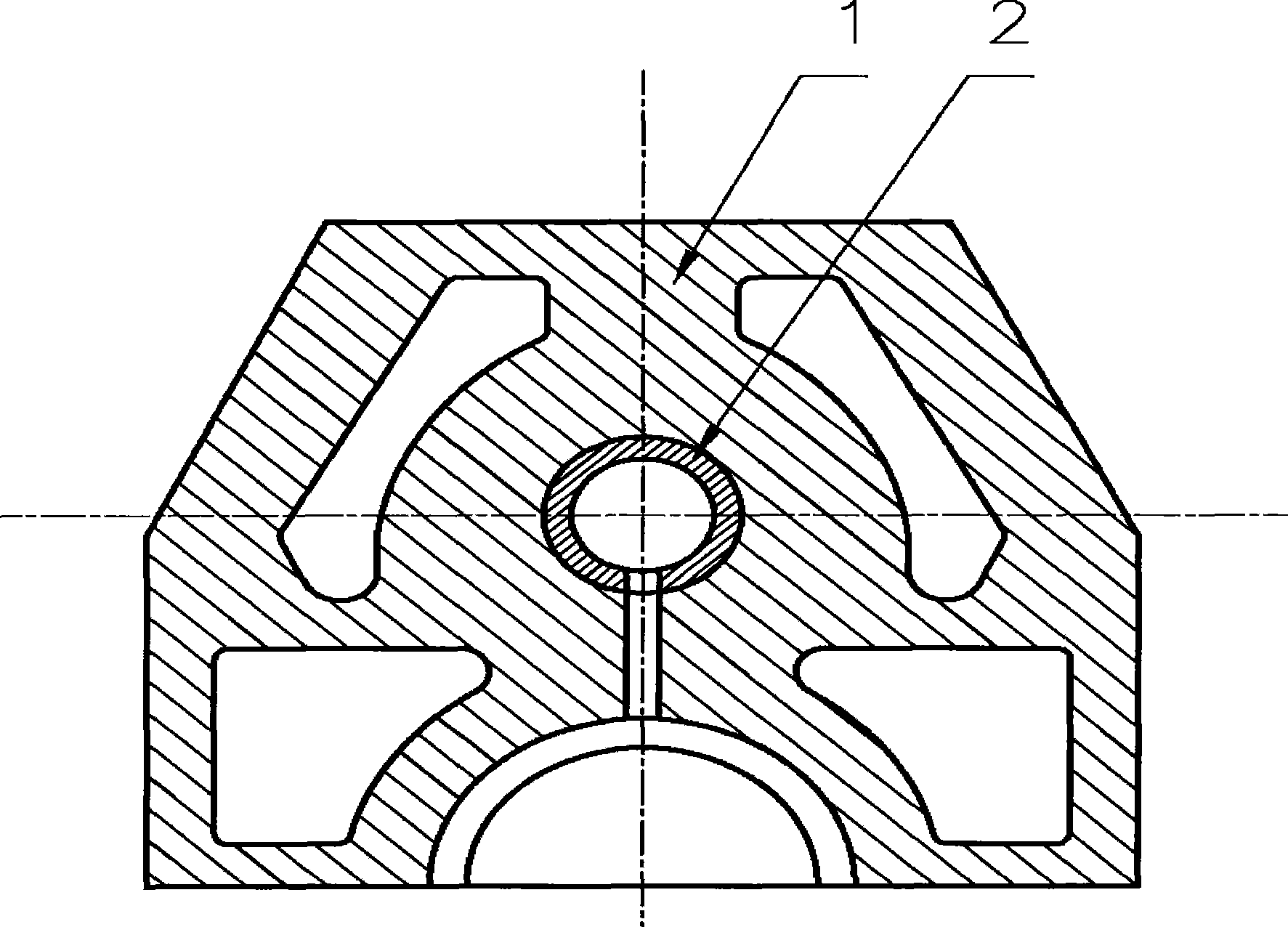

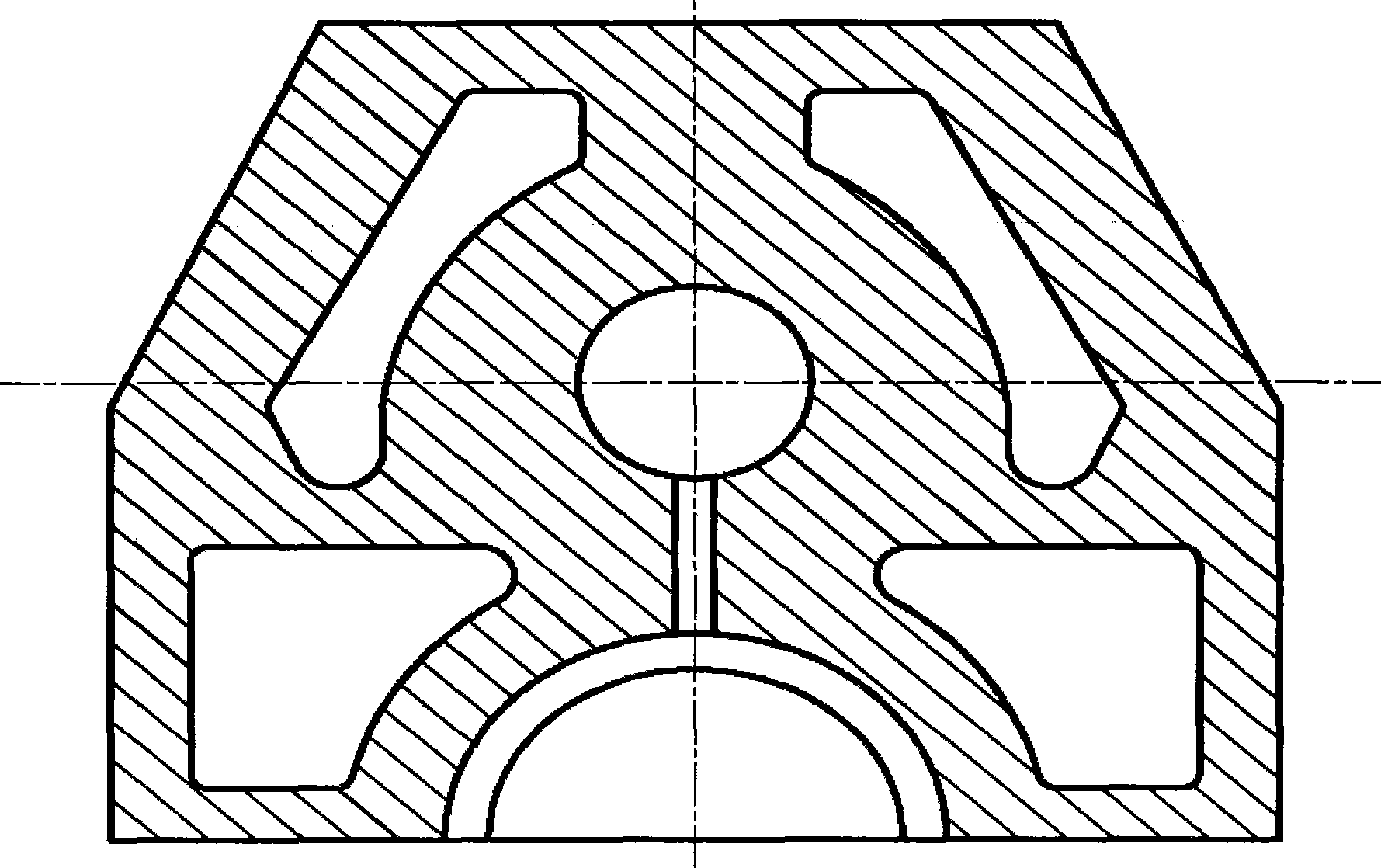

Composite material used for casting aluminum alloy box body oil duct and method thereof

InactiveCN103480794AContinuous adjustment of thermophysical parametersAvoid the hidden danger of entering the oil passageFoundry mouldsFoundry coresBodies oilSurface finish

The invention belongs to the field of casting technologies, and particularly relates to a composite material used for casting an aluminum alloy box body oil duct and a method of the composite material used for casting the aluminum alloy box body oil duct. In order to solve the deep hole casting technical problem which is difficult to solve through an original casting technique, avoid the phenomenon that drilling is performed after hole-forming through an inlaying-cast steel pipe, and thus the oil duct is not homocentric and the aluminum base face is scratched, and solve the problem that a box body oil duct made of a common sand core can not meet the requirement for leakproofness, the composite material comprises metal pills, iron powder, roughing sand and a self-hardening resin sand binding agent, the oil duct core is made from the composite material to take place of an oil duct hole made of a steel pipe, interlayer defects can not be generated between the steel pipe and an aluminum substrate, and the potential hazard that steel scrapes enter the oil duct is avoided. According to the oil duct core made from the composite material, a compact chilling layer can be formed around the oil duct and meet the requirement for the leakproofness of the oil duct and is easy to scatter and low in gas forming, the surface of the oil duct is good in smoothness, and the oil duct can meet use requirements even if the oil duct is not subjected to machining.

Owner:STATE RUN NO 616 FACTORY

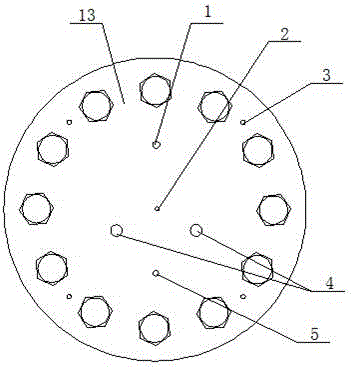

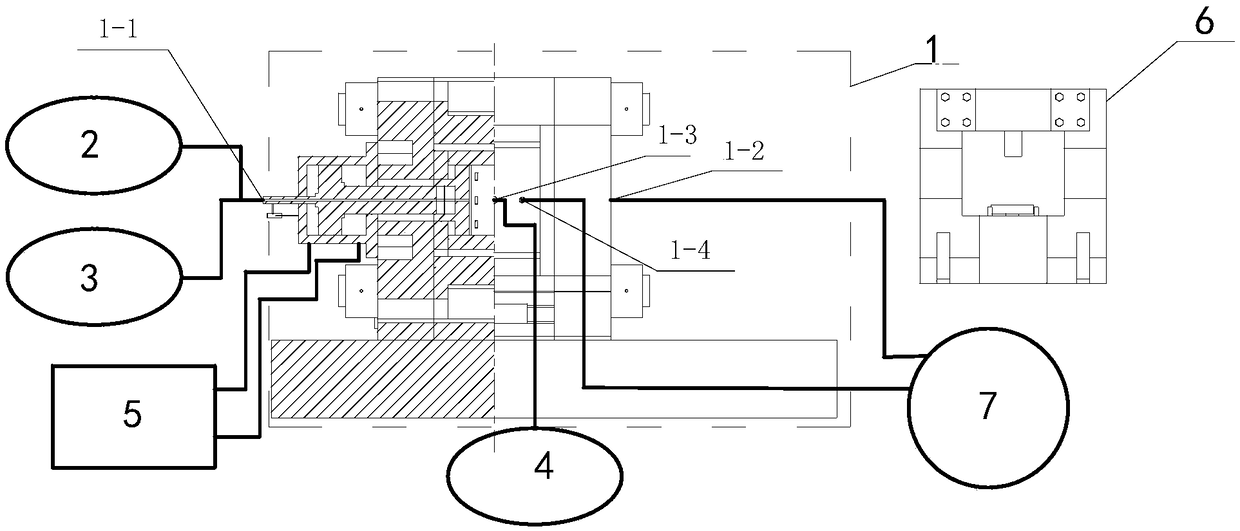

Device and method for testing local corrosion in deep-sea simulation environments

InactiveCN106501168ASimple structureEasy to installWeather/light/corrosion resistanceButt jointAuxiliary electrode

The invention provides a device and a method for testing local corrosion in deep-sea simulation environments, and belongs to the field of simulation test equipment for deep-sea environments. The device comprises a test cabin, a test cabin cover and an electrode assembly. The electrode assembly is based on a three-electrode system and is fixed onto the test cabin cover by the aid of an electrode water-tight connector, the electrode water-tight connector is provided with a wire-wire butt-joint needle bed, a working electrode is an electrode array, the electrode array comprises a plurality of micro-electrodes, and the micro-electrodes are matched with a working electrode water-tight connector; a reference electrode is fixedly connected onto a plug-in cable matched with a reference electrode water-tight connector, and an auxiliary electrode is fixedly connected onto a plug-in cable matched with an auxiliary electrode water-tight connector. The method is based on the device. The device and the method have the advantages that the device is simple in structure, convenient to mount and high in universality, requirements on testing array electrodes in simulation deep-sea high-pressure environments can be met, and-sealing requirements of test environments can be met; the device and the method can be used for research on local corrosion behavior and mechanisms in the deep-sea simulation environments.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

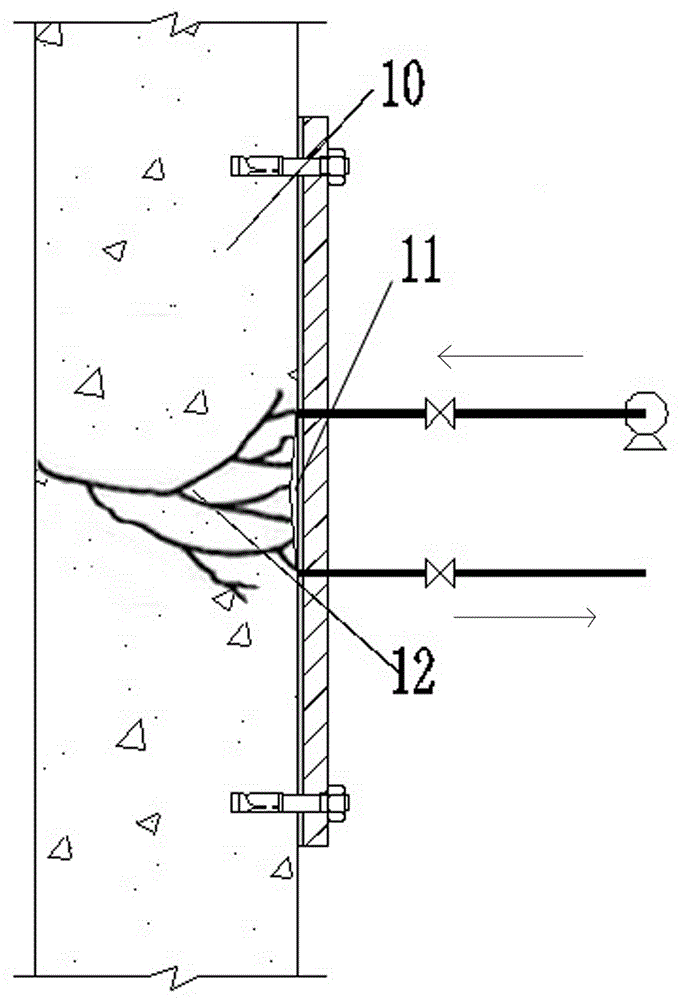

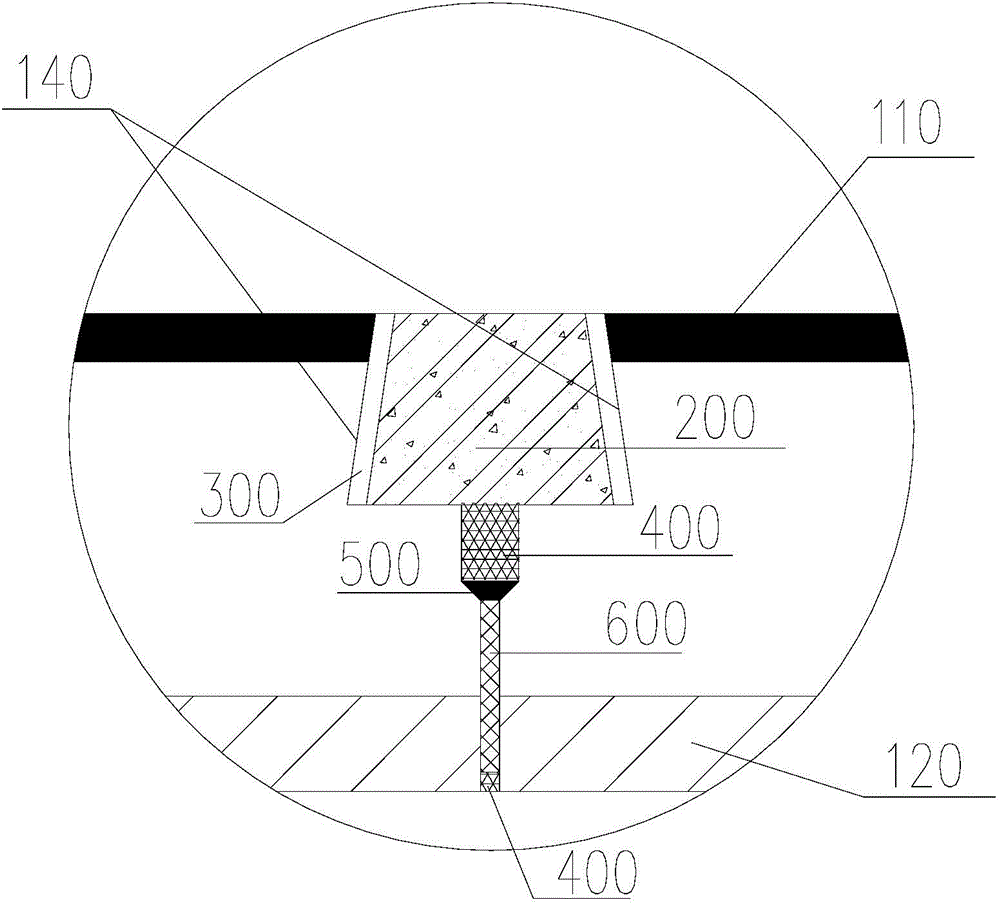

Leakage repairing device for pressure-bearing reinforced concrete structure and construction method thereof

ActiveCN104088254AFacilitate communicationImprove sealingMarine site engineeringReinforced concreteRebar

A leakage repairing device for a pressure-bearing reinforced concrete structure comprises a double-layer sealing and reinforcing plate and a crack grouting and draining device, wherein the outer wall surface of a seepage crack portion is fixedly covered with the double-layer sealing and reinforcing plate. The double-layer sealing and reinforcing plate is composed of a rubber sealing backing plate on the inner side and a reinforcing steel plate on the outer side and is anchored to structure concrete around the seepage crack portion through expansion bolts around a plate body. The crack grouting and draining device is separately arranged on the upper side and the lower side of the seepage crack portion and comprises a grouting pipe at the upper portion and a first draining pipe at the lower portion. The outer wall surface of the seepage crack portion is provided with a flow guide groove through which a plurality of cracks are communicated. The grouting pipe, the flow guide groove and the first draining pipe are communicated. The leakage repairing device can be quickly manufactured at the construction site, the whole structure repairing process only takes several minutes, the leakage repairing device can be conveniently disassembled in the later stage without influencing the appearance of the concrete structure, and the solution method high in efficiency and fast to implement in a limited construction period is achieved.

Owner:泛华建设集团有限公司

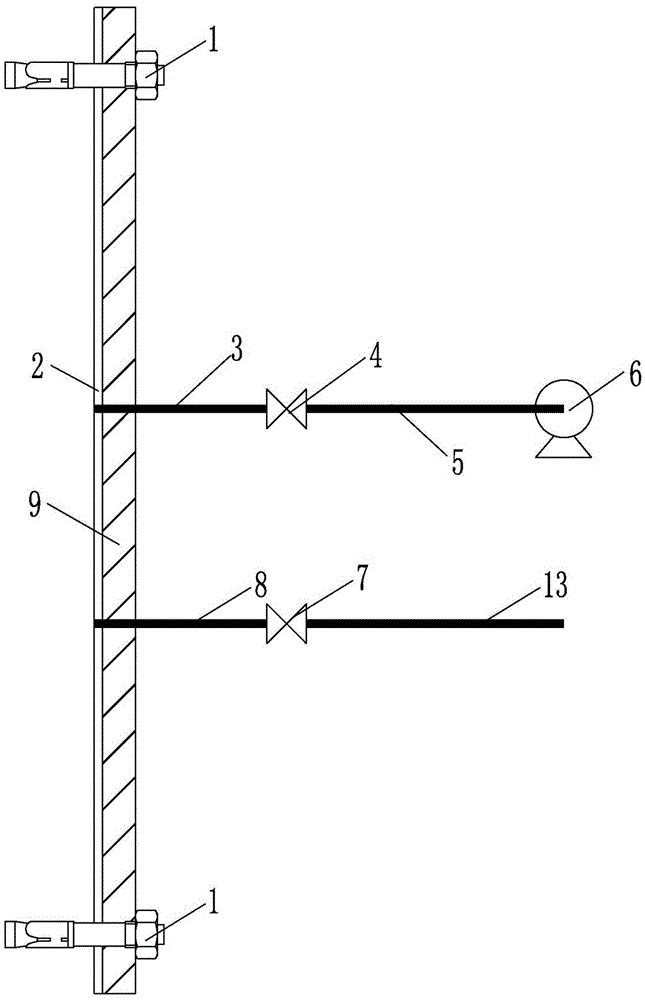

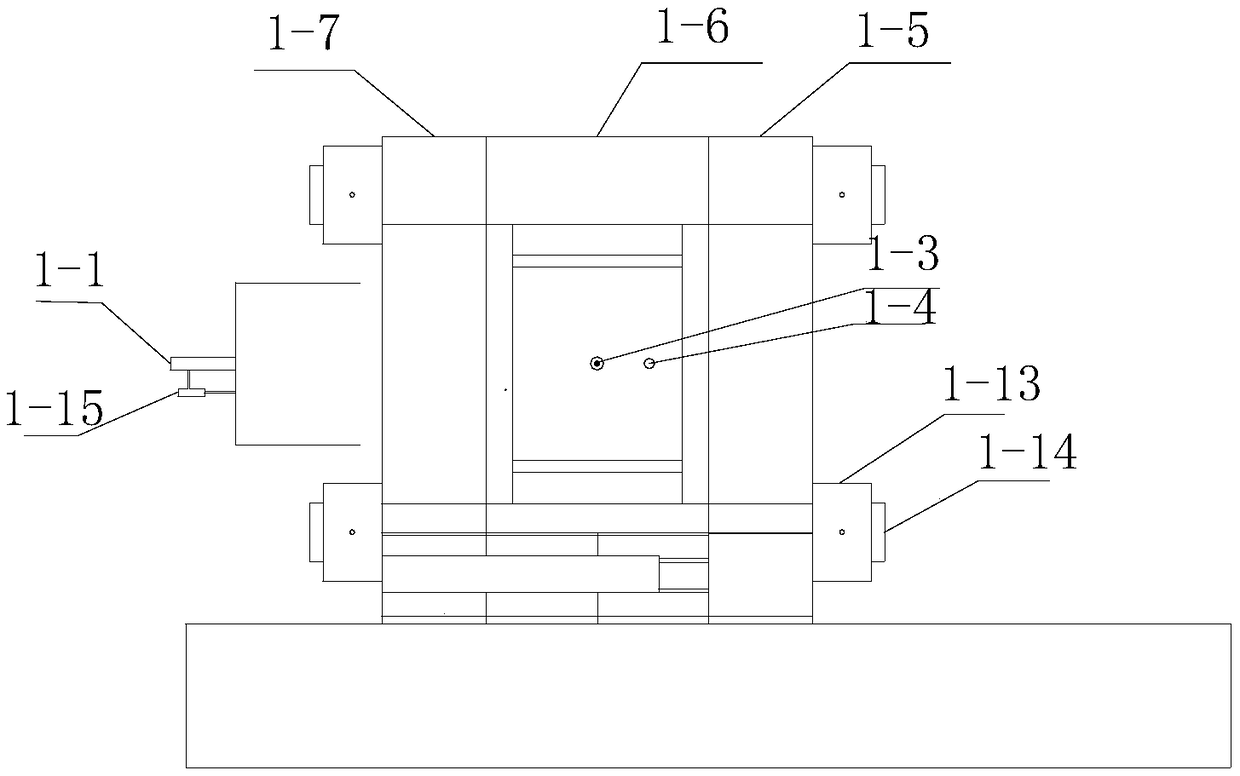

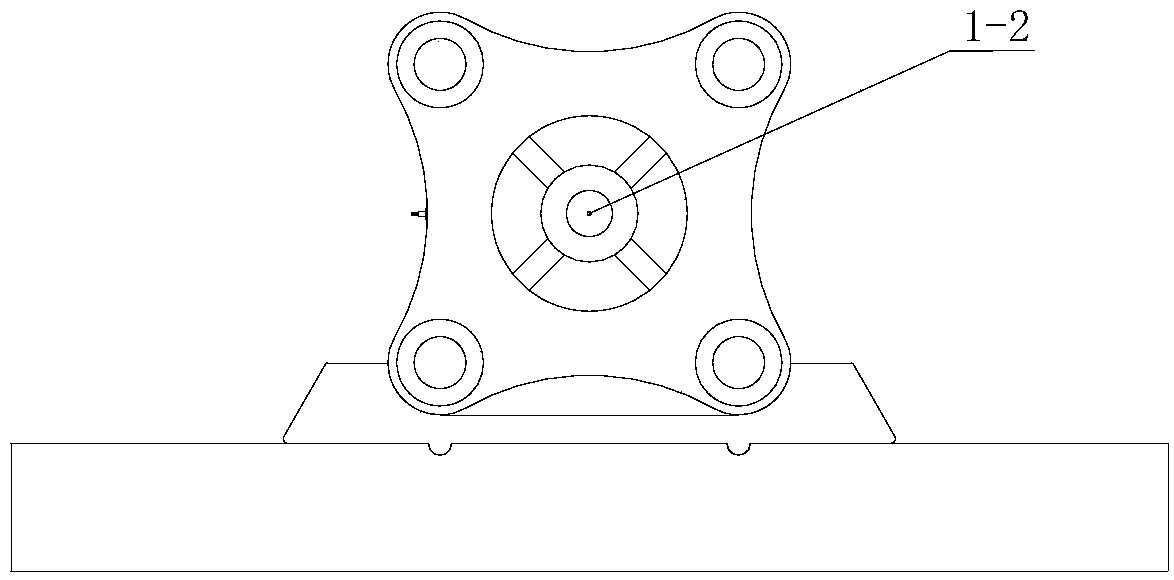

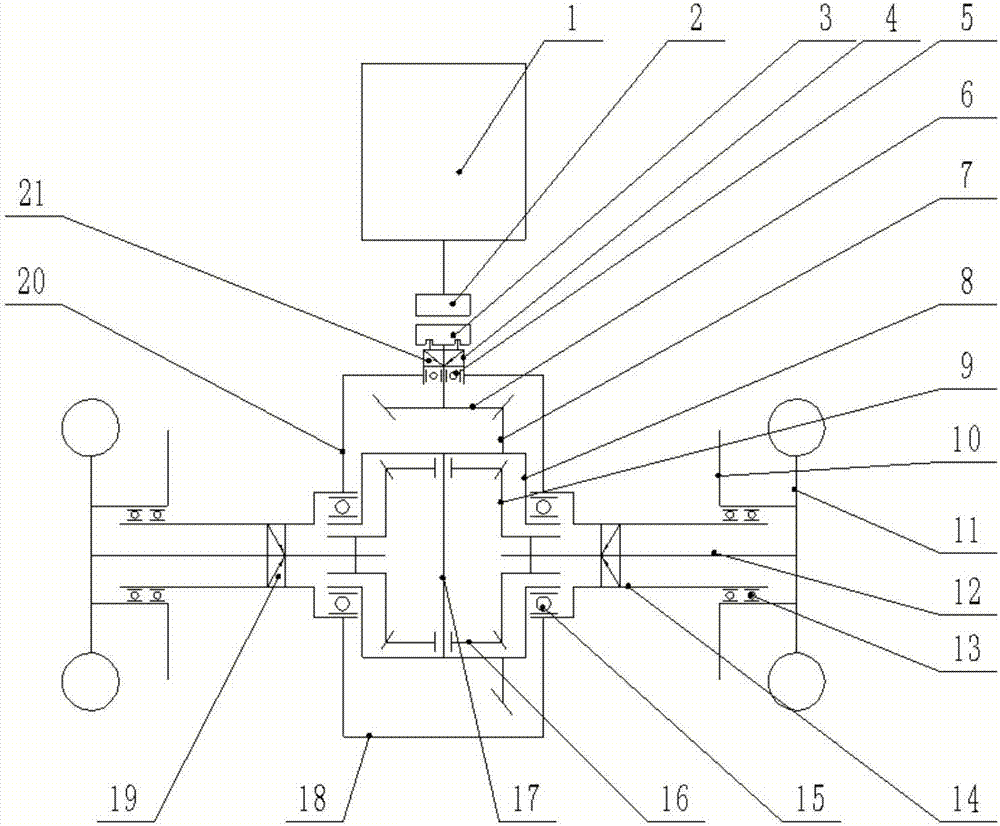

Simulation test system and test method for coal stratum gas dynamic permeability improvement seepage and displacement

ActiveCN109386270AThe structure is easy to disassembleHigh degree of mechanizationSurveyFluid removalMulti fieldData acquisition

The invention discloses a simulation test system and a test method for coal stratum gas dynamic permeability improvement seepage and displacement, which comprise a fluid injection system, a model sealing loading system and a data acquisition, processing and control system. The simulation test system and the test method for coal stratum gas dynamic permeability improvement seepage and displacementcan achieve the function of injecting fluid (gas, steam and liquid) into large-scale coal and rock bodies under different loads, can be used for simulating permeability improvement measures such as coal seam hydraulic fracturing, hydraulic cutting, blasting cracking and the like, can be used for simulating coal seam gas increasing measures such as gas injection, heat injection and the like, can monitor physical quantities such as fluid flow, pressure, solid stress, strain, temperature and the like in the coal and rock bodies in real time, and can find out multi-field coupling evolution rules such as a gas pressure field, a stress field, a deformation, a temperature field and the like in the fluid seepage process under the conditions of pressure bearing and pressure relief. The whole systemhas the advantages of simple structure, clear division of labor and convenient disassembly and assembly, can provide test parameters for permeability improvement and production improvement technologies such as hydraulic fracturing, hydraulic cutting, blasting cracking, gas injection, heat injection and the like, and can provide a verification platform for theoretical research.

Owner:SHANDONG UNIV +1

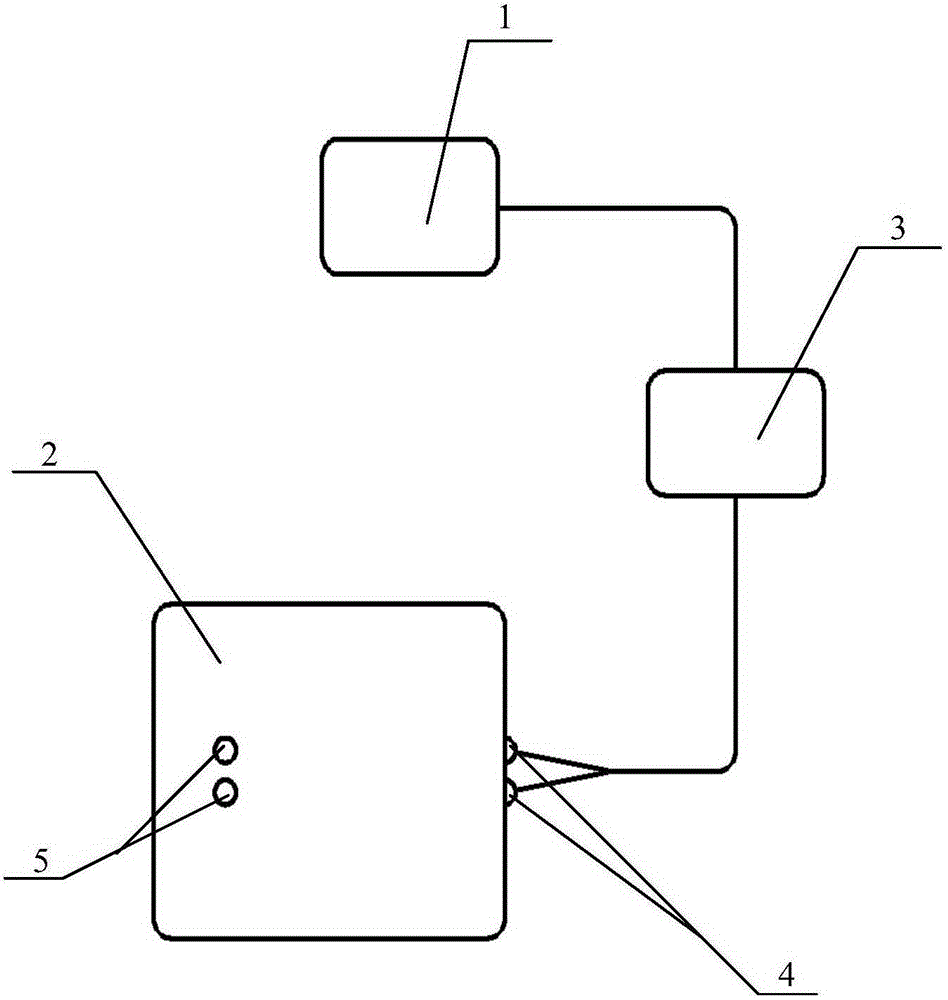

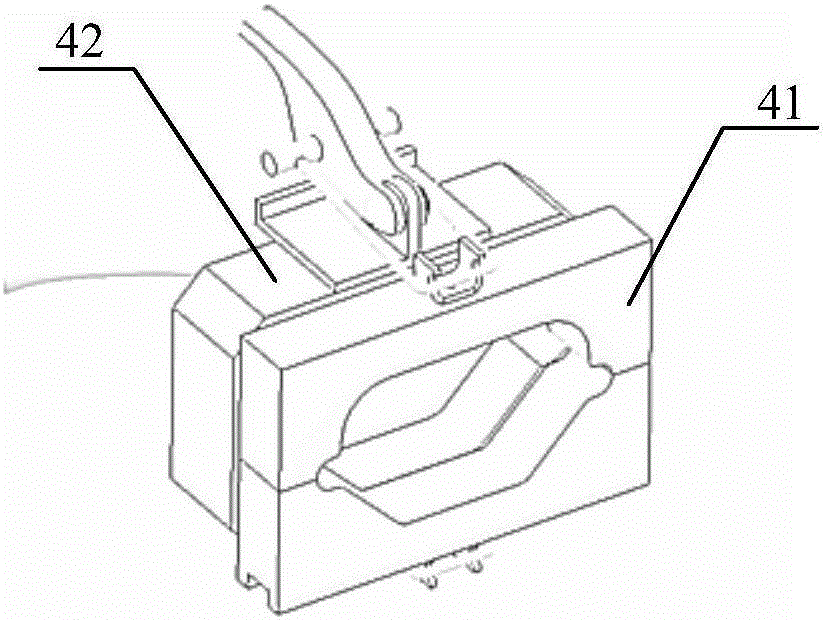

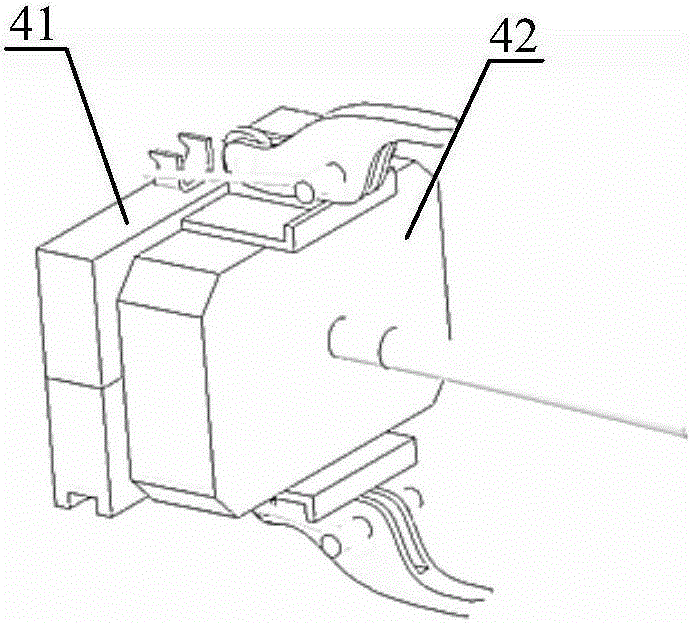

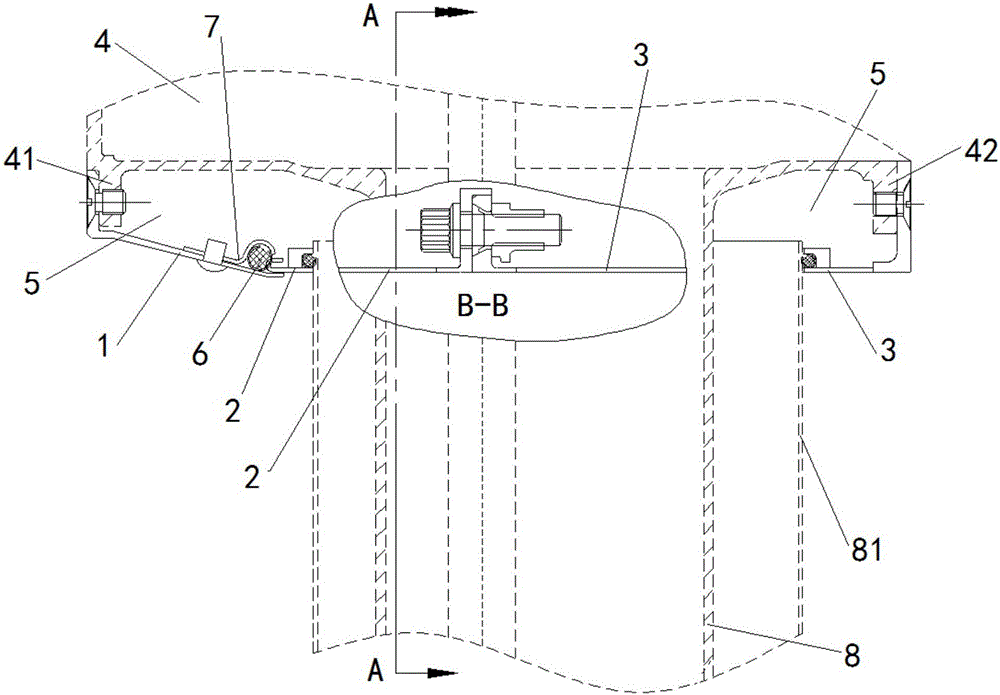

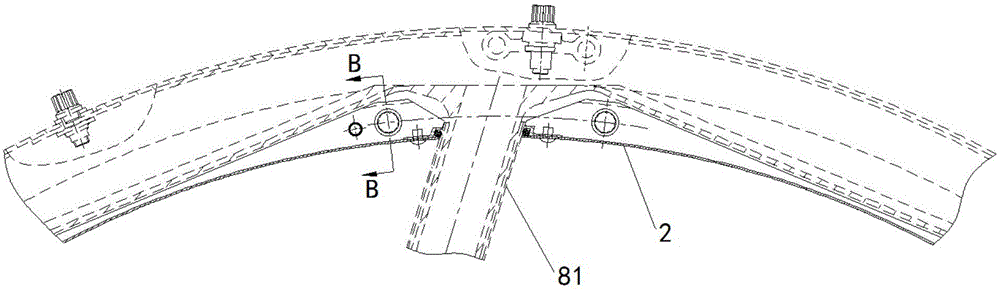

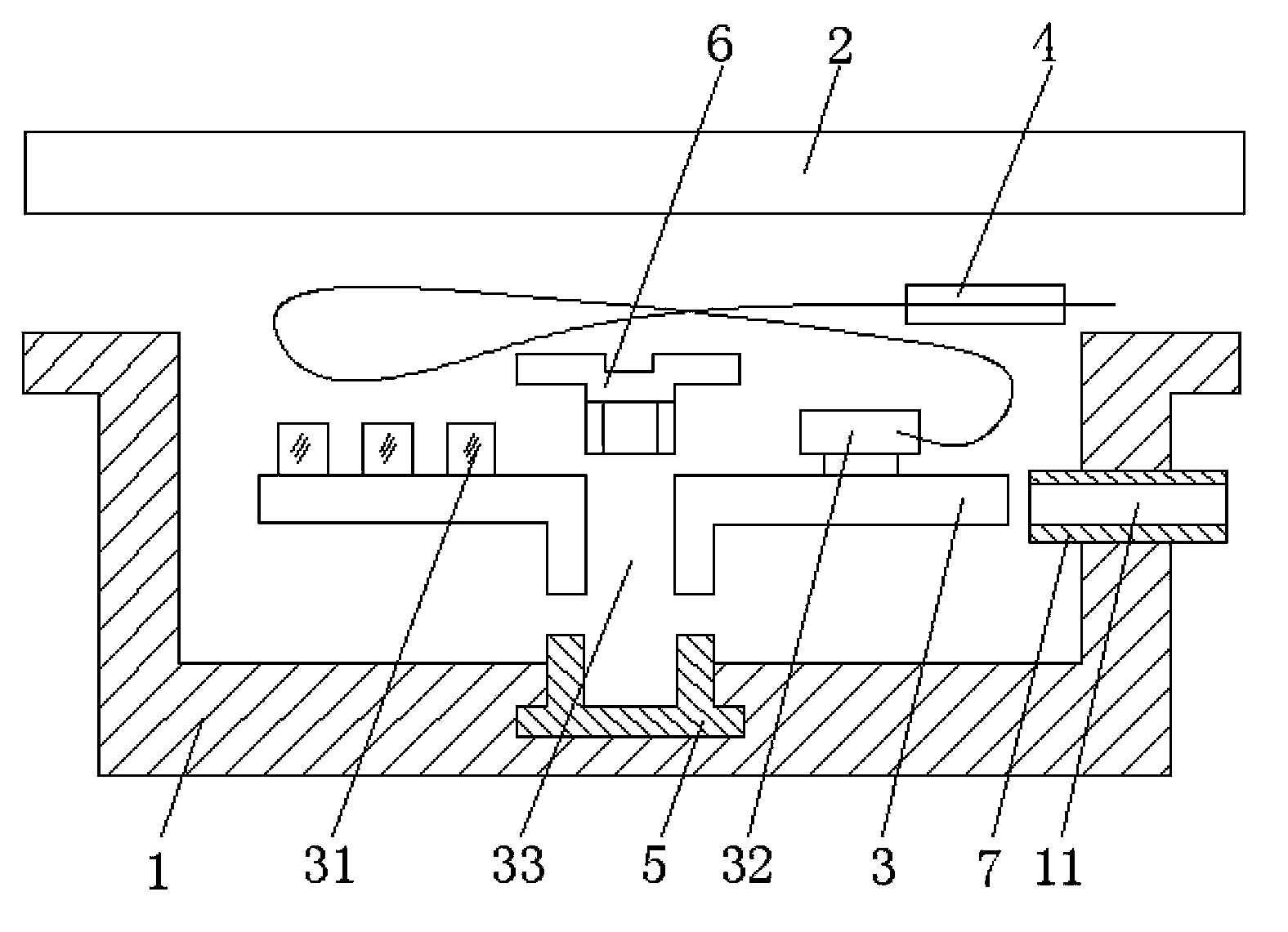

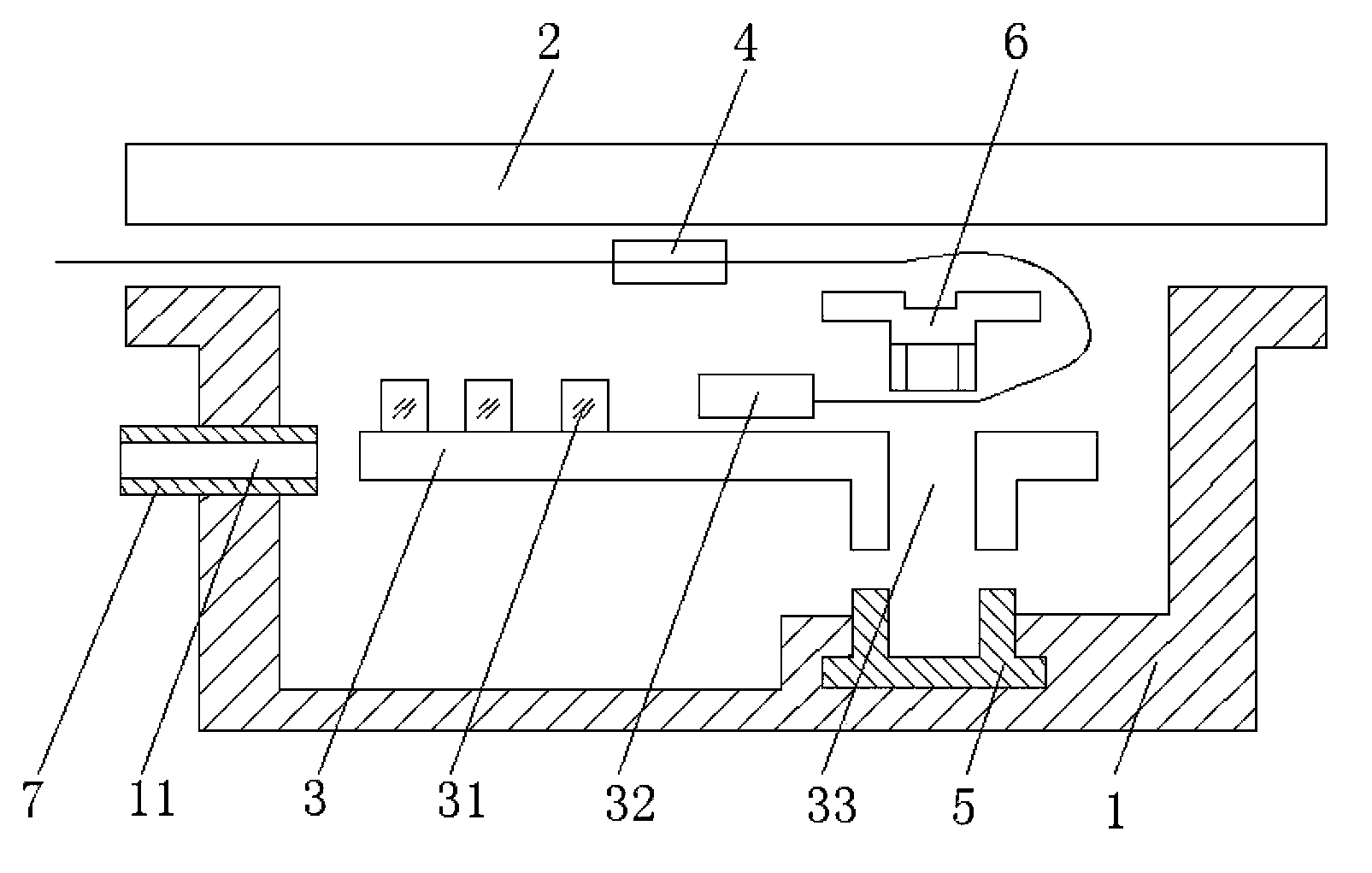

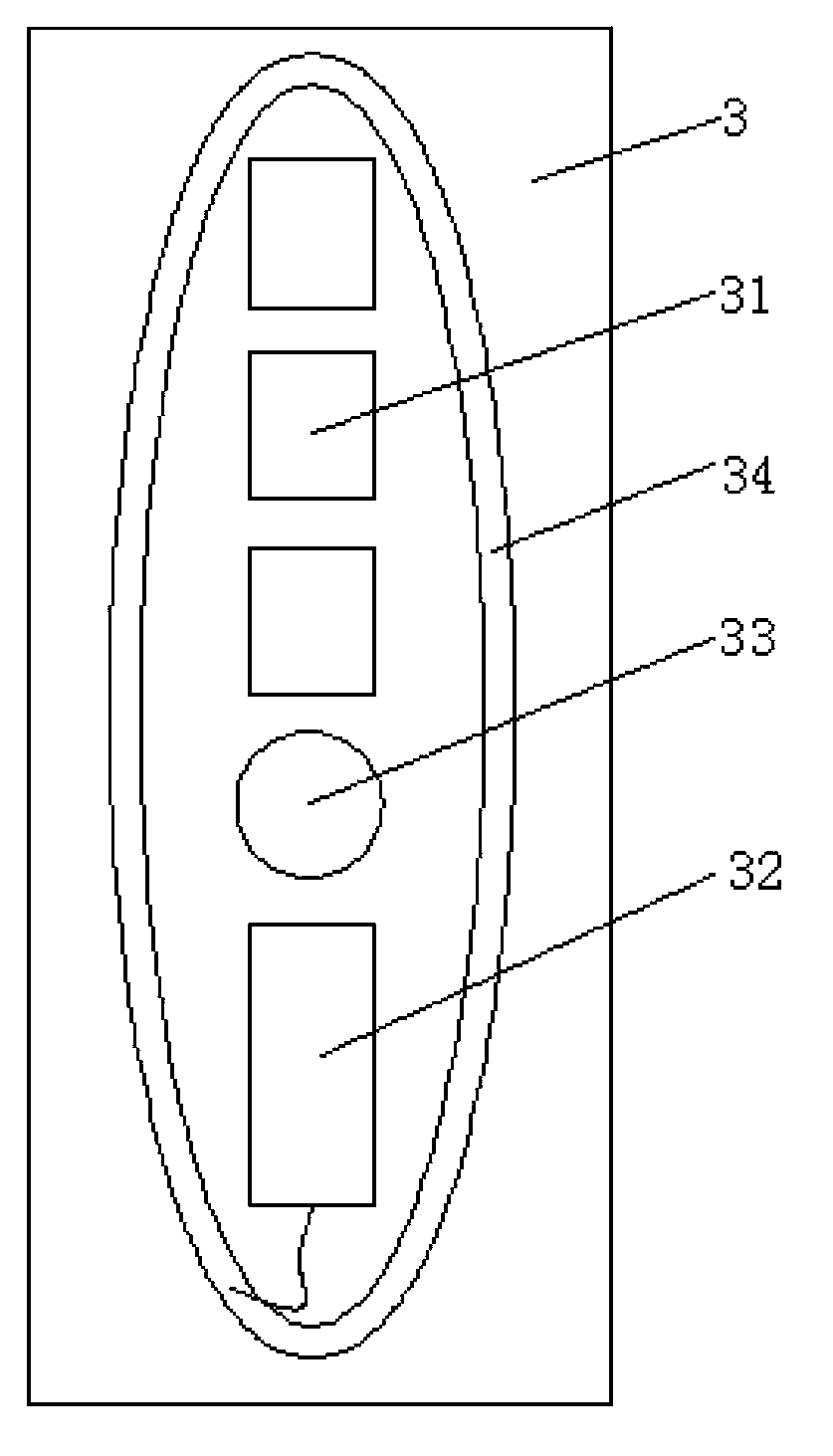

Sealing testing apparatus of power battery pack

InactiveCN105352677AMeet the tightness requirementsImprove the efficiency of leak testingMeasurement of fluid loss/gain ratePower batteryElectrical battery

The invention discloses a sealing testing apparatus of a power battery pack. The testing apparatus comprises a gas source, an air tightness detection device, first plugging devices and second sealing devices. The gas source, the air tightness detection device, and a power battery pack are successively connected. Compressed air generated by the gas source enters the air tightness detection device through an air pipe and then enters the power battery pack through the first plugging devices. Preset time of the sealing testing apparatus is set and the air tightness detection device is started; and the air tightness detection device works within the preset time to obtain a pressure drop value or leakage rate of the power battery pack within the preset time. And then the obtained pressure drop value or leakage rate is compared with a preset standard value; when the obtained pressure drop value or leakage rate is lower than or equal to the set standard value, the sealing performance of the power battery pack meets the requirement; and if the obtained pressure drop value or leakage rate is higher than the set standard value, the sealing performance of the power battery pack does not meet the requirement.

Owner:深蓝汽车科技有限公司

A kind of silicone potting glue and its preparation method and application

ActiveCN102295911AImprove applicabilityNo metal corrosionOther chemical processesAdhesivesRoom temperatureElectronic component

The invention relates to an organic silicon pouring sealant, a preparation method and application thereof. The organic silicon pouring sealant comprises a component A and a component B. The preparation method comprises the steps of: respectively preparing the component A and the component B according to the requirement of a formula, cooling to room temperature, during the application, and statically mixing the component A and the component B according to the weight ratio of 1: (1-1.2) for 20-30min to ensure that the component A is uniformly mixed with the component B to obtain the organic silicon pouring sealant. Compared with the prior art, the organic silicon pouring sealant has excellent applicability to various materials without metal corrosion, can achieve insulation, heat conductionand inflaming retarding requirements according to the requirements without damaging electronic components, has better operating performance, is easy to blend, and is suitable for encapsulation production application of a manual or general sealant injection device.

Owner:马鞍山海鹰新材料有限公司

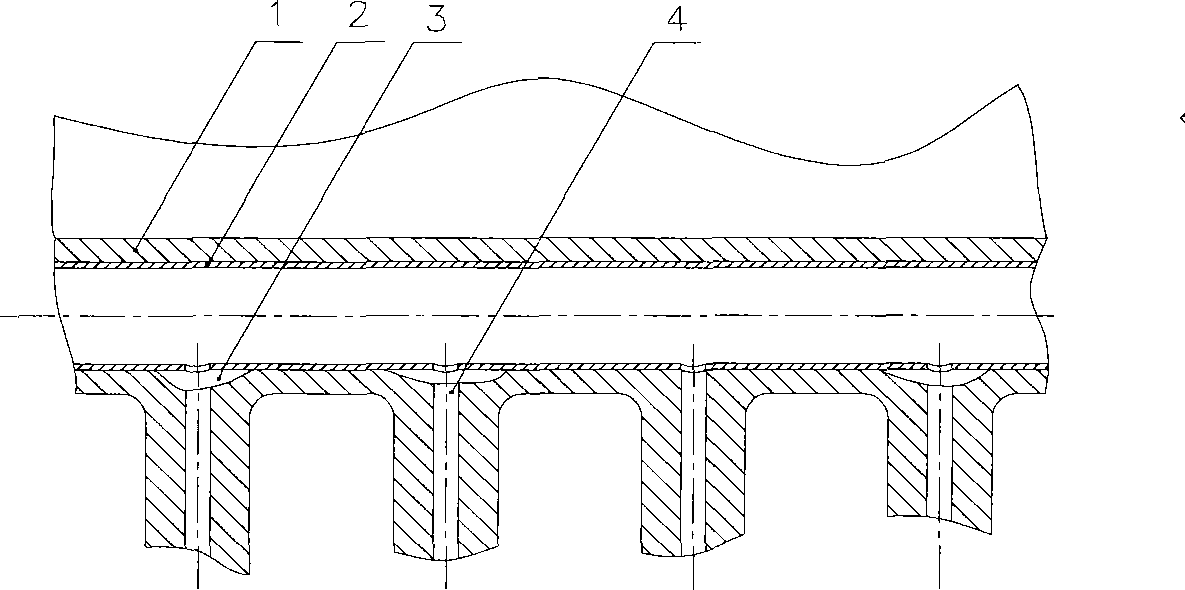

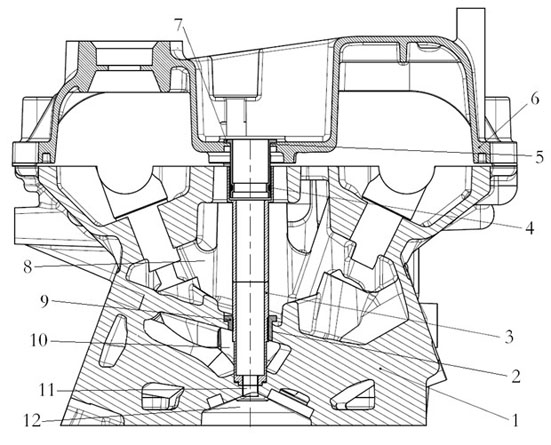

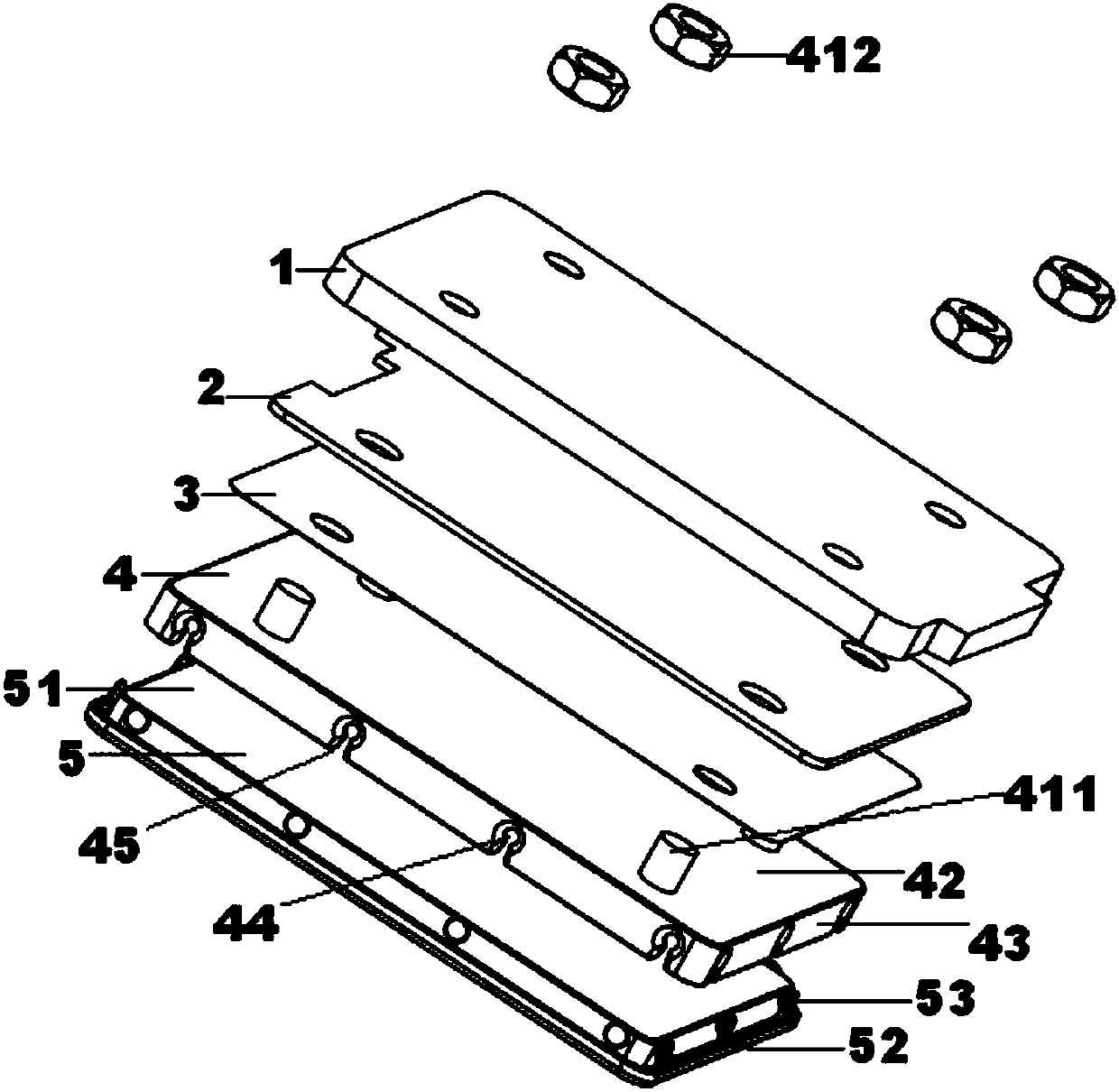

Turbine bearing case heat insulation flowing channel and engine with same

ActiveCN106640233ASatisfy Thermal CoordinationMeet the tightness requirementsLeakage preventionMachines/enginesEngineeringTurbine

The invention discloses a turbine bearing case heat insulation flowing channel and an engine with the same, and relates to the technical field of engines. The turbine bearing case heat insulation flowing channel includes a first heat insulation plate, a second heat insulation plate, a third heat insulation plate, and a bearing case; a first installation edge and a second installation edge are axially arranged on the bearing case; one end of the first heat insulation plate is fixedly connected to the first installation edge; one end of the second heat insulation plate is in lap connection with the other end of the first heat insulation plate; one end of the third heat insulation plate is fixedly connected to the other end of the second heat insulation plate, and the other end of the third heat insulation plate is fixedly connected to the second installation edge; and the first heat insulation plate, the second heat insulation plate, the third heat insulation plate and the bearing case form a cooling cavity. The advantages of the invention are that the first heat insulation plate and the second heat insulation plate are in lap connection, the axial heat coordination of the case can be met, cooling of the bearing case is achieved, and the service life of the bearing case can be improved.

Owner:AECC SHENYANG ENGINE RES INST

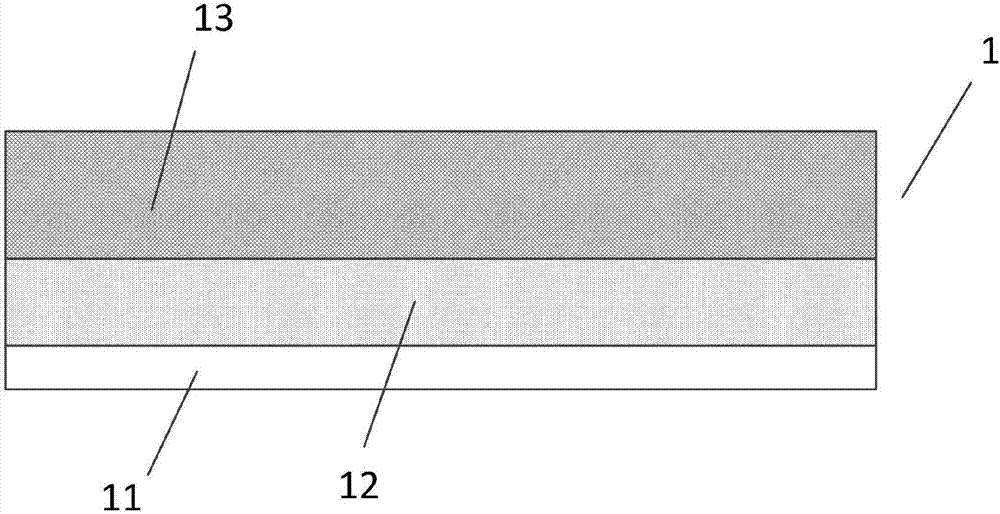

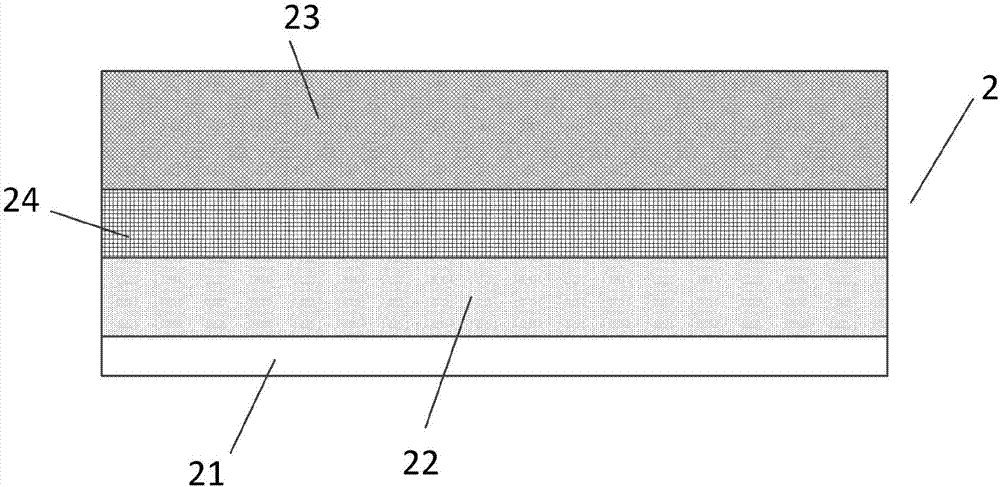

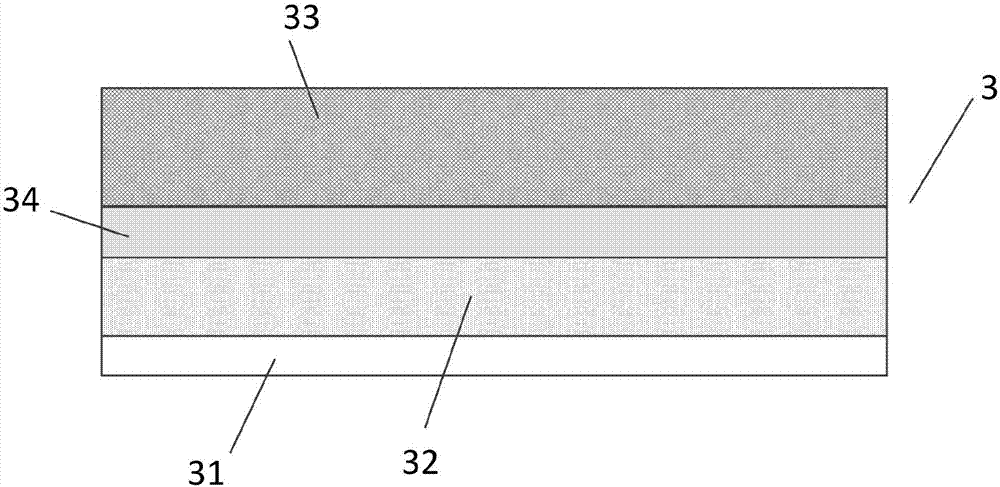

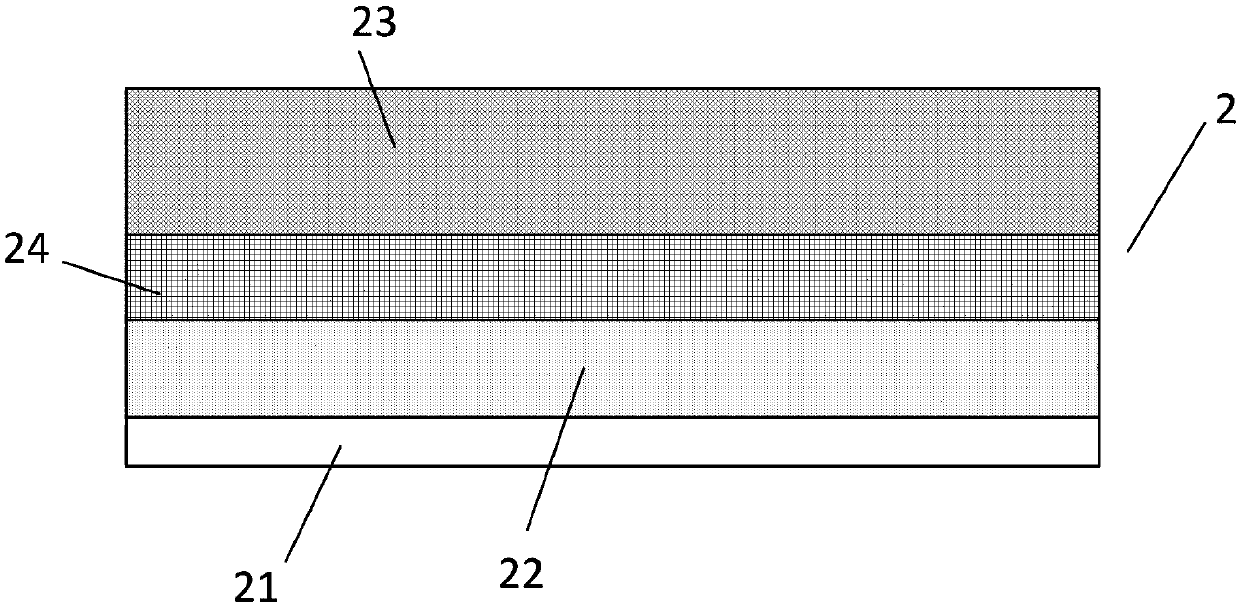

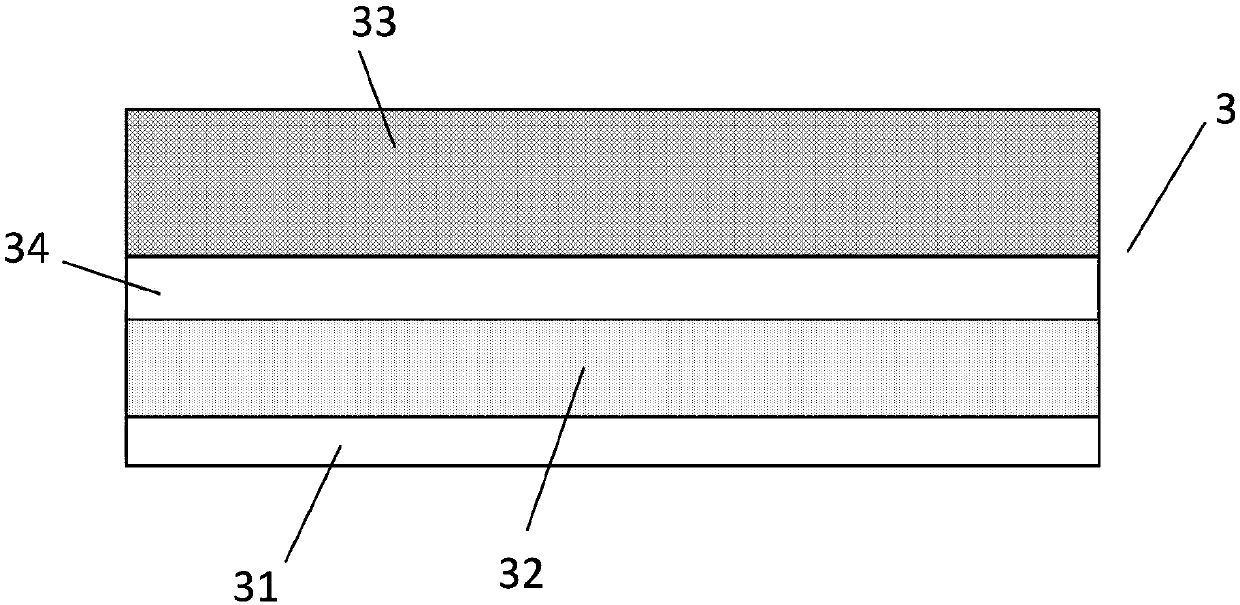

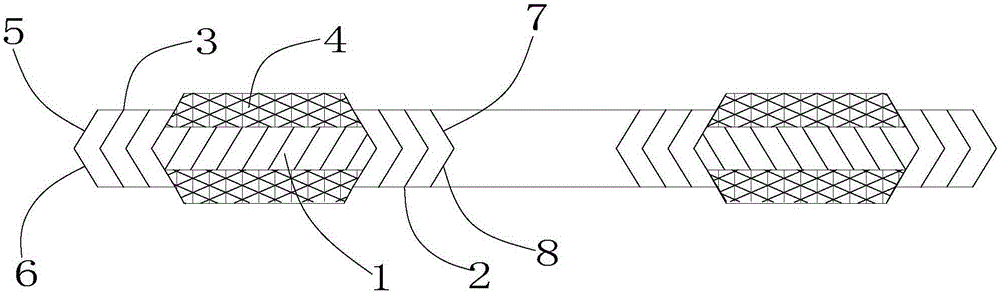

Electromagnetic shielding film for cable

ActiveCN106952678AExcellent flexibilityGood softness and toughnessConductive layers on insulating-supportsInsulated cablesElectromagnetic interferenceEngineering

Embodiments of the invention disclose an electromagnetic shielding film for a cable, relates to the wire rod manufacturing field, and is used to solve the problems of easy fractures of an existing electromagnetic shielding film and large time and electric energy consumption in the preparation process. The electromagnetic shielding film for the cable comprises a first metal layer, a conductive layer and a protection film; the first metal layer covers ecderon of a conductor of the cable, and is used for shielding an electromagnetic interference and being taken as a medium; the conductive layer is disposed on the first metal layer and is used for shielding the electromagnetic interference, and the conductive layer comprises a curing agent, metal particles and polyurethane for bearing the metal particles; and the protection film is disposed on the conductive layer, and is used for providing protection for the electromagnetic shielding film.

Owner:NANCHANG UNITETEC TECH CO LTD

Engine cylinder cover for combustion development

InactiveCN101956624APrevent leakageEliminate errorsCylinder headsSealing arrangements for enginesCombustion chamberCopper

The invention relates to an engine cylinder cover for combustion development at the combustion development experiment stage of an automobile engine. The engine cylinder cover comprises a cylinder cover and a cylinder hood fixed on the top of the cylinder cover, wherein the cylinder cover is provided with first and second mounting holes for communicating a return oil cavity and a cooling water passage and communicating the cooling water passage and a combustion chamber; and copper sleeves are arranged in the mounting holes. Cylinder pressure sensors are arranged at the lower ends of the copper sleeves so that the cylinder pressure sensors are arranged in the combustion chamber of the cylinder cover; and the cylinder cover does not leak air, water and oil.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

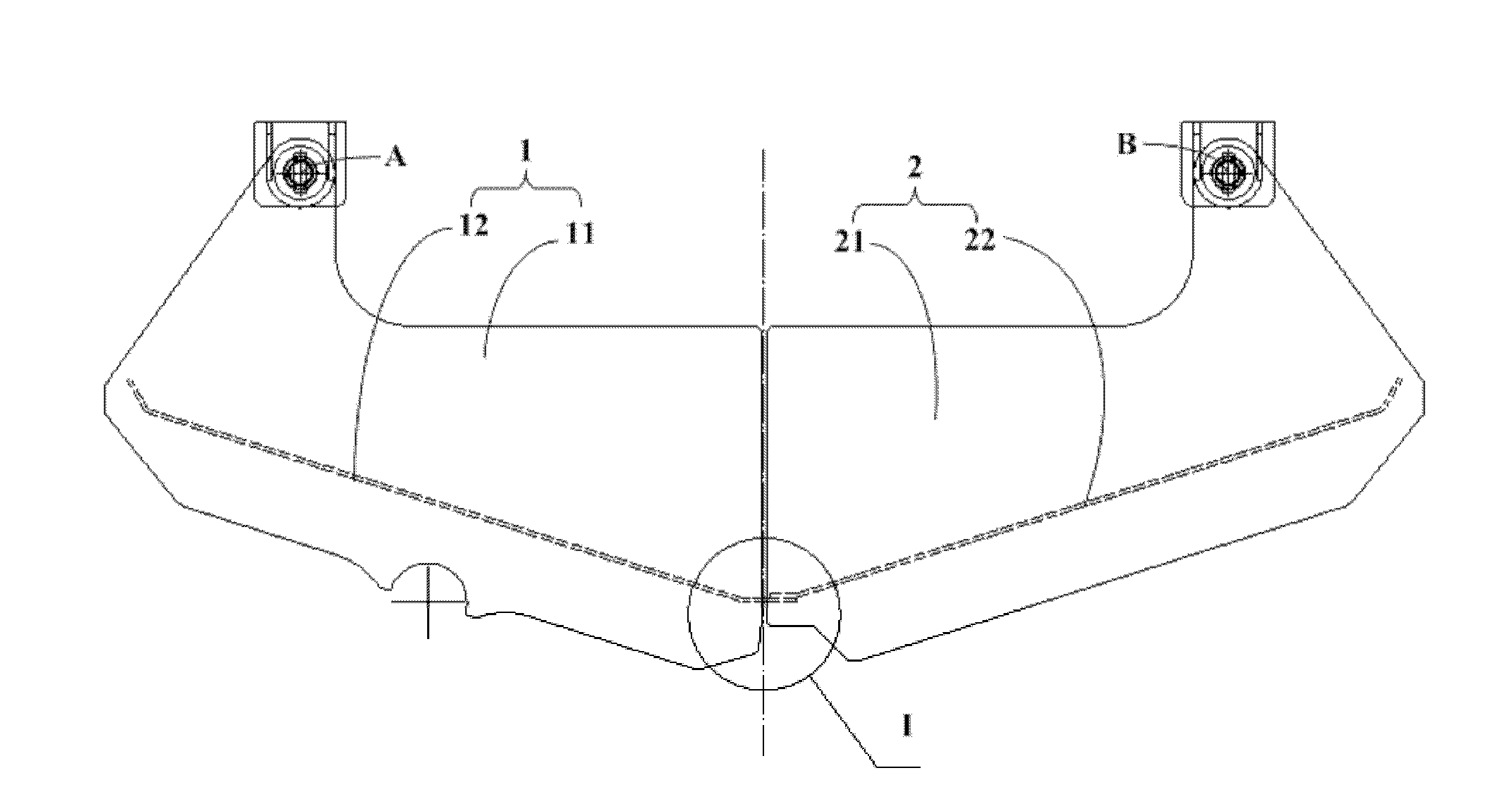

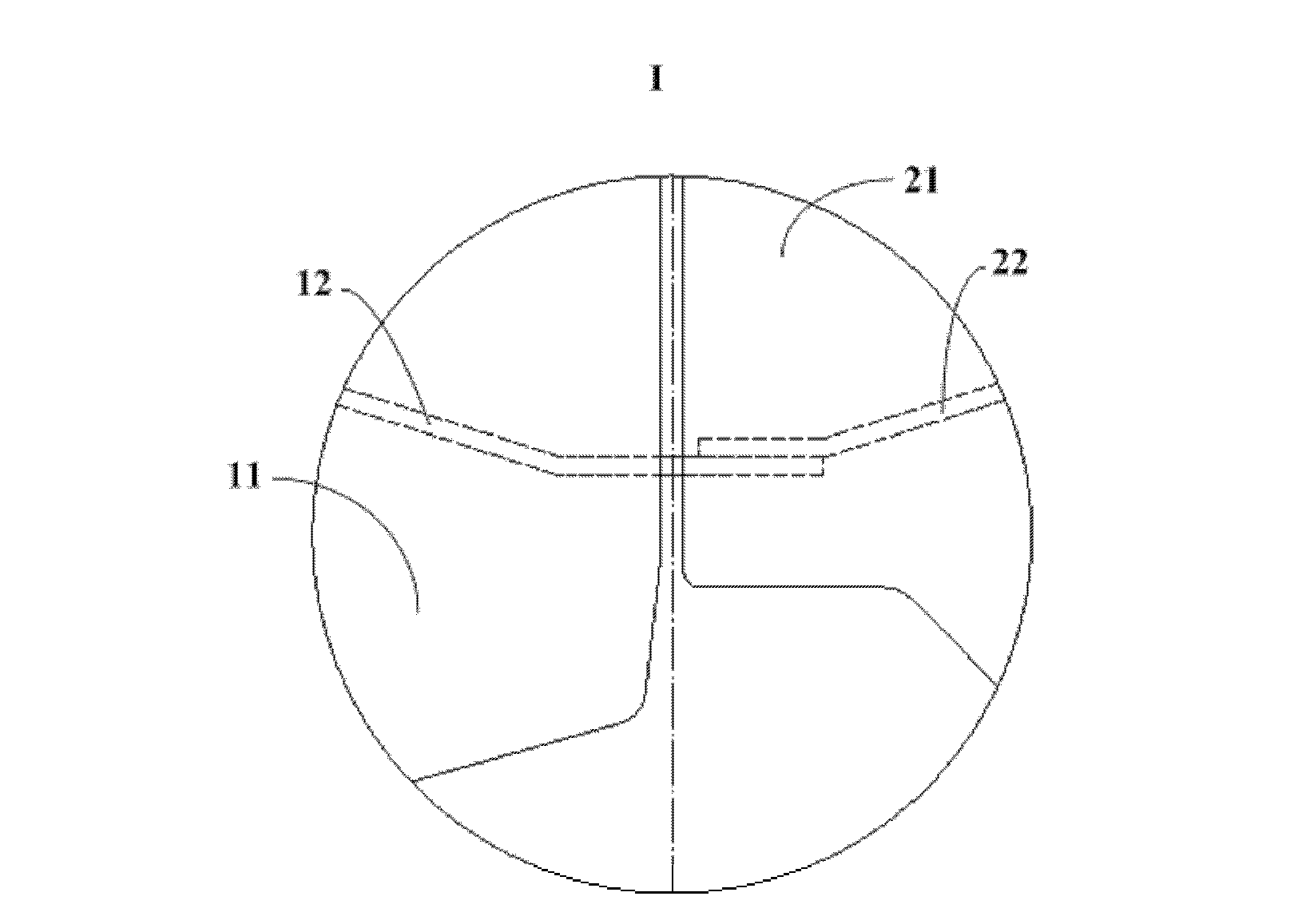

Bottom door device and hopper car

The invention provides a bottom door device and a hopper car. The bottom door device is provided with a first bottom door and a second bottom door, wherein the first bottom door is provided with a first door end plate and a first bottom door plate which are welded and fixed; the second bottom door is provided with a second door end plate and a second bottom door plate which are welded and fixed; and the first bottom door plate and the second bottom door plate are subjected to labyrinth seal. In the bottom door device and the hopper car which are provided by the invention, the labyrinth seal is adopted to replace the lap joint seal in the prior art, the requirement of tightness still can be satisfied on the premise that the two bottom door plates do not have a closing sequence, and the structure of the traditional bottom door device is optimized.

Owner:CRRC QIQIHAR ROLLING CO LTD

Cutting ring and glasses plate and processing method thereof

ActiveCN101858343ASatisfy compatibilityMeet the tightness requirementsPositive displacement pump componentsLiquid/solution decomposition chemical coatingMegasonic cleaningBoron nitride

The invention discloses a cutting ring and a glasses plate, which comprise a cutting ring and a glasses plate matrix provided with an abrasion-resistant layer, wherein the abrasion-resistant layer is a diamond or cubic boron nitride composite plating layer wrapped by a nickel layer carcass. The processing method comprises the following steps of: cleaning a material by adopting layer-by-layer piling and ultrasonic wave, plating the material in one layer at every time with the thickness of only one diamond granule or cubic boron nitride granule, and piling the material layer by layer to form a composite plating layer so as to form the abrasion-resistant layer of the cutting ring and the glasses plate matrix. The abrasion-resistant layer not only has extremely excellent abrasion resistance, but also has the characteristics of good adhesiveness and strong impact resistance. Compared with the hard alloy abrasion-resistant layer, the service life of the plating layer with the same thickness under the same working condition is about 20 times longer; and the surface of the formed plating layer is uniform and flat so as to meet the requirement of workpiece cooperation or leak tightness of the cutting ring and the glasses plate.

Owner:浏阳湘德机械制造厂

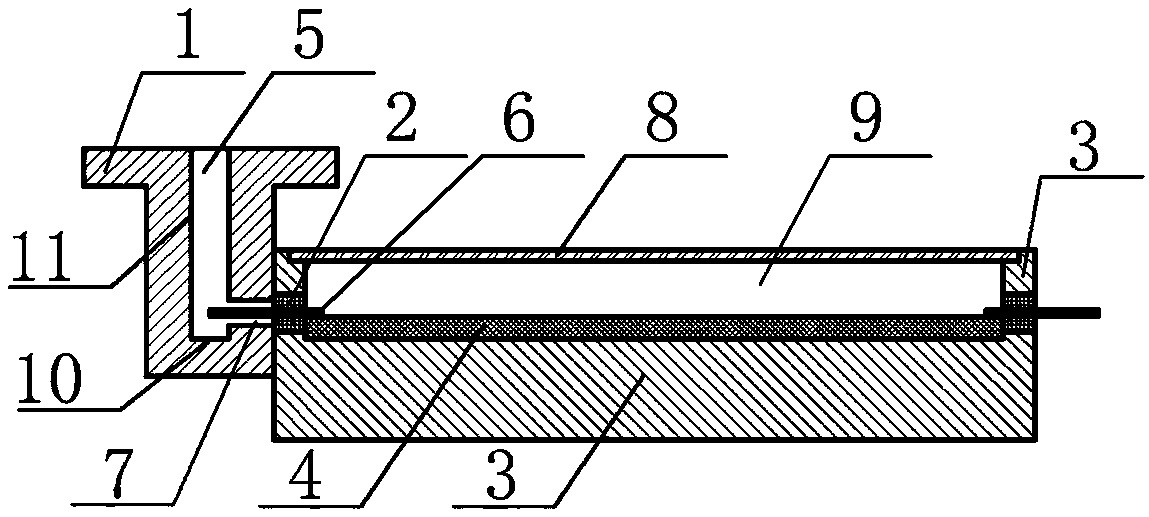

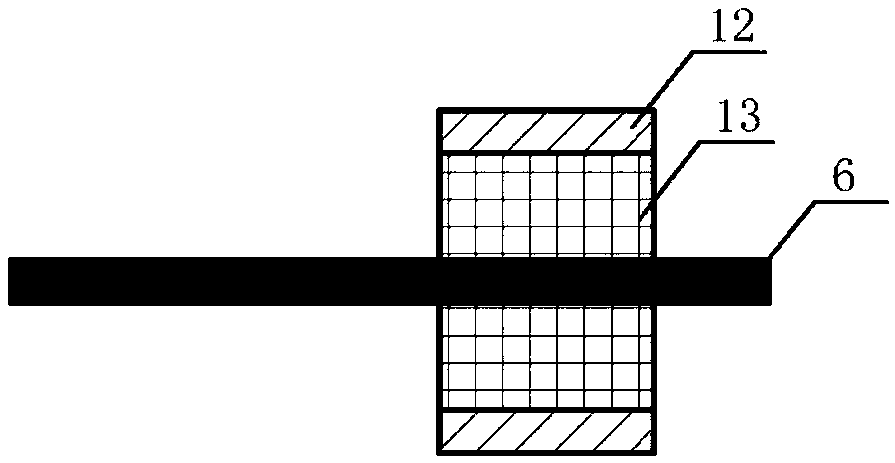

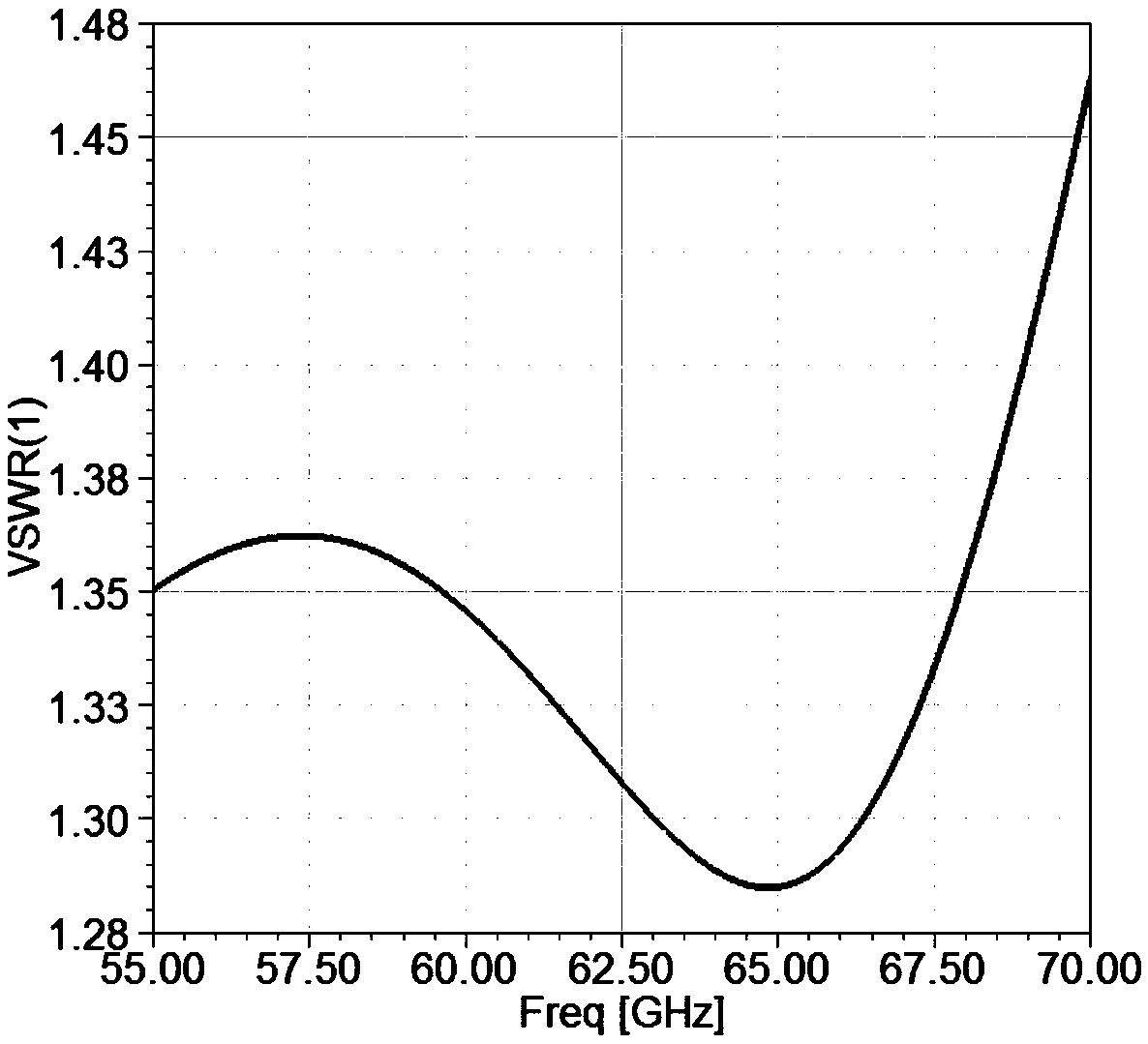

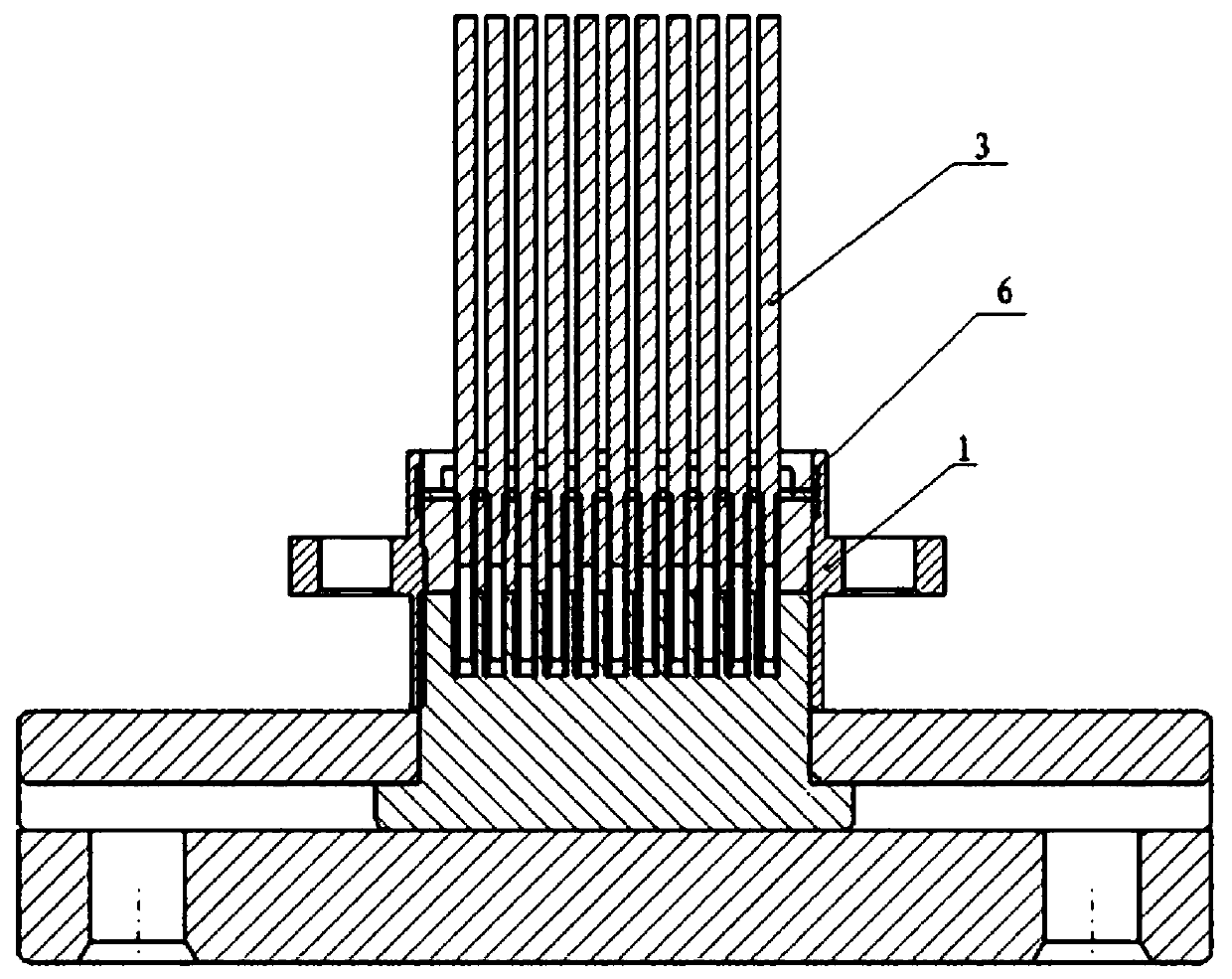

Waveguide coaxial microstrip conversion circuit

InactiveCN109524753AMeet the tightness requirementsEasy to useCoupling devicesMicrowave cavityElectrical conductor

The invention discloses a waveguide coaxial microstrip conversion circuit comprising a rectangular waveguide joint, a coaxial insulator, a microwave circuit box body and a microstrip circuit. The coaxial insulator comprises an inner conductor, an outer conductor and an insulating support structure. One end of the inner conductor passes through a through hole set in a waveguide wall to extend intoa waveguide cavity of the rectangular waveguide joint, and the other end of the inner conductor is connected to a microstrip line. A cover plate is arranged above the microwave circuit box body, and asealed microwave cavity is formed between the cover plate and the box body. According to the invention, one end of the inner conductor of the coaxial insulator passes extends into the cavity of the rectangular waveguide joint, the conversion of waveguide and coaxality is achieved, at the same time, the sealing performance requirement of the microwave circuit box body can be satisfied, the other end is connected to the microstrip line through a welding, bonding or crimping mode, the conversion of coaxality and the microstrip line is achieved, and the direction of a waveguide port is perpendicular to the direction of a microstrip transmission line. The rectangular waveguide joint can be disassembled and can be replaced with a coaxial connector for easy testing during commissioning.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

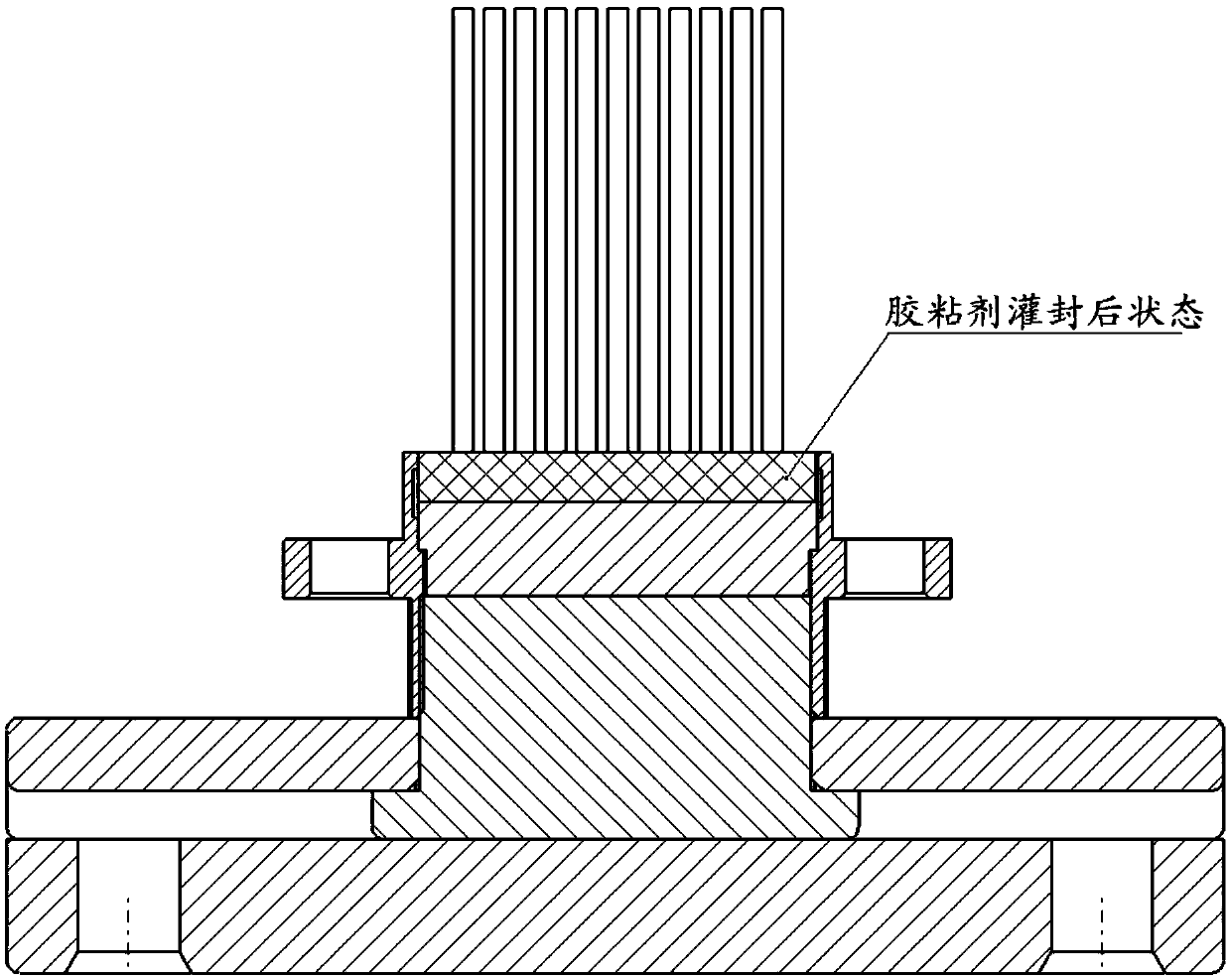

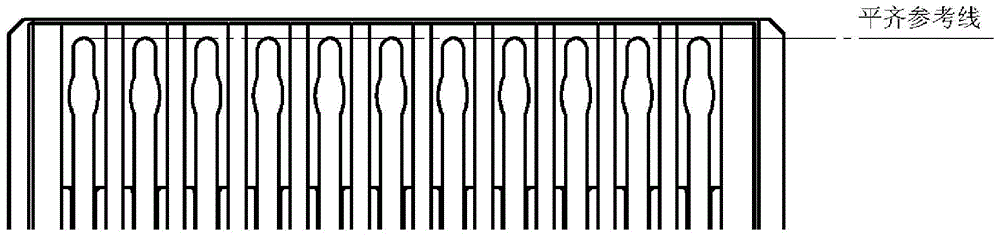

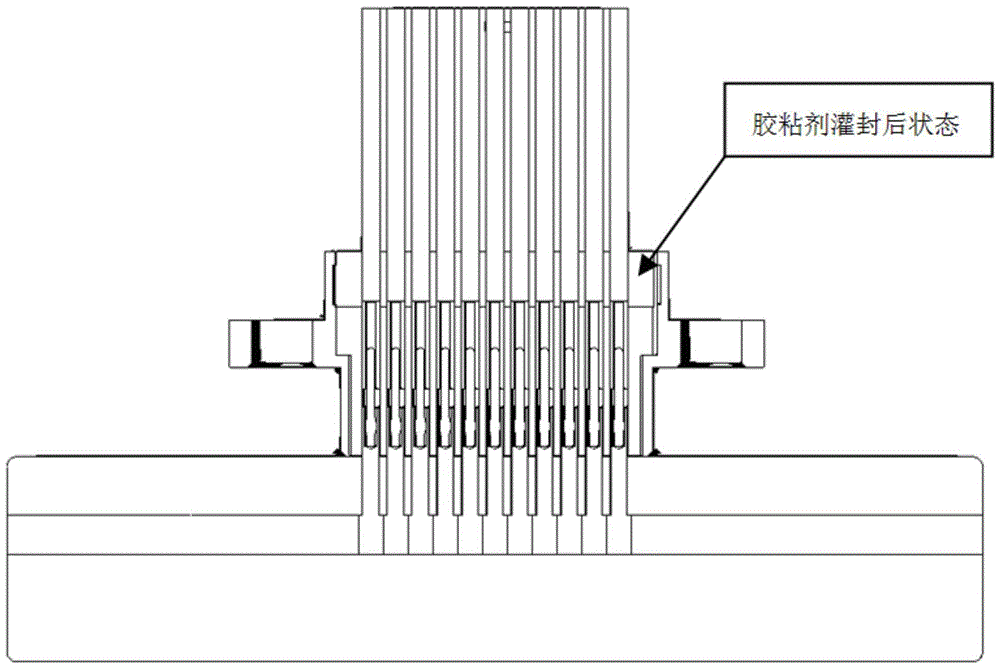

Technological method for encapsulating micro-rectangular jack electric connector

InactiveCN105514665AMeet the tightness requirementsSolve the sealing problemContact member assembly/disassemblyCouplings bases/casesChemistryElectricity

The invention discloses a technological method for encapsulating a micro-rectangular jack electric connector. The technological method comprises the following steps: 1, preparation of an adhesive: preparing the adhesive from an adhesive A and an adhesive B DG-3S of China BlueStar Chemical Engineering Research and Design Co. Ltd. according to the mass ratio of the adhesive A to the adhesive B of (1.5-2):1, and continuously stirring for 1 to 2 minutes until the adhesives are uniformly mixed and the colors of the adhesives are consistent. According to the technological method for encapsulating the micro-rectangular jack electric connector, the problems that the process is complicated, the cost is high, minimized product sealing is inconvenient, and the sealing property of a micro-rectangular electric connector is affected due to the deficiencies of low medium pressure resistance and low airtightness in rubber piece sealing and glass sintering sealing modes are solved. Certain instruction significance is provided for developing a micro-rectangular connector into a super-micro-rectangular connector, meeting the requirement on the sealing property of the super-micro-rectangular connector.

Owner:沈阳兴华航空电器有限责任公司

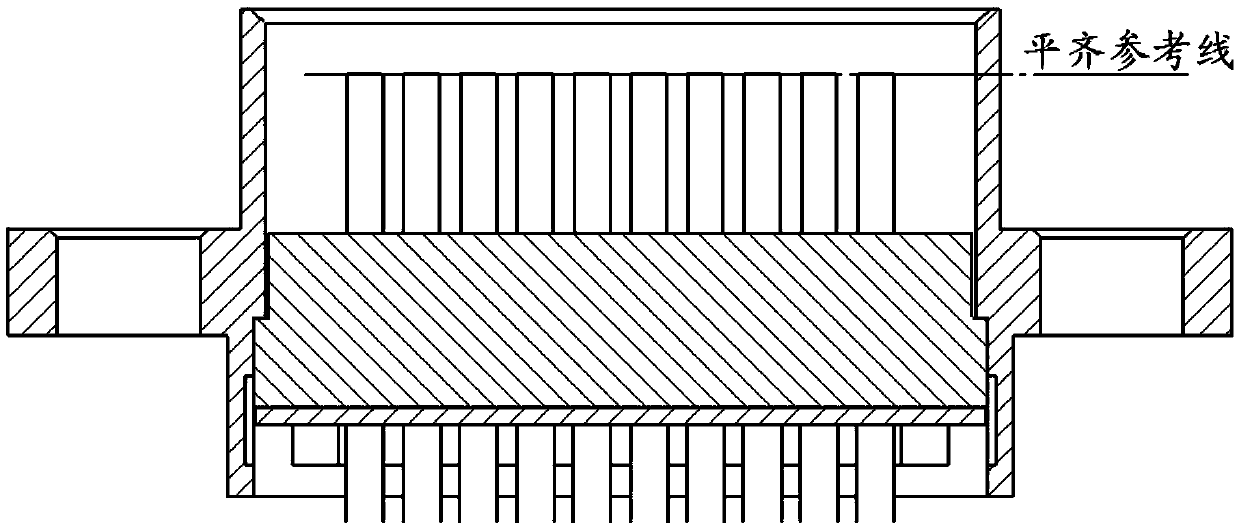

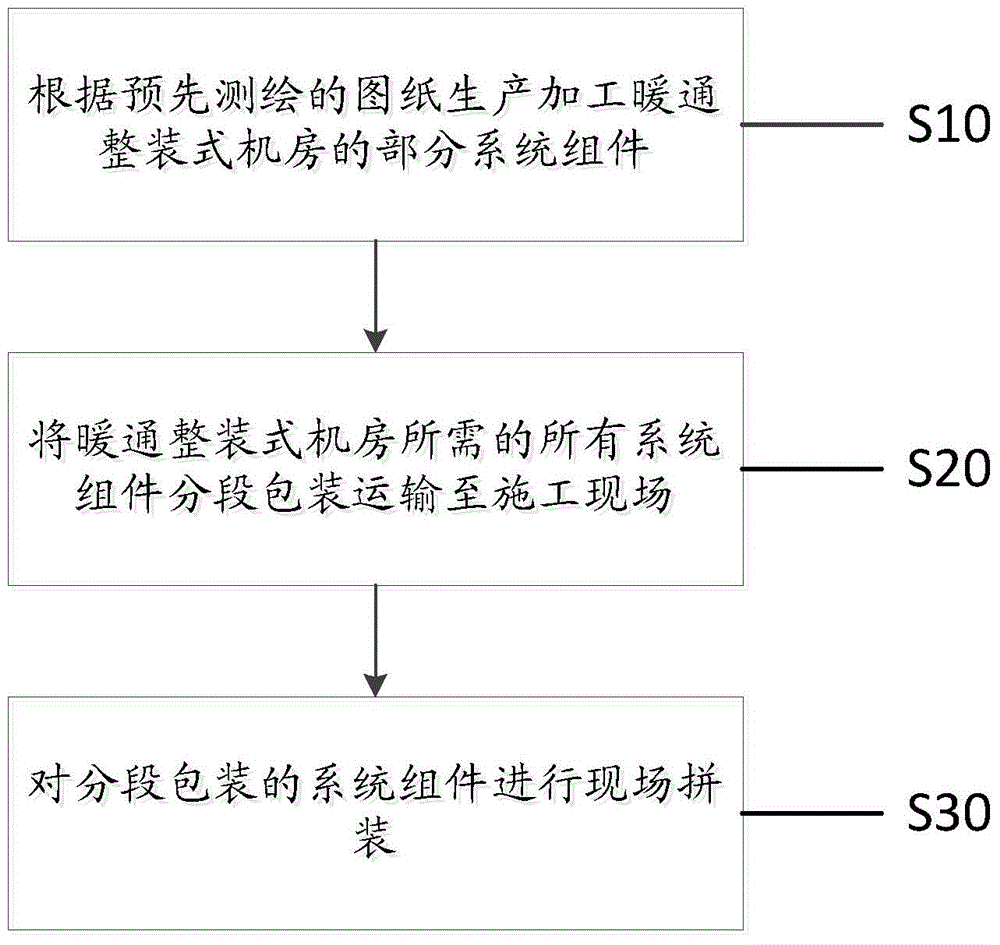

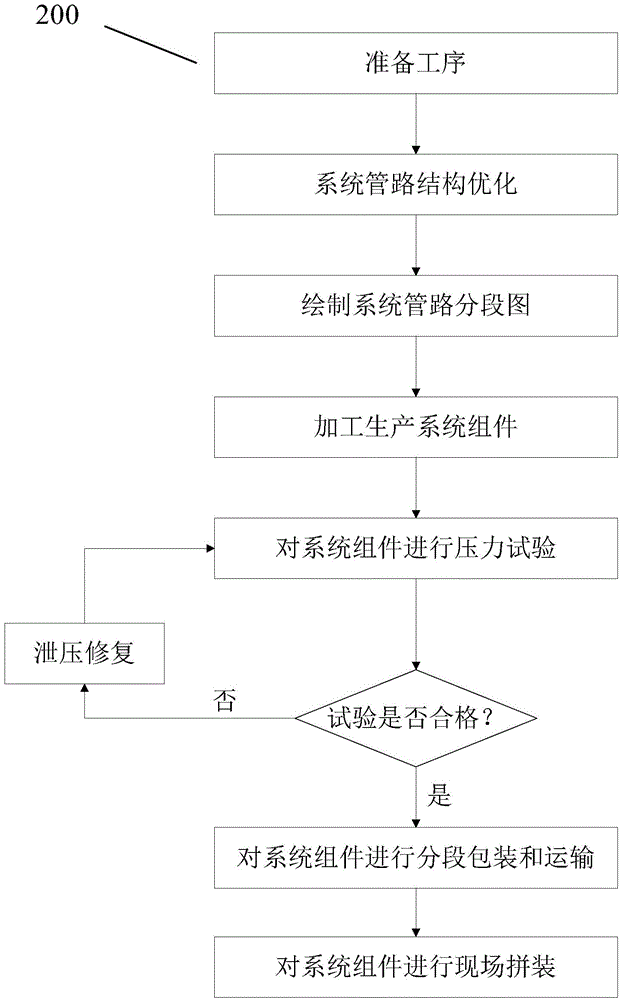

Assembling method of heating and ventilation integral machine room and heating and ventilation integral machine room

ActiveCN104912356AReduce rework rateSave materialBuilding material handlingIndustrial buildingsPartial systemWork period

The invention provides an assembling method of a heating and ventilation integral machine room. The method comprises the following steps of: producing partial system assemblies required by the processing of the heating and ventilation integral machine room according to a drawing surveyed and mapped in advance; performing segmented packaging on all system assemblies required by the heating and ventilation integral machine room and transporting all of the system assemblies required by the heating and ventilation integral machine room to a construction field; and performing field splicing on the segmented packaged system assemblies. By aiming at the problems in the prior art, the invention aims at providing the assembling method of the heating and ventilation integral machine room and the heating and ventilation integral machine room assembled according to the assembling method, so that the defects of low assembling work efficiency, long installing work period and material waste of the existing machine room system are overcome; and the material-saving assembling method with high installation efficiency and the heating and ventilation integral machine room assembled according to the method are provided for machine room system assembly.

Owner:ANHUI SINO SOURCE NEW ENERGY TECH CO LTD

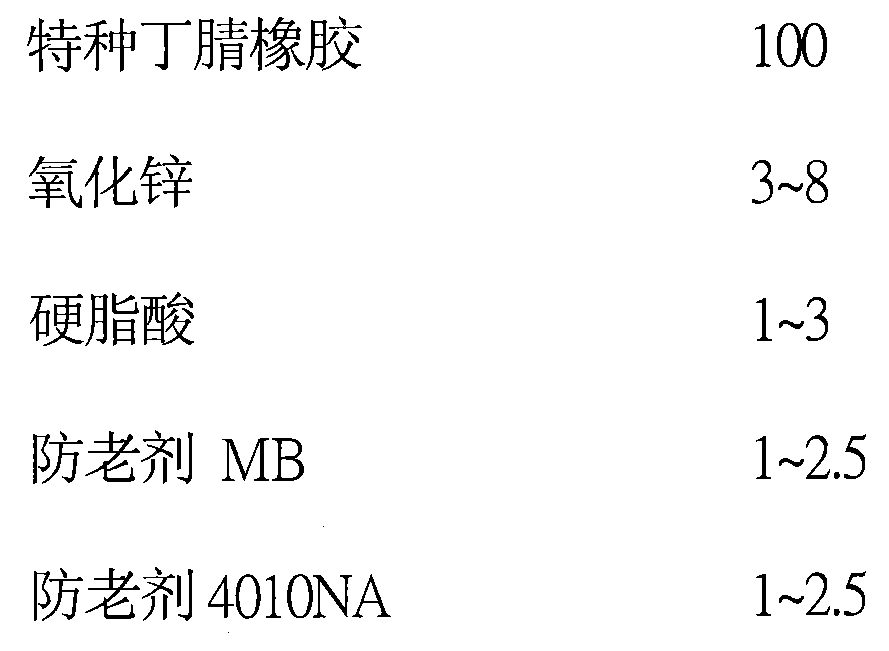

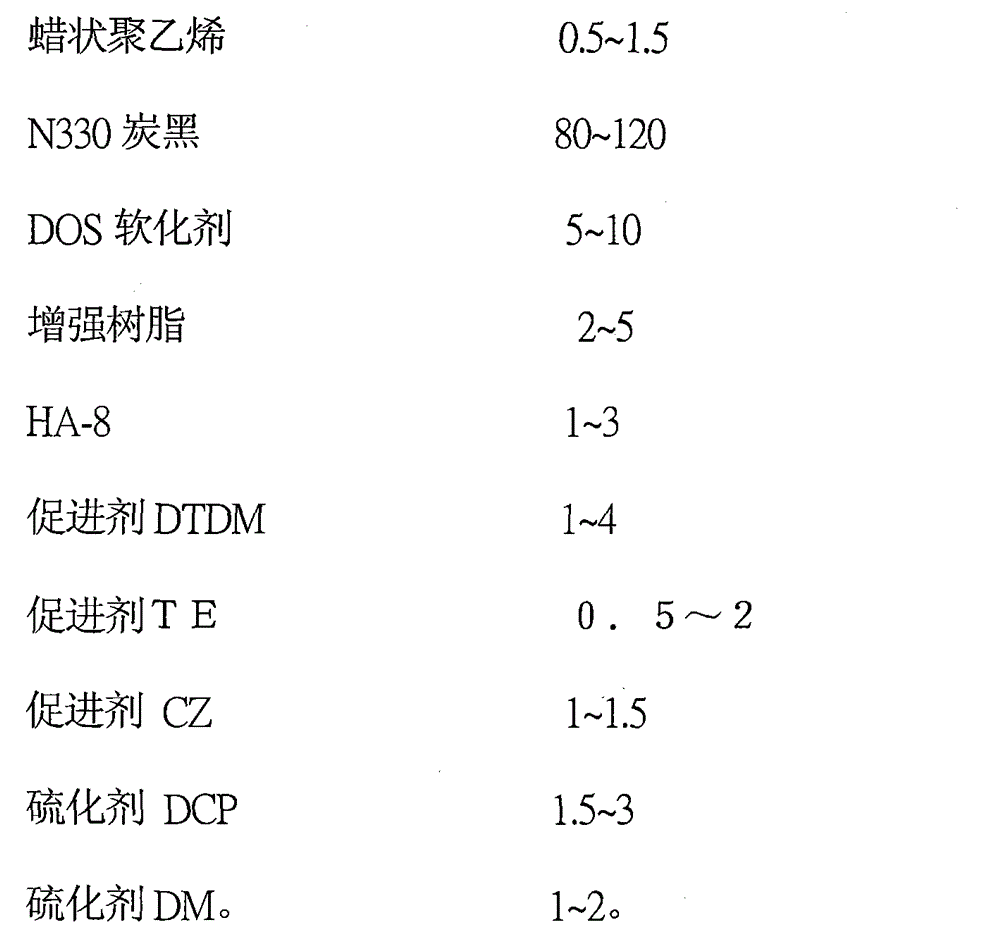

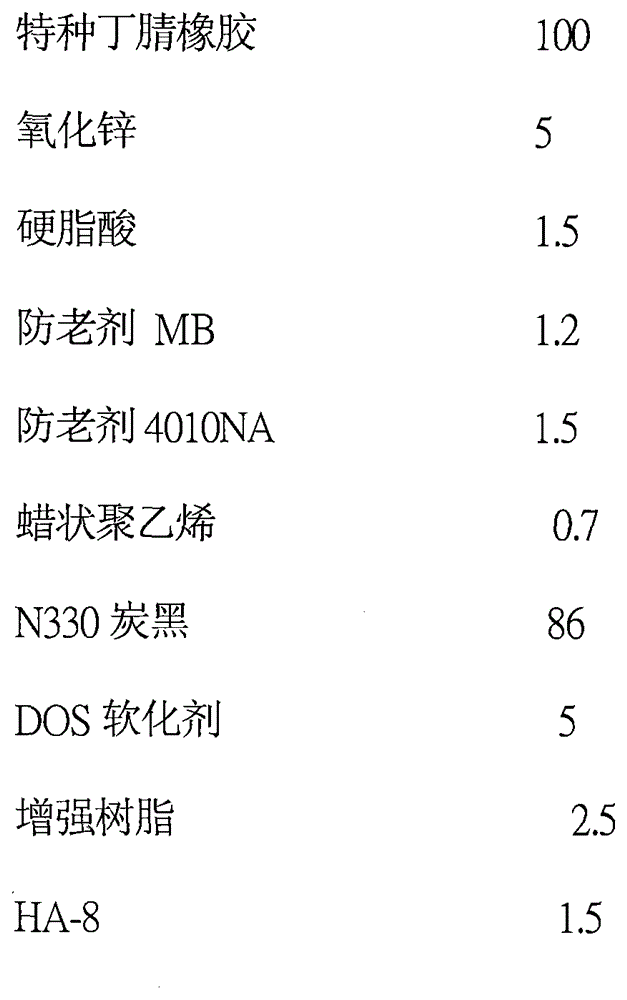

Preparation process of ultralow-temperature-resistant mixing material

The invention relates to a preparation process of an ultralow-temperature-resistant mixing material. A rubber compound, which is resistant to minus 50 DEG C and has an excellent processing property, is suitable for mold pressing vulcanization molding. Special buna-N rubber is adopted as a base material, carbon black N330 is taken as a filler, reinforced resin, wax-shaped polyethylene and HA-8 are taken as modifying agents, DOS is taken as a softening agent, and meanwhile an appropriate amount of anti-aging agents 4010NA and MB, active agent zinc oxide and stearic acid as well as vulcanizating agents DCP, DTDM, CZ, DM and TE are taken as ingredients, so that the ultralow-temperature-resistant mixing material is formed through compounding, smelting and cooking. The ultralow-temperature-resistant mixing material has the performance advantages and practicability that firstly, a sealing element produced by using the ultralow-temperature-resistant mixing material can meet the sealing performance requirements of coal mine hydraulic support upright columns and jacks and is normally used under the condition of minus 50 DEG C; secondly, the ultralow-temperature-resistant mixing material is good in processability in production and higher in product percent of pass, and the production cost is relatively reduced; thirdly, the performance of the ultralow-temperature-resistant mixing material accord with the HG / T 3326-2007 standard.

Owner:XIANYANG KELONG SPECIAL RUBBER PROD

Micro-zone repair welding method for aluminum alloy defect

ActiveCN101011771AIncrease energy densityShort heating timeArc welding apparatusPulse energyMaterials science

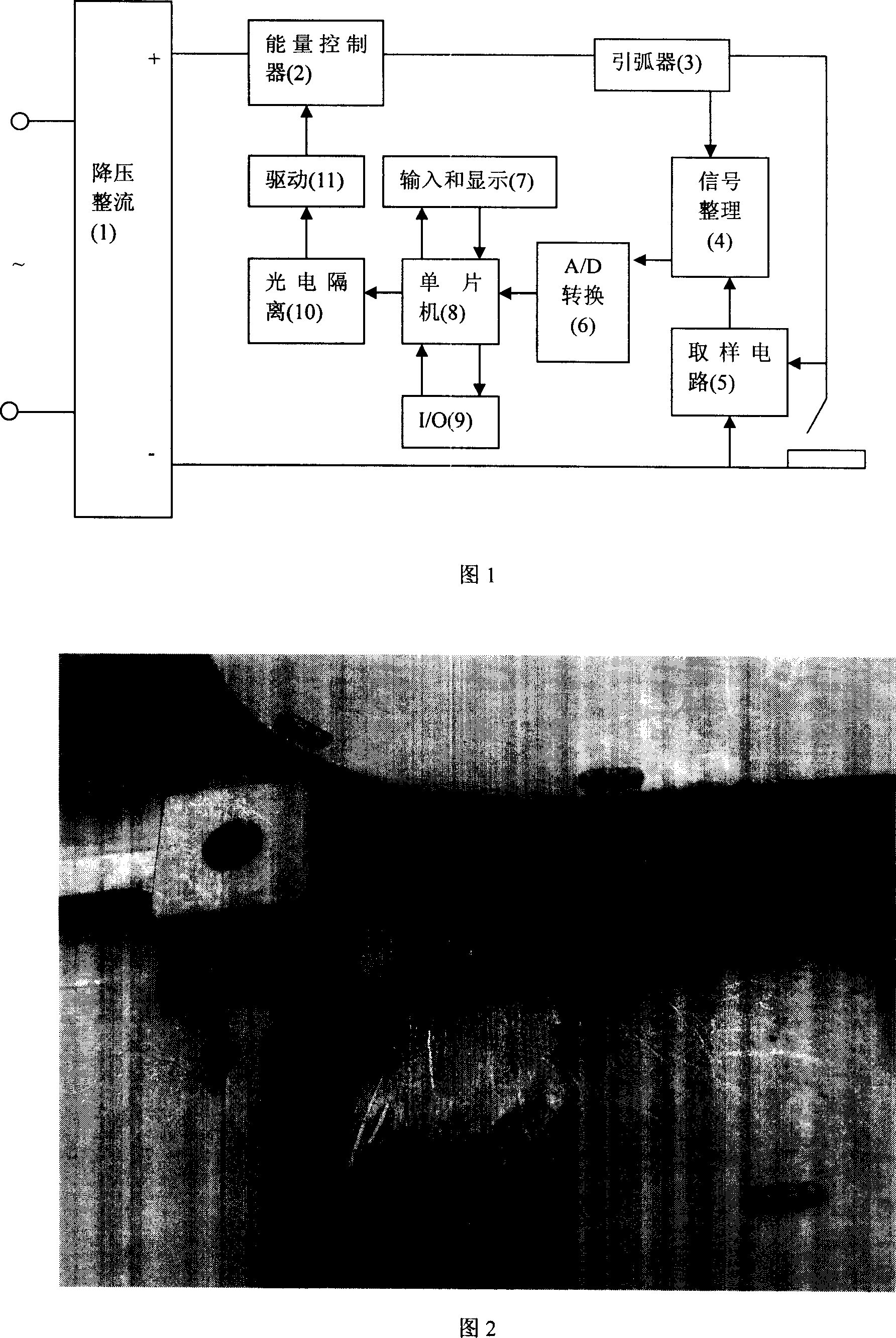

The repairing welding for aluminum alloy defects starts with deciding defect location, trimming before the welding, degreasing for the repairing area, micro zone weld repairing using pulse energy, inspecting the working piece to make sure the repairing quality, till the nonexistence of leakage of the part. It also relates to the pulse energy micro bonding machine. Without affecting the dimension of the base metal, it can repair the defect, meeting the sealing requirement.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

An electromagnetic shielding film for cables

ActiveCN106952678BGood flexibilityShort curing timeConductive layers on insulating-supportsInsulated cablesWire rodElectrical conductor

Embodiments of the invention disclose an electromagnetic shielding film for a cable, relates to the wire rod manufacturing field, and is used to solve the problems of easy fractures of an existing electromagnetic shielding film and large time and electric energy consumption in the preparation process. The electromagnetic shielding film for the cable comprises a first metal layer, a conductive layer and a protection film; the first metal layer covers ecderon of a conductor of the cable, and is used for shielding an electromagnetic interference and being taken as a medium; the conductive layer is disposed on the first metal layer and is used for shielding the electromagnetic interference, and the conductive layer comprises a curing agent, metal particles and polyurethane for bearing the metal particles; and the protection film is disposed on the conductive layer, and is used for providing protection for the electromagnetic shielding film.

Owner:NANCHANG UNITETEC TECH CO LTD

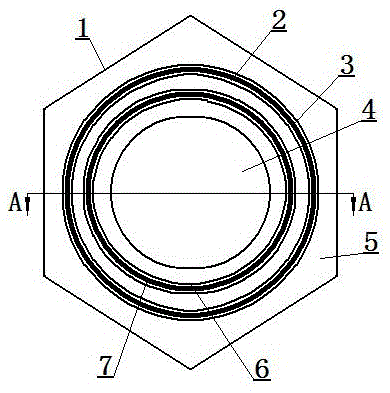

Hexagonal nut with seal rings

InactiveCN105605072APrevent misalignment and deformationInhibit sheddingWashersNutsSoft magnetArchitectural engineering

The invention discloses a hexagonal nut with seal rings. A nut end face outside a screw hole is provided with an inner circular groove and an outer circular groove, the inner circular groove and the outer circular groove are axially identical, an inner seal ring and an outer seal ring are arranged in the inner circular groove and the outer circular groove respectively, and heights of the inner seal ring and the outer seal ring are equal and larger than depths of the bottoms of the inner circular groove and the outer circular groove. A nut body is made from a magnet attracting iron material, the inner seal ring and the outer seal ring are rubber soft magnets, and magnetic surfaces of the inner seal ring and the outer seal ring are positioned upwards to enable the inner seal ring and the outer seal ring to be attracted in the inner circular groove and the outer circular groove respectively under the magnetic action. The hexagonal nut with the seal rings has the advantages that excellent sealing effects are achieved since deflection and deformation of the seal rings are prevented, and the seal rings are protected from being lost resulted from shedding from a screw rod.

Owner:罗福仲

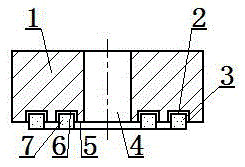

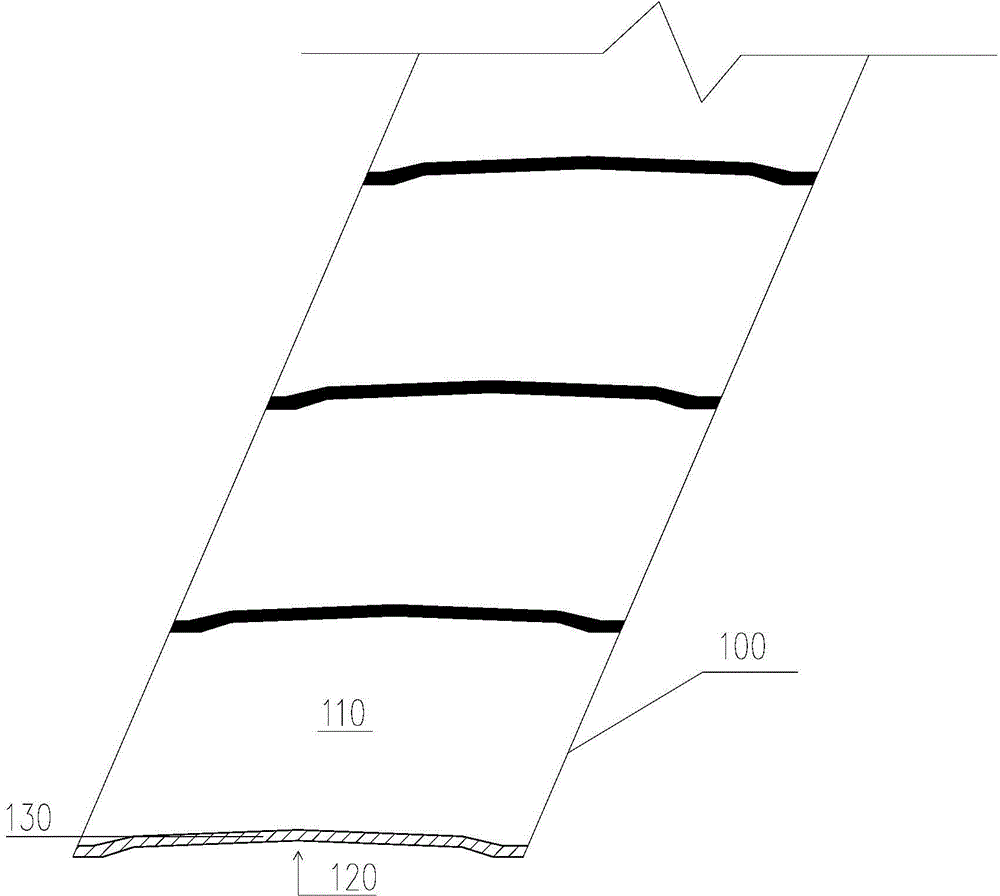

Flue sheet structure for tunnel exhaust duct

ActiveCN104088657AReduce long-term deflectionMeet surface roughnessTunnel/mines ventillationFlueRebar

The invention discloses a flue sheet structure for a tunnel exhaust duct. The flue sheet structure comprises a plurality of prefabricated flue plates, the prefabricated flue plates are sequentially spliced in the length direction of a tunnel, and the cross sections of the prefabricated flue plates are in arch shapes. Each prefabricated flue plate comprises the convex top face, the concave bottom face and the two butt-joint end faces, wherein the two butt-joint end faces are arranged in a back-to-back mode, the convex top face and the concave bottom face are arranged between the two butt-joint end faces, the convex top face is located above the convex bottom face, and long-strip-shaped notches are formed in the connecting positions of the two butt-joint end faces and the convex top face. The adjacent prefabricated flue plates are connected in a butt joint mode through the butt-joint end faces and the notches, and the notches are filled with cast-in-place reinforced concrete. According to the flue sheet structure, the plates of the arch-shaped structures are adopted, and long-term deflection under the dead-load effect of the structure can be reduced; meanwhile, seepage water at a tunnel vault can be collected towards the two sides of a flue sheet through the arch-shaped gradient to be discharged into tunnel drainage ditches so that influences, caused by the wet environment, on inner-flue mechanical equipment can be reduced.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

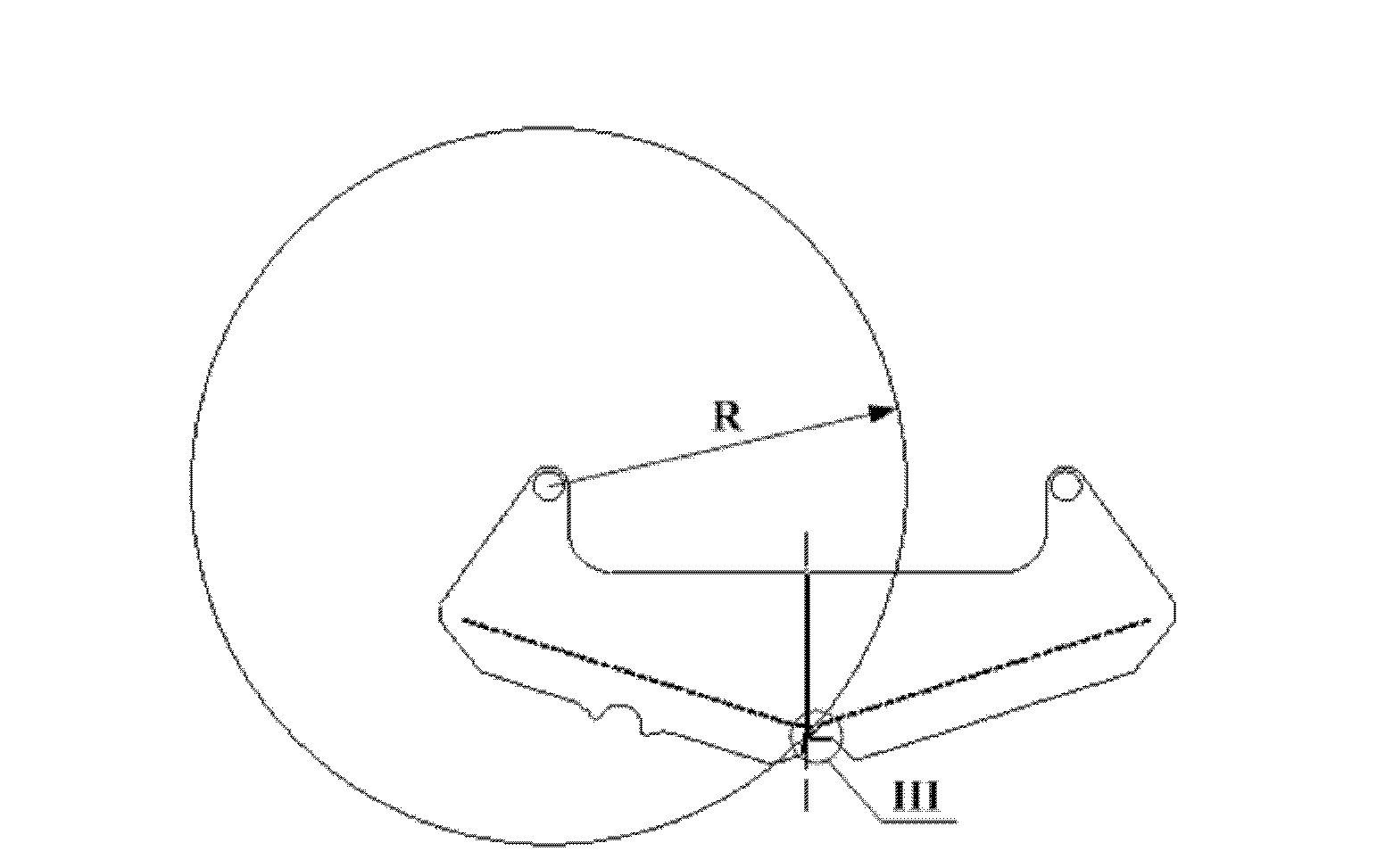

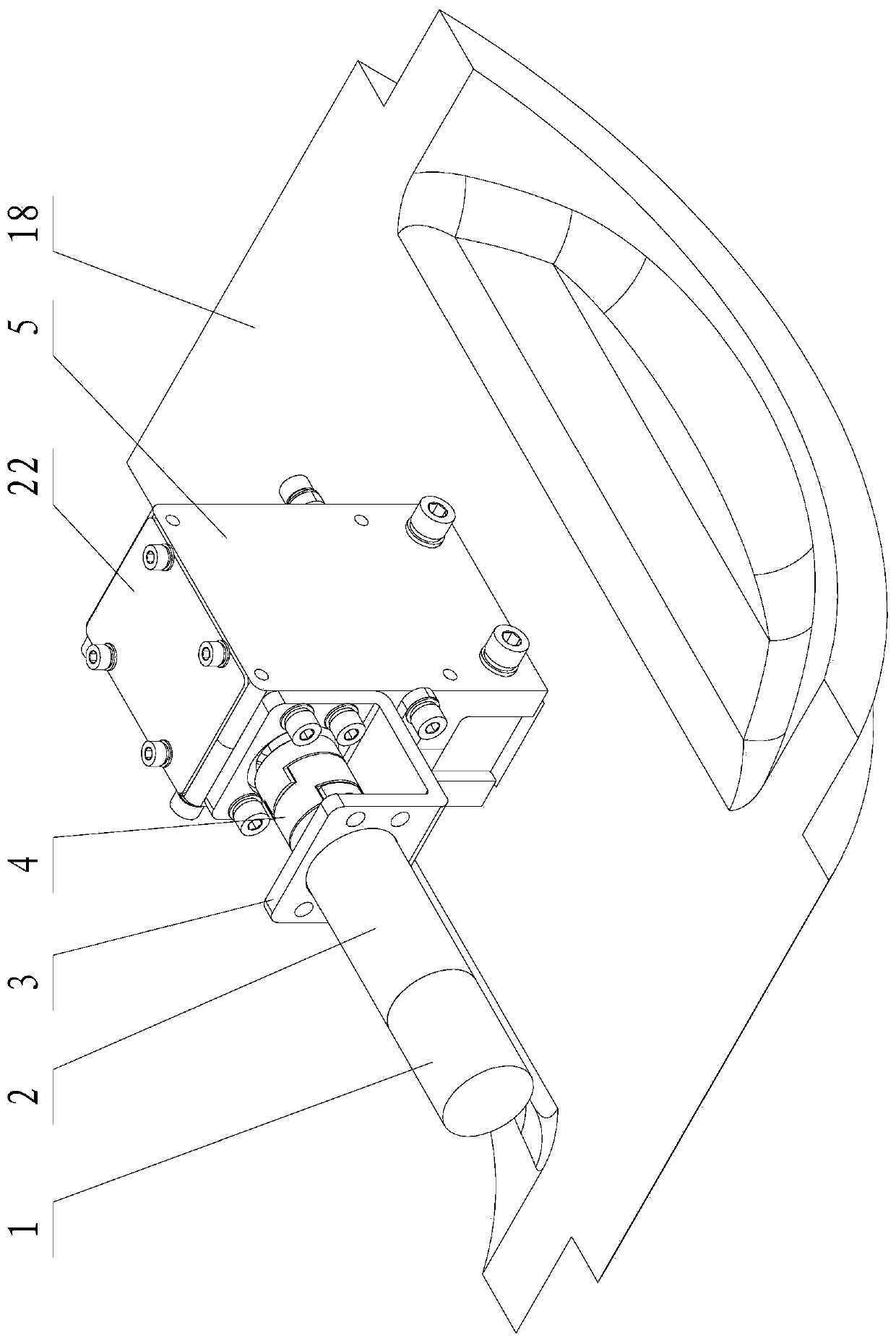

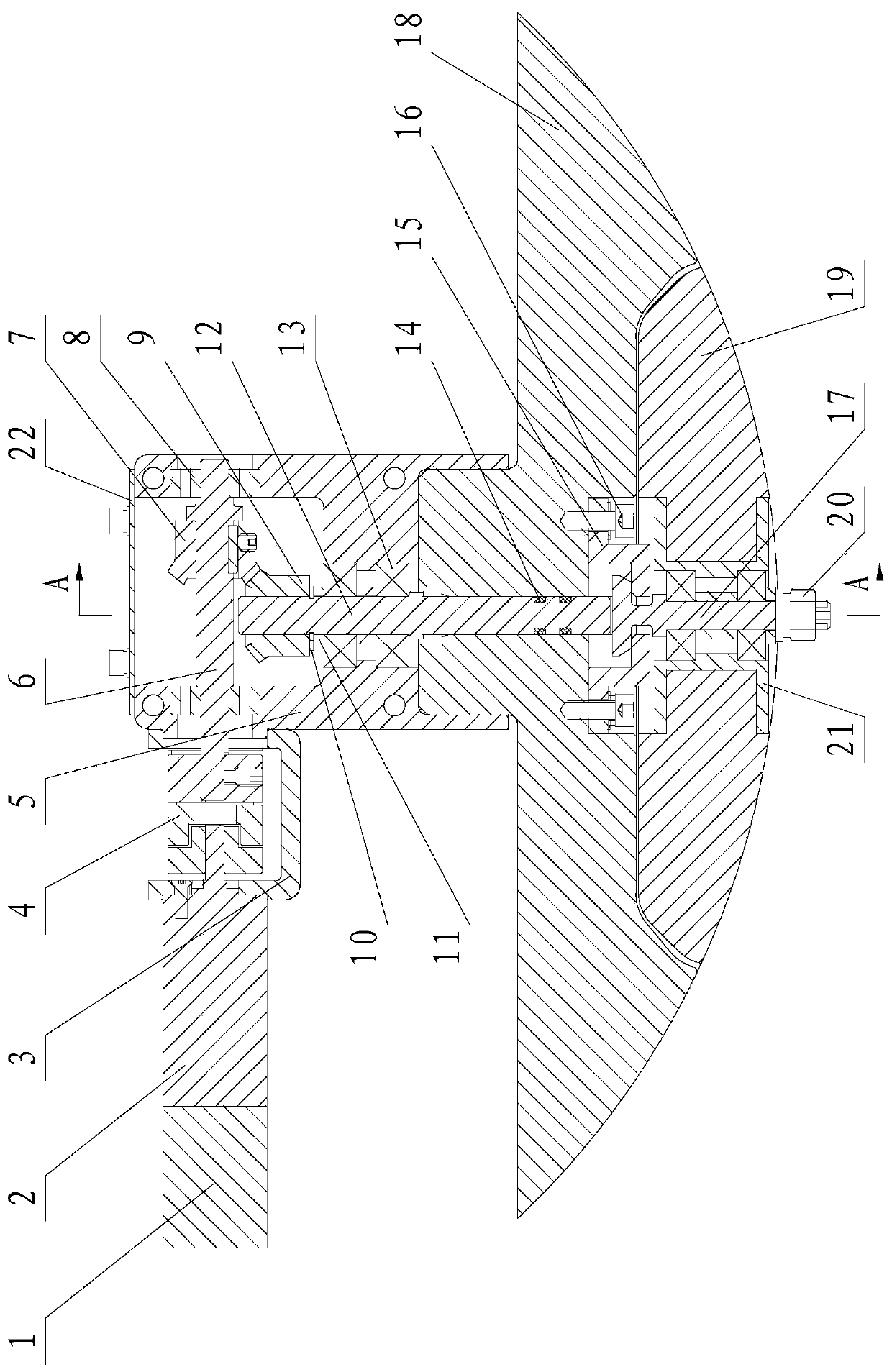

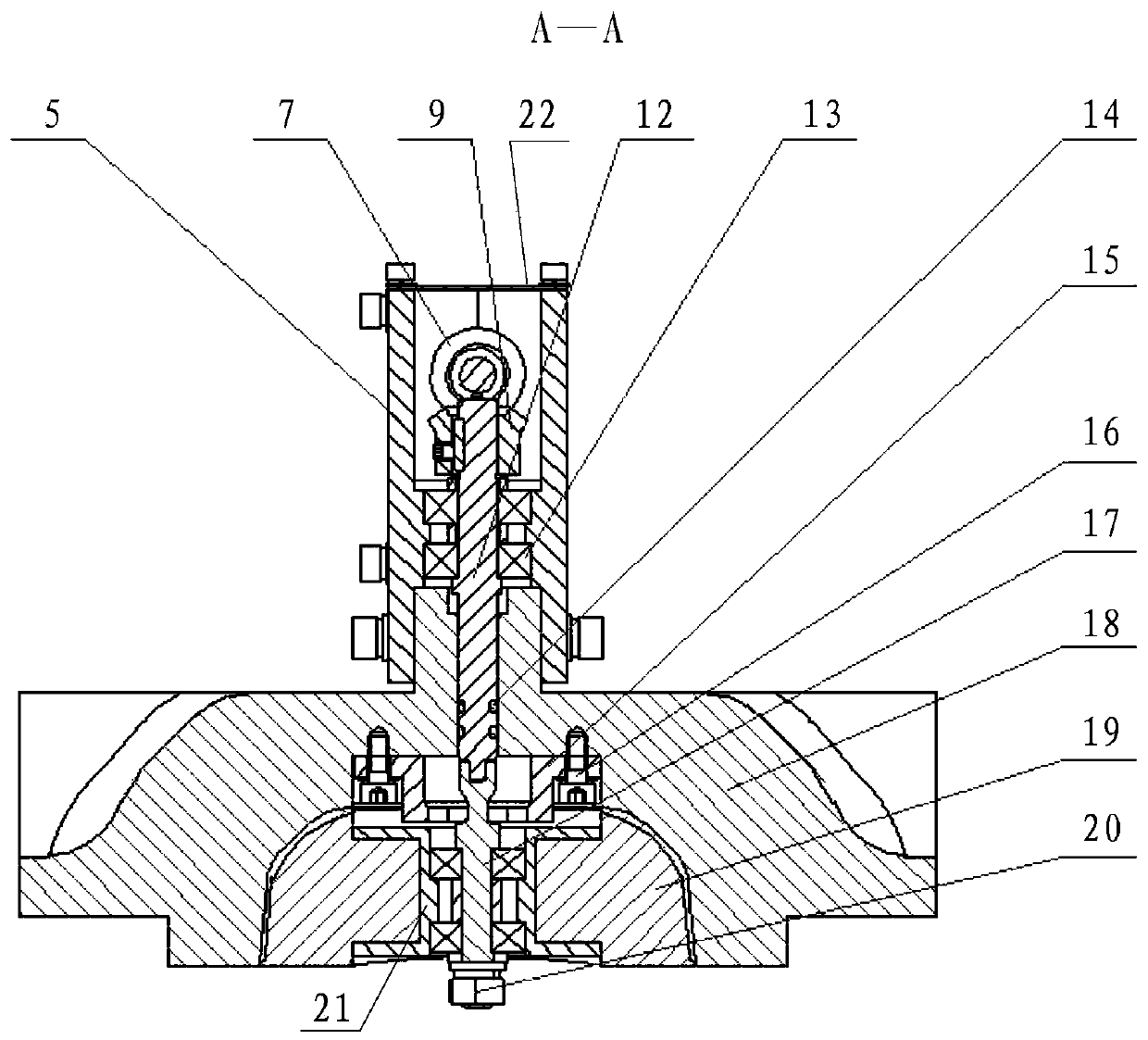

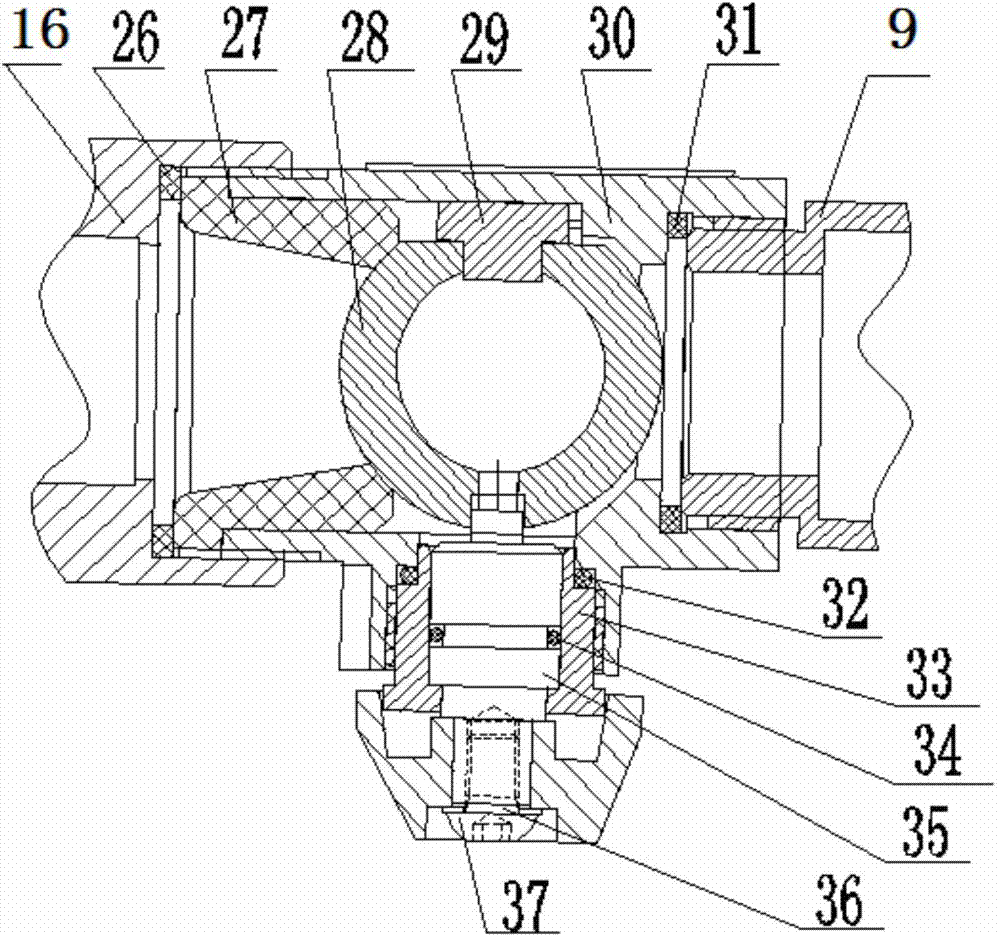

Emergency load rejection device for underwater robot

ActiveCN110979604AMaintain hydrodynamic propertiesAdapt to pressure requirementsUnderwater equipmentNuclear energy generationGear driveGear wheel

The invention belongs to the field of underwater robots, and particularly relates to an emergency load rejection device for an underwater robot. The torque is transmitted to a load rejection horizontal shaft after a direct current motor is decelerated by a planetary gear reducer, the load rejection horizontal shaft transmits rotary motion to a load rejection vertical shaft through gear transmission, the load rejection vertical shaft transmits rotation to a lead block supporting piece through a rectangular notch, and a rectangular sliding groove is formed between the lead block supporting pieceand a load rejection tray. When the lead block supporting piece rotates to be parallel to the sliding groove of the load rejection tray, a load rejection lead block acts on the lead block supportingpiece through gravity and falls off from the sliding groove, so that the load rejection lead block is separated from a carrier. After the underwater robot discards a part of mass in emergency, the gravity of the underwater robot is smaller than the buoyancy, and therefore the underwater robot can safely float out of the water surface. The device has the advantages of being simple and compact in structure, high in efficiency, easy to control, low in cost, good in underwater sealing performance, capable of being repeatedly used, easy to install and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

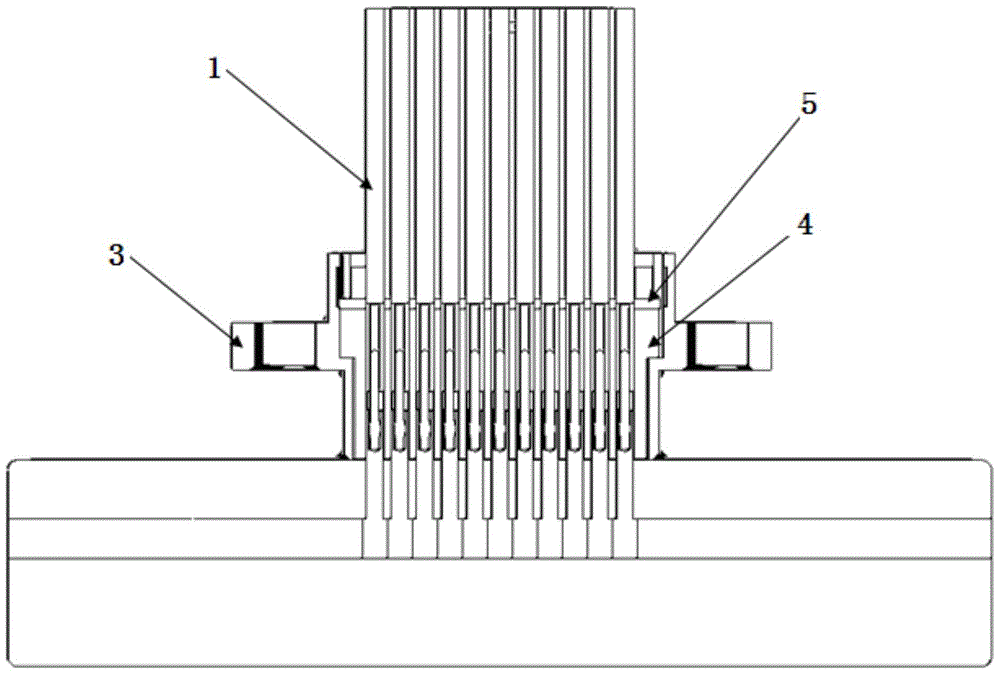

Combined wound gasket

The invention discloses a combined wound gasket which solves the problems that an existing metal wound gasket is prone to damage and prone to falling apart. The combined wound gasket comprises a pressure bearing ring. An initial pressure inner ring is arranged on the inner side of the pressure bearing ring, and an initial pressure outer ring is arranged on the outer side of the pressure bearing ring. The initial pressure inner ring and the initial pressure outer ring are each of a V-shaped structure. V-shaped openings are formed oppositely. The upper end of the pressure bearing ring, the V-shaped upper edge of the inner ring and the V-shaped upper edge of the outer ring form an upper cavity. The lower end of the pressure bearing ring, the V-shaped lower edge of the inner ring and the V-shaped lower edge of the outer ring form a lower cavity. Non-metal filler is arranged both in the upper cavity and the lower cavity. According to the combined wound gasket, due to cooperation of the initial pressure inner ring and the initial pressure outer ring with the oppositely-formed V-shaped openings and the pressure bearing ring, the combined wound gasket has the beneficial effects of being reasonable in structure and ingenious in conception; and the non-metal filler is arranged both in the upper cavity and the lower cavity, and therefore the whole combined wound gasket has good torsion resistance, bending resistance, shearing resistance and other mechanical properties and is high in anti-deformation capacity and free of the phenomena that the combined wound gasket falls apart and is squashed.

Owner:自贡鑫剑密封科技有限公司

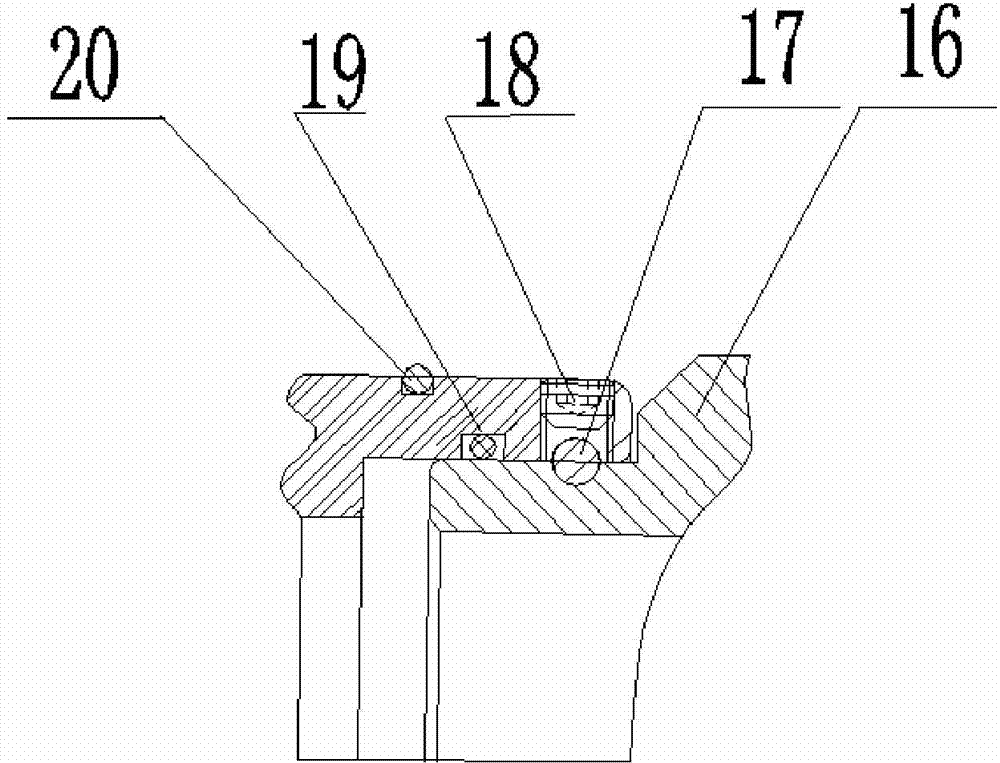

Drive axle for suspension type monorail vehicle bogie

InactiveCN107200025AAvoid premature wearEasy to operateElectric motor propulsion transmissionElevated railway with suspended vehicleBogieCoupling

The invention provides a drive axle for a suspension type monorail vehicle bogie. The drive axle comprises a motor, a coupler, a main speed reducer, a differential mechanism, a wheel transmission device, a drive axle shell and an accessory; the motor is connected with the coupler, the coupler is connected with the main speed reducer, the main speed reducer is connected with the differential mechanism, and the differential mechanism is connected with the wheel transmission device; power input by the motor is transmitted to the main speed reducer through the coupler to be coupled to amplify the torque, and then is output to the wheel transmission device after the differential mechanism balances the rotating speed torque; a wheel hub drives a vehicle. The drive axle for the suspension type monorail vehicle bogie provides large power, large torque and high rotating speed, is resistant to strong impact and extreme environments, low in weight and high in reliability, and has the service life of 30 years.

Owner:重庆凯瑞传动技术有限公司 +1

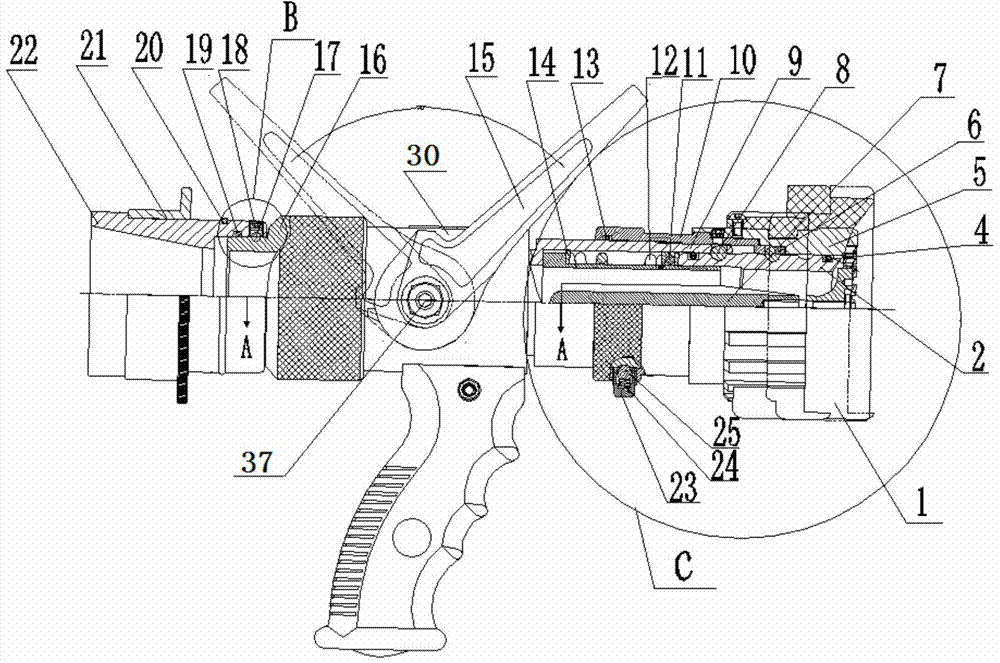

Water diffuser branch

InactiveCN104740810AMeet the tightness requirementsAvoid damagePlug valvesValve members for absorbing fluid energyHigh pressure waterHigh pressure

The invention discloses a water diffuser branch comprising a water inlet part, a valve body (30) and a water outlet part, which are sequentially connected with one another, wherein a valve cavity is formed in the valve body; a ball valve sealing seat (27) is arranged at a water inlet end of the valve cavity; a fixed guide block (29) which extends towards the center of the valve cavity is arranged in the valve cavity; a switch handle (15) is fixedly arranged on the outer wall of the valve body; a ball valve (28) is arranged in the valve cavity; one end of the ball valve sinks inwards to form a positioning hole; the end part of the fixed guide block extends into the positioning hole; the other end of the ball valve is connected with a rotating shaft (35); the rotating shaft is connected with the switch handle (15) through the valve body, so that the switch handle is capable of switching on or off the ball valve by driving the rotating shaft; a first sealing ring (26) is arranged at the connected part of the ball valve sealing seat and the water inlet part; and a second sealing ring (31) is arranged at the connected part of the valve body and the water outlet part. The water diffuser branch is capable of bearing high pressure water and is capable of spraying water mist, so that the utilization rate of fire-fighting water is improved.

Owner:芜湖神途工业装备有限公司

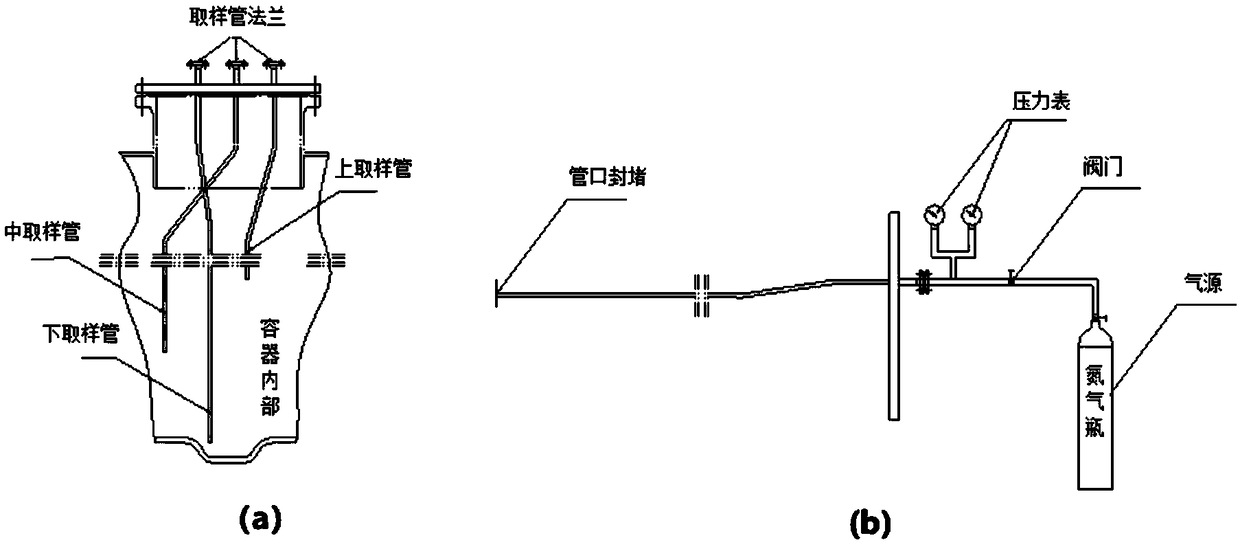

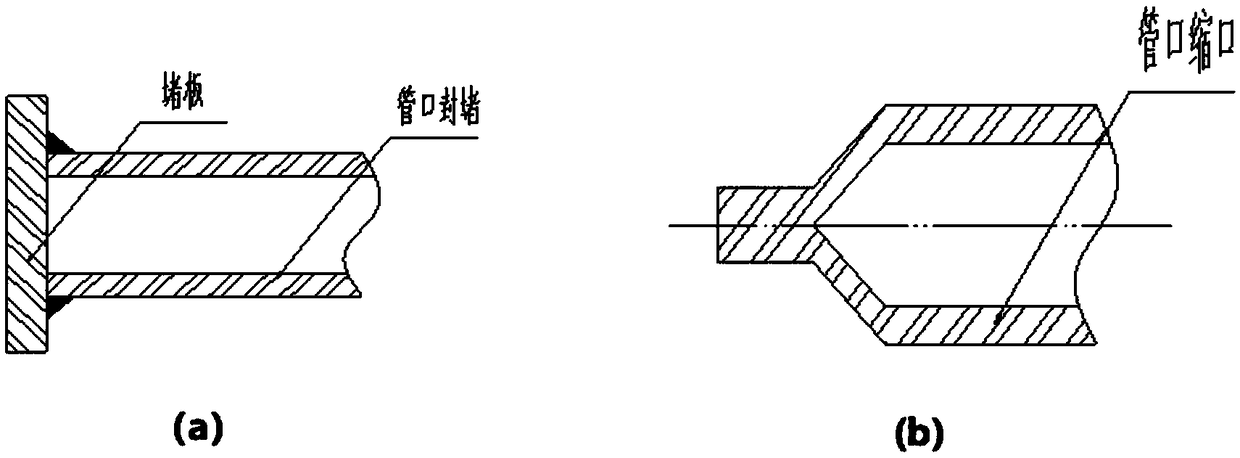

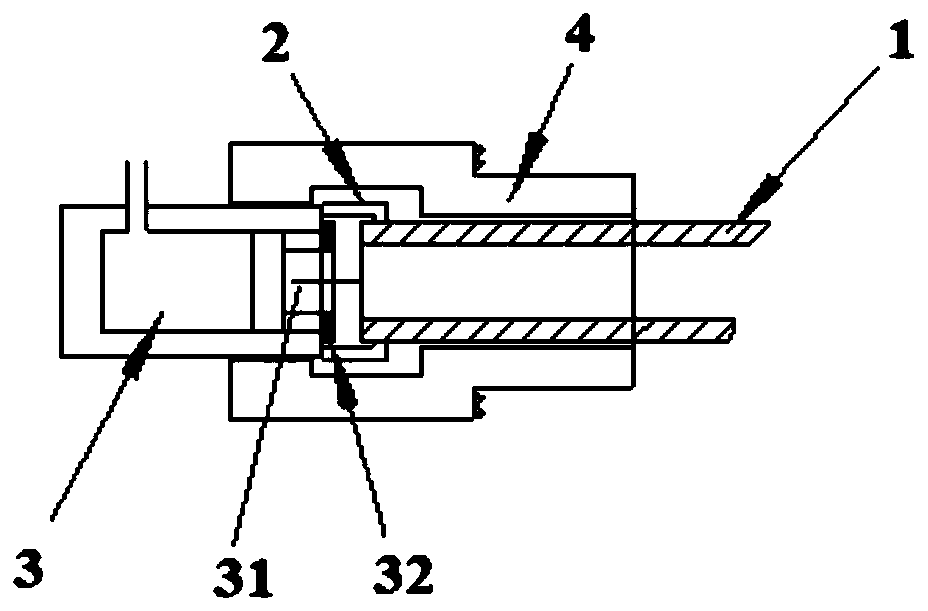

Airtight plugging device and method for sampling pipeline

PendingCN109458515AStrong pressing forceWon't breakPipe elementsFluid-tightness measurement using fluid/vacuumNondestructive testingDrill

The invention discloses an airtight plugging device and method for a sampling pipeline. The device is used for plugging a pipe orifice of the sampling pipeline and comprises a cutting sleeve, an oil cylinder and a drill chuck, wherein one end of the cutting sleeve is connected with the oil cylinder, and the other end of the cutting sleeve is used for being arranged on the pipe orifice of the sampling pipeline in a sealing and sleeving mode; one end of the drill chuck is arranged on the outer wall of the oil cylinder in the sealing and sleeving mode, and the other end of the drill chuck is usedfor being fastened on the outer wall of the sampling pipeline close to the pipe orifice of the sampling pipeline in the sealing mode; the cutting sleeve, the oil cylinder and the drill chuck are coaxially arranged; and the drill chuck can lock the oil cylinder, the cutting sleeve and the sampling pipeline. The airtight plugging device and method have the advantages of easiness in operation and high efficiency. The oil cylinder is strong in compression force and good in sealing effect. The tested pipe orifice cannot be damaged, and nondestructive testing is realized. The drill chuck forms a double-safety mechanism, therefore the device cannot fly out to hurt people during testing, and the safety is high.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Optical fiber element packaging box

ActiveCN103832704AReduce sensitivityMeet the tightness requirementsDamagable goods packagingEngineeringOptical fiber cable

The invention relates to an optical fiber element packaging box. The optical fiber element packaging box comprises a plastic shell and a plastic cover, wherein the plastic shell and the plastic cover are connected in a sealing mode. A through hole is formed in one side face of the plastic shell, an optical platform and an optical metal pipe are arranged in the plastic shell, an optical element set and a collimator are fixed on the optical platform, the output end of the collimator is connected with one end of an optical fiber, the optical fiber is sealed on the optical metal pipe through soldering tin, and the optical metal pipe is sealed and fixed in the through hole of the plastic shell. A nut is arranged on the bottom of the plastic shell. The optical platform is provided with a through hole, a screw penetrates through the through hole to enable the optical platform to be locked and fastened to the nut, and the optical platform is fixed in the plastic shell. Through the adoption of the structure, the optical platform is fixed through the single screw, the contact surface of the optical platform with the external world can be reduced, and external disturbance caused by environment temperature changes or external stress changes can be effectively prevented from influencing optical elements on the optical platform.

Owner:SHANGHAI BRANCH FUZHOU GAOYI COMM CO LTD

Filling and sealing technique for stranded elastic contact pin micro-rectangular electric connector

InactiveCN105680274AMeet the tightness requirementsSolve the sealing problemContact member assembly/disassemblyDustproof/splashproof/drip-proof/waterproof/flameproof connectionDielectricAdhesive

The invention discloses a filling and sealing technique for a stranded elastic contact pin micro-rectangular electric connector. The filling and sealing technique for the stranded elastic contact pin micro-rectangular electric connector comprises the following steps: (1) preparation of adhesives, namely selecting a DG-3S adhesive A and an S adhesive B of the Zhonglan Chenguang chemical research design Co., LTD, and preparing the adhesive A and the S adhesive B at the mass ratio of (1.5-2) to 1, continuously stirring the adhesive A and the S adhesive B for 1-2 minutes until the adhesives are evenly mixed and are consistent in color; and (2) fixed filling and sealing of an insulator, namely enclosing the insulator into a shell until being assembled in place. According to the filling and sealing technique for the stranded elastic contact pin micro-rectangular electric connector, the problem that the sealing property of the micro-rectangular electric connector is affected by the disadvantages that rubber part sealing and glass sintering sealing methods are complicated in process, high in cost, not beneficial to sealing of miniaturized products, poor in dielectrics voltage-resistance, poor in air-tightness and the like is solved.

Owner:沈阳兴华航空电器有限责任公司

Environment-friendly sealing sponge for automobile air conditioner and preparation method thereof

The invention discloses environment-friendly sealing sponge for an automobile air conditioner and a preparation method thereof, and relates to the technical field of air conditioner sealing sponge. The environment-friendly sealing sponge for the automobile air conditioner is prepared from the following raw materials in parts by weight: 80-95 parts of bio-based EPDM, 10-15 parts of polylactic acid fiber, 30-40 parts of carbon black, 1-2 parts of stearic acid, 1-2 parts of zinc oxide, 30-40 parts of kaolin, 25-35 parts of heavy calcium carbonate, 1-3 parts of cashew nut shell oil, 1-2 parts of a foaming agent AC, 1-2 parts of a foaming agent OBSH, 1-2 parts of an accelerant PZ, 1-2 parts of an accelerant NS, 2-4 parts of PEG4000, 1-2 parts of a silane coupling agent, 2-3 parts of sulphur, 1-2 parts of DCP and 1-2 parts of a stabilizer. The environment-friendly sealing sponge for the automobile air conditioner uses the bio-based EPDM as a raw material, so that dependence on a petroleum resource is reduced and the environment-friendly sealing sponge is environment-friendly and renewable; the added biodegradable polylactic acid fiber can further improve the strength and the elasticity of the material; through a reasonable matching ratio of the components, the prepared material is better in performance, high in tensile strength, low in volume weight and small in permanent deformation, and a requirement on the sealing performance of the automobile air conditioner can be met better.

Owner:SHENZHEN WOHAISEN TECH CO LTD

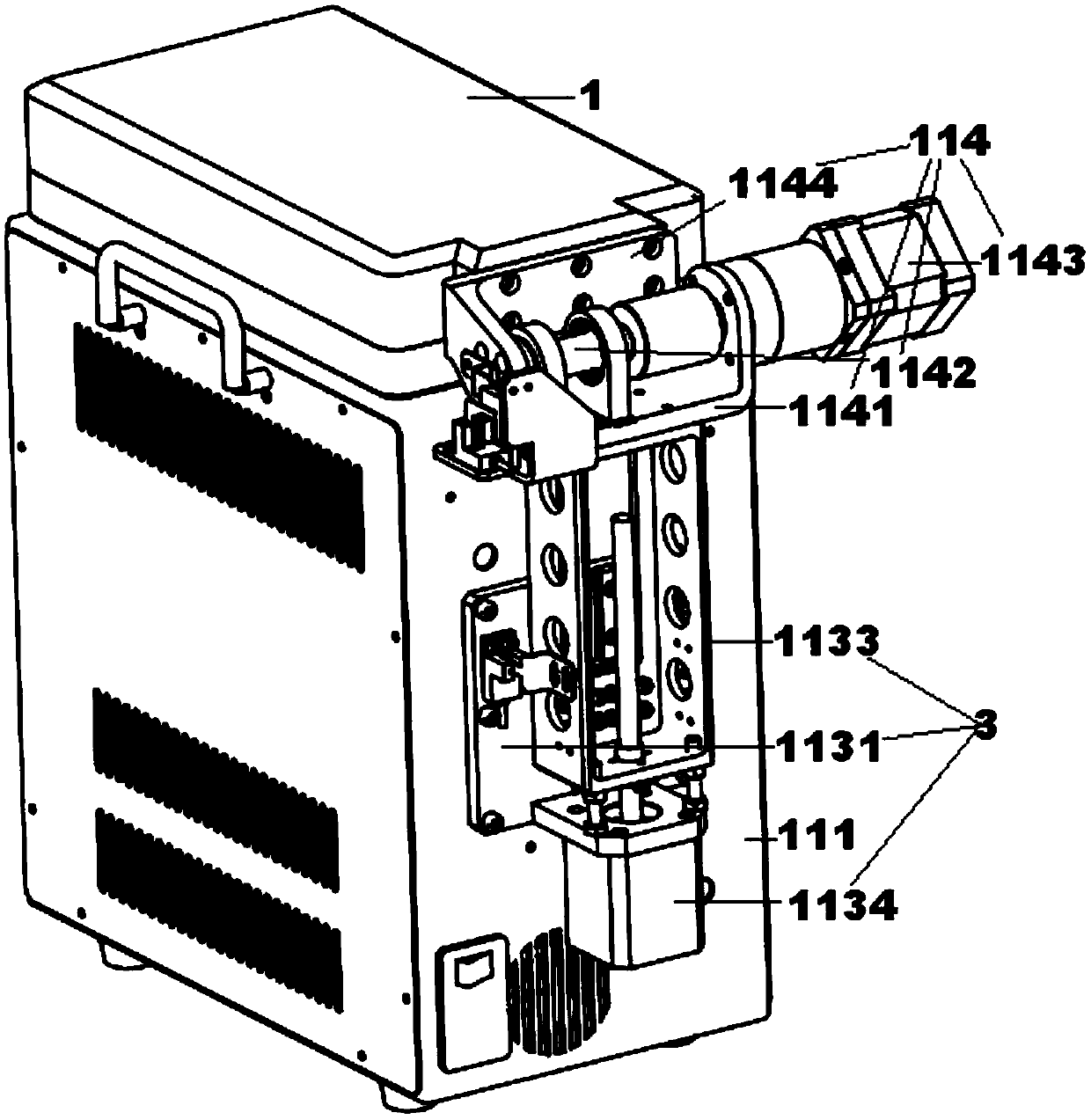

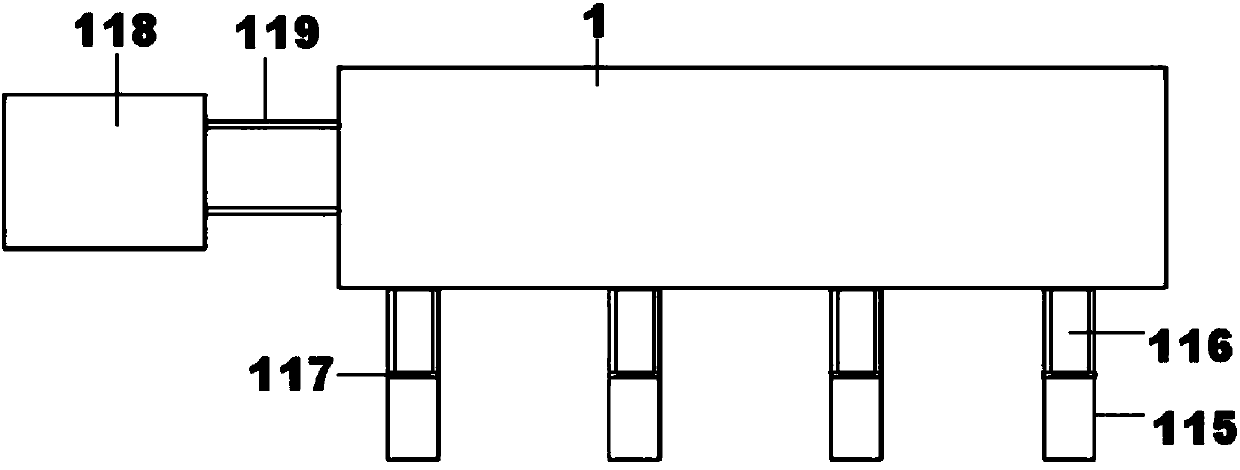

Hot cover device of gene amplification device and control method thereof

ActiveCN106987522ASo as not to damageMeet the tightness requirementsBioreactor/fermenter combinationsBiological substance pretreatmentsComputer moduleAir pump

The invention discloses a hot cover device of a gene amplification device and a control method thereof; the hot cover device comprises a hot cover pressing plate, a hot cover heat isolating cushion, a heating film, a hot cover aluminum plate and a flexible hot cover cushion which are orderly arranged from top to bottom. The device further comprises a controller arranged on the box body, a lifting structure and a rotating structure connected to the upper end of the lifting structure; the hot cover is connected with the rotating structure, multiple vertical drums corresponding to every test tube insert hole in a gene amplification module are arranged on the hot cover, and an air sac is arranged in every vertical drum; the lower end of the air sac is provided with a cover plate, and every air sac is connected with the gas storage tank through a gas guide pipe; a pressure sensor is arranged in the gas storage tank and a gas pump is arranged on the gas storage tank. The hot cover device is featured by good sealing effect and high detecting accuracy.

Owner:杭州柏恒科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com